Patents

Literature

65results about How to "Guaranteed high growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

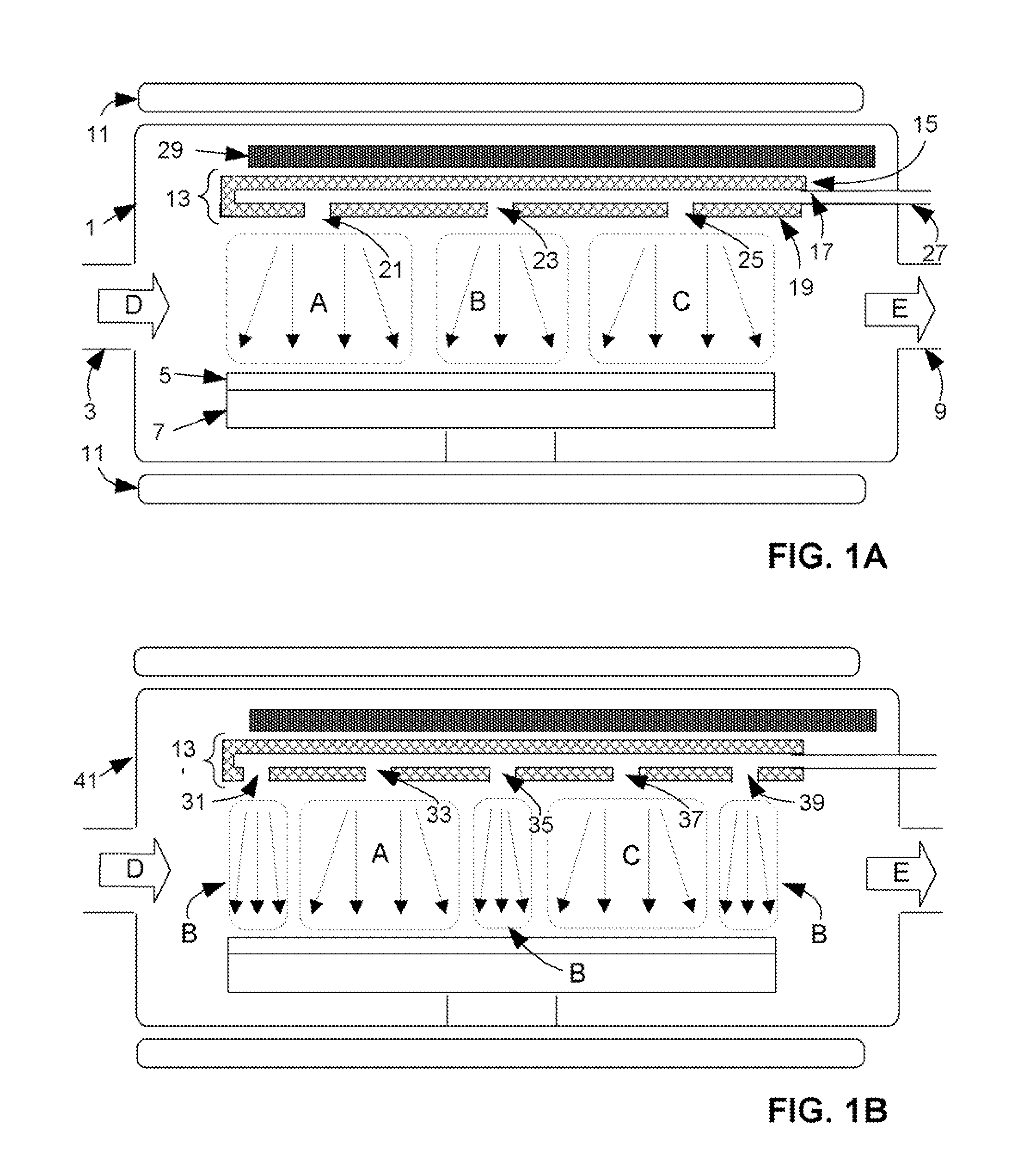

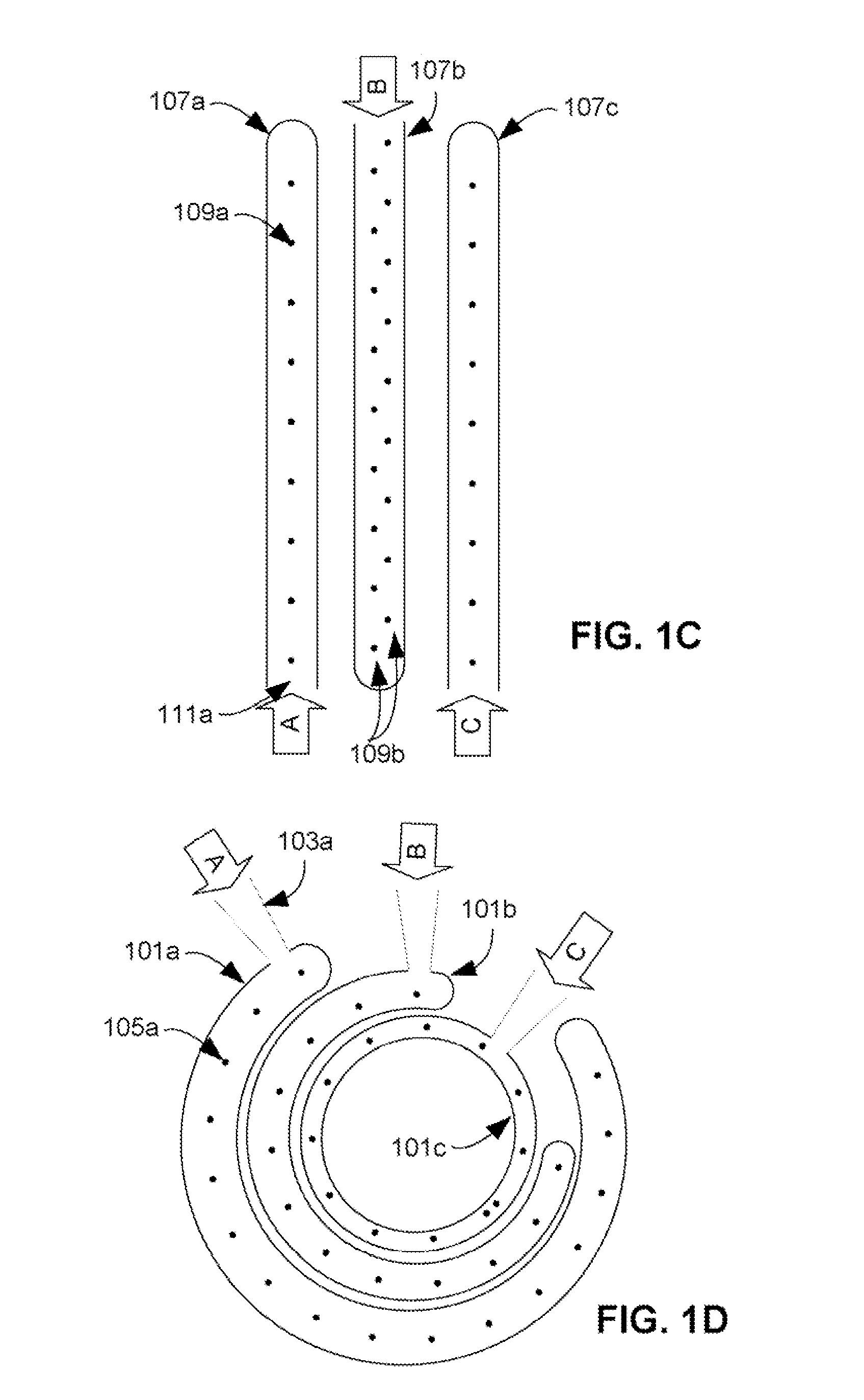

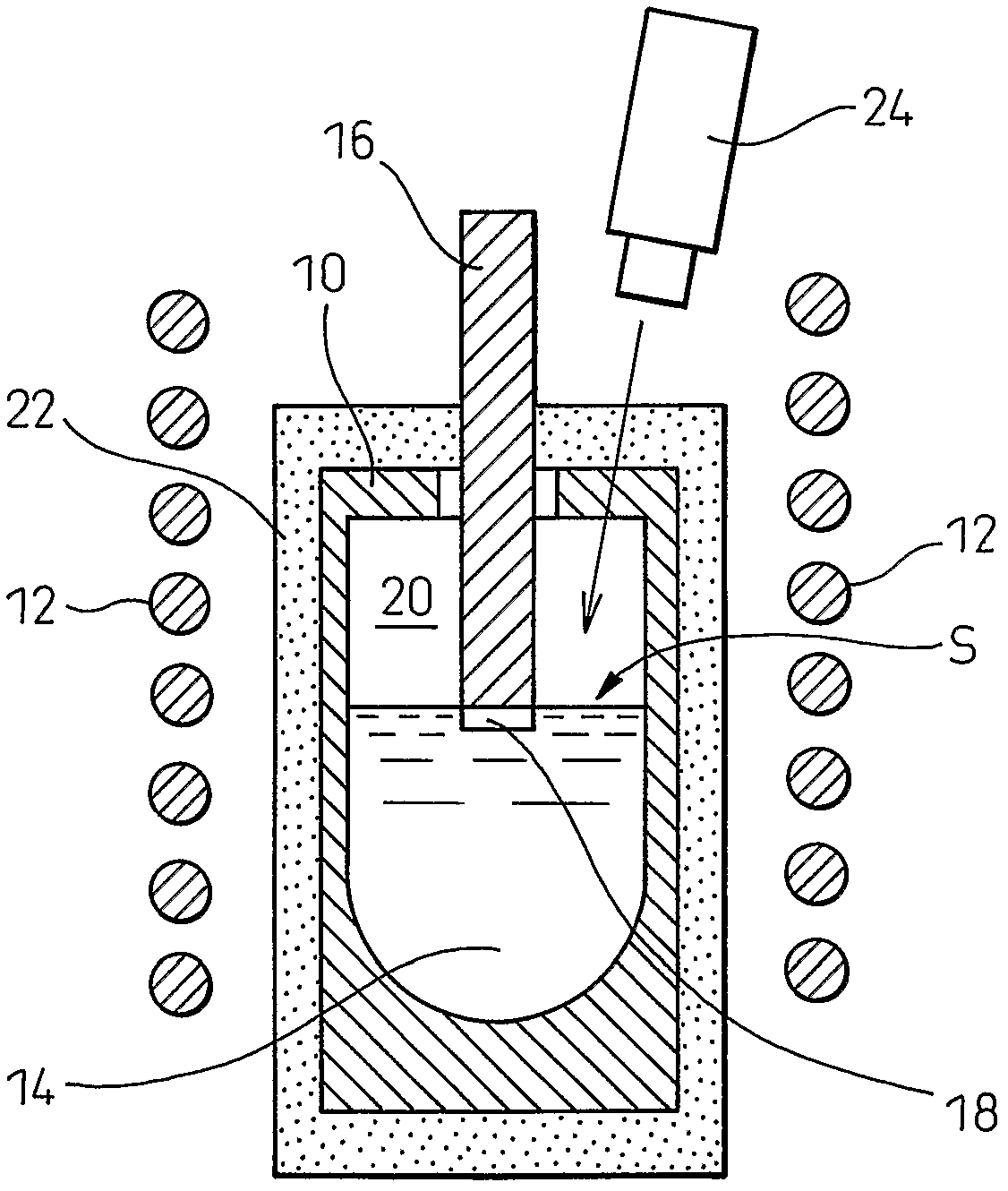

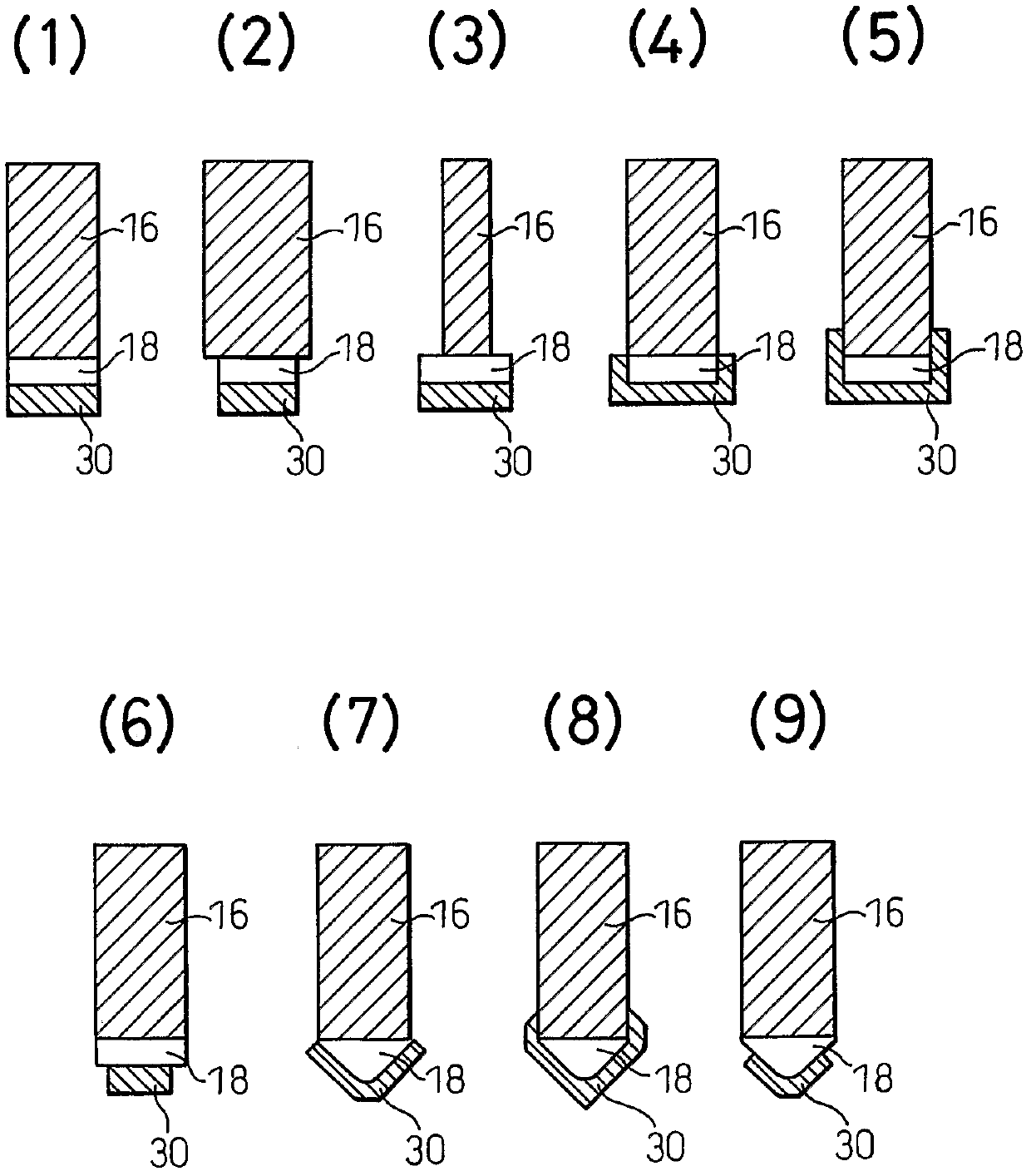

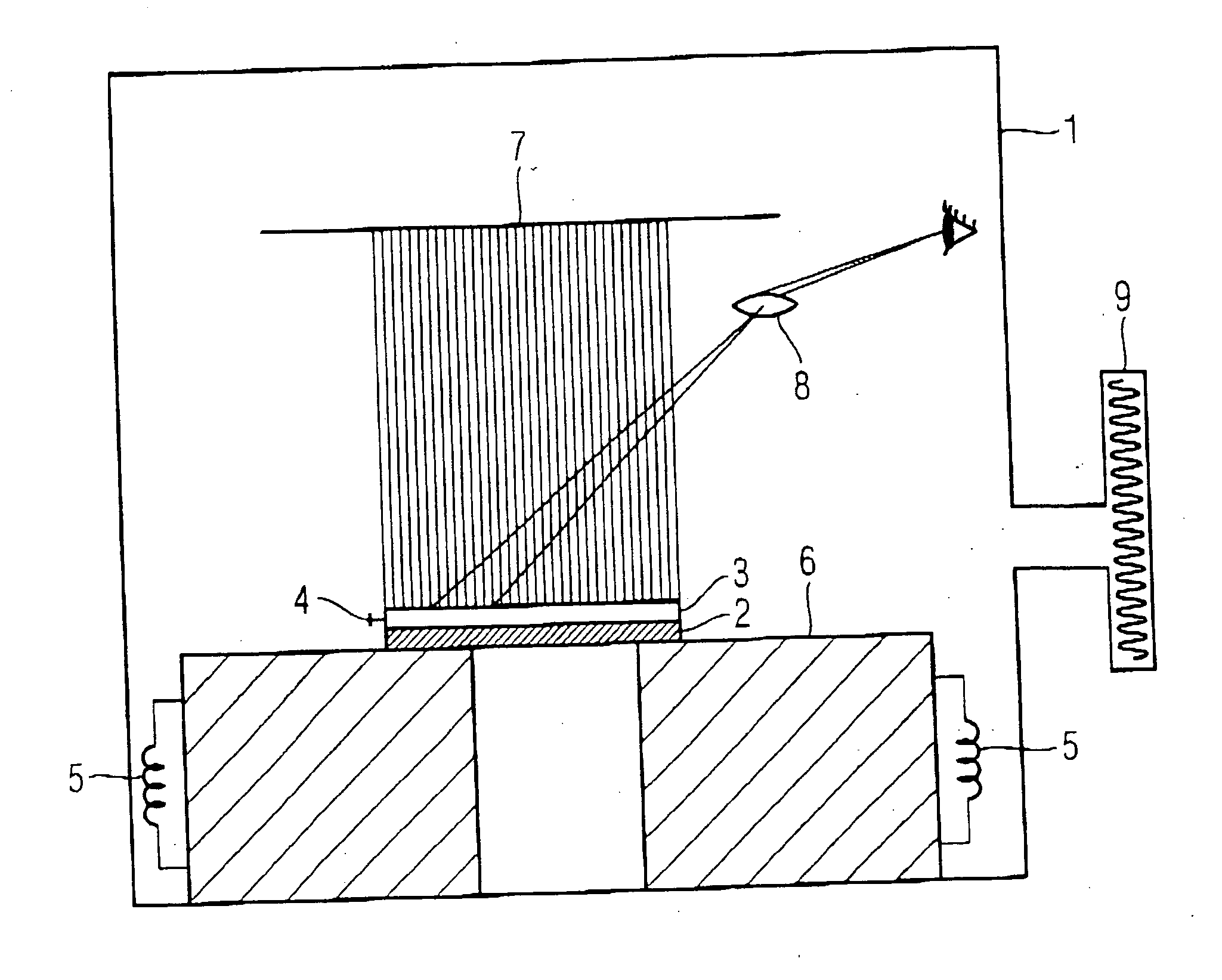

Apparatus for delivering precursor gases to an epitaxial growth substrate

InactiveUS20100258053A1Precise deliveryIncrease volumePipe supportsServomotor componentsGas syringeProduct gas

This invention provides gas injector apparatus that extends into a growth chamber in order to provide more accurate delivery of thermalized precursor gases. The improved injector can distribute heated precursor gases into a growth chamber in flows that spatially separated from each other up until they impinge of a growth substrate and that have volumes adequate for high volume manufacture. Importantly, the improved injector is sized and configured so that it can fit into existing commercial growth chamber without hindering the operation of mechanical and robot substrate handling equipment used with such chambers. This invention is useful for the high volume growth of numerous elemental and compound semiconductors, and particularly useful for the high volume growth of Group III-V compounds and GaN.

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

Polypeptide preparation for microorganism ferment making feed and preparation method

InactiveCN101120724AGuaranteed survivalThe equipment is easy to operateFood processingAnimal feeding stuffBiotechnologyMicroorganism

The present invention relates to a preparation method for microbial polypeptide preparation with the use of lactic acid bacteria and bacillus subtilis, and which is characterized in that the high yield enzyme and high quantity production strains is selected and trough the integration of original microwave-induction and rays-induction, wherein the production process applies the liquid-alone culture and solid-composite culture, adds special product promoter into the medium, the content of soybean peptide is high, at the same time which is rich in metabolic products such as peptidoglycan, microbial antioxidants and enzymes. The present invention has the advantage of low production cost, faster cycle, and faster absorption for animal after breeding, high daily increasing in weight, immunity enhancing, and stress rising, which has obvious effect in breeding and is a safe and high efficient new feed additive.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

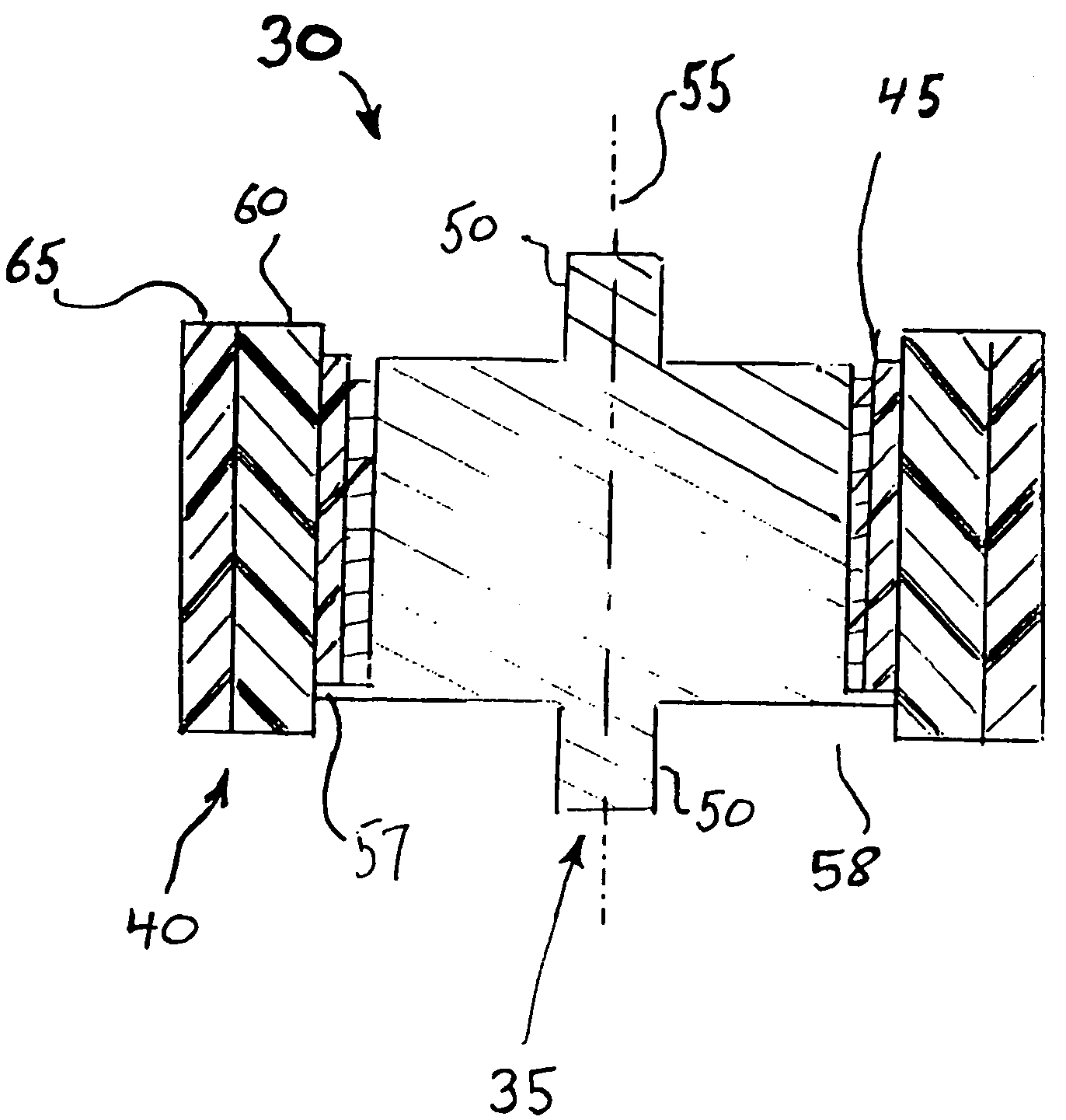

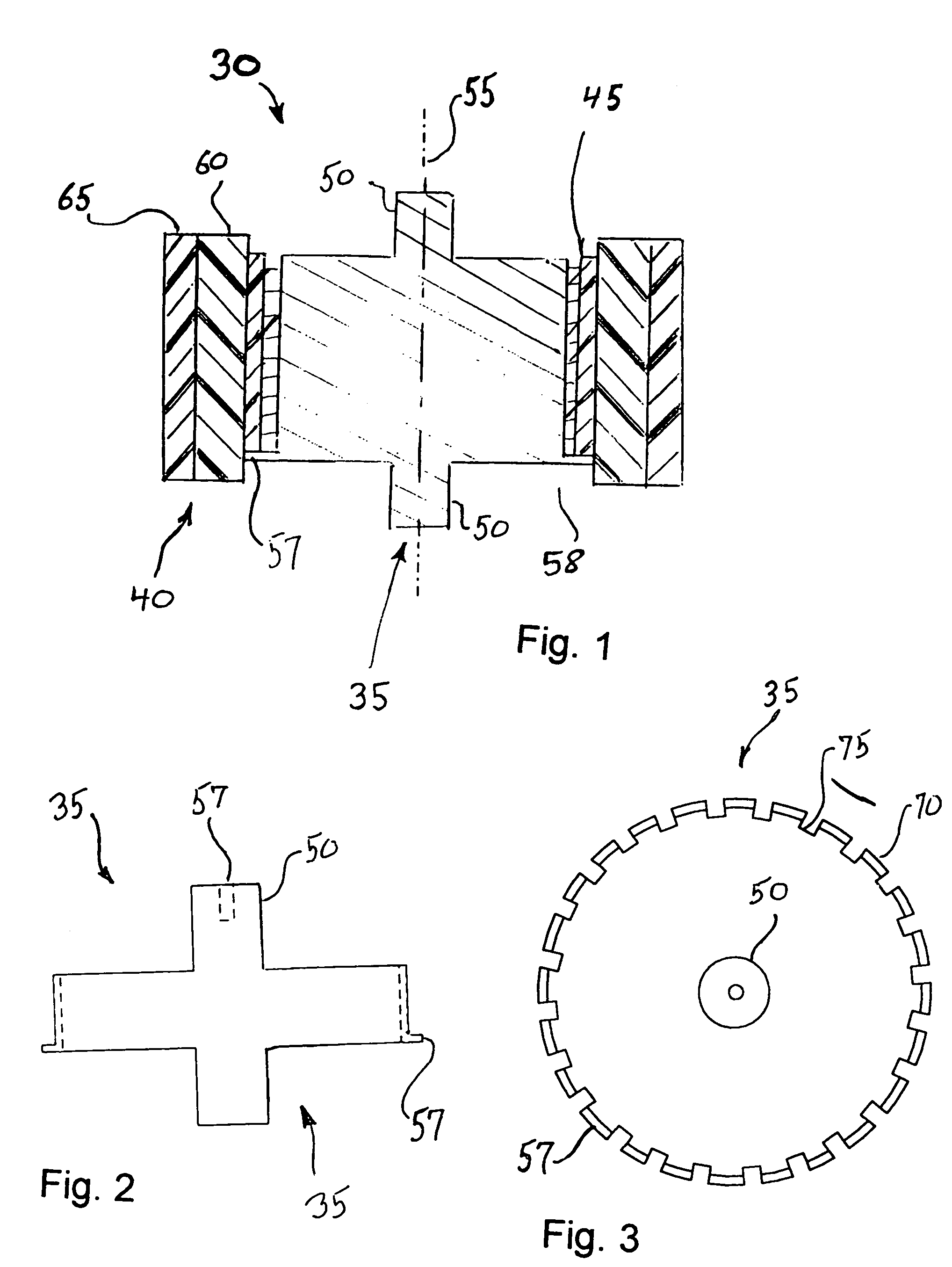

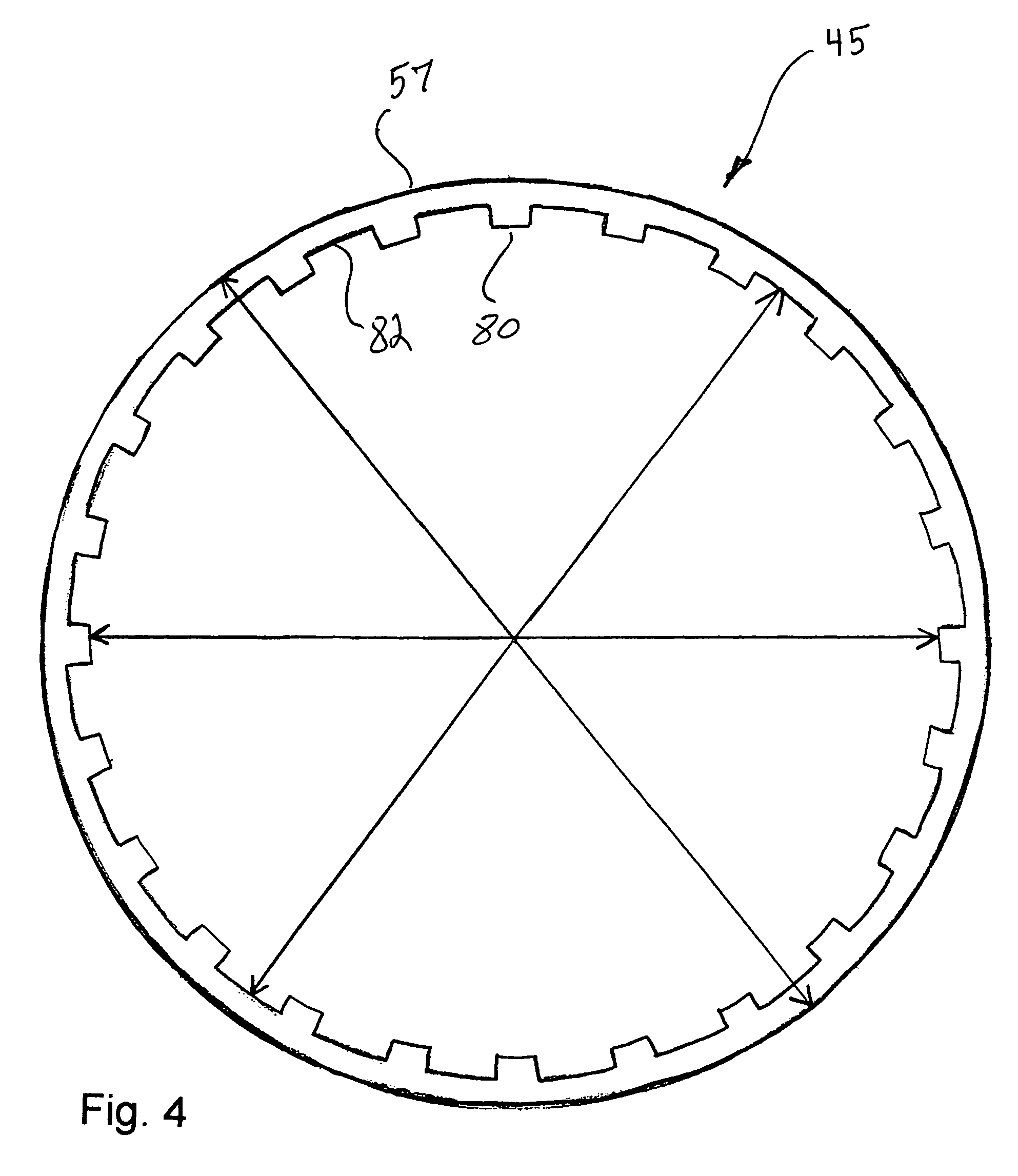

Flywheel hub-to-rim coupling

A flywheel system includes an annular rim mounted for high speed rotation on a flywheel hub. The hub has a radially splined exterior surface facing radially outwards. The rim includes an annular rim liner having an axis of rotation coinciding with the axis of rotation of the hub, and having an inner surface facing radially inward. The inner surface of the rim liner has integral splines projecting radially inward and extending axially. The rim liner splines mate with the hub splines. The flywheel rim liner has a modulus of elasticity el, and a density ρl, and a liner ratio Rl equal to El / ρl. The flywheel rim has a modulus of elasticity er in the hoop direction and a density ρr; and a rim ratio Rr equal to Er / ρr. The materials and configuration of the rim and rim liner are designed so that Rl is less than or equal to Rr, so said flywheel rim liner grows radially with the rim.

Owner:TORAY COMPOSITES (AMERICA) INC

Microorganism feed additive capable of promoting goose liver development and preparation method thereof

InactiveCN101084780AGrowth inhibitionInhibition of reproductionAnimal feeding stuffAccessory food factorsCelluloseBiotechnology

The invention relates to a method for preparing microbial feed additive used for promoting growth of goose liver. All of the microbial strain is screened out from the animal intestinal tract. The method comprises culturing all the strains on the same culture medium through combined culture, constituting powerful compound microbial community by using mixed sync solid fermentation process, and forming effective enzyme producing ability to make the product has amount of physiologic metabolite such as organized enzyme for analysing cellulose and fructose, peptide, antioxidants, free amino acid, and vitamin. The invention can promote feed digestion and absorption of animal, promote synthesize and utilization of protein, enhance immunologic competence of livestock, fowl and aquatic livestock, and improve feed conversion ratio and production capacity of breed animal. The inventive product has good practicability and pertinency.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

In-bottle production method of detoxified small seed ball of east lily

InactiveCN1762205AShorten the cultivation cycleReduce manufacturing costHorticulture methodsPlant tissue cultureShoot apexLilium

The invention provides a process for producing the oriental lily sterilized seed globule in the bottle, comprising: choosing explant, sterilizing, inducing culture and getting the sterilized stem tip, then breeding culture, subculture, and producing the sterilized seed globule in the bottle directly. The invention produces the sterilized seed globule in the bottle directly to avoid the problem of long period of ball forming and the accumulation of virus existing in the oriental lily, the seed globule can be planted in the soil when out of the bottle, and the survival rate is high. The breeding procedure of the sterilized seed globule is simplified by modifying and optimizing the whole producing procedure for the lily seed globule, and the breeding time of sterilizing the oriental lily is shortened greatly, the quality of seed globule is improved when the producing cost is decreased, which reinforces market competitive power of the domestic self-breeding seed globule and is suitable for the mass production of the oriental lily sterilized seed globule.

Owner:FLOWER RES INST OF YUNNAN ACAD OF AGRI SCI

Method for preparing functional microbial preparation from lactic acid bacillus and yeast

InactiveCN101715877AGuaranteed high growthGuaranteed retentionFungiBacteriaBiotechnologyHigh concentration

The invention relates to a method for preparing a functional microbial preparation from lactic acid bacillus and yeast, which is characterized in that: liquid of beneficial strains is adopted for culture; cell walls of the strains are collected centrifugally; a strain group is subjected to solid amplification culture; and a culture is added with the collected cell walls rich in polysaccharide. The method has the advantages that: high-concentration lactobacillus in the product can obviously improve the digestion and absorption of bred animals, and the generated metabolic products such as peptidogly can improve the immunity of the animals to pathogen; the high-concentration yeast in the product can improve rich single cell proteins required by the growth of the animals, and simultaneously the yeast cells are subjected to full wall breaking, and release a great amount of beta-1,3-glucan so as to obviously improve the immunity to Gram positive bacteria and Gram negative bacteria; and grain crops and common feeds are adopted as main raw materials for a culture medium, the production cost is reduced, and the method is easy to promote in animal breeding.

Owner:SHANGHAI ENCHUANG BIOTECH RES INST

Preparation method for producing microbe polysaccharides formulation using lactobacillus and microzyme

The invention relates to a method for preparing microbiological polysaccharide product by using lactic acid bacillus and yeast. It is characterized in that it employs liquid culture of benefitial bacteria, collects bacteria cell wall through centrifugation, solid enlargement culturing bacteria group, adding polysaccharide- rich cell wall into culture medium. The high- concentration lactic acid bacteria in product can distinctively improve digestion and absorption for aquatic animal, generated peptidoglycan increases immunity of aquatic animal to pathogenesis; high- concentration yeast in the product can increase single-cell protein amount needed for fish growth, the yeast cell is broke, and releases a large amount of beta- 1, 3- dextran, which can apparently increase immunocompetence for Gram-positive bacteria and Gram-negative bacteria. The invention employs grain crop and commonly used feedstuff carrier as main raw material for culture medium, which reduces production cost, and fermentation device and production equipment are commonly used, which is easy for spread in aquaculture.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

Microbial preparation for improving eel liver growth and its making method

InactiveCN101073585AGuaranteed retentionGuaranteed special effectsFungiBacteriaIntestinal structureHigh concentration

The invention is concerned with a microorganism feedstuff additive to promote the growth of eels, especially to improve the compound function to liver. Culture one or some of the selected lichen bacillus, plant lactobacillus, lactobacillus casei and beer yeast. Carry domesticationhe and train the multiple bacteria and zymosis with culture medium and asepsis water, dry quickly with low temperature through drying mechine, add special carrier, crush and sift out to get production. It has the greatest amout of live bacterium and active metabolized produce, and the production has microorganism with high concentration and abundant active metabolized stuff. Those bacteria and metabolized stuff can improve the intestines function of eels to speed the composing of bile and special protein divided form liver. It also improves the water for living and it is a kind of zoology agriculture production.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

Multidimensional feed additive for sow

InactiveCN101040672APromote secretionGuaranteed high growthAnimal feeding stuffAccessory food factorsVitamin B12Vitamin K3

The invention provides a multivitamin feed addictive for pigs which comprises the following constituents (by weight portions): 50% vitamin E 10-20 parts, 500000IU / g vitamin A 1.0-5.0 parts, 5000000IU / g vitamin D3 0.2-0.6 parts, 50% vitamin K3 0.2-0.6 part, vitamin B1 0.1-0.5 part, vitamin B2 0.5-1.0 part, vitamin B6 0.2-0.6 part, 1% vitamin B12 0.1-0.5 part, nicotinic acid 2.0-6.0 parts, anti-oxidizing quinoline 3.0-8.0 parts, chaff powder 3.0-8.0 parts, alta-mud 0.2-0.8 part, pantothenic acid 1.0-4.0 parts, and folic acid 0.2-0.6 part, 2% biotin 1.0-5.0 parts, chaff powder 5.0-12.0 parts, nano zinc oxide 10.0-20.0 parts, the feed addictive can be used for accelerating galactosis and enhancing animal's ability to fight diseases.

Owner:乐建来

Process for producing SiC single crystal

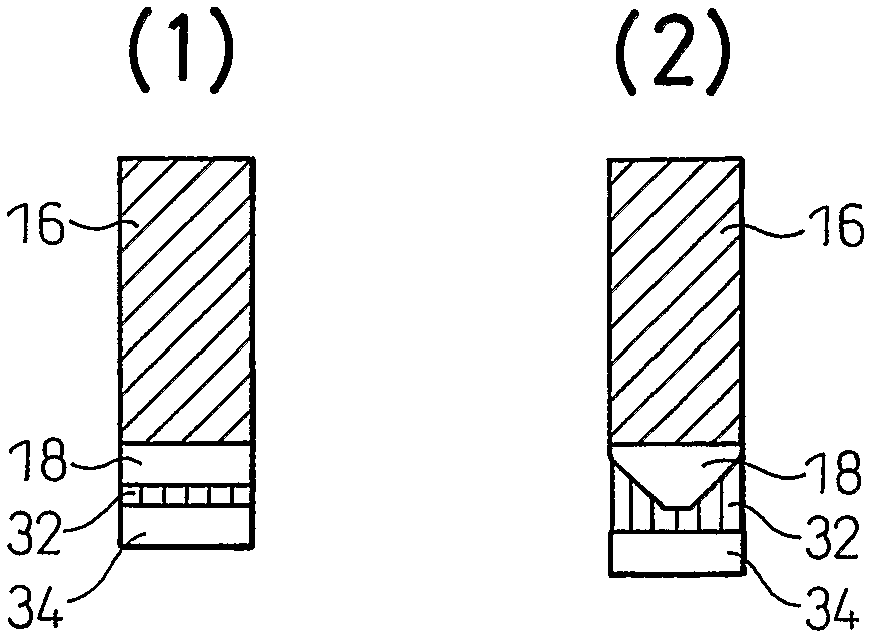

ActiveCN102449208AIncrease supersaturationGuaranteed high growthPolycrystalline material growthLiquid-phase epitaxial-layer growthSeed crystalGraphite crucible

Disclosed is a process for producing an SiC single crystal by a solution method. The process can prevent defects attributable to seed touch in which seed crystals are brought into contact with a solution to grow SiC single crystals with reduced defect density. The process comprises bringing SiC seed crystals into contact with a melt containing Si within a graphite crucible to grow SiC single crystals on the SiC seed crystals and is characterized in that, after the contact of the solution with the SiC seed crystals, the temperature of the solution is once raised to a temperature that is above the temperature in the contact and above the temperature in the growth.

Owner:TOYOTA JIDOSHA KK

Polypeptide and microbial preparation for improving ox myotendinous development and its production

InactiveCN101074420AGuaranteed retentionGuaranteed special effectsFungiBacteriaHigh concentrationDigestion

A polypeptide and microbial feed additive for improving beef muscle belly connective tissue synthetic function is safe and non-toxic. The process is carried out selecting natto rod, lichenized bacillus, plant lactobacillin, cheese lactobacillin and beer yeast, independent or composite culturing to obtain composite bacterium, naturalizing while expansion culturing, solid fermenting with culture medium and aseptic water, fast low-temperature drying by drier, adding into special carrier, crushing and screening to obtain final product. It obtains high-concentration enteric beneficial microbial pool and mixtures of health-care soybean peptide, oligo-peptide and short peptide containing natto-kinase. It's practical and economical, and it tastes good and can improve digestion-absorbing function of beef for protein in feed.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

Flower pot plant hold up device

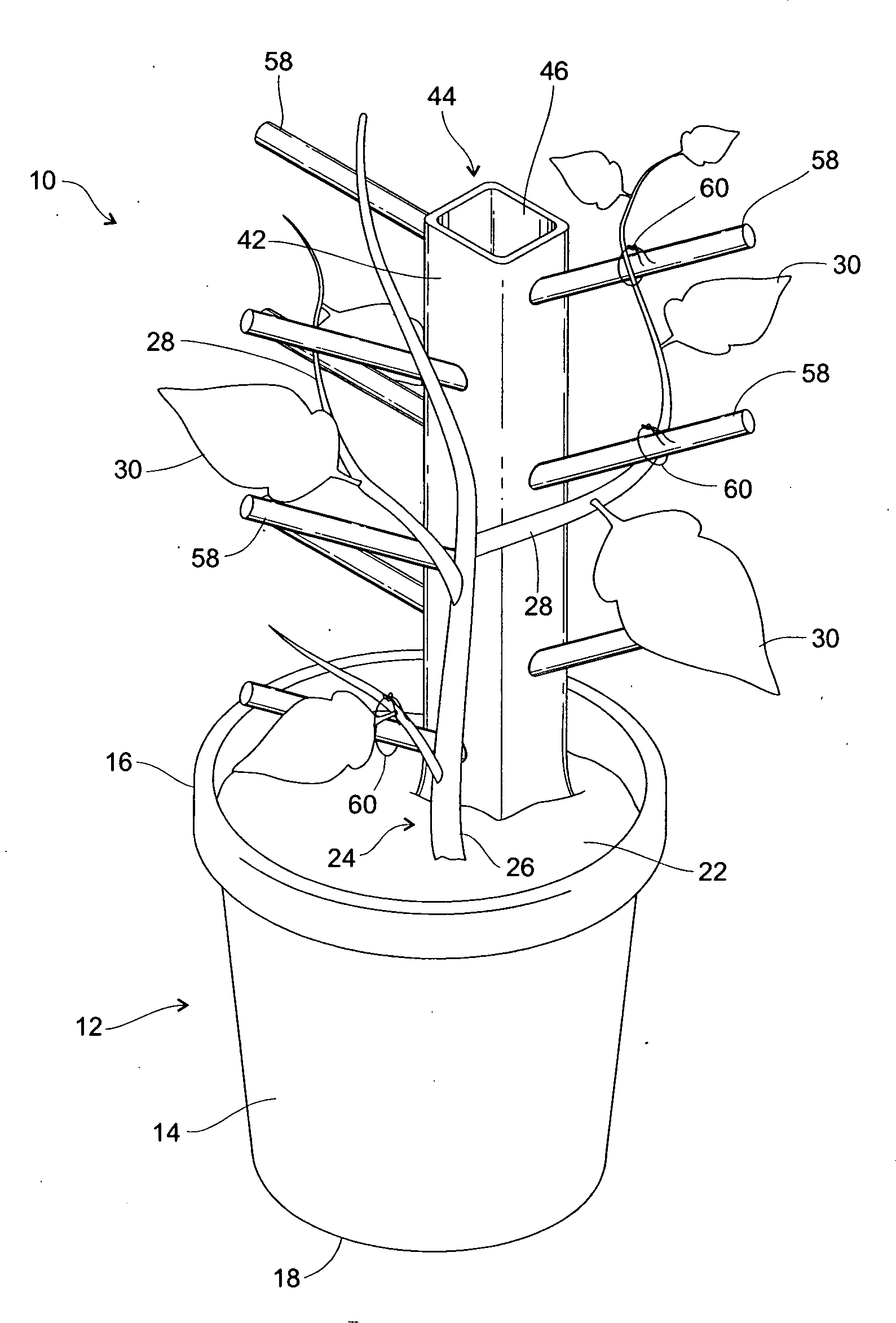

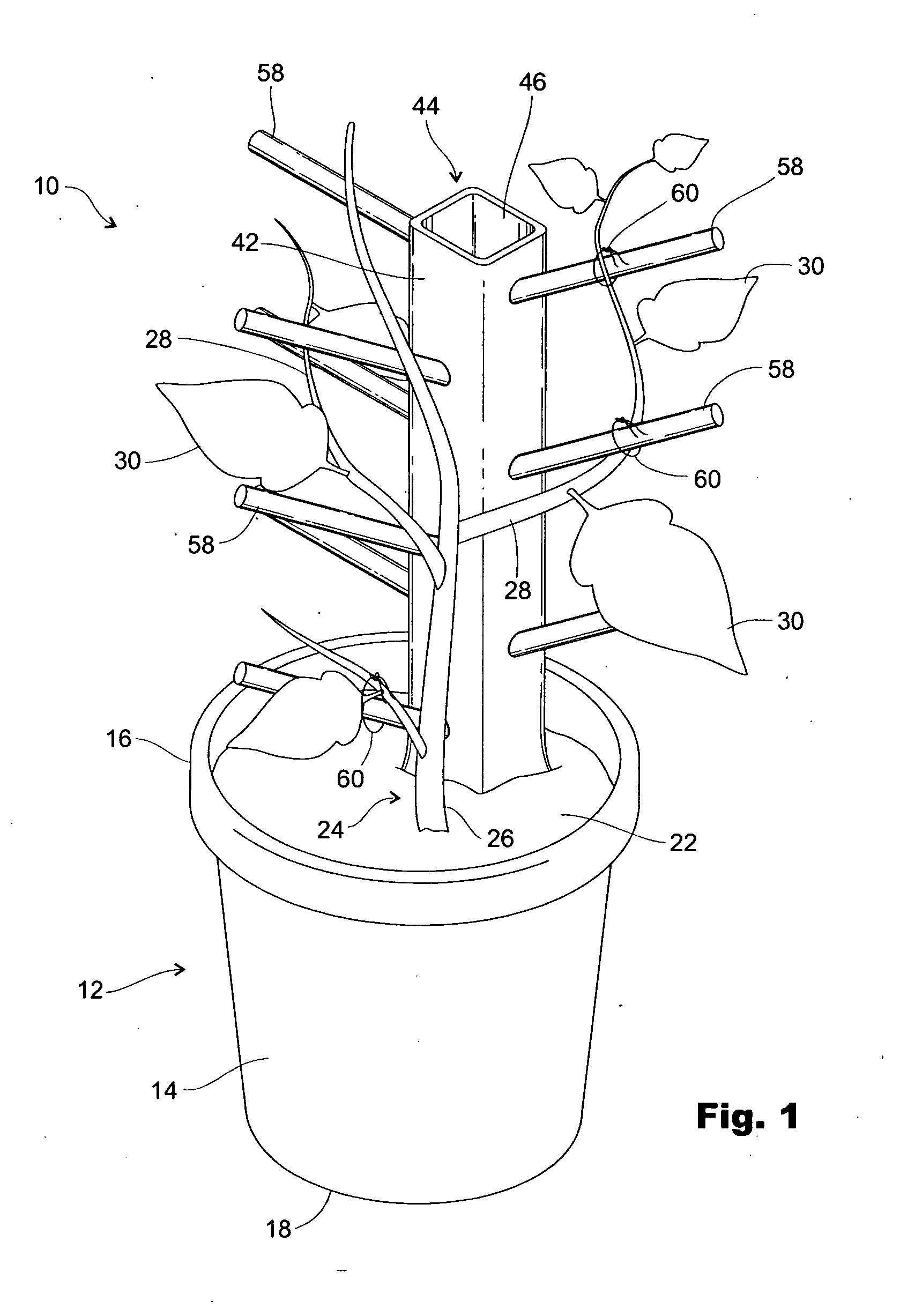

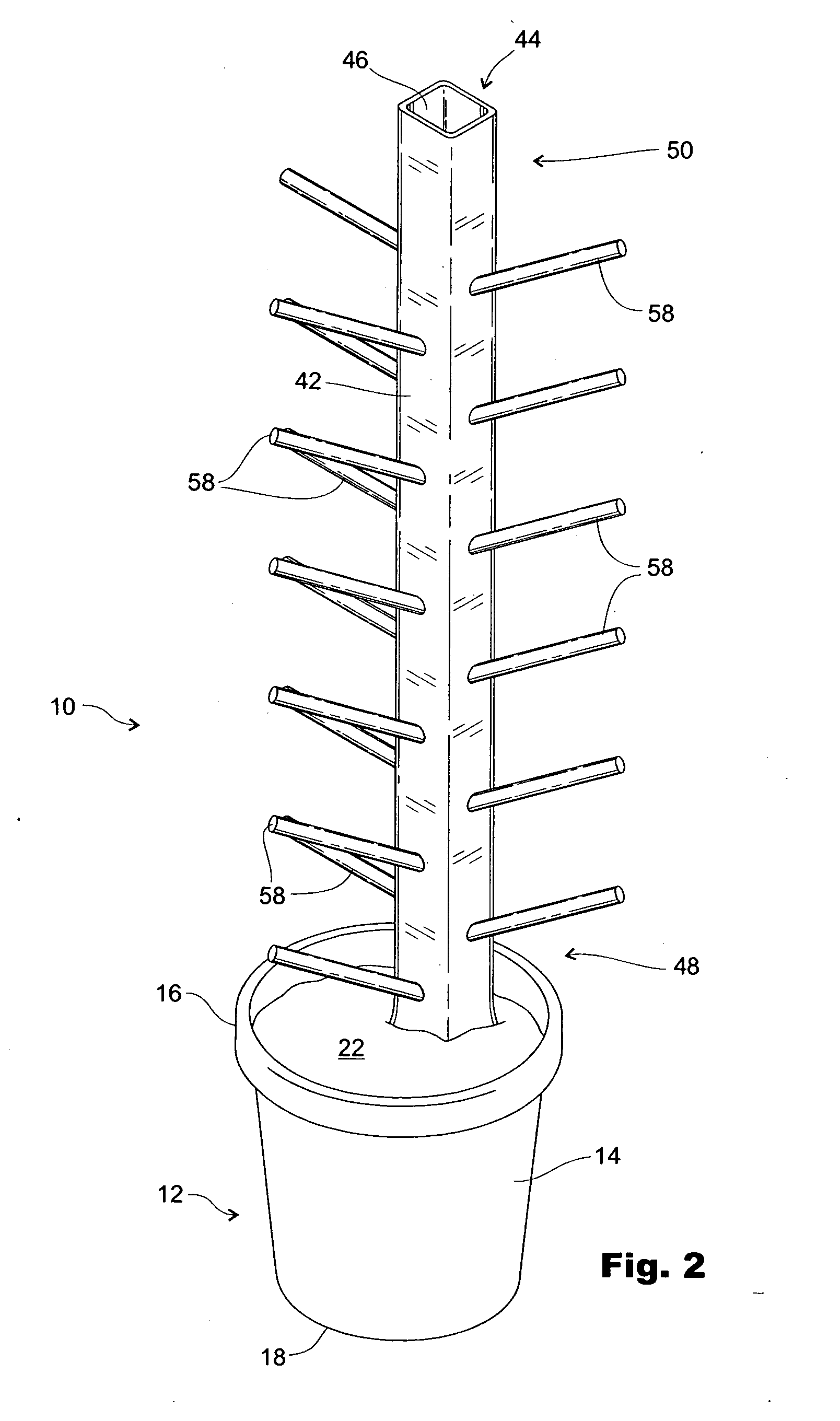

InactiveUS20090272032A1Guaranteed high growthIncrease heightCultivating equipmentsPlant supportsGrowth plantEngineering

A flower pot plant hold up device for training a plant to grow straight and tall includes a base for placement within a flower pot and a support pole vertically extending from the base and eccentrically mounted thereto so that the plant grows upward from the center of the flower pot. The support pole includes a plurality of apertures spaced along its vertical extension with each aperture capable of receiving therein an arm that is oriented at a 35 degree angle relative to the vertical extension of the support pole and wherein the trunk, stem, limbs, and branches of the plant are tied to the arms, and as the plant grows straight along the support pole various parts of the plant can be untied and retied to the arms to accommodate the upward growth of the plant and arms can be inserted and removed as needed to also accommodate the plant's straight and tall growth.

Owner:KIFF SR HERBERT J

Semen-Abietis-Deliavayi fast seedling-nursing method

InactiveCN1849878AGuaranteed high growthShorten the breeding cycleSeed and root treatmentClimate change adaptationGreenhouseSemen

The present invention relates to a method for quickly cultivating seedling of fir. Said method includes the following steps: in the course of cultivating seedling making the young seedling undergo the process of light-supplementing treatment by adopting artificial electro optic light source, then making seedling-training treatment outside of greenhouse. Besides, said invention also provides the concrete requirements of the above-mentioned every step.

Owner:BEIJING FORESTRY UNIVERSITY

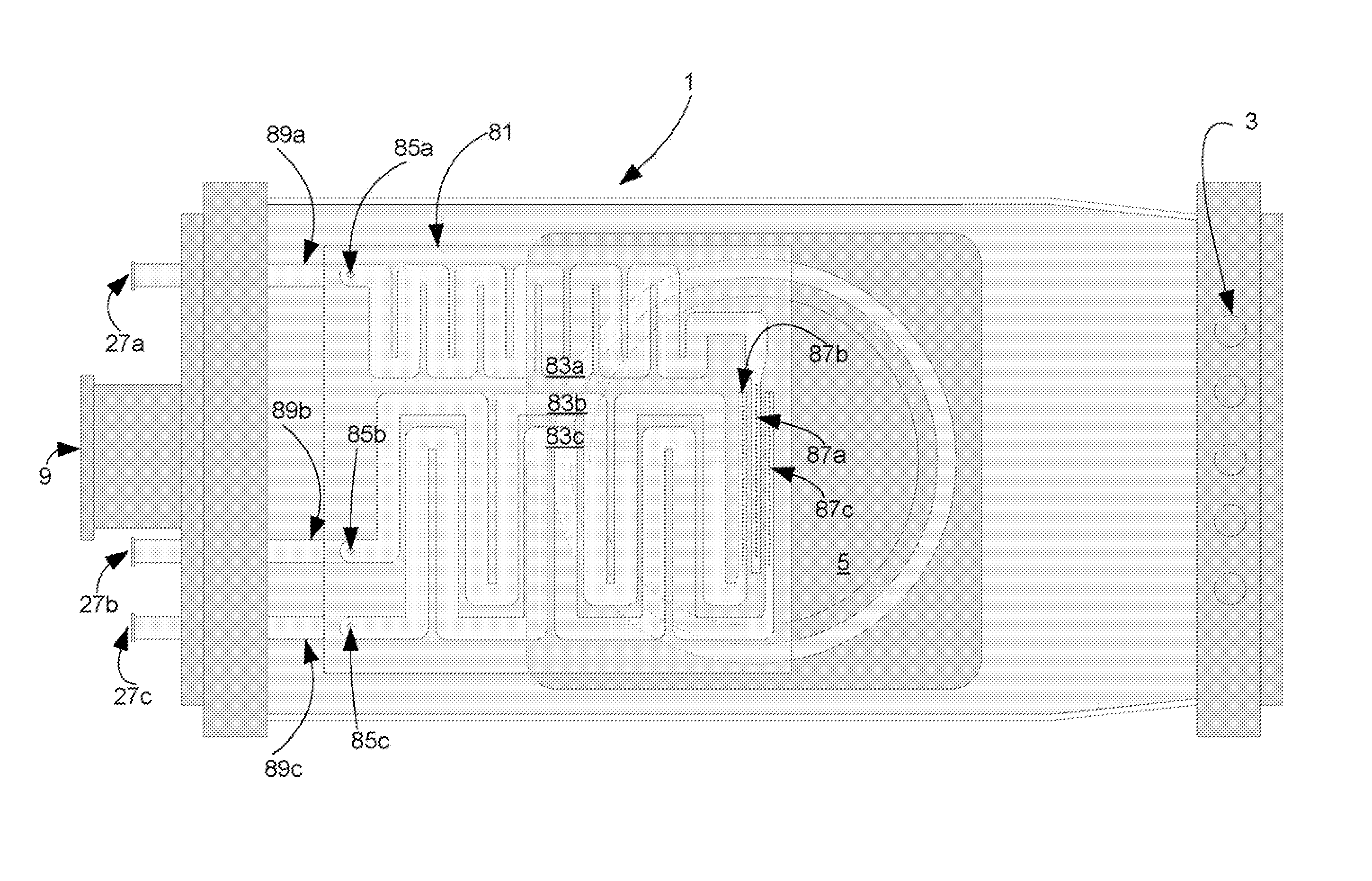

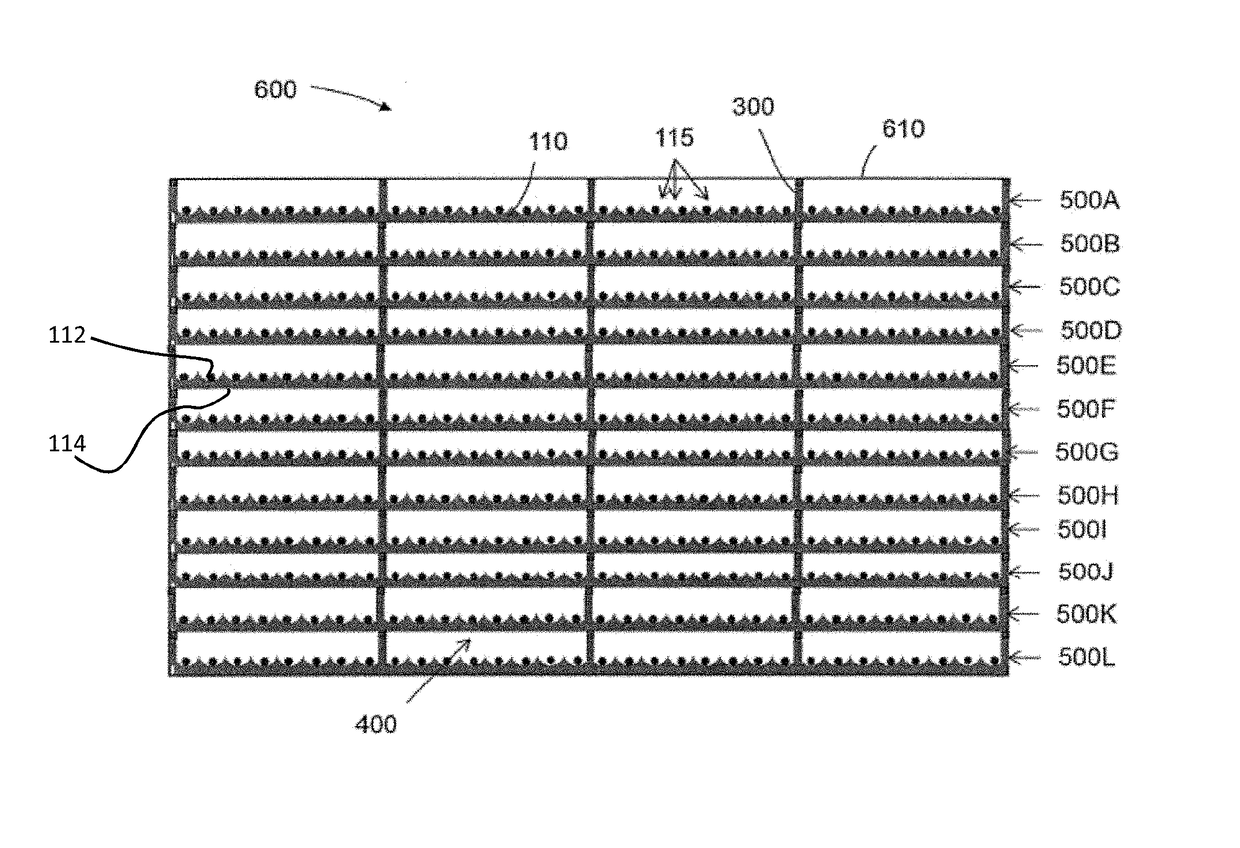

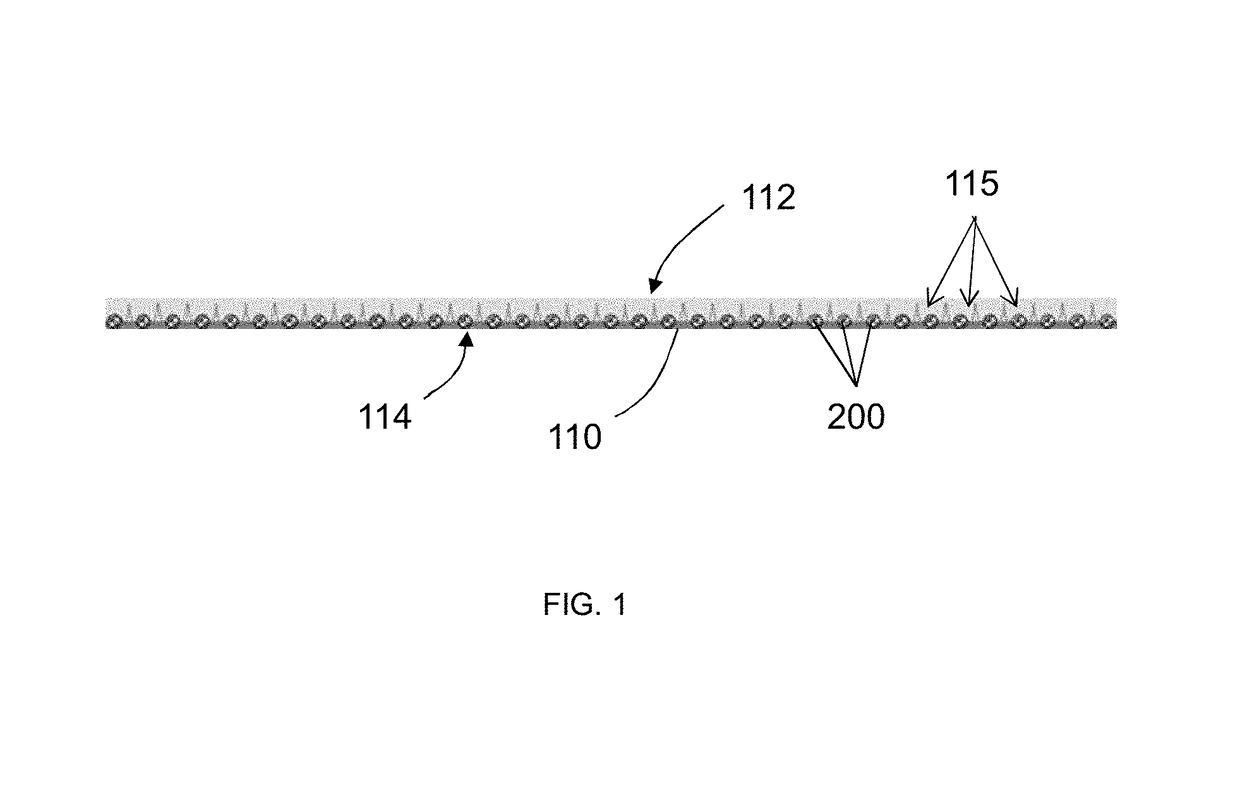

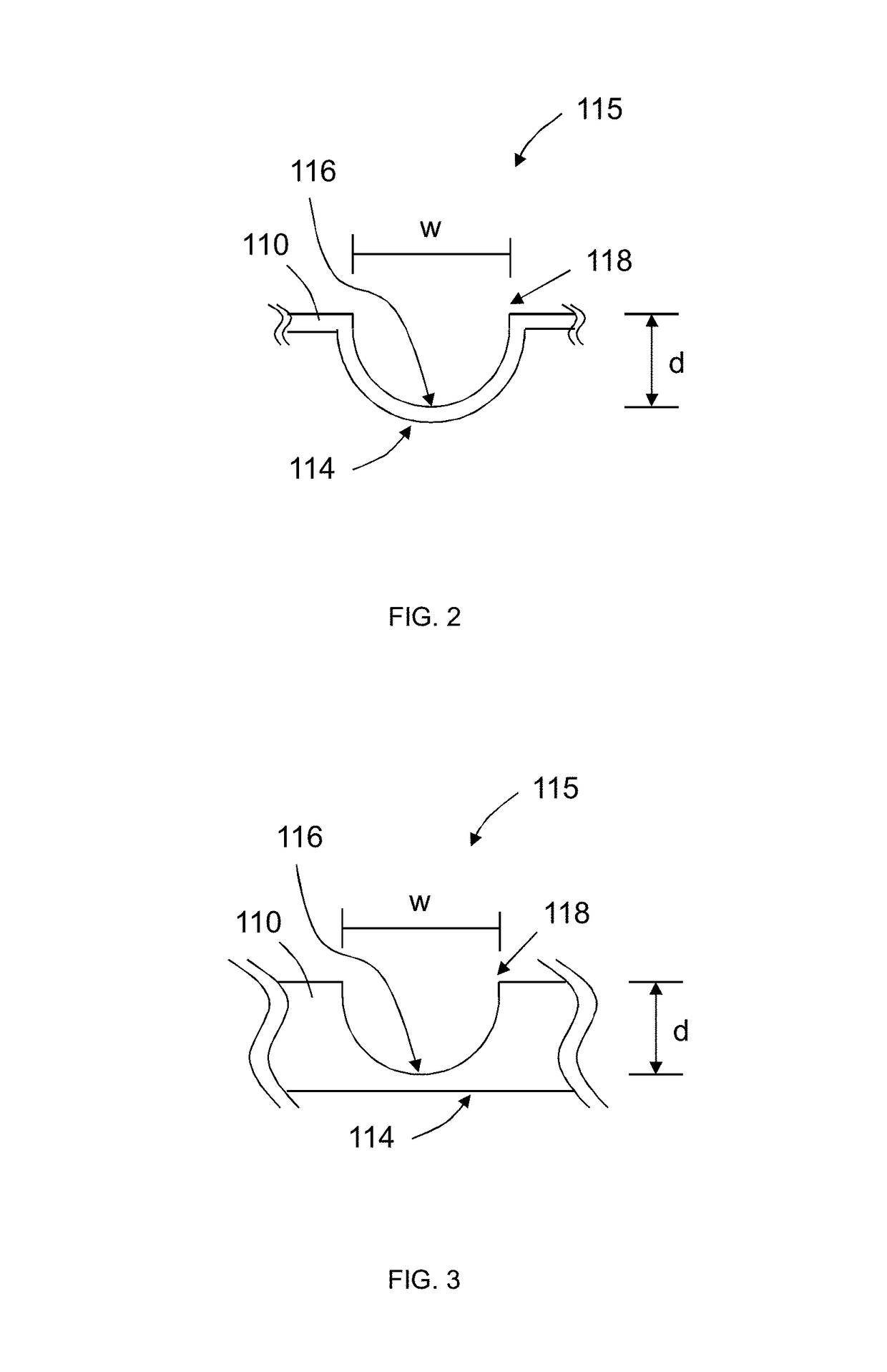

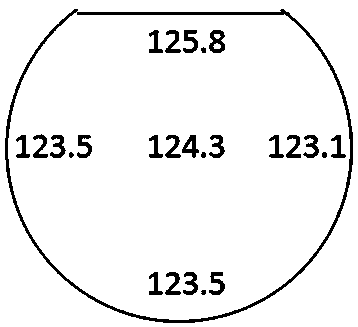

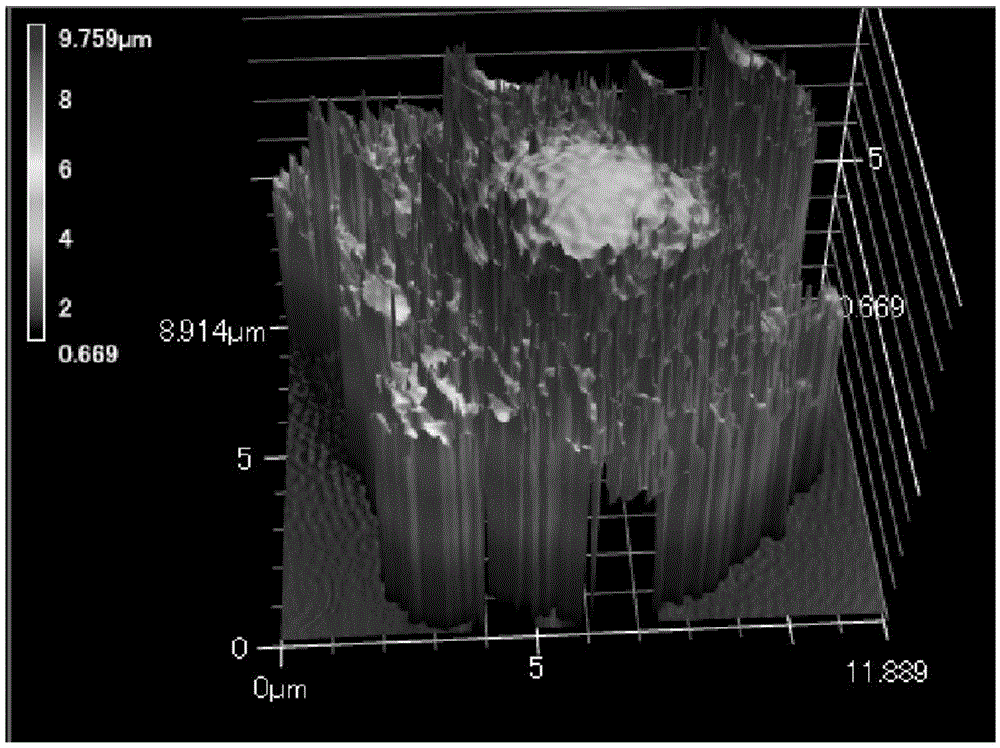

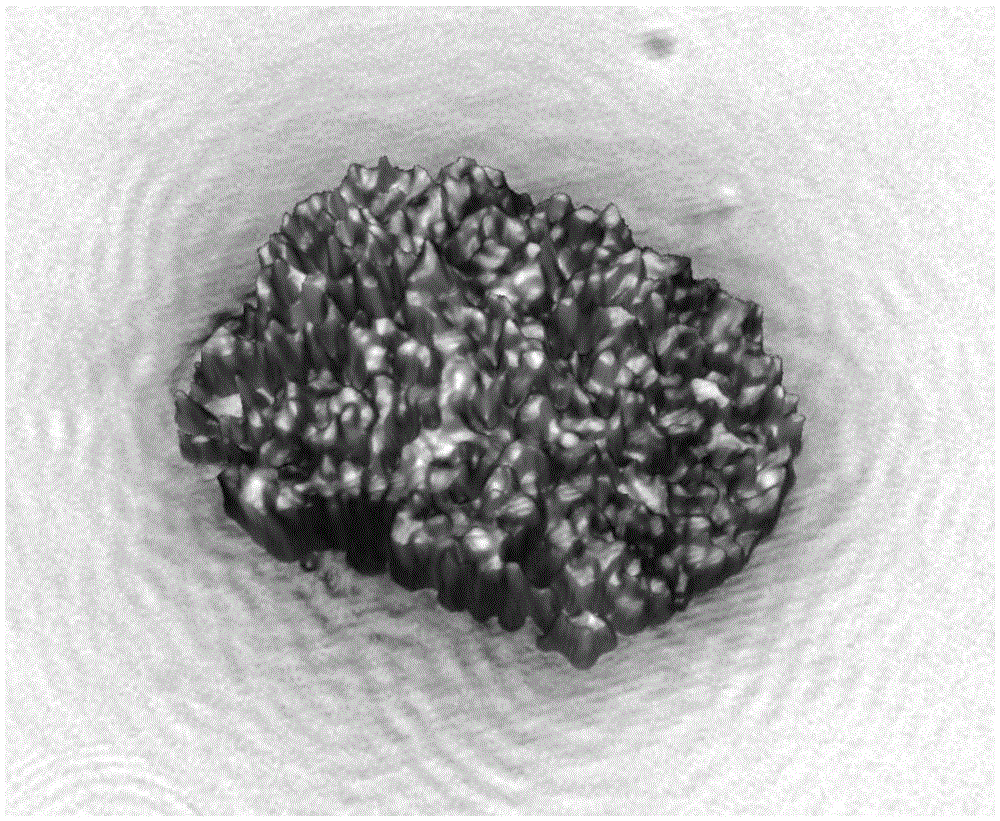

Perfusion bioreactor platform

ActiveUS20170306281A1Promote formationHigh cell density cell growthBioreactor/fermenter combinationsBiological substance pretreatmentsPerfusion bioreactorNadir

A cell culture apparatus includes one or more plates having a first major surface and an opposing second major surface. The first major surface comprises a structured surface defining a plurality of wells. Each well has an interior surface defining an upper aperture and a nadir, wherein the upper aperture of each well has a diametric dimension in a range from 100 micrometers to 2000 micrometers. The apparatus also includes a plurality of spacers extending from the first major surface along a length of the bottom surface. A plurality of flow channels are defined between adjacent rails.

Owner:CORNING INC

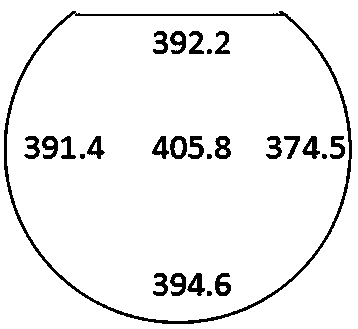

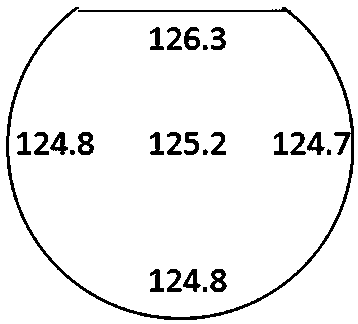

Preparation method of silicon epitaxial wafer for high-voltage power device

ActiveCN110379704AImprove crystal qualityReduce high temperature heating timeSemiconductor/solid-state device manufacturingChemical vapor deposition coatingReaction rateHigh pressure

The invention discloses a preparation method of a silicon epitaxial wafer for a high-voltage power device. According to the method, a reaction cavity of the epitaxial equipment is purified and the content of impurities accumulated in the cavity is reduced by long-time purging of large-flow hydrogen before epitaxial growth; the nonlinear gradient heating is adopted, so that the stress accumulated in the heating stage is released in time, and the generation probability of defects is reduced; and the reaction rate is significantly improved by shortening the distance between a quartz bell jar anda base of the reaction cavity of the epitaxial equipment and adopting a large-flow trichlorosilane and hydrogen proportioning mode, and high-speed epitaxial growth is realized under the premise of ensuring good crystallization quality of the silicon epitaxial wafer. The problem of comprehensive control on thickness, resistivity and crystallization quality in the existing preparation process is overcome by adopting the method of sectional growth of the silicon epitaxial wafer layer. the prepared silicon epitaxial wafer has a bright surface, is free from dislocation, staggered layers, slip linesand fog defects, realizes the controllability of material indexes such as thickness, resistivity and defects and meets the use requirements of the high-voltage power device.

Owner:CHINA ELECTRONICS TECH GRP NO 46 RES INST

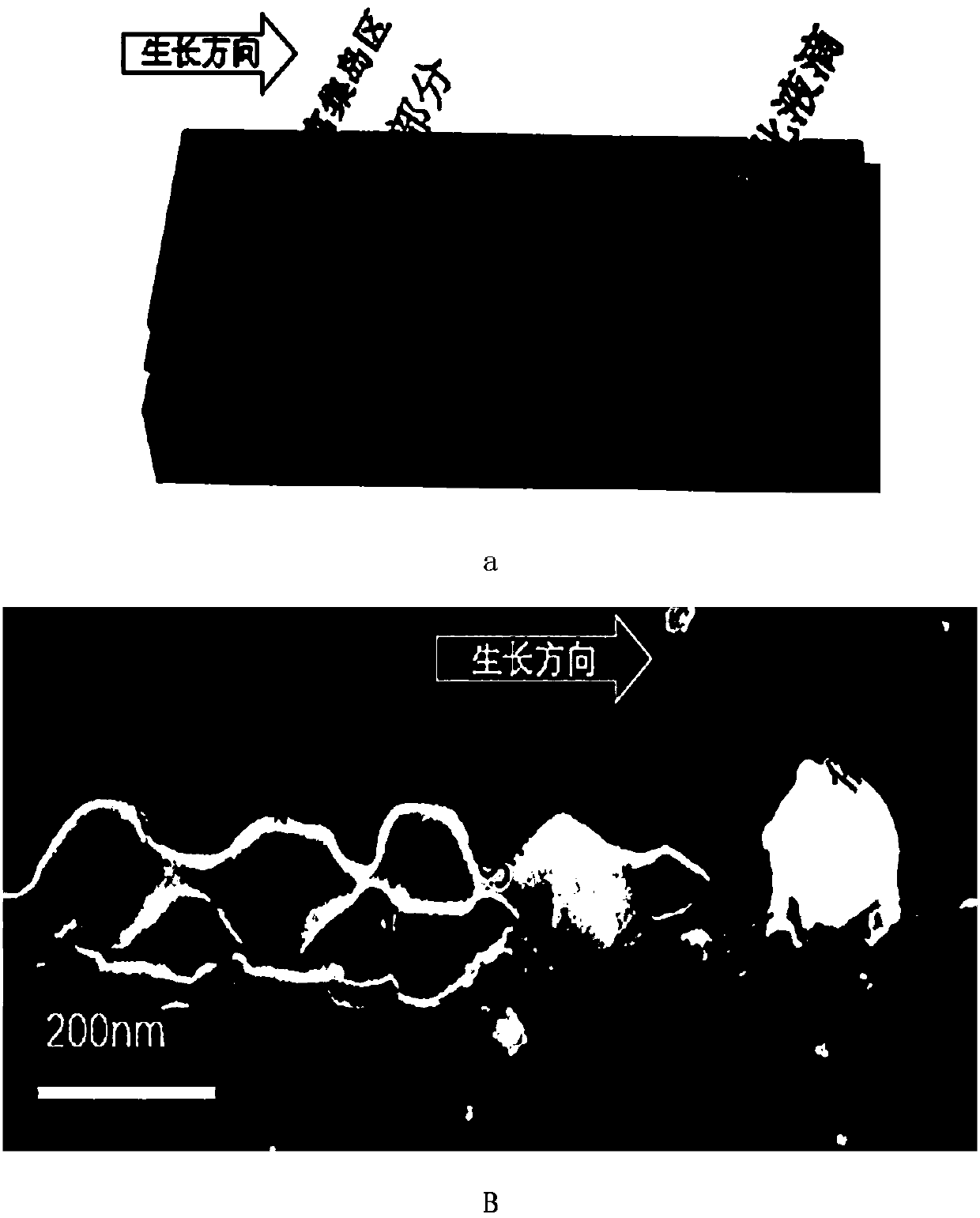

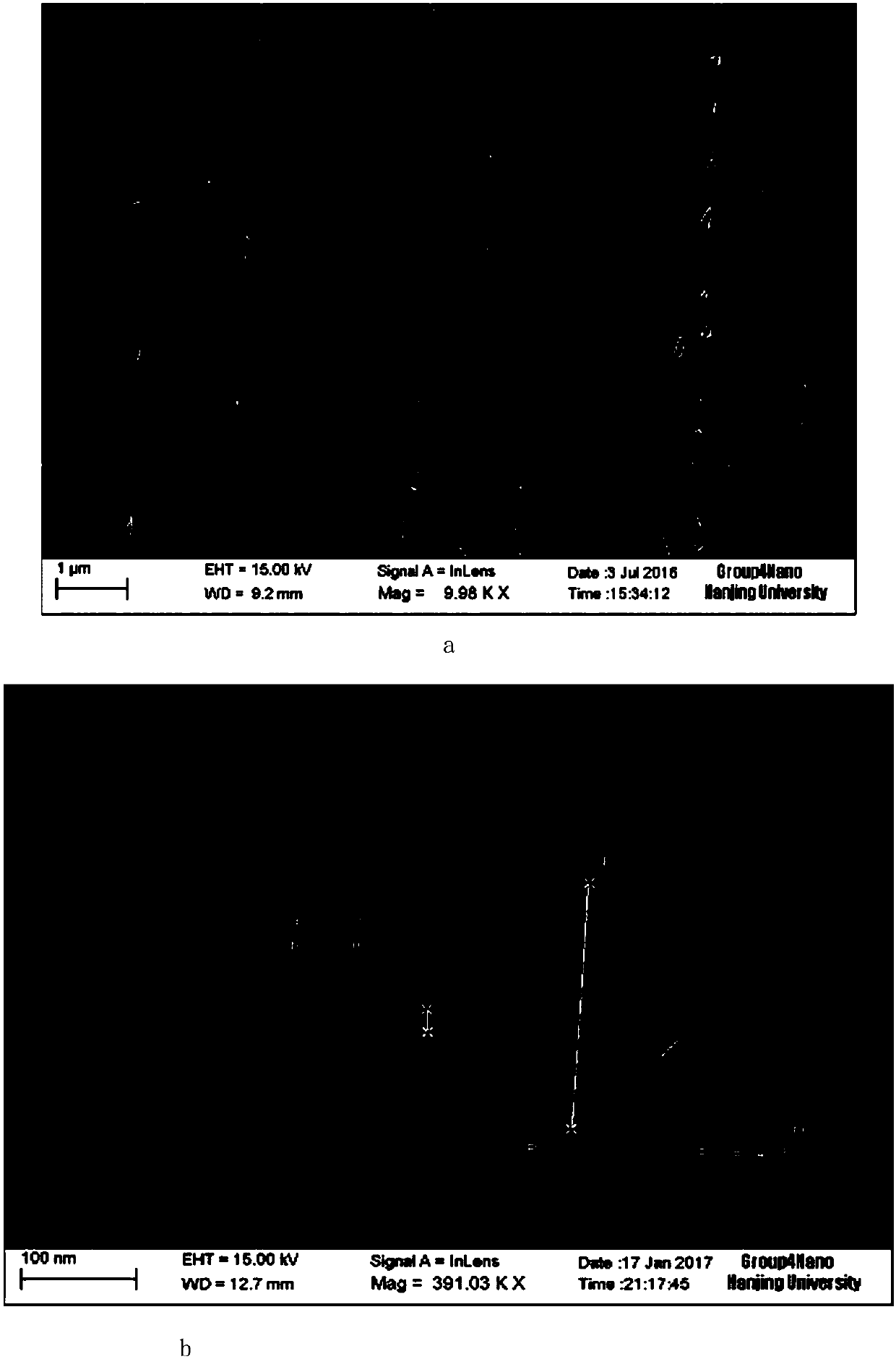

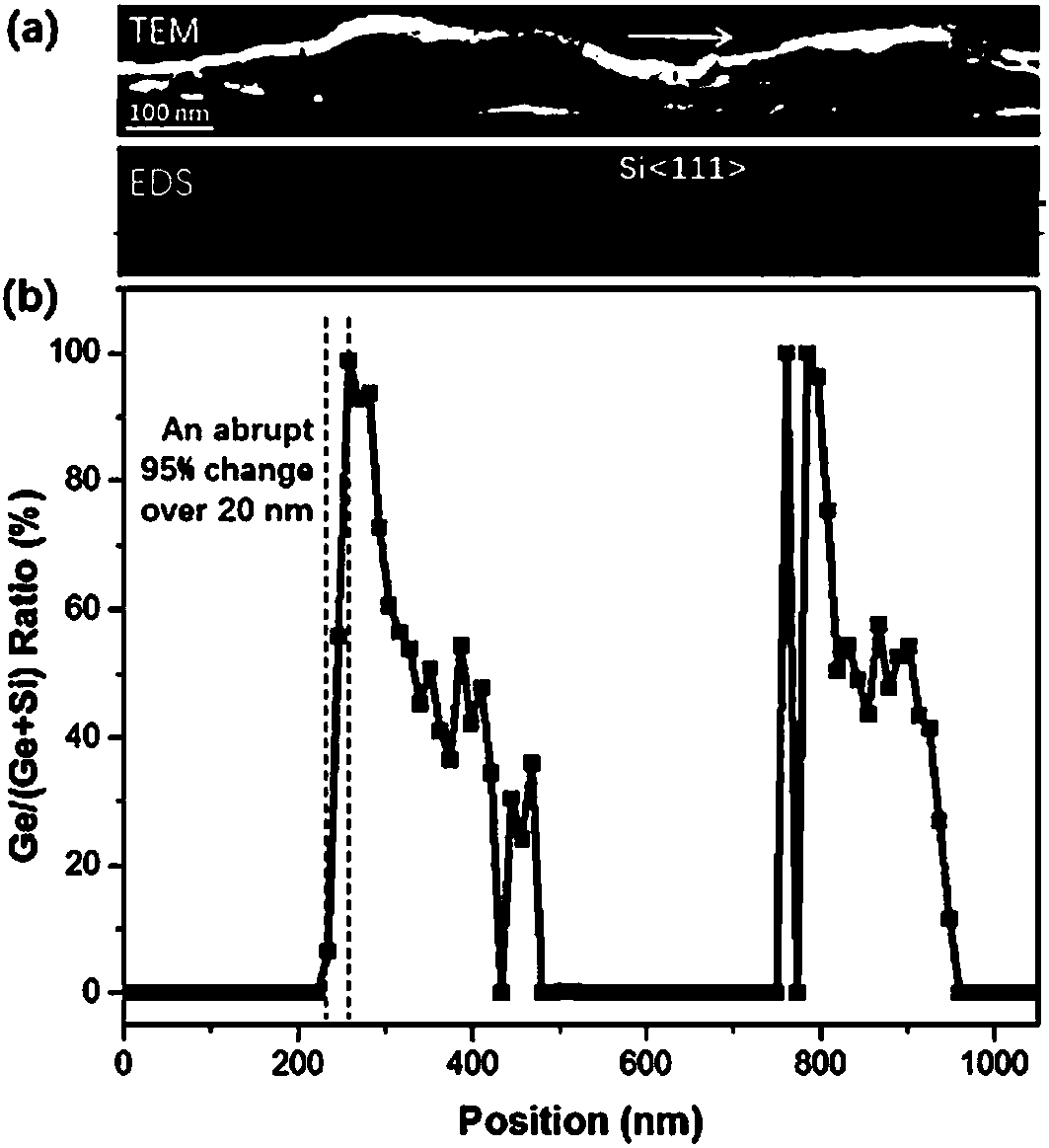

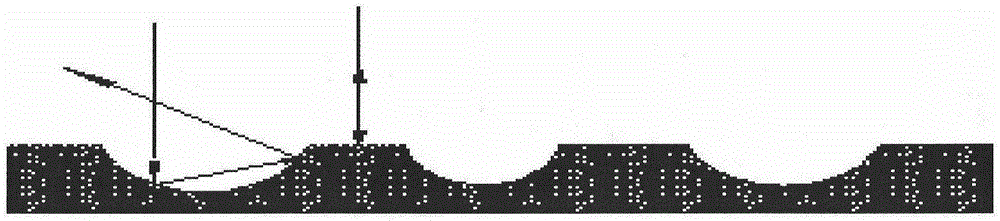

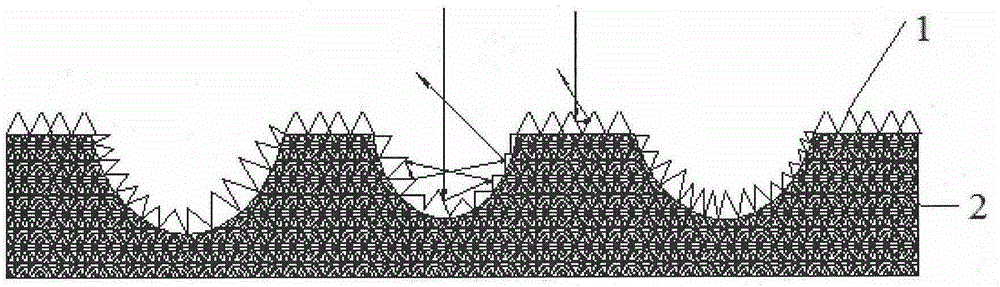

Method of growth morphology and component control over plane germanium silicon and relative nanowires based on heterogeneous laminated amorphous film supply

ActiveCN107640741AGuaranteed high growthRegulation transmissionNanostructure manufactureWide areaHigh concentration

The invention provides a method for preparation of heterogeneous or alloy semiconductor nanowires by means of a laminated amorphous precursor layer. With the silicon germanium system as an example, amorphous silicon (a-Si) / amorphous germanium (a-Ge) laminated film is used as the precursor, the silicon germanium chain nanowire structure of spontaneous phase separation is prepared, the laminated layer amorphous film is used as the precursor layer, through absorption of metal droplets and the plane nanowire growth process, plane silicon germanium nanowires of spontaneous phase separation are achieved, its morphology can be controlled through the thickness of the laminated layer and the laminated sequence, and the silicon germanium chain structure is regulated; when the amorphous germanium layer is on the bottom of the a-Si / a-Ge structure, the wide area of the silicon and germanium nanowires is the high-concentration area of germanium, while the thin nanowires are connected to a high-concentration area of silicon; or the silicon germanium alloy nanowire structure with a uniform diameter is achieved by the reverse laminated sequence, or the silicon-germanium alternate area structure including microzone intervals is formed.

Owner:NANJING UNIV

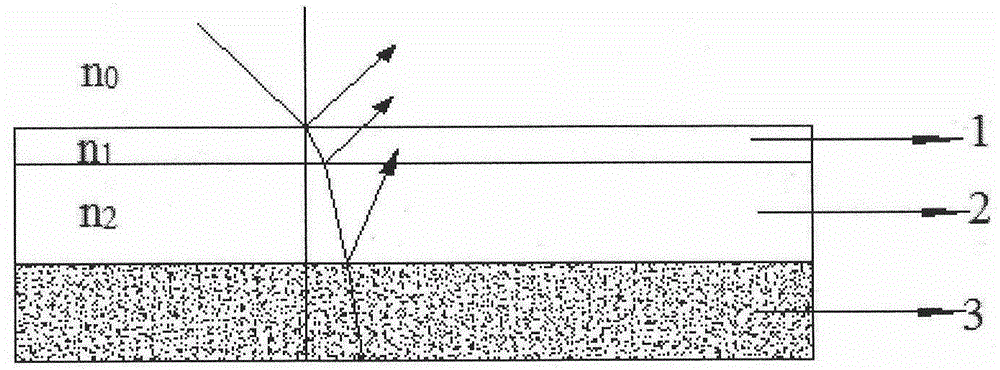

Double antireflection layer structure of solar cell reflection film and preparation method thereof

InactiveCN104966756AReduce energy consumptionHigh refractive indexFinal product manufacturePhotovoltaic energy generationTransmittanceRefractive index

The invention relates to a double antireflection layer structure of a solar cell reflection film and a preparation method thereof. The double antireflection layer structure is formed by an upper antireflection layer, a crater antireflection layer and a base layer in sequence. The crater antireflection layer in the middle is provided with arc-slope concave craters. The upper antireflection layer is composited on the upper surface of the crater antireflection layer and is formed by a bottom layer film and particles densely arranged thereon, wherein the surface of each particle has a suede shape. The bottom layer film and the upper surface of the crater antireflection layer are integrated and jointly form the concave craters. The crater layer is prepared through deposition by adopting the PECVD technology; the PECVD technology can be used to prepare the uniform and performance-stable crater layer structure; the controllability is high; and the thickness of the antireflection layer can be controlled accurately. A solar cell has more than 90 % high transmissivity. The antireflection layer is simple in specific processes, quick in deposition time and low in energy consumption; the double antireflection layers has sequentially-increasing refractive rate; and the structure can provide possibility for large-area industrial production.

Owner:常德东腾新能源有限公司

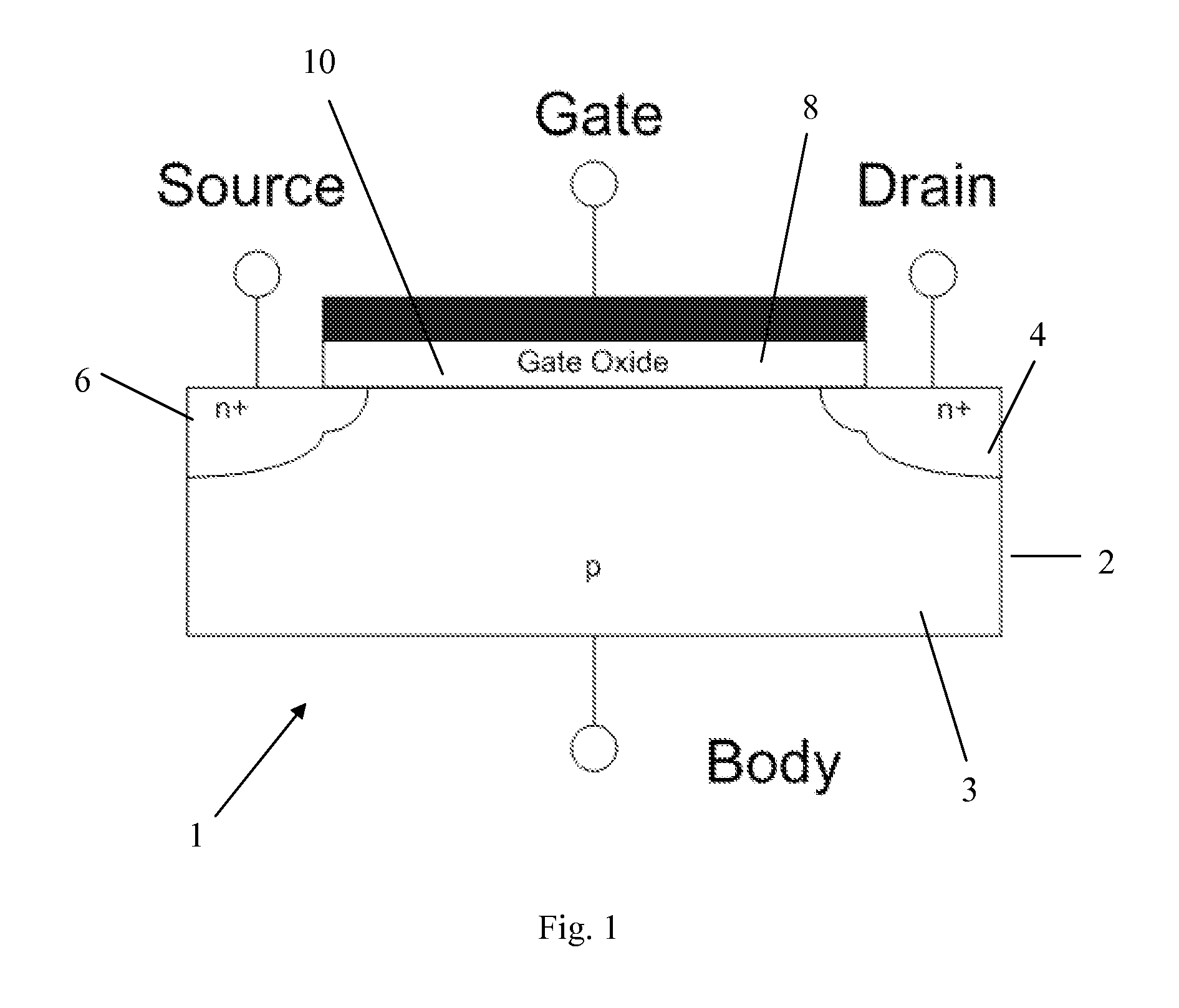

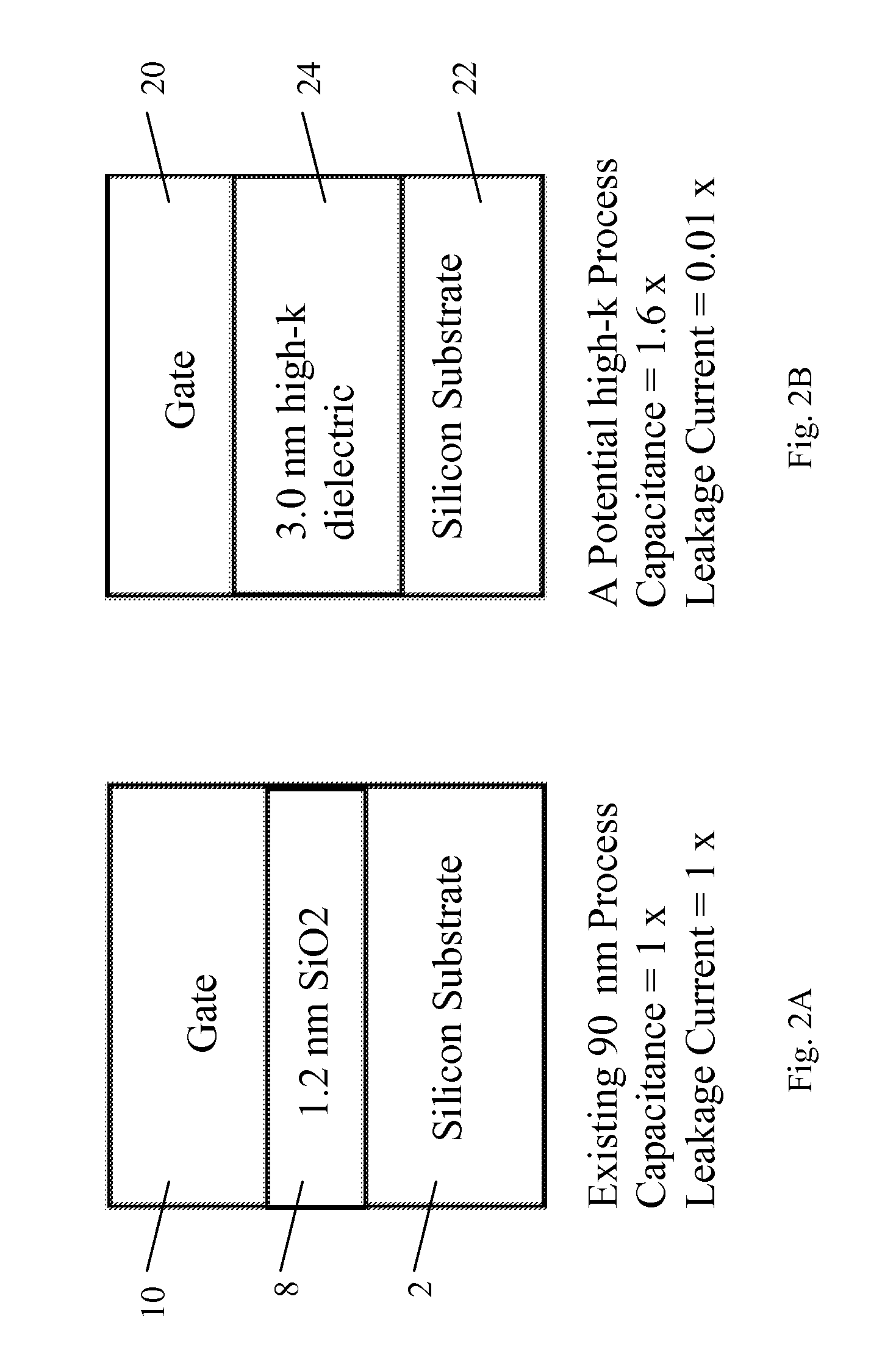

Method of forming an oxide thin film

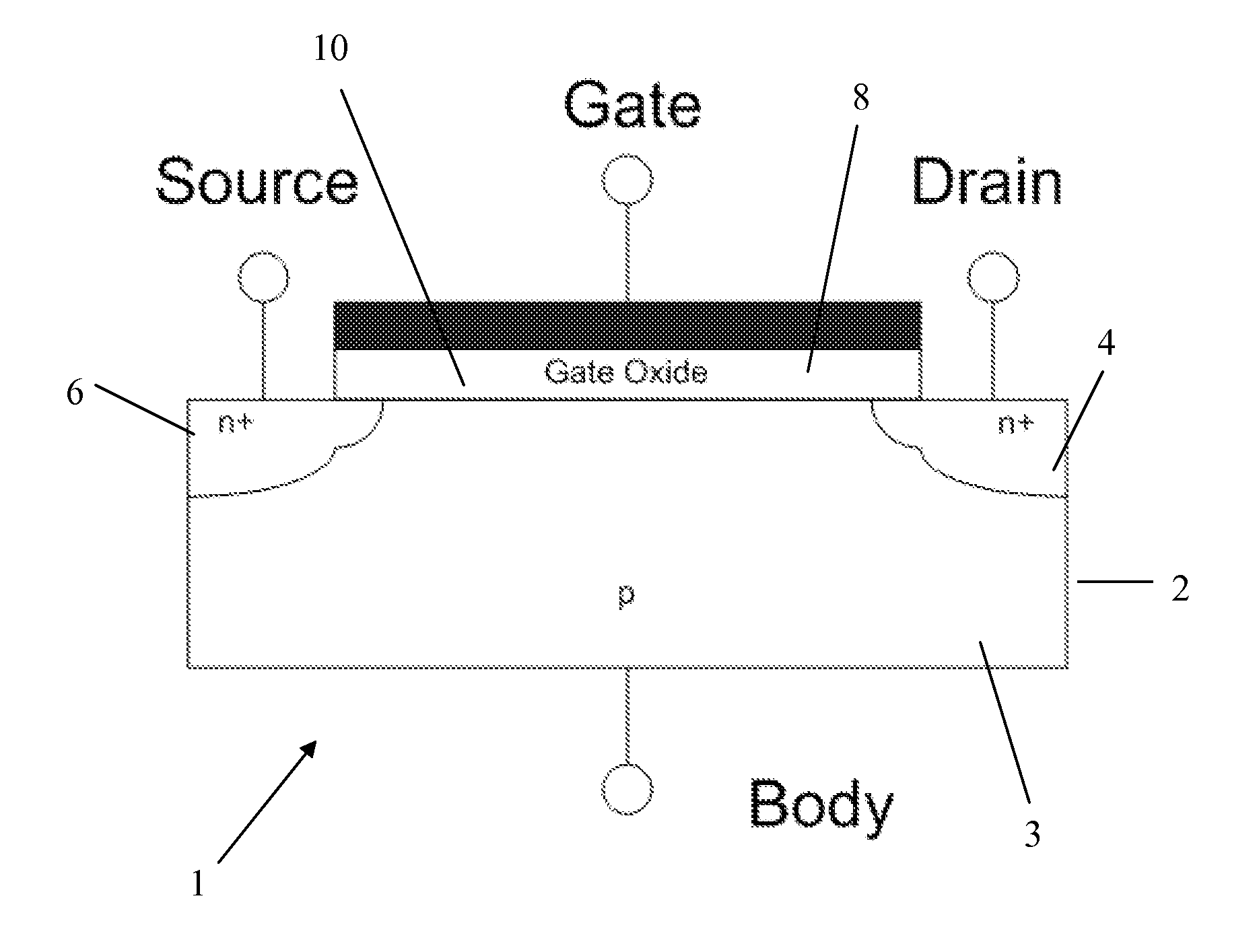

InactiveUS20100109130A1Simple structureGood physical propertiesSemiconductor/solid-state device detailsSolid-state devicesAcid derivativeMetal

A thin oxide film is formed by atomic layer deposition (ALD) onto a substrate by exposing the substrate to a first precursor comprising a metal organic alkoxide or amide or heteroleptic derivatives thereof and subsequently exposing the substrate to a second precursor comprising an ALD compatible carboxylic acid or carboxyl acid derivative compound. The sequential exposure to the first and second precursors may be repeated until a sufficient film thickness of an oxide of the metal has been deposited on the substrate. This process allows growth of an oxide thin film or nanostructure, on any suitable substrate. It permits formation of a high-κ dielectric oxide thin film on the substrate with similar dielectric properties to a much thinner SiO2 film. Furthermore, the films grown can exhibit very good structural and physical properties. The process also provides high self-control of thin film growth with high reproducibility and reliability. In particular, the films can be synthesized with excellent similarity even on uneven surfaces and present a very smooth surface finish with very low roughness.

Owner:UNIV AVEIRO

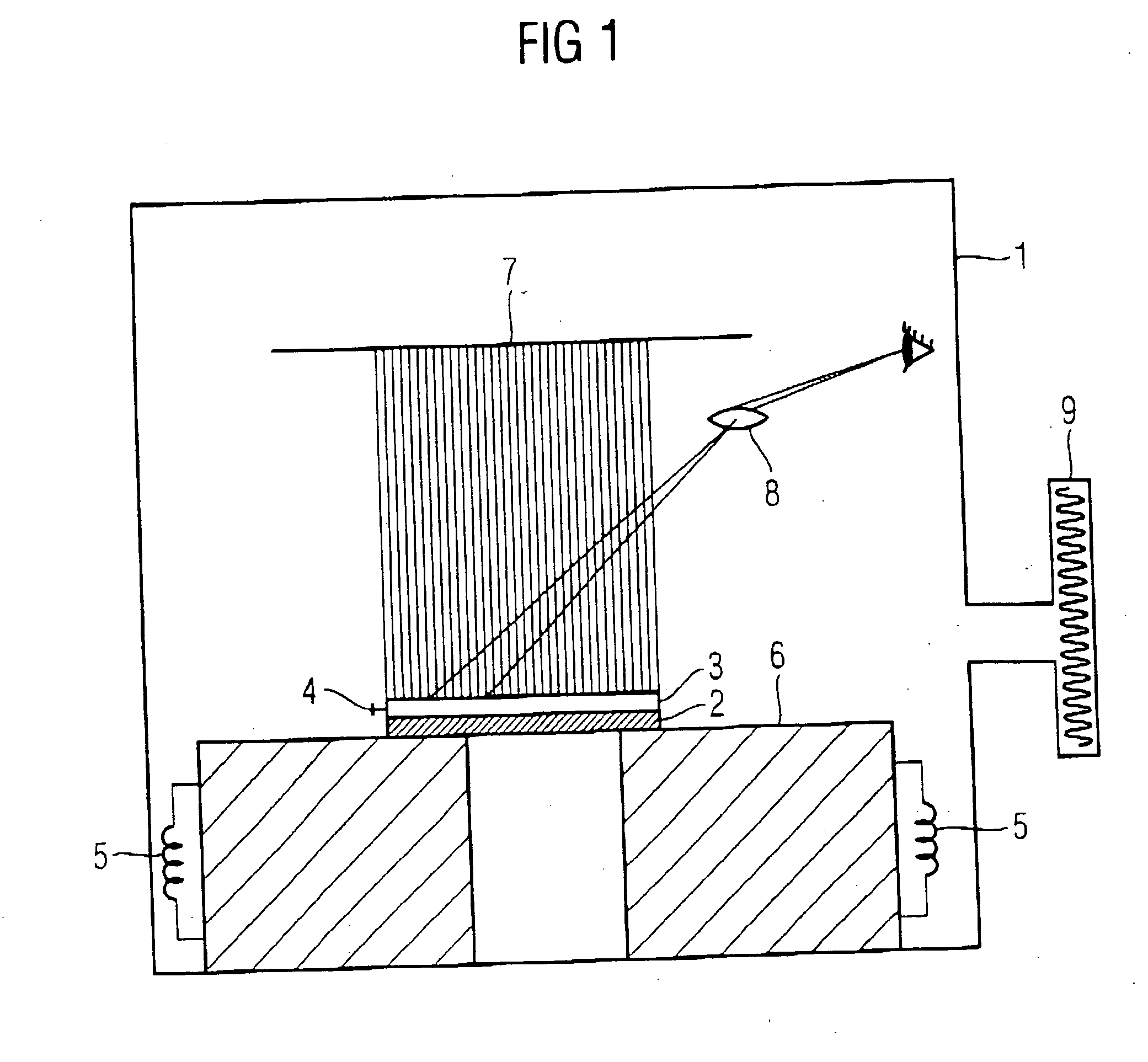

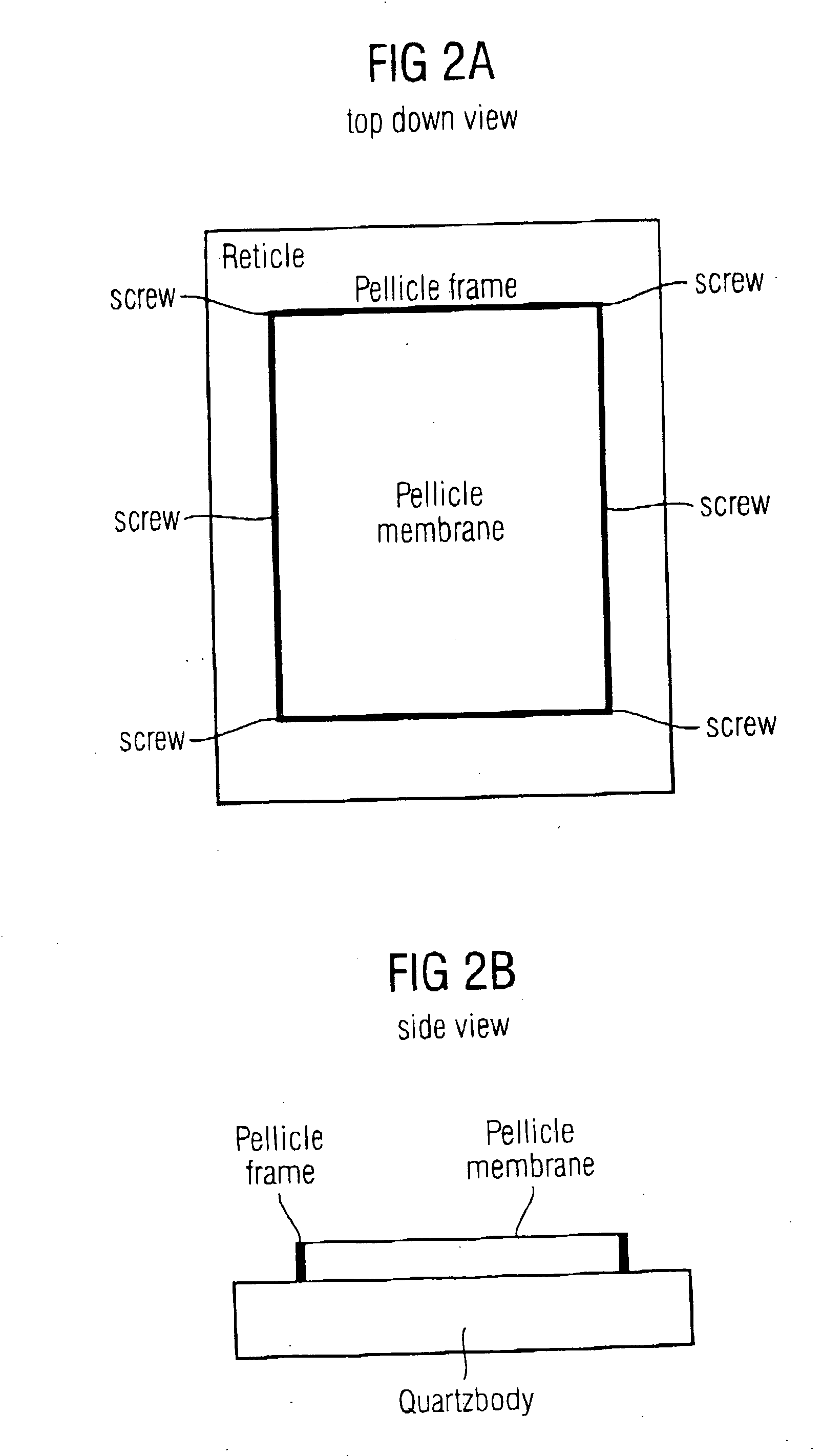

Method for cleaning lithographic apparatus

InactiveUS20060243300A1The method is simple and fastGuaranteed high growthLighting and heating apparatusElectrostatic cleaningElectrical and Electronics engineeringEngineering

Owner:INFINEON TECH AG

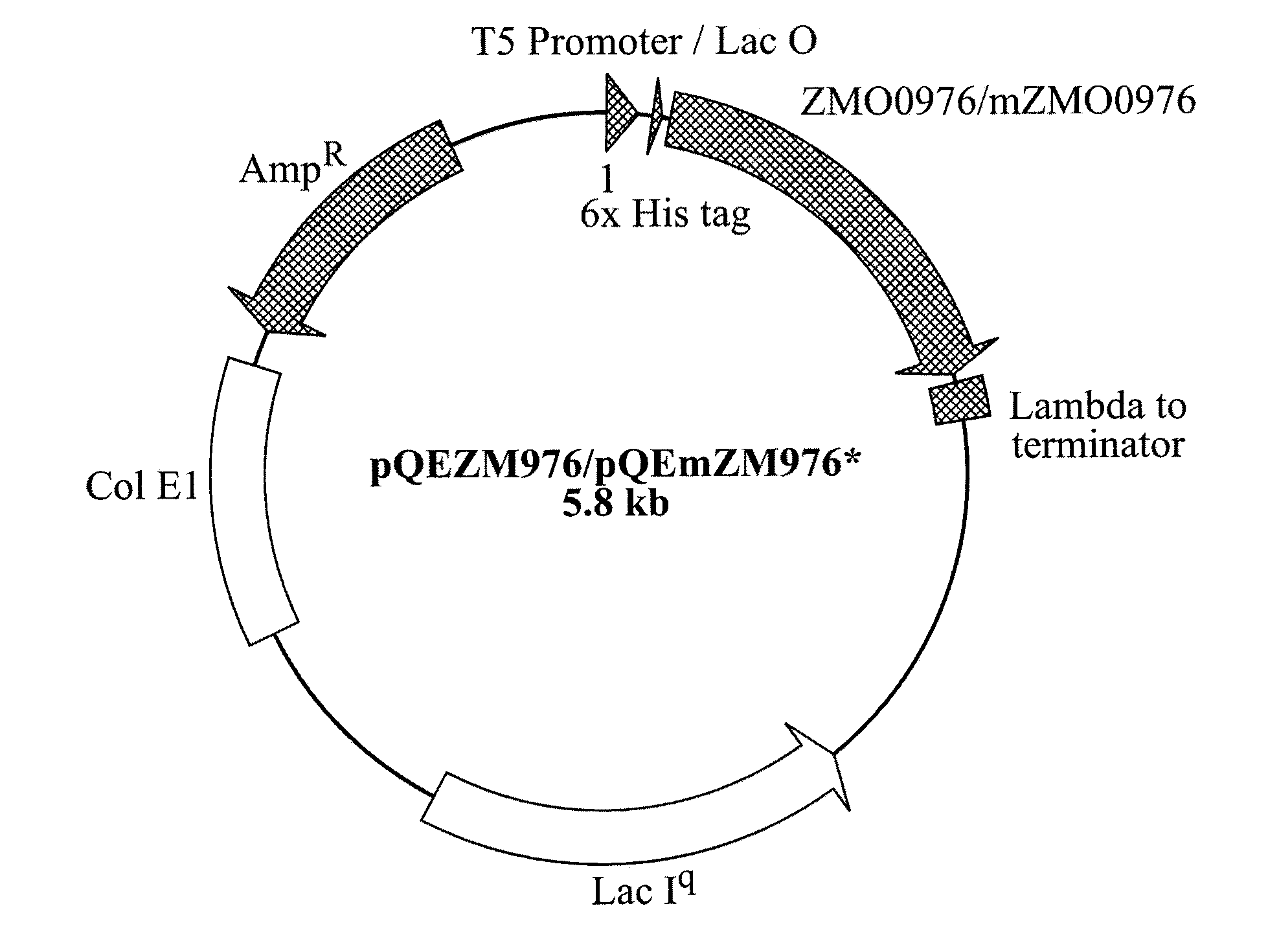

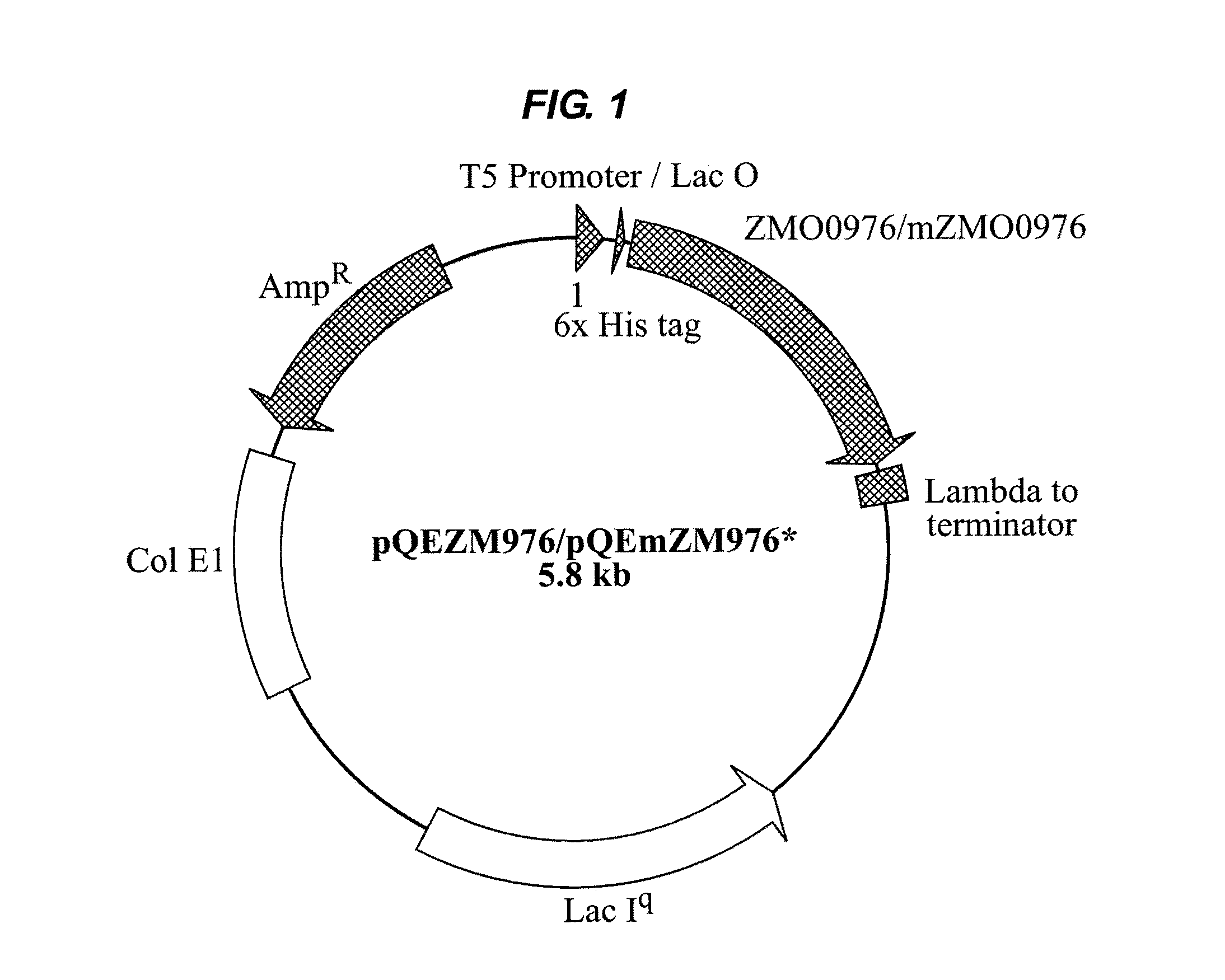

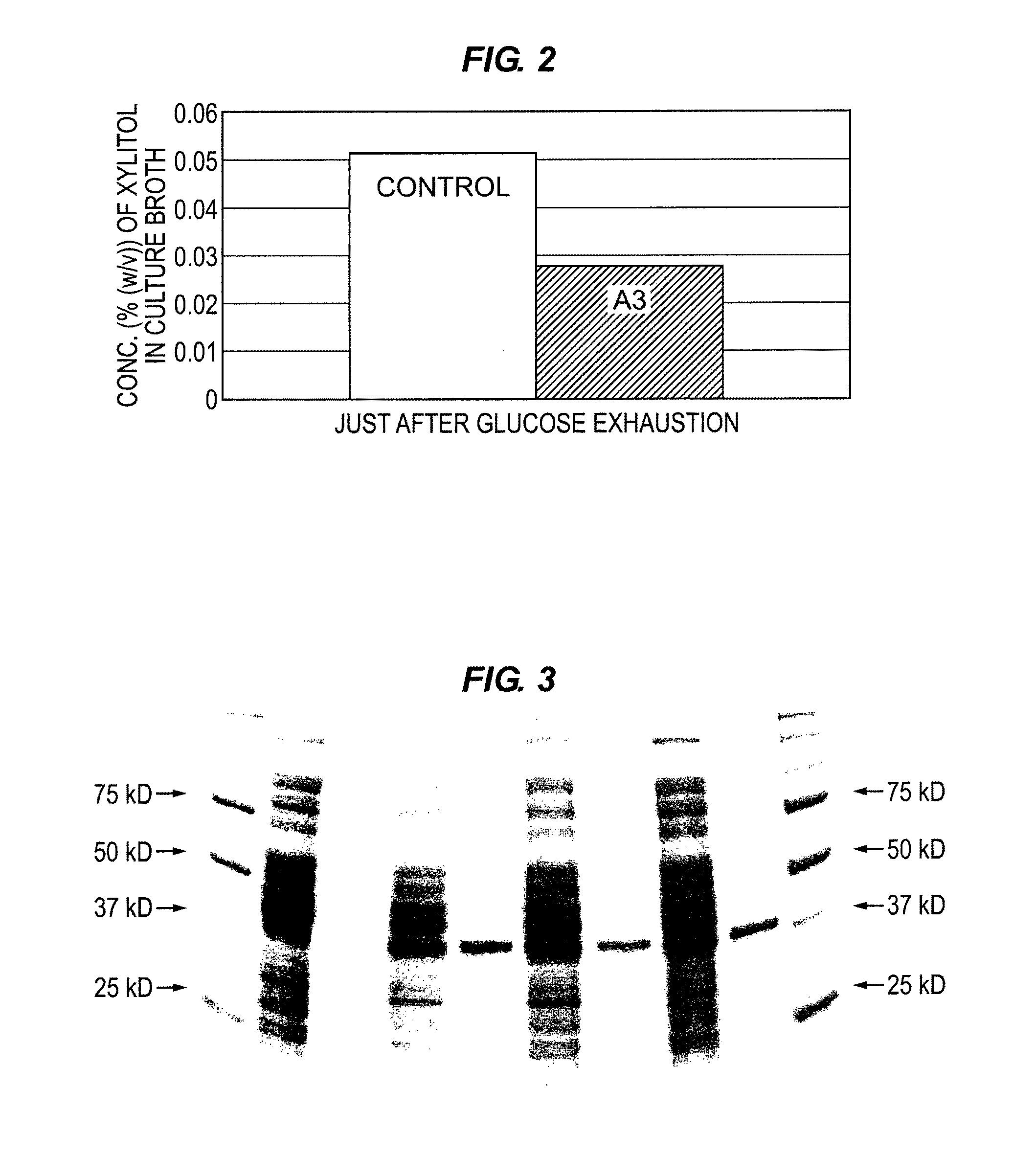

Industrial Applications of A Novel Aldo/Keto Reductase Of Zymomonas Mobilis

InactiveUS20120196342A1Reducing xylitol productionIncreased ethanol yieldBacteriaBiofuelsXylose fermentationFurfural

The present invention relates to methods of reducing the toxicity of lignocellulosic hydrolysates which comprise one or more inhibitors. One method reduces the amount of furfural inhibitor leading to a more effective process. Another method reduces the amount of xylitol produced during the fermentation of xylose present in lignocellulosic hydrolysates. Naturally occurring aldo / keto reductase enzymes, as well as, enzymes produced by recombinant cells or by selective adaptation may be employed.

Owner:GEORGIA TECH RES CORP

Method of preparing microbial feed additive for reducing cholesterol level of vitellus

InactiveCN101129162AThe equipment is easy to operateShort induction periodAnimal feeding stuffYolkLactobacillus

The invention discloses a microbe additive and making method by using cholesterol metabolic path to modulate egg poultry through lactic acid bacteria, which is characterized by the following: utilizing bacillus subtilis to manufacture soybean polypeptide; reducing the content of yolk cholesterol; combining the microwave induction and ray induction to ferment bacteria; improving the sieving production and enzyme production; accelerating the growth of soybean polypeptide; improving the egg production and immunity of egg poultry; reducing the usage of antibiotics; providing a safe and high-effective agricultural biological agent.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

Raw material for high-speed growth of silicon carbide crystals and silicon carbide crystal growing method

InactiveCN105603530AIncrease the amount of sublimationGood suspensionPolycrystalline material growthFrom condensed vaporsCrucibleSemiconductor

The invention relates to a raw material for high-speed growth of silicon carbide crystals and a silicon carbide crystal growing method, and belongs to the technical field of semiconductors. The raw material for high-speed growth of the silicon carbide crystals and the silicon carbide crystal high-speed growing method are provided for solving the problem that existing silicon carbide crystals are small in growing speed and low in efficiency. The raw material contains silicon carbide particles, the average particle size of the silicon carbide particles is smaller than 5 mum or at least two types of silicon carbide particles which are in different shapes and / or have different particle sizes are mixed to form a mixed raw material, and the raw material at last contains a type of silicon carbide particles with the average particle size smaller than 5 mum. The silicon carbide crystal growing method comprises the following steps: placing the raw material in a crucible; and heating the crucible and enabling the raw material in the crucible to be recrystallized after sublimating so as to obtain the silicon carbide crystals. The purpose of increasing sublimating speed and efficiency can be achieved.

Owner:TAIZHOU BEYOND TECH

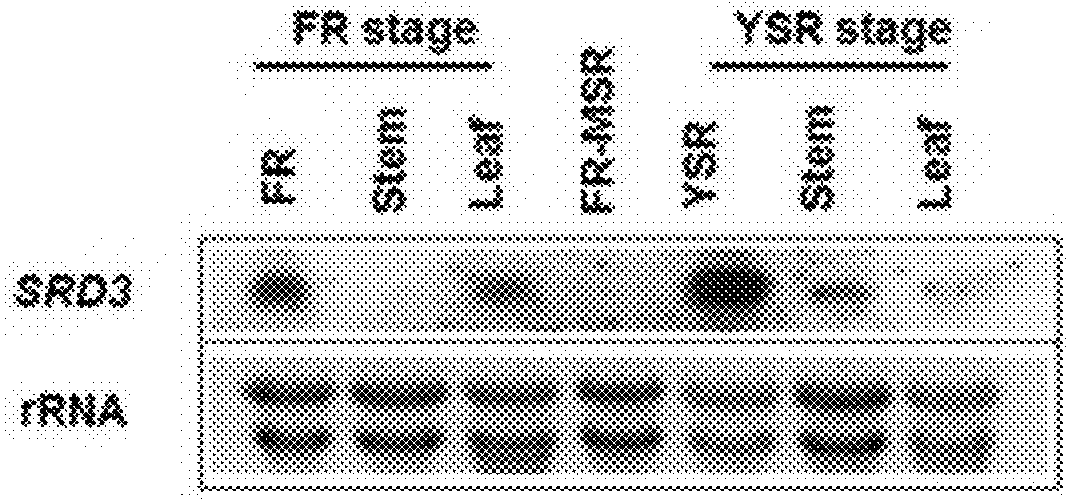

NOVEL GENE IbENOD93 AND TRANSGENIC PLANTS USING THE SAME

ActiveUS20160032302A1Enhancing root thickening growthPromote maturityMicroorganismsClimate change adaptationOpen reading frameNovel gene

The present invention relates to a novel gene, IbENOD93, and transgenic plants using the same. More specifically, the present invention provides an IbENOD93 gene, an open reading frame (ORF) of the IbENOD93 gene, a recombinant vector comprising the gene or the ORF, and a transformant transformed with the vector. Moreover, the present invention provides a composition for enhancing root thickening growth and promoting maturation in a plant having storage root(s). Furthermore, the present invention provides a method for producing a transgenic plant having storage root(s) with enhanced thickening growth, and a method for regulating or enhancing root thickening growth and maturation in a plant having storage root(s). According to the present invention, it is possible to promote the thickening growth of storage roots as well as the growth of aerial part. Therefore, the present invention can be effectively used to promote the thickening growth of storage roots of high-value root crops such as ginseng, sweet potato, etc. and to produce early-maturing transgenic plants.

Owner:KOREA UNIV RES & BUSINESS FOUND

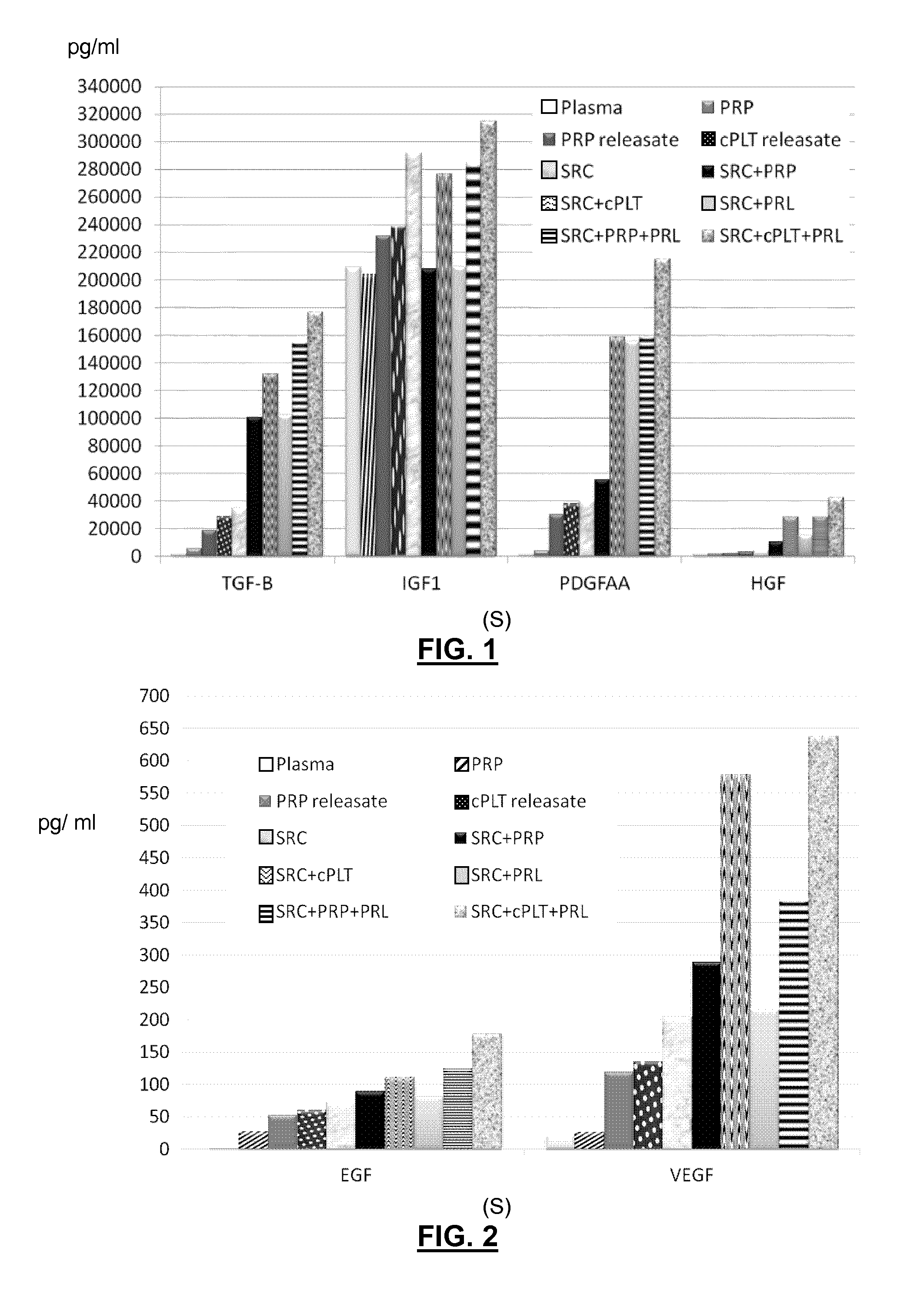

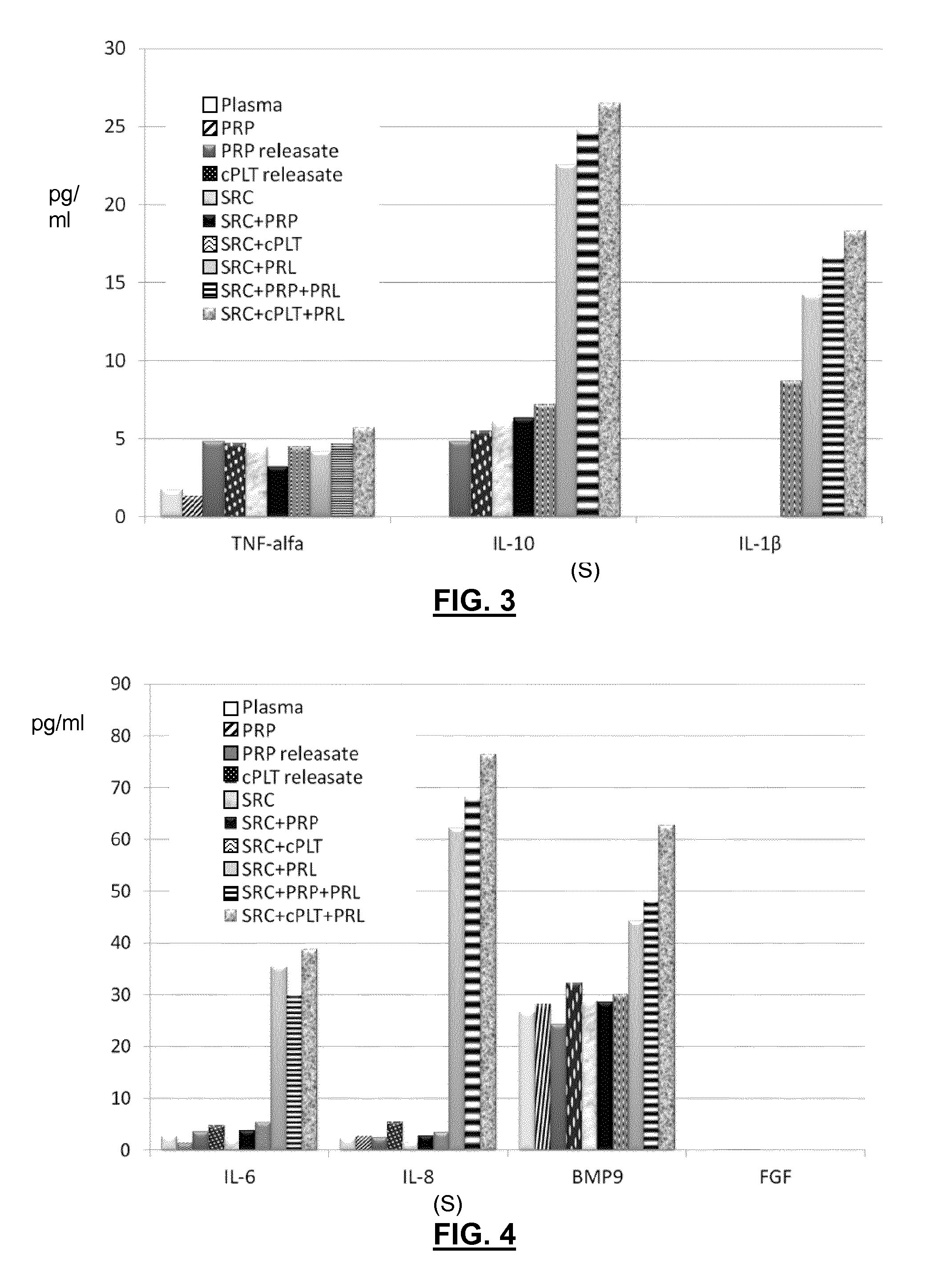

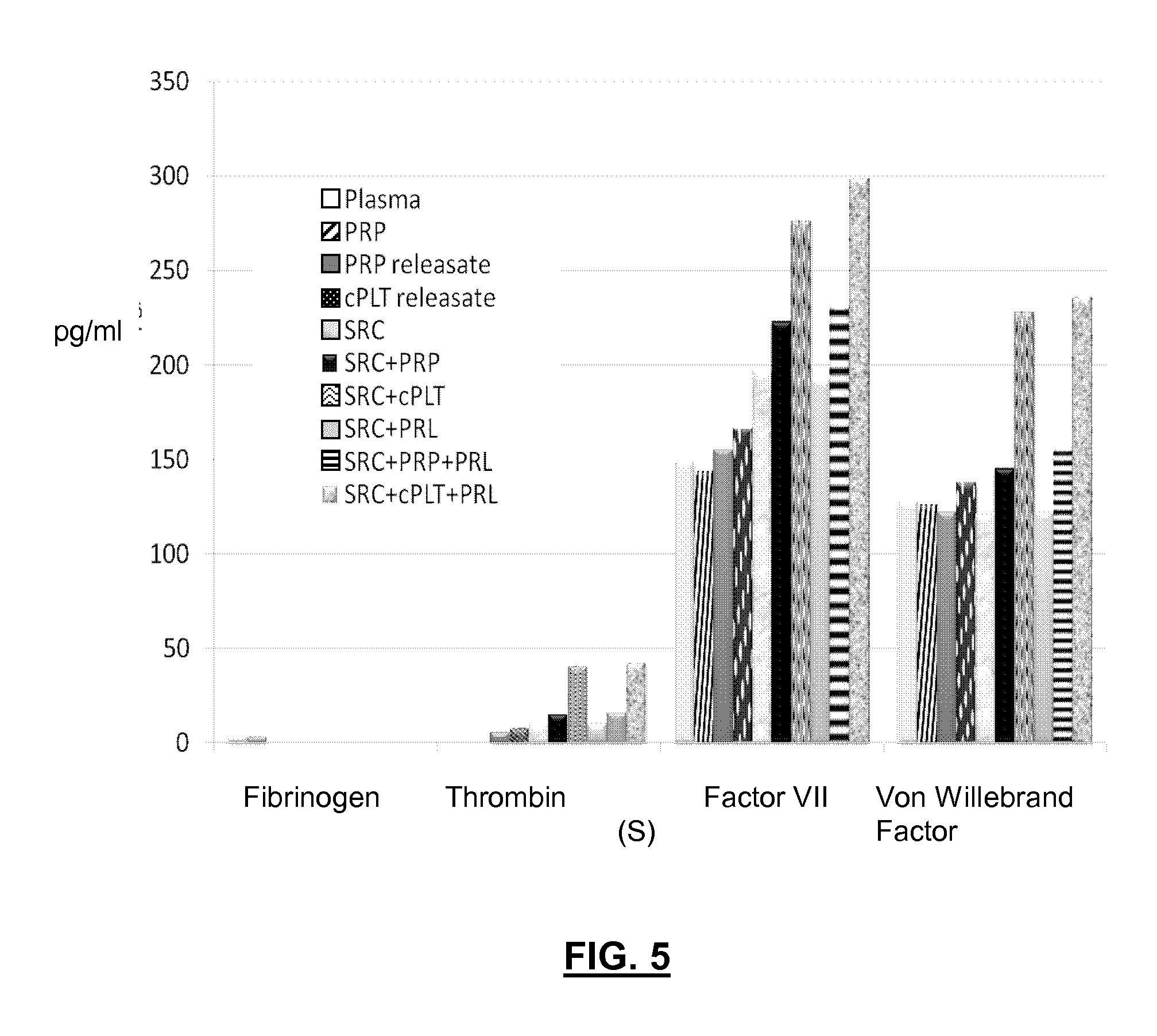

Method for obtaining a cytokine-rich composition and composition obtained by means of this method

InactiveUS20160263193A1Convenient restGuaranteed high growthNervous disorderPeptide/protein ingredientsHigh concentrationWhite blood cell

The invention relates to a method for preparing serums, said serums comprising cytokines and coagulation factors, and for preparing fibrin gel compositions, wherein the method comprises submitting an isolated biological sample comprising platelets and / or leukocytes to different steps of different gravity force to obtain supernatants with high concentrations of cytokines and coagulation factors. The invention also encompasses serums obtainable by this method, and other derived products comprising them. Uses of the products are disclosed, in particular its use as tissue regeneration.

Owner:NTE SENER HEALTHCARE SA

Wire covering material composition, an insulated wire and a wiring harness

InactiveUS7868253B2Wire covering material composition is favorableGuaranteed high growthPlastic/resin/waxes insulatorsInsulated cablesPolytetramethylene terephthalatePhosphoric Acid Esters

A wire covering material composition which is systematically different from a polyolefin resin composition and which possesses favorable flame retardancy, tensile elongation and wear resistance, having 100 parts by weight of a polymer blend containing 40-95 wt % of polybutylene terephthalate, and 1 to 30 parts by weight of a phosphoric ester compound with respect to 100 parts by weight of the polymer blend, wherein 5 to 100 wt % of the total content of the polybutylene terephthalate in the polymer blend is made up of polybutylene terephthalate, whose molecular weight distribution Mw / Mn (where Mw: weight-average molecular weight; Mn: number-average molecular weight) is greater than or equal to 2.5.

Owner:AUTONETWORKS TECH LTD +2

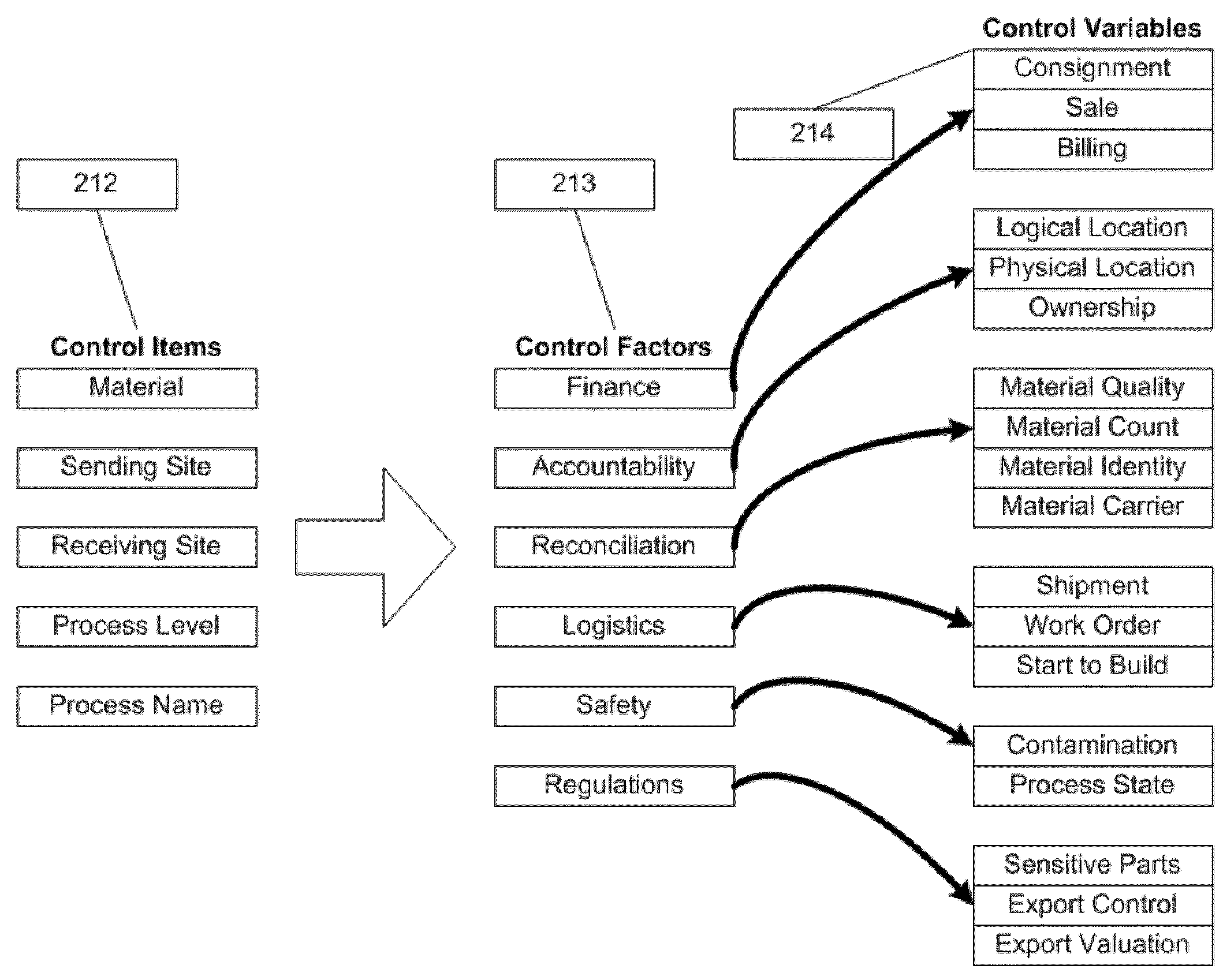

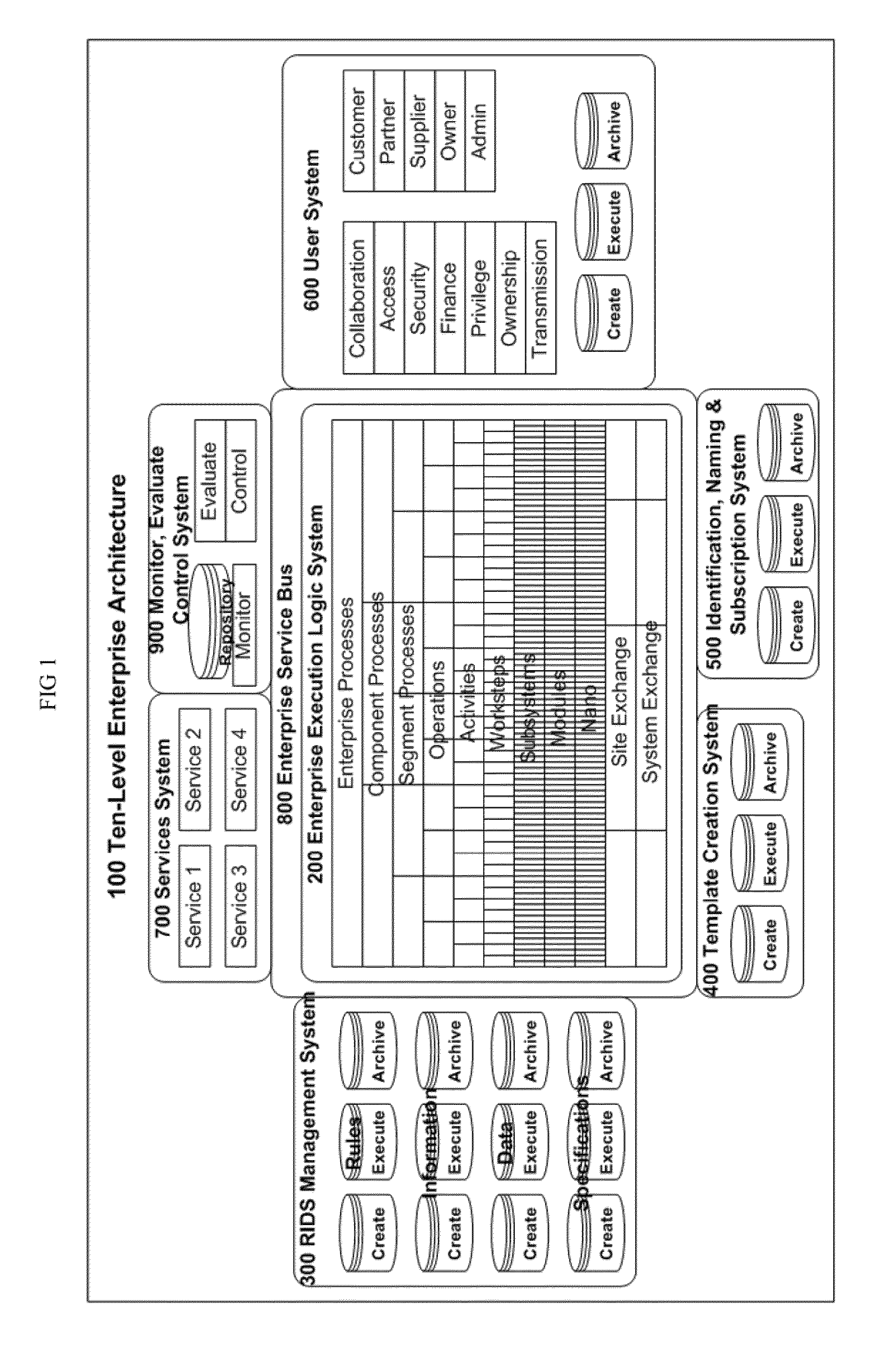

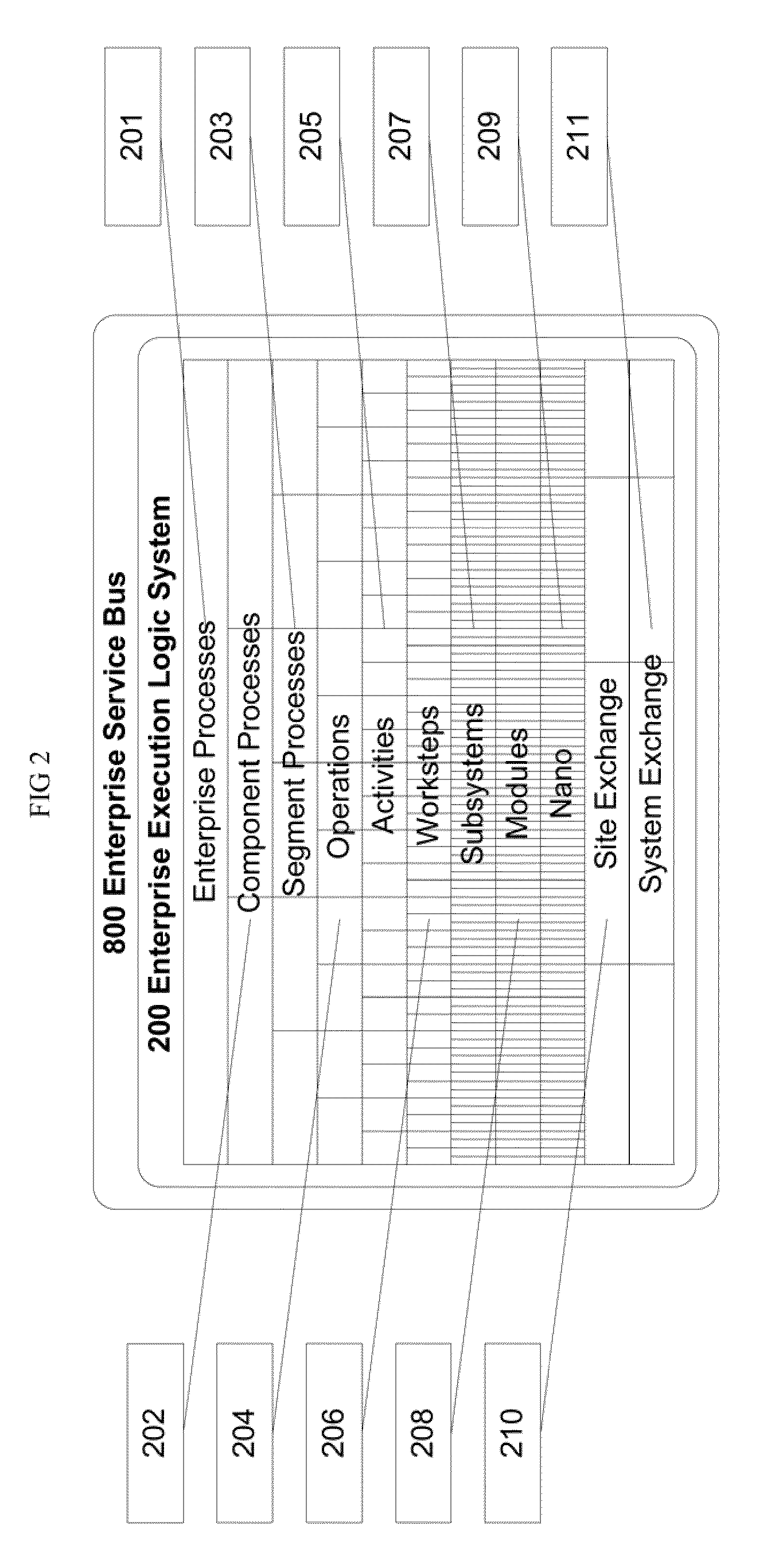

Ten-Level Enterprise Architecture Systems and Tools

InactiveUS20100268561A1Business impossibleExtensibility impossibleResourcesElectrical appliancesManagement processEnterprise process

This disclosure describes sets of systems and tools that drive complex enterprise execution logic top to bottom, end to end and site to site through the discrete execution and control of ten levels of mission-critical enterprise structure:1. Execution logic: drive operations end to end, top to bottom, site to site2. Rules: govern a process step execution3. Information: track states of enterprise objects or go / no decisions4. Data: capture and use measurements or events5. Specifications: guide operation for particular programs6. Templates: prepackage execution logic models7. Identification: name critical enterprise resources for common management8. Users: represent the extended enterprise community9. Services: provide physical or logical procedures, functions, modifications or measurements10. Controls: monitor, evaluate and control named material at specific process stepsThe ten-level enterprise architecture provides effective and efficient tools for executing complex globally collaborative enterprise processes.

Owner:ENRIGHT KERRY JOHN

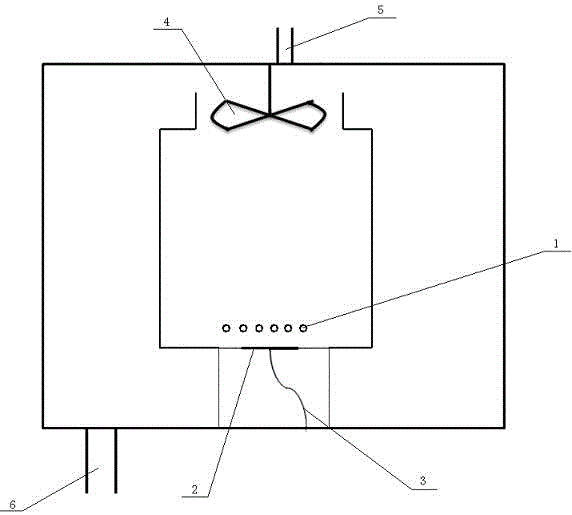

Growing device of gas inner circulation type hot wire chemical vapor deposition (CVD) diamond films

InactiveCN102719804AAchieve large area growthReduce consumptionChemical vapor deposition coatingHydrogenAir pump

The invention relates to a growing device of gas inner circulation type hot wire CVD diamond films. The device comprises a sealed vacuum chamber provided with a reaction chamber inside. A fan is arranged at the top end of the inner wall of the reaction chamber, and a hot wire array composed of a plurality of parallel vertical tungsten wires is arranged below the fan; two ends of the hot wire array are connected with direct current, a substrate plate is arranged below the hot wire array, and a thermocouple is arranged on the substrate plate; an air inlet is arranged on the outer wall of the vacuum chamber on the upper side portion of the fan; and an air pumping opening is arranged on the lower side portion of the outer wall of the vacuum cavity. According to the growing device, large area and high speed growth of diamond films can be achieved, and consumption of hydrogen is reduced.

Owner:LANZHOU UNIVERSITY

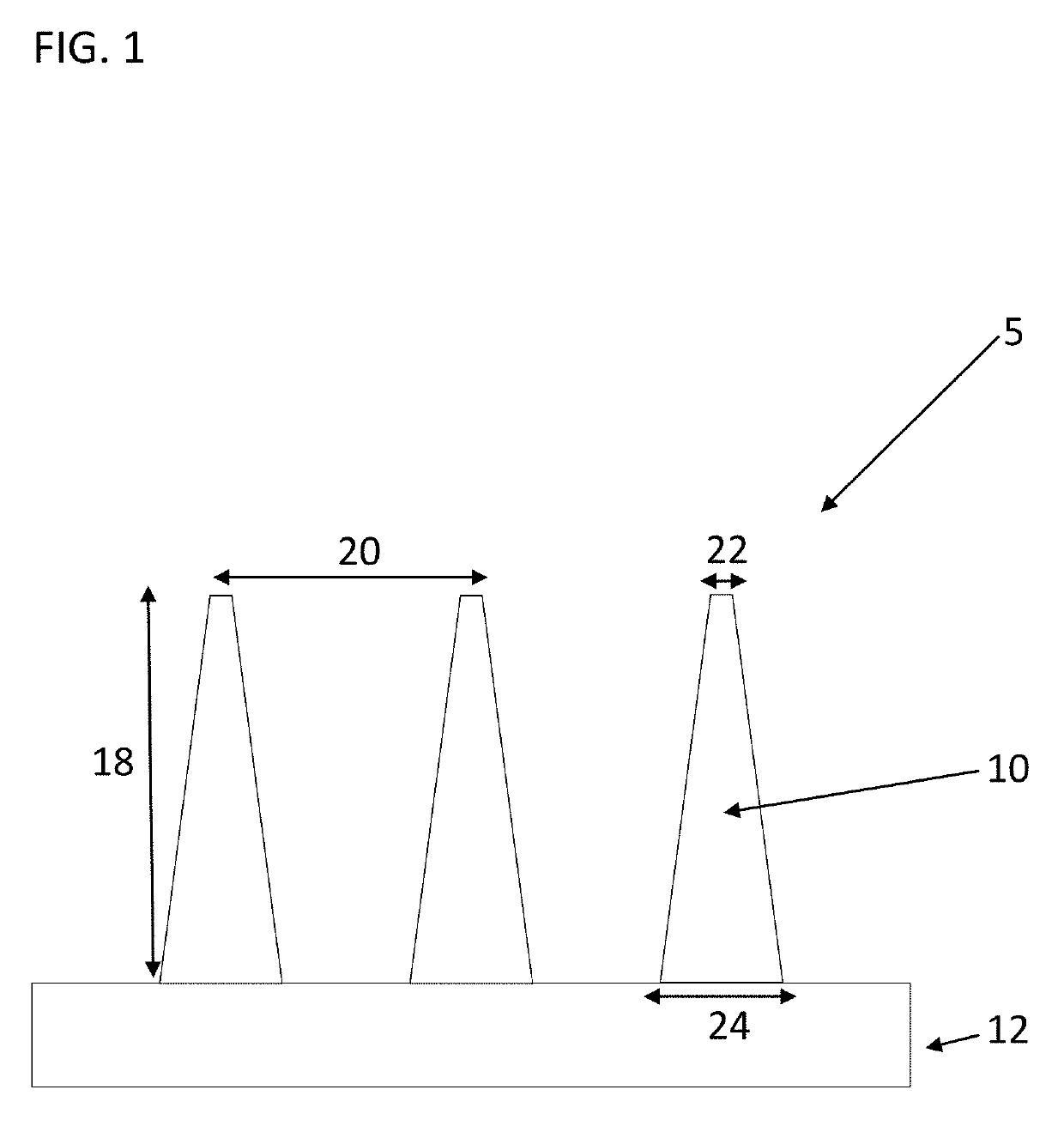

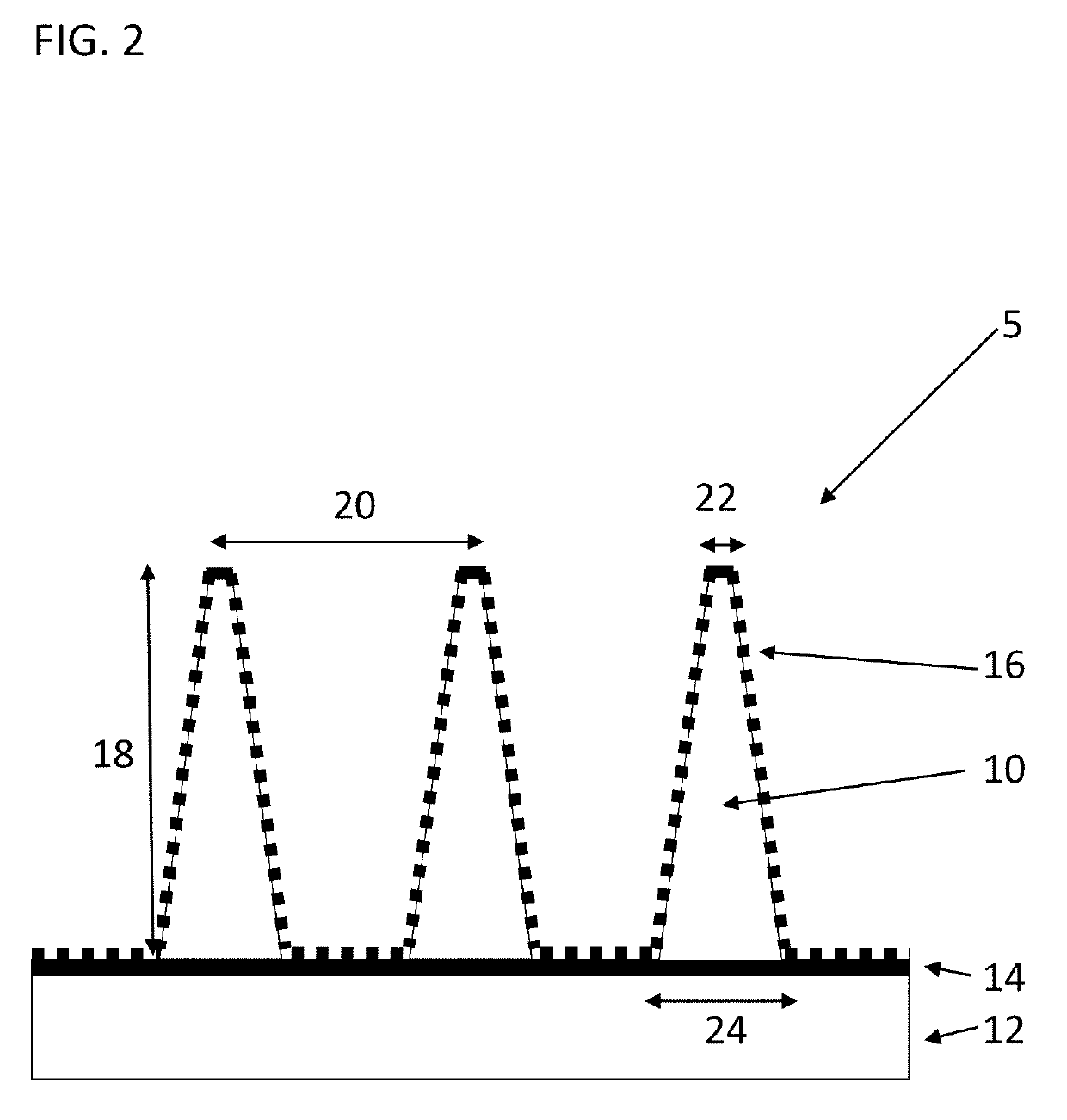

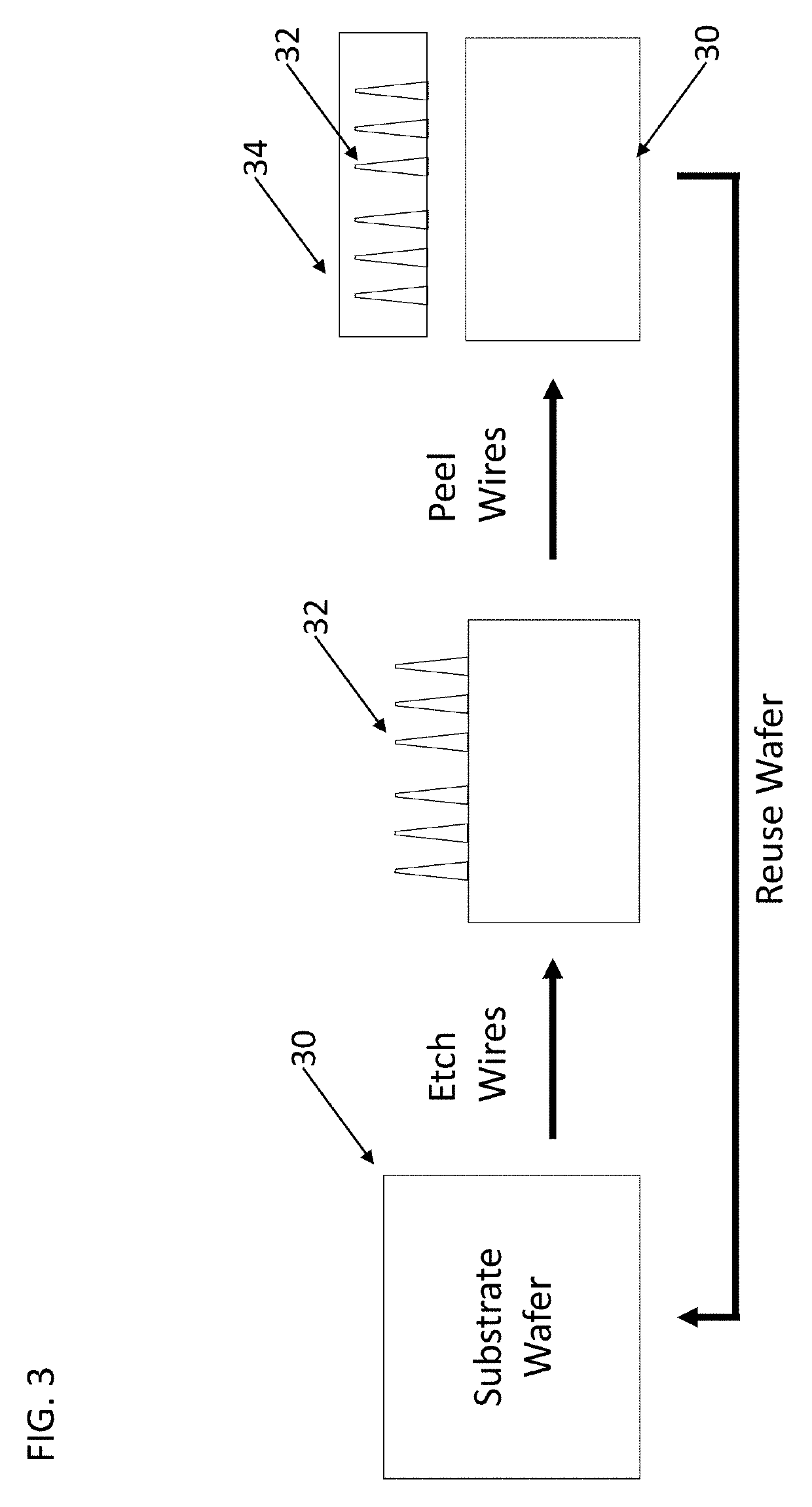

Epitaxy-Free Nanowire Cell Process for the Manufacture of Photovoltaics

ActiveUS20190312168A1Reduce manufacturing costImprove efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionNanowire

Photovoltaics configured to be manufactured without epitaxial processes and methods for such manufacture are provided. Methods utilize bulk semiconducting crystal substrates, such as, for example, GaAs and InP such that epitaxy processes are not required. Nanowire etch and exfoliation processes are used allowing the manufacture of large numbers of photovoltaic cells per substrate wafer (e.g., greater than 100). Photovoltaic cells incorporate electron and hole selective contacts such that epitaxial heterojunctions are avoided during manufacture.

Owner:CALIFORNIA INST OF TECH

Feed for Luchuan pigs, and preparation method thereof

InactiveCN106912703AHelp secretionPromote healingFood processingAnimal feeding stuffBiotechnologyPeanut meal

The invention provides a feed for Luchuan pigs. The feed is mainly prepared from, by weight, soybean residue, sorghum flour, rice bran, sweet potato powder, wheat bran, peanut meal, green lemon, Ampelopsis brevipedunculata, roxburgh rose, Physalis alkekengi, Sterculia nobilis, Rubus hirsutus, Lonicera fragrantissima subsp. Standishii, cucurbita pepo L. var.patisson, amaranthus retroflexus, codium fragile, enteromorpha, chenopodium album Linn, pepper leaf, scagassum, sarcodia montagneana, rice sprout, passion fruit, radix acanthopanacis semticosi, rhizoma dryopteris crassirhizomae, water chestnut, and table salt. The preparation method is simple; the obtained feed is capable of clearing heat and detoxifying, promoting digestion and absorption, promoting conception, increasing the fecundability of sows, and increasing embryo survival rate.

Owner:广西神龙王农牧食品集团有限公司

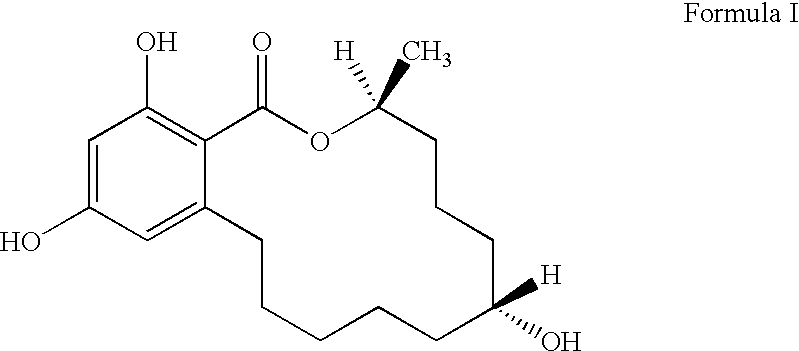

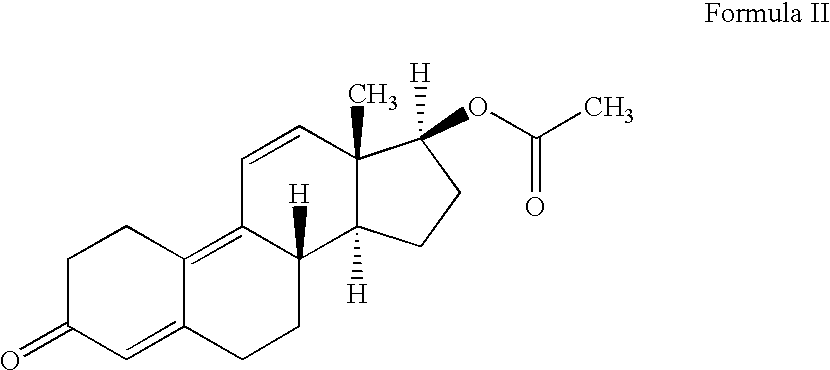

Growth stimulant compositions

InactiveUS7767708B2Convenient amountIncrease probabilityBiocidePowder deliveryDual releaseGrowth stimulant

An improved weight and growth stimulant for domesticated animals such as cattle, pigs and sheep is comprised of an anabolic agent that is subcutaneously administered in the form of a dual release implant formulation. Increased gains are particularly improved when zeranol is administered in an immediate-release and controlled-release formulation which allows for a one-time dosage injection.

Owner:SCHERING PLOUGH ANIMAL HEALTH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com