High-integration high-precision servo control device for control moment gyros

A technology for controlling torque gyroscopes and servo control devices, applied in program control, computer control, general control systems, etc., can solve the problems of low integration, increased power consumption, volume, quality and cost of control torque gyroscope servo systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

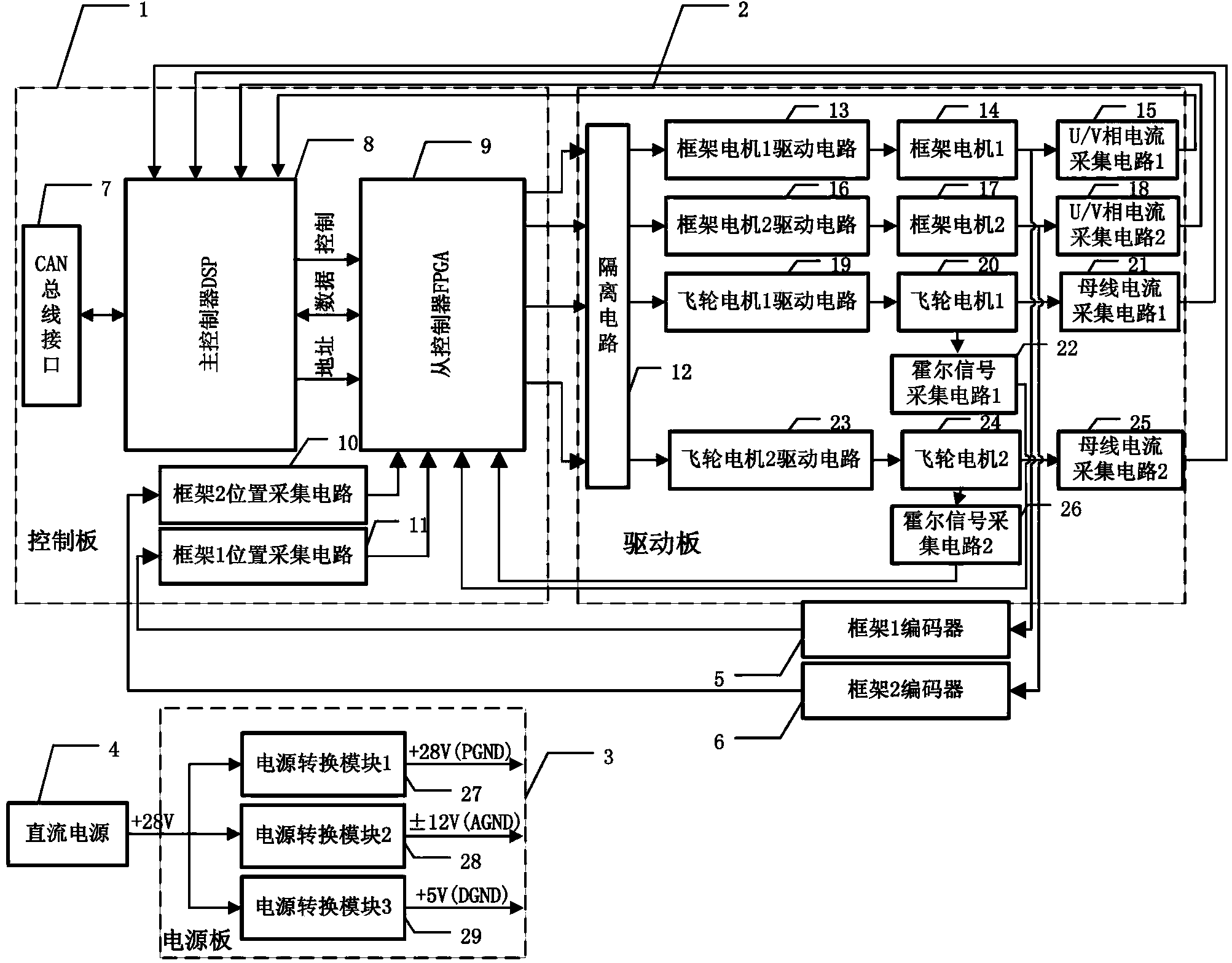

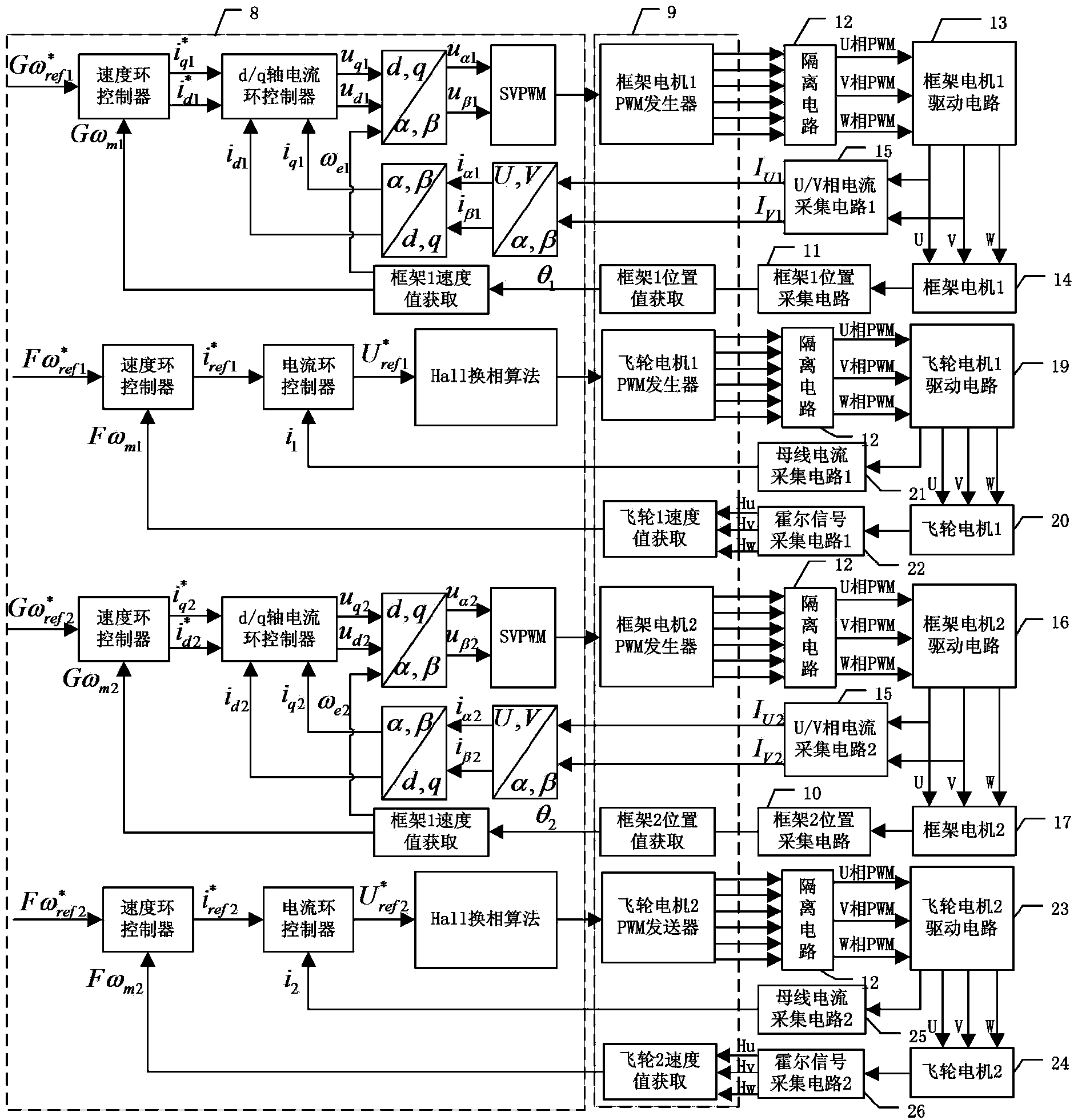

[0032] The present invention can simultaneously perform high-precision servo control on two sets of control torque gyroscopes. The main controller DSP8 receives the control torque gyroscope group servo instructions through the CAN bus interface 7, including frame motor I14, flywheel motor I20, frame motor II17 and flywheel motor II24 servo command, and trigger the servo program that controls the torque gyroscope group.

[0033] Taking the control torque gyro servo control of a single set as an example, use the U / V phase current acquisition circuit I15 to obtain the U phase and V phase currents of the frame motor I14 in real time, and obtain the d / q axis current value i after coordinate transformation q1 i d1 , utilize the frame I position acquisition circuit 11 to acquire the frame I position θ of the frame motor I14 in real time 1 , further calculate the angular velocity Gω m1 , the main controller DSP8 according to the expected speed of the frame motor I14 and the feedba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com