Binary composite catalyst for preparing biodegradable copolyester

A binary composite and catalyst technology, applied in the field of catalyst systems, can solve the problems of easy hydrolysis failure, slow polymerization reaction speed, low molecular weight of products, etc., and achieve the effects of improving polycondensation reaction efficiency, good thermal stability and shortening reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

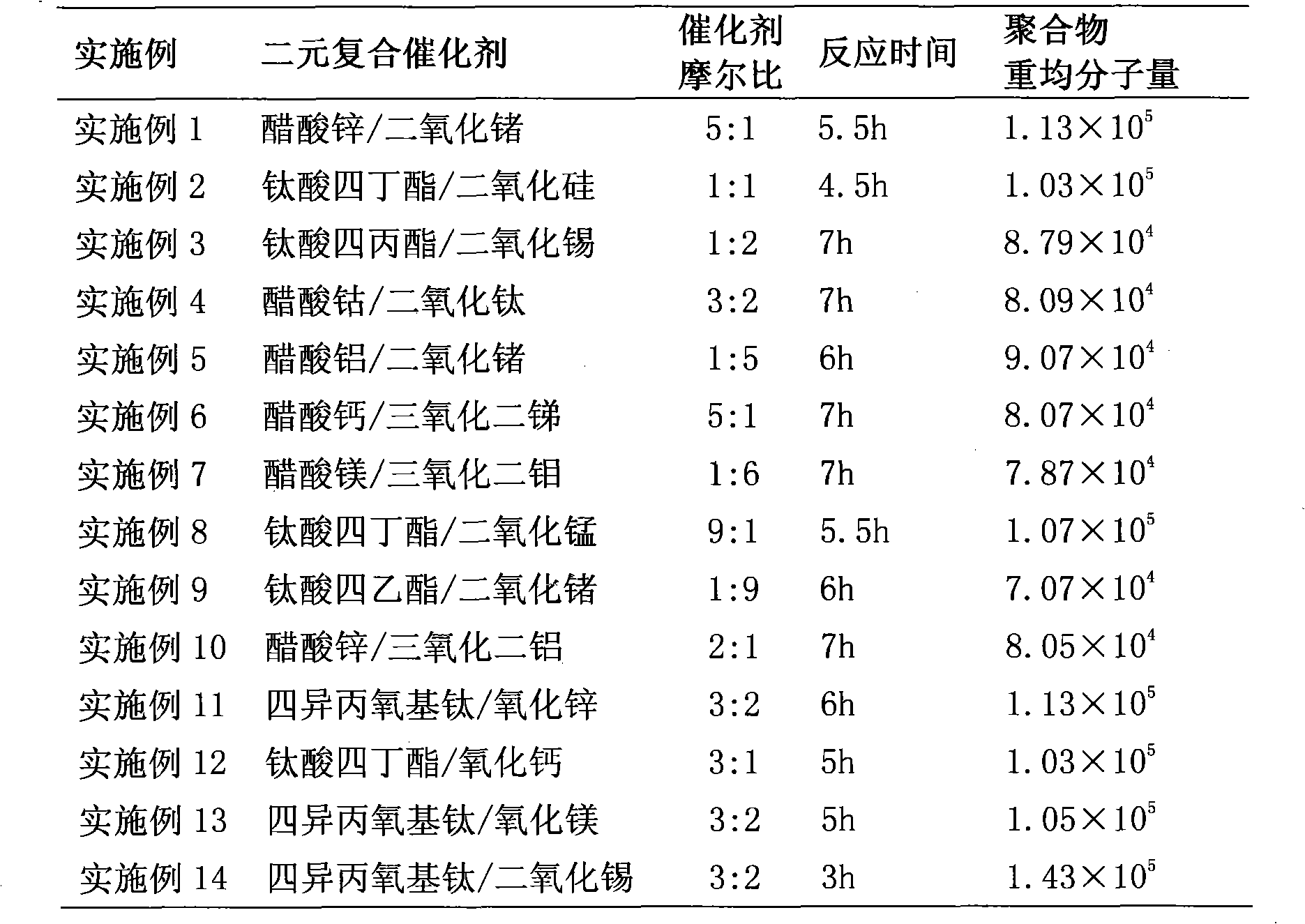

Examples

Embodiment 1

[0020] Under the protection of nitrogen, put 0.7mol terephthalic acid, 0.3mol succinic acid and 1.5mol 1,4-butanediol into the reaction kettle, stir slowly to make it a paste, then add 0.50mmol zinc acetate and 0.20 mmol of germanium dioxide, the temperature was gradually raised to 220°C, the stirring rate was 100rpm, the pressure of the reaction system was adjusted to 70kPa, and the esterification reaction was carried out while maintaining the temperature and pressure, and the reaction time was 1.5h. After the esterification is completed, enter the polycondensation stage, raise the temperature to 235 ° C, adjust the reaction pressure, and proceed in two stages. The first stage is the pre-condensation stage, the vacuum is 30kPa, and the time is 1h, and then slowly transition into the second stage , That is, the high vacuum stage, the vacuum degree is 30Pa, the reaction time is 3h, and the PBST copolyester is obtained.

[0021] The weight average molecular weight measured by GP...

Embodiment 2

[0023] Under the protection of nitrogen, put 0.7mol terephthalic acid, 0.3mol succinic acid and 1.5mol 1,4-butanediol into the reaction kettle, stir slowly to make it a paste, and then add 0.30mmol tetrabutyl titanate Ester and 0.30mmol of silicon dioxide, the temperature is gradually raised to 220°C, the stirring rate is 100rpm, the pressure of the reaction system is adjusted to 70kPa, and the esterification reaction is carried out at this temperature and pressure, and the reaction time is 1.5h. After the esterification is completed, enter the polycondensation stage, raise the temperature to 235 ° C, adjust the reaction pressure, and proceed in two stages. The first stage is the pre-condensation stage, the vacuum is 30kPa, and the time is 1h, and then slowly transition into the second stage , That is, the high vacuum stage, the vacuum degree is 30Pa, the reaction time is 2h, and the PBST copolyester is obtained.

[0024] The weight average molecular weight measured by GPC met...

Embodiment 3

[0026] Under the protection of nitrogen, put 0.7mol terephthalic acid, 0.3mol succinic acid and 1.5mol 1,4-butanediol into the reaction kettle, stir slowly to make it into a paste, and then add 0.20mmol tetrapropylene titanate Ester and 0.40mmol tin dioxide, the temperature was gradually raised to 220°C, the stirring rate was 100rpm, the pressure of the reaction system was adjusted to 70kPa, and the esterification reaction was carried out at this temperature and pressure, and the reaction time was 2h. After the esterification is completed, enter the polycondensation stage, raise the temperature to 235 ° C, adjust the reaction pressure, and proceed in two stages. The first stage is the pre-condensation stage, the vacuum is 30kPa, and the time is 1h, and then slowly transition into the second stage , That is, the high vacuum stage, the vacuum degree is 30Pa, the reaction time is 4h, and the PBST copolyester is obtained.

[0027] The weight average molecular weight measured by GP...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com