Patents

Literature

471 results about "Germanium oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Germanium oxide may refer to: Germanium dioxide, GeO₂, the best known and most commonly encountered oxide of germanium containing germanium. Germanium monoxide, GeO, a stable but not well characterised compound containing germanium

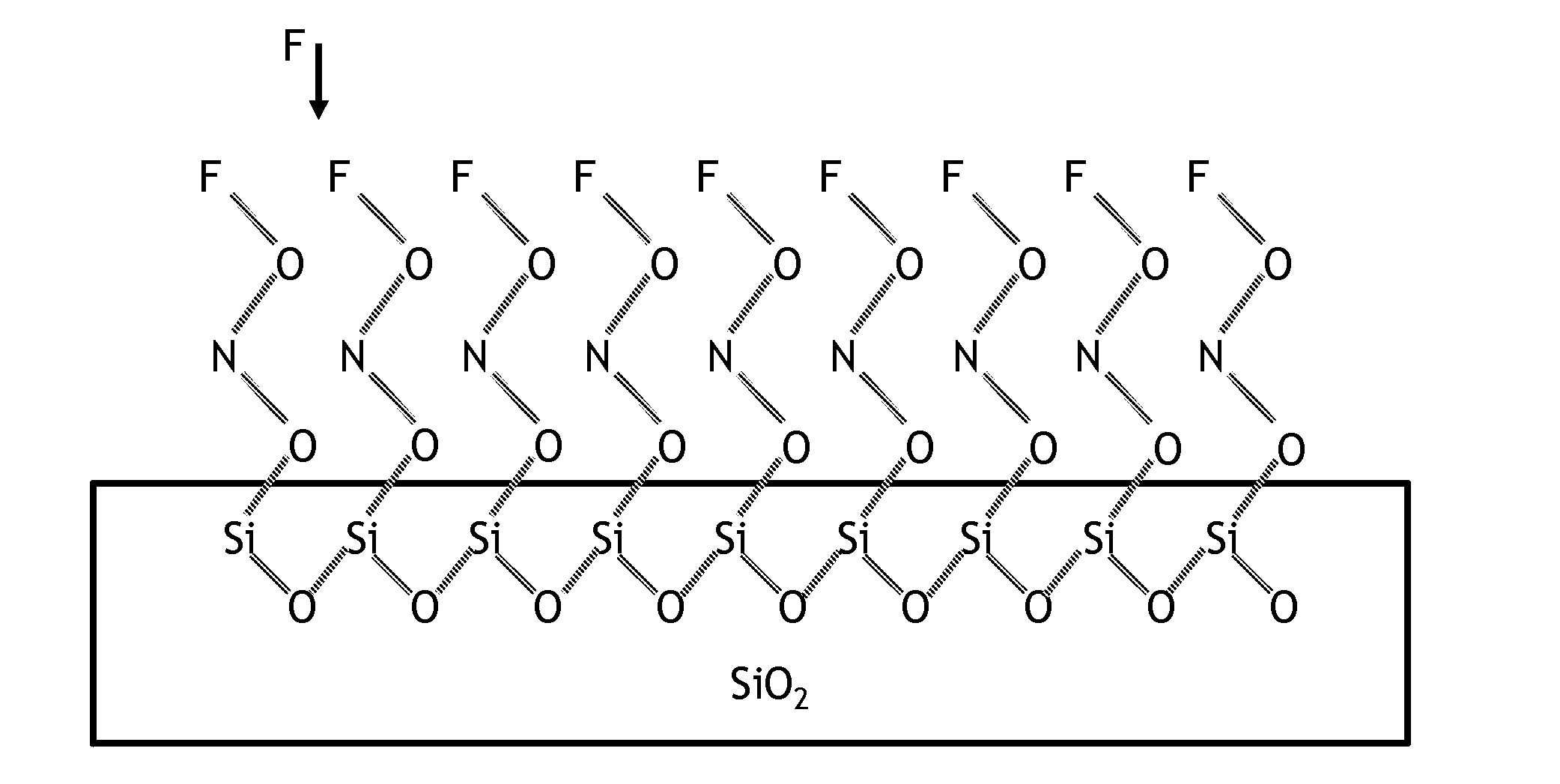

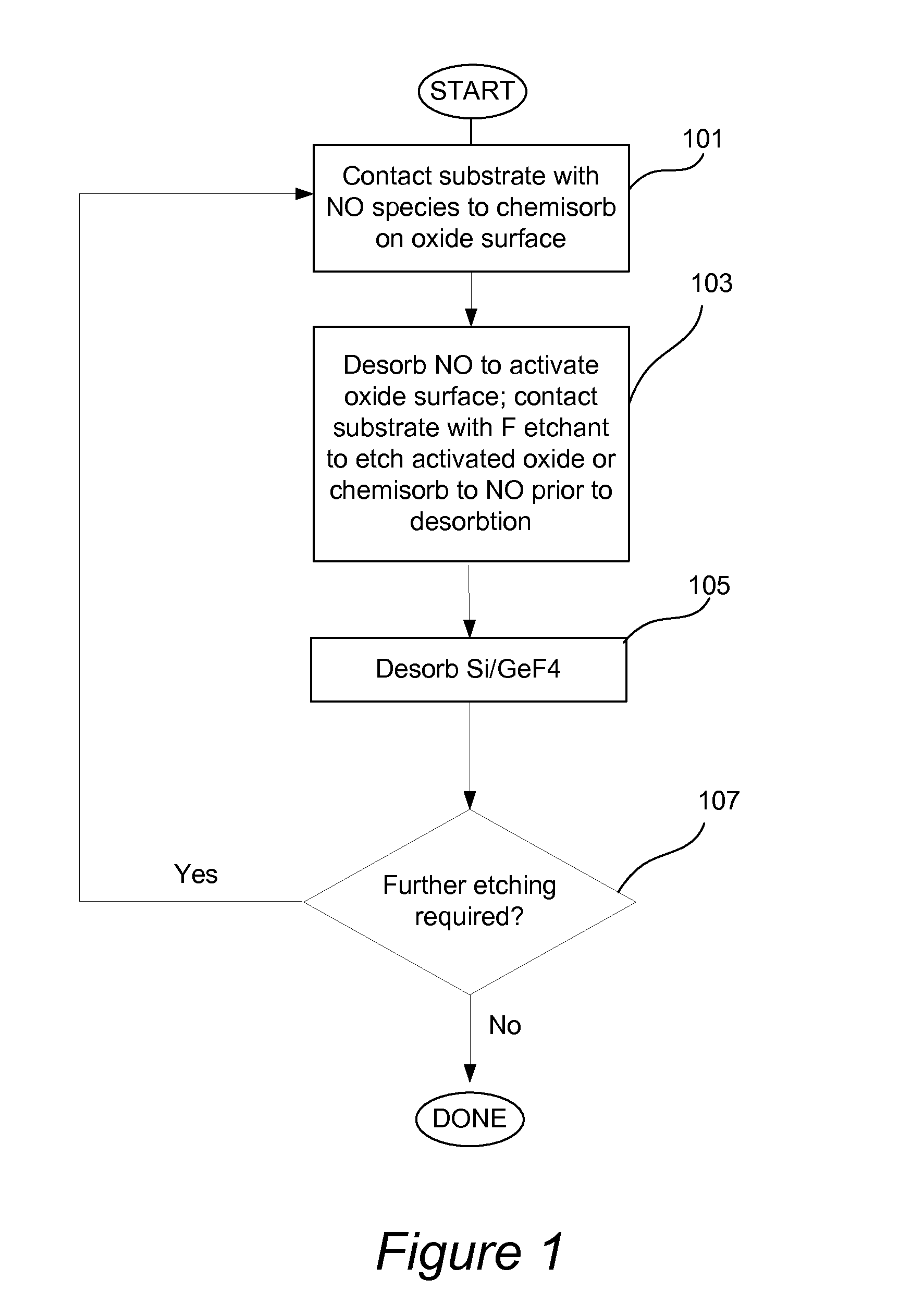

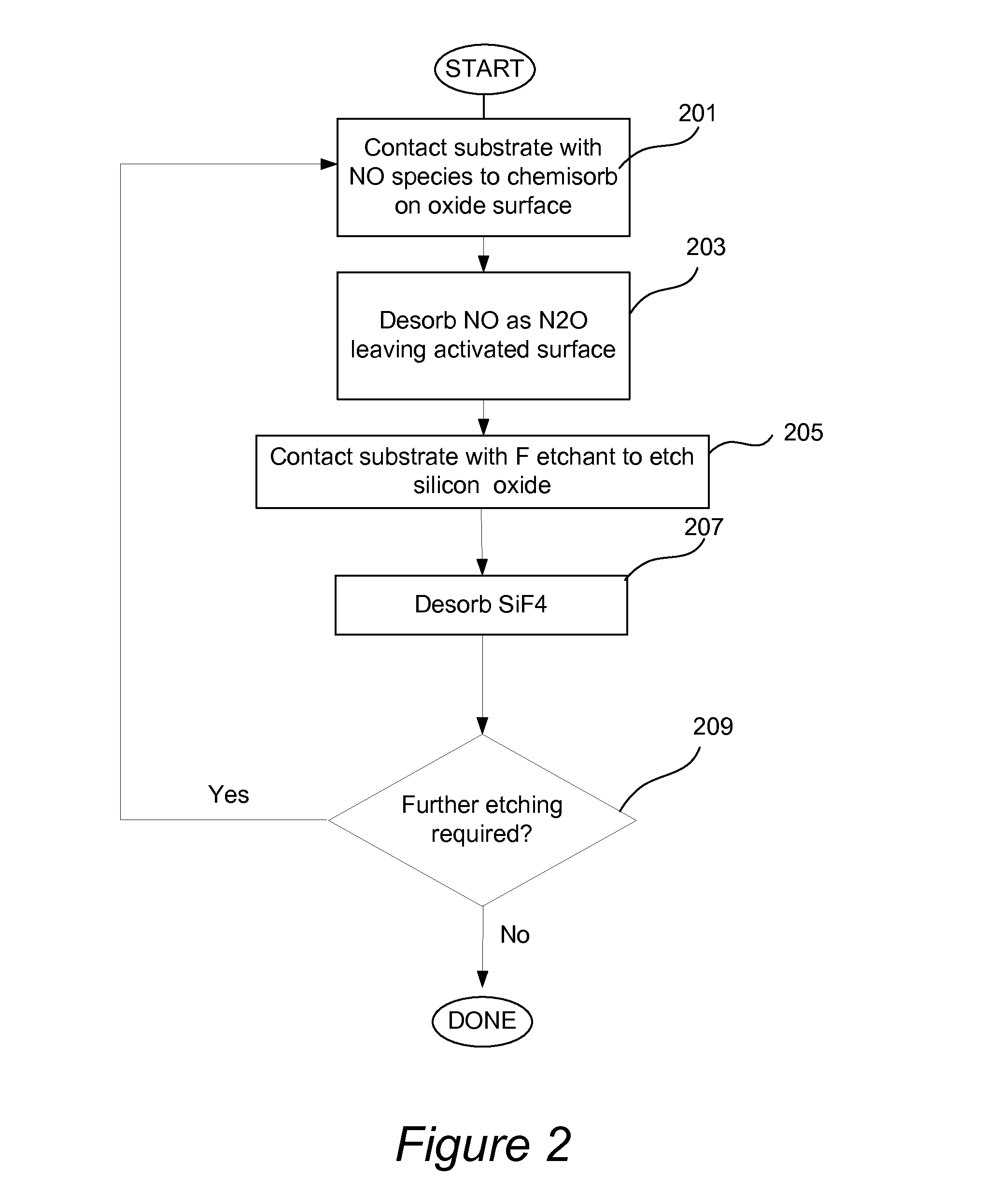

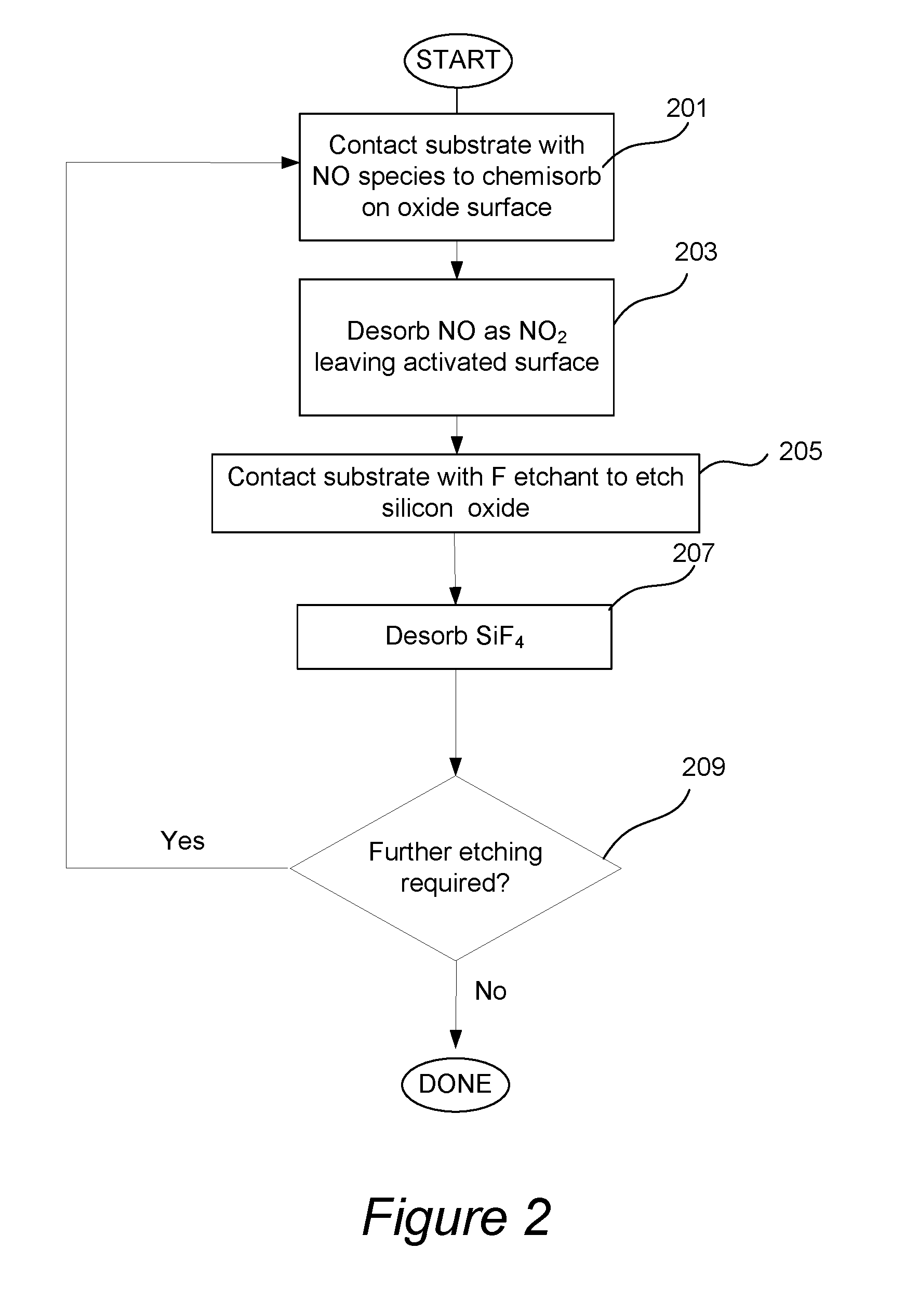

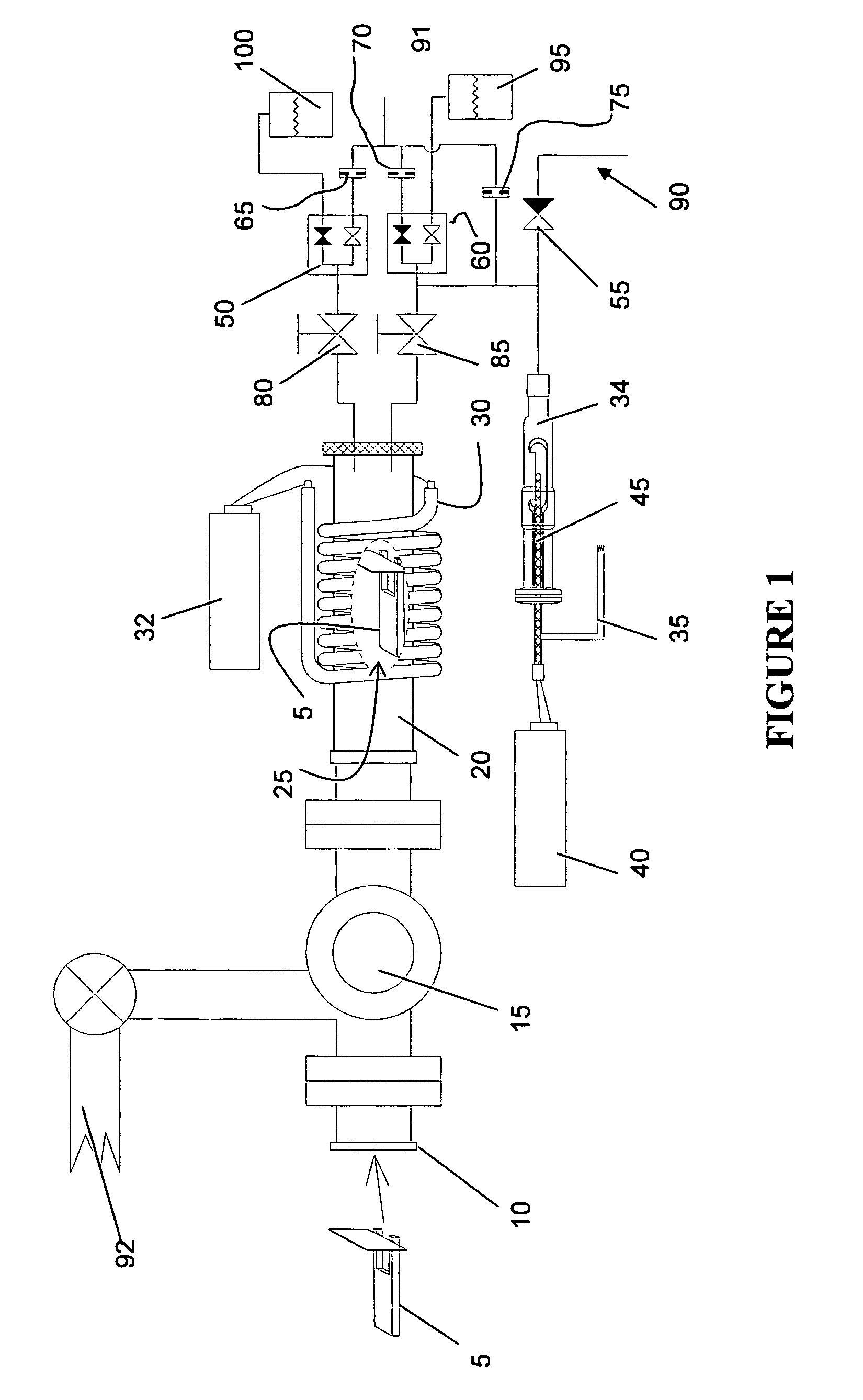

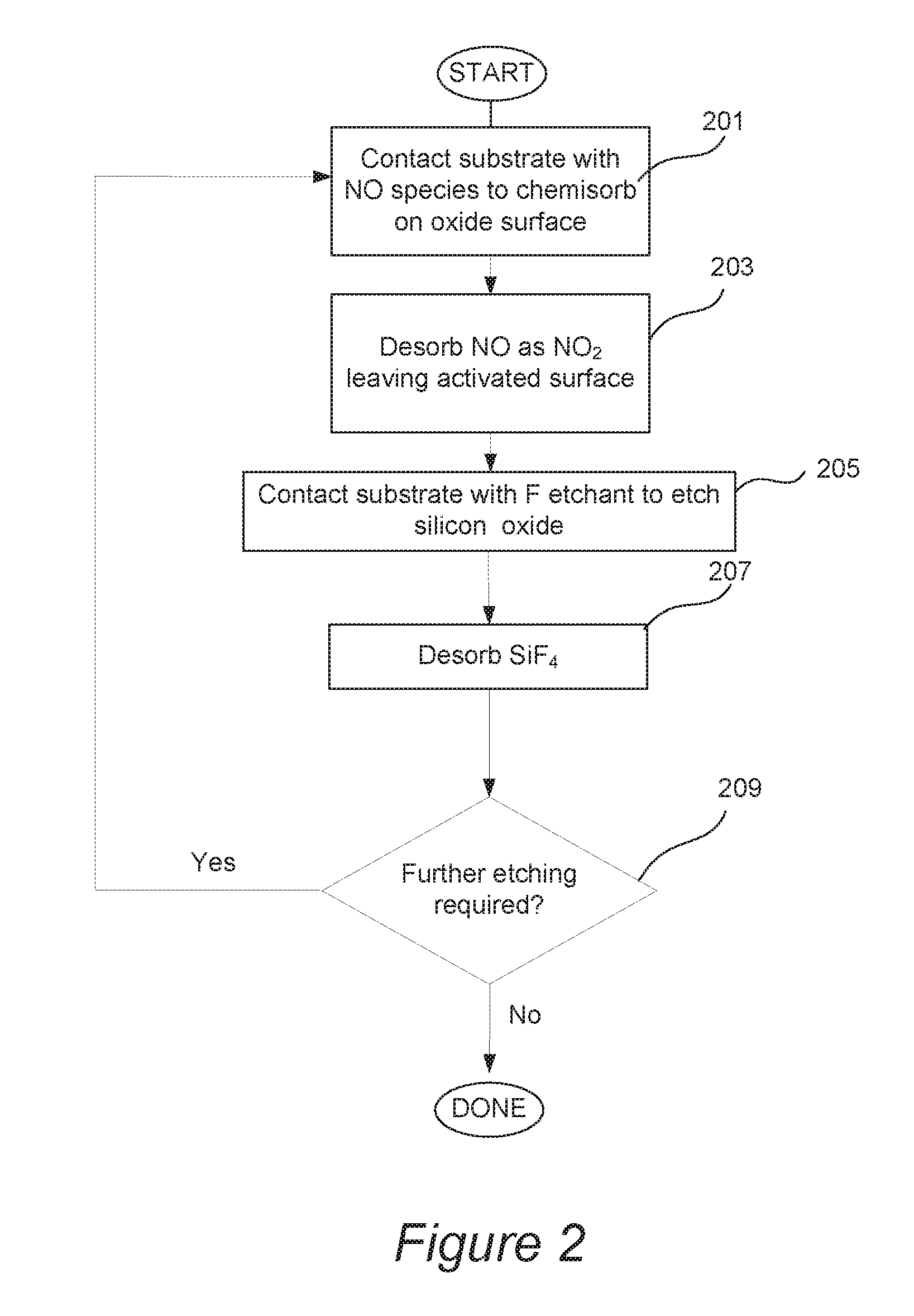

Isotropic atomic layer etch for silicon oxides using no activation

ActiveUS20160196969A1Electric discharge tubesSemiconductor/solid-state device manufacturingGate dielectricSilicon oxide

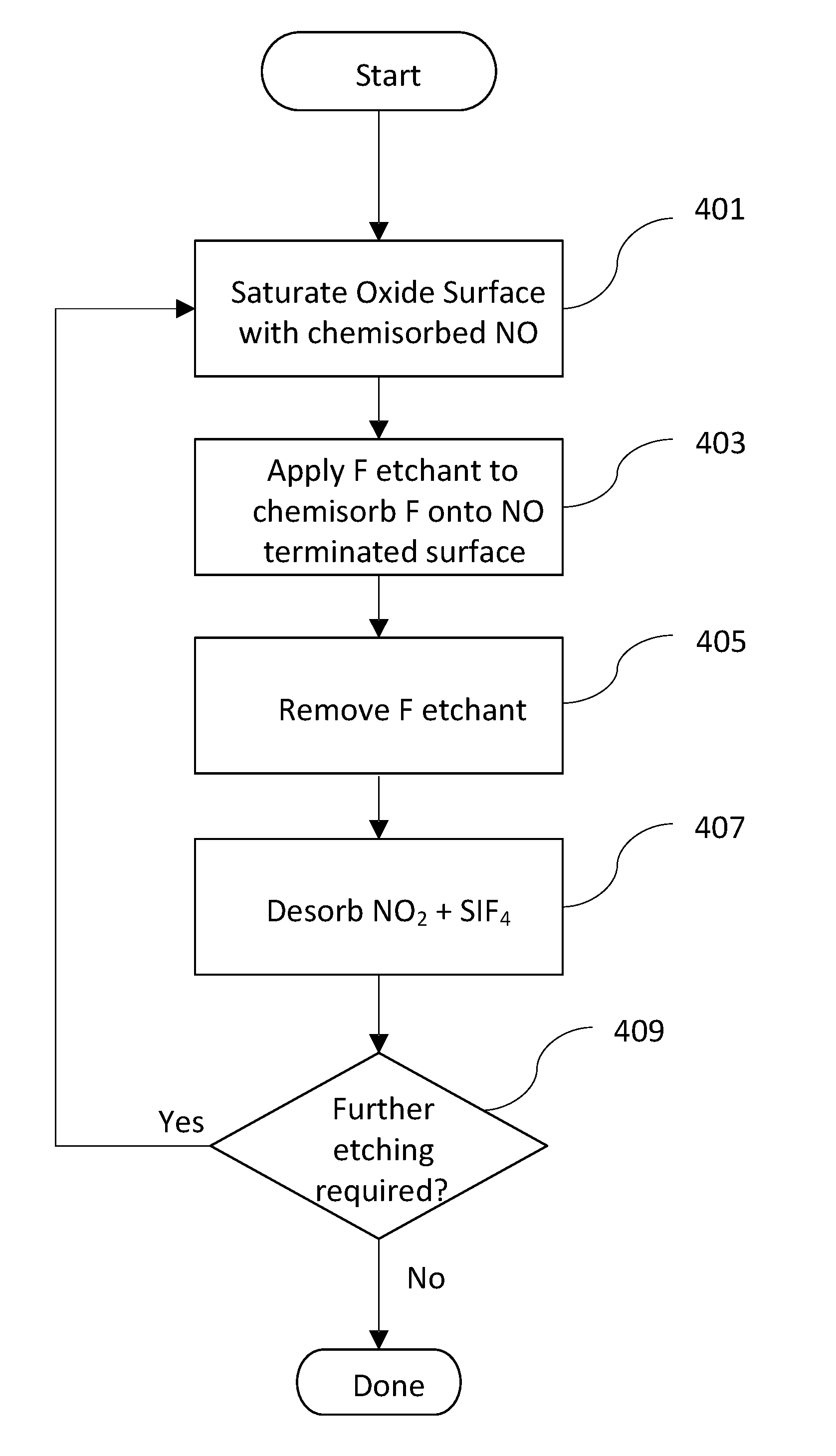

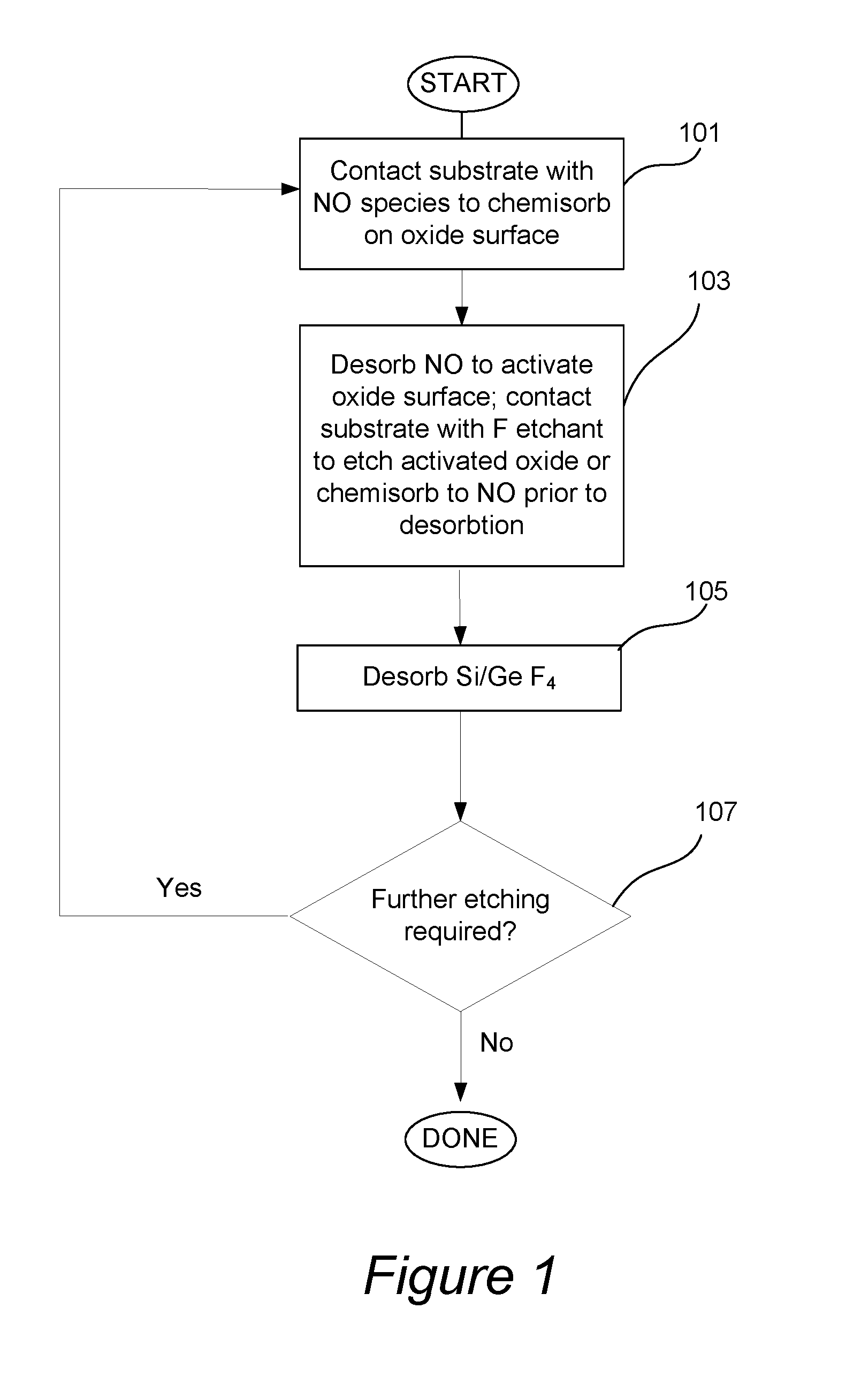

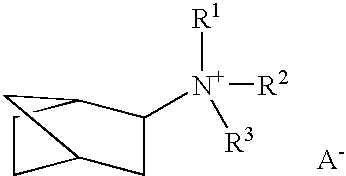

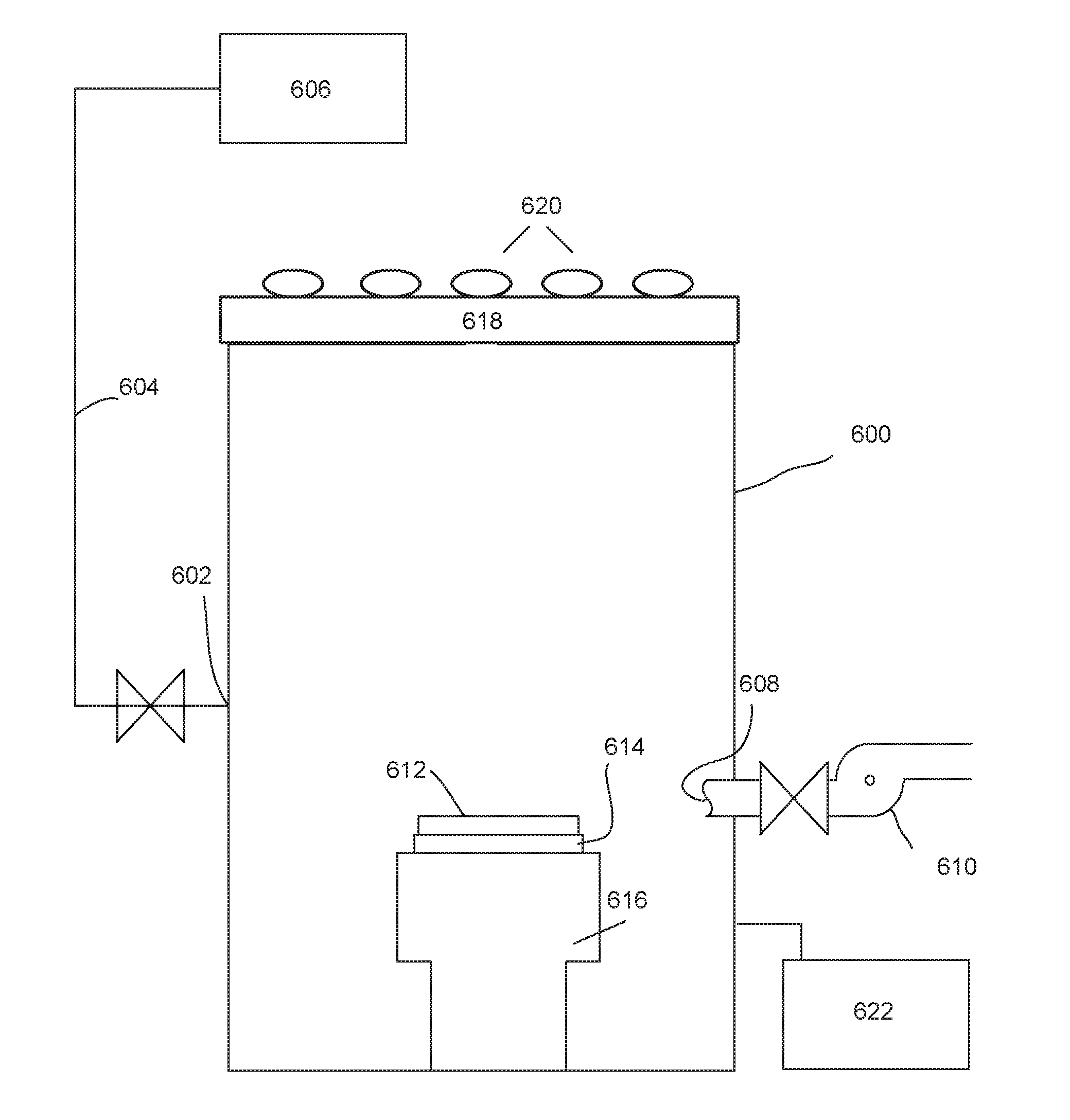

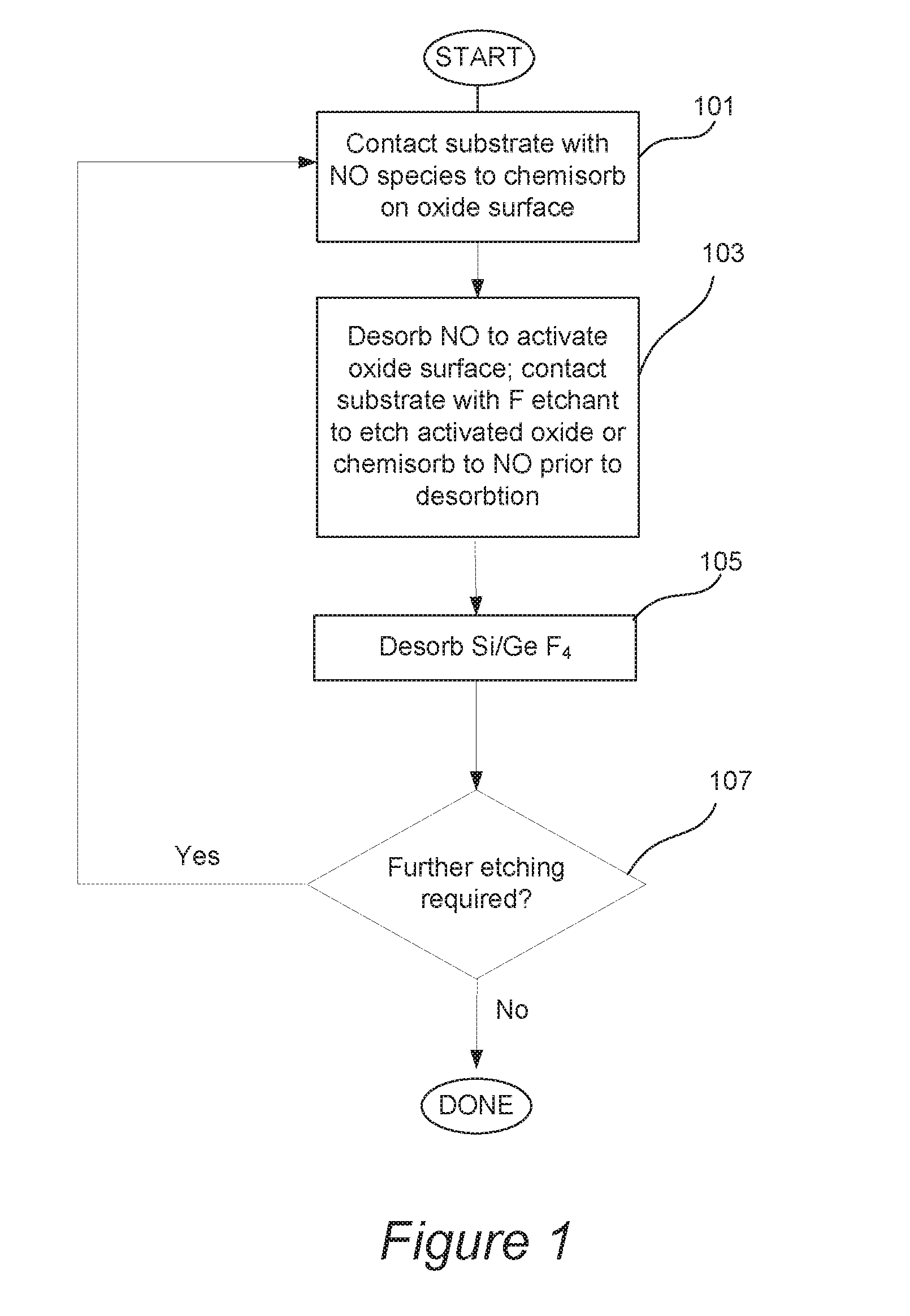

Methods for controlled isotropic etching of layers of silicon oxide and germanium oxide with atomic scale fidelity are provided. The methods make use of NO activation of an oxide surface. Once activated, a fluorine-containing gas or vapor etches the activated surface. Etching is self-limiting as once the activated surface is removed, etching stops since the fluorine species does not spontaneously react with the un-activated oxide surface. These methods may be used in interconnect pre-clean applications, gate dielectric processing, manufacturing of memory devices, or any other applications where accurate removal of one or multiple atomic layers of material is desired.

Owner:LAM RES CORP

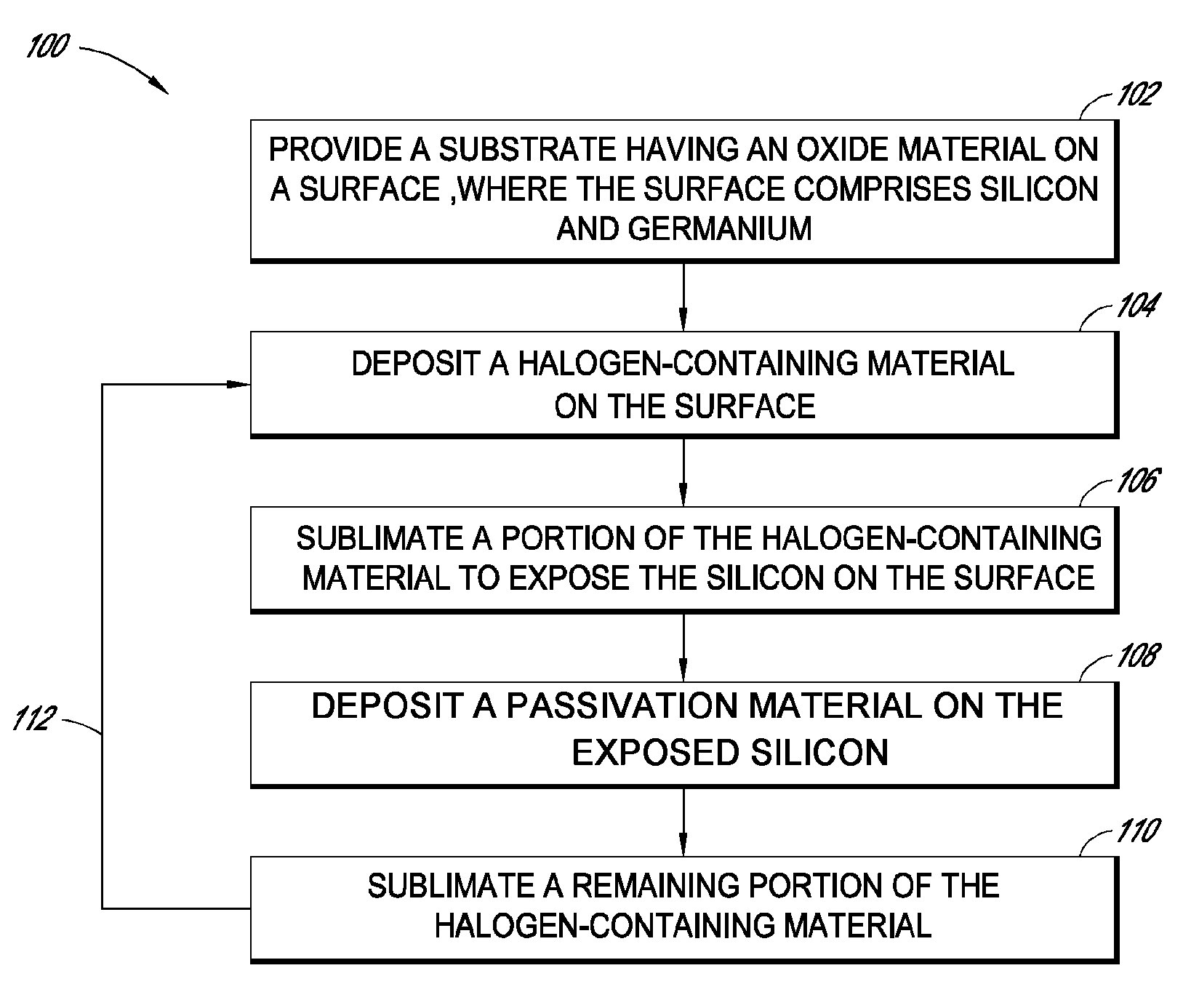

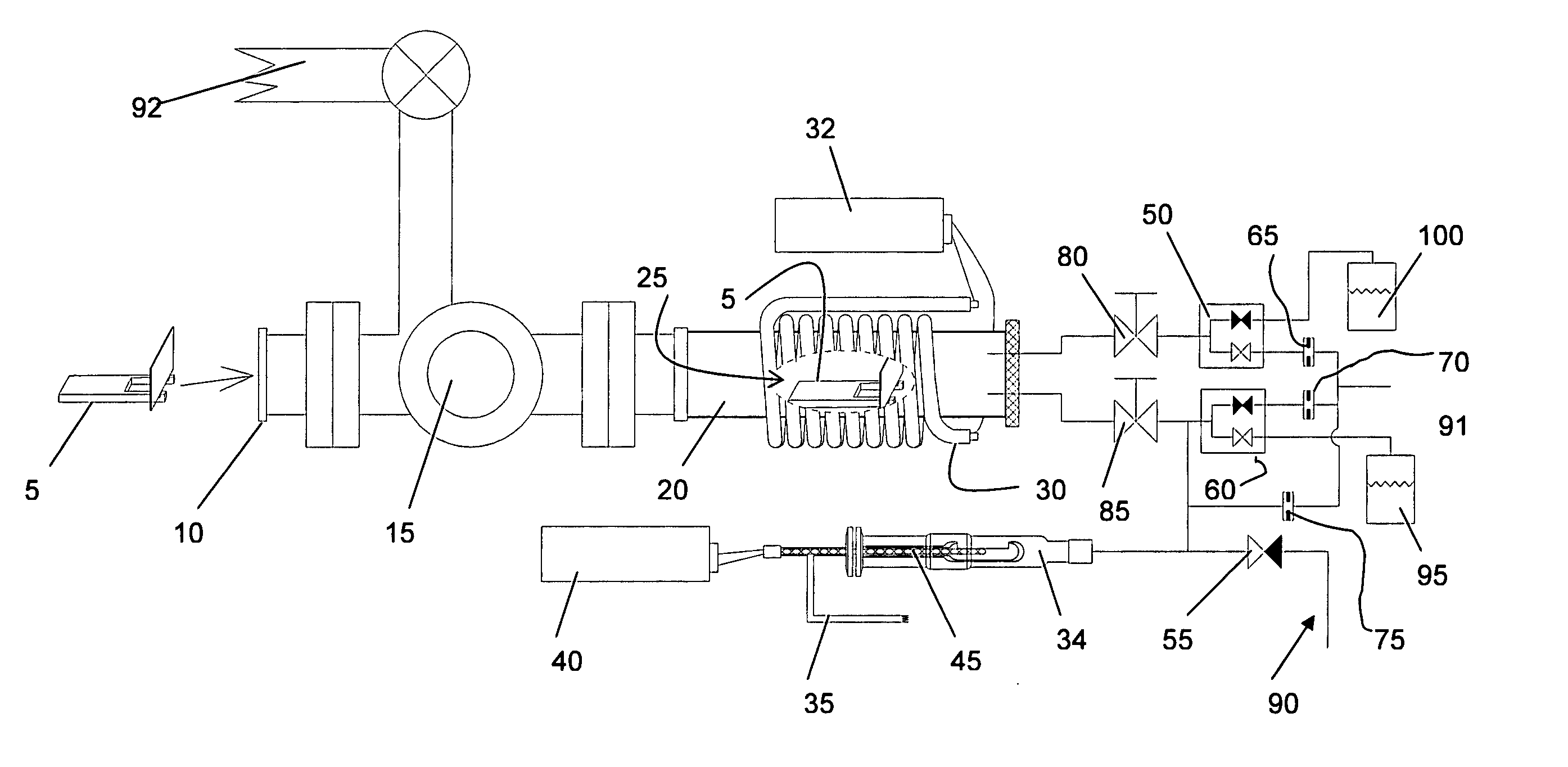

Germanium oxide pre-clean module and process

ActiveUS9474163B2Printed circuit liquid treatmentSemiconductor/solid-state device manufacturingChemical speciesHalogen

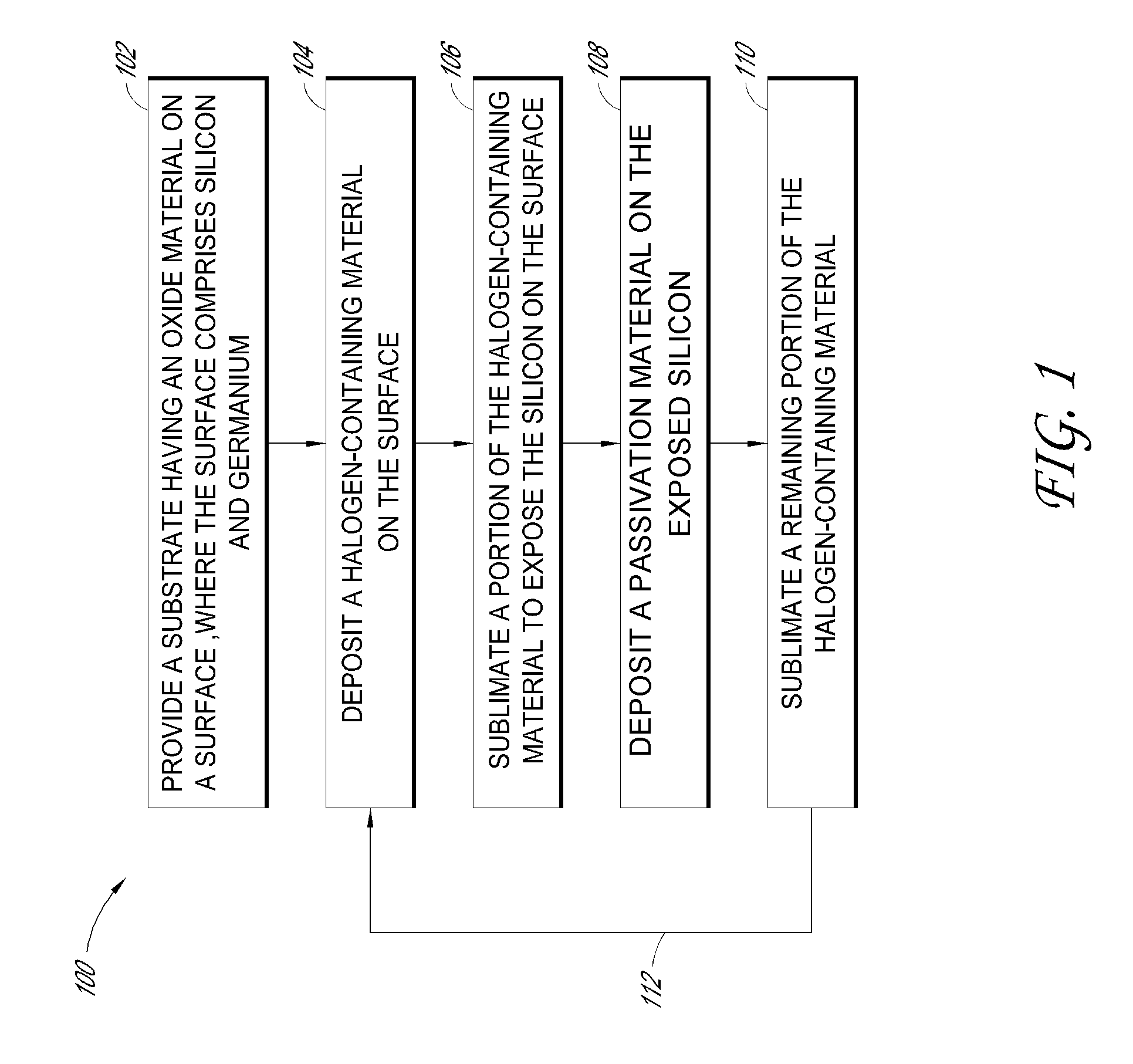

In some embodiments, a method for integrated circuit fabrication includes removing oxide material from a surface of a substrate, where the surface includes silicon and germanium. Removing the oxide material includes depositing a halogen-containing pre-clean material on a silicon oxide-containing surface and sublimating a portion of the halogen-containing pre-clean material to expose the silicon on the surface. A passivation film is deposited on the exposed silicon. The passivation film may include chlorine. The passivation film may prevent contamination of the silicon surface by chemical species from the later sublimation, which may be at a higher temperature than the earlier sublimation. Subsequently, a remaining portion of the halogen-containing pre-clean material and the passivation film are sublimated. A target material, such as a conductive material, may subsequently be deposited on the substrate surface.

Owner:ASM IP HLDG BV

Isotropic atomic layer etch for silicon oxides using no activation

ActiveUS9425041B2High selectivityReduce defective rateElectric discharge tubesSemiconductor/solid-state device manufacturingGate dielectricSilicon oxide

Methods for controlled isotropic etching of layers of silicon oxide and germanium oxide with atomic scale fidelity are provided. The methods make use of NO activation of an oxide surface. Once activated, a fluorine-containing gas or vapor etches the activated surface. Etching is self-limiting as once the activated surface is removed, etching stops since the fluorine species does not spontaneously react with the un-activated oxide surface. These methods may be used in interconnect pre-clean applications, gate dielectric processing, manufacturing of memory devices, or any other applications where accurate removal of one or multiple atomic layers of material is desired.

Owner:LAM RES CORP

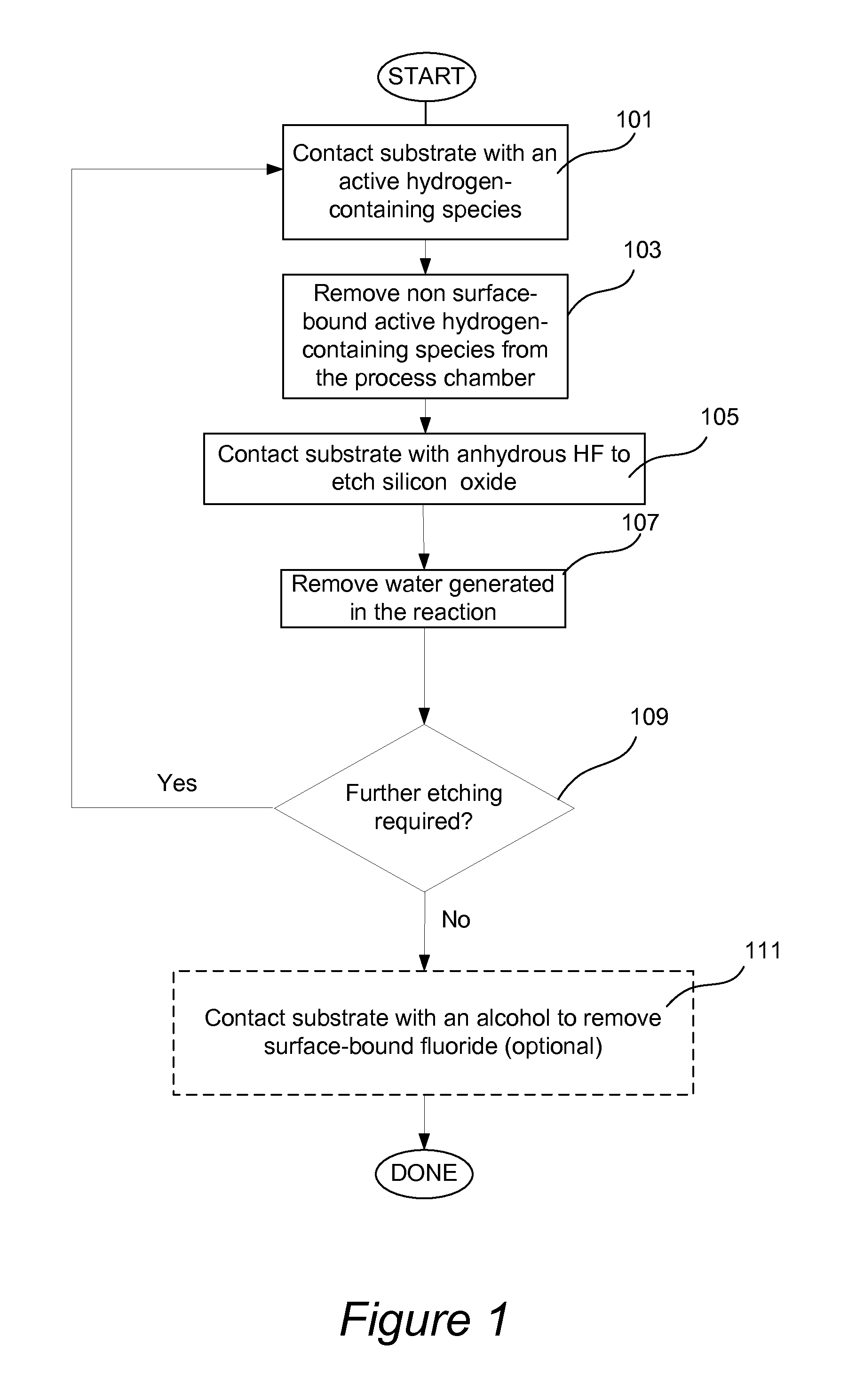

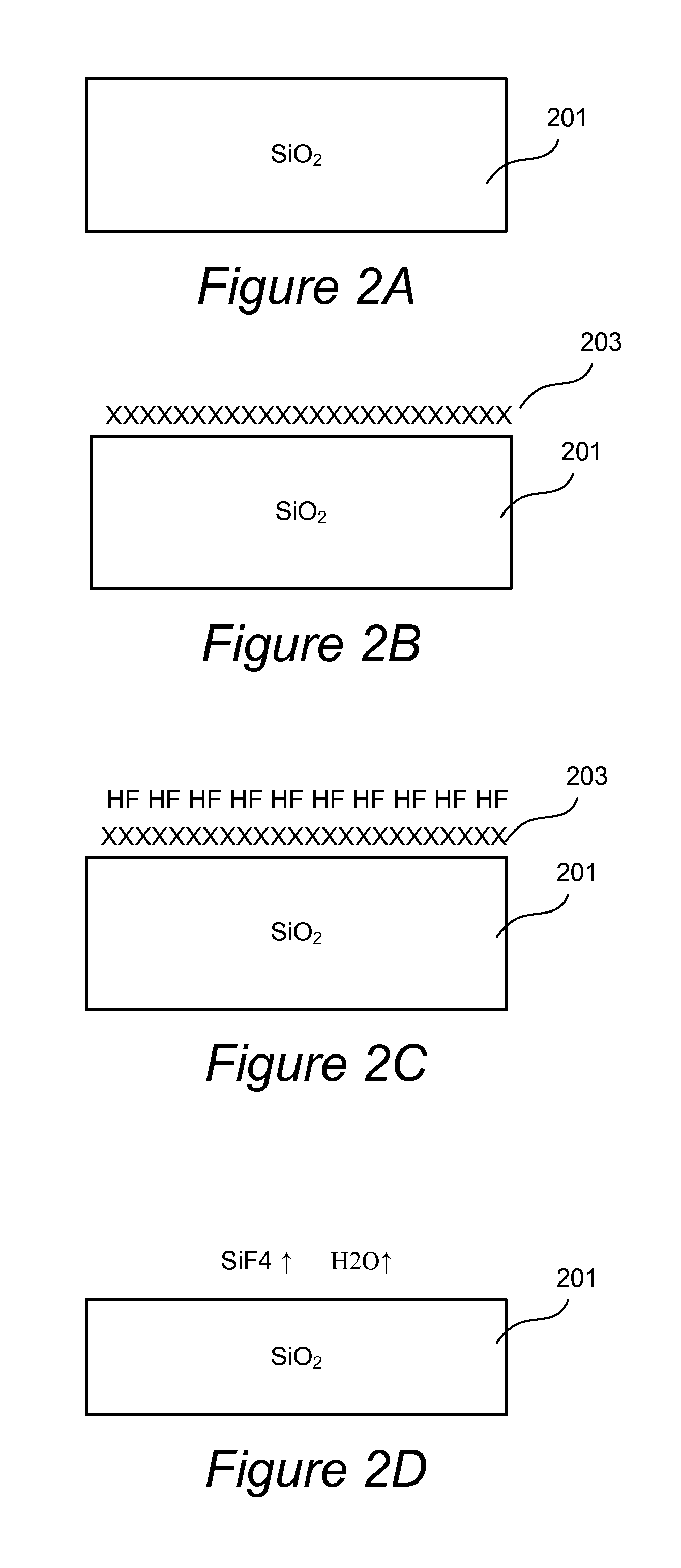

Isotropic atomic layer etch for silicon and germanium oxides

ActiveUS9431268B2Rapid and controlled changeElectric discharge tubesSemiconductor/solid-state device manufacturingAlcoholHydrogen

Methods for controlled isotropic etching of layers of silicon oxide and germanium oxide with atomic scale fidelity are provided. The methods make use of a reaction of anhydrous HF with an activated surface of an oxide, with an emphasis on removal of water generated in the reaction. In certain embodiments the oxide surface is first modified by adsorbing an OH-containing species (e.g., an alcohol) or by forming OH bonds using a hydrogen-containing plasma. The activated oxide is then etched by a separately introduced anhydrous HF, while the water generated in the reaction is removed from the surface of the substrate as the reaction proceeds, or at any time during or after the reaction. These methods may be used in interconnect pre-clean applications, gate dielectric processing, manufacturing of memory devices, or any other applications where accurate removal of one or multiple atomic layers of material is desired.

Owner:LAM RES CORP

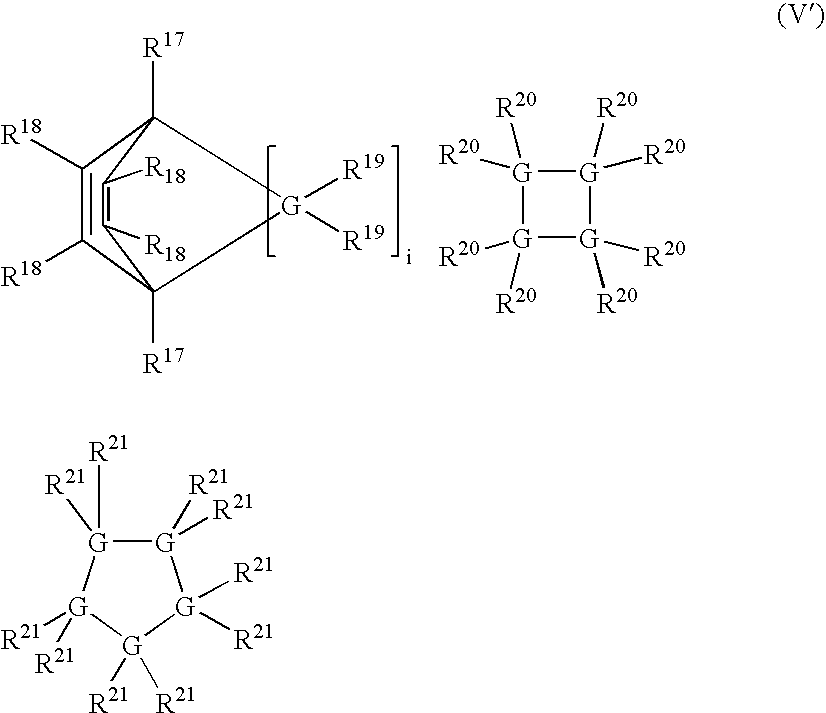

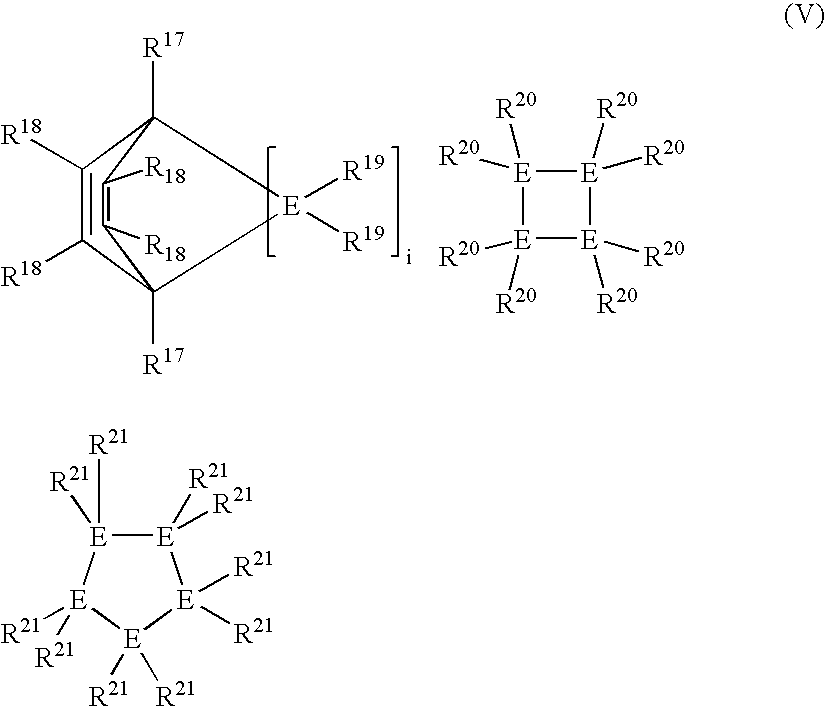

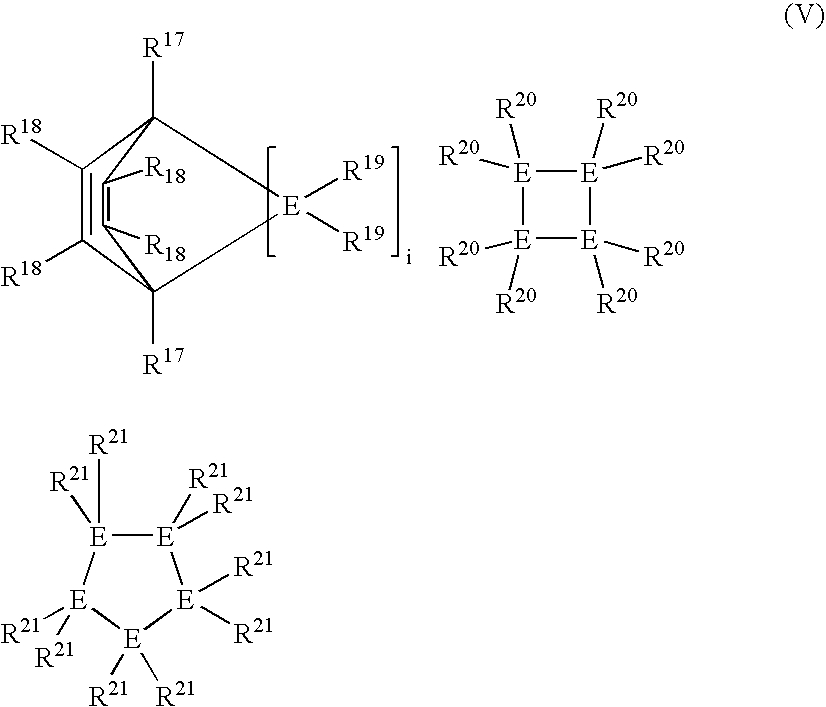

Linear and cross-linked high molecular weight polysilanes, polygermanes, and copolymers thereof, compositions containing the same, and methods of making and using such compounds and compositions

Methods are disclosed of making linear and cross-linked, HMW (high molecular weight) polysilanes and polygermanes, polyperhydrosilanes and polyperhydrogermanes, functional liquids containing the same, and methods of using the liquids in a range of desirable applications. The silane and germane polymers are generally composed of chains of Si and / or Ge substituted with R′ substituents, where each instance of R′ is, for example, independently hydrogen, halogen, alkenyl, alkynyl, hydrocarbyl, aromatic hydrocarbyl, heterocyclic aromatic hydrocarbyl, SiR″3, GeR″3, PR″2, OR″, NR″2, or SR″; where each instance of R″ is independently hydrogen or hydrocarbyl. The cross-linked polymers can be synthesized by dehalogenative coupling or dehydrocoupling. The linear polymers can be synthesized by ring-opening polymerization. The polymers can be further modified by halogenation and / or reaction with the source of hydride to furnish perhydrosilane and perhydrogermane polymers, which are used in liquid ink formulations. The synthesis allows for tuning of the liquid properties (e.g., viscosity, volatility, and surface tension). The liquids can be used for deposition of films and bodies by spincoating, inkjetting, dropcasting, etc., with or without the use of UV irradiation. The deposited films can be converted into amorphous and polycrystalline silicon or germanium, and silicon or germanium oxide or nitride by curing at 400-600 DEG C. and (optionally) laser- or heat-induced crystallization (and / or dopant activation, when dopant is present).

Owner:ENSURGE MICROPOWER ASA

Codeposition of hafnium-germanium oxides on substrates used in or for semiconductor devices

InactiveUS20050266700A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHafniumSemiconductor

Methods of film deposition using metals and metal oxides. A thin film of germanium oxide and an oxide of a non-germanium metal is deposited by ALD by alternating deposition of first and second precursor compounds, wherein the first precursor compound includes a metal other than germanium, and the second precursor compound includes germanium.

Owner:JURSICH GREGORY M +1

Reduction of oxides of nitrogen in a gas stream using high-silics molecular sieve CHA

A process for the reduction of oxides in a gas stream (e.g., automotive exhaust) uses a catalyst comprising a molecular sieve having the CHA crystal structure and having a mole ratio of greater than 50 to 1500 of (1) an oxide selected from silicon oxide, germanium oxide or mixtures thereof to (2) an oxide selected from aluminum oxide, iron oxide, titanium oxide, gallium oxide or mixtures thereof.

Owner:CHEVROU USA INC

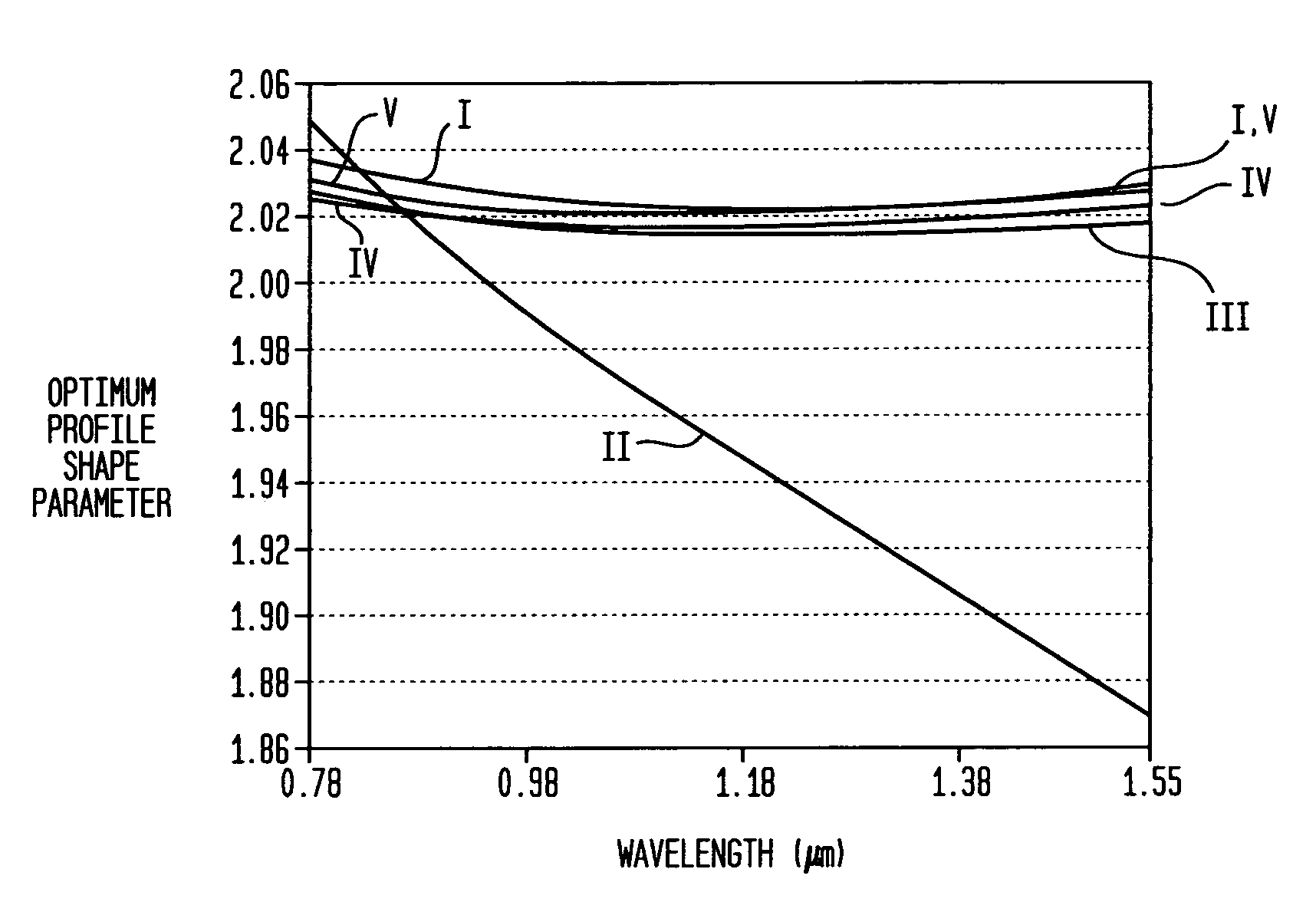

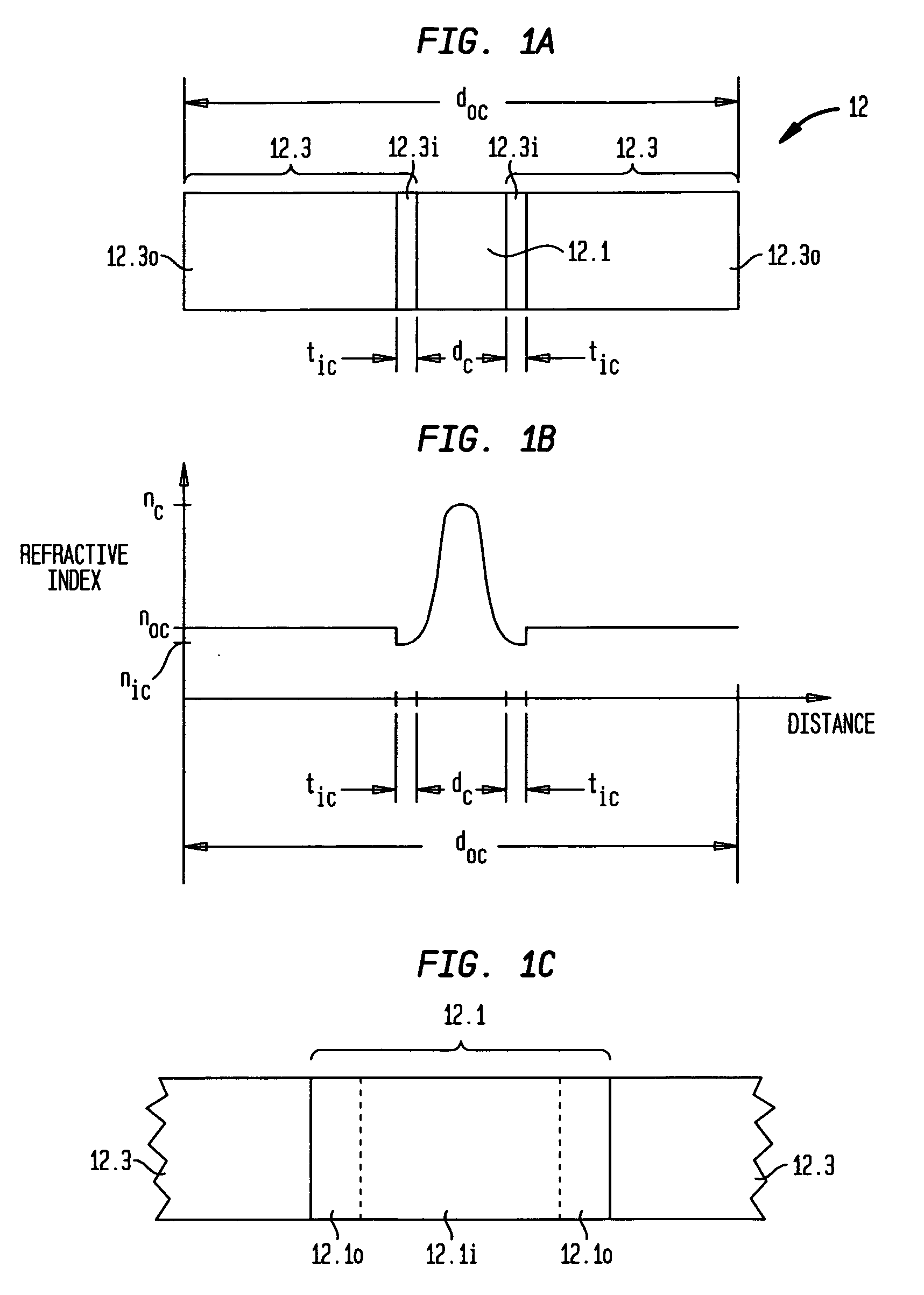

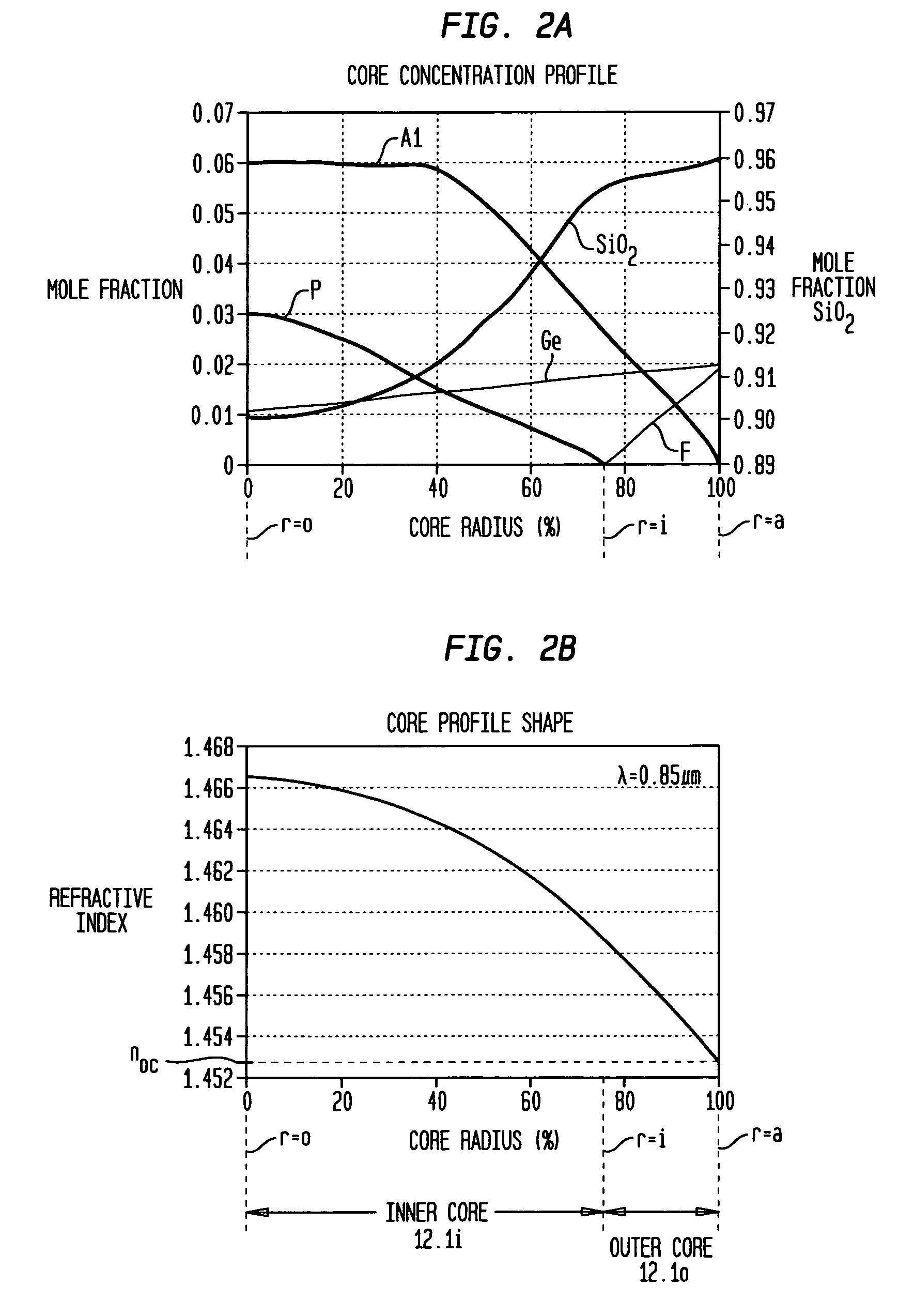

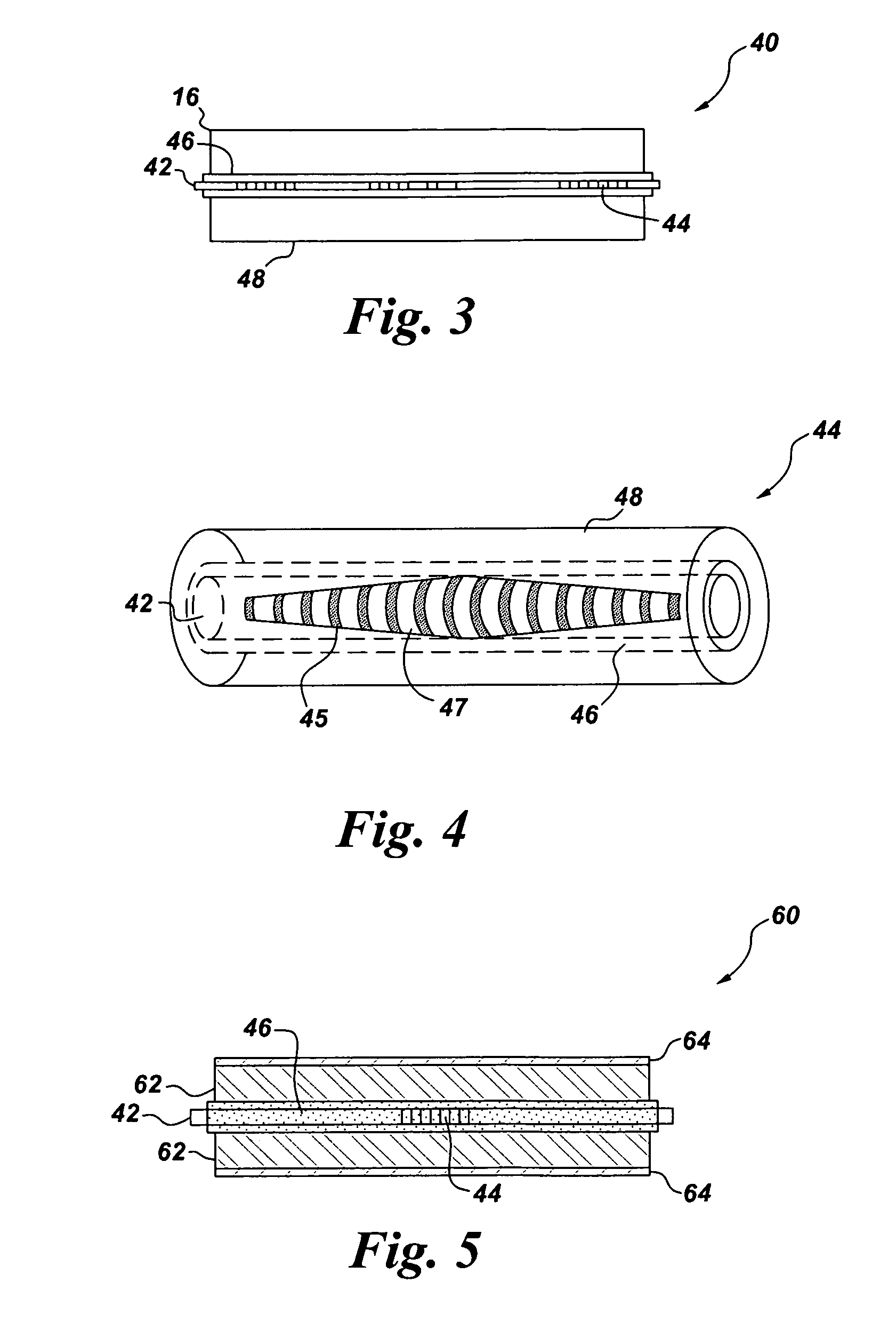

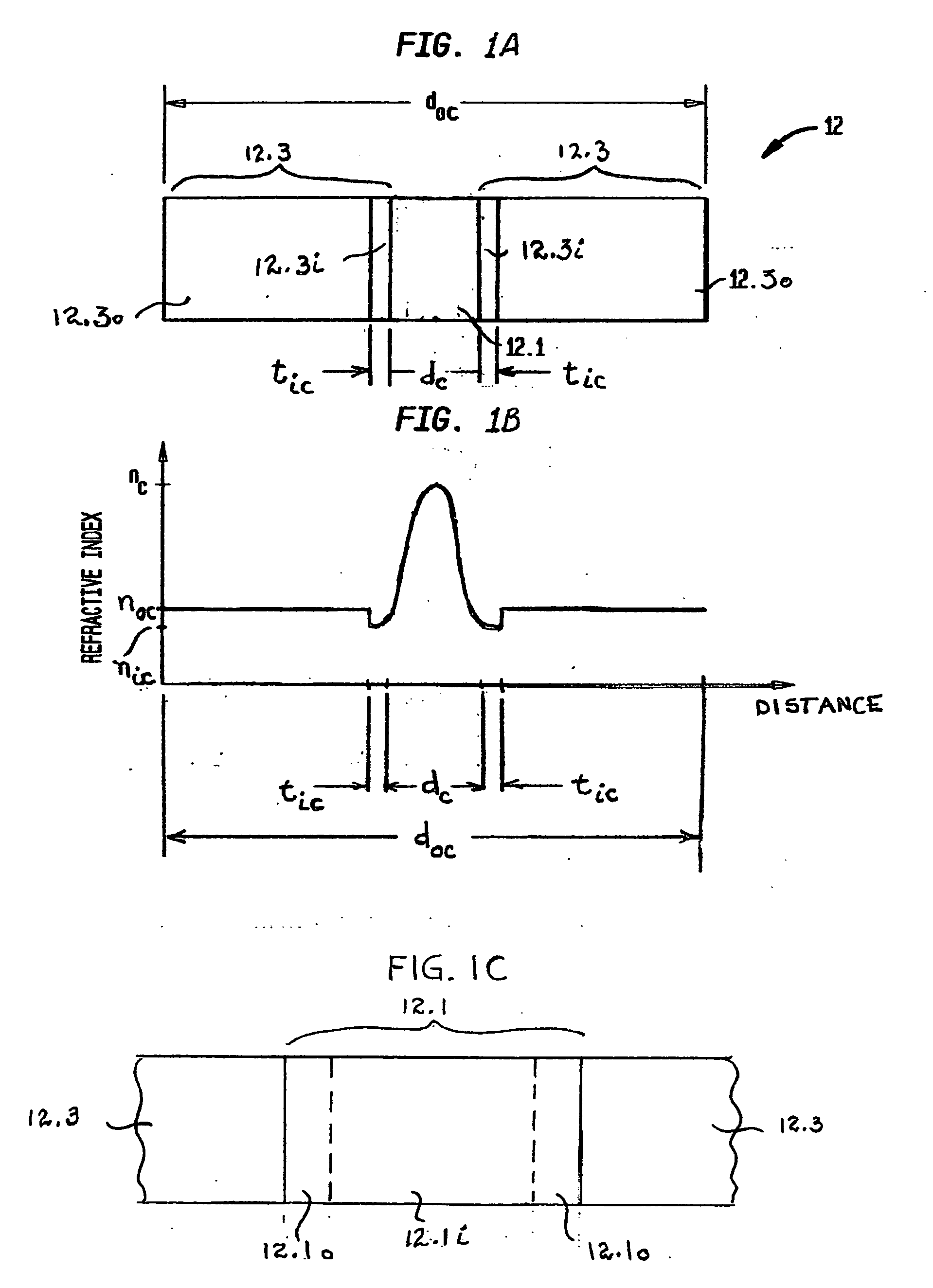

Multi-wavelength, multimode optical fibers

ActiveUS7421174B2Optical fibre with graded refractive index core/claddingOptical waveguide light guideFiberRefractive index

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

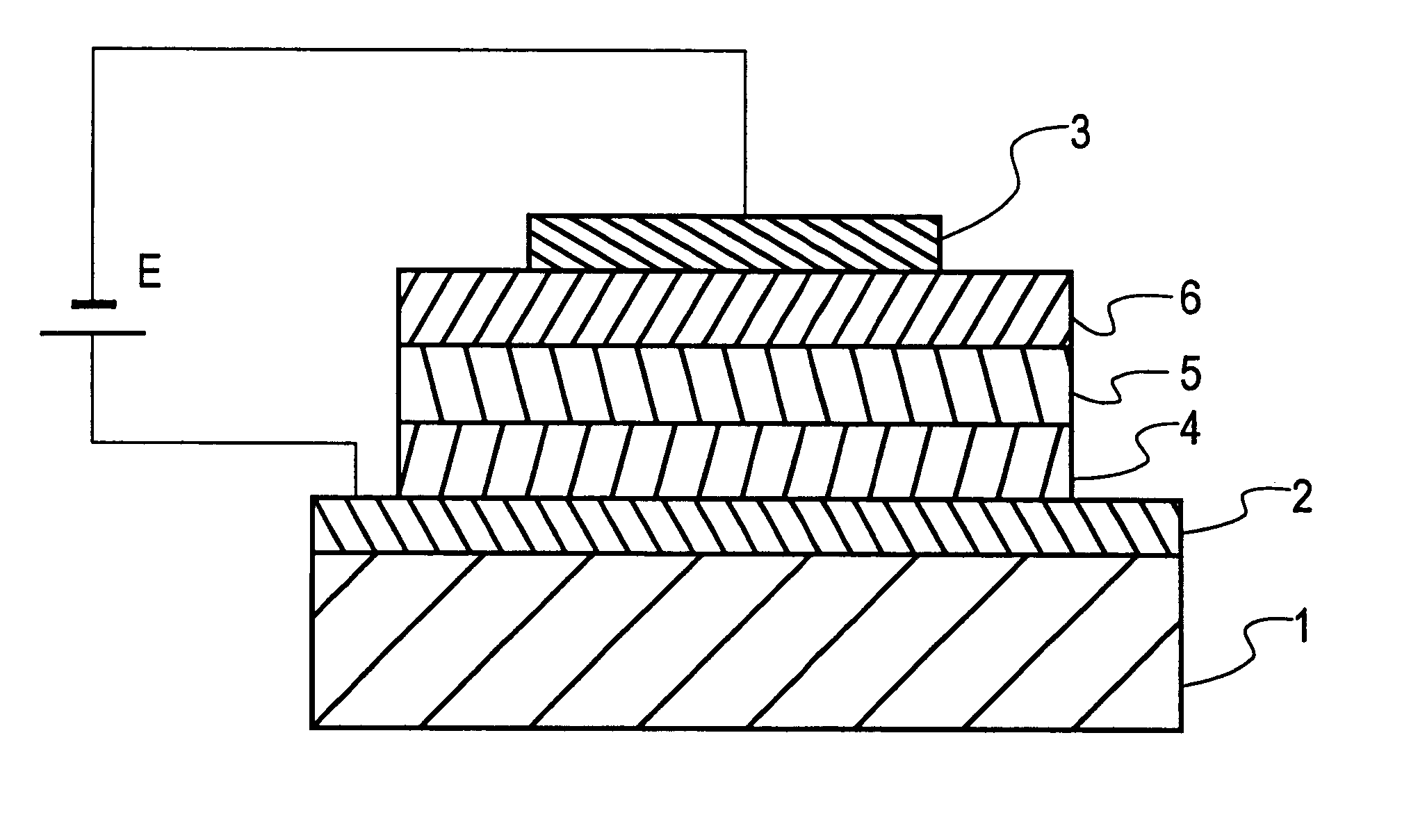

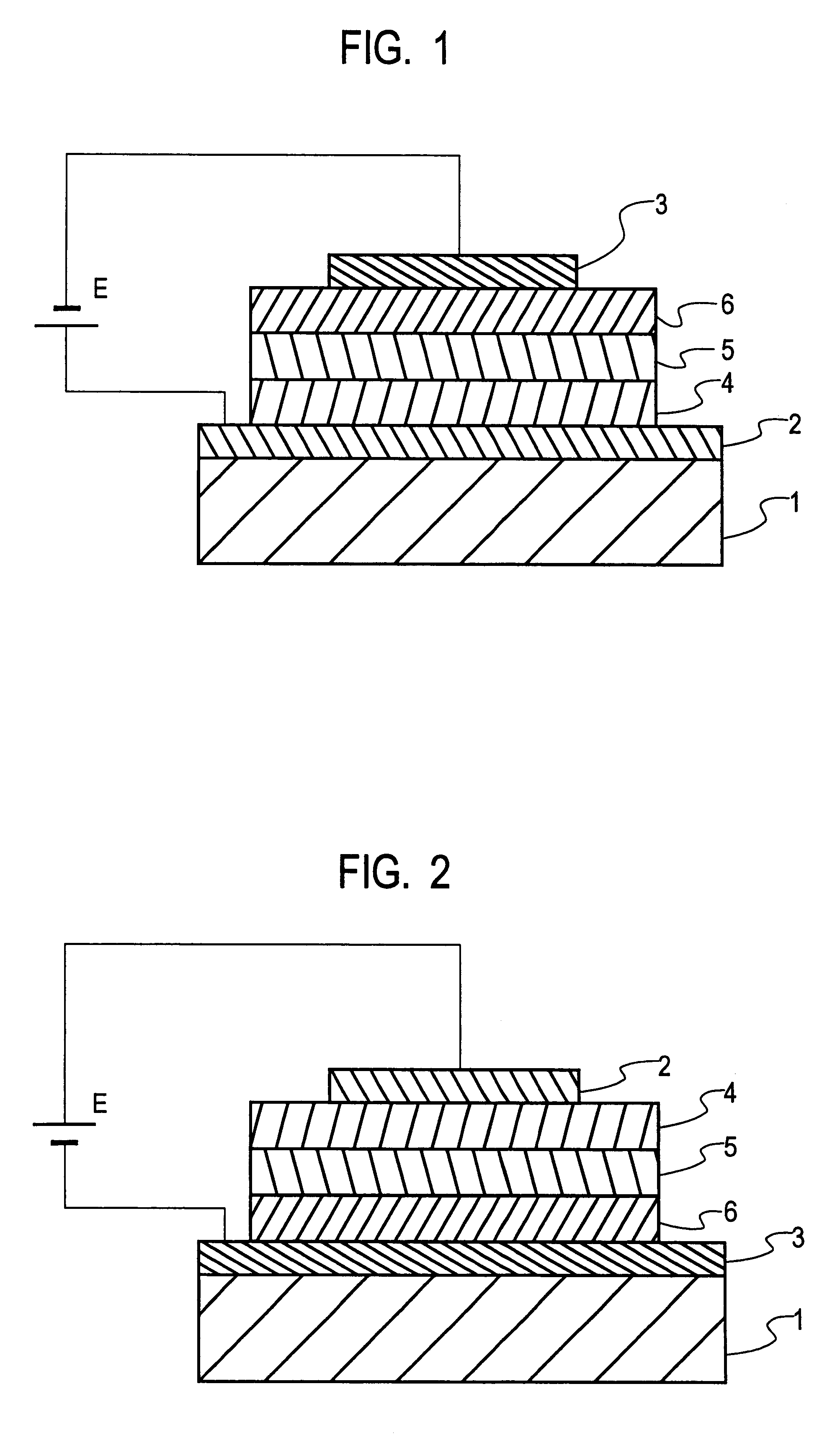

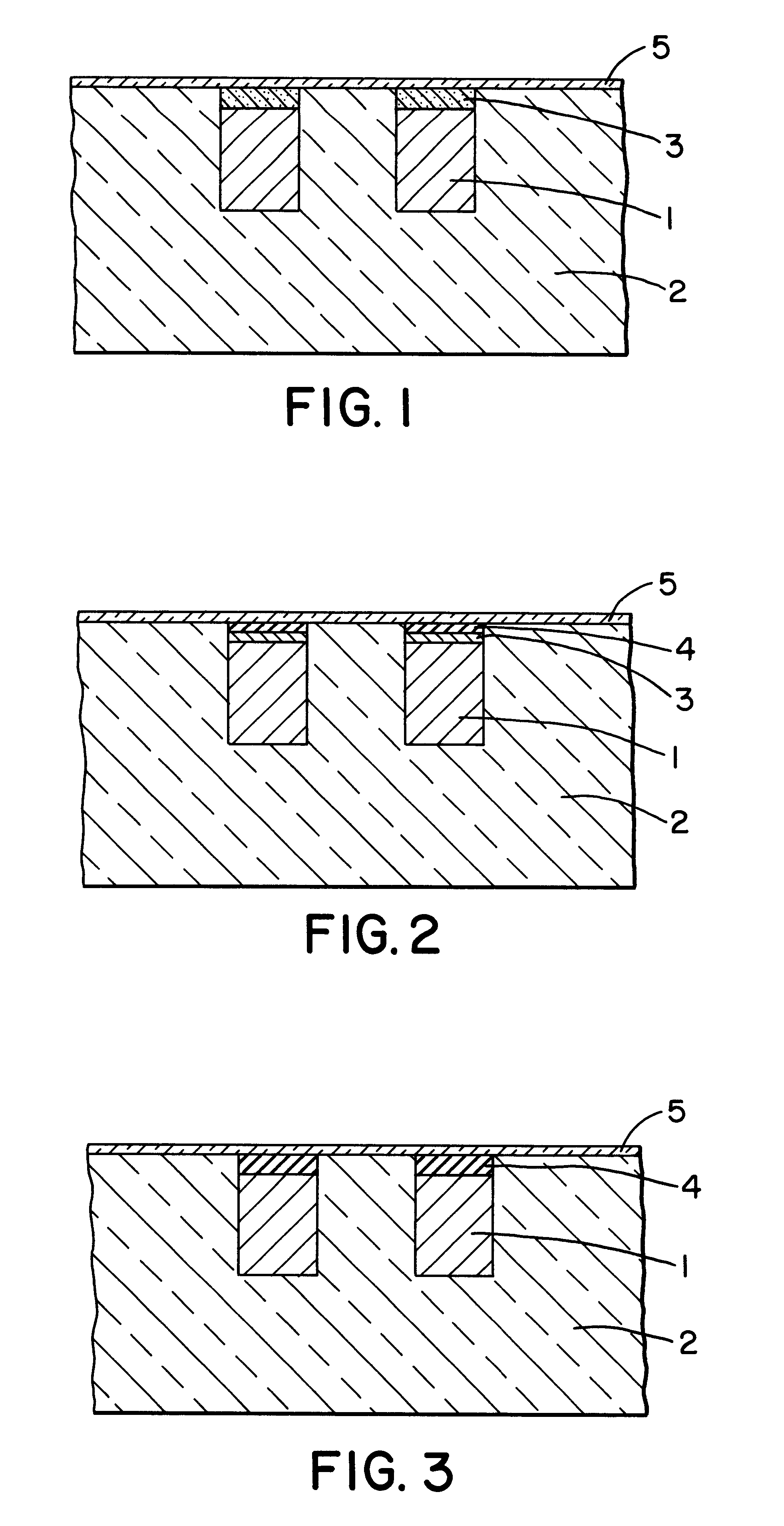

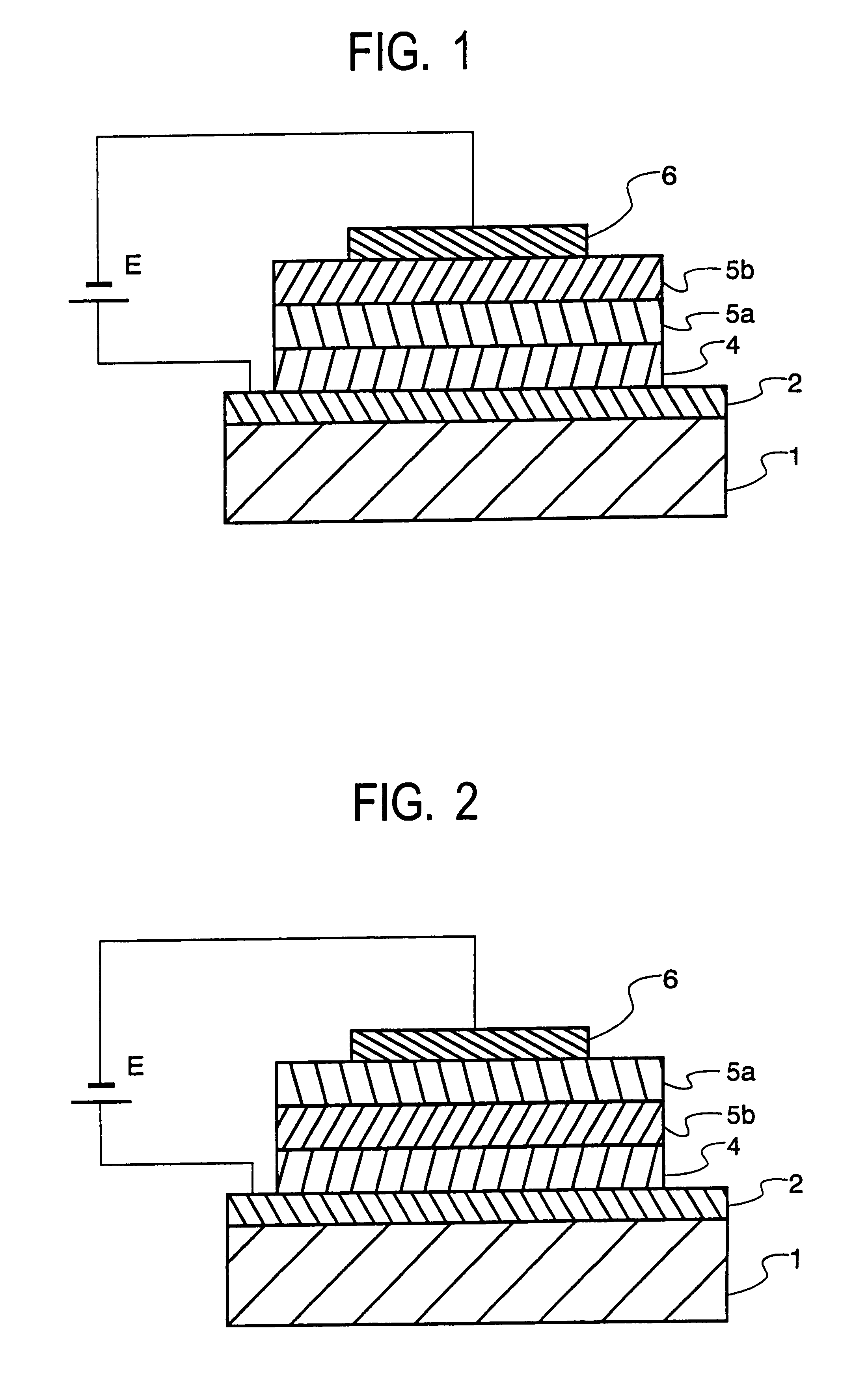

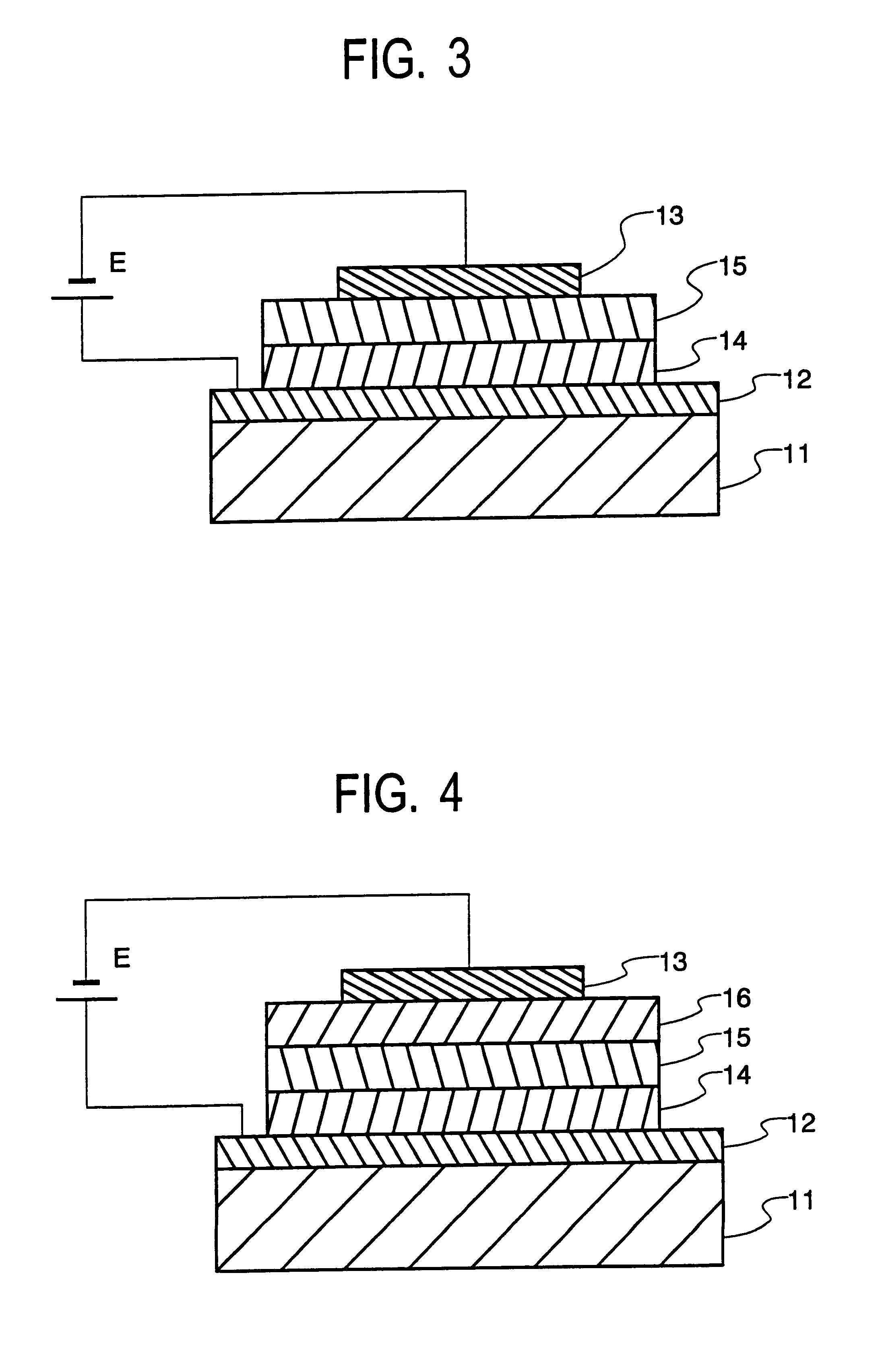

Organic electroluminescent device having a conjugated polymer and an inorganic insulative electron injecting and transporting layer

InactiveUS6404126B1Improve efficiencyLong lastingDischarge tube luminescnet screensElectroluminescent light sourcesRubidium oxideLithium oxide

An organic electroluminescent device having high efficiency, a long life time, and low cost, includes a substrate, a hole injecting electrode and an electron injecting electrode formed on the substrate, an organic material-containing organic layer between the electrodes, and an inorganic insulative electron injecting and transporting layer between the light emitting layer and the electron injecting electrode. The organic layer includes a light emitting layer containing a conjugated polymer, and the inorganic insulative electron injecting and transporting layer comprises three components. The first component is at least one oxide selected from the group consisting of lithium oxide, rubidium oxide, potassium oxide, sodium oxide, and cesium oxide. The second component is at least one of strontium oxide, magnesium oxide, and calcium oxide. The third component consists of silicon oxide, germanium oxide, or mixtures thereof.

Owner:TDK CORPARATION

Surface modified colloidal abrasives, including stable bimetallic surface coated silica sols for chemical mechanical planarization

A composition and an associated method for chemical mechanical planarization (or other polishing) are described. The composition includes a surface-modified abrasive modified with at least one stabilizer and at least one catalyst differing from the at least one stabilizer. The composition can further include a medium containing the abrasive and an oxidizing agent (e.g., hydrogen peroxide), wherein the at least one catalyst is adapted to catalyze oxidation of a substrate by the oxidizing agent. Preferably, the abrasive is alumina, titania, zirconia, germania, silica, ceria and / or mixtures thereof, the stabilizer is B, W and / or Al, and the catalyst is Cu, Fe, Mn, Ti, W and / or V. Both the stabilizer and the catalyst are immobilized on the abrasive surface. The method includes applying the composition to a substrate to be polished, such as substrates containing W, Cu and / or dielectrics.

Owner:VERSUM MATERIALS US LLC

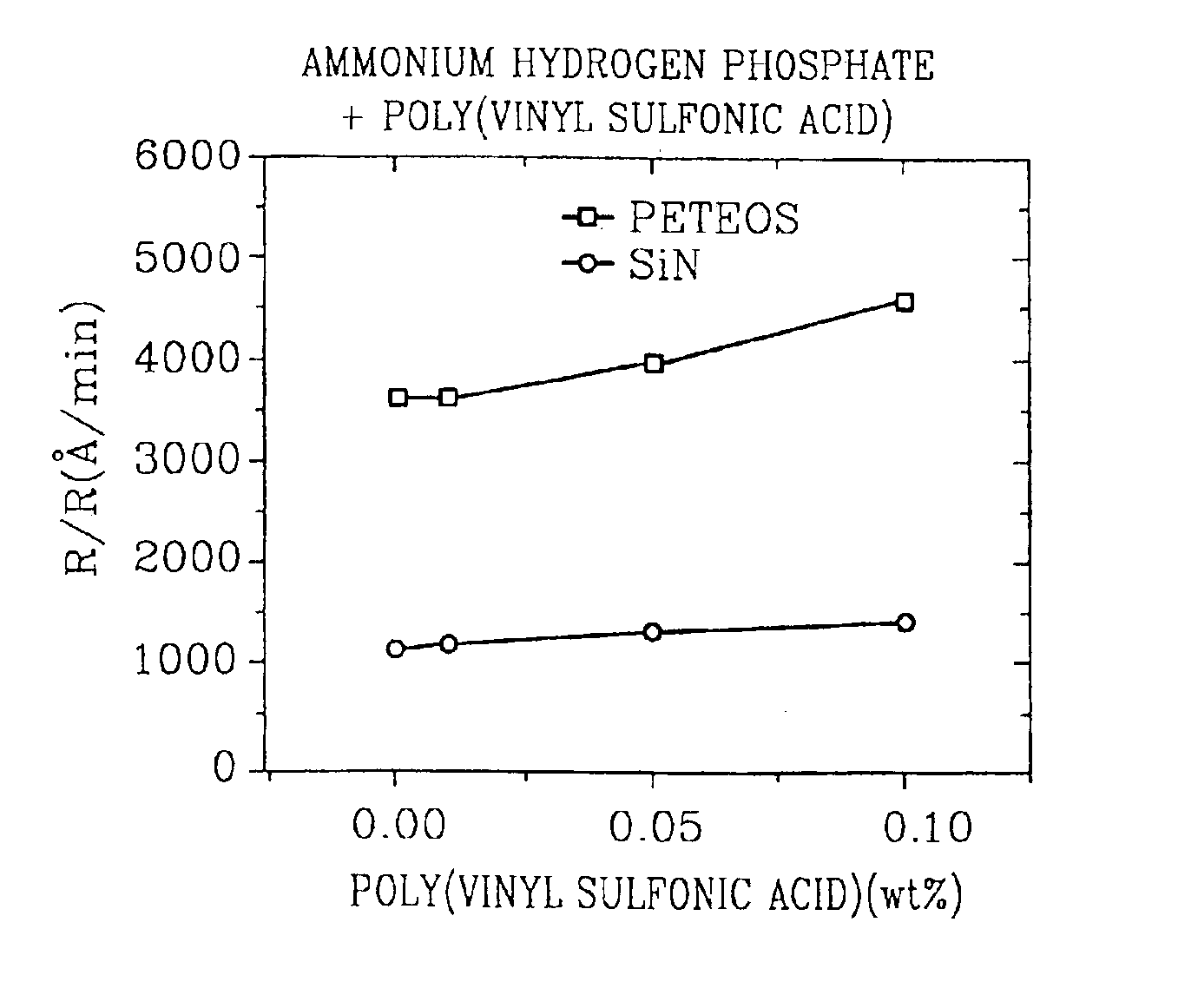

Chemical/mechanical polishing slurry, and chemical mechanical polishing process and shallow trench isolation process employing the same

InactiveUS6914001B2Improved removal selectivityHigh selectivityOther chemical processesDecorative surface effectsIonSilicon nitride

A CMP oxide slurry includes an aqueous solution containing abrasive particles and two or more different passivation agents. Preferably, the aqueous solution is made up of deionized water, and the abrasive particles are a metal oxide selected from the group consisting of ceria, silica, alumina, titania, zirconia and germania. Also, a first passivation agent may be an anionic, cationic or nonionic surfactant, and a second passivation agent may be a phthalic acid and its salts. In one example, the first passivation agent is poly-vinyl sulfonic acid, and the second passivation agent is potassium hydrogen phthalate. The slurry exhibits a high oxide to silicon nitride removal selectivity.

Owner:SAMSUNG ELECTRONICS CO LTD

Codeposition of hafnium-germanium oxides on substrates used in or for semiconductor devices

InactiveUS7312165B2Semiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialPhysical chemistry

Methods of film deposition using metals and metal oxides. A thin film of germanium oxide and an oxide of a non-germanium metal is deposited by ALD by alternating deposition of first and second precursor compounds, wherein the first precursor compound includes a metal other than germanium, and the second precursor compound includes germanium.

Owner:JURSICH GREGORY M +1

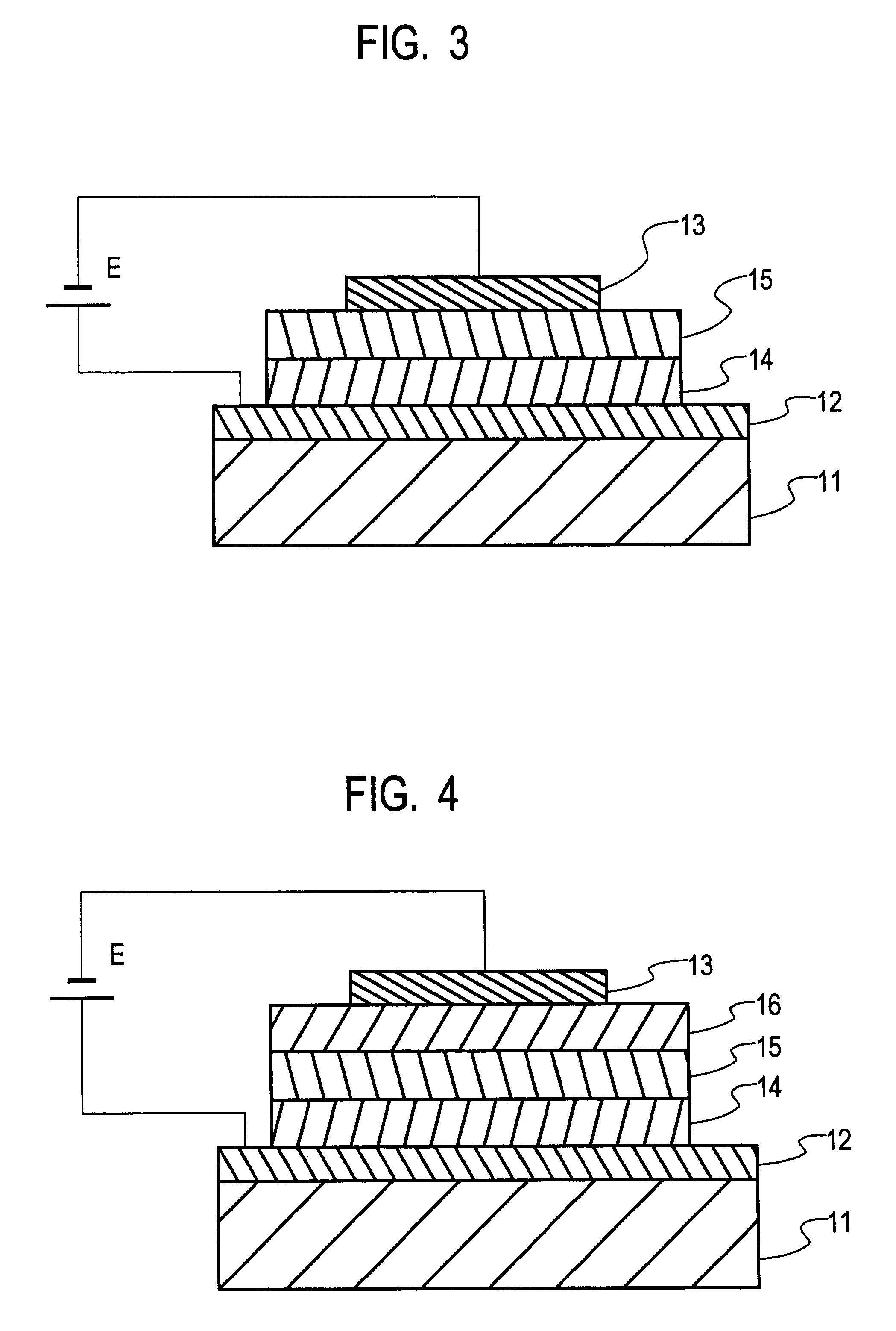

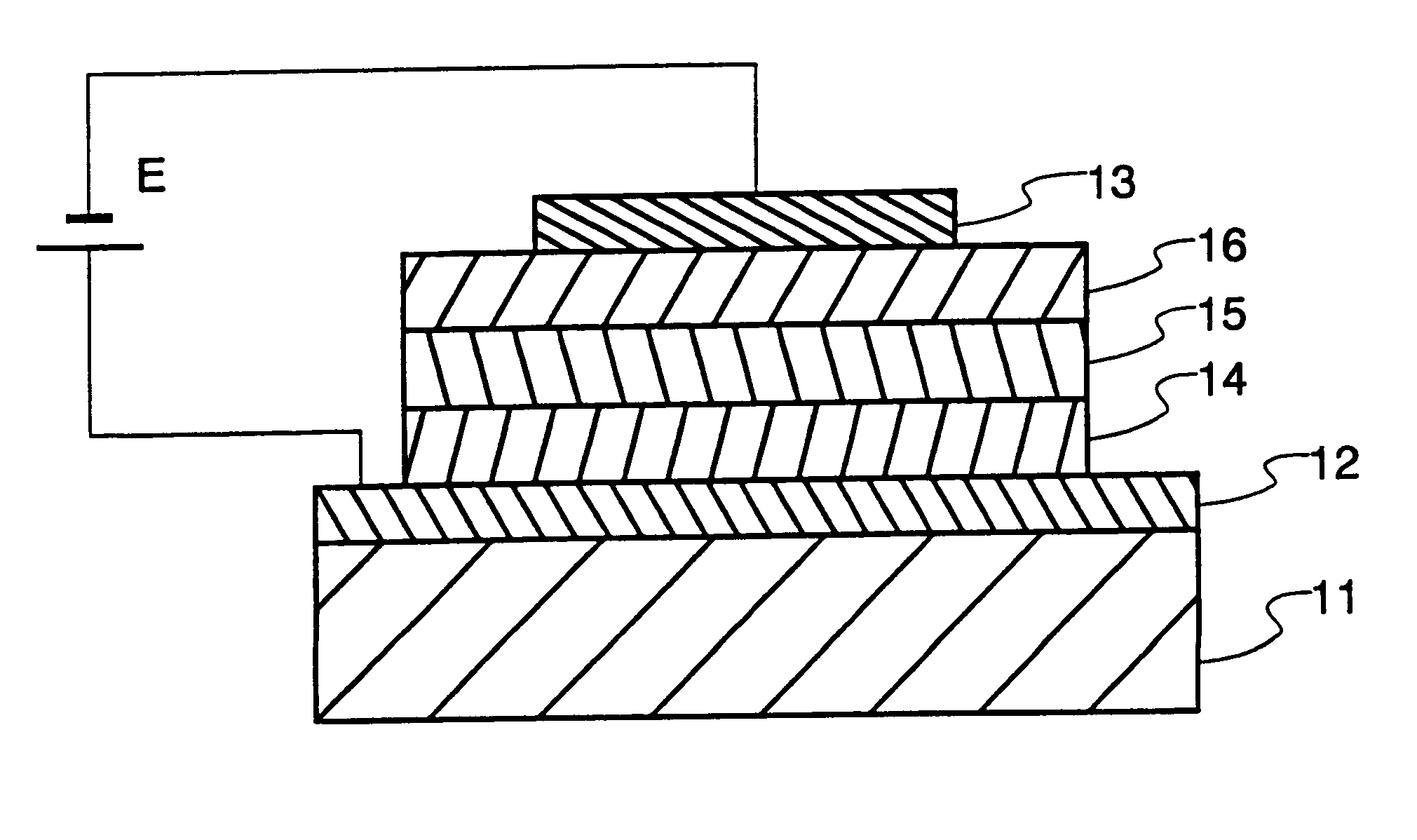

Organic electroluminescent device

InactiveUS6303239B1Improve stabilityImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesRubidium oxideLithium oxide

An object of the invention is to achieve an organic EL device which has an extended life, weather resistance, high stability, and high efficiency, and is inexpensive as well. This object is accomplished by the provision of an organic EL device comprising a substrate, a pair of a hole injecting electrode and a cathode formed on the substrate, and an organic layer located between these electrodes and taking part in at least a light emission function, wherein between the organic layer and the cathode there is provided an inorganic insulating electron injecting and transporting layer comprising a first component comprising at least one oxide selected from the group consisting of lithium oxide, rubidium oxide, potassium oxide, sodium oxide and cesium oxide, a second component comprising at least one oxide selected from the group consisting of strontium oxide, magnesium oxide and calcium oxide, and a third component comprising silicon oxide and / or germanium oxide.

Owner:TDK CORPARATION

Method for improving adhesion to copper

InactiveUS6271595B1Poor materialImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesGermanideOptoelectronics

Poorly adherent layers such as silicon nitride and silicon dioxide exhibit improved adhesion to copper member by providing an intervening germanium-containing layer. The germanium-containing layer is copper germanide, germanium oxide, germanium bitride or combinations thereof. The germanium-containing layer enhances the adhesion such that the poorly adherent layer is less susceptible to delamination from the copper member.

Owner:GLOBALFOUNDRIES INC

Organic electroluminescent device

InactiveUS6198219B1Improve performanceImprove efficiencyDischarge tube luminescnet screensElectroluminescent light sourcesLithium oxideRubidium oxide

The invention provides an organic EL device comprising a substrate, a hole injecting electrode and a negative electrode formed on the substrate, an organic layer containing an organic material between the electrodes, the organic layer including a light emitting layer having at least a light emitting function, and an electron injecting and transporting layer containing an electron transporting organic material and an inorganic insulative electron injecting and transporting layer formed of an inorganic material between the negative electrode and the light emitting layer. The inorganic insulative electron injecting and transporting layer contains at least one oxide selected from the group consisting of lithium oxide, rubidium oxide, potassium oxide, sodium oxide, cesium oxide, strontium oxide, magnesium oxide, and calcium oxide as a main component, and silicon oxide, germanium oxide or a mixture of silicon oxide and germanium oxide as a stabilizer. This construction ensures better performance than prior art devices having electron injecting and transporting layers using organic materials, a high efficiency, long life, weather resistance, and high stability.

Owner:TDK CORPARATION

Ge-doped AZO target and preparation method thereof

InactiveCN101575207AHigh light transmittanceLow resistivityVacuum evaporation coatingSputtering coatingAdhesiveTransmittance

The invention relates to a Ge-doped AZO target, comprising 1-10% of alumina and 0.1-5% of germanium oxide and the balance zinc oxide by weight percentage. The invention also provides a preparation method of the Ge-doped AZO target, including the steps: S1, the raw material of zinc oxide, alumina and germanium oxide powder is weighed respectively in preset proportion, binding agent is added, and water is added for even mixing; S2, the mixture is dried, and the powder is formed by pressing to form a blank body with preset shape and strength; S3, the blank body is sintered at normal pressure and normal atmosphere with the sintering temperature of 1200-1600 DEG C. Transparent conductive film prepared by adopting the target provided by the invention has the characteristics of high light transmittance, low resistance, good film adhesive power, complete and compact structure and good stability.

Owner:CSG HOLDING

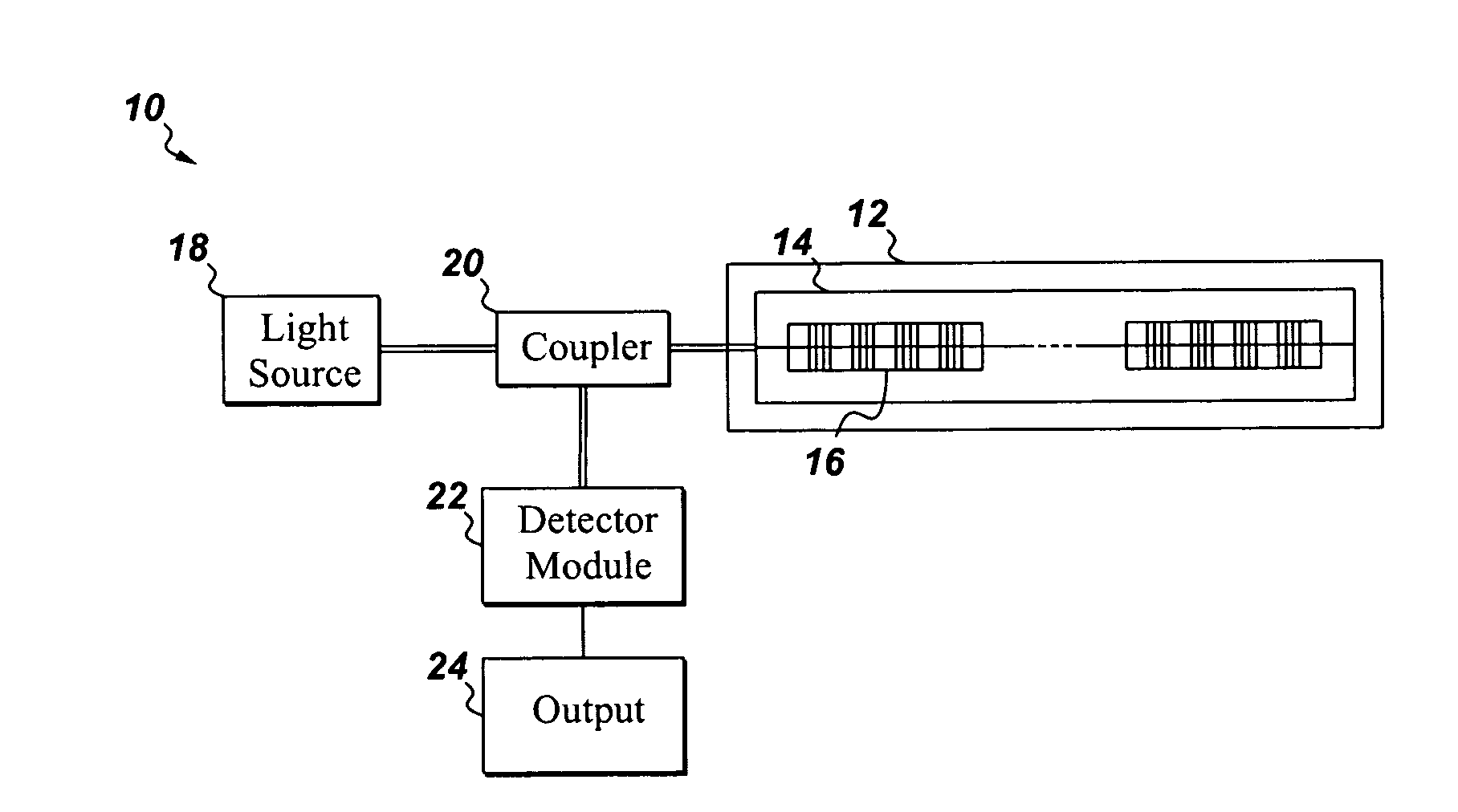

Fiber Bragg grating and fabrication method

ActiveUS7574075B2Increase photosensitivityIncrease the number ofGlass making apparatusOptical fibre with multilayer core/claddingFiberGrating

A method of fabrication of a thermally stabilized Type I fiber Bragg grating-based temperature sensing device includes doping a fiber core material with germanium or germanium oxide for enhancing photosensitivity, co-doping the fiber core material with fluorine or chorine or for increasing a mean coordination number; and ultraviolet laser inscribing a periodic or quasiperiodic modulated refractive index structure in the fiber core using a laser energy operating at less than 1000 milliJoules per square centimeter per pulse. The resulting sensor is operable for more than 1000 hours at temperatures up to at least 550 degrees Celsius.

Owner:AIR PROD & CHEM INC

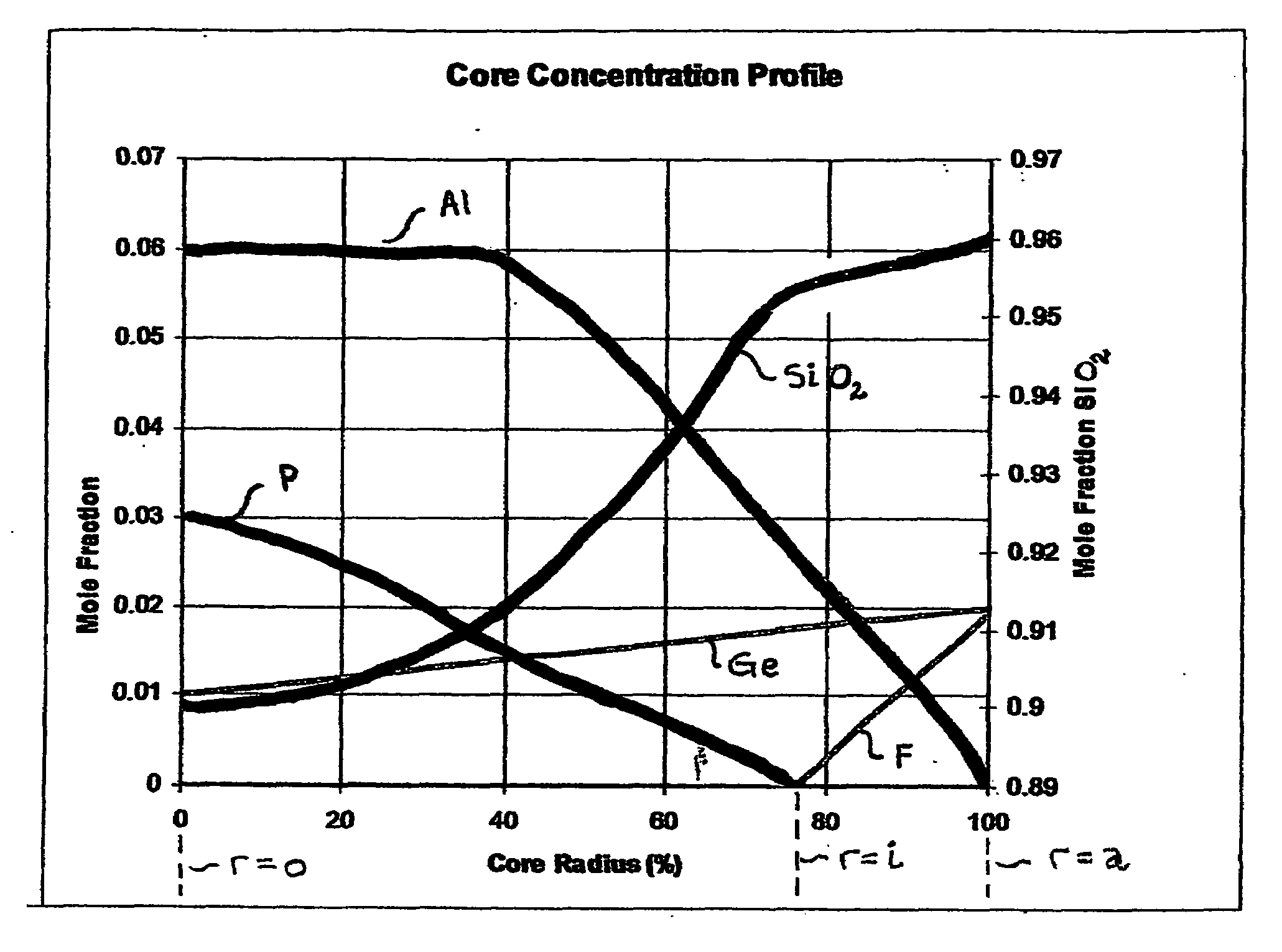

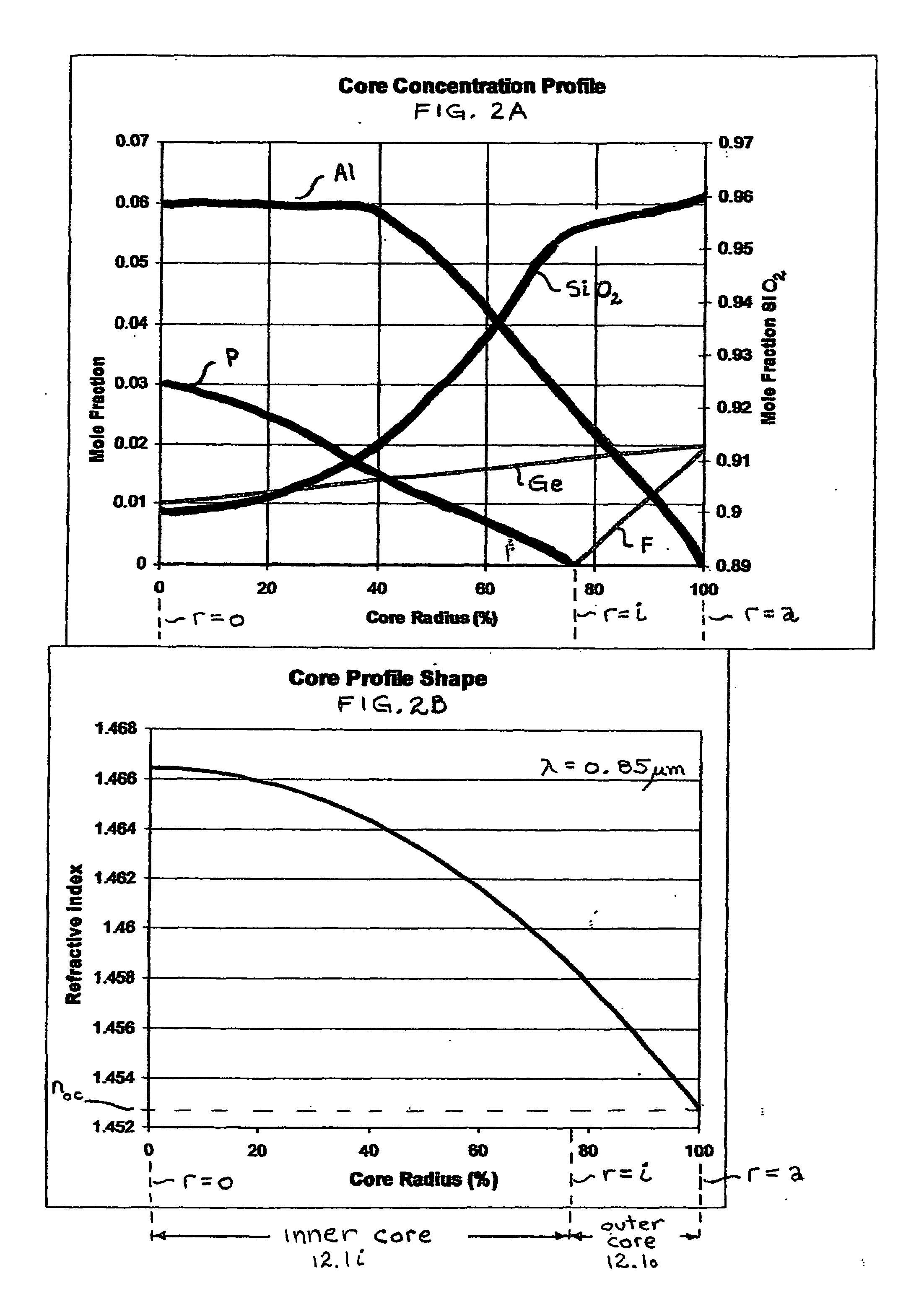

Multi-wavelength, multimode optical fibers

ActiveUS20080050075A1Little changeOptical fibre with graded refractive index core/claddingOptical waveguide light guideFiberRefractive index

A silicate optical fiber comprises a graded index silicate core co-doped with aluminum oxide, phosphorus oxide, germanium oxide and fluorine in unique compositions that we have discovered allow multimode, multi-wavelength operation without significant intermodal dispersion. Illustratively, the core comprises a multiplicity of compositions whose refractive indices are graded from a maximum at or near the center of the core to a minimum at the interface with the cladding. Each core composition resides within a sub-volume of a 5 dimensional phase space in which an optimum core profile shape is essentially constant over the wavelength range of operation of the fiber. For operation in the wavelength range of about 0.78 μm to 1.55 μm, each composition preferably comprises no more than approximately 6 mole % Al2O3, 9 mole % P2O5, 6 mole % GeO2, 6 mole % F, and 90-100 mole % SiO2.

Owner:FURAKAWA ELECTRIC NORTH AMERICA INC

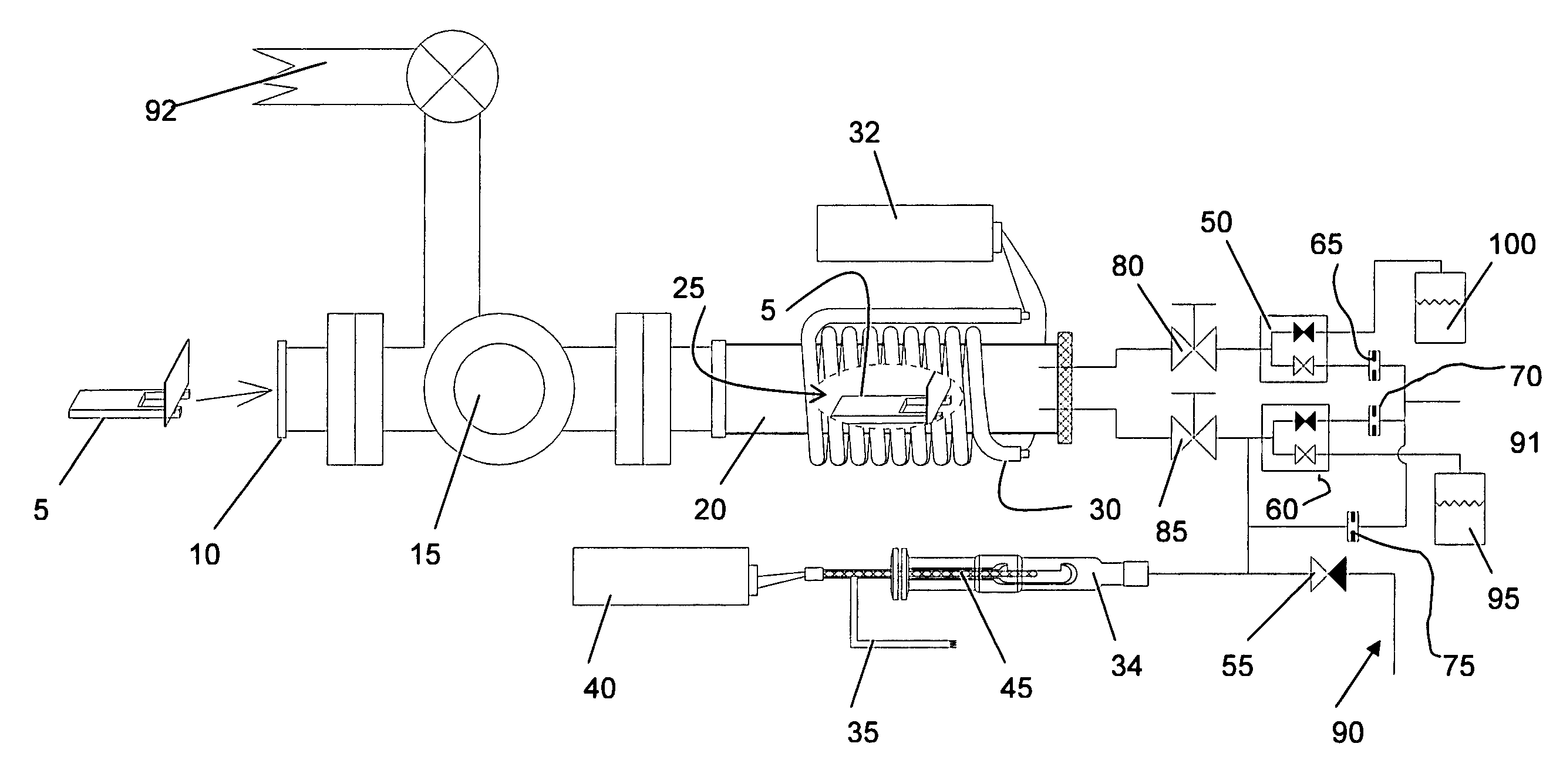

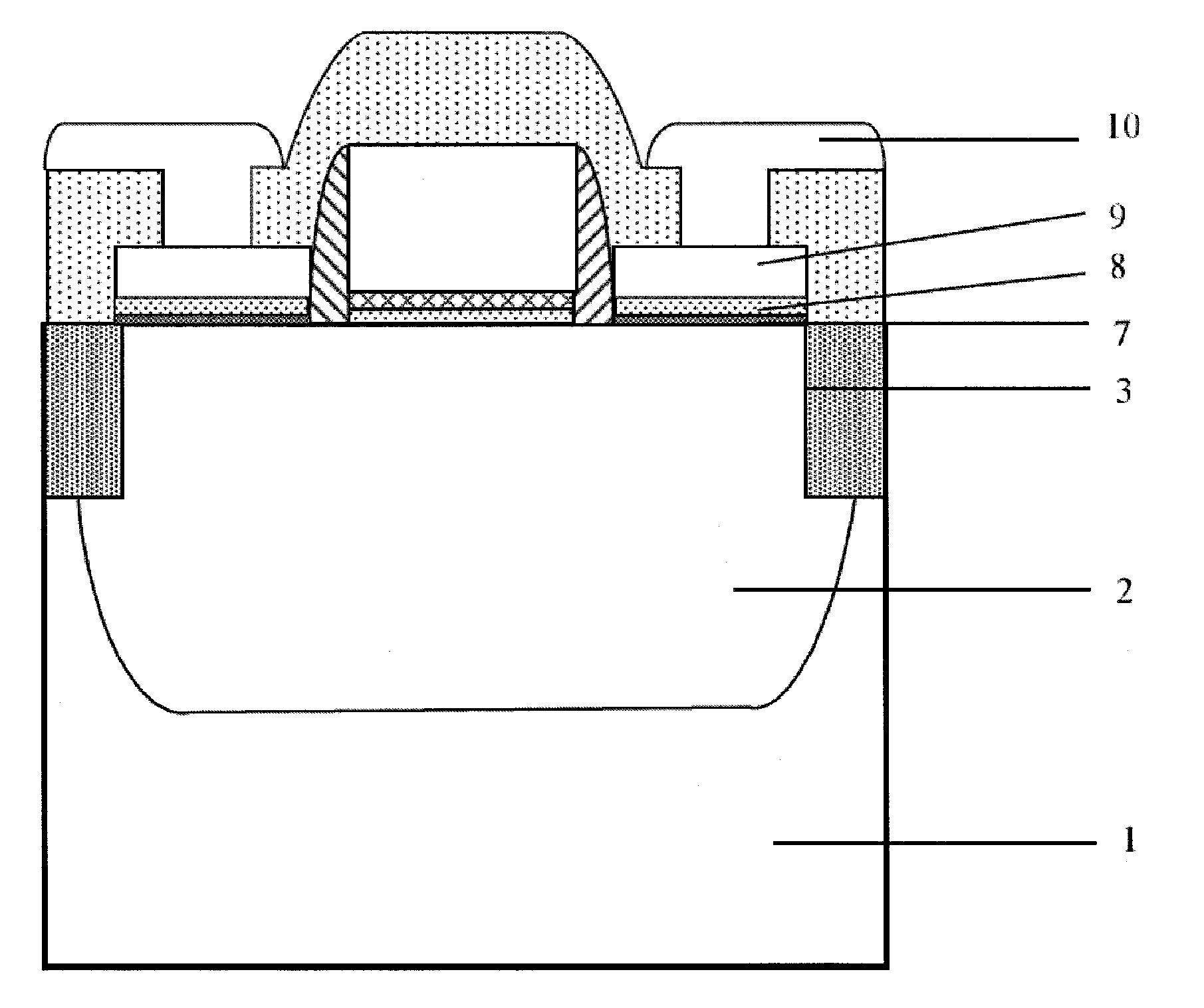

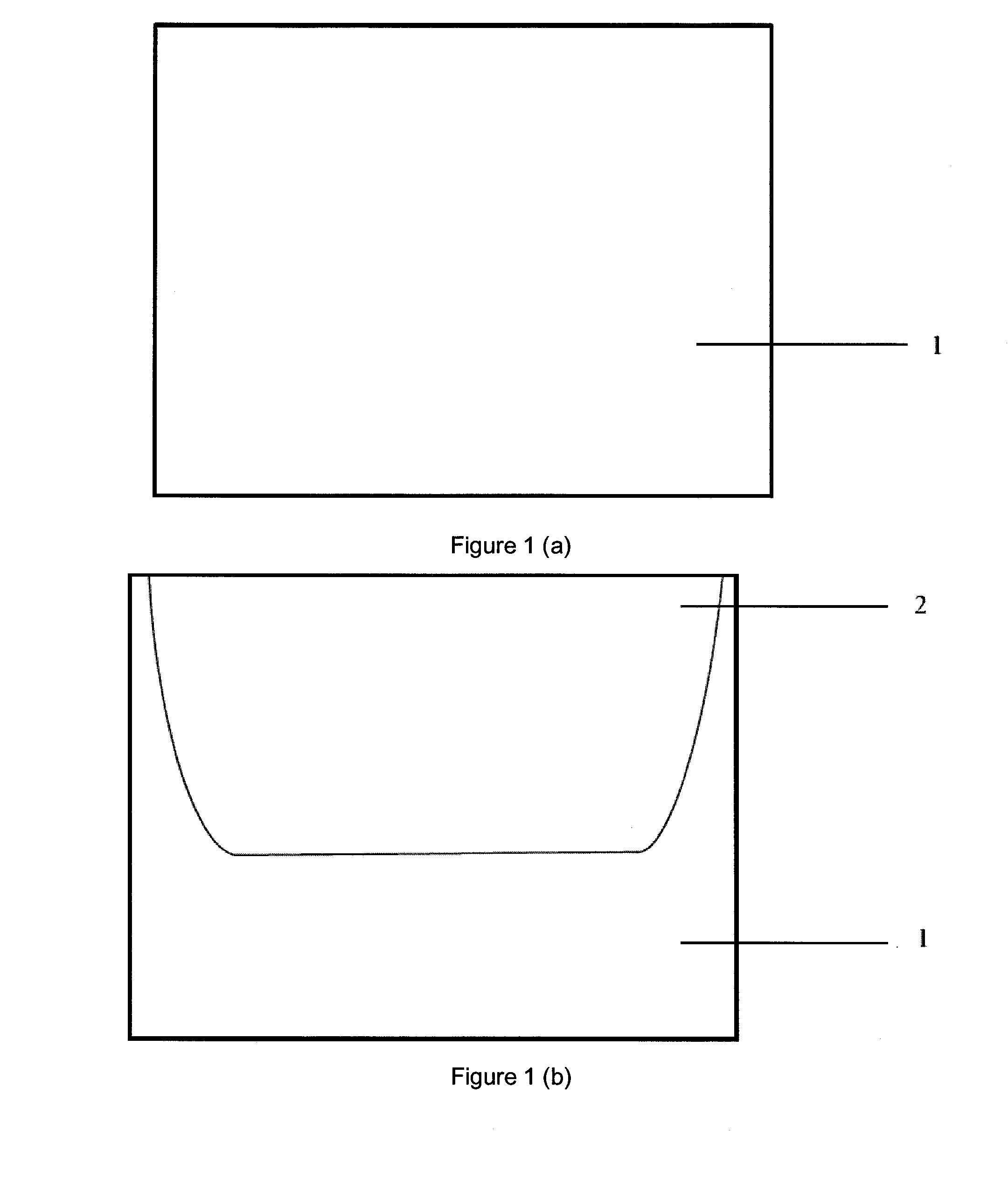

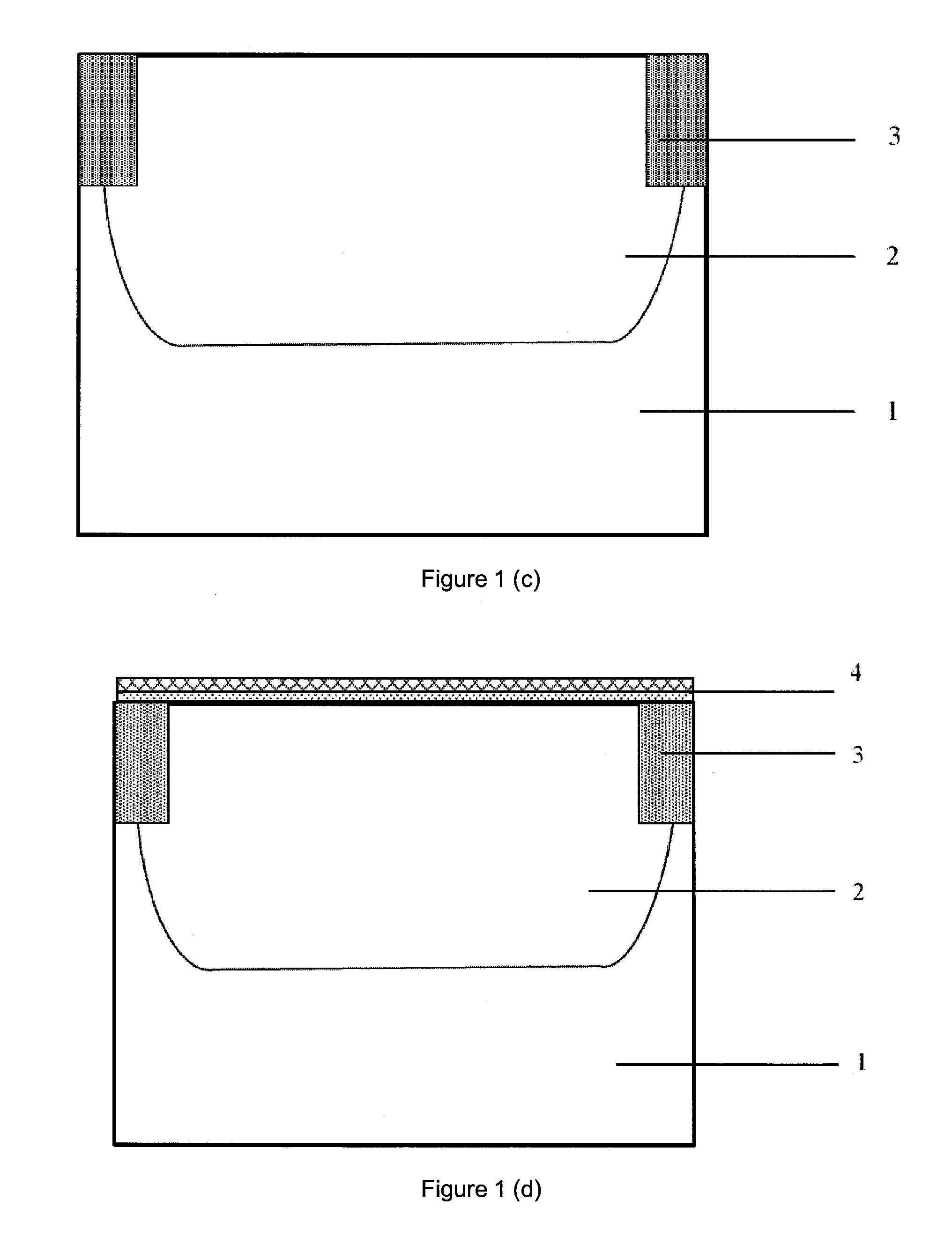

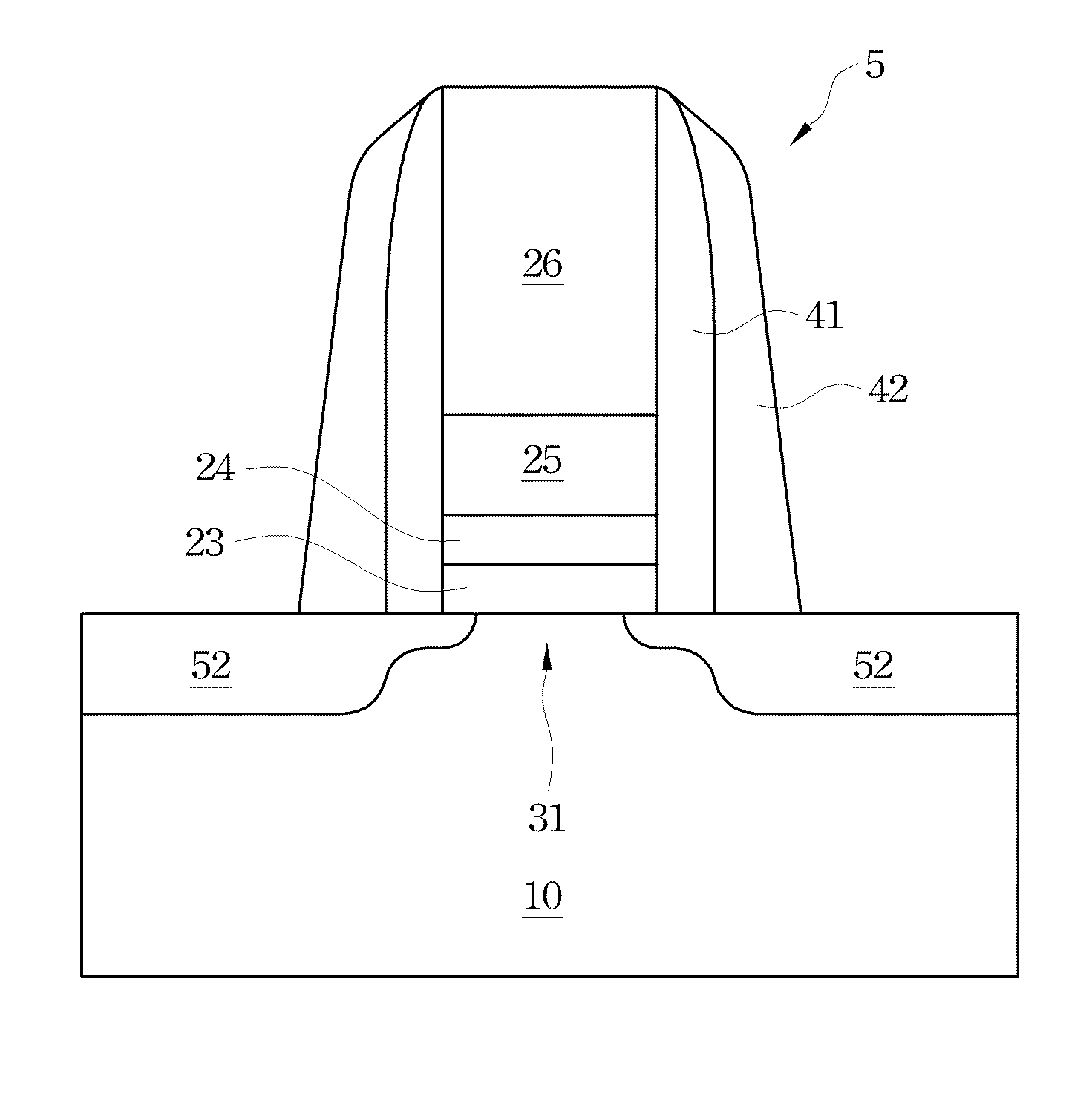

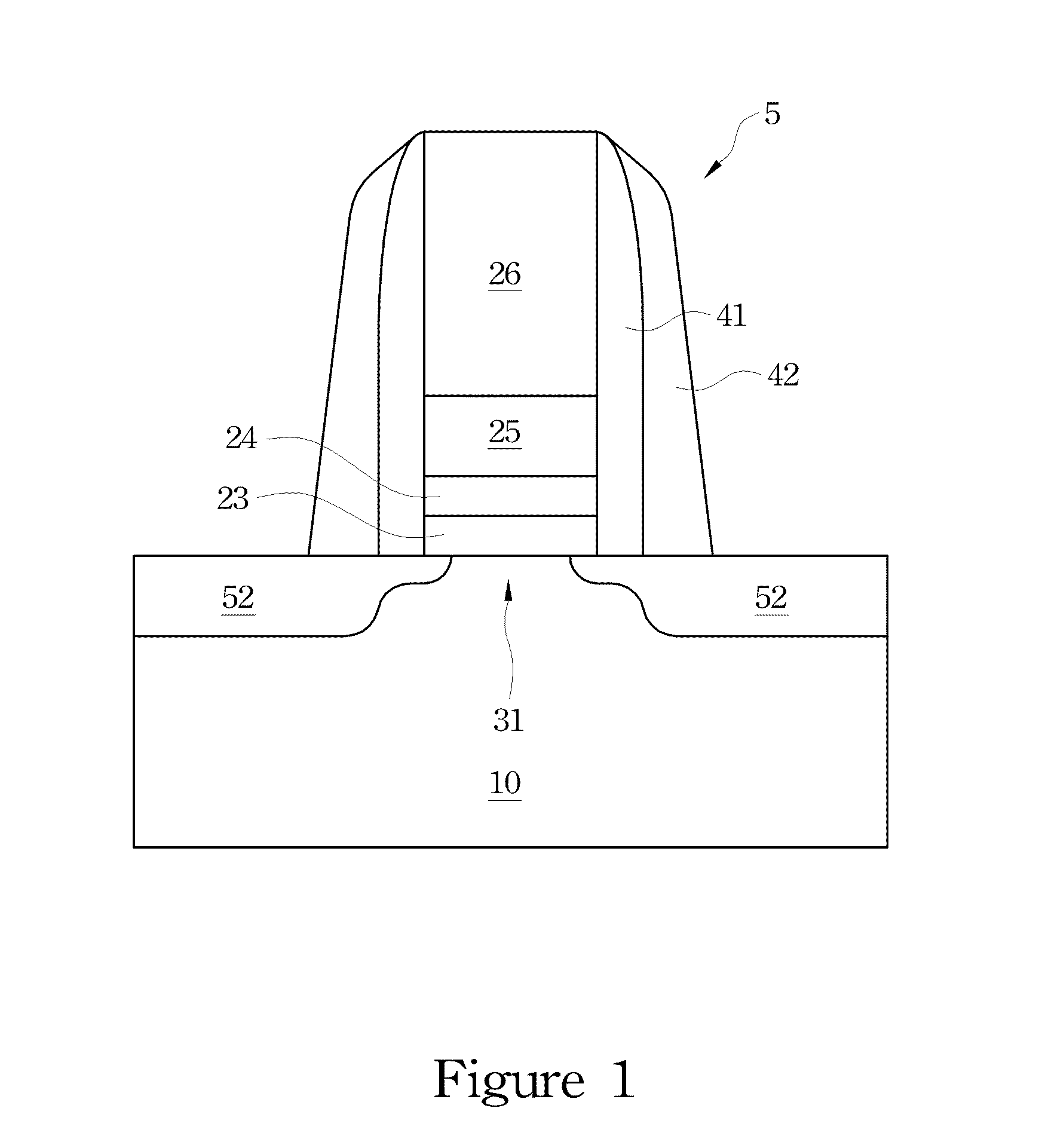

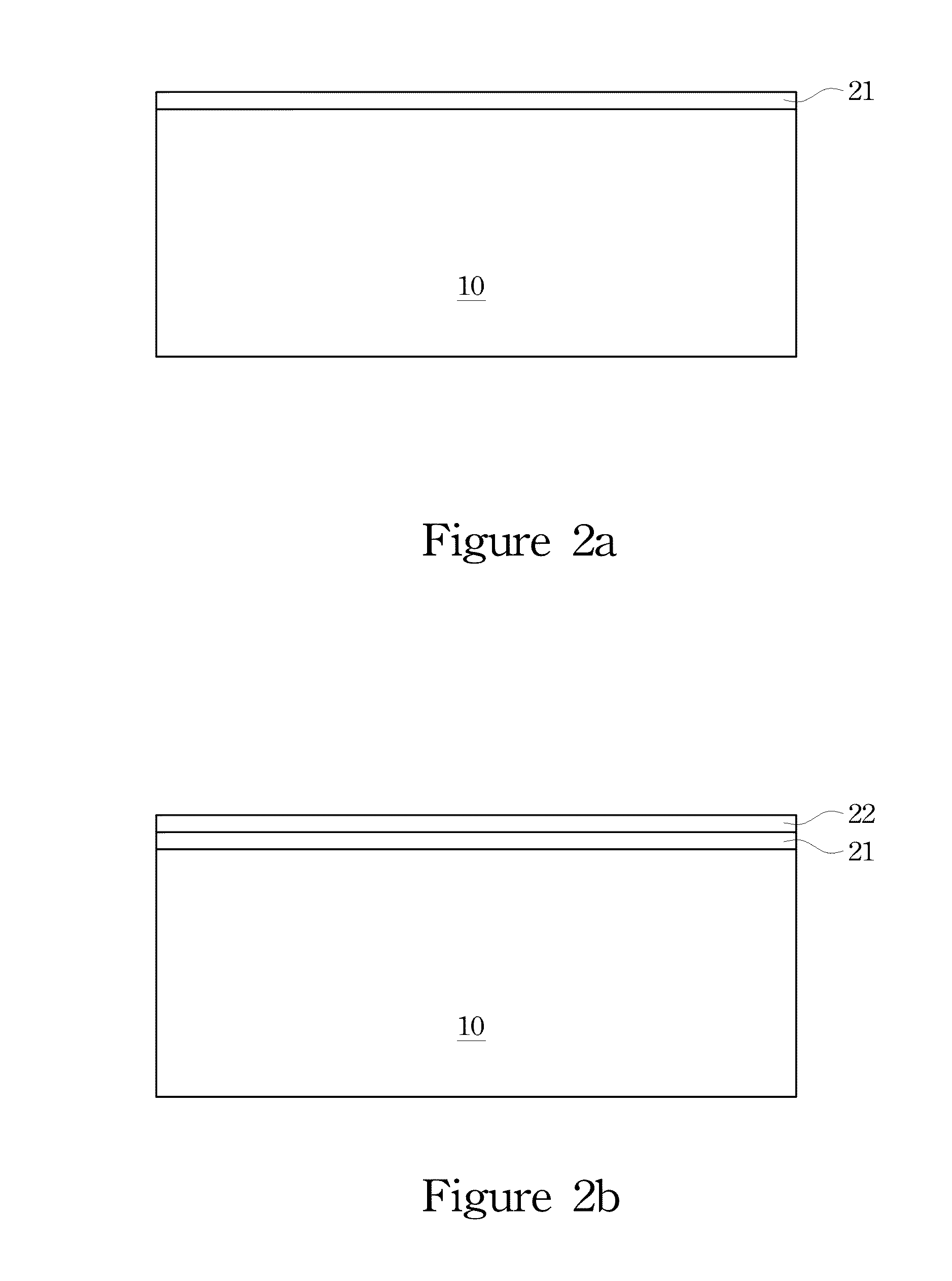

Ge-based nmos device and method for fabricating the same

ActiveUS20140117465A1Alleviate Fermi level pinning effectReduce electron barrierSemiconductor/solid-state device manufacturingSemiconductor devicesSchottky barrierDielectric layer

The embodiments of the present invention provide a Ge-based NMOS device structure and a method for fabricating the same. By using the method, double dielectric layers of germanium oxide (GeO2) and metal oxide are deposited between the source / drain region and the substrate. The present invention not only reduces the electron Schottky barrier height of metal / Ge contact, but also improves the current switching ratio of the Ge-based Schottky and therefore, it will improve the performance of the Ge-based Schottky NMOS transistor. In addition, the fabrication process is very easy and completely compatible with the silicon CMOS process. As compared with conventional fabrication method, the Ge-based NMOS device structure and the fabrication method in the present invention can easily and effectively improve the performance of the Ge-based Schottky NMOS transistor.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Multi-ion health-preserving solution and preparation method and application thereof

ActiveCN102068019AGood technical effectConvenient treatmentCosmetic preparationsToilet preparationsDiseaseSeawater

The invention discloses a multi-ion health-preserving solution, which contains alkaline concentrated solution and acidic concentrated solution; and the multi-ion health-preserving solution is characterized in that: the alkaline concentrated solution contains the following components in part by weight: 800 to 1200 parts of concentrated seawater mother liquor; 280 to 420 parts of sylvite; 18 to 33 parts of wollastonite; and 0.15 to 0.45 parts of germanium oxide; and the acidic concentrated solution contains the following components in part by weight: 400 to 600 parts of calcium ion water; 145 to 225 parts of citric acid solution; 0.4 to 0.6 parts of germanium oxide; 14 to 26 parts of tourmaline; 24 to 36 parts of sugar; and 280 to 420 parts of white vinegar. The invention also discloses a preparation method and application of the multi-ion health-preserving solution. The multi-ion health-preserving solution has the effects of radical conversion, toxin expulsion and balance-circulation synergism, and products made from the multi-ion health-preserving solution as additive, such as drinking water, cosmetic solution, washing water, food and antialcoholic products, have disease-preventing-and-treating, senility-deferring, cosmetic and body-building effects.

Owner:上海心动能科技有限公司

Gas separation using high-silica molecular sieve CHA

Gasses are separated using a molecular sieve having the CHA crystal structure and having a mole ratio of greater than 50 to 1500 of (1) an oxide selected from silicon oxide, germanium oxide or mixtures thereof to (2) an oxide selected from aluminum oxide, iron oxide, titanium oxide, gallium oxide or mixtures thereof.

Owner:CHEVROU USA INC

Isotropic atomic layer etch for silicon oxides using no activation

ActiveUS20160329221A1High selectivityReduce defective rateElectric discharge tubesSemiconductor/solid-state device manufacturingActivation methodSelf limiting

Methods for controlled isotropic etching of layers of silicon oxide and germanium oxide with atomic scale fidelity are provided. The methods make use of NO activation of an oxide surface. Once activated, a fluorine-containing gas or vapor etches the activated surface. Etching is self-limiting as once the activated surface is removed, etching stops since the fluorine species does not spontaneously react with the un-activated oxide surface. These methods may be used in interconnect pre-clean applications, gate dielectric processing, manufacturing of memory devices, or any other applications where accurate removal of one or multiple atomic layers of material is desired.

Owner:LAM RES CORP

Bismuth oxide glass and process of making thereof

An optically active glass containing bismuth oxide and germanium oxide is disclosed which comprises 0.1 up to less than 5 mol-% of B2O3 and SiO2 in total. In addition the glass comprises 10 to 60 mol-% of Bi2O3 and 10 to 60 mol-% of GeO2. The glass may further comprise 0-15 wt-% of rare earths, 0-30 wt-% of M′2O, 0-20 wt-% of M″O, 0-15 wt-% of La2O3, 0-40 wt-% of Ga2O3, 0-10 wt-% of Gd2O3, 0-20 wt-% of Al2O3, 0-10 wt-% of CeO2, 0-30 wt-% of ZnO, wherein M′ is at least one component selected from the group formed by Li, Na, K, Rb and Cs, and wherein M″ is at least one component selected from the group formed by of Be, Mg, Ca, Sr and Ba. Also a suitable method of preparation is disclosed.

Owner:SCHOTT AG

Far-infrared negative-ion ceramic and preparation method thereof

The invention discloses a far-infrared negative-ion ceramic. The ceramic comprises the following components by weight: 0.1 to 0.18 part of magnesium oxide, 0.2 to 0.29 part of calcium oxide, 1.80 to 2.78 parts of potassium oxide, 22 to 25 parts of aluminium oxide, 71 to 72.4 parts of silicon dioxide, 0.23 to 0.28 part of sodium oxide, 0.1 to 0.13 part of ferric oxide, 1 to 3 parts of tourmaline and 1 to 3 parts of germanium oxide. The invention also provides a manufacturing method for the far-infrared negative-ion ceramic by using the above-mentioned components; and the far-infrared negative-ion ceramic has the advantages of mildness, beautiful appearance, and comprehensive functions of emitting far infrared wave and releasing negative ions.

Owner:XIAMEN MEIJU INFORMATION TECH CO LTD

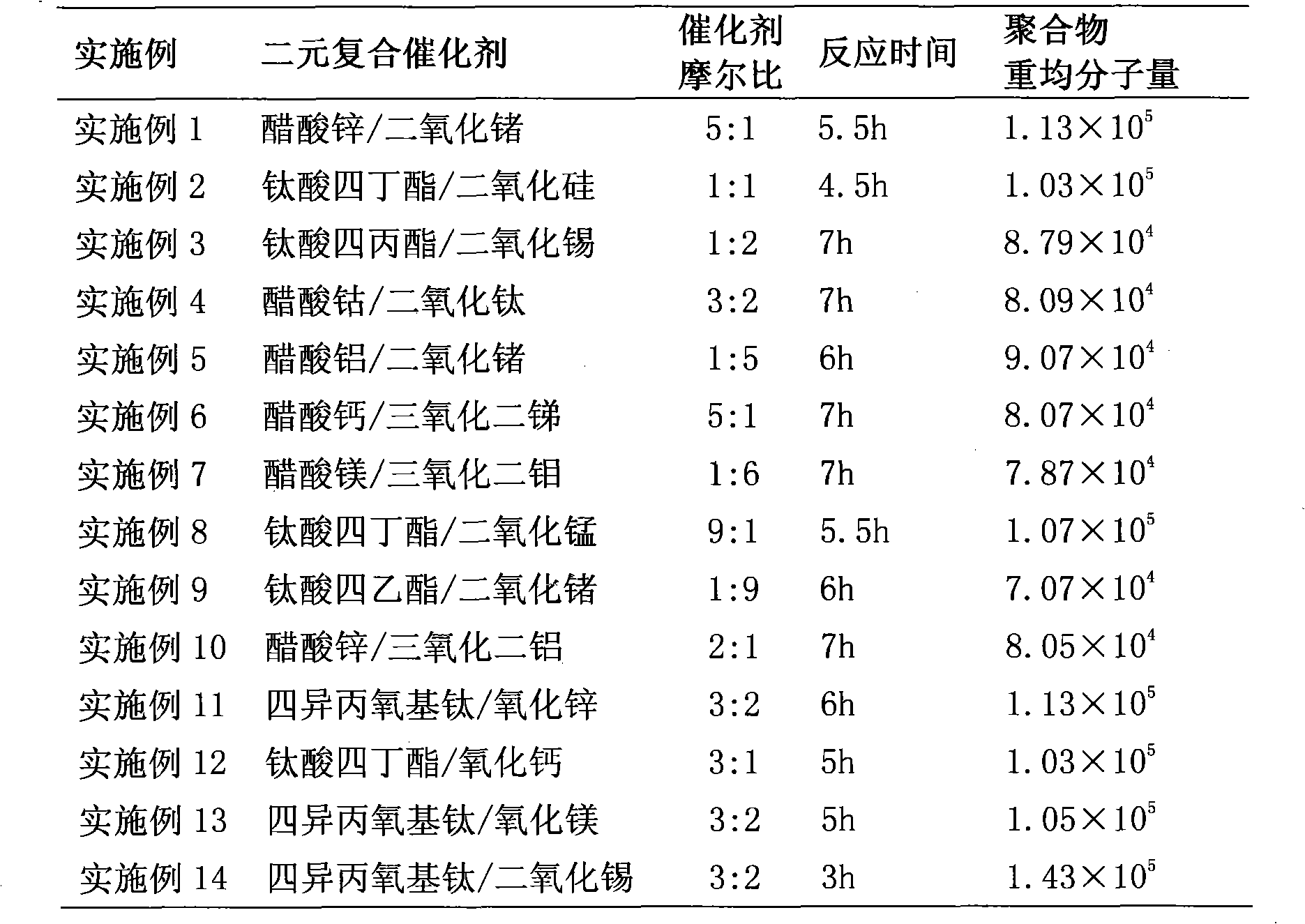

Binary composite catalyst for preparing biodegradable copolyester

InactiveCN101525429AInhibit side effectsImprove the efficiency of polycondensation reactionSilicon oxideManganese oxide

The invention belongs to the field of catalyst systems for synthesizing polyester, and provides a binary composite catalyst for preparing biodegradable copolyester. The binary composite catalyst is a binary system consisting of organometallic compounds chosen from cobalt, aluminum, calcium, titanium, magnesium and zinc, and metal oxides chosen from titanium oxide, molybdenum oxide, tin oxide, magnesium oxide, calcium oxide, zinc oxide, manganese oxide, aluminum oxide, silicon oxide, germanium oxide and antimony oxide, and mol ratio of the organometallic compounds to the metal oxides is 1:9-9:1. The catalyst is applicable to preparing aliphatic / aromatic poly (butylene succinate-co-terephthalate), and the binary composite catalyst can effectively inhibit side reactions, and improve polycondensation reaction efficiency and molecular weight of the product.

Owner:DONGHUA UNIV

Low dielectric constant porous films

ActiveUS20050215065A1Low dielectric constantImprove electricityPlastic/resin/waxes insulatorsSemiconductor/solid-state device manufacturingSilicon oxideBoron oxide

A porous dielectric film for use in electronic devices is disclosed that is formed by removal of soluble nano phase porogens. A silicon based dielectric film having soluble porogens dispersed therein is prepared by chemical vapor deposition (CVD) or by spin on glass (S.O.G.). Examples of preferable porogens include compounds such as germanium oxide (GeO2) and boron oxide (B2O3). Hot water can be used in processing to wet etch the film, thereby removing the porogens and providing the porous dielectric film. The silicon based dielectric film may be a carbon doped silicon oxide in order to further reduce the dielectric constant of the film. Additionally, the porous dielectric film may be treated by an electron beam to enhance the electrical and mechanical properties of the film.

Owner:APPLIED MATERIALS INC

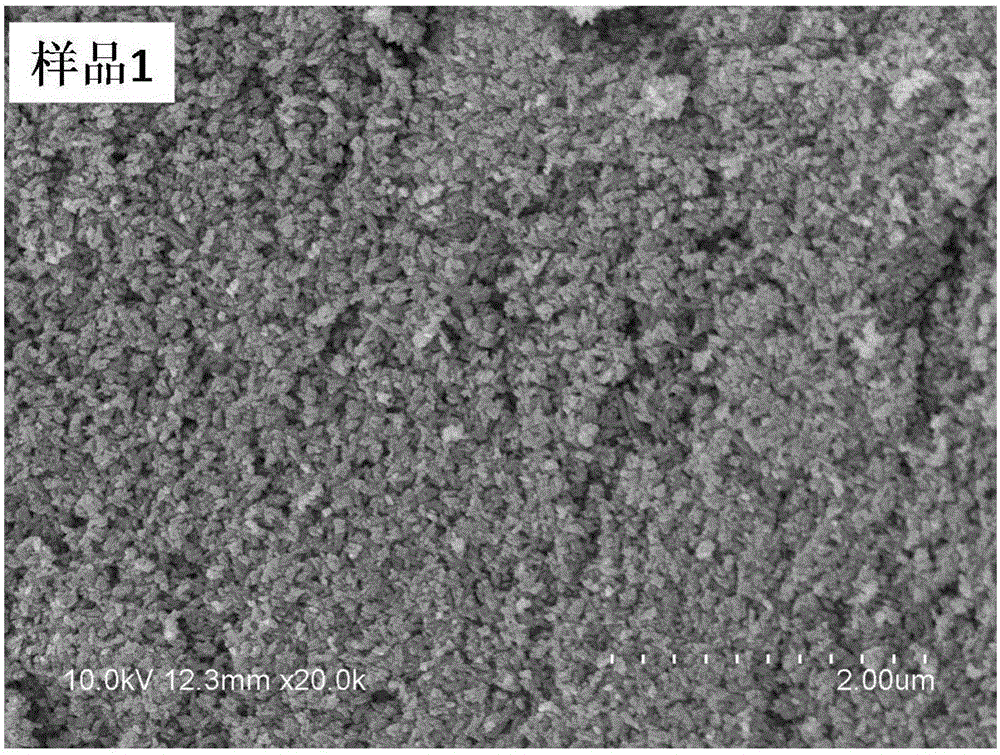

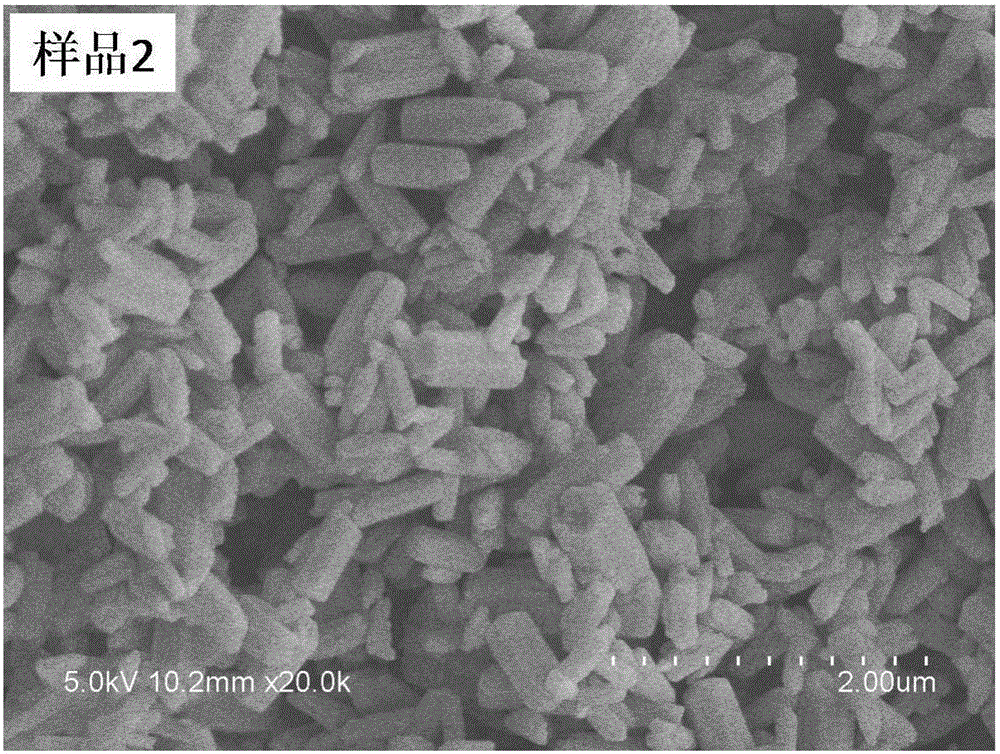

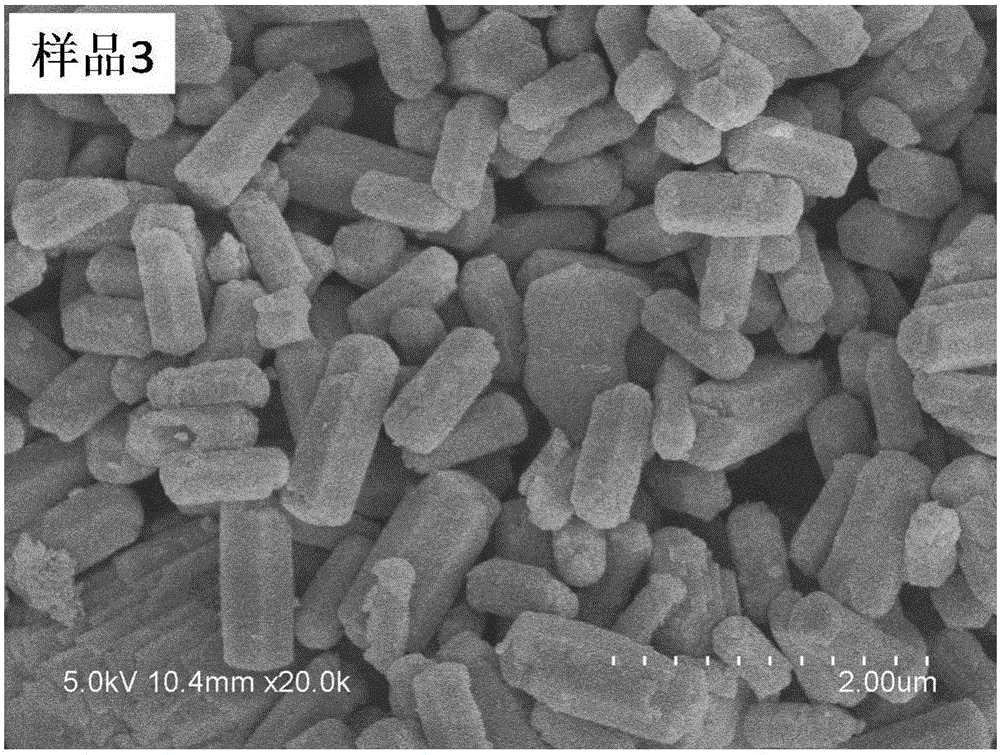

Hydrothermal preparation method of rod-like zinc germanate with adjustable size

InactiveCN106186049AMeet the special needs of the sizeHigh yieldGermanium compoundsZinc germanateSodium germanate

The invention discloses a hydrothermal preparation method of rod-like zinc germanate with an adjustable size. The hydrothermal preparation method comprises the following steps: (1) preparing a precursor: mixing sodium carbonate and germanium oxide solid powder at the mol ratio of 1 to 1; calcining under the condition that the temperature is 700 DEG C to 1000 DEG C for 8h to 24h to prepare sodium germanate solid powder; (2) taking the sodium germanate as a germanium source and adding amino acid into a sodium germanate solution, wherein the adding mol ratio of the sodium germanate to the amino acid is 1 to (0.5 to 5); uniformly stirring a mixed solution under the condition of 40 DEG C to 80 DEG C; (3) adding a zinc acetate solution into the mixed solution of the step (2), wherein the adding mol ratio of zinc acetate to the sodium germanate is 1 to 1; loading the mixed solution into a reaction kettle and carrying out a hydrothermal reaction for 3h to 12h under the condition that the temperature is 120 DEG C to 200 DEG C; washing a product with water until the product is neutral; drying under reduced pressure, and grinding to prepare the rod-like zinc germanate. The hydrothermal preparation method is simple and convenient to operate; a sodium germanate nano-rod has an adjustable size, can be synthesized in a large batch and is low in cost.

Owner:NANJING UNIV

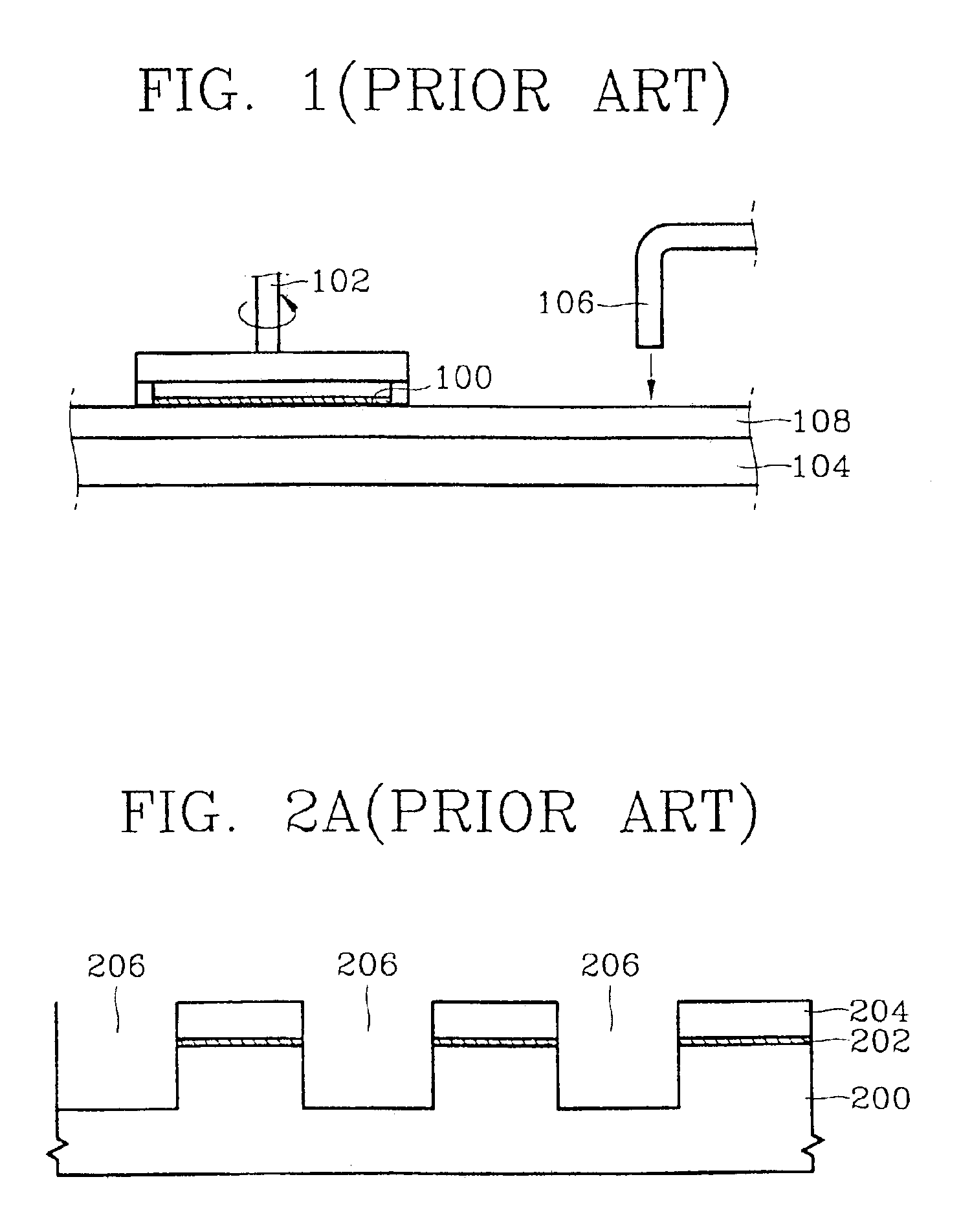

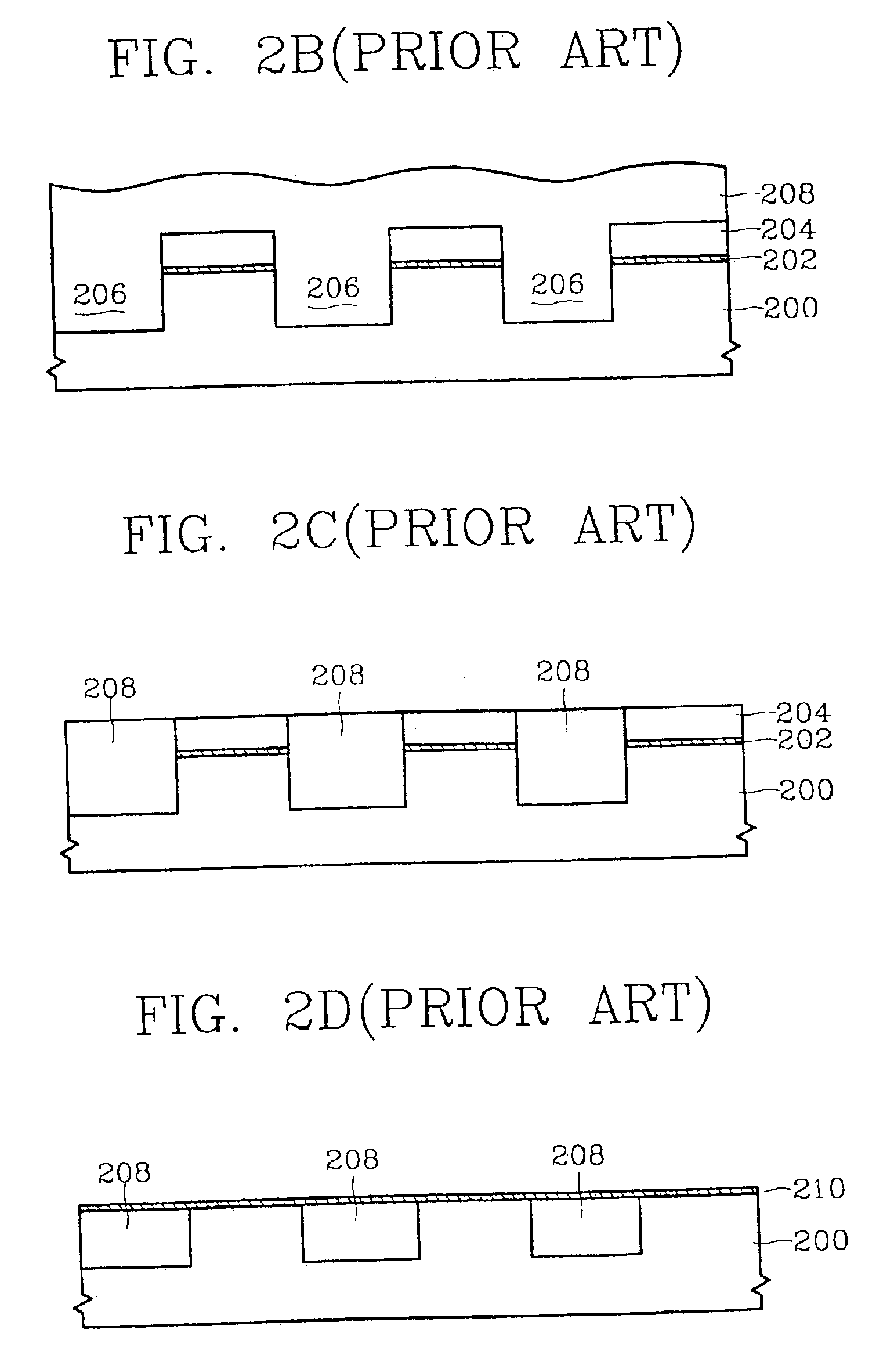

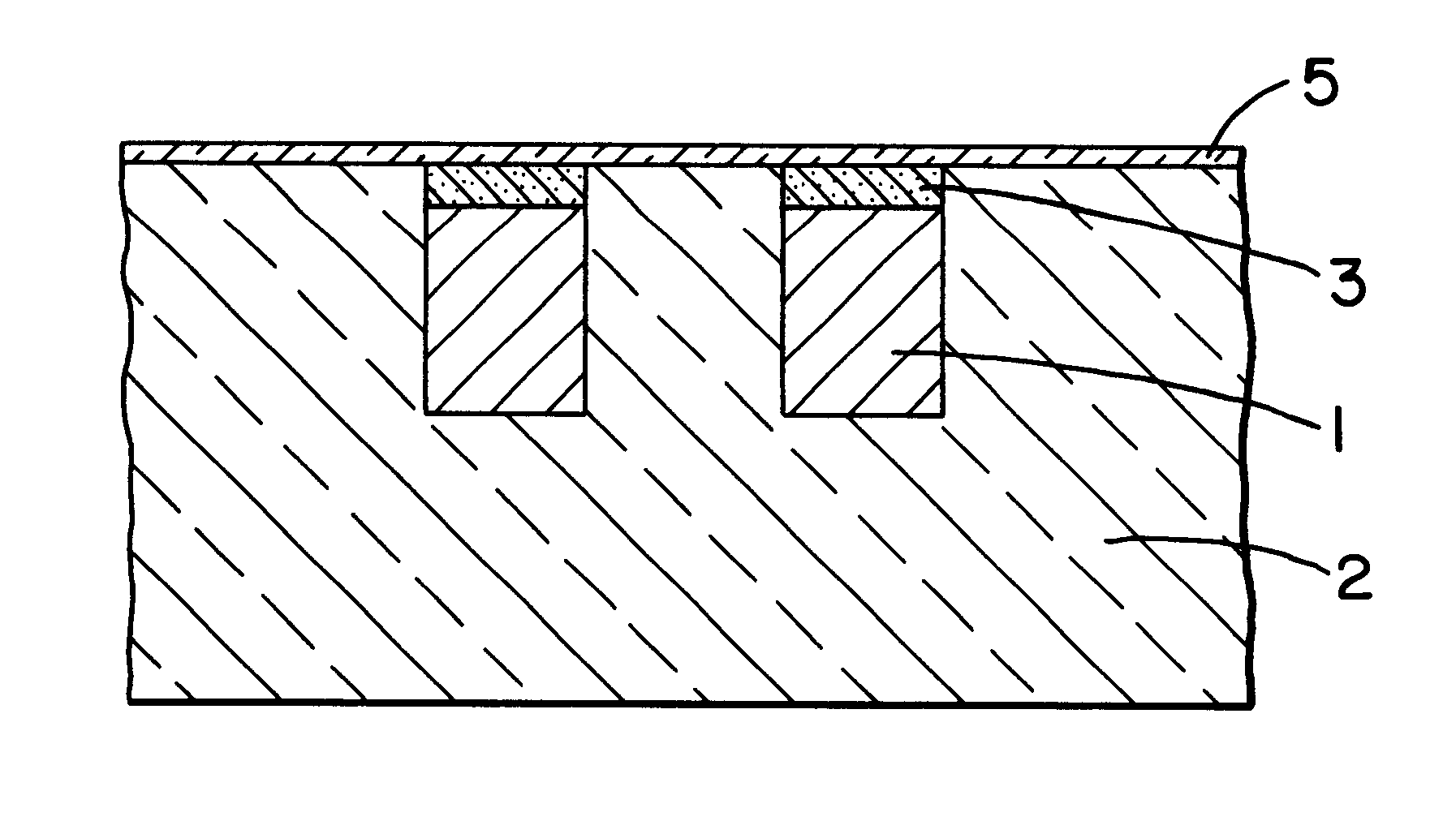

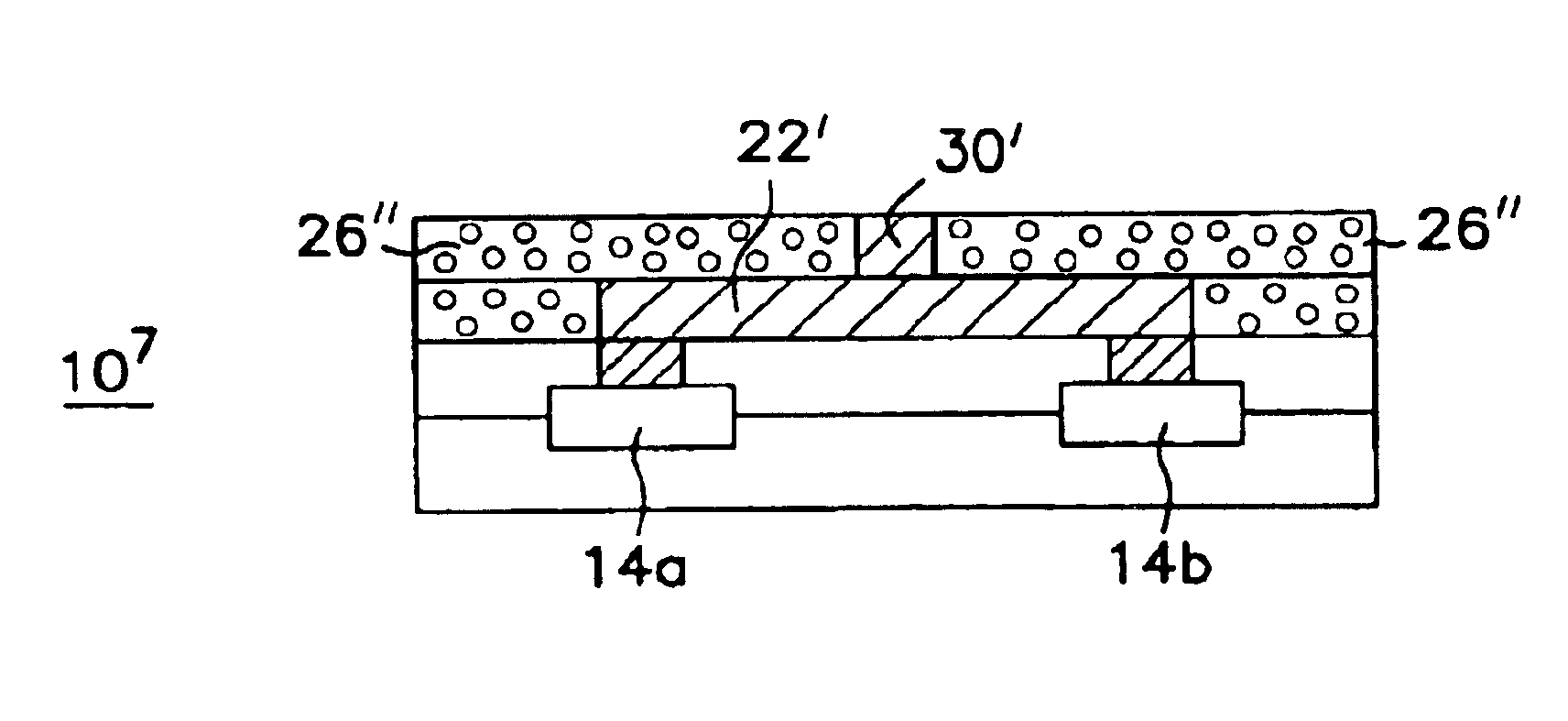

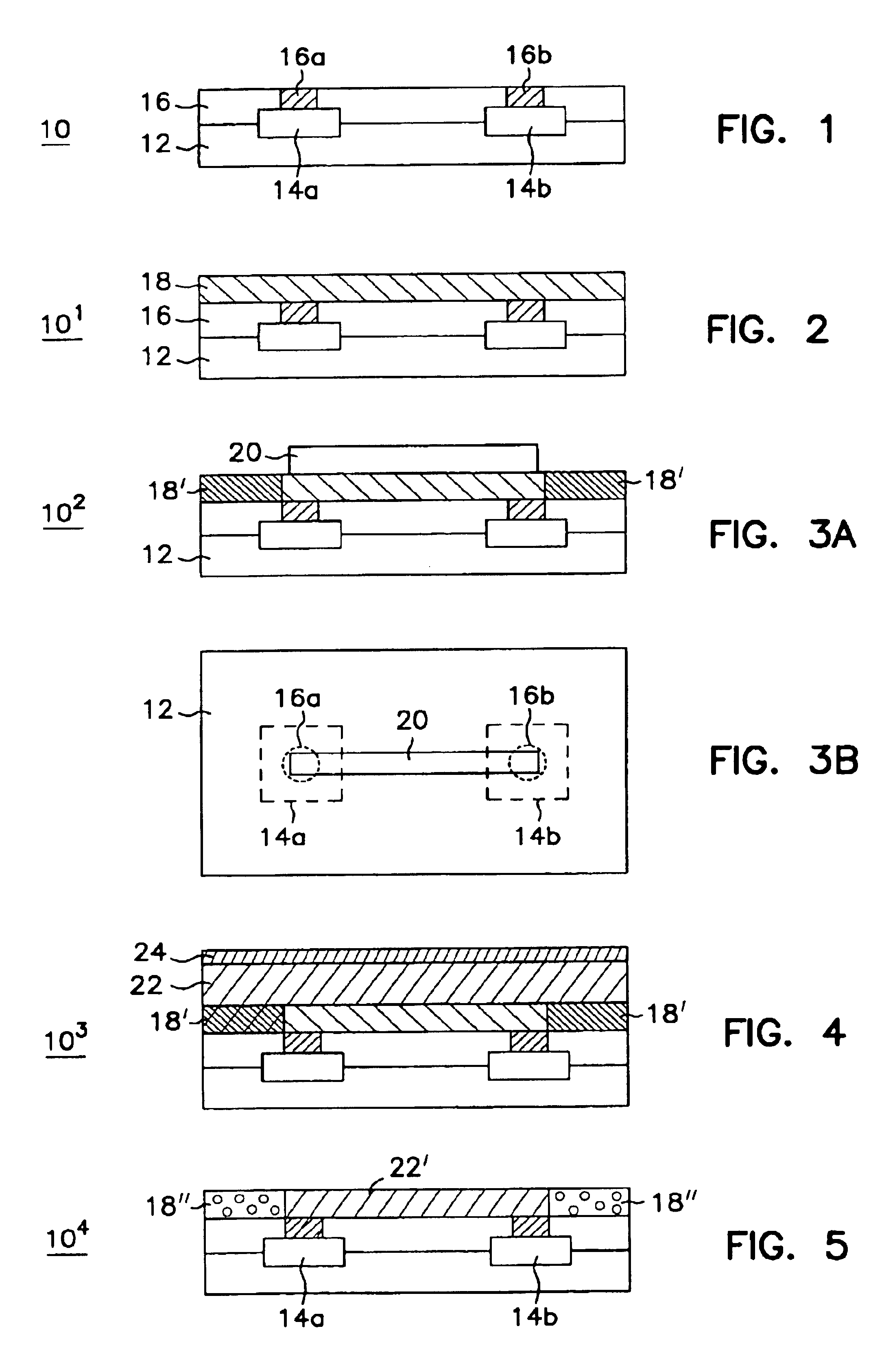

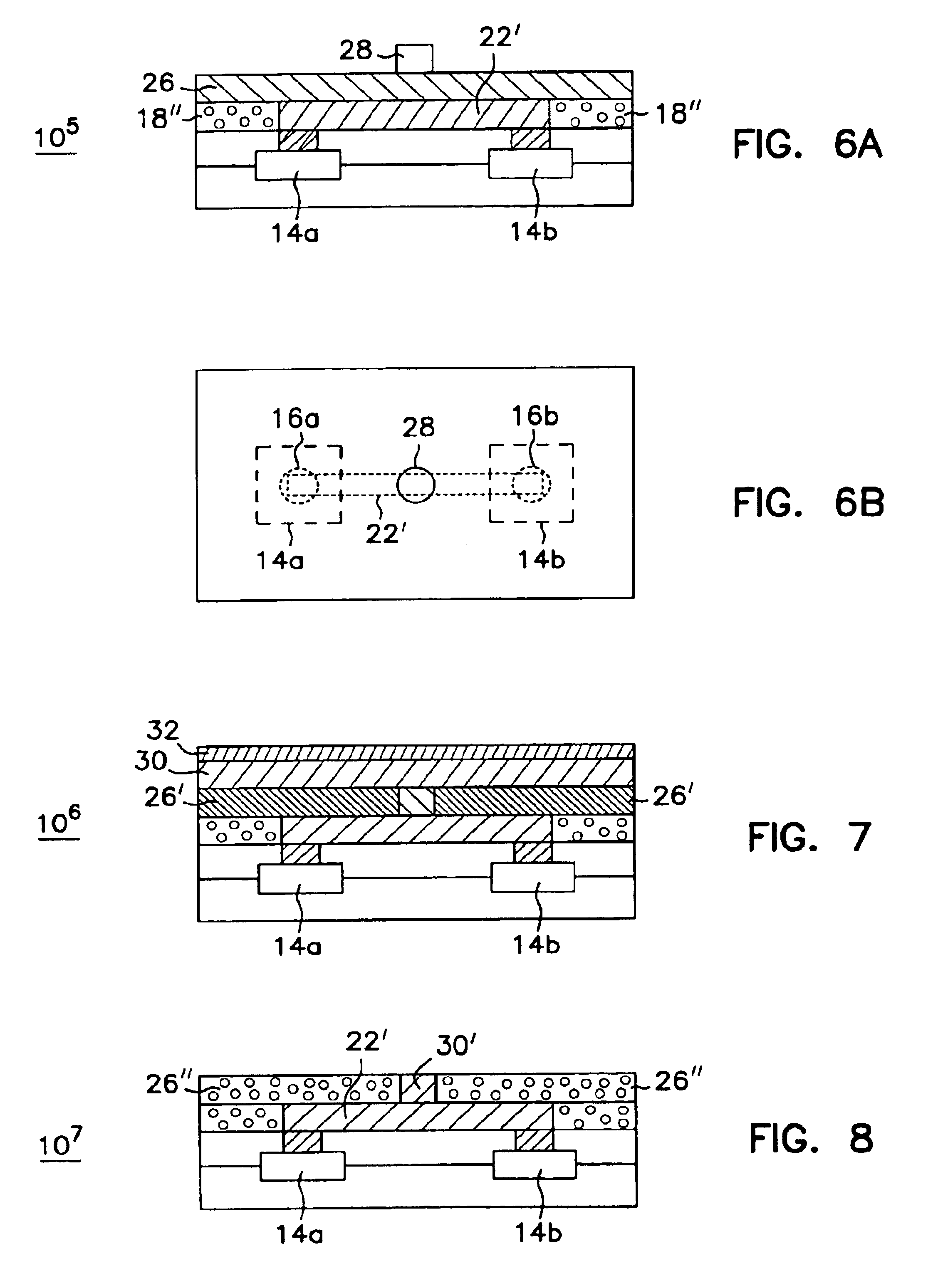

Methods and structures for metal interconnections in integrated circuits

InactiveUS6879017B2Time-consuming to eliminateEliminates trench-digging stepSemiconductor/solid-state device detailsSolid-state devicesCapacitanceMetal interconnect

A typical integrated-circuit fabrication requires interconnecting millions of microscopic transistors and resistors with metal wires. Making the metal wires flush, or coplanar, with underlying insulation requires digging trenches in the insulation, and then filling the trenches with metal to form the wires. The invention provides a new “trench-less” or “self-planarizing” method of making coplanar metal wires. Specifically, one embodiment forms a first layer that includes silicon and germanium; oxidizes a region of the first layer to define an oxidized region and a non-oxidized region; and reacts aluminum or an aluminum alloy with the non-oxidized region. The reaction substitutes, or replaces, the non-oxidized region with aluminum to form a metallic wire coplanar with the first layer. Another step removes germanium oxide from the oxidized region to form a porous insulation having a very low dielectric constant, thereby reducing capacitance.

Owner:ROUND ROCK RES LLC

Germanium Field Effect Transistors and Fabrication Thereof

ActiveUS20100237444A1Easy to useTransistorSemiconductor/solid-state device manufacturingOptoelectronicsField-effect transistor

Germanium field effect transistors and methods of fabricating them are described. In one embodiment, the method includes forming a germanium oxide layer over a substrate and forming a metal oxide layer over the germanium oxide layer. The germanium oxide layer and the metal oxide layer are converted into a first dielectric layer. A first electrode layer is deposited over the first dielectric layer.

Owner:TAIWAN SEMICON MFG CO LTD

Preparation method of germanium-doped high-energy-density lithium cobaltate composite positive material

ActiveCN103872315AIncrease energy densityImprove conductivityCell electrodesSecondary cellsLithium oxideHigh energy

The invention relates to a preparation method of a germanium-doped high-energy-density lithium cobaltate composite positive material. The chemical formula of the germanium-doped composite lithium cobaltate is as follows: LiCo<1-x-y-z>Mgx AlyGezO2, wherein x is 0.22 to 0.3, y is 0.15 to 0.25, and z is 0.035 to 0.05. The method comprises the following steps of (1) preparing high-density spherical cobaltosic oxide; (2) smelting lithium oxide, cobaltosic oxide, aluminum oxide, magnesium oxide and germanium oxide, cooling, ball milling the mixture, and sintering the mixture to obtain a precursor of the germanium-doped lithium cobaltate composite positive material; and (3) mixing the precursor and a mixture of acetylene black and phenolic resin to be sintered to obtain a product. According to the prepared germanium-doped lithium cobaltate composite positive material, the high-purity high-density cobaltosic oxide is adopted as a raw material, so that the energy density of the composite material is improved; the Ge is doped while Al and Mg are doped so as to improve the activity and stability of the substances, and carbon cladding is also adopted in the preparation process, so that the conductivity and stability of the material can be improved.

Owner:深圳市天劲新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com