Photovoltaic application of amorphous germanium thin film

A technology of amorphous germanium and amorphous silicon germanium, applied in the field of multi-junction photovoltaic devices based on amorphous silicon, can solve the problems of high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

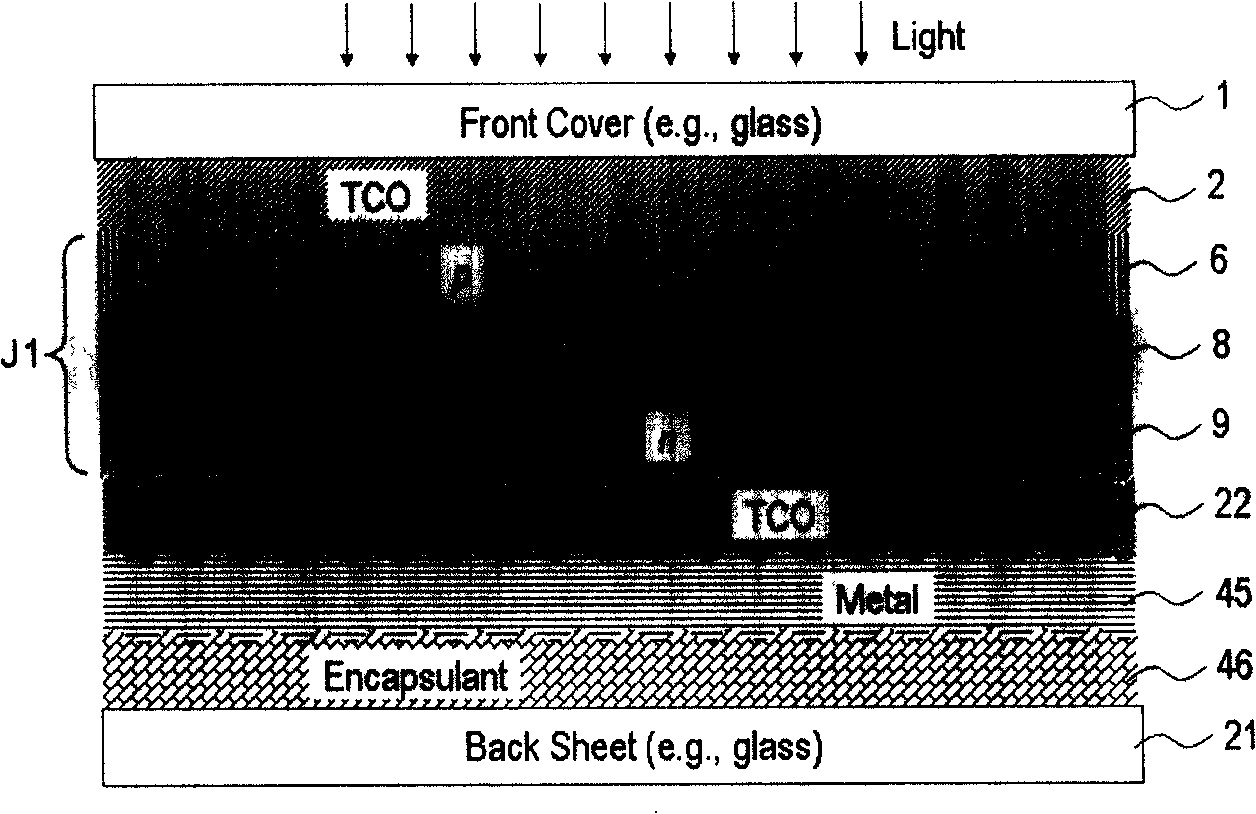

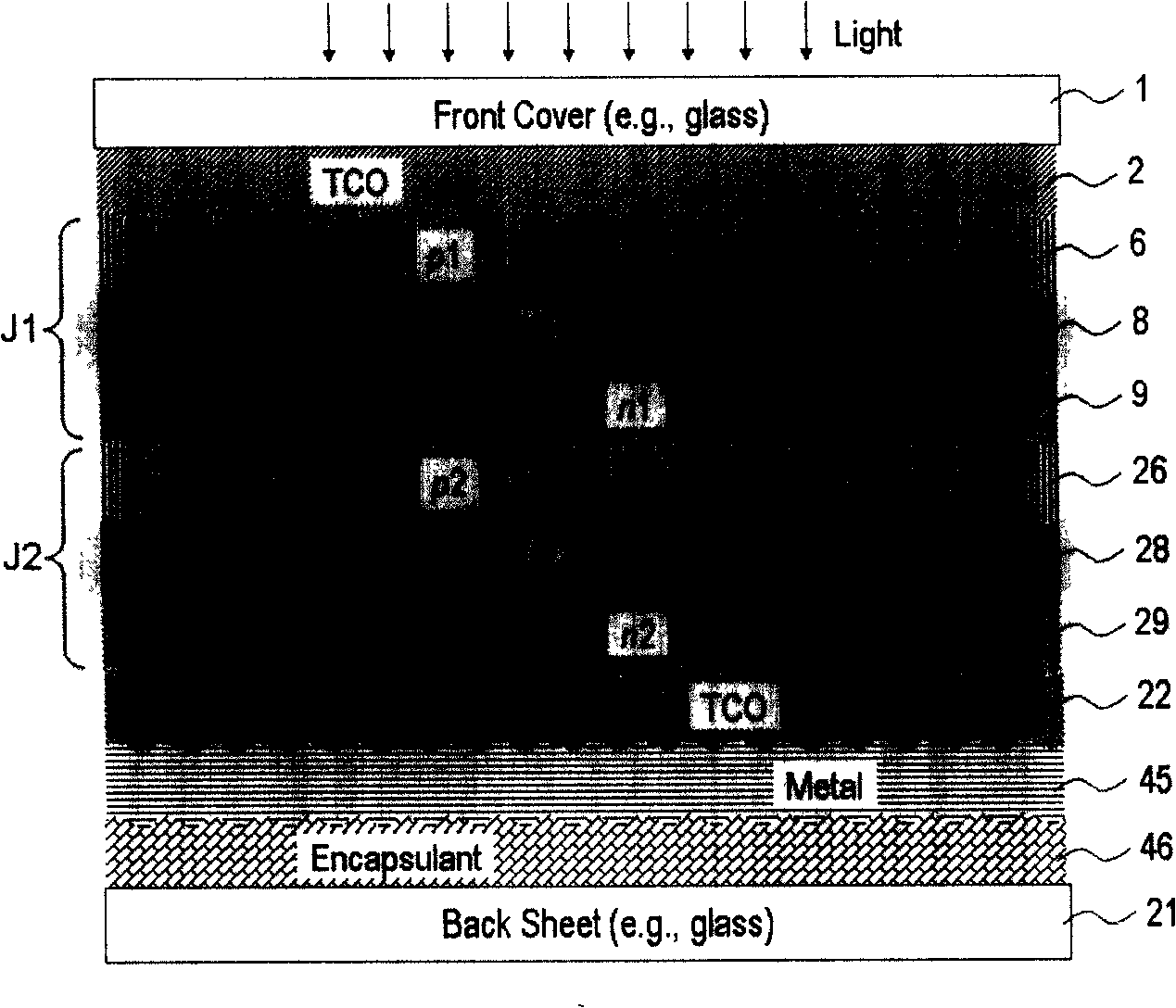

[0034] like Figure 4 As shown, the first example is a triple-junction photovoltaic cell, and its detailed film structure is as follows Image 6 shown. The triple-junction photovoltaic cell includes a top junction J1 made of amorphous silicon, a middle junction J2 made of nanocrystalline silicon and a bottom junction J3 made of amorphous silicon germanium (a-Si / nc-Si / a-Ge). They are also called the first knot, the second knot and the third knot respectively, and represent Image 6 The p-i-n sequences 6-8-9, 26-28-29 and 36-38-39 in . The advantage of this combination of different intrinsic layers is that each photovoltaic cell can be produced relatively quickly. The intrinsic layer 8 of amorphous silicon of the top junction J1 is only 700nm thick and can be easily deposited, and it is used to absorb blue light. The nanocrystalline silicon intrinsic layer 28 of the second junction cell J2 needs to absorb green light and some red light to generate enough photocurrent to coop...

Embodiment 2

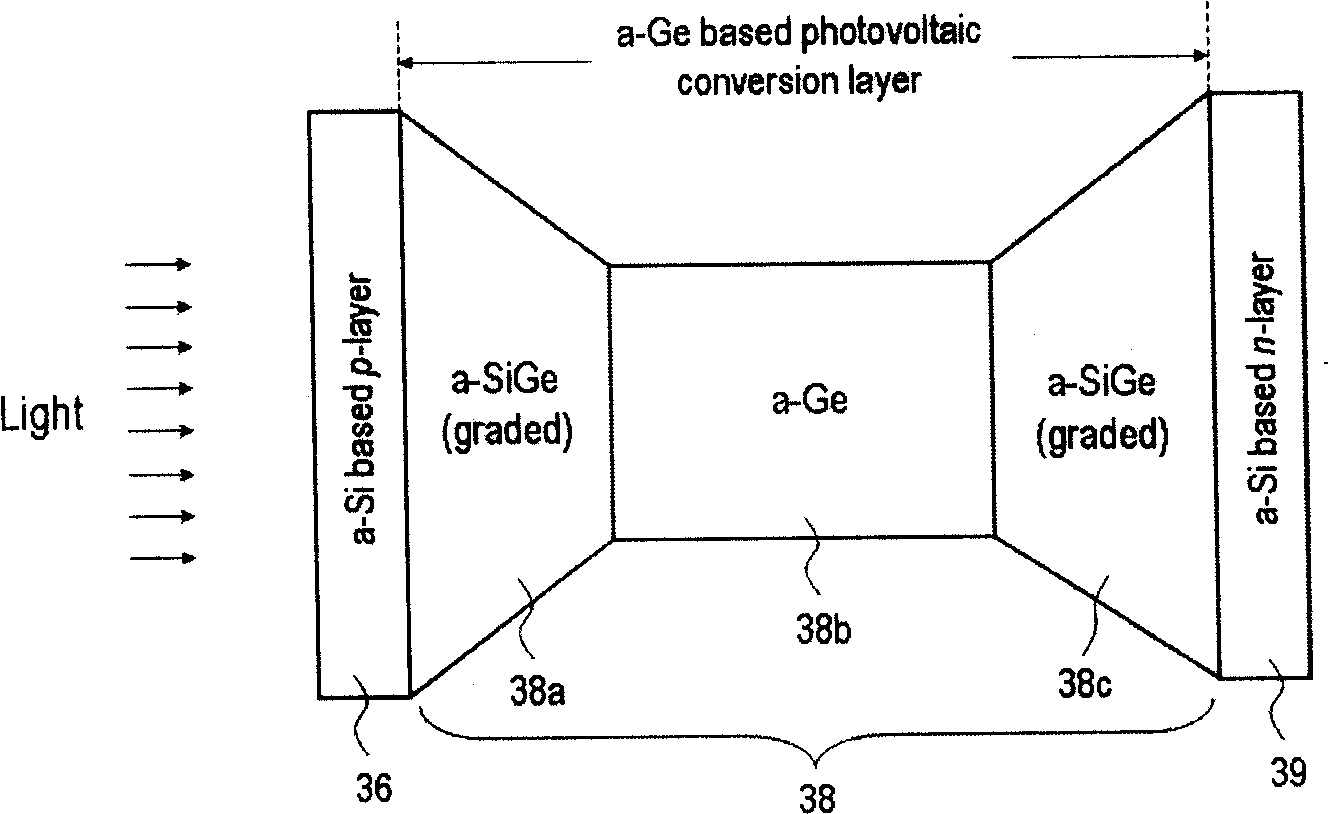

[0037] Figure 5 is another example of a triple junction photovoltaic cell where the third junction (bottom junction) contains an intrinsic layer of amorphous germanium. The detailed film structure of the device is as follows Figure 7 shown. It includes an interlayer R1 made of transparent conductive oxide (TCO) ZnO, placed between the second junction J2 and the third junction J3. The p-i-n configurations of photovoltaic units J1, J2 and J3 are 6-8-9, 26-28-29, 36-38-39 respectively, such as Figure 7 shown. Mezzanine R1 (such as Figure 7 32) has the effect of generating an abrupt index of refraction at the interface between the silicon-based thin film and the TCO, so that unabsorbed light is reflected into the second junction photovoltaic cell J2. The first junction and the second junction of the device described in this example are made of amorphous silicon with an energy band gap between 1.8-1.7eV, while the third junction is made of amorphous germanium and related b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com