Double-acting refrigeration compressor

A refrigeration compressor, double-acting technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problem that the cylinder parts cannot move relatively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

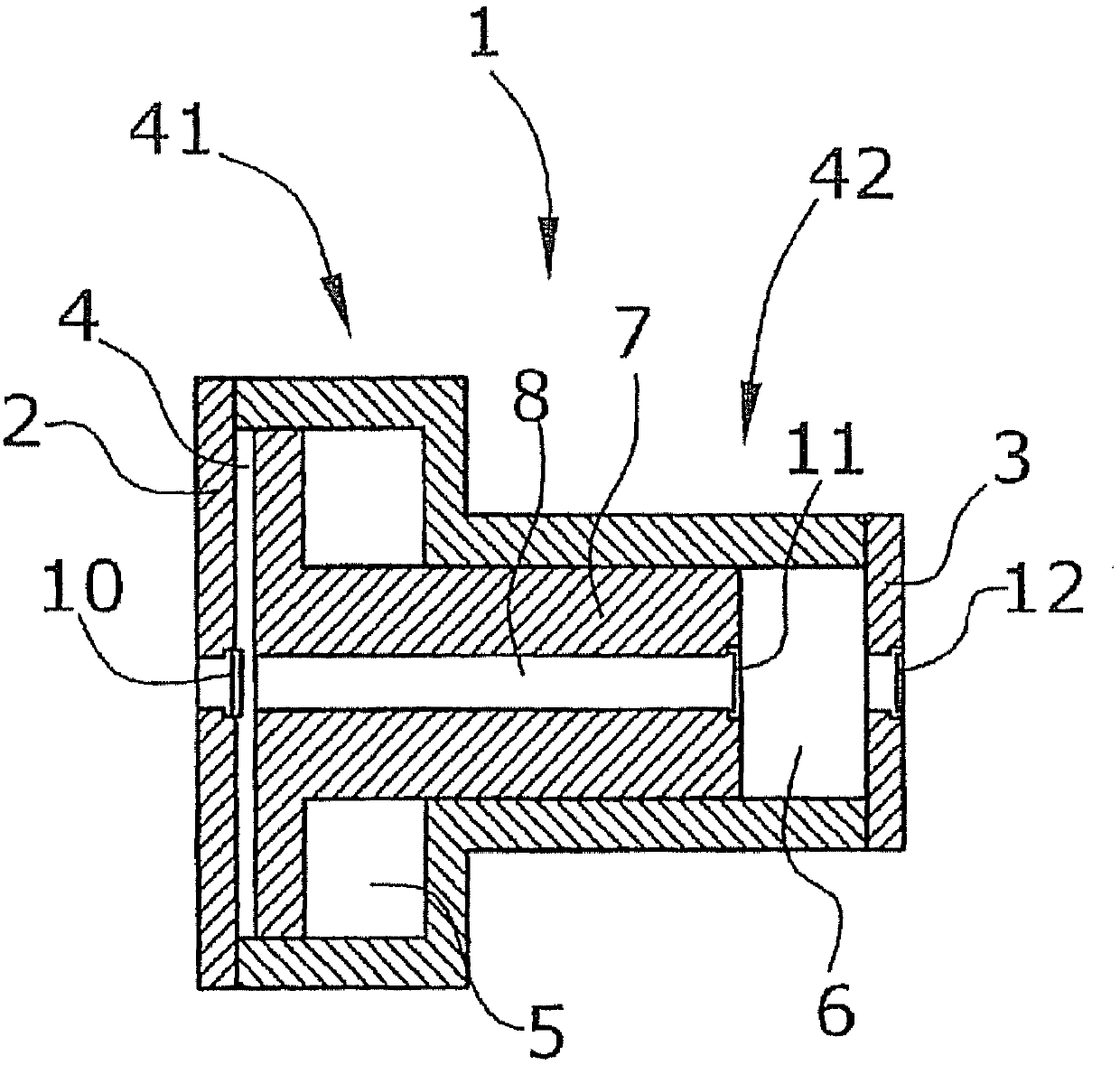

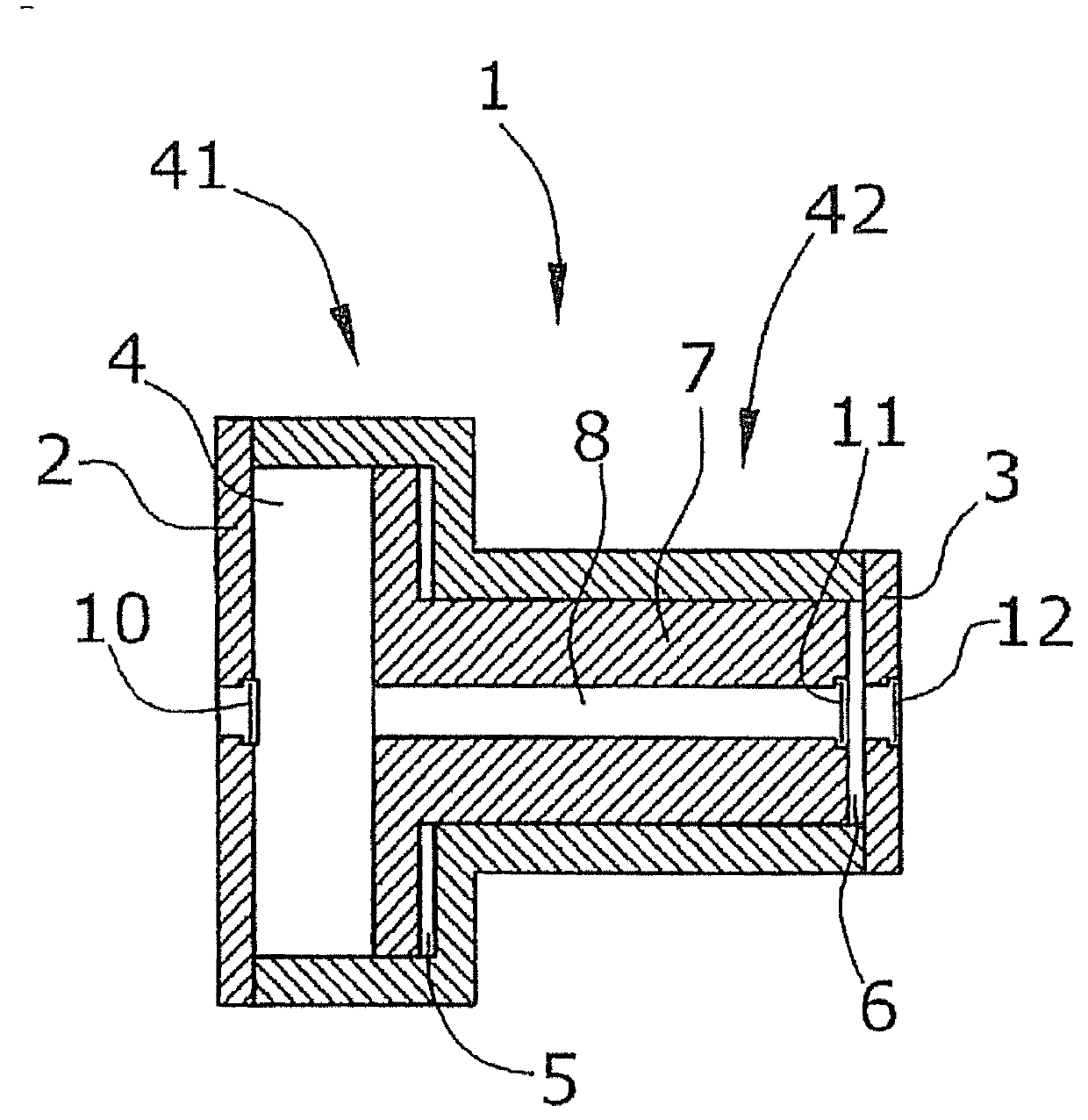

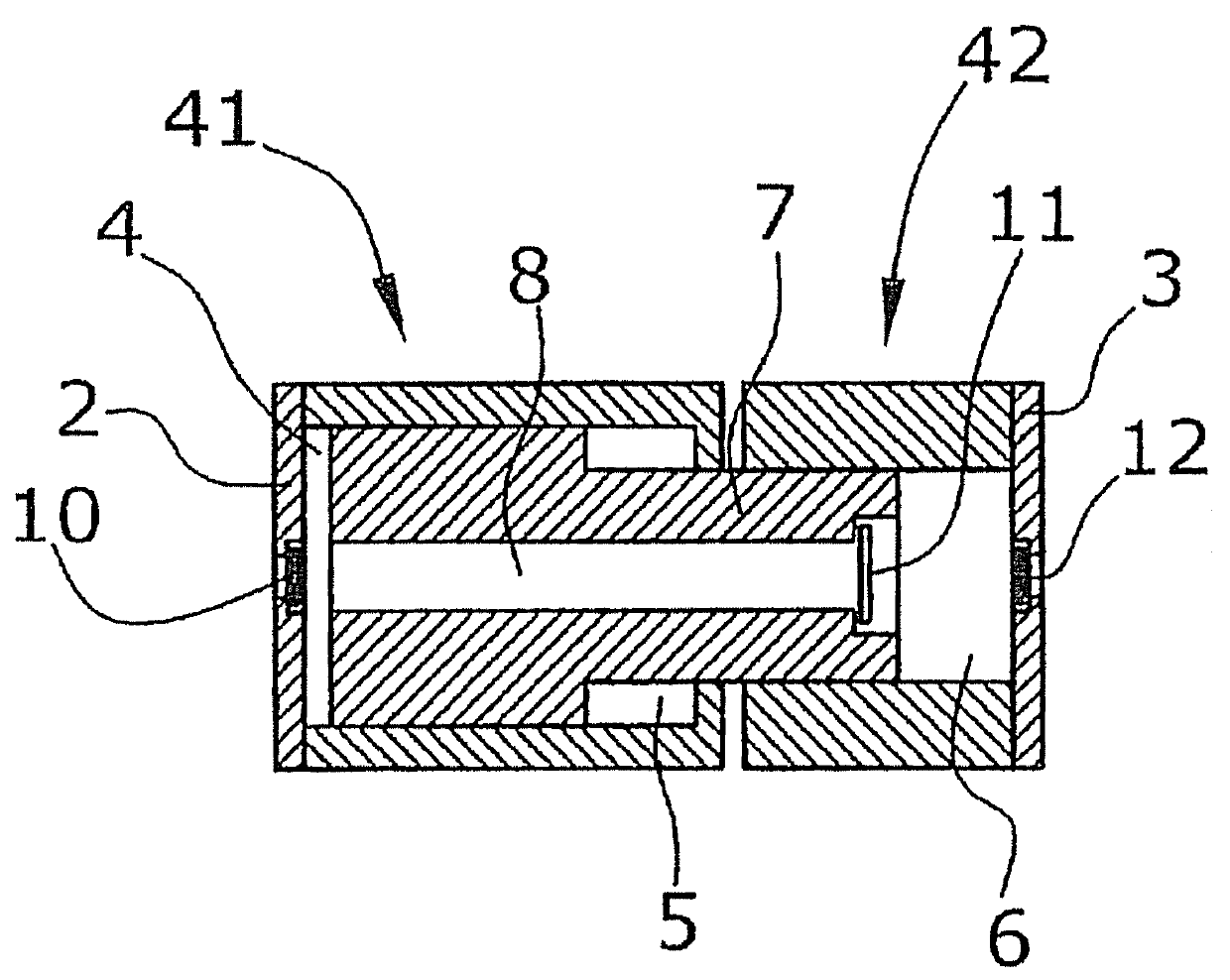

[0030] The refrigeration compressor of the first embodiment is as figure 1 and 2 As shown, the compressor system comprises a step-in cylinder 1 in which a piston 7 with a central flow channel 8 is guided axially. The cylinder is terminated by a suction valve plate 2 in which a suction valve 10 is inserted and a discharge valve plate 3 in which a discharge valve 12 is inserted. The flow channel 8 is terminated by a further valve 11 on the outlet side.

[0031] In this arrangement, the larger-diameter left part of the step-in cylinder 1 forms the first cylinder part 41 and the smaller-diameter right part of the step-in cylinder 1 forms the second cylinder part 42 . In this way, the two cylinder parts 41 , 42 are integrally connected to form the cylinder 1 .

[0032] The basic functions of this double-acting single-row free-piston compressor are described as follows:

[0033] Via drive means not yet described here, the piston will perform a linear oscillation. This can be re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com