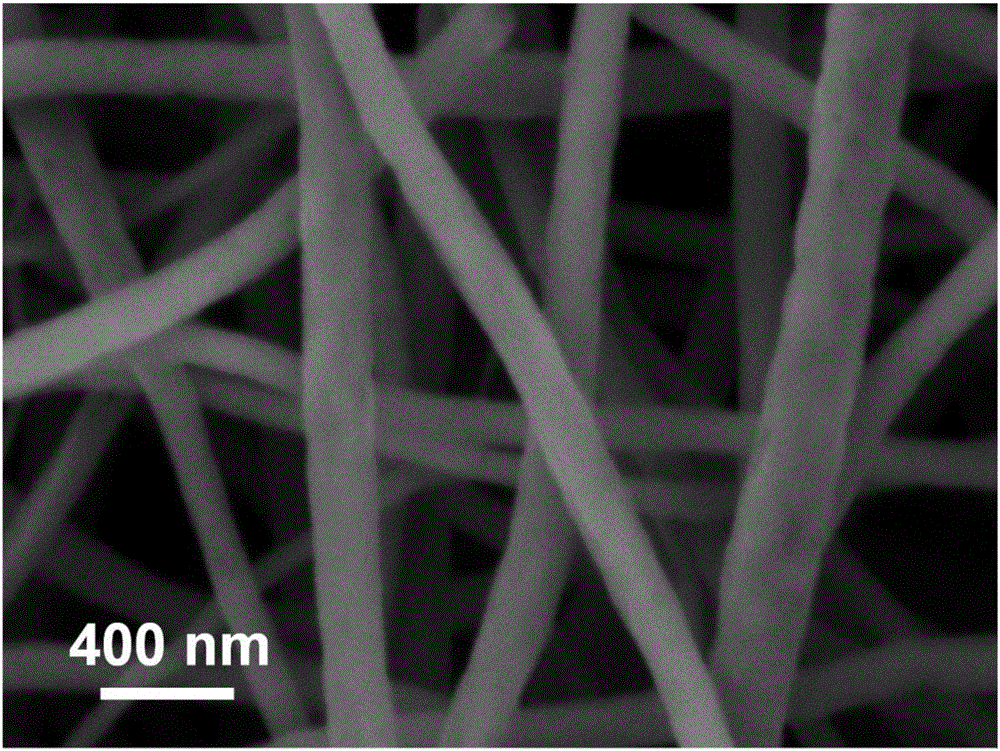

Amorphous germanium oxide/porous carbon nanofiber and preparation method thereof

A nanofiber, germanium oxide technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of affecting the electrical contact between the active material and the current collector, the degradation of the battery cycle performance, and the material rate capacity Low-level problems, to achieve the effect of improving capacity and cycle performance, improving electron transmission performance, and the method is simple and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Weigh 2g of germanium powder with an electronic balance, and put it into a ball mill tank together with 50g of small balls with diameters ranging from 5 to 15mm for ball ink. The mass ratio of balls to materials is 25:1. The rotational speed of the ball mill jar was 300 rpm, and the ball mill was performed for 2 hours to obtain germanium nanoparticles.

[0035] (2) Weigh 0.4g each of P123 and germanium nanoparticles with an electronic balance, place in a 20ml sample bottle, inject 8.8g of N-N dimethylformamide, then accurately weigh 0.8g of polyacrylonitrile and dissolve in the above sample bottle , the sample vial was sealed with parafilm, heated to 60°C and stirred for 24 hours.

[0036] (2) The aluminum foil paper with a cut area of 40cm×40cm is close to the flat collector, put 5ml of spinning solution sample into the injection needle, connect the positive pole of the high voltage generator to the spinneret, and the negative pole to the flat collector. The flo...

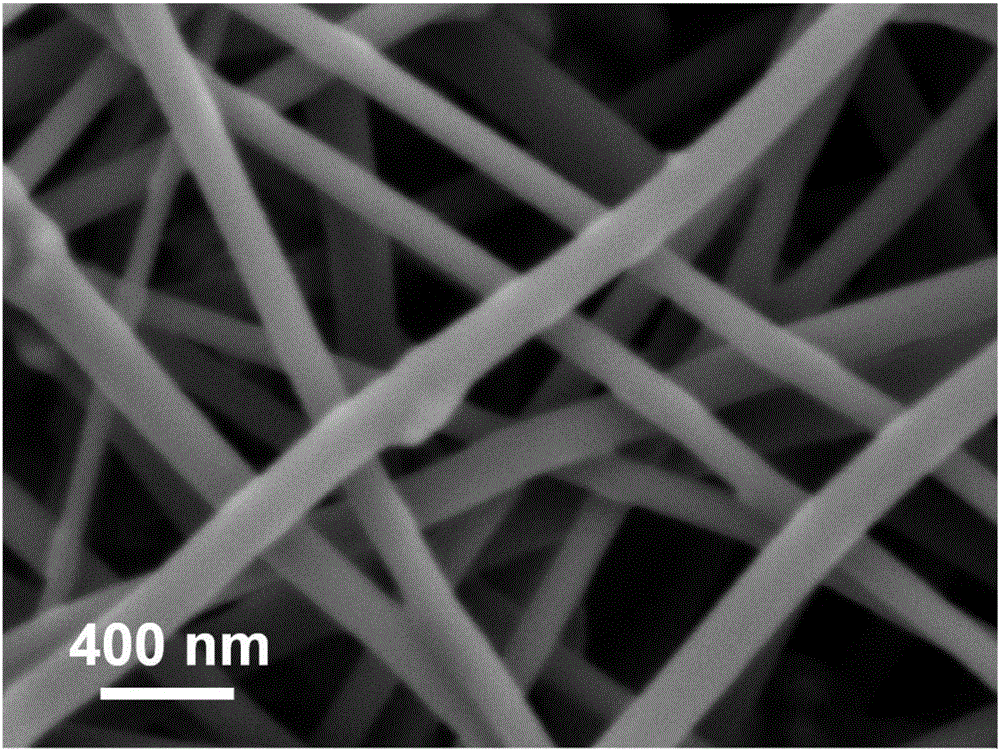

Embodiment 2

[0039] (1) Weigh 2g of germanium powder with an electronic balance, and put it into a ball mill tank together with 50g of small balls with diameters ranging from 5 to 15mm for ball milling. The mass ratio of balls to materials is 25:1. The rotational speed of the ball mill jar was 400 rpm, and the ball mill was performed for 3 hours to obtain germanium nanoparticles.

[0040] (2) Weigh each 0.3g of P123 and germanium nanoparticles with an electronic balance, place in a 20ml sample bottle, inject 8.9g of N-N dimethylformamide, then accurately weigh 0.6g of polyacrylonitrile and dissolve in the above sample bottle , the sample vial was sealed with parafilm, heated to 60°C and stirred for 24 hours.

[0041] (2) The aluminum foil paper with a cut area of 40cm×40cm is close to the flat collector, put 5ml of spinning solution sample into the injection needle, connect the positive pole of the high voltage generator to the spinneret, and the negative pole to the flat collector. The...

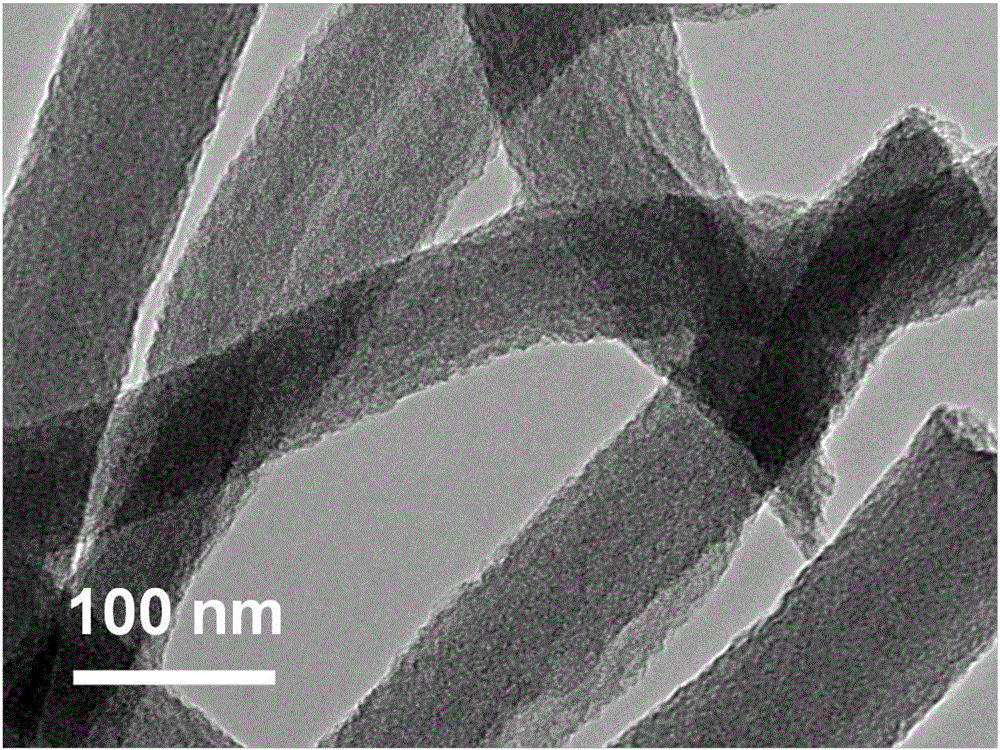

Embodiment 3

[0044] (1) Weigh 2g of germanium powder with an electronic balance, and put it into a ball mill pot together with 50g of small balls with diameters ranging from 5 to 15mm for ball milling. The mass ratio of balls to materials is 25:1. The rotational speed of the ball mill jar was 400 rpm, and the ball mill was performed for 3 hours to obtain germanium nanoparticles.

[0045] (2) Weigh 0.2g each of P123 and germanium nanoparticles with an electronic balance, place in a 20ml sample bottle, inject 9.2g of N-N dimethylformamide, then accurately weigh 0.8g of polyacrylonitrile and dissolve in the above sample bottle , the sample vial was sealed with parafilm, heated to 60°C and stirred for 24 hours.

[0046] (2) The aluminum foil paper with a cut area of 40cm×40cm is close to the flat collector, put 5ml of spinning solution sample into the injection needle, connect the positive pole of the high voltage generator to the spinneret, and the negative pole to the flat collector. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Molar mass | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com