Overload protection device

A technology of overload protection and hub flange, which is applied in the direction of automatic clutches, clutches, mechanical equipment, etc., can solve problems such as pressure fluctuations, assembly accuracy deviations, large vibrations and noises, and achieve vibration and noise prevention and accurate working torque. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

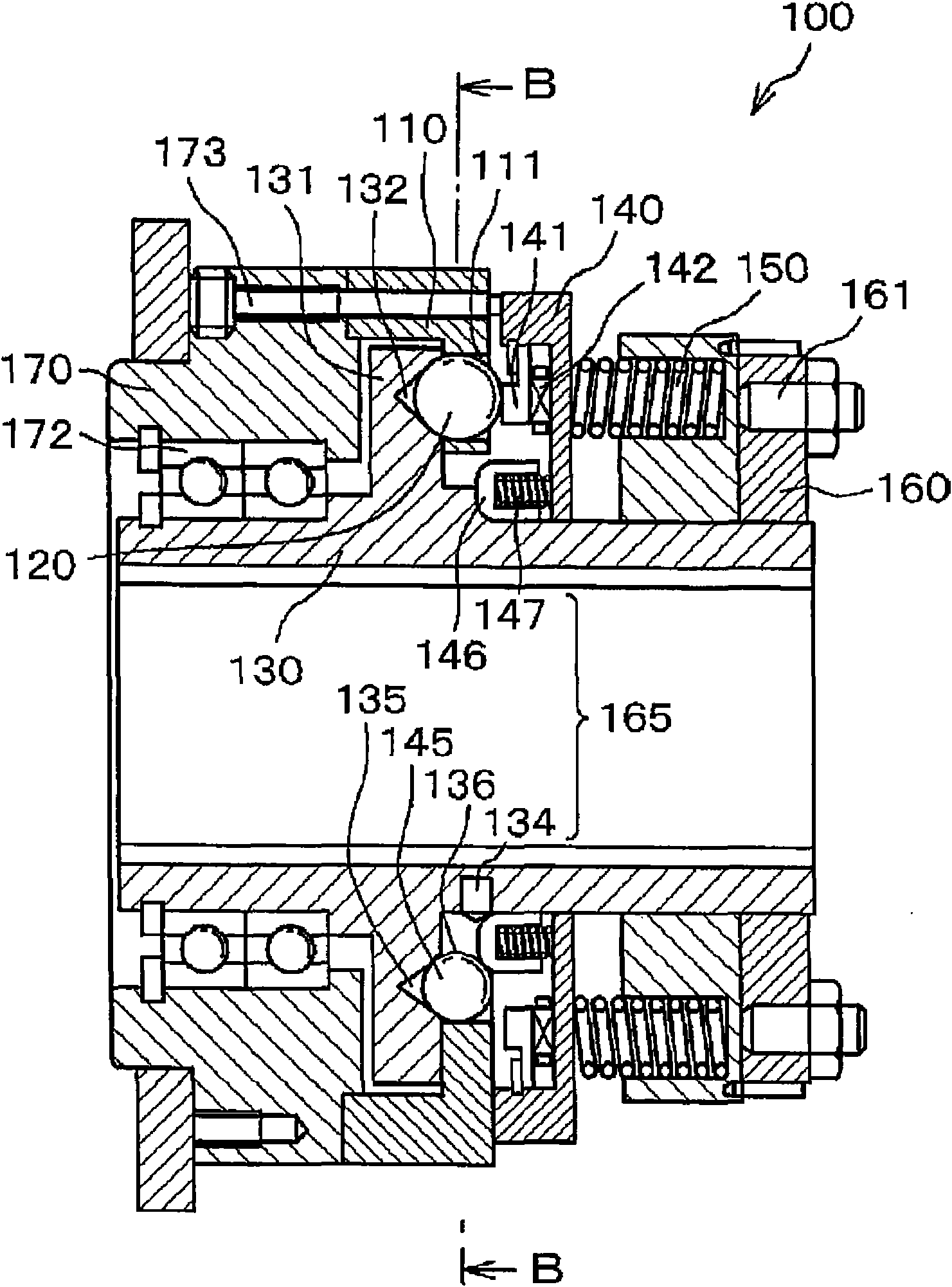

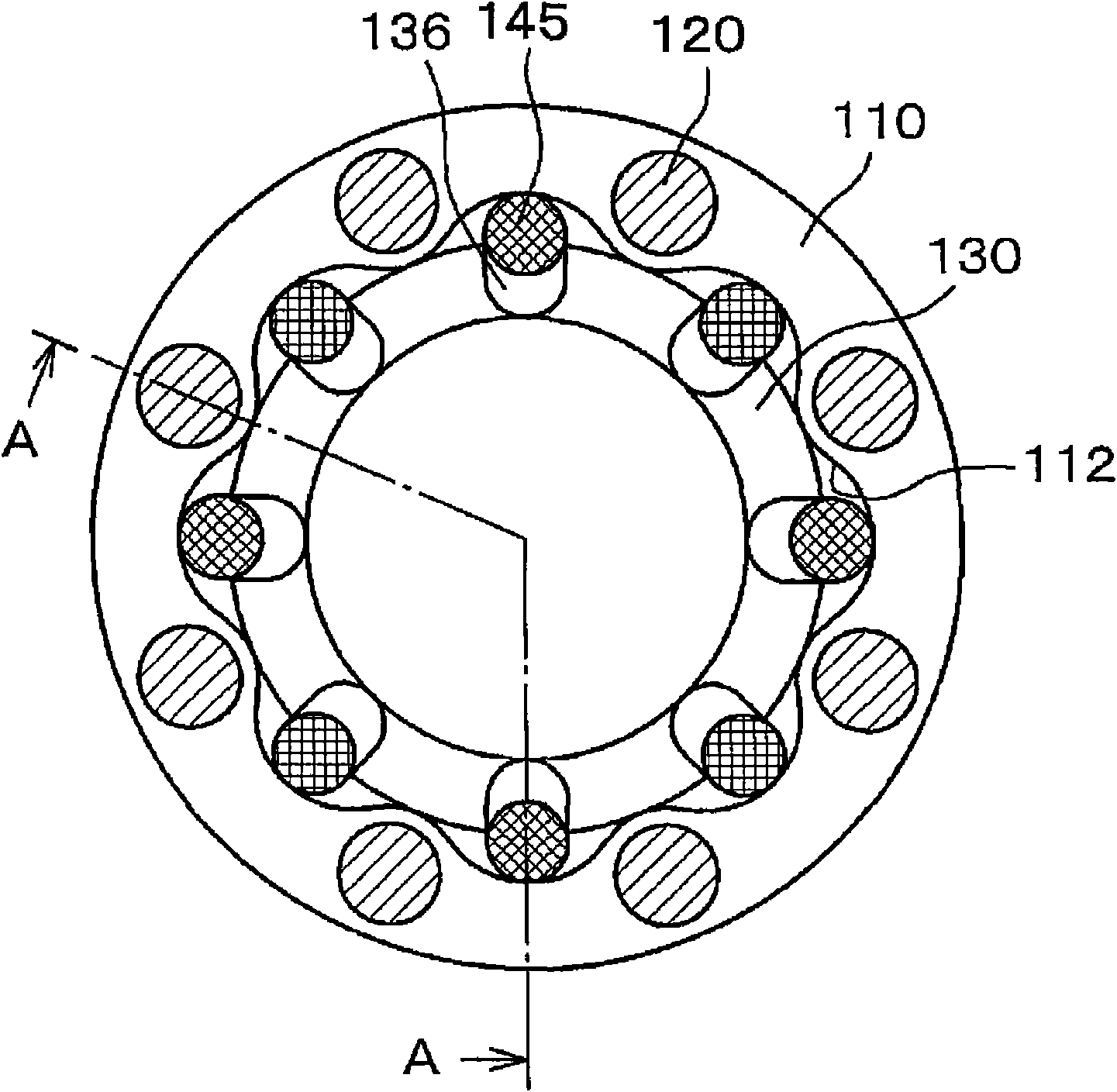

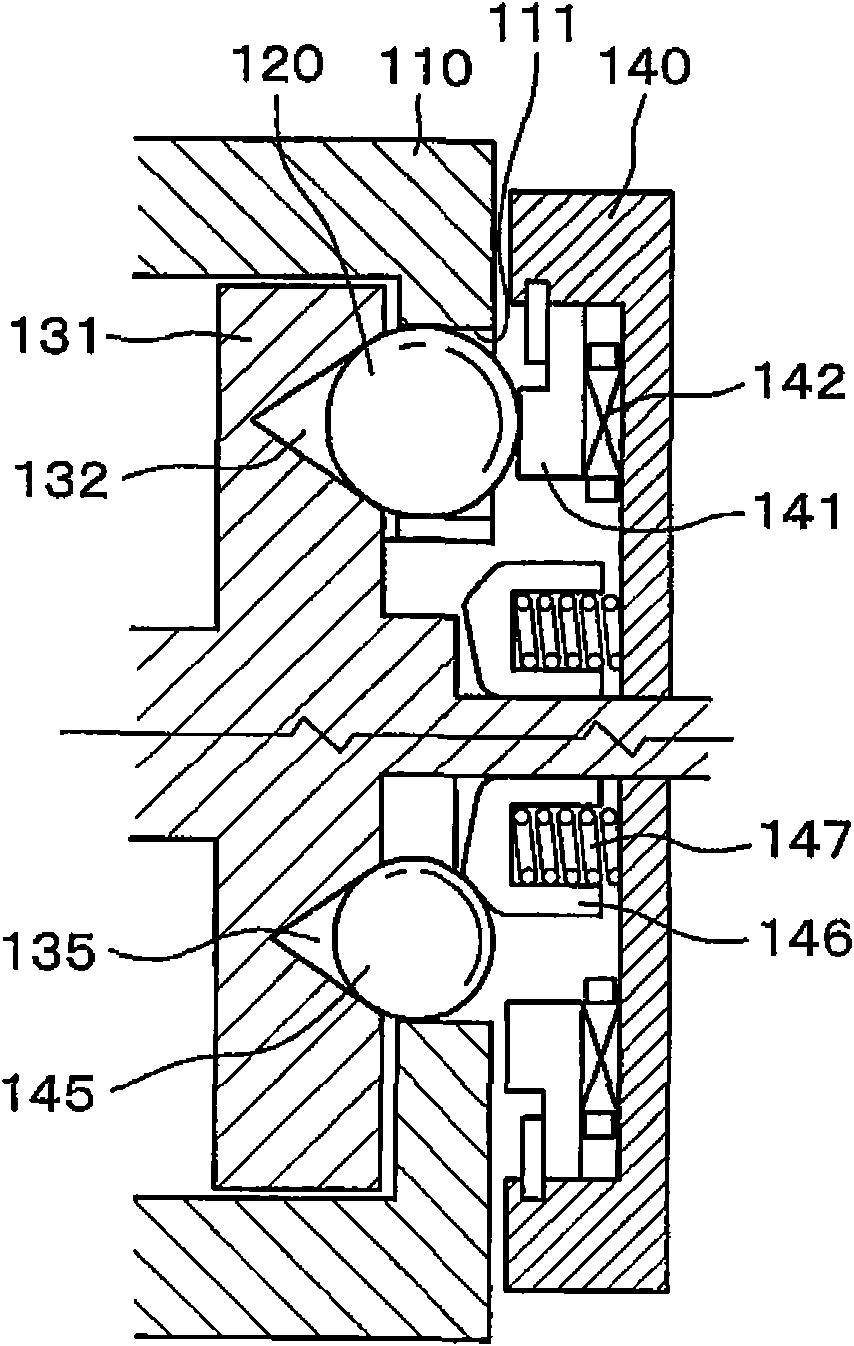

[0048] The overload protection device of the present invention has: a central flange holding a torque transmission element in a plurality of through holes provided in the direction of the rotation axis, disposed opposite to the central flange in the direction of the rotation axis, and having a function of engaging with the torque transmission element. The hub flange of the concave part of the hub flange, the pressing plate provided opposite to the central flange on the opposite side of the hub flange in the direction of the rotation axis and pressing the torque transmission element toward the direction of the hub flange, and the pressing plate when overloaded A holding mechanism for holding in a state of retreating against a pressing force, the above-mentioned holding mechanism includes: a stop ring provided on the side of the above-mentioned central flange of the above-mentioned pressing plate, and a holding ball arranged on the inner peripheral side of the above-mentioned cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com