Hydrothermal preparation method of rod-like zinc germanate with adjustable size

A zinc germanate, rod-shaped technology, applied in the field of hydrothermal preparation of rod-shaped zinc germanate, to achieve the effect of mild conditions, high specific surface area, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

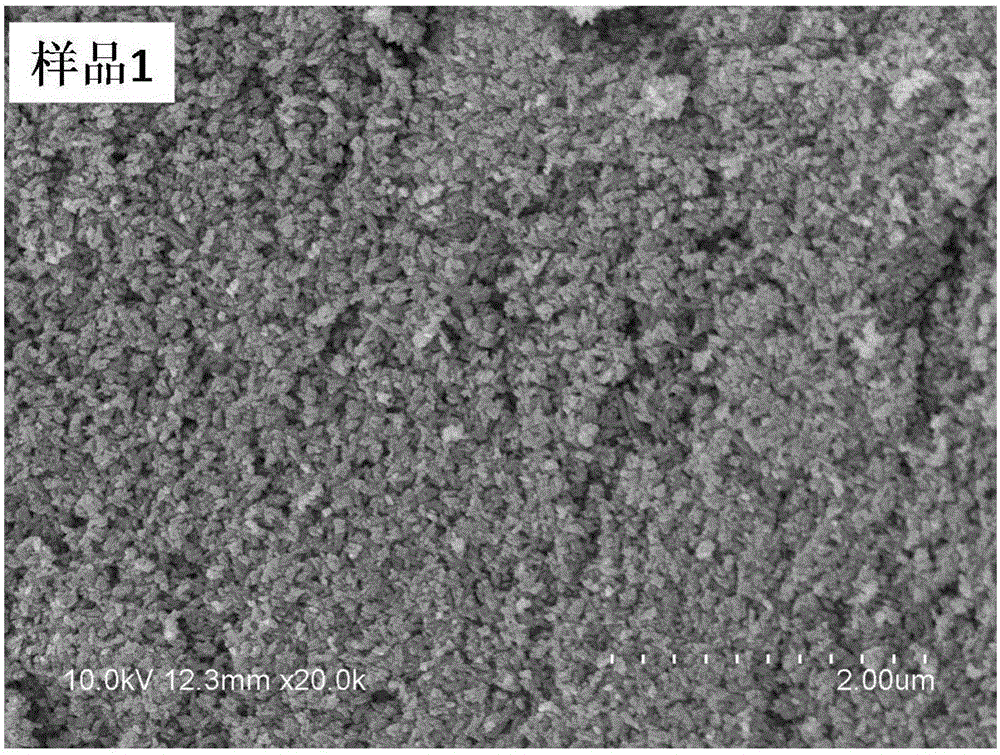

Embodiment 1

[0026] The invention provides a hydrothermal preparation method of rod-shaped zinc germanate with adjustable size, comprising the following steps:

[0027] (1) Precursor preparation: Mix sodium carbonate and germanium oxide solid powder at a molar ratio of 1:1, grind for 30 at room temperature, place the mixture in a muffle furnace, heat up to 700°C at room temperature through 70°C, and keep warm After 8 hours, rapid decompression cooling, the obtained sodium germanate solid was further ground for 60 minutes;

[0028] (2) Using sodium germanate as the source of germanium, make it into a sodium germanate solution with a concentration of 0.01mol / L, and use arginine as a surfactant to add it to the sodium germanate solution, wherein the sodium germanate The molar ratio to arginine is 1:0.5; the mixed solution is placed at 40°C and stirred evenly;

[0029] (3) Using zinc acetate dihydrate as the zinc source, it is made into a zinc acetate solution with a concentration of 0.01mol / ...

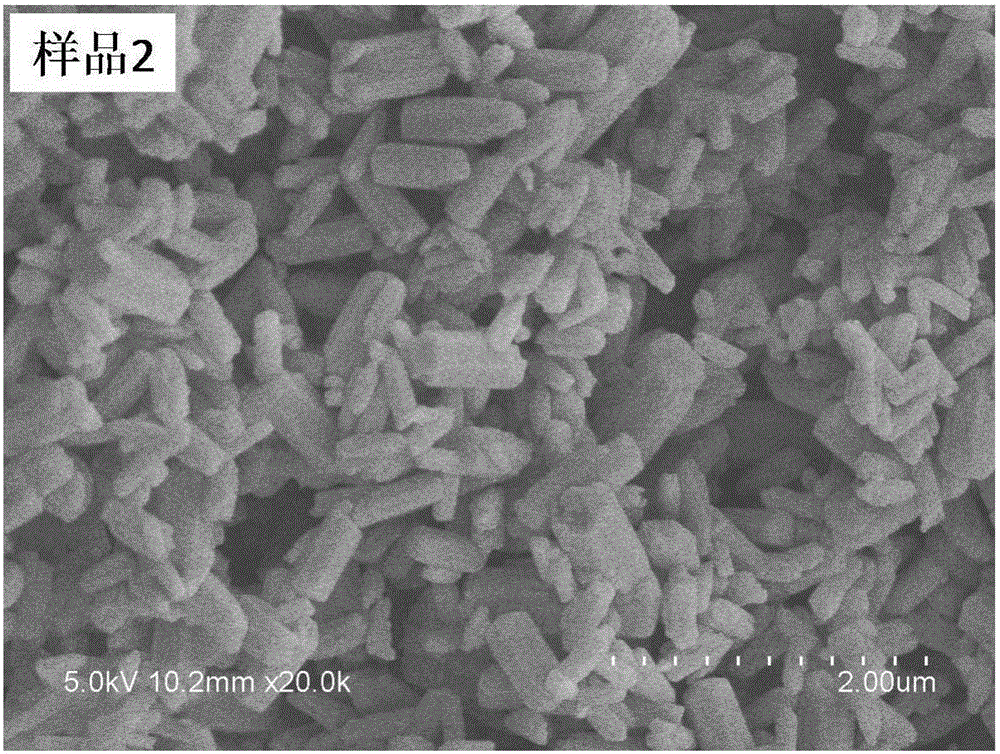

Embodiment 2

[0033] The difference between embodiment 2 and embodiment 1 is:

[0034] (1) Precursor preparation: mix sodium carbonate and germanium oxide solid powder at a molar ratio of 1:1, grind for 40 minutes at room temperature, place the mixture in a muffle furnace, heat up to 800°C after 80 minutes at room temperature, and keep warm After 12 hours, rapid decompression cooling, the obtained sodium germanate solid was further ground for about 40 minutes;

[0035] (2) Using sodium germanate as the source of germanium, make it into a sodium germanate solution with a concentration of 0.02mol / L, and use tyrosine as a surfactant to add it to the sodium germanate solution, wherein the sodium germanate The molar ratio to tyrosine is 1:2; put the mixed solution at 50°C and stir evenly;

[0036] (3) Using zinc acetate dihydrate as the zinc source, it is made into a zinc acetate solution with a concentration of 0.02mol / L, and the zinc acetate solution is added to the mixed solution in step (2)...

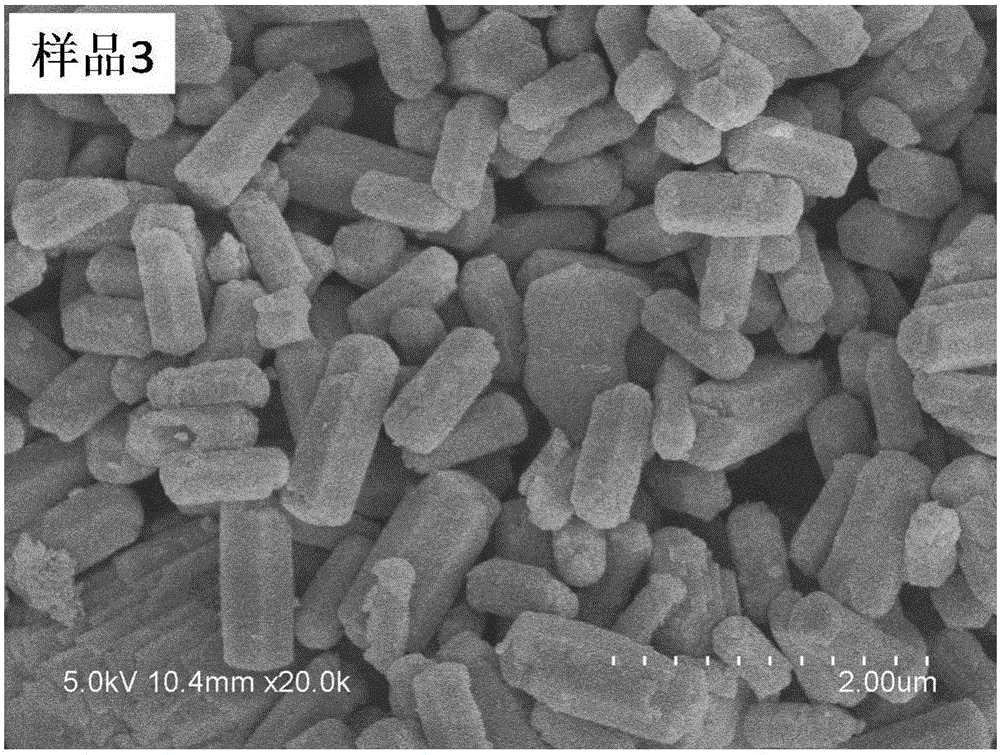

Embodiment 3

[0040] The difference between embodiment 3 and embodiment 1 is:

[0041] (1) Precursor preparation: Mix sodium carbonate and germanium oxide solid powder at a molar ratio of 1:1, grind for 50 minutes at room temperature, place the mixture in a muffle furnace, heat up to 900°C after 90 minutes at room temperature, and keep warm After 16 hours, rapid cooling under reduced pressure, the obtained sodium germanate solid was further ground for about 50 minutes;

[0042] (2) Using sodium germanate as the germanium source, make it into a sodium germanate solution with a concentration of 0.04mol / L, use tryptophan as a surfactant, add it to the sodium germanate solution, wherein sodium germanate The molar ratio to tryptophan is 1:3; the mixed solution is placed at 60°C and stirred evenly;

[0043] (3) Using zinc acetate dihydrate as the zinc source, it is made into a zinc acetate solution with a concentration of 0.05mol / L, and the zinc acetate solution is added to the mixed solution in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com