Nanometer silica film three-layer stacked solar cell and preparation method thereof

A technology of nano-silicon thin film and stacked solar, which is applied in coating, circuit, photovoltaic power generation, etc., can solve the problems of thin-film solar cell efficiency decline, large optical band gap of amorphous silicon, etc., and achieve low light-induced attenuation effect, band Gap adjustable range is high, the effect of no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

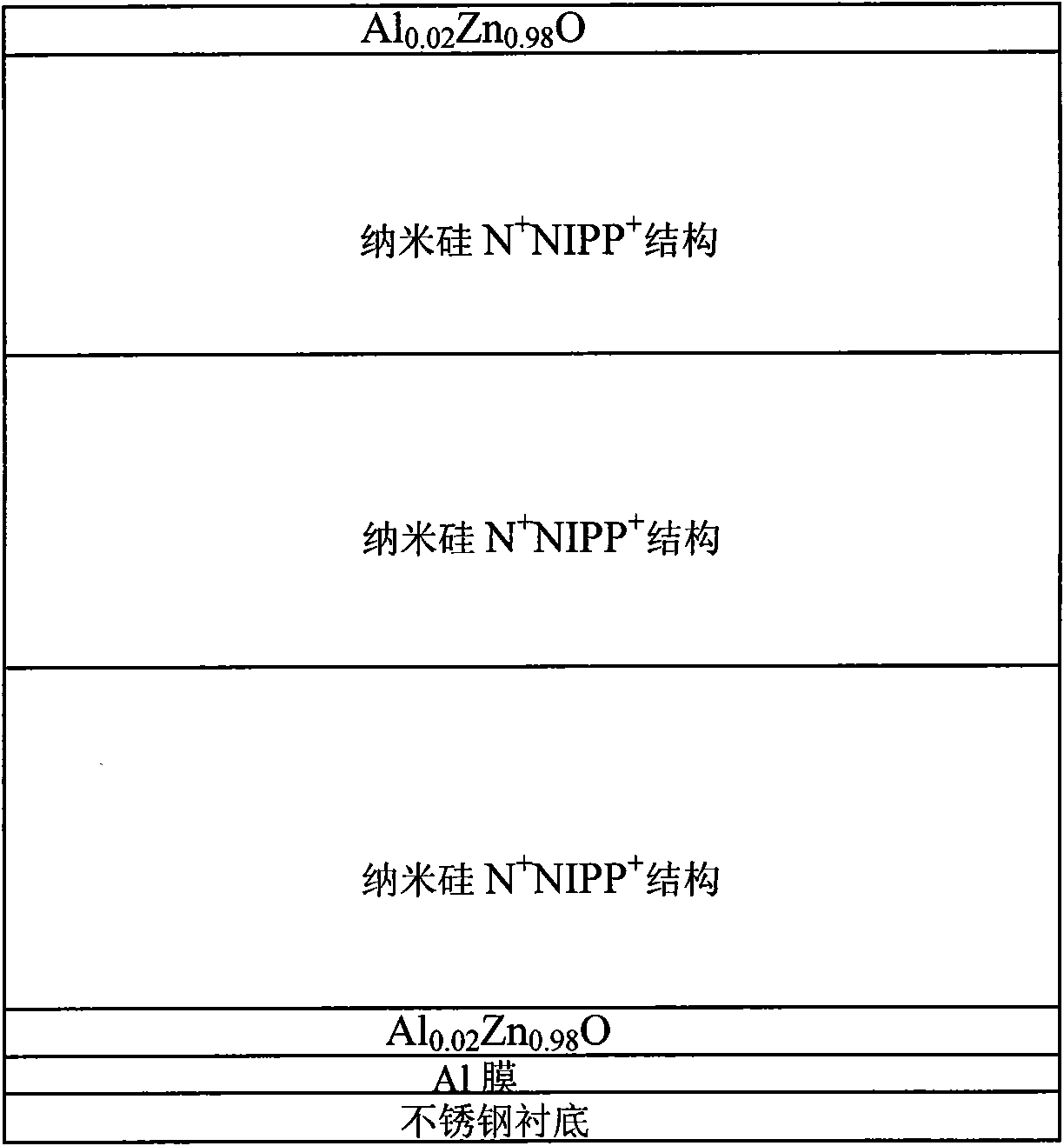

[0027] 1. Structural design of solar cells

[0028] Design top cell, middle cell and bottom cell as N on stainless steel substrate + NIPP + Structured nano-silicon thin-film triple-stack solar cells. increase N + Layer, P + It is to reduce contact resistance, increase short-circuit current and open-circuit voltage; at the same time, the existence of P layer and N layer makes I / P, N / P interface energy band mismatch transition slowly, reducing interface state density, thereby increasing open-circuit voltage and fill factor.

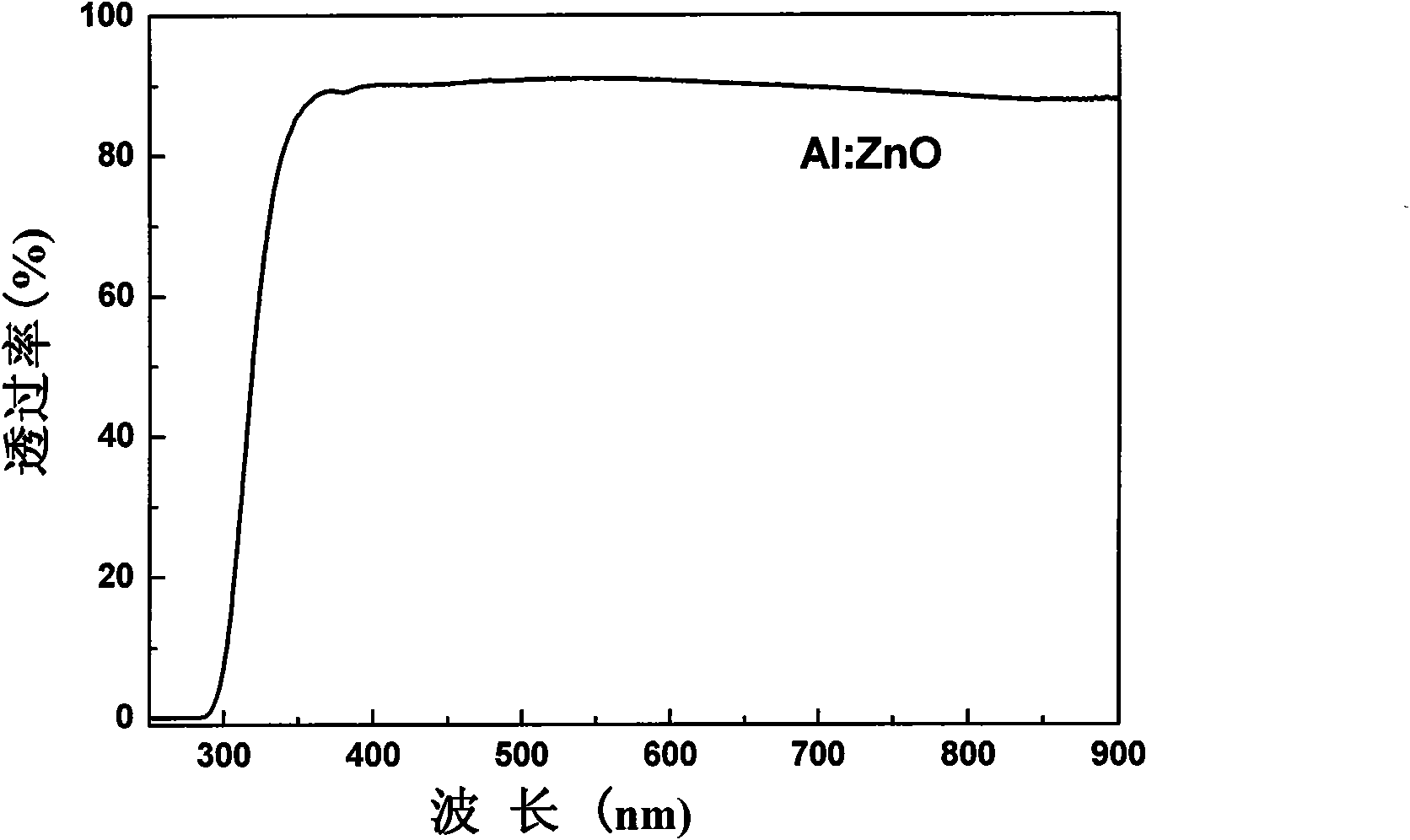

[0029] Using Al x Zn 1-x The O(x=0.02) / Al composite back electrode enhances the reflection of long-wavelength light, increases the light absorption and utilization of the solar cell, and prevents Al from diffusing into the cell. The textured structure of the upper electrode increases light absorption.

[0030] 2. Preparation of triple stack solar cells

[0031] 2.1 Cleaning of the substrate sheet

[0032] The stainless steel substrate was ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com