Patents

Literature

82 results about "Enterprise process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enterprise Process Model is a model that shows the full end‐to‐end activity (high‐level view) needed to create the outcome (service or product) of the process. Enterprise Process Models may also be known as value chain models.

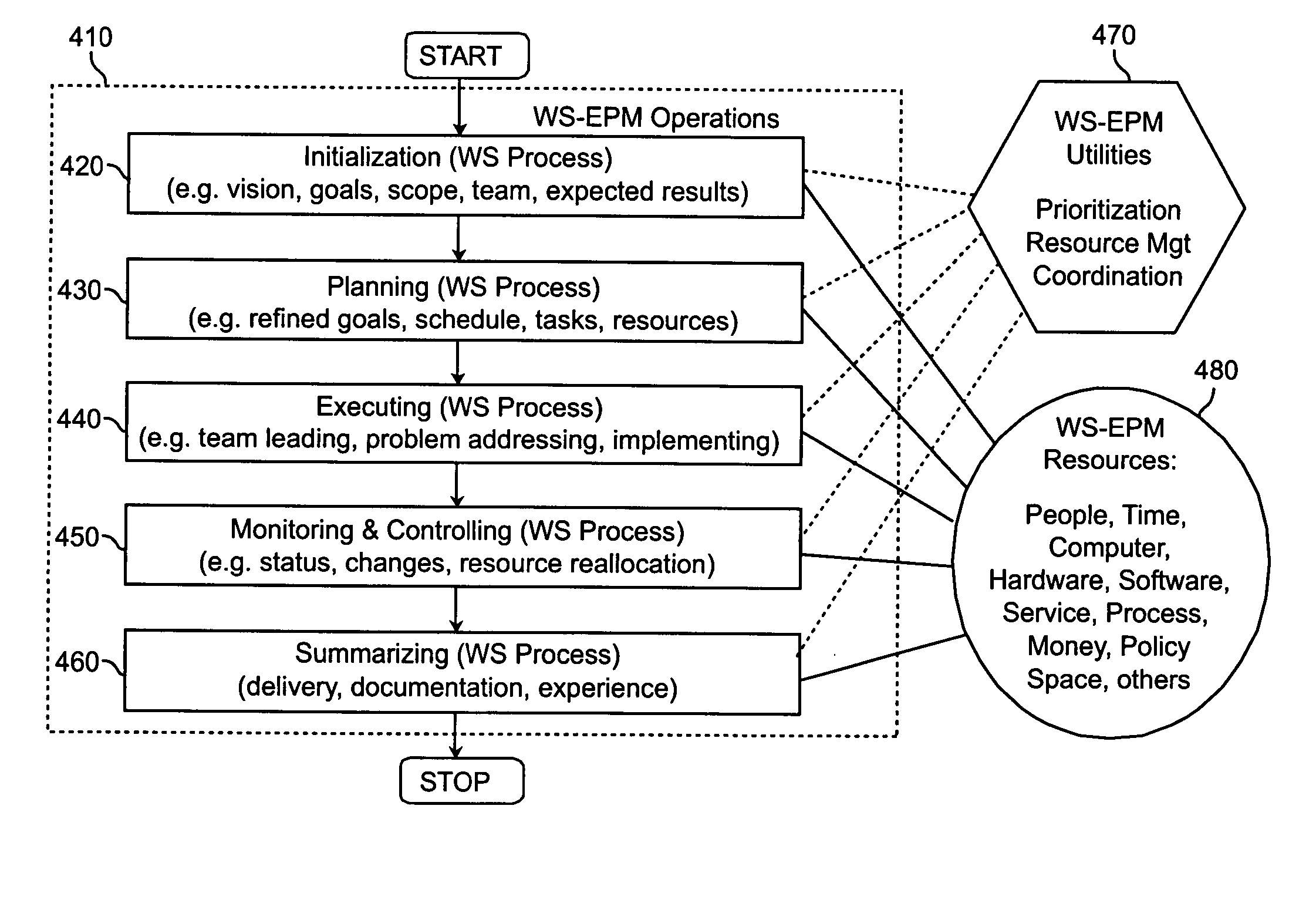

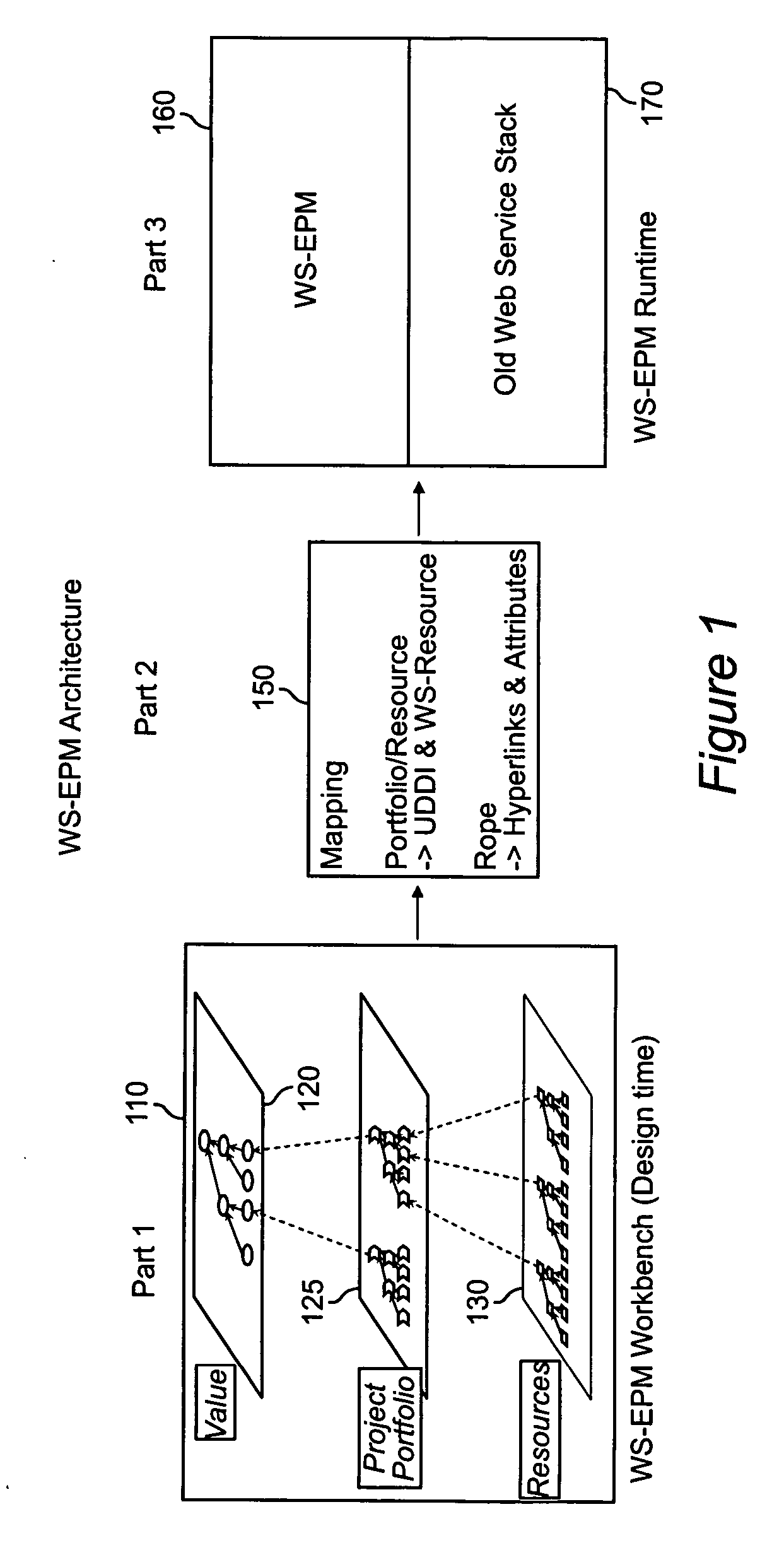

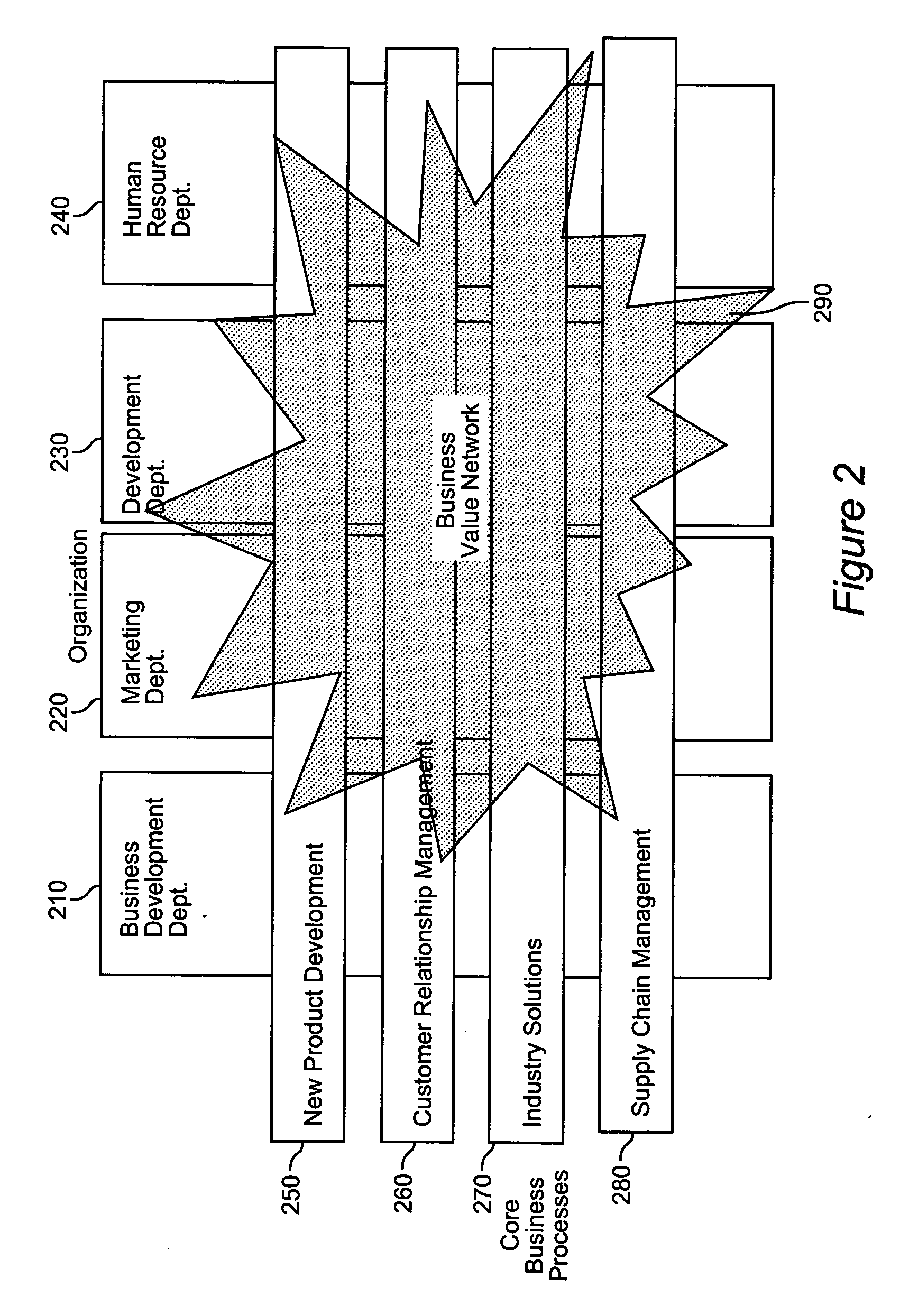

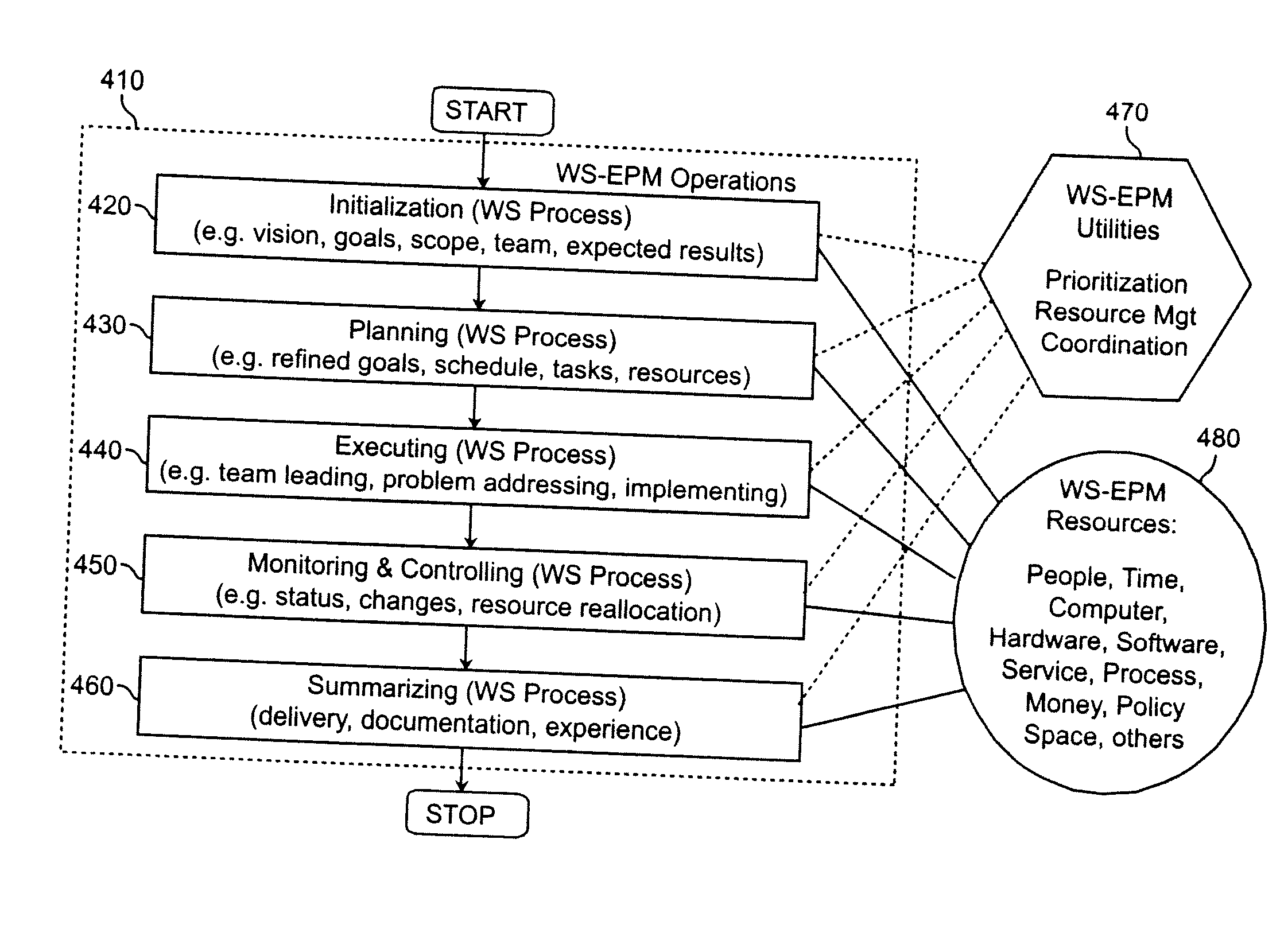

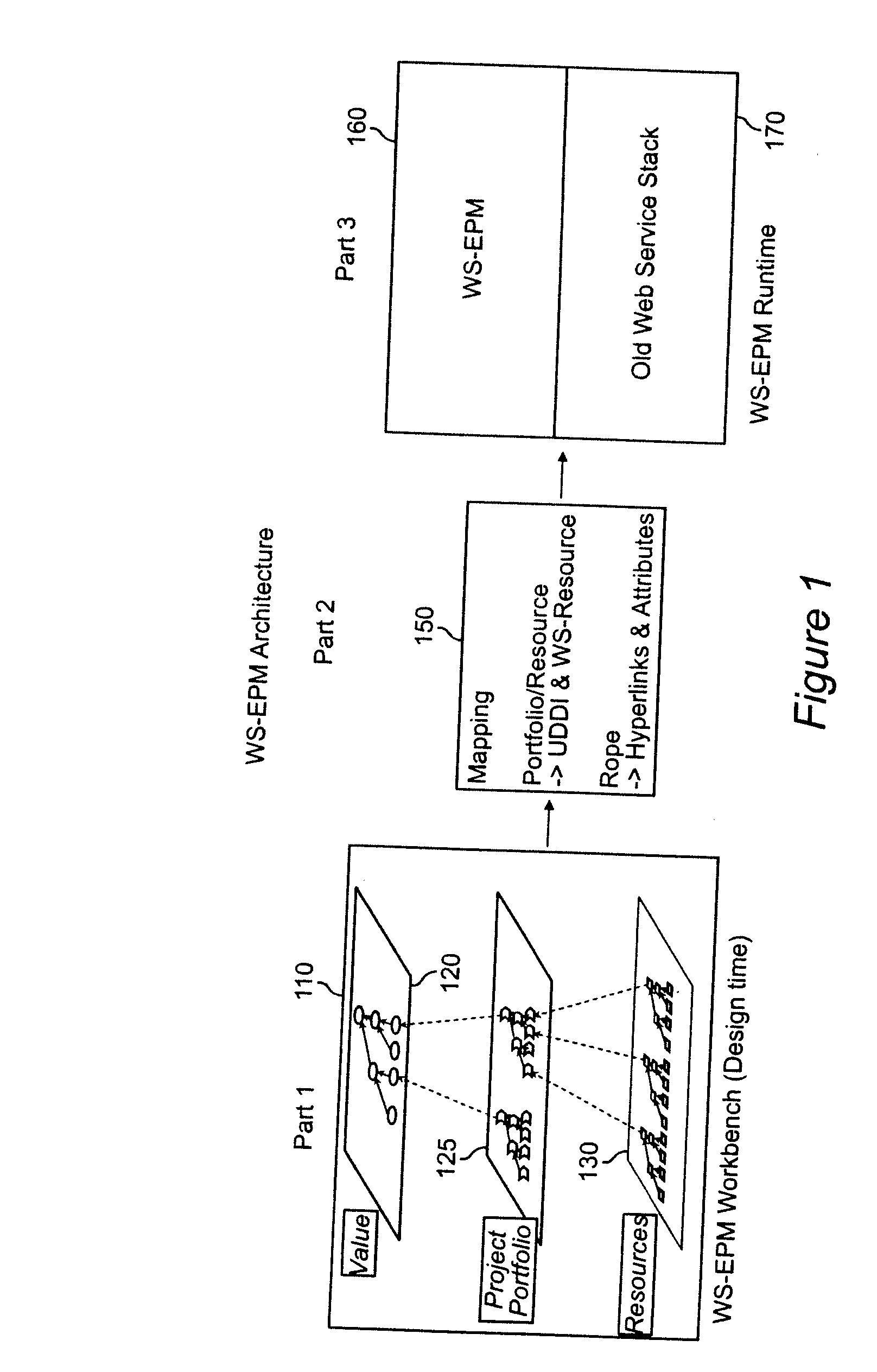

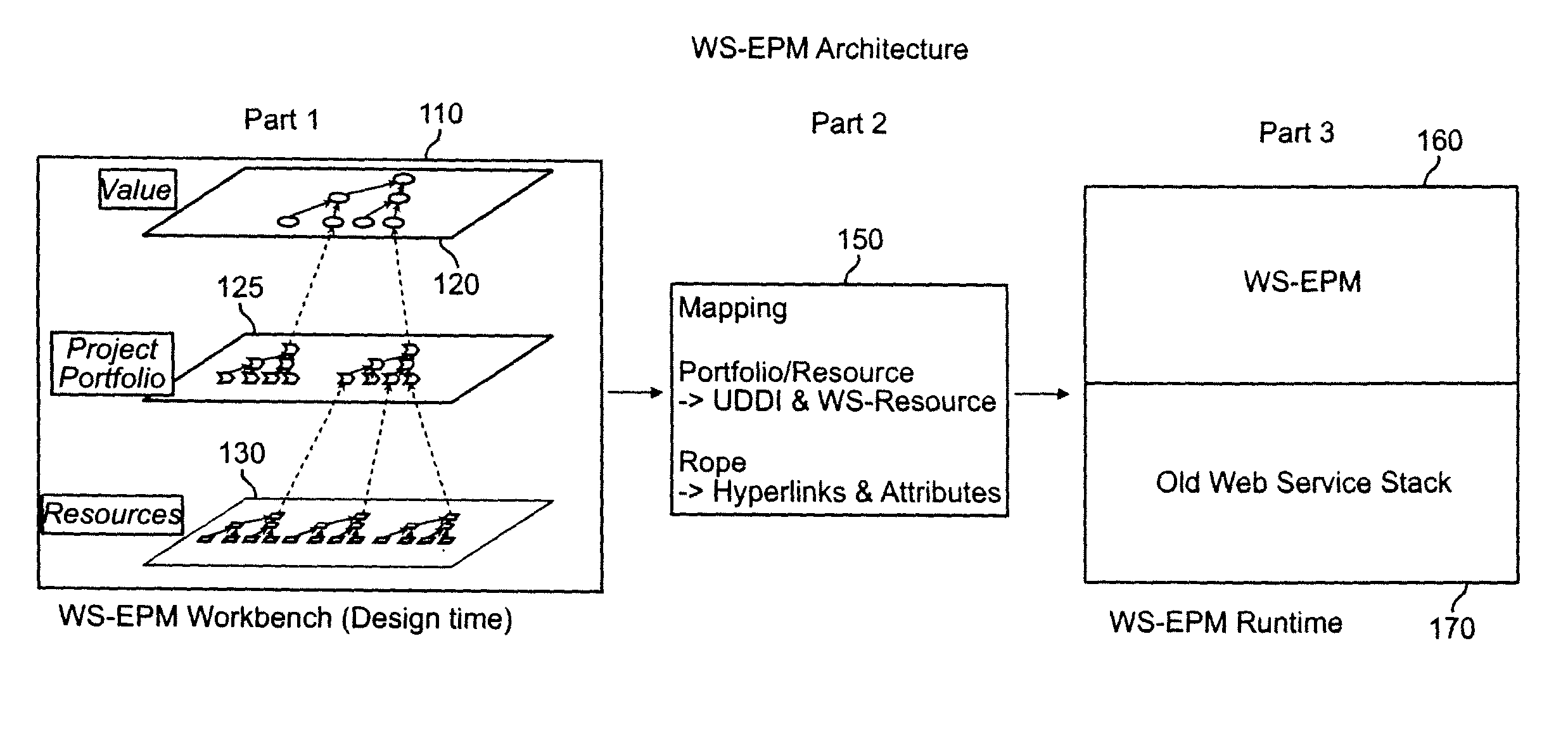

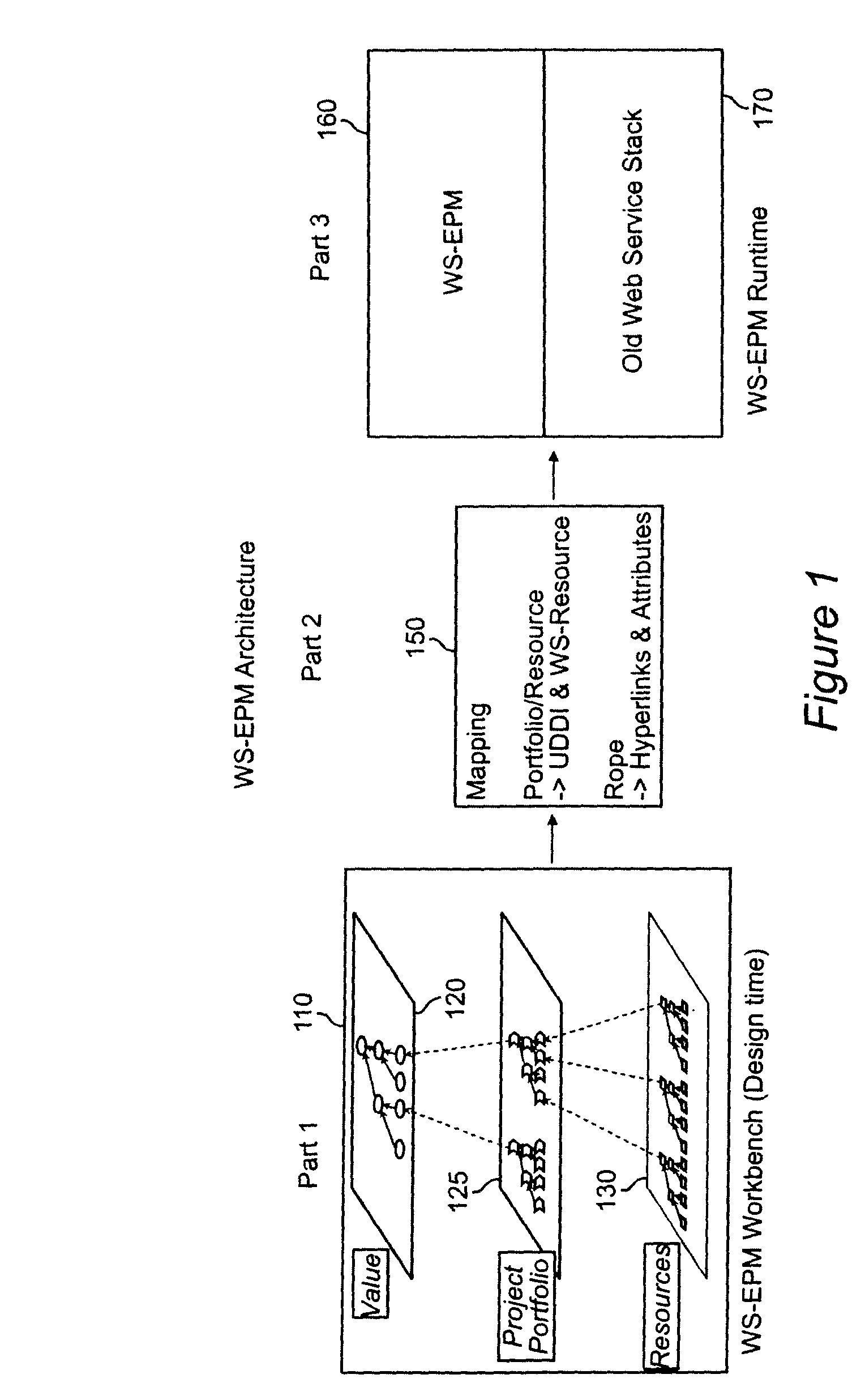

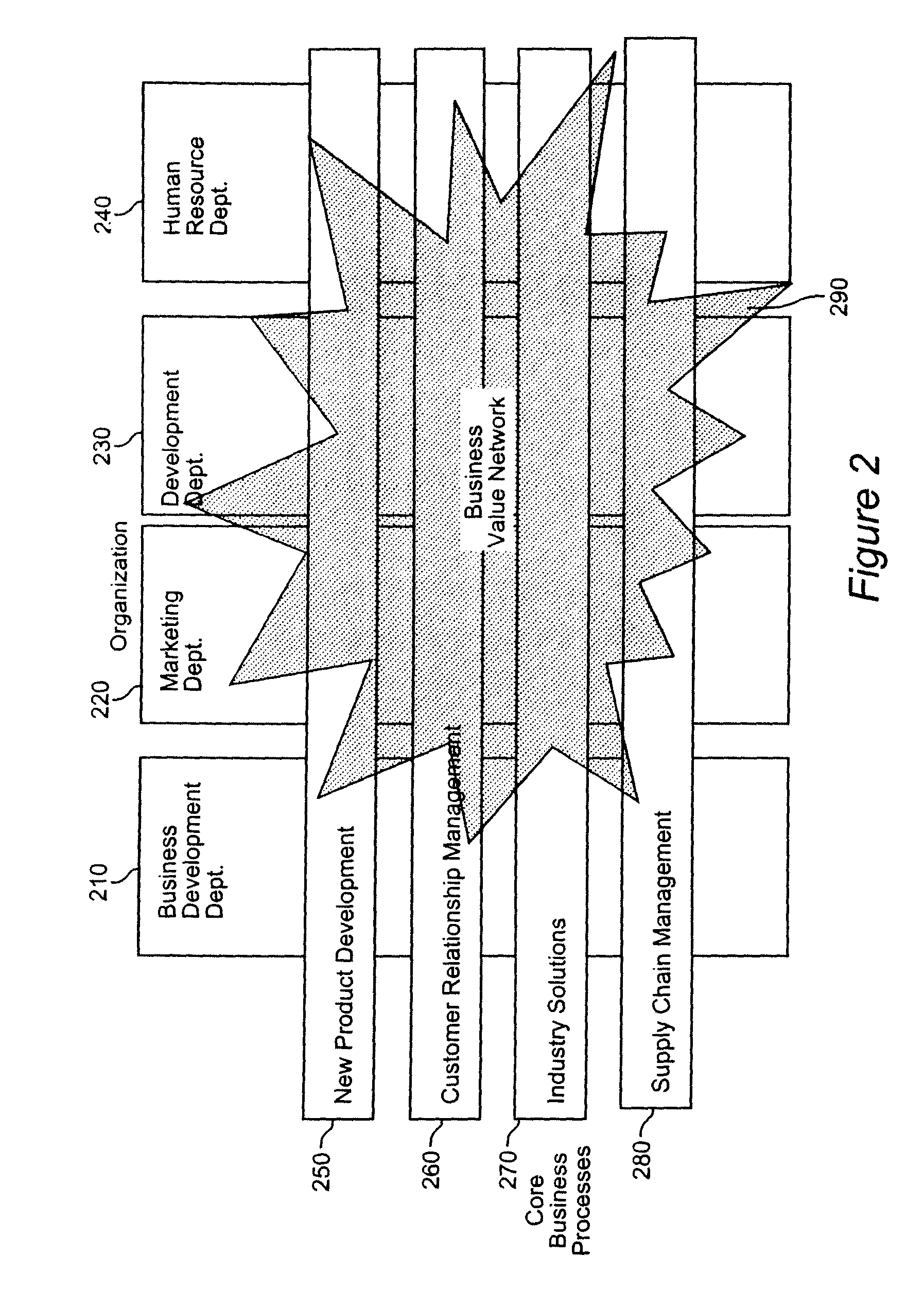

Method and apparatus for enabling enterprise project management with service oriented resource and using a process profiling framework

InactiveUS20070022404A1ResourcesSpecific program execution arrangementsService oriented enterpriseHyperlink

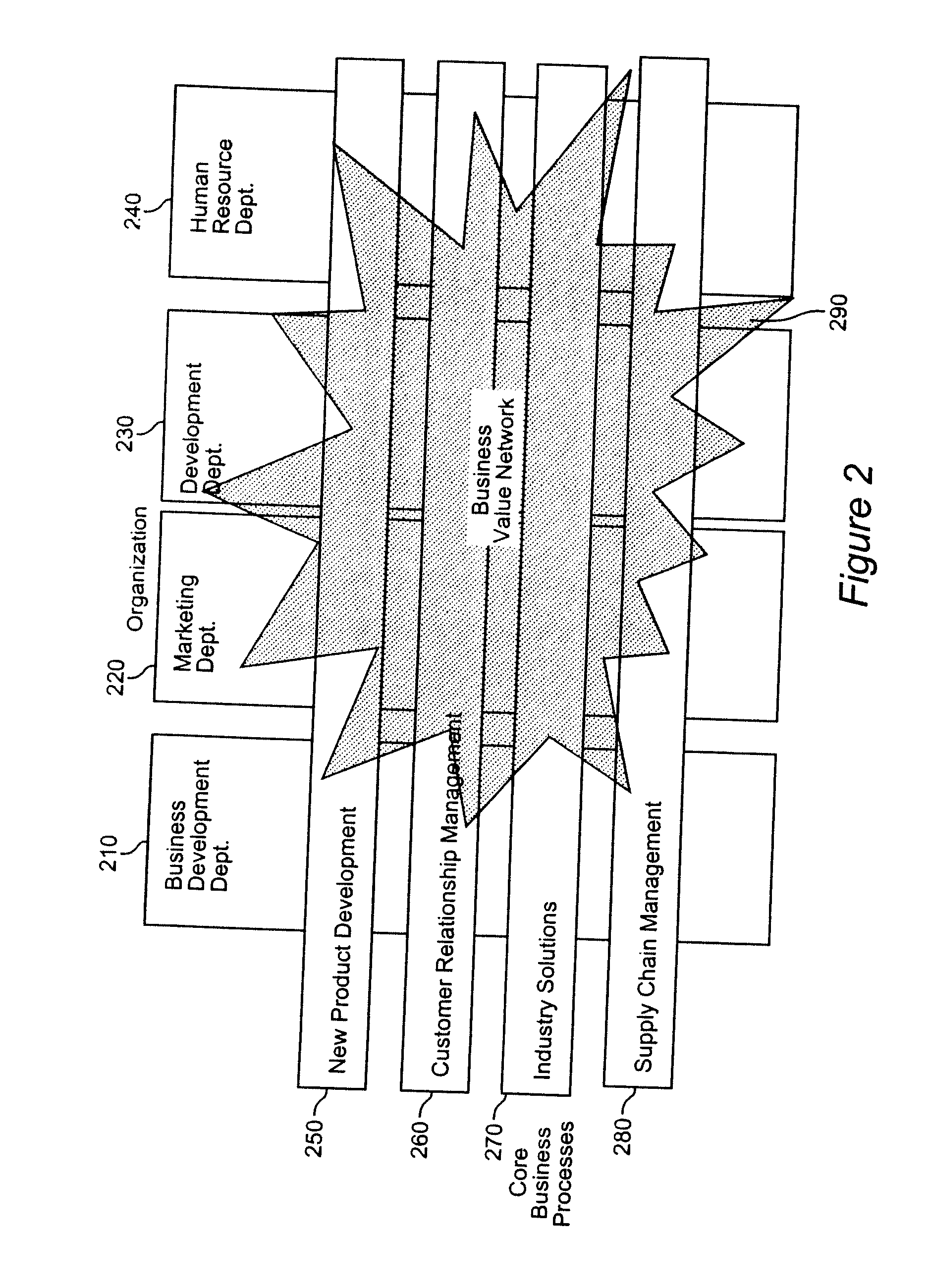

A service-oriented architecture for enterprise project management integrates business processes, human resources and project management within an enterprise or across the value chain network. A representation having direction and attributes is provided to show the dependencies between a business value layer and a project-portfolio layer, and between the project-portfolio layer and resources. The representation is mapped to a Web Services representation in UDDI, Web Services interfaces, and Web Services based business processes through rope hyper-linking.

Owner:IBM CORP

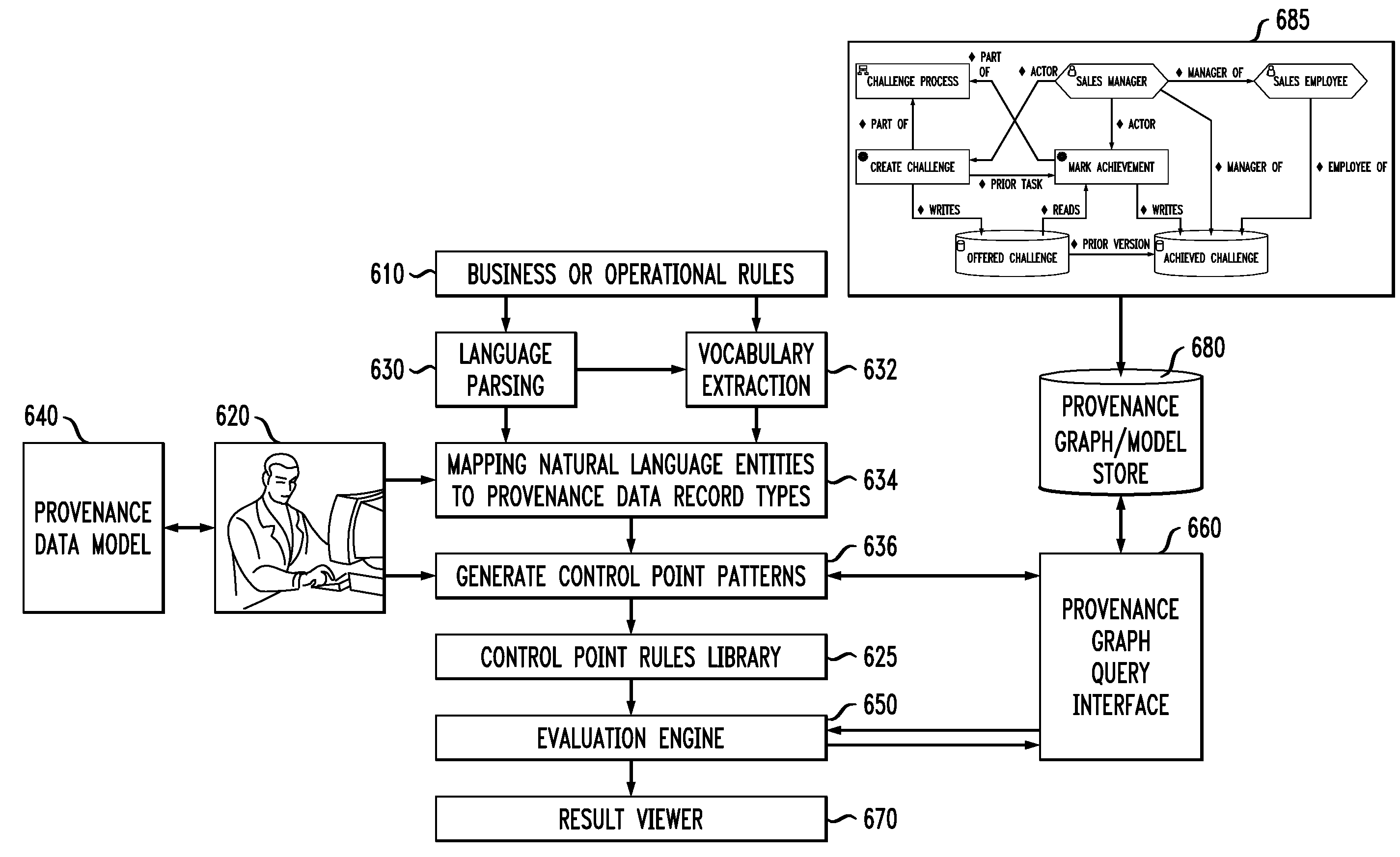

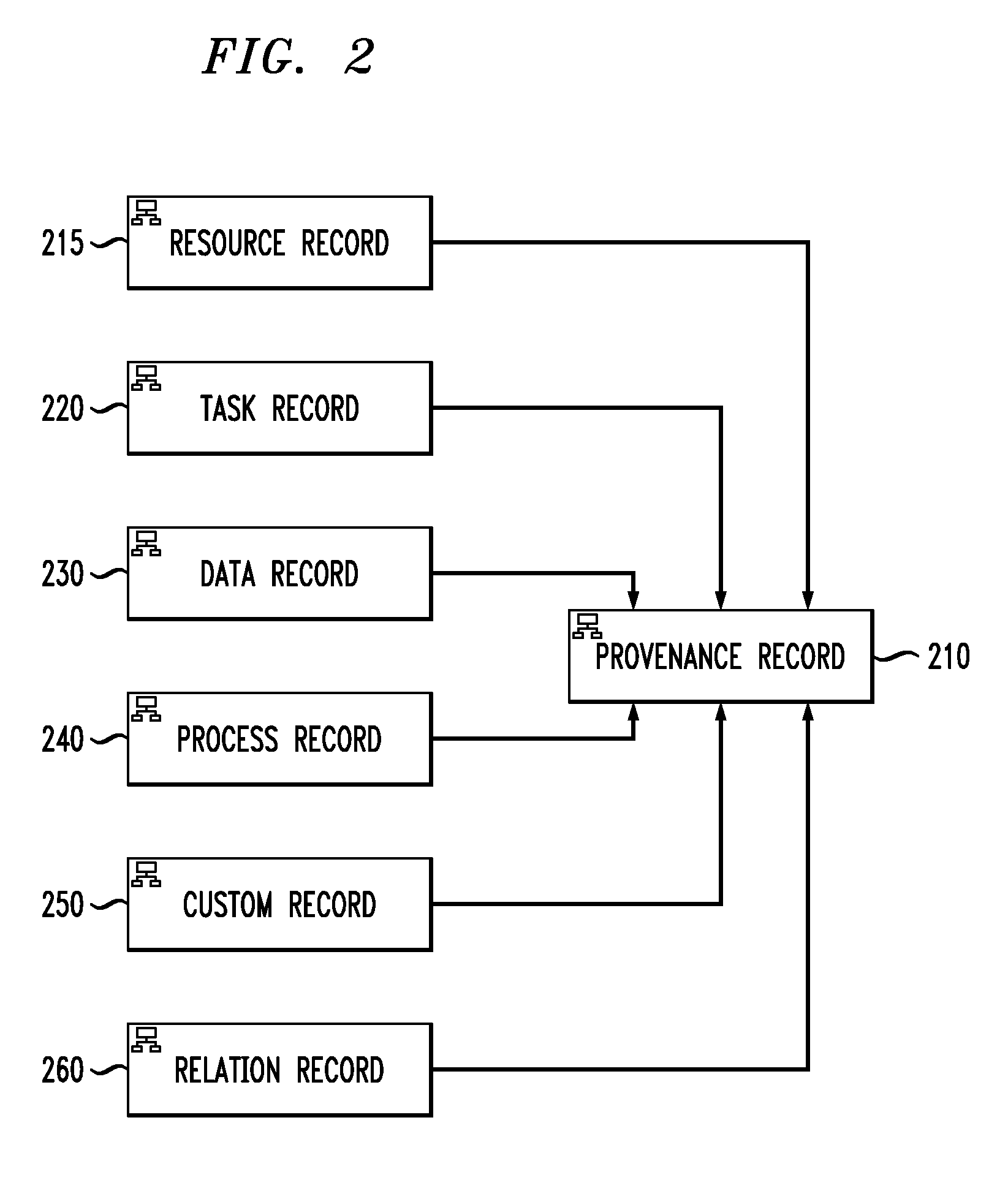

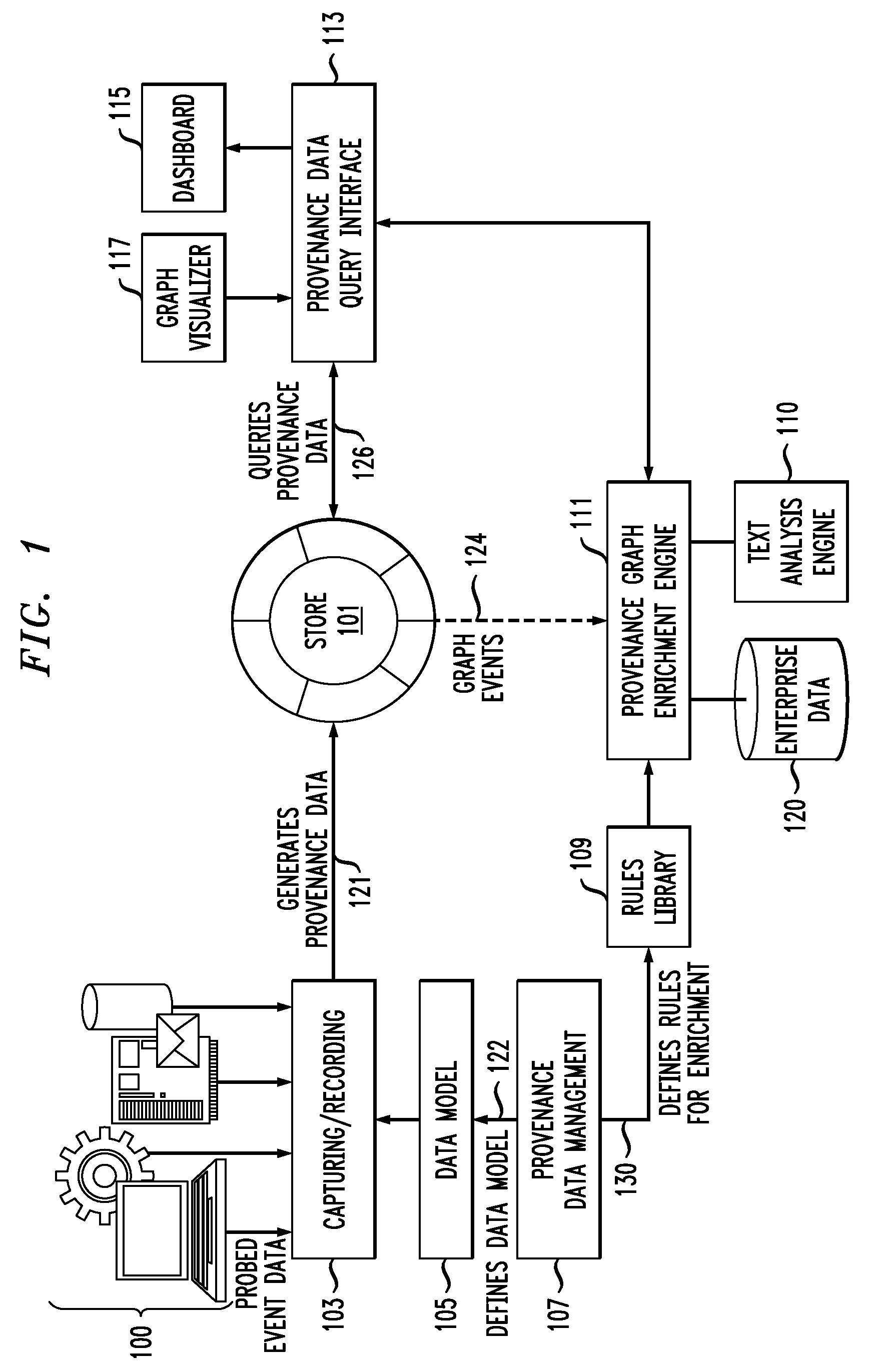

Validating Compliance in Enterprise Operations Based on Provenance Data

InactiveUS20100114628A1Low costDrawing from basic elementsDigital data processing detailsData validationEnterprise process

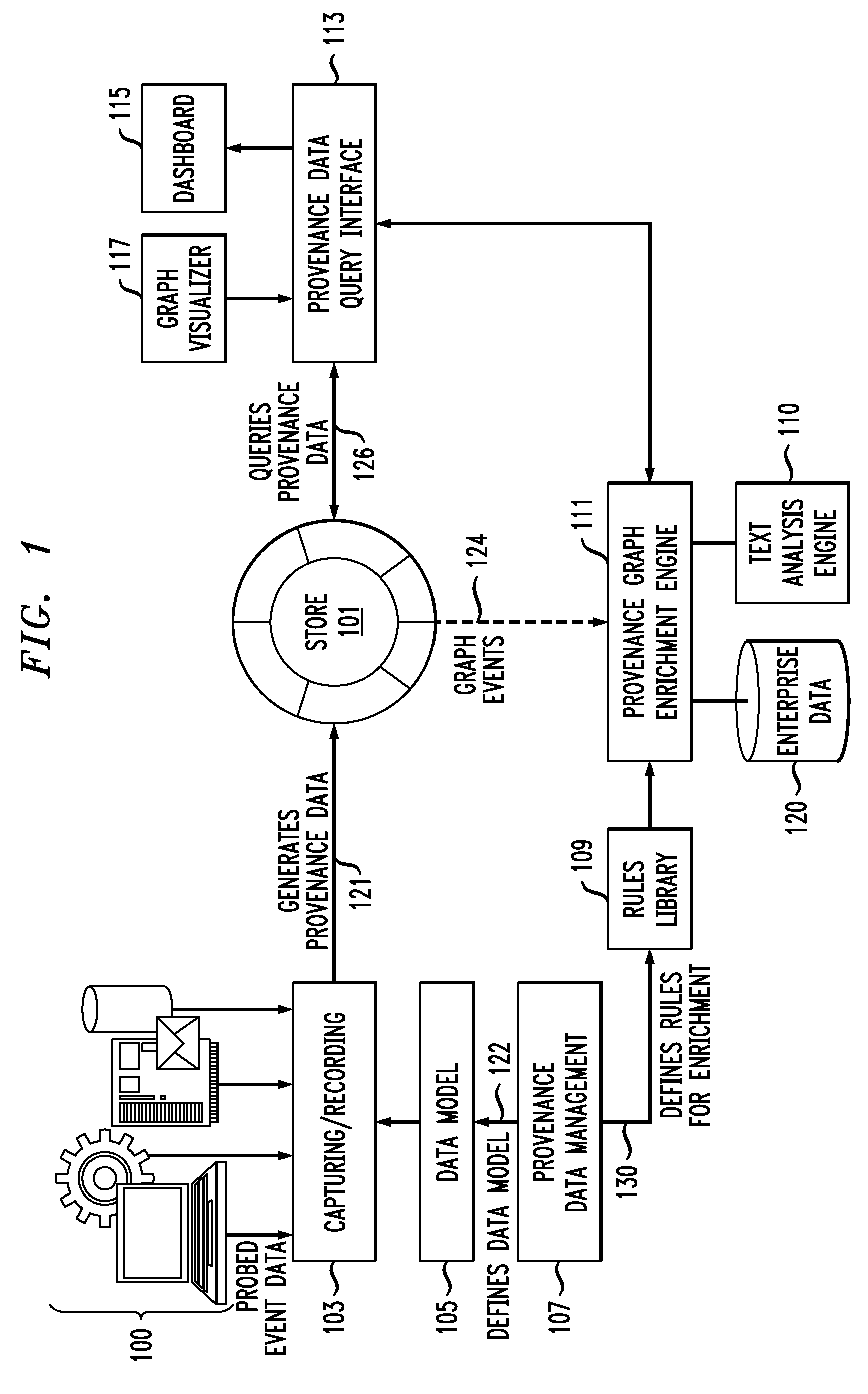

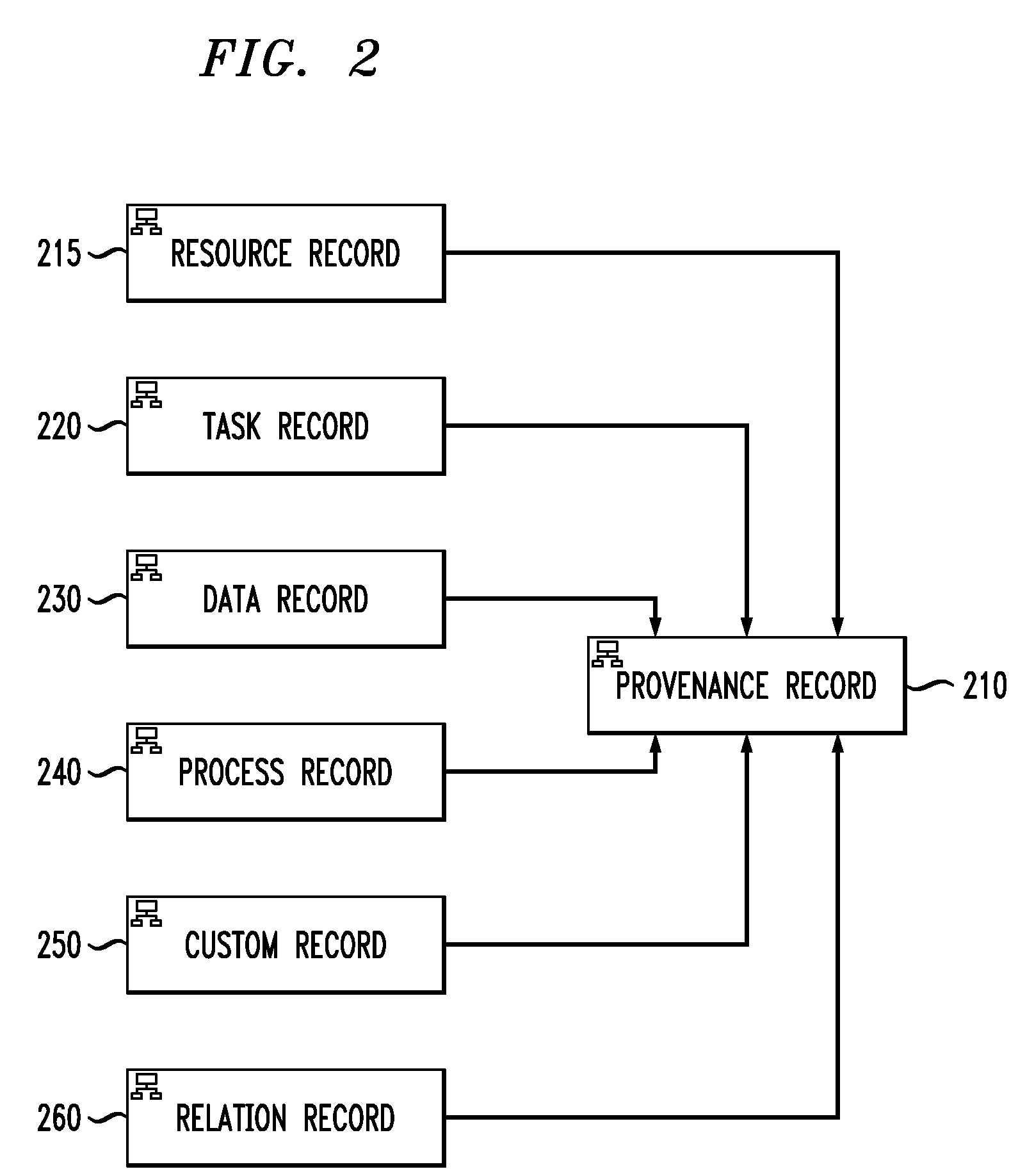

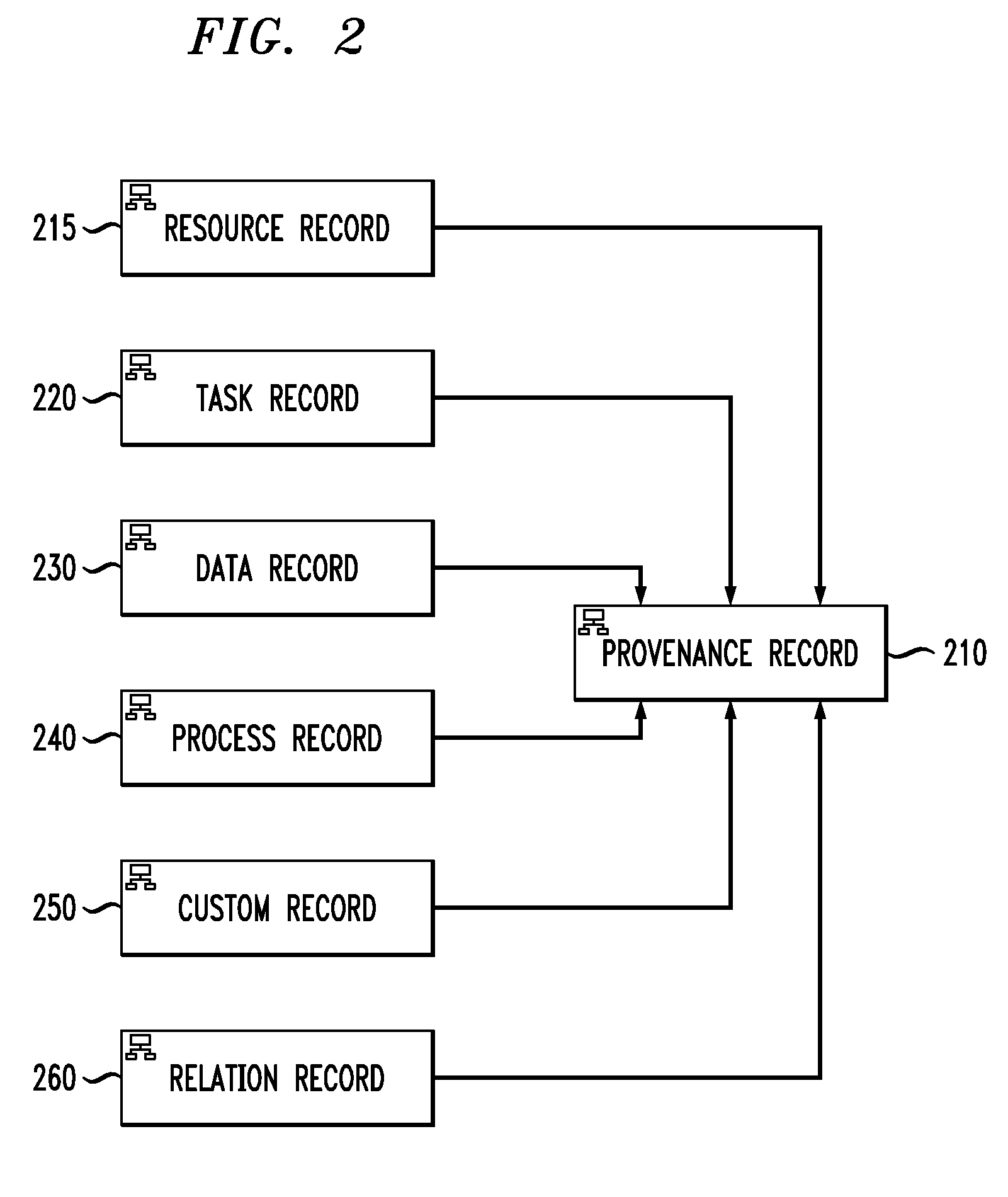

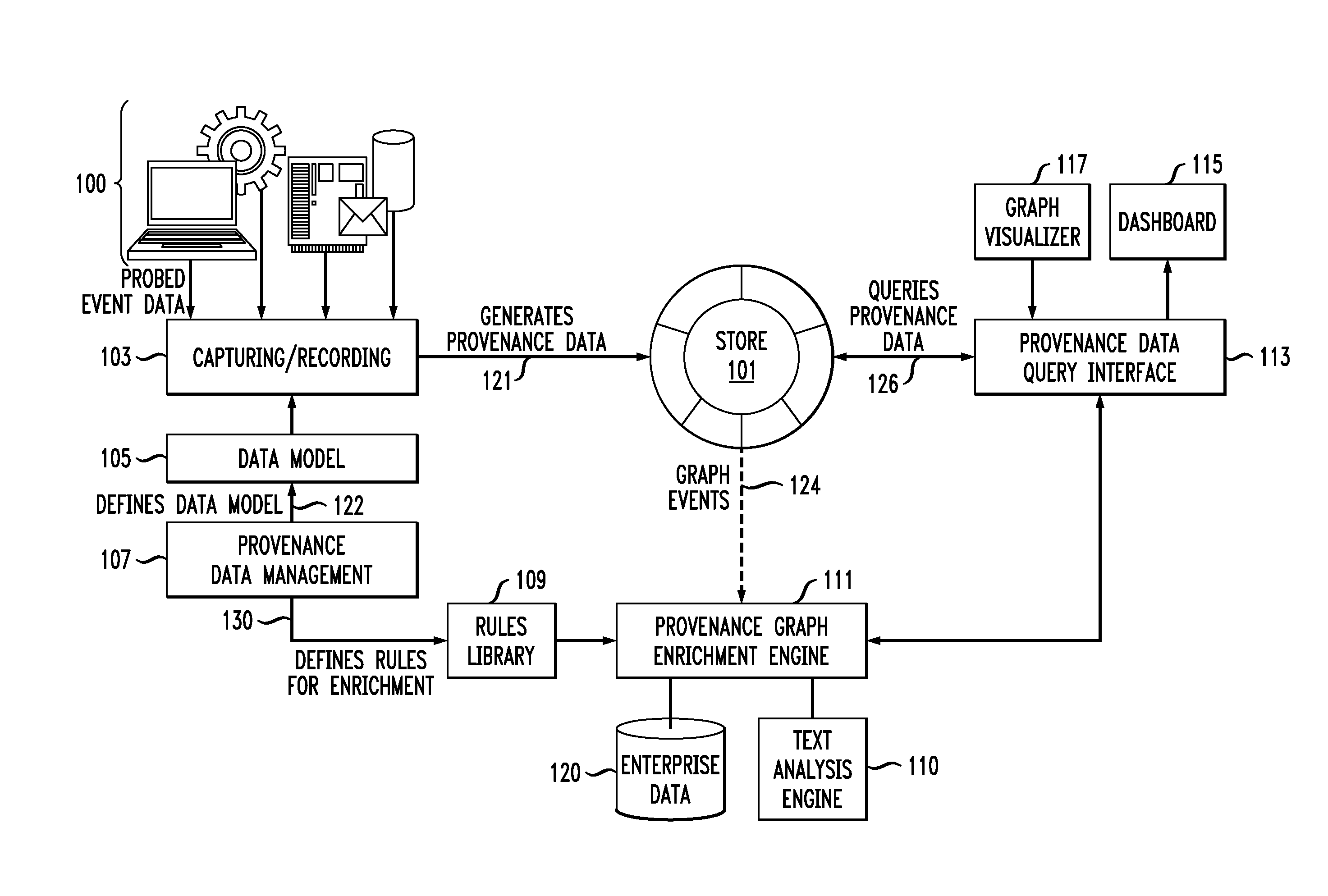

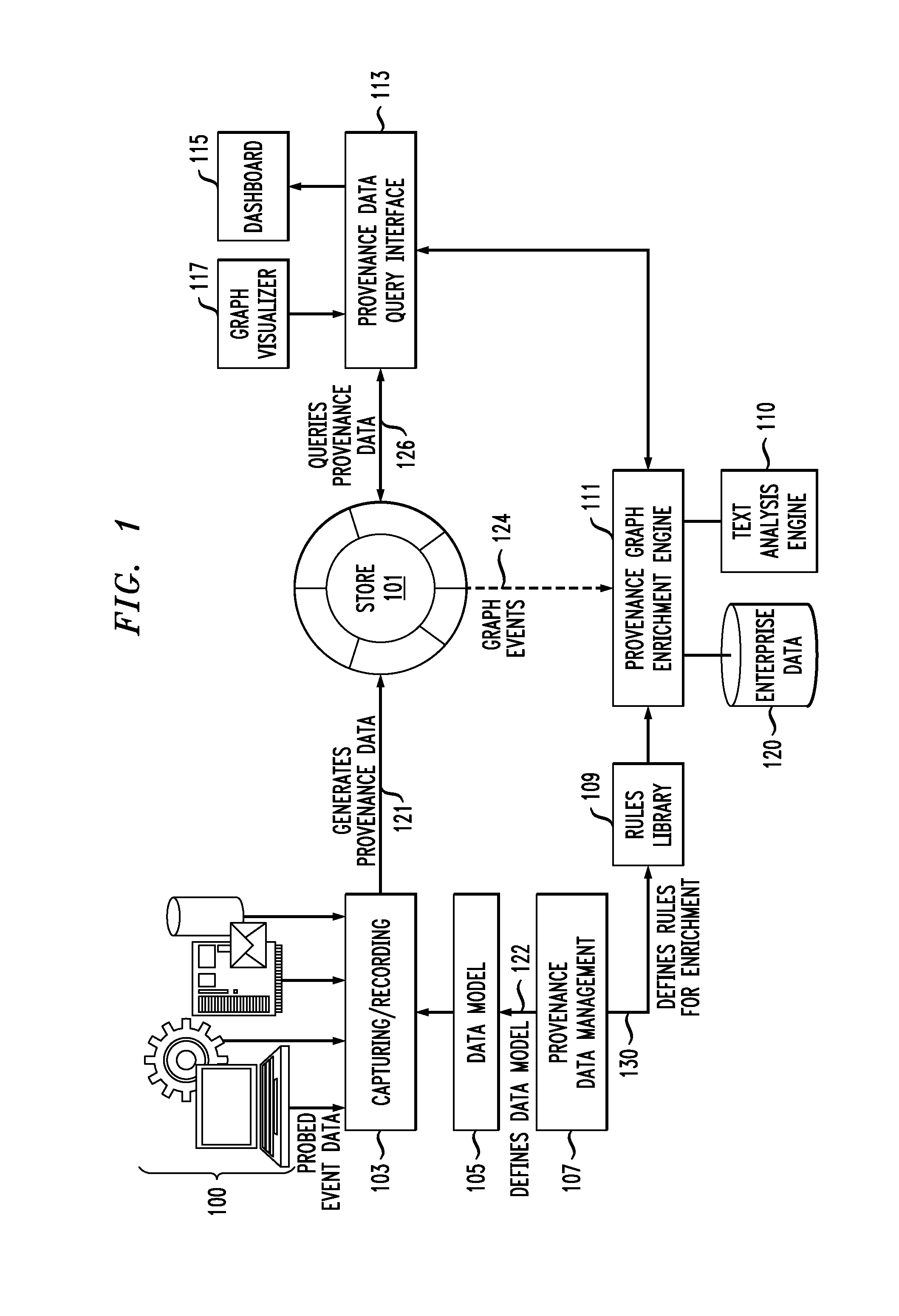

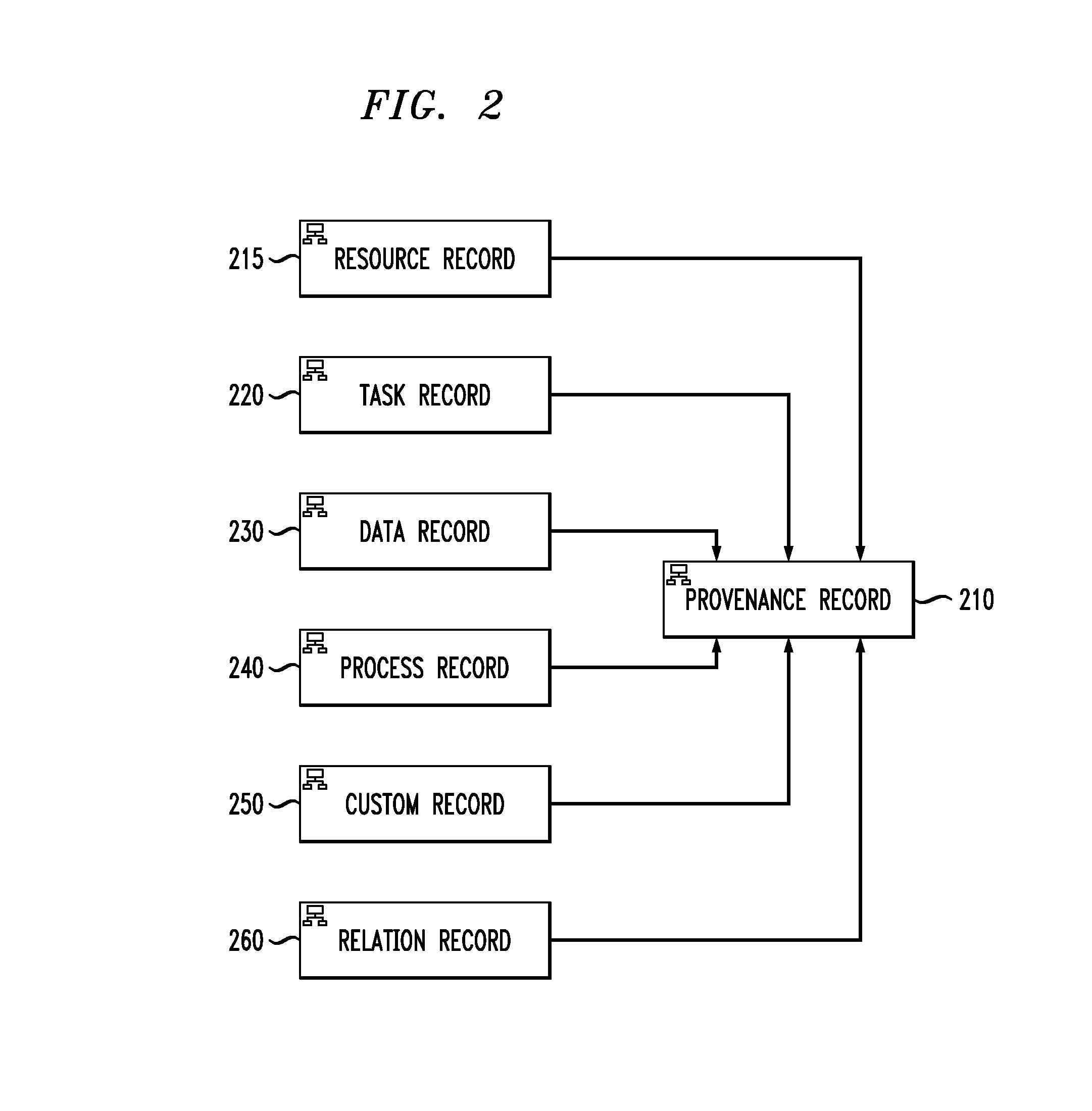

Techniques are disclosed for validating compliance with enterprise operations based on provenance data. For example, a computer-implemented method for validating that an enterprise process is in compliance with a rule comprises the following steps. Provenance data is generated, wherein the provenance data is based on collected data associated with an actual end-to-end execution of the enterprise process and is indicative of a lineage of one or more data items. A provenance graph is generated that provides a visual representation of the generated provenance data, wherein nodes of the graph represent records associated with the collected data and edges of the graph represent relations between the records. A correlation is generated between one or more entities in the rule and one or more record types in the provenance data. One or more control points are generated in accordance with the generated correlation. A validation is performed as to whether the enterprise process is in compliance with the rule using the one or more control points.

Owner:IBM CORP

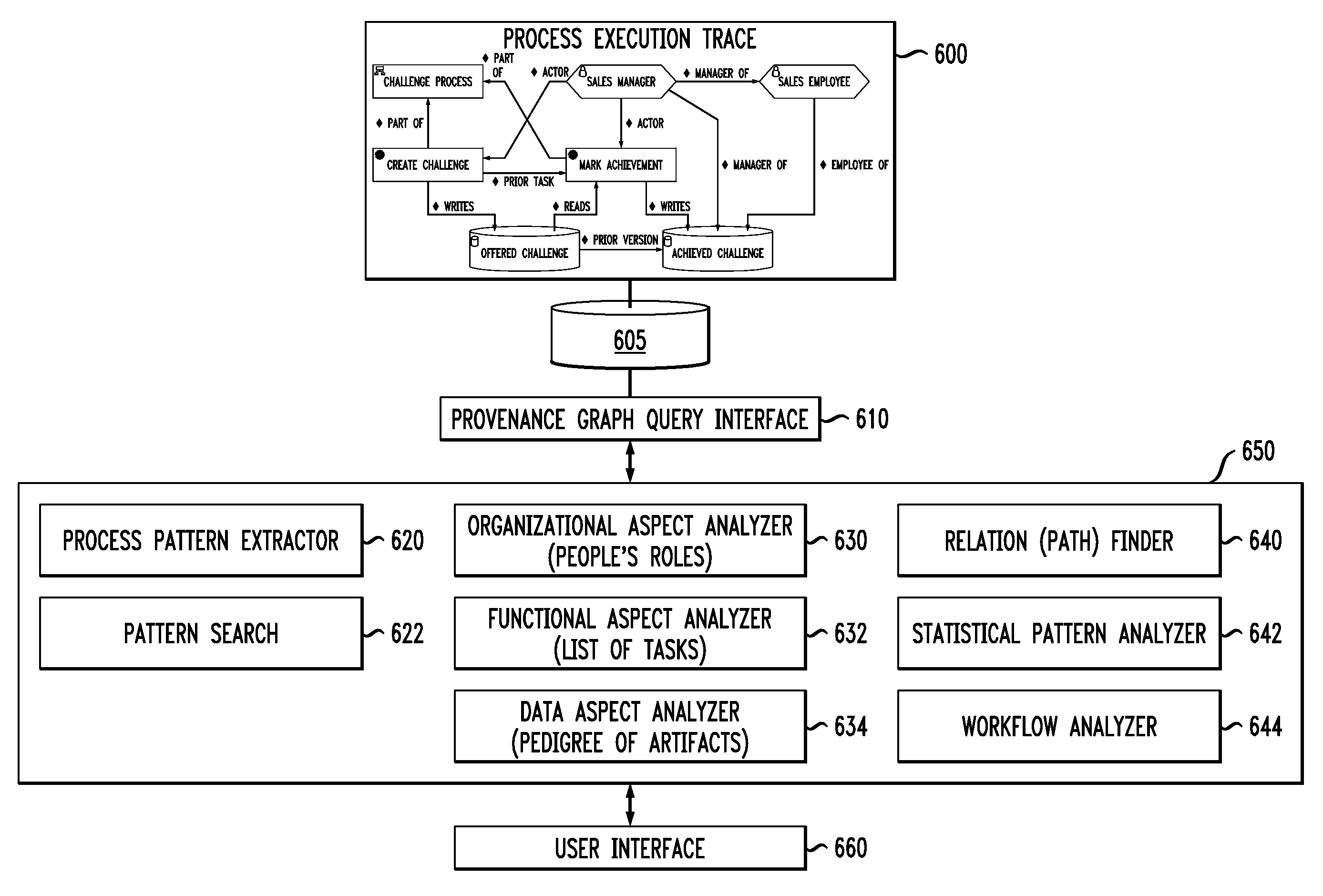

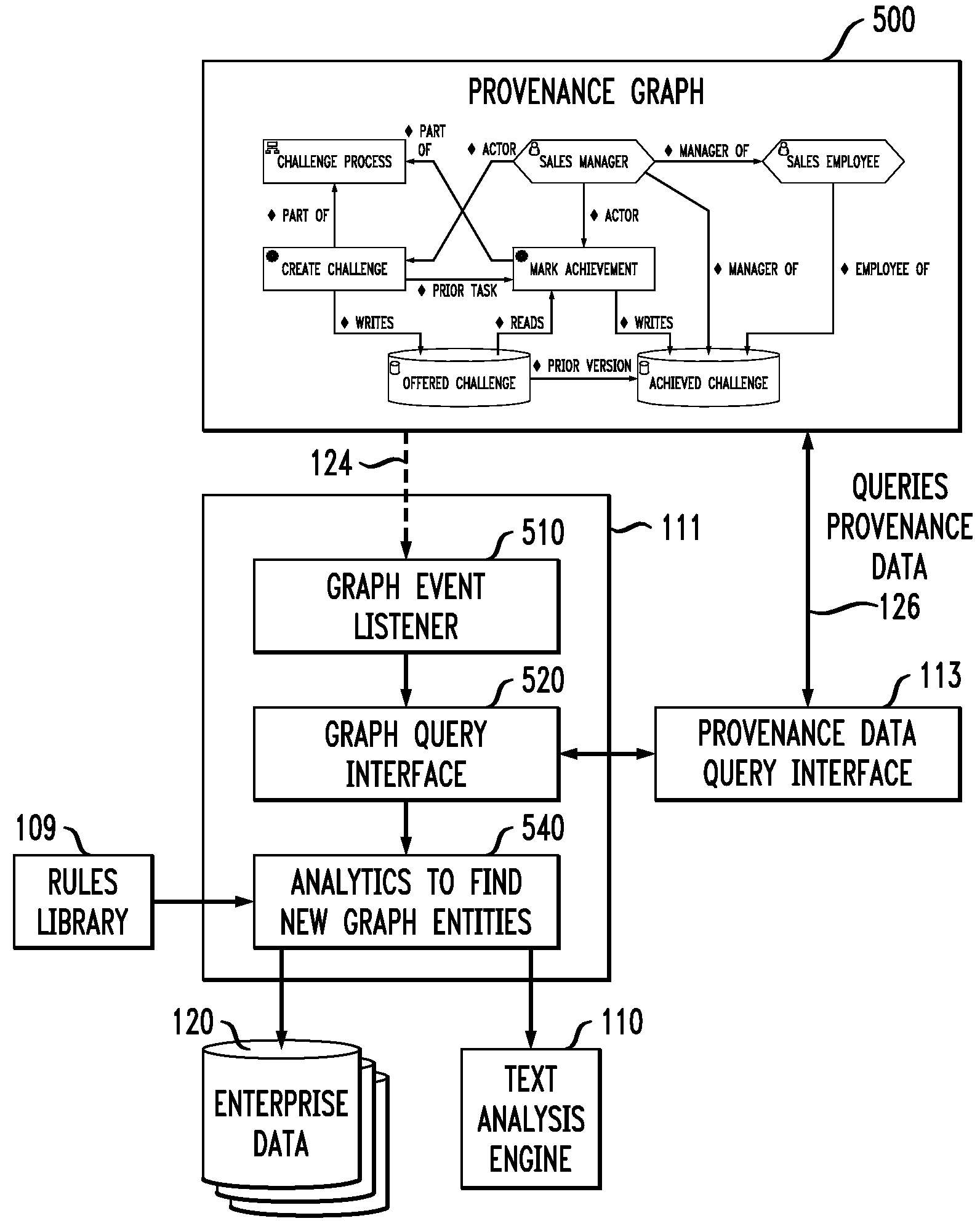

Extracting Enterprise Information Through Analysis of Provenance Data

Techniques are disclosed for extracting information through analysis of provenance data. For example, a computer-implemented method of extracting information regarding an execution of an enterprise process comprises the following steps. Provenance data is generated, wherein the provenance data is based on collected data associated with an actual end-to-end execution of the enterprise process and is indicative of a lineage of one or more data items. A provenance graph is generated that provides a visual representation of the generated provenance data, wherein nodes of the graph represent records associated with the collected data and edges of the graph represent relations between the records. At least a portion of the generated provenance data from the graph is analyzed so as to extract information about the execution of the enterprise process based on the analysis.

Owner:IBM CORP

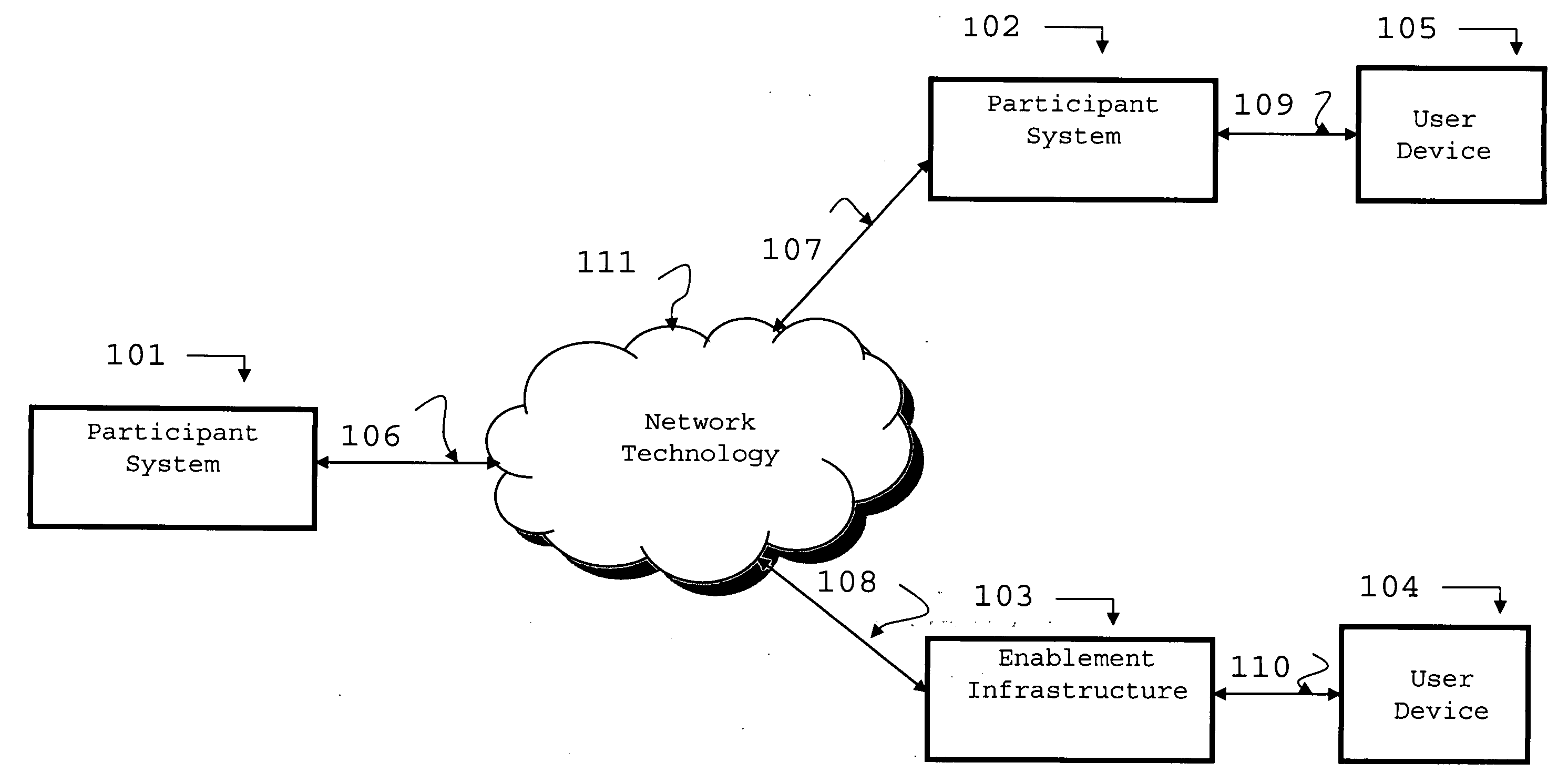

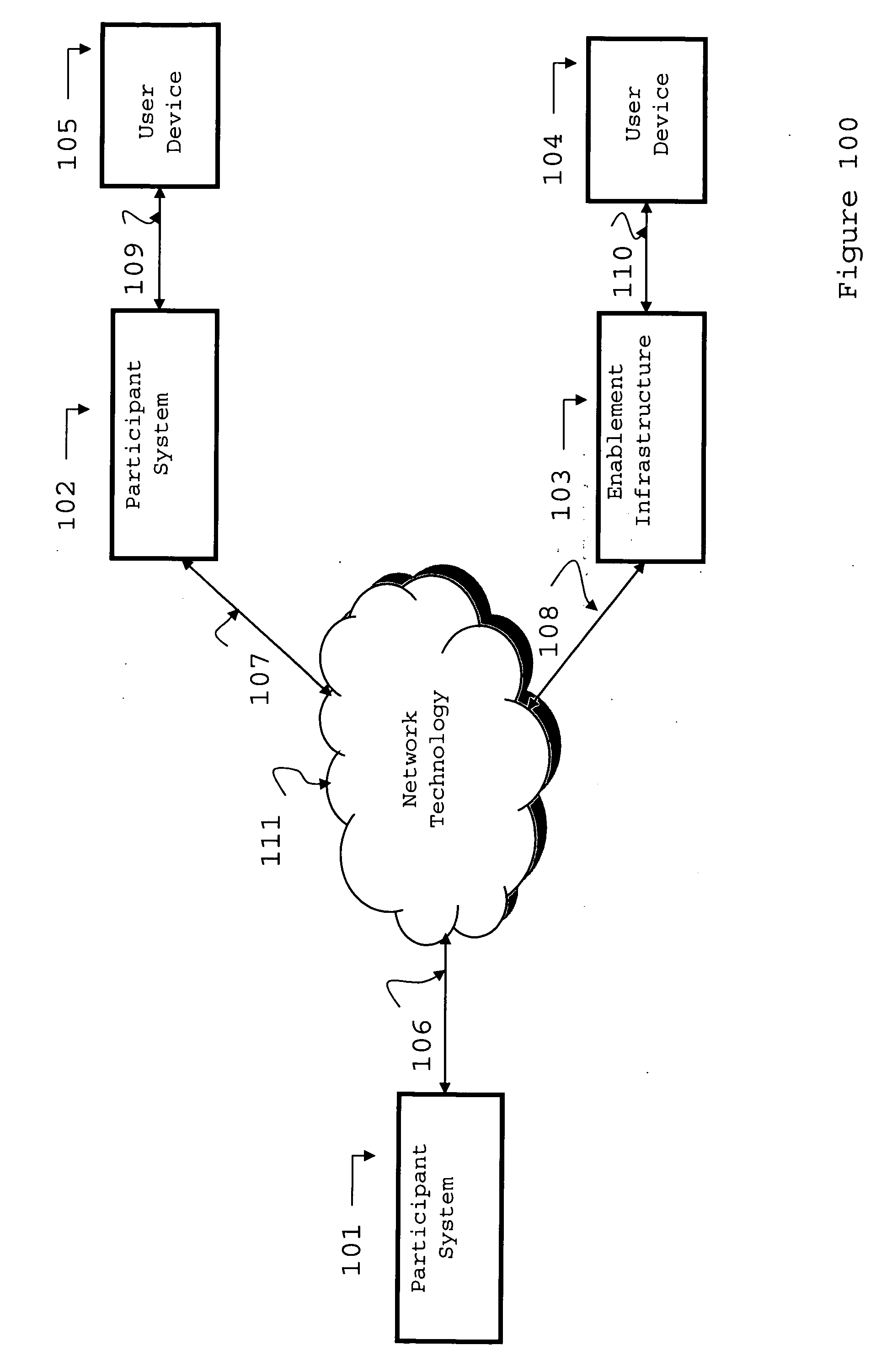

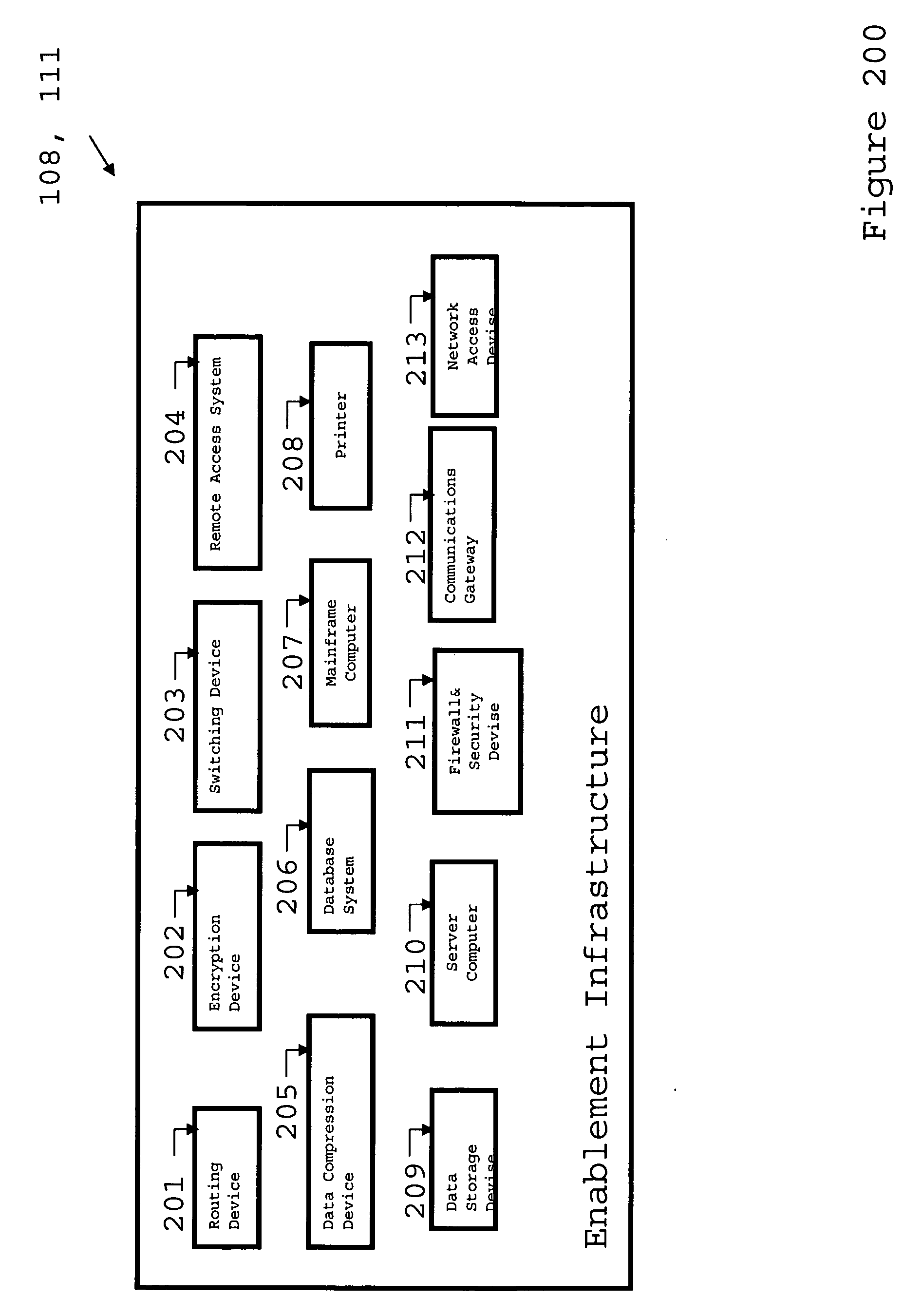

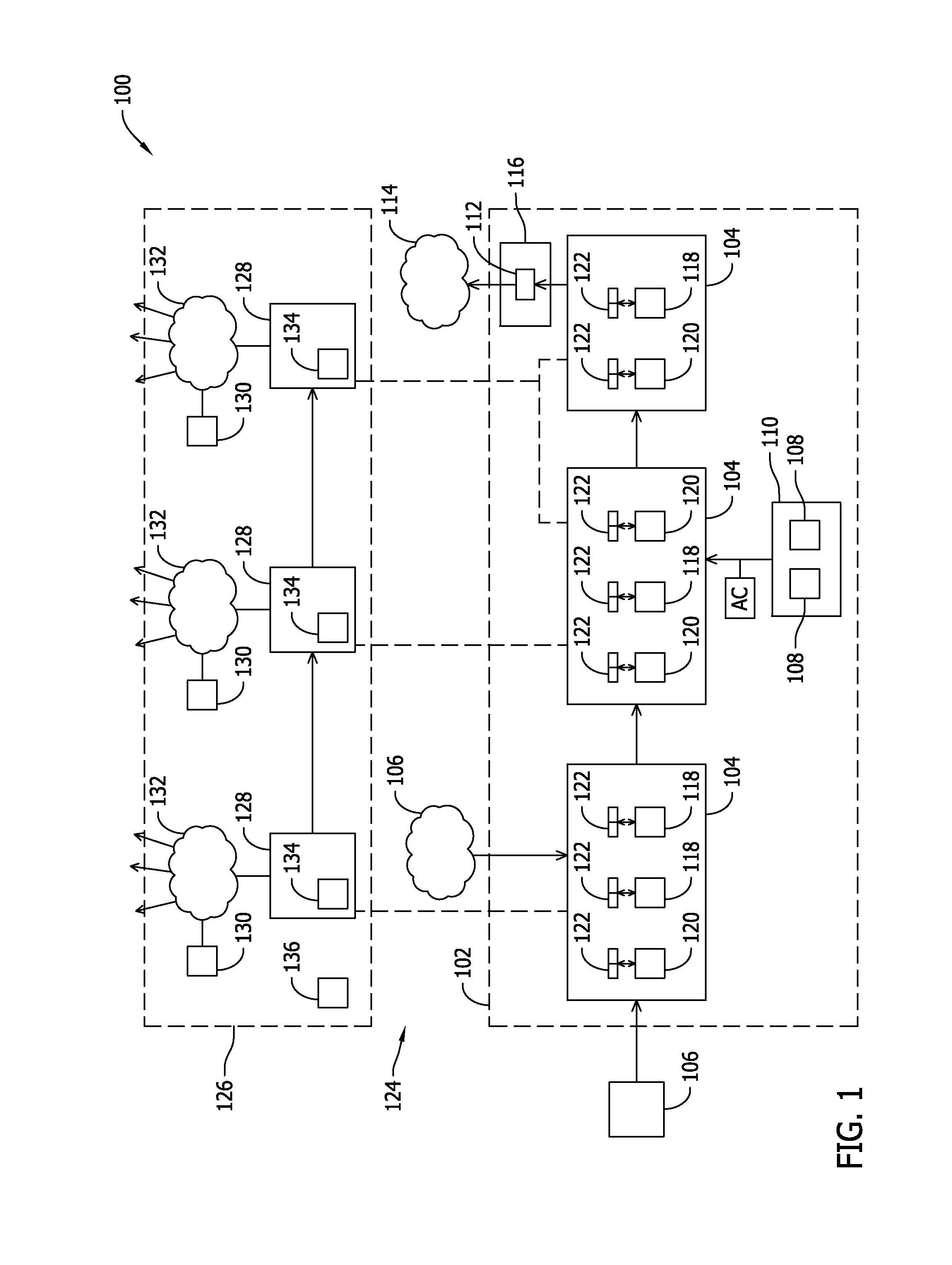

System for seamless enablement of compound enterprise-processes

This invention relates to activities pertaining to life-cycle-stages of enterprise-processes, whether implemented within the boundary of a single organization or spanning several organizational boundaries. In particular it relates to (1) establishing a community of participant-systems and a schema to create collaborative capabilities (2) establishing a combination of one or more methods and one or more technologies to impart seamlessness to the end-to-end flow of information and content related to the life-cycle stages of the process, (3) establishing end-to-end visibility to key parameters and (4) establishing ways to control the course and speed of activities associated with one or more life-cycle stages.

Owner:PULIANDA ARUNKUMAR GANAPATHI

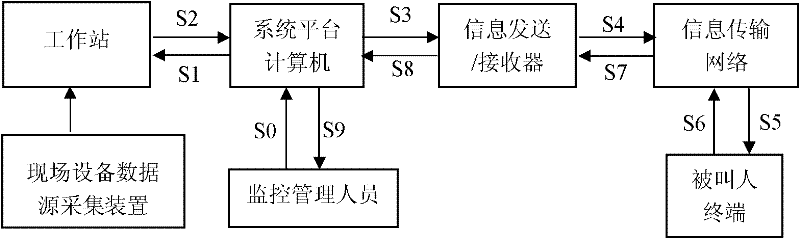

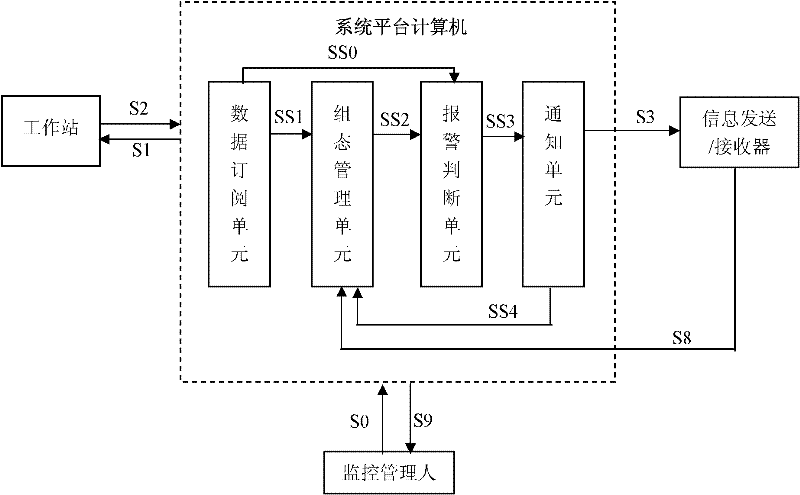

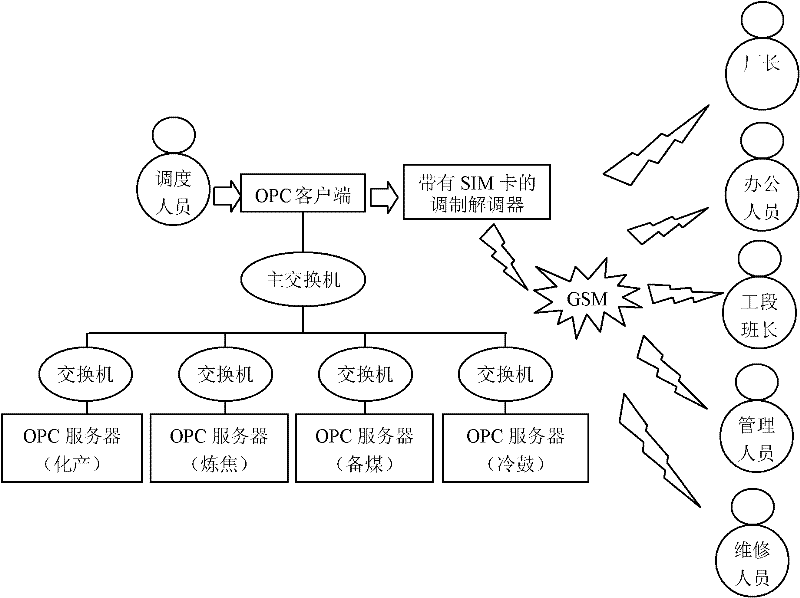

Real-time alarm system for industrial enterprise and method thereof

ActiveCN102200769AImprove understandingKeep abreast ofTotal factory controlProgramme total factory controlInformation transmissionEnterprise process

The invention provides a real-time alarm system for industrial enterprise and a method thereof. The system comprises work stations, a system platform computer, an information transmitter-receiver, an information transmission network, and a called terminal. According to the invention, technical methods such as industrial data communication and mobile phone short message sending are used to carry out real-time monitoring of industrial enterprise process data, send alarm information in real time and realize the real-time alarm function for industrial enterprise.

Owner:中广核智能科技(深圳)有限责任公司

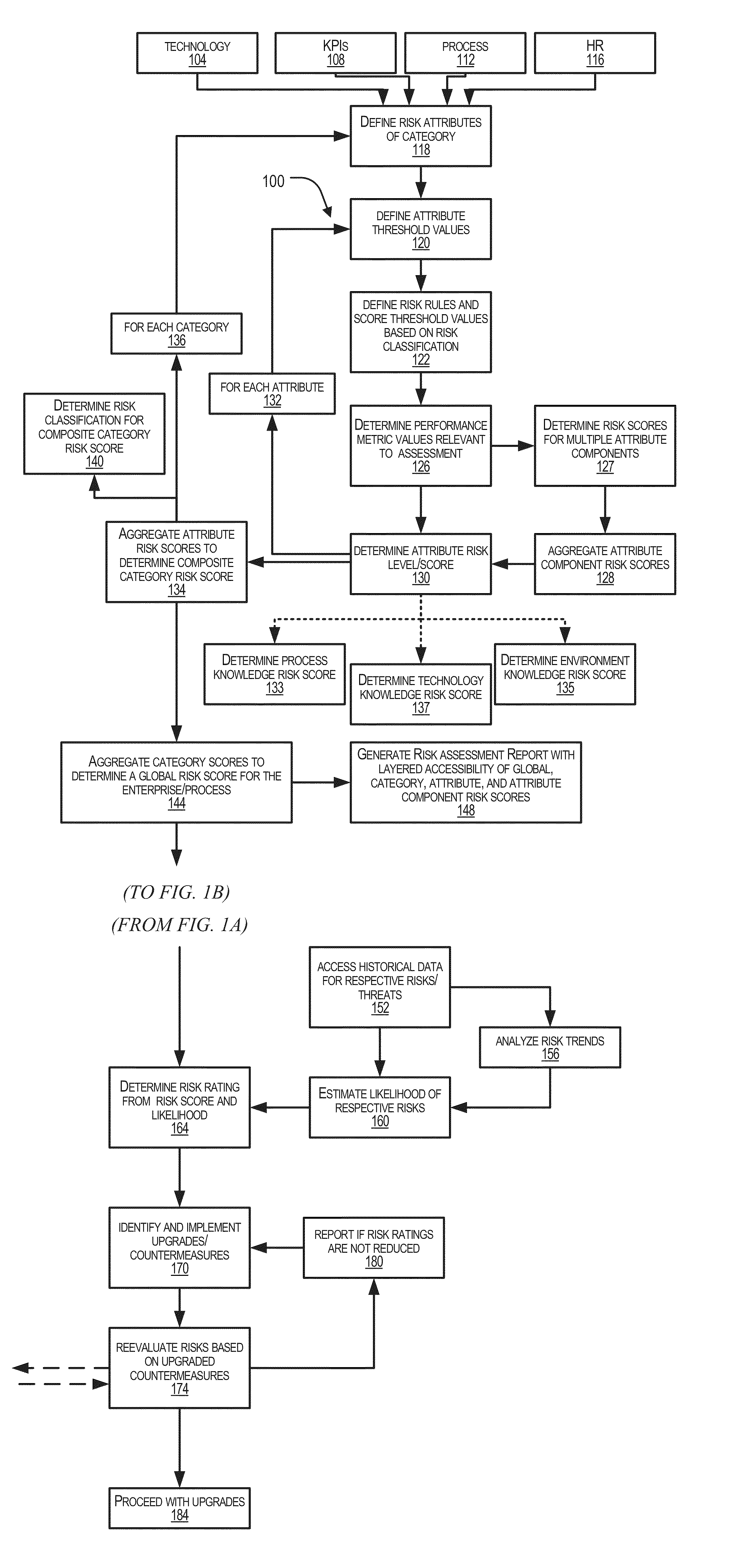

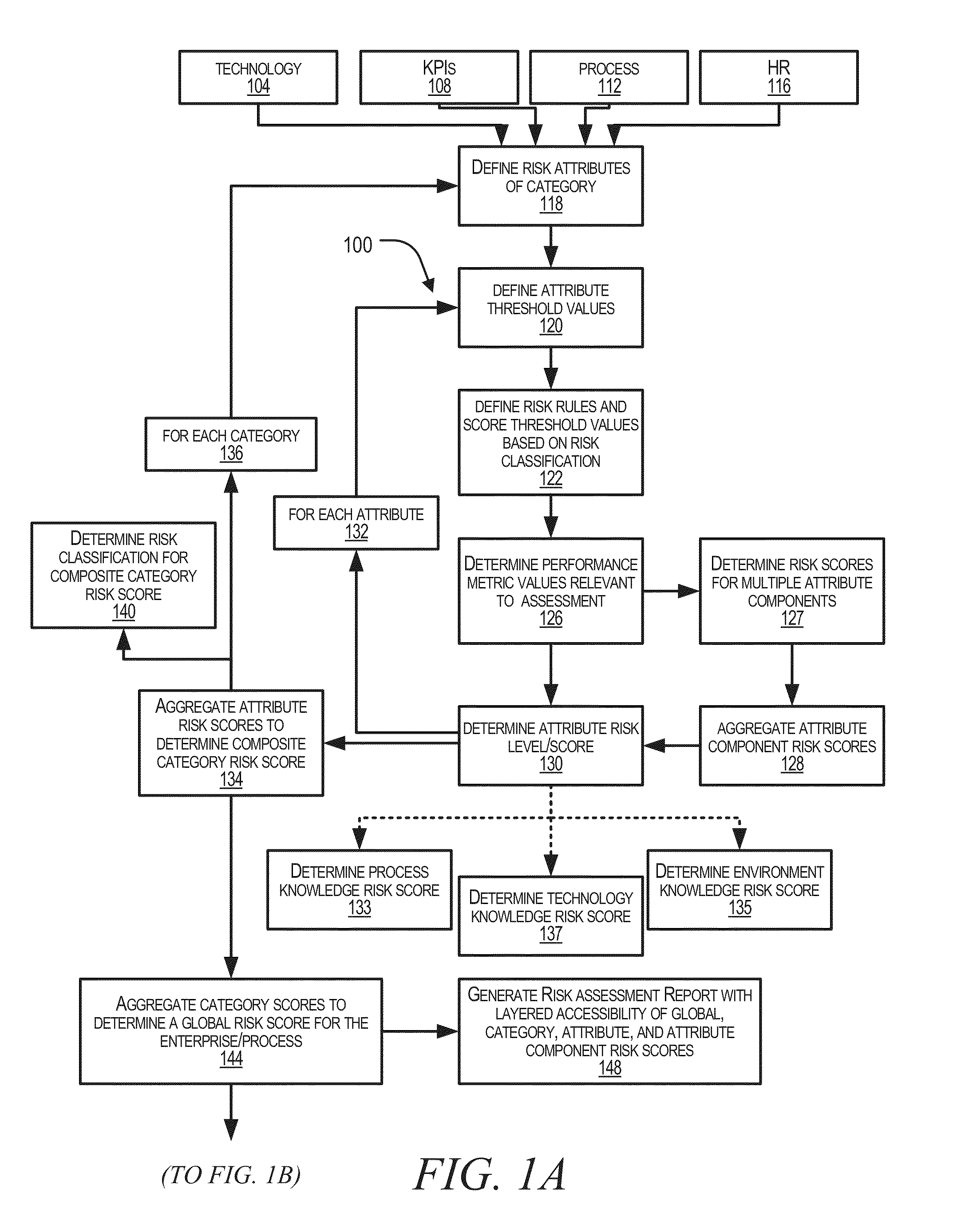

Risk management methods and systems for enterprise processes

Methods and systems are provided to manage risk in an enterprise process by performing quantitative risk assessment for a plurality of enterprise resource categories, including a human resource category, that contribute to performance of the process. A plurality of risk values for the respective resource categories are thus determined. Risk assessment is performed based on a comparative analysis of the respective resource category risk values. Quantitative risk assessment for the human resource category comprises calculating an assessed knowledge metric value that indicates measured knowledge of people that contribute to the process, and quantifying a knowledge risk by correlating the assessed knowledge metric value with predefined knowledge metric thresholds.

Owner:HCL AMERICA INC

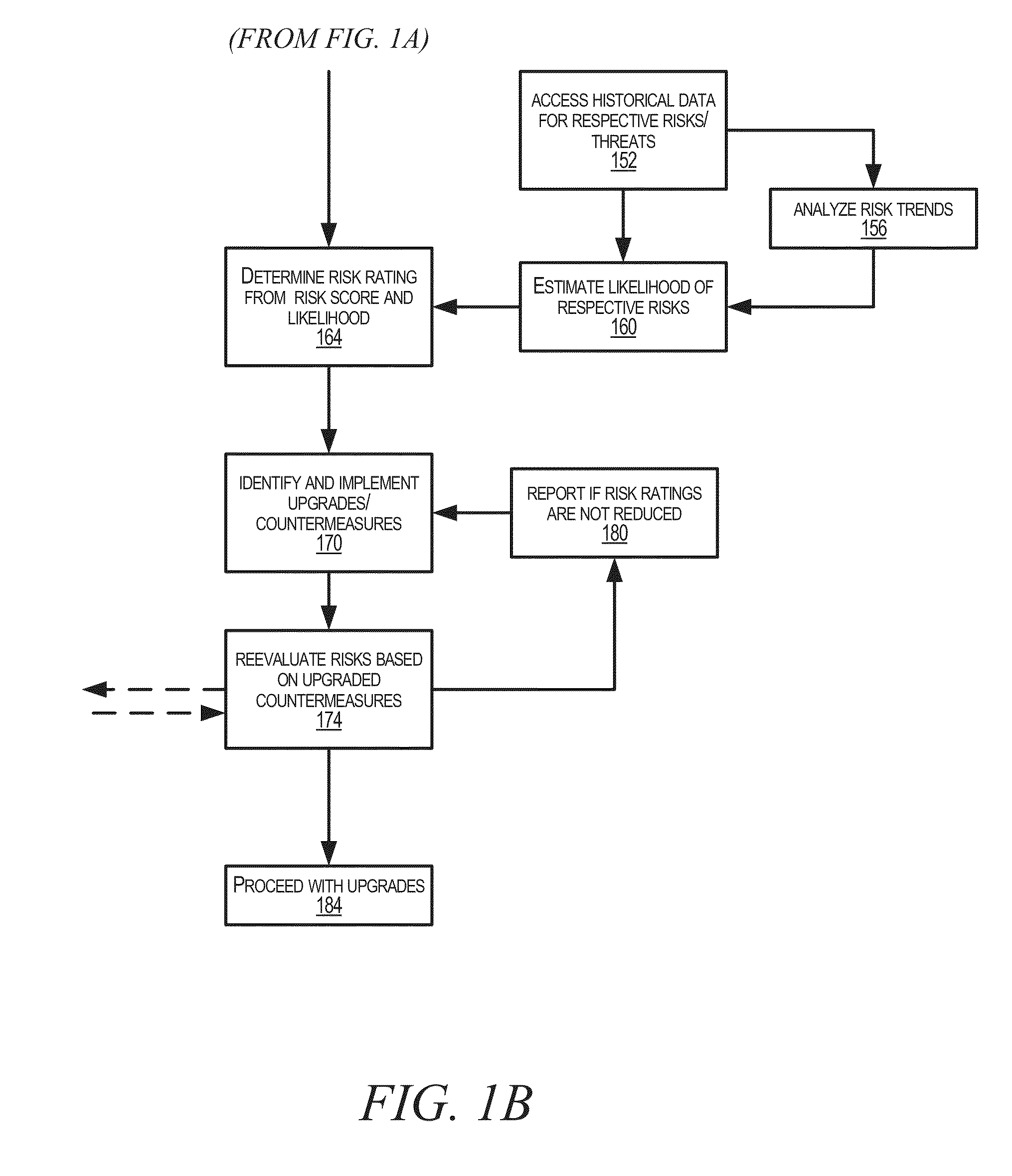

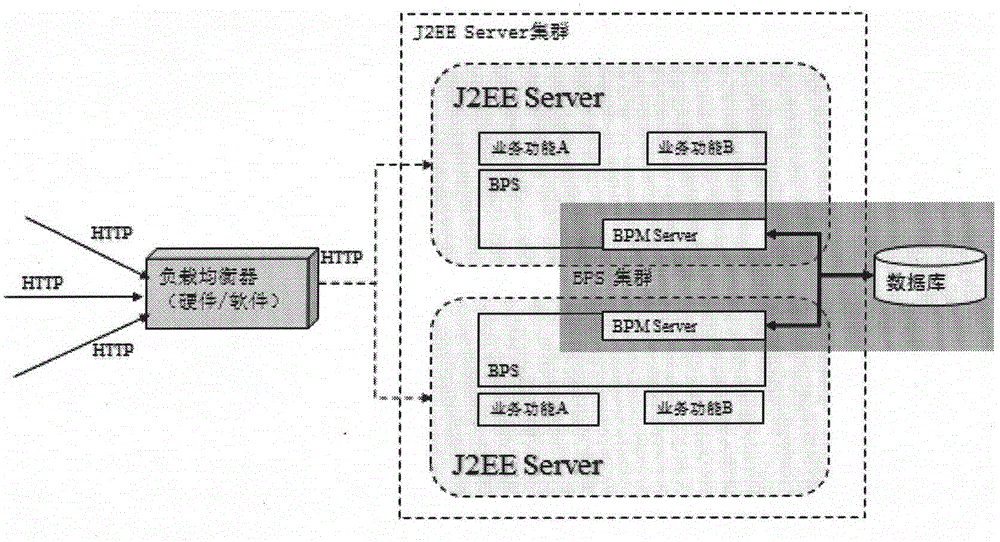

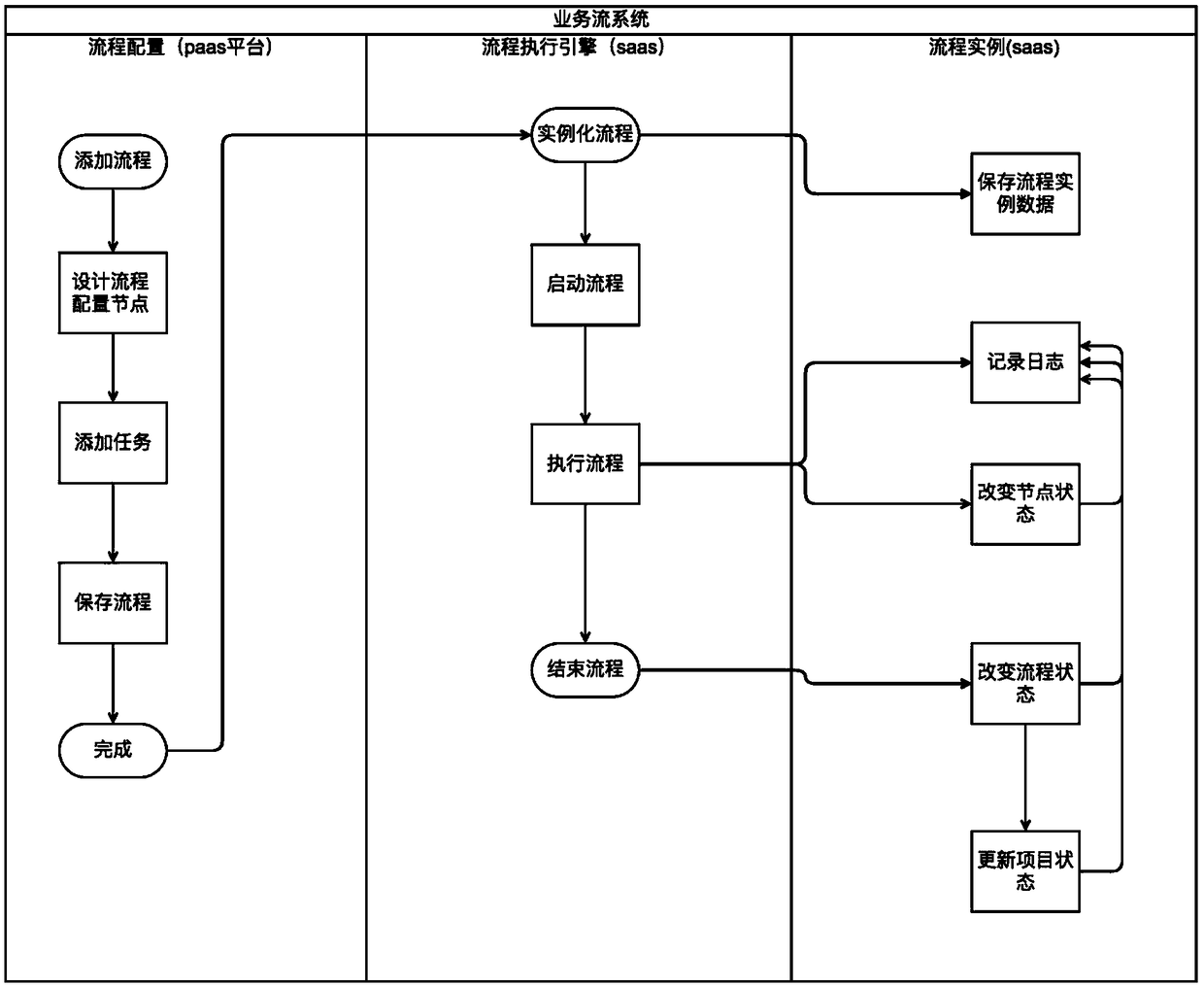

Method for monitoring process flow across business system

The invention discloses a method for monitoring the flow of a cross-business system, firslyt, BPM allocates a unique enterprise flow real example number for each flow when beginning the flow, wherein, the number is reserved constantly for transmission during the process of flow transfer; a business flow system provides a public service interface for receiving the flow processing information to a business flow monitoring database. At the same time of processing a business node, each business system transmits business data to business flow monitoring service and submits the information about flow node treatment; a business flow monitoring platform classifies and reconstructs the flows according to the unique flow real example number allocated by the BPM, thus acquiring the flowing status and the business information for the cross-business system flow. The invention can assure good stability for the enterprise information integral infrastructure and have brilliant expandability.

Owner:JIANGSU ELECTRIC POWER CO

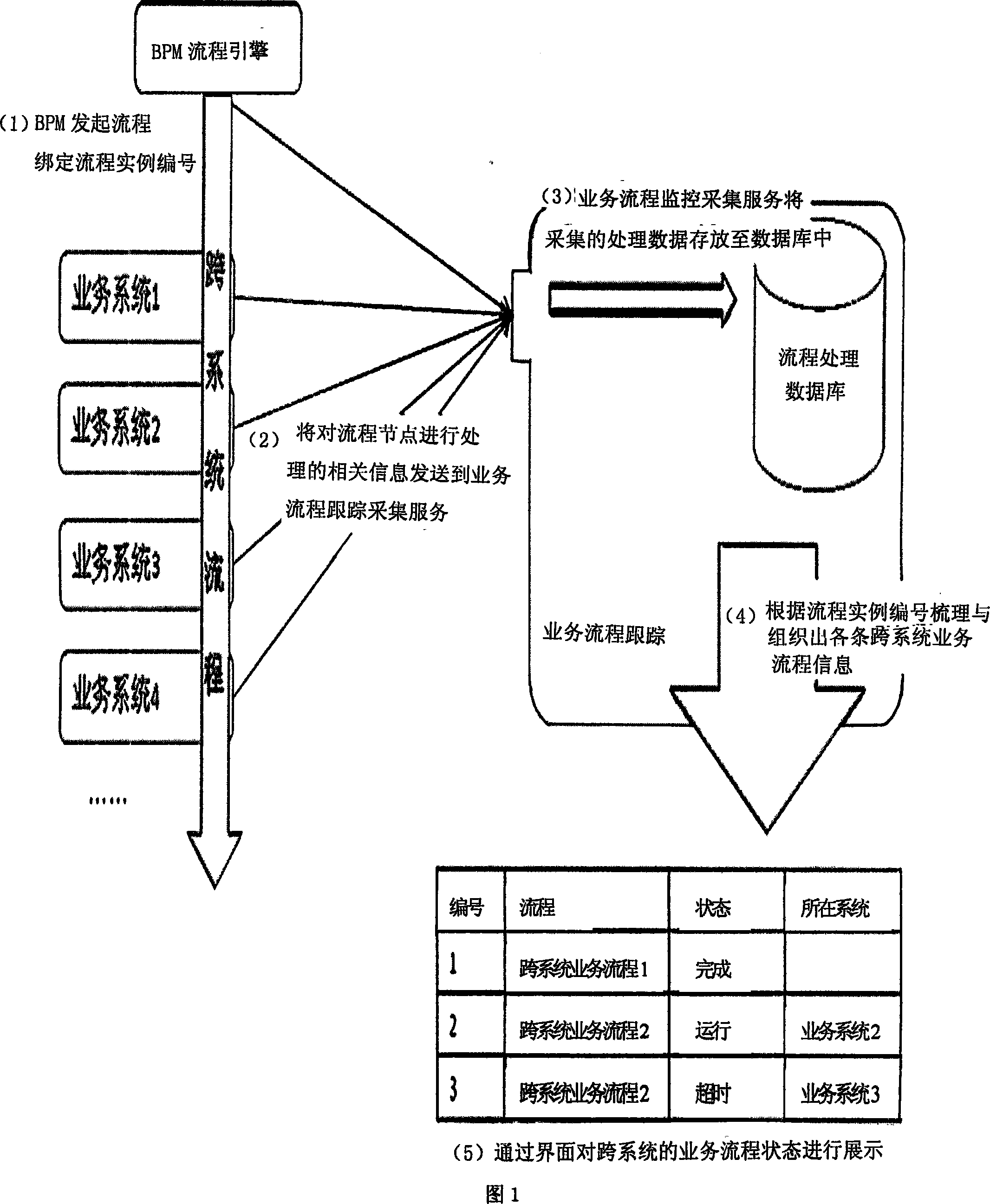

Fusion-based multiple-system process centralized processing method

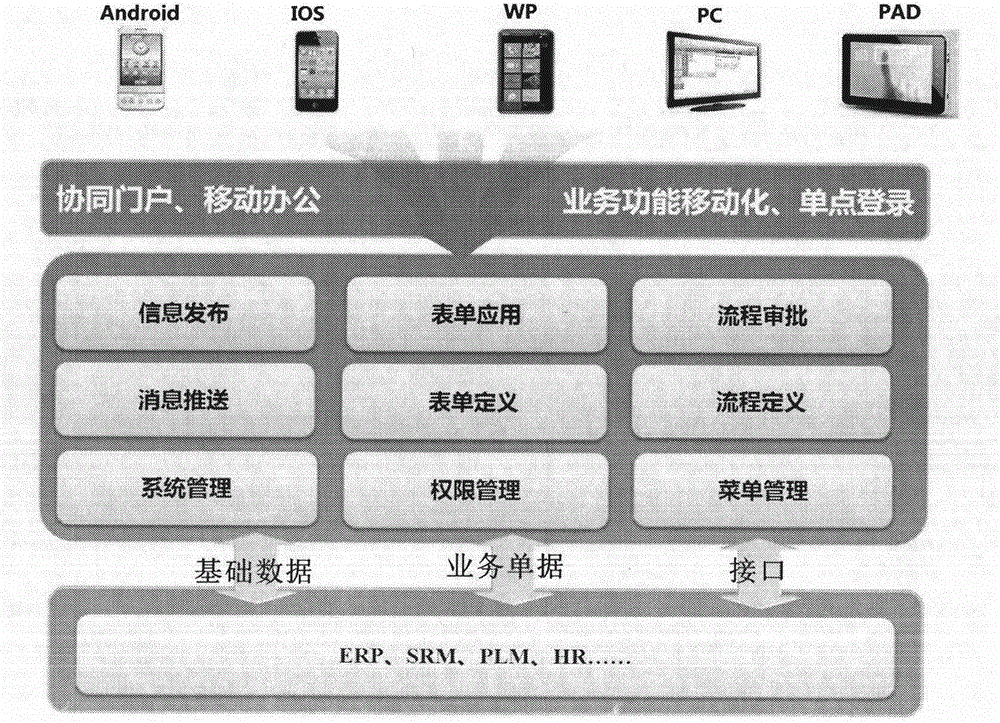

InactiveCN105335821ATimely processingCost reduction needsOffice automationResourcesEnterprise processComputer terminal

The invention discloses a fusion-based multiple-system process centralized processing method. The method includes the following steps that: S1, based on a Primeton BPS (business process suite) process engine and a FlEX technology, a task list is designed on a business process management platform; S2, business processes are designed through a visual process designer; S3, the task list is examined through a list engine composed of an Excel-like visual list designer and an application interface according to the business processes; and S4, various kinds of system data and completed task list results can be displayed to a user through a mobile terminal and by means of a report engine, and reports can be checked dynamically, and process examination businesses can be processed timely. With the fusion-based multiple-system process centralized processing method of the invention adopted, urgent needs for enterprise business process management and resource integration can be satisfied, and therefore, the complexity of the operation of the user can be reduced, and information can be timely transmitted, and office efficiency can be improved, and business needs can be fast responded, and enterprise operation and maintenance costs can be reduced.

Owner:GUANGZHOU SIE CONSULTING CO LTD

Influencing Behavior of Enterprise Operations During Process Enactment Using Provenance Data

InactiveUS20100114630A1Saves enterprises significantly against integrity lapses and penaltiesDrawing from basic elementsResourcesEnterprise processProcess behavior

Techniques are disclosed for influencing behavior of enterprise operations during process enactment using provenance data. For example, a computer-implemented method of influencing a behavior of an enterprise process comprises the following steps. Provenance data is generated, wherein the provenance data is based on collected data associated with at least a partial actual execution of the enterprise process and is indicative of a lineage of one or more data items. A provenance graph is generated that provides a visual representation of the generated provenance data, wherein nodes of the graph represent records associated with the collected data and edges of the graph represent relations between the records. At least a portion of the generated provenance data from the graph is analyzed to generate an execution pattern corresponding to the at least partial actual execution of the enterprise process. The execution pattern is compared to one or more previously stored patterns. A determination is made as to whether or not to alter the enterprise process based on a result of the comparison.

Owner:SERVICENOW INC

Method and apparatus for enabling enterprise project management with service oriented resource and using a process profiling frameword

A service-oriented architecture for enterprise project management integrates business processes, human resources and project management within an enterprise or across the value chain network. A representation having direction and attributes is provided to show the dependencies between a business value layer and a project-portfolio layer, and between the project-portfolio layer and resources. The representation is mapped to a Web Services representation in UDDI, Web Services interfaces, and Web Services based business processes through rope hyper-linking.

Owner:IBM CORP

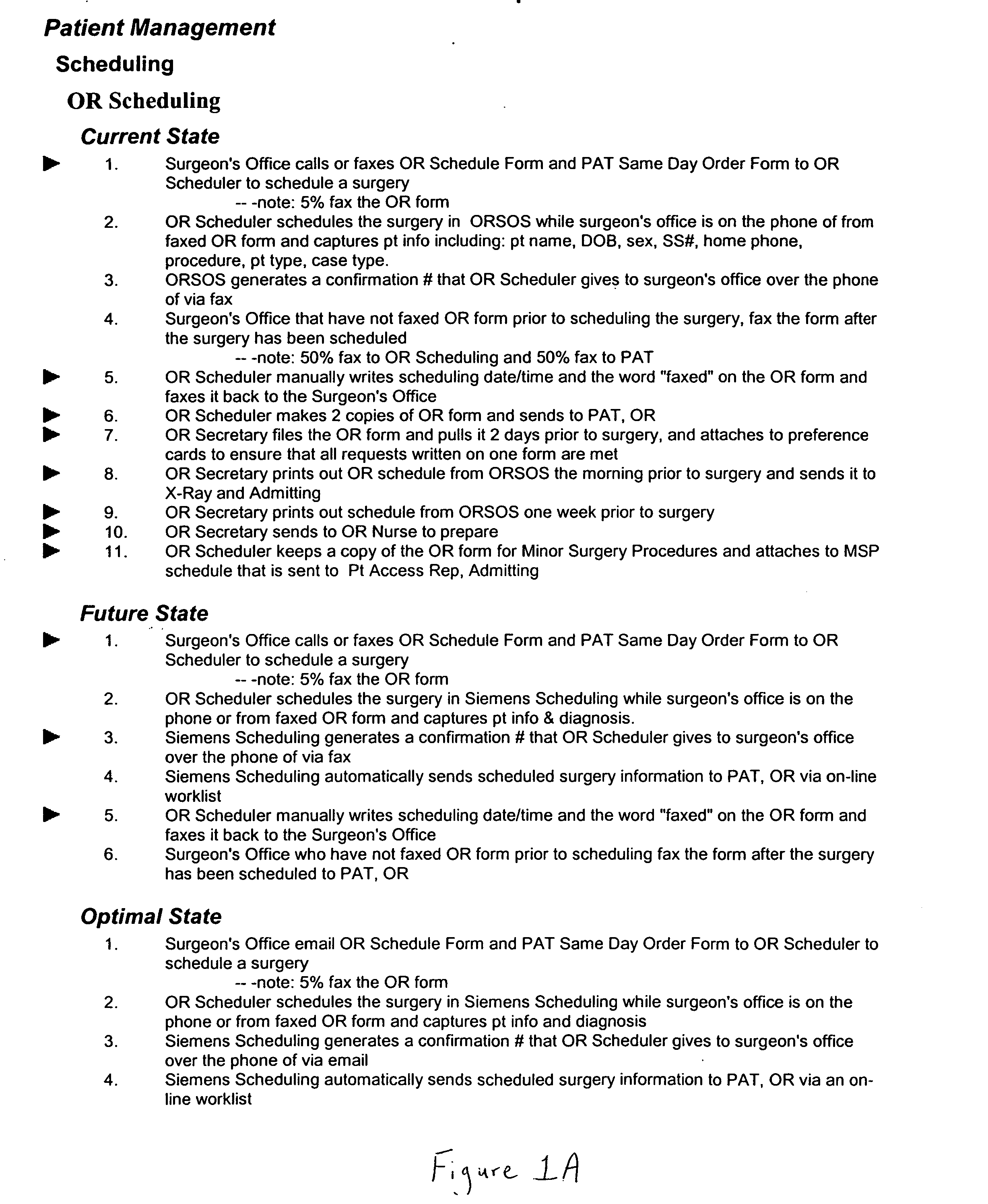

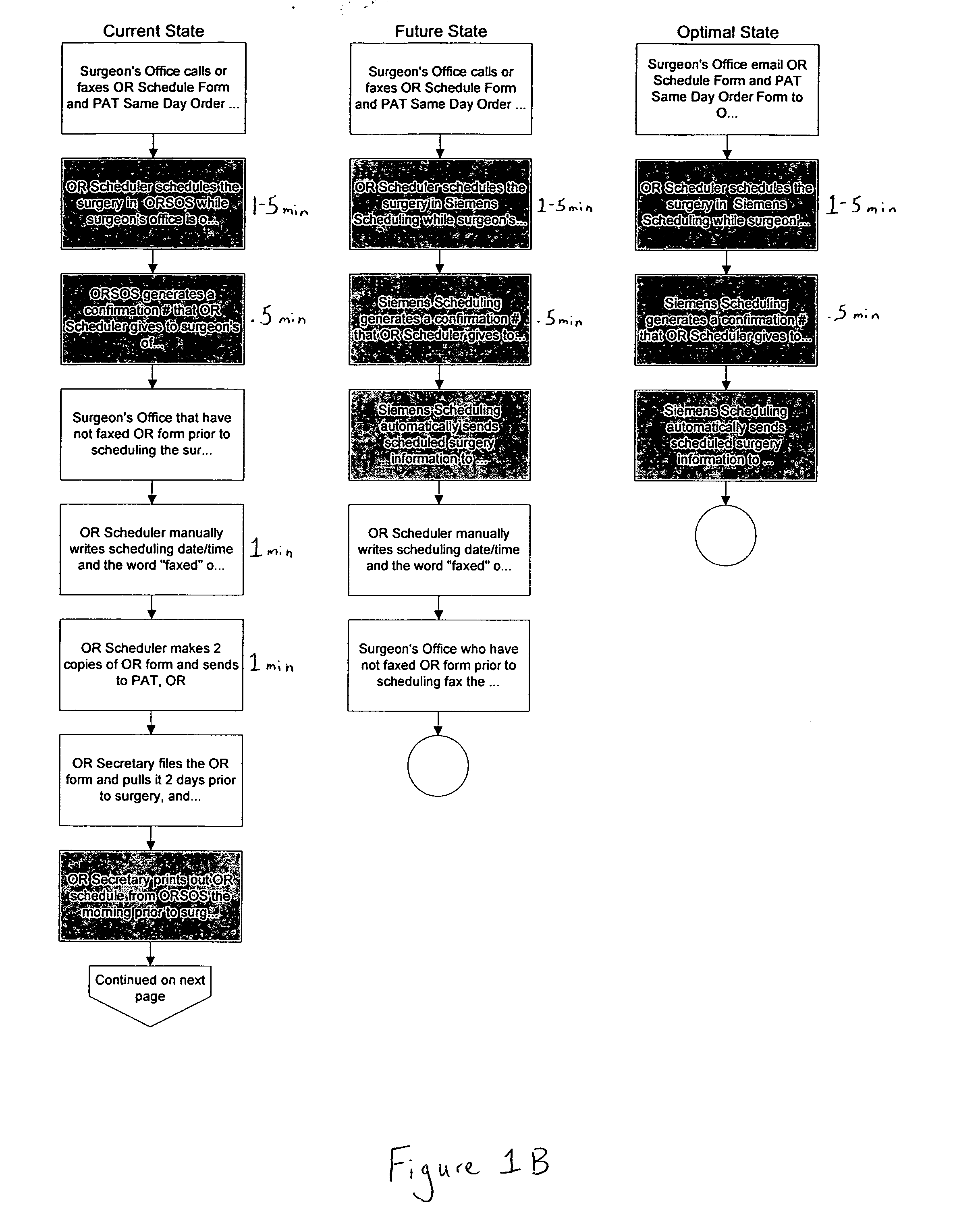

Enterprise process documentation and analysis system and method

InactiveUS20060206366A1Eliminate cumbersomeTime-consuming to eliminateCash registersResourcesDocumentation procedureEnterprise process

According to an exemplary embodiment of this invention a method of displaying a process characterized by multiple process steps is provided. The process comprises the step of displaying a first process flow representing the process in a flow chart format on a report, wherein the first process flow represents a first characterization of the process. A second process flow is displayed representing the process in a flow chart format adjacent the first process flow displayed on the report, wherein the second process flow represents a second characterization of the process that is different from the first characterization of the process.

Owner:INNOFLO

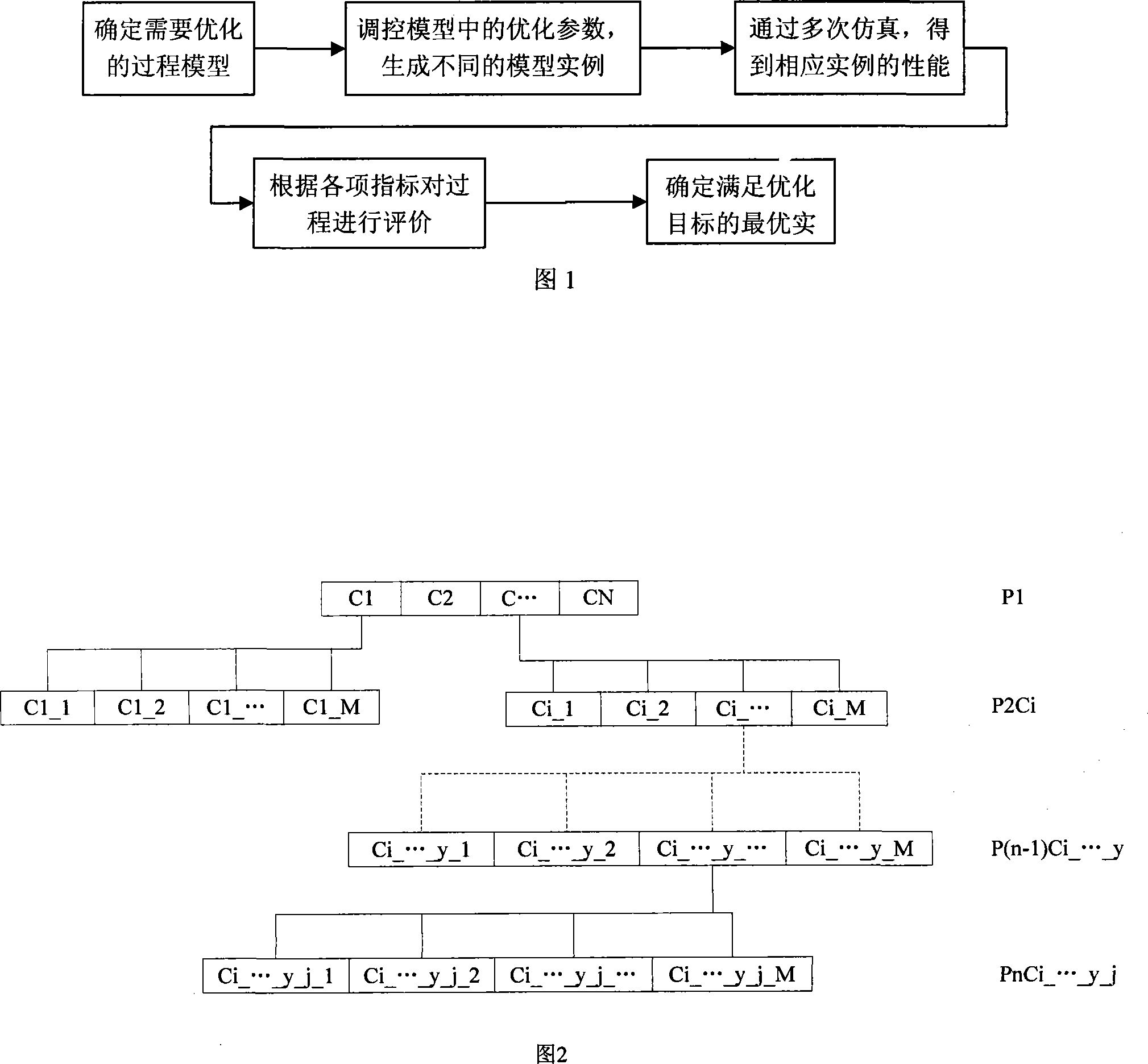

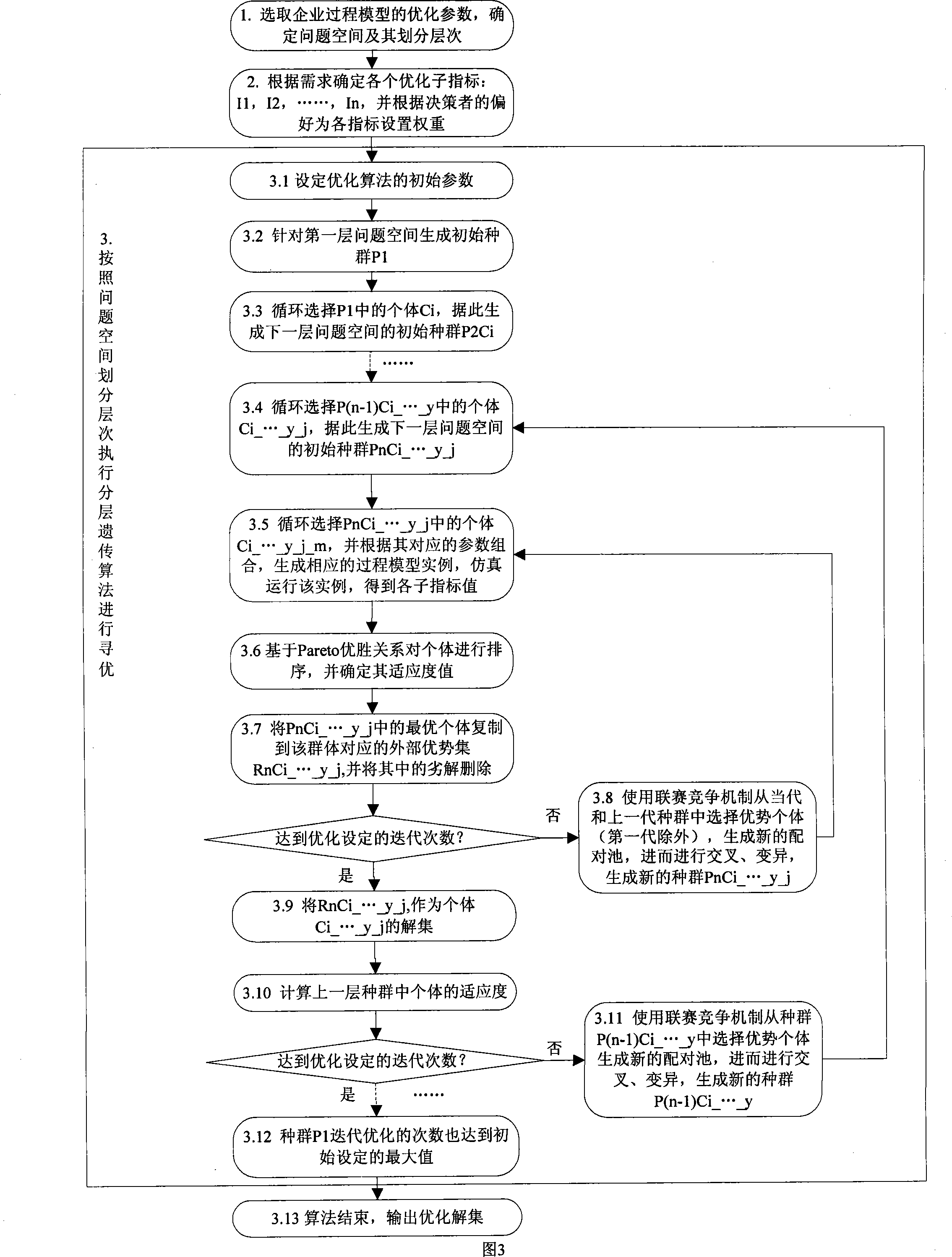

Enterprise process model multi-target parameter optimizing method based on genetic algorithm

InactiveCN101231720ADiversity guaranteedOptimal objective functionGenetic modelsOffice automationGeneration rateResource utilization

The invention relates to the enterprise engineering and the information technology field, and discloses an optimization method for the multi-objective enterprise process model parameters, which is based on the genetic algorithm. In the optimization field of the enterprise process model parameters, most optimization methods use the countermeasure weighing principle to combine each sub-goal into a single objective, so as to process an optimization objective, thus, some defects exist in the comprehensive evaluation process. Aiming mainly at various optimal parameters, such as the production rate of the product, the quantities of various resources, the persistent time of each activity and the configuration schemes for the required resources, as well as the scheduling strategies for the selectable resources, the invention comprehensively evaluates a plurality of indexes, such as the running time, the running cost, the final product quality, the utilization rate of the product, the queue length, etc. The invention adopts the method which divides the problem space in a multi-layer way to process the combinatorial constraint relationship among the various optimal parameters, thereby increasing the flexibility of the optimization parameter selection, and avoiding the analysis calculation to the ineffective parameter combination scheme, furthermore facilitating the maintenance of the group diversity.

Owner:BEIHANG UNIV

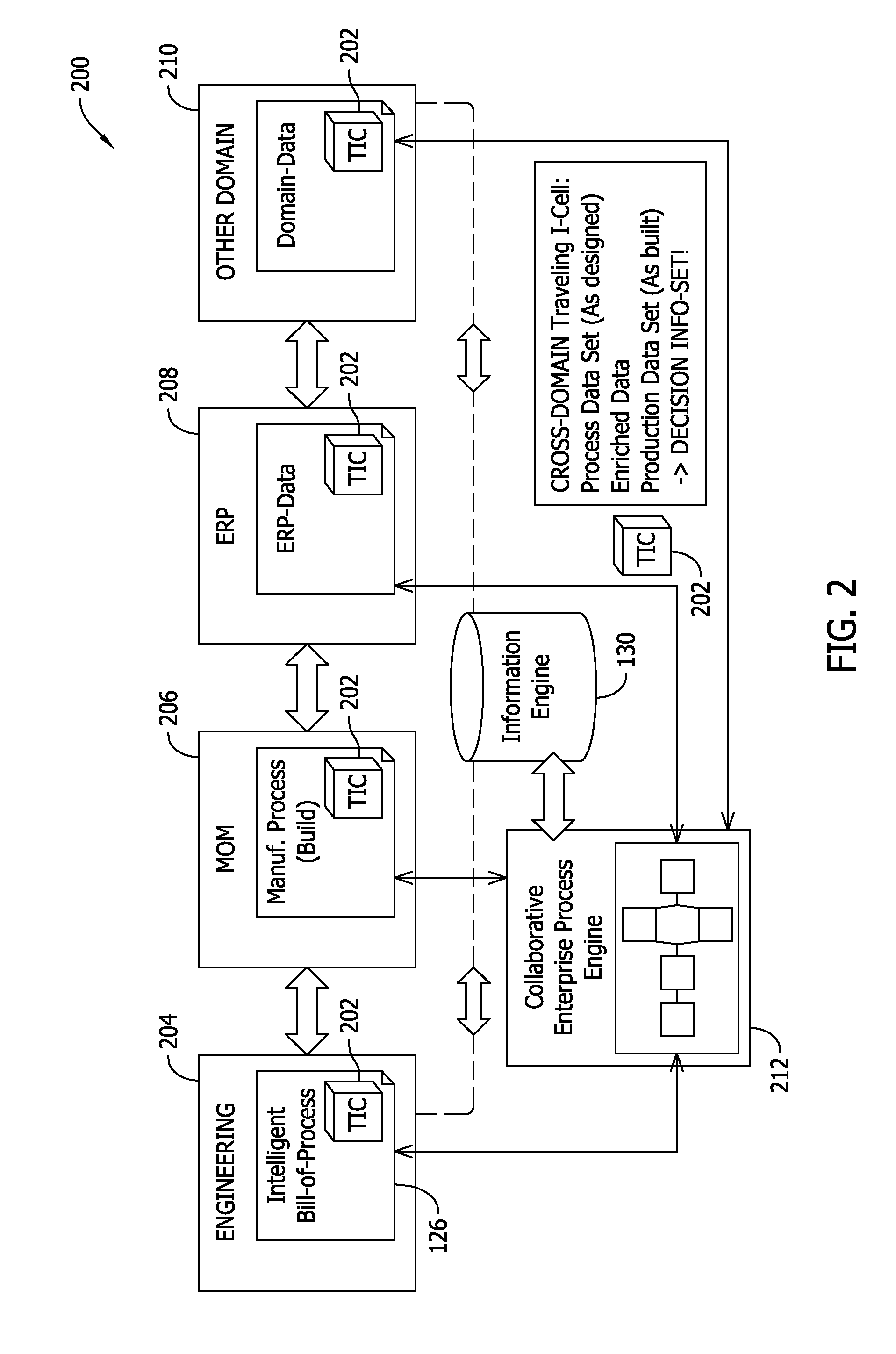

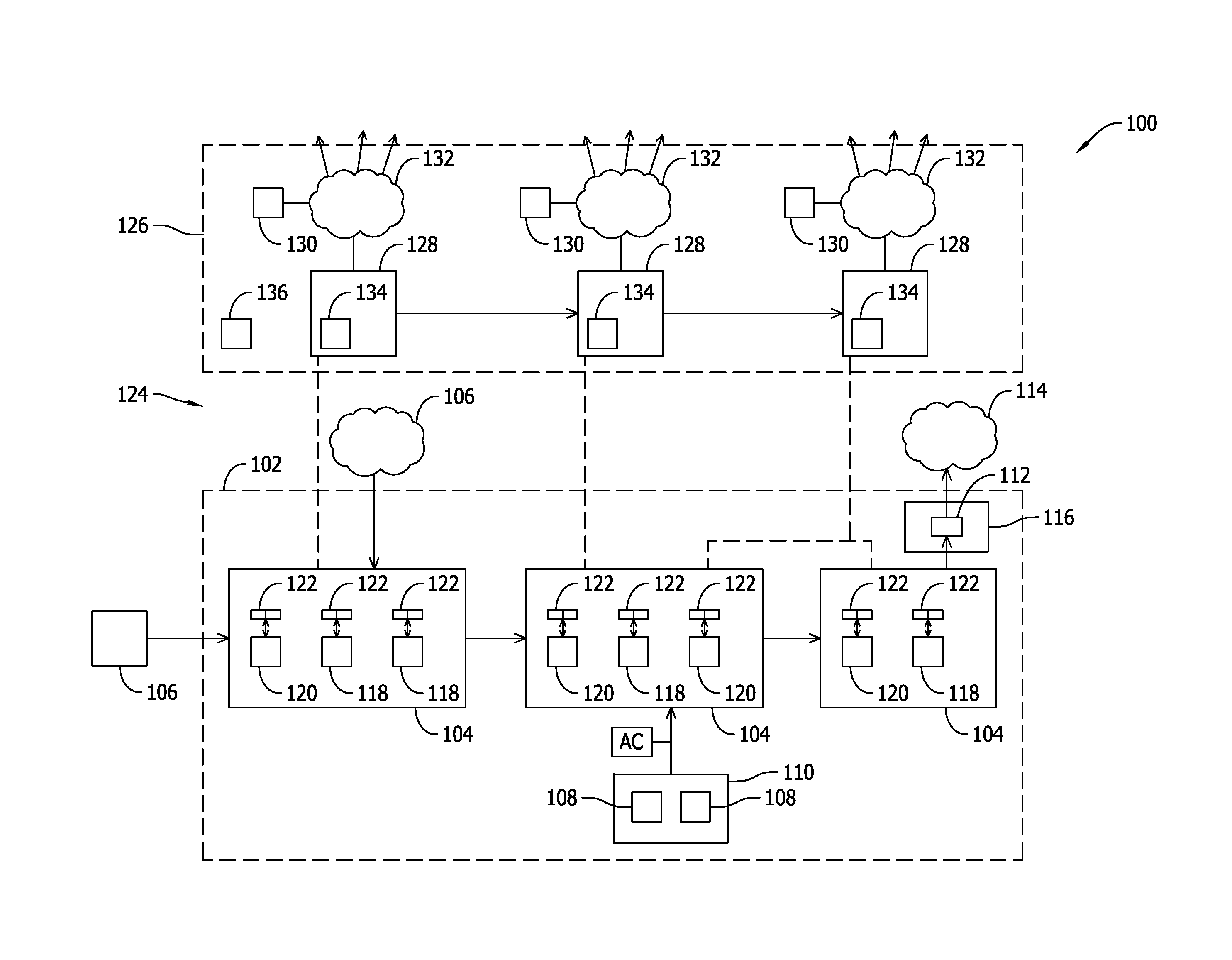

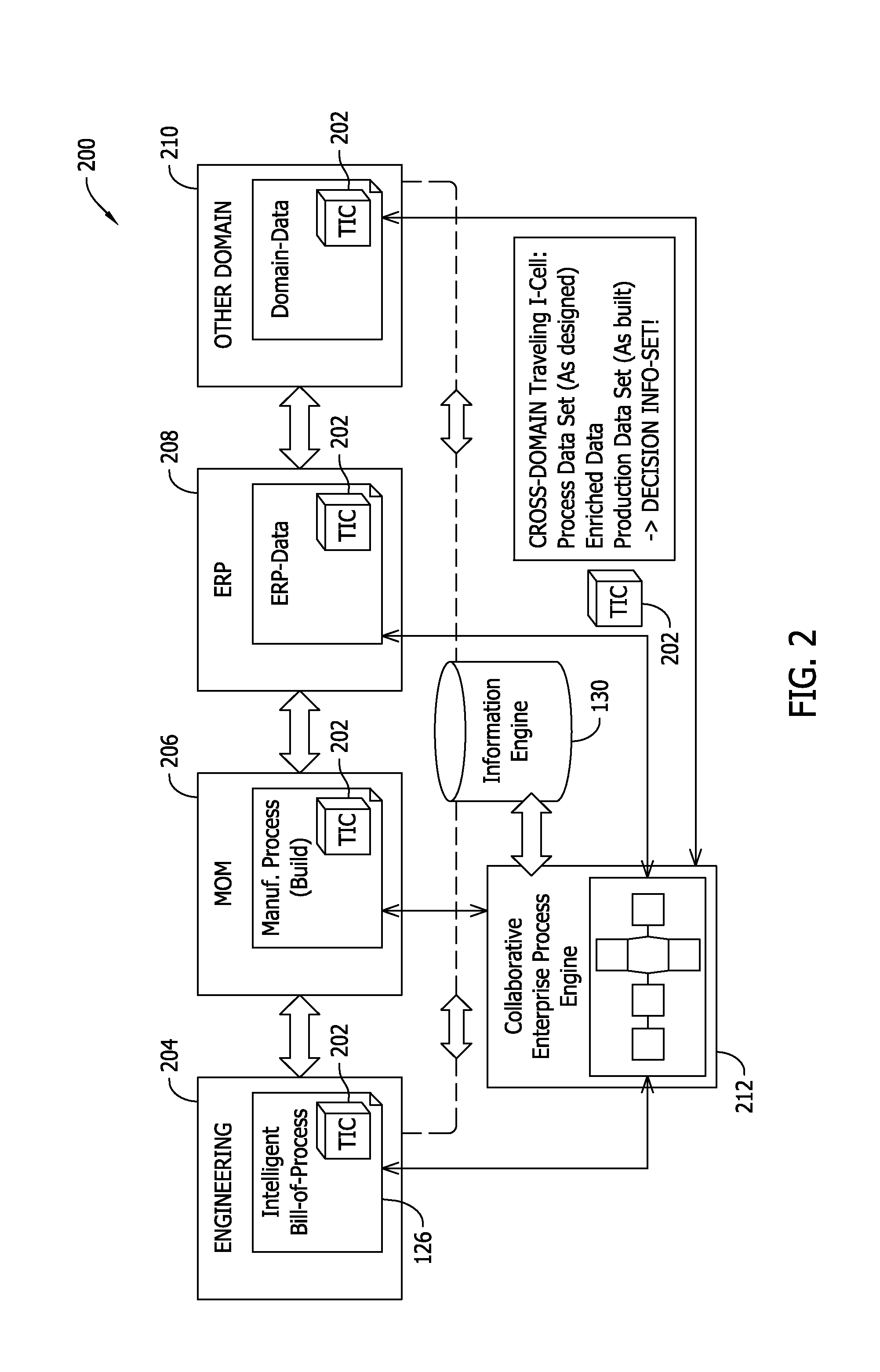

Method and system for an information engine for analytics and decision-making

A method and a system for a management decision-making facilitator within an enterprise are provided. The method includes storing a plurality of predefined enterprise process event state definitions and at least one respective threshold for each enterprise process event state definition in an information engine and receiving enterprise process data relating to a plurality of enterprise process states associated with the plurality of enterprise process event state definitions from the information engine. The method also includes analyzing the received enterprise process data in real time and generating a visualization of the enterprise based on at least one of the historical data, current information, and predicted data, the visualization including a representation of the enterprise process event states.

Owner:DASSAULT SYST AMERICAS CORP

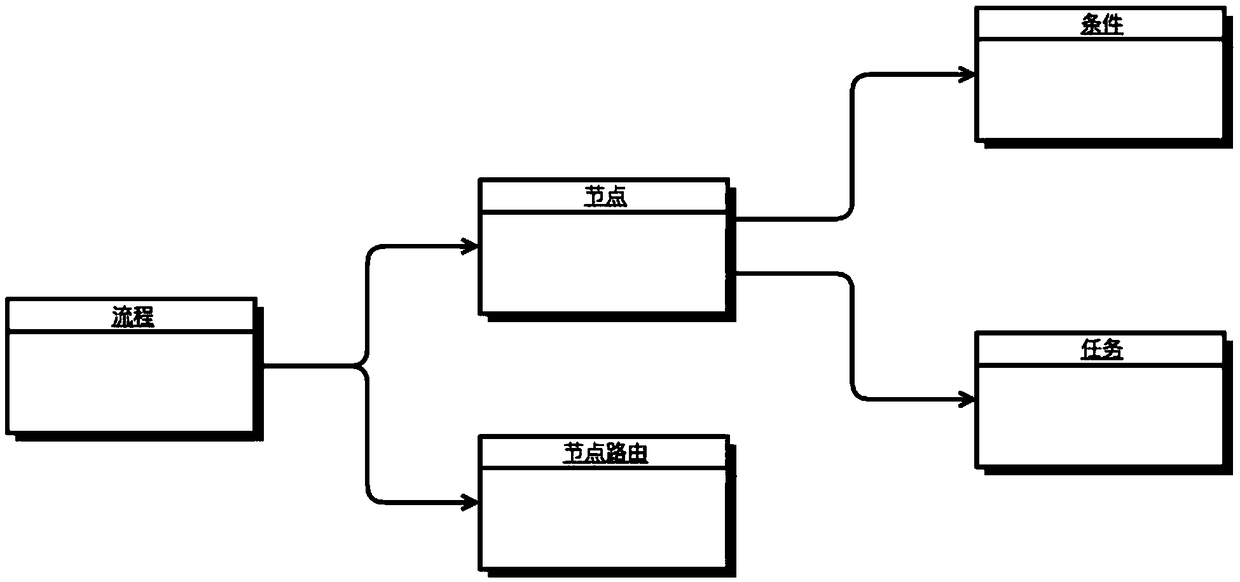

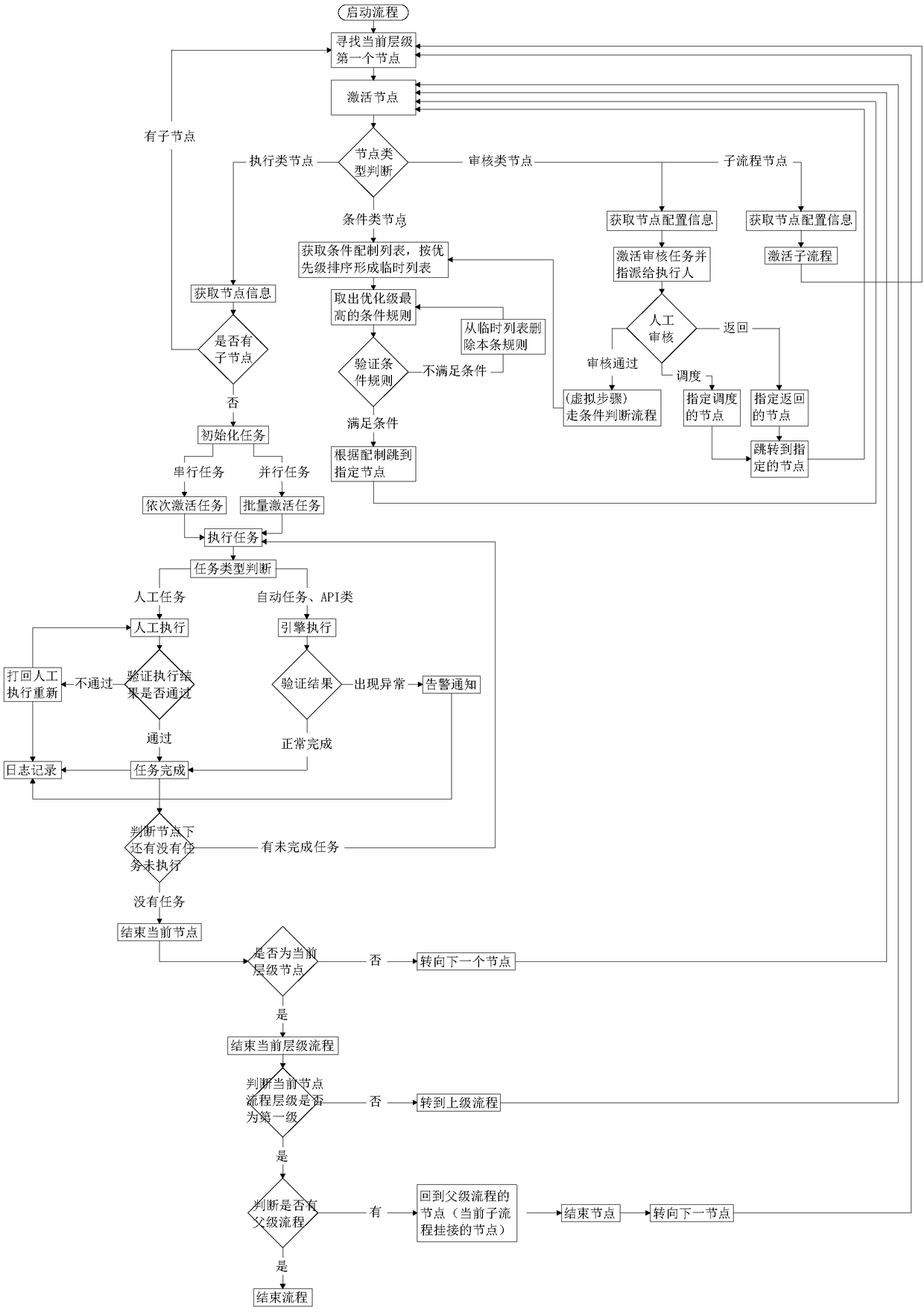

Low-code platform business process configuration system

InactiveCN109254759ASolve problems that meet new business needsSolve information silosSoftware designOffice automationControl flowDirected graph

The invention discloses a low-code platform business process configuration system, comprising a process module, a routing module, a condition module and a process engine. The process module is composed of a plurality of node modules and a plurality of task modules. The nodes are connected through a routing module, which is used to control the direction of the flow. The task module includes human task and automatic task. The conditional module is used to control the flow of the process, the conditional module is associated with the routing module and automatic tasks, and the process engine is used to propel the execution of the process. The low-code platform business process configuration system of the invention can enable the legacy systems in an enterprise to interact in a unified and universal manner, solves the problem of integrating the existing legacy systems of an enterprise to construct and combine new business processes to meet the new business needs, and avoids the informationisolated island. And the system abstracts the enterprise business process into directed graph, and provides visual modeling tools for users, and enables the enterprise process designers to customizethe enterprise business process quickly.

Owner:重庆戴昂科技有限公司

Extracting enterprise information through analysis of provenance data

Techniques are disclosed for extracting information through analysis of provenance data. For example, a computer-implemented method of extracting information regarding an execution of an enterprise process comprises the following steps. Provenance data is generated, wherein the provenance data is based on collected data associated with an actual end-to-end execution of the enterprise process and is indicative of a lineage of one or more data items. A provenance graph is generated that provides a visual representation of the generated provenance data, wherein nodes of the graph represent records associated with the collected data and edges of the graph represent relations between the records. At least a portion of the generated provenance data from the graph is analyzed so as to extract information about the execution of the enterprise process based on the analysis.

Owner:INT BUSINESS MASCH CORP

Methods and systems for intelligent enterprise bill-of-process with embedded cell for analytics

A method and a system for organizing management information within an enterprise are provided. The method includes storing an enterprise bill of process (eBOP) comprising a plurality of enterprise process events and at least one respective threshold for each enterprise process event in an information engine and receiving enterprise process data relating to the plurality of enterprise process events from an information engine. The enterprise process data includes historical data relating to the enterprise process events, real-time current information relating to the enterprise process events, predicted data based on the historical data, the current data and measured or derived parameters associated with the at least some of the plurality of enterprise process events, and algorithmic models of at least one of the enterprise process events including parameters, variables, and measurements. The method further includes generating immediate actions directing subscribed parties to perform determined remedial procedures of an action plan.

Owner:DASSAULT SYST AMERICAS CORP

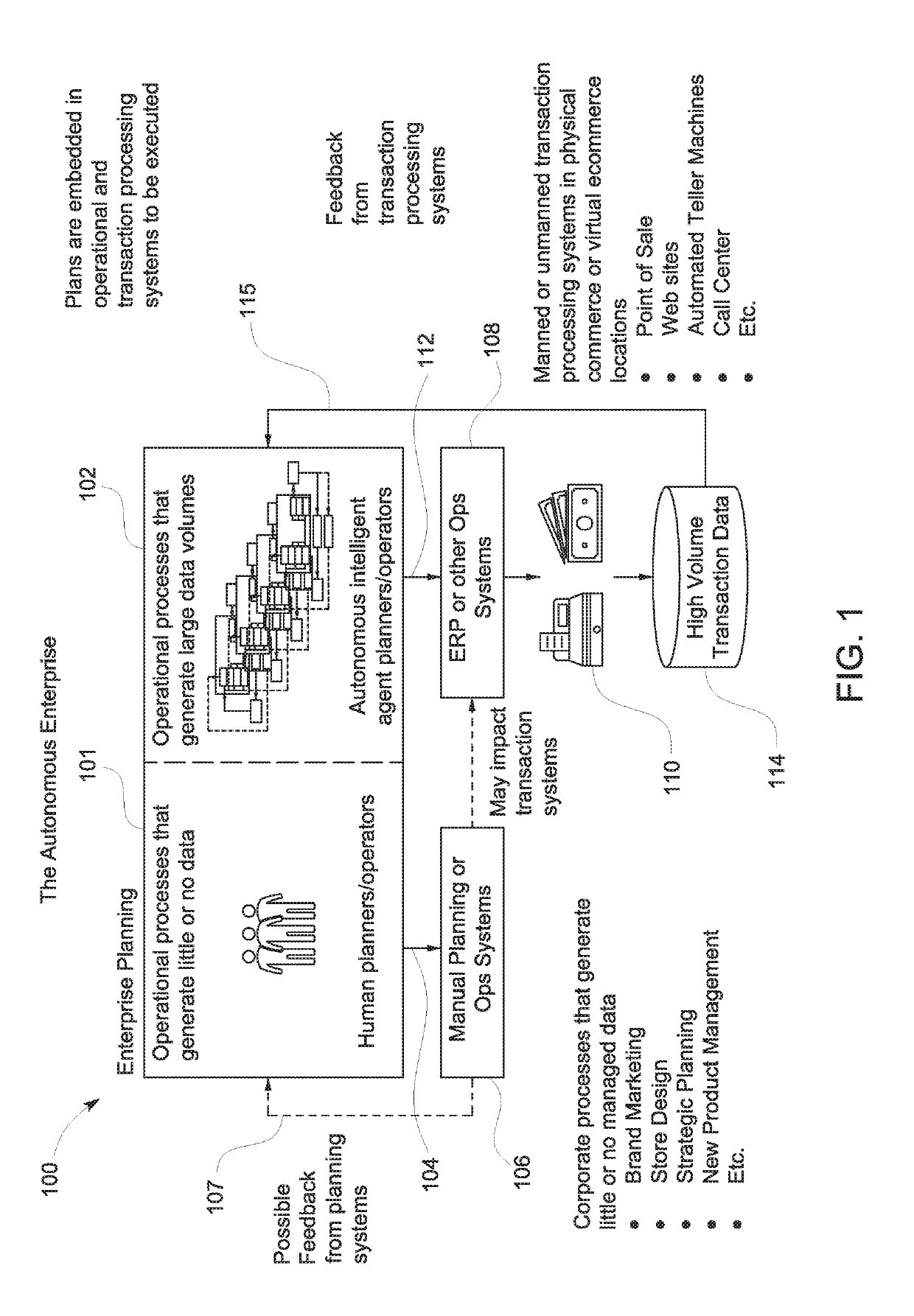

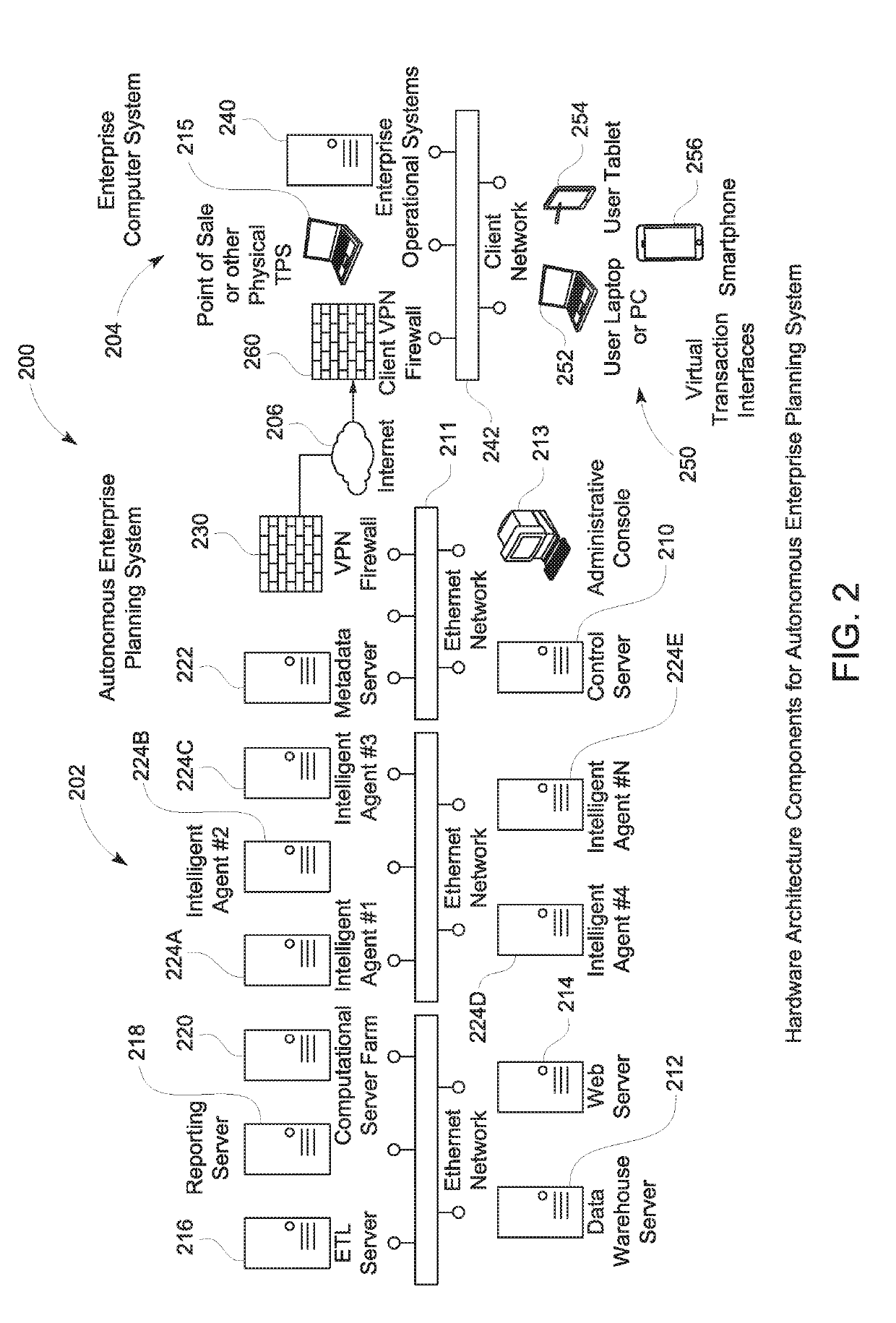

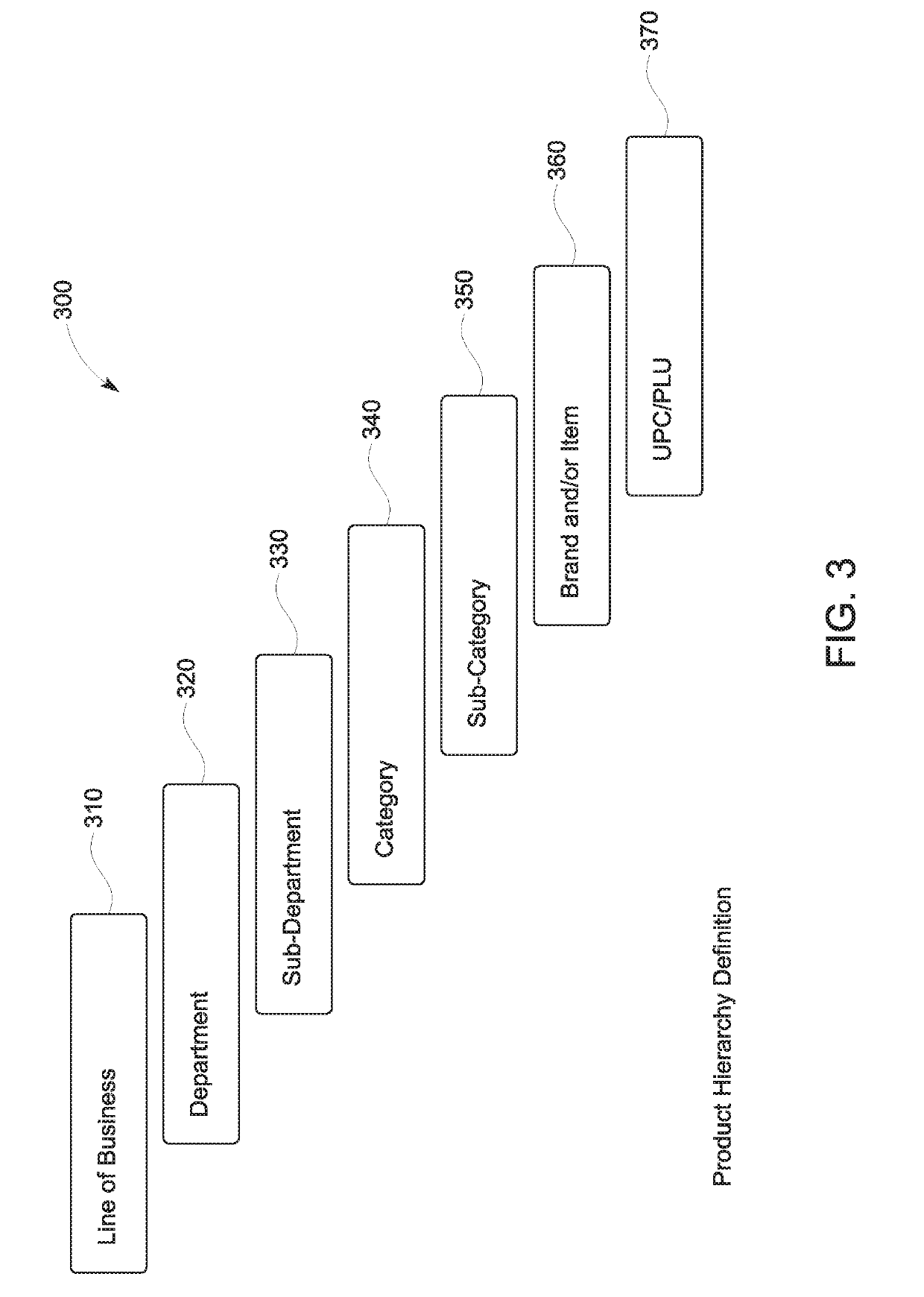

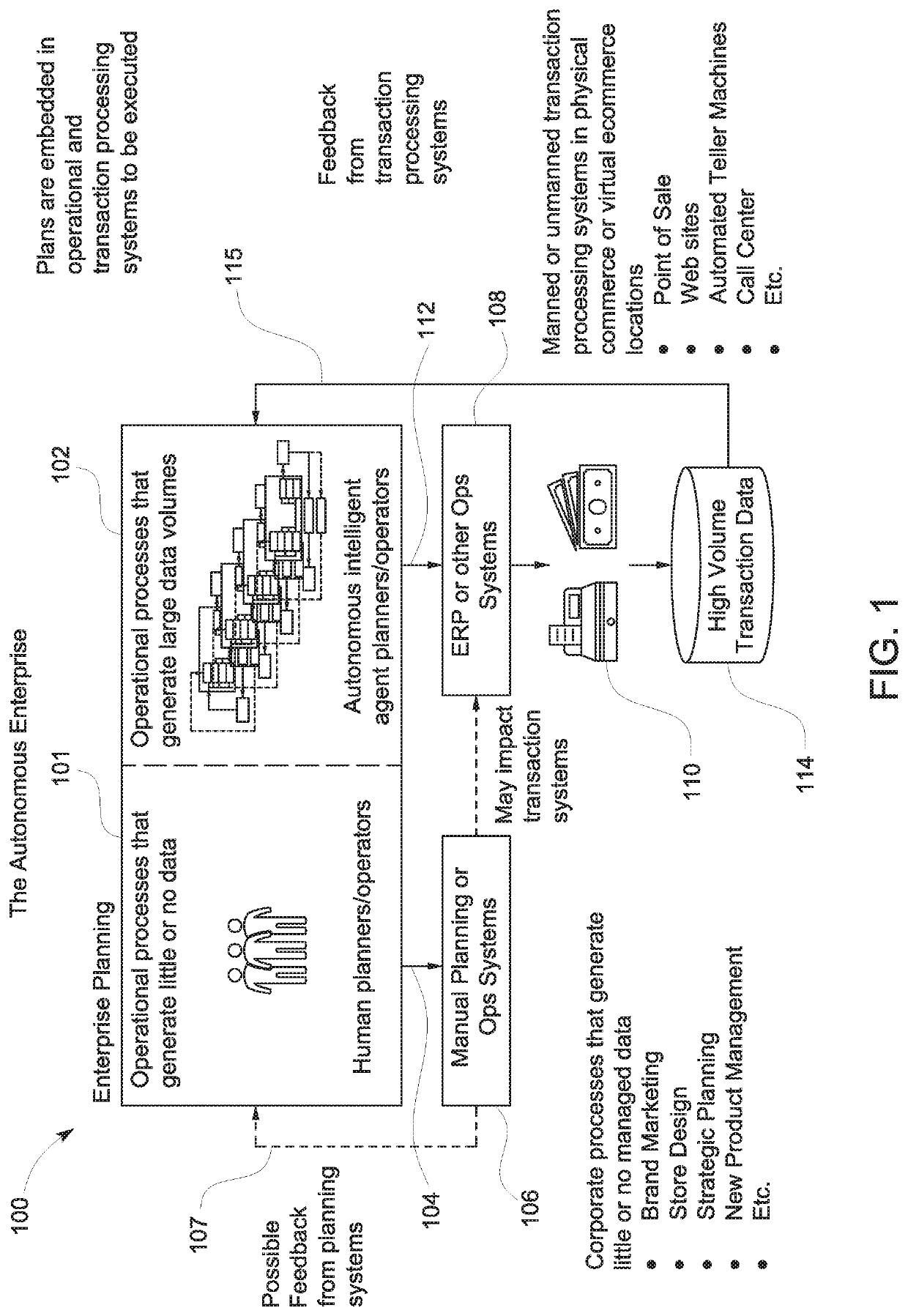

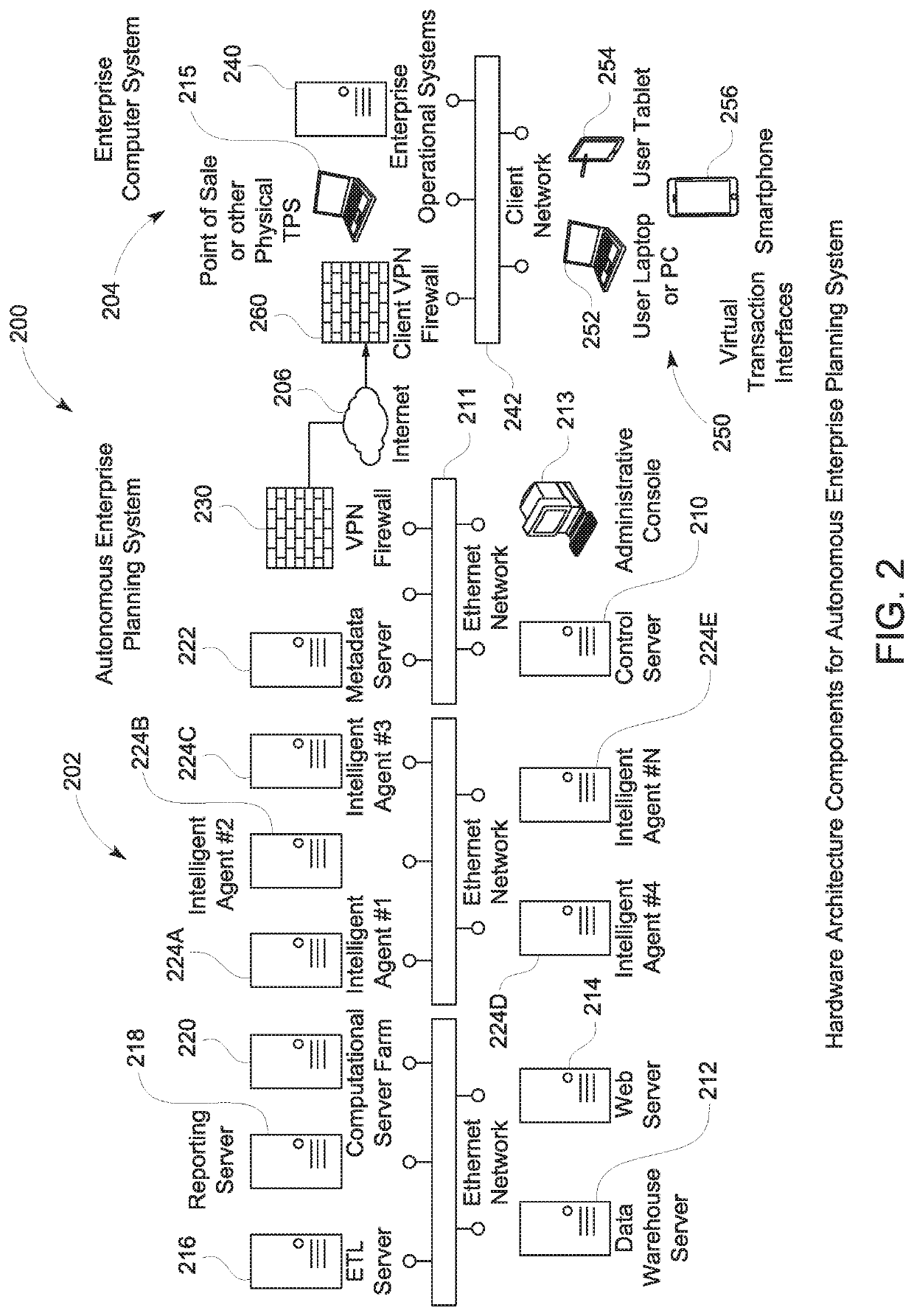

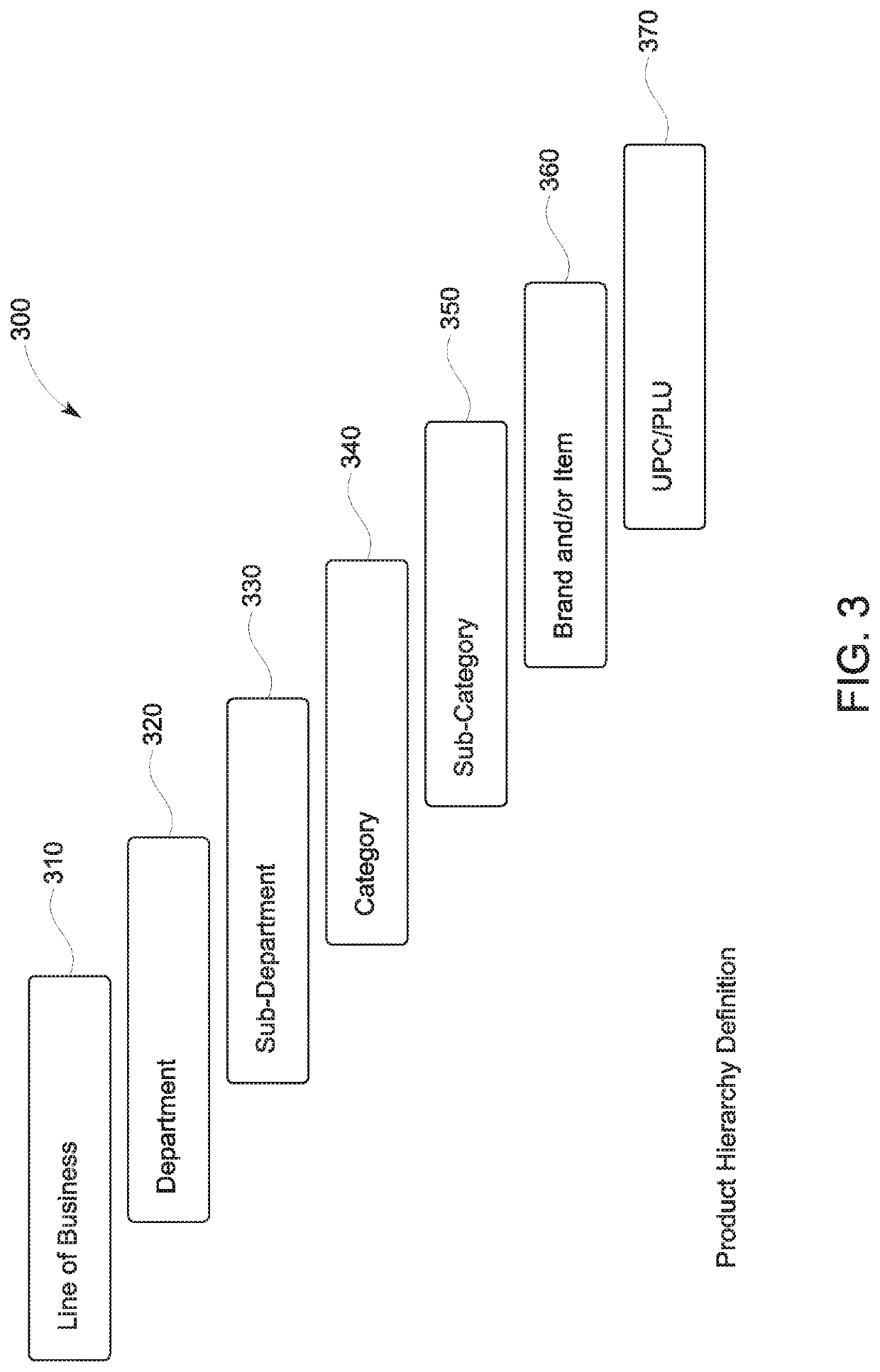

System and method for operating an enterprise on an autonomous basis

A computer system and computer-implemented method for autonomous enterprise planning for instance in a retail enterprise comprising retail planning processes such as assortment planning, regular price planning, promotional product planning, promotional pricing, inventory allocation, size / pack optimization, markdown pricing, or in an insurance enterprise comprising insurance underwriting, adjudication, fraud detection and subrogation. The computer system can comprise a data input module configured to input sensory data from an enterprise computer system, a data processor module configured to pre-process said inputted sensory data and generate pre-processed sensory data, a data storage module configured to store the inputted sensory data and the pre-processed sensory data, a calculation module configured to execute an enterprise state model and generate an optimized output for the enterprise process based on the inputted sensory data, a plurality of agent modules configured to execute a sub-process associated with the enterprise process and generate a sub-process decision output.

Owner:DAISY INTELLIGENCE CORP

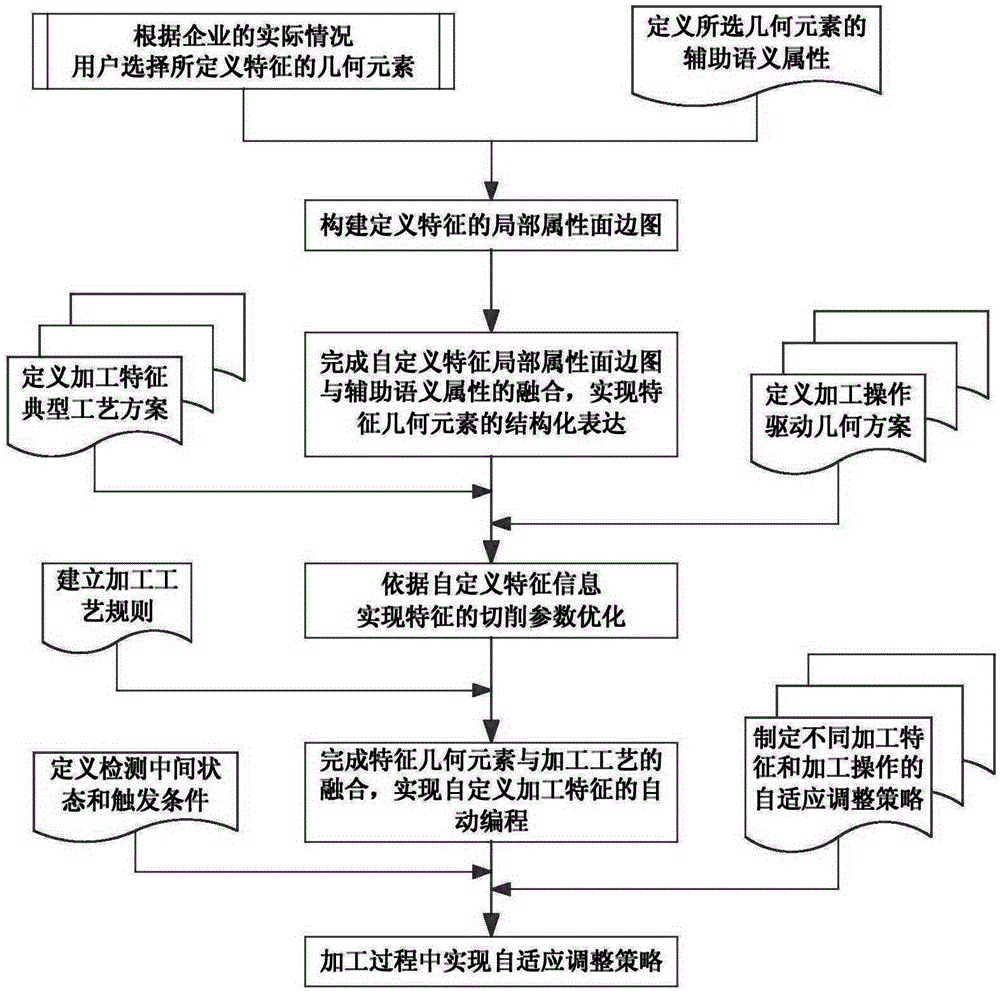

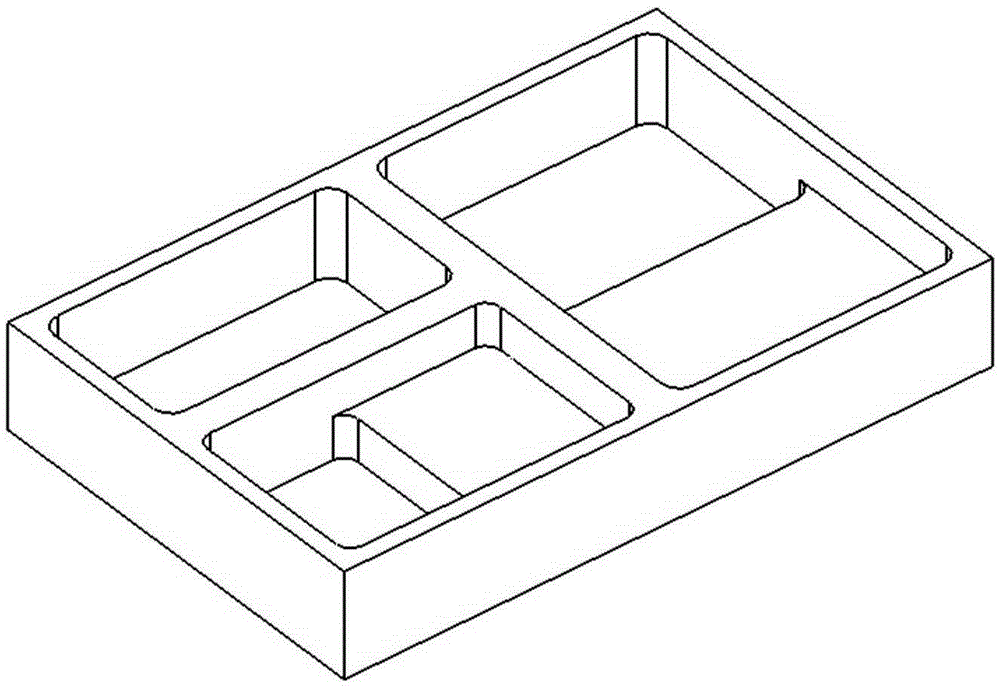

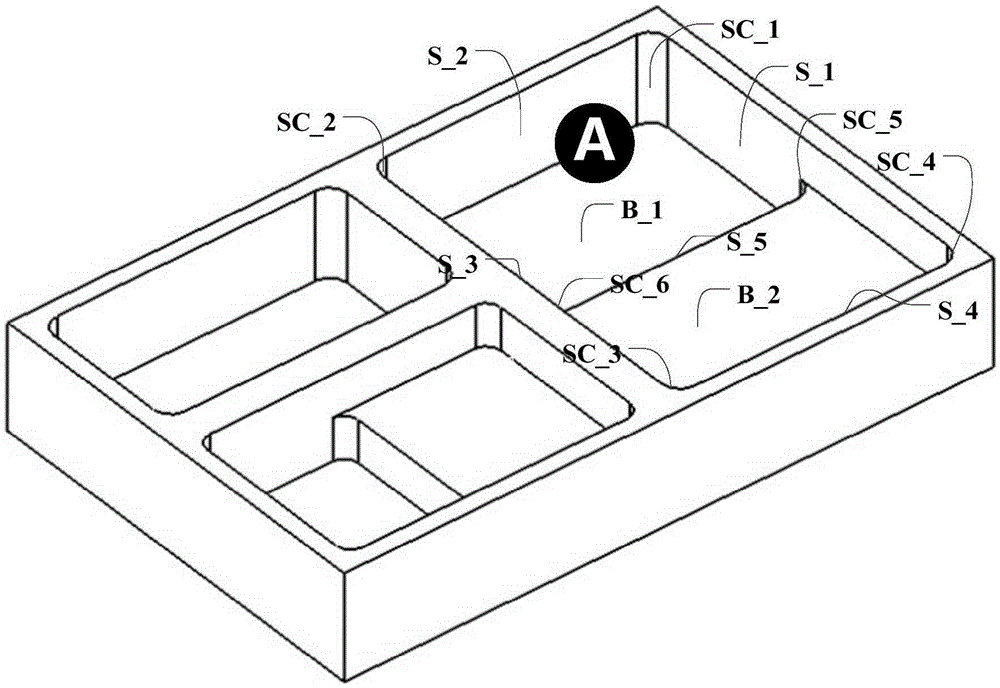

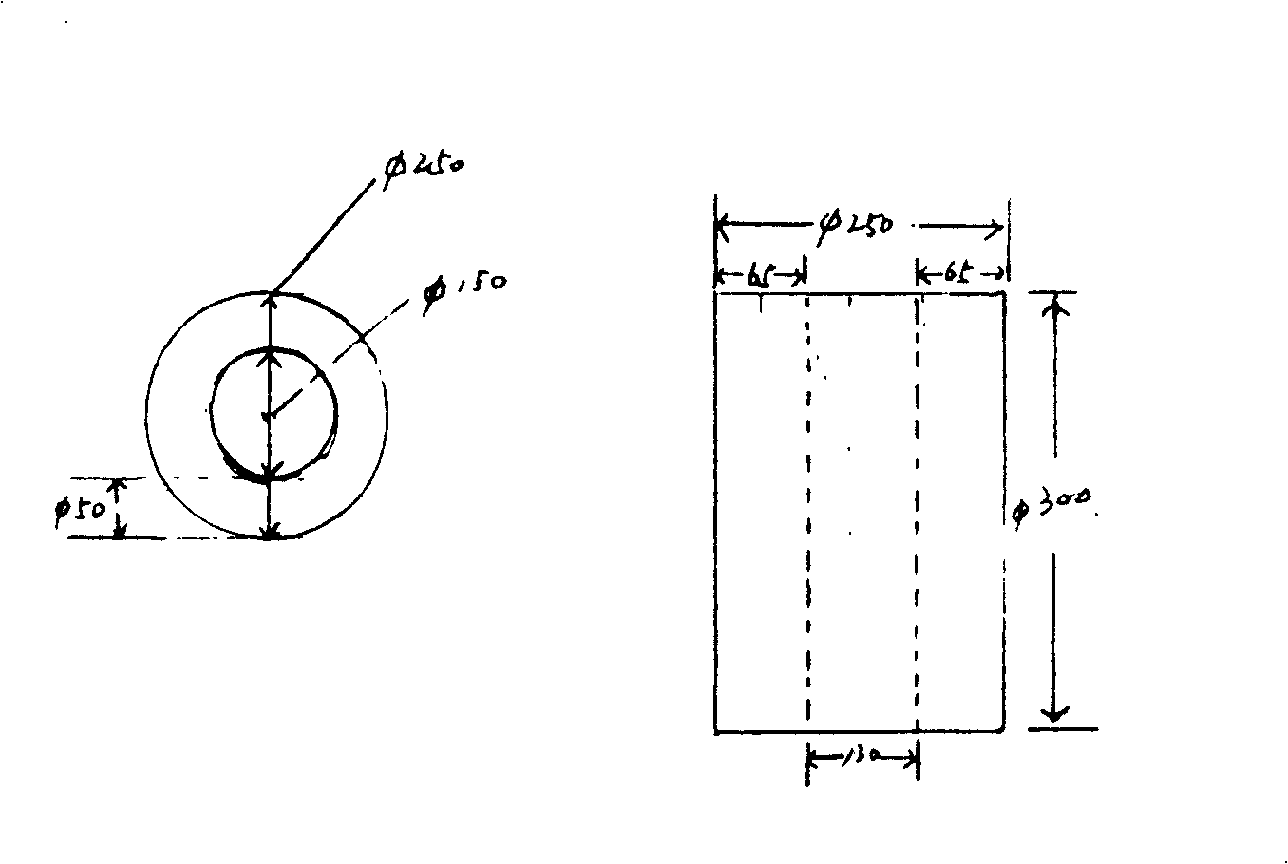

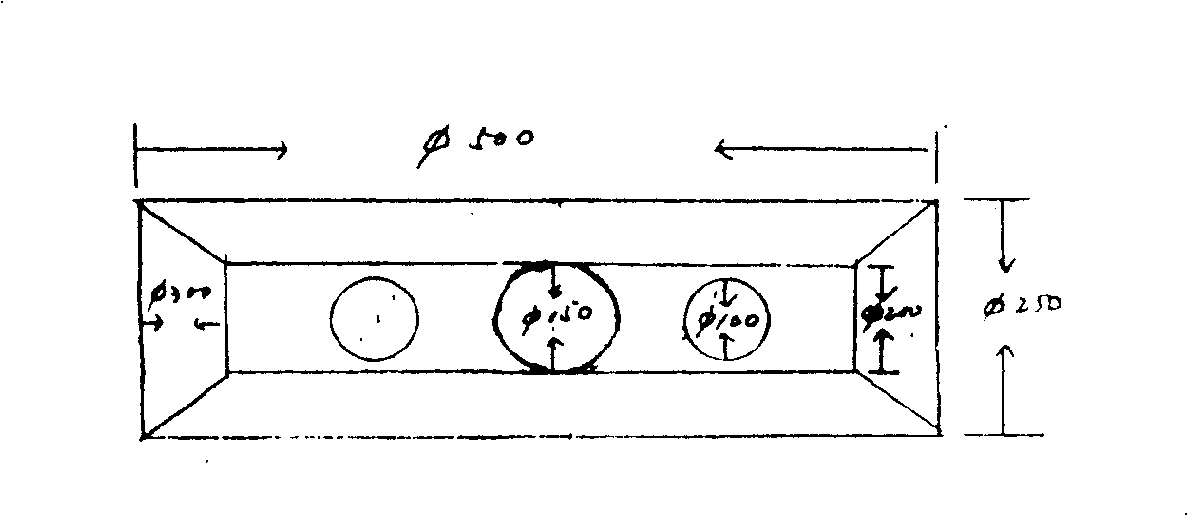

Numerical control machining feature customizing method

InactiveCN105242639AShorten the manufacturing cycleImprove programming efficiencyProgramme controlComputer controlNumerical controlComputer Aided Design

The invention discloses a numerical control machining feature customizing method. According to the method, a user customizes a geometric shape and a machining process scheme of a machining feature according to machining resources of an enterprise, the structure of a part and the programming habit based on a three-dimensional CAD (Computer Aided Design) model of the part. The user customizes geometric elements of the machining feature and a connection relationship thereof, and a matching rule between geometric and machining processes is established according to key process parameters of the machining feature. A cutting parameter optimization model is established according to the information of the customized machining feature, to optimize the customized machining feature. An analytic program is established to accomplish association between the geometric elements of the customized machining feature and the machining process and realize automatic programming of numerical control machining of the customized machining feature, and a position to be detected and an adaptive adjustment strategy in the machining process are set out. The method can improve the programming efficiency and the programming quality of a complex structural member, shorten the manufacturing period of a part and simultaneously realize accumulation of enterprise process knowledge.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

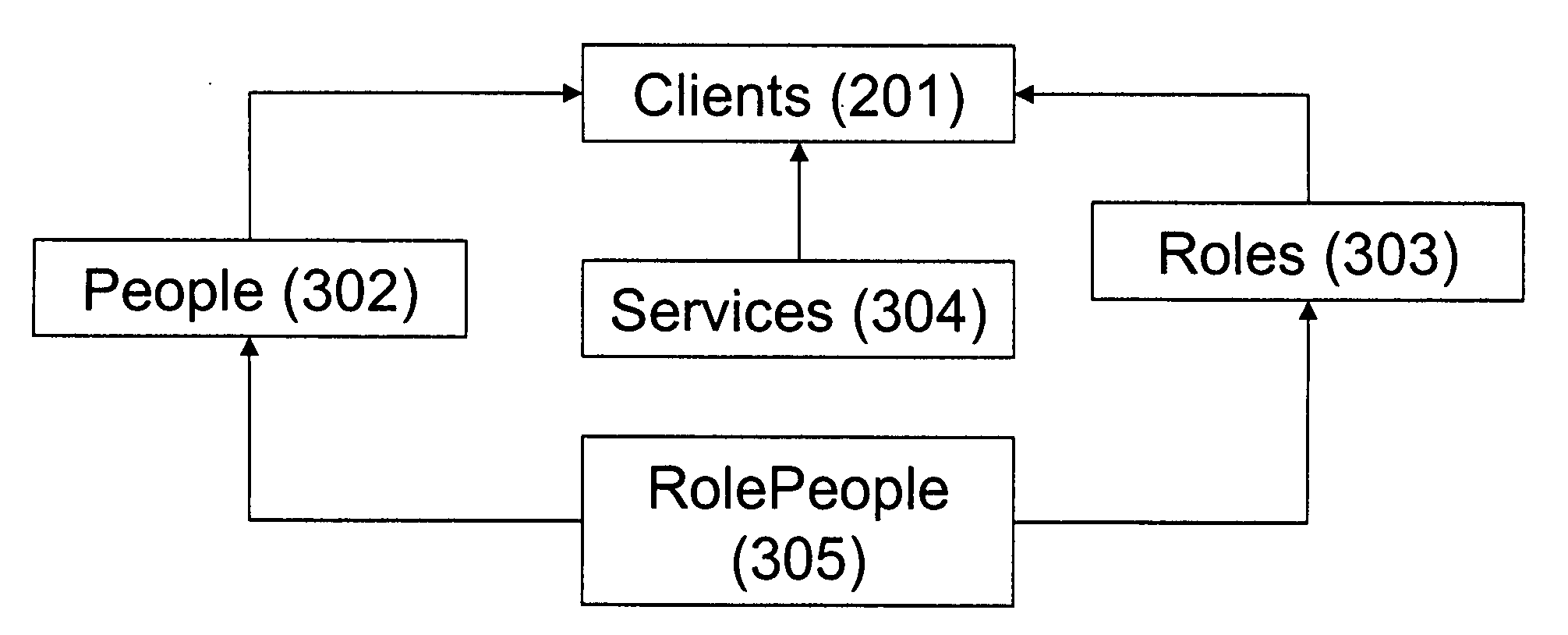

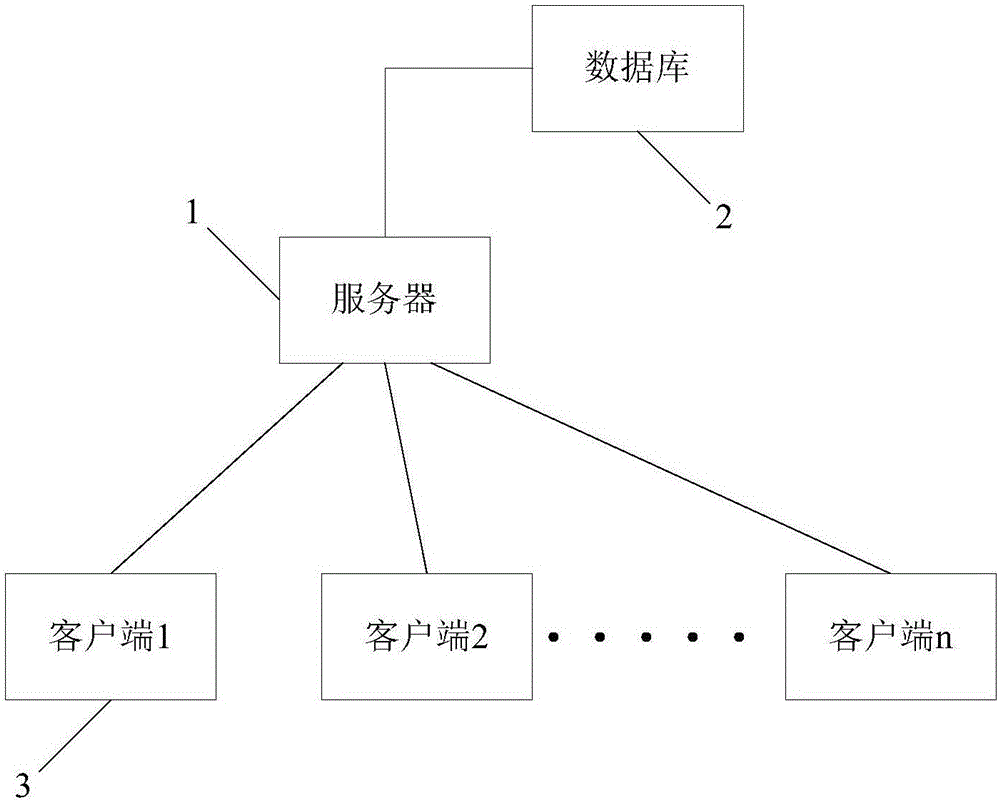

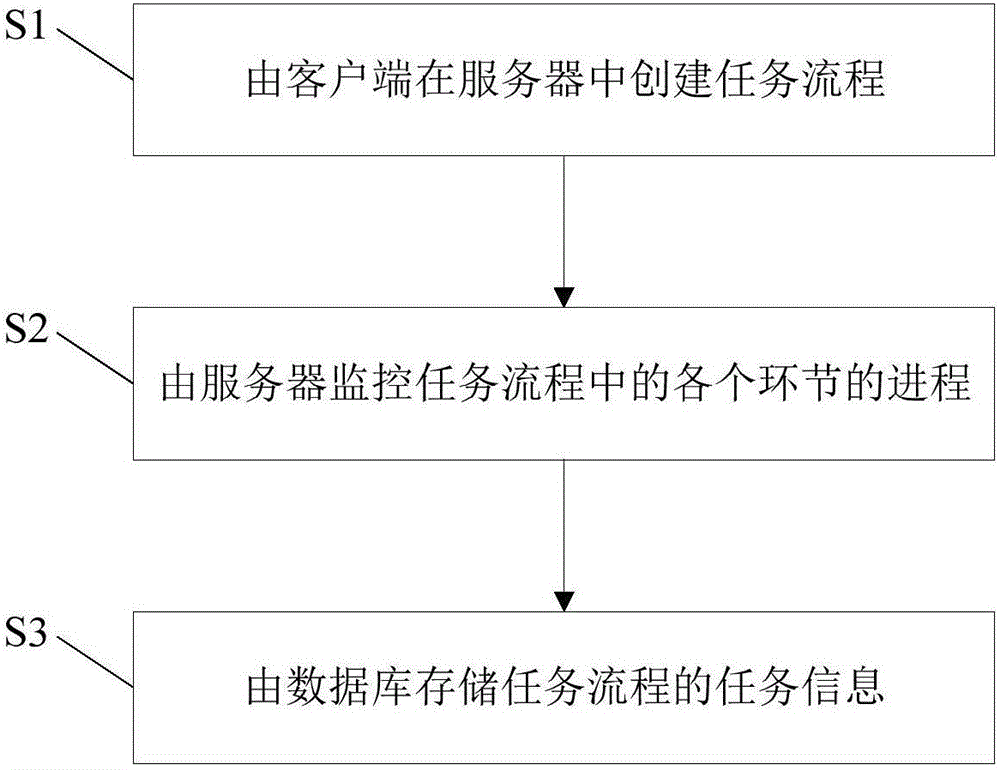

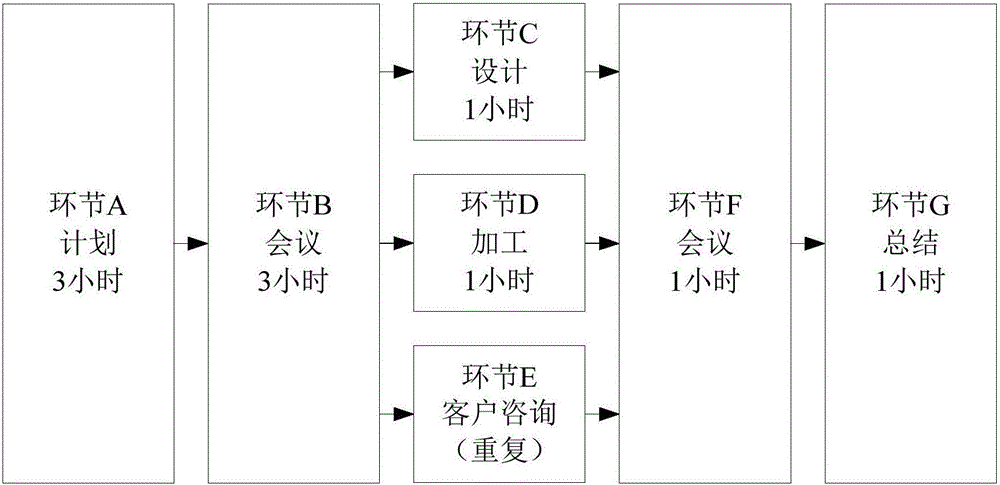

Task management system and task management method thereof

InactiveCN106447282AFlexible useEasy to useOffice automationResourcesEnterprise processNetwork communication

The present invention provides a task management system and a task management method thereof, belongs to the technical field of network communications, and can solve the technical problem that the existing customized enterprise process software is inconvenient to use. The task management system comprises a server, a database and multiple clients. The clients are used for creating a task process in the server; and the database is used for storing task information of the task process.

Owner:李传堃

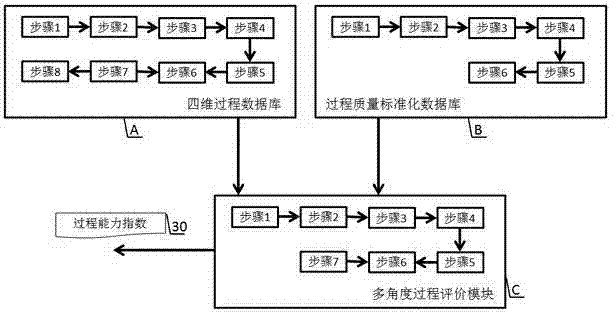

Four-dimensional multi-angle evaluation system for enterprise process management

InactiveCN104217279AGuaranteed uptimeGuarantee the quality of operationResourcesSpecial data processing applicationsData OriginProcess quality

The invention discloses a four-dimensional multi-angle evaluation system for enterprise process management, relates to the technical field of information, and belongs to the technical field of aided decision-making and comprehensive evaluation. The four-dimensional multi-angle evaluation system comprises three functional modules, respectively being a four-dimensional process database, a process quality standardization database and a multi-angle process evaluation module; the evaluation system performs an evaluation process including the steps of: customizing a process quality standardization system and storing event information of the four-dimensional process database, and a random multi-angle process capability evaluation method is adopted. The key point of the four-dimensional multi-angle evaluation system is to construct a four-dimensional process data model of enterprise production management events; according to the four-dimensional multi-angle evaluation system, true and objective evaluation from multiple directions of the enterprise production management process is thoroughly achieved, all data for analyzing comes from actual events in an enterprise production management process, and the more scientific and comprehensive multi-angle process capability evaluation method is adopted. The four-dimensional multi-angle evaluation system is reasonable in design and strong in practicability, and can provide important references and actual bases for optimization and reorganization operation of an enterprise business process.

Owner:北京中电拓方科技股份有限公司

Method and apparatus for enabling enterprise project management with service oriented resource and using a process profiling framework

InactiveUS8219967B2ResourcesSpecific program execution arrangementsHyperlinkService oriented enterprise

A service-oriented architecture for enterprise project management integrates business processes, human resources and project management within an enterprise or across the value chain network. A representation having direction and attributes is provided to show the dependencies between a business value layer and a project-portfolio layer, and between the project-portfolio layer and resources. The representation is mapped to a Web Services representation in UDDI, Web Services interfaces, and Web Services based business processes through rope hyper-linking.

Owner:INT BUSINESS MASCH CORP

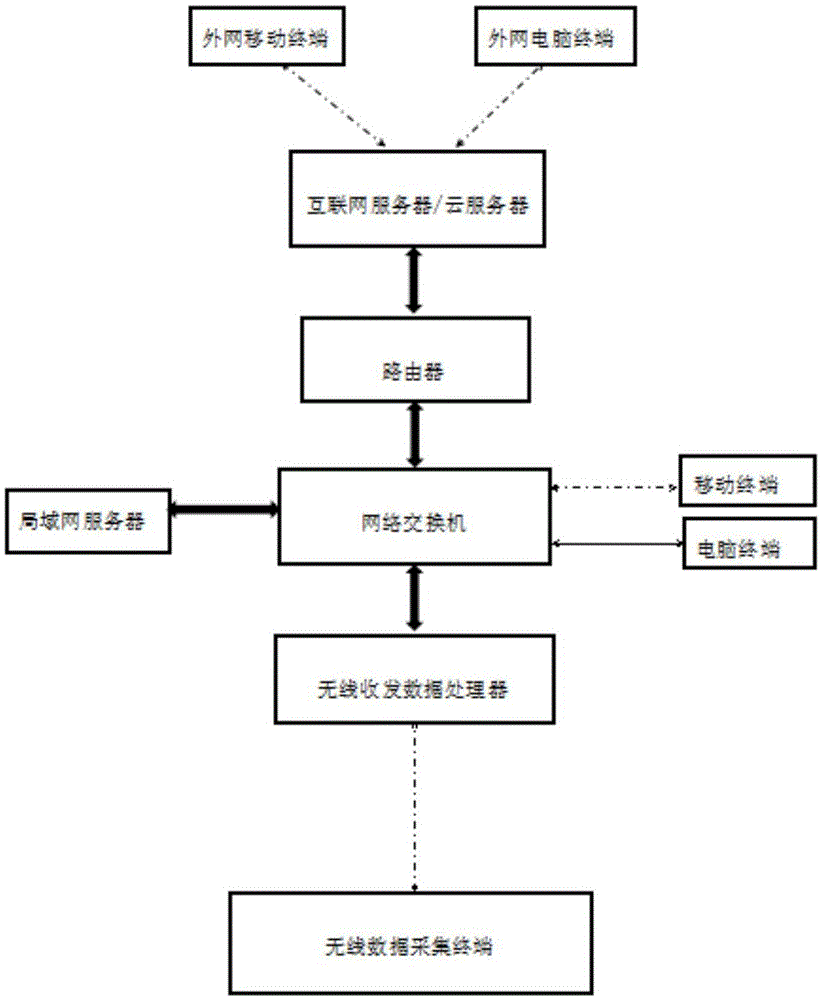

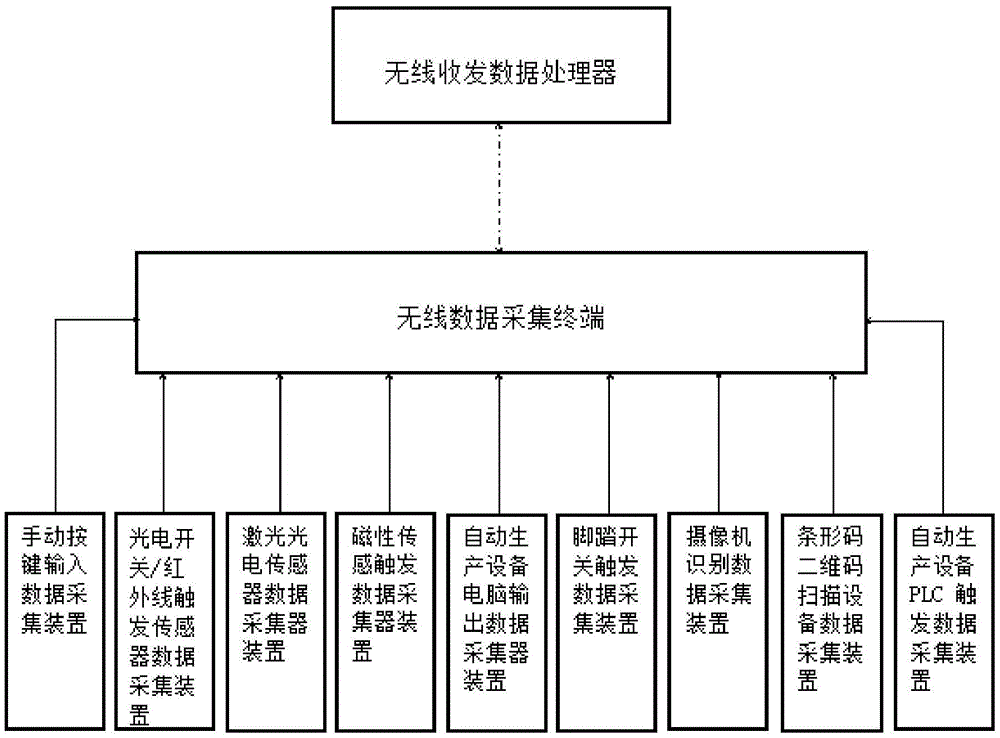

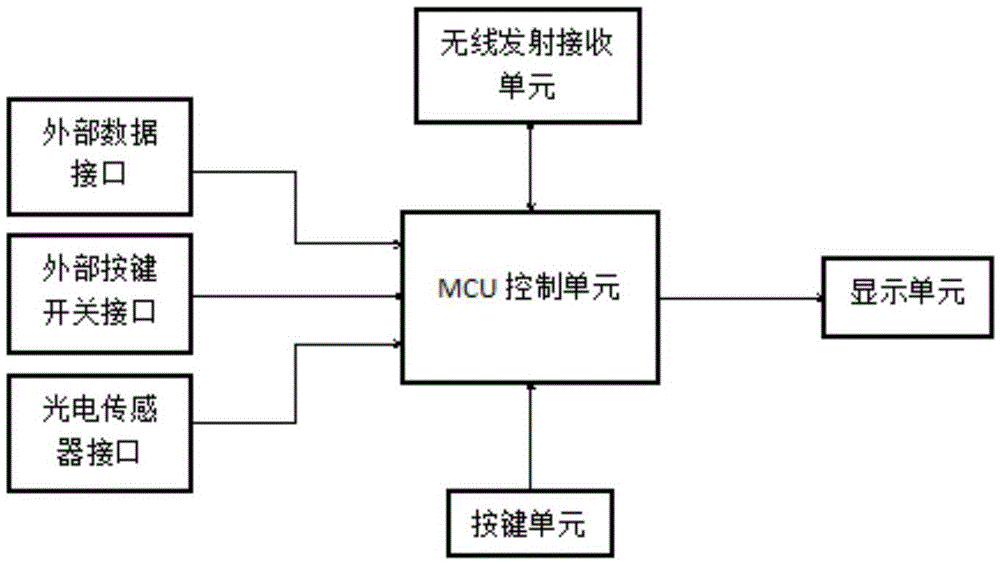

Intelligent enterprise process management system

InactiveCN105550829ALow costEasy to upgradeOffice automationResourcesNetwork ComputerProduction control

The present invention discloses an intelligent enterprise process management system. The system comprises an external network mobile terminal, an external network computer terminal, an Internet server / cloud server, a router, a network switch, a local area network server and a wireless transmission data processor. The network switch is connected with the route, the local area network server, the wireless transmission data processor, the mobile terminal and a computer terminal, the wireless transmission data processor is connected with a wireless data acquisition terminal, and the route is connected with the external network mobile terminal and the external network computer terminal through the Internet server / cloud server. The intelligent enterprise process management system is able to be simply and flexibly installed at any one place of work in a production line so as to allow each productive enterprise to update the original production line in low-cost, convenient and simple mode, effectively improve the production management capability, save managers' production data statistics time, improve personnel production data and enthusiasm, and finally generate considerable economic benefit for enterprises.

Owner:谢飞

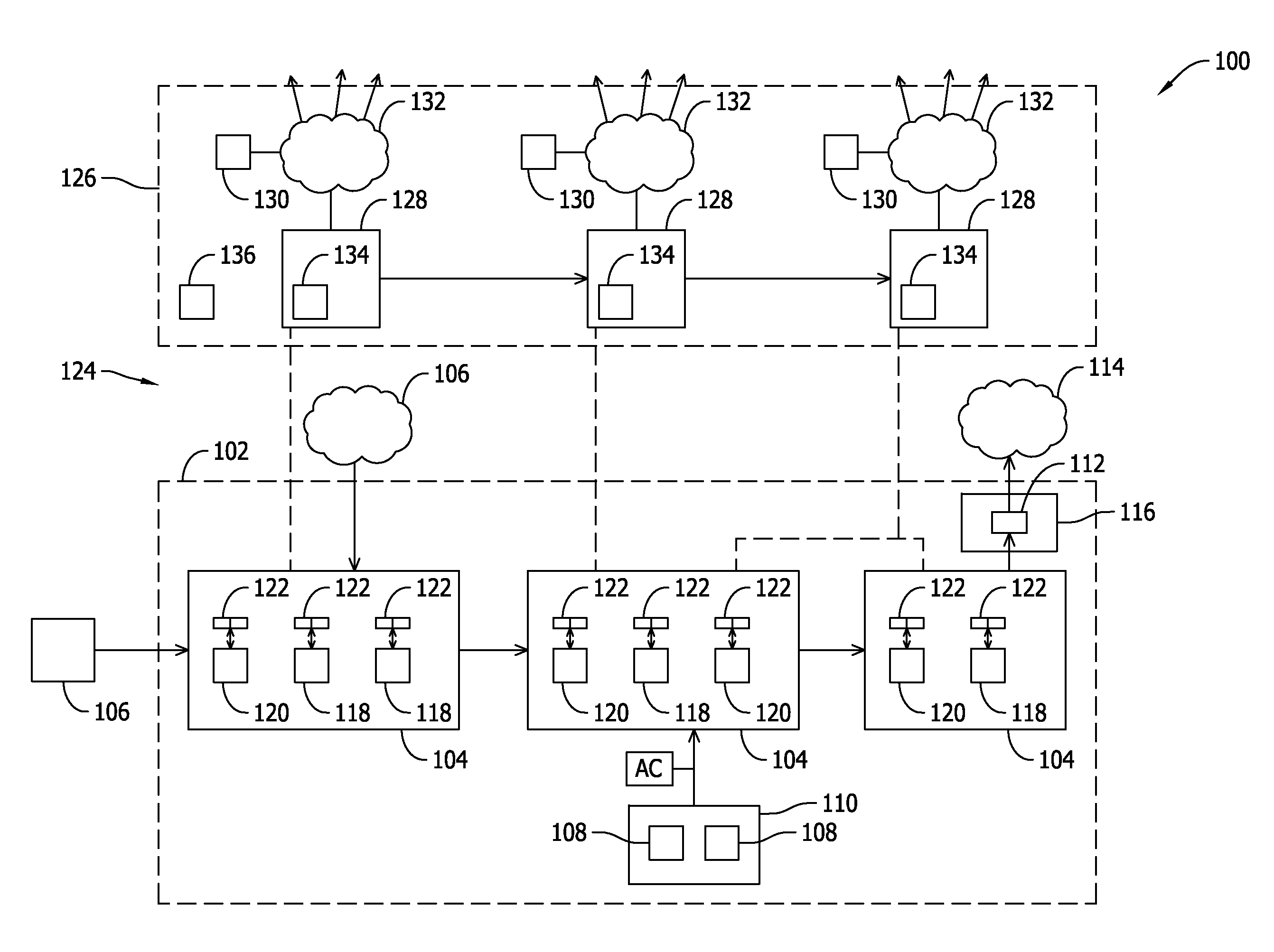

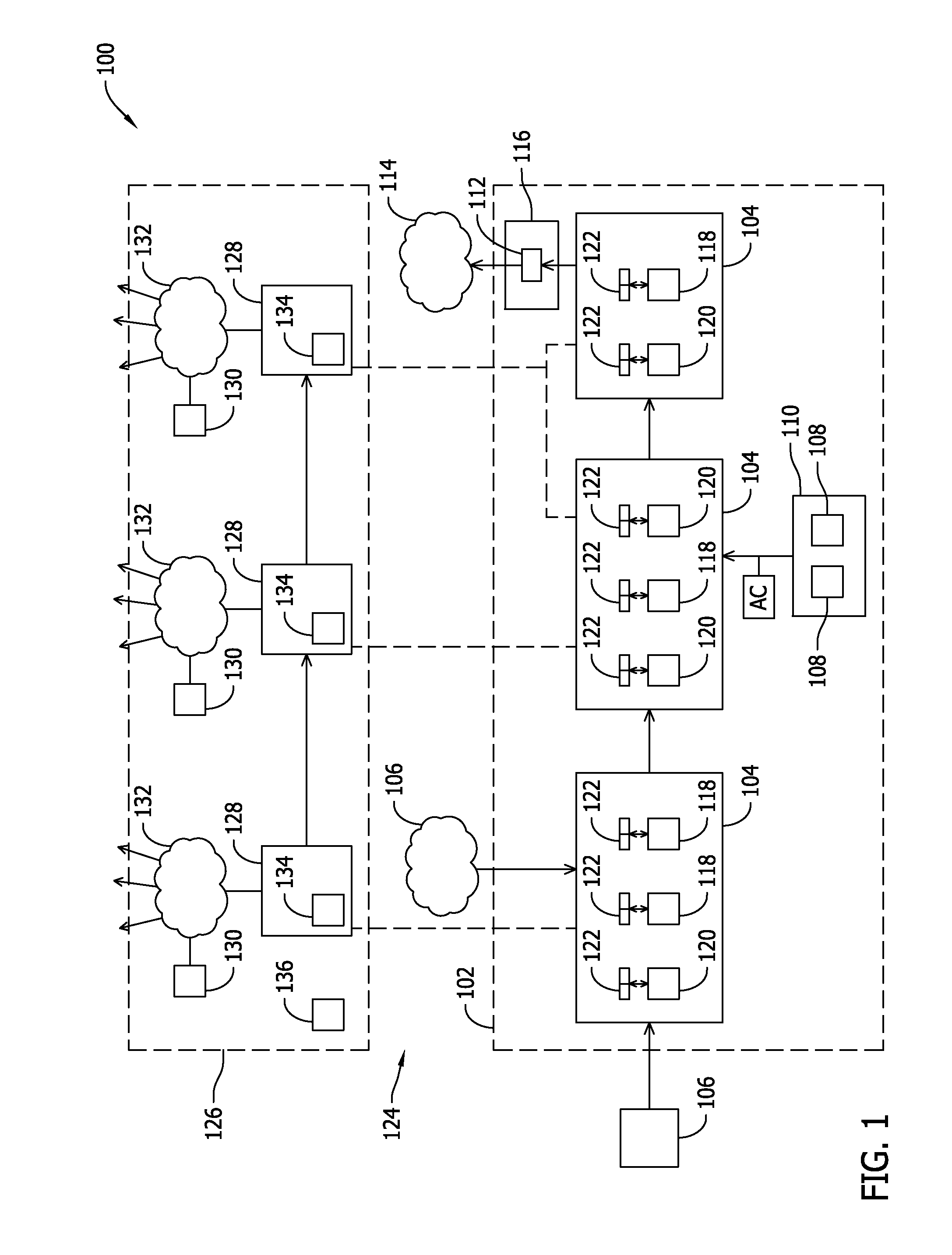

System and method for operating an enterprise on an autonomous basis

A computer system and computer-implemented method for autonomous enterprise planning for instance in a retail enterprise comprising retail planning processes such as assortment planning, regular price planning, promotional product planning, promotional pricing, inventory allocation, size / pack optimization, markdown pricing, or in an insurance enterprise comprising insurance underwriting, adjudication, fraud detection and subrogation. The computer system can comprise a data input module configured to input sensory data from an enterprise computer system, a data processor module configured to pre-process said inputted sensory data and generate pre-processed sensory data, a data storage module configured to store the inputted sensory data and the pre-processed sensory data, a calculation module configured to execute an enterprise state model and generate an optimized output for the enterprise process based on the inputted sensory data, a plurality of agent modules configured to execute a sub-process associated with the enterprise process and generate a sub-process decision output.

Owner:DAISY INTELLIGENCE CORP

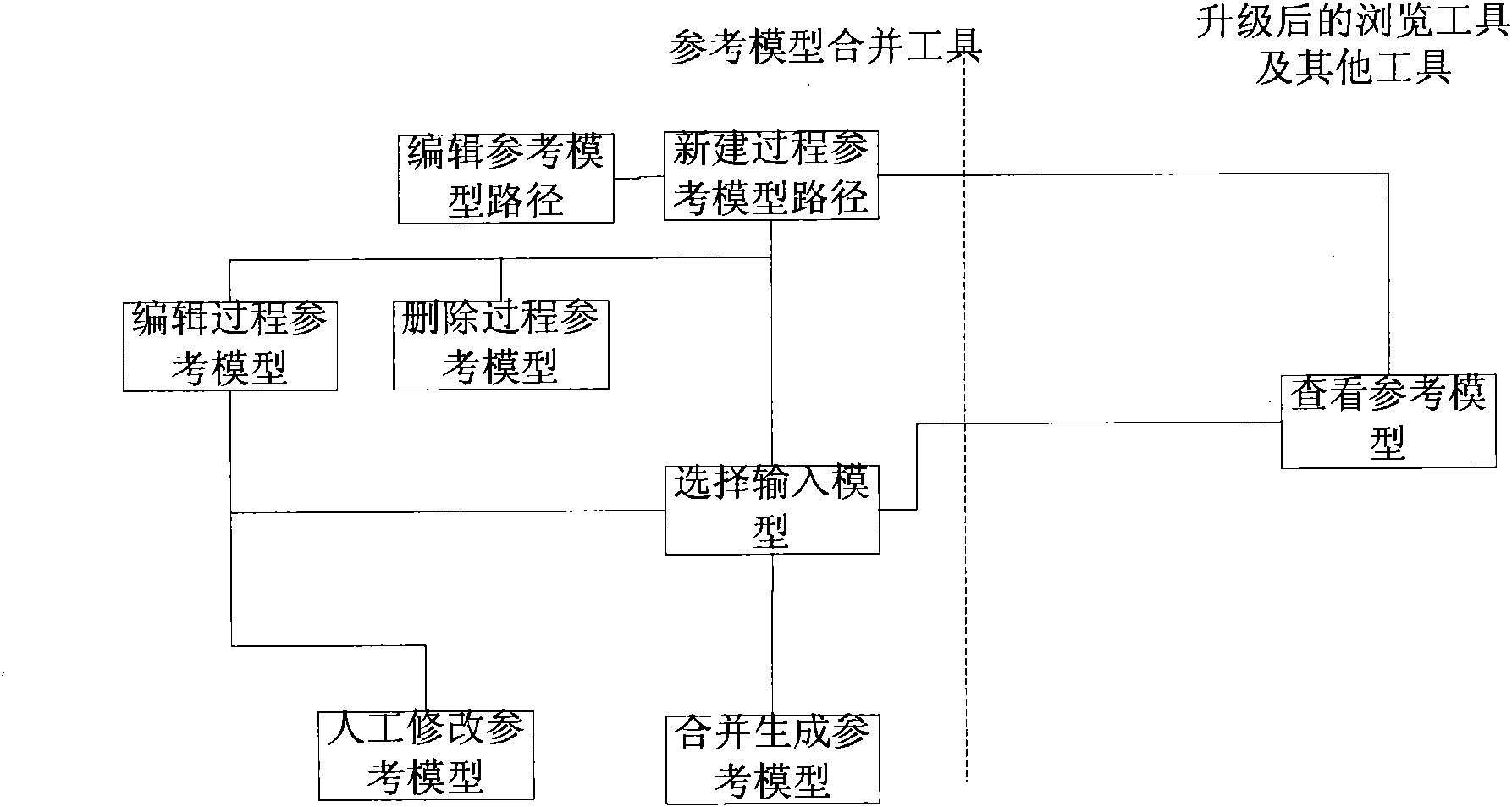

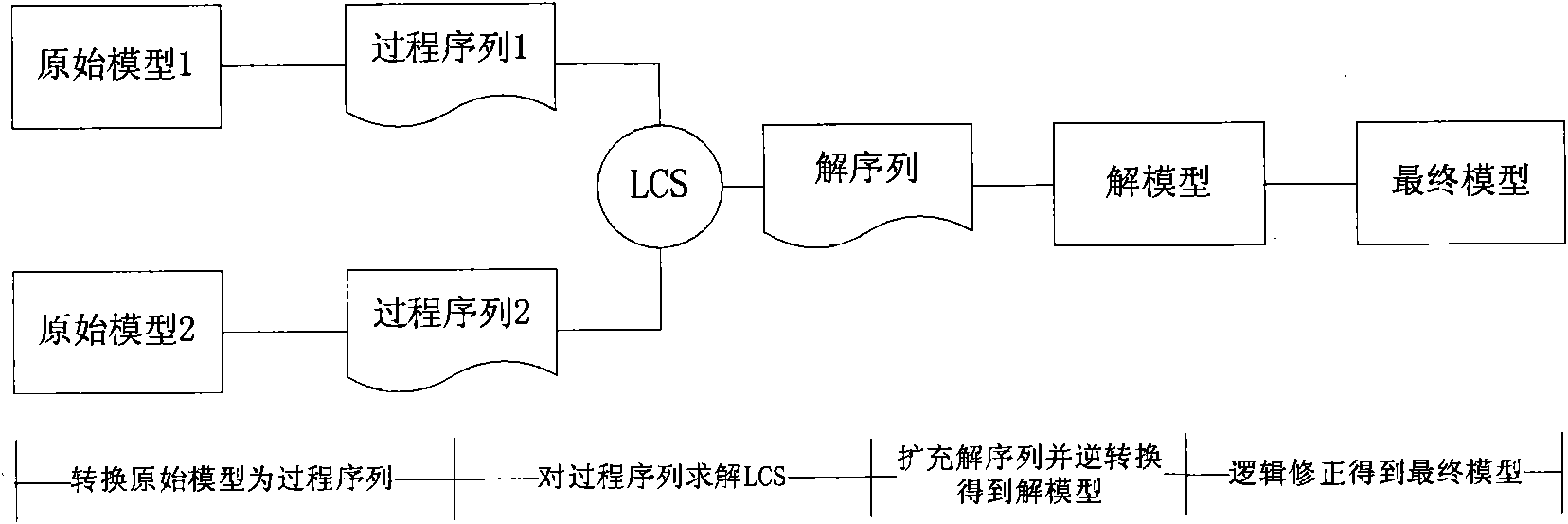

Method for building integrated enterprise process reference model based on model combination

InactiveCN101853444AGood feature supplementGuaranteed uptimeSpecial data processing applicationsReference modelLongest common subsequence problem

The invention discloses a method for building an integrated enterprise process reference model based on model combination, which belongs to the field of modeling technology. The invention is characterized in that the method is realized on a platform formed by sequentially connecting a plurality of users, the Internet and servers, and an enterprise process reference model can be semi-automatically obtained by converting original enterprise models into character strings for combination, wherein the enterprise models are two modeled enterprise process models which are selected form an enterprise model database, approved by modeling experts, and put into practice. A best-fit enterprise model is obtained by the following steps of: firstly, obtaining a longest common subsequence of two process sequences; and then respectively building an auxiliary progression based on the longest common subsequence for the two process sequences; and finally obtaining the Levenshtein distance of the minimum operation time for covering one process sequence into the other process sequence by basic operation. The invention can effectively improve the reusage of enterprise model knowledge so as to effectively improve the modeling efficiency.

Owner:TSINGHUA UNIV

Environment-protecting degradable bio sand fixing agent

The invention relates to a sand solidification agent which is a multifunctional product that has the advantages of advanced technology, environment protection, energy-saving performance, lowered production cost, time and labor saving performance, low energy consumption, high efficiency, high quality and simplified process. A complicated process is directly converted into an integrated new process and a new procedure. 3-4 hours are required from the reaction to the completion of the product in a traditional process for producing the sand solidification agent. Thus, the production scale is restricted. In the process, raw materials are added in a tank and stirred. Only a plurality minutes are required for a small tank from the reaction of the raw materials to the completion of the product, and ten minutes or so or twenty minutes are required for the reaction in a large tank to complete the product. Compared with the traditional process, the quality is improved, the investment is reduced, the process is shortened, the resources and time are saved and the efficiency is improved. Large scale production can be realized. The efficiency of the new process is more than ten times of the old process, and the cost is one third of the old process. Compared in the (sand solidification agent) industrial development production enterprise process field, the multifunctional product is the front runner in the nation in technology and production efficiency and speed.

Owner:韩文锦

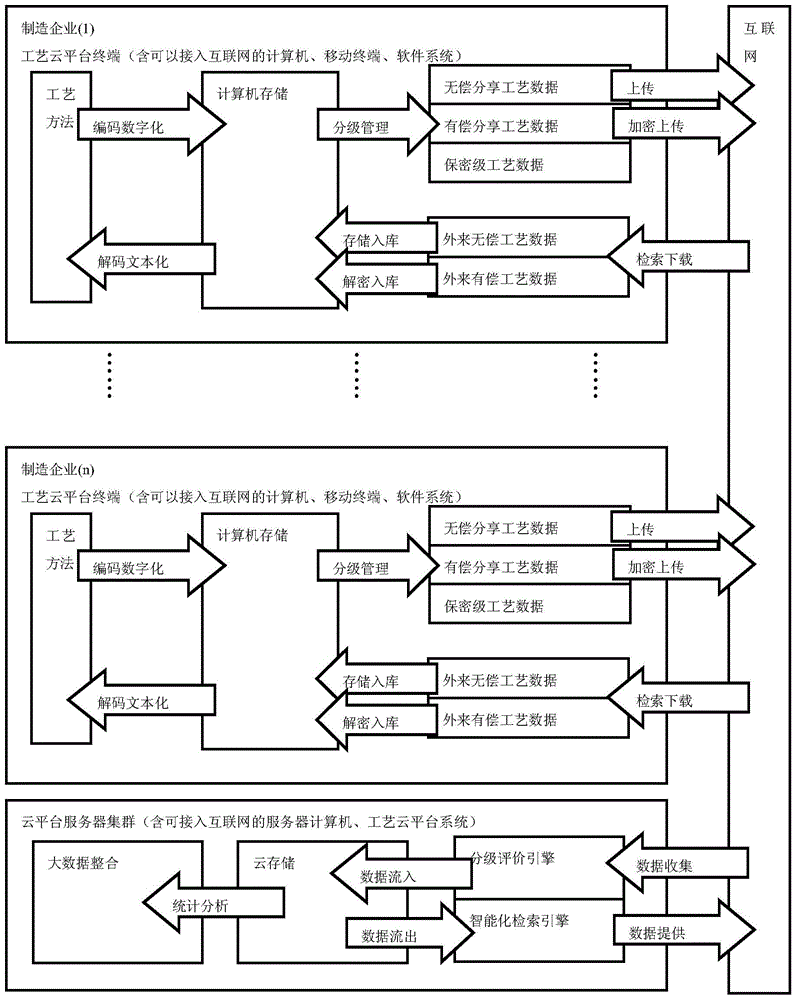

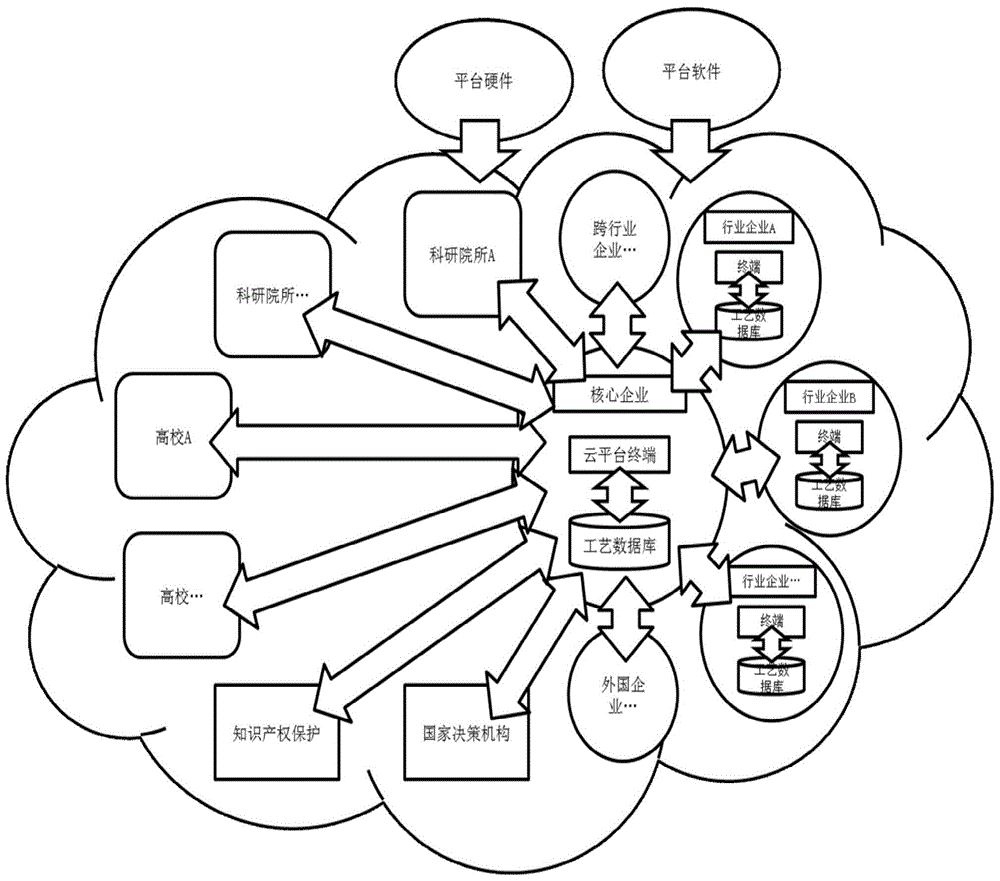

Implement method of technological data cloud platform in manufacturing industry

InactiveCN104881817AIncrease valueSafe storageData processing applicationsTransmissionEnterprise processThe Internet

The invention relates to an implement method of a technological data cloud platform in the manufacturing industry. The implement method includes the following steps of digitalized storage: saving manufacturing enterprise process files in a computer after the files are digitalized; grading management: performing grading management on the process data, including sharing technological data and secrecy technological data, saved in the computer; and sharing mechanism: transmitting the sharing technological data to a cloud platform server cluster via the Internet. When a manufacturing platform starts technological retrieval via a cloud platform terminal, a retrieval engine designs parameters base on the products submitted by the enterprise, reads data from cloud storage, generates results, and transmits the results back to an enterprise terminal, and after the results are decoded, the process files to be displayed or printed are generated. The implement method communicates the technological data islands in the manufacturing industry, so that the technological data generates circulation values to make an industrial chain be communicated, a new industrial mode is formed, and industrial big data gathered by a system gives the support to the national development of correlation relevant standards and industrial development strategies.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

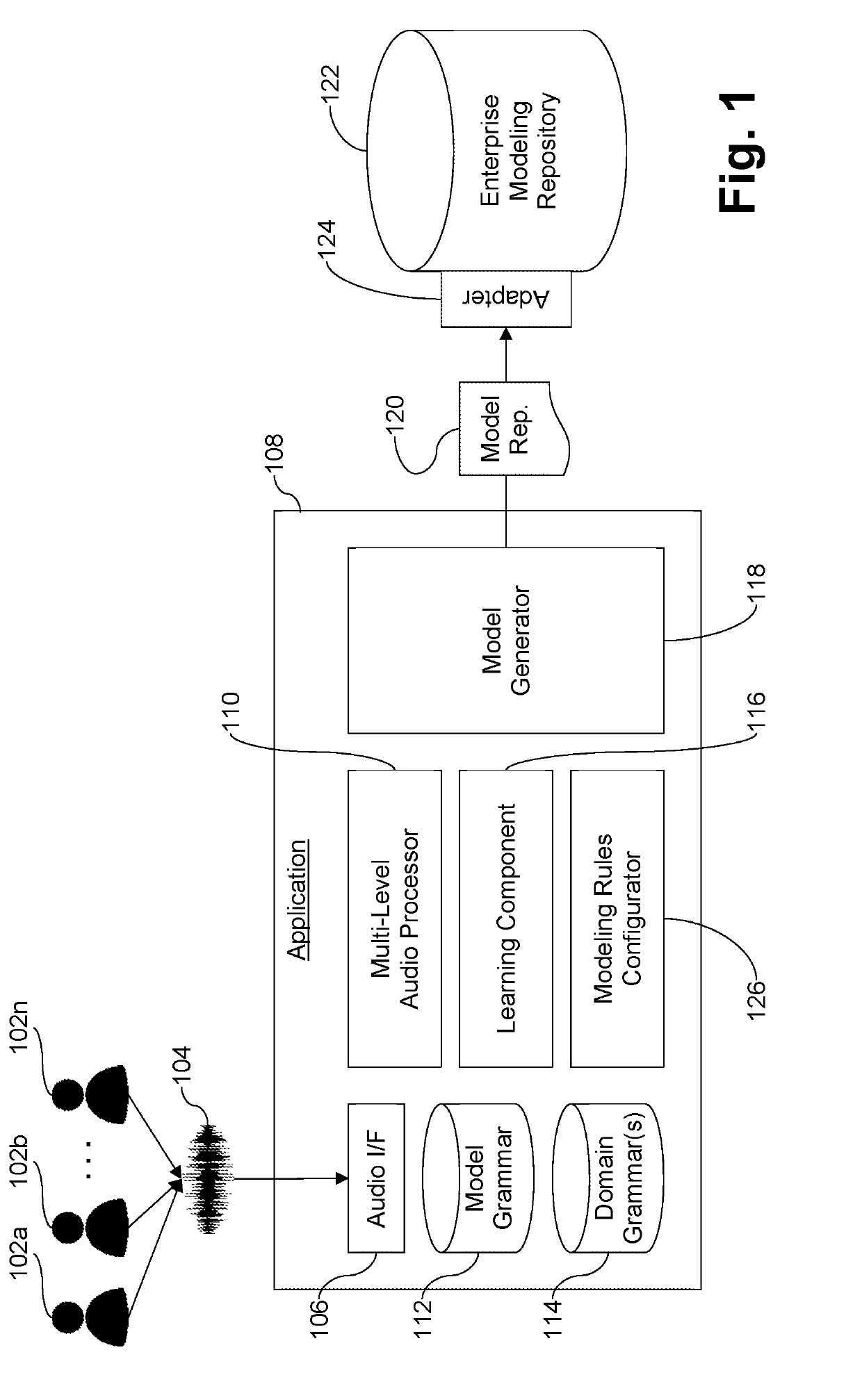

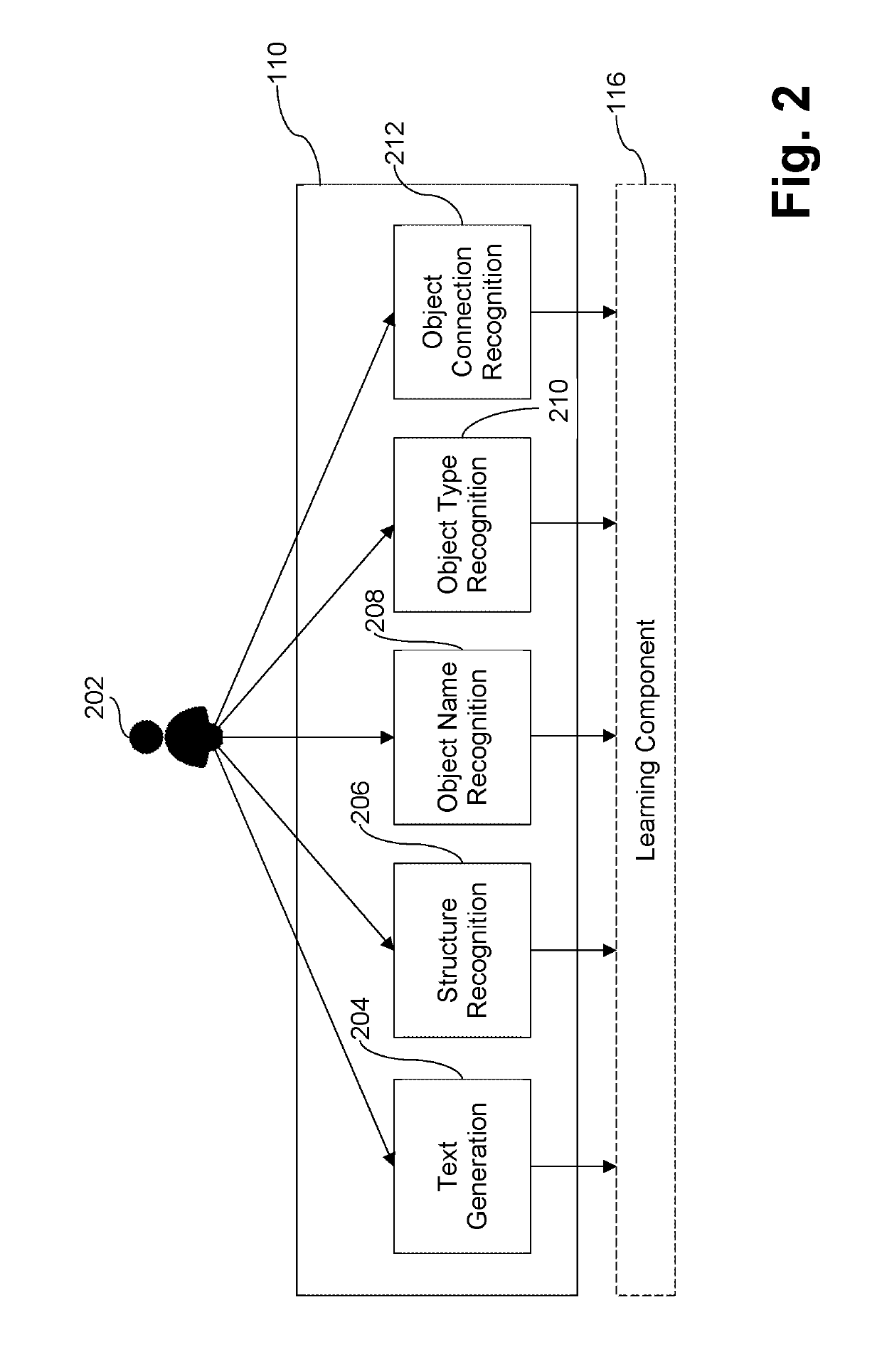

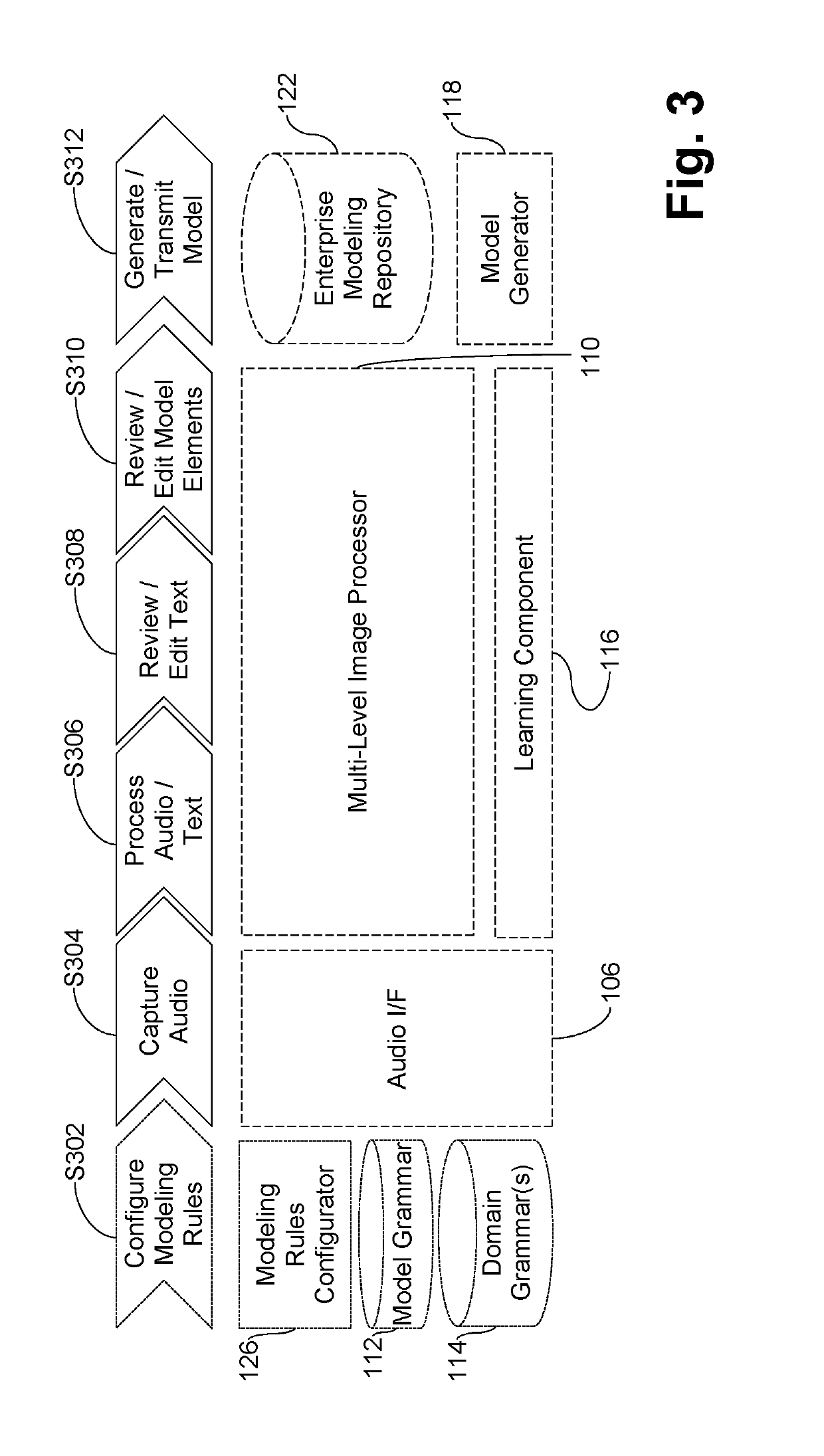

System and/or method for interactive natural semantic digitization of enterprise process models

ActiveUS20190318730A1Reduce labor burdenCreate quicklySemantic analysisSpeech recognitionEnterprise modellingEnterprise process

Certain example embodiments relate to techniques for creating computerized models usable with enterprise modeling platforms implementing formalized modeling languages. Audio input of an orally-described model having semantic concepts associable with the formalized language but following a natural language pattern rather than an input pattern expected by the formalized language is received. At least some of the semantic concepts are recognizable from a domain-specific grammar that includes possible semantic concepts that are arranged hierarchically and associated with a domain to which the computerized model being created belongs. At least some others are recognizable from a general grammar that includes other possible semantic concepts that are relevant to the computerized model and that are arranged hierarchically but that are domain-independent. A digitized iteratively-reviewed version of the orally-described model is transformed into the computerized model via rules defining relationships between elements therein, and the formalized language.

Owner:SOFTWARE AG

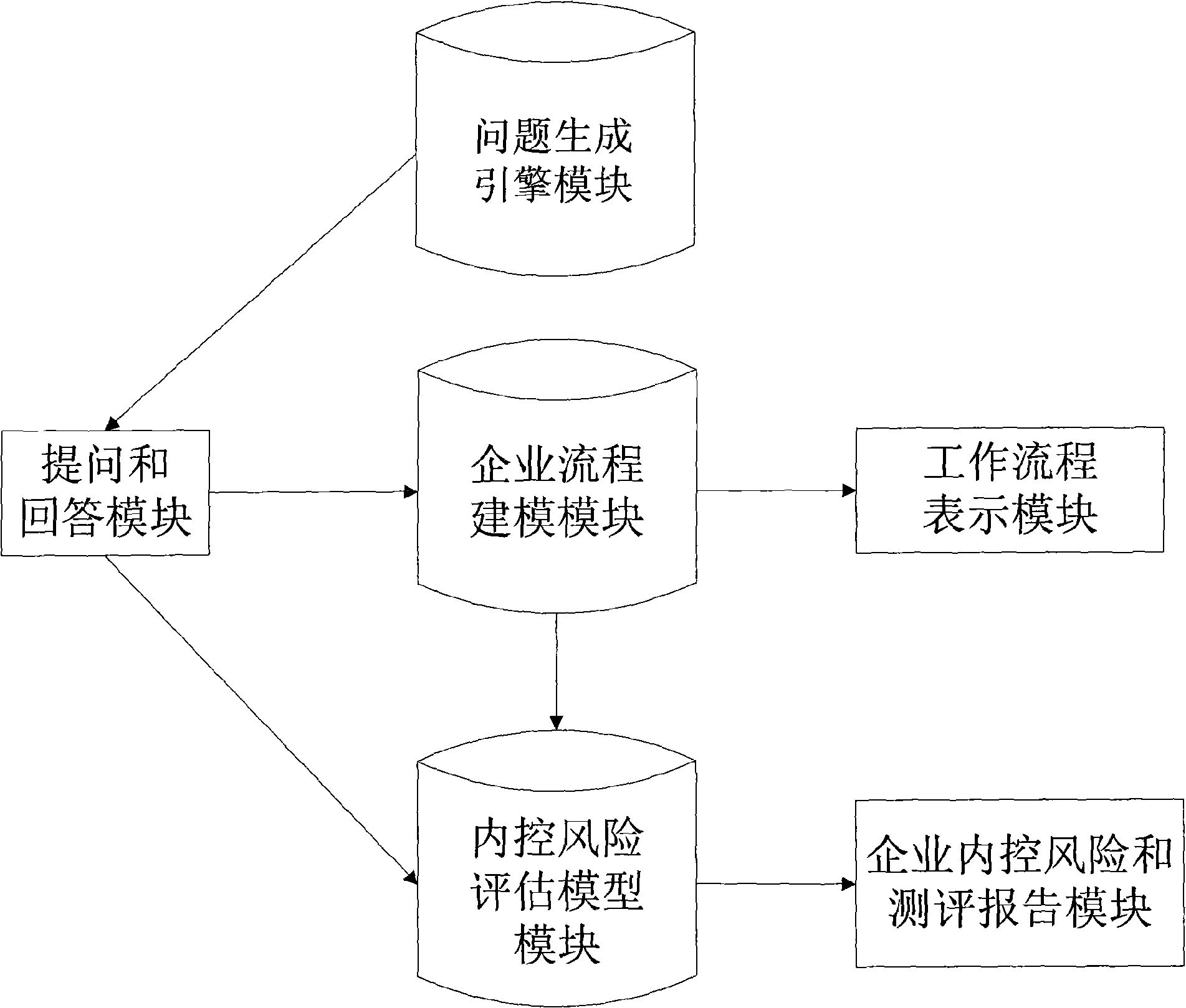

Interactive answer testing system and method orient to internal control of company

The invention relates to an interaction question-answering evaluation system and a method facing enterprise internal control, comprising: a question generation engine module for generating questions aiming at enterprise working process; a question-answering module for providing the generated questions and giving subsequent questions according to answers of the questions; an enterprise process modeling module for building the enterprise working process module according to the questions; an internal control risk assessment model module for analyzing the answer of the questions and the working process module and generating an internal control risk assessment model. The invention can make staff allodium answer the given question so that the system can automatically give the working process module described by a flow chart and a narrative file. Via arranging questions and the answer of user, the invention can gain risk of the enterprise existed in the process and corresponding severity, and give a risk point of the enterprise internal control. The invention is in stead of existing consultant reference mode and is provided with nice interactivity.

Owner:上海立信锐思信息管理有限公司

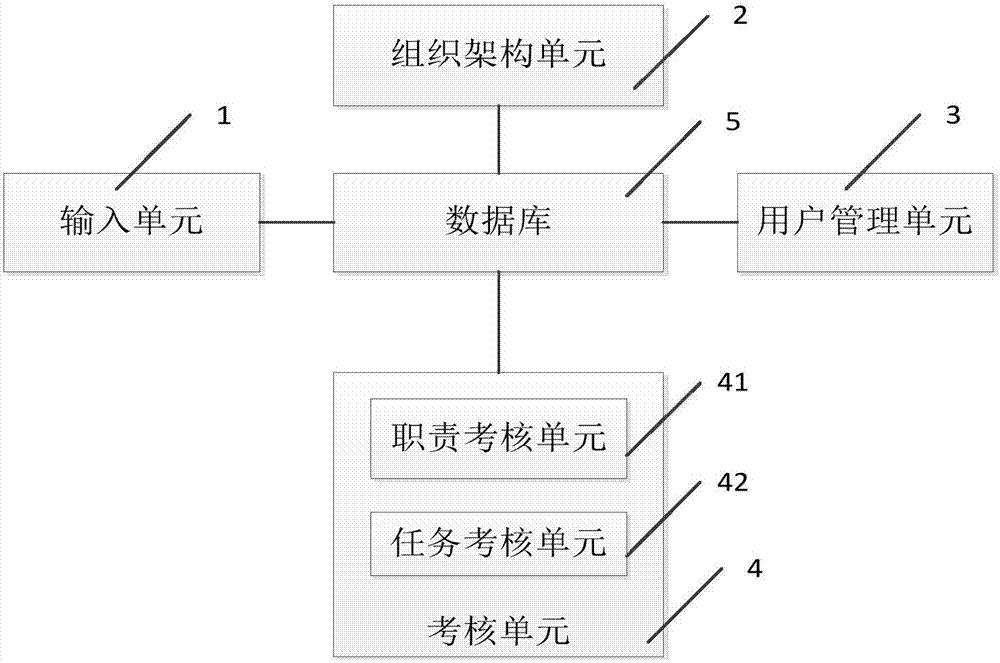

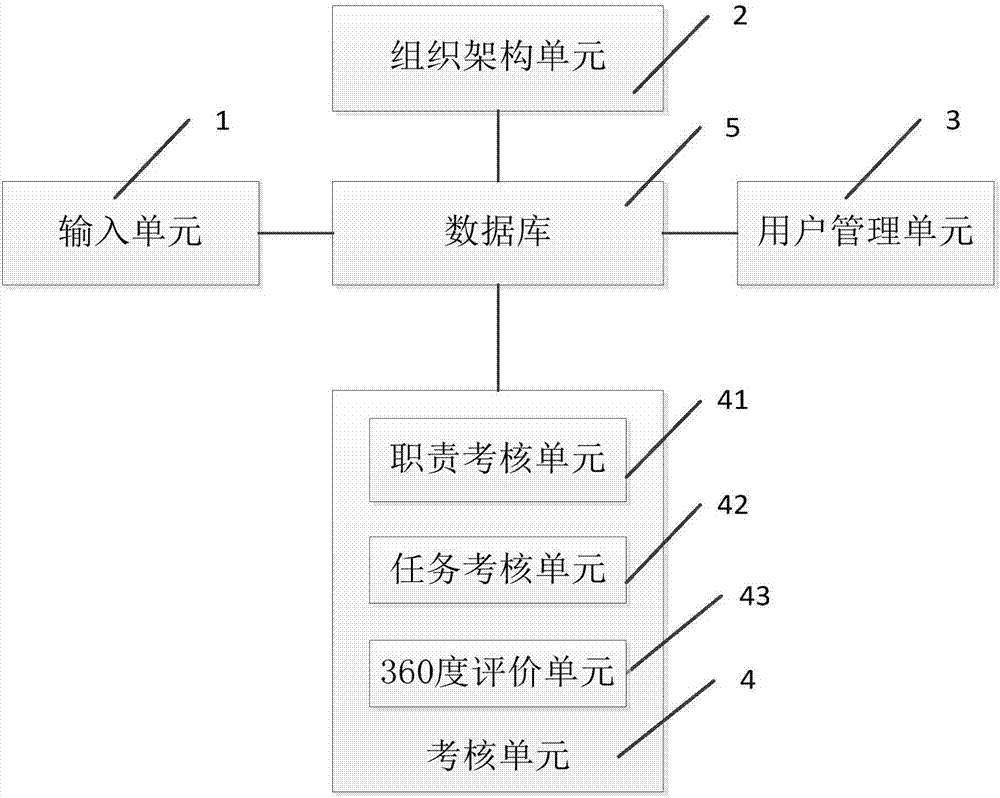

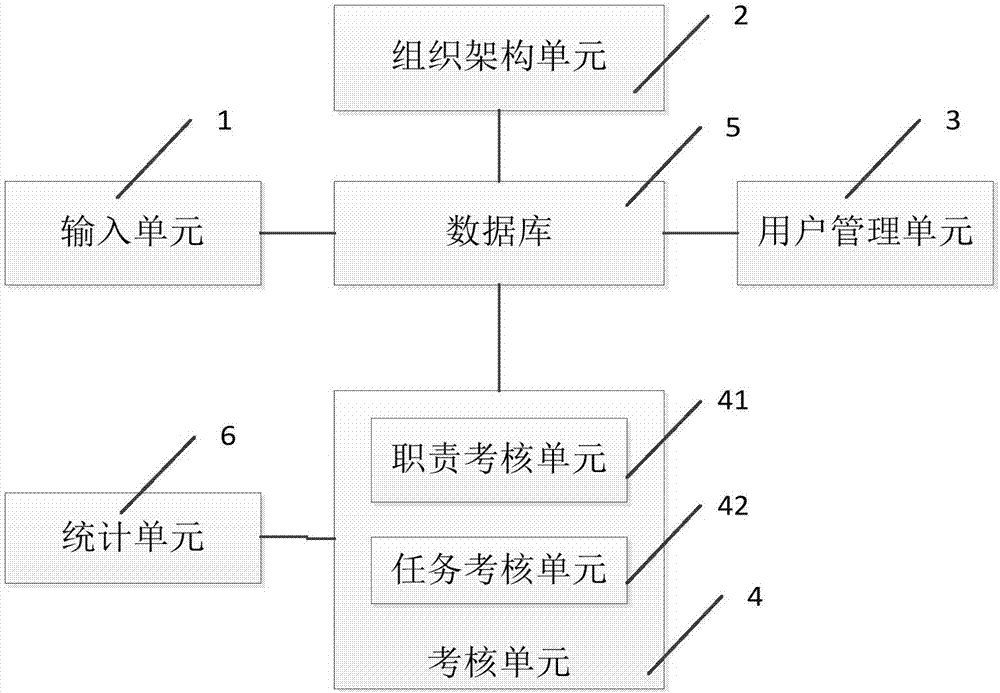

Enterprise process checking system

InactiveCN107578156APromote resultsEnsure objectivityOffice automationResourcesTask completionEnterprise process

The invention provides an enterprise process checking system, and relates to the technical field of management systems. The enterprise process checking system comprises an input unit, an organizational structure unit, a user management unit, a checking unit and a database, the organizational structure unit is used for setting organizational structure grades according to the organizational structure of the enterprise; the user management unit is used for managing the basic information of the user and managing the user authority according to the organizational structure grades; the checking unitcomprises a responsibility checking unit and a task checking unit, and the responsibility checking unit is used for checking according to employee duty clauses; and the task checking unit is used for checking according to the task completion condition; By collecting and checking the behavior information of employees in the daily work, the employees are urged to fulfill their tasks on the basis of compliance with discipline, good results are guaranteed by a good process. The employees can check the details of their punishment, the checking results of their goals and tasks and the satisfactiondegrees of their service levels, so as to ensure the fairness and impartiality of the employee checking link.

Owner:陈爱吾

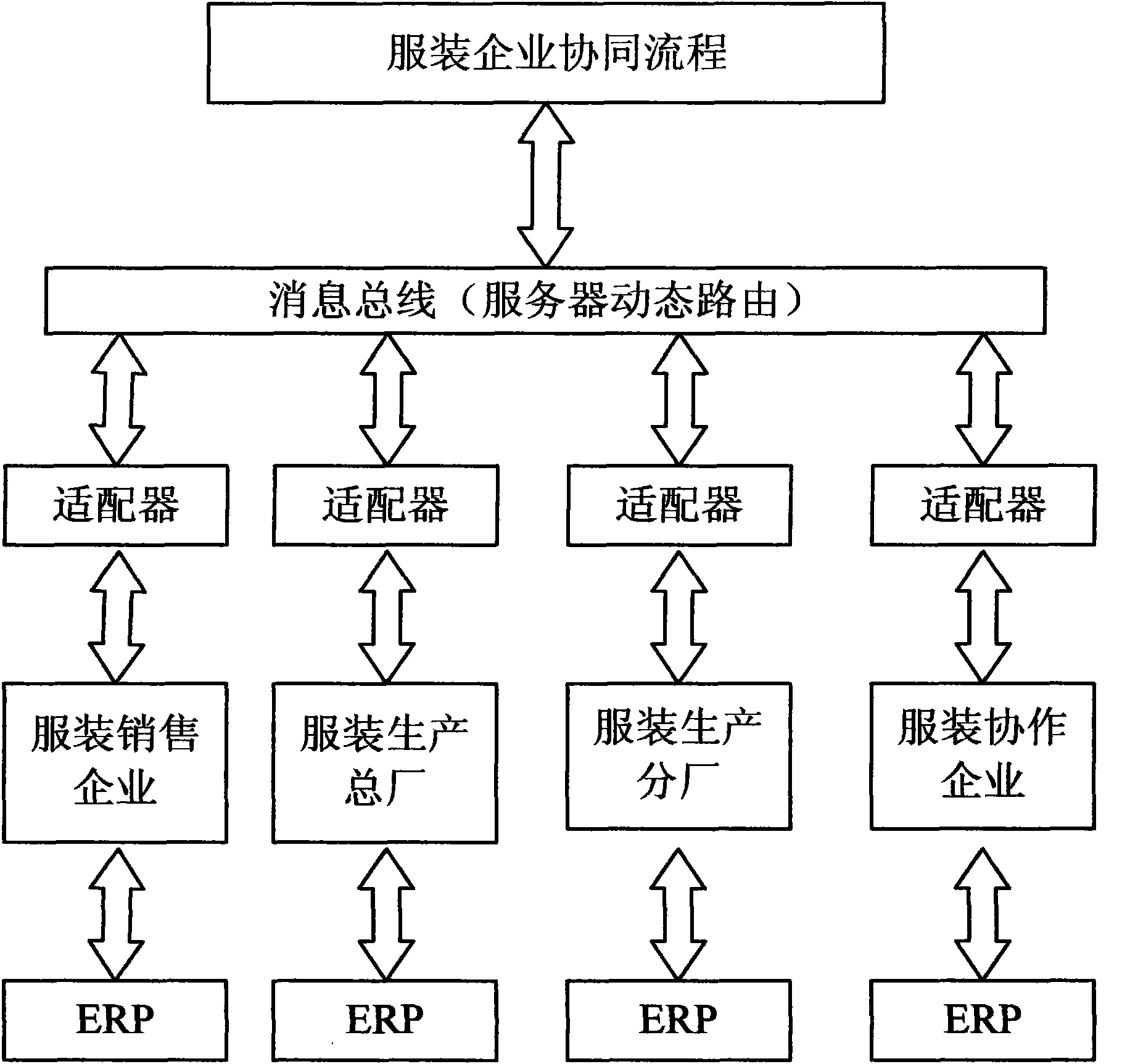

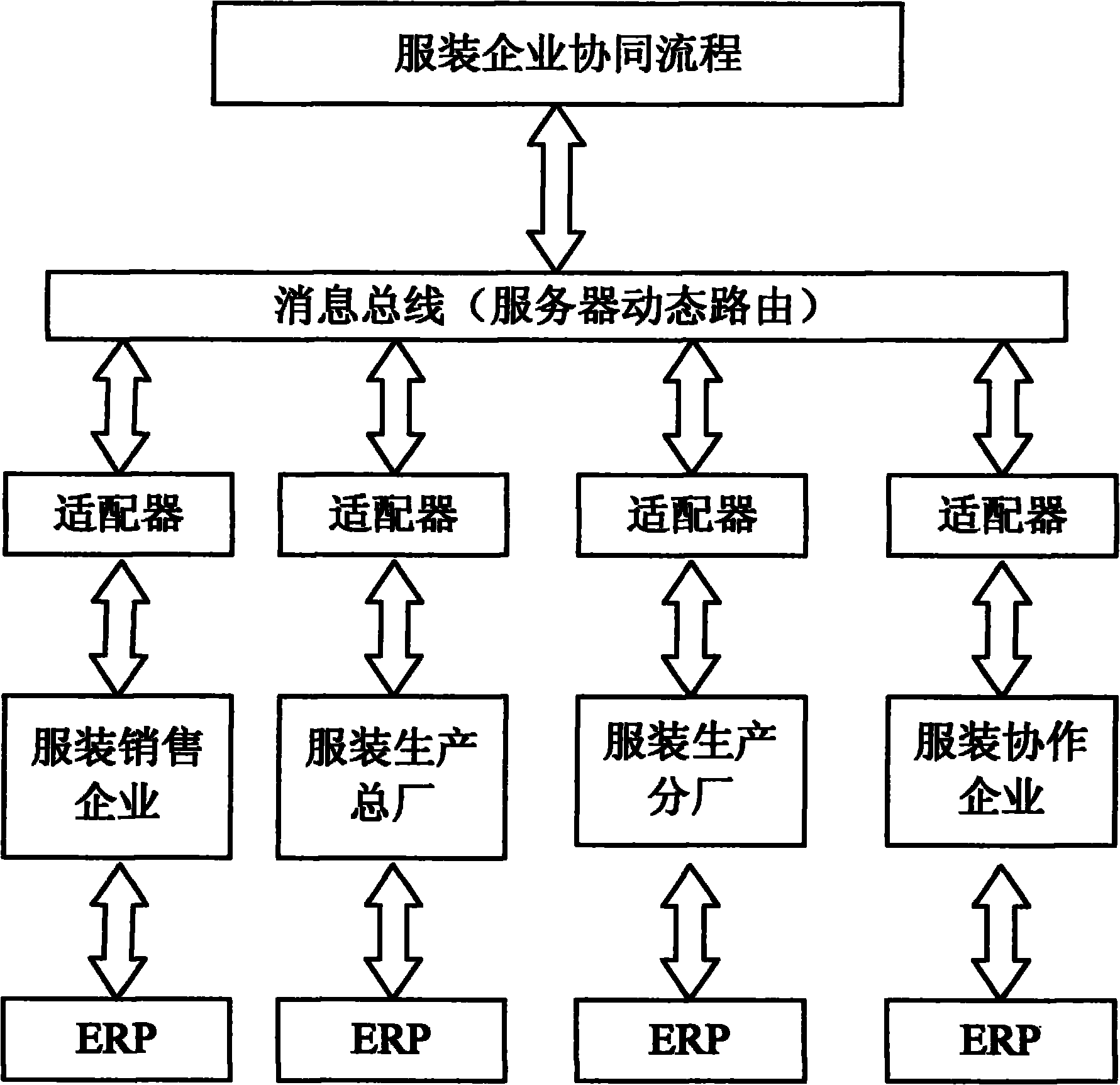

SOA (service oriented architecture)-based clothing enterprise collaboration flow path integration method

InactiveCN102096853AImprove development efficiencyHighly integratedResourcesTransmissionEnterprise processEnterprise resource planning

The invention provides an SOA (service oriented architecture)-based clothing enterprise collaboration flow path integration method which comprises the steps: 1) building an SOA integration development system platform which comprises at least one of message buses; 2) modeling and analyzing a collaboration flow path, and offering a target collaboration flow path by combining with the current situation of the existing ERP (enterprise resource planning) system of each enterprise; 3) under the SOA architecture, integrating the existing ERP system of each enterprise at a resource layer, and integrating the message buses at a service layer; 4) developing a Mediation procedure of an adapter; 5) connecting the ERP of each enterprise to the message buses WESB (websphere enterprise service bus) by the websphere process server deploy in the manner of Web Services; and 6) searching service routing information by the WESB according to the content of an SOAP (simple object access protocol) packet, dynamically routing a request to a corresponding service, and routing the calling operation of an ERP system resource service and analyzing a service data pair by the Mediation of the adapter to realize the clothing sale, the clothing production, and the assist of the collaboration of the production enterprise flow path. The method is used for developing a cross-industry, cross-region and cross-platform integrated collaboration management system in the clothing enterprises.

Owner:DONGGUAN GOSCIEN ELECTRICAL & MECHANICAL TECH SERVICES +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com