Patents

Literature

101 results about "Velocity feedback" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

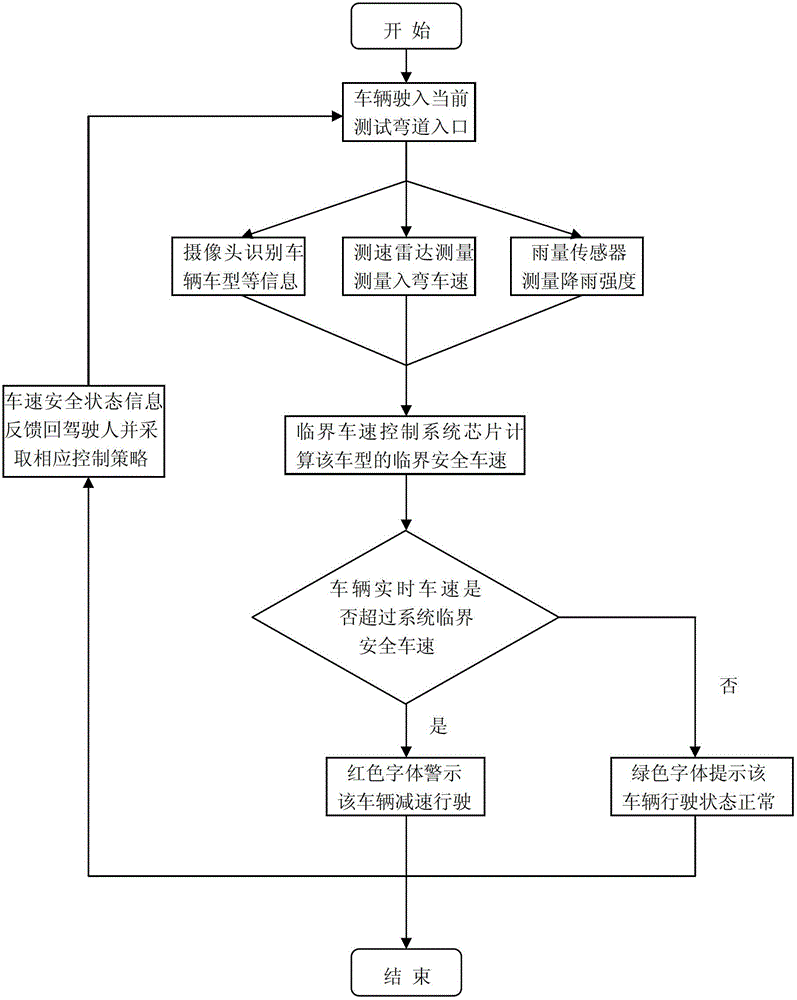

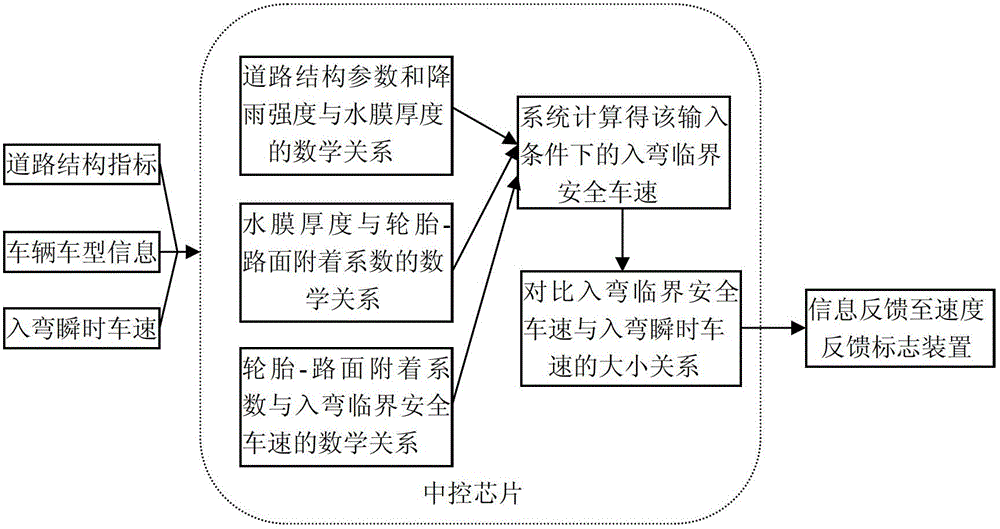

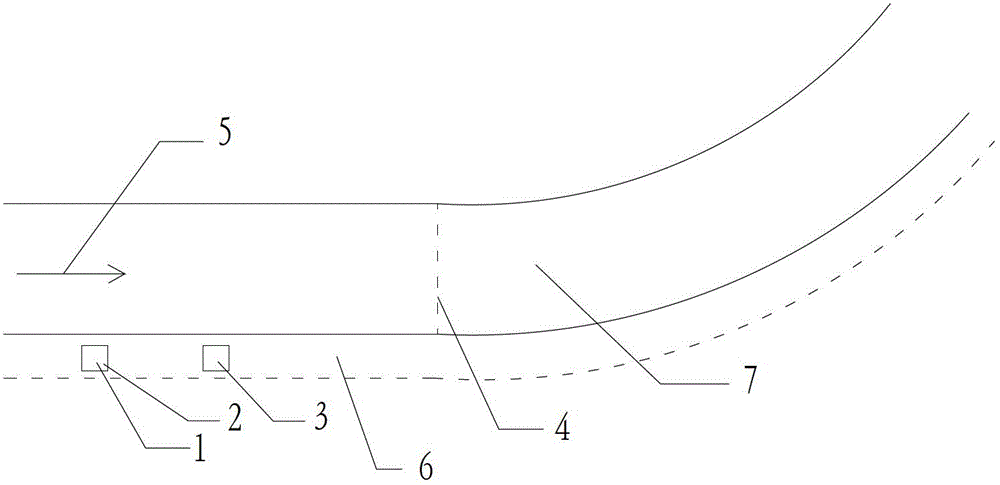

Implementation method of speed feedback sign system for bend steering vehicle speed safety state prewarning

ActiveCN102723001AAvoid accidentsReduce security risksAnti-collision systemsSurveillance cameraLight-emitting diode

The invention discloses an implementation method for a speed feedback sign for bend steering vehicle speed safety state prewarning. The speed feedback sign system which consists of a monitoring camera, a rain sensor and a speed feedback sign device is arranged on the roadbed side of a road in front of a bend entrance in a retrograde vehicle direction, wherein a central control chip, a speed measuring radar, a light emitting diode (LED) display screen and prompting characters are arranged in the speed feedback sign device; a driver is warned to control the vehicle speed within a proper range before a vehicle enters a bend according to the conditions such as types of driven vehicles, weather conditions and road alignment conditions, so that traffic accidents after the vehicle enters the bend are prevented, and bend entrance critical safe vehicle speed corresponding to different vehicle types can be prompted in real time aiming at the change of road adhesion coefficients caused by different weather conditions and different bend road sections, and vehicle speed information and running states are fed back to the driver before the vehicle enters the bend; and therefore, enough time for the driver to adjust the vehicle speed is ensured and the road operation safety is improved.

Owner:CHANGAN UNIV

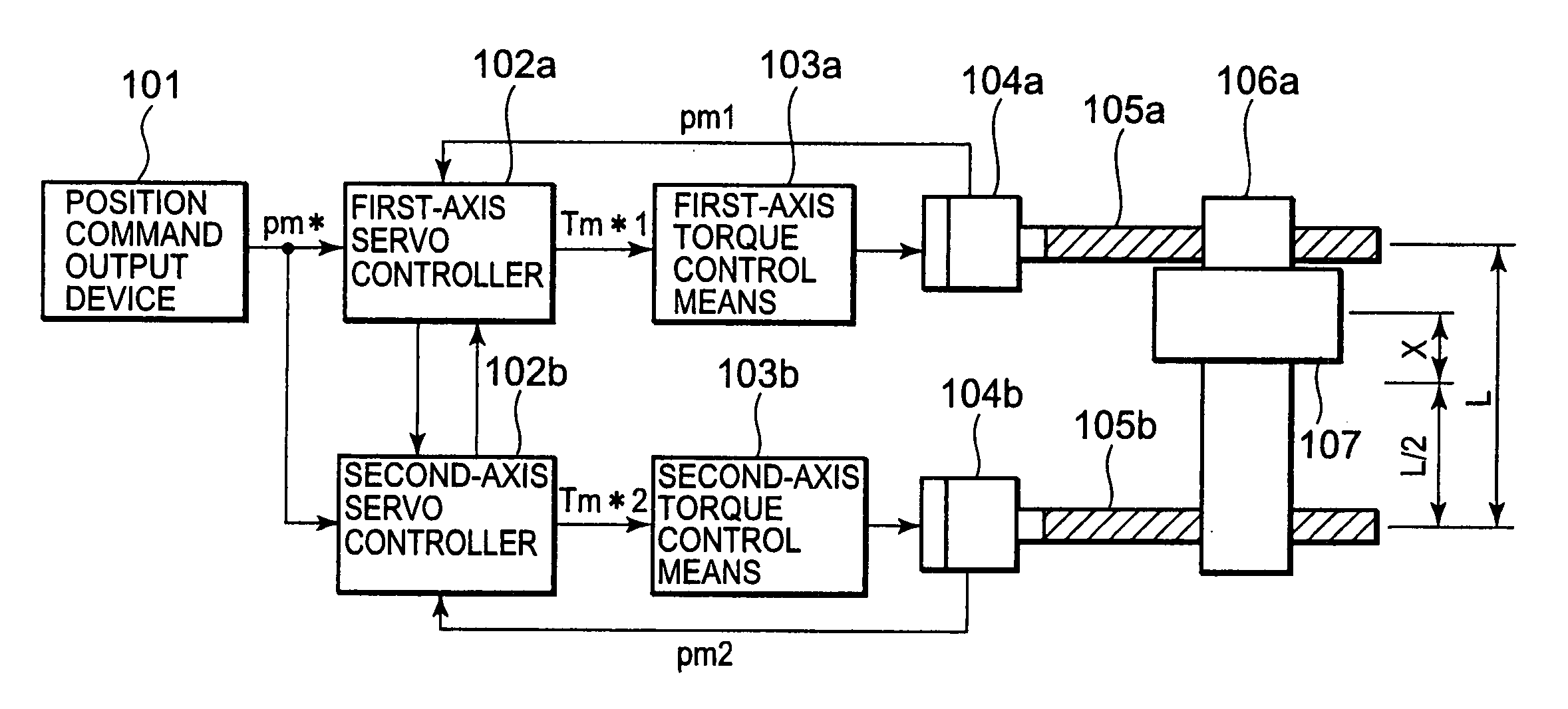

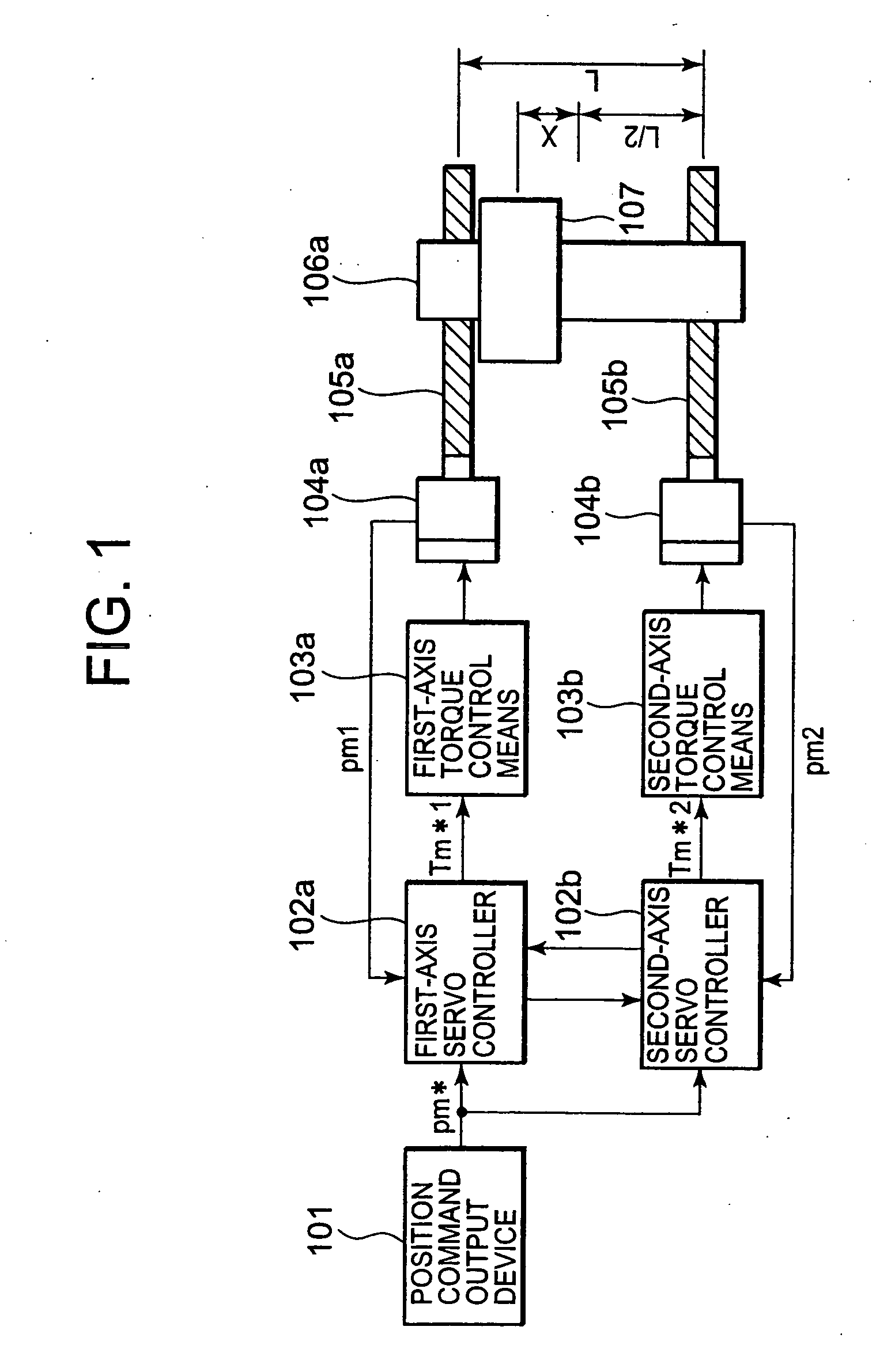

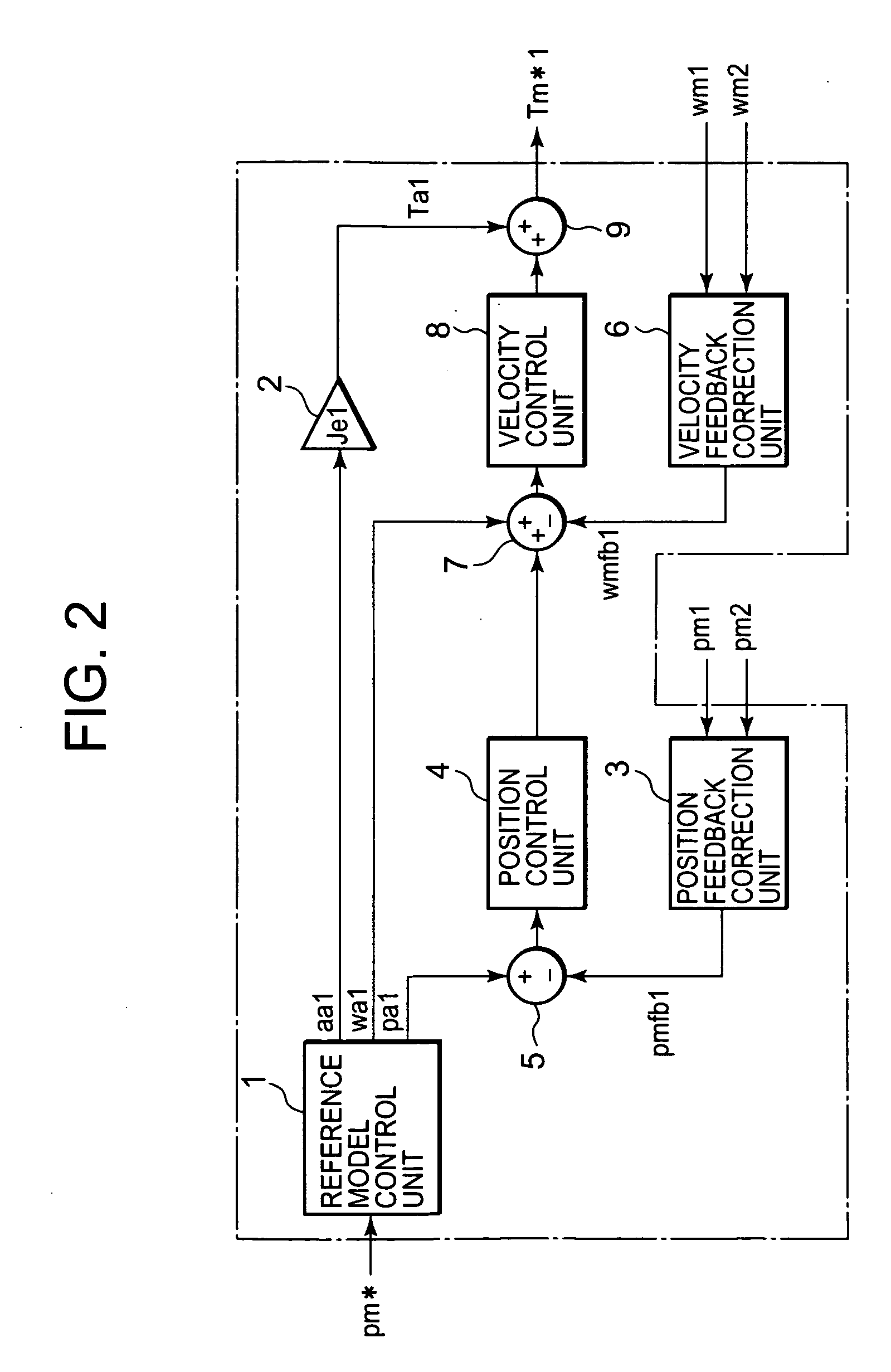

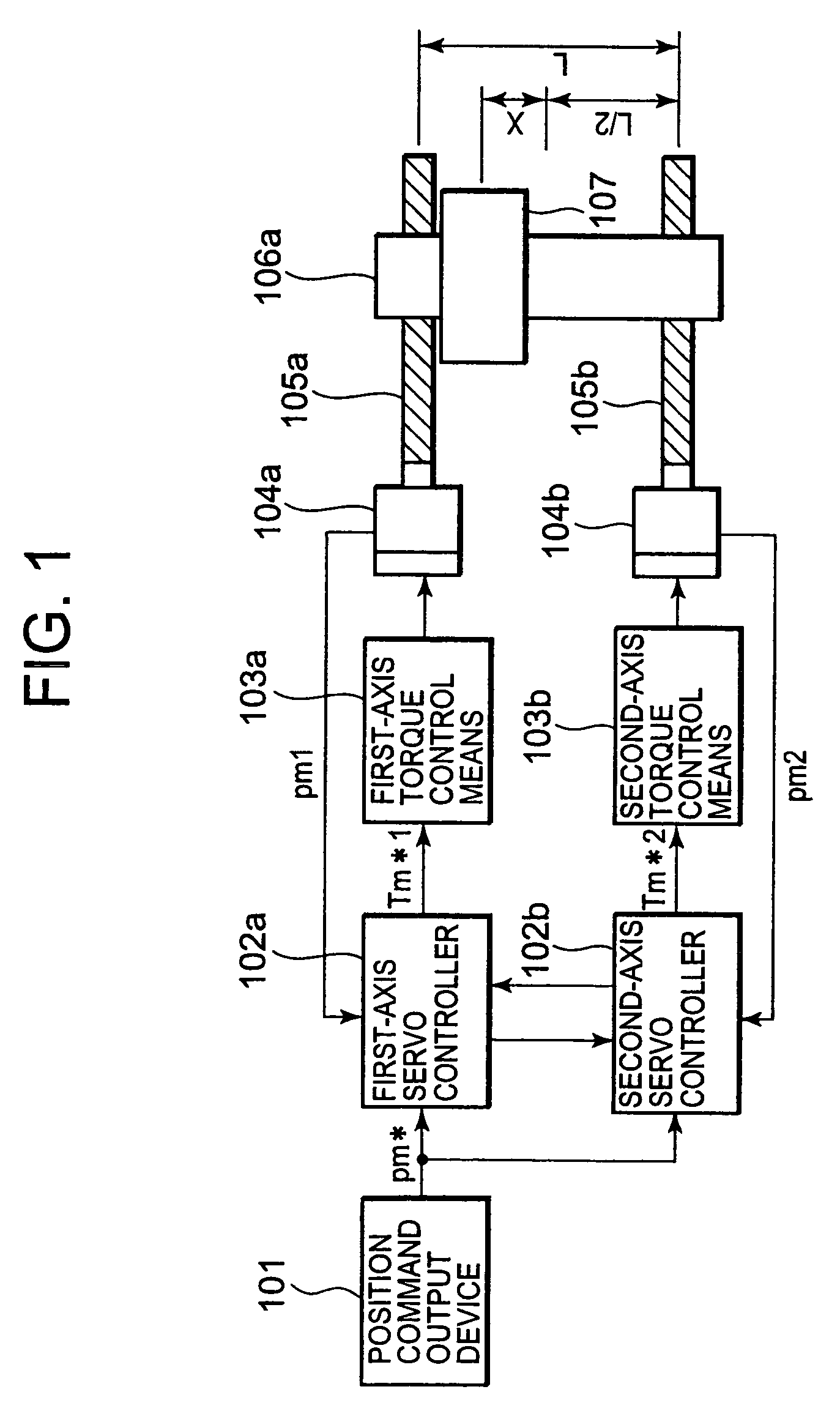

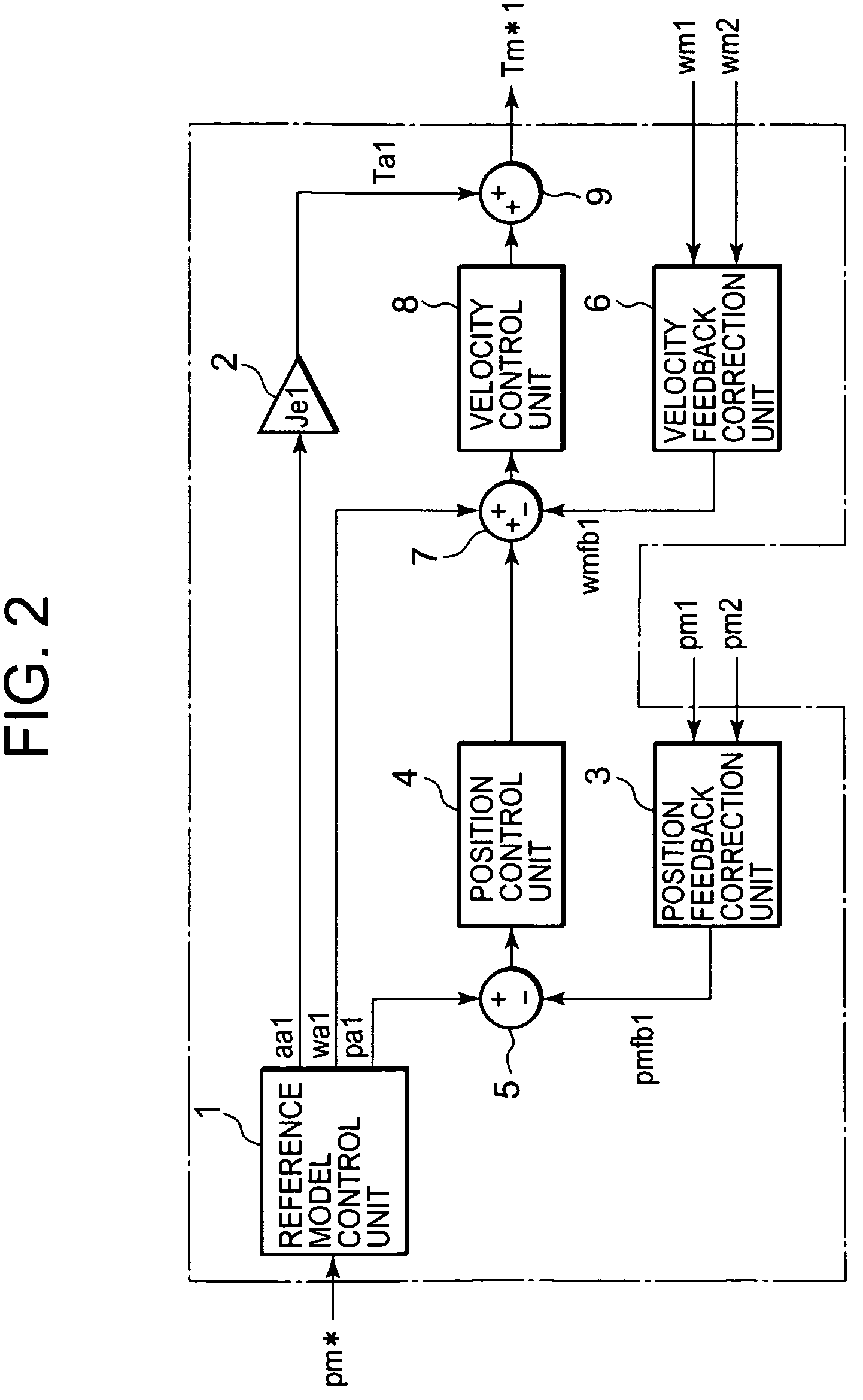

Servo controller

ActiveUS20060186845A1Suppress position deviationAutomatic control devicesDC motor speed/torque controlPosition controlPAL

In a servo controller according to the invention, a position feedback correction unit (3) calculates a first-axis position feedback signal (pmfb1) based on a first-axis position (pm1) as a self-axis position, and a second-axis position (pm2) as an other-axis position; and a deviation between a model position (pal) and the first-axis position feedback signal (pmfb1) is inputted from a subtracter (5) to a position control unit (4), which performs positional control to output a velocity command. A velocity feedback correction unit (6) calculates a first-axis velocity feedback signal (wmfb1) from a first-axis velocity (wm1) as the self-axis velocity, and a second-axis velocity (wm2) as the other-axis velocity; and the velocity control unit (8) adds a model velocity (wa1) and the velocity command outputted from the position control unit (5), and subtracts the first-axis velocity feedback signal (wmfb1) therefrom, and outputs a feedback torque command (Tfb1) based on the corrected velocity command.

Owner:MITSUBISHI ELECTRIC CORP

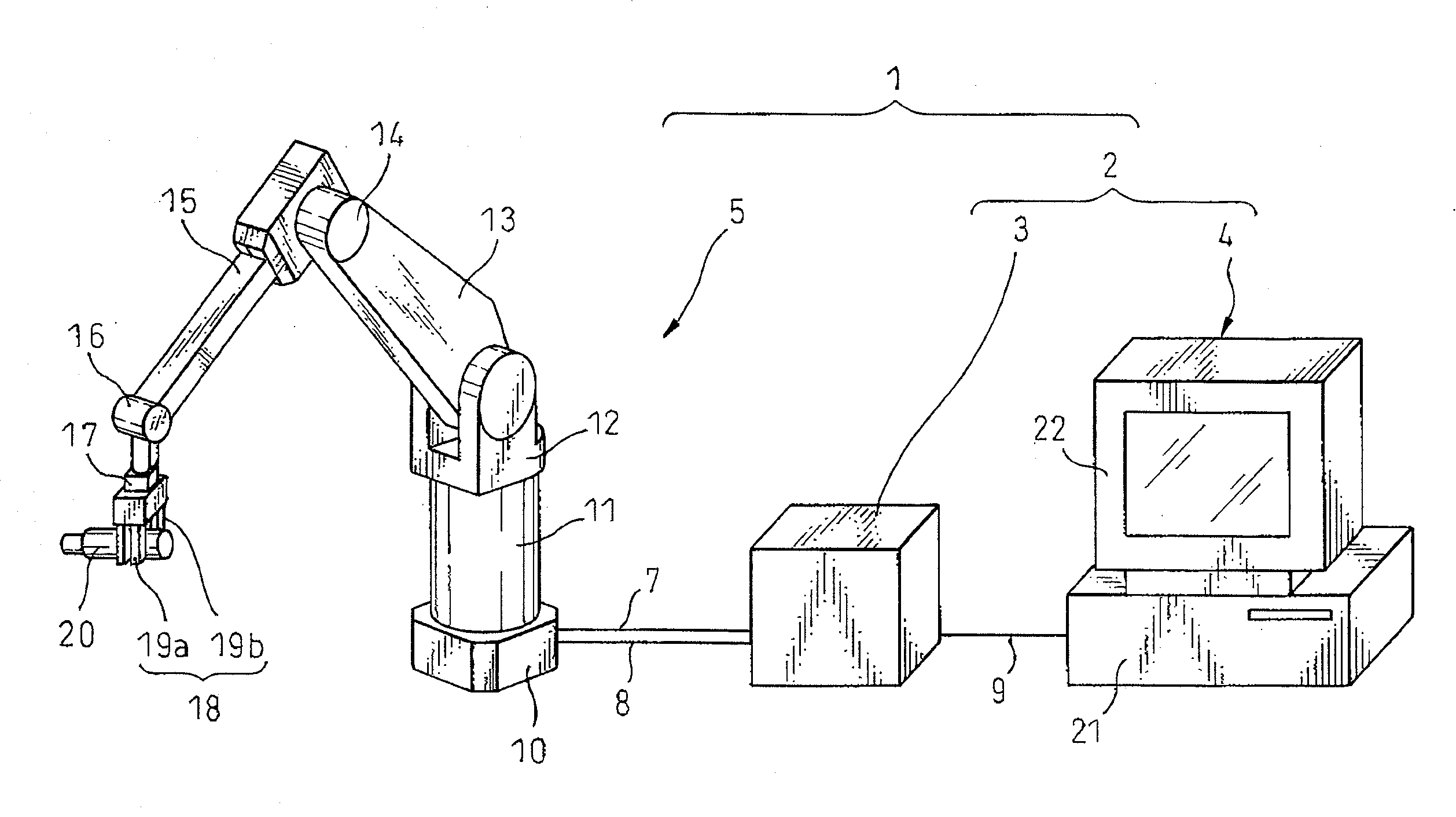

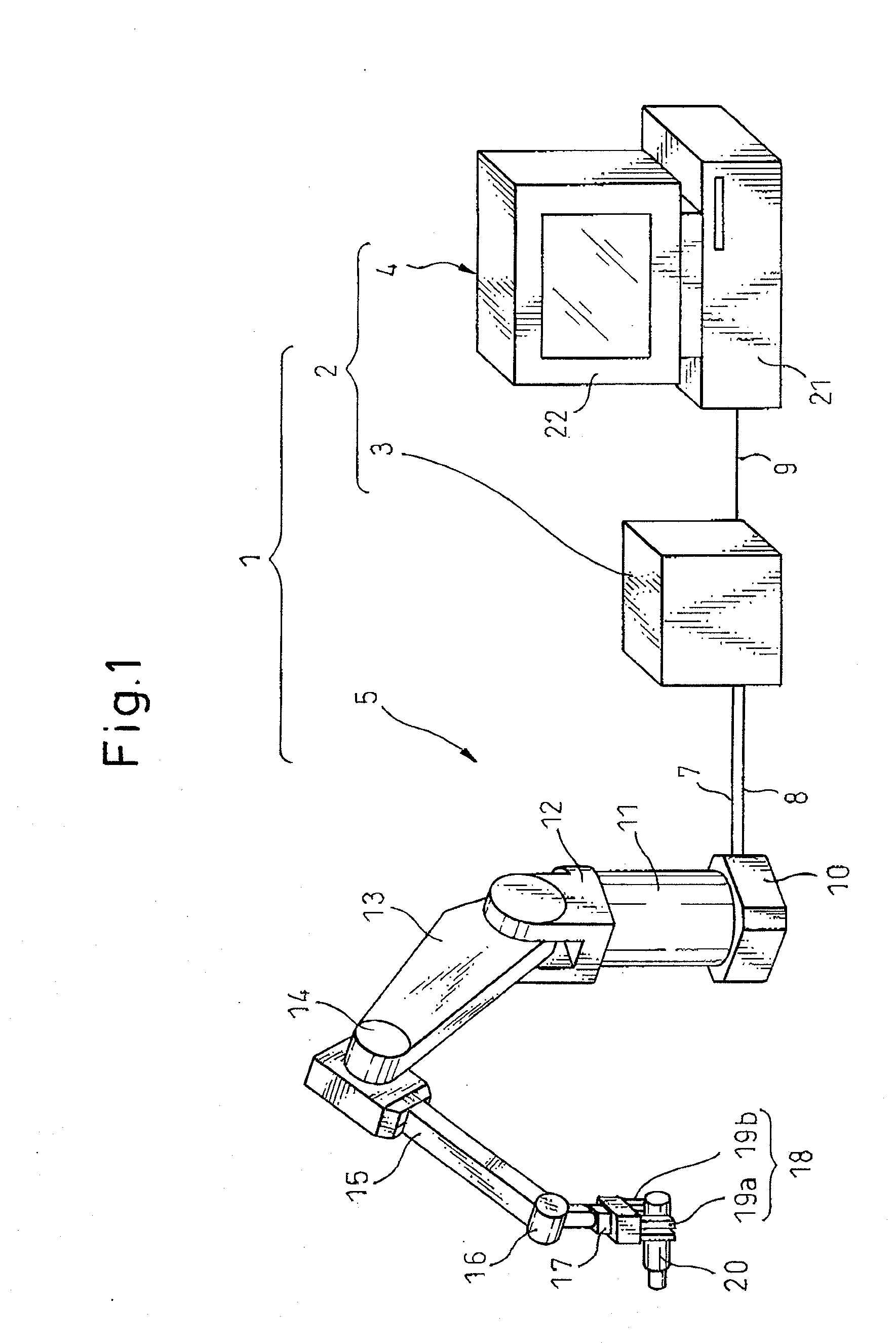

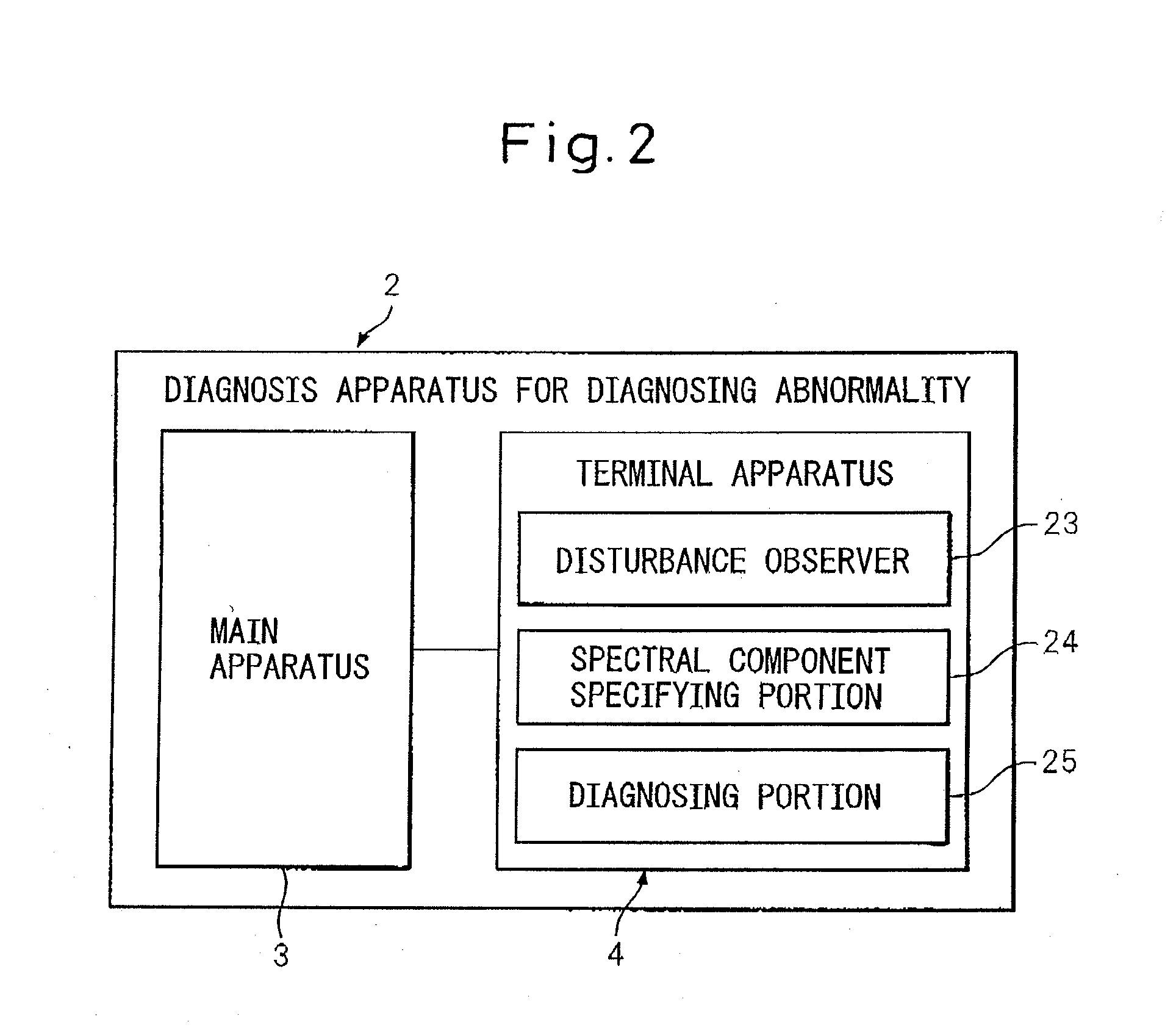

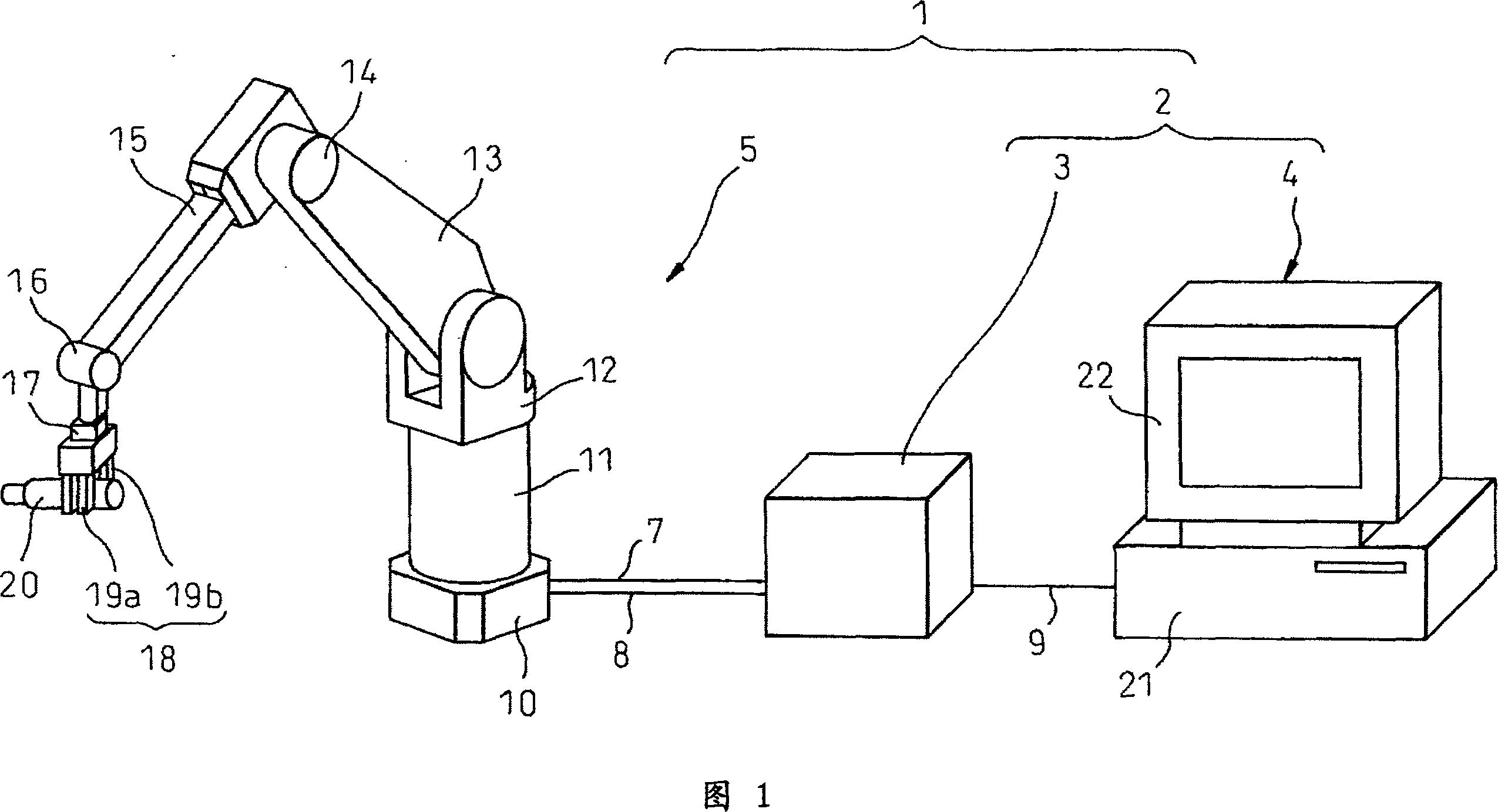

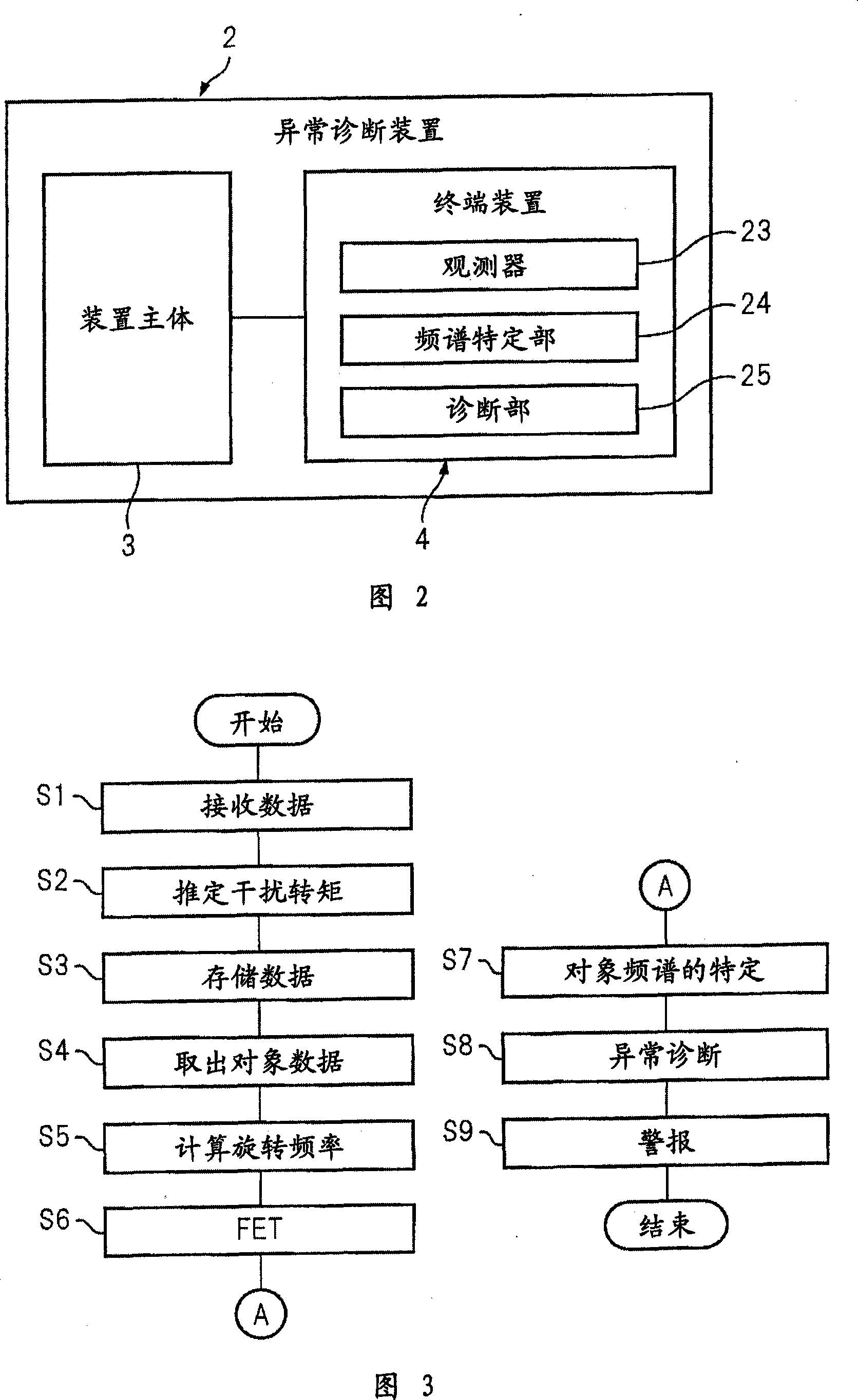

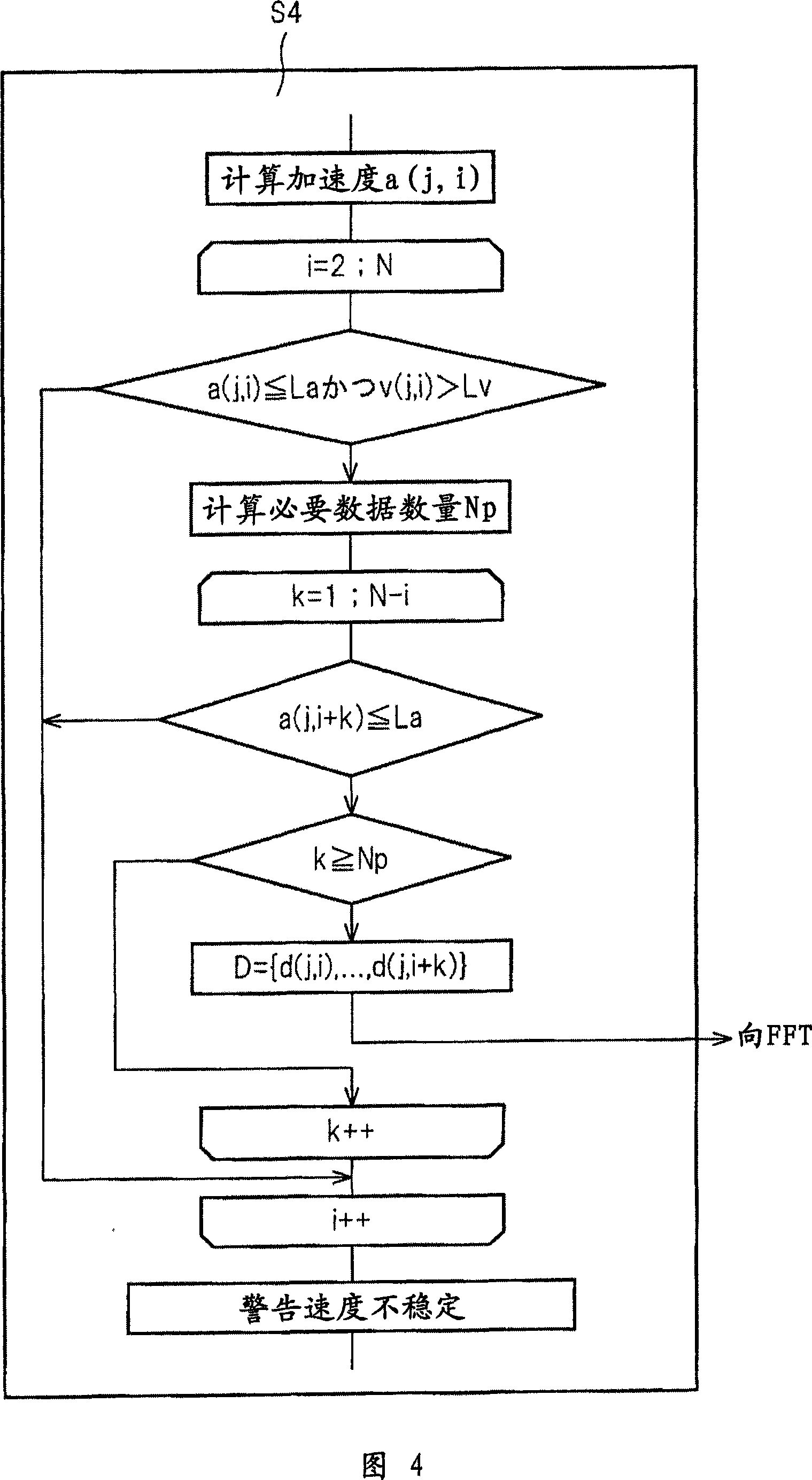

Method of diagnosing abnormality of reduction gear and apparatus for carry out the method

InactiveUS20080215292A1Improve usabilityIncrease productivityMachine part testingNuclear monitoringFrequency spectrumMedial axis

An apparatus for carry out a method of diagnosing abnormality of a reduction gear, the reduction gear including an intermediate shaft element disposed between an input shaft and an output shaft and rotating in proportion to a rotation of the input shaft to transmit the rotation to the output shaft, the apparatus has: a disturbance observer that obtains an estimated disturbance value regarding the reduction gear, based on a torque instruction and a velocity feedback-value acquired when a pair of driven members which rotate relative to each other with a motor as a driving source are in relative rotation at a constant velocity; a specific spectral component specifying portion for extracting a specific spectral component corresponding to a constant multiple of a rotational frequency of the intermediate shaft element from a frequency components of the estimated disturbance value obtained by frequency analysis; and a diagnosing portion, which compares an amplitude of the specific spectral component specified by the specific spectral component specifying portion with a threshold value, and diagnoses an abnormality in a case where the amplitude of the specific spectral component exceeds the threshold value, or a normality in a case where the amplitude of the specific spectral component is equal to or less than the threshold value.

Owner:FANUC LTD

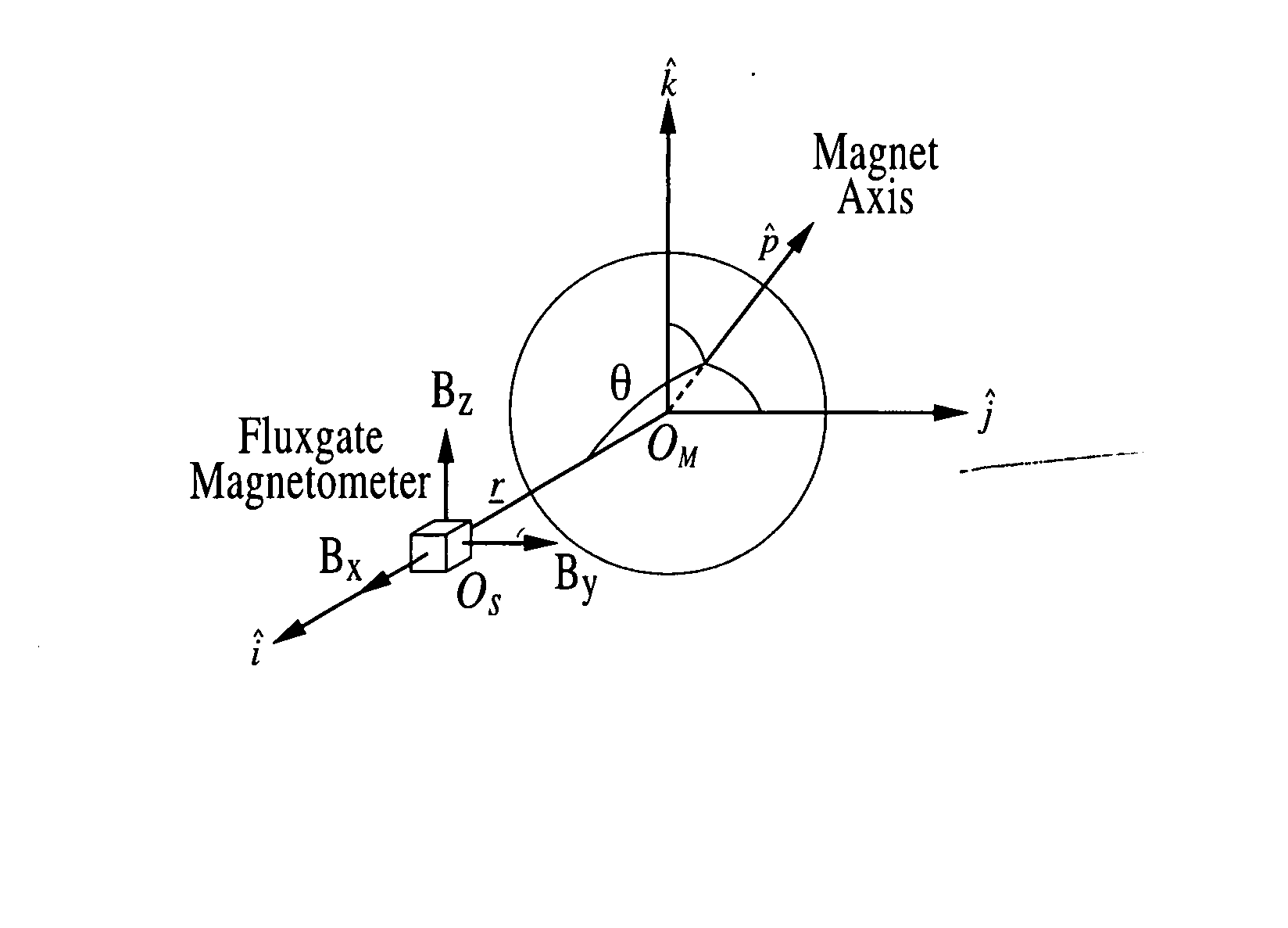

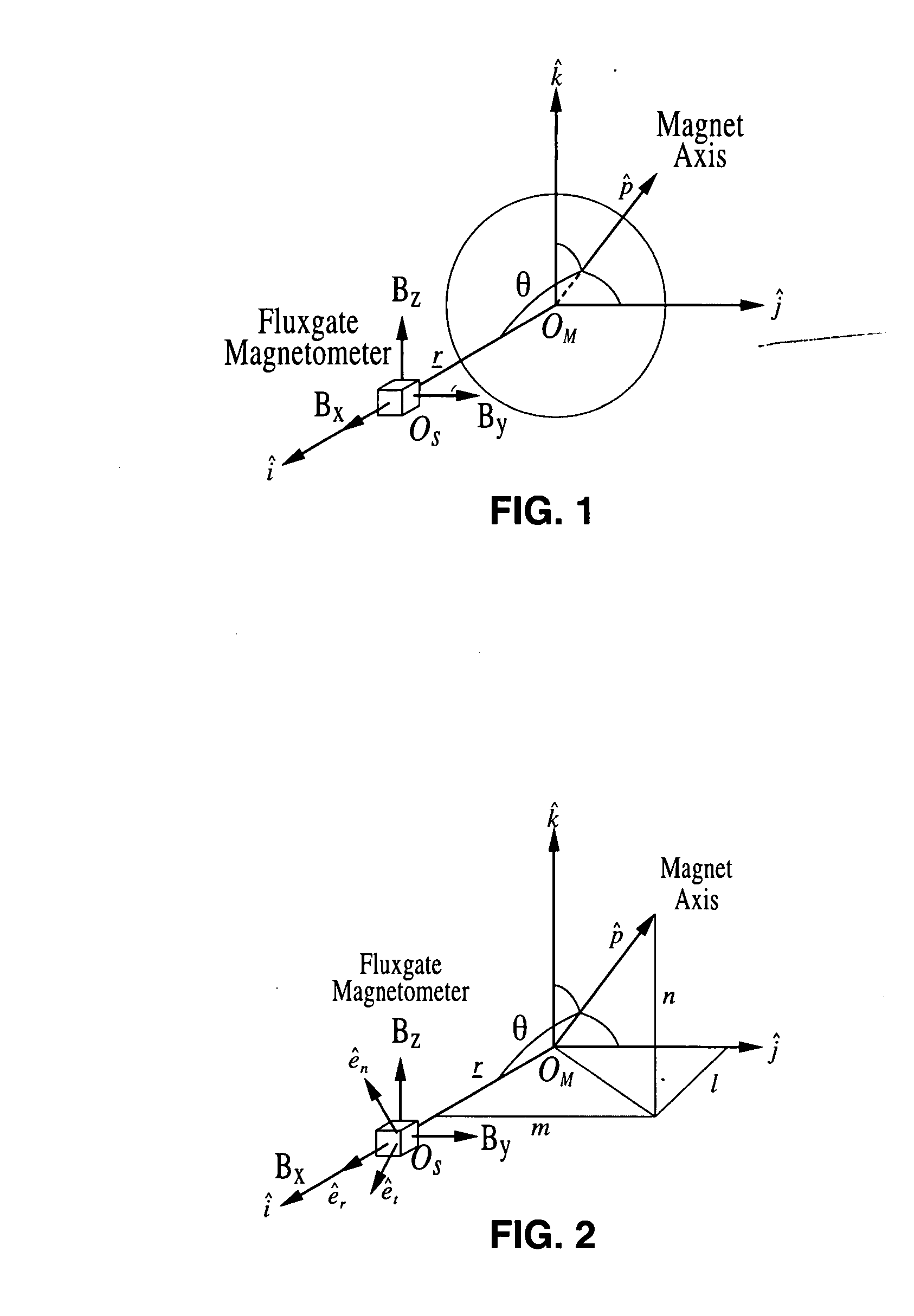

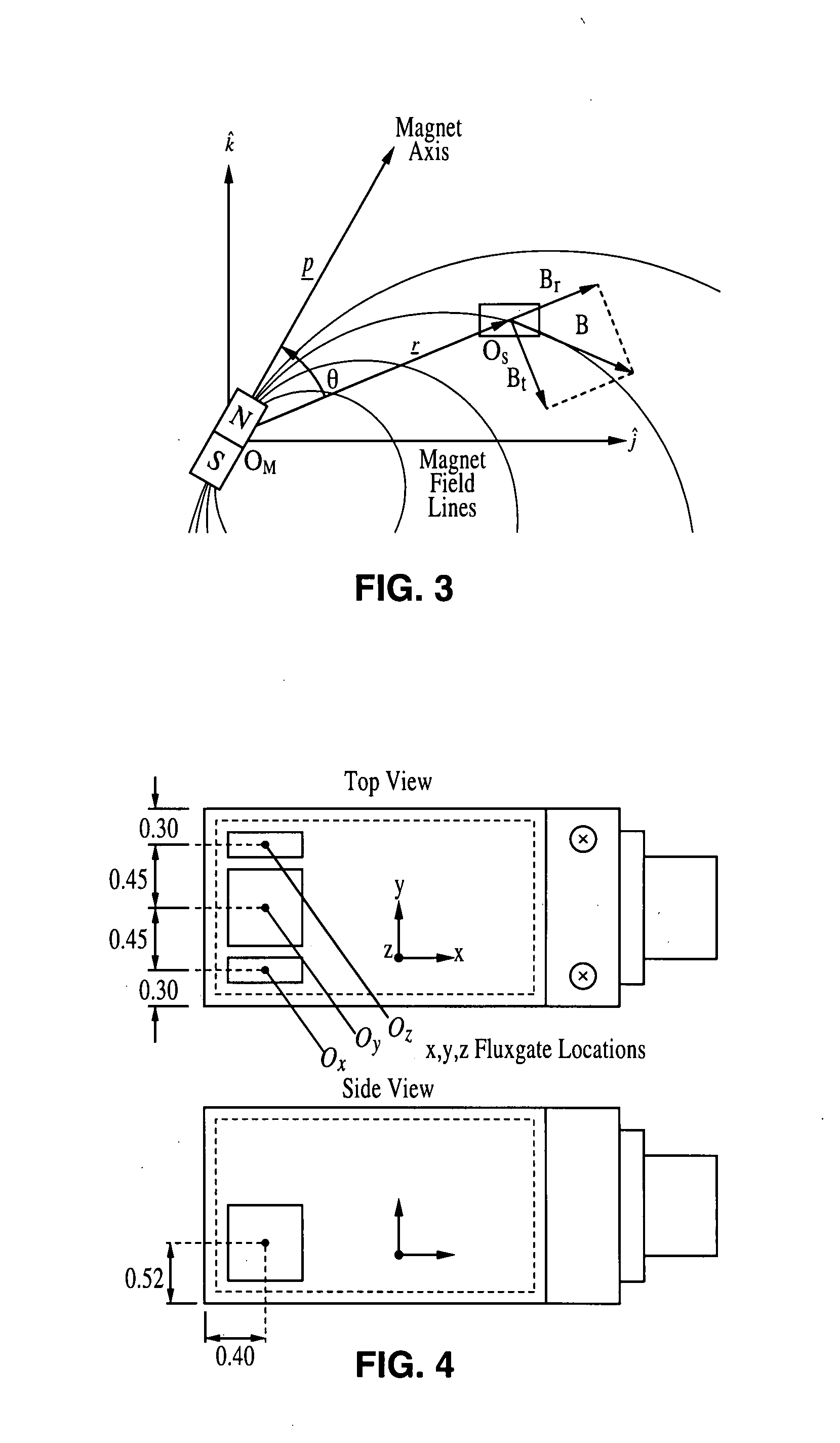

Three-dimensional, non-contacting, angular motion sensor

A three-dimensional non-contacting angular motion sensor, based on magnetometry, has been developed for velocity feedback in the ball wheel mechanism, which serves as the drivetrain for a class of omnidirectional mobile platforms. More generally, this scheme tracks rigid-body rotation about a fixed point with an undefined axis of rotation. The approach involves tracking the time-varying magnetic field of a permanent disc magnet, embedded at the center of the sphere. This data is then used to determine the absolute orientation of the magnet axis. Finally, an approach based on the natural invariants of rigid-body motion is used to determine the instantaneous axis of rotation and the angular speed of the sphere about this axis.

Owner:RGT UNIV OF CALIFORNIA

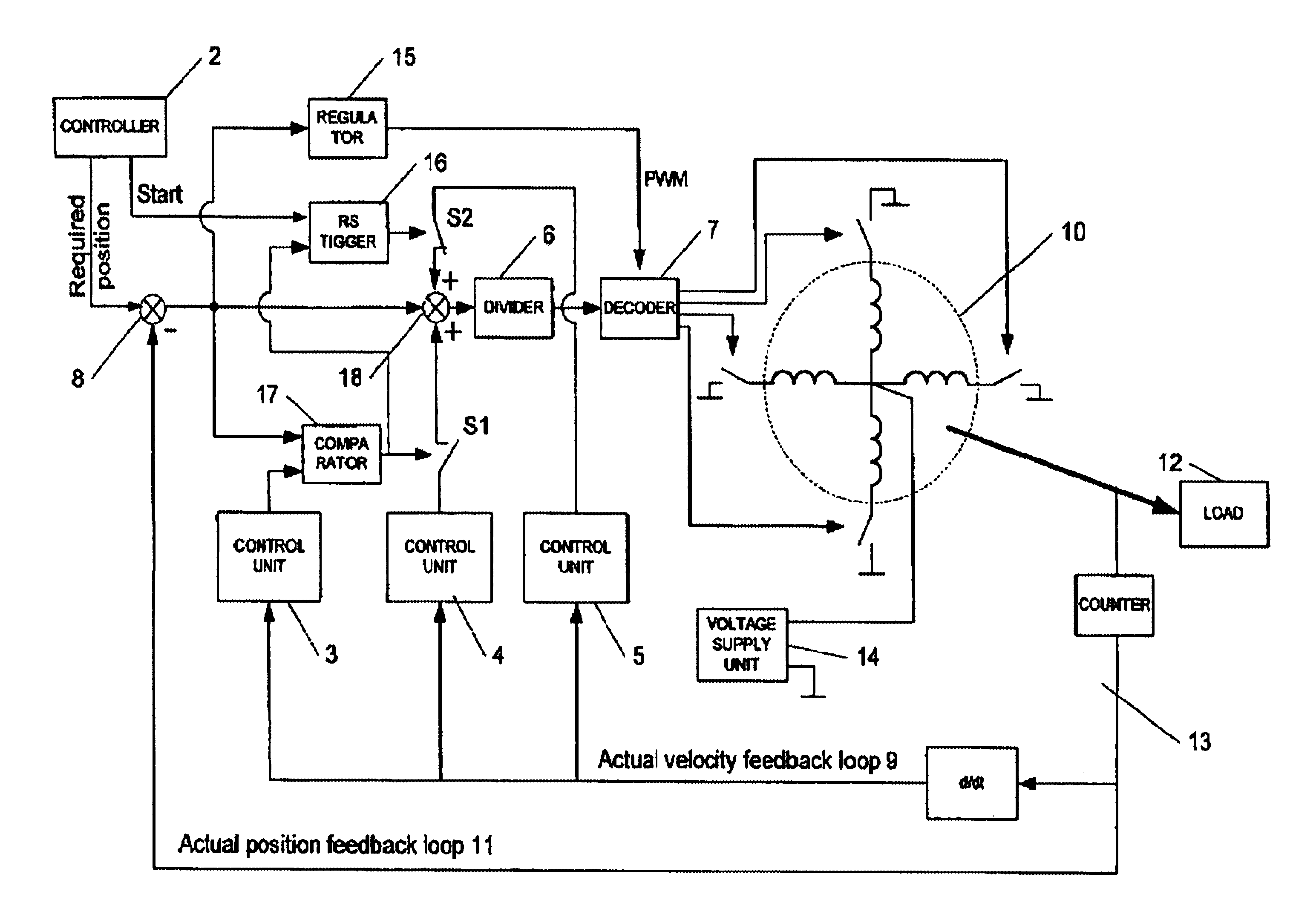

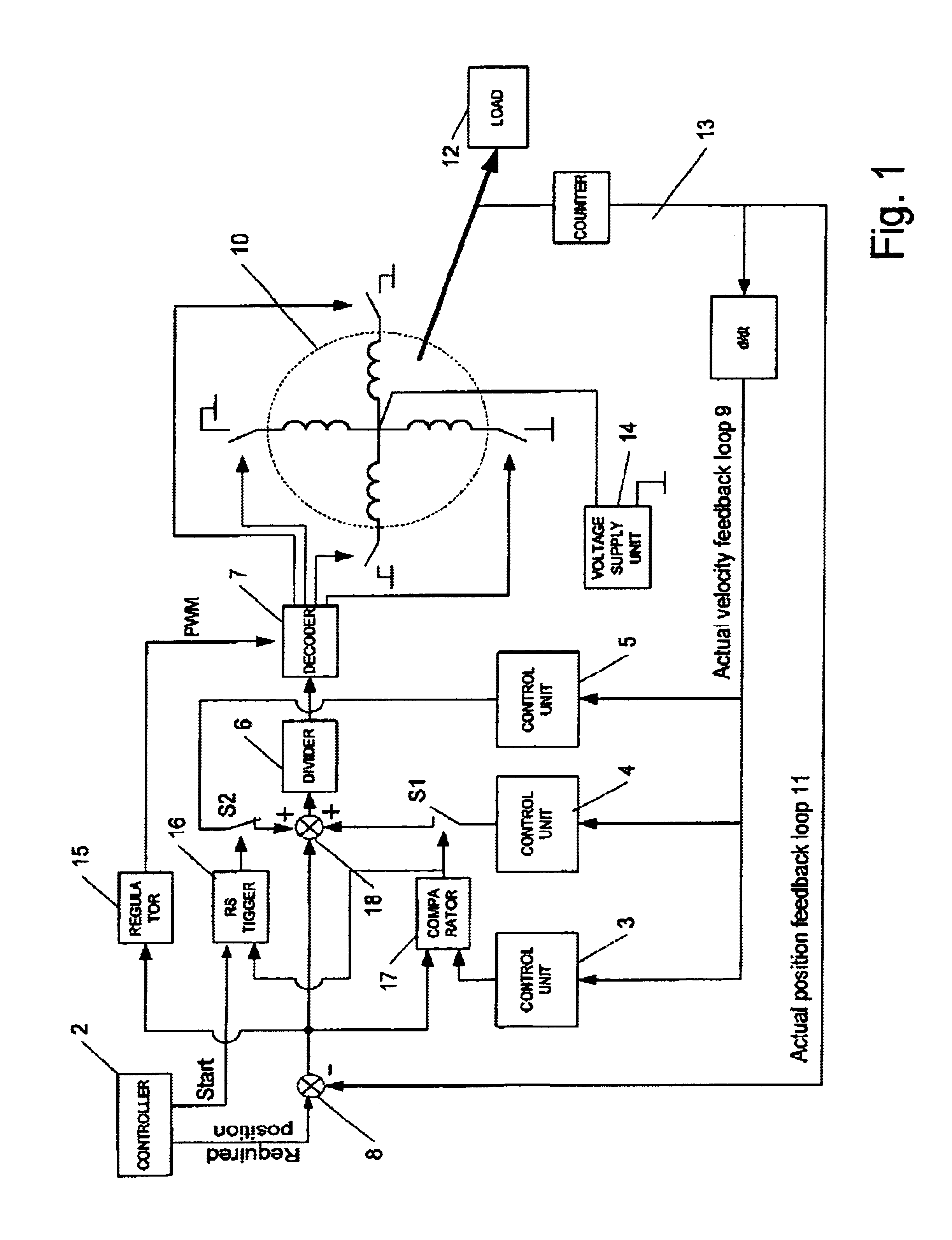

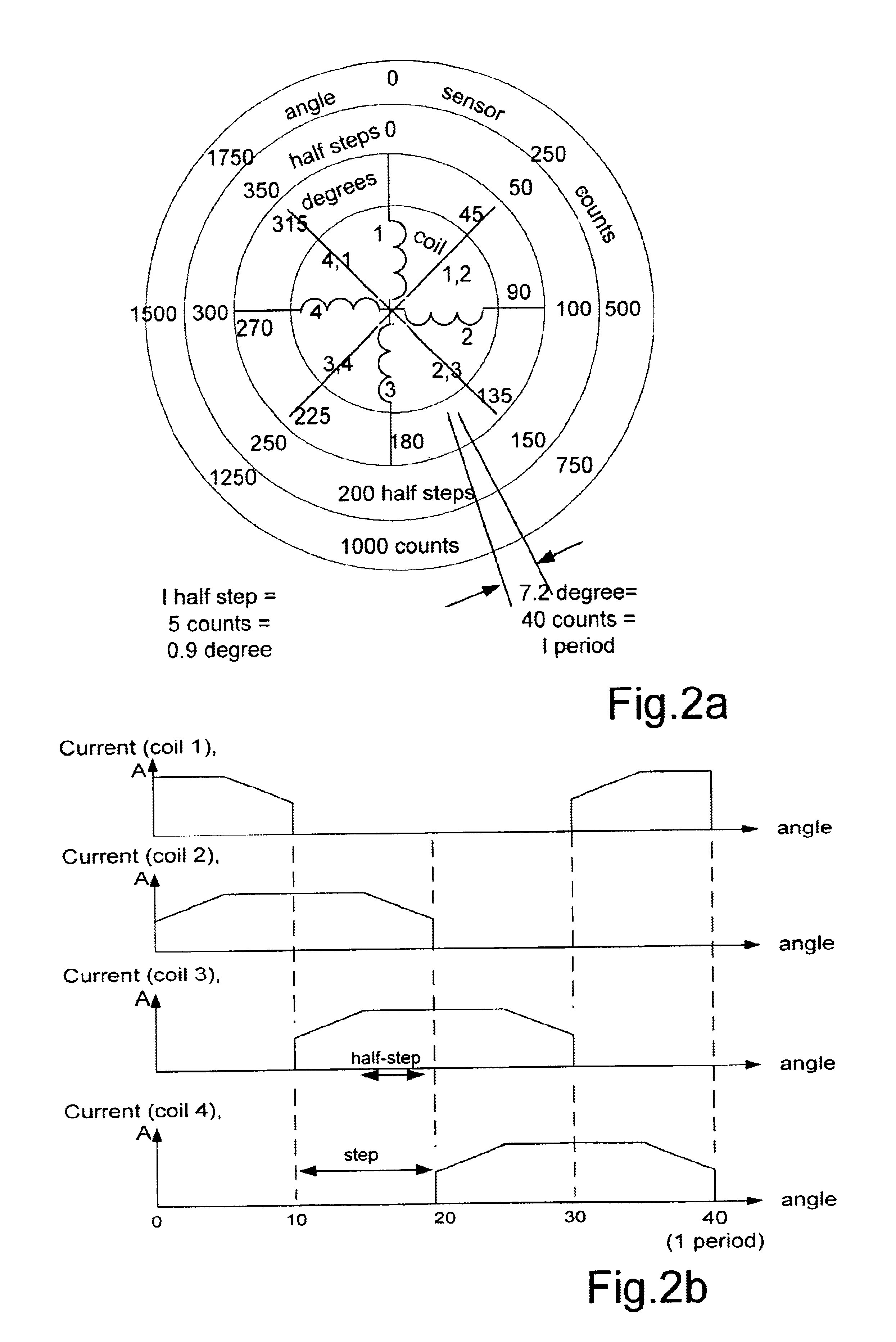

Method and apparatus for controlling acceleration and velocity of a stepper motor

InactiveUS6870346B2Easy to controlLess expenseComputer controlSimulator controlConstant frequencyEngineering

A method and apparatus for controlling acceleration and velocity of a stepper motor in which a phase offset is selected depending on motor velocity. The optimal phase offset indicates the position of the winding which generates the maximal driving moment. The increase of the driving force and the extension of the range of steady-state movement is achieved for advanced motor coils commutation with constant frequency using velocity feed back and gradual step-wise phase shift where the phase offset is selected depending on rotor velocity. The invention may be effectively applied to servomotors, stepper motors, motors having certain limitations on movement parameters, such as limitations on acceleration and other types of motors.

Owner:MIND FUSION LLC

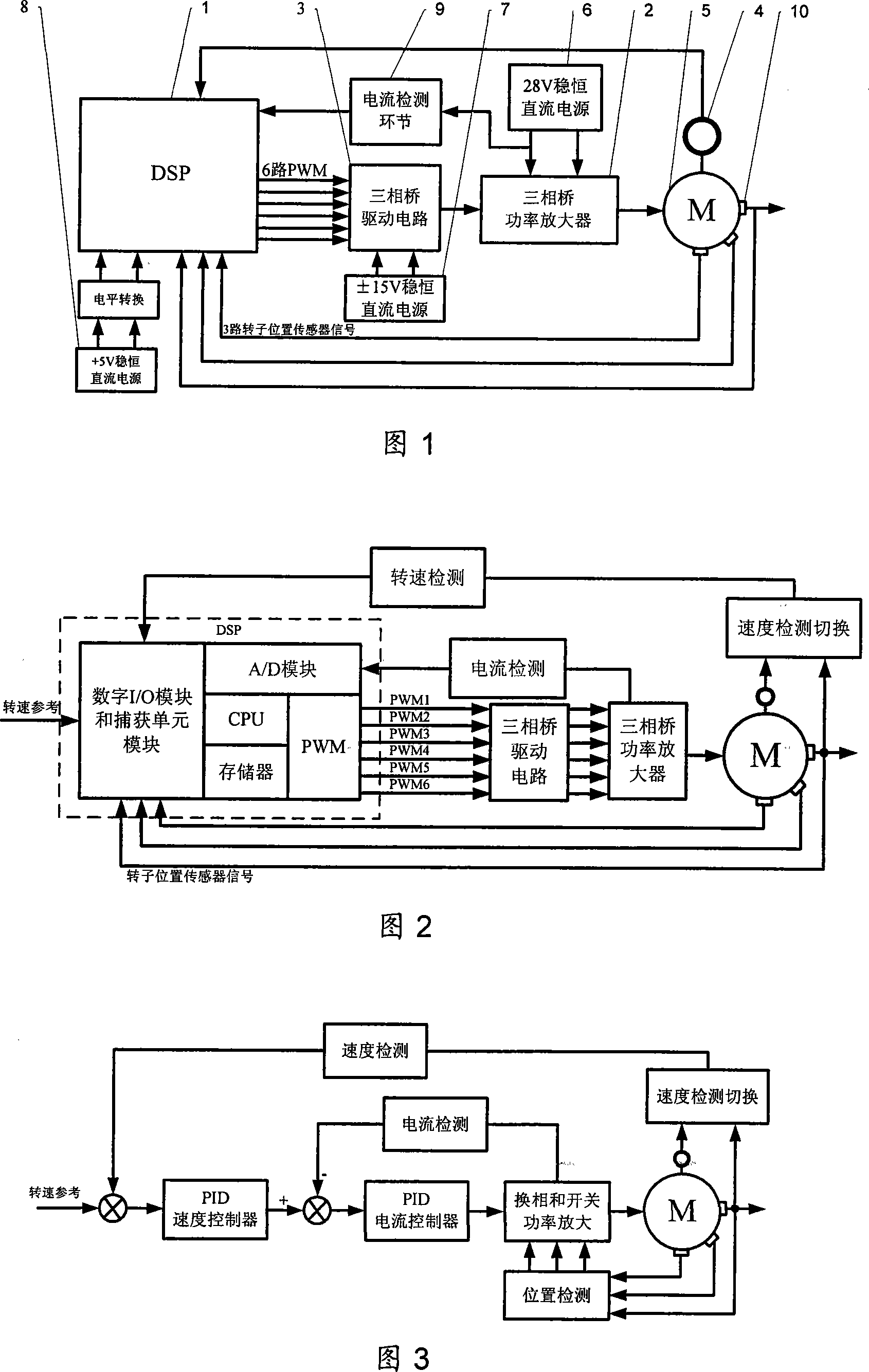

Highly precise speed mode control system for magnetic floating counteractive flywheel electromotor

InactiveCN101127501ASingle motor speed/torque controlVehicle position/course/altitude controlLow speedAttitude control

The utility model relates to a high precision velocity-mode control system of a magnetic levitation counteractive flywheel motor, which is used in a high precision attitude control executive device of a new-generation satellite with high-stability, namely the high precision velocity controlling of the magnetic levitation counteractive flywheel motor. The utility model mainly comprises a controller with a DSP as the core, a three-phase bridge power amplifier, a three-phase bridge drive circuit, an increment type shaft angle encoder, a three-phase permanent magnetic brushless direct current motor, a 28V steady direct current power supply, a +15V steady direct current power supply, a plus or minus 5V steady direct current power supply, a current checking part and Hall-effect rotor position sensor. Through the two channels of orthogonal encoding pulse signal of the increment type shaft angle encoder, the utility model provides the low-velocity controlling of the magnetic levitation counteractive flywheel motor with the velocity feedback when the velocity is in the electrically allowable rotational speed range of the increment type shaft angle encoder to realize the high precision velocity-mode controlling of the magnetic levitation counteractive flywheel motor; the signal of the Hall-effect rotor position sensor is used as the velocity feedback when the velocity is out of the electrically allowable rotational speed range of the increment type shaft angle encoder.

Owner:BEIHANG UNIV

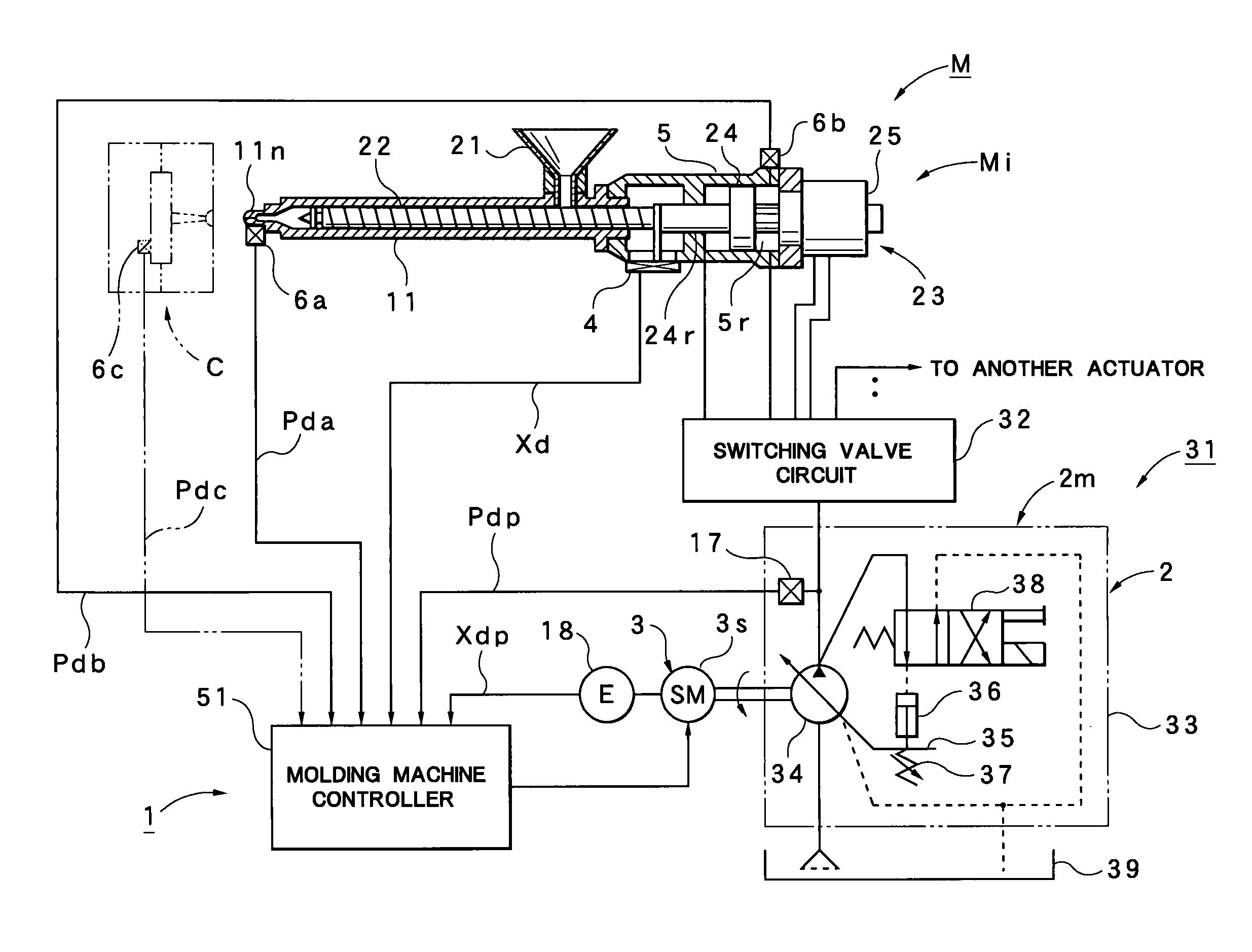

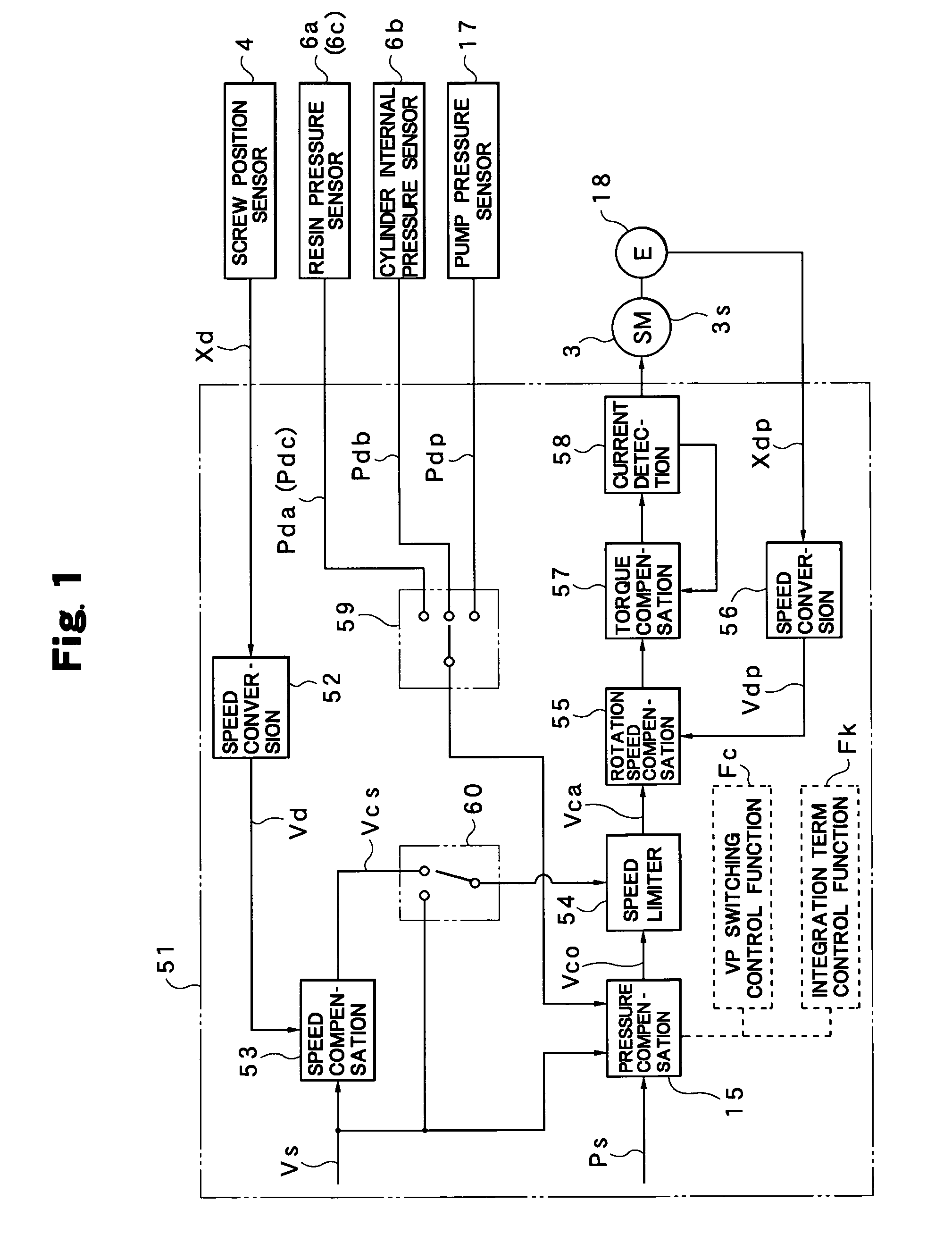

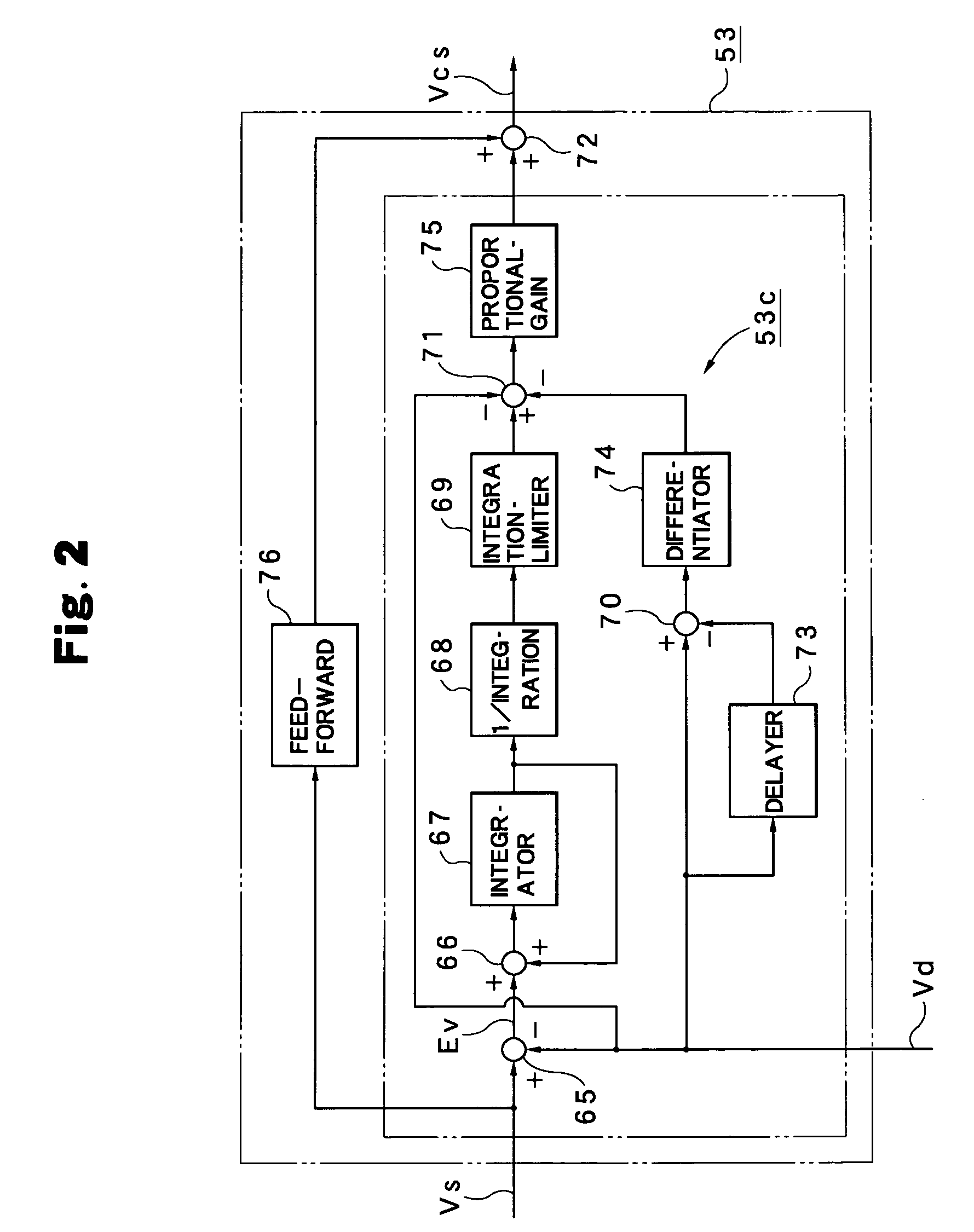

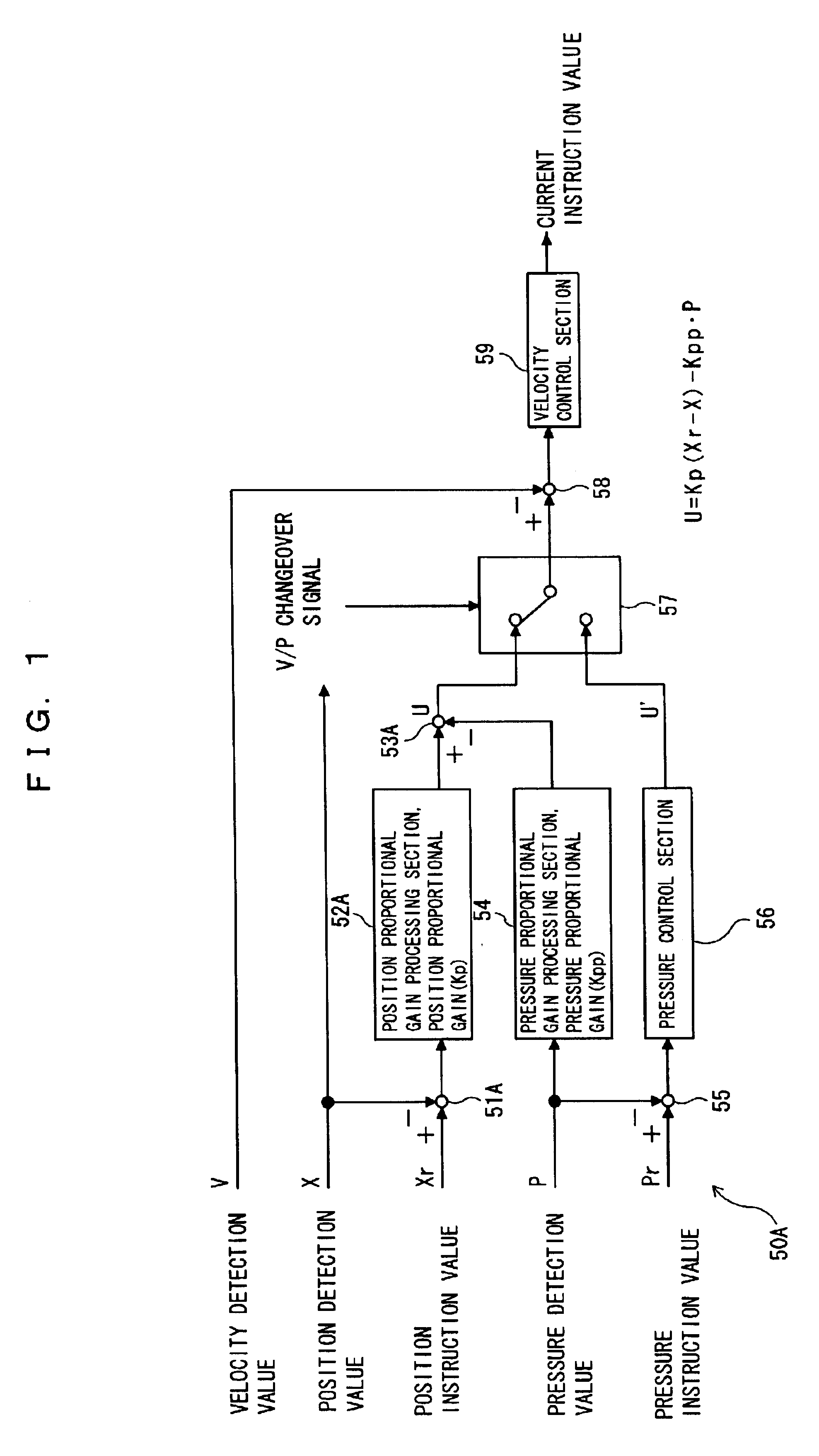

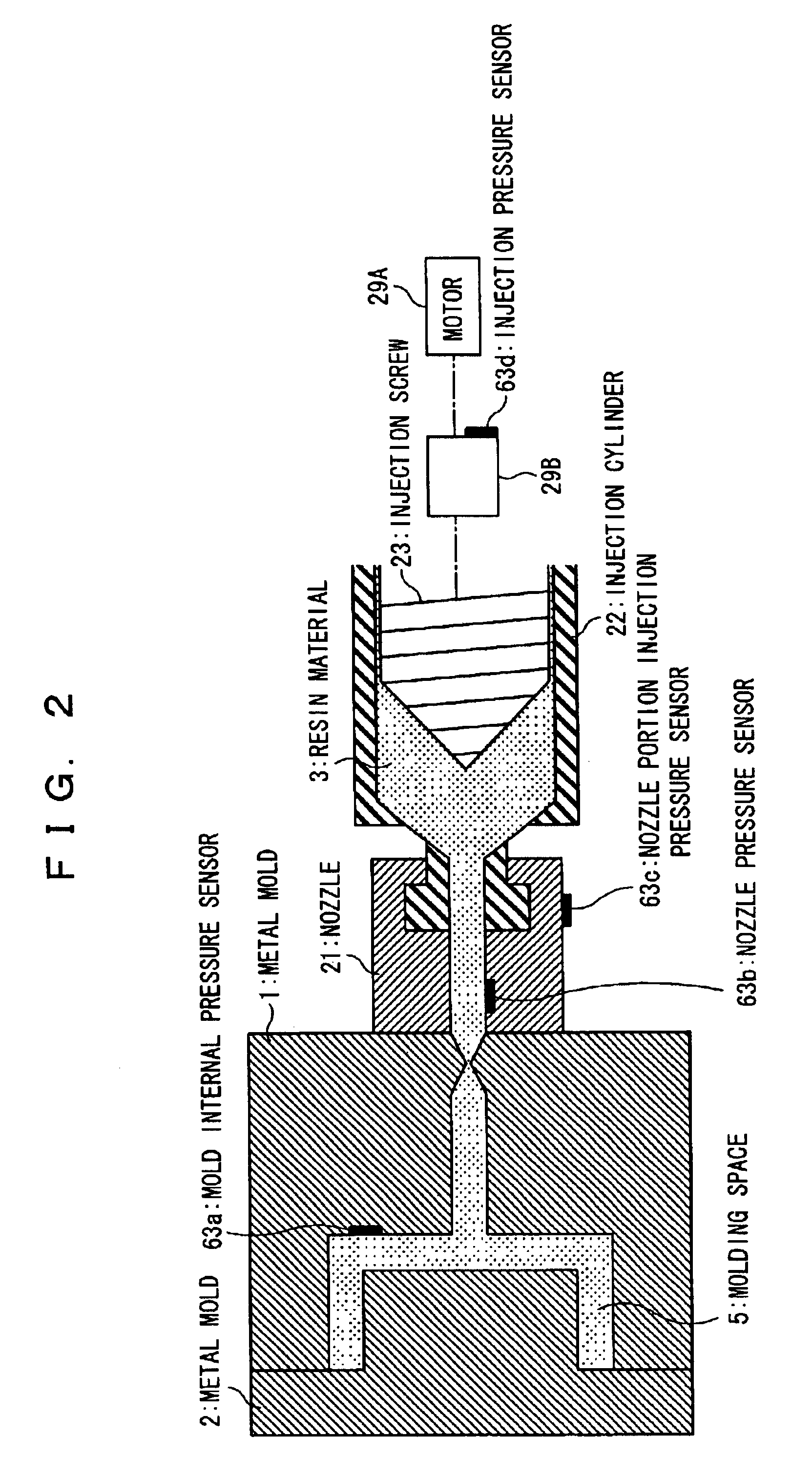

Controller of injection molding machine

Owner:NISSEI PLASTIC IND CO LTD

Motor drive with velocity noise filter

ActiveUS7187142B2Easy to controlImprove noise immunityDC motor speed/torque controlAC motor controlMotor driveControl theory

A drive unit for controlling a motor includes a position feedback device and a velocity noise filter. The position feedback device is operable to generate a position signal relating to a position of the motor. The velocity noise filter is coupled to the position feedback device and operable to filter the position signal over a predetermined number of samples to generate a velocity feedback signal for the motor.

Owner:ROCKWELL AUTOMATION TECH

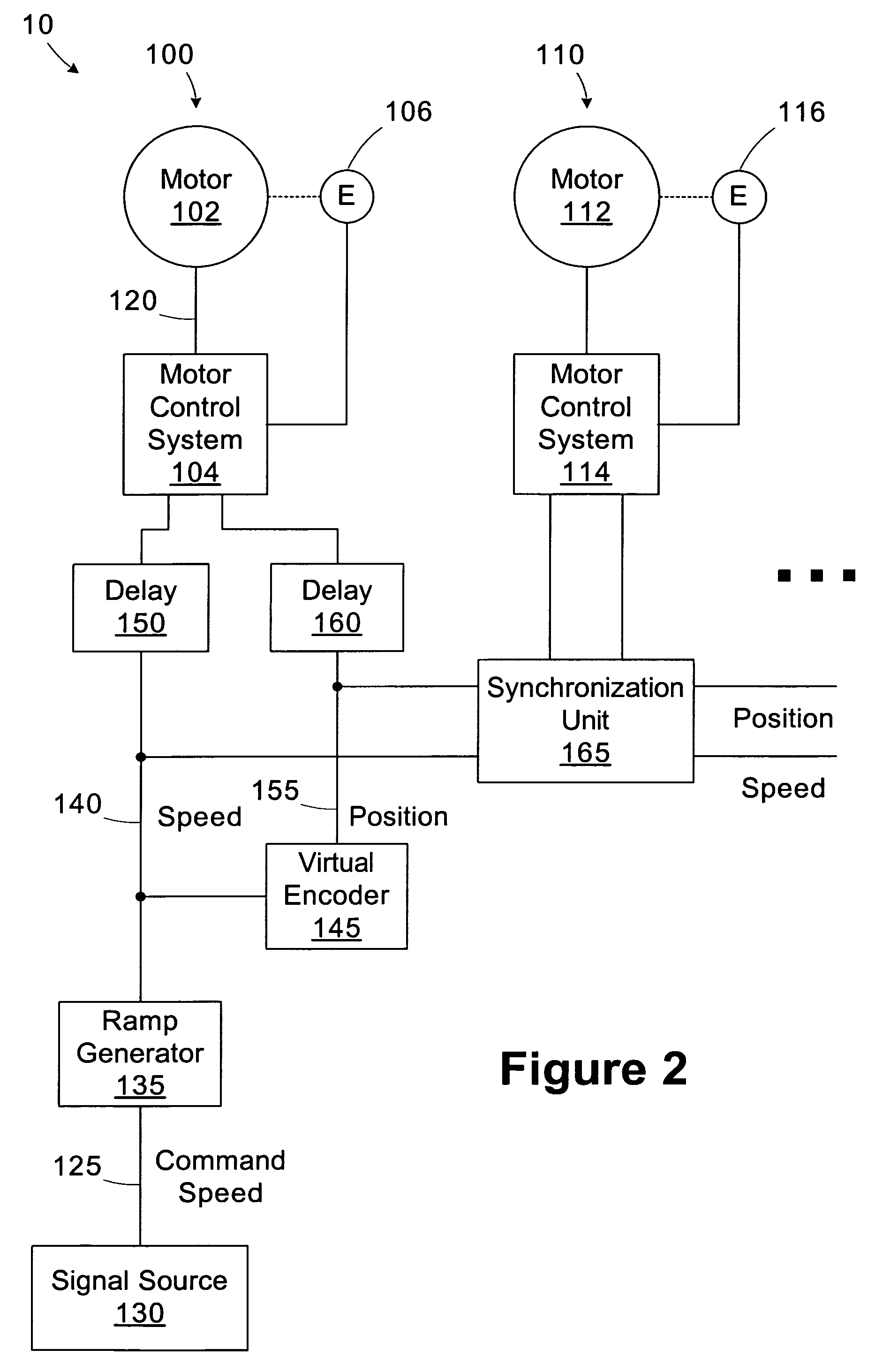

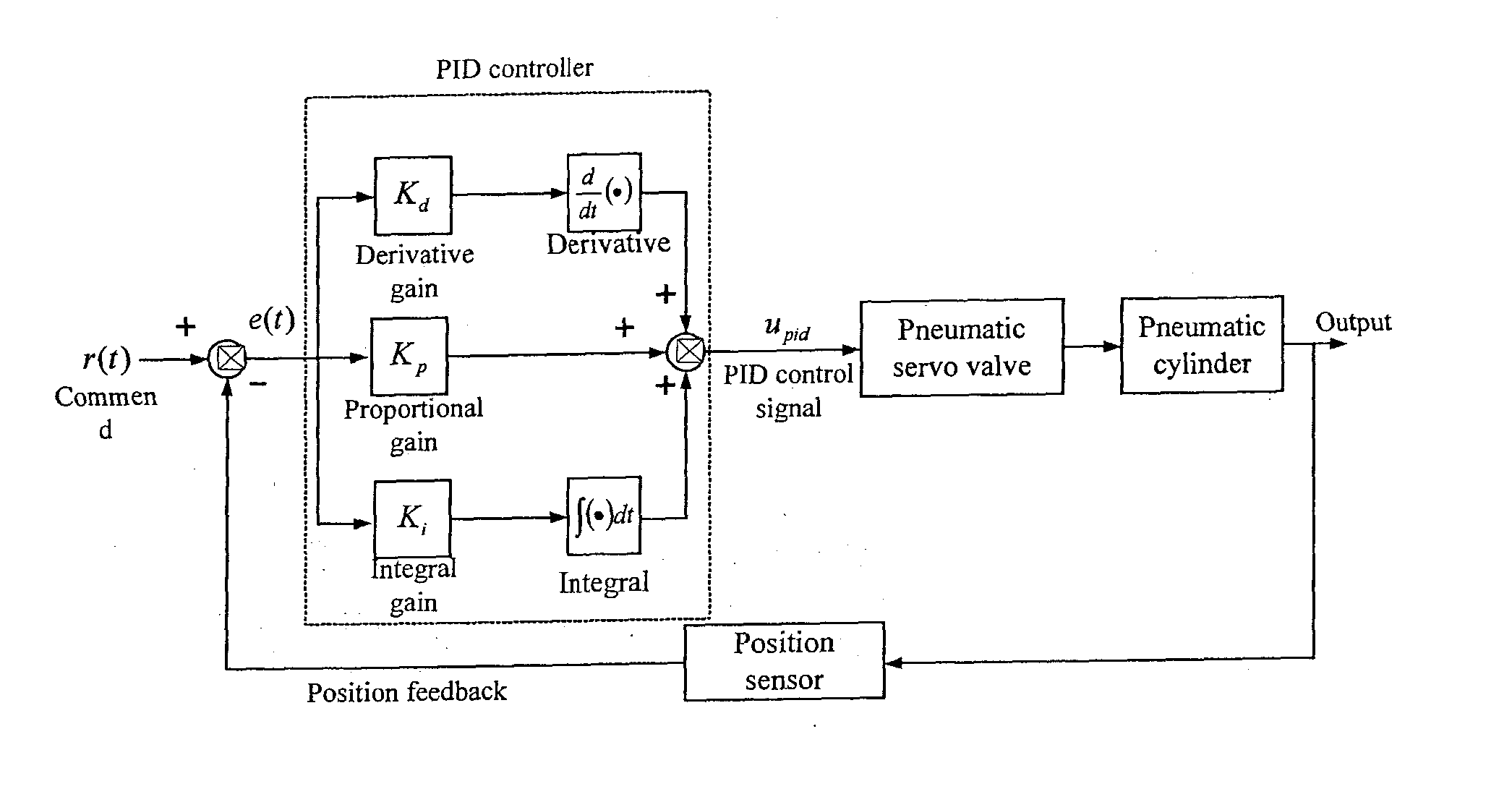

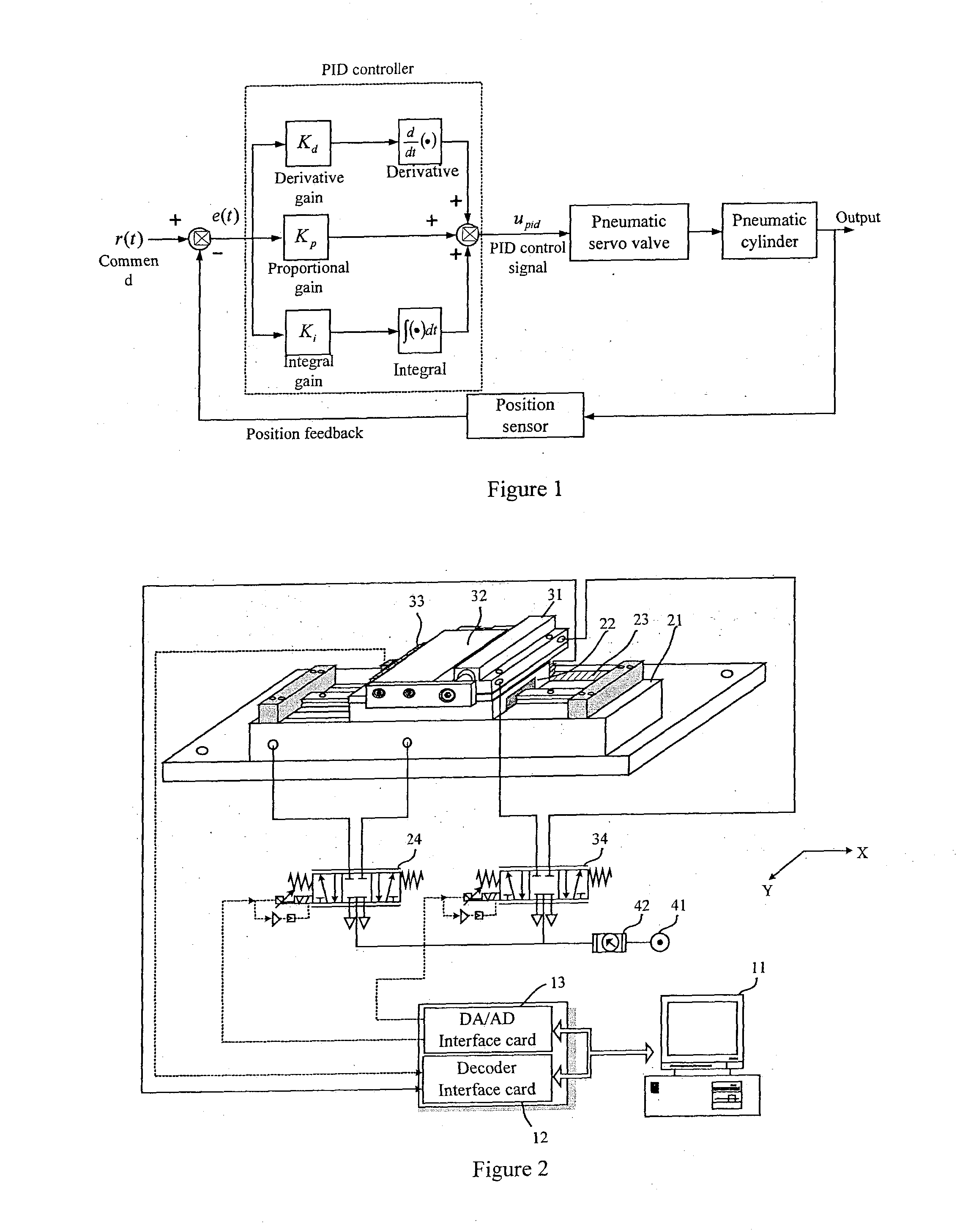

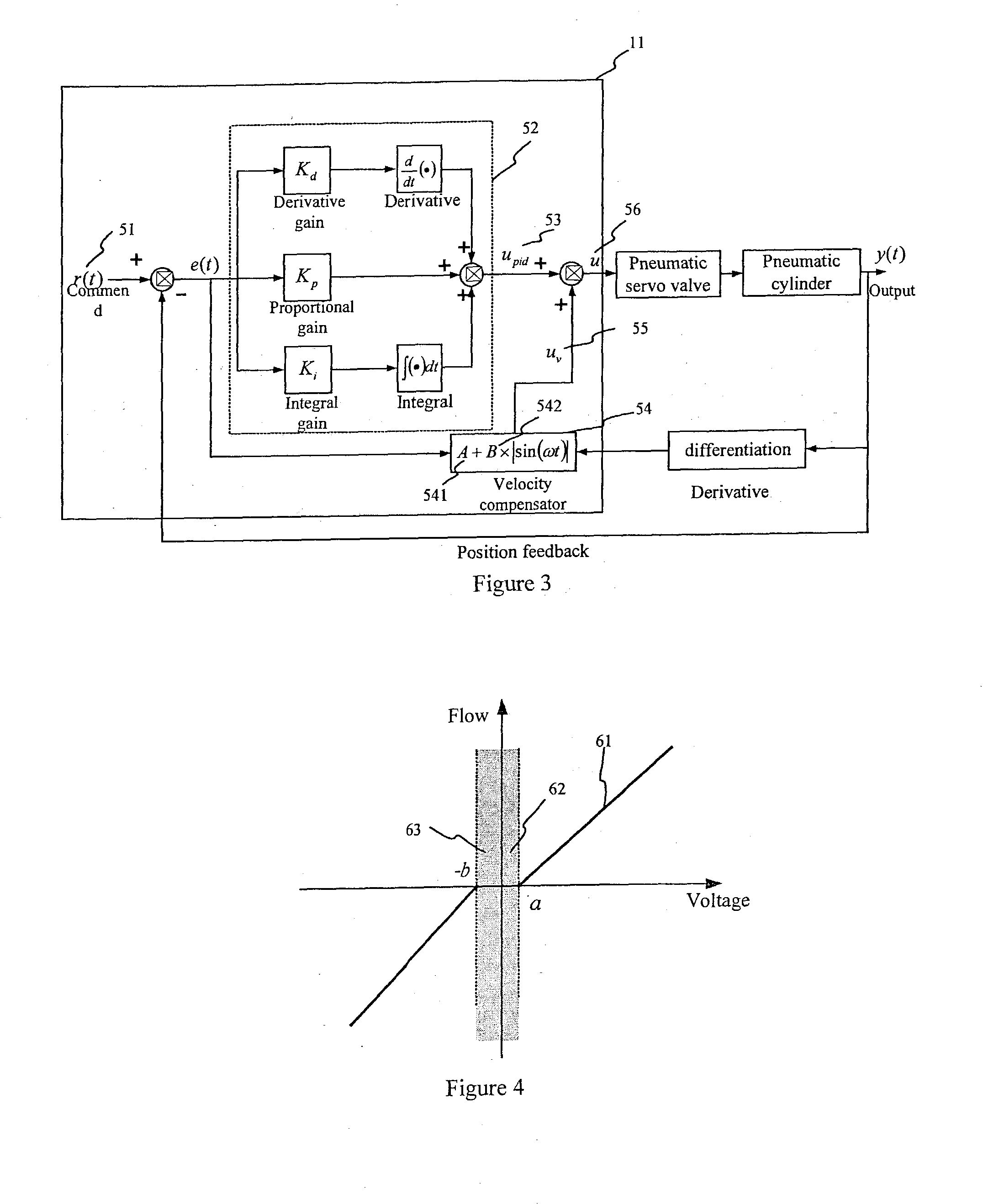

Design and control method of a micro-nanometer precision servo pneumatic X-Y positioning table

InactiveUS20050004689A1Precise positioningComputer controlSimulator controlControl signalFriction force

A micro-nanometer precision servo pneumatic X-Y positioning table comprises by two slide air cylinders and drives the two slide air cylinders by the servo control rule to make the pneumatic table to get the purpose of X-Y two degrees of freedom precision positioning. However, the pneumatic servo system is a high time-variant and nonlinear system and the nonlinear friction force; causes the stick-slip phenomenon of the servo pneumatic system. Therefore the. micro-nanometer precision servo pneumatic X-Y positioning table in accordance with the present invention has a new velocity feedback compensation method to overcome the nonlinear friction force and the stick-slip phenomenon. The new method is to add a velocity compensation signal, which periodic frequency is larger than the system's natural frequency into the control signals. The method is to put the velocity compensation signal directly into the servo valve control signals. By this method; it is able to avoid the complex control rules and the calculation of the feedback compensation and to get higher precision positioning. The positioning precision of the micro-nanometer servo pneumatic X-Y positioning table is about the resolution of the linear scale (ex. in this case 20 nanometer, is the resolution of the used optical linear scale; if the resolution is 10 nanometer the precision can be also 10 nanometer) not only for long stroke but also for micro-step command.

Owner:SHIH MING CHANG +1

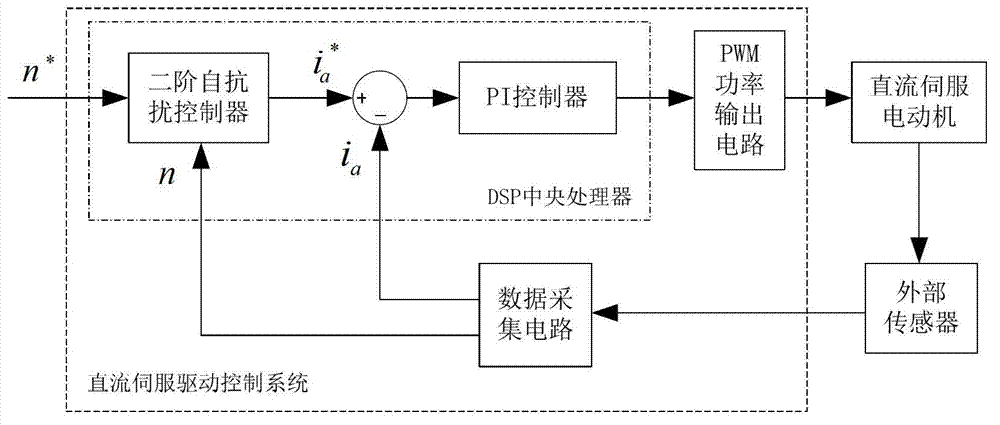

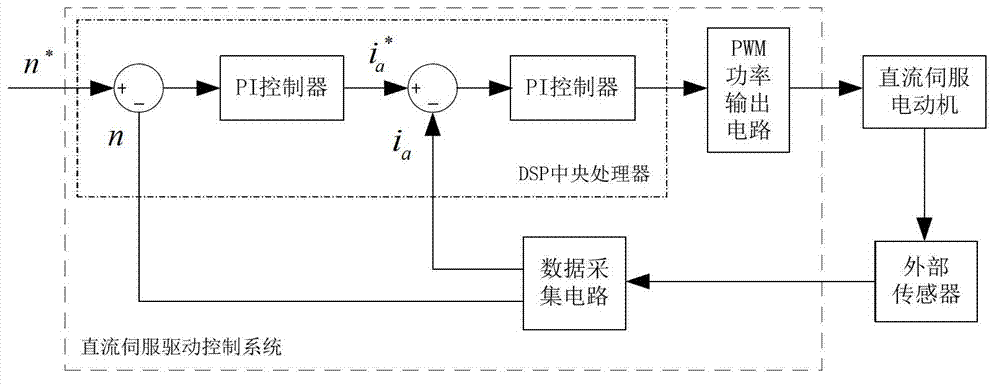

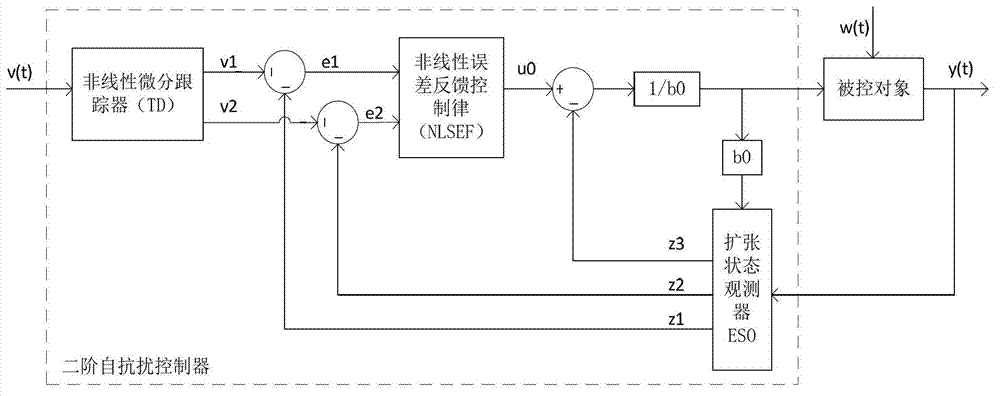

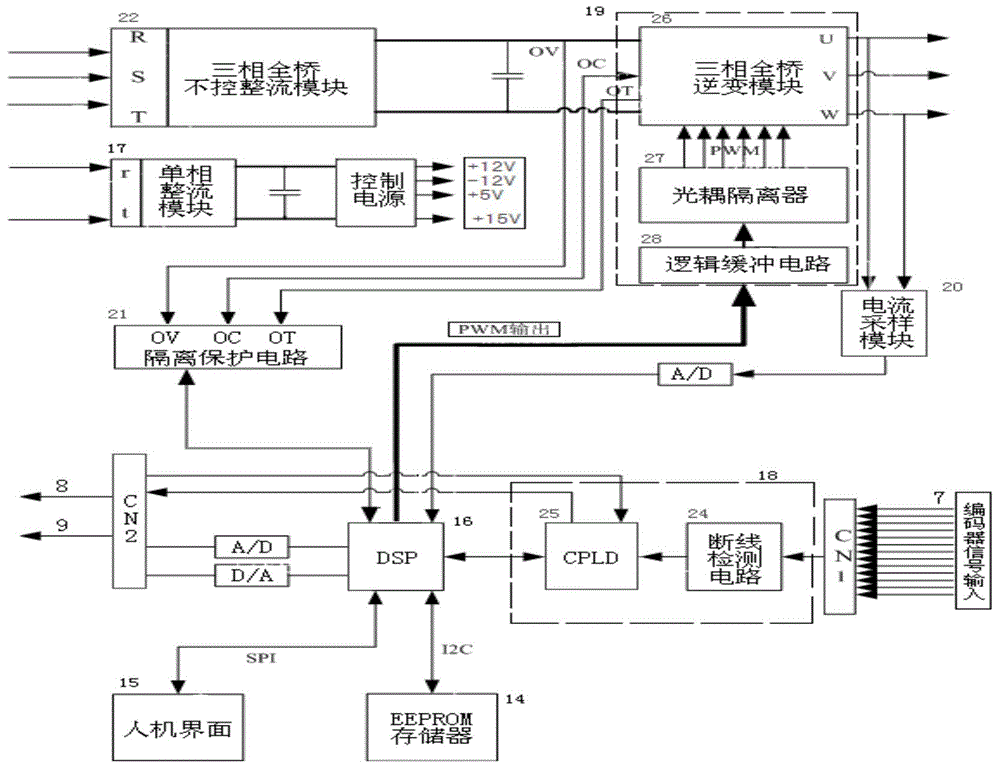

DC (direct control) servo drive control system

InactiveCN103208958AHeavy computationThe solution is not easy to achieveField or armature current controlControl signalData acquisition

An DC servo drive control system consists of a data acquisition circuit, a DSP (Digital Signal Processor) CUP (central processing unit) and a PWM (Pulse-Width Modulation) power output circuit, wherein the DSP CUP includes a second order active-disturbance-rejection controller and a PI (proportional-integral) controller. The input end of the DSP CUP receives a velocity set value sent by an upper computer and an DC servo-motor velocity feedback value and a current feedback value which are sent by an external sensor in a feedback mode, and the velocity set value, the DC servo-motor velocity feedback value and the current feedback value are output to the PWM power output circuit after being processed by the DSP CUP; and the output end of the PWM power output circuit is connected with an DC servo-motor which is the controlled object of the DC servo drive control system. The input end of the data acquisition circuit is connected with the external sensor, the output end of the data acquisition circuit is connected with the input end of the DSP CUP, the data of the DC servo-motor collected by the external sensor are transmitted to the PWM power output circuit after being sent to the DSP CUP for being processed through the data acquisition circuit, and the WM power output circuit outputs control signals to control the DC servo-motor.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

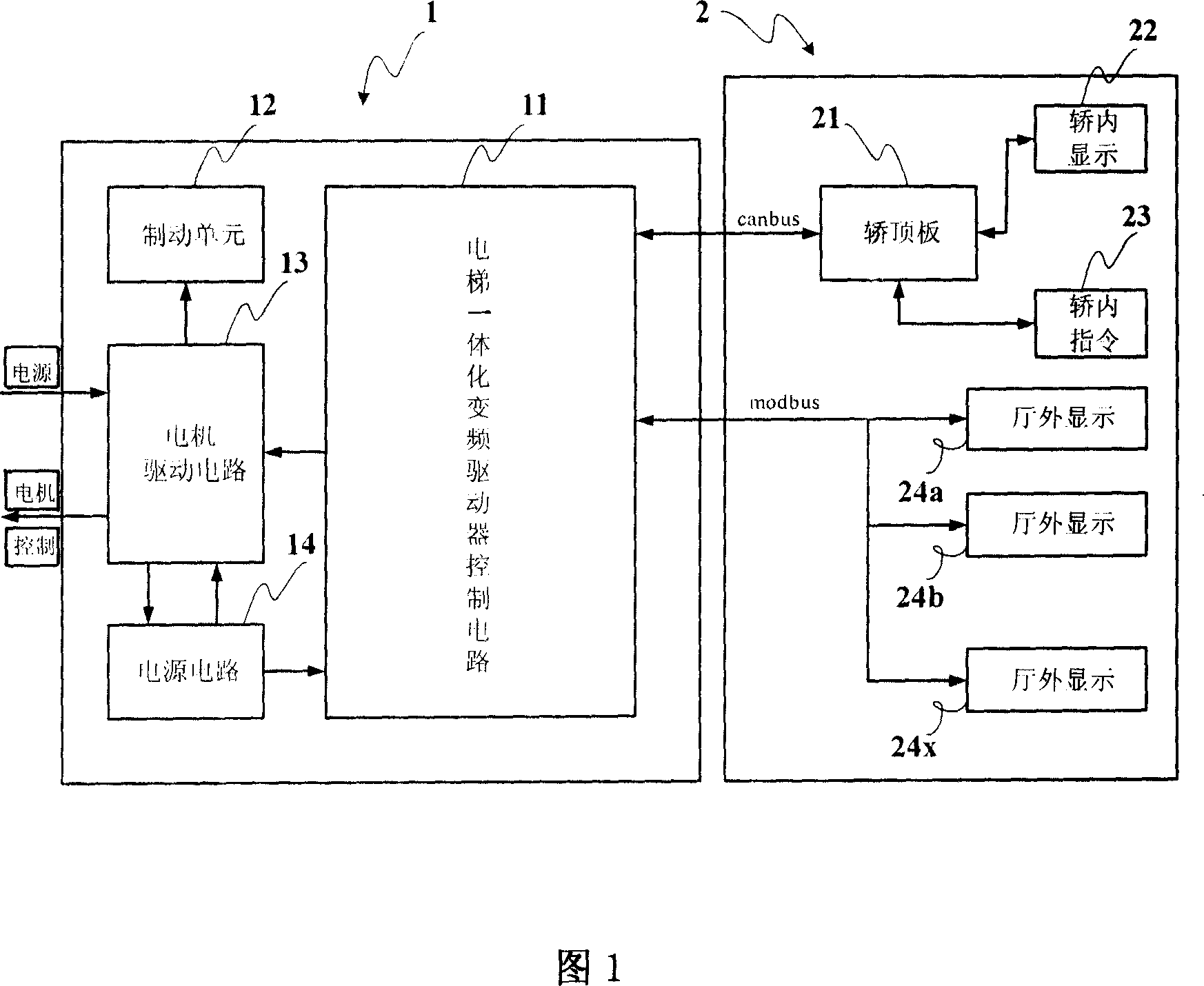

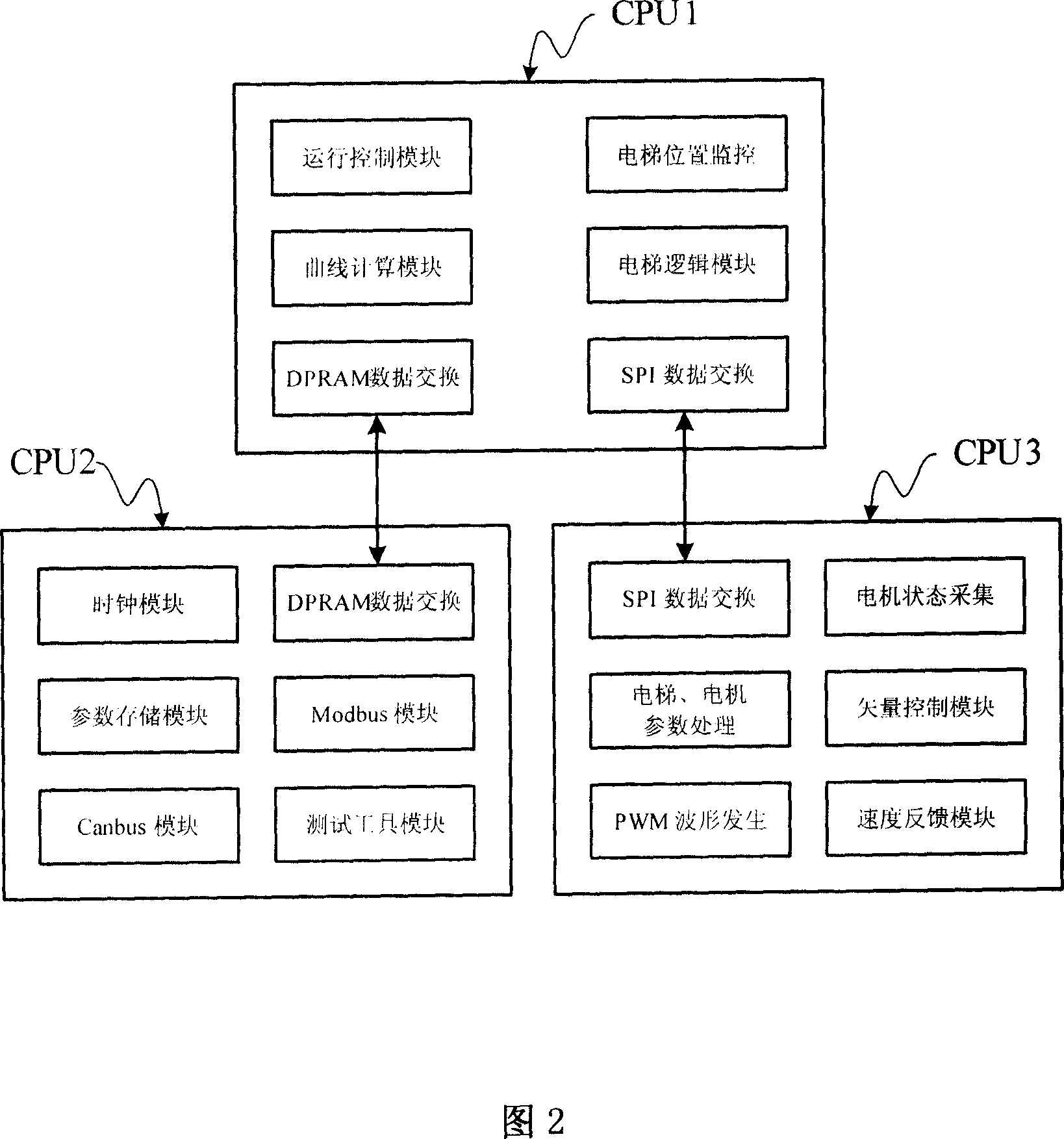

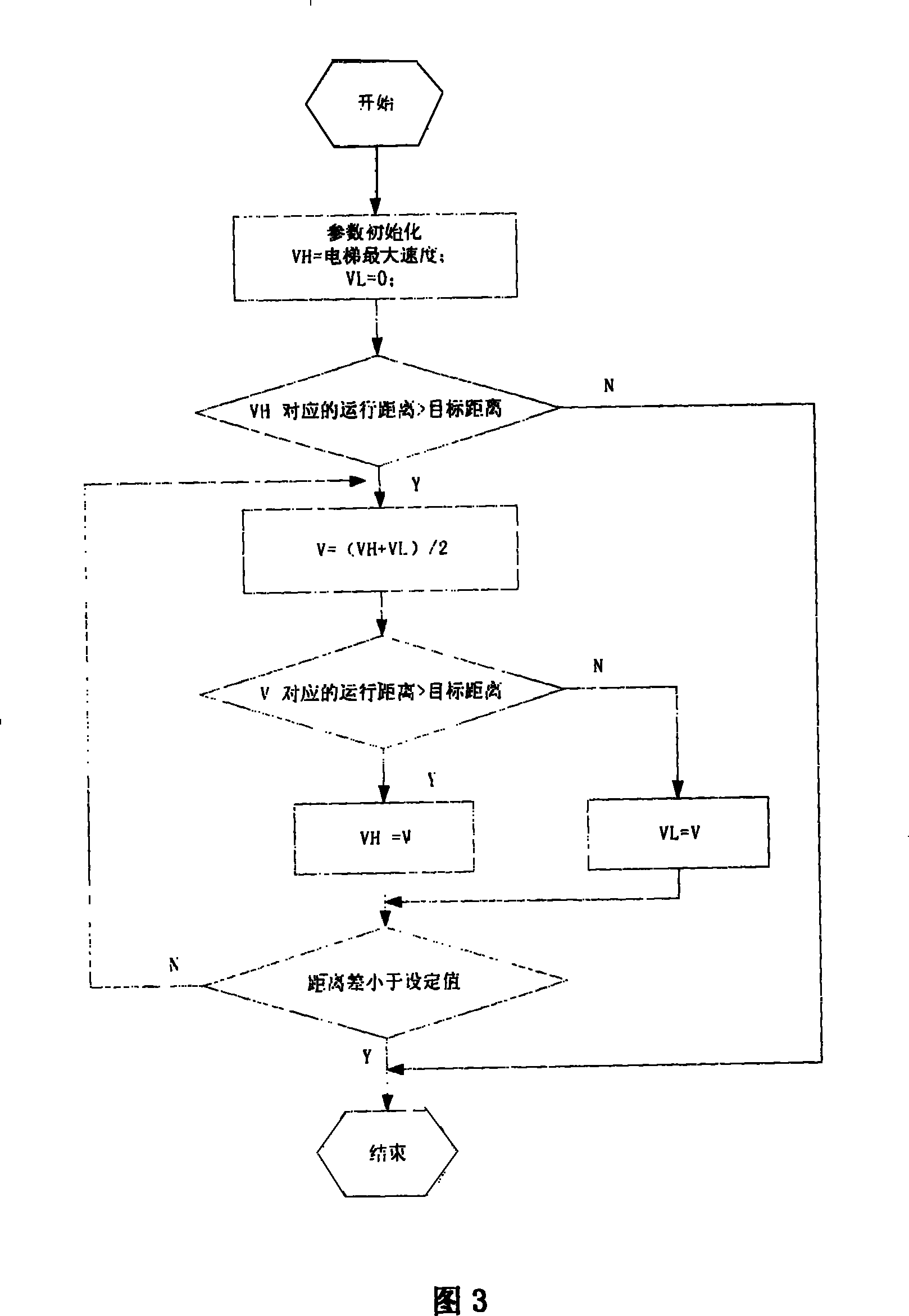

Integral frequency conversion controller for elevator

Owner:SUZHOU INOVANCE TECH CO LTD +1

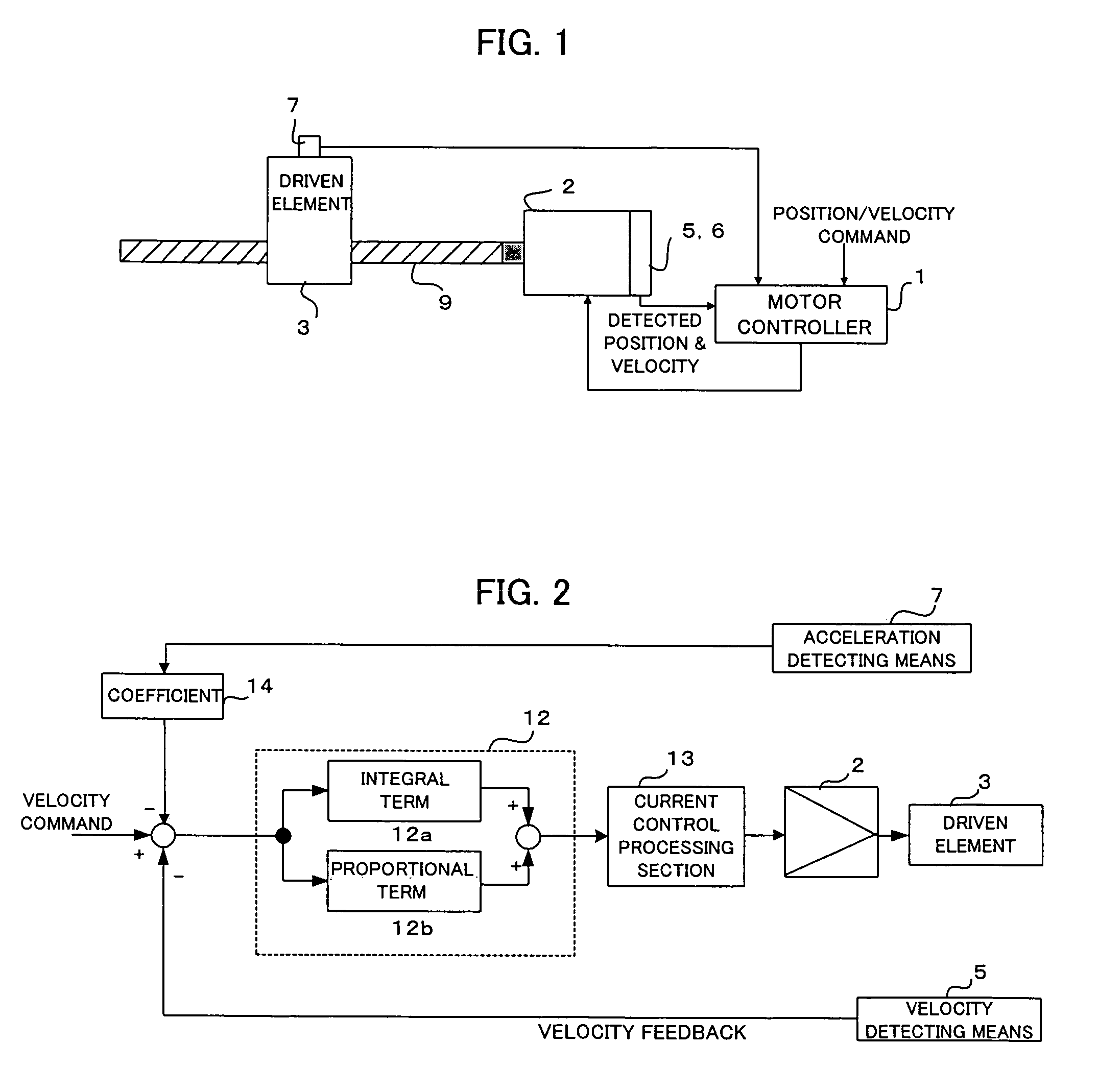

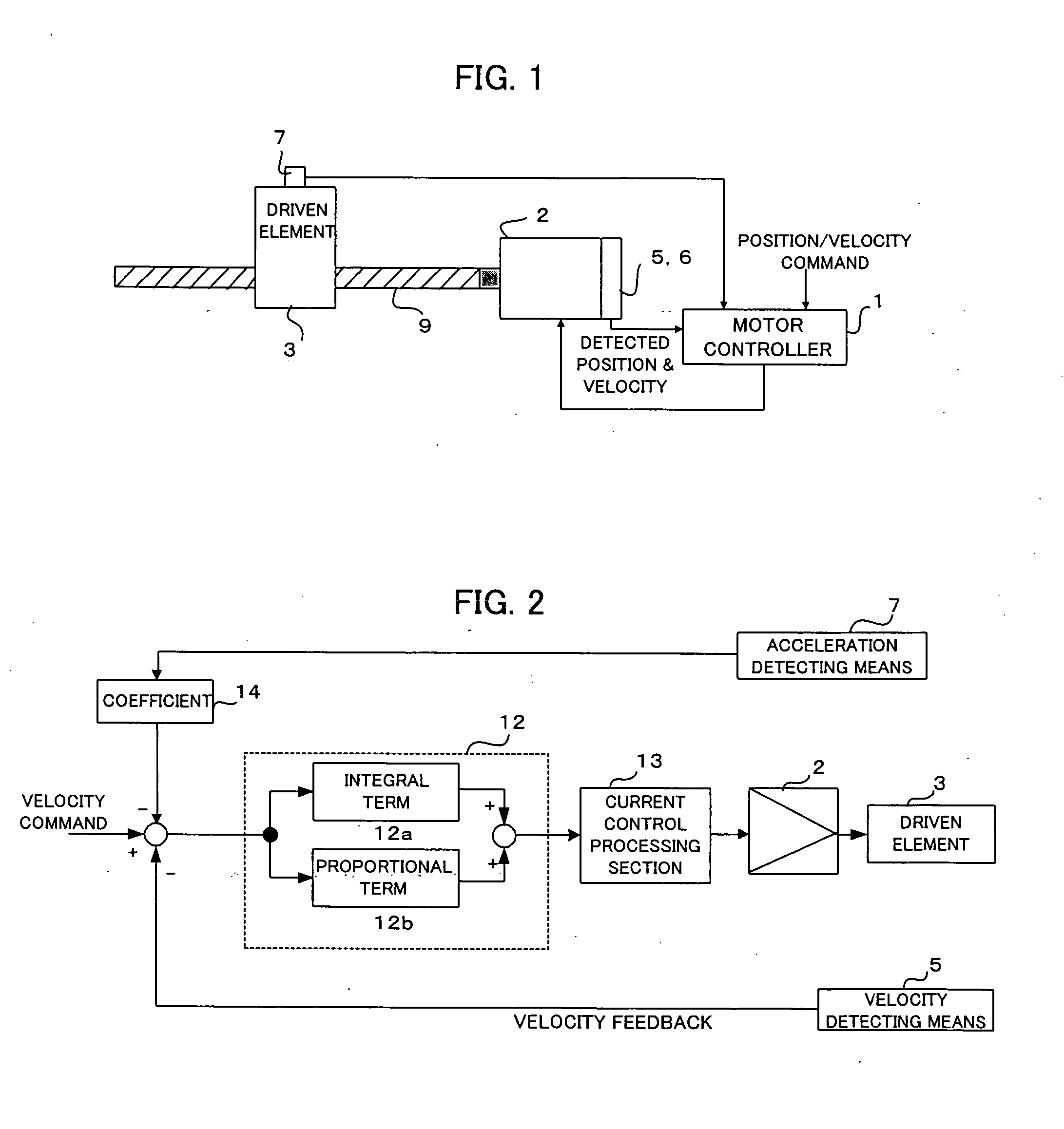

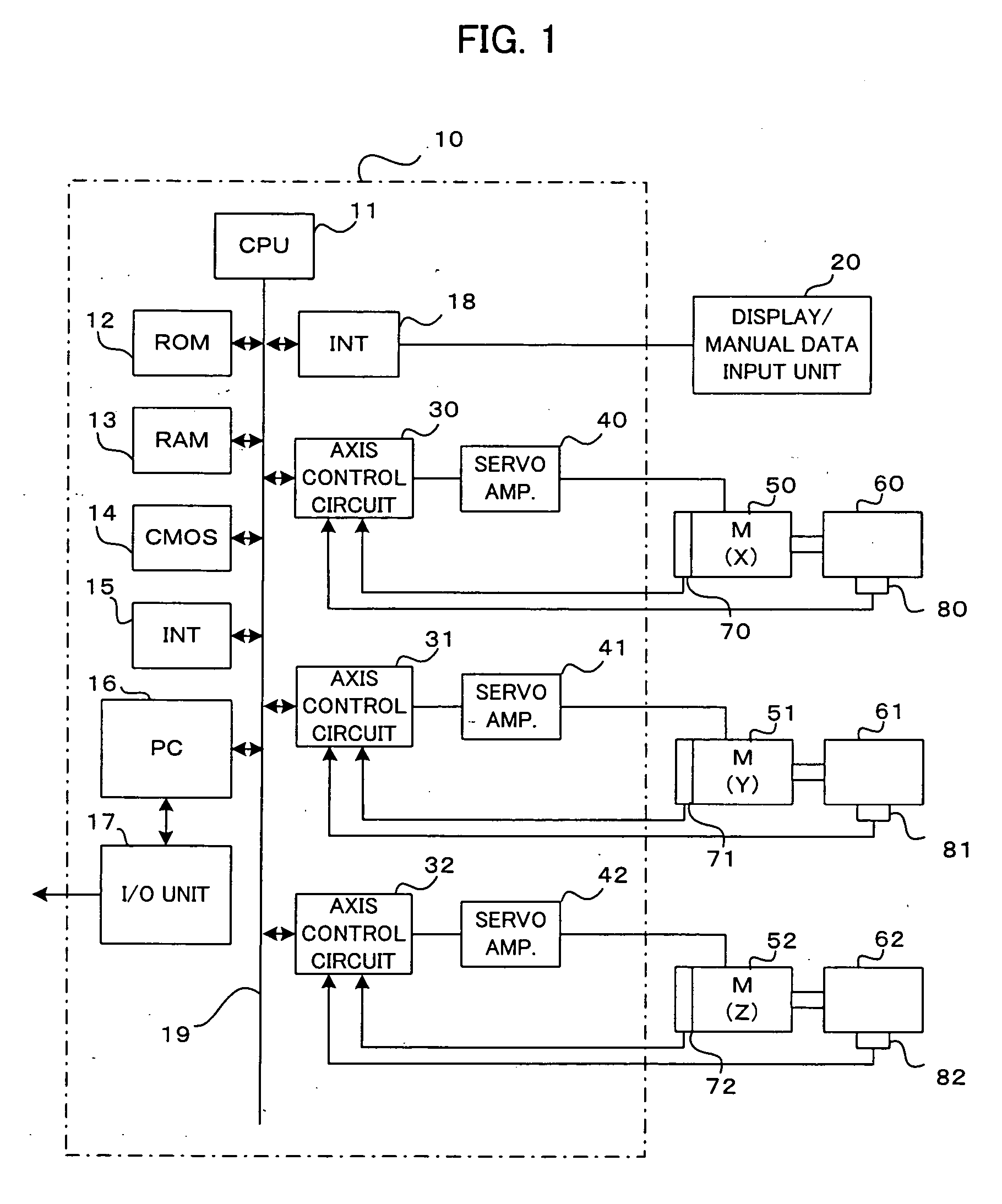

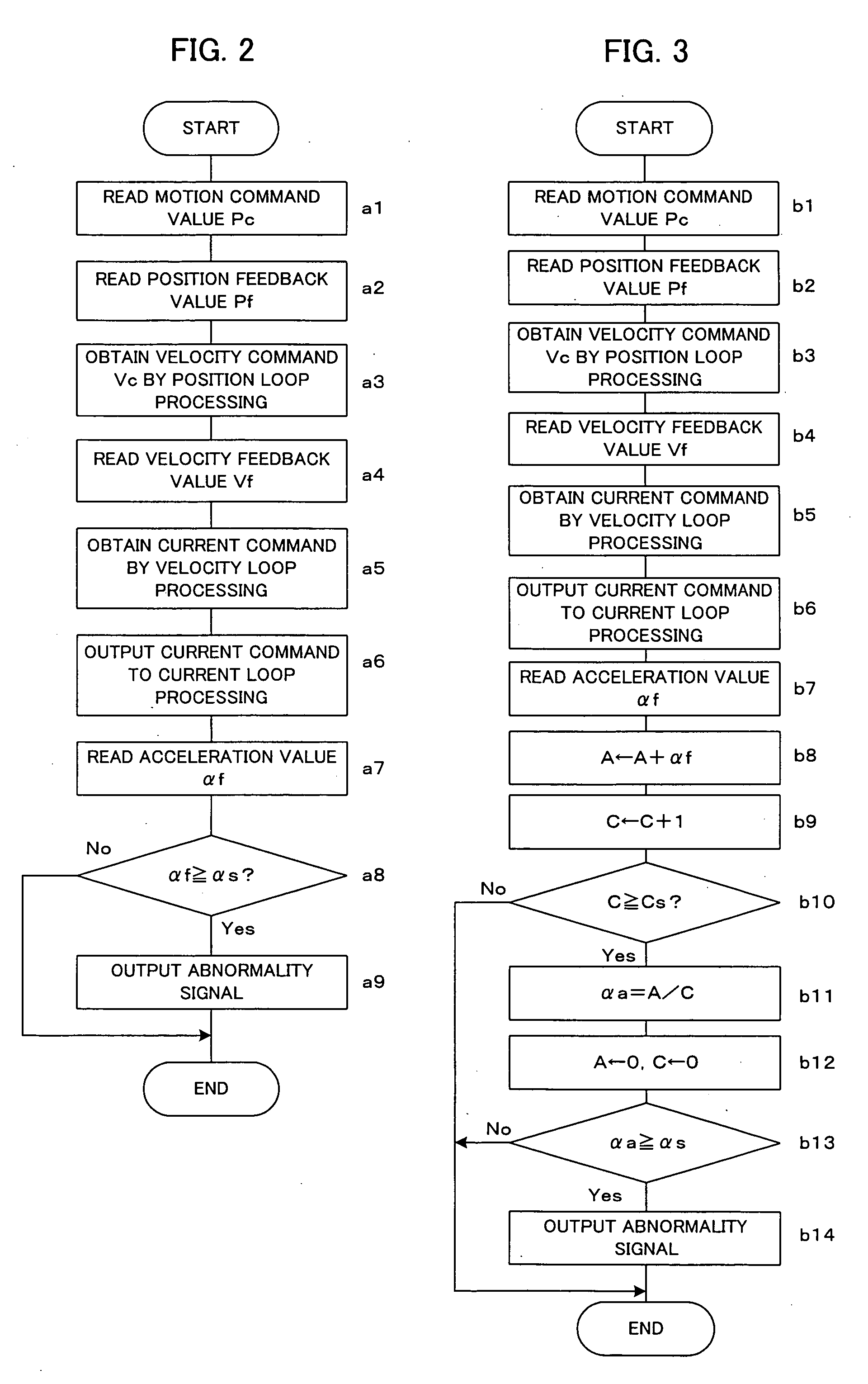

Controller

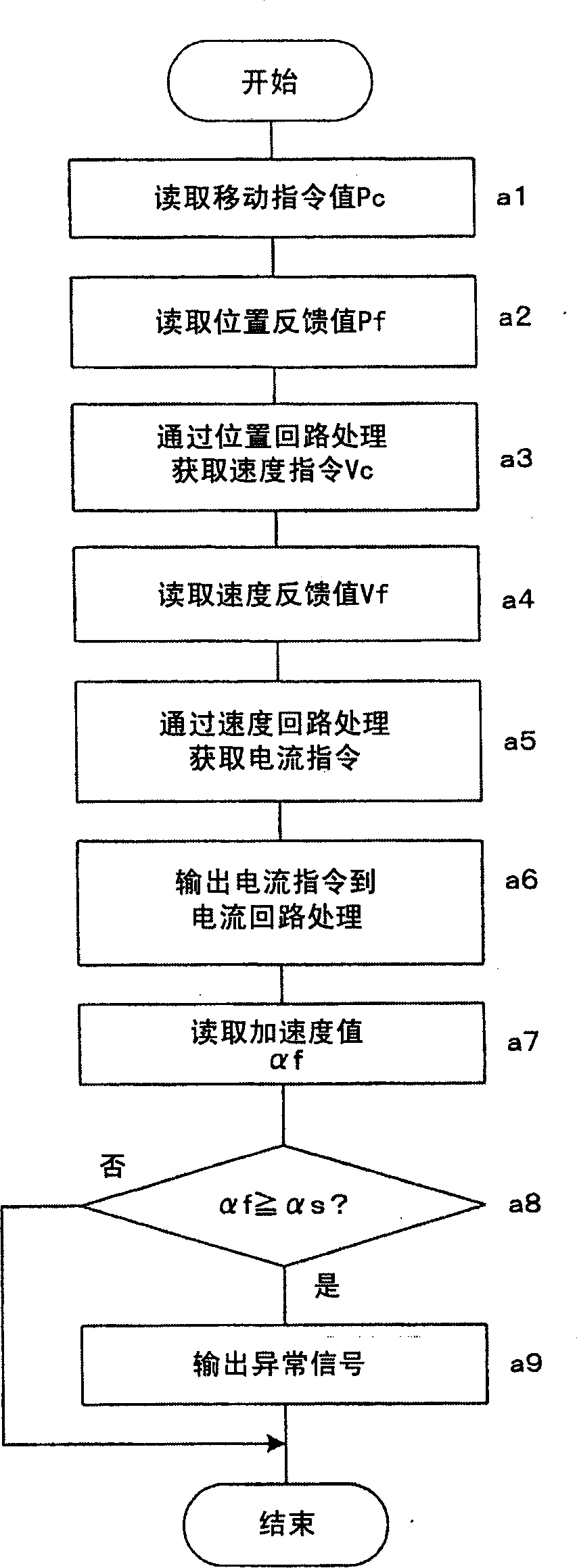

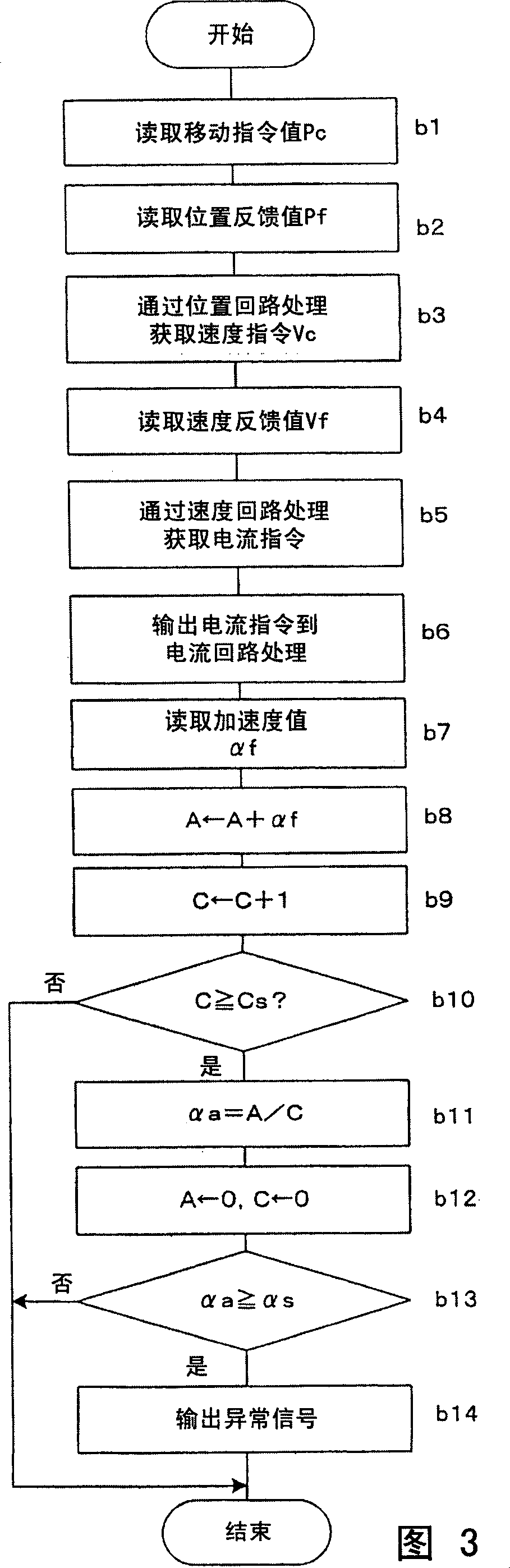

InactiveCN1781658AAvoid downtimeDetect vibrationProgramme controlAutomatic control devicesMachining vibrationsPower flow

It is disclosed that it is used to detect the maintenance needs and abnormal operation of the machine due to the long-term change resulting in the reduction of power. The acceleration detection device is attached to the driven element driven by the servo motor. The processor of each axis control circuit for feedback control of servo motor position and speed performs position and speed feedback control processing for each position / speed control cycle, thereby acquiring current commands and outputting the commands to current loop processing. The detected acceleration value αf is read from the acceleration detection means. When the detected acceleration value is not less than the threshold αs, an abnormal signal is output to display a warning and stop the machine from working. Since the acceleration of the driven element is directly detected by the acceleration detection device, it is possible to safely detect machine abnormalities such as common vibrations due to machine aging, collision of the driven element with other objects, or breakage of the element.

Owner:FANUC LTD

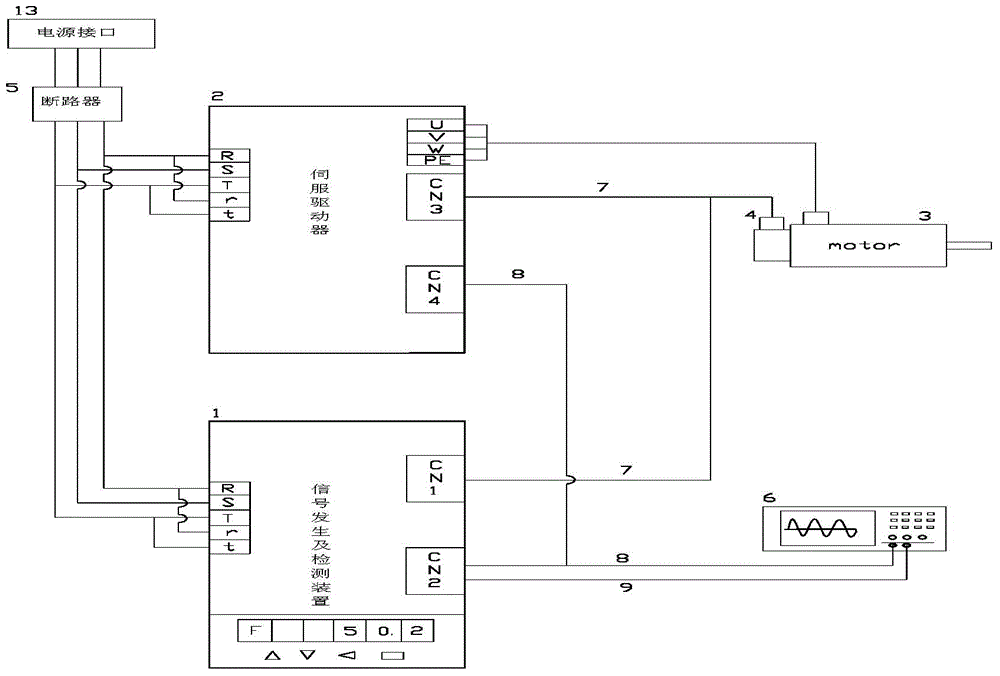

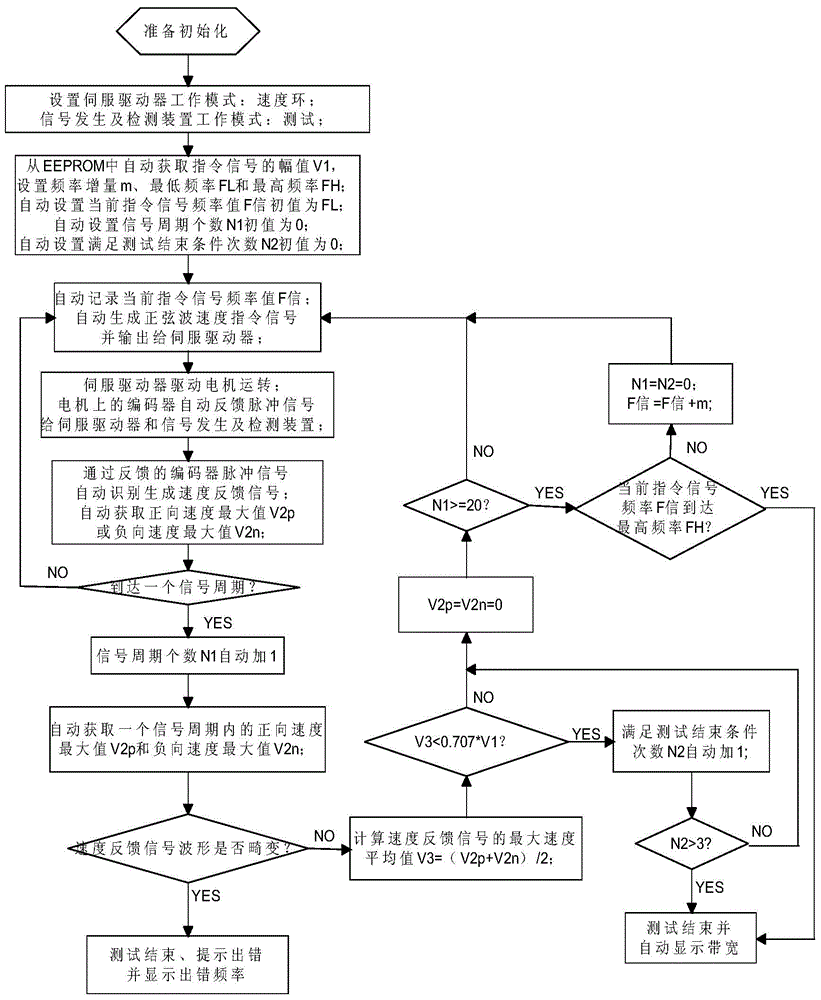

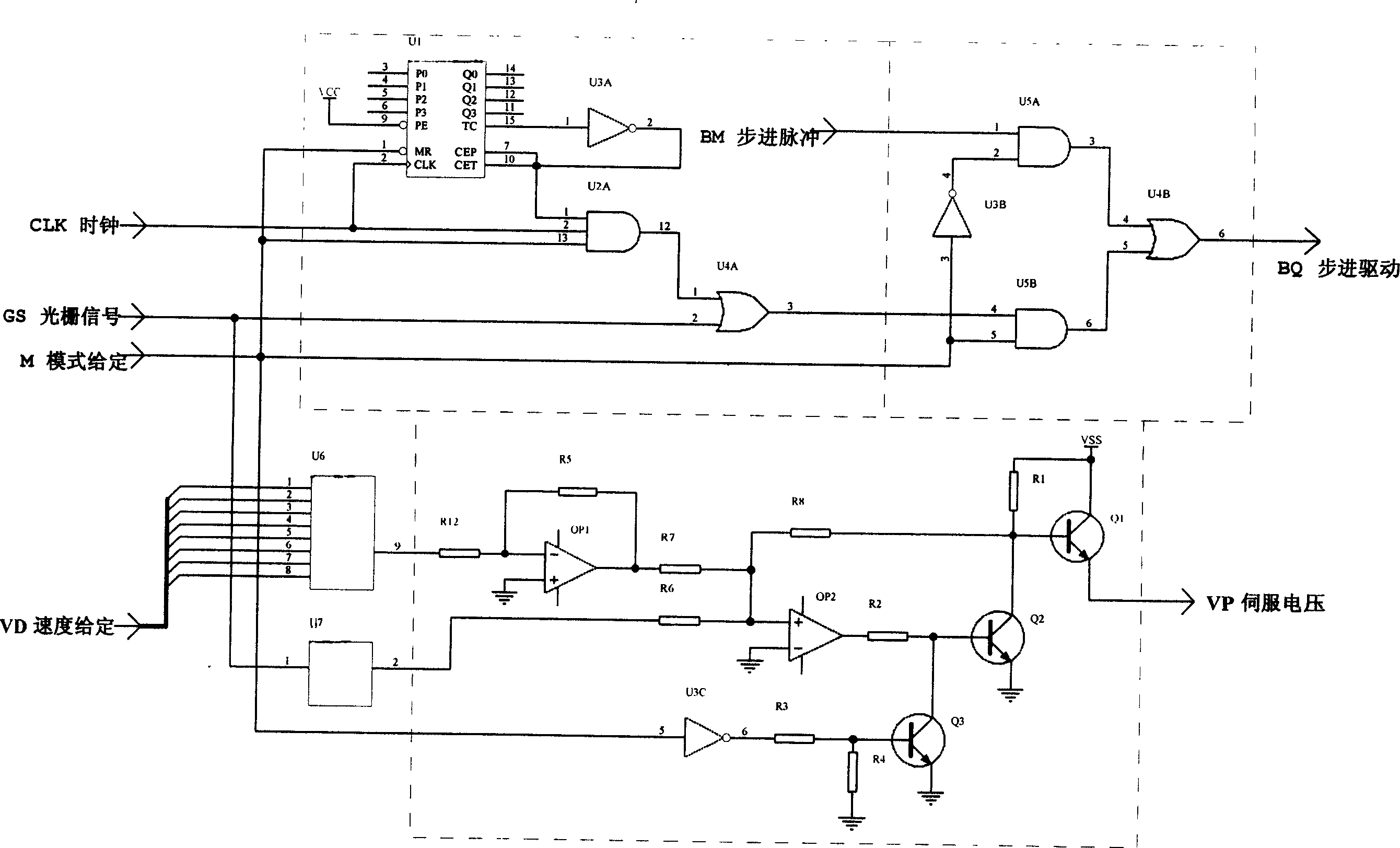

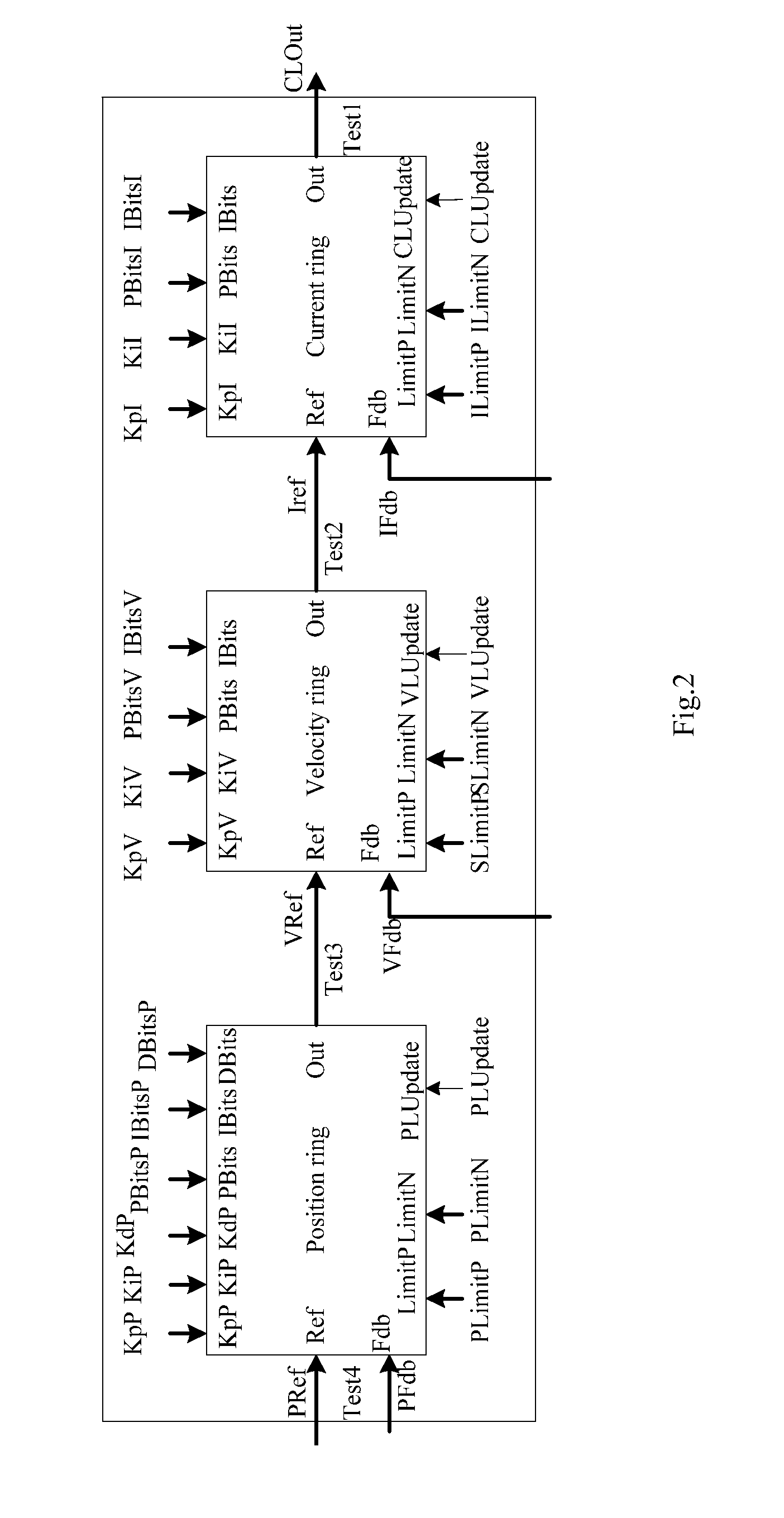

Servo driver bandwidth testing platform and method

ActiveCN104483582AMeet the test requirementsSimple structureElectrical testingSignal responseAutomation

The invention provides a servo driver bandwidth testing platform which comprises a signal generation and detection device, a servo driver, a motor and an encoder. The signal generation and detection device is connected with the servo driver and used for sending a sine wave velocity command signal to the servo driver. The servo driver is connected with the motor. The signal generation and detection device and the servo driver are both connected with the encoder. The testing platform is simple in structure, high in velocity feedback signal response speed, high in automation degree and free of artificial judgment errors. The invention further provides a servo driver bandwidth testing method. According to the method, the signal generation and detection device automatically sends the sine wave velocity command signal, automatically recognizes and generates a velocity feedback signal through a pulse signal fed back by the encoder, automatically compares the waveform of the velocity feedback signal with the waveform of the sine wave velocity command signal and automatically displays a bandwidth testing result.

Owner:NINGBO HIRDEN IND CONTROL SYST

Method of diagnosing abnormality of reduction gear and apparatus for carry out the method

ActiveCN101114171AImprove operating rateImprove productivityMachine part testingElectric testing/monitoringFrequency spectrumReduction drive

An apparatus for carry out a method of diagnosing abnormality of a reduction gear, the reduction gear including an intermediate shaft element disposed between an input shaft and an output shaft and rotating in proportion to a rotation of the input shaft to transmit the rotation to the output shaft, the apparatus has: a disturbance observer that obtains an estimated disturbance value regarding the reduction gear, based on a torque instruction and a velocity feedback-value acquired when a pair of driven members which rotate relative to each other with a motor as a driving source are in relative rotation at a constant velocity; a specific spectral component specifying portion for extracting a specific spectral component corresponding to a constant multiple of a rotational frequency of the intermediate shaft element from a frequency components of the estimated disturbance value obtained by frequency analysis; and a diagnosing portion, which compares an amplitude of the specific spectral component specified by the specific spectral component specifying portion with a threshold value, and diagnoses an abnormality in a case where the amplitude of the specific spectral component exceeds the threshold value, or a normality in a case where the amplitude of the specific spectral component is equal to or less than the threshold value.

Owner:FANUC LTD

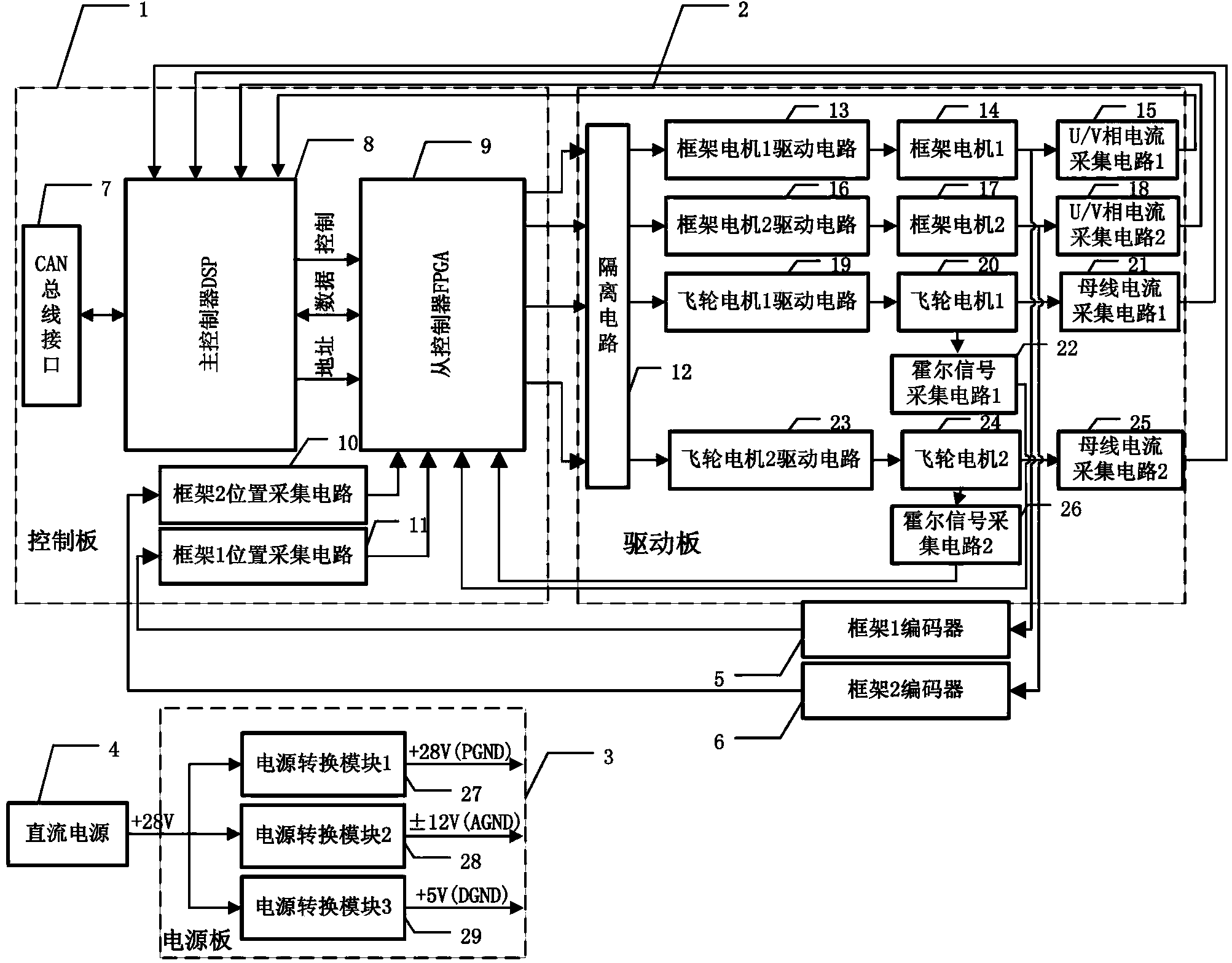

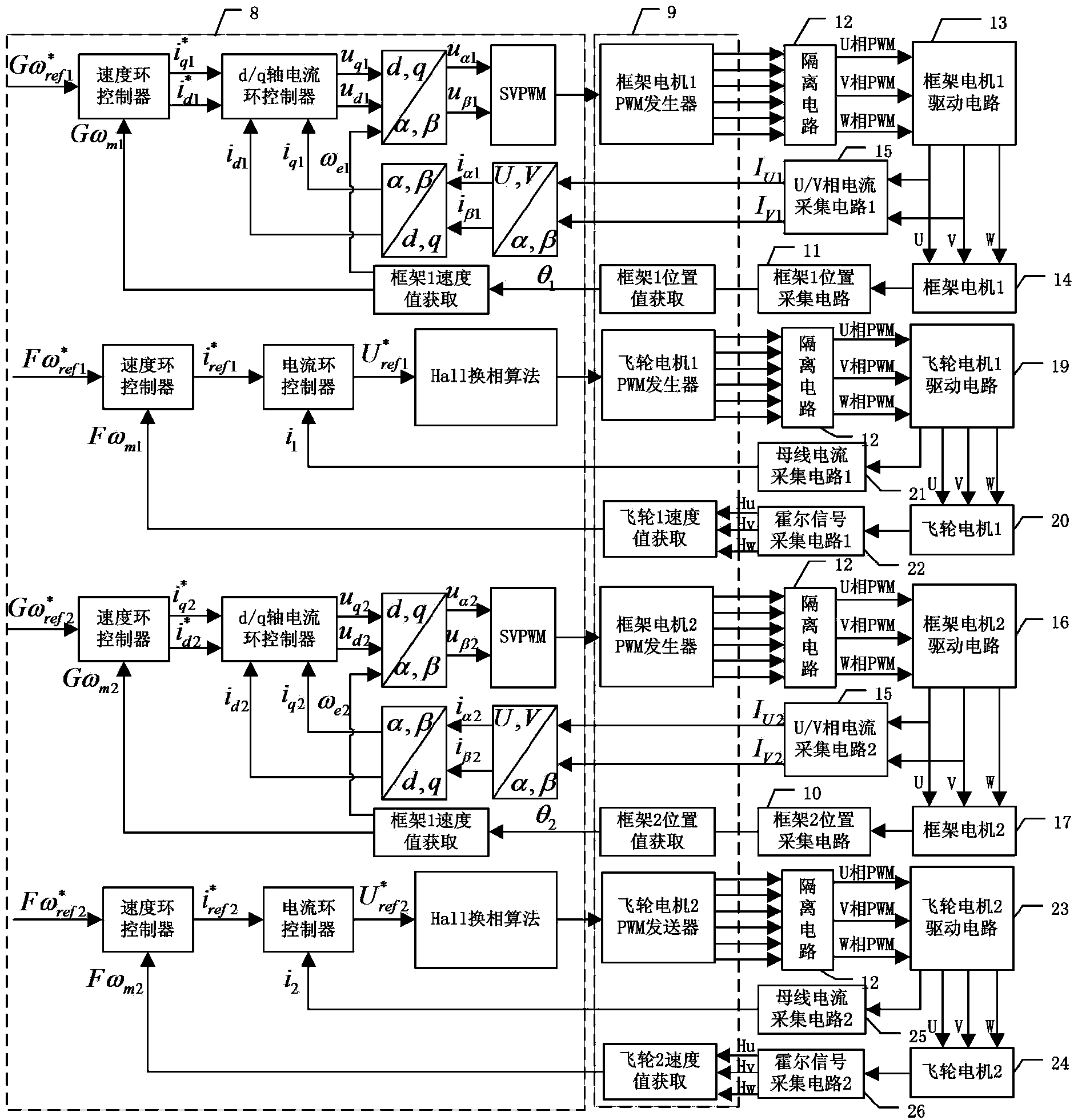

High-integration high-precision servo control device for control moment gyros

InactiveCN104044756AMeet the use requirementsProgramme controlComputer controlPhase currentsElectric machine

The invention discloses a high-integration high-precision servo control device for a control moment gyros, and is applied to the satellite attitude control executing mechanism. A slave controller FPGA acquires frame angular position signals of two frame motors through two frame position acquisition circuits respectively in real time, and acquires angular velocity signals of two flywheel motors through two hall signal acquisition circuits respectively in real time, and the signals are sent to a master controller DSP through an address / data / control bus to serve as respective velocity feedback values; the master controller DSP respectively acquires current values of the two frame motors and the two flywheel motors through two U / V phase current acquisition circuits and two busbar current acquisition circuits to serve as respective current feedback values; the master controller DSP carries out double closed-loop control over the velocity and current of the four sets of motors by combining with a corresponding servo control algorithm according to respective velocity and current feedback values, to produce a PWM instruction, the slave controller FPGA produces PWM according to the instruction, and high-precision servo control over the four sets of motors is realized.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

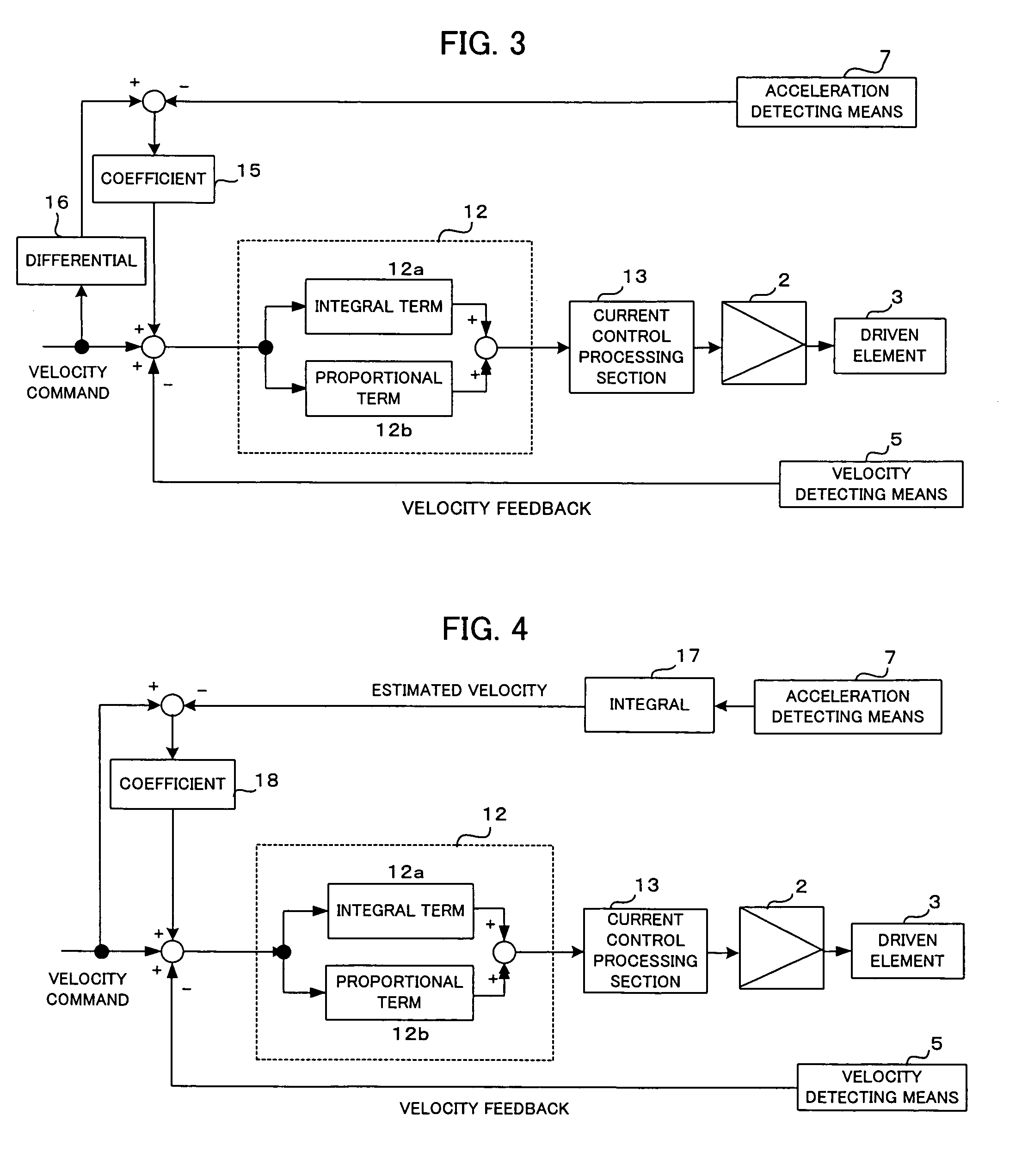

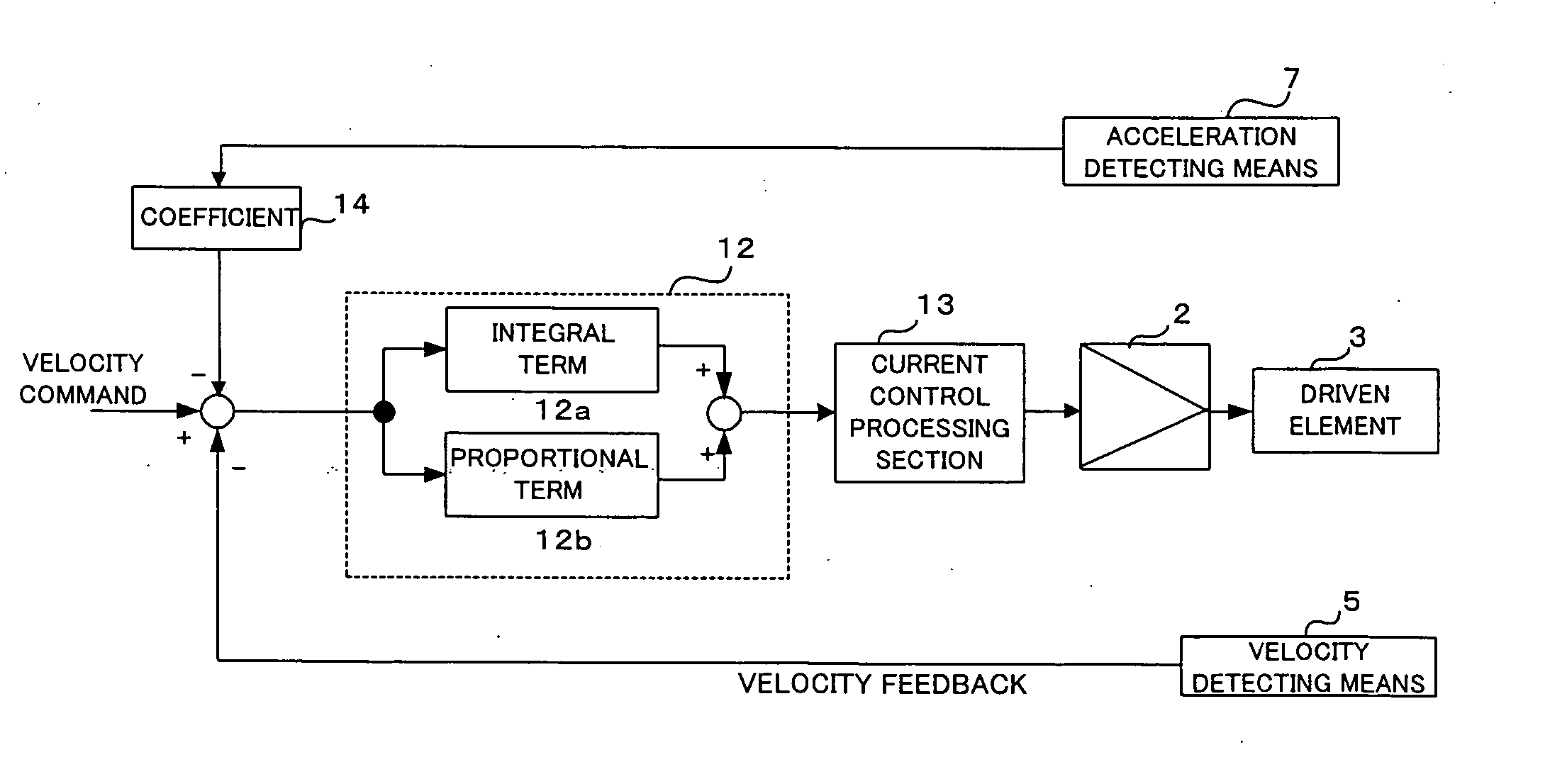

Controller

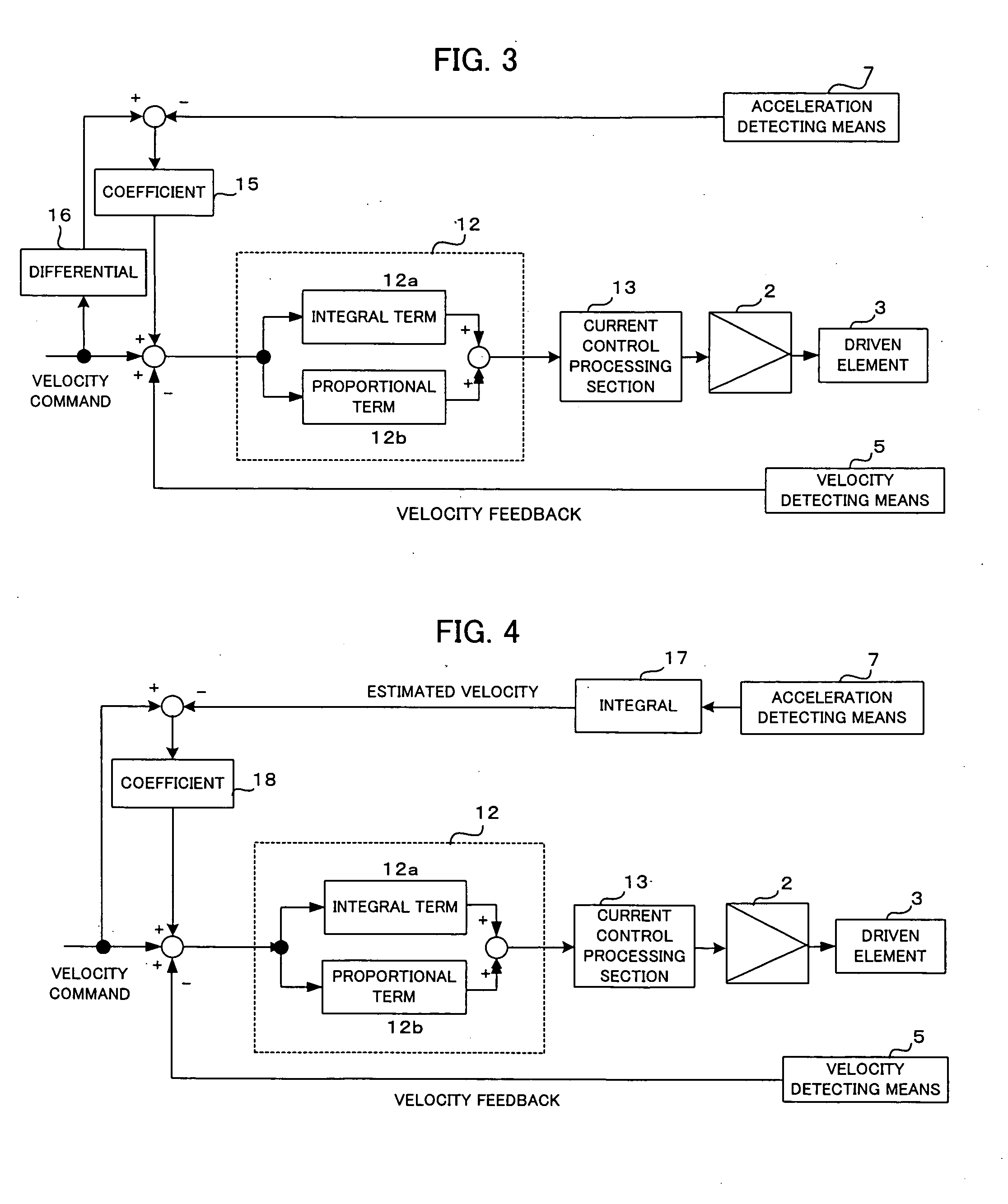

ActiveUS7187148B2Accurate informationRestrained accuratelyDC motor speed/torque controlAC motor controlEngineeringServomotor

Disclosed is a controller for restraining vibration of a driven element driven by a servomotor. The driven element driven by the servomotor is provided with acceleration detecting means. A correction value is obtained by multiplying a detected acceleration value detected by the acceleration detecting means by a coefficient. Correction is made by subtracting the correction value from a velocity command, and velocity feedback control is executed in a velocity control processing section to obtain a current command. Further, the servomotor is driven by current control processing, whereupon the driven element is moved. If the detected acceleration value is increased by vibration of the driven element, the velocity command is corrected to restrain the vibration, so that the vibration of the driven element can be restrained. Processing time can be shortened to restrain the vibration of the driven element by executing the correction of the velocity command based on the detected acceleration value for each velocity control period.

Owner:FUJITSU LTD +1

Cascade speed regulating device for current zero-crossing speed measurement for hardware detection

InactiveCN102647151ANormal speed regulation energy saving controlQuick measurementAC motor controlLinear/angular speed measurementElectric machineClosed loop

The invention relates to a cascade speed regulating device for current zero-crossing speed measurement for hardware detection. The cascade speed regulating device can realize normal speed regulation energy-saving control by adopting a current zero-crossing detection circuit and a DSP (digital signal processor) processor to acquire the velocity of a winding motor as the outer-loop velocity feedback signal of a double closed loop control algorithm. Since the current zero-crossing detection circuit can acquire the velocity signal of the winding motor indirectly from the rotor current, the cascade speed regulating device circuit is immune to environment, mechanical vibration and so on, and is quick and accurate in measurement, thereby enhancing the system stability.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

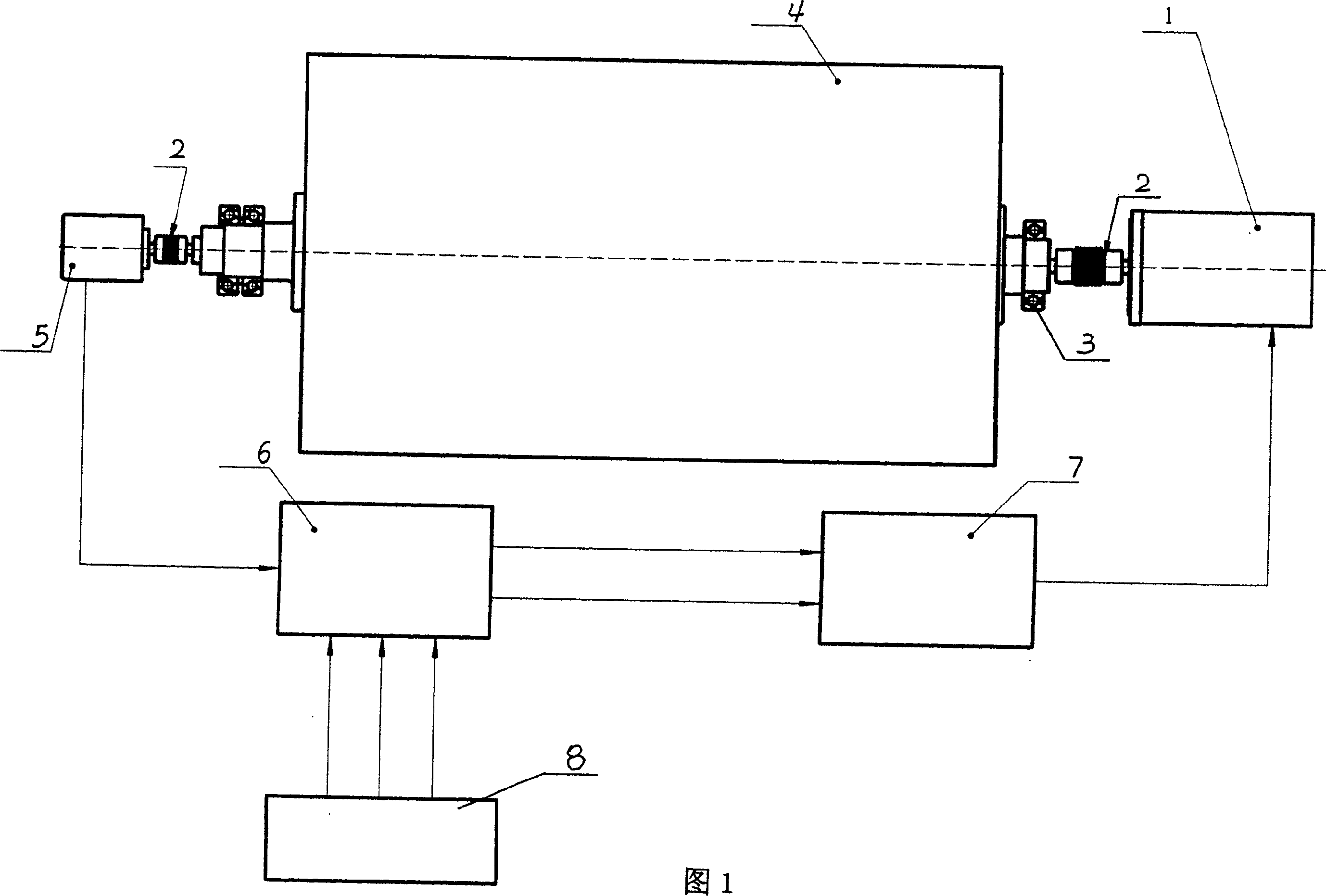

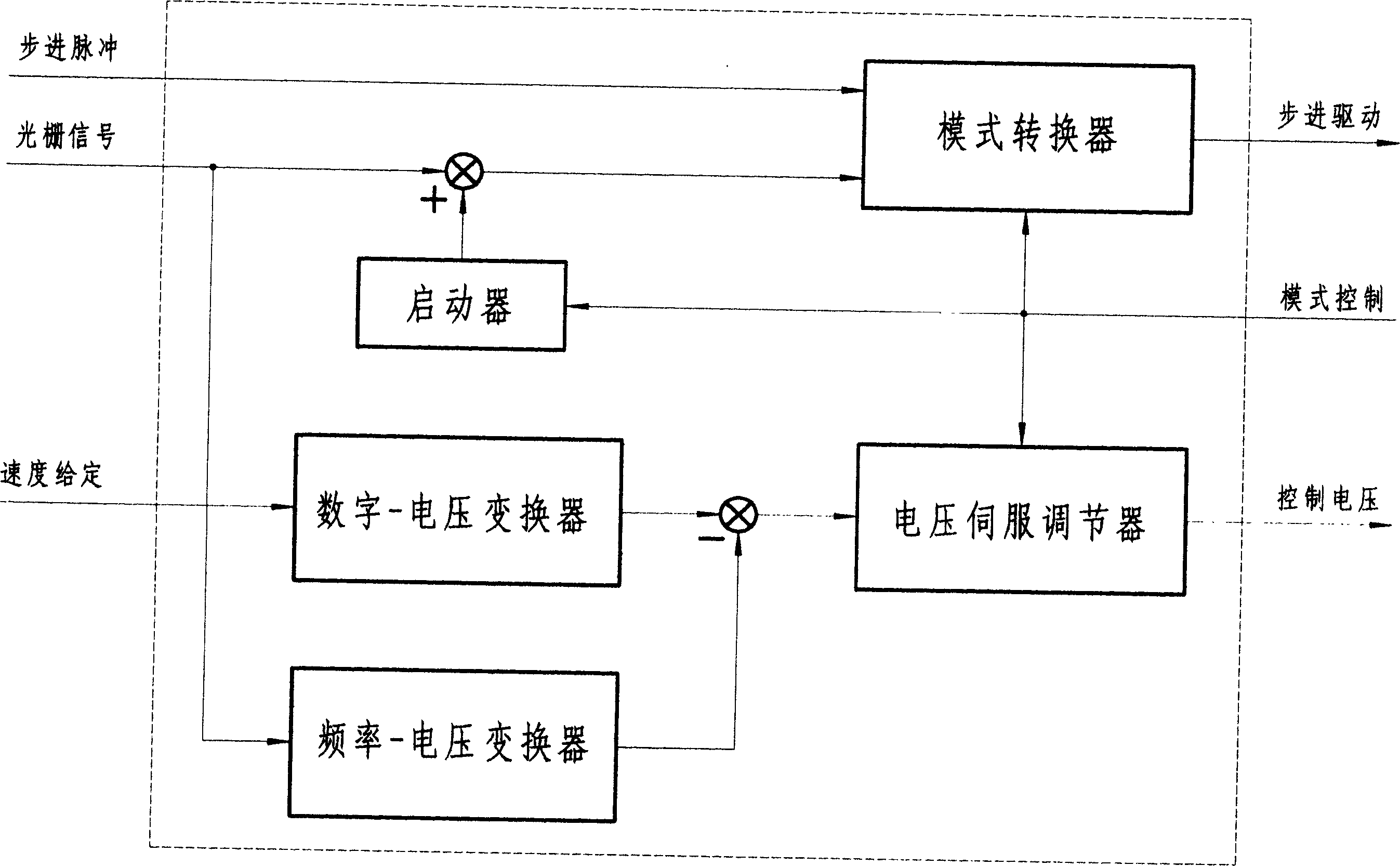

Dual-mode control method and system for stepping motor

InactiveCN1595787AImplement working modeImprove working precisionSingle motor speed/torque controlDynamo-electric converter controlGratingMode control

The invention is a step motor double-mode control method and system, and the method includes a open-loop step mode that a mode switcher directly feeds a step pulse signal from a computer to a driver and a DC brushless closed-loop speed servo mode that the mode switcher receives a grating signal as a step pulse to feed the grating signal to the driver and simultaneously the grating signal also acts as a speed feedback signal to compare with a given speed signal, their difference value drives a voltage servo regulator to give a proper control voltage and it maintains a constant starting difference value between the driving pulse sent from the step driver and the obtained driving pulse. And the system includes a load driven by step motor, a grating sensor connected with the other end of the load, a controller connected with the grating sensor, a control computer connected with the controller and a step driver that drives the step motor.

Owner:深圳市东方宇之光科技股份有限公司

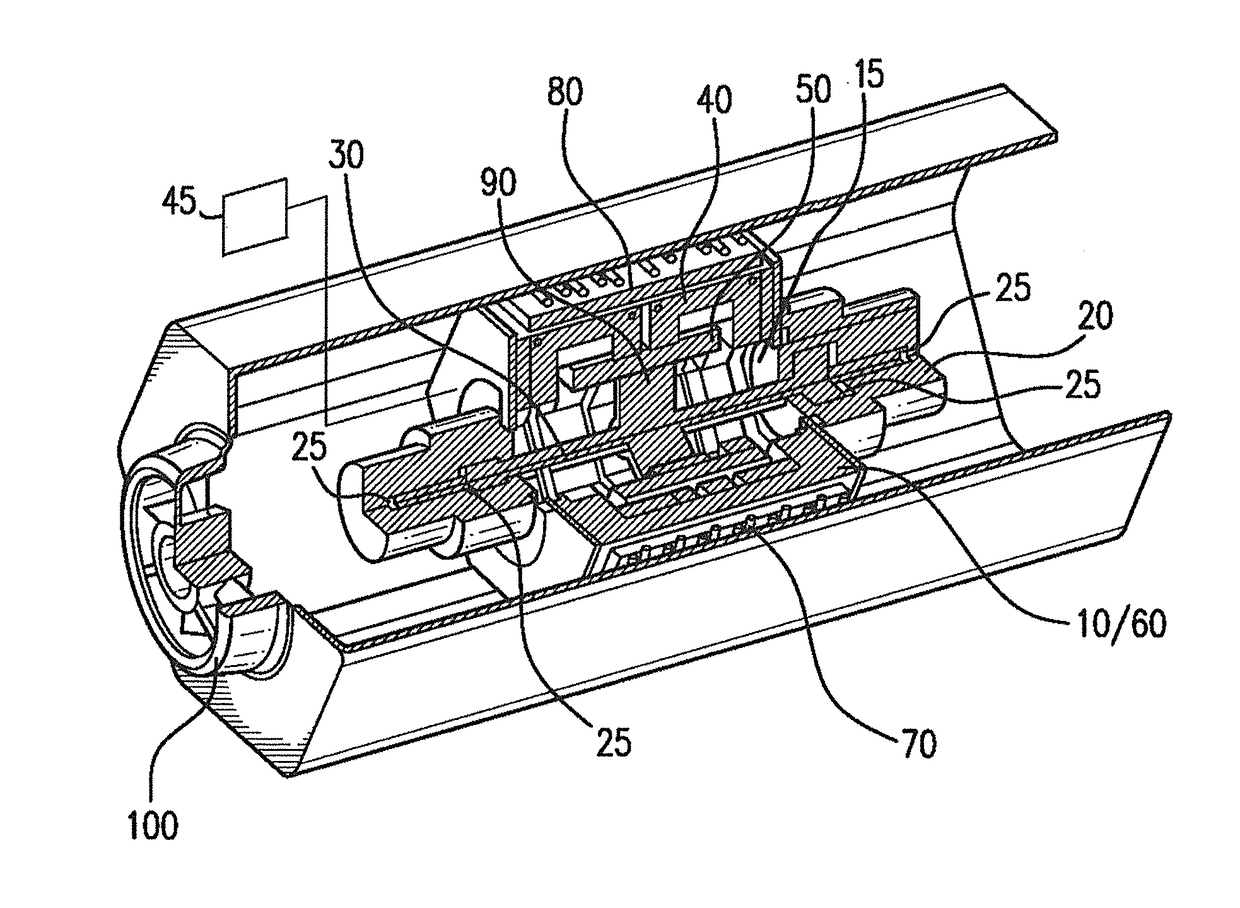

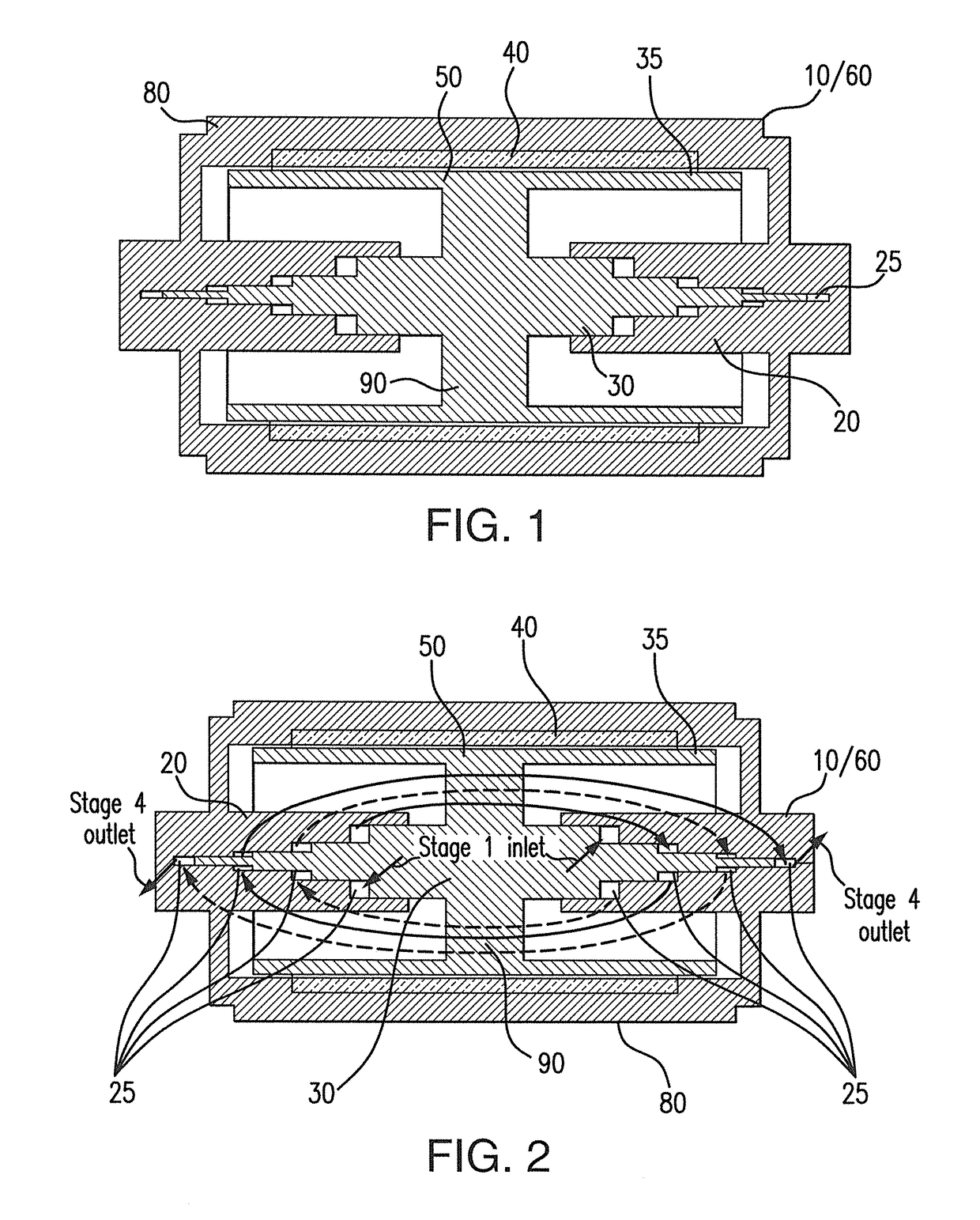

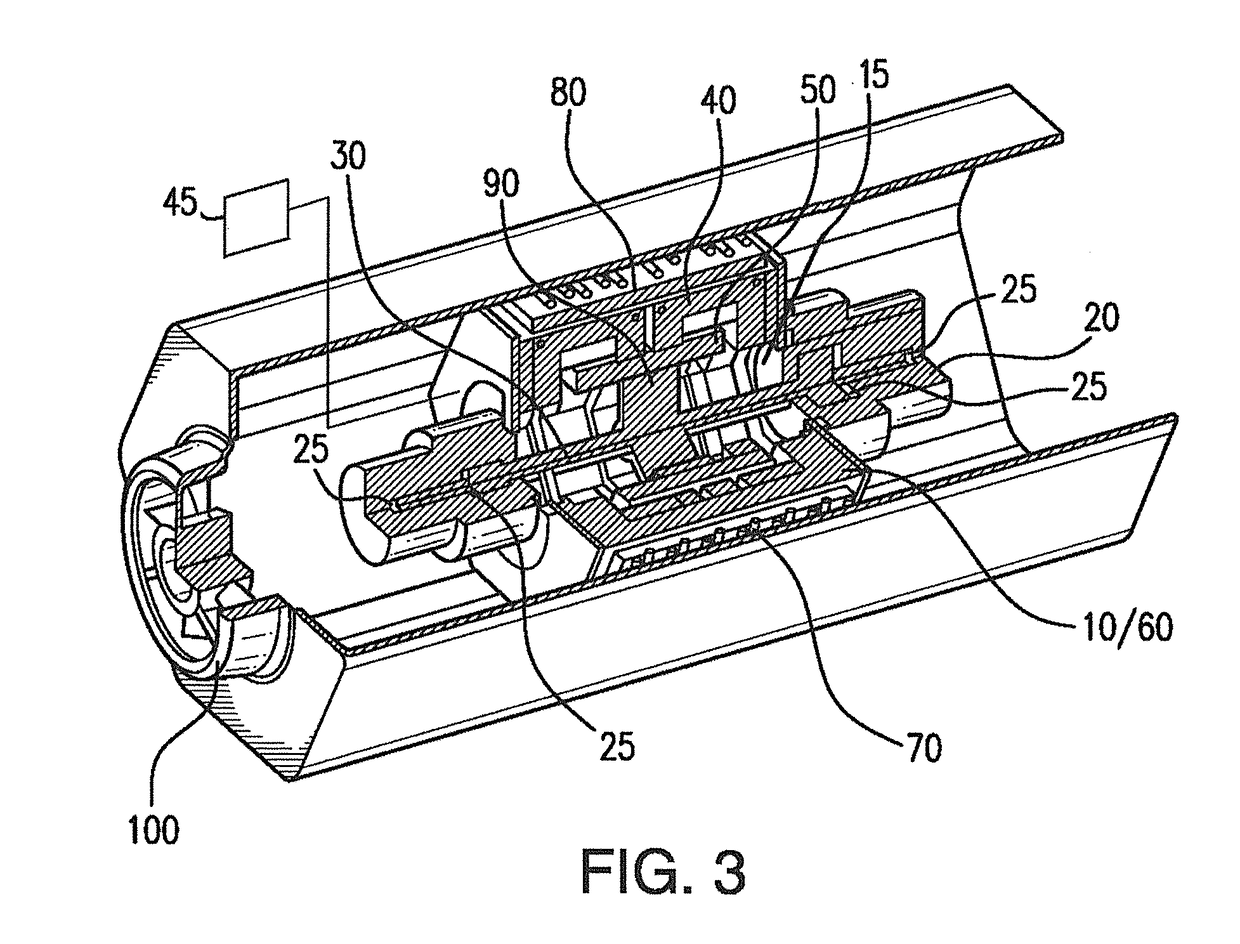

Free piston linear motor compressor and associated systems of operation

ActiveUS20180051690A1Increased durabilityImproves compressor system efficiencyFree piston pumpsMotor parameterPower flowReciprocating motion

A linear motor compressor including a compressor housing and a cylinder housing having a plurality of opposing compression chambers. A piston freely reciprocates within the cylinder housing using a linear electric motor. A piston position feedback control system provides adaptive current output as a function of position feedback and / or velocity feedback from the piston and / or the electric motor, to directly power and control the electric motor, wherein the piston reciprocates without assistance from a mechanical spring or other equivalent centering force.

Owner:GAS TECH INST +1

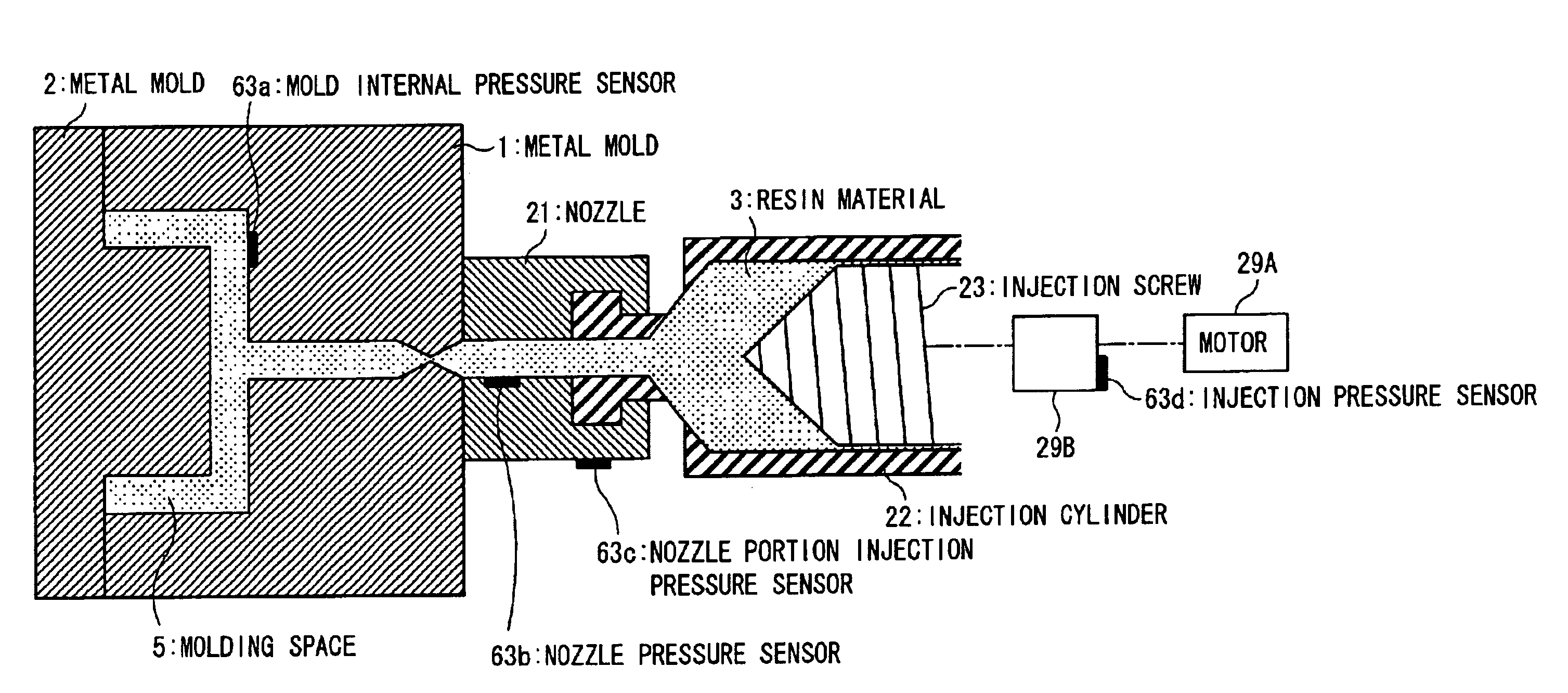

Electric injection molding machine for controlling injection speed and injection pressure of electric injection molding machine

InactiveUS6854967B2Stable controlAuxillary shaping apparatusFood shapingInjection pressureInjection moulding

The invention relates to an electric injecting molder and an injection velocity and injection pressure controlling method for an electric injecting molder, and it is an object of the present invention to make it possible, in injection molding by an electric injection molder, to mold stable resin products having a minimized dispersion in the quality even if the operation environment varies. When an injection screw (23) disposed in an injection cylinder (22) is driven to move in forward and backward directions by an electric motor (29A) to inject resin material (3) in the injection cylinder (22) into a metal mold (1, 2) to fill the metal mold (1, 2), the electric motor (29A) is first velocity-controlled to fill the resin material (3) into the metal mold (1, 2), and, after the filling, the electric motor (29A) is pressure-controlled to replenish the resin material for shrinkage of the resin. Upon the velocity control, a velocity target value for the injection screw (23) is corrected in response to a force detection value so that the velocity target value for the injection screw (23) may decrease as the force detection value increases to perform velocity feedback control of the electric motor (29A) so that a velocity detection value from velocity detection means may be equal to the velocity target value.

Owner:MITSUBISHI HEAVY IND LTD

Controller

ActiveUS20060113946A1Accurate acceleration informationImprove responseDC motor speed/torque controlAC motor controlEngineeringFeedback control

Disclosed is a controller for restraining vibration of a driven element driven by a servomotor. The driven element driven by the servomotor is provided with acceleration detecting means. A correction value is obtained by multiplying a detected acceleration value detected by the acceleration detecting means by a coefficient. Correction is made by subtracting the correction value from a velocity command, and velocity feedback control is executed in a velocity control processing section to obtain a current command. Further, the servomotor is driven by current control processing, whereupon the driven element is moved. If the detected acceleration value is increased by vibration of the driven element, the velocity command is corrected to restrain the vibration, so that the vibration of the driven element can be restrained. Processing time can be shortened to restrain the vibration of the driven element by executing the correction of the velocity command based on the detected acceleration value for each velocity control period.

Owner:FUJITSU LTD +1

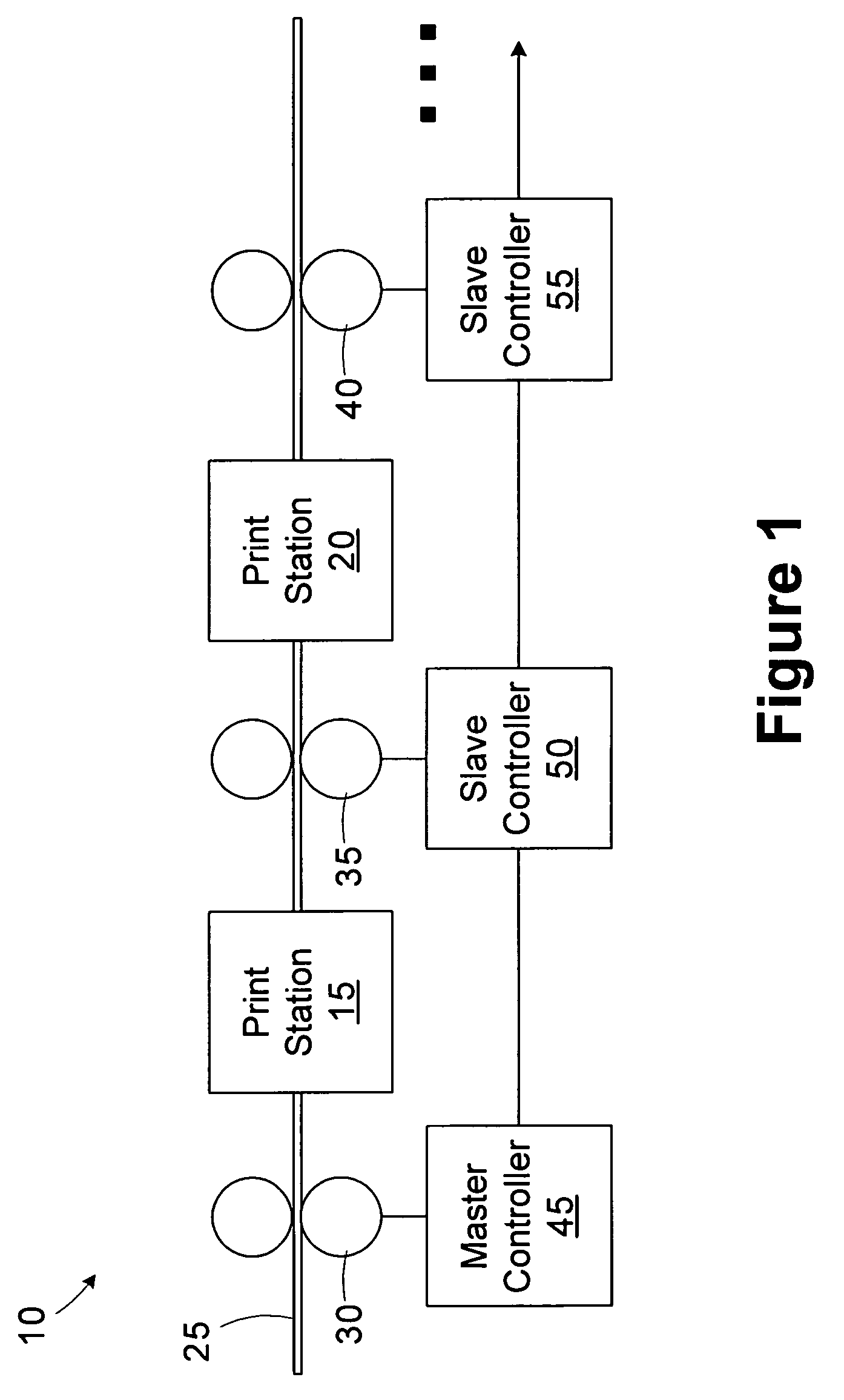

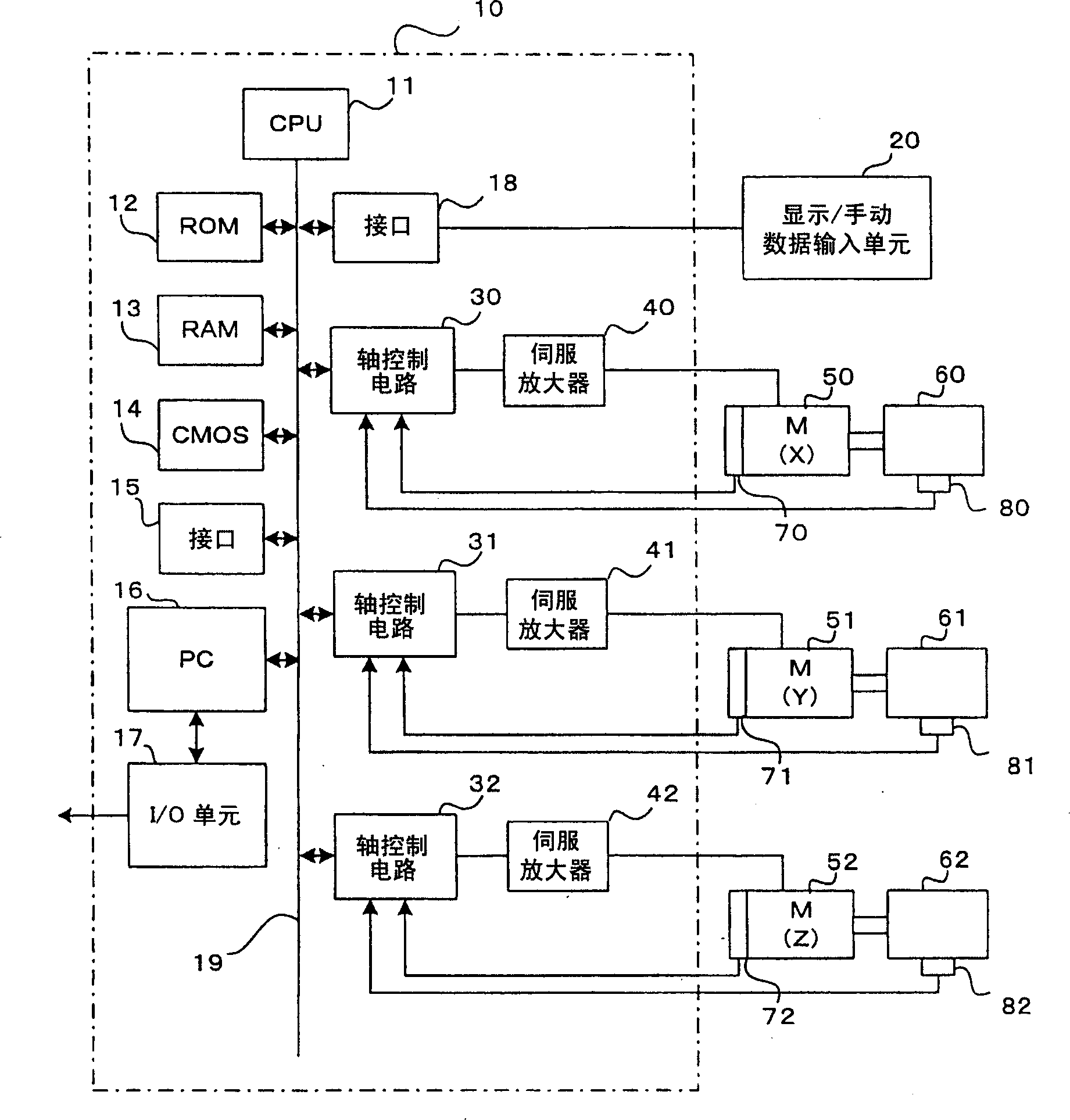

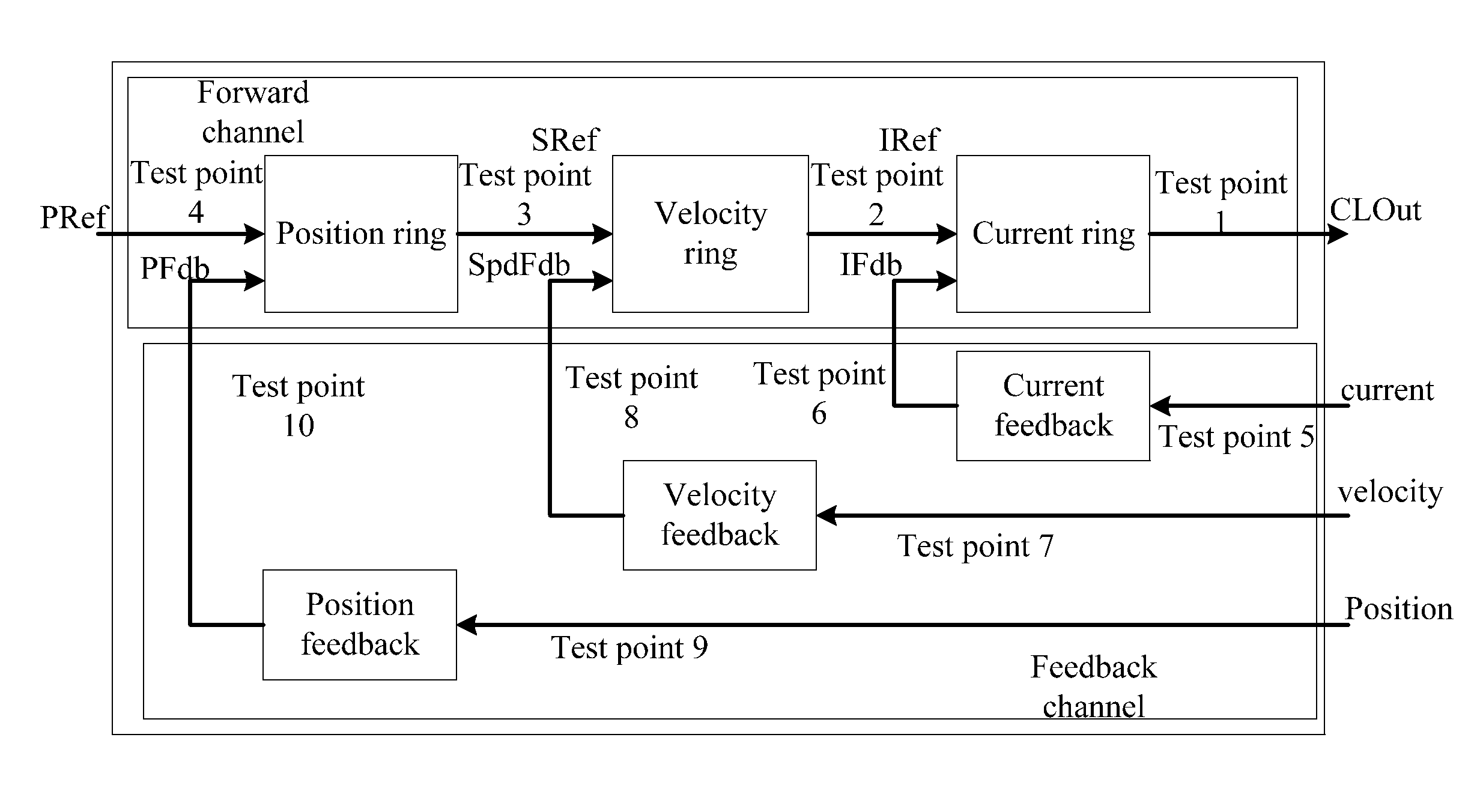

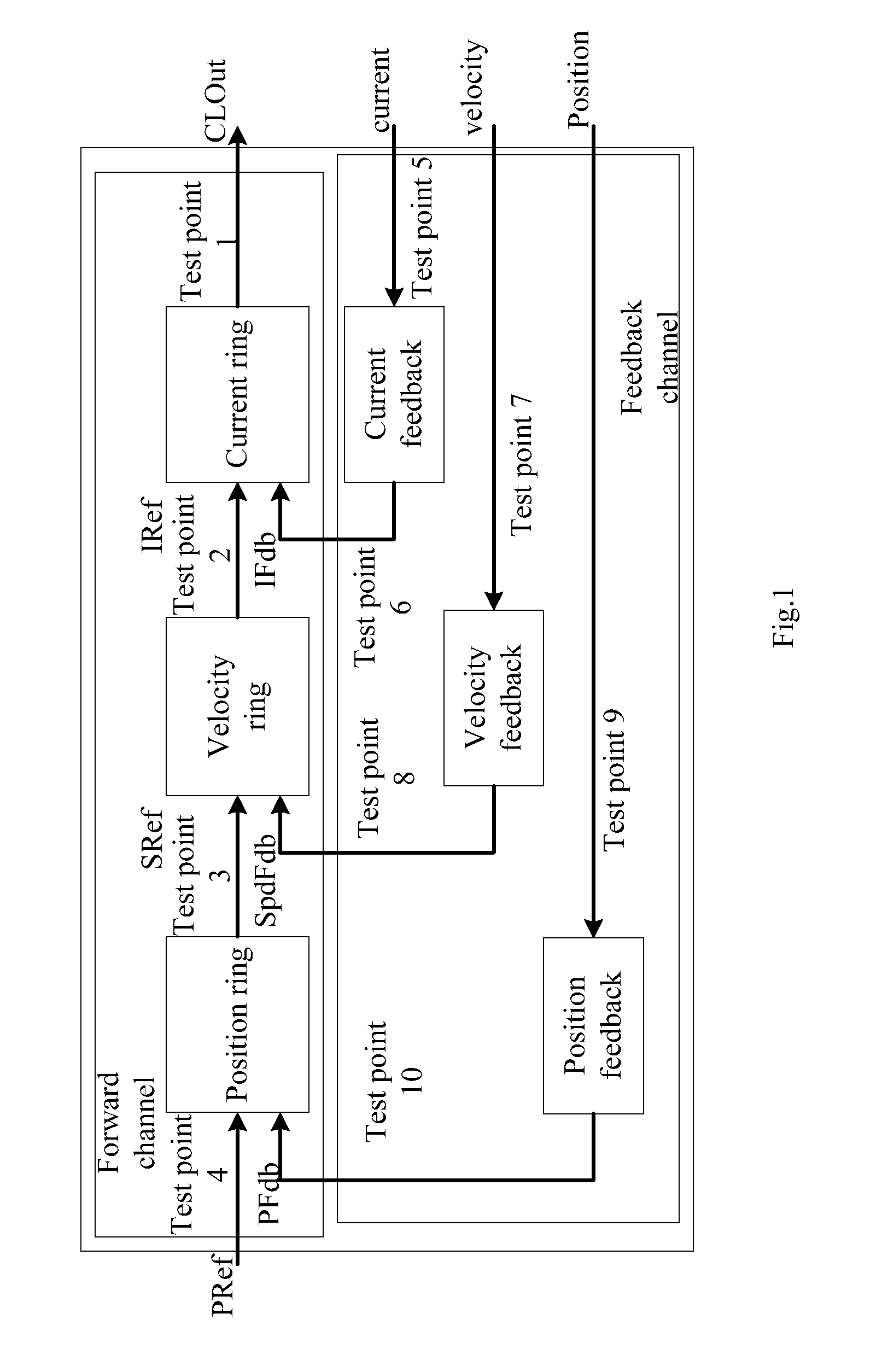

Control System of Multi-Shaft Servo Motor

InactiveUS20110127942A1Minimized volumeImprove reliabilityComputer controlSimulator controlElectric machineEngineering

The present invention relates to a control system of multi-shaft servo motor, wherein, comprises a position loop module (400) for receiving a position loop given value and a position feedback value of respective shelves and figuring out a velocity loop given value; a velocity loop module (500) for receiving the velocity loop given value and a velocity feedback value of respective shelves and figuring out a current loop given value; a current loop module (200) for receiving the current loop given value and a current feedback value of respective shelves and outputting a current loop output value; a PWM signal generation module (300) for receiving the current loop output value from the current loop module (200) and generating a PWM signal for controlling respective shelves of the servo motor; and a multi-shaft time sequence control module (700) for controlling the position loop module (400), the velocity loop module (500), the current loop module (200) and the PWM signal generation module to receive and process the signals.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

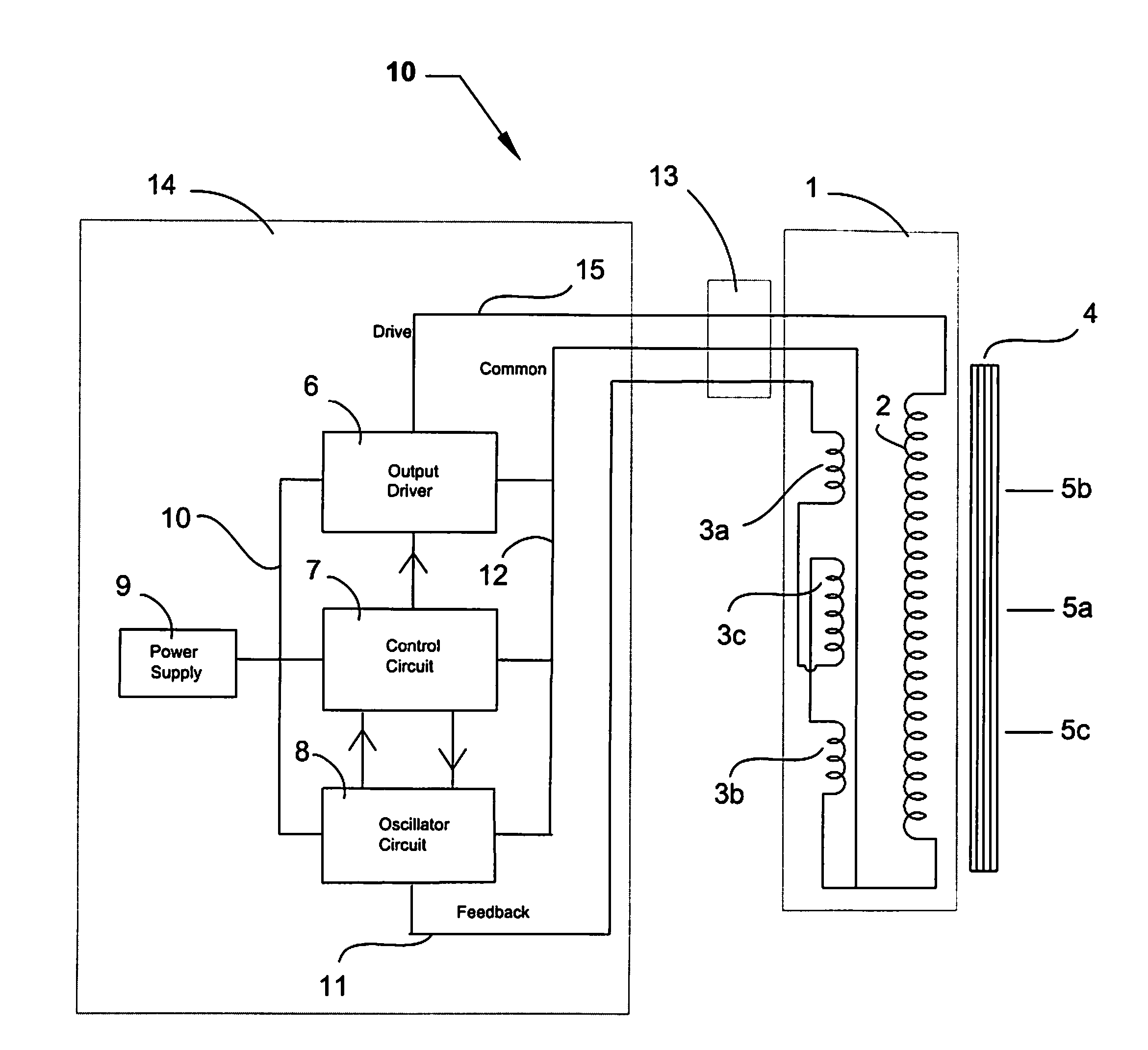

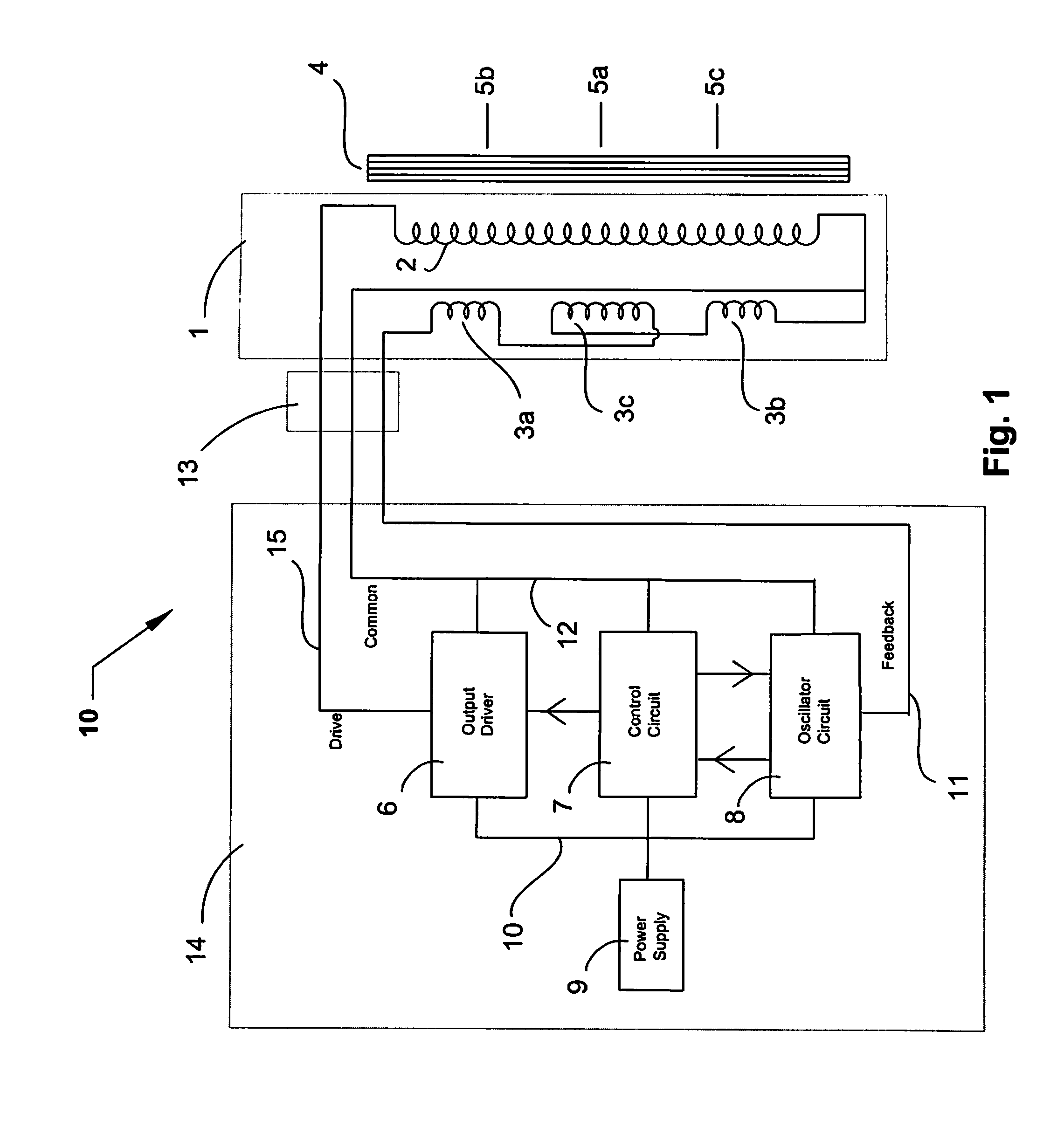

Ultrasonic system controls, tool recognition means and feedback methods

ActiveUS20110241576A1Minimize impactCompensation effectPiezoelectric/electrostriction/magnetostriction machinesResistance/reactance/impedenceCapacitanceSignal conditioning

An ultrasonic electro-mechanical resonant system and instrument that provides improvements in the design and implementation of a feedback system. The disclosed configuration and orientation of coils enhance the motional or velocity feedback signals while minimizing the effects of transformer coupling. A two coil and a three coil approach is disclosed that takes advantage of non-homogeneous magnetic fields. An asymmetrical arrangement enables velocity signals to be coupled into the coils without requiring additional signal conditioning or capacitive elements.

Owner:RN HLDG LLC

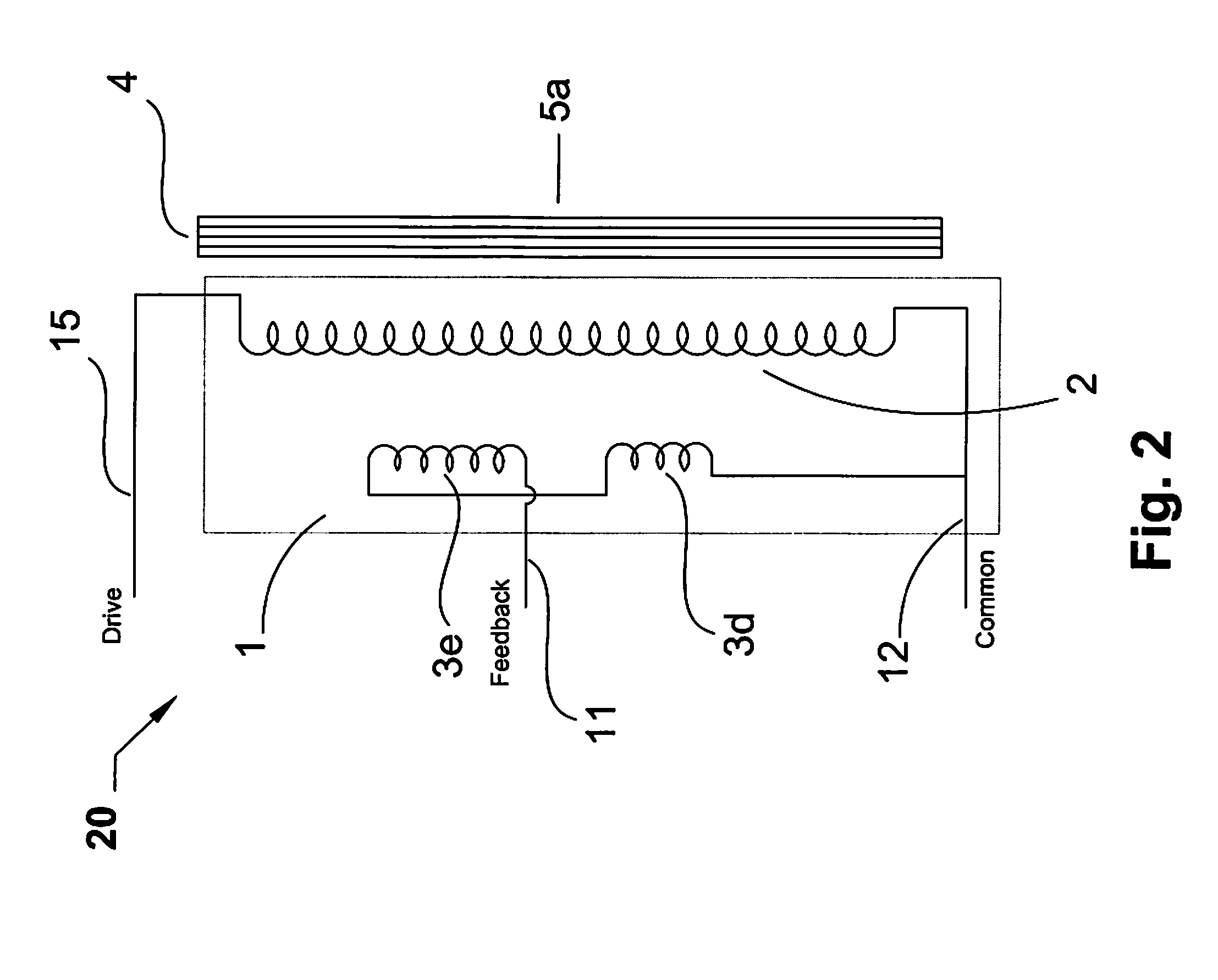

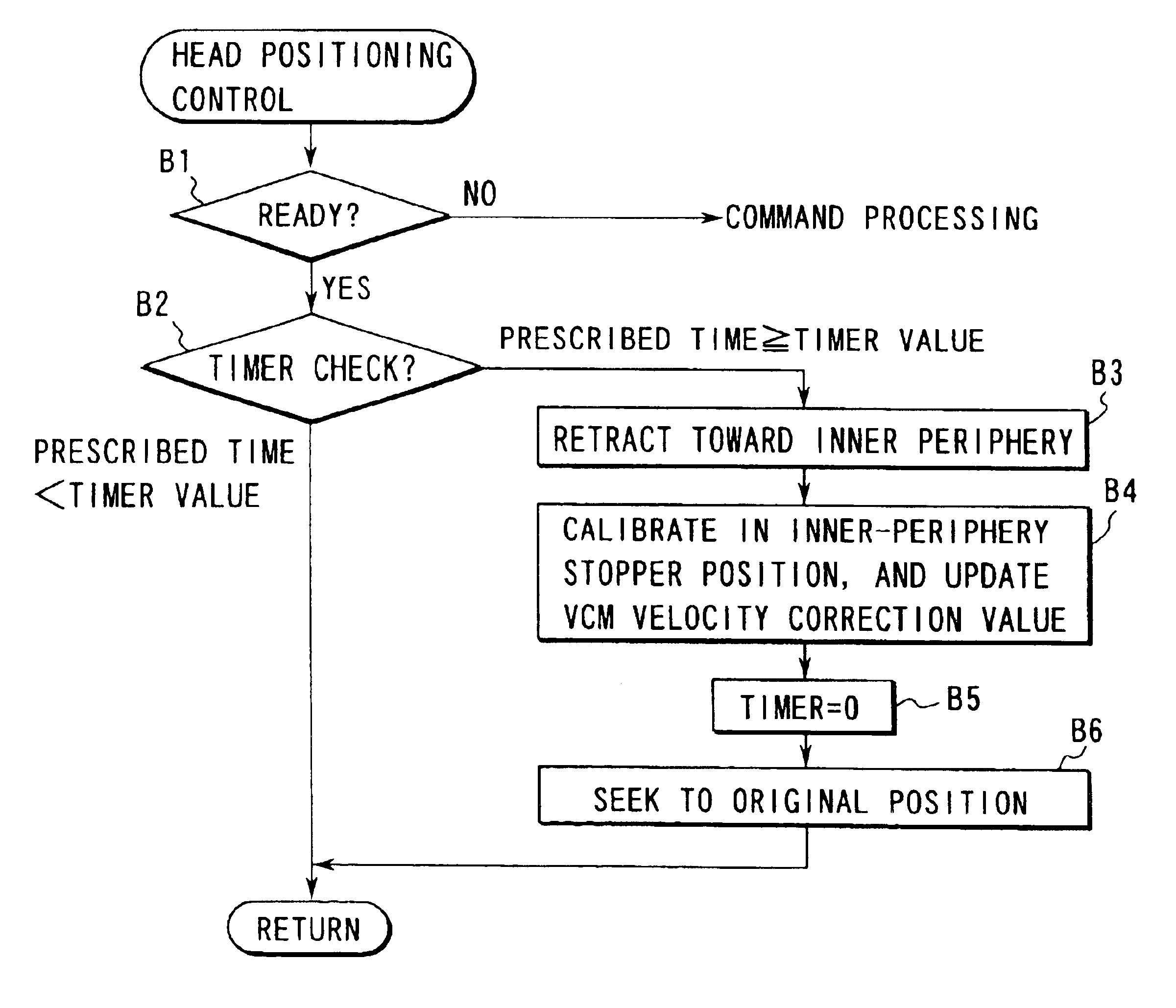

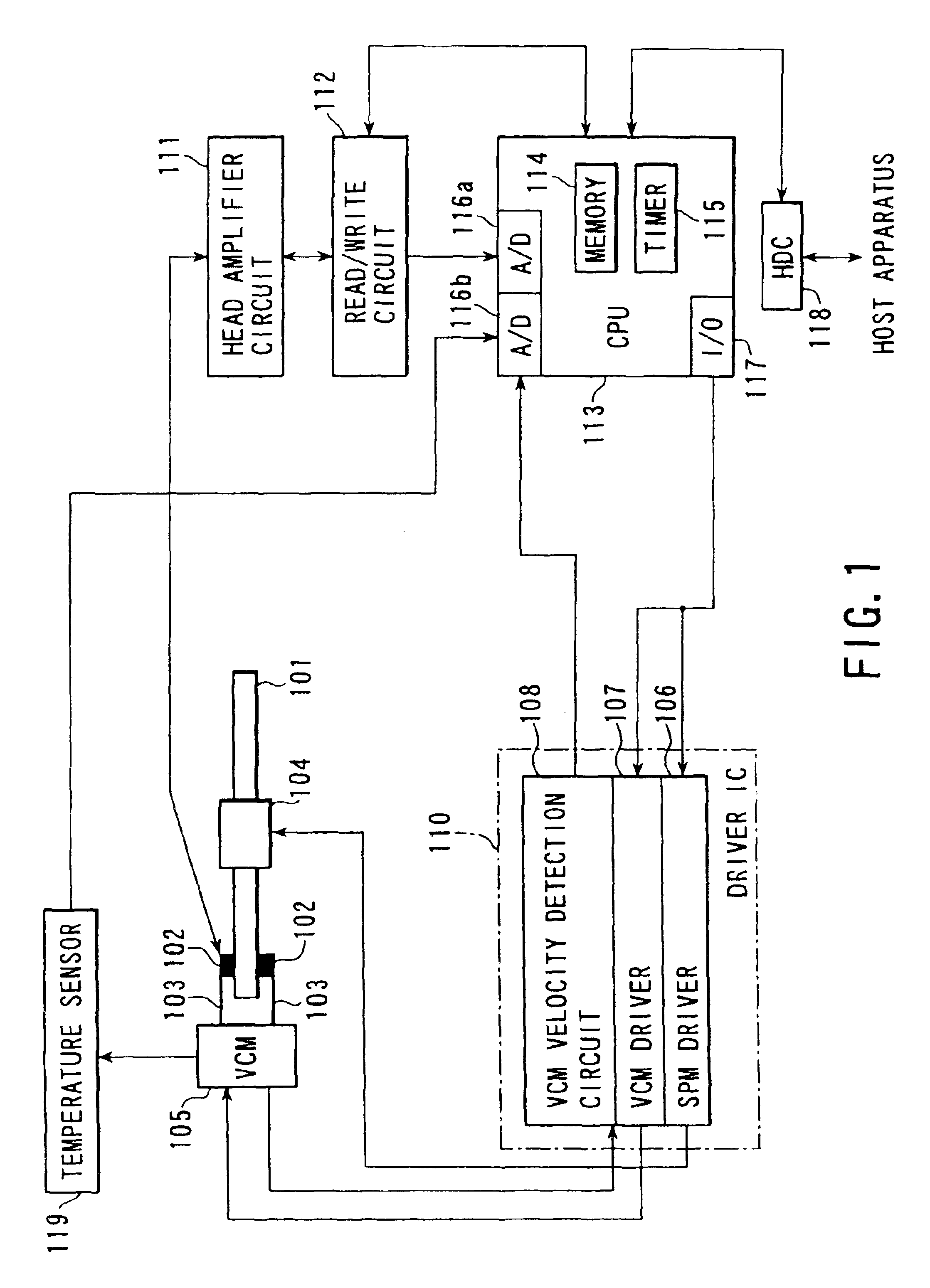

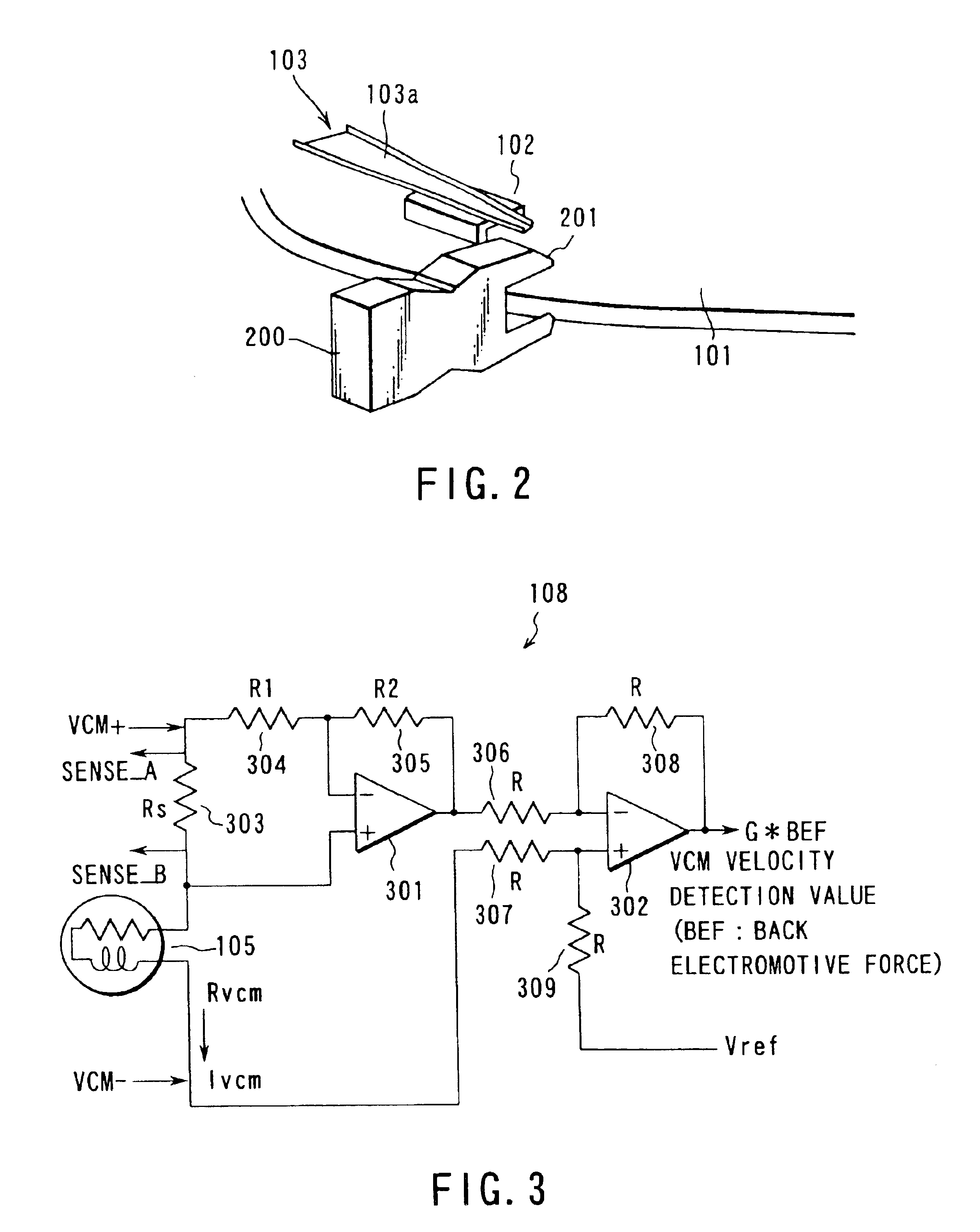

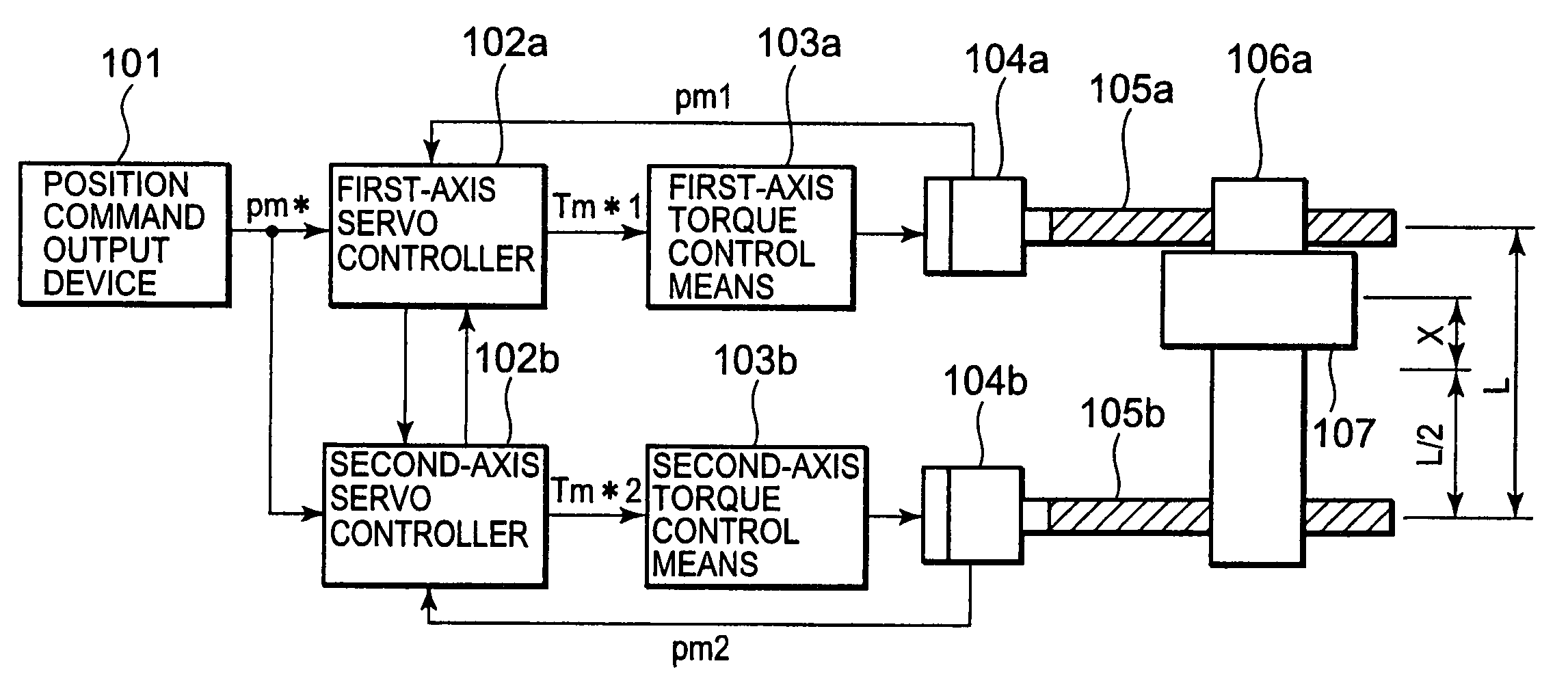

Calibration method for use in head loading/unloading type disk apparatus

InactiveUS6922302B2The relationship is accurateAccurate feedback controlDisposition/mounting of recording headsFilamentary/web record carriersControl theoryTimer

In a head loading / unloading type disk apparatus, accurate velocity feedback control is implemented by correcting any error in a VCM velocity detection value, which is caused by a temperature change or the like. At the start of loading control for loading a head from a ramp onto a disk, a carriage is pushed against an outer-periphery stopper to set the actual velocity of a VCM to zero. In this state, a VCM velocity detection value detected by a VCM velocity detection circuit is read out. On the basis of this velocity detection value, calibration for correcting the relationship between the VCM current value and the VCM velocity detection value is performed. In the period of head positioning control after the loading, an operation using a timer is periodically performed in which the carriage is pushed against an inner-periphery stopper, the calibration is reexecuted, and the head is returned to the original head position.

Owner:KK TOSHIBA

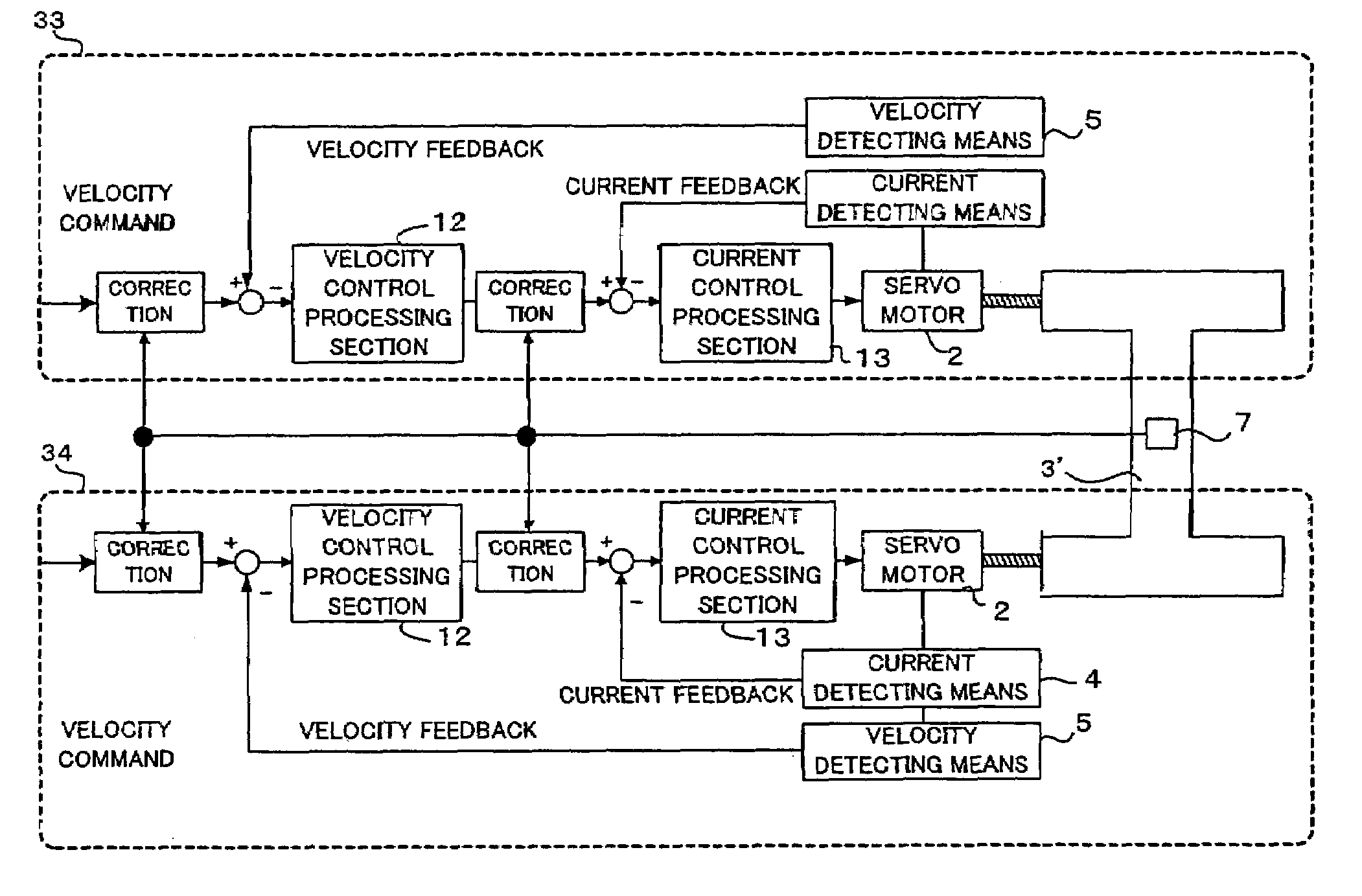

Servo controller

ActiveUS7671553B2Suppress position deviationAutomatic control devicesDC motor speed/torque controlEngineeringPosition control

In a servo controller according to the invention, a position feedback correction unit (3) calculates a first-axis position feedback signal (pmfb1) based on a first-axis position (pm1) as a self-axis position, and a second-axis position (pm2) as an other-axis position; and a deviation between a model position (pa1) and the first-axis position feedback signal (pmfb1) is inputted from a subtracter (5) to a position control unit (4), which performs positional control to output a velocity command. A velocity feedback correction unit (6) calculates a first-axis velocity feedback signal (wmfb1) from a first-axis velocity (wm1) as the self-axis velocity, and a second-axis velocity (wm2) as the other-axis velocity; and the velocity control unit (8) adds a model velocity (wa1) and the velocity command outputted from the position control unit (5), and subtracts the first-axis velocity feedback signal (wmfb1) therefrom, and outputs a feedback torque command (Tfb1) based on the corrected velocity command.

Owner:MITSUBISHI ELECTRIC CORP

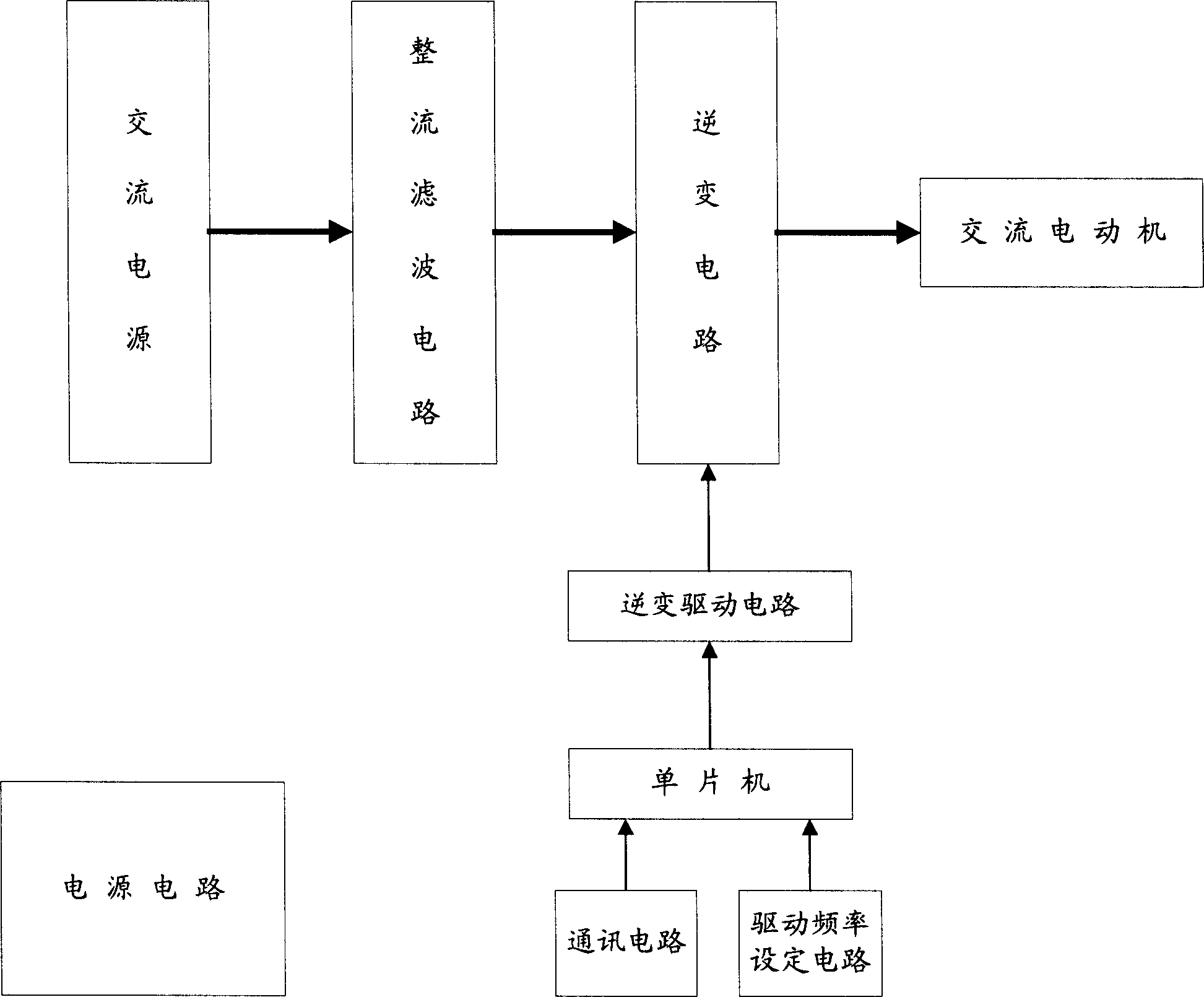

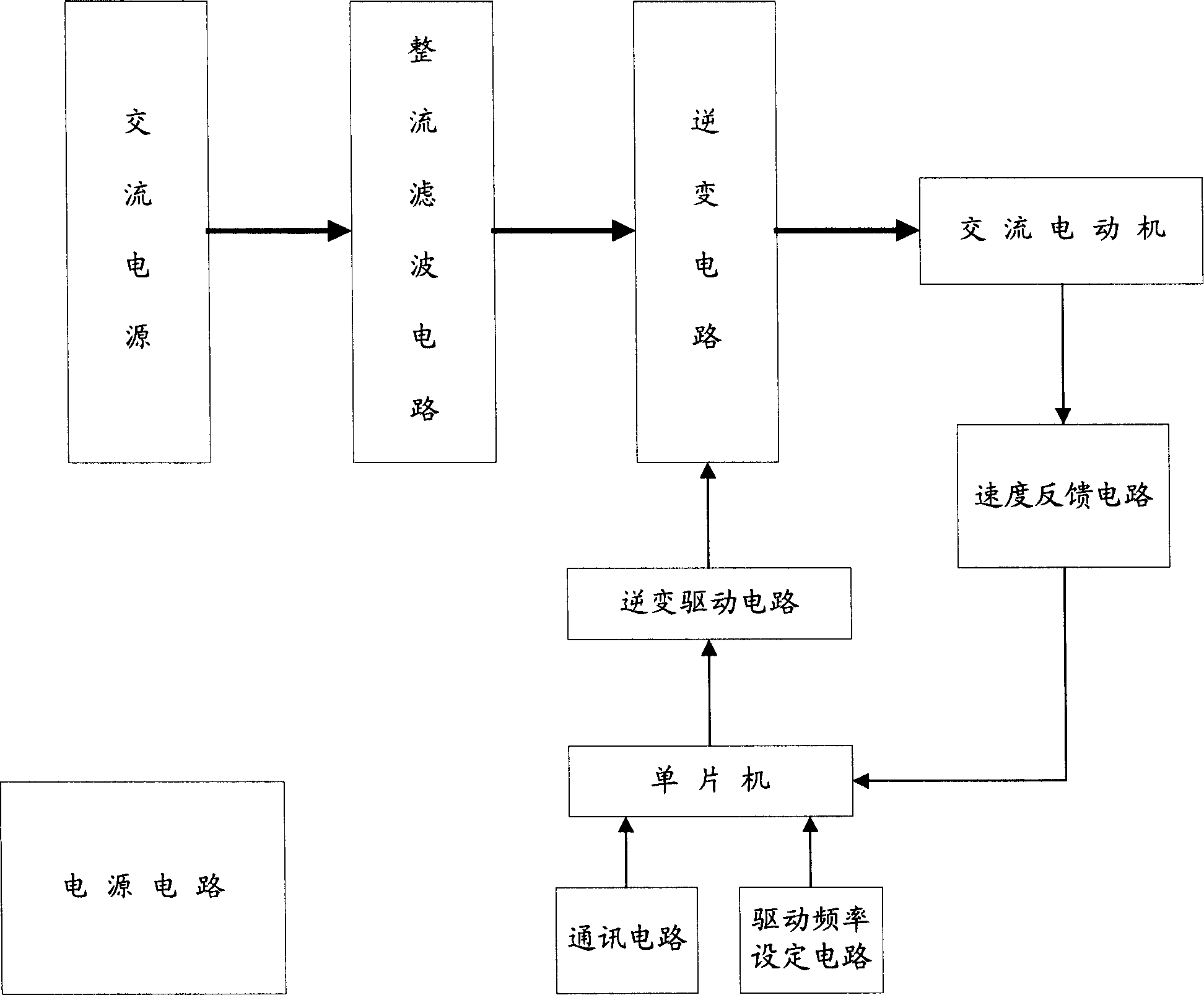

Velocity feedback circuit for variable frequency control device of alternating current motor and method therefor

InactiveCN1877982ASolve speed feedback problemFree from damageAC motor controlElectric variable regulationMicrocontrollerFeedback circuits

The invention discloses an AC motor speed feedback circuit with AC frequency conversion controller as single chip machine, which comprises the following parts: speed-measuring unit, receiving circuit, separating circuit, output circuit and single chip machine, wherein the speed-measuring unit generates period and speed-measuring signal in relative with AC motor rotary speed, which outputs the signal; the receiving circuit receives speed detecting signal of speed-measuring element, which transmits the signal into fitful electric parameter; the separating circuit receives the transmitted speed measuring signal from receiving circuit, which outputs electric separating signal; the output circuit receives speed-measuring signal separated by circuit separation, which transmits the measuring signal into pulse signal to output to single-chip machine output end; the single-chip machine receives speed measuring signal and accumulates the signal, which adjusts driving power frequency and voltage of AC motor.

Owner:HAIER GRP CORP +1

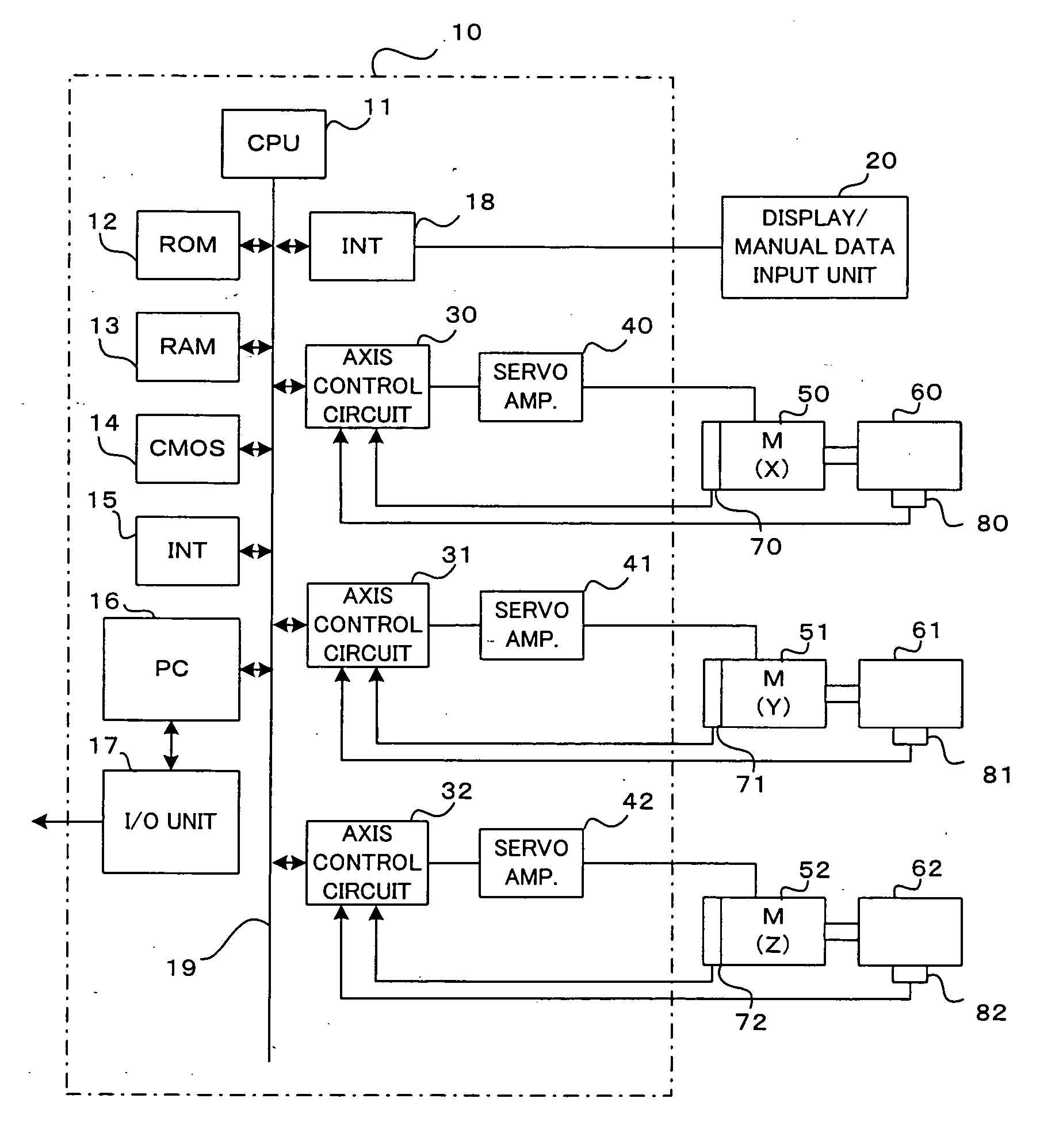

Controller

InactiveUS20060184256A1Accurate detectionPrevent crashProgramme controlAdaptive controlEngineeringServomotor

Disclosed is a controller for detecting need of maintenance, abnormal operation, etc. of a machine attributable to reduction of its strength caused by secular change. Acceleration detecting means are attached to driven elements that are driven by servomotors. Respective processors of axis control circuits for feedback-controlling the positions and velocities of the servomotors perform position and velocity feedback control processing for each position / velocity control period, thereby obtaining current commands, and output the commands to current loop processing. Detected acceleration values af are read from the acceleration detecting means. When the detected acceleration values af are not smaller than a threshold value as, an abnormality signal is outputted, whereupon an alarm is displayed and the machine operation is stopped. Since the accelerations of the driven elements are detected directly by the acceleration detecting means, abnormality of the machine, such as frequent vibration attributable to aging of the machine, collision of the driven elements with other objects, or breakage of parts, can be detected securely.

Owner:FANUC LTD

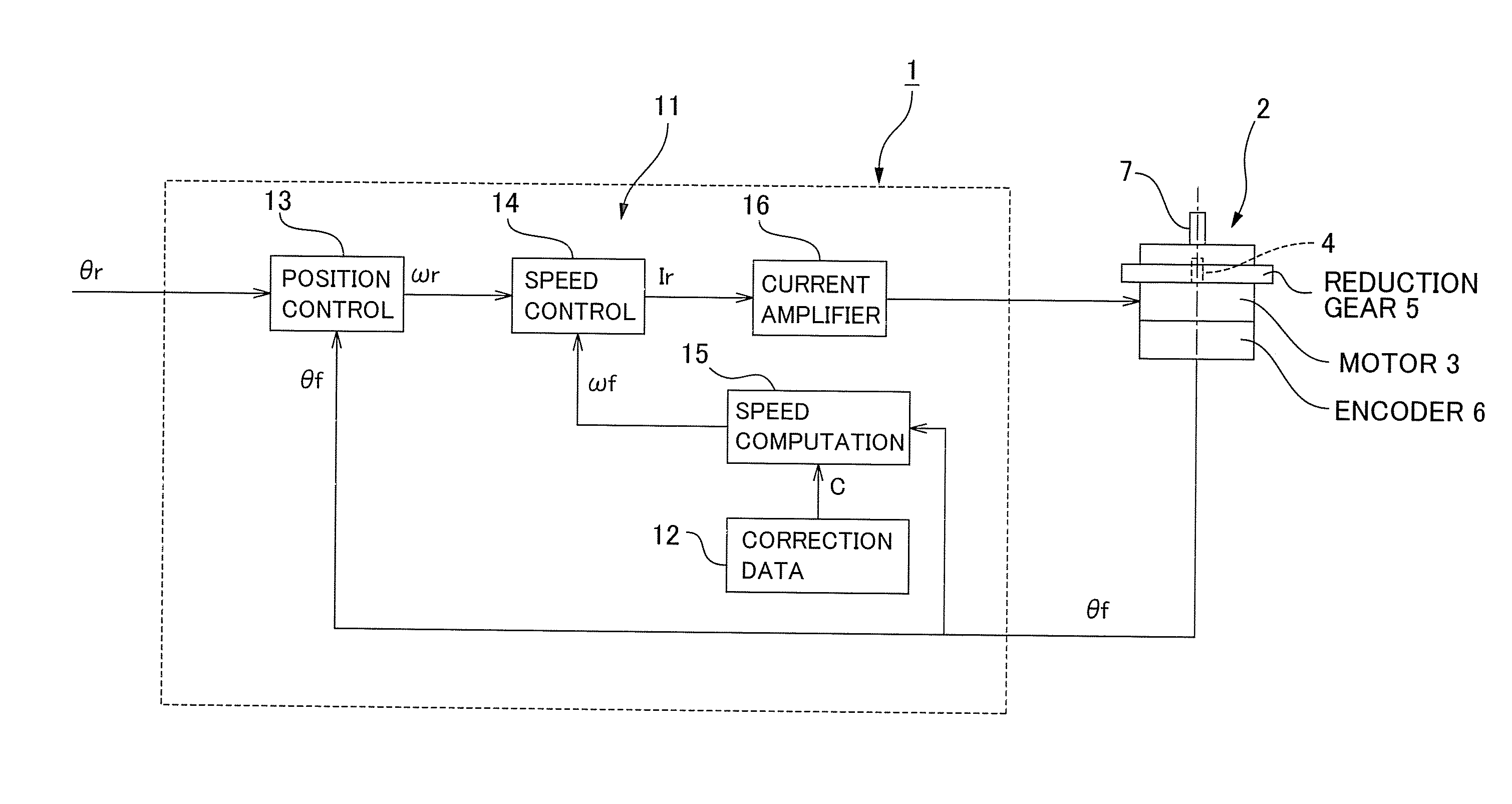

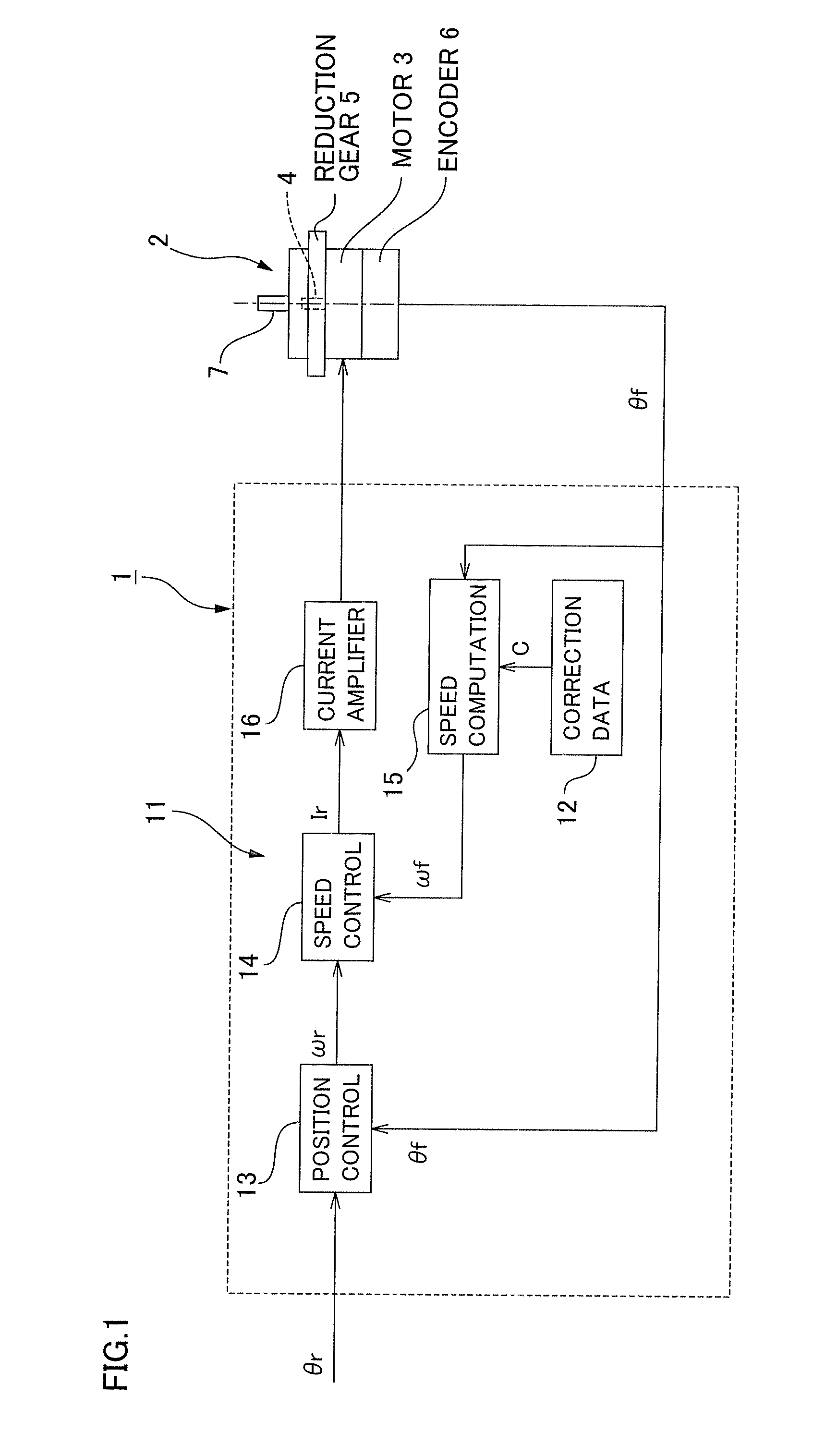

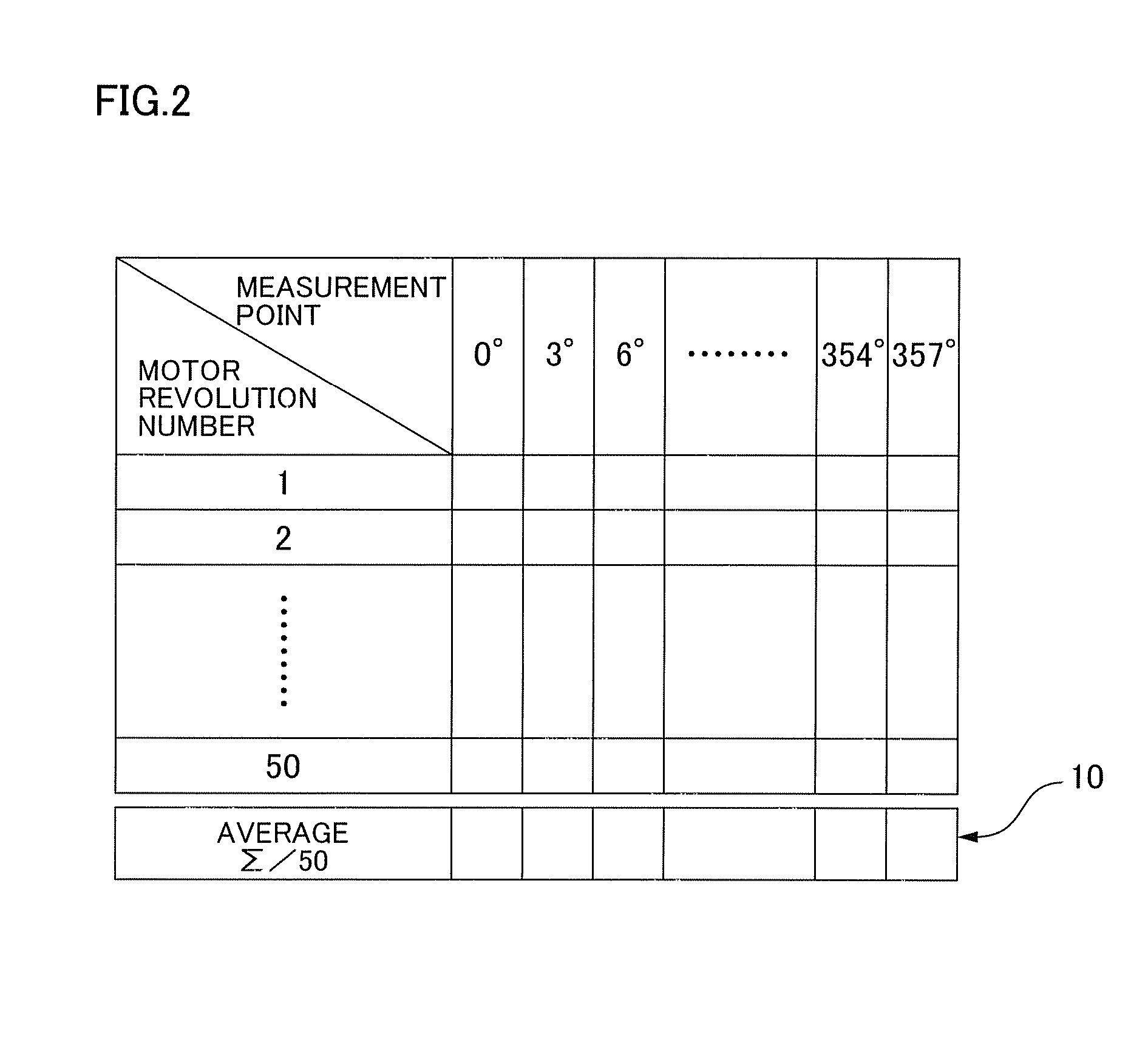

Method for suppressing variation in speed of actuator

InactiveUS20090015188A1Suppress mutationTorque ripple controlElectric motor controlGear driveGear wheel

The drive controller of an actuator previously measures positioning error of an actuator output shaft caused by the angle transmission error of a wave gear drive and stores it as correction data. In a feedback control loop, a speed feedback value ωf is computed using the detected position feedback value θf, after corrected by the correction data, of the actuator output shaft, and a current command Ir is computed using it, thus performing drive control on a motor. Since a speed component caused by the angle transmission error of the wave gear drive has been added to the rotational speed of a motor with regard to the speed feedback value ωf, a variation in rotational speed of the actuator output shaft caused by the angle transmission error of a wave gear drive can be suppressed effectively.

Owner:HARMONIC DRIVE SYST IND CO LTD

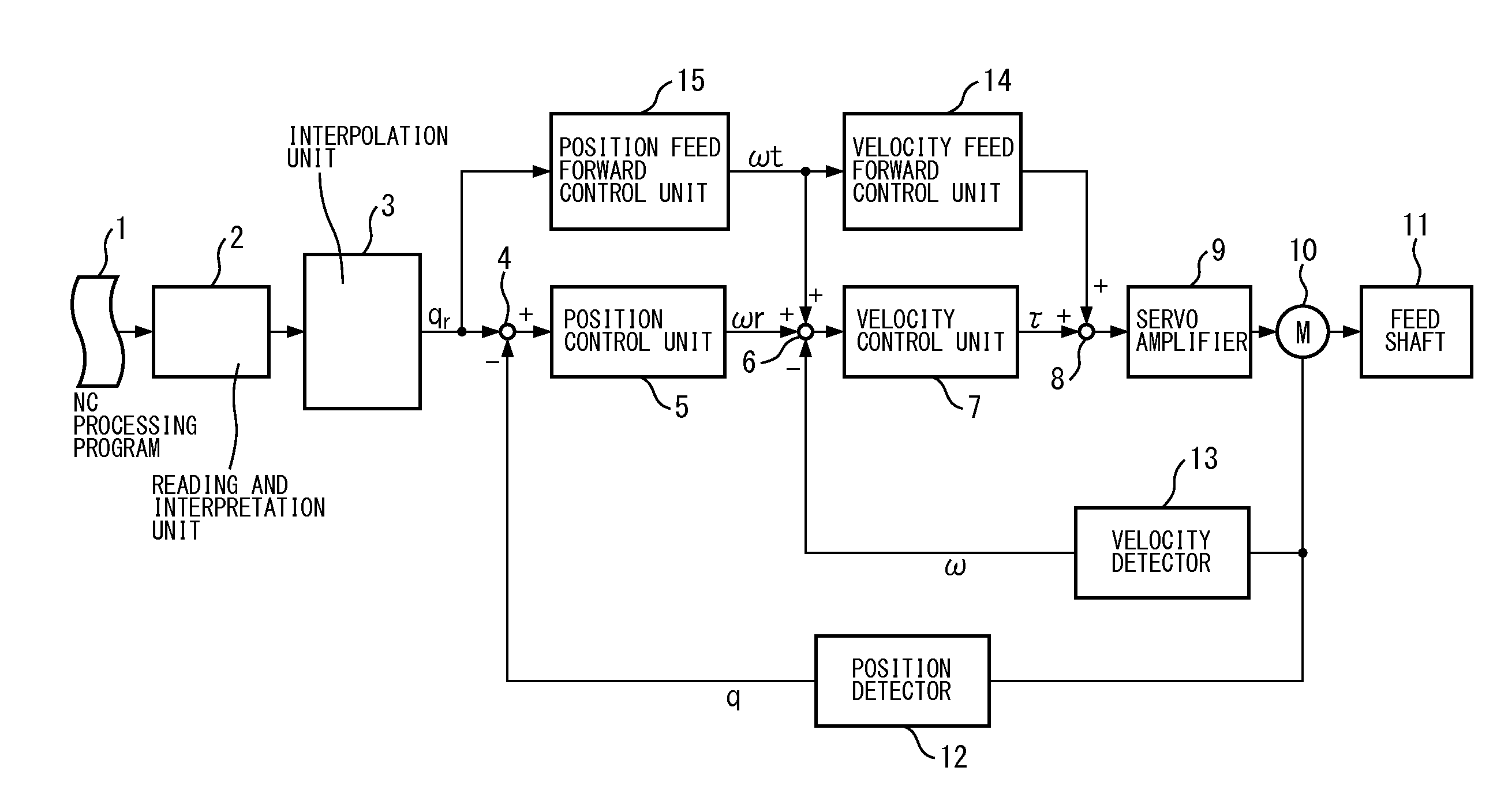

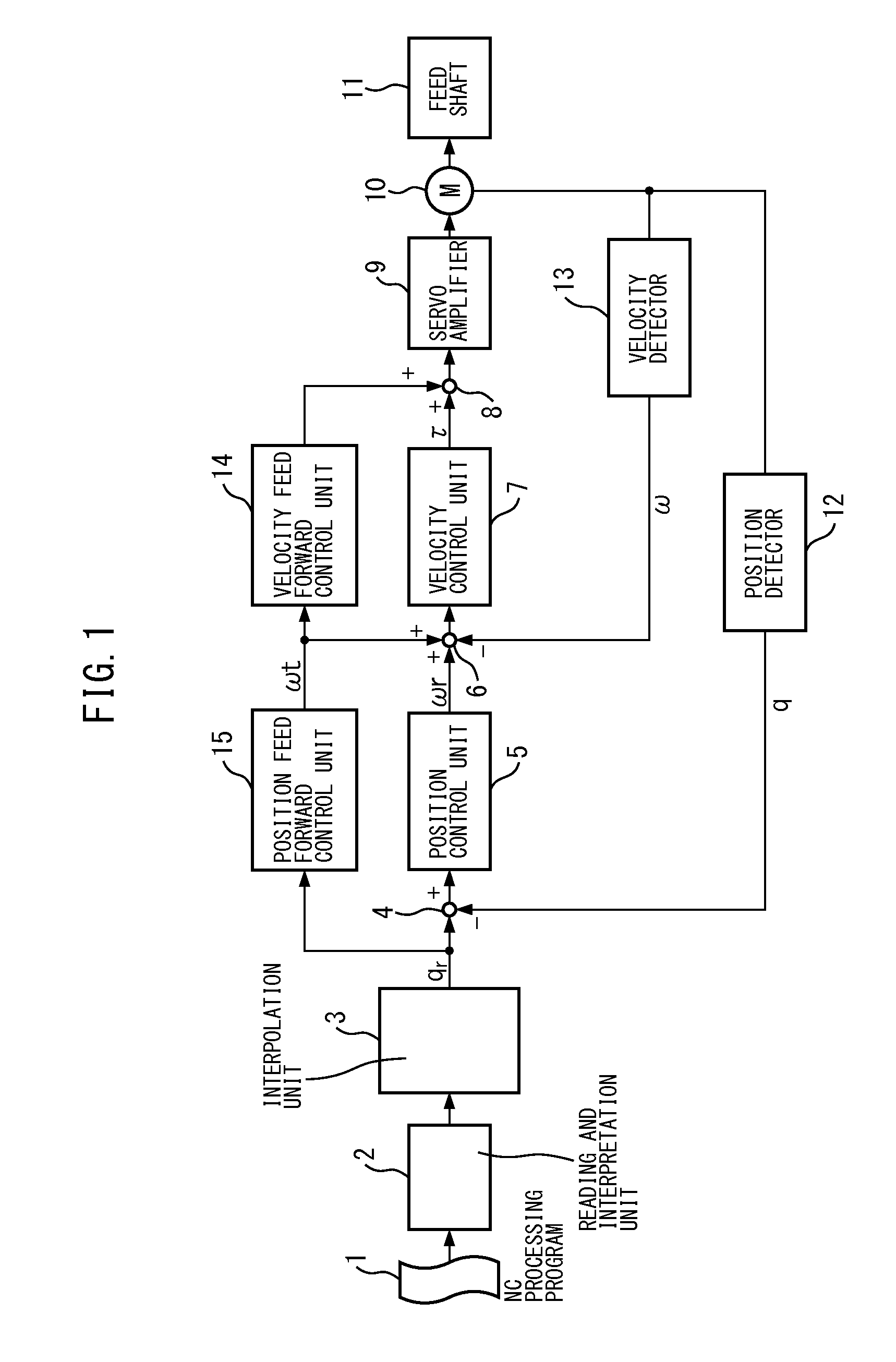

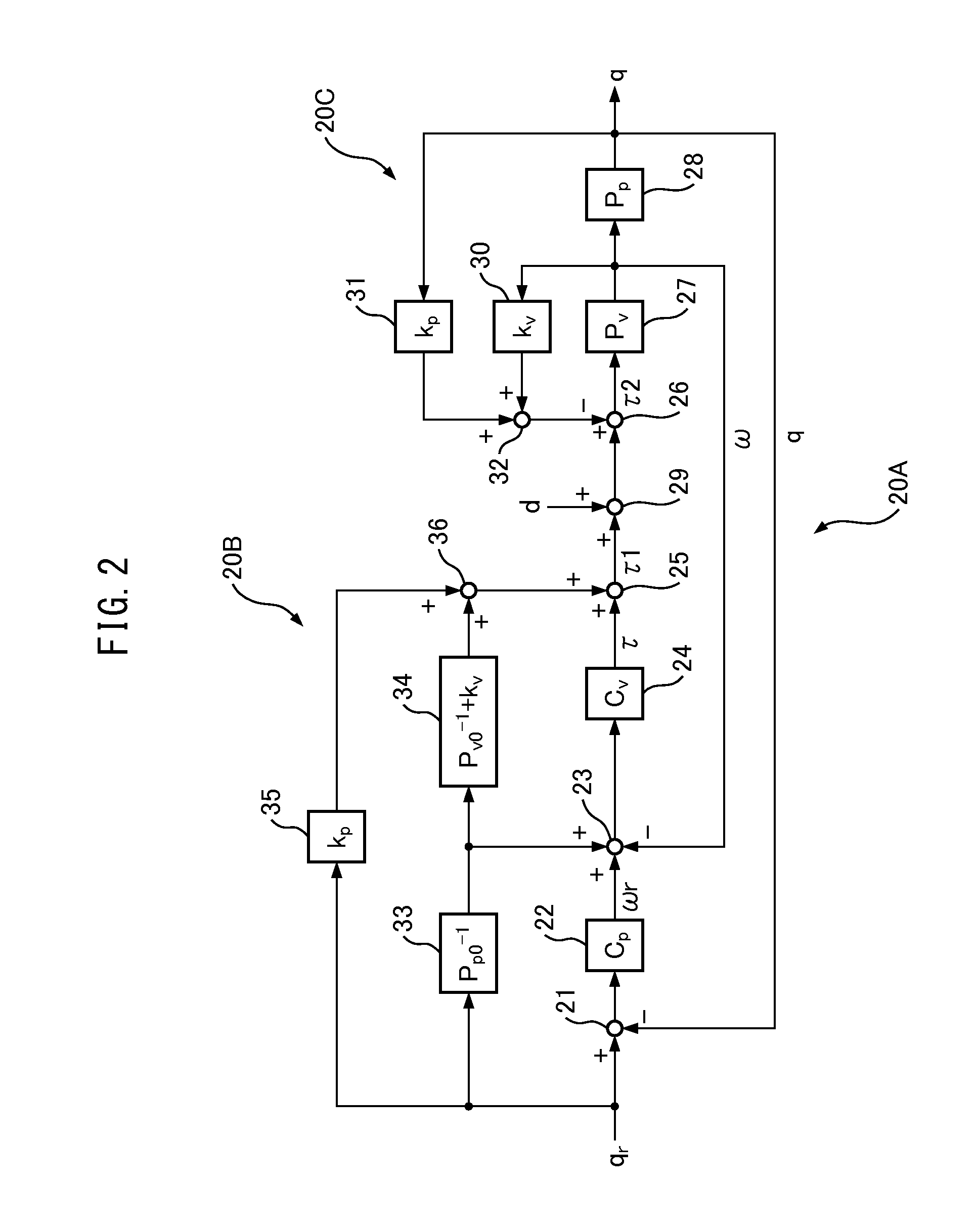

Working machine feed axis control method and feed axis control device

ActiveUS20160004248A1Process stabilityFeedback gain is increasedSpecial data processing applicationsNumerical controlCouplingGain setting

A working machine feed axis control device: disposes a velocity feedback loop and forms a cascade coupling on the inner side of a location feedback loop; comprises a velocity gain setting apparatus (30) which multiplies the output of the velocity feedback look by a first gain (kv), and a location gain setting apparatus (31) which multiplies the output of the location feedback loop by a second gain (kp); subtracts the output of the velocity gain setting apparatus (30) and the output of the location gain setting apparatus (31) from a torque instruction (τ); and outputs the remaining torque instruction (τ) to a subject to be controlled (27).

Owner:MAKINO MILLING MASCH CO LTD

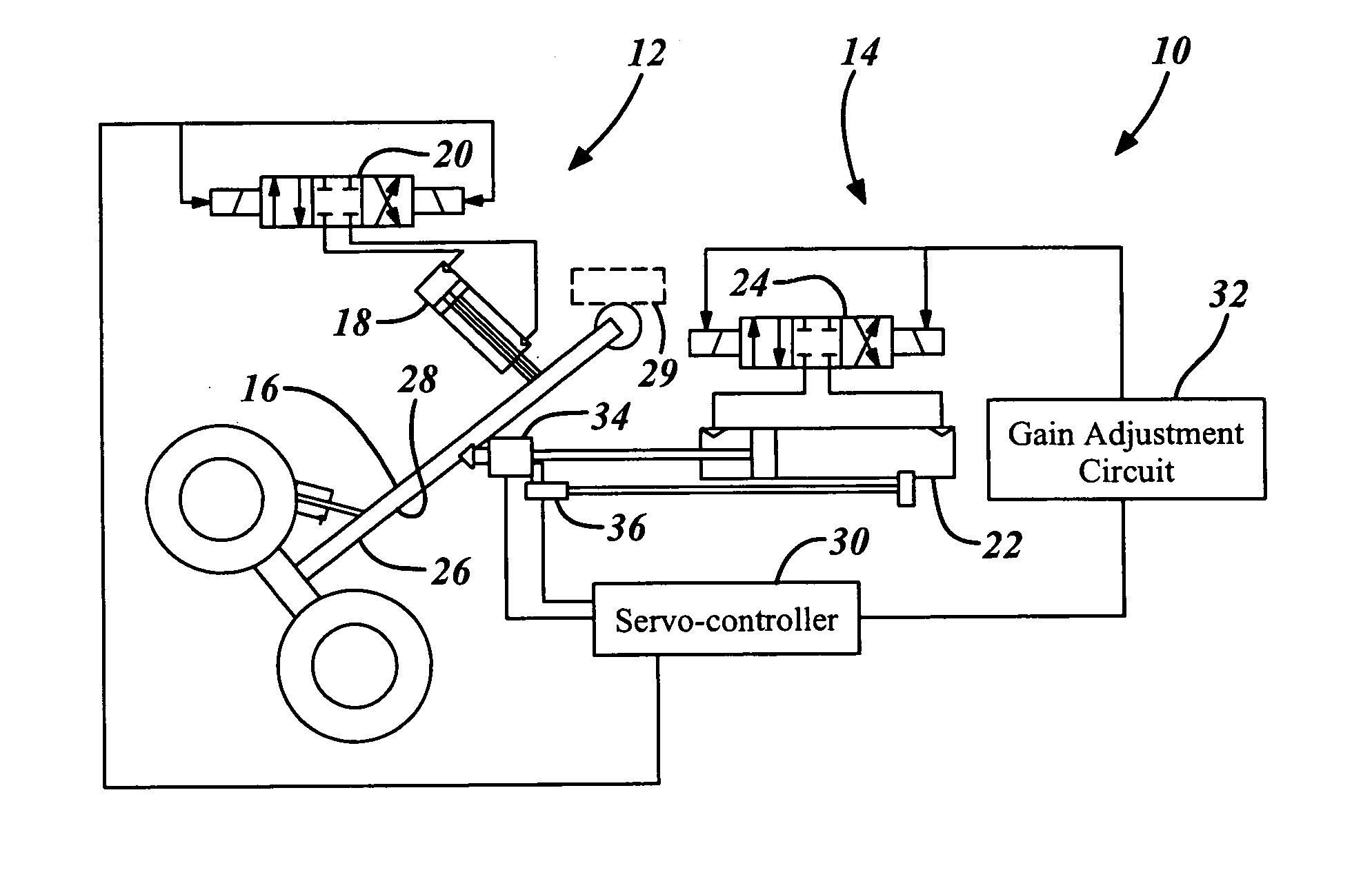

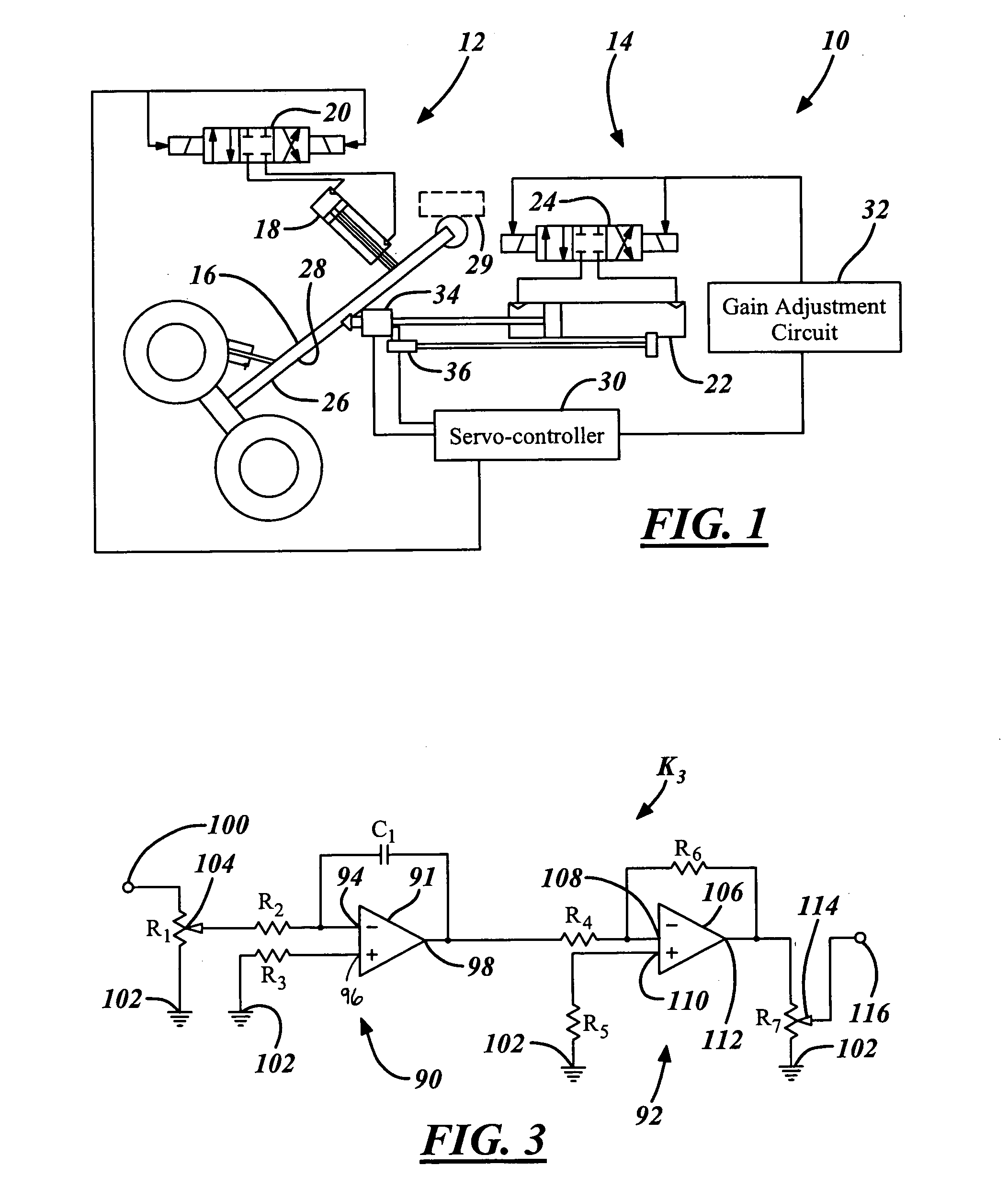

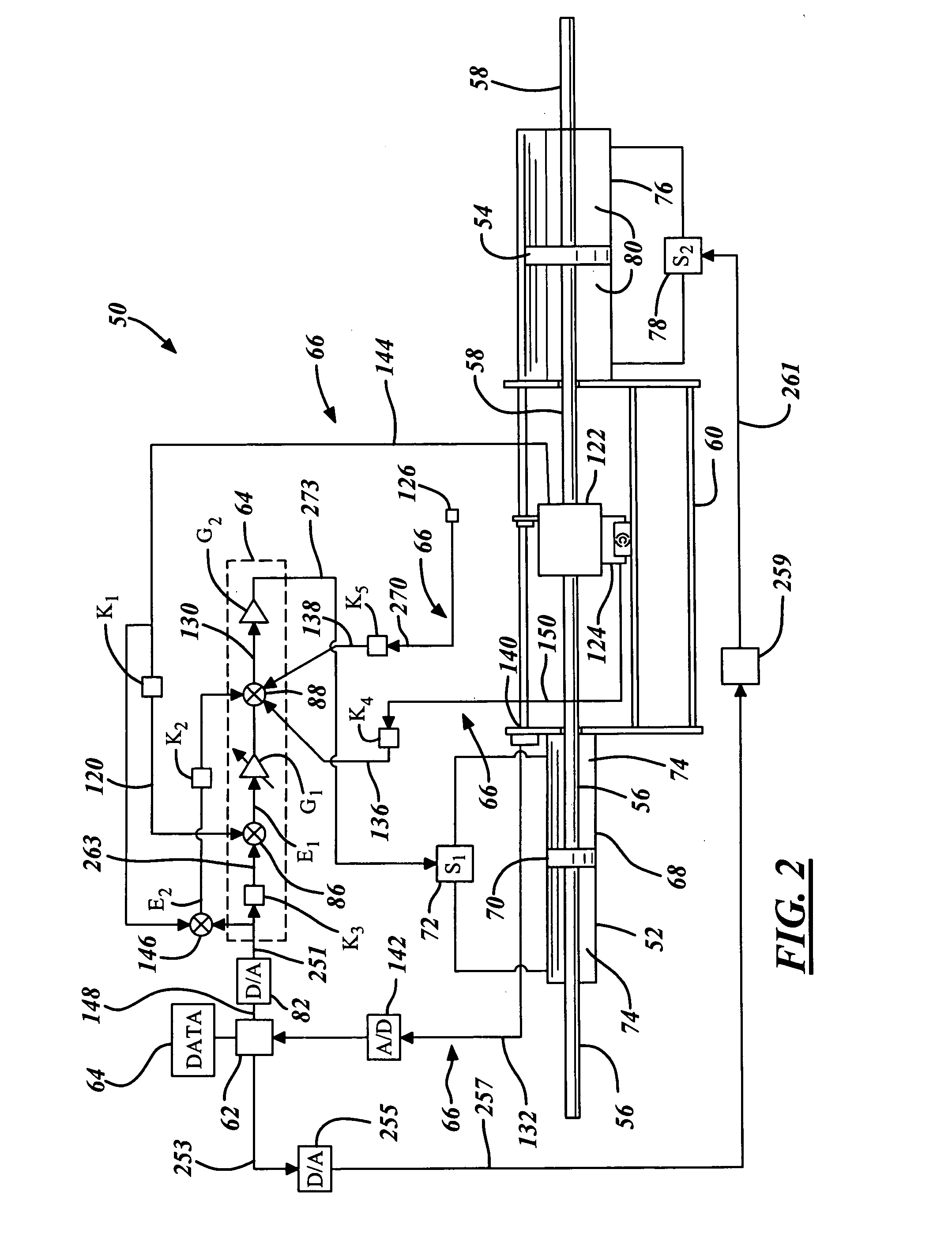

Velocity feedback compensation for force control systems

ActiveUS20070051184A1Improve stabilityCycle fastForce measurementUsing electrical meansControl systemSignal generator

A force control system (50, 300) for actuation of a test object (54, 304) includes a force actuator (52, 356) that is coupled to and applies a force on the test object (54, 304). A velocity signal generator (124, 310) is in a feedback configuration relative to the force actuator and generates a velocity signal (150, 324) that is indicative of the velocity of the test object (54, 304). A controller (62, 302) is coupled to the force actuator (52, 356) and to the velocity signal generator (124, 310) and generates a desired applied force signal (130, 380) in response to the velocity signal (150, 324).

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com