Patents

Literature

89 results about "Amorphous germanium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

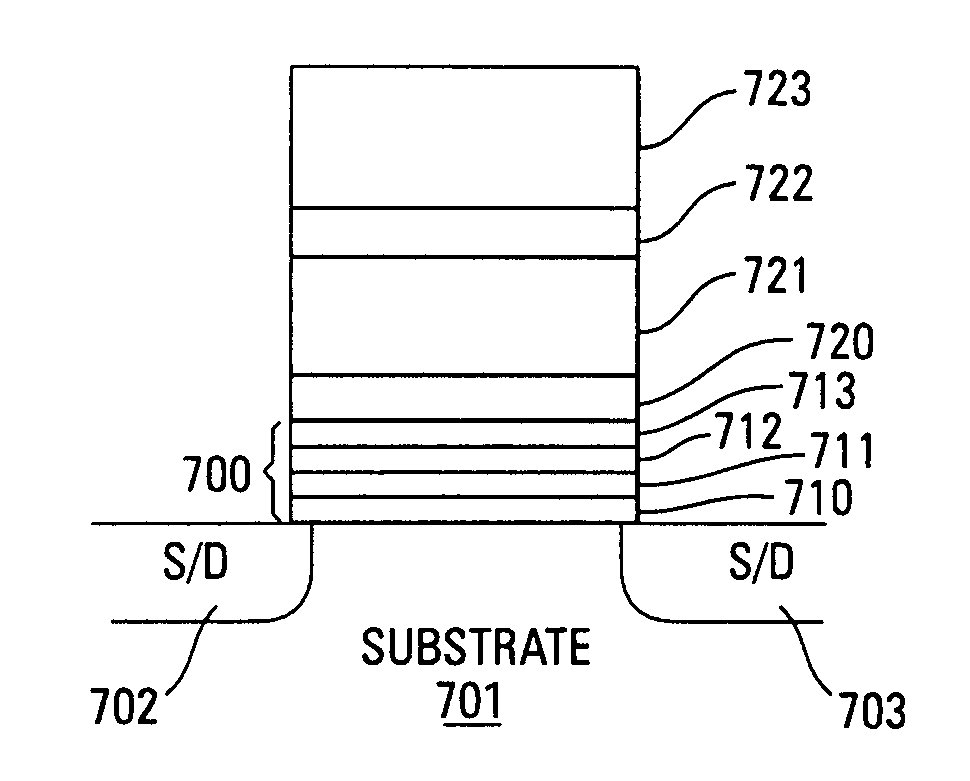

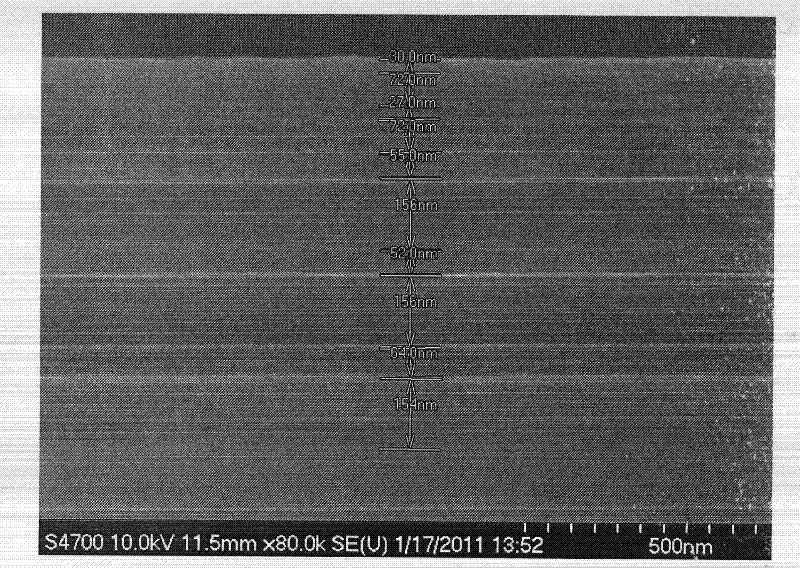

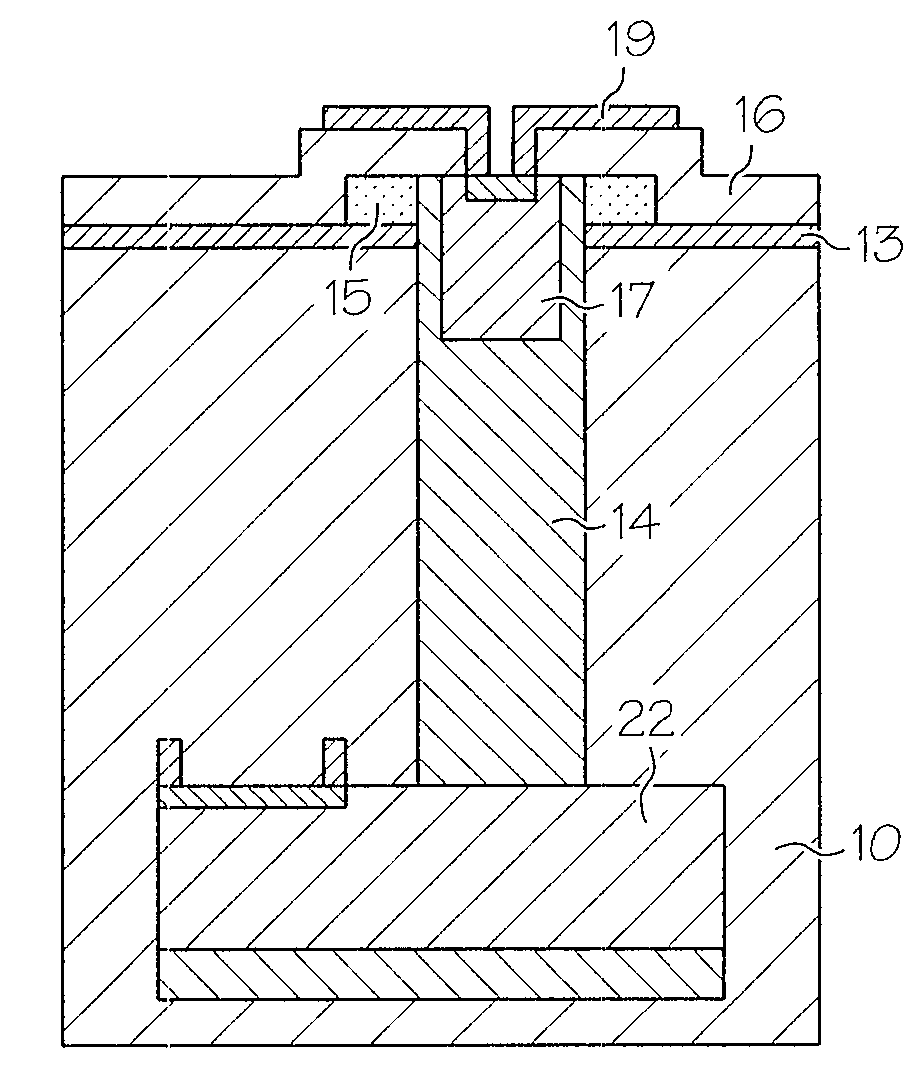

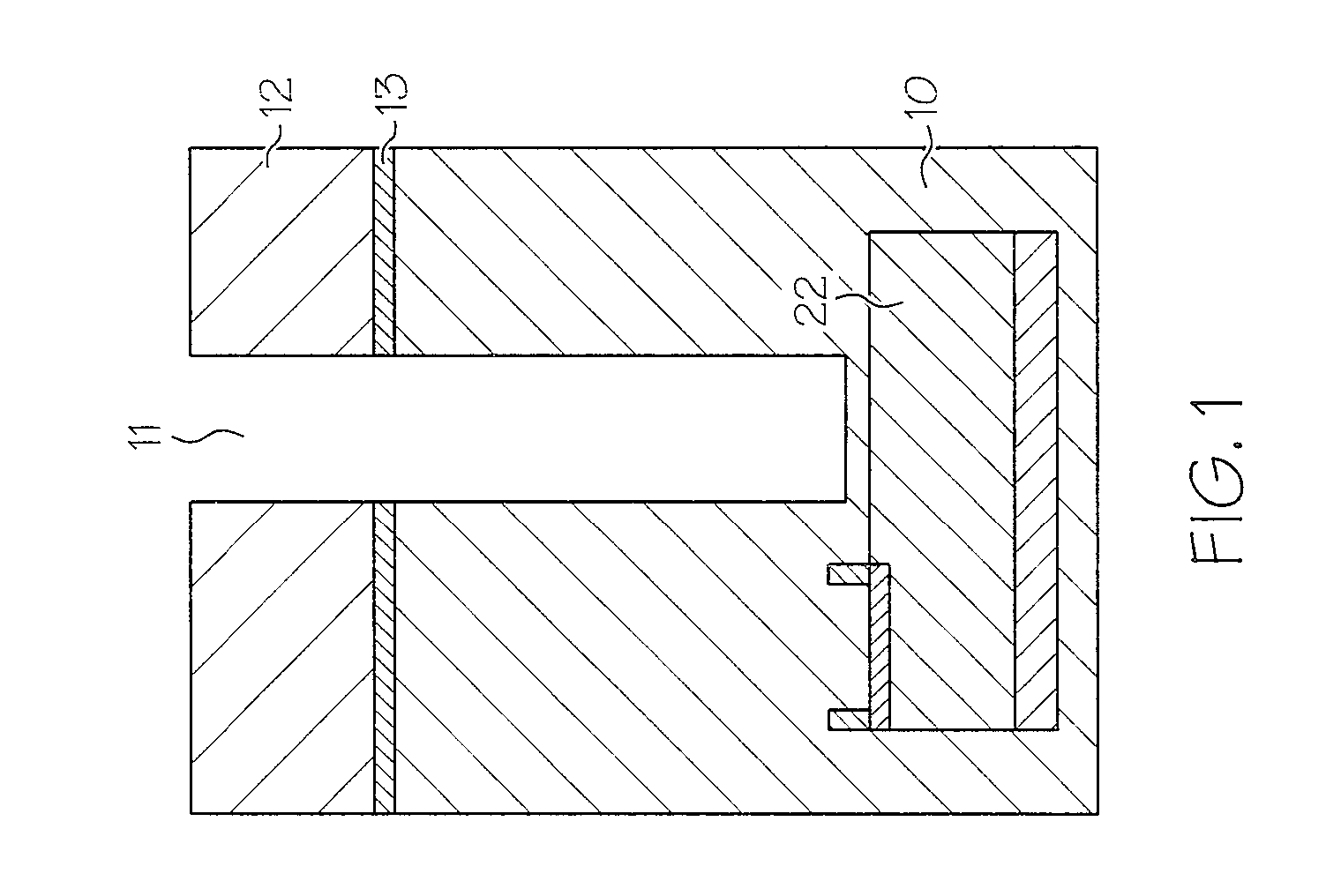

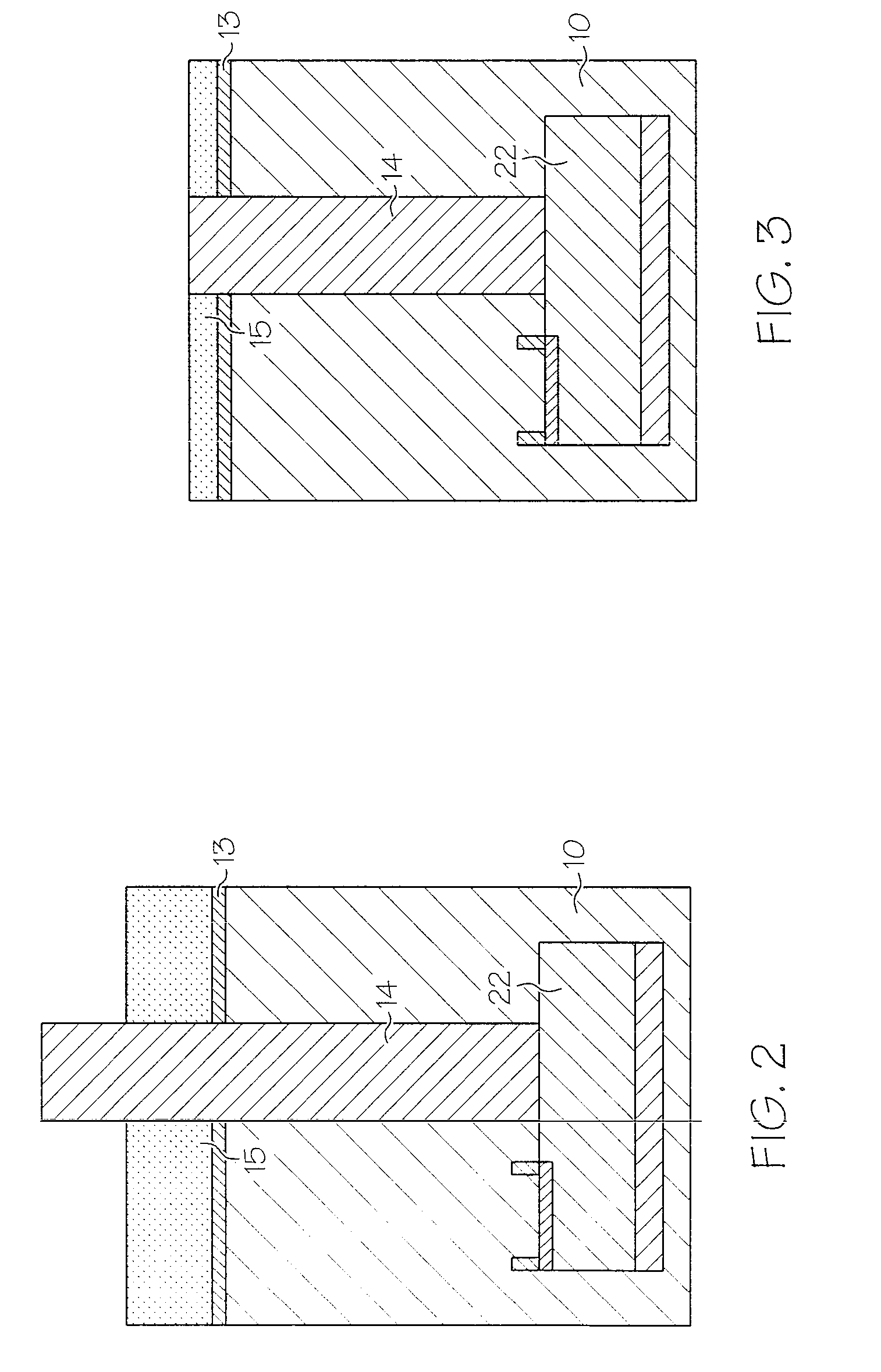

Enhanced multi-bit non-volatile memory device with resonant tunnel barrier

A non-volatile memory cell uses a resonant tunnel barrier that has an amorphous silicon and / or amorphous germanium layer between two layers of either HfSiON or LaAlO3. A charge trapping layer is formed over the tunnel barrier. A high-k charge blocking layer is formed over the charge trapping layer. A control gate is formed over the charge blocking layer. Another embodiment forms a floating gate over the tunnel barrier that is comprised of two oxide layers with an amorphous layer of silicon and / or germanium between the oxide layers.

Owner:MICRON TECH INC

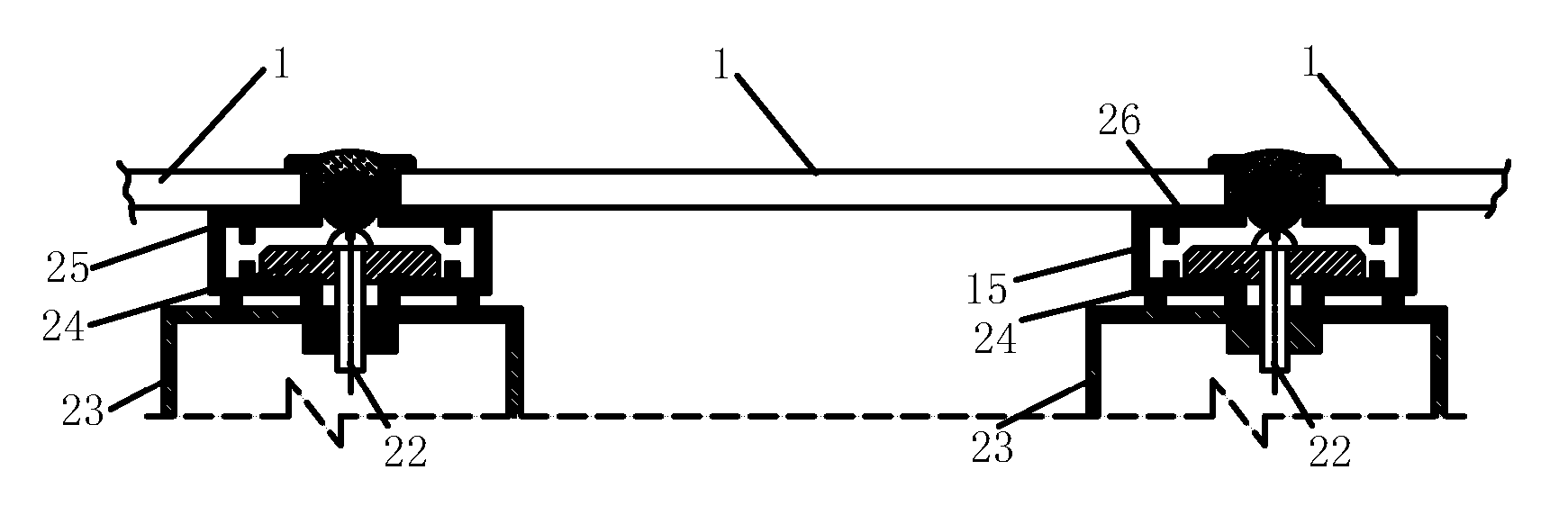

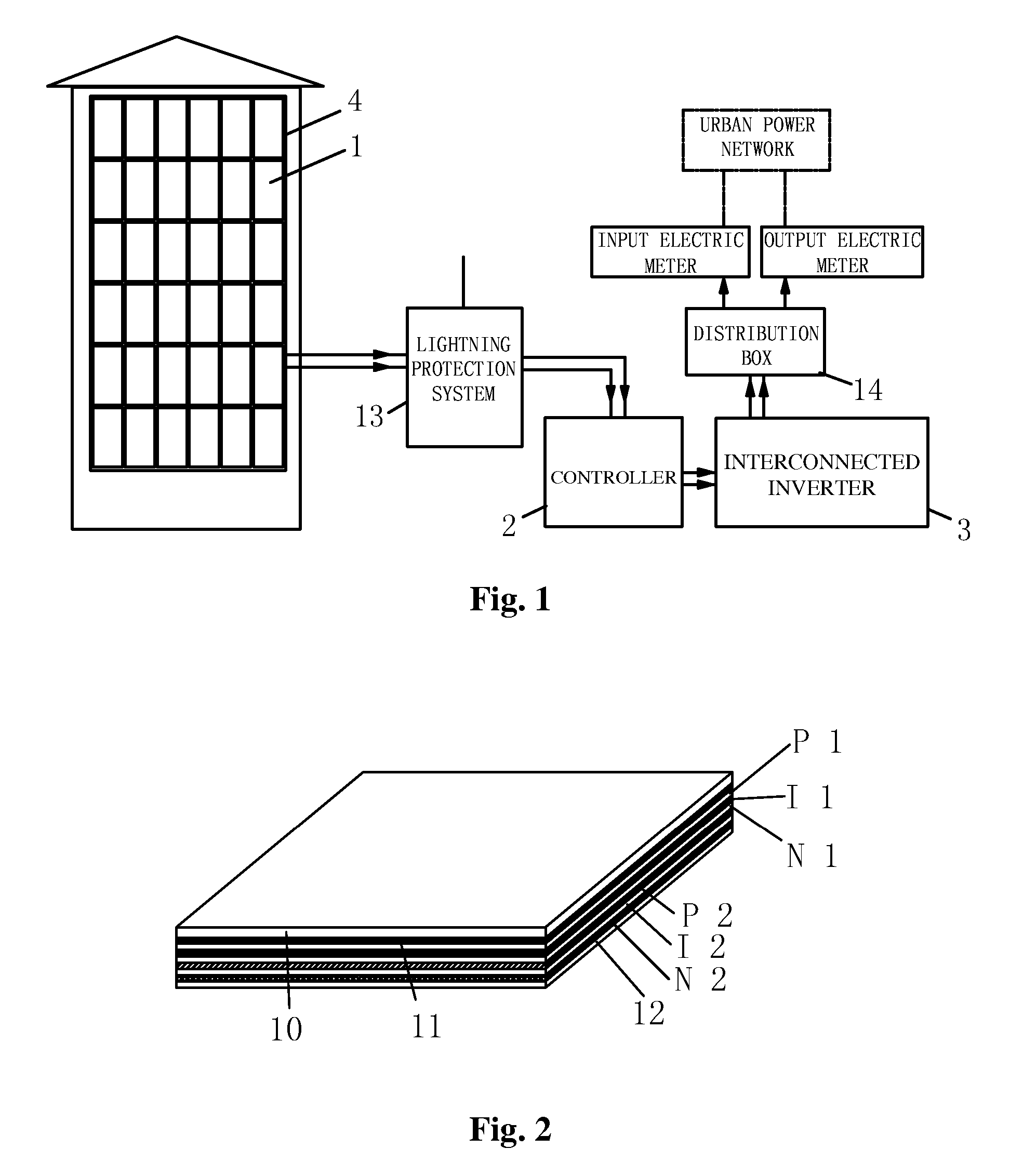

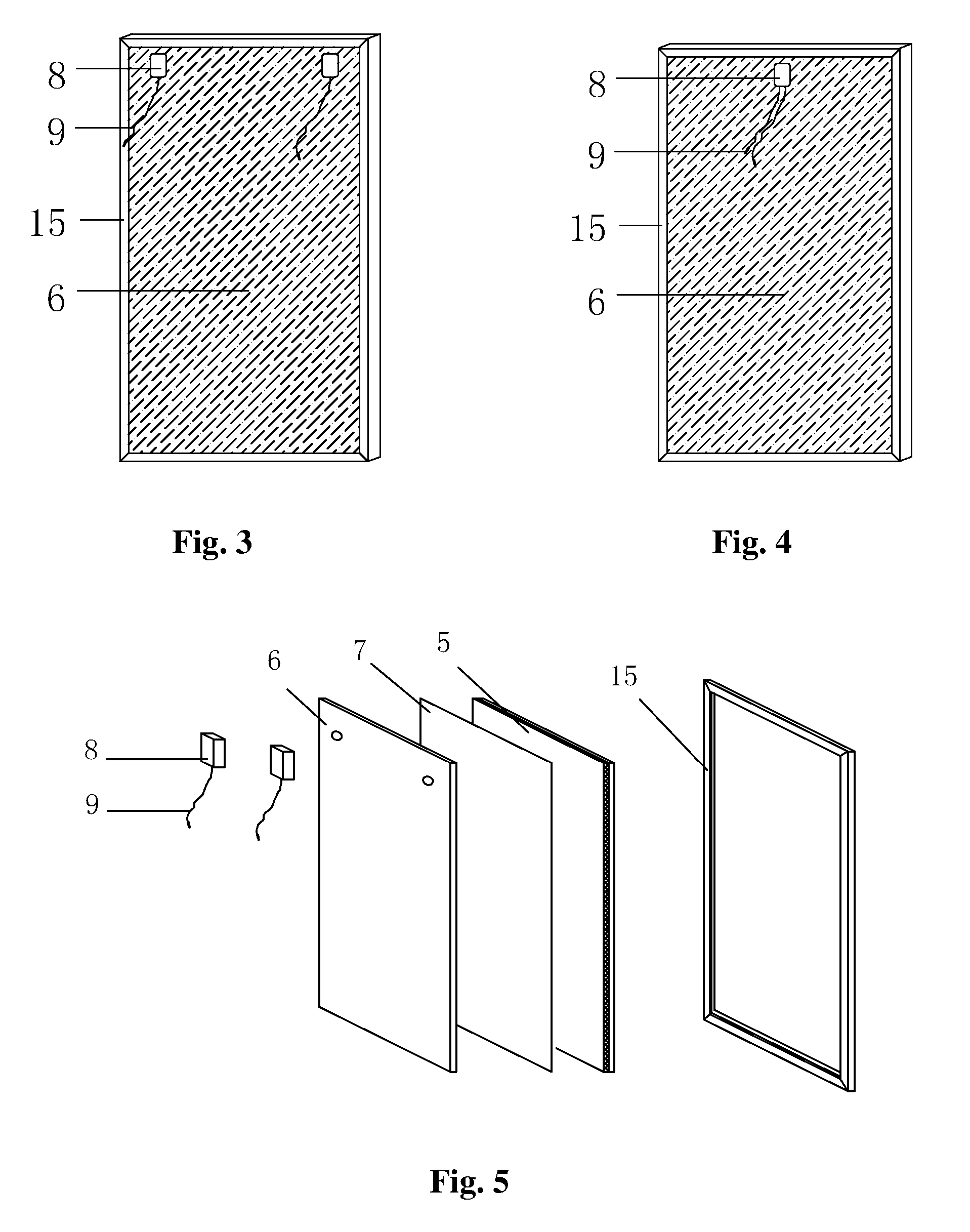

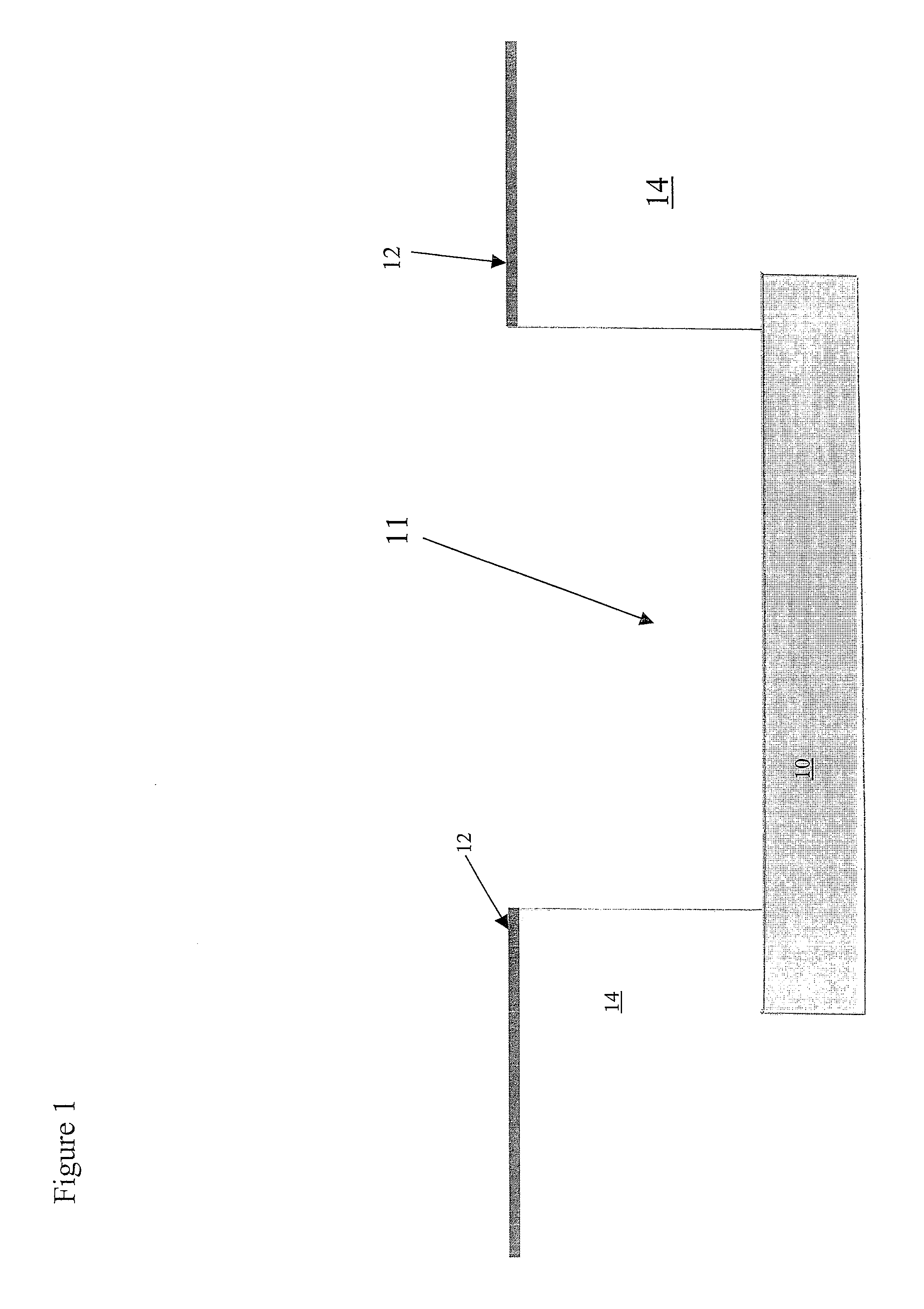

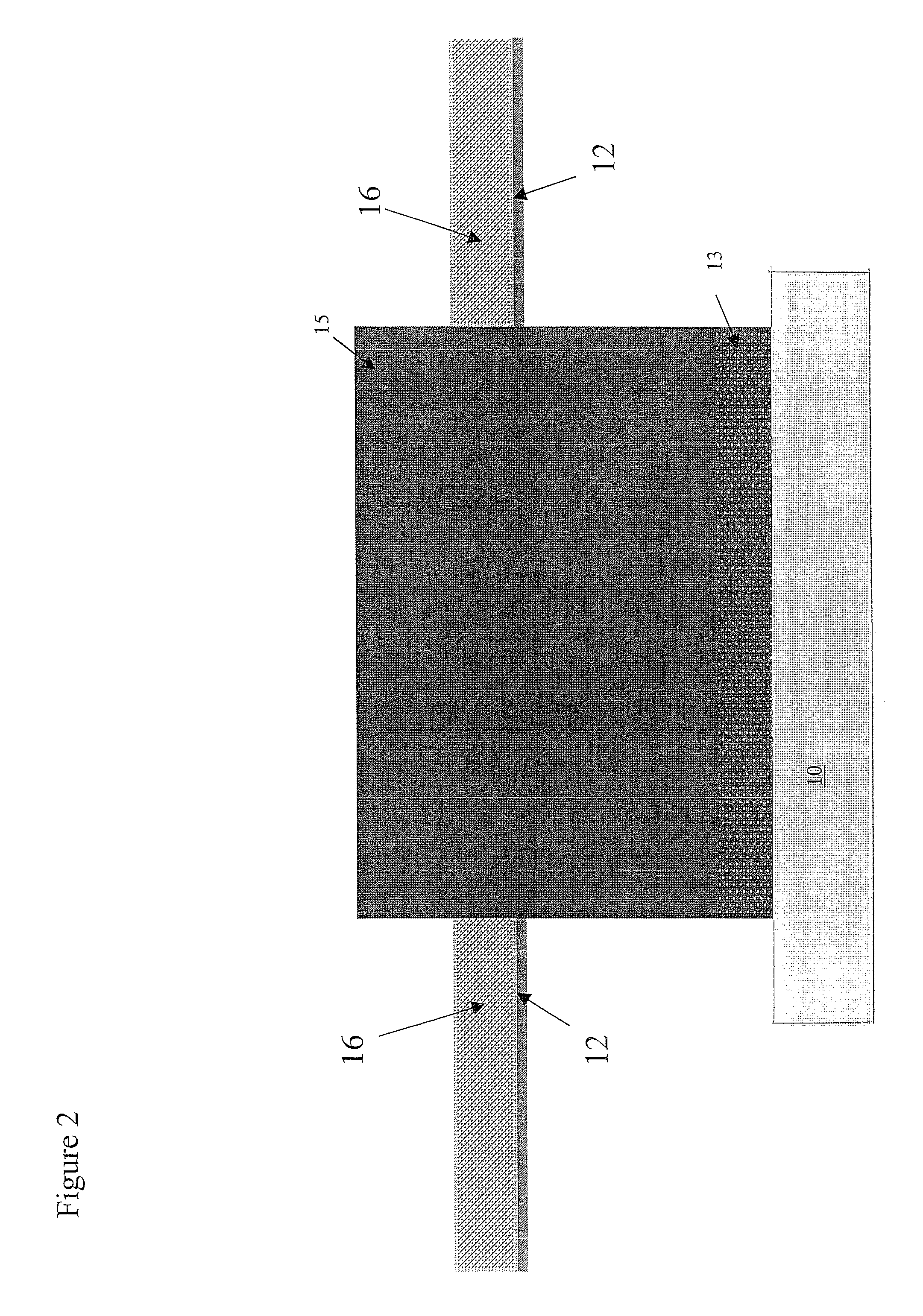

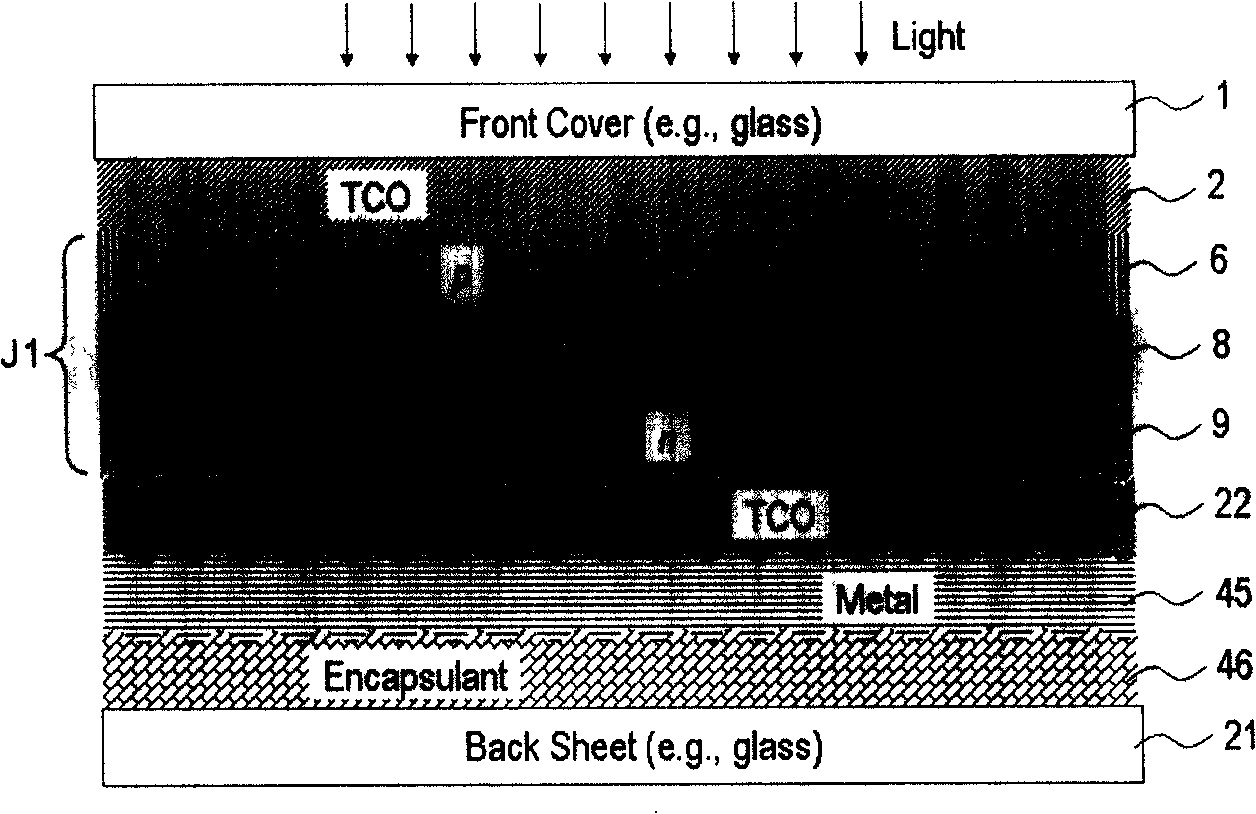

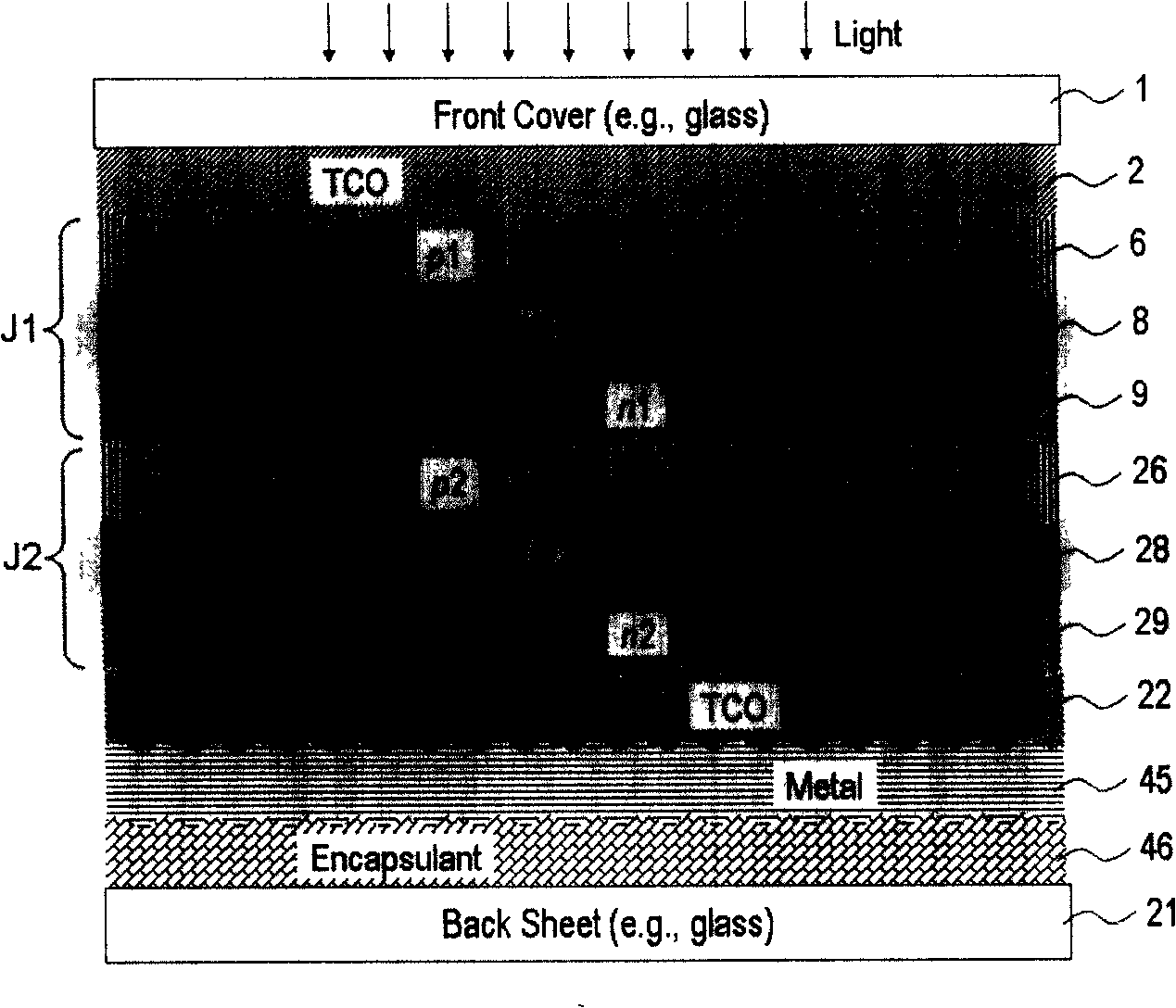

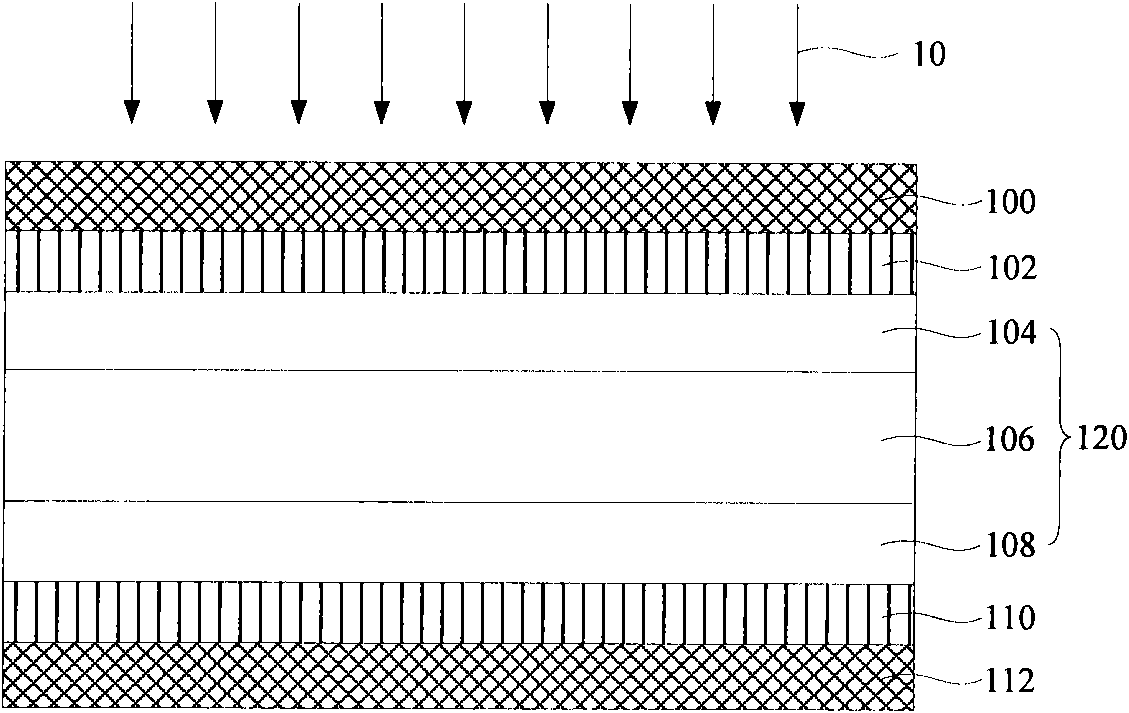

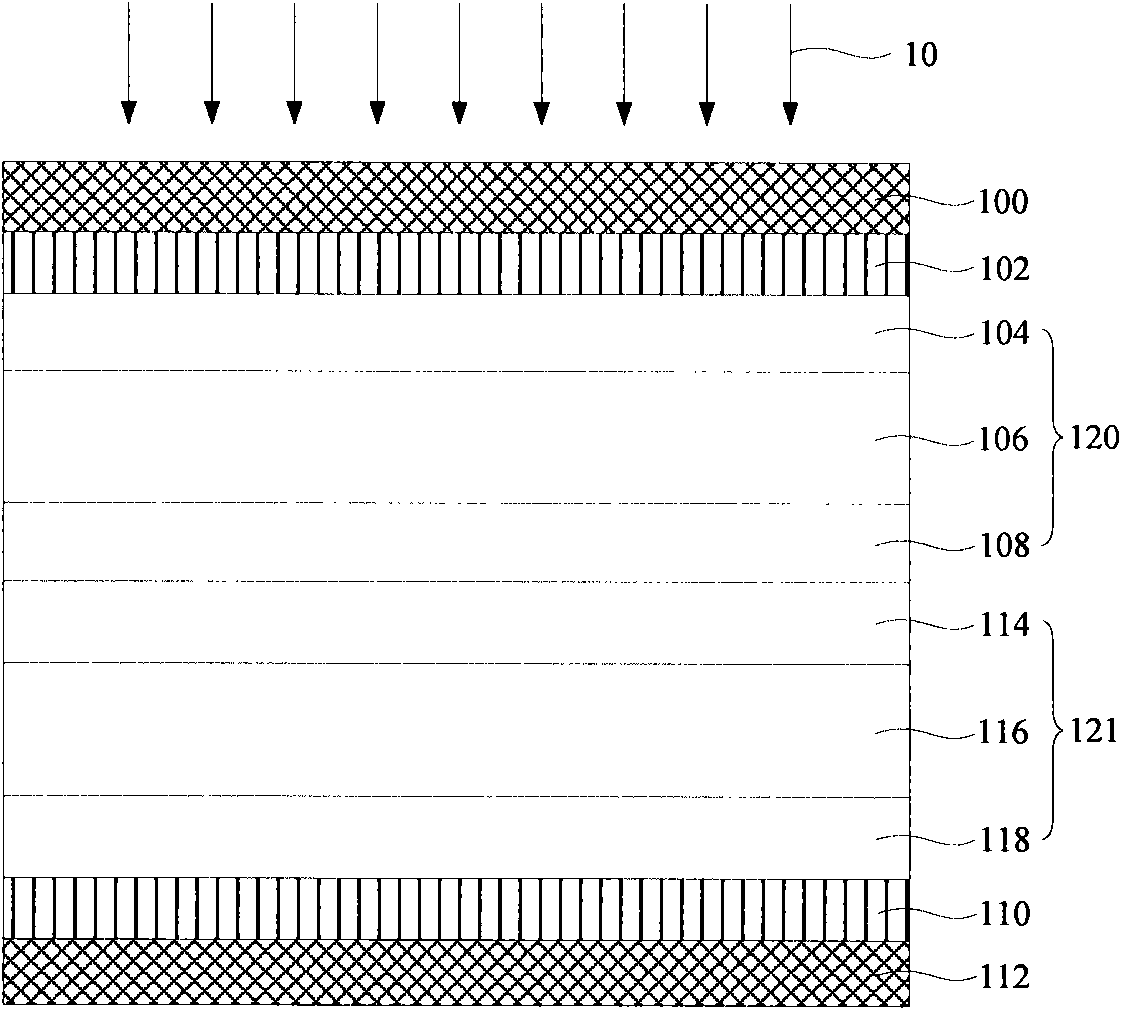

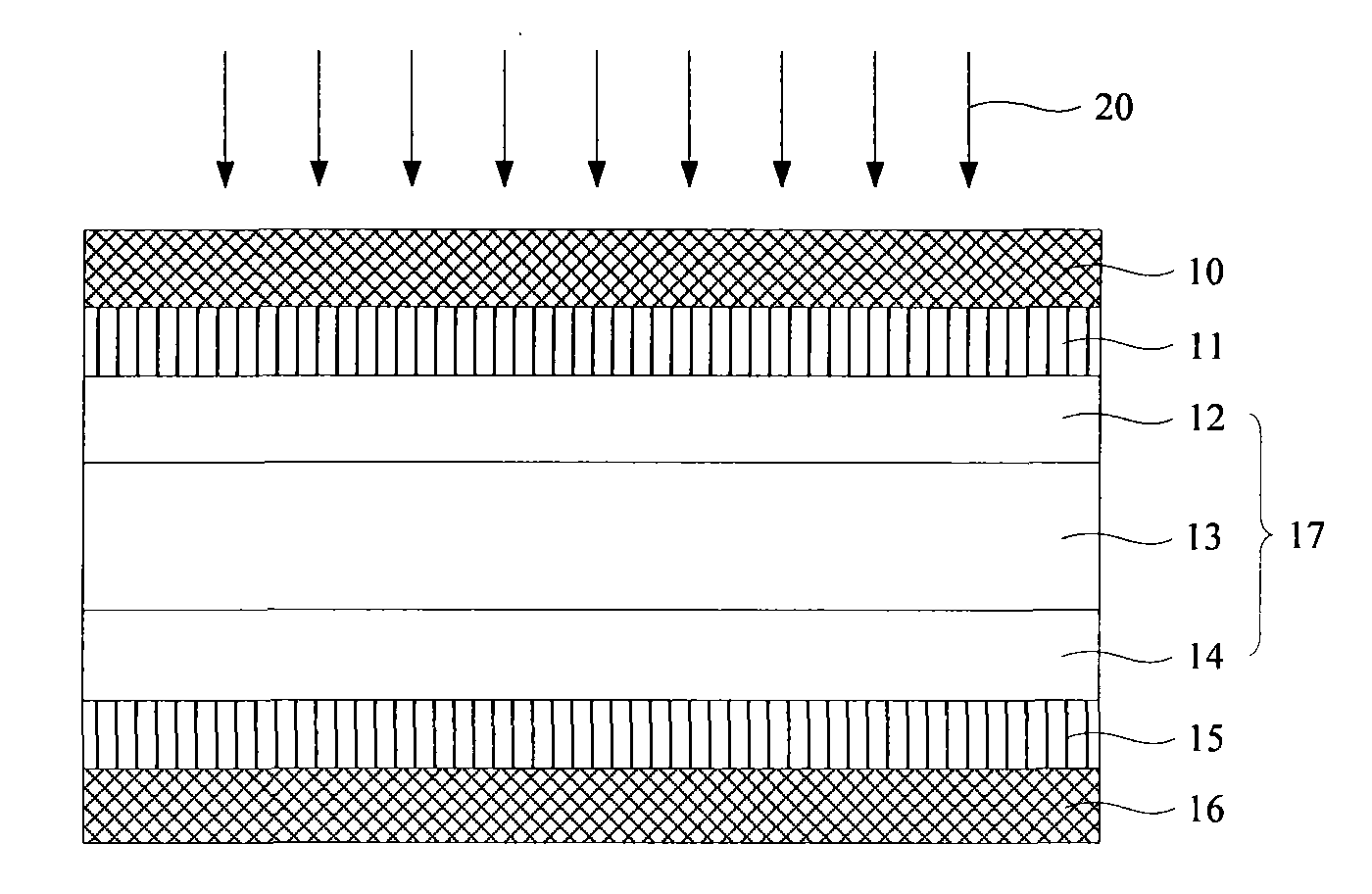

Integrated amorphous silicon double-junction solar cell curtain wall and methods for manufacturing and using the same

InactiveUS20080092952A1Provide energyImprove performanceFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSolar power

Provided is an integrated amorphous silicon double-junction solar cell curtain wall, comprising a plurality of photovoltaic curtain wall plates, each of which being encapsulated by a double-junction amorphous silicon solar cell chip with a glass substrate, a glass plate, a glue film, a junction box, a lead and a frame; and an electric control unit having a controller; wherein an output of the photovoltaic curtain wall plate is connected to the controller of the electric control unit. A double-junction double-layer solar cell top cell film layer and a bottom cell film layer are disposed on a glass substrate of the cell chip, each of the top cell film layer and the bottom cell film layer comprising a P-layer, an I-layer, and an N-layer; an I-layer of the top cell film layer is amorphous silicon; and an I-layer of the bottom cell film layer is amorphous silicon or amorphous germanium-silicon. The invention solves problems of solar power generation and application, and features with good energy saving effect, safety, reliability and wide applications. Generated energy of the cell chip per square meter is 30-60 W, photoelectric conversion efficiency is 5-7%, an attenuation rate is 20-30%, output efficiency after conversion is approximately 80%. The invention is usable for solar power generation and wall decoration of buildings.

Owner:CHEN WUKUI +2

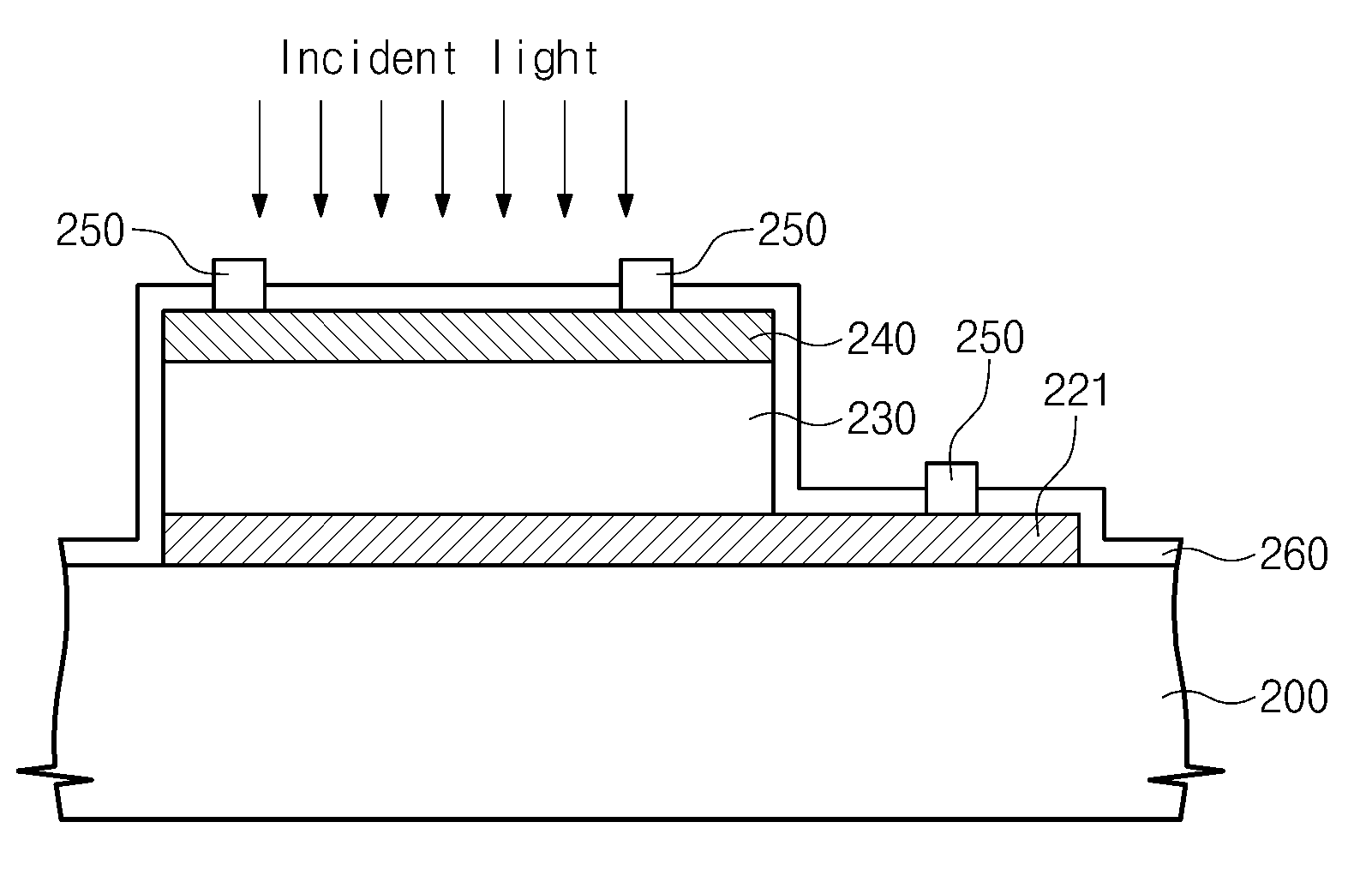

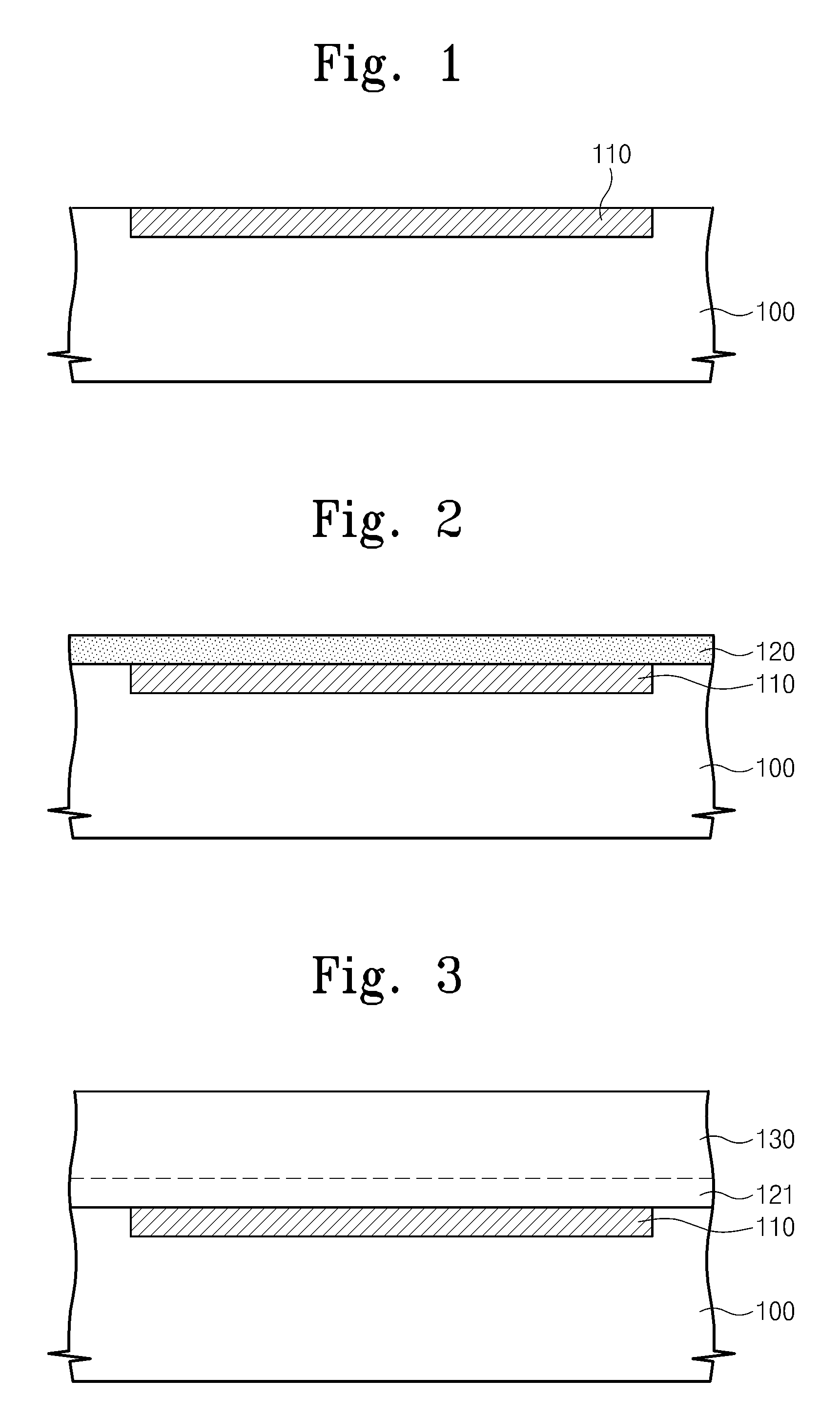

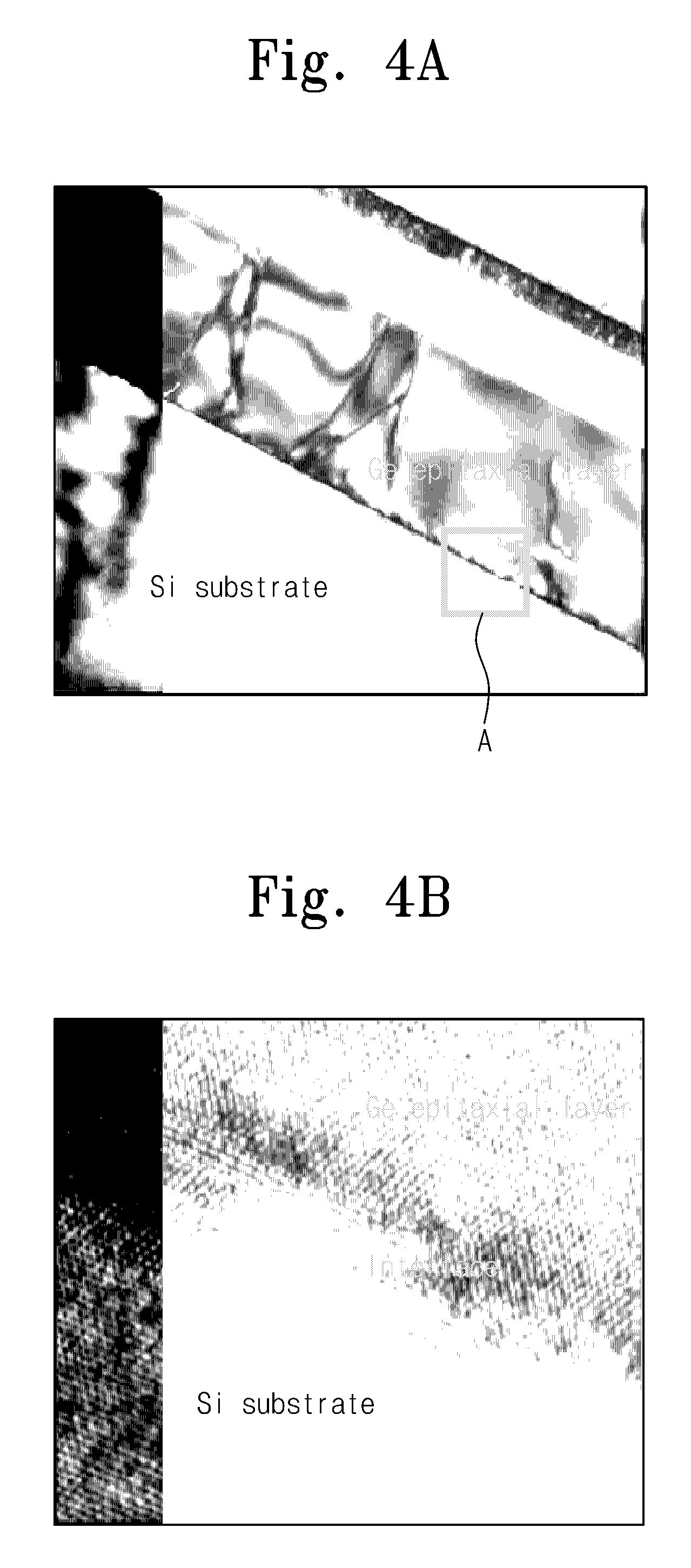

Germanium photodetector and method of fabricating the same

Provided is a germanium photodetector having a germanium epitaxial layer formed without using a buffer layer and a method of fabricating the same. In the method, an amorphous germanium layer is formed on a substrate. The amorphous germanium layer is heated up to a high temperature to form a crystallized germanium layer. A germanium epitaxial layer is formed on the crystallized germanium layer.

Owner:ELECTRONICS & TELECOMM RES INST

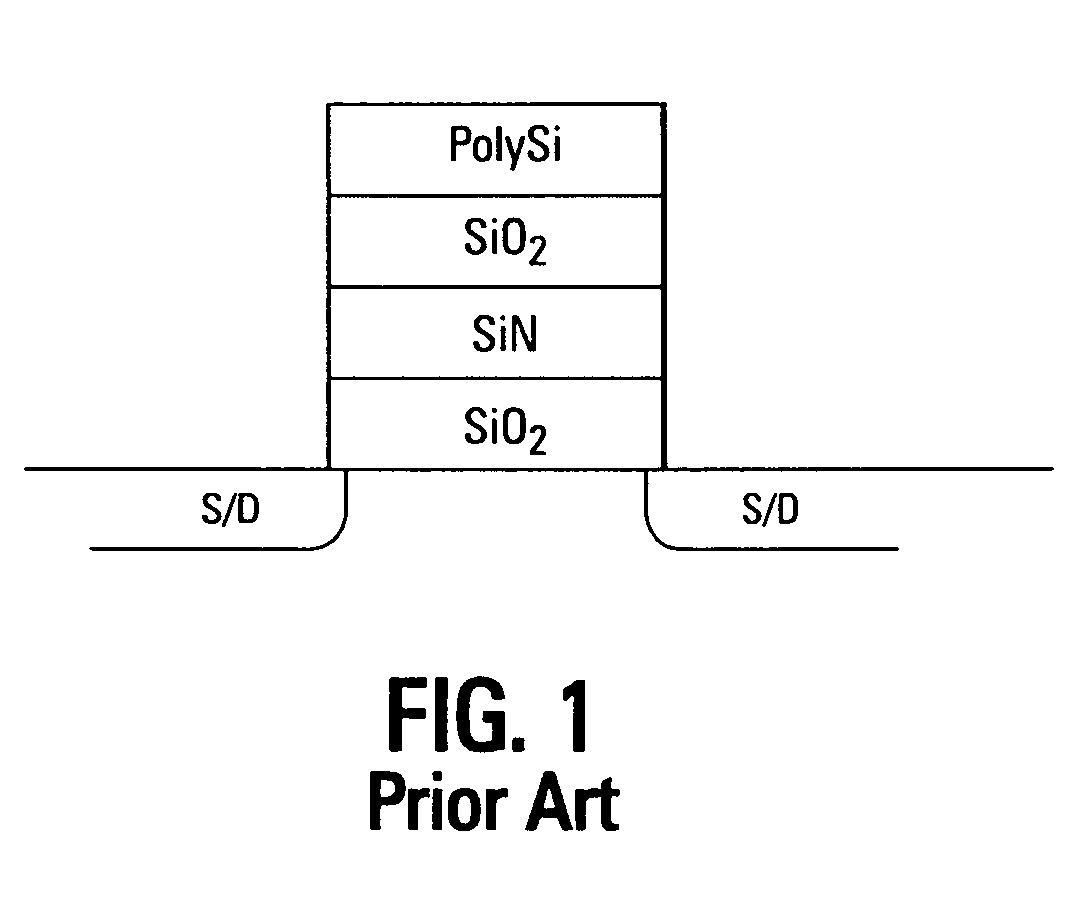

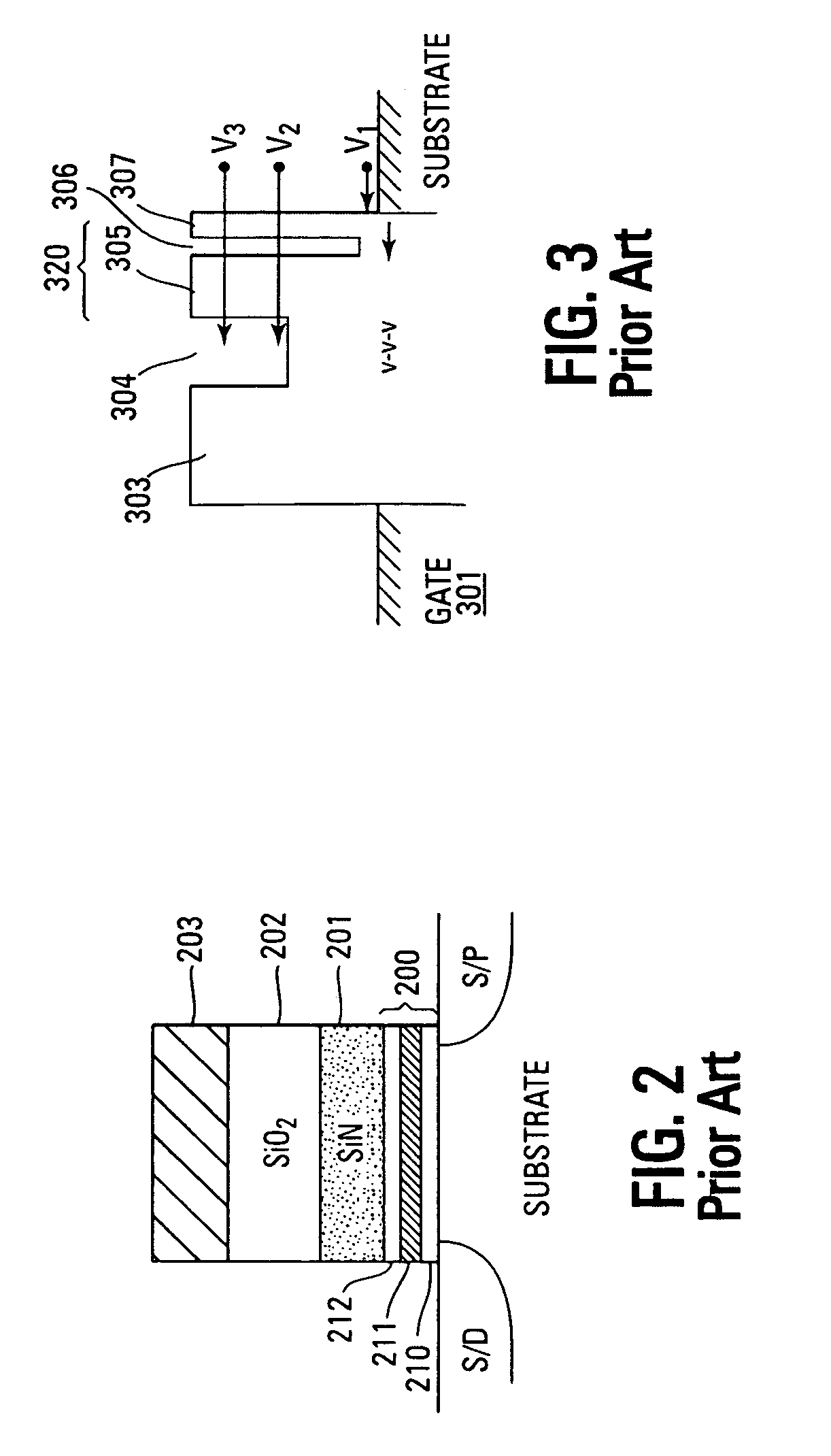

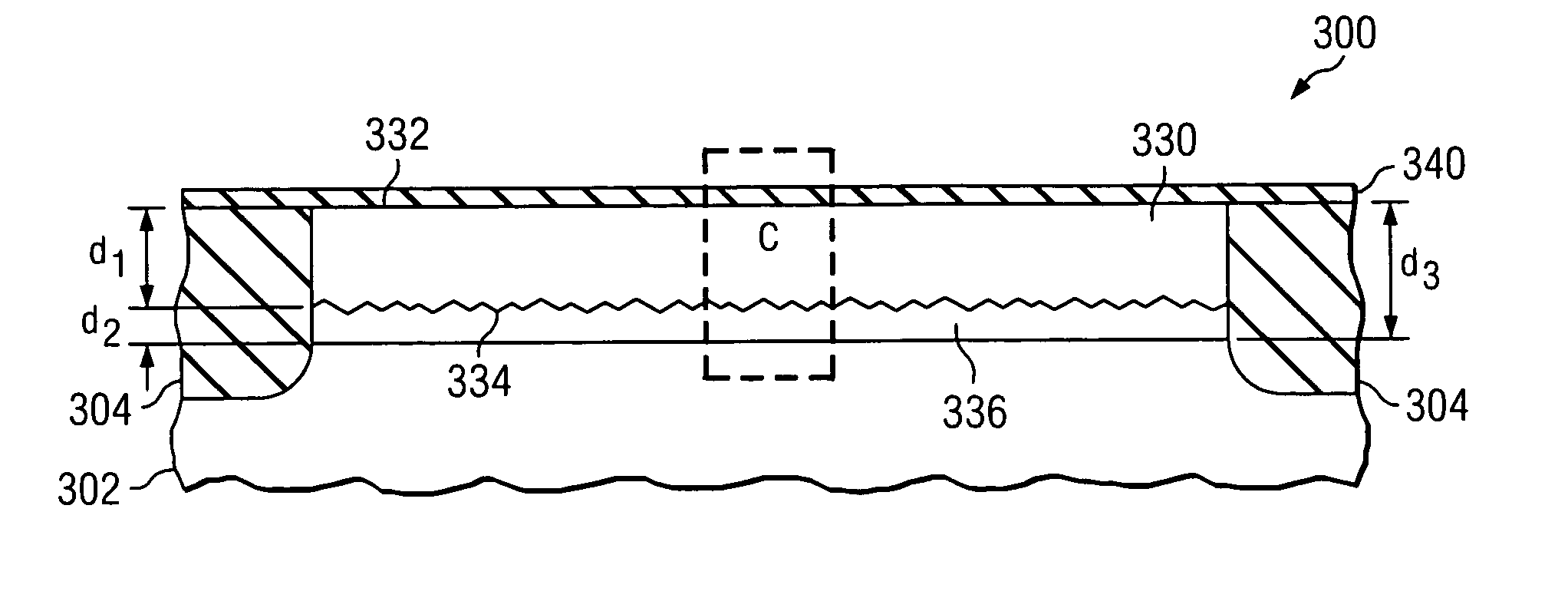

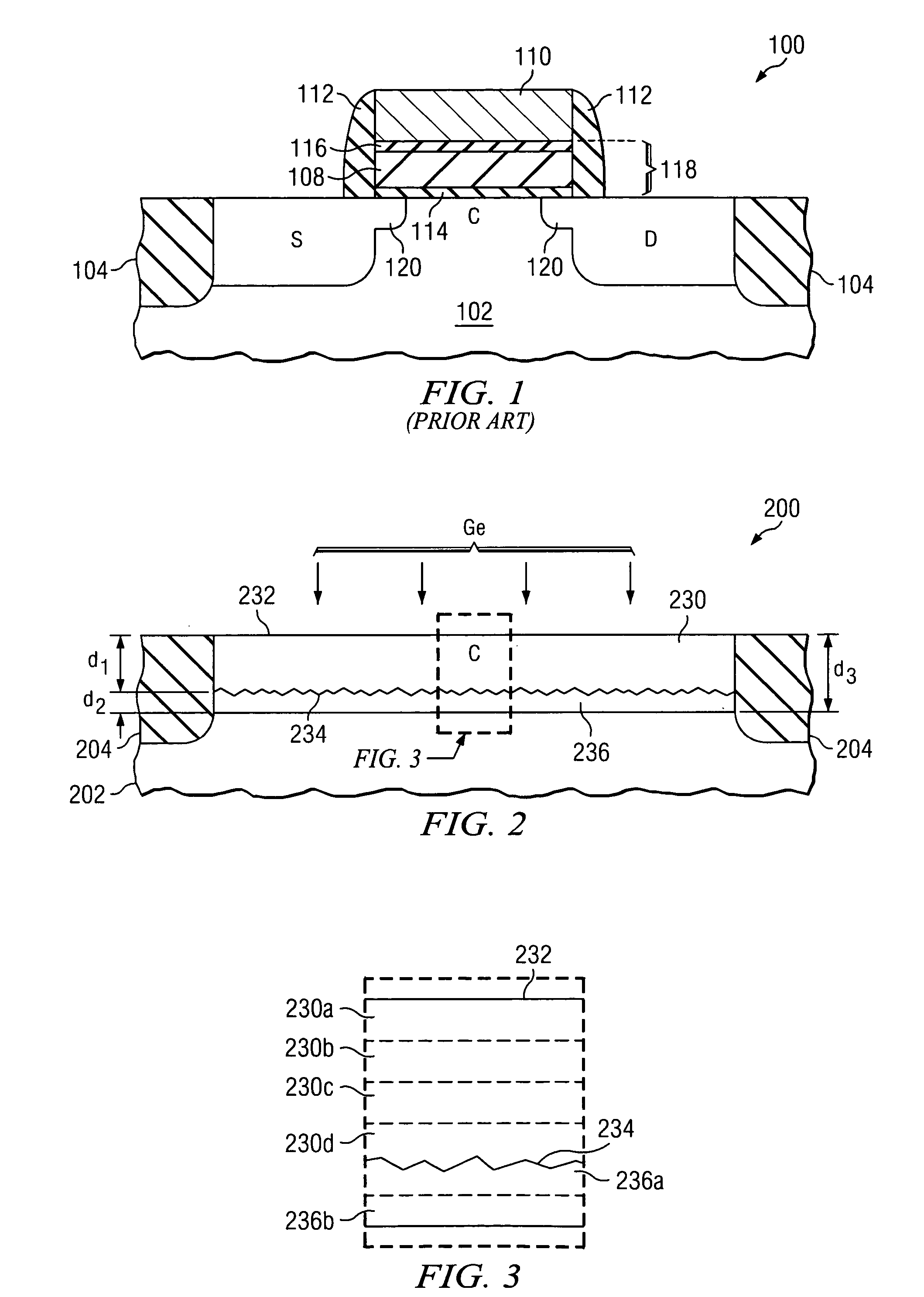

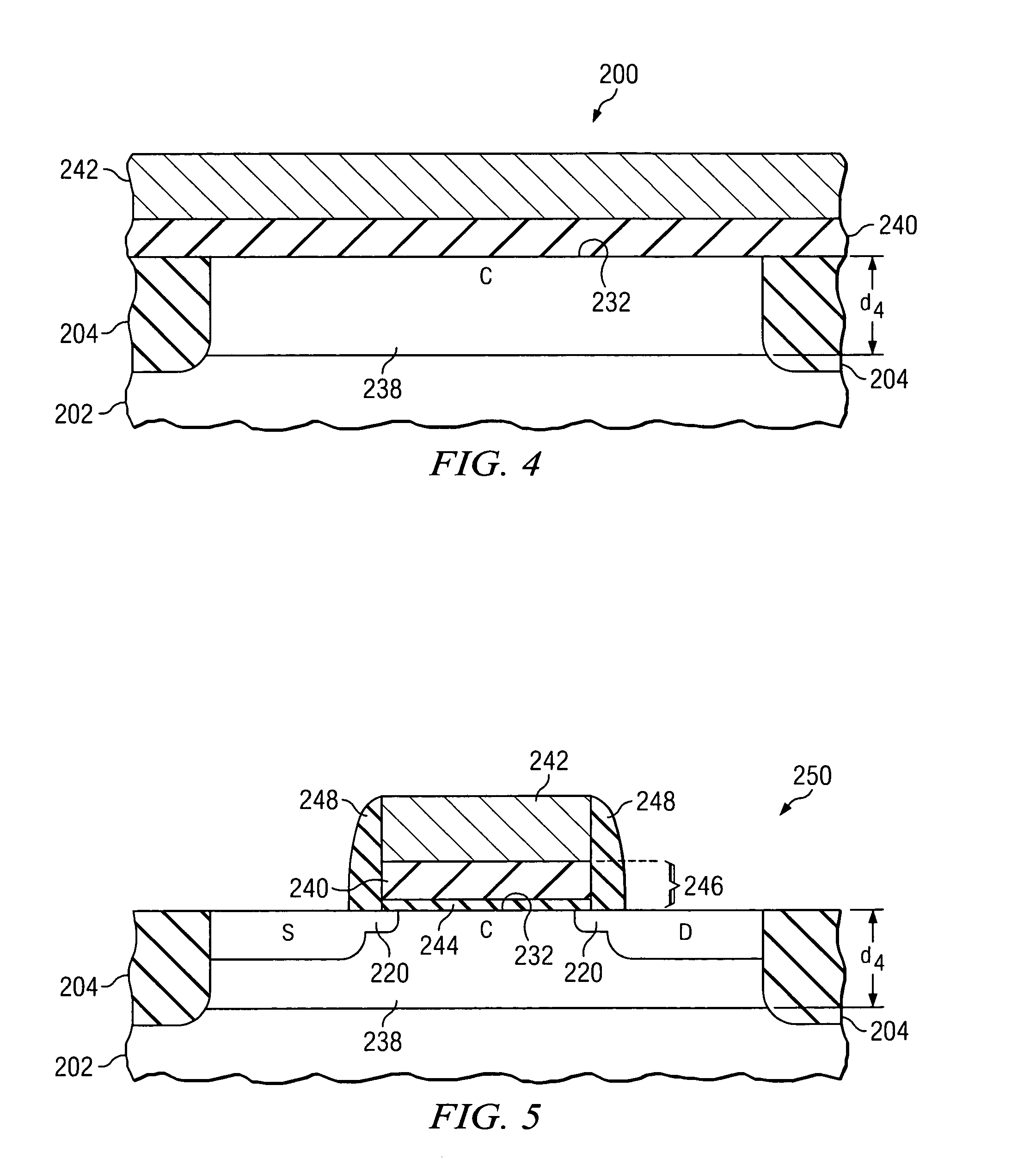

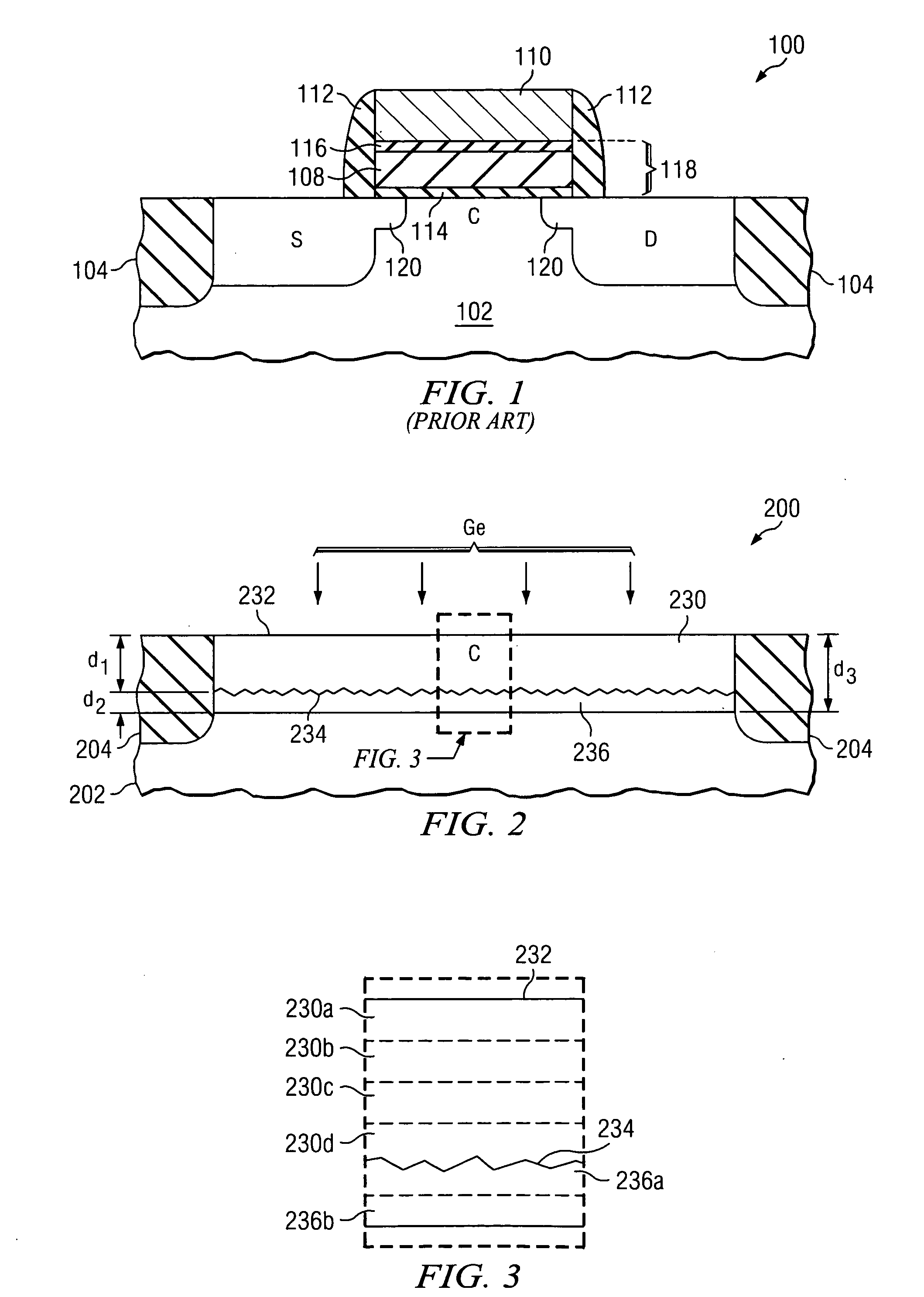

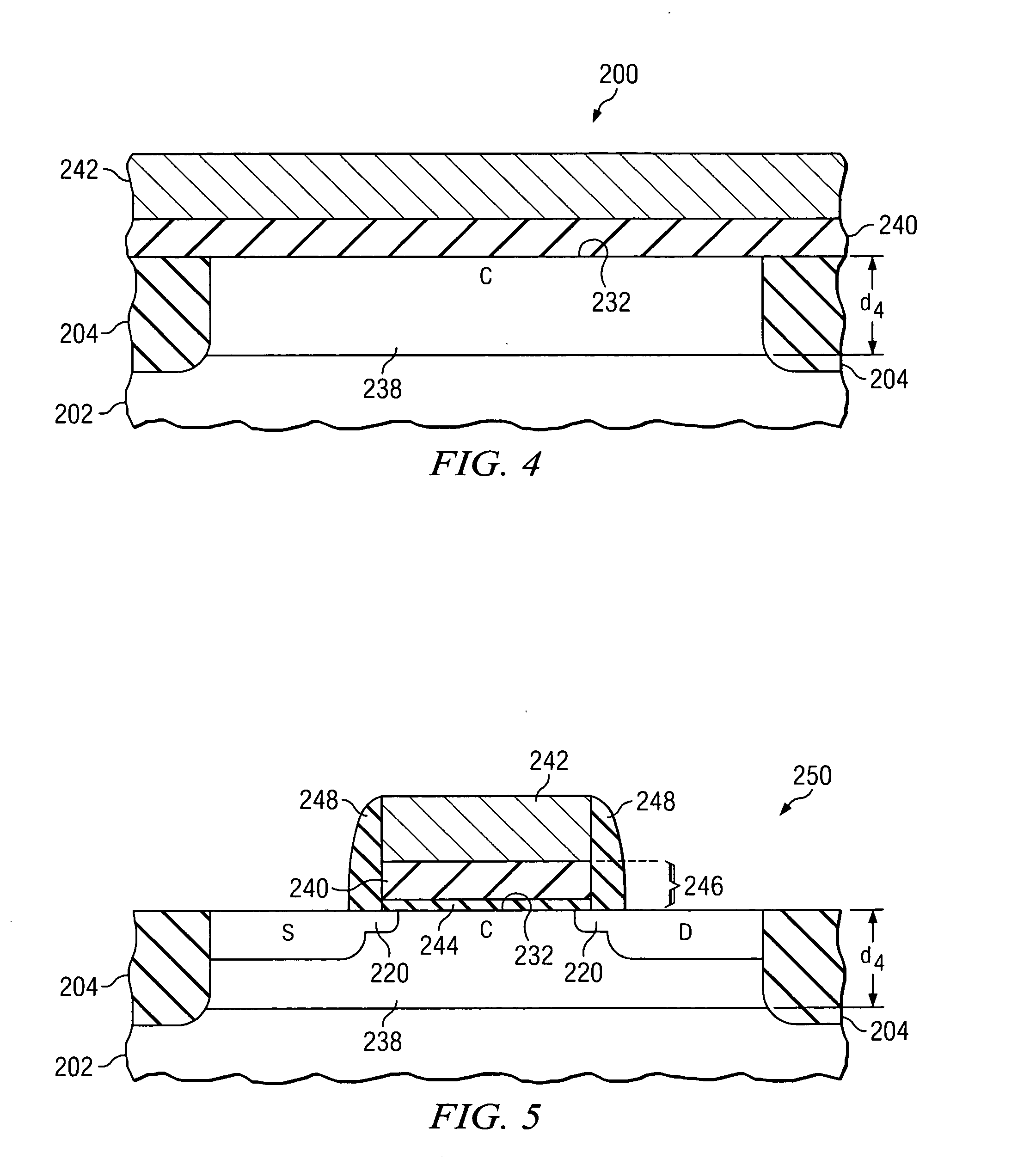

Transistor with shallow germanium implantation region in channel

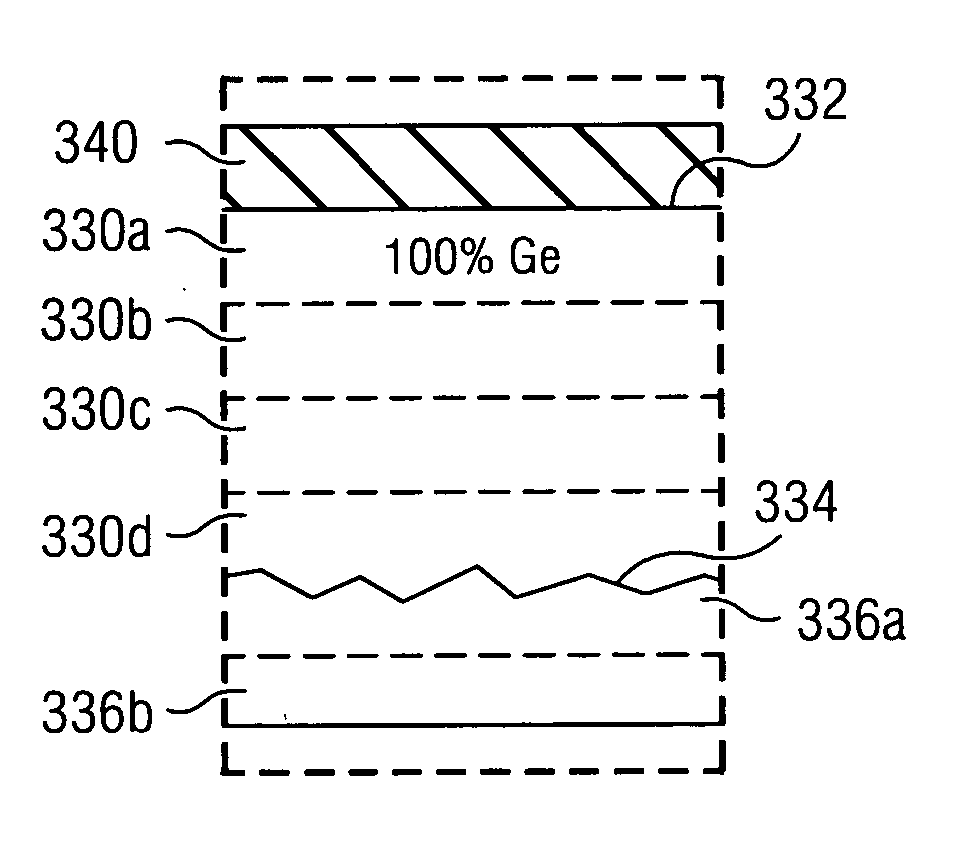

ActiveUS7094671B2Improve mobilityEliminate damageTransistorFrom solid stateMaterials scienceTransistor

A method of manufacturing a transistor and a structure thereof, wherein a very shallow region having a high dopant concentration of germanium is implanted into a channel region of a transistor at a low energy level, forming an amorphous germanium implantation region in a top surface of the workpiece, and forming a crystalline germanium implantation region beneath the amorphous germanium implantation region. The workpiece is annealed using a low-temperature anneal to convert the amorphous germanium region to a crystalline state while preventing a substantial amount of diffusion of germanium further into the workpiece, also removing damage to the workpiece caused by the implantation process. The resulting structure includes a crystalline germanium implantation region at the top surface of a channel, comprising a depth below the top surface of the workpiece of about 120 Å or less. The transistor has increased mobility and a reduced effective oxide thickness (EOT).

Owner:INFINEON TECH AG

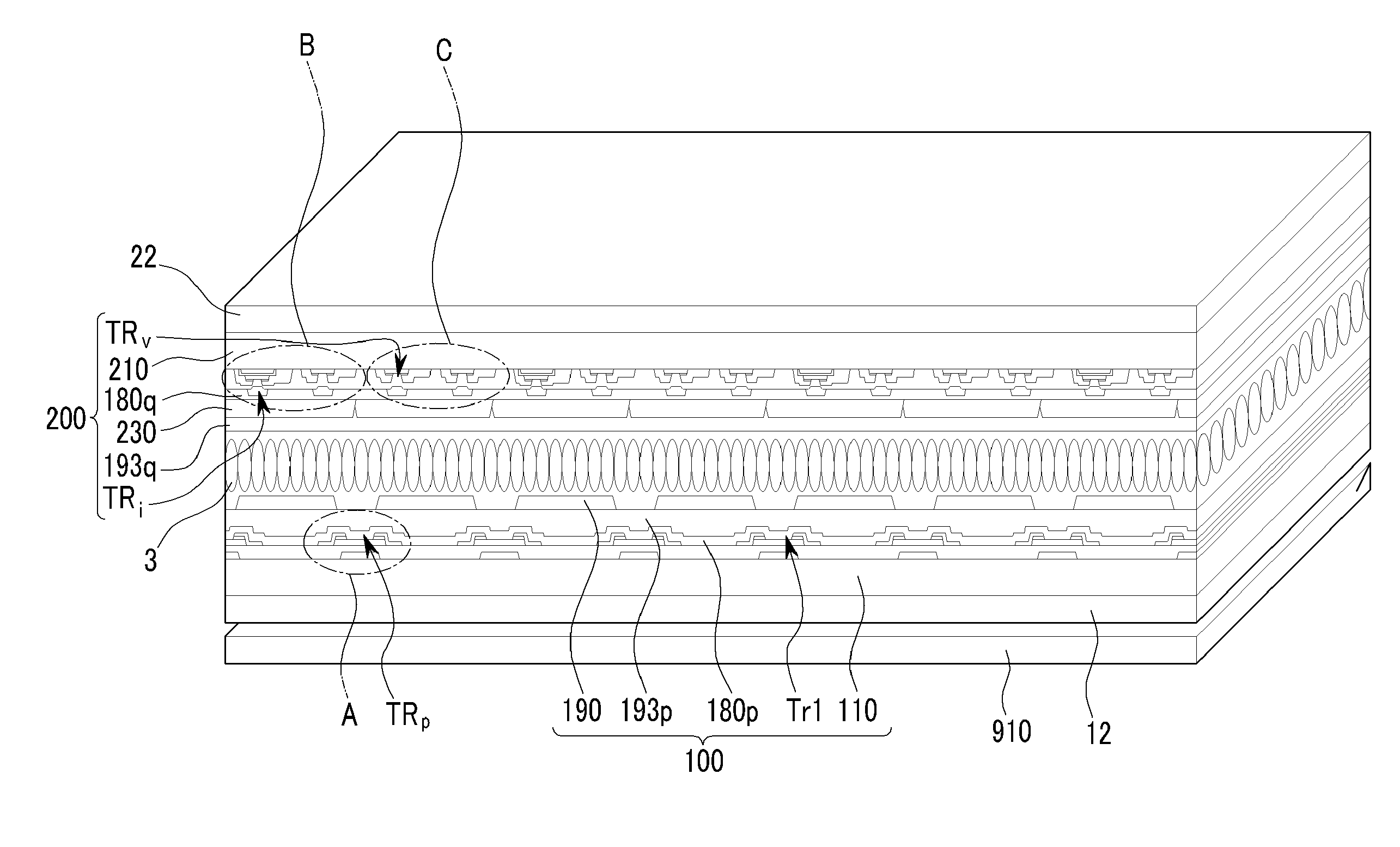

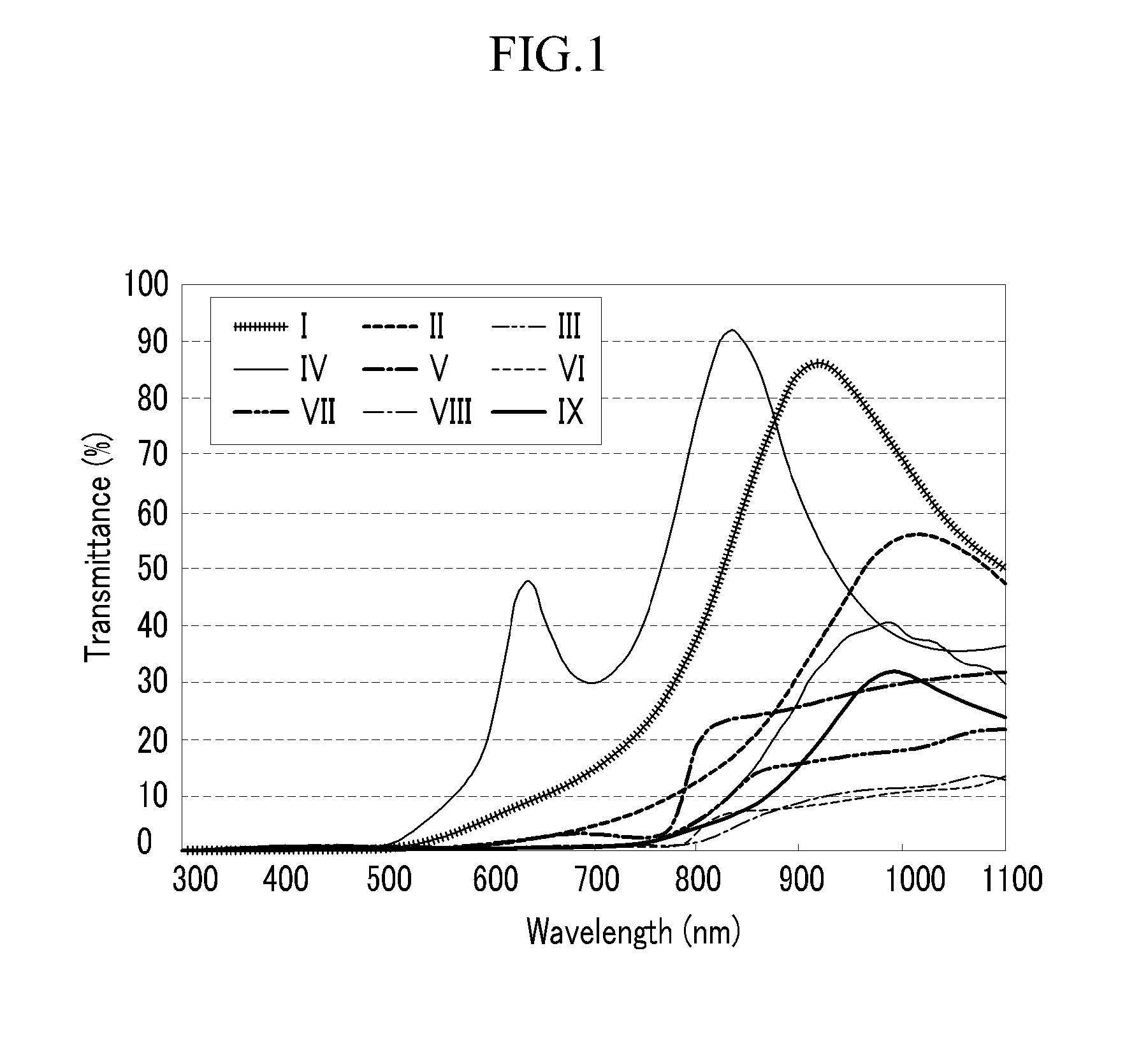

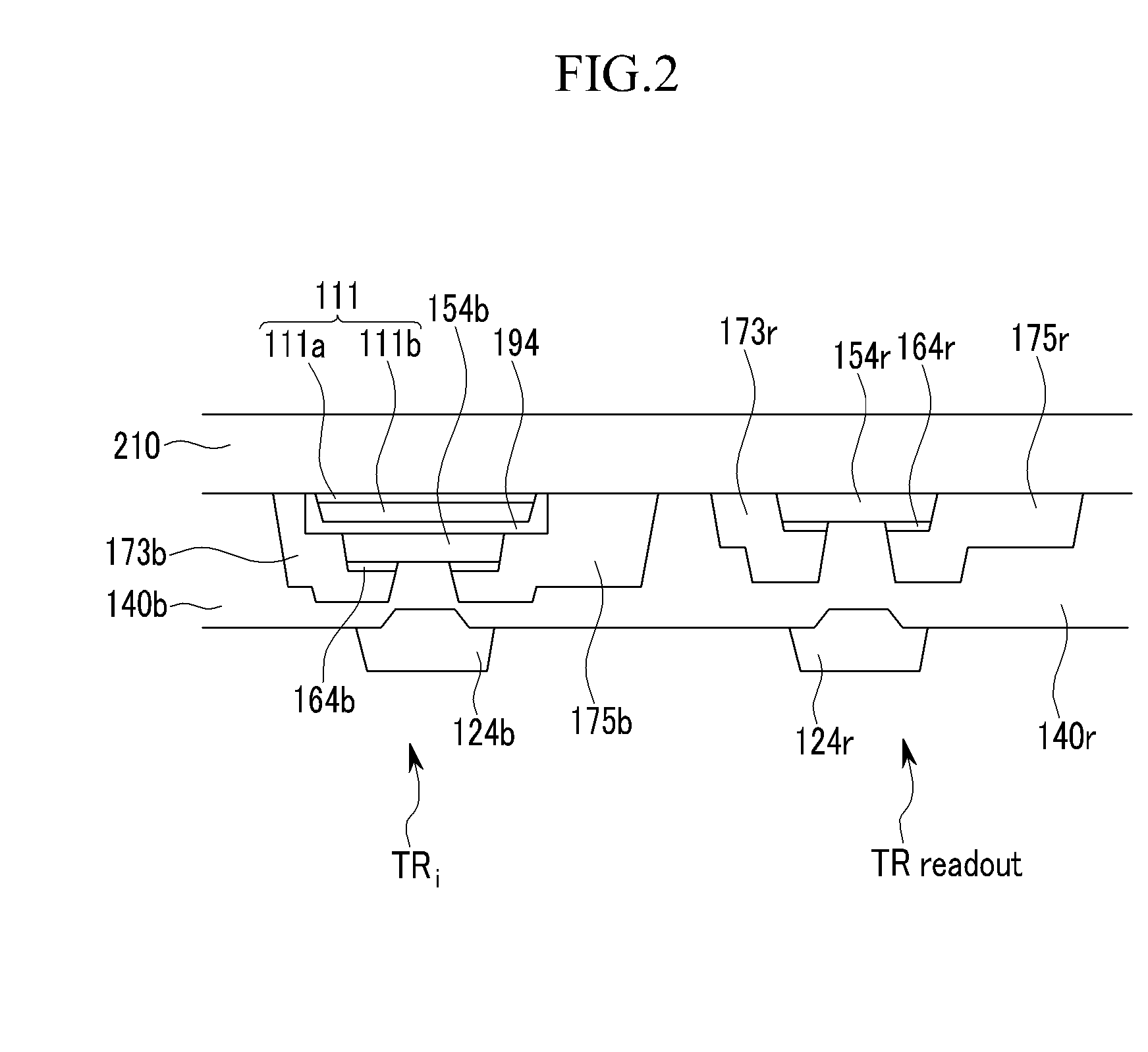

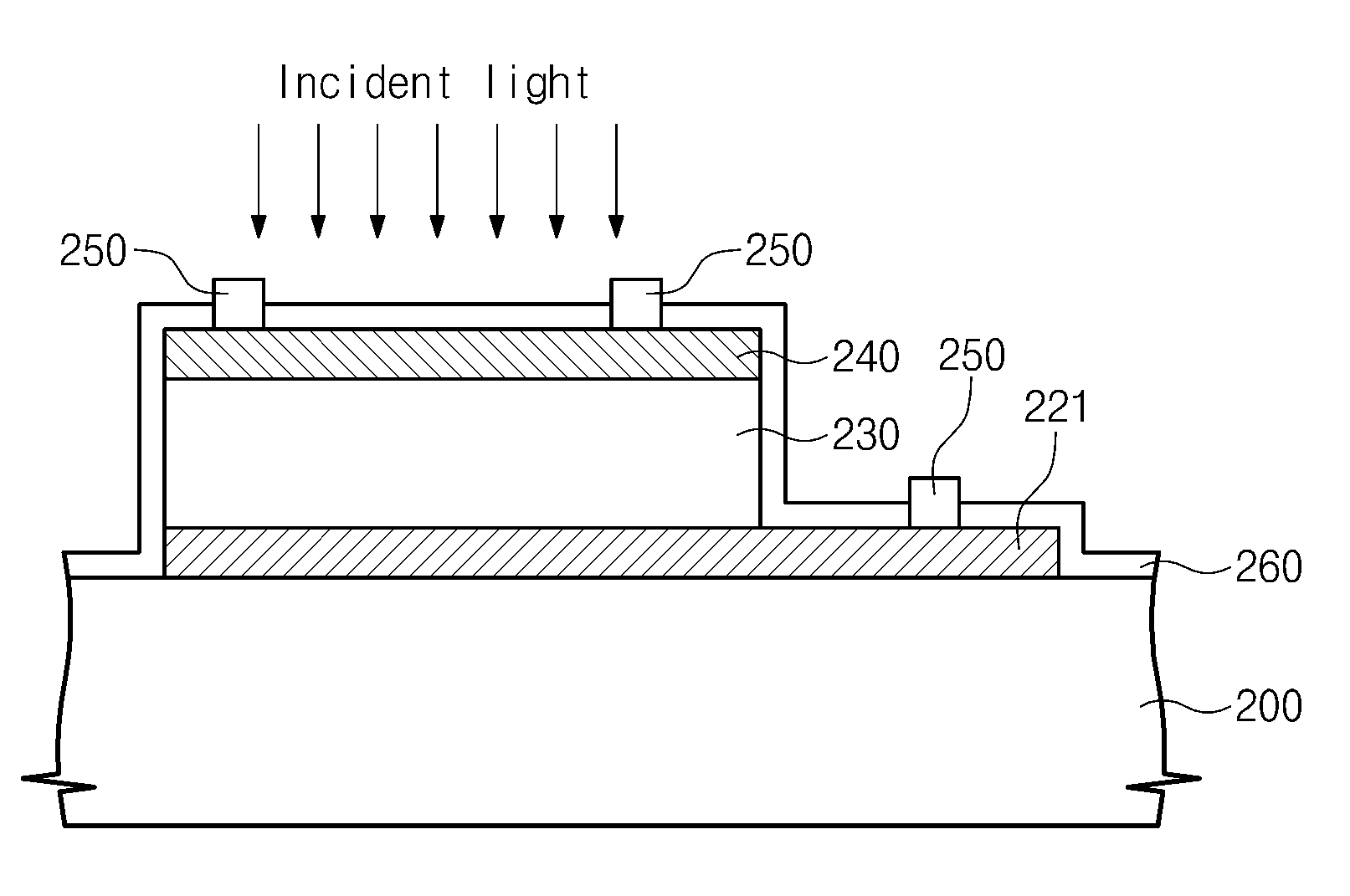

Visible-light blocking member, infrared sensor including the visible-light blocking member, and liquid crystal display device including the infrared sensor

ActiveUS20110032461A1Effective blockingRadiation pyrometryNitrogen compoundsInfraredLiquid-crystal display

In a visible-light blocking member, an infrared sensor including the visible-light blocking member, and a liquid crystal display including the infrared sensor, a visible-light blocking member is a structure including amorphous germanium or a compound of amorphous germanium and has higher transmittance for a wavelength of an infrared ray region than for a wavelength of a visible light region. Accordingly, sensitivity to infrared rays may be increased by applying the visible-light blocking member to the infrared sensor.

Owner:SAMSUNG DISPLAY CO LTD

Method for manufacturing lateral germanium detectors

InactiveUS8343792B2Solid-state devicesSemiconductor/solid-state device manufacturingResistSingle crystal

An improved method for manufacturing a lateral germanium detector is disclosed. A detector window is opened through an oxide layer to expose a doped single crystalline silicon layer situated on a substrate. Next, a single crystal germanium layer is grown within the detector window, and an amorphous germanium layer is grown on the oxide layer. The amorphous germanium layer is then polished to leave only a small portion around the single crystal germanium layer. A dielectric layer is deposited on the amorphous germanium layer and the single crystal germanium layer. Using resist masks and ion implants, multiple doped regions are formed on the single crystal germanium layer. After opening several oxide windows on the dielectric layer, a refractory metal layer is deposited on the doped regions to form multiple germanide layers.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

Germanium photodetector and method of fabricating the same

Provided is a germanium photodetector having a germanium epitaxial layer formed without using a buffer layer and a method of fabricating the same. In the method, an amorphous germanium layer is formed on a substrate. The amorphous germanium layer is heated up to a high temperature to form a crystallized germanium layer. A germanium epitaxial layer is formed on the crystallized germanium layer.

Owner:ELECTRONICS & TELECOMM RES INST

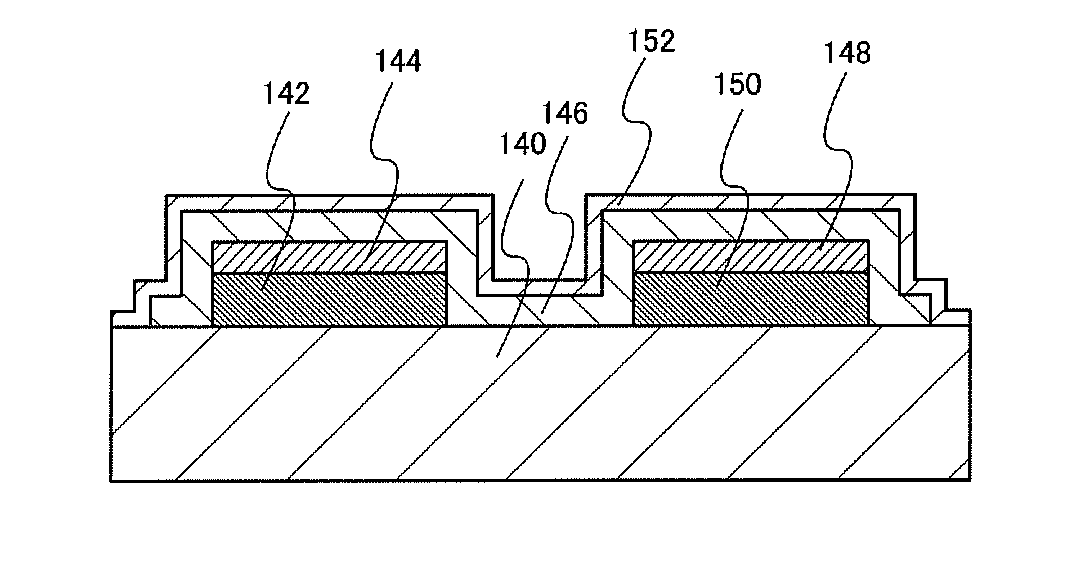

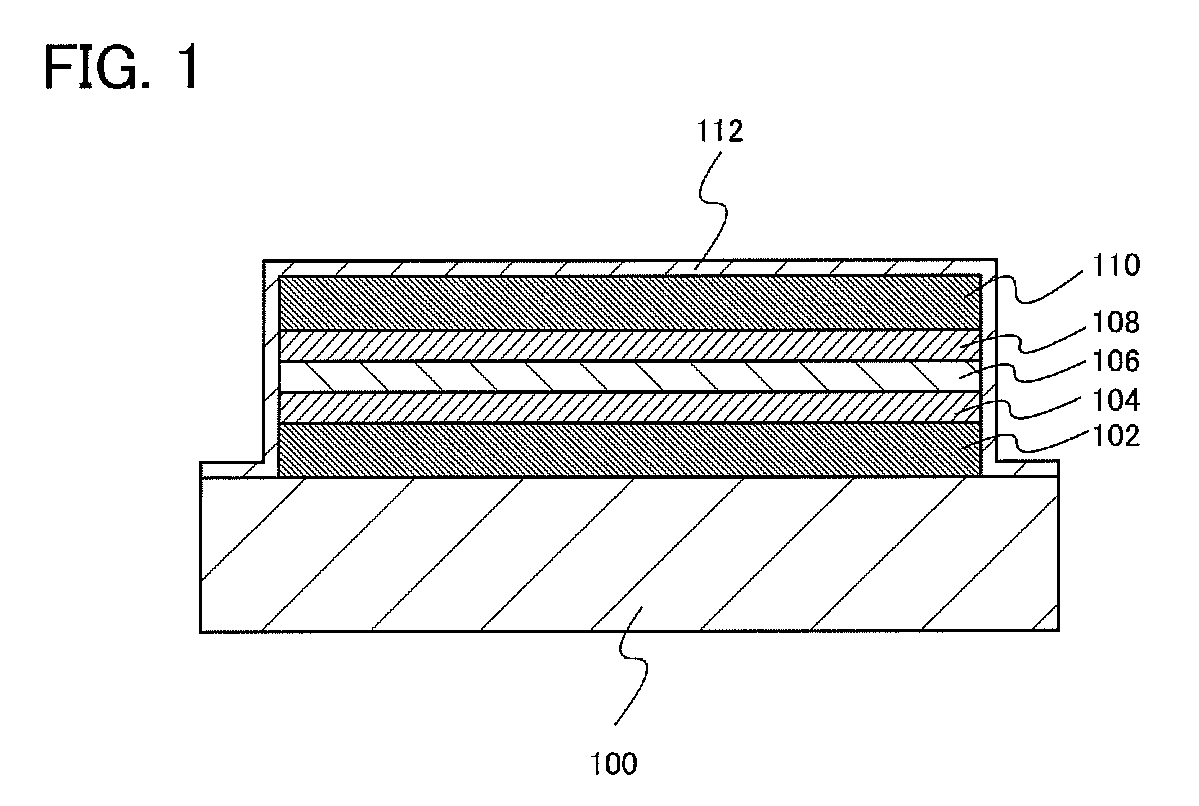

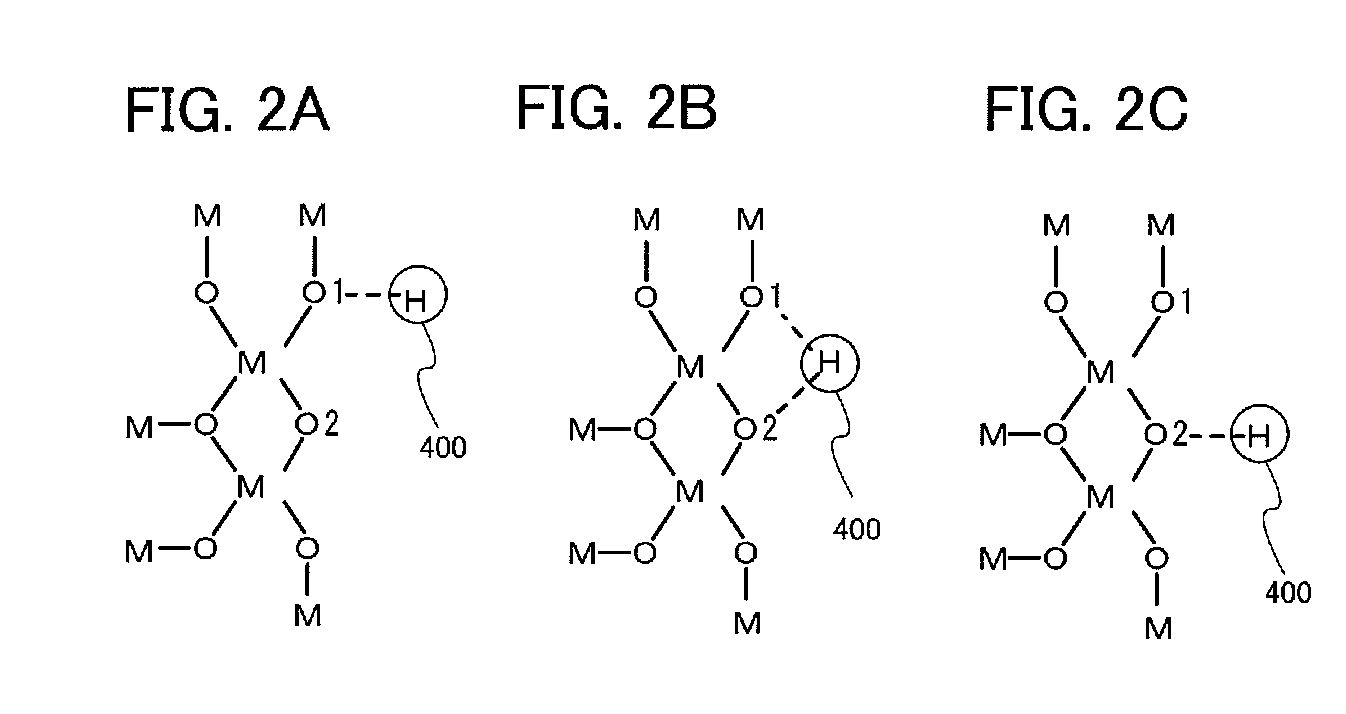

Redox capacitor and manufacturing method thereof

ActiveUS20110073991A1Simple structureIncrease the concentration of hydrogenHybrid capacitor electrolytesHybrid capacitor electrodesIndiumVanadium oxide

To provide a redox capacitor that can be used at room temperature and a manufacturing method thereof. Amorphous semiconductor including hydrogen is used as an electrolyte of a redox capacitor. As a typical example of the amorphous semiconductor including hydrogen, an amorphous semiconductor including a semiconductor element such as amorphous silicon, amorphous silicon germanium, or amorphous germanium can be used. As another example of the amorphous semiconductor including hydrogen, oxide semiconductor including hydrogen can be used. As typical examples of the oxide semiconductor including hydrogen, an amorphous semiconductor including a single-component oxide semiconductor such as zinc oxide, titanium oxide, nickel oxide, vanadium oxide, and indium oxide can be given. As another example of oxide semiconductor including hydrogen, a multi-component oxide semiconductor such as InMO3(ZnO)m (m>0 and M is one or more metal elements selected from Ga, Fe, Ni, Mn, and Co) can be used.

Owner:SEMICON ENERGY LAB CO LTD

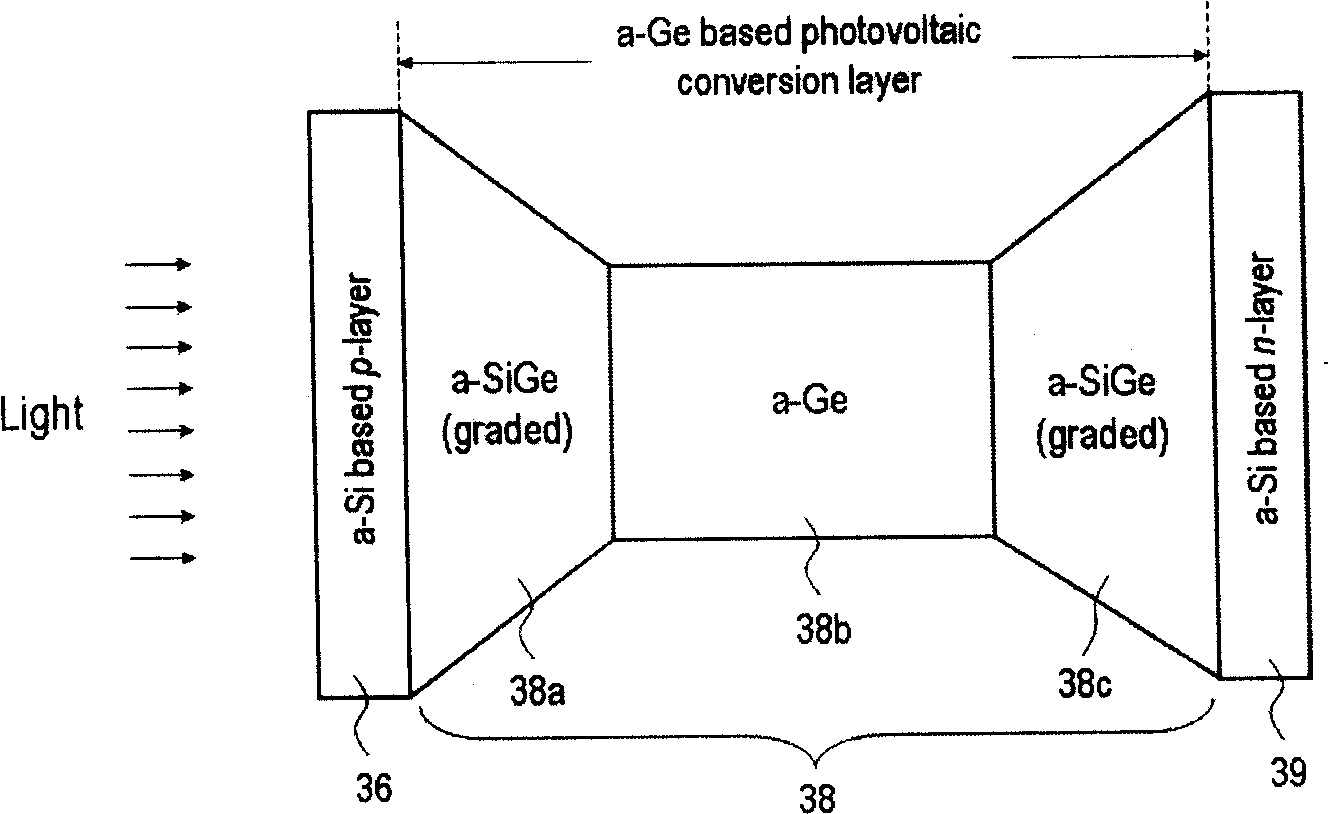

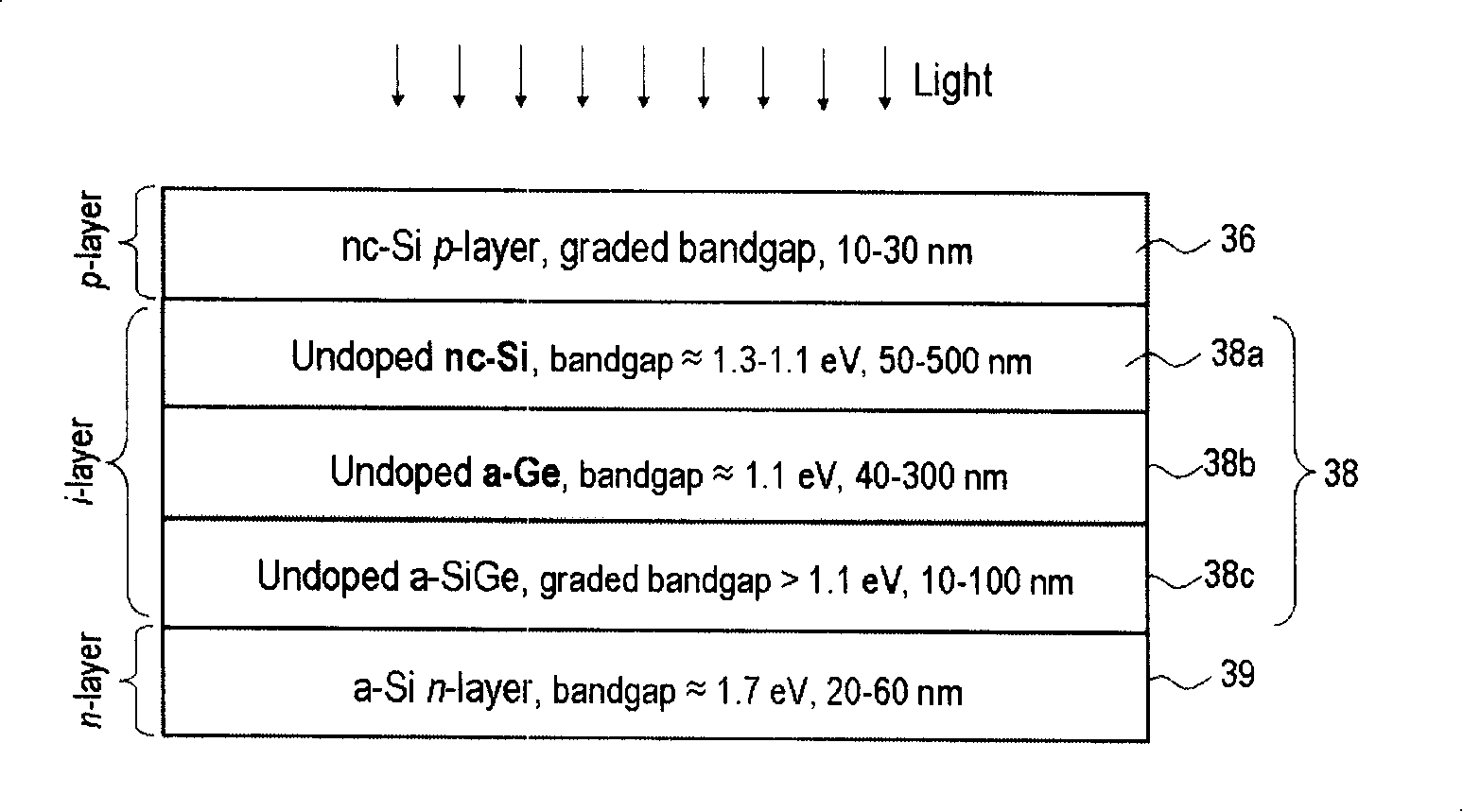

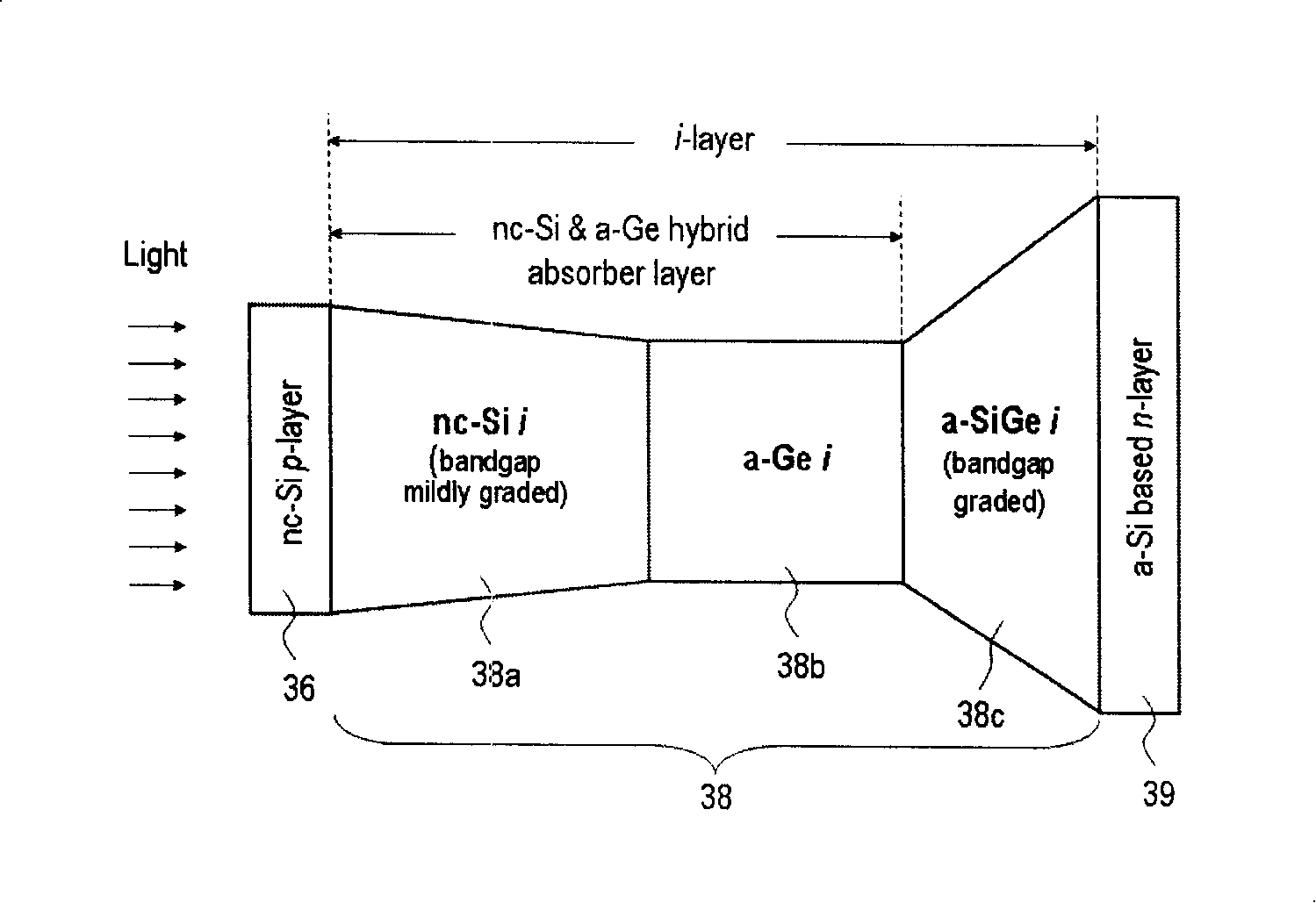

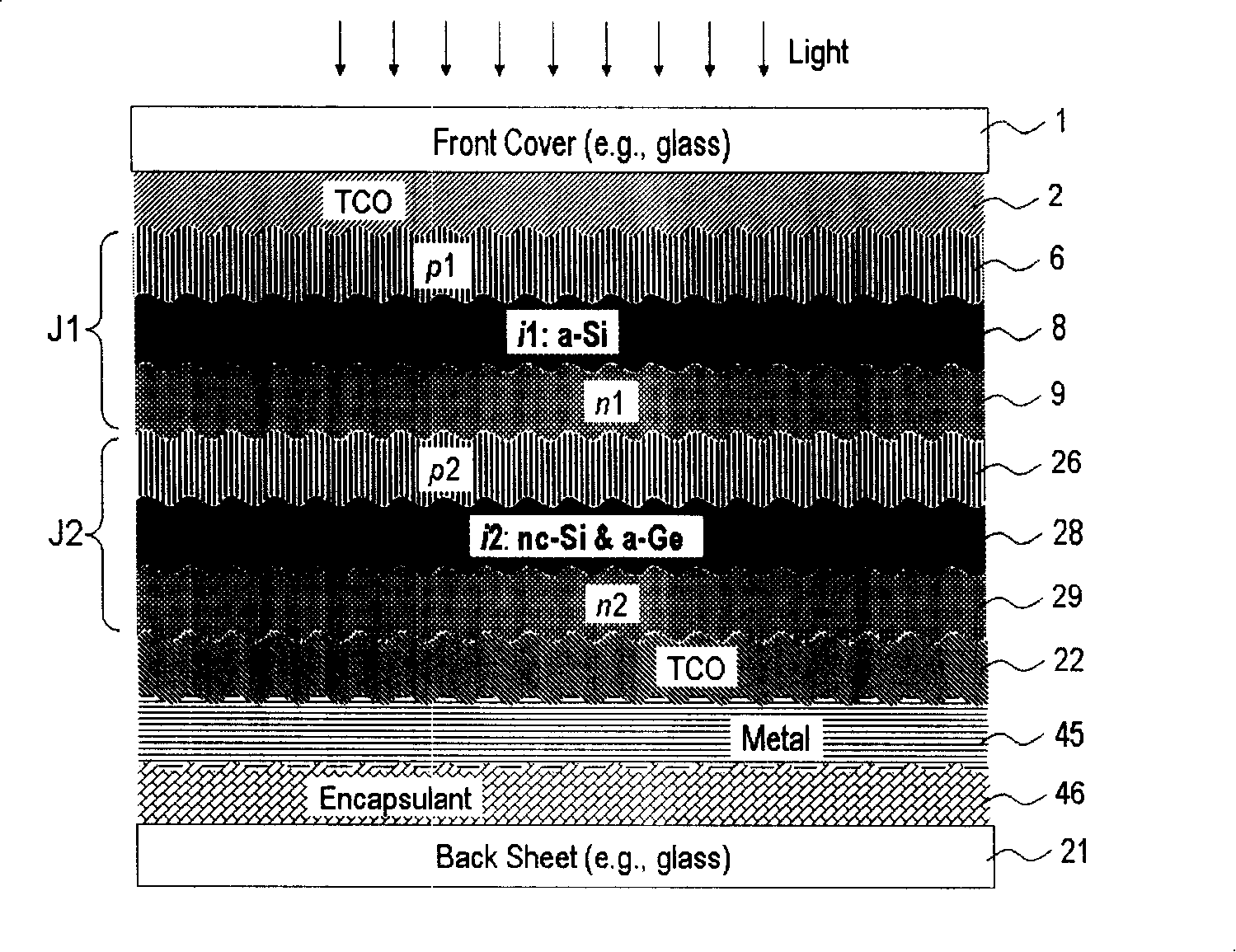

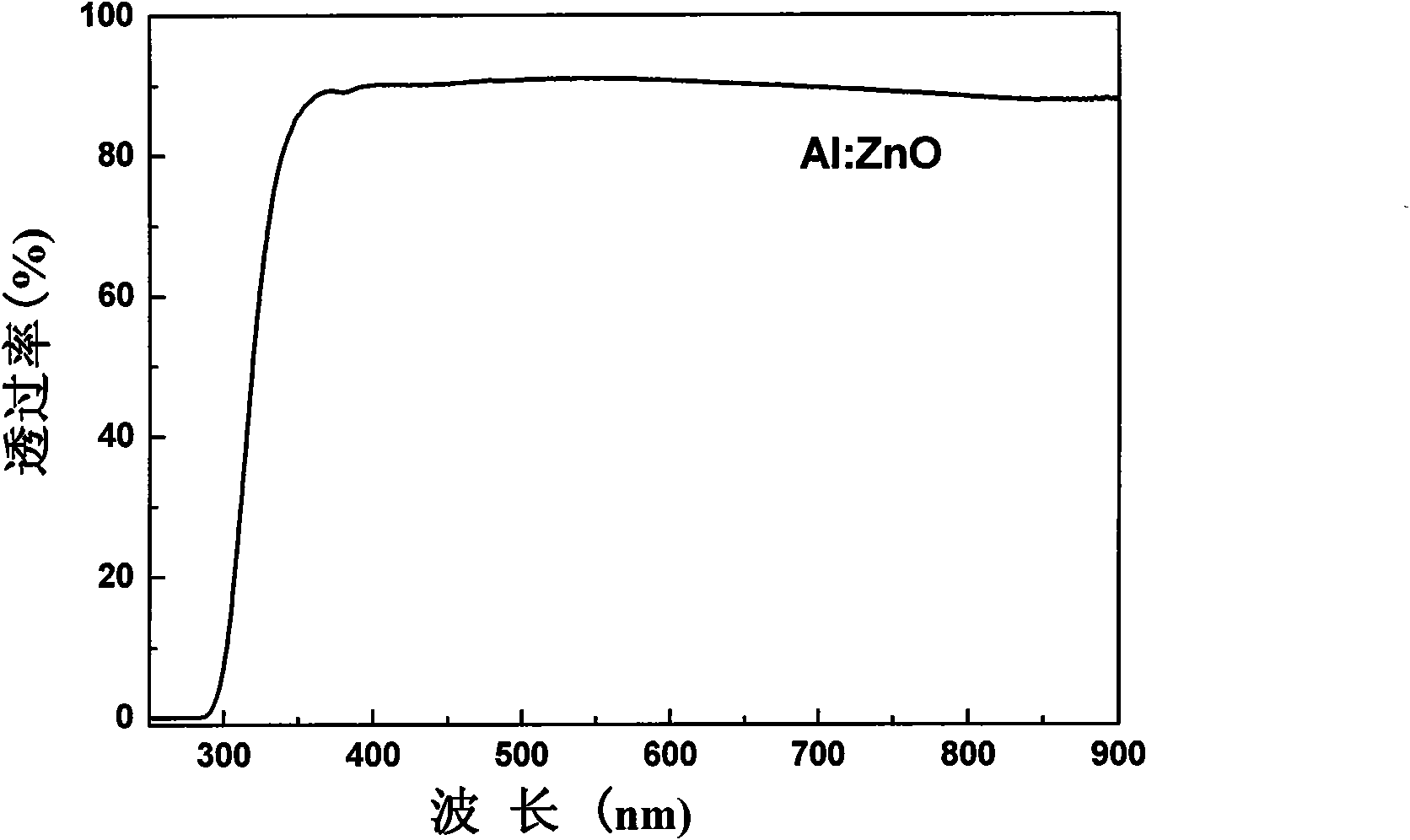

Photovoltaic application of amorphous germanium thin film

The present invention discloses a multi-junction photovoltaic device with simpler structure and lower cost. The multi-junction photovoltaic device comprises of first junction, second junction and third junction based on silicon film photovoltaic cell with folding structure. The third cell intrinsic i layer comprises of at least one amorphous germanium film whose band gap is less than 1.1eV, and buffer layer containing grads band gap amorphous germanium silicon alloy and / or film based on nano crystal silicon. The multi-junction photovoltaic device containing amorphous germanium has good capability and can be produced by low cost equipment.

Owner:BEIJING XINGZHE MULTIMEDIA TECH

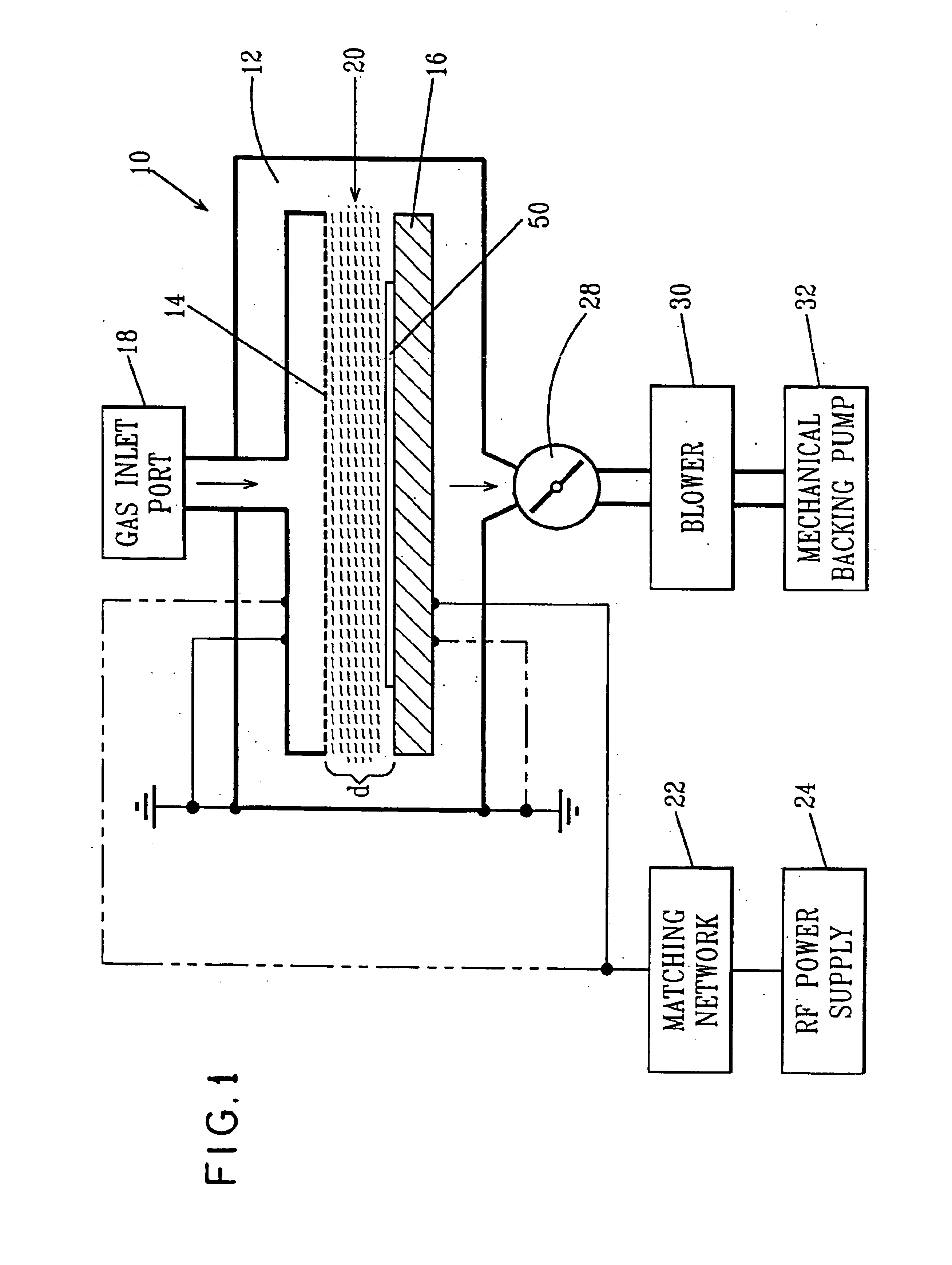

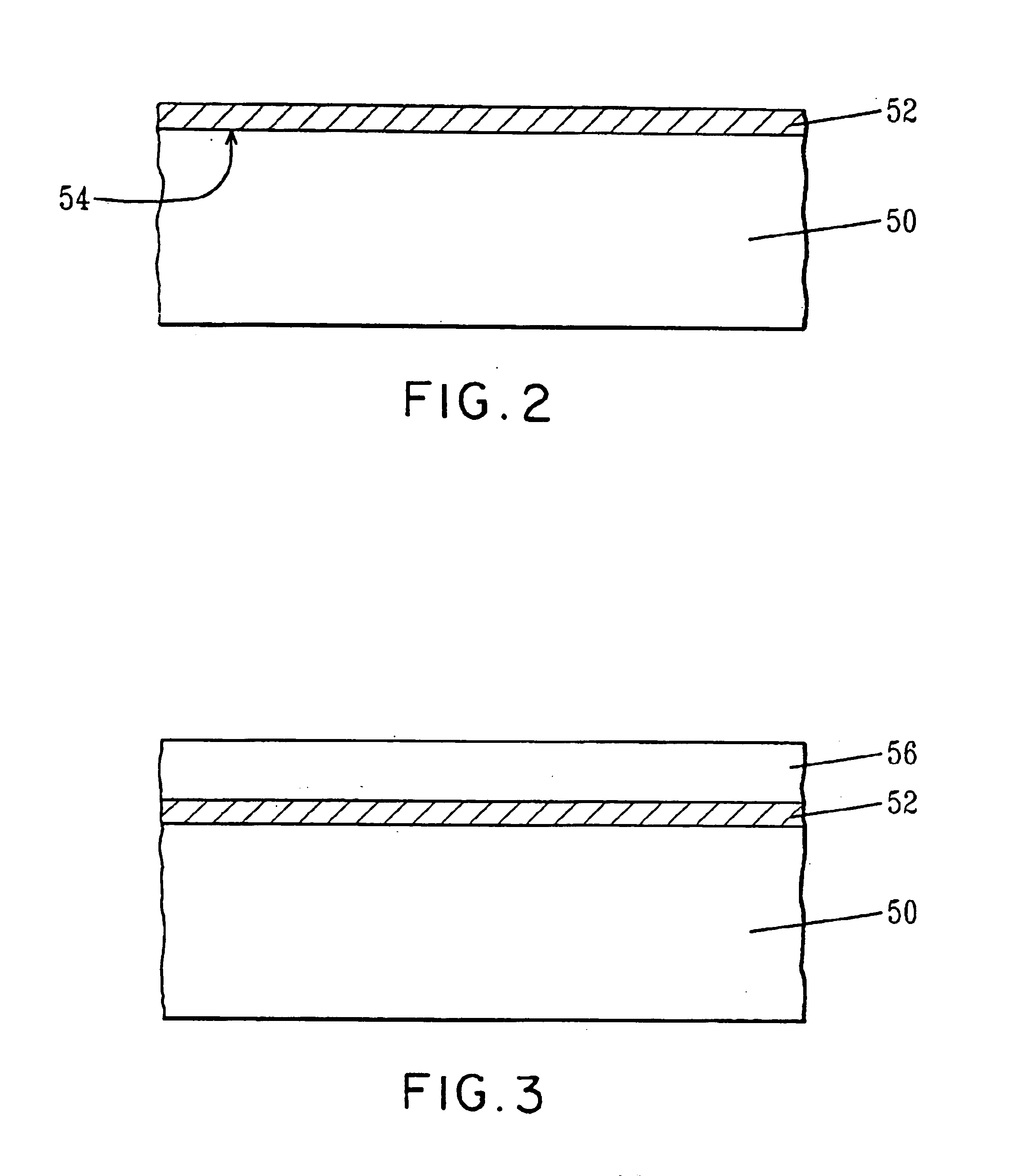

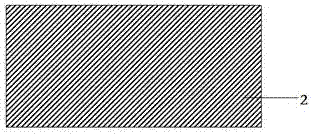

Low-temperature plasma deposited hydrogenated amorphous germanium carbon abrasion-resistant coatings

A method of forming a hydrogenated amorphous germanium carbon (a-GeCx:H) film on a surface of an infrared (IR) transmissive material such as a chalcogenide is provided. The method includes positioning an IR transmissive material in a reactor chamber of a parallel plate plasma reactor and thereafter depositing a hydrogenated amorphous germanium carbon (a-GeCx:H) film on a surface of the IR transmissive material. The depositing is performed at a substrate temperature of about 130° C. or less and in the presence of a plasma which is derived from a gas mixture including a source of germanium, an inert gas, and optionally hydrogen. Optical transmissive components, such as IR sensors and windows, that have improved abrasion-resistance are also provided.

Owner:LOCKHEED MARTIN CORP

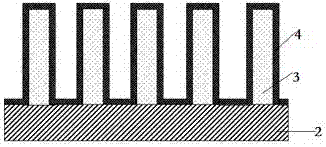

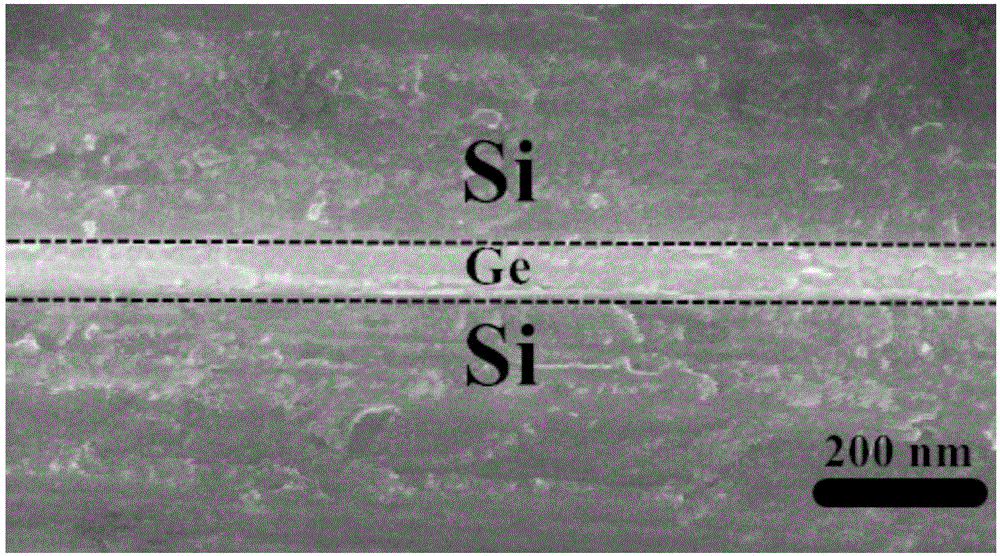

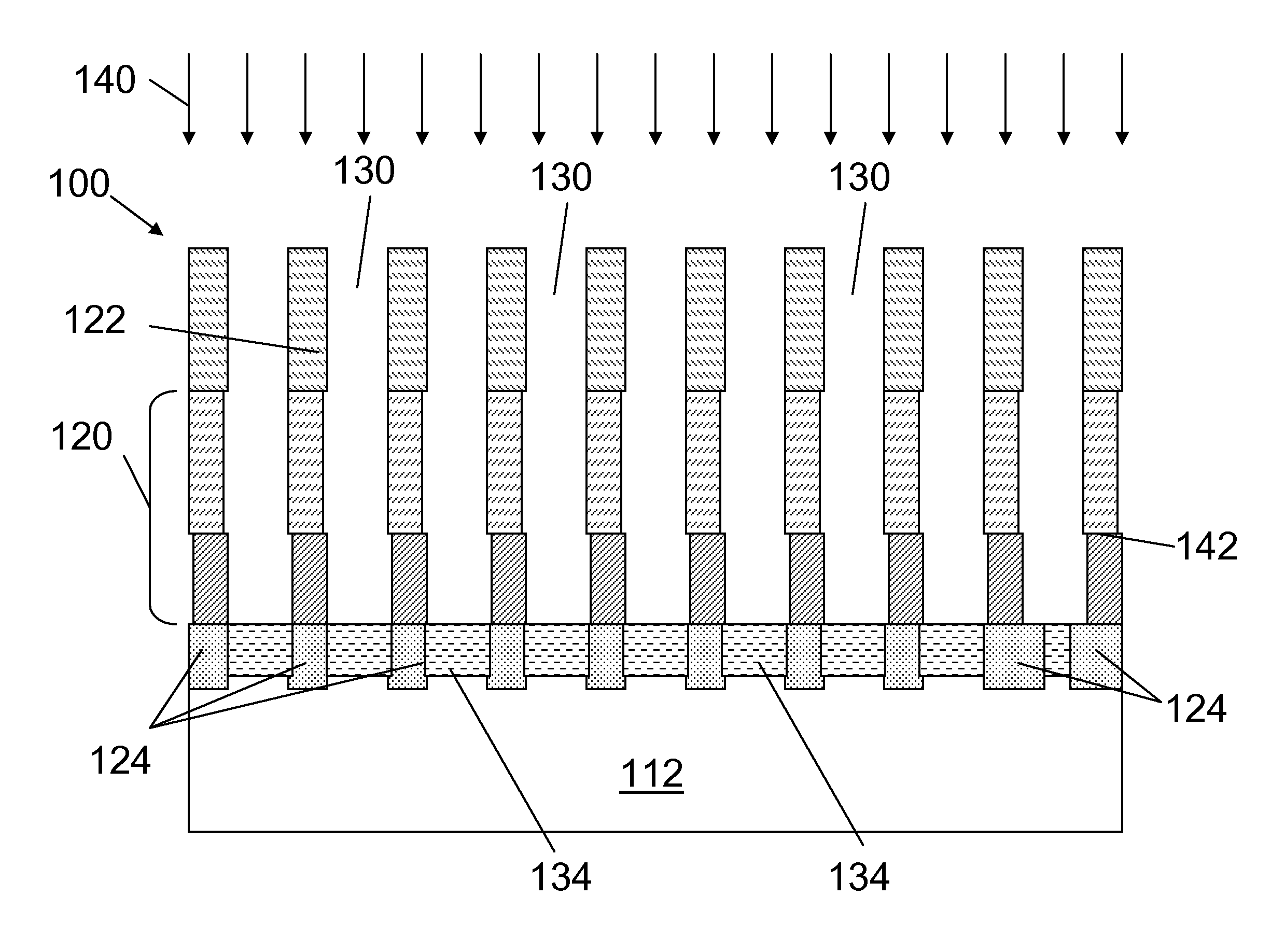

Preparation method for silicon-germanium black phosphorus alkene PIN heterojunction solar cell

ActiveCN107394013AImprove absorption efficiencyImprove photoelectric conversion efficiencyFinal product manufactureNanotechnologyHeterojunctionSemiconductor materials

The invention provides a preparation method for a silicon-germanium black phosphorus alkene PIN heterojunction solar cell. The method comprises the steps: washing an N-type silicon substrate, preparing an N-type silicon nanowire array in the N-type silicon substrate, sequentially forming an intrinsic amorphous germanium layer, a P-type black phosphorus alkene layer and a transparent conductive layer, finally forming a back electrode on the back surface of the N-type silicon substrate and forming an upper electrode on the transparent conductive layer. The preparation method is simple, and the setting of the silicon nanowire array improves the sunlight absorption efficiency of the solar cell. The black phosphorus alkene serves as the novel two-dimensional semiconductor material, and forms a PIN heterojunction with the N-type silicon nanowire array and the intrinsic amorphous germanium layer. The PIN heterojunction can achieve the effective photoelectric conversion. Moreover, the setting of a radial structure facilitates the separation and transmission of electronic hole pairs, and further improves the photoelectric conversion efficiency of the solar cell.

Owner:厦门鸾创科技有限公司

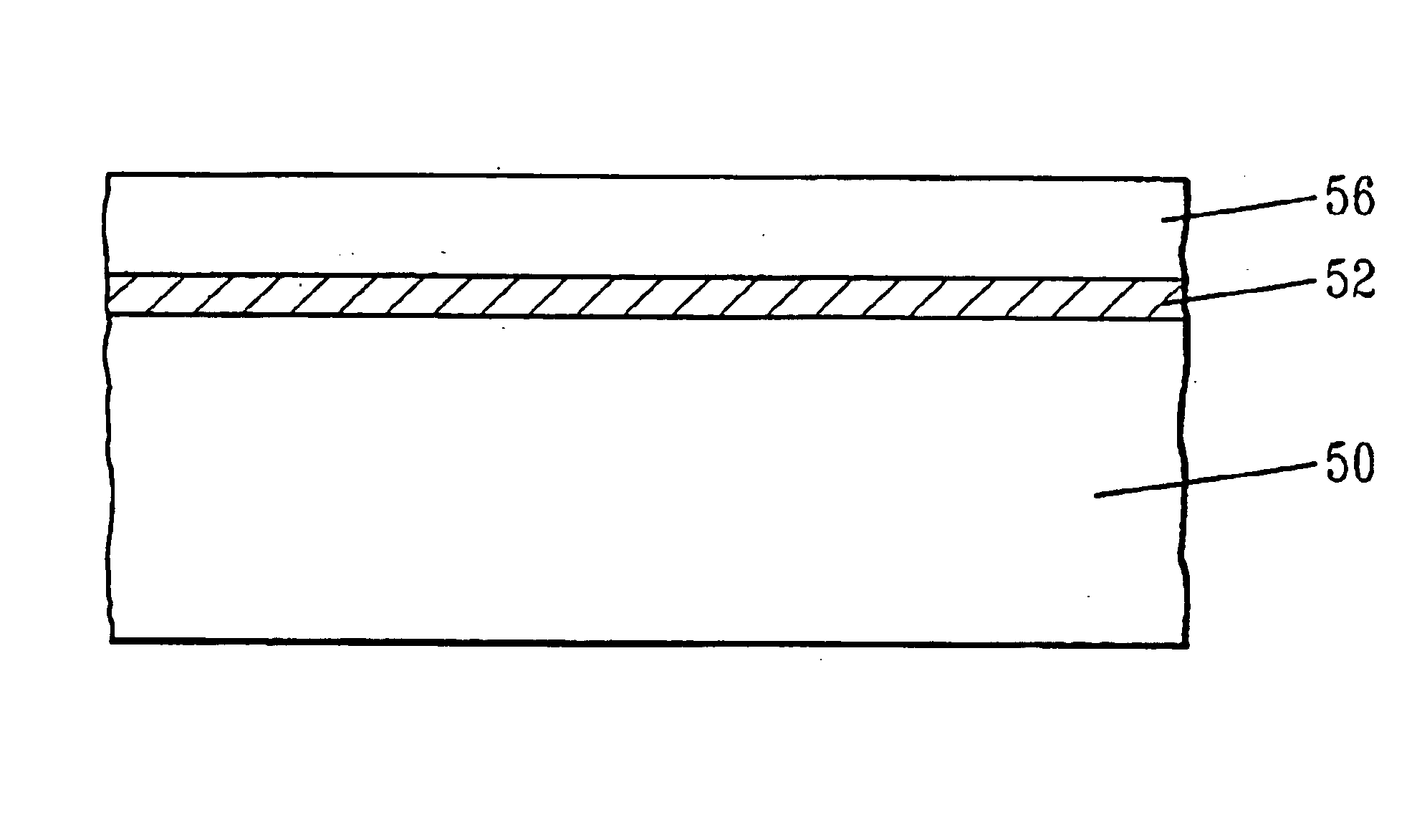

Transistor with shallow germanium implantation region in channel

ActiveUS20050205858A1Reducing thermal budgetImproving gate dielectric qualityTransistorFrom solid stateAmorphous germaniumOxide

A method of manufacturing a transistor and a structure thereof, wherein a very shallow region having a high dopant concentration of germanium is implanted into a channel region of a transistor at a low energy level, forming an amorphous germanium implantation region in a top surface of the workpiece, and forming a crystalline germanium implantation region beneath the amorphous germanium implantation region. The workpiece is annealed using a low-temperature anneal to convert the amorphous germanium region to a crystalline state while preventing a substantial amount of diffusion of germanium further into the workpiece, also removing damage to the workpiece caused by the implantation process. The resulting structure includes a crystalline germanium implantation region at the top surface of a channel, comprising a depth below the top surface of the workpiece of about 120 Å or less. The transistor has increased mobility and a reduced effective oxide thickness (EOT).

Owner:INFINEON TECH AG

Nano crystal silicon and non crystal germanium mixed absorption layer for multi-node light voltage part based on film silicon

InactiveCN101237000AGuaranteed uptimeLow costFinal product manufacturePhotovoltaic energy generationNanocrystalline siliconNanocrystal

The present invention discloses a p-i-n type photovoltaic battery which comprises a novel i layer absorption layer with a narrow band gap. The front part of the absorption layer is made from nanometer crystal silicon, the middle part is made from amorphous germanium material, and the back part is made from amorphous germanium silicon. The photovoltaic battery comprising a mixed-type i layer can be perfectly utilized as a base layer battery of a multi-junction photovoltaic device based on the silicon film. The photovoltaic battery has the advantages of good performance, strong reliability and low production cost.

Owner:BEIJING XINGZHE MULTIMEDIA TECH

Thin-film photoelectric converter and fabrication method therefor

InactiveUS20110146756A1Improve featuresImprove FFFinal product manufacturePV power plantsPhotoelectric conversionCrystalline silicon

A conventional thin-film photoelectric converter using amorphous germanium or crystalline silicon as a photoelectric conversion layer is problematic in that light having a long wavelength of 1100 nm or more cannot be used for photoelectric conversion, and is inefficient. The problem is solved by a thin-film photoelectric converter including one or more photoelectric conversion units each having a photoelectric conversion layer sandwiched between a p-type semiconductor layer and an n-type semiconductor layer, wherein the photoelectric conversion layer of at least one photoelectric conversion unit includes an intrinsic or weak n-type crystalline germanium semiconductor, and the absorption coefficient of infrared-absorption peak at wave number of 935±5 cm−1 of the crystalline germanium semiconductor is less than 6000 cm−1. The problem is also solved by a thin-film photoelectric converter having an crystalline germanium semiconductor whose absorption coefficient of infrared-absorption peak at wave number of 960±5 cm−1 of the is less than 3500 cm−1.

Owner:KANEKA CORP

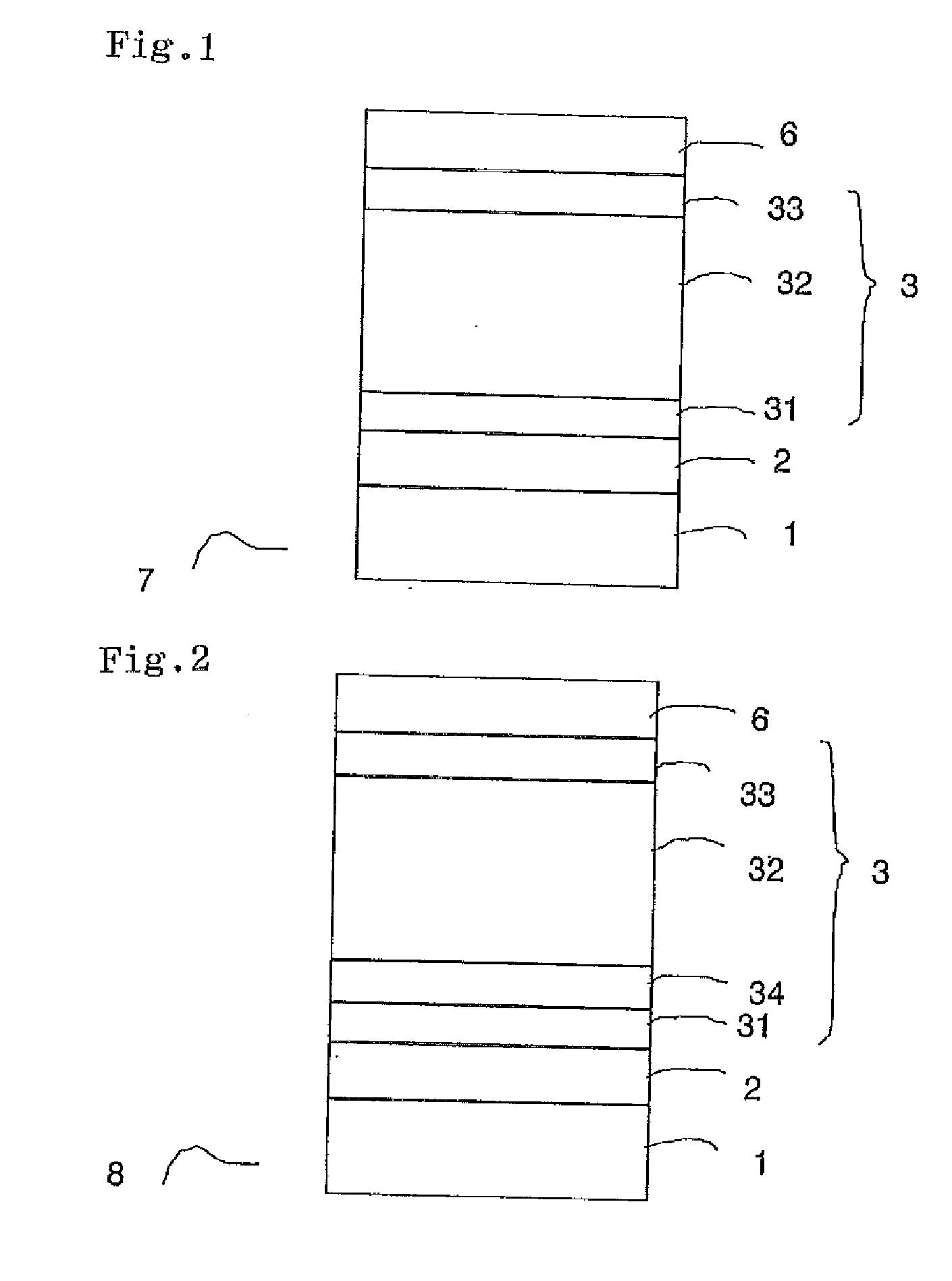

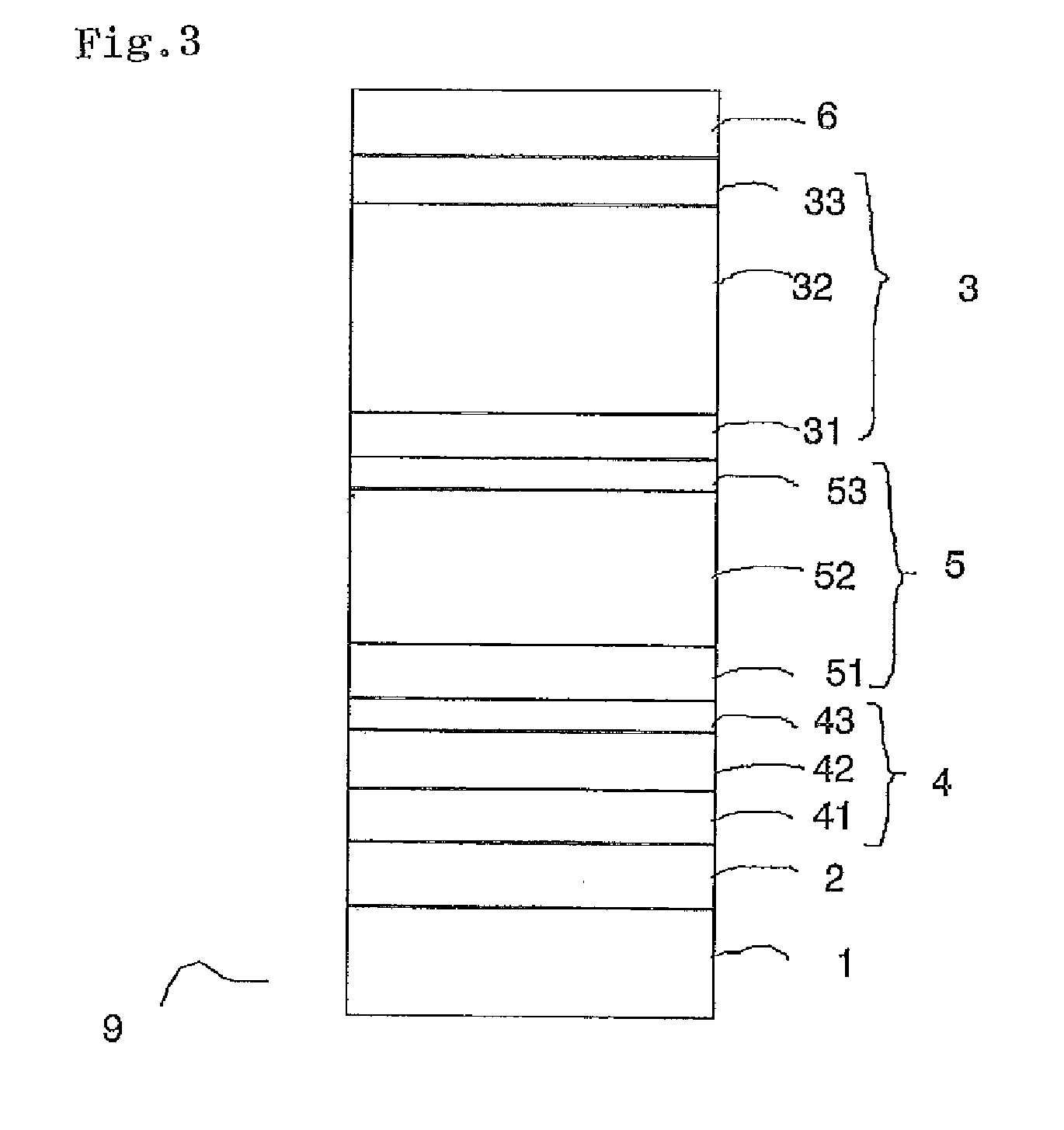

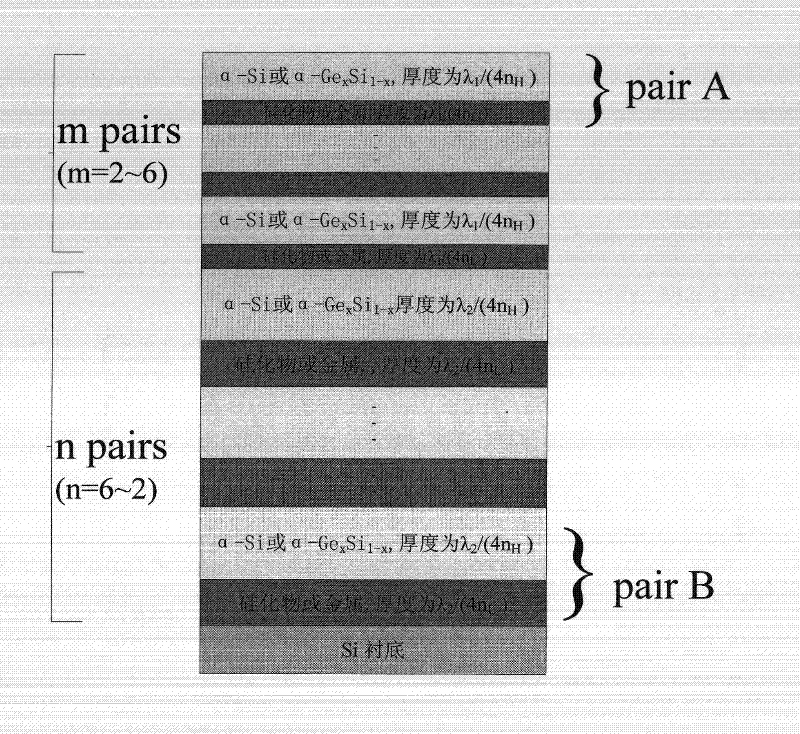

Wide spectrum high reflectivity irregularly shaped distributed Brag reflector (IDBR) and manufacturing method thereof

InactiveCN102354712ASimple processCompatible with mass production processFinal product manufactureChemical vapor deposition coatingSilicon solar cellHigh reflectivity

The invention relates to a wide spectrum high reflectivity irregularly shaped distributed Brag reflector (IDBR) and a manufacturing method thereof. The IDBR is characterized in that: through growing m pairs of DBR (distributed Brag reflector)-A multilayer films of a centre wavelength of lambda1 (lambda1= 400-700 nm) on n pairs of DBR (distributed Brag reflector)-B multilayer films of a centre wavelength of lambda2 (lambda2= 700-1300 nm), the IDBR is formed. The DBR-A or DBR-B is formed by periodically alternative combination of amorphous silicon (or amorphous germanium-silicon alpha-Ge[x]Si[1-x], x is larger than 0 and is less than or equals to 1 ) and silicide or metal (including SN, SiO[2], Ag or Al) film, thick and thin layer thicknesses T[H] and T[L] are determined by formulas T[H]= lambda[1(2)] / (4n[H]) and T[L]= lambda[1(2)] / (4n[L]) respectively, and n[L] and n[H] represent thin and thick layer refraction coefficients respectively. The IDBR in the invention can realize a high average reflectivity of more than 89% in a wide spectrum range of a wavelength of 400nm to 1270 nm, and is suitable for an ultra-thin (less than or equals to 50 micrometers) crystal silicon solar cell and an ultra-thin film solar cell.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

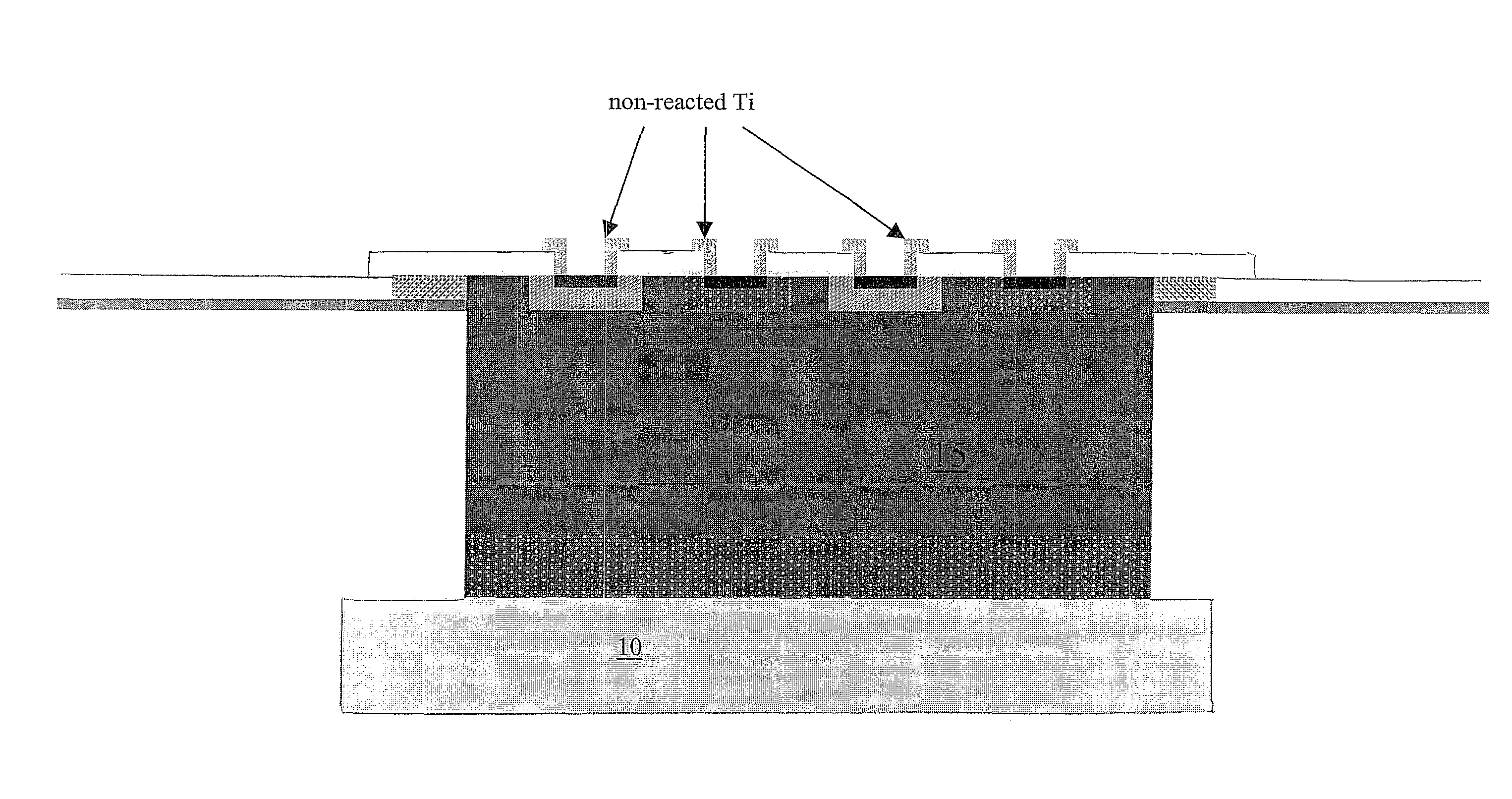

Method for Manufacturing Vertical Germanium Detectors

InactiveUS20100029033A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationSingle crystal substrateOptoelectronics

An improved method for manufacturing a vertical germanium detector is disclosed. Initially, a detector window is opened through an oxide layer on a single crystalline substrate. Next, a single crystal germanium layer is grown within the detector window, and an amorphous germanium layer is grown on the oxide layer. The amorphous germanium layer is then polished and removed until only a portion of the amorphous germanium layer is located around the single crystal germanium layer. A tetraethyl orthosilicate (TEOS) layer is deposited on the amorphous germanium layer and the single crystal germanium layer. An implant is subsequently performed on the single crystal germanium layer. After an oxide window has been opened on the TEOS layer, a titanium layer is deposited on the single crystal germanium layer to form a vertical germanium detector.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

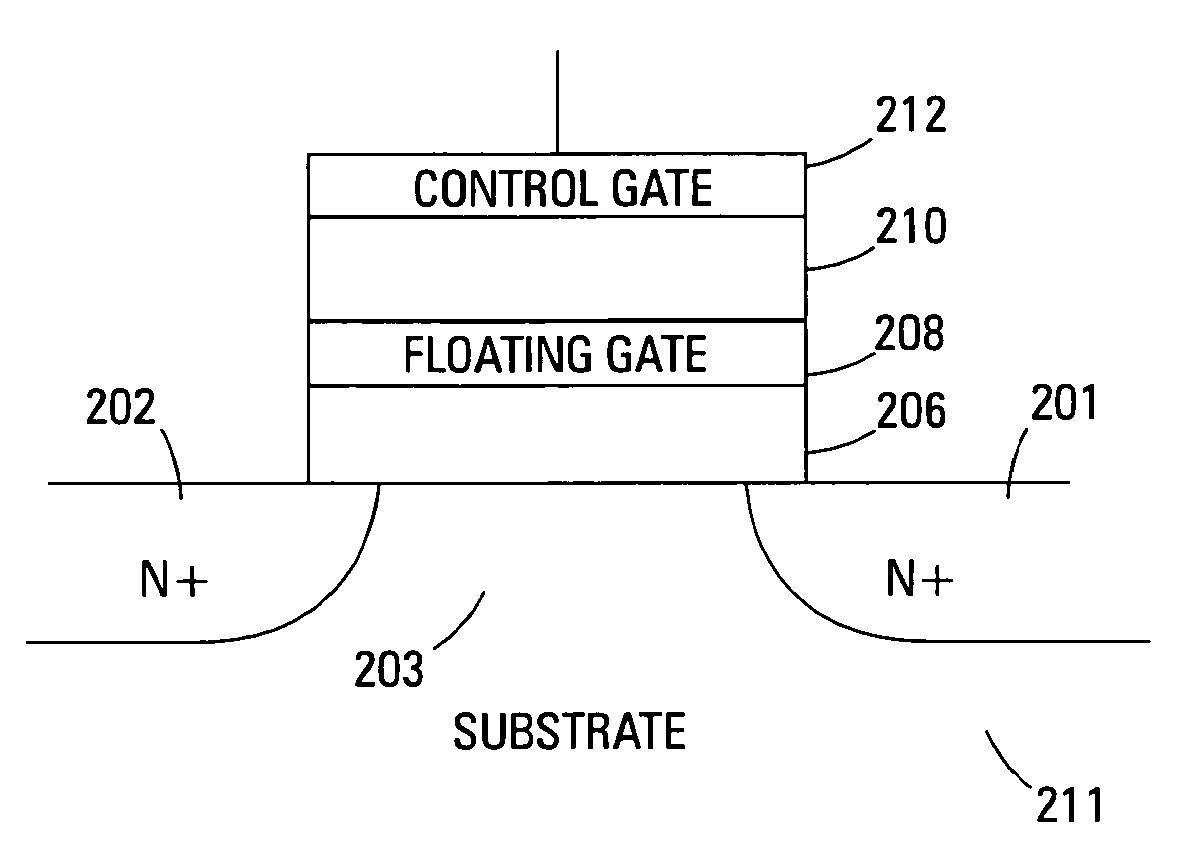

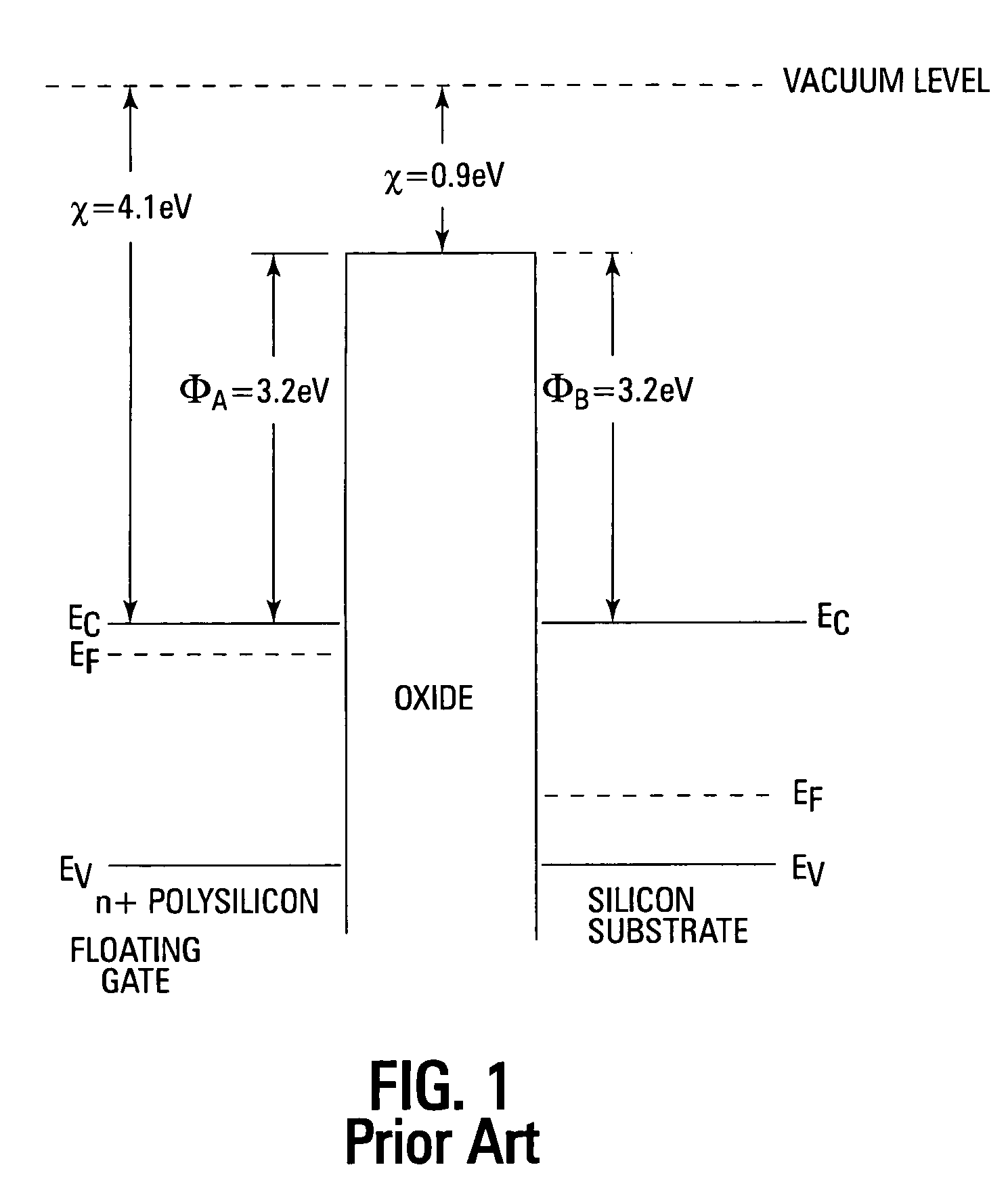

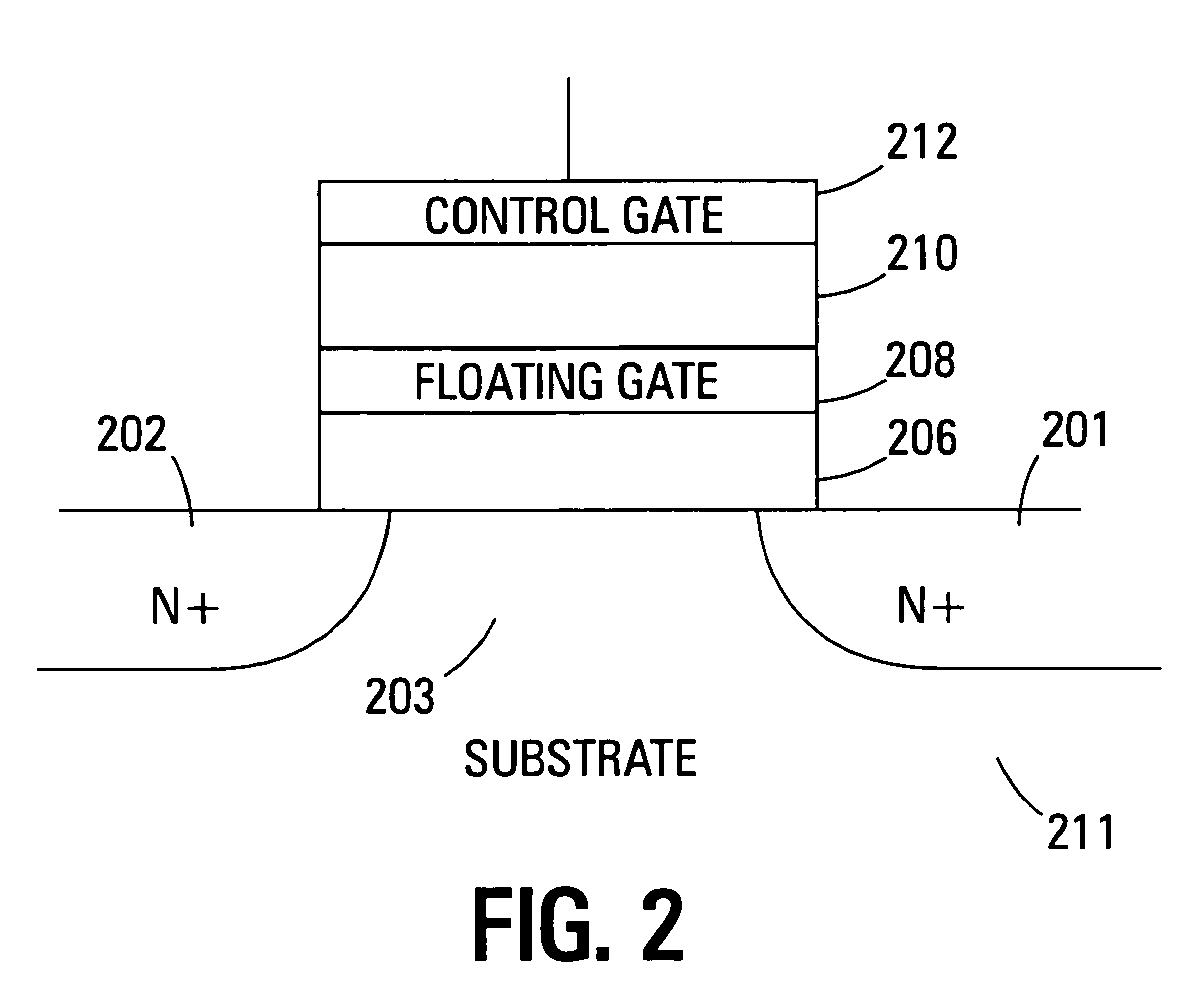

Flash memory device having a graded composition, high dielectric constant gate insulator

A graded composition, high dielectric constant gate insulator is formed between a substrate and floating gate in a flash memory cell transistor. The gate insulator is comprised of amorphous germanium or a graded composition of germanium carbide and silicon carbide. If the composition of the gate insulator is closer to silicon carbide near the substrate, the electron barrier for hot electron injection will be lower. If the gate insulator is closer to the silicon carbide near the floating gate, the tunnel barrier can be lower at the floating gate.

Owner:MICRON TECH INC

Lamination structure and thin film solar cell with same

ActiveCN101640226AEnhanced light absorptionMaintain light absorptionPhotovoltaic energy generationSemiconductor devicesNanocrystalline siliconNano crystalline

The invention provides a lamination structure and a thin film solar cell with the lamination structure. A lamination structure of hydrogenated nano-crystalline silicon and hydrogenated amorphous germanium is adopted as an intrinsic i layer of a p-i-n type thin film solar cell, and has strong capability of absorbing red light and infrared ray. A multijunction thin film solar cell taking the lamination structure as a bottom junction has higher conversion efficiency and lower production cost.

Owner:GS SOLAR FU JIAN COMPANY +1

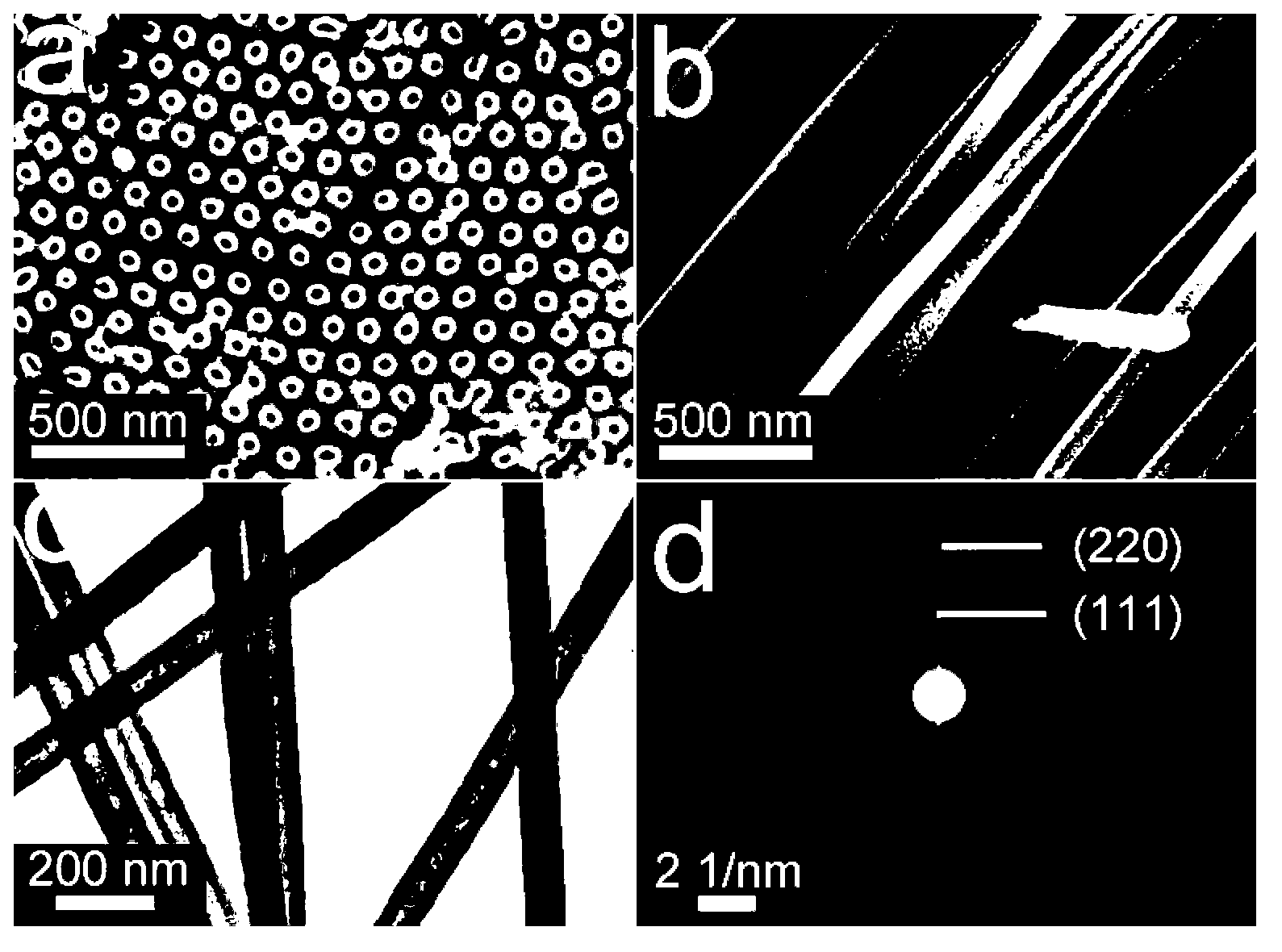

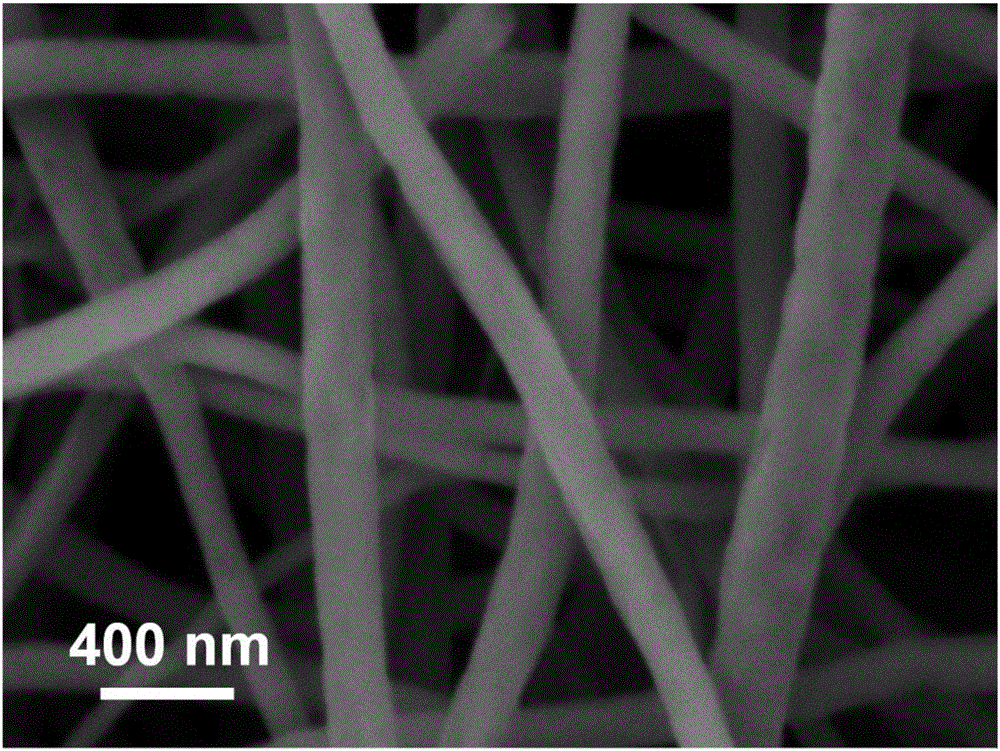

Method for preparing germanium nanotubes

The invention discloses a method for preparing germanium nanotubes. The method includes the steps of firstly, adopting secondary anodic oxidation process to obtain a thorough-hole alumina template, soaking the through-hole alumina template in nickel nitrate solution to remove nickel nitrate from the surface of the template so as to obtain the thorough-hole alumina template with nickel nitrate deposited in holes; secondly, placing the thorough-hole alumina template with nickel nitrate deposited in the holes into a mixed atmosphere of hydrogen argon to be subjected to reduction reaction at the temperature of from 300 DEG C to 380 DEG C for 10-30 minutes, then placing the thorough-hole alumina template with nickel nitrate deposited in the holes into the mixed atmosphere of germane hydrogen argon to be subjected to vapor deposition at the temperature of from 300 DEG C to 380 DEG C for 10-30 minutes to obtain the alumina template with the germanium nanotubes deposited inside the holes; and finally, placing the alumina template with the germanium nanotubes deposited inside the holes into aqueous alkali to remove the alumna template to obtain the germanium nanotubes composed of nickel diffusing evenly in amorphous germanium which has the ratio of germanium to nickel being (95.05-99.95%):(0.05-4.95%). By the method, possibility is provided to a research of characteristics of light, electricity and the like of the germanium nanotubes and an application thereof. Hopefully, the method for preparing the germanium nanotubes can be widely used in the fields of light, electronic device and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

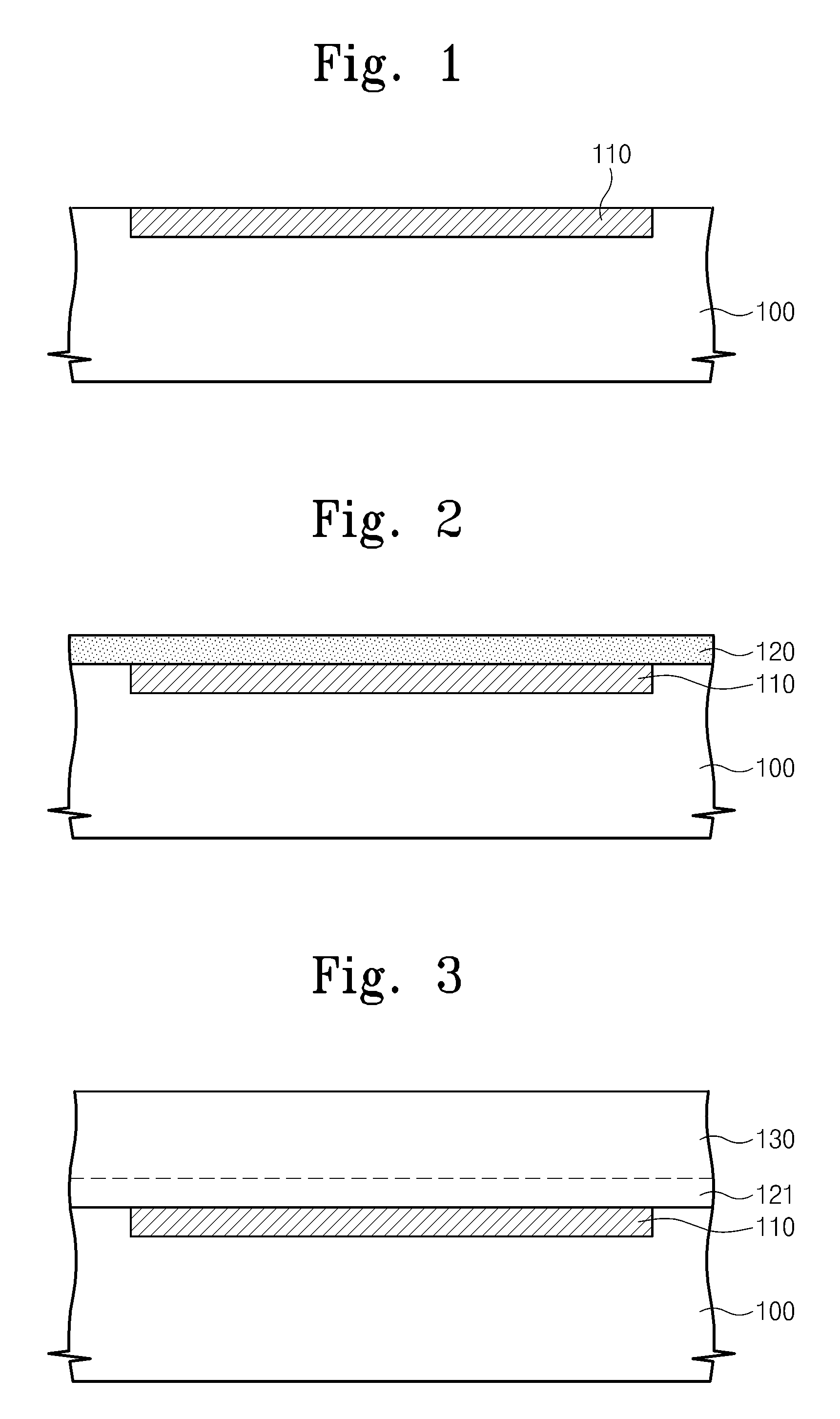

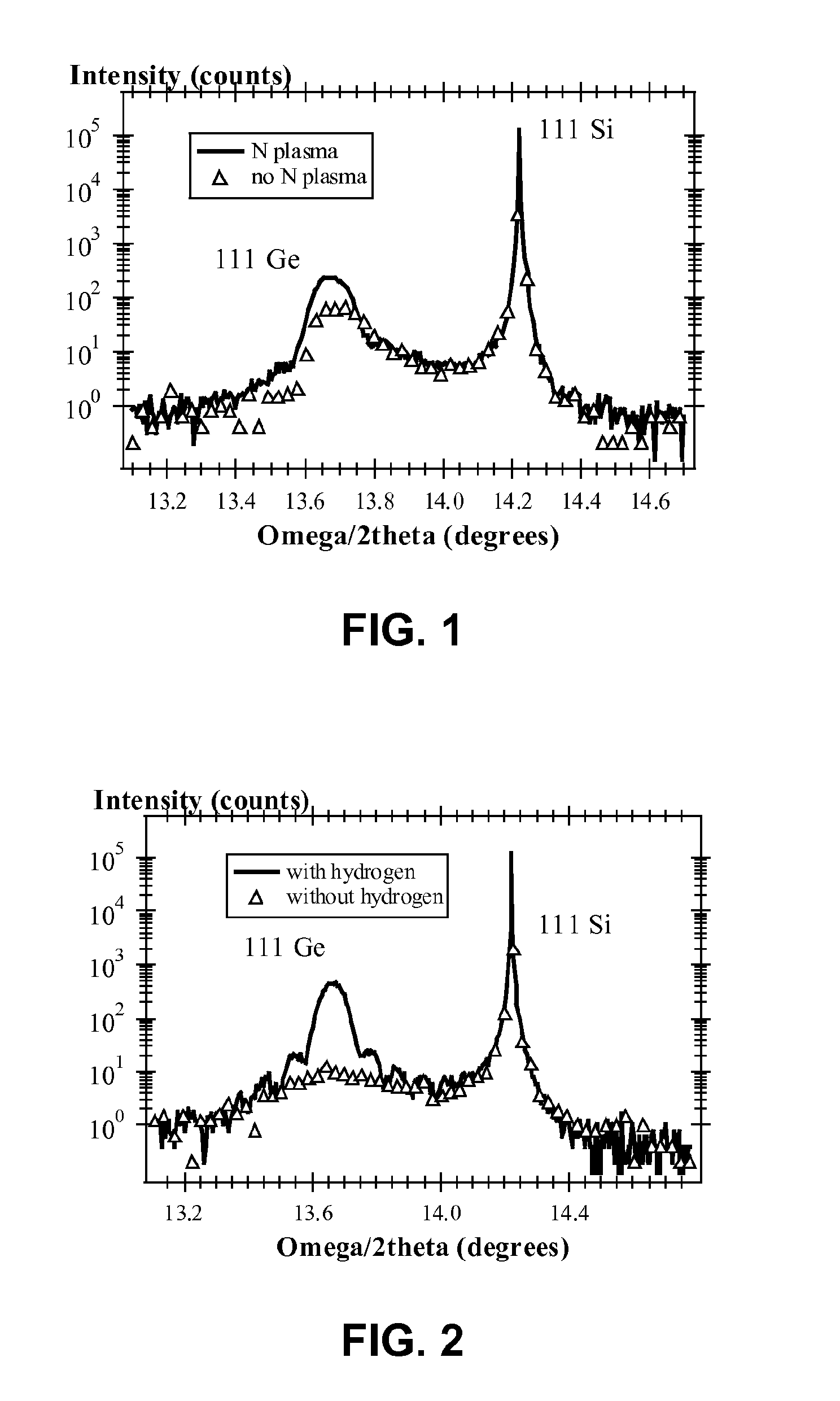

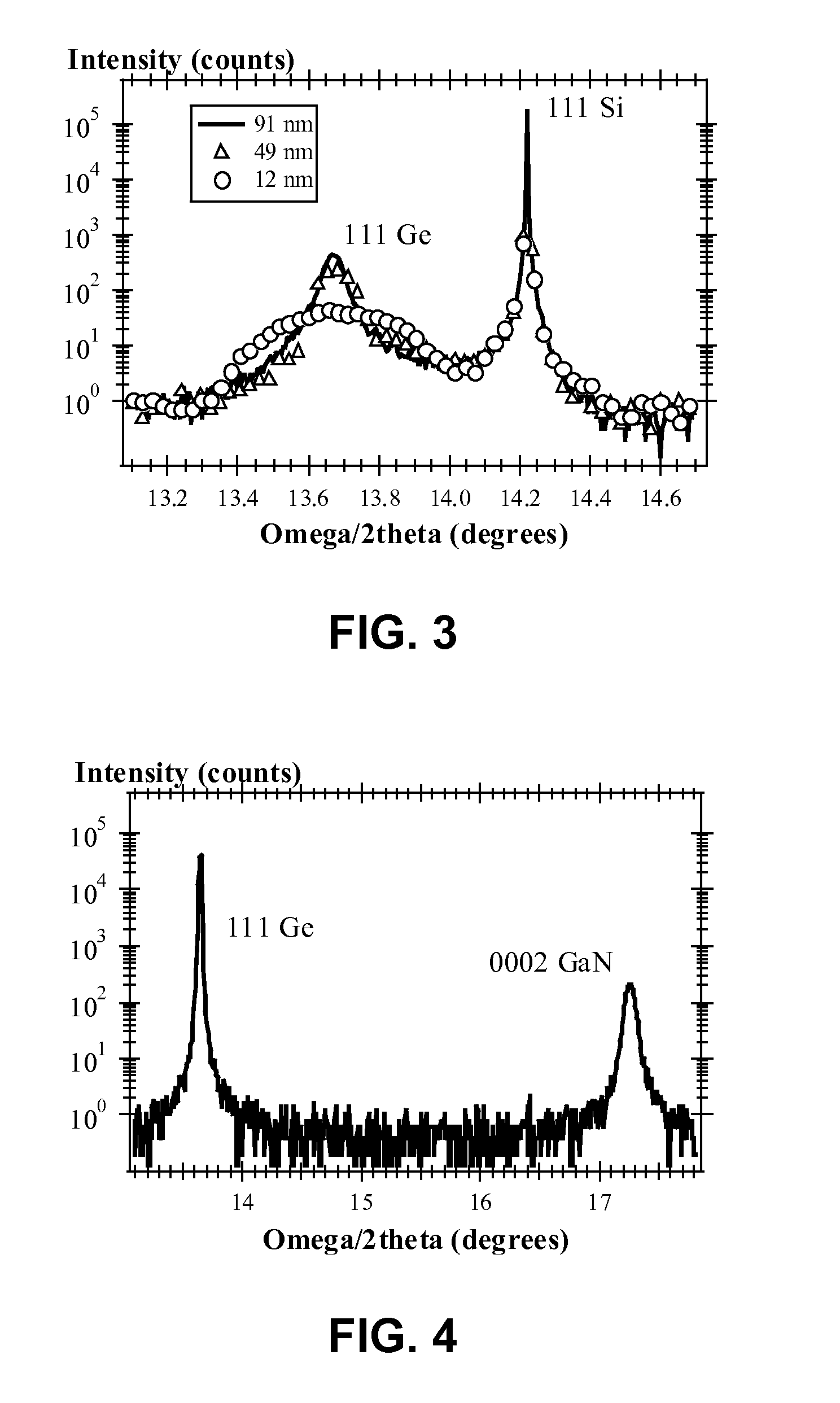

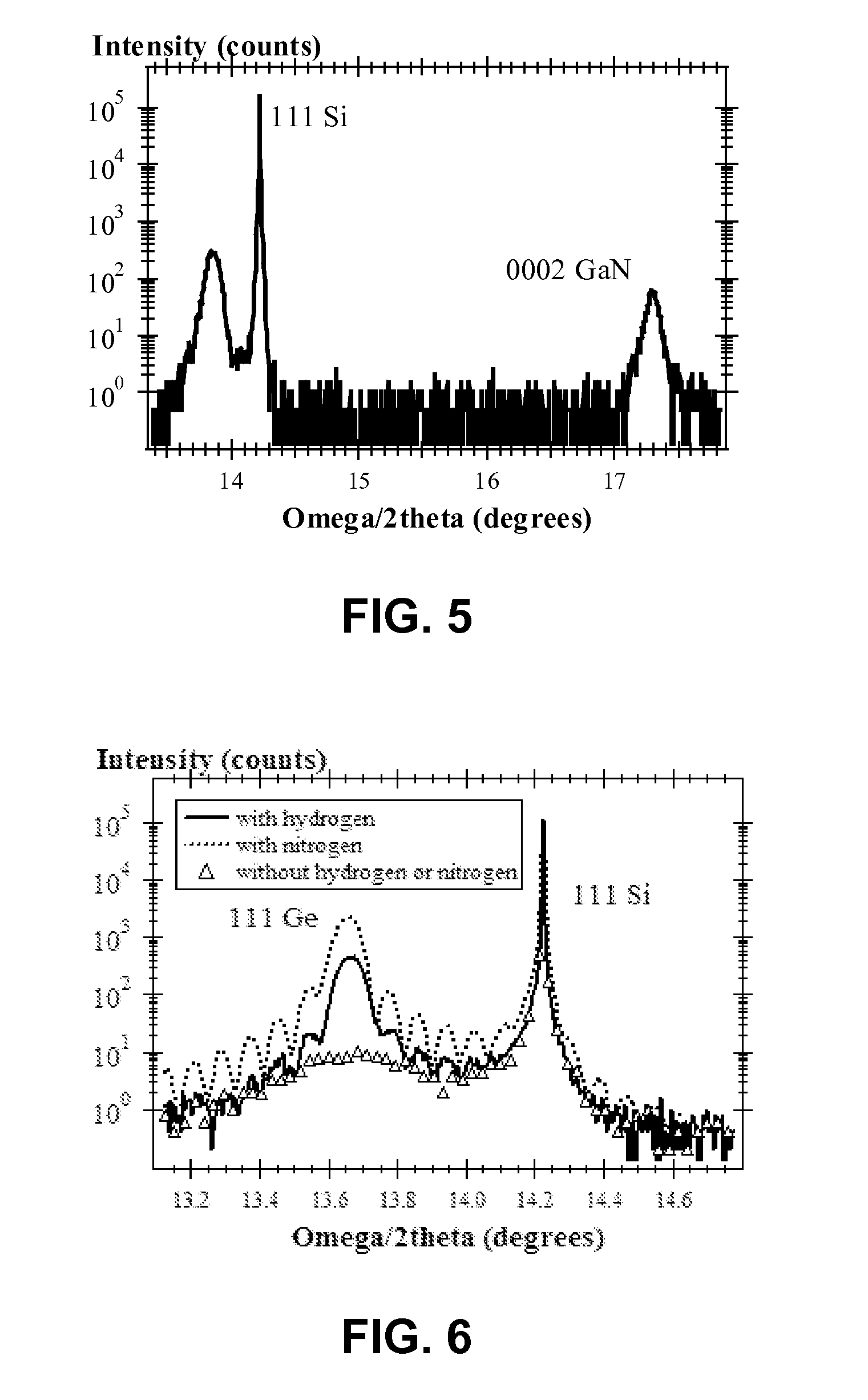

Method for producing a crystalline germanium layer on a substrate

The present invention provides a method for providing a crystalline germanium layer on a crystalline base substrate having a crystalline surface. The method comprises cleaning the base substrate for removing contaminants and / or native oxides from the surface, providing an amorphous germanium layer on the surface of the base substrate while exposing to the base substrate to a hydrogen source such as e.g. a hydrogen plasma, a H2 flux or hydrogen originating from dissociation of GeH4 and / or to a non-reactive gas source such as N2, He, Ne, Ar, Kr, Xe, Rn or mixtures thereof, and crystallising the amorphous germanium layer by annealing the base substrate so as to provide a crystalline germanium layer. The present invention also provides a method for the production of a photovoltaic cell or a photo-electrolysis cell or for forming a CMOS device by using the method according to embodiments of the invention and a substrate comprising a crystalline germanium layer formed by a method according to embodiments of the invention.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

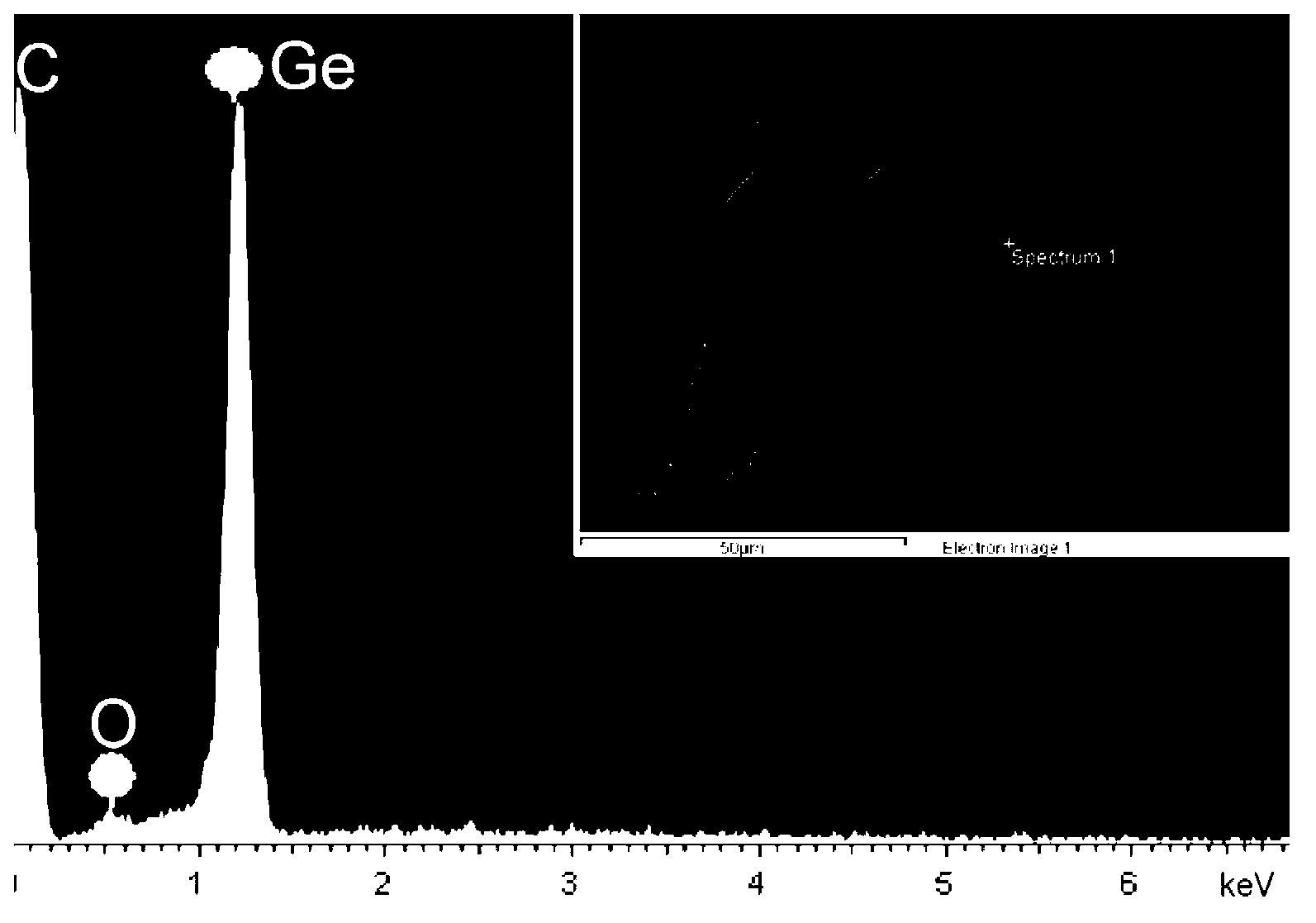

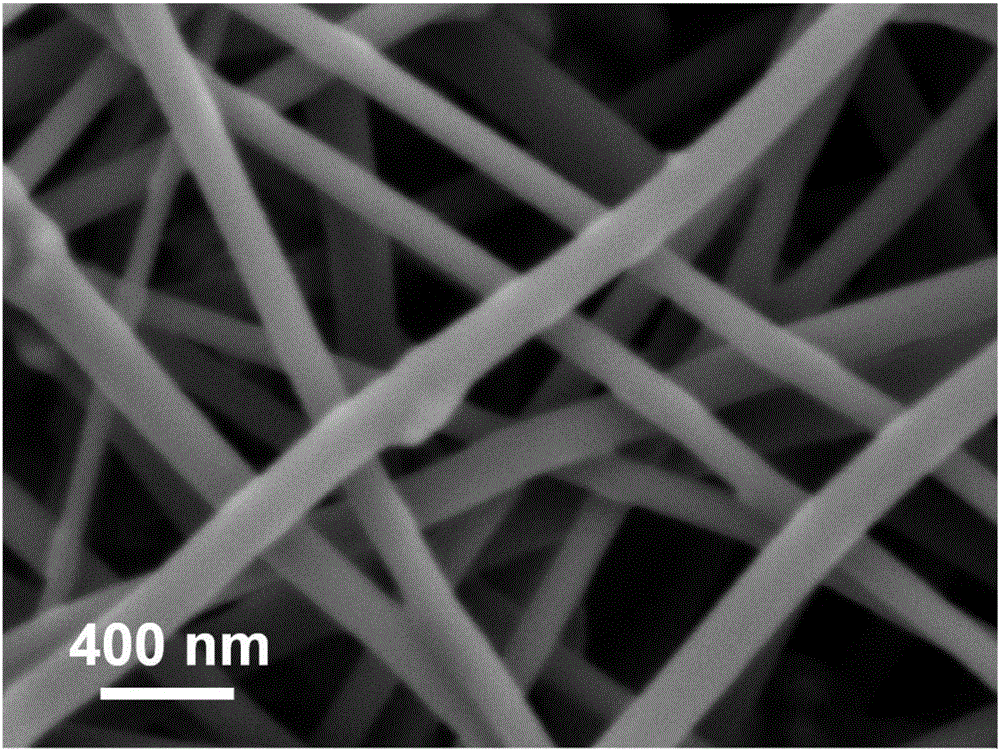

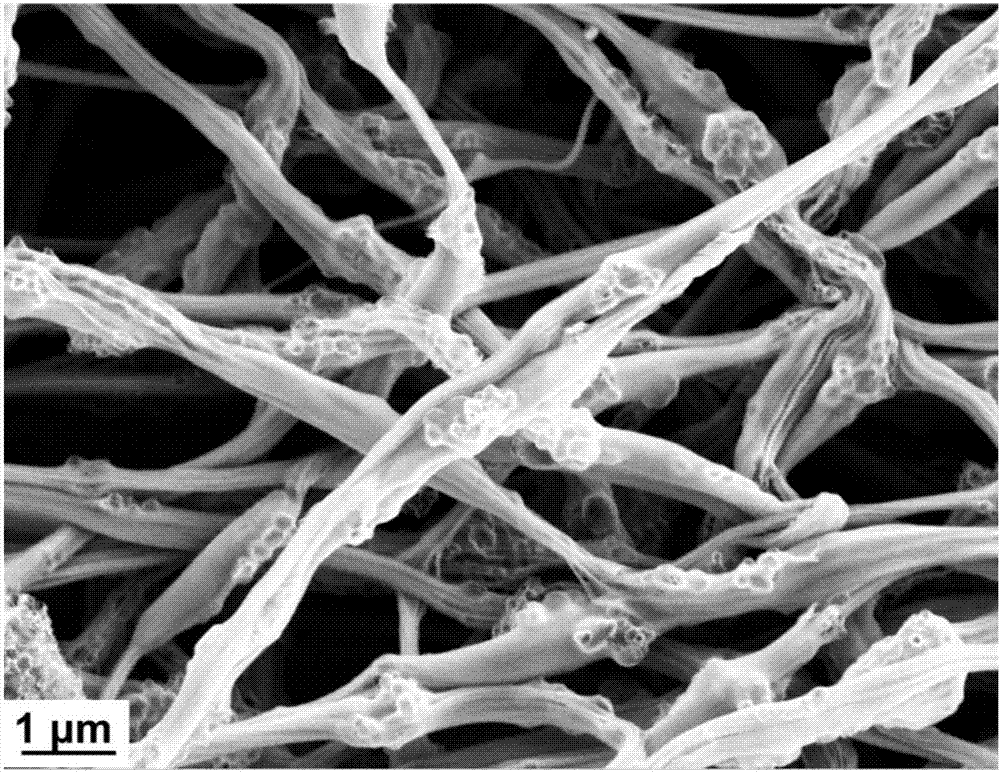

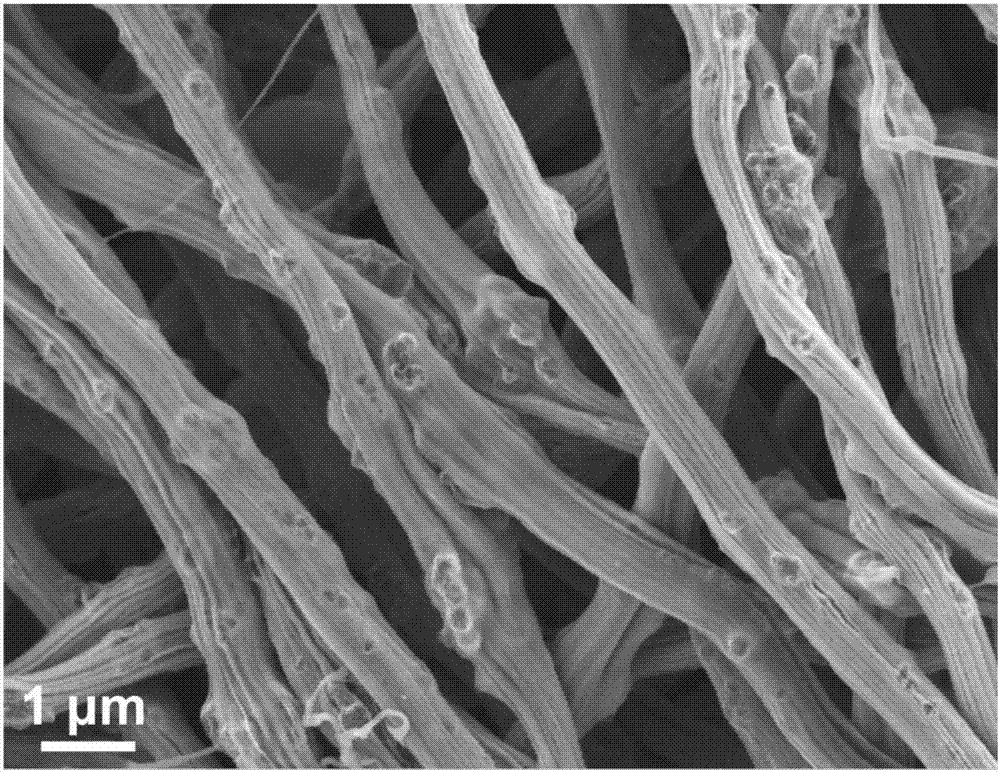

Amorphous germanium oxide/porous carbon nanofiber and preparation method thereof

ActiveCN105958025AImprove conductivityImprove the conductivity, so that the rate capacity of lithium-ion batteriesMaterial nanotechnologyCell electrodesElectronic transmissionFiber

The invention relates to the field of negative electrode materials for lithium-ion batteries, in particular to an amorphous germanium oxide / porous carbon nanofiber and a preparation method thereof. The amorphous germanium oxide / porous carbon nanofiber comprises a porous carbon nanofiber and an amorphous germanium oxide located on the porous carbon nanofiber; and the mass percentage of the germanium oxide is 10%-40%. A large number of micropores exist in the porous carbon nanofiber, so that active sites of an active material are increased. The electronic transmission performance between the active material and a current collector is improved, so that improvement of the capacity of the lithium-ion battery is facilitated.

Owner:浙江技立新材料股份有限公司

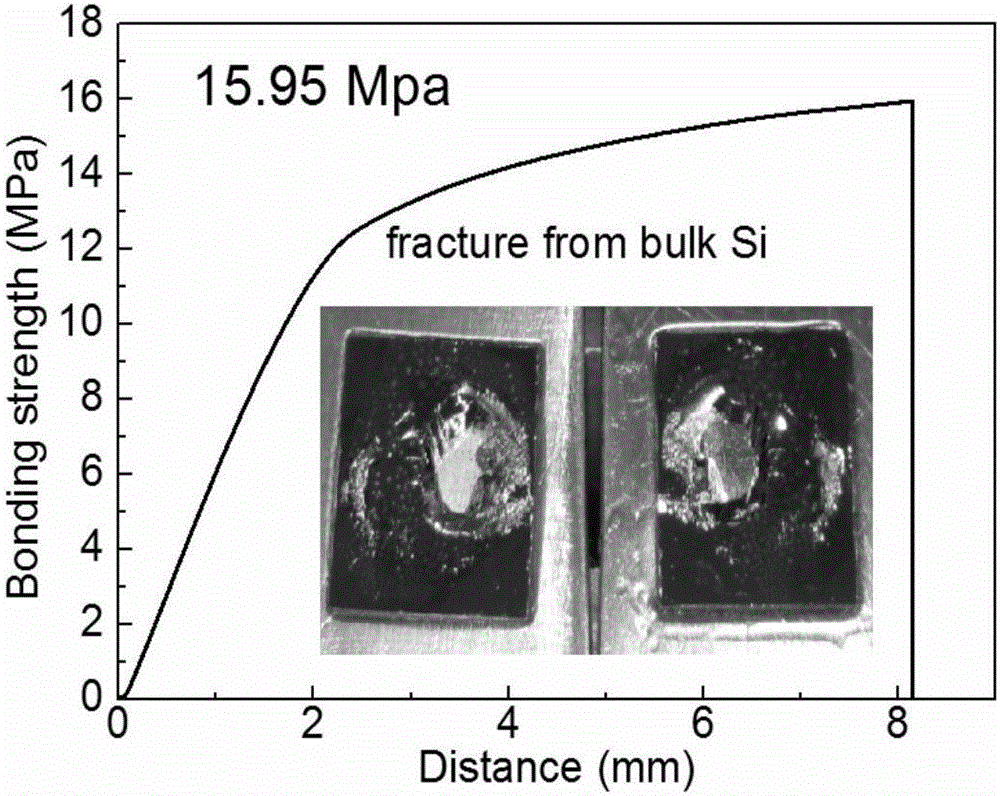

Method for realizing Si-Si bonding through adoption of amorphous germanium film

InactiveCN106847681AAchieve crystallizationAvoid incompatibilitiesVacuum evaporation coatingSolid-state devicesOptoelectronicsHigh intensity

The present invention provides a method for realizing Si-Si bonding through adoption of an amorphous germanium film, and relates to a Si wafer bonding method. The method comprises: selecting Si substrate materials with crystal direction as (100), performing cleaning; boiling the substrate materials through adoption of a mixed solution of H2SO4 and H2O2, and immersing the substrate materials in a mixed solution of HF and H2O2; boiling the processed Si wafer in a mixed solution of NH4OH, H2O2 and H2O, and immersing Si wafer in a mixed solution of HF and H2O2; boiling the processed Si wafer in a mixed solution of HCL, H2O2 and H2O, and immersing the Si wafer in a mixed solution of HF and H2O2; drying the processed Si wafer to put the Si wafer into a direct current magnetron sputtering system, filling Ar gas into a sputtering chamber when the base pressure of the sputtering chamber is smaller than 1*10<-4>Pa; sputtering a-Ge thin film through regulation of direct current sputtering current and sample holder rotation speed; and realizing high-intensity Si-Si bonding through adoption of a hydrophilic a-Ge layer.

Owner:XIAMEN UNIV

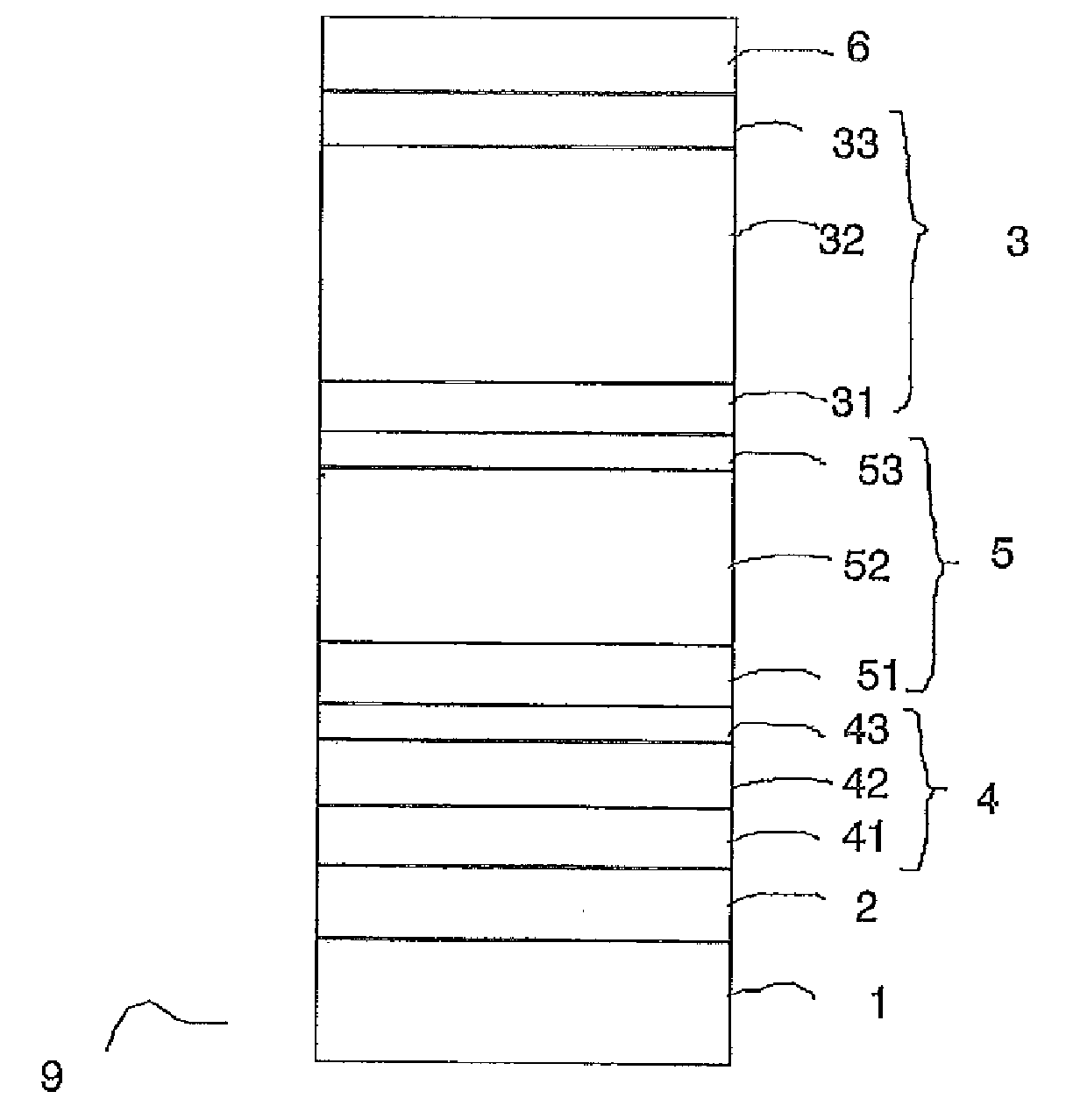

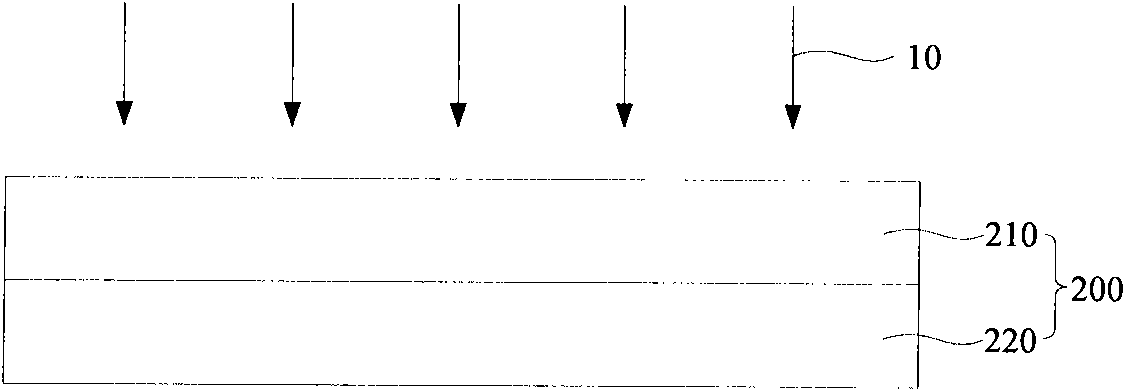

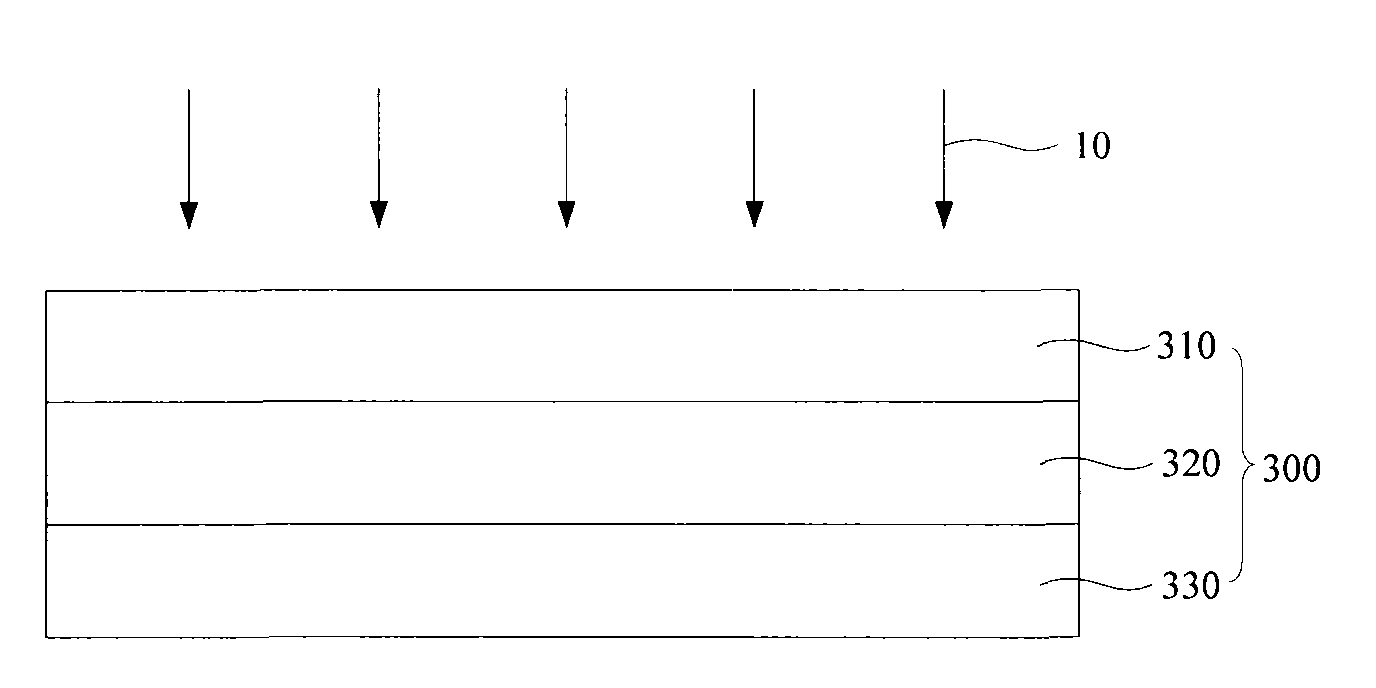

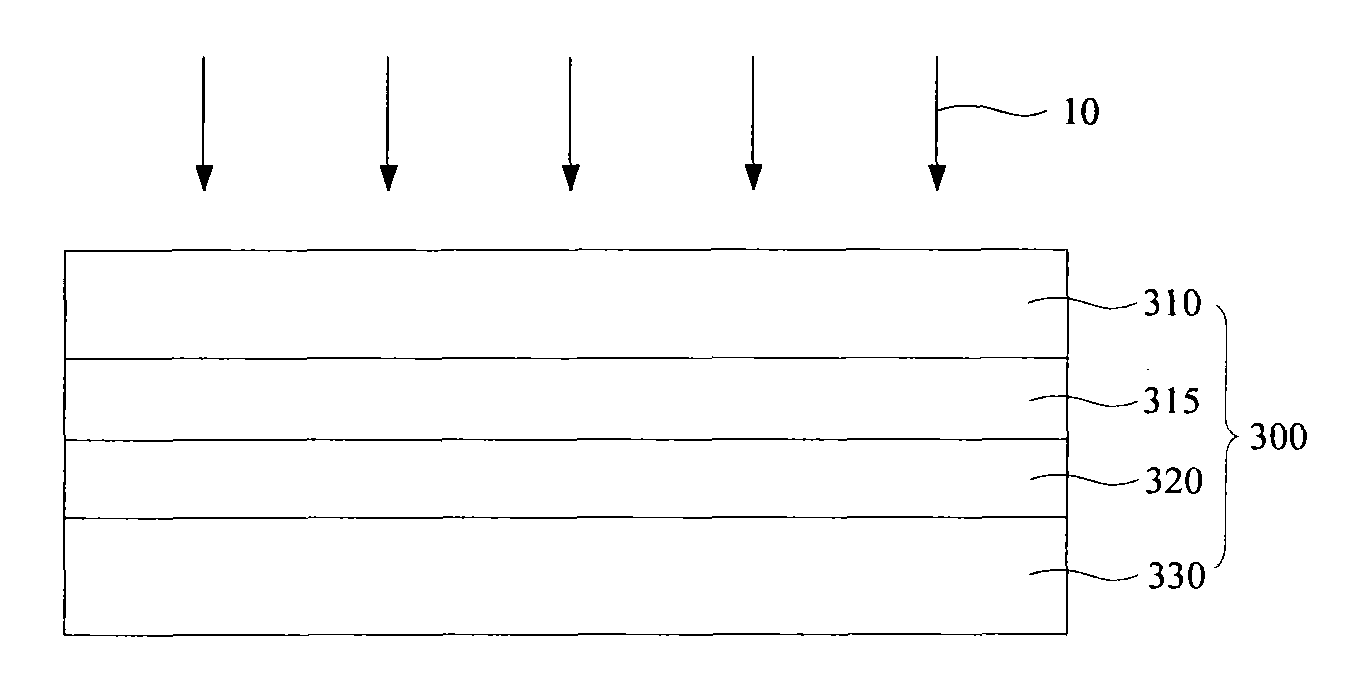

Semiconductor structure and thin-film photovoltaic device having same

InactiveCN101651166AImprove light absorptionImprove photoelectric conversion efficiencyPhotovoltaic energy generationSemiconductor devicesSemiconductor structureNanocrystalline silicon

The invention discloses a semiconductor structure and a thin-film photovoltaic device having the same. The semiconductor structure is used for light absorption of the thin-film photovoltaic device, and comprises a silicon, including amorphous silicon or nanocrystalline silicon, based p layer, an amorphous germanium intrinsic i layer on the surface of the p layer and a silicon, including amorphoussilicon, nanocrystalline silicon or a-SiGe, based n layer on the surface of the amorphous germanium intrinsic i layer. The thin-film photovoltaic device is a three junction photovoltaic device comprising a top junction optical-to-electric conversion unit, a middle junction optical-to-electric conversion unit and a bottom junction optical-to-electric conversion unit, wherein the intrinsic layer ofthe top junction optical-to-electric conversion unit is the amorphous silicon; the intrinsic layer of the middle junction optical-to-electric conversion unit is the nanocrystalline silicon; and the intrinsic layer of the bottom junction optical-to-electric conversion unit is the amorphous germanium. The semiconductor structure and the thin-film photovoltaic device have the same can further improvethe performance of the multi-junction thin-film photovoltaic device and lower industrialized manufacturing cost.

Owner:GS SOLAR FU JIAN COMPANY +1

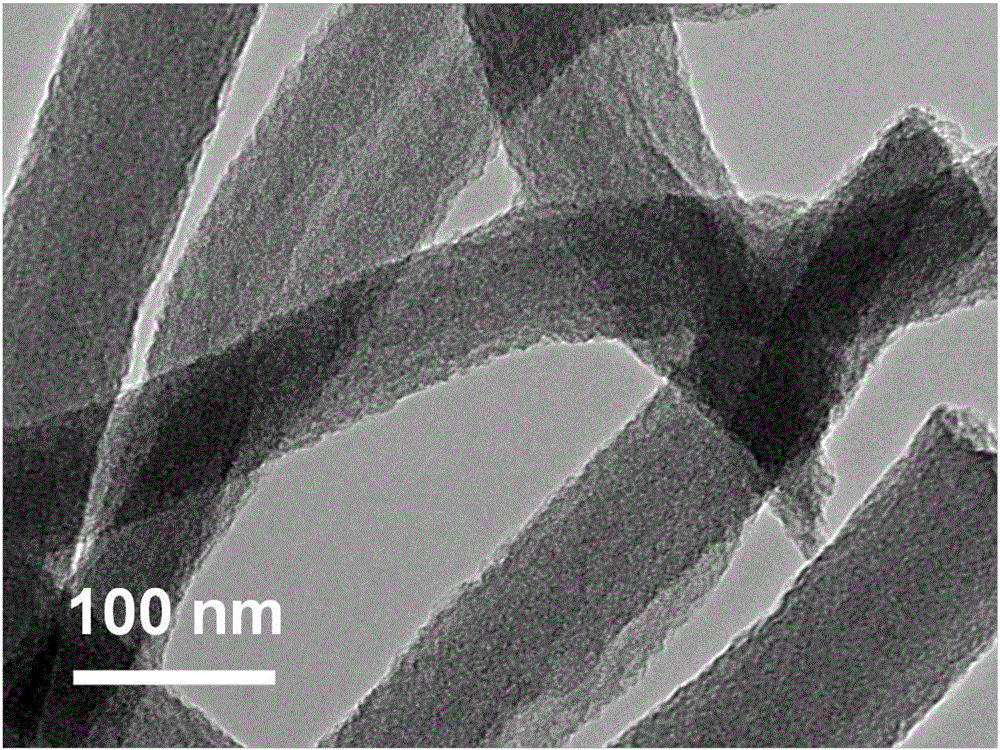

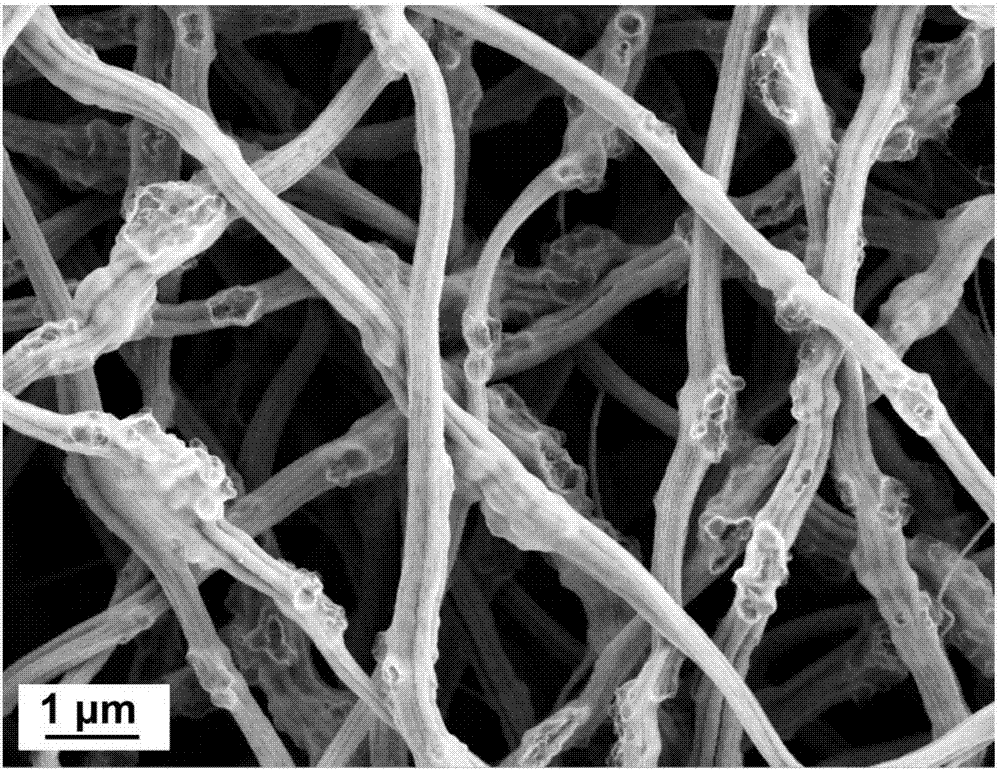

Amorphous germanium dioxide/multi-tube carbon nanofiber and preparation method thereof

ActiveCN107482194AIncrease capacityInhibition of volume changeMaterial nanotechnologyCell electrodesFiberCarbon fibers

The invention relates to the field of lithium ion battery anode materials, in particular to an amorphous germanium dioxide / multi-tube carbon nanofiber and a preparation method thereof. The amorphous germanium dioxide / multi-tube carbon nanofiber comprises a tube carbon nanofiber and amorphous germanium dioxide positioned on the multi-tube carbon nanofiber, wherein the mass percentage content of the germanium dioxide is 10%-60%. The amorphous germanium dioxide / multi-tube carbon nanofiber prepared with the method is beneficial to improvement of the capacity and cycle performance of a lithium ion battery, and the method is simple, controllable and easy to operate.

Owner:ZHEJIANG SCI-TECH UNIV

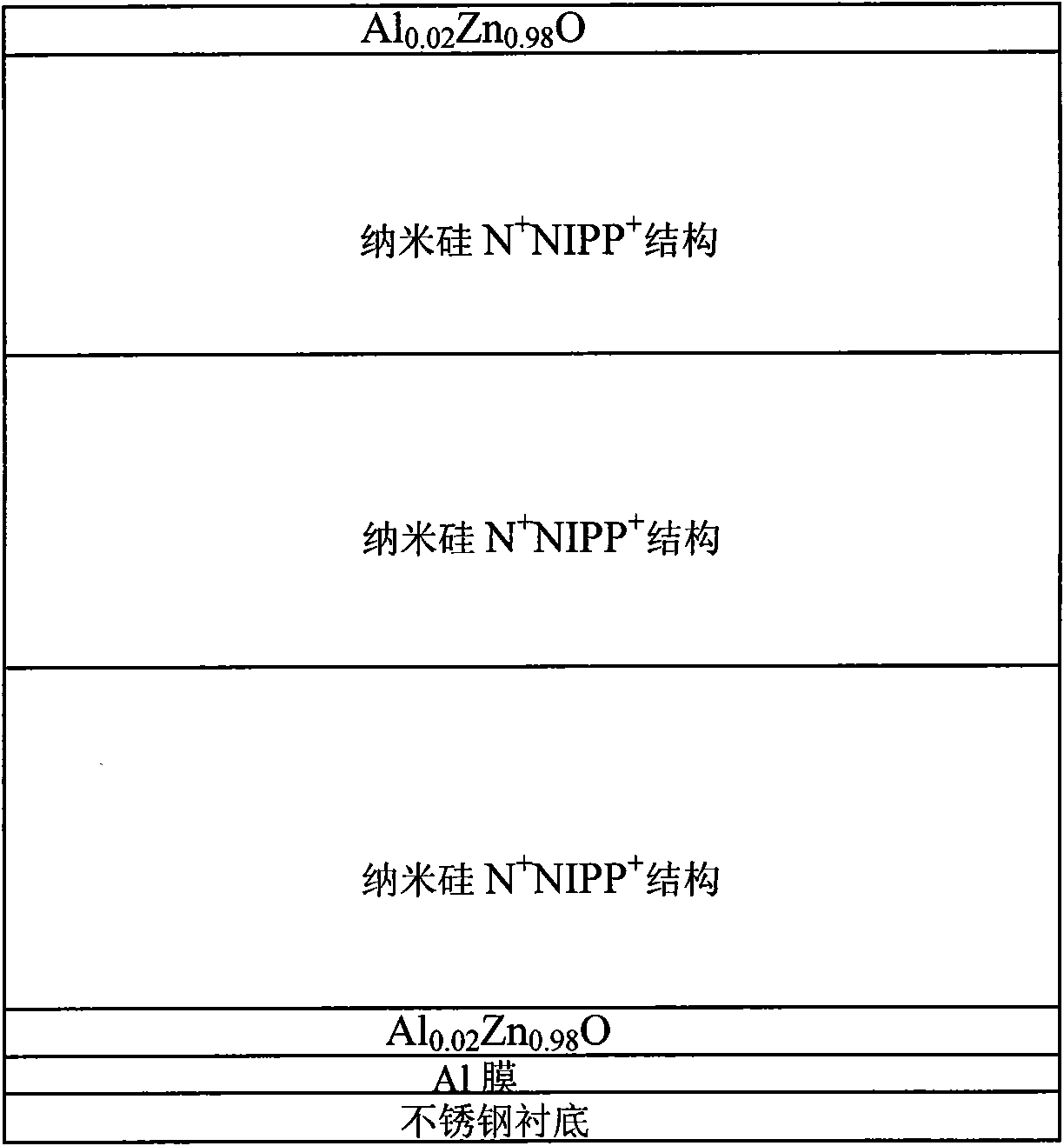

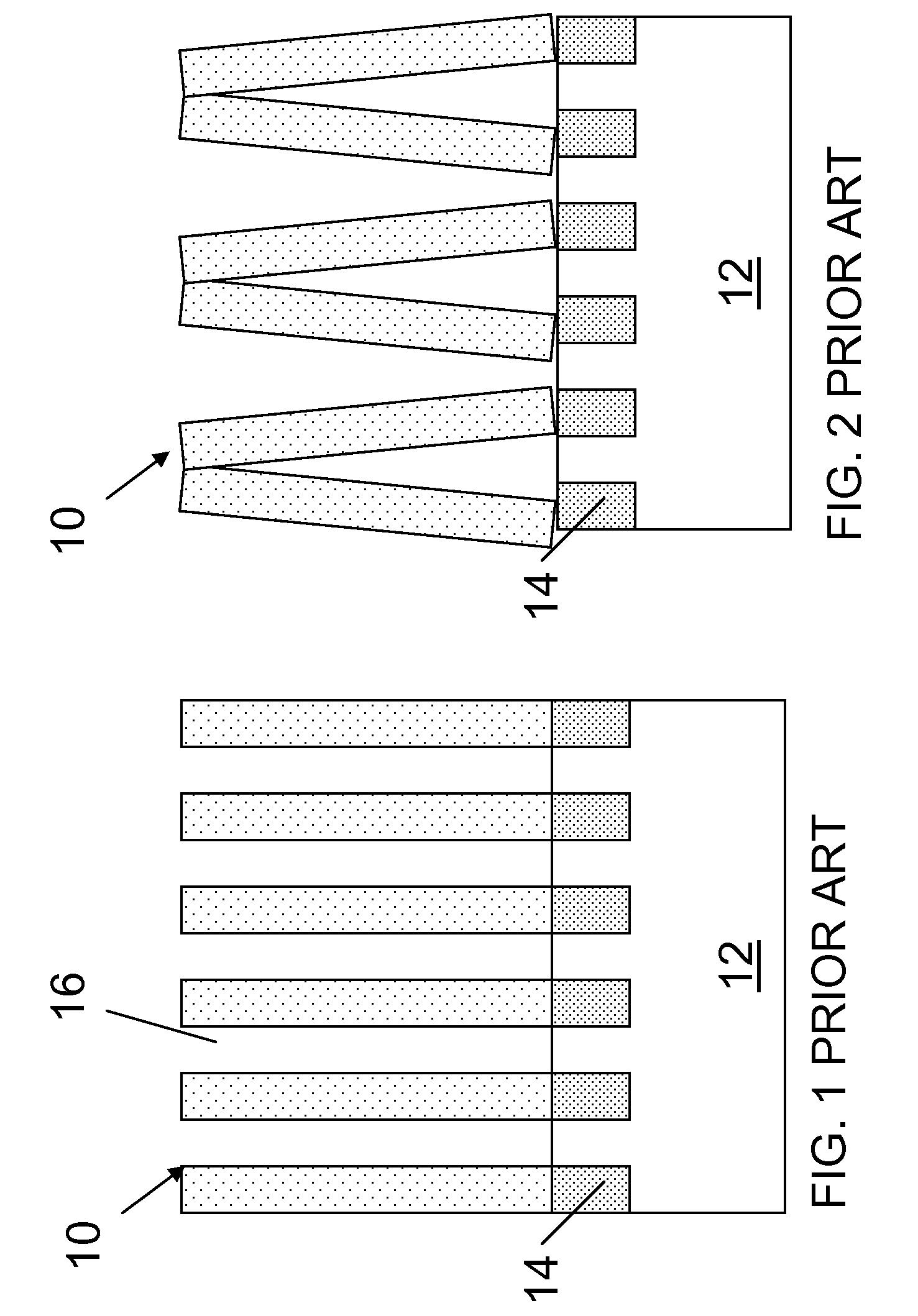

Nanometer silica film three-layer stacked solar cell and preparation method thereof

InactiveCN101540345AReduce usageLow costFinal product manufactureVacuum evaporation coatingHigh absorptionElectrical battery

The invention relates to a film solar cell and a preparation method thereof, in particular to a nanometer silica film three-layer stacked solar cell and a preparation method thereof. The method of plasma enhanced chemical vapor deposition (PECVD) is adopted for preparing a hydrogenated nanometer silica film (nc-Si:H). An nc-Si:H / nc-Si:H / nc-Si:H film three-layer stacked solar cell is prepared on a soft metal or polyimide film substrate. The top cell, the middle cell and the bottom cell adopt the N<+>NIPP<+> structure. The method of radio frequency sputtering is adopted for depositing an Al / AlxZn1-xO double-layer back electrode and an AlxZn1-xO film upper electrode. The invention avoids the use of amorphous silicon and expensive amorphous germanium silicon; the relatively thinner nanometer silica film three-layer stacked solar cell with high efficiency and stability is obtained on the soft substrate by taking advantage of the adjustable scope of the band gap of nanometer silica width, the relatively higher absorption coefficient and lower photoinduced damping effect. The invention achieves simple process and low cost of the used materials and causes no pollution to the environment.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

Mask forming and implanting methods using implant stopping layer and mask so formed

InactiveUS20070275563A1Aspect ratio maskReduce dispersionSemiconductor/solid-state device manufacturingThin material handlingHigh densityCarbide

Methods of forming a mask for implanting a substrate and implanting using an implant stopping layer with a photoresist provide lower aspect ratio masks that cause minimal damage to trench isolations in the substrate during removal of the mask. In one embodiment, a method of forming a mask includes: depositing an implant stopping layer over the substrate; depositing a photoresist over the implant stopping layer, the implant stopping layer having a density greater than the photoresist; forming a pattern in the photoresist by removing a portion of the photoresist to expose the implant stopping layer; and transferring the pattern into the implant stopping layer by etching to form the mask. The implant stopping layer may include: hydrogenated germanium carbide, nitrogenated germanium carbide, fluorinated germanium carbide, and / or amorphous germanium carbon hydride (GeHX), where X includes carbon. The methods / mask reduce scattering during implanting because the mask has higher density than conventional masks.

Owner:ALSEPHINA INNOVATIONS INC

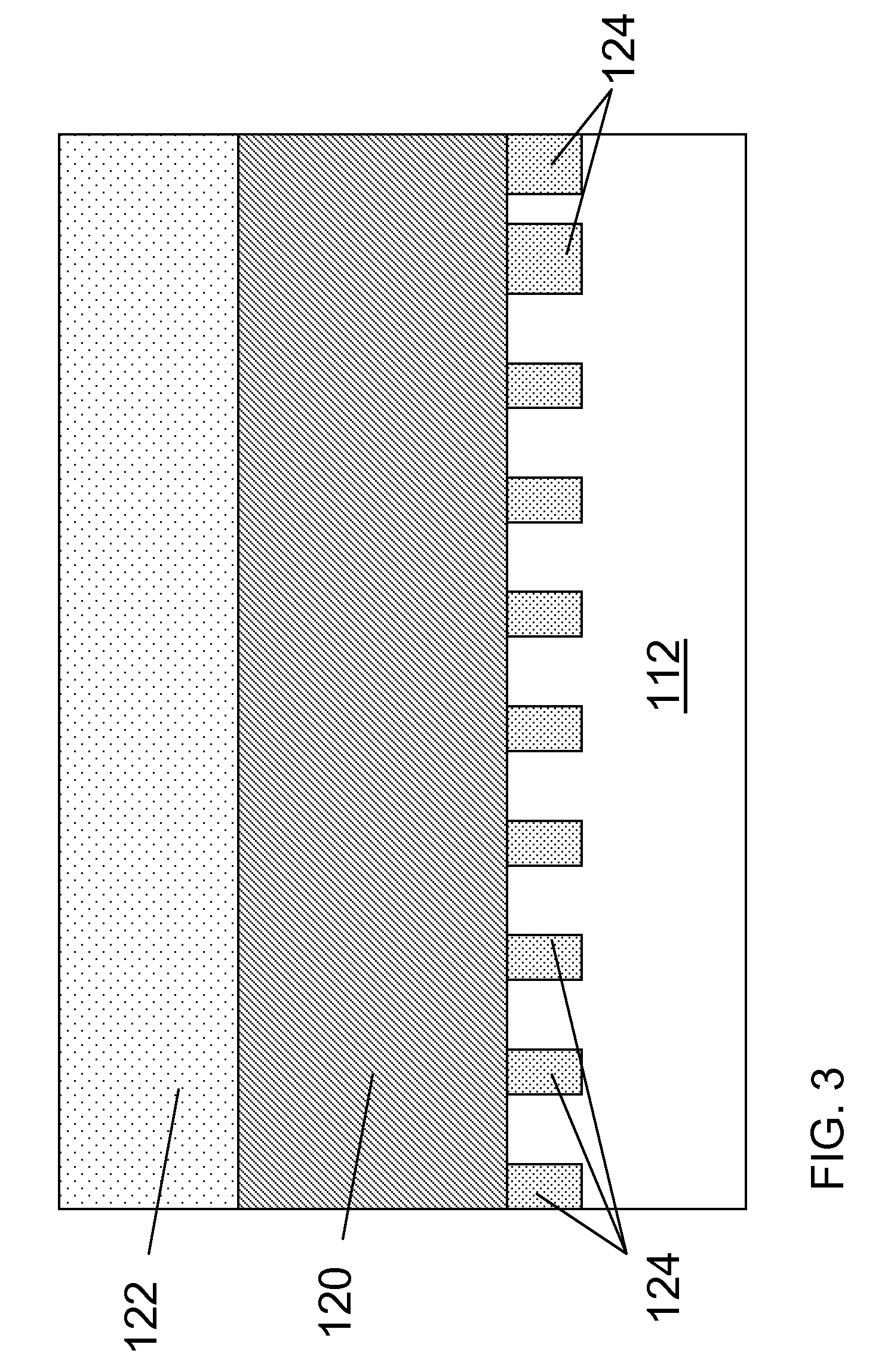

POROUS AMORPHOUS GeOx AND ITS APPLICATION AS AN ANODE MATERIAL IN LI-ION BATTERIES

InactiveUS20150171426A1Large capacityImprove cycle stabilityMaterial nanotechnologyNon-metal conductorsHierarchical porousStructural stability

Amorphus germanium oxide materials are provided that are composed of germanium and oxygen having a formula GeOx, where 0.01≦x≦1.99. The germanium oxide forms nanoscale hierarchical porous agglomerates that have high capacity, high diffusivity of lithium, and enhanced cycling stability. The enhanced or superior performance (structural stability and reactivity) of these materials is due to the formation of ultrafine primary nanoparticles, amorphization, pore formation, preferably of nanoscale nature, and the incorporation of oxygen. These amorphous germanium oxide materials may serve as high-capacity anode materials and afford an enhanced capacity applicable for electrochemical cells such as Li-ion batteries.

Owner:BROOKHAVEN SCI ASSOCS

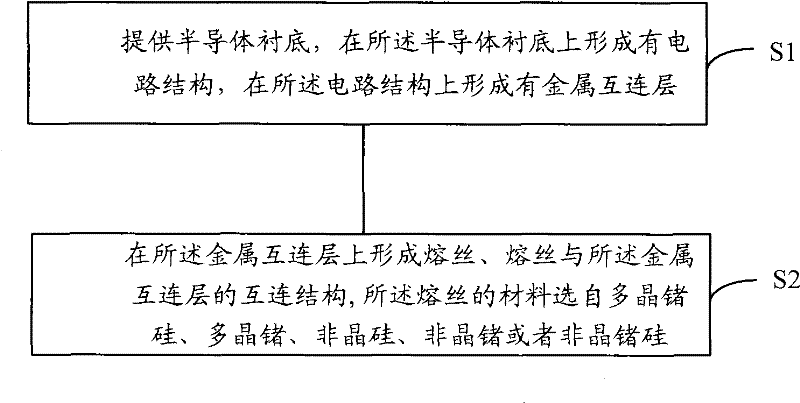

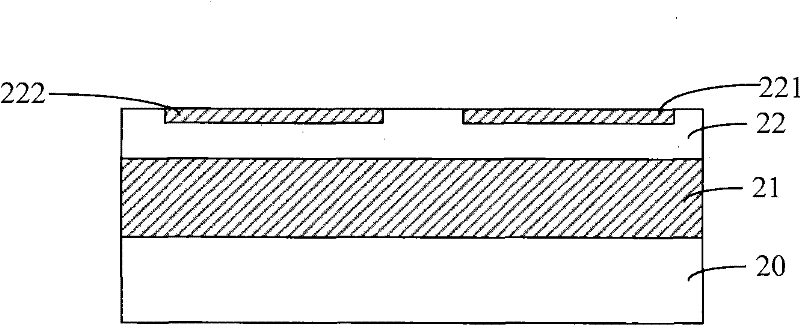

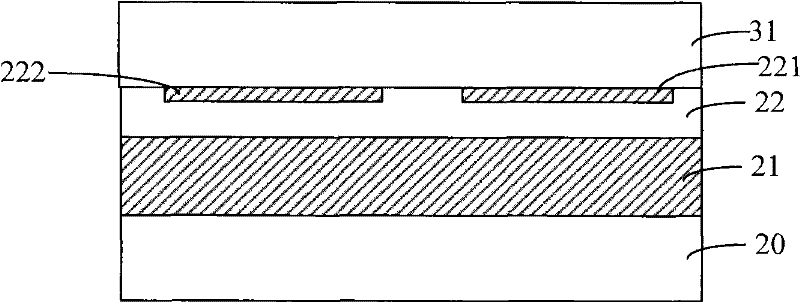

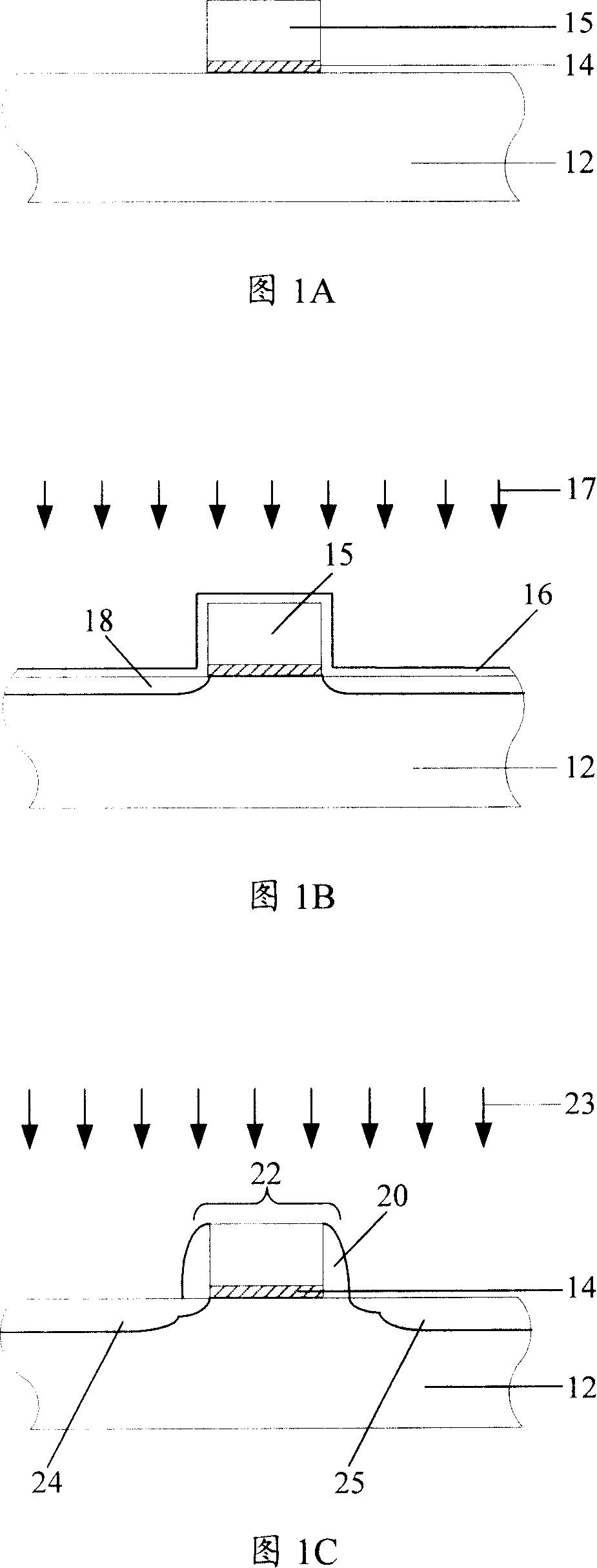

Fuse structure and method for forming the same

ActiveCN102347269AWon't breakReduce areaSemiconductor/solid-state device detailsSolid-state devicesManufacturing cost reductionAmorphous silicon

A fuse structure and a method for forming the same are disclosed. The method is characterized in that: a semiconductor substrate is provided, wherein a circuit structure is formed on the semiconductor substrate and a metal interconnection layer is formed on the circuit structure; a fuse and an interconnection structure of the fuse and the metal interconnection layer are formed on the metal interconnection layer, wherein a material of the fuse is selected from polycrystalline germanium silicon, polycrystalline germanium, amorphous silicon, amorphous germanium or amorphous germanium silicon. Resistances of the polycrystalline germanium silicon, polycrystalline germanium, amorphous silicon, amorphous germanium or amorphous germanium silicon are high. When a polycrystalline germanium silicon fuse, a polycrystalline germanium fuse, an amorphous silicon fuse, an amorphous germanium fuse or an amorphous germanium silicon fuse are fused, a needed fusing current is small so that a relevant circuit structure is not easy to be destroyed. The fuse structure formed by using the method does not occupy a chip area when stacking on the metal interconnection layer. Therefore, the chip area can be saved and manufacturing costs can be reduced. A formation process is simple.

Owner:XIAN YISHEN OPTOELECTRONICS TECH CO LTD

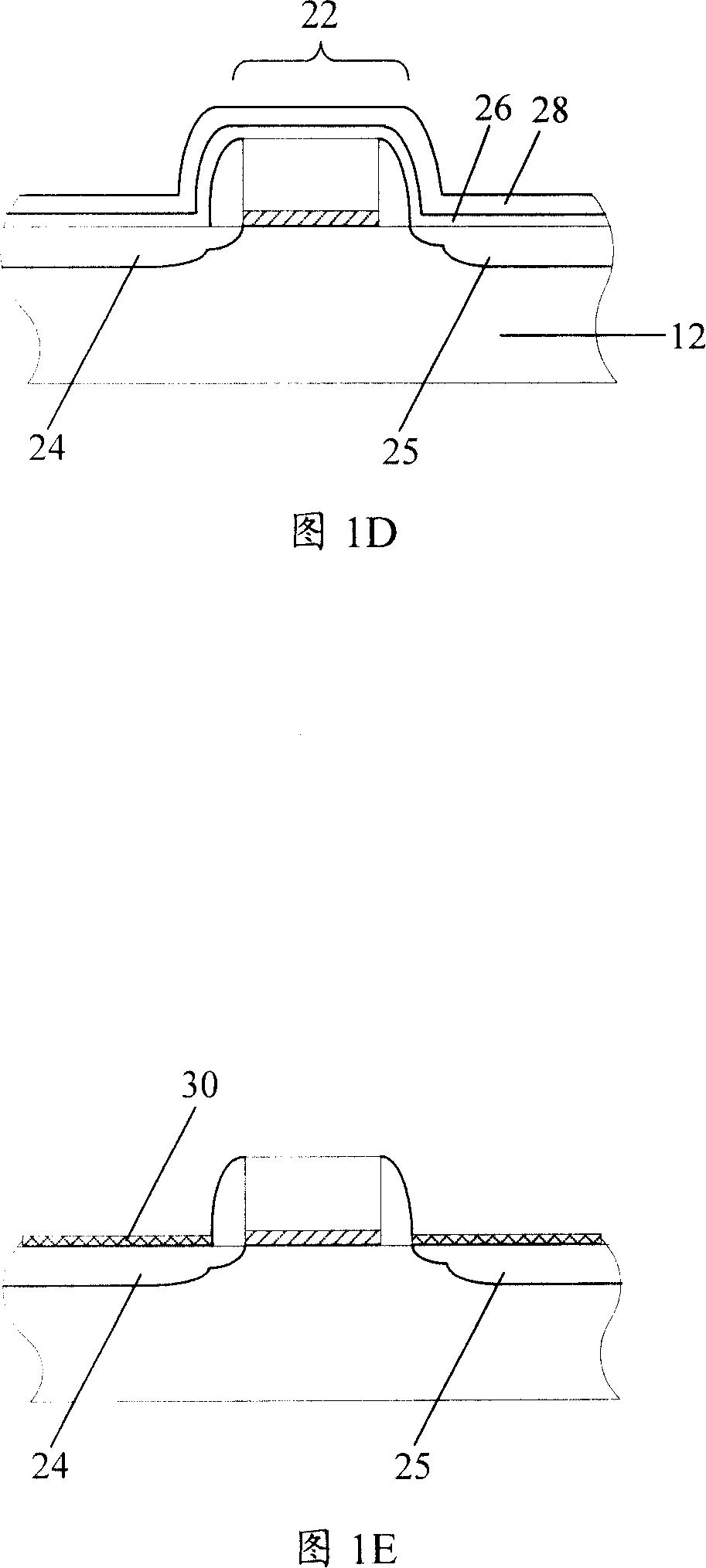

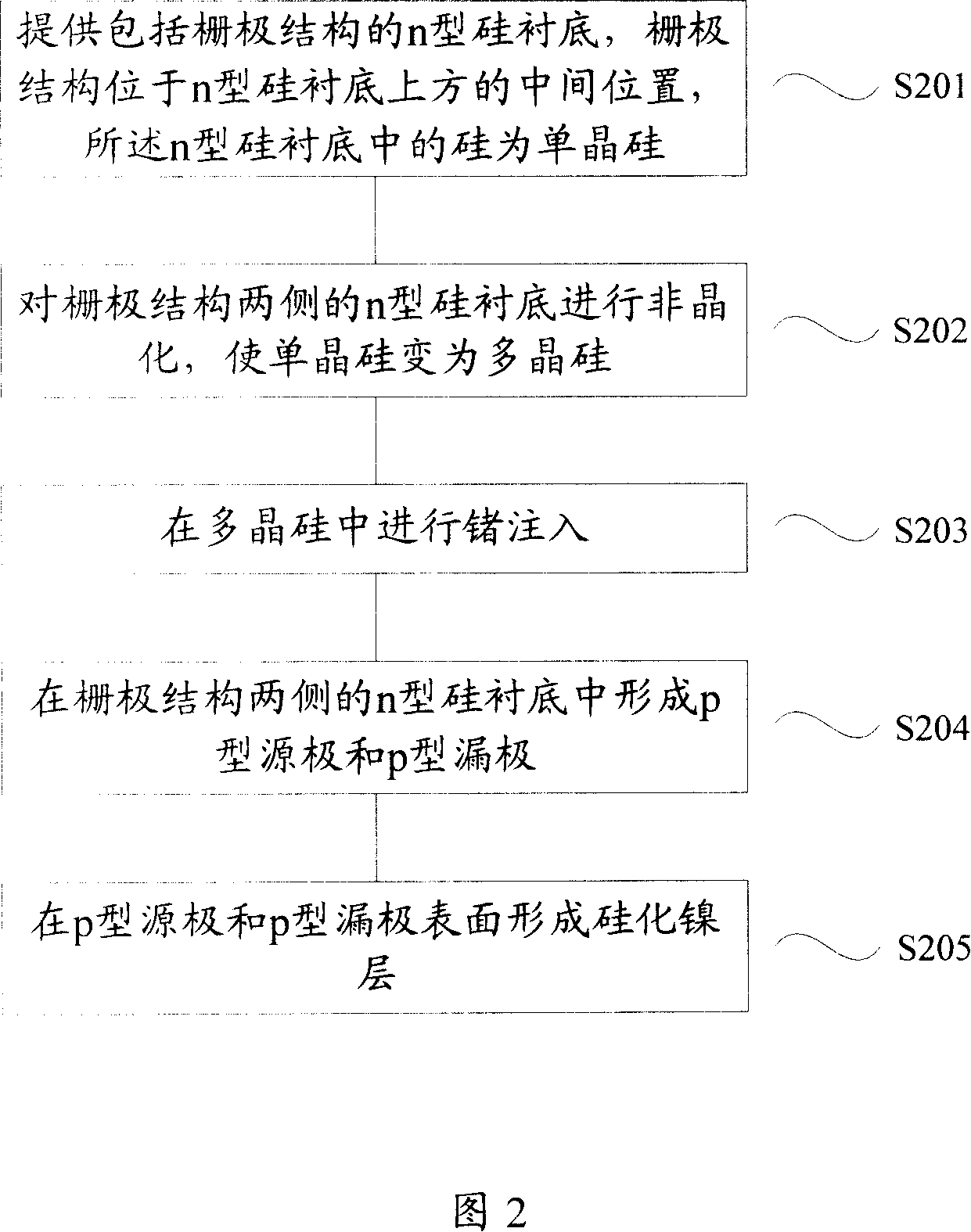

Method for improving silicate nickel layer performance and method for forming PMOS transistor

InactiveCN101136336AWill not cause leakage currentSemiconductor/solid-state device manufacturingSemiconductor devicesTransistorPolycrystalline silicon

This invention relates to a method for forming SiNi2 layers and PMOS transistors, which first of all provides an n-type substrate of a grid structure to inject amorphous germanium onto the substrate , forms a source and a drain in the substrate of the two sides of the grid structure and anneals them, deposits a cover layer on the substrate and the grid structure and forms a Ni layer on the cover layer to be annealed, and the Ni layer is reacted with Si on the surface of the source and the drain to form a SiNi2 layer, eliminates unreacted Ni and cover layers to form a PMOS transistor after succeeded internal linking, in which, amorphous germanium is injected into n-type substrate before forming the source and the drain to turn monocrystal silicon in it to polysilicon then to be doped with germanium, therefore, Si2Ni4 will not be generated at the same time when the succeeded Ni layer reacts with the silicon substrate to form a SiNi2 layer nor peak phenomenon in the Si substrate.

Owner:SEMICON MFG INT (SHANGHAI) CORP

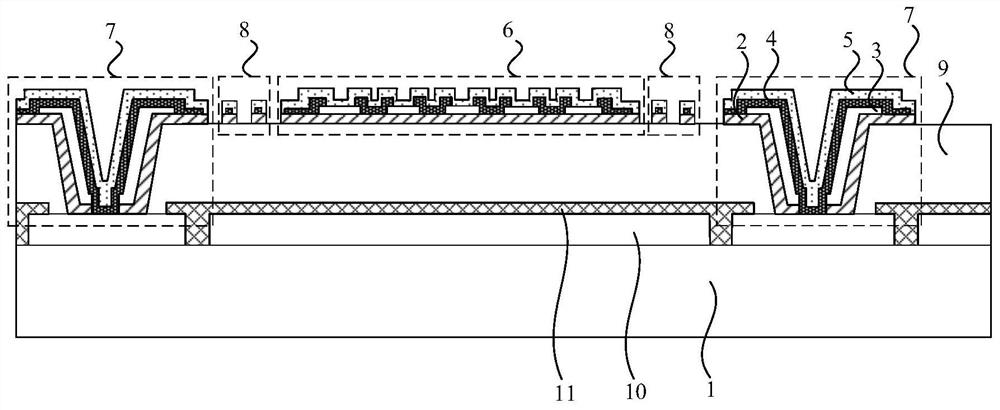

Infrared detector and preparation method thereof

ActiveCN113328002AShort thermal response timeImprove infrared responsivityFinal product manufactureSemiconductor devicesResponsivityDielectric layer

The invention relates to an infrared detector and a preparation method thereof. The infrared detector comprises a substrate, a thermosensitive layer, a dielectric layer, an electrode layer and a passivation layer, wherein the thermosensitive layer, the dielectric layer, the electrode layer and the passivation layer are located on the substrate, the dielectric layer is located between the thermosensitive layer and the electrode layer, the thermosensitive layer is located on one side, close to the substrate, of the dielectric layer, and the passivation layer is located on one side, away from the substrate, of the electrode layer. The infrared detector comprises a plurality of infrared detector pixels arranged in a matrix, each infrared detector pixel comprises an absorption plate structure, at least two micro-bridge columns and at least two beam structures, and the absorption plate structures are connected to the corresponding micro-bridge columns through the corresponding beam structures; the thermosensitive layer covers the area where the absorption plate structure and the beam structure are located, and the passivation layer covers the area where the absorption plate structure and the beam structure are located; and the material for forming the thermosensitive layer comprises one or more of amorphous silicon, amorphous carbon, amorphous germanium or amorphous silicon germanium. According to the technical scheme, the thermal response time of the infrared detector is shortened, and the infrared response rate of the infrared detector is improved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com