Patents

Literature

62 results about "Amorphous silicon germanium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lamination solar battery

ActiveCN104979421AWide spectral response rangeAct as a barrierPhotovoltaic energy generationSemiconductor devicesUltraviolet lightsNanocrystalline silicon

The invention relates to a lamination solar battery. The lamination solar battery is composed of an amorphous silicon film top battery, a perovskite middle battery and a nanocrystalline silicon bottom battery, or has a double-lamination structure taking an amorphous silicon film battery as a top battery and a perovskite battery as a bottom battery. The optical band gaps of three materials, i.e., amorphous silicon, perovskite and nanocrystalline silicon (crystalline silica) match well (1.75eV, 1.5eV and 1.12eV) so that light of different wavebands can be absorbed segment by segment. The amorphous silicon film top battery and the nanocrystalline silicon bottom battery (or the crystalline silica, nanocrystalline silicon germanium and amorphous silicon germanium) clamp the perovskite therebetween so as to protect the perovskite battery and reduce the influence exerted by atmosphere and water on the perovskite battery. At the same time, the amorphous silicon top battery can absorb ultraviolet light so as to protect a perovskite sub-battery. Besides, an amorphous silicon layer at the top has better UV and blue light response than the perovskite battery so that the defects of the perovskite middle battery are made up for.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Flexible photovoltaic integrated power supply system

ActiveCN103280846ASmall additional weightIncreased power-to-weight ratioBatteries circuit arrangementsSecondary cellsIndiumElectrical battery

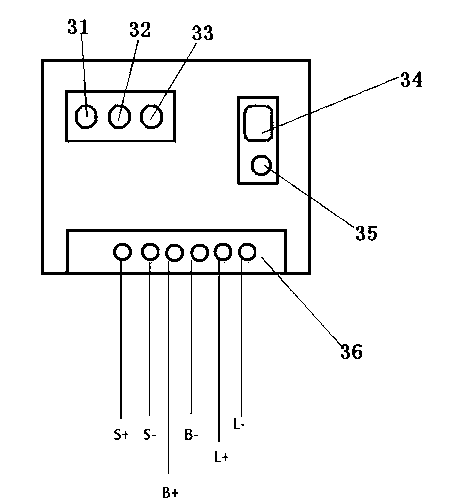

The invention discloses a flexible photovoltaic integrated power supply system. The power supply system comprises a physical power supply, a chemical power supply and a power supply controller. Solar energy is converted into electric energy through the physical power supply. A flexible thin film solar battery module is adopted and comprises an amorphous silicon thin film solar battery module, a microcrystalline silicon thin film solar battery module, an amorphous silicon-germanium thin film solar battery module, and a laminated solar battery module consisting of the amorphous silicon thin film solar battery module, the microcrystalline silicon thin film solar battery module and the amorphous silicon-germanium thin film solar battery module, or a copper-indium-gallium-selenium thin film solar battery module. The chemical power supply adopts a storage battery component which comprises a nickel-cadmium battery module, a nickel-hydrogen battery module, a lithium ion battery module, an alkaline-manganese charging battery module or a lead-acid storage battery module. The power supply controller is a solar power supply single output controller with the model of V-ST10, is respectively connected with the physical power supply, the chemical power supply and the load, and is used for regulating and controlling the physical power supply and the chemical power supply. The flexible photovoltaic integrated power supply system provided by the invention has the advantages of good flexibility, light weight, high intensity, good environment tolerance and the like.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

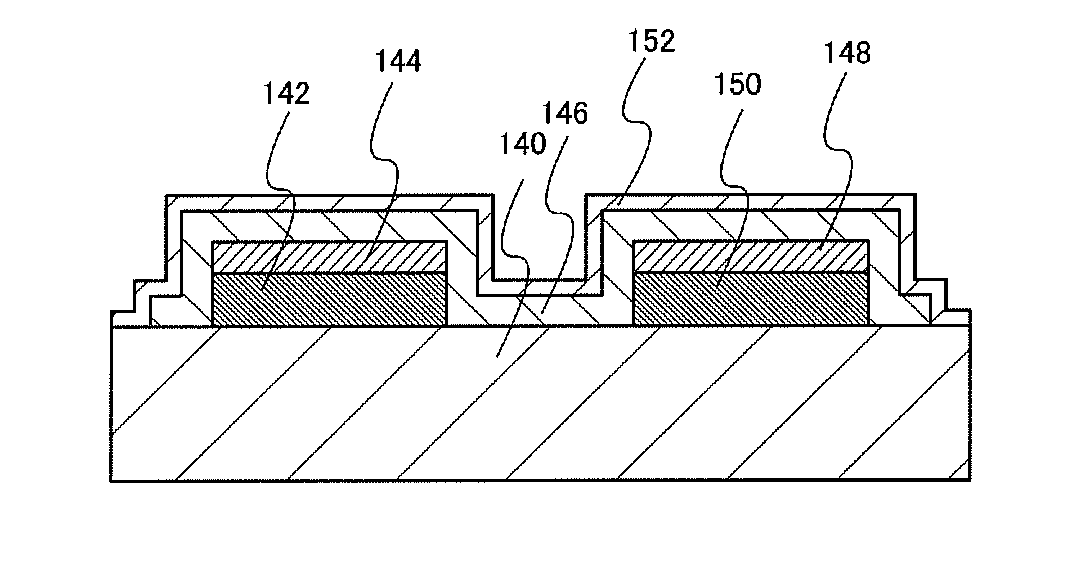

Redox capacitor and manufacturing method thereof

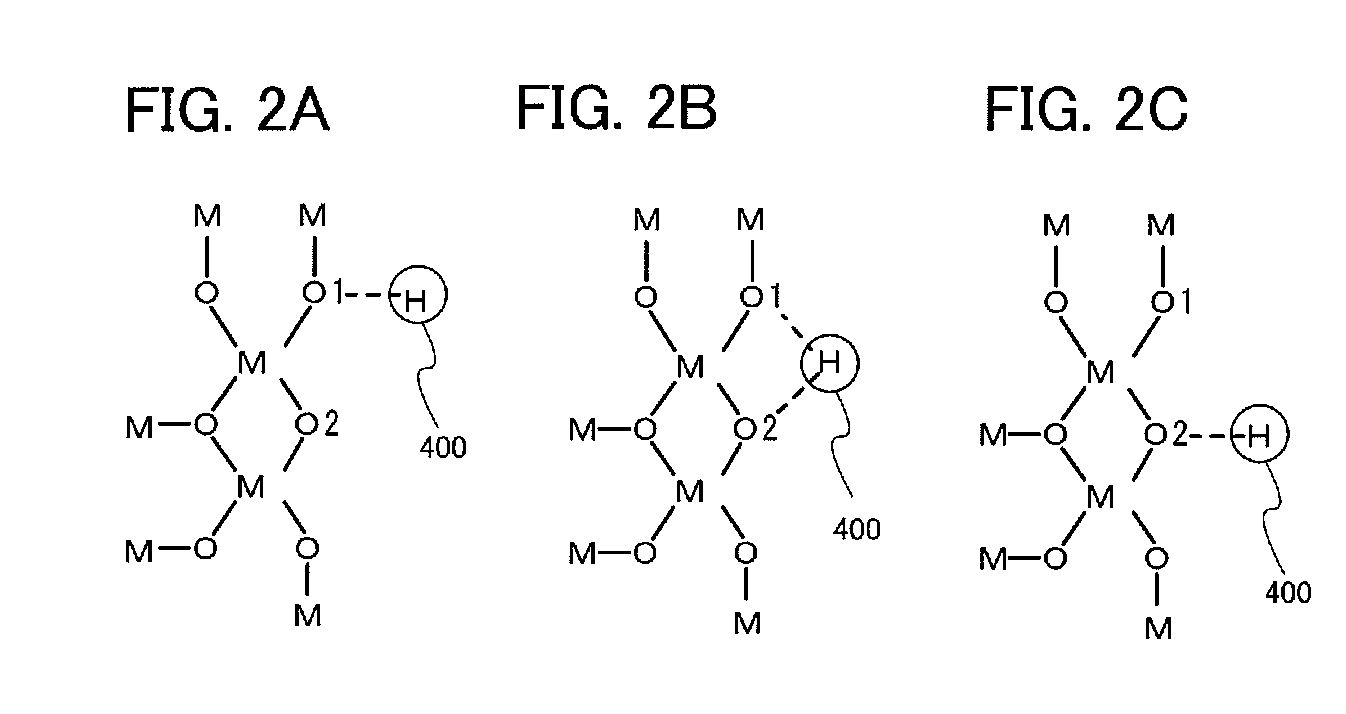

ActiveUS20110073991A1Simple structureIncrease the concentration of hydrogenHybrid capacitor electrolytesHybrid capacitor electrodesIndiumVanadium oxide

To provide a redox capacitor that can be used at room temperature and a manufacturing method thereof. Amorphous semiconductor including hydrogen is used as an electrolyte of a redox capacitor. As a typical example of the amorphous semiconductor including hydrogen, an amorphous semiconductor including a semiconductor element such as amorphous silicon, amorphous silicon germanium, or amorphous germanium can be used. As another example of the amorphous semiconductor including hydrogen, oxide semiconductor including hydrogen can be used. As typical examples of the oxide semiconductor including hydrogen, an amorphous semiconductor including a single-component oxide semiconductor such as zinc oxide, titanium oxide, nickel oxide, vanadium oxide, and indium oxide can be given. As another example of oxide semiconductor including hydrogen, a multi-component oxide semiconductor such as InMO3(ZnO)m (m>0 and M is one or more metal elements selected from Ga, Fe, Ni, Mn, and Co) can be used.

Owner:SEMICON ENERGY LAB CO LTD

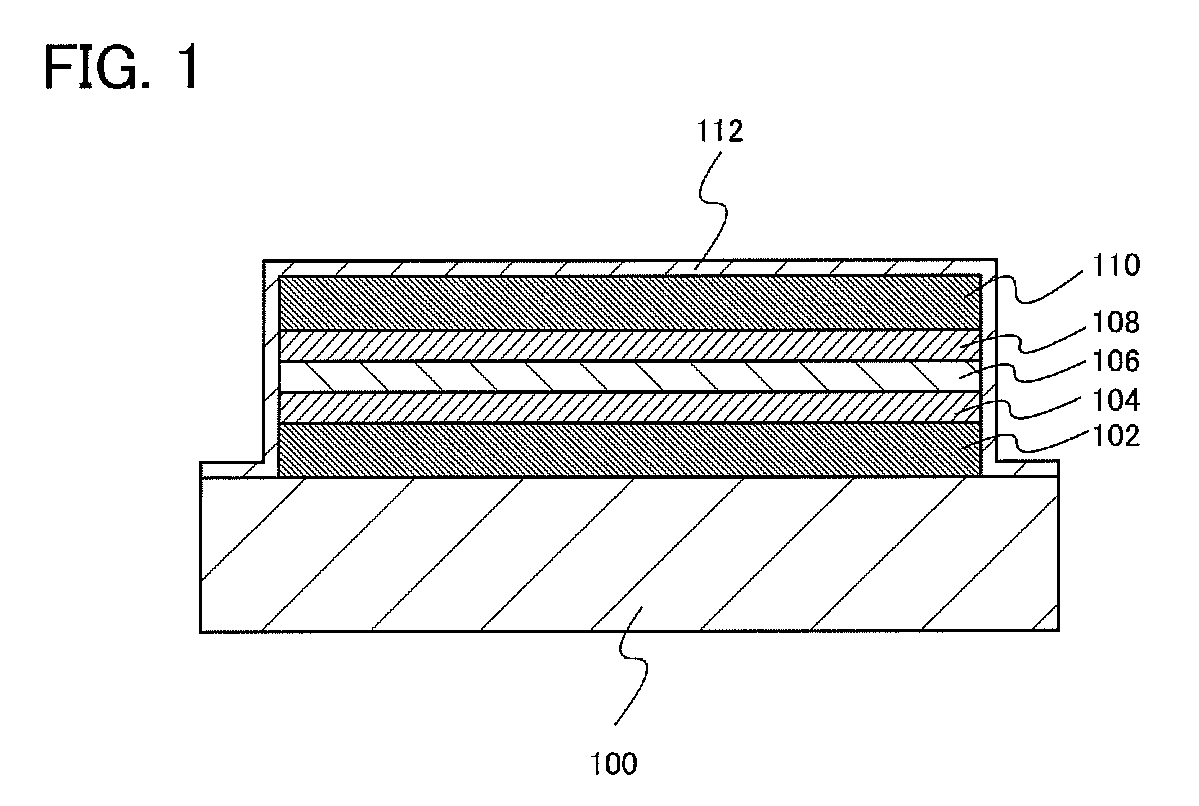

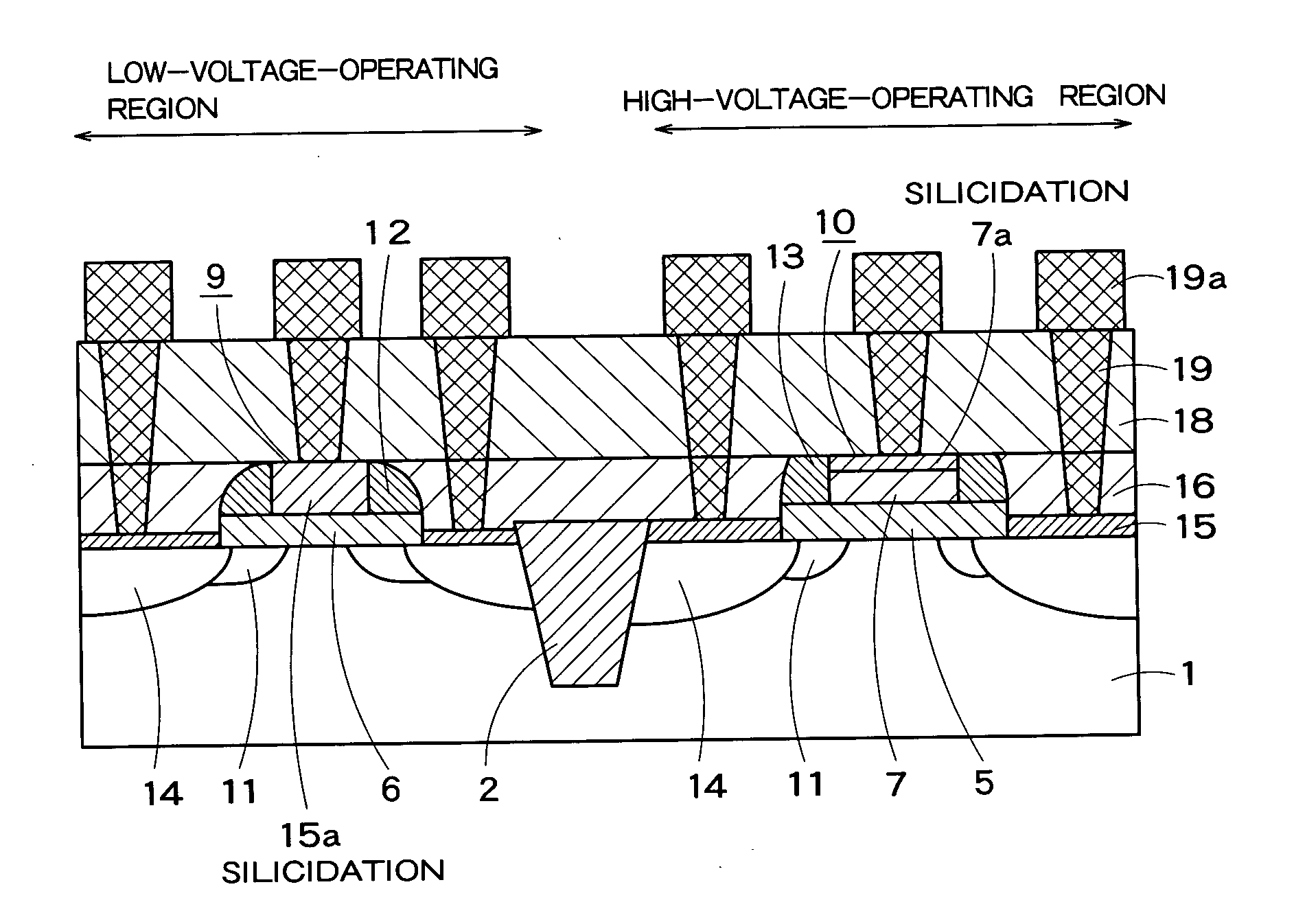

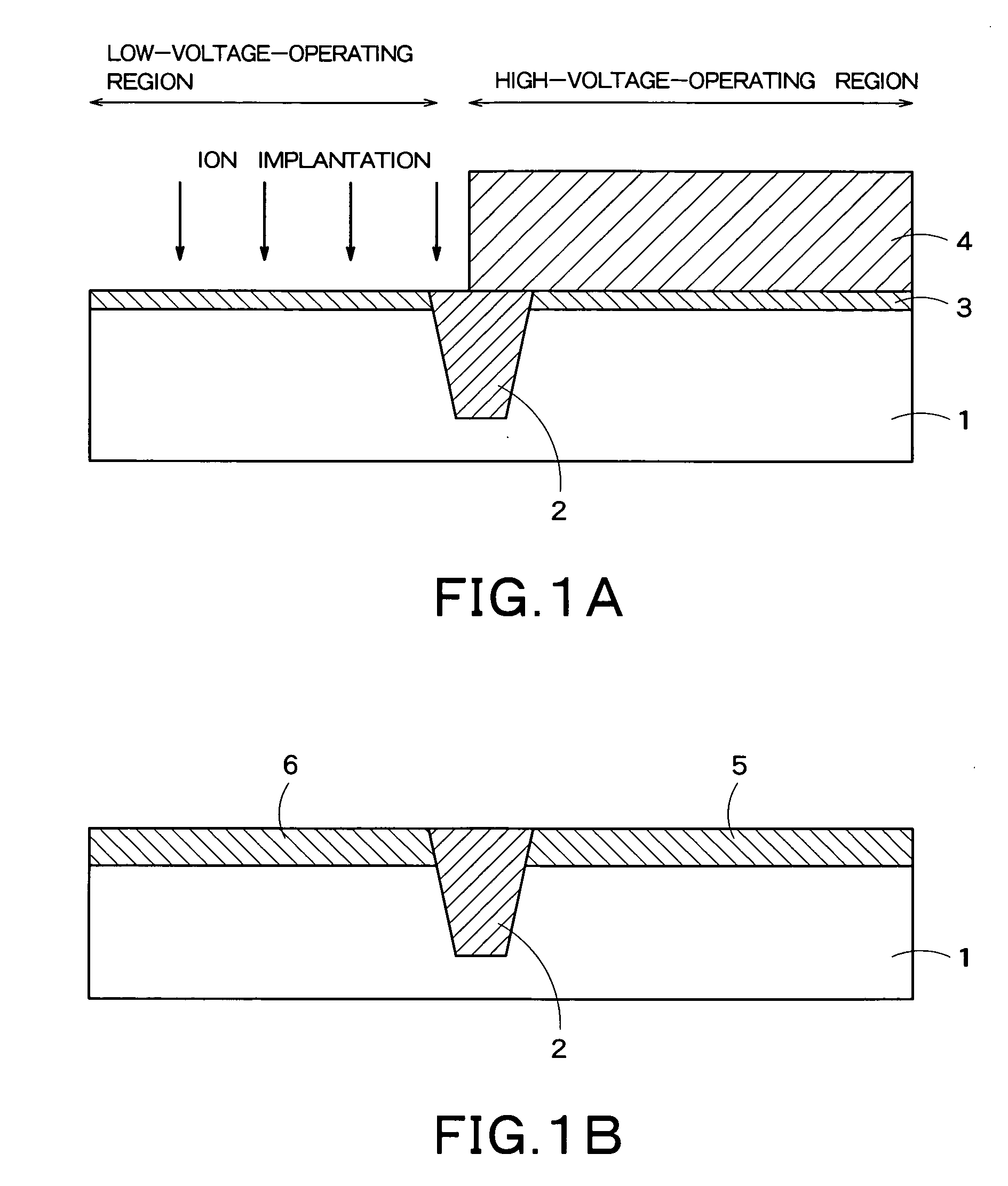

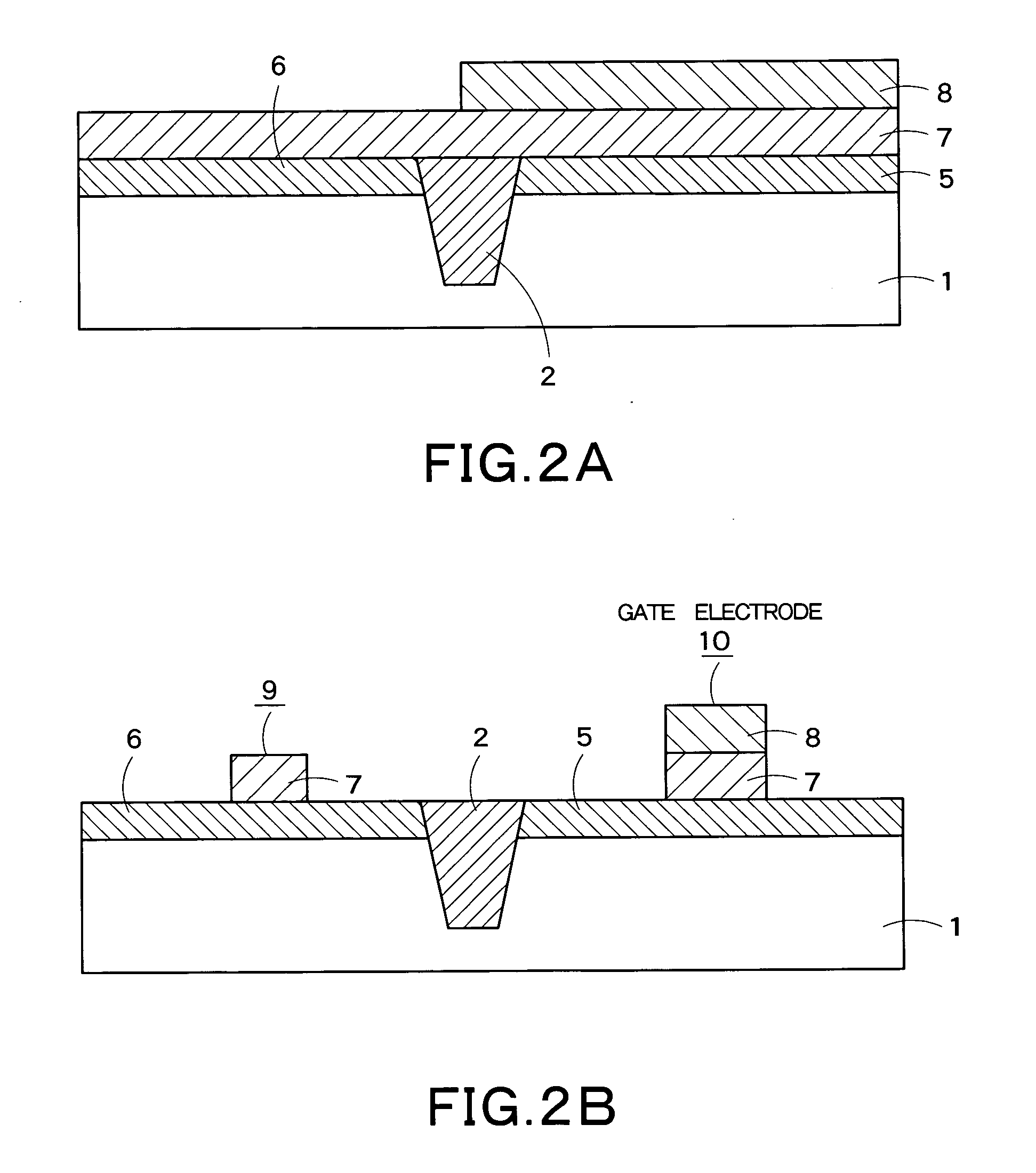

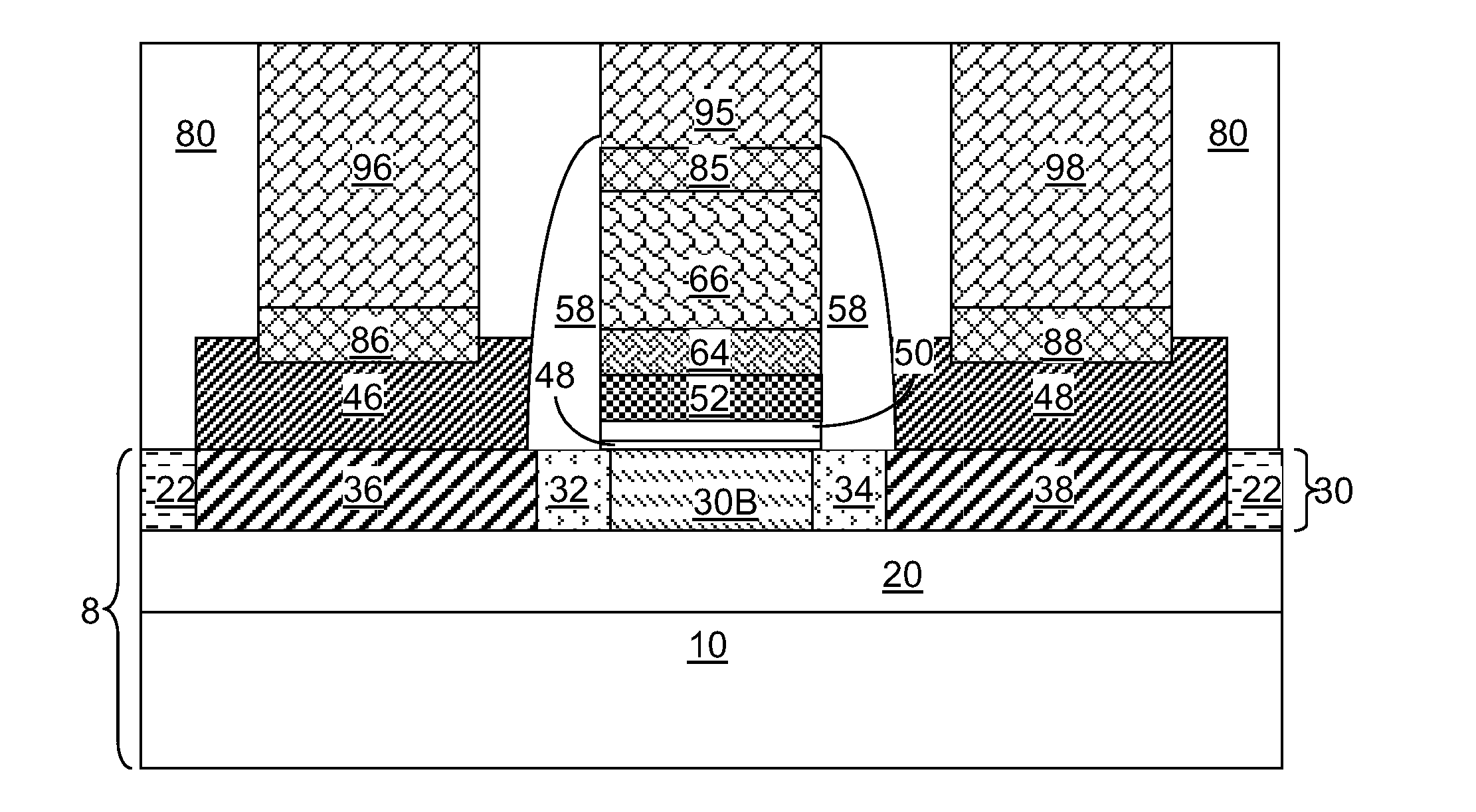

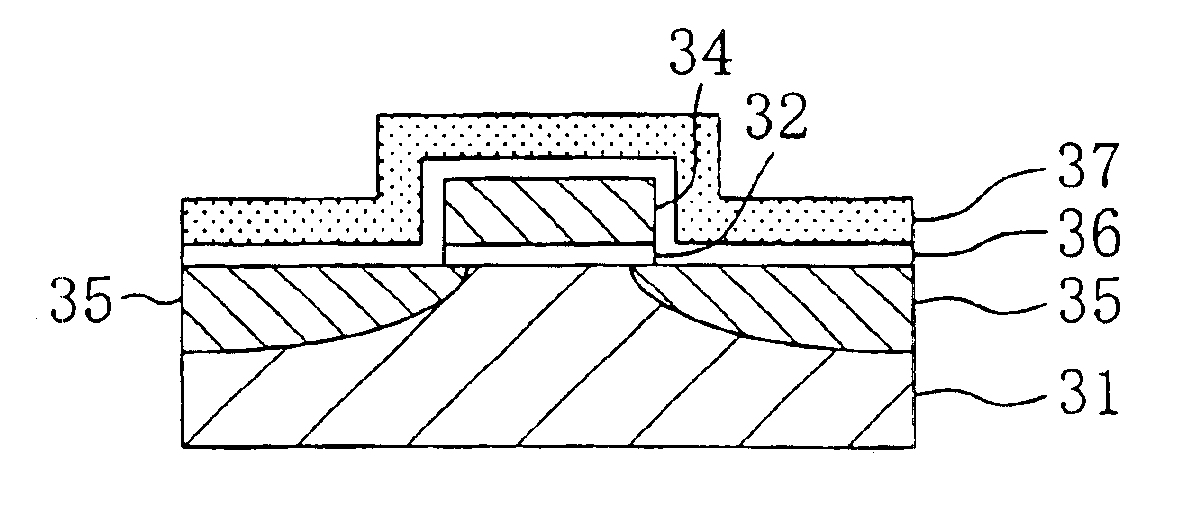

Semiconductor device and its fabrication method

InactiveUS20060237788A1Solid-state devicesSemiconductor/solid-state device manufacturingSalicideMOSFET

A semiconductor device has a semiconductor substrate, a first MOSFET which has a first gate insulating film made of a high dielectric material formed above the semiconductor substrate and a first gate electrode formed above the first gate insulating film, an insulating film which is formed directly on sidewalls of the first gate electrode and made of a material having dielectric constant smaller than that of the first gate insulating film, and a second MOSFET which has a second gate insulating film made of a material having dielectric constant smaller than that of the first gate insulating film formed above the semiconductor substrate and a second gate electrode formed above the second gate insulating film, wherein the first gate electrode is formed of a first silicide or a first metal; and the second gate electrode is formed including a film made of at least one of polysilicon, amorphous silicon, polysilicon germanium and amorphous silicon germanium.

Owner:KK TOSHIBA

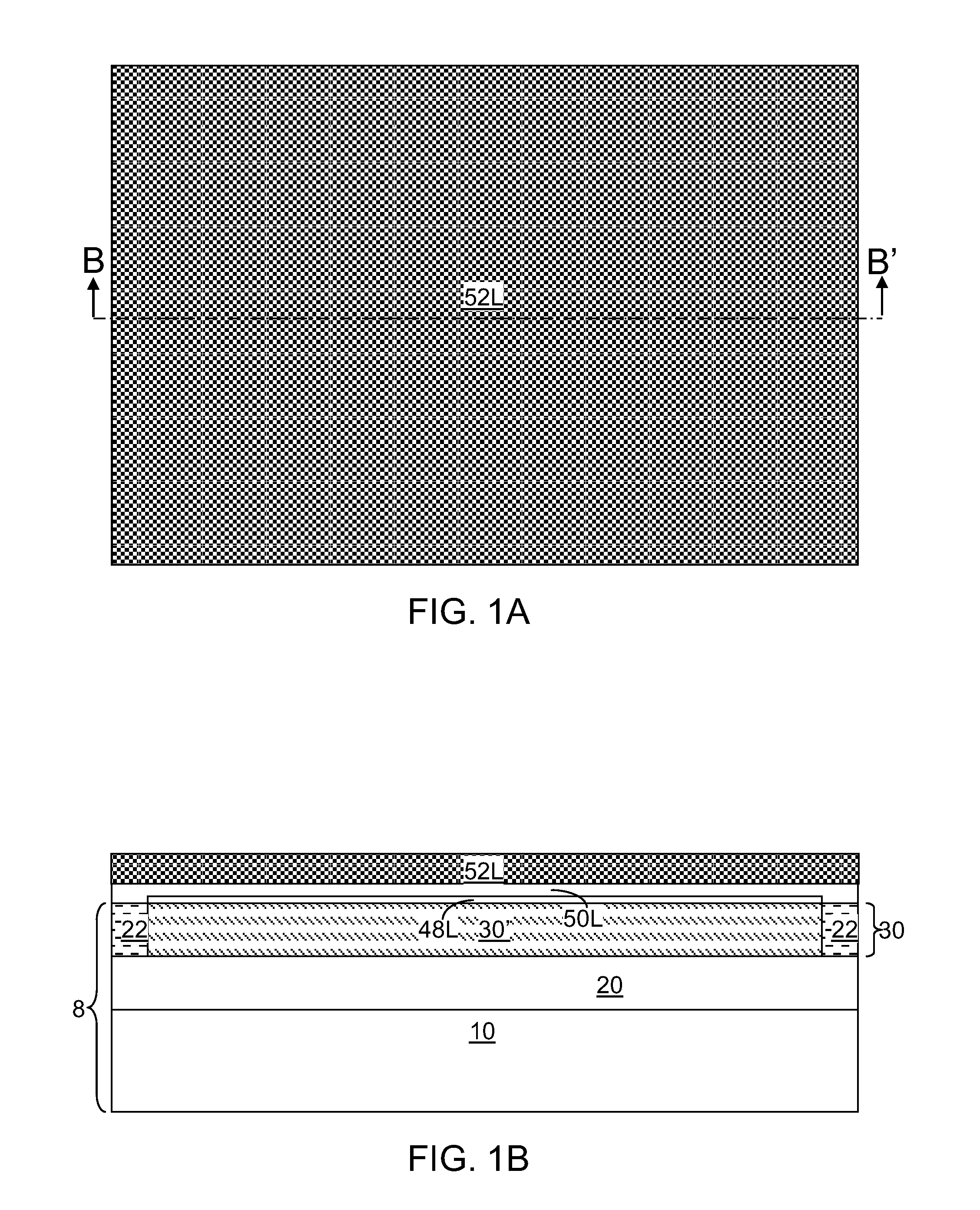

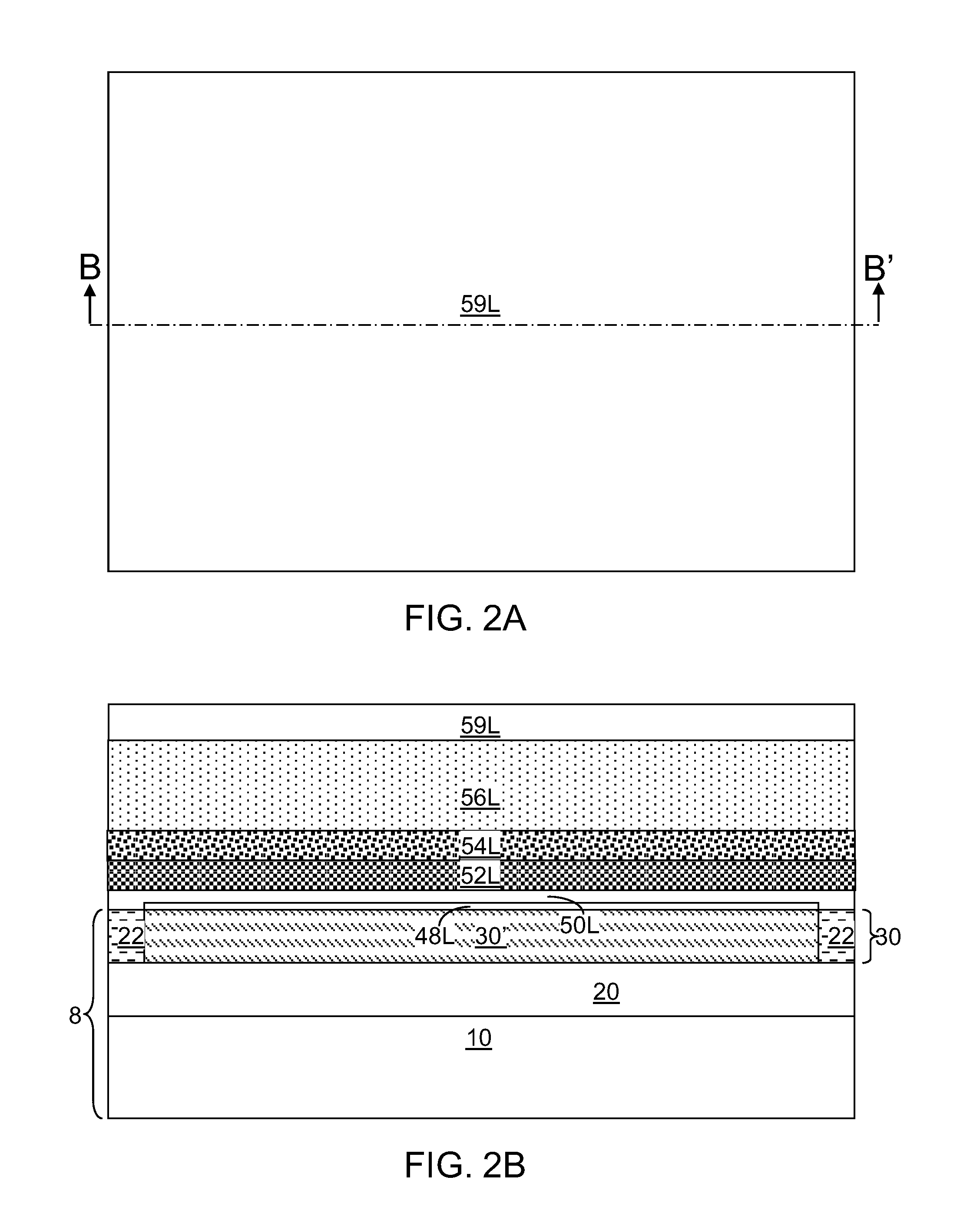

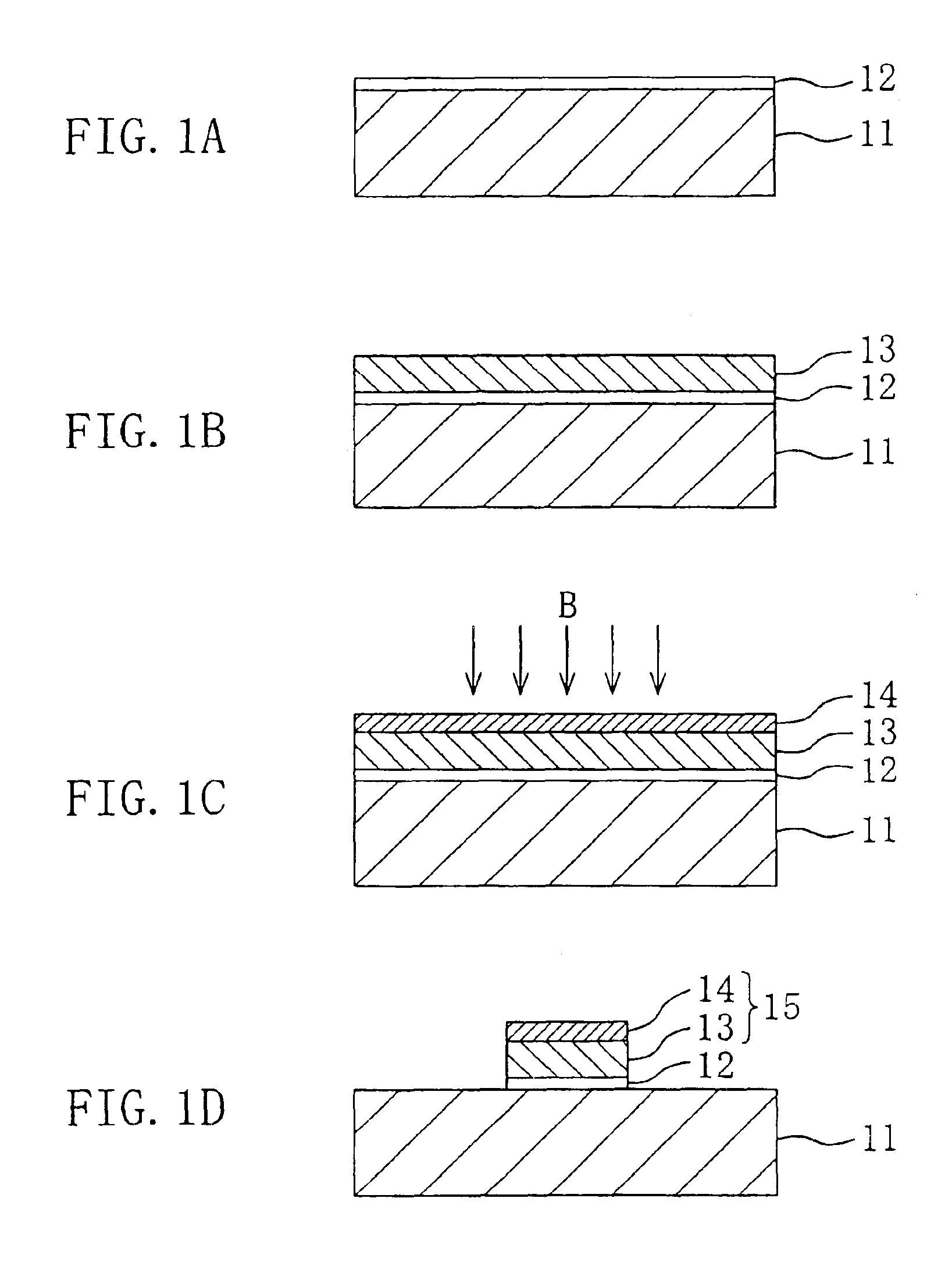

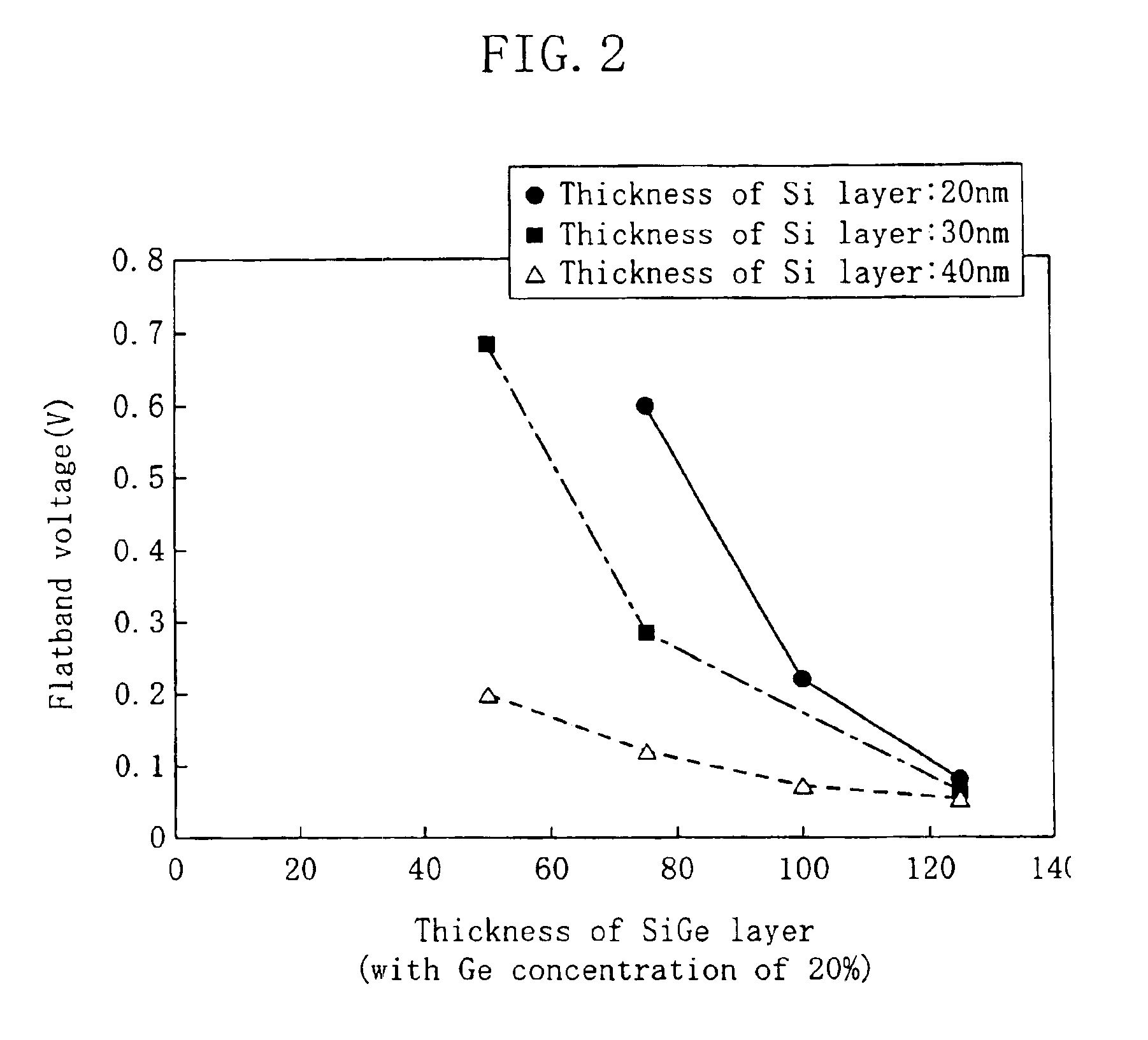

Mosfet gate electrode employing arsenic-doped silicon-germanium alloy layer

InactiveUS20130032897A1Reduction in Schottky barrierFacilitated DiffusionTransistorSemiconductor/solid-state device manufacturingMOSFETSemiconductor materials

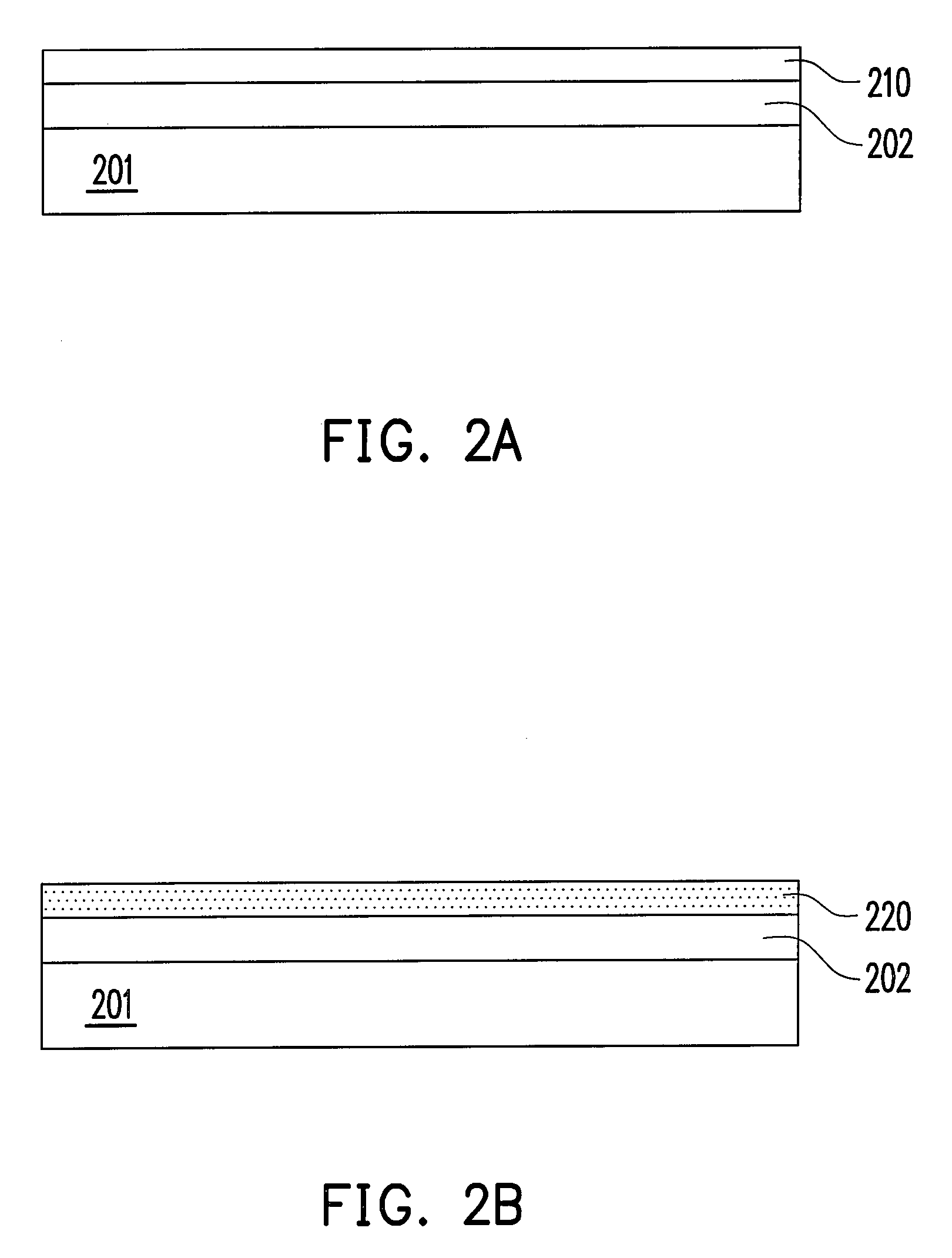

A stack of a gate dielectric layer, a metallic material layer, an amorphous silicon-germanium alloy layer, and an amorphous silicon layer is deposited on a semiconductor substrate. In one embodiment, the amorphous silicon-germanium alloy layer is deposited as an in-situ amorphous arsenic-doped silicon-germanium alloy layer. In another embodiment, the amorphous silicon-germanium alloy layer is deposited as intrinsic semiconductor material layer, and arsenic is subsequently implanted into the amorphous silicon-germanium alloy layer. The stack is patterned and annealed to form a gate electrode.

Owner:IBM CORP

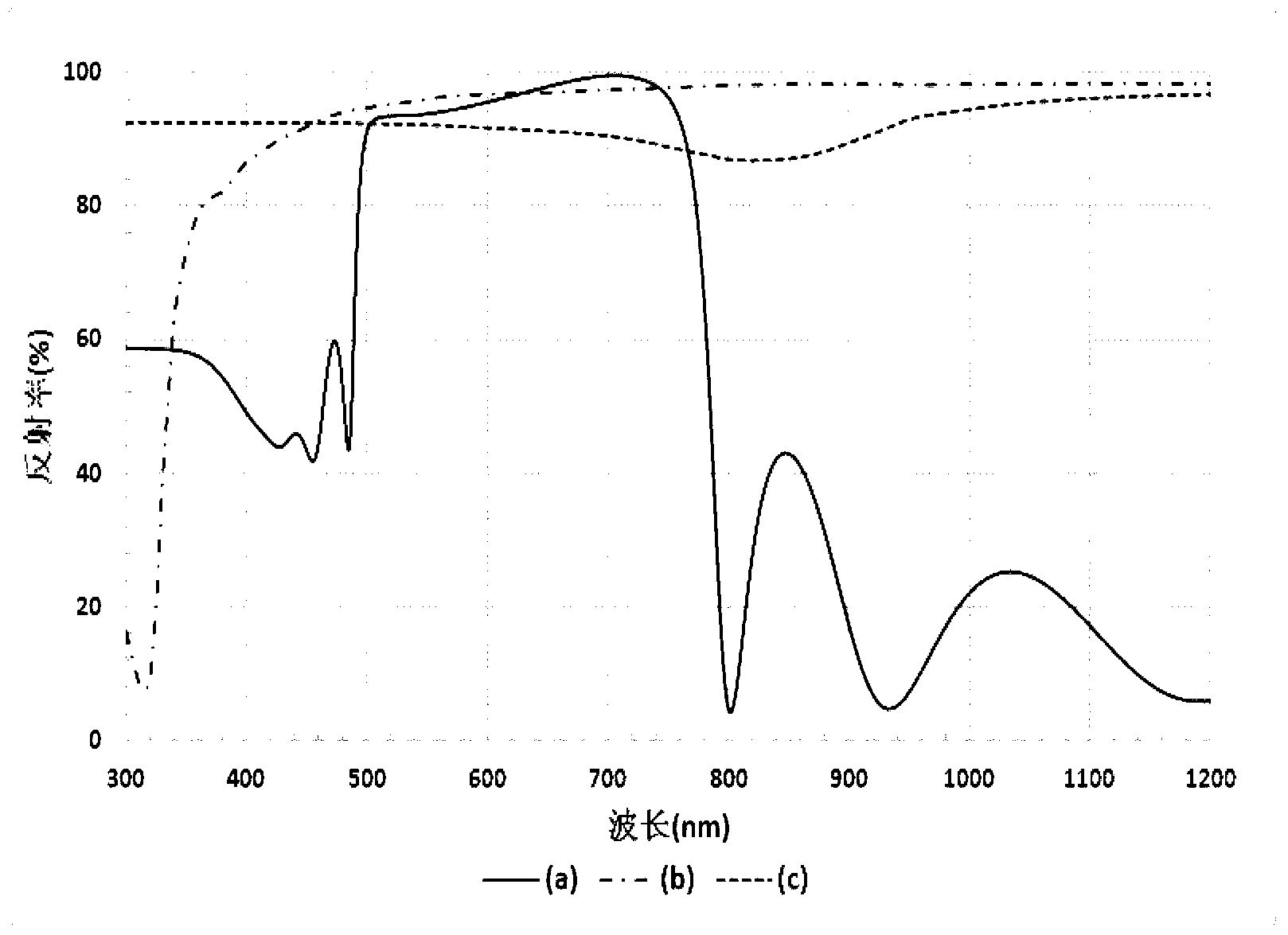

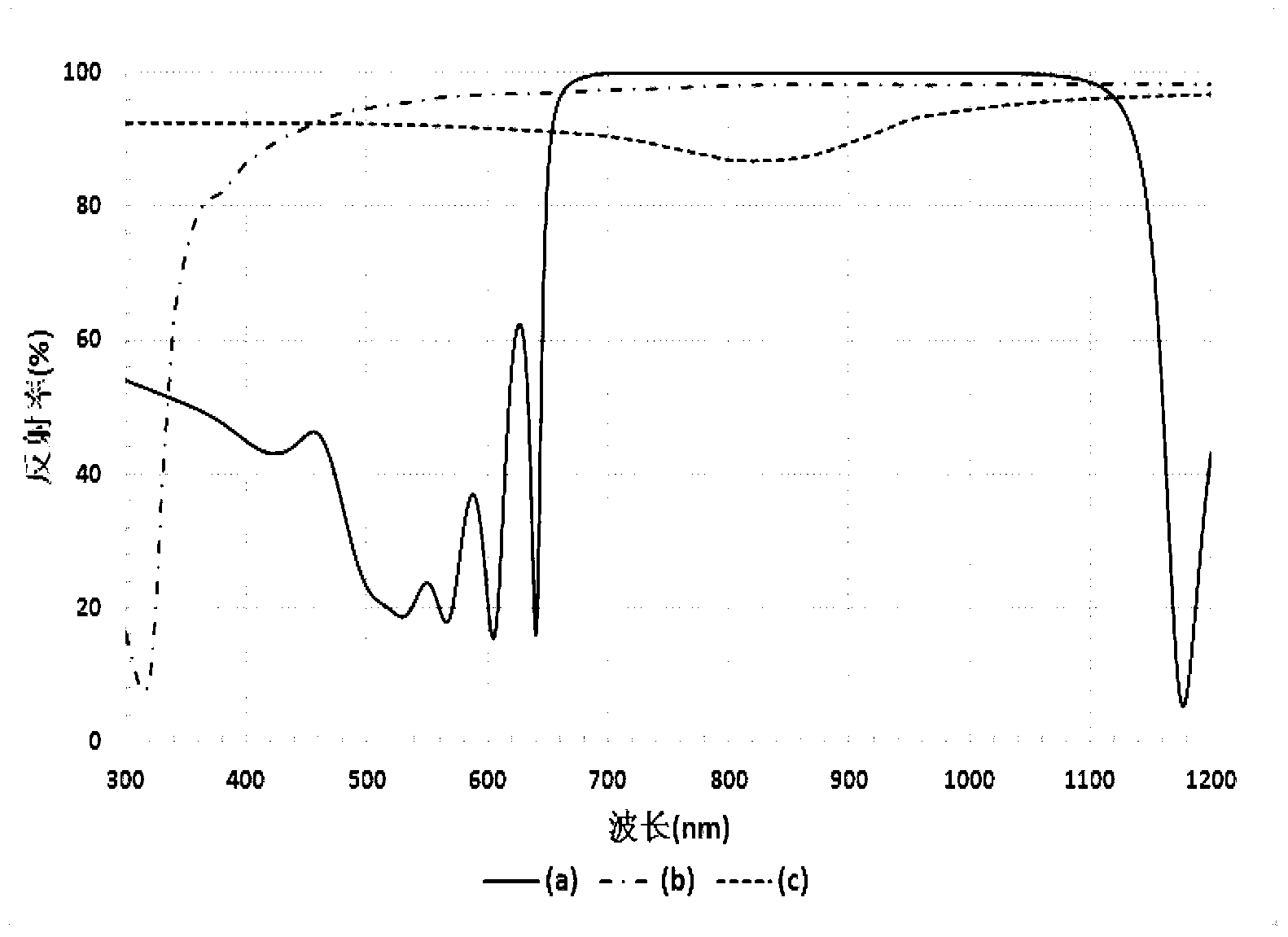

Photonic crystal back reflector provided with adjustable forbidden band and applied to silicon-based thin-film solar cell

InactiveCN103296145AImprove reflectivityIncrease the open circuit voltageFinal product manufacturePhotovoltaic energy generationBack reflectorRefractive index

The invention discloses a photonic crystal back reflector provided with an adjustable forbidden band and applied to a silicon-based thin-film solar cell. The photonic crystal back reflector is composed of low-refraction-index media and high-refraction-index media which are overlapped in a periodic mode. Through adjustment of the thickness of a period, an average reflectivity of 96% can be obtained in a wave band of 500-750mm, an average reflectivity of 99% can be obtained in a wave band of 650-1100nm, and an average reflectivity of 99% can be obtained in a wave band of 700-1200nm. The photonic crystal back reflector is suitable for serving as a back reflector of a unijunction amorphous silicon thin film solar cell, a back reflector of a double-junction amorphous silicon / microcrystalline silicon laminated solar cell and a back reflector of a triple-junction amorphous silicon / amorphous silicon germanium / amorphous silicon laminated solar cell. The photonic crystal back reflector provided with the adjustable forbidden band and applied to the silicon-based thin-film solar cell has the advantages that due to the fact that a photonic crystal is used as the back reflector of the silicon-based thin-film solar cell, the problems that an Ag back reflector is high in cost and other metal back reflectors are low in reflectivity are solved, high efficiency and decrease of the cost of raw materials are guaranteed, improvement of the open-circuit voltage of the cell is facilitated, the stability of the cell is improved, the photonic crystal back reflector is compatible with the cell technology, reduction of equipment investment and the plant area is facilitated, and productivity is improved.

Owner:NANKAI UNIV

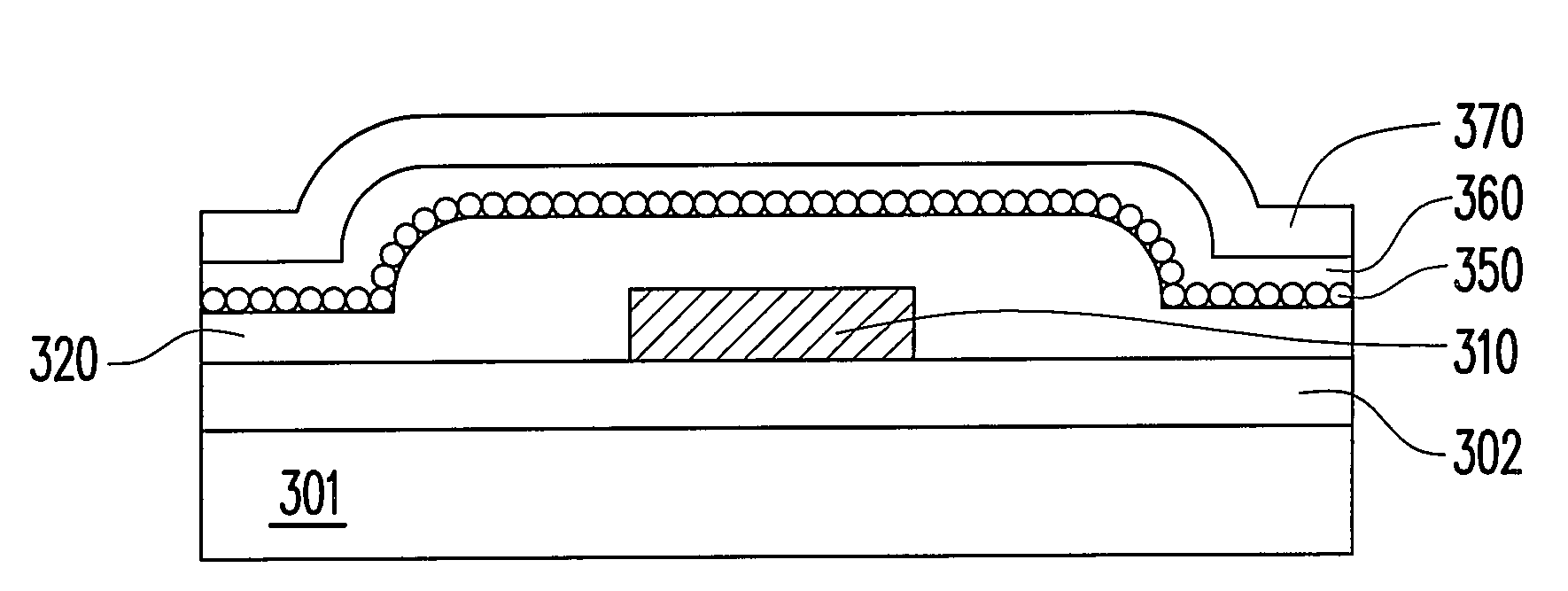

Memory cell and fabricating method thereof

A fabricating method of a memory cell including the following steps is provided. First, a poly-Si island including a source doped region, a drain doped region, and a channel region located therebetween is formed on a substrate. Then, a dielectric layer is formed on the poly-Si island. Afterward, an amorphous silicon-germanium (α-SiGe) layer is formed on the dielectric layer. Next, a laser annealing process is performed to oxidize the α-SiGe layer into a silicon oxide layer, so as to separate out Ge atoms from the α-SiGe layer to form a Ge quantum dot layer between the silicon oxide layer and the dielectric layer. After that, a control gate is formed on the silicon oxide layer.

Owner:IND TECH RES INST

Silicon-based heterojunction double-side solar cell and preparation method thereof

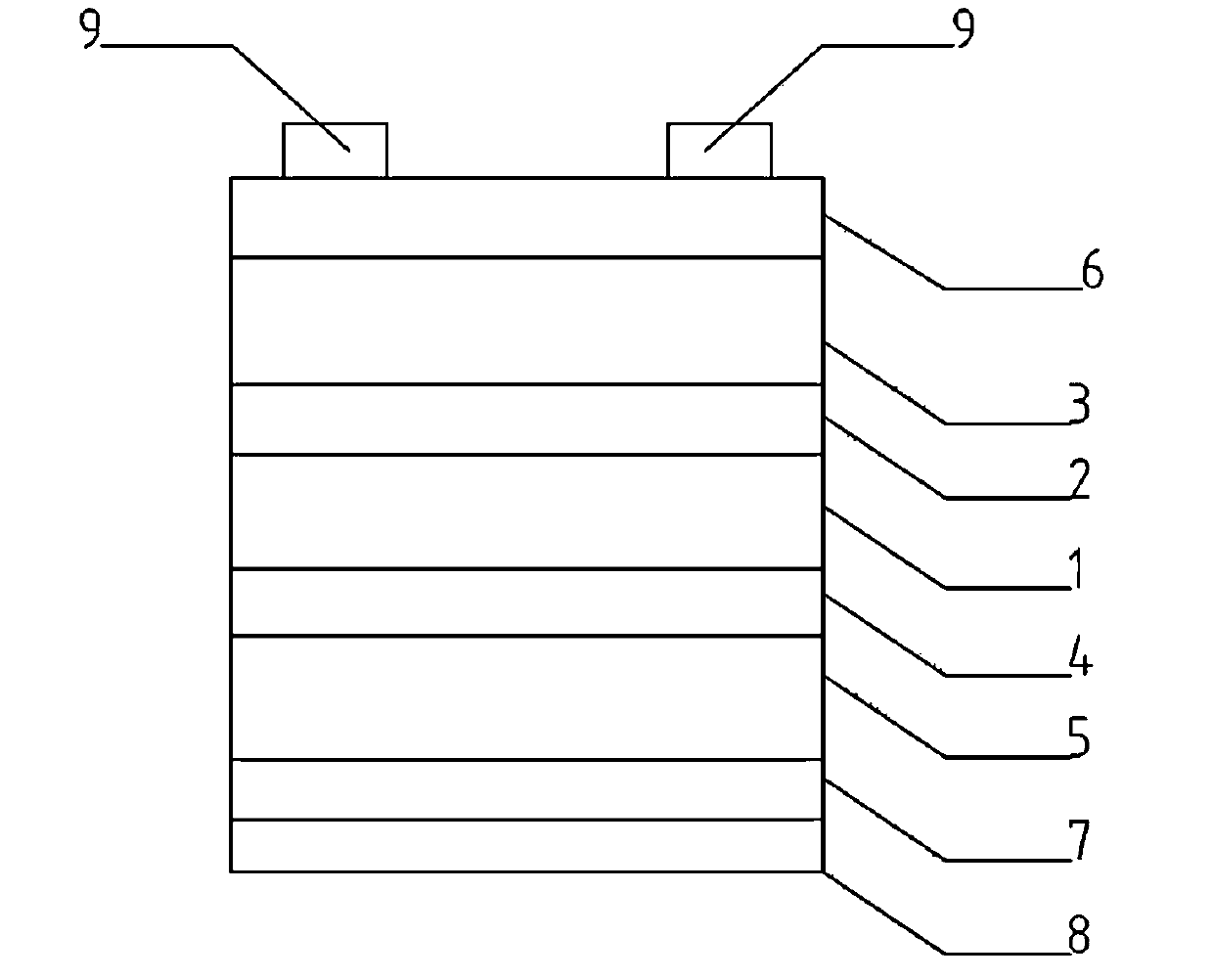

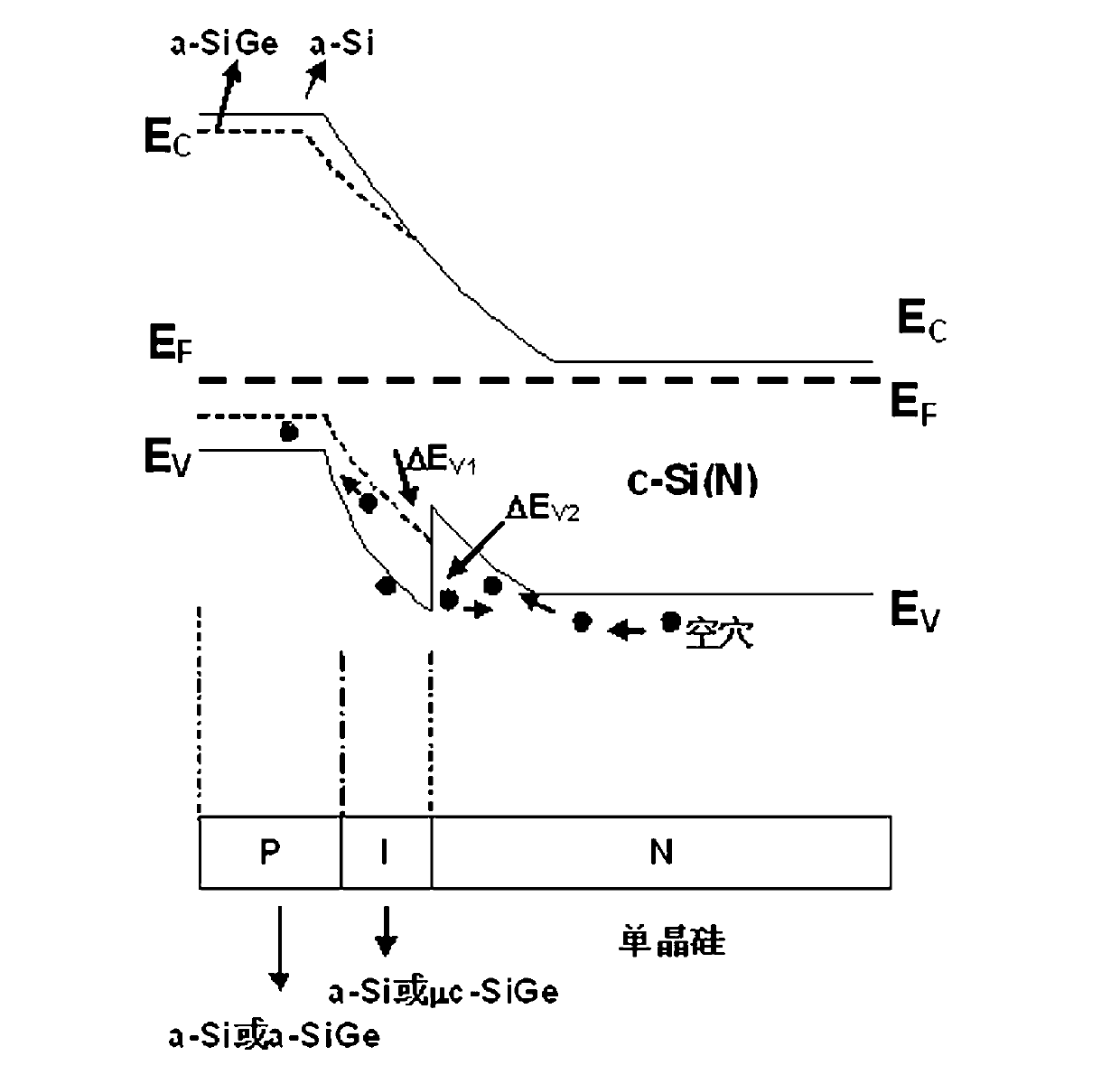

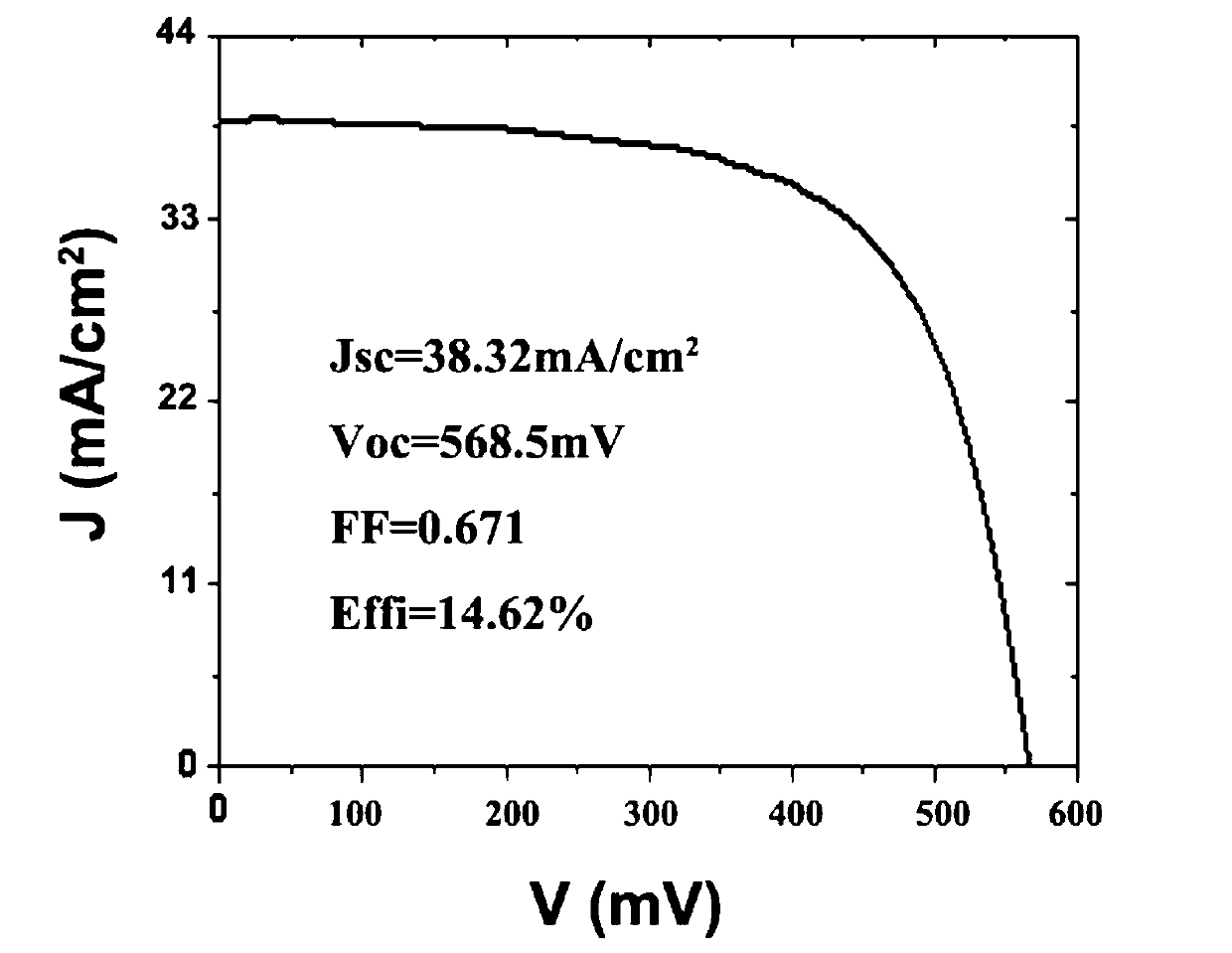

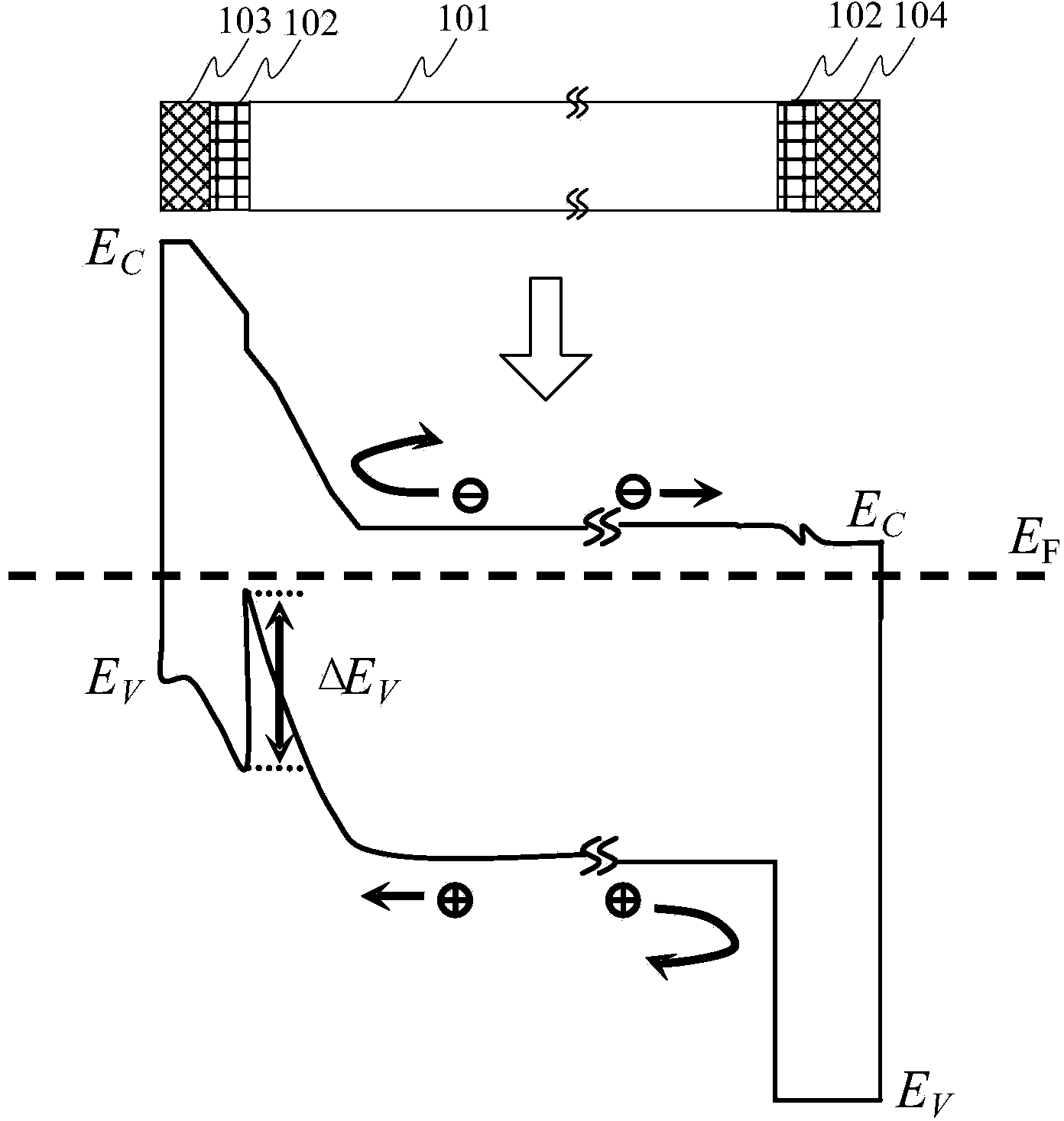

ActiveCN102738291AReduce hindranceIncrease currentFinal product manufacturePhotovoltaic energy generationHeterojunctionGas phase

The invention discloses a silicon-based heterojunction double-side solar cell and a preparation method of the silicon-based heterojunction double-side cell. The conventional amorphous-silicon thin-film is replaced by the amorphous-silicon germanium alloy as an emitting diode of the heterojunction cell, at the same time, an intrinsic microcrystalline silicon germanium thin-film is used as an interface buffer layer of the cell, so that valence-band offset caused by the heterojunction band mismatch can be reduced effectively, the block influence on the holes is decreased, and the collection of the photovoltaic minority carrier holes is facilitated, furthermore the photovoltaic performance index of the solar cell is increased. The intrinsic microcrystalline silicon germanium thin film, a P-type doped amorphous-silicon germanium thin film, an intrinsic amorphous-silicon thin-film and an N+ type doped amorphous-silicon thin-film are prepared on two sides of the N-type microcrystalline silicon wafer by the radio frequency plasma enhanced chemical vapor deposition, the purpose of effectively collecting a photovoltaic carrier is achieved. The heterojunction double-side solar cell with 14.62% of photoelectric conversion efficiency is prepared on the double-side polished FZ-type microcrystalline silicon wafer by the process.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

Oxygen-doped amorphous silicon germanium film, heterojunction crystalline silicon solar cell and manufacturing method

ActiveCN104393121AImprove continuityEasy to collectFinal product manufacturePhotovoltaic energy generationHeterojunctionElectrical battery

The invention provides an oxygen-doped amorphous silicon germanium film used for passivating the crystalline silicon surface, a heterojunction crystalline silicon solar cell and a manufacturing method. The manufacturing method of the oxygen-doped amorphous silicon germanium film used for passivating the crystalline silicon surface comprises steps of providing a crystalline silicon substrate and adopting a chemical vapor deposition method to deposit the oxygen-doped amorphous silicon germanium film on the surface of the crystalline silicon substrate. Through adjusting the oxygen concentration and the germanium concentration in a reaction gas flow, dense oxygen-doped amorphous silicon germanium film material with continuous and adjustable band gap can be obtained, the material uses oxygen and germanium to suppress interface epitaxy and adjust the band gap of the material, effective collection of hole carriers can be realized, and the efficiency of the heterojunction crystalline silicon solar cell can be effectively improved.

Owner:ZHONGWEI NEW ENERGY CHENGDU CO LTD

Method for making optical waveguides

InactiveCN101910899AReduce stressEffective for annealingNanoopticsOptical light guidesAlloyWaveguide

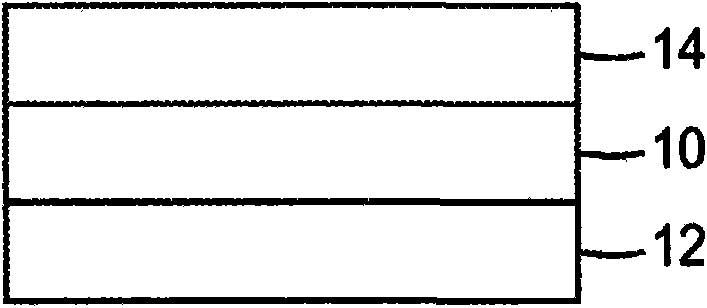

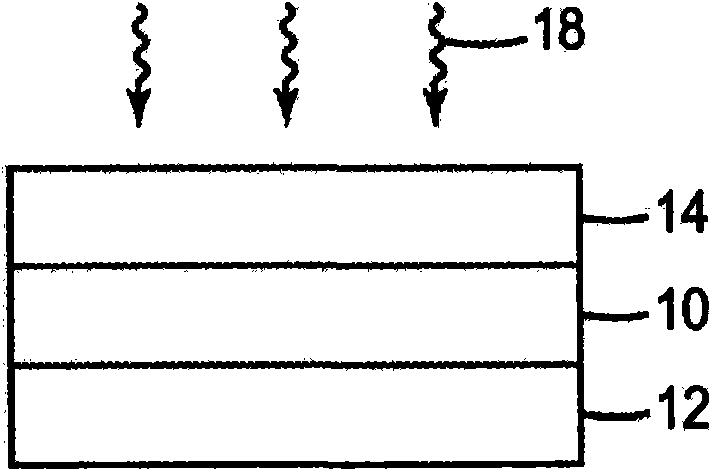

A method for making a waveguide comprises (a) providing a waveguide structure comprising a substrate (22), a lower cladding (20) layer on the substrate, and a core layer (24) comprising silicon nitride, amorphous silicon, or amorphous silicon-germanium alloy on the lower cladding layer; (b) patterning the core layer; and (c) annealing (28) the waveguide structure.

Owner:3M INNOVATIVE PROPERTIES CO

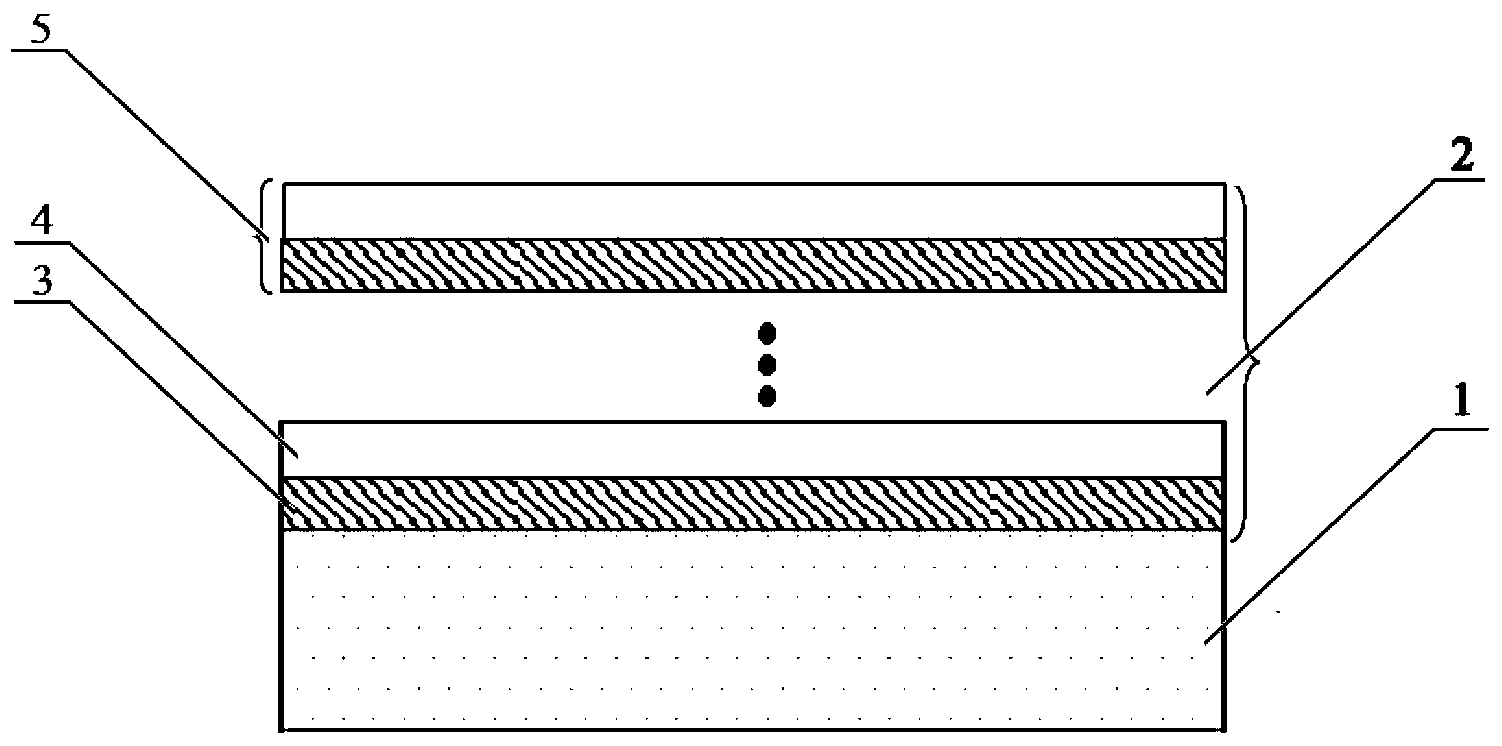

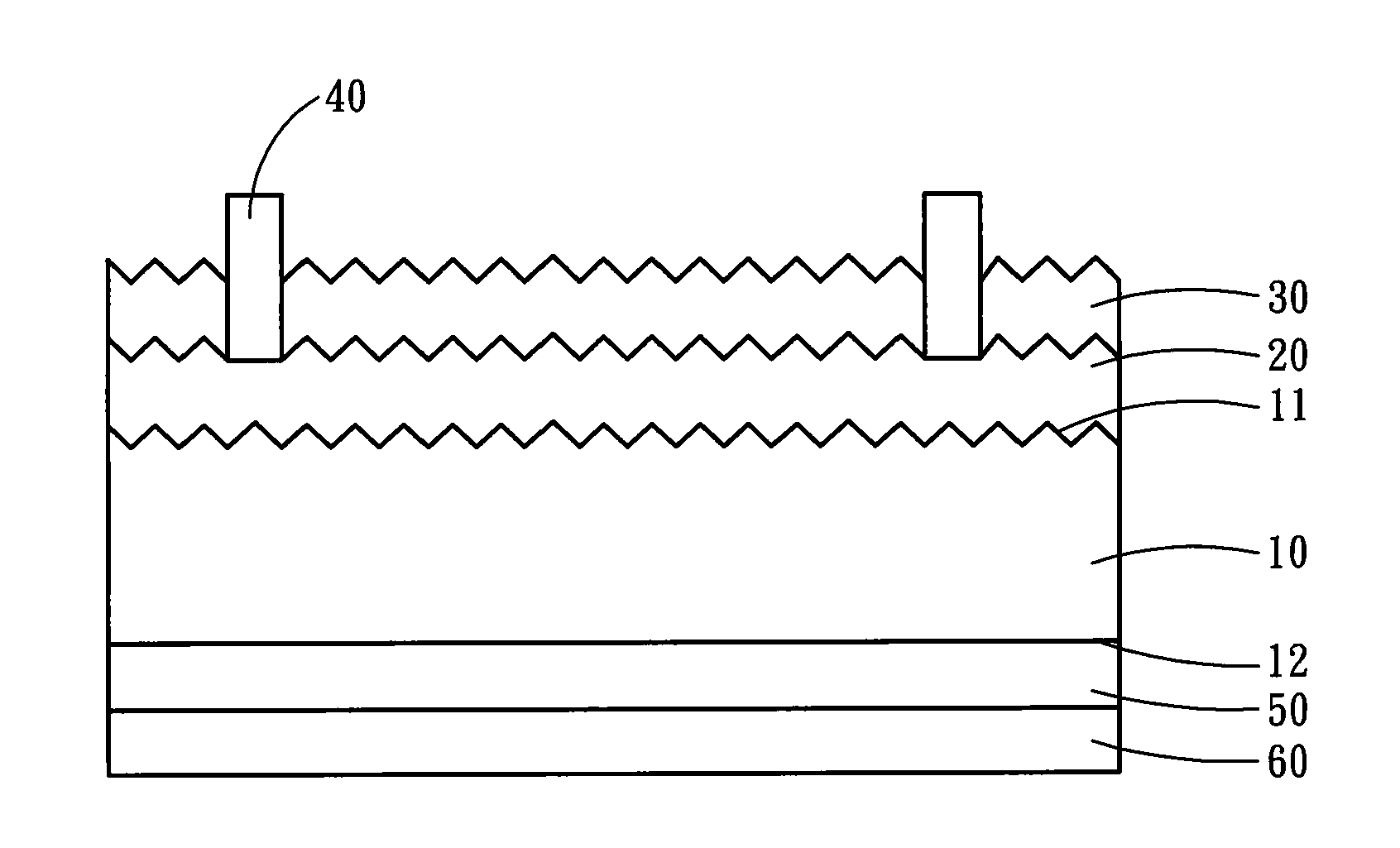

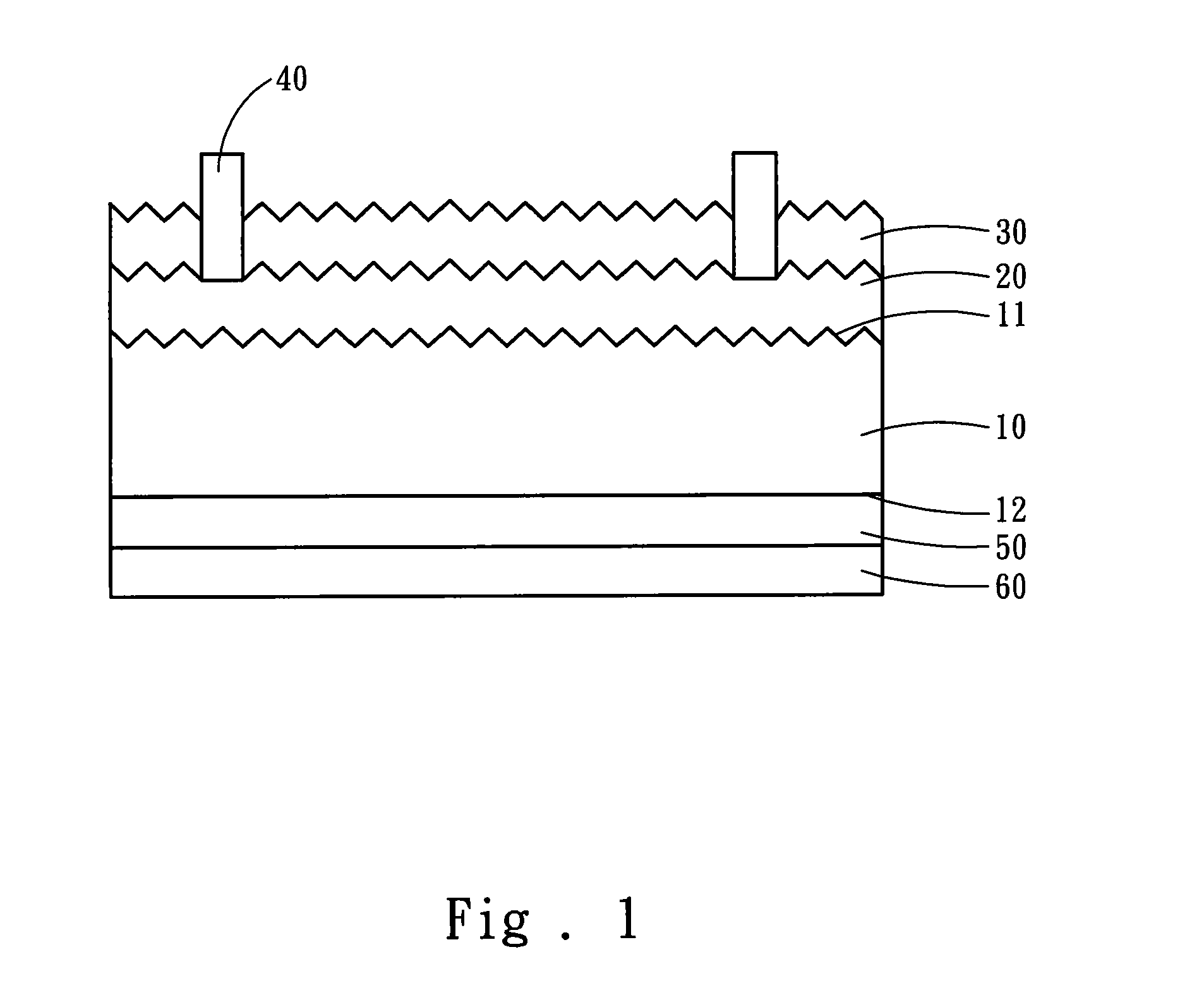

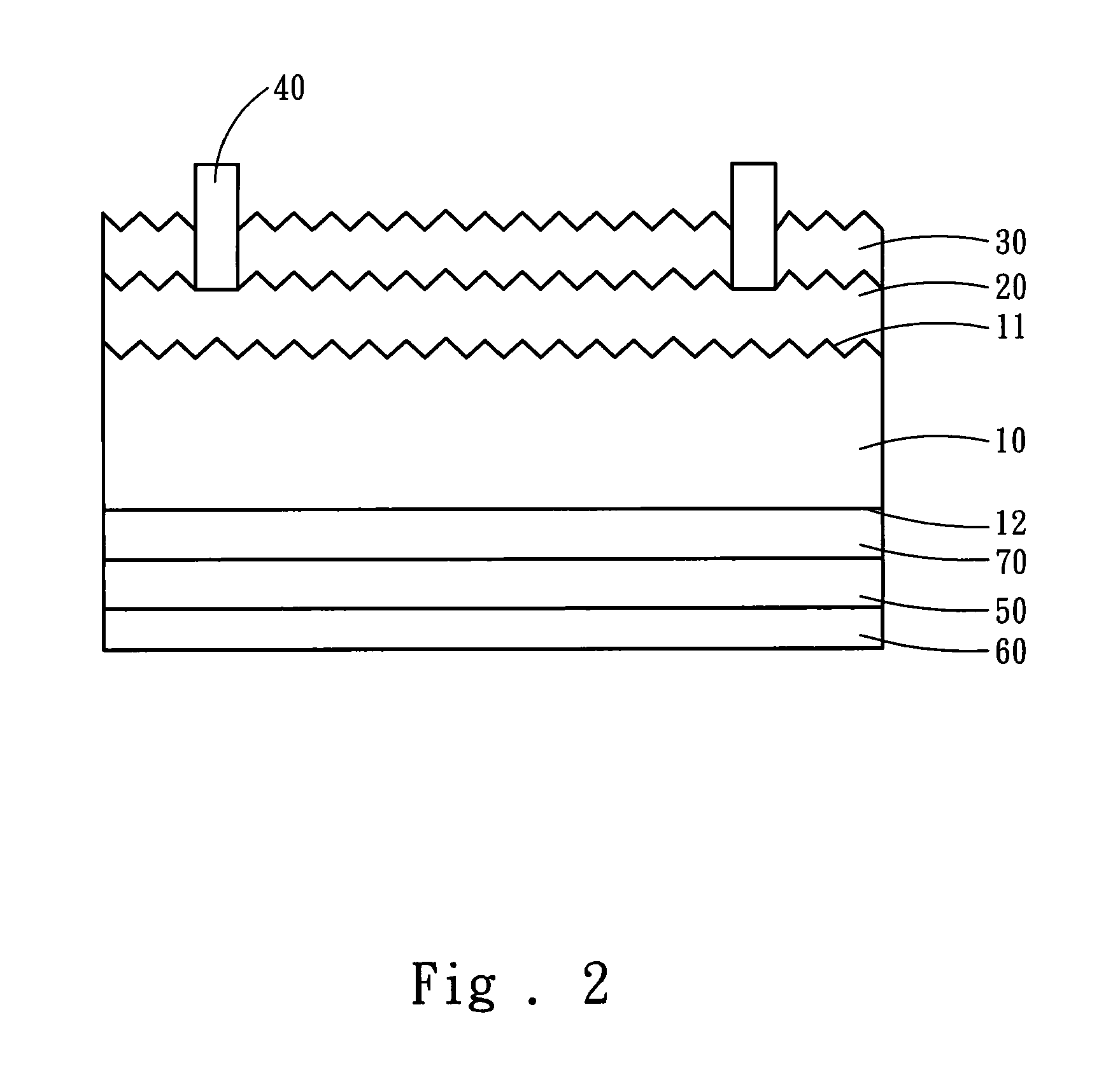

Flexible substrate silicon-based multi-junction laminated thin-film solar battery and manufacturing method thereof

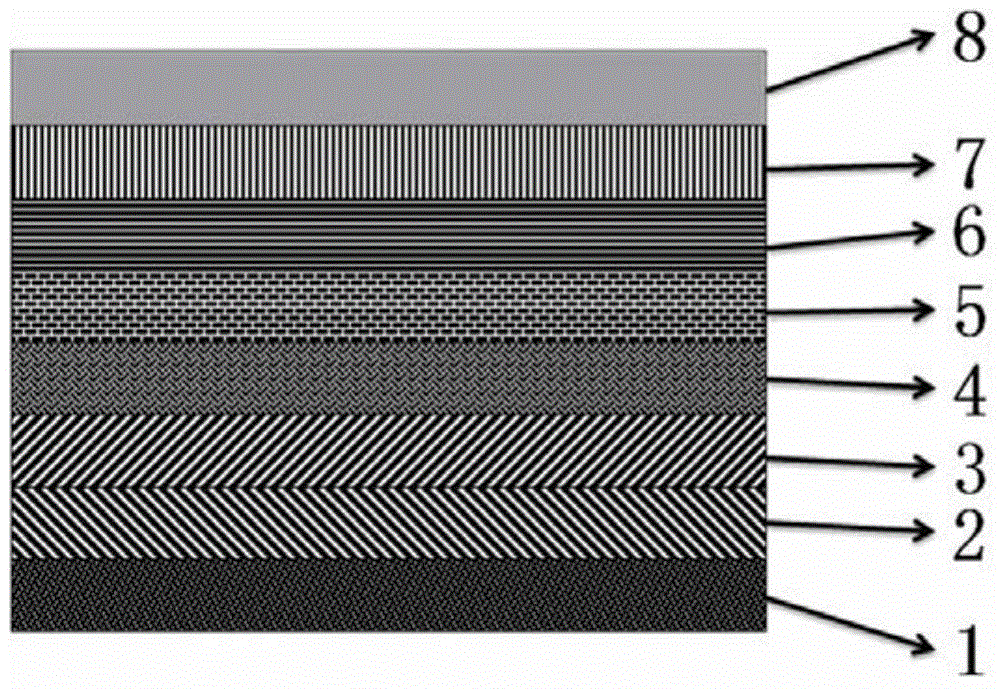

InactiveCN103077981AImprove electrical uniformityImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationPolyesterMetal foil

The invention relates to a photovoltaic solar cell and discloses a flexible substrate silicon-based multi-junction laminated thin-film solar battery. The flexible substrate silicon-based multi-junction laminated thin-film solar battery comprises a back reflection electrode, microcrystalline silicon (muc-Si:H) or amorphous silicon germanium (a-SiGe:H) bottom battery, an amorphous silicon (a-Si:H) top battery, a transparent conducting film and a metal grid line which are sequentially deposited on a metal foil or polyester film substrate, wherein the bottom battery is electrically connected with the top battery by adopting a composite tunneling junction. The invention also discloses a manufacturing method for the battery. The manufacturing method comprises the following steps of: carrying out sputtering deposition on the back reflection electrode; depositing microcrystalline silicon or amorphous silicon germanium bottom battery; depositing the amorphous silicon top battery; carrying out sputtering deposition on transparent conducting films such as ITO (Indium Tin Oxide), SnO2.F, ZnO:Al, ZnO:Ga and the like; carrying out electro chemical passivation; preparing the metal grid line and the like. The flexible substrate silicon-based multi-junction laminated thin-film solar battery disclosed by the invention has the beneficial effects that the conversion efficiency of the battery and the large-area uniformity are increased, high efficiency and high power specific weight ratio are obtained and the like; and meanwhile, a preparation process is simple and the scale production can be realized.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

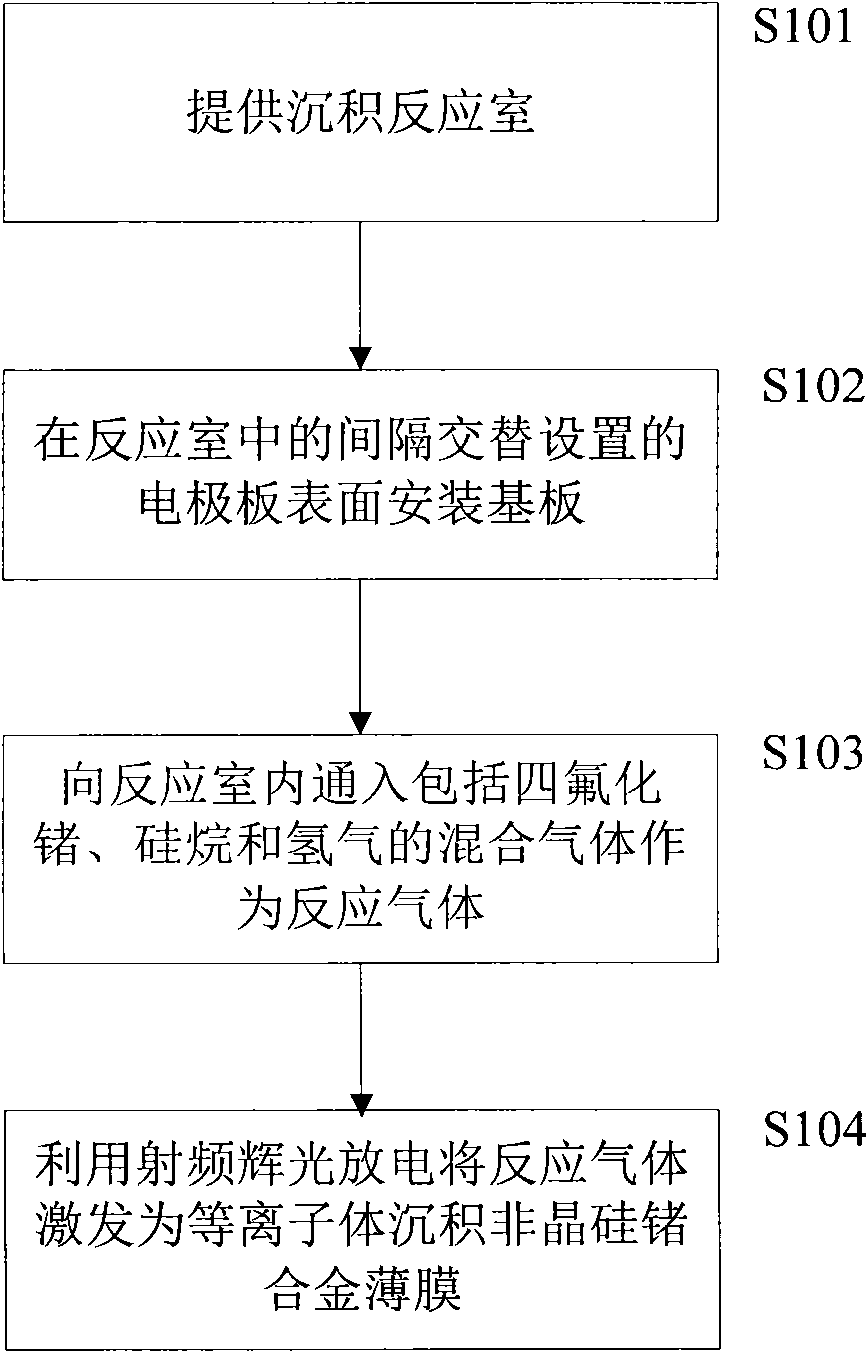

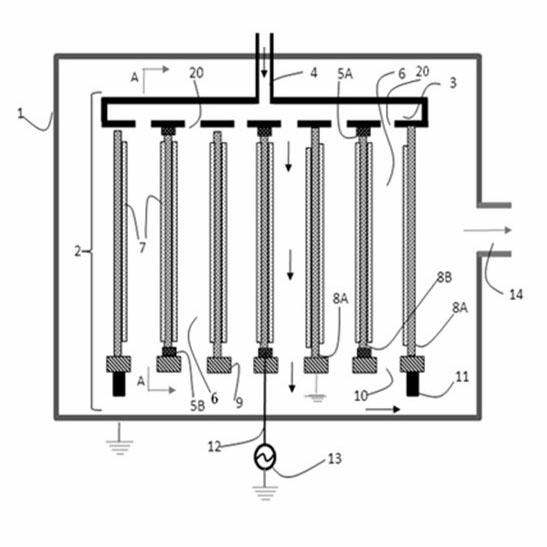

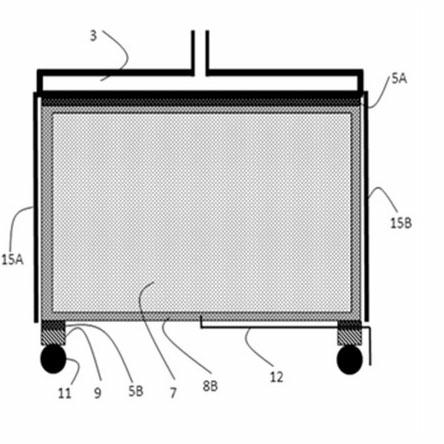

Method for manufacturing film solar cell

InactiveCN101626049AImprove stabilityImprove featuresFinal product manufactureChemical vapor deposition coatingPlasma depositionRadio frequency

The invention discloses a method for manufacturing a film solar cell, which comprises the following steps: providing a deposition reaction chamber; putting a substrate on the surface of an electrode plate in the reaction chamber; introducing reaction gases comprising germanium tetrafluoride, silicane and hydrogen into the reaction chamber; and using radio-frequency glow discharge to excite the reaction gases into plasma to deposite a amorphous silicon-germanium film. The method for manufacturing the film solar cell can remarkably improve evenness of band gap and thickness of amorphous silicon-germanium films deposited on the large-area substrate in batch in a large-sized PECVD deposition device.

Owner:GS SOLAR FU JIAN COMPANY +1

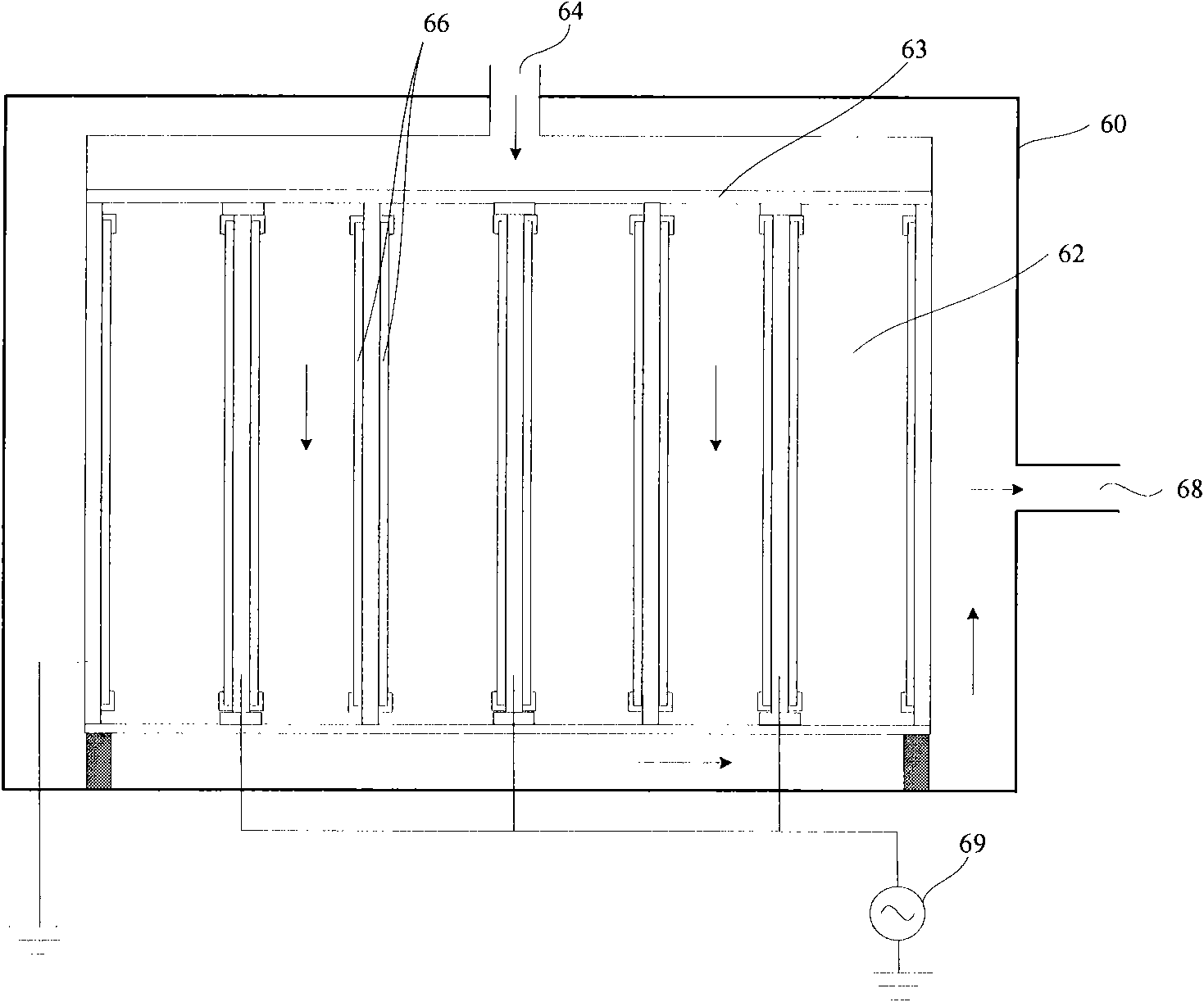

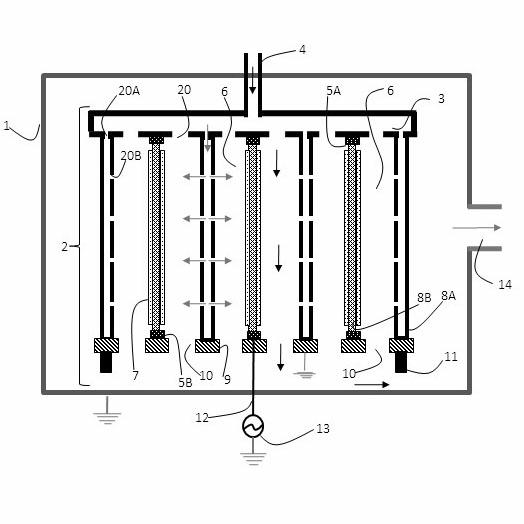

Method for preparing amorphous silicon germanium thin-film batteries with box type PECVD (plasma enhanced chemical vapor deposition) equipment

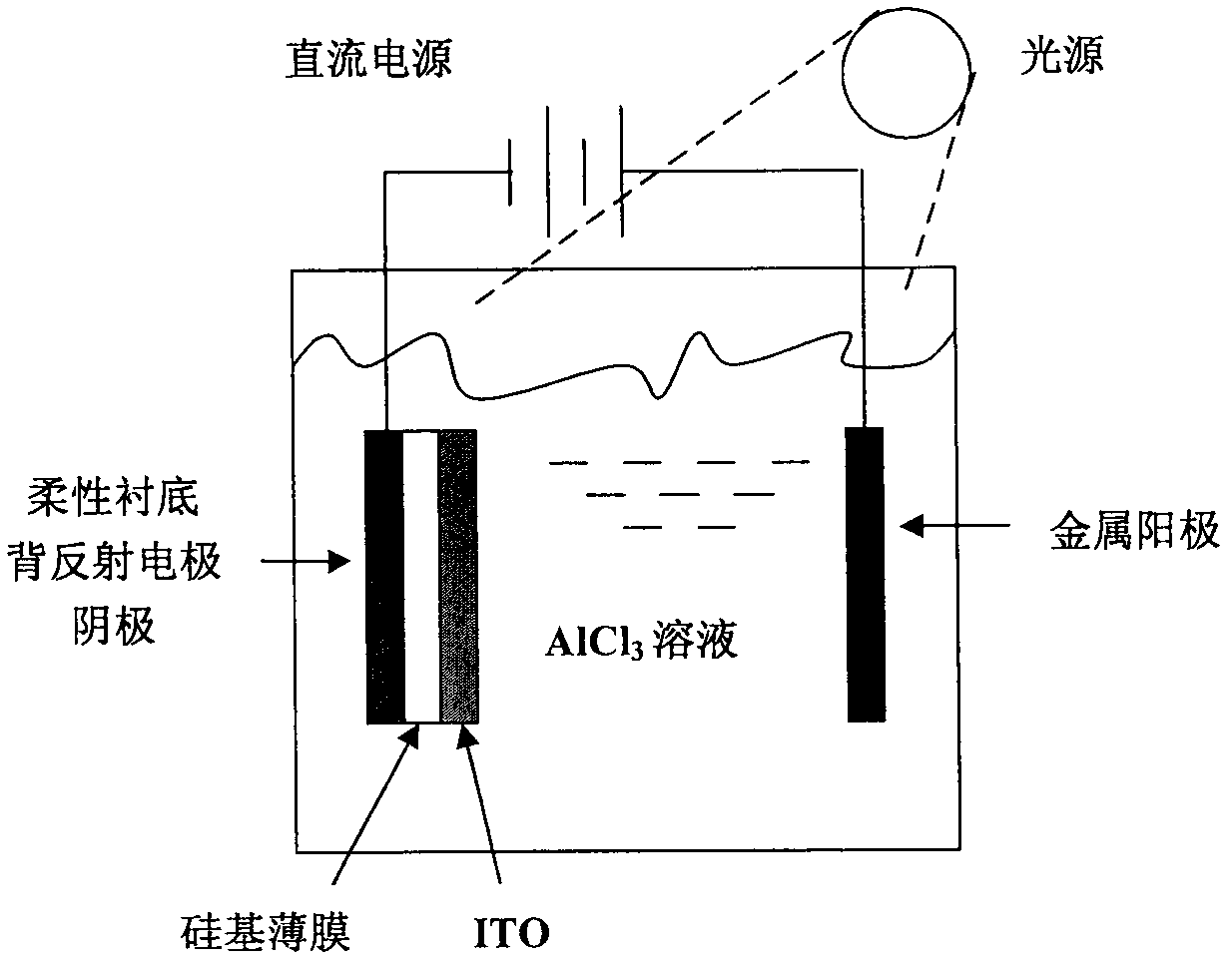

InactiveCN102634774AImprove performanceSolve for uniformityFinal product manufactureChemical vapor deposition coatingThermal chemical vapor depositionDecomposition

The invention solves the problem that during the process of preparing amorphous silicon germanium thin-film battery components, the germanium content on a glass substrate of a prepared amorphous silicon germanium thin film is not due to different decomposition speeds and decomposition amounts of gas on the upper end and the lower end of the substrate, which affects the performance of the battery components, and provides an equipment for preparing amorphous silicon germanium thin-film batteries and a preparation method of the equipment. The equipment solves the problem of non-uniform germanium content on the upper and the lower parts of the glass substrate in a manner of gas compensation through design modification of the structure of partial electrodes generating a plasma field, and achieves low-cost and easily implemented preparation of large-area amorphous silicon germanium thin films and amorphous silicon-germanium thin-film batteries with uniform component content by using a box type PECVD (plasma enhanced chemical vapor deposition) equipment.

Owner:YUNNAN NORMAL UNIV

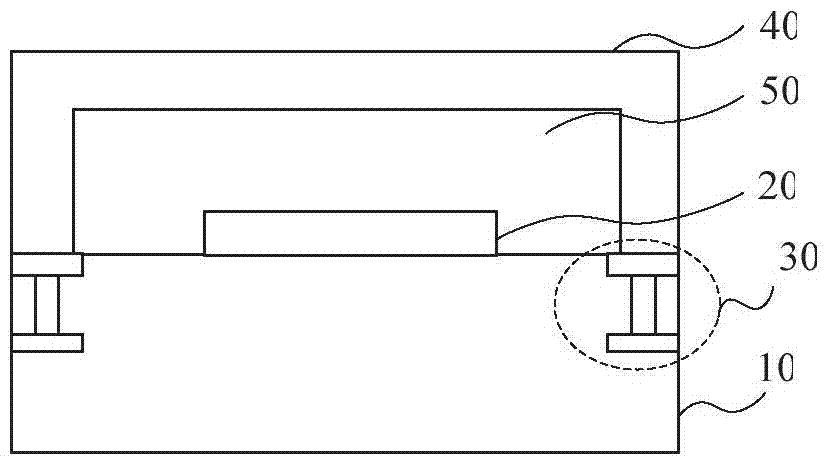

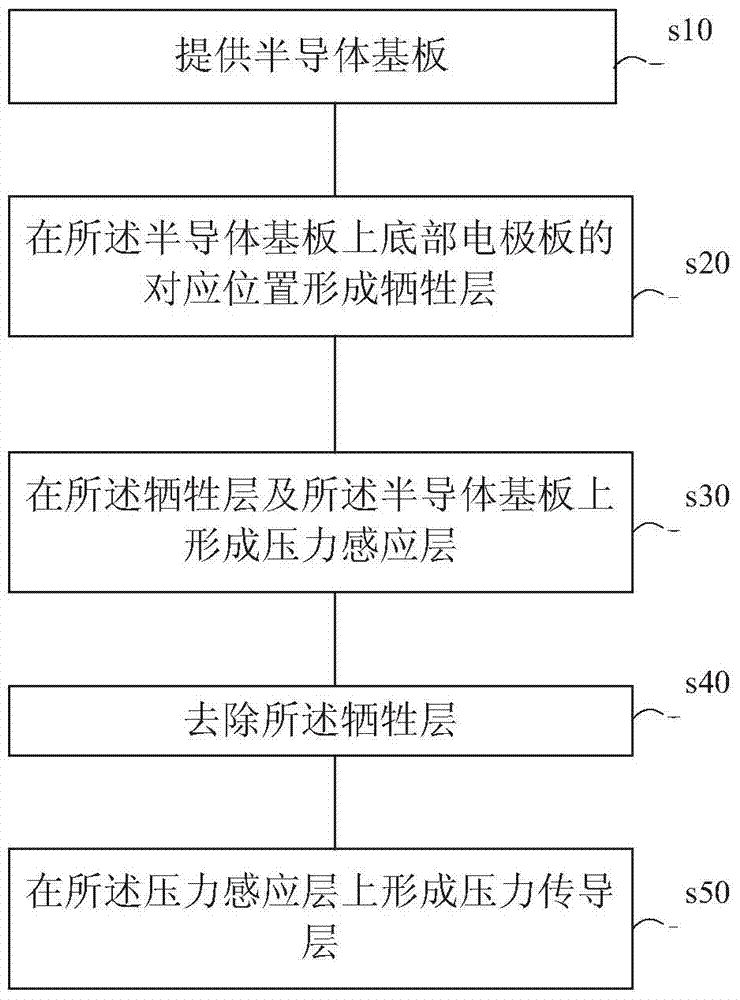

Pressure sensor and manufacturing method thereof

ActiveCN103900740AReduce thicknessImprove performanceDecorative surface effectsForce measurementCMOSPressure sense

The invention provides a pressure sensor and a manufacturing method of the pressure sensor. The manufacturing method of the pressure sensor comprises the steps that a semiconductor substrate is provided, wherein a CMOS circuit, an interconnection circuit and a bottom plate electrode are embedded in the semiconductor substrate, the CMOS circuit, the interconnection circuit and the bottom plate electrode are arranged in a stacked mode, and the interconnection circuit on the periphery of the bottom plate electrode is exposed from the semiconductor substrate; a sacrificial layer is formed on the position, corresponding to the bottom plate electrode, on the semiconductor substrate; a pressure sensing layer is formed on the sacrificial layer and on the semiconductor substrate; the sacrificial layer is removed, and a cavity is defined by the pressure sensing layer and the semiconductor substrate; a pressure conducting layer is formed on the pressure sensing layer and located above the cavity, wherein the pressure sensing layer is formed by forming a silicon germanium-noncrystalline silicon-silicon germanium stacked structure on the sacrificial layer. Compared with the prior art, due to the fact that the composite stacked structure is adopted by the pressure sensing layer, stress in the pressure sensing layer can be reduced; due to the fact that the stacked structure with multiple layers is adopted, the thickness of membranes, made of the same material, of each layer is reduced, stress is greatly reduced, and the performance of devices is improved.

Owner:ZHEJIANG JUEXIN MICROELECTRONICS CO LTD

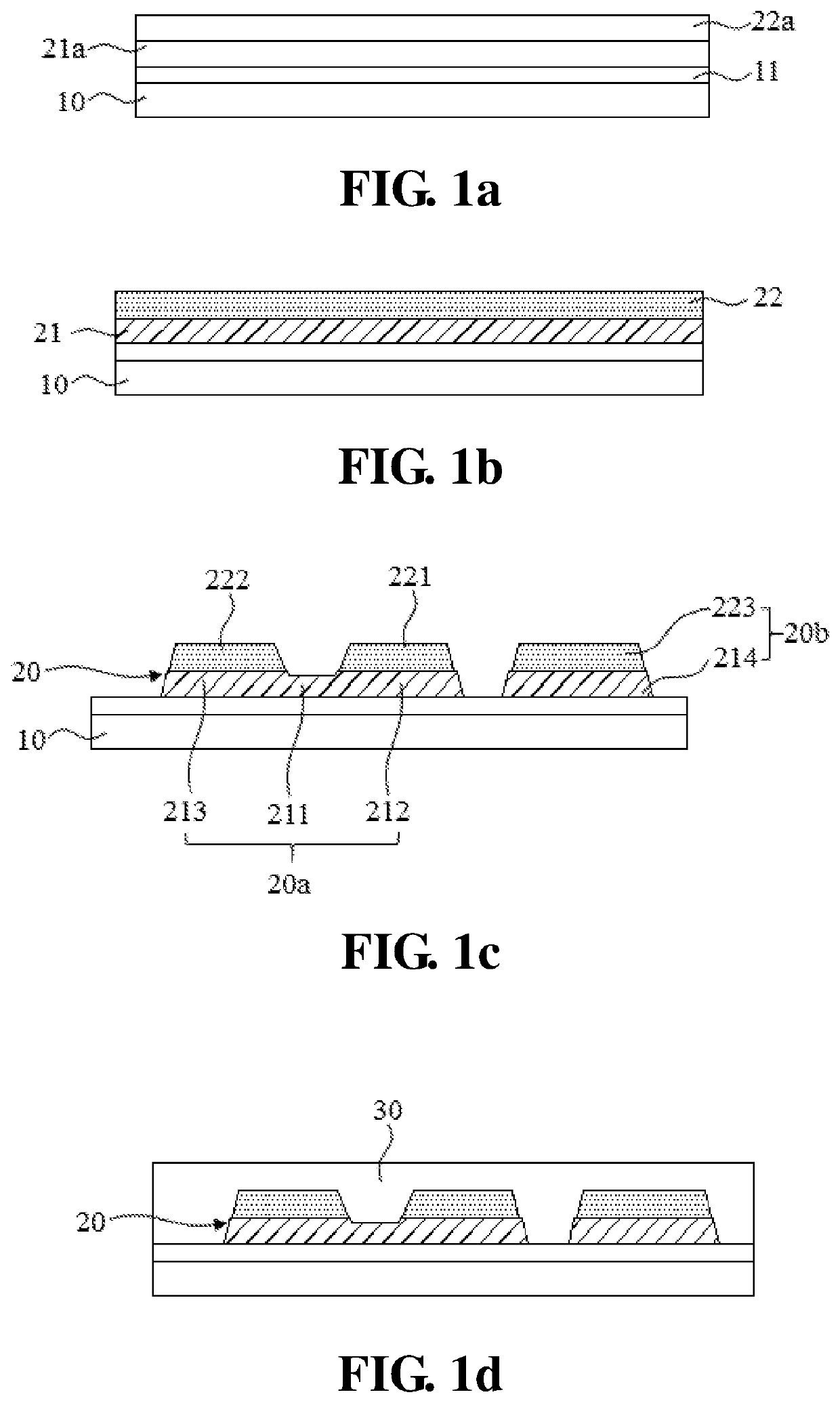

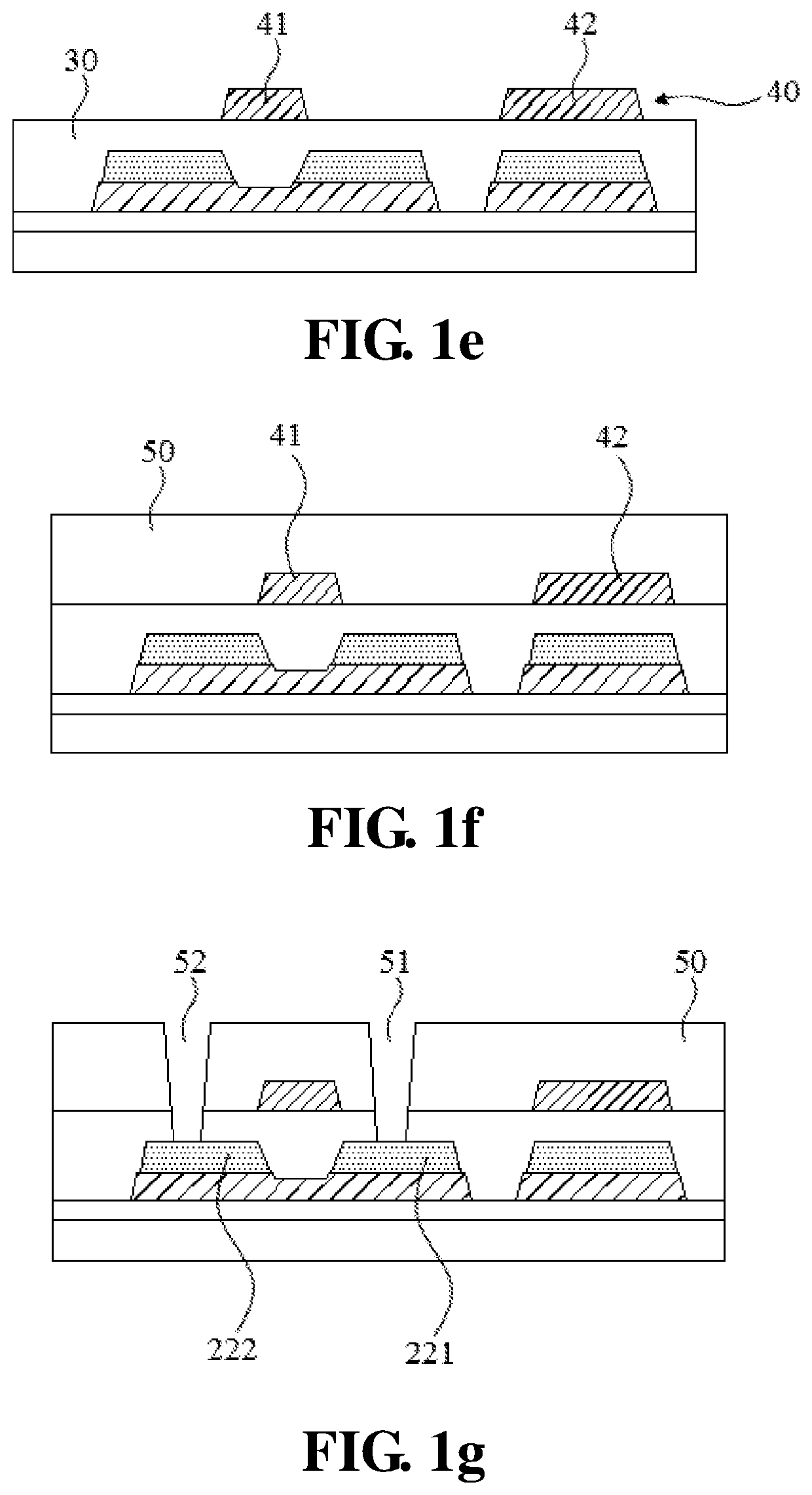

TFT substrate manufacturing method and TFT substrate

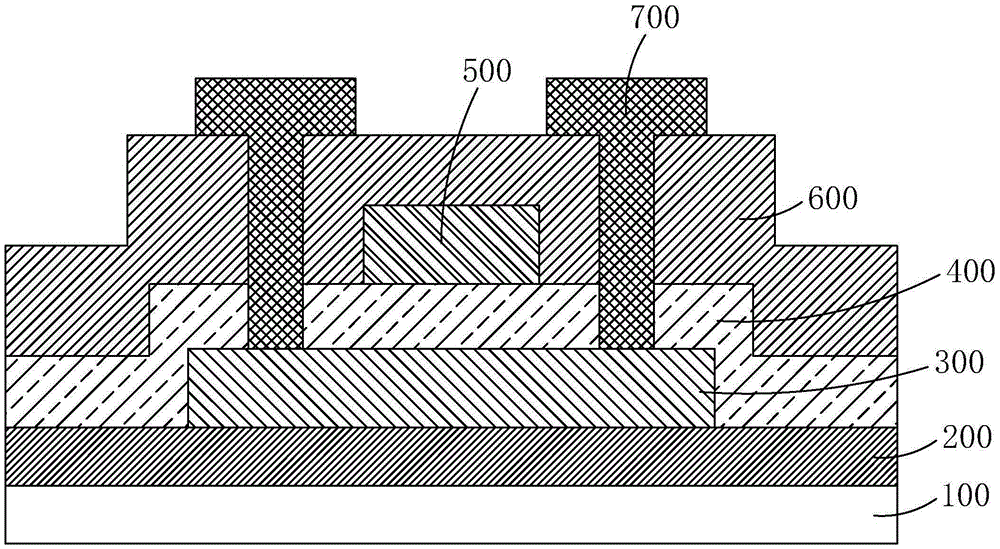

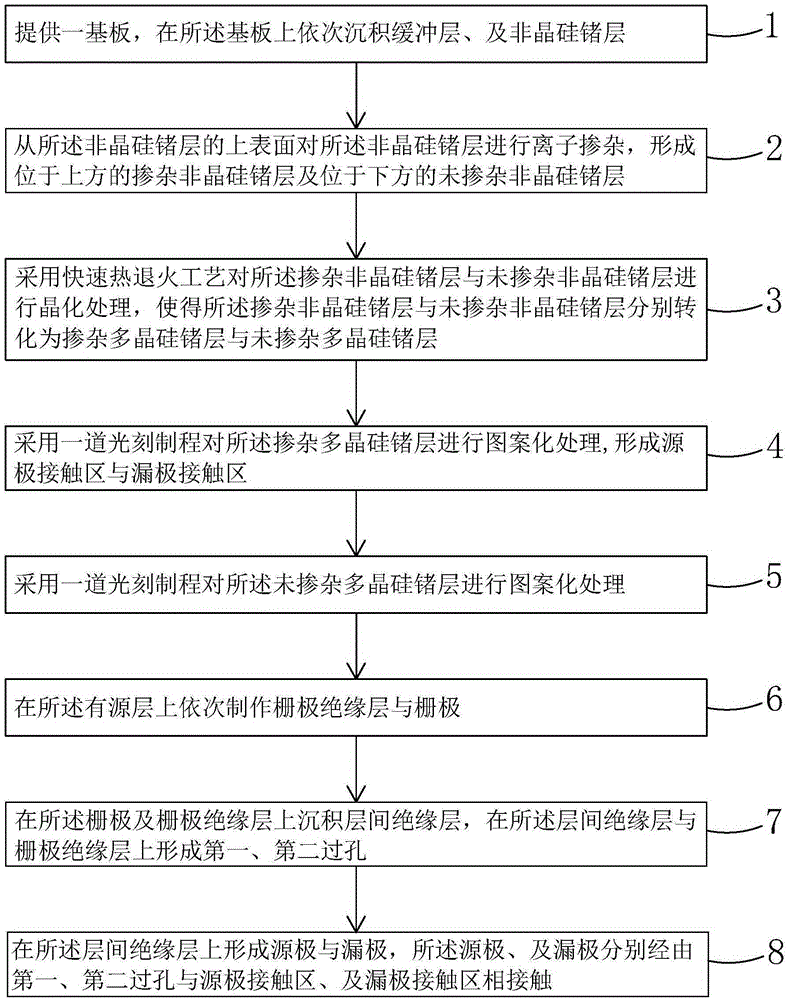

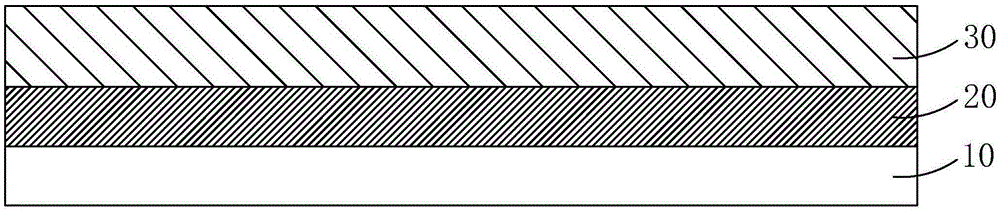

ActiveCN105355593AImprove electrical performanceShorten crystallization timeSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsCrystallization temperature

The invention provides a TFT substrate manufacturing method and a TFT substrate. The TFT substrate manufacturing method comprises the steps of depositing a buffer layer and an amorphous silicon germanium layer on a substrate; implanting doped ions at the upper portion of the amorphous silicon germanium layer so as to form a doped amorphous silicon germanium layer; employing a rapid thermal annealing process for crystallization processing on the doped amorphous silicon germanium layer and the un-doped amorphous silicon germanium layer. Because the crystallization process begins from the doped amorphous silicon germanium layer and the crystallization temperature of the doped amorphous silicon germanium layer is low, the crystallization process can be carried out at a low temperature; because the un-doped amorphous silicon germanium layer in contact with the doped amorphous silicon germanium layer can be crystallized continuously at the low temperature, the doped polysilicon germanium layer and the un-doped polysilicon germanium layer can be obtained; compared with prior art, like existing solid phase crystallization, the crystallization process of the present invention can be carried out at a lower temperature, and the crystallization time can be shortened; the crystallization effect can be improved; and larger and more uniform crystal grains can be obtained.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Solar cell based on silicon nanowires

InactiveCN105789346AImprove collection efficiencyChange structurePhotovoltaic energy generationSemiconductor devicesTrappingP type silicon

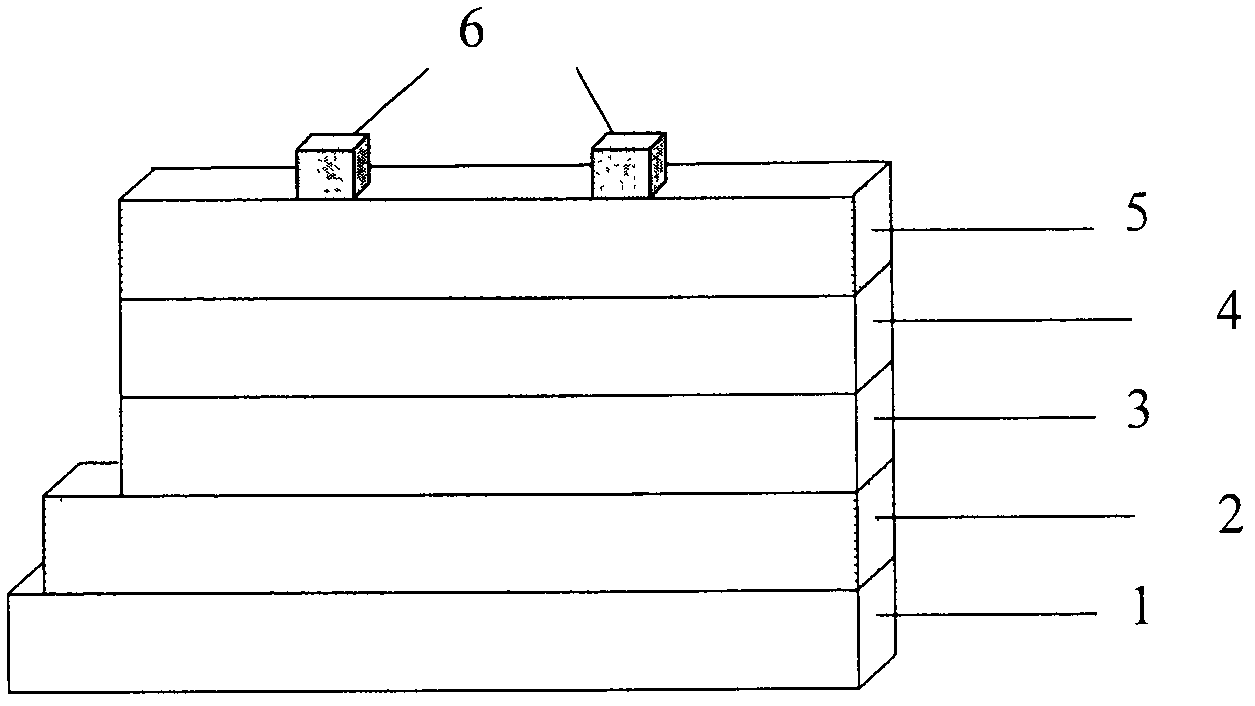

The invention discloses a solar cell based on silicon nanowires. The solar cell comprises a back electrode (6) and a P-type silicon substrate (5), and is characterized in that: the upper surface of the P-type silicon substrate (5) adopts a silicon nanowire array structure, an i-type layer (4), an N-type amorphous silicon layer (3) and an indium tin oxide transparent conductive film (2) are laminated on the surface of the silicon nanowire array structure in sequence, the top end of the silicon nanowire array structure is provided with a positive electrode (1), the i-type layer (4) comprises a microcrystalline silicon intrinsic layer, an amorphous silicon germanium intrinsic layer, an amorphous silicon intrinsic layer and a microcrystalline silicon carbide intrinsic layer which are laminated on the surface of the silicon nanowire array structure in sequence. Since the surface of the P-type silicon substrate adopts the nanowire structure, the solar cell based on the silicon nanowires has good light trapping effect, increases carrier collection efficiency, changes structure and materials of the i-type layer, improves its passivation property, and improves energy conversion efficiency of the solar cell.

Owner:黄广明

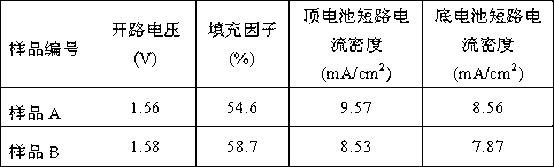

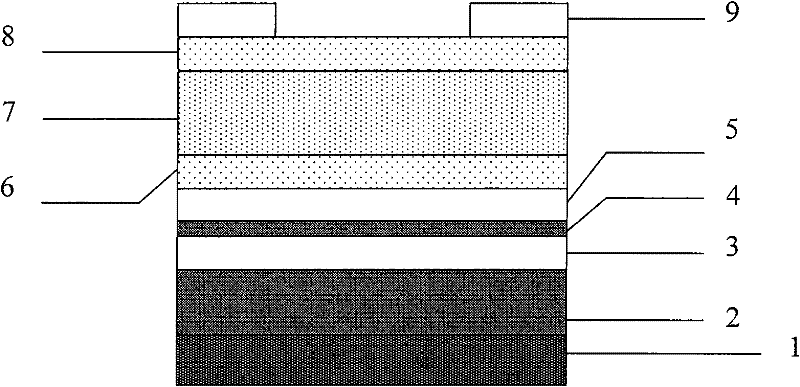

Silicon-based multi-junction tandem solar cell with flexible substrate and interlayer

InactiveCN102938430AImprove photoelectric conversion efficiencyImprove stabilityPhotovoltaic energy generationSemiconductor devicesBack reflectorPolyester

The invention discloses a silicon-based multi-junction tandem solar cell with a flexible substrate and an interlayer. The solar cell comprises a metal foil or polyester film flexible substrate, a back reflector electrode, a microcrystalline silicon or amorphous silicon germanium bottom cell, an interlayer and an amorphous silicon top cell, which are sequentially arranged from bottom to top, and a top cell, wherein the top electrode is a transparent conductive thin film; and the interlayer is a transparent conductive thin film located between the top cell and the bottom cell, can reflect short-wavelength light with a wavelength smaller than 650nm to 700nm and can transmit long-wavelength light with a wavelength larger than 650nm to 700nm. The interlayer can reflect a portion of incident light originally entering the bottom cell to the top cell so as to increase the short-circuit current density of the top cell. The cell structure provided by the invention is good to improve the short-circuit current density of the silicon-based multi-junction tandem solar cell, thereby improving photoelectric conversion efficiency and stability of the cell.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Solar cell integrating monocrystalline silicon and silicon-germanium film

InactiveUS20110132456A1Improve sunlight absorptionLow costFinal product manufacturePhotovoltaic energy generationBack surface fieldMetal electrodes

The present invention discloses a solar cell integrating monocrystalline silicon and a SiGe film, which comprises an N-type amorphous silicon-germanium (SiGe) film formed on a P-type monocrystalline silicon substrate. The P-type monocrystalline silicon substrate has a roughened surface to capture sunlight. A transparent conductive layer is stacked on the N-type amorphous SiGe film. Metal electrodes are formed on the transparent conductive layer and penetrate the transparent conductive layer to contact the N-type amorphous SiGe film. A P-type polycrystalline SiGe film is formed on the backside of the P-type monocrystalline silicon substrate. A back surface field is arranged below the P-type polycrystalline SiGe film to prevent from the recombination of major carriers. A backside metal electrode layer is arranged below the back surface field to function as a backside electrode and decrease the contact resistance. Thereby, the present invention can effectively promote the absorption rate of solar energy.

Owner:NATIONAL YUNLIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

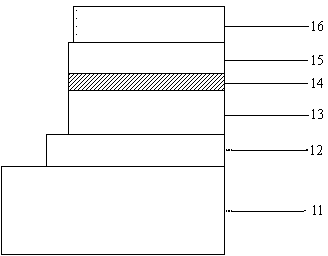

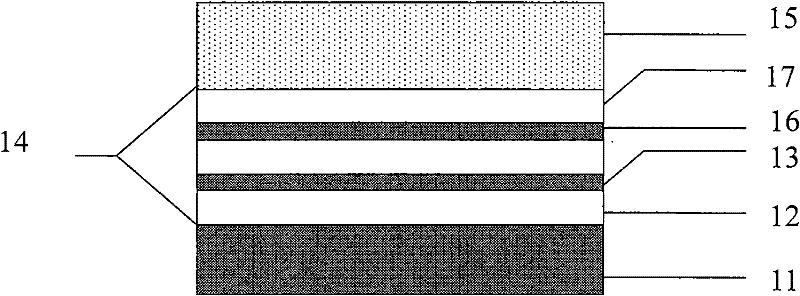

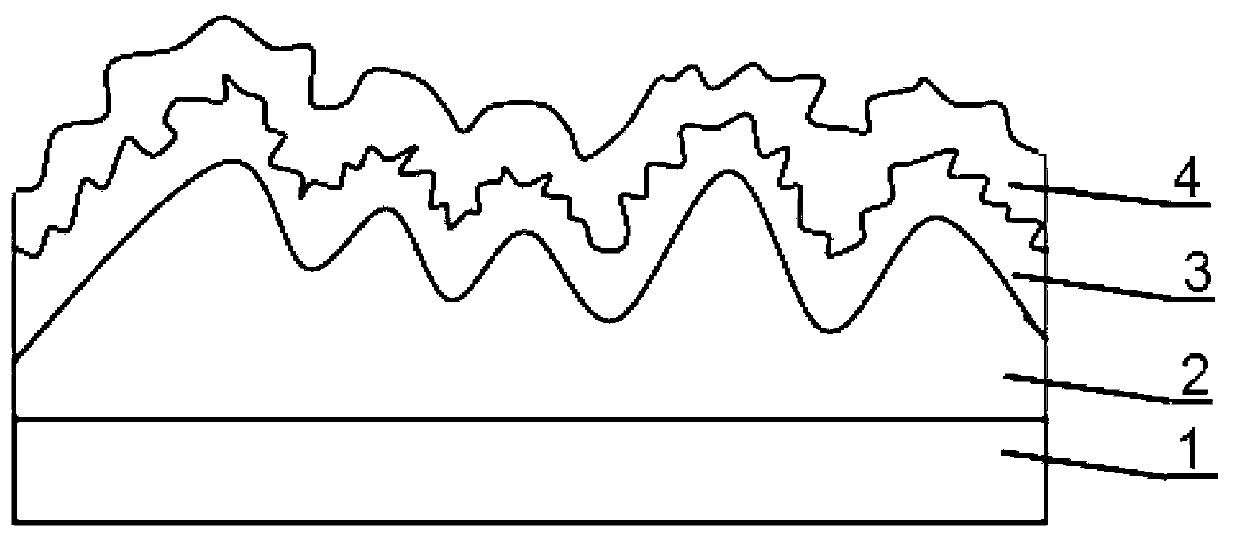

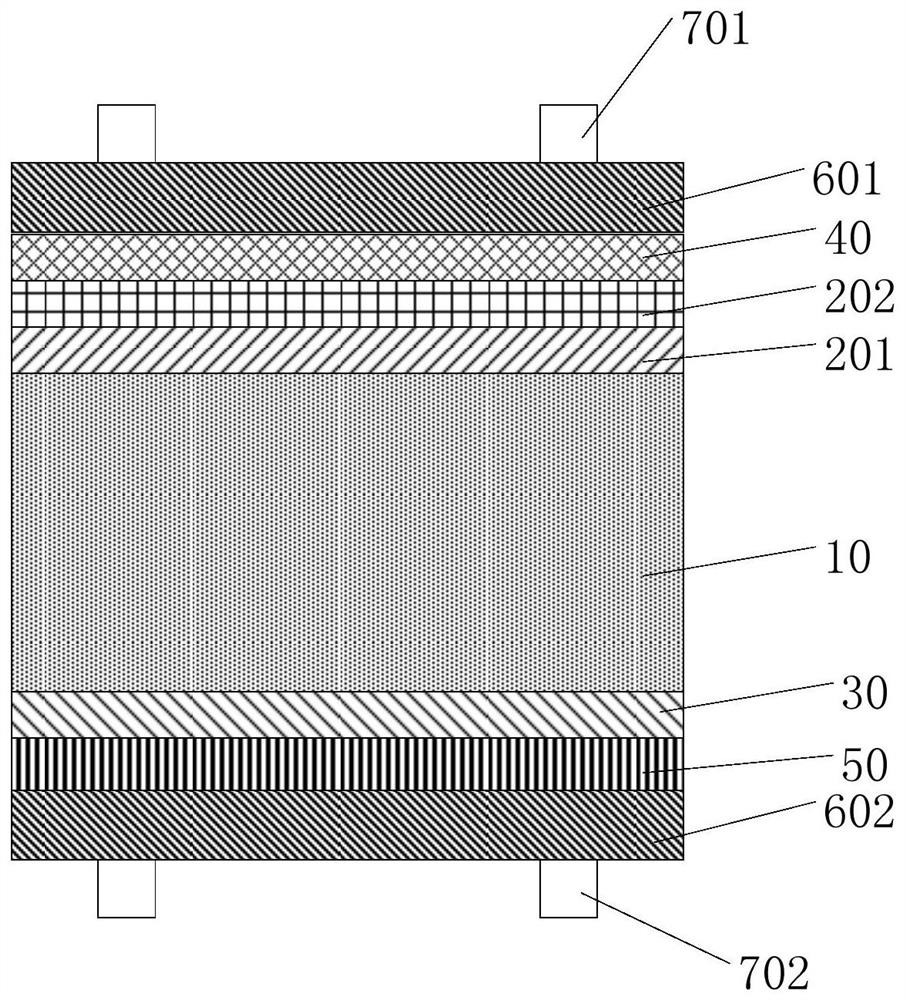

A multilayer back reflector structure for thin film solar cells

InactiveCN102270672AIncrease short circuit currentImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor devicesBack reflectorMicrocrystalline silicon

The invention discloses a multi-layer back reflection mirror structure for thin film solar cells. Comprising film (11) and periodic structure (14); Described film (11) is Ag film or Al film; Described periodic structure (14) is made of oxide conductive film (12) and ultra-thin film (13 ) film composed of a double-layer structure, and a layer of oxide conductive film (17); the double-layer structure can be repeated 1-5 times. The multi-layer back reflector structure provided by the invention has higher reflectivity in visible light and near-infrared bands, and solar cells can obtain higher short-circuit current. It can be applied to thin-film solar cells with absorption layers made of amorphous silicon, microcrystalline silicon, nano-silicon, amorphous silicon germanium, copper indium gallium selenide, and cadmium telluride, as well as various stacked solar cells composed of them.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Semiconductor device having an amorphous silicon-germanium gate electrode

A silicon germanium layer is deposited over a semiconductor substrate with a gate insulating film interposed between the substrate and the silicon germanium layer. Then, an upper silicon layer in an amorphous state is deposited on the silicon germanium layer. Thereafter, a gate electrode is formed by patterning the silicon germanium layer and the upper silicon layer.

Owner:PANASONIC CORP

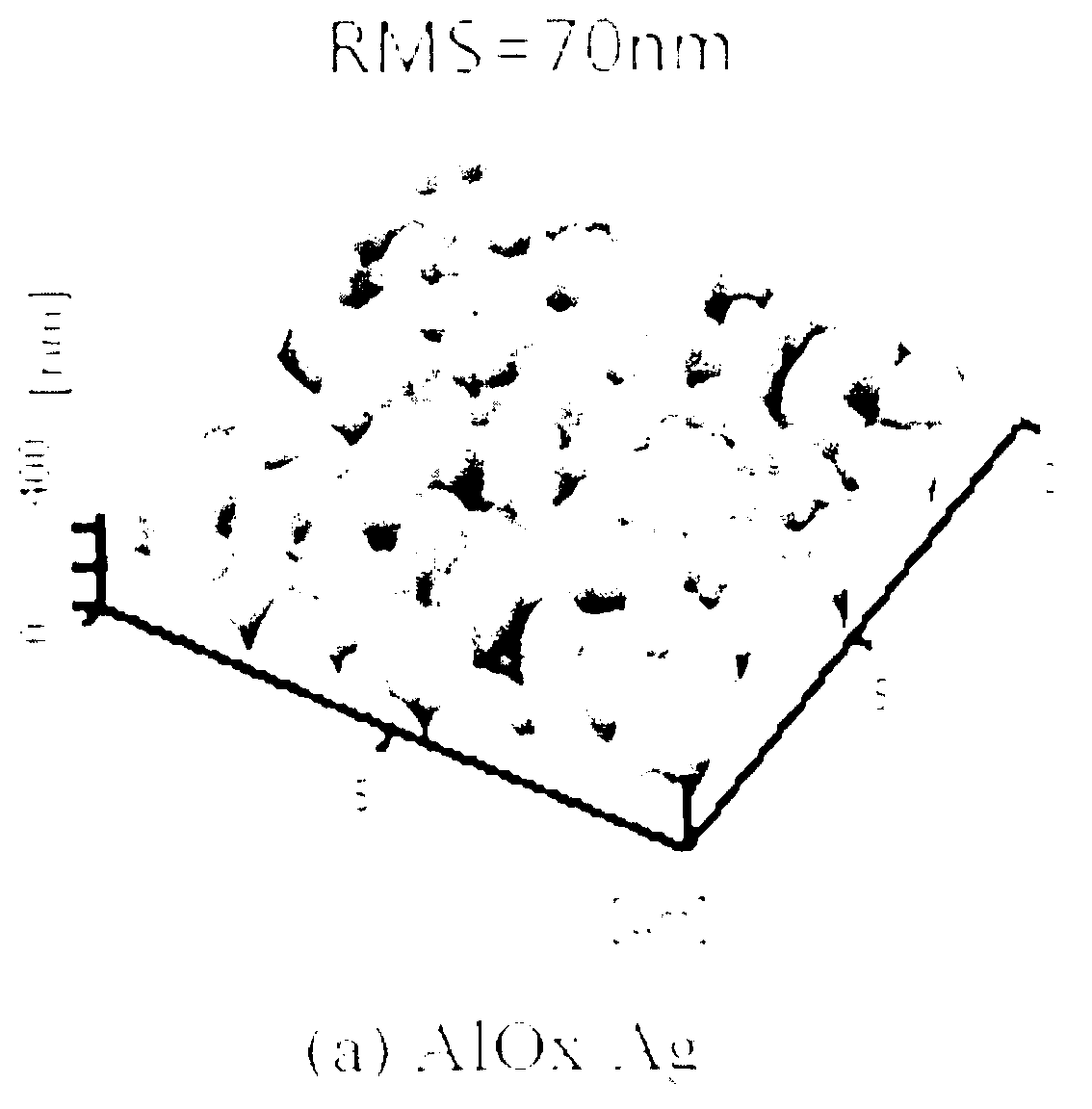

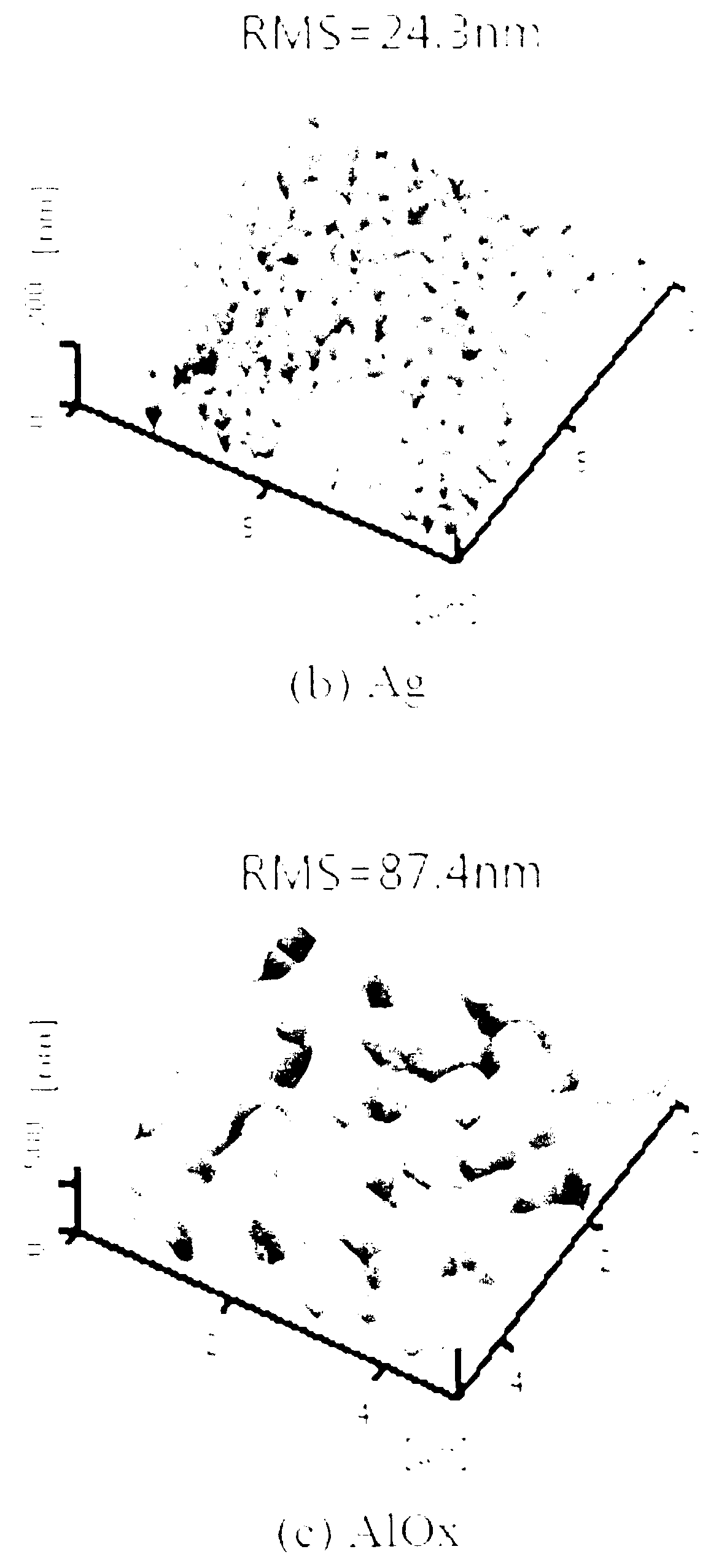

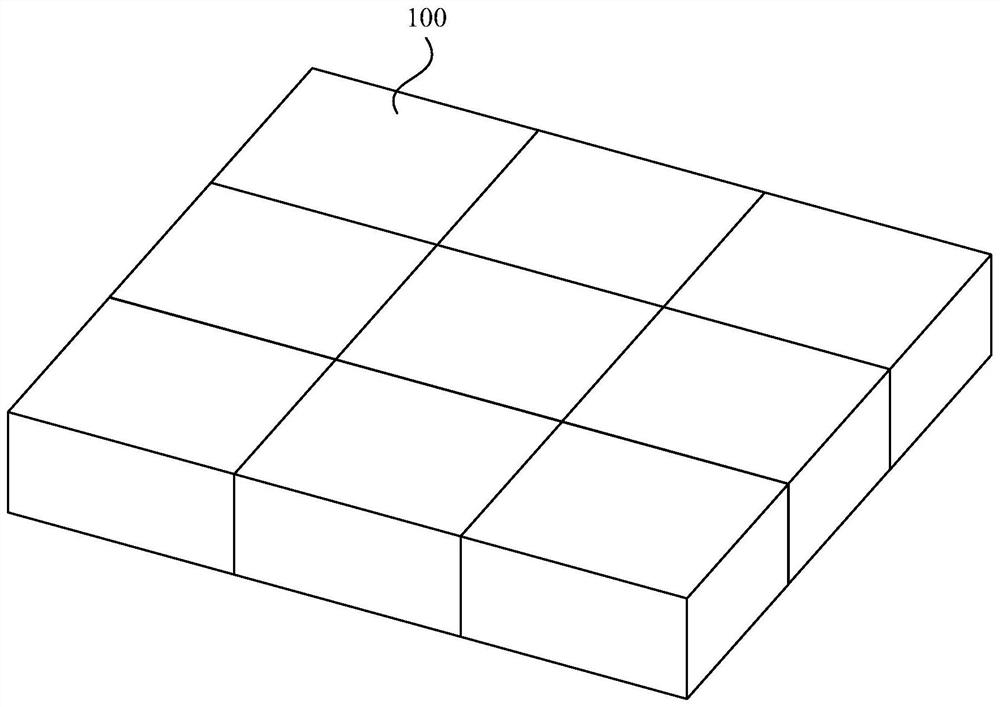

High-reflection and high-velvet-degree back electrode based on AlOx/Ag/ZnO structure

InactiveCN103280466AIncrease scatteringImprove the scattering effectFinal product manufactureSemiconductor devicesNano siliconThin membrane

The invention discloses a high-reflection and high-velvet-degree back electrode based on an AlOx / Ag / ZnO structure. The high-reflection and high-velvet-degree back electrode consists of a substrate, an AlOx thin film which has an outstanding long-wave light trapping effect and has a large suede structure, an Ag thin film which has wide-spectral-domain high reflectivity to sunshine and a medium layer ZnO thin film and has a laminated structure. A preparation method comprises the following steps of putting the cleaned substrate into a deposition system, sequentially depositing the AlOx thin film, the Ag thin film and the medium layer ZnO thin film, and manufacturing the composite back electrode based on the AlOx / Ag / ZnO structure. The high-reflection and high-velvet-degree back electrode has the advantages that the composite back electrode with the structure has the high-velvet-degree characteristic caused by the AlOx with the large-suede structure and also has the high reflectivity caused by the Ag thin film; the utilization rate and the conversion efficiency of light in a solar battery can be obviously improved; and the composite back electrode can be widely applied to unijunction and multi-junction laminated solar batteries made of materials such as amorphous silicon, amorphous silicon germanium, microcrystalline silicon, microcrystalline silicon germanium and nanometer silicon.

Owner:NANKAI UNIV

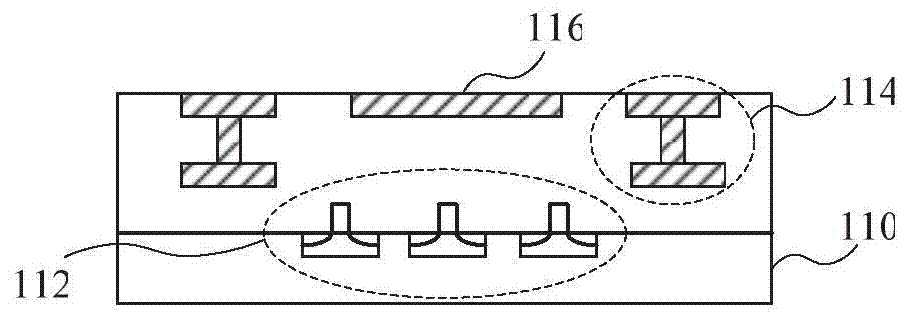

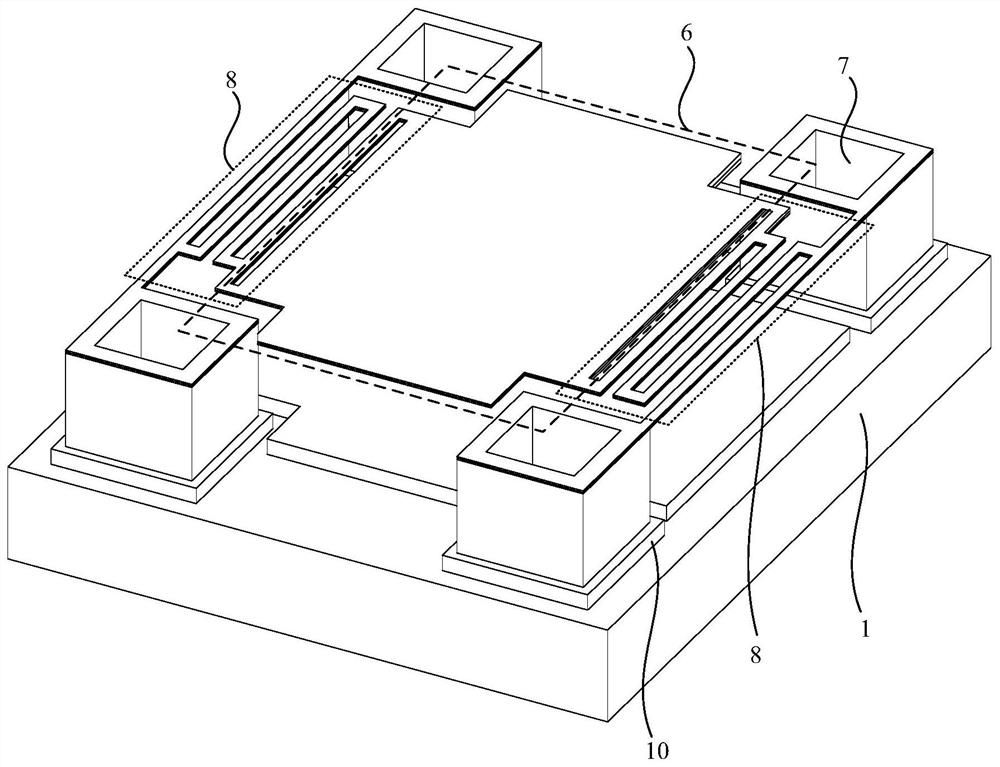

Infrared detector and preparation method thereof

ActiveCN113328002AShort thermal response timeImprove infrared responsivityFinal product manufactureSemiconductor devicesResponsivityDielectric layer

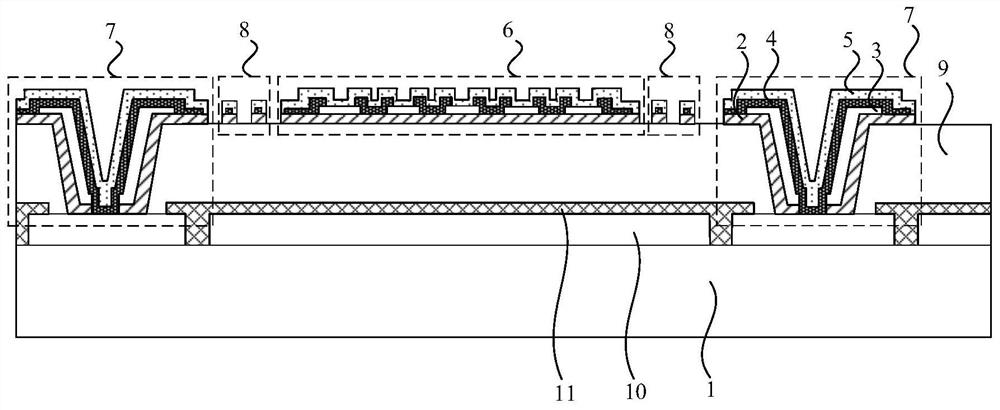

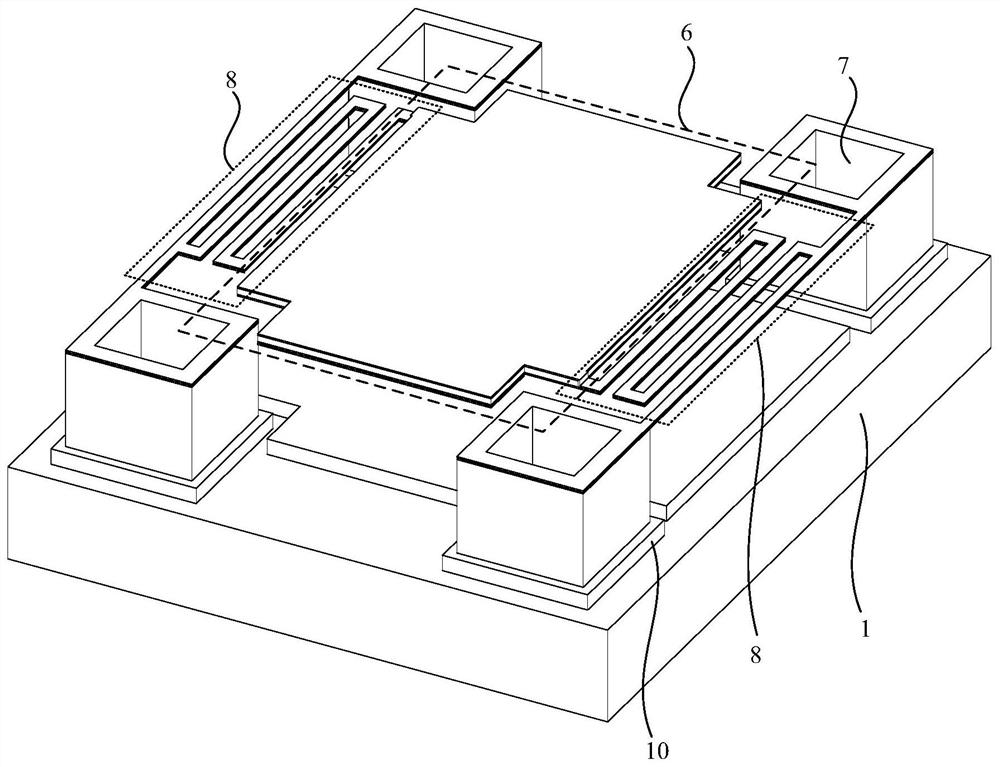

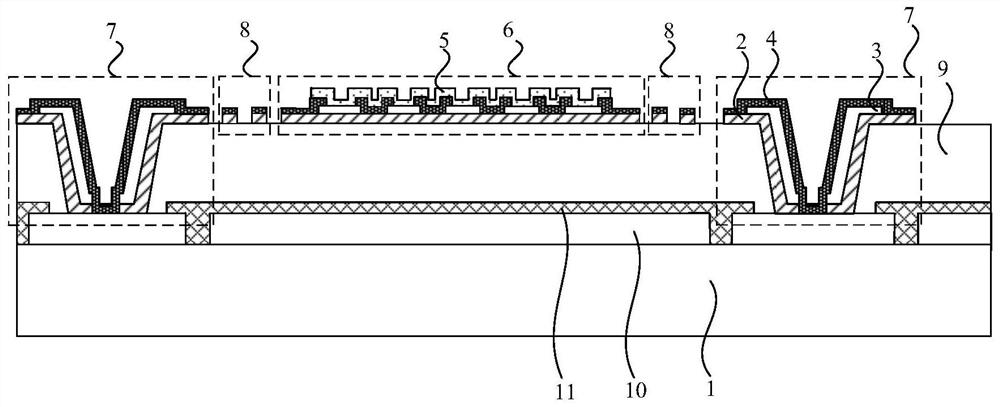

The invention relates to an infrared detector and a preparation method thereof. The infrared detector comprises a substrate, a thermosensitive layer, a dielectric layer, an electrode layer and a passivation layer, wherein the thermosensitive layer, the dielectric layer, the electrode layer and the passivation layer are located on the substrate, the dielectric layer is located between the thermosensitive layer and the electrode layer, the thermosensitive layer is located on one side, close to the substrate, of the dielectric layer, and the passivation layer is located on one side, away from the substrate, of the electrode layer. The infrared detector comprises a plurality of infrared detector pixels arranged in a matrix, each infrared detector pixel comprises an absorption plate structure, at least two micro-bridge columns and at least two beam structures, and the absorption plate structures are connected to the corresponding micro-bridge columns through the corresponding beam structures; the thermosensitive layer covers the area where the absorption plate structure and the beam structure are located, and the passivation layer covers the area where the absorption plate structure and the beam structure are located; and the material for forming the thermosensitive layer comprises one or more of amorphous silicon, amorphous carbon, amorphous germanium or amorphous silicon germanium. According to the technical scheme, the thermal response time of the infrared detector is shortened, and the infrared response rate of the infrared detector is improved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

Silicon-based solar cell and monocrystalline silicon piece passivation method thereof

ActiveCN105244411AAvoid damageReduce compoundingFinal product manufacturePhotovoltaic energy generationSilanesSolar cell

The invention provides a silicon-based solar cell and a monocrystalline silicon piece passivation method thereof. The method comprises the following steps of 1) cleaning of a monocrystalline silicon piece in which the monocrystalline silicon piece is cleaned to remove a oxide layer, metal ions and organic matters at the surface of the monocrystalline silicon piece; 2) dehydration of the monocrystalline silicon piece in which the cleaned monocrystalline silicon piece is dried and dehydrated; and 3) deposition of hydrogenated amorphous silicon germanium in which the dried monocrystalline silicon piece is placed in a plasma enhanced chemical vapor deposition system and preheated at the deposition temperature of 180 to 220 DEG C and the plasma excitation power of 10 to 20W, hydrogenated amorphous silicon germanium is deposited at the two sides of the monocrystalline silicon piece in the atmosphere of silane, germane and hydrogen, and passivation of the monocrystalline silicon piece is completed. According to the passivation method of the invention, the whole passivation process can be realized in the environment of 180 to 220 DEG C, and thermal damage is reduced; and the plasma excitation power in the whole passivation process ranges from 10 to 20W, plasma damage is reduced, the minority carrier life is high, and the passivation effect is good.

Owner:SHAANXI NORMAL UNIV

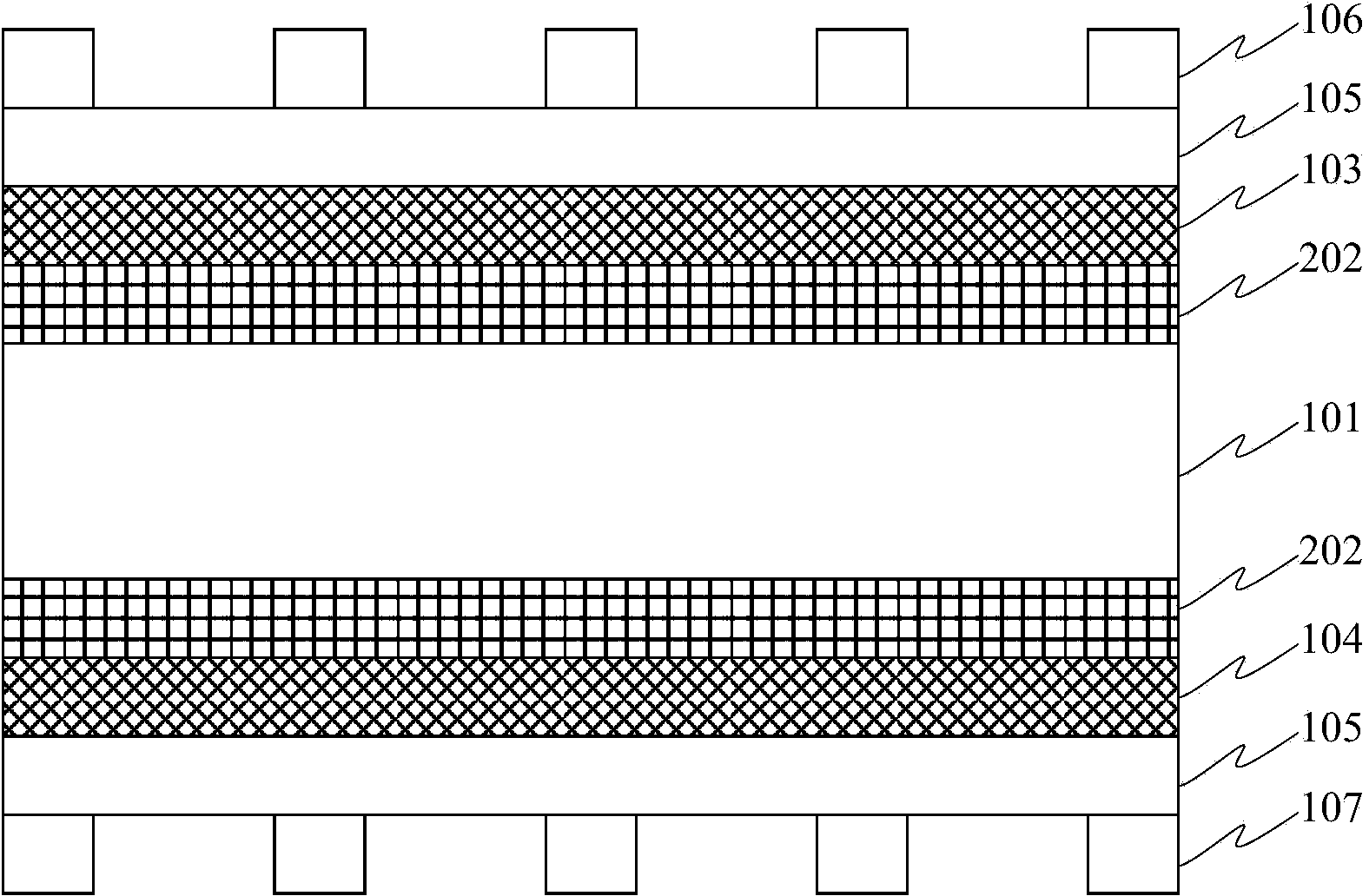

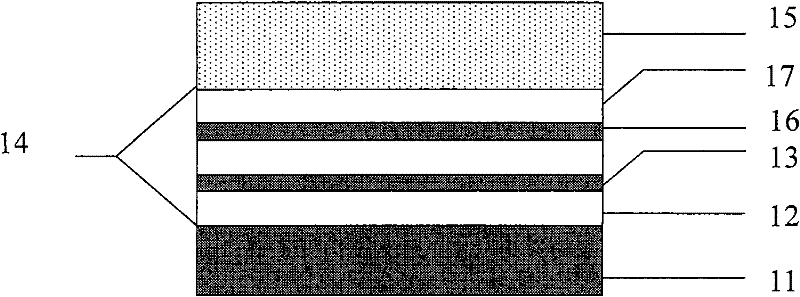

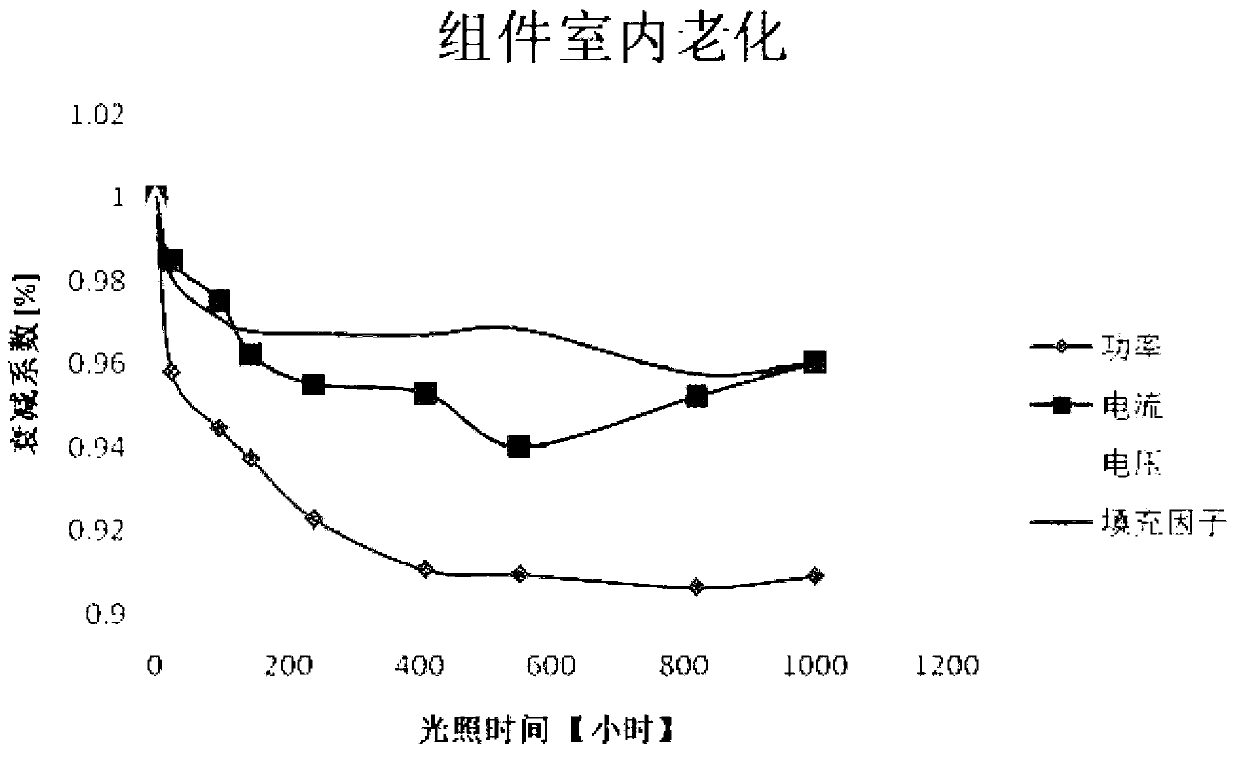

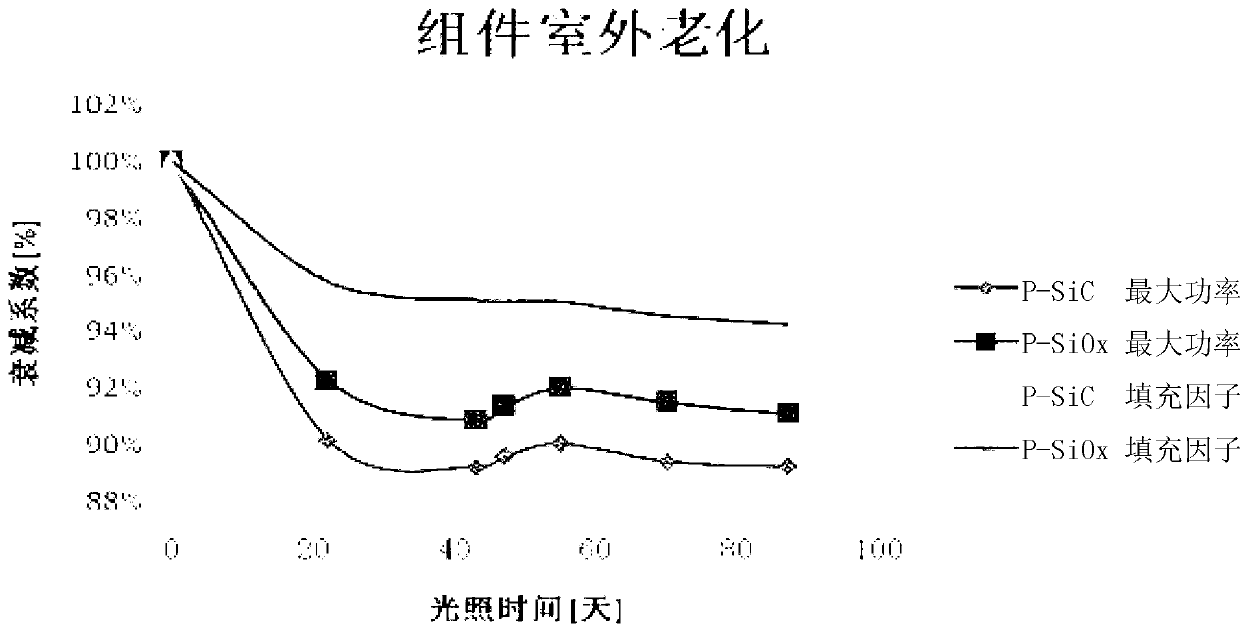

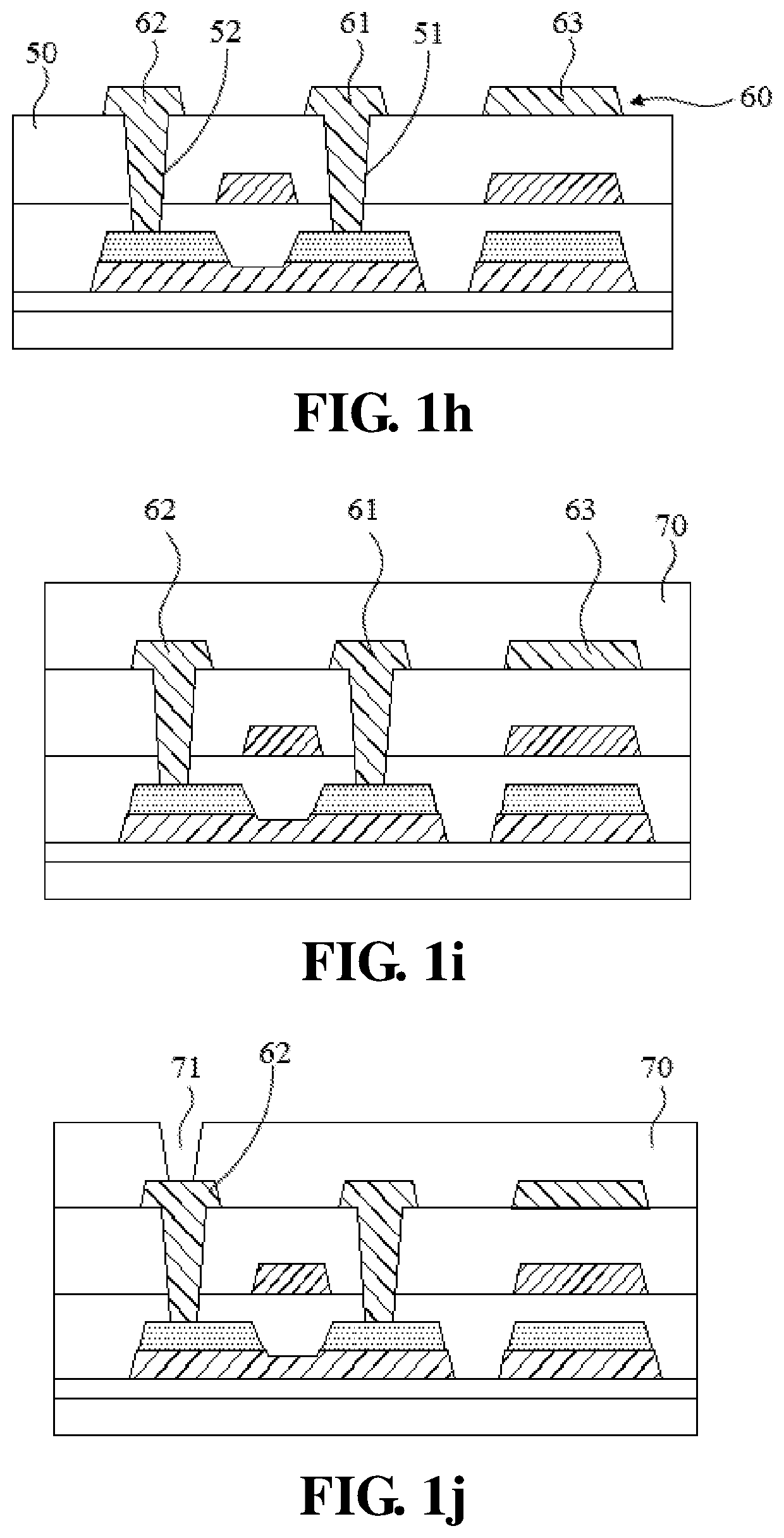

Amorphous silicon germanium thin-film solar cell having double-layer interface band gap buffer layer

ActiveCN105280736AEasy transferReduce chance of recombinationPhotovoltaic energy generationSemiconductor devicesMicro nanoCharge carrier

The invention discloses an amorphous silicon germanium thin-film solar cell having a double-layer interface band gap buffer layer. The amorphous silicon germanium thin-film solar cell comprises an electrode I, an n-type doped amorphous silicon thin film, an n-i buffer layer, a continuously variable band gap intrinsic (i type) amorphous silicon germanium thin film, an i-p double-layer band gap buffer layer, a p-type doped amorphous silicon thin film and an electrode II which are successively prepared on a substrate; and the electrode I and the electrode II are respectively a bottom electrode and a top electrode of the cell. A digital flowmeter is controlled through a computer, the continuously variable band gap amorphous silicon germanium thin film is prepared, and hole transmission is effectively increased; and, through adoption of the double-layer band gap buffer layer structure, energy band mismatching of a p-type window layer and the amorphous silicon germanium thin film is reduced, and then recombination of carriers at an interface defect state is reduced. Furthermore, the invention provides a method for preparing a micro-nano structure on a back reflection electrode, the optical paths of light rays in the cell can be increased, and then light absorption is increased.

Owner:GRIMAT ENG INST CO LTD

Infrared detector and preparation method thereof

ActiveCN113328003AShort thermal response timeImprove infrared responsivityFinal product manufactureSolid-state devicesResponsivityDielectric layer

The invention relates to an infrared detector and a preparation method thereof. The infrared detector comprises a substrate, a thermosensitive layer, a dielectric layer, an electrode layer and a passivation layer, wherein the thermosensitive layer, the dielectric layer, the electrode layer and the passivation layer are located on the substrate; the dielectric layer is located between the thermosensitive layer and the electrode layer; the thermosensitive layer is located on one side, close to the substrate, of the dielectric layer; the passivation layer is located on one side, away from the substrate, of the electrode layer. The infrared detector comprises a plurality of infrared detector pixels arranged in a matrix, each infrared detector pixel comprises an absorption plate structure, at least two micro-bridge columns and at least two beam structures, and the absorption plate structures are connected to the corresponding micro-bridge columns through the corresponding beam structures; the thermosensitive layer covers the area where the absorption plate structure and the beam structure are located. The material for forming the thermosensitive layer comprises one or more of amorphous silicon, amorphous carbon, amorphous germanium or amorphous silicon germanium; the passivation layer covers the area where the absorption plate structure is located; and the material for forming the electrode layer at least comprises a titanium-tungsten alloy. According to the technical scheme, the infrared response rate of the infrared detector is improved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

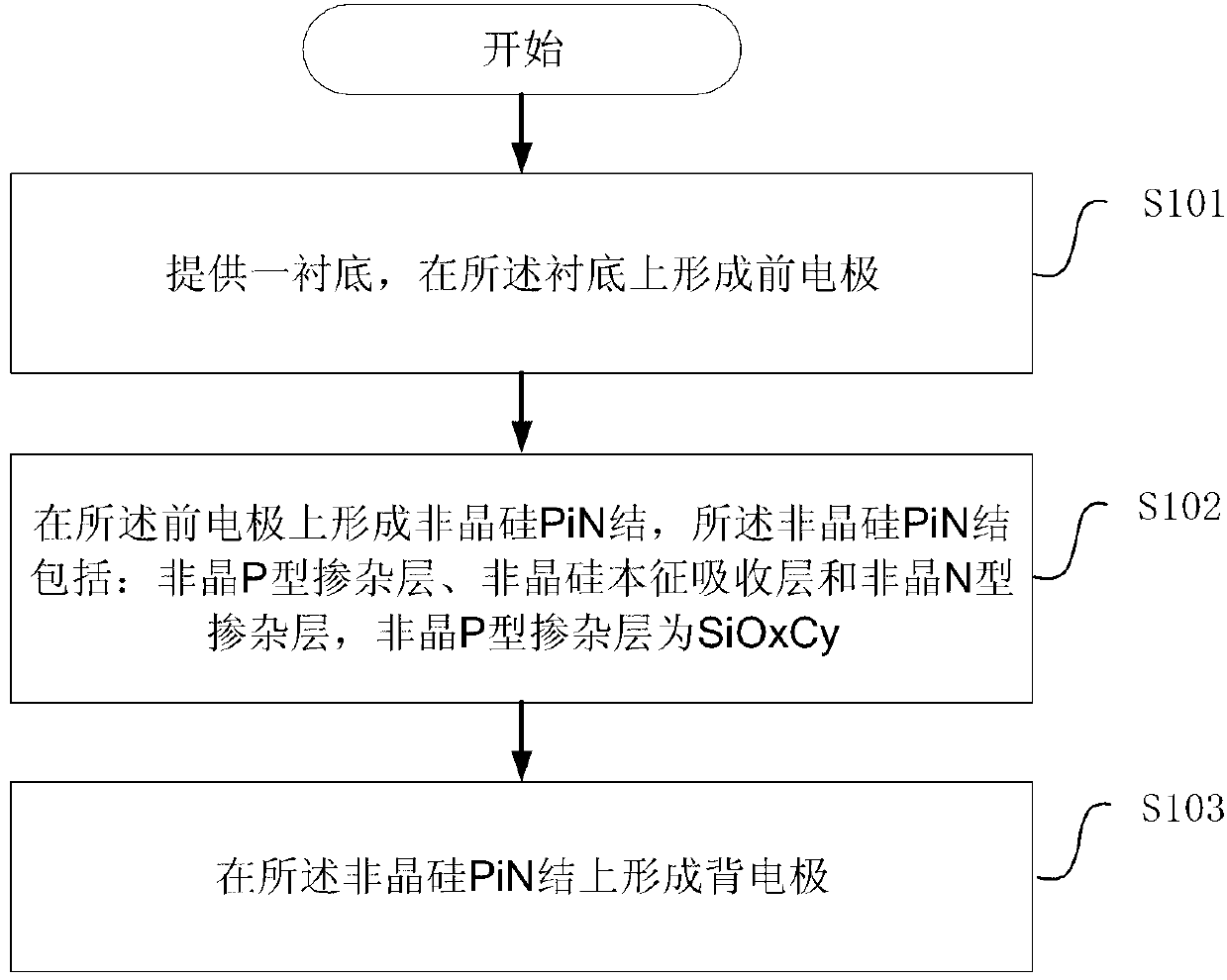

Manufacturing method and structure of solar battery

InactiveCN102956756AAddressing the Optical Band GapSolve the characteristicsFinal product manufacturePhotovoltaic energy generationSilicon thin filmSolar battery

The invention discloses a manufacturing method of a solar battery. In According to the manufacturing method, a C-O (Carbohydrate Oxidation) codoping method is adopted to prepare an amorphous p-type doped layer of an amorphous silicon roof cell of a silicon thin-film solar battery such as an amorphous silicon unijunction thin-film battery, and an amorphous silicon / amorphous silicon-germanium or amorphous silicon / microcrystalline silicon battery. Correspondingly, the invention further provides a solar battery structure formed through the manufacturing method disclosed by the invention. The manufacturing method and the solar battery structure can effectively eliminate the contradiction so far existing between the optical band gap and electric conduction property of the amorphous p-type doped layer prepared by silica, and the stability and the photoelectric conversion efficiency of the solar battery are improved.

Owner:ZHEJIANG ASTRONERGY

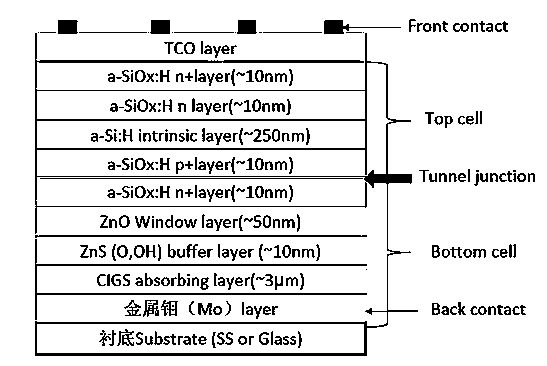

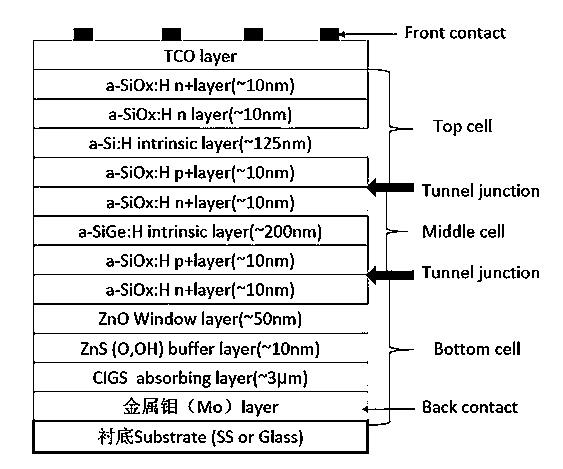

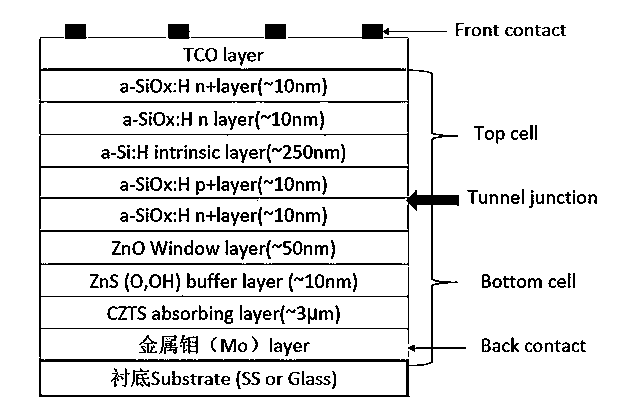

Novel stacked thin-film solar cell and manufacturing method thereof (a-Si:H/a-SiGe:H/CIGS or CZTS stacked solar cell and manufacturing method thereof)

InactiveCN104269450AImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationCZTSIntrinsics

The invention belongs to the field of efficient and low-cost thin-film solar cell and particularly provides a novel stacked thin-film solar cell and a manufacturing method thereof (an a-Si:H / a-SiGe:H / CIGS or CZTS stacked solar cell and a manufacturing method thereof). The manufacturing method comprises the steps of using glass as a substrate and preparing all layers of thin films according to the sequence of Mo, a CIGS or CZTS bottom cell absorption layer, a ZnS (O, OH) bottom cell buffering layer, a ZnO bottom cell window layer, a cell pre-deposited transition layer in n-type heavy doping a-SiOx: H, a cell back electrode layer in p-type heavy doping a-SiOx: H, a cell intrinsic layer in a-SiGe: H, a cell window layer in the n-type heavy doping a-SiOx: H, a top cell back electrode in the p-type heavy doping a-SiOx: H, an a-Si: H top cell intrinsic layer, an n-type a-SiOx: H top cell window layer, an n-type heavy doping a-SiOx: H top cell window layer, a transparent conductive ITO thin film and a Ag / Al metal grid line front electrode. The copper indium gallium selenide or copper zinc tin sulfide / amorphous silicon germanium / amorphous silicon three-junction stacked thin-film solar cell is formed.

Owner:YUNNAN NORMAL UNIV

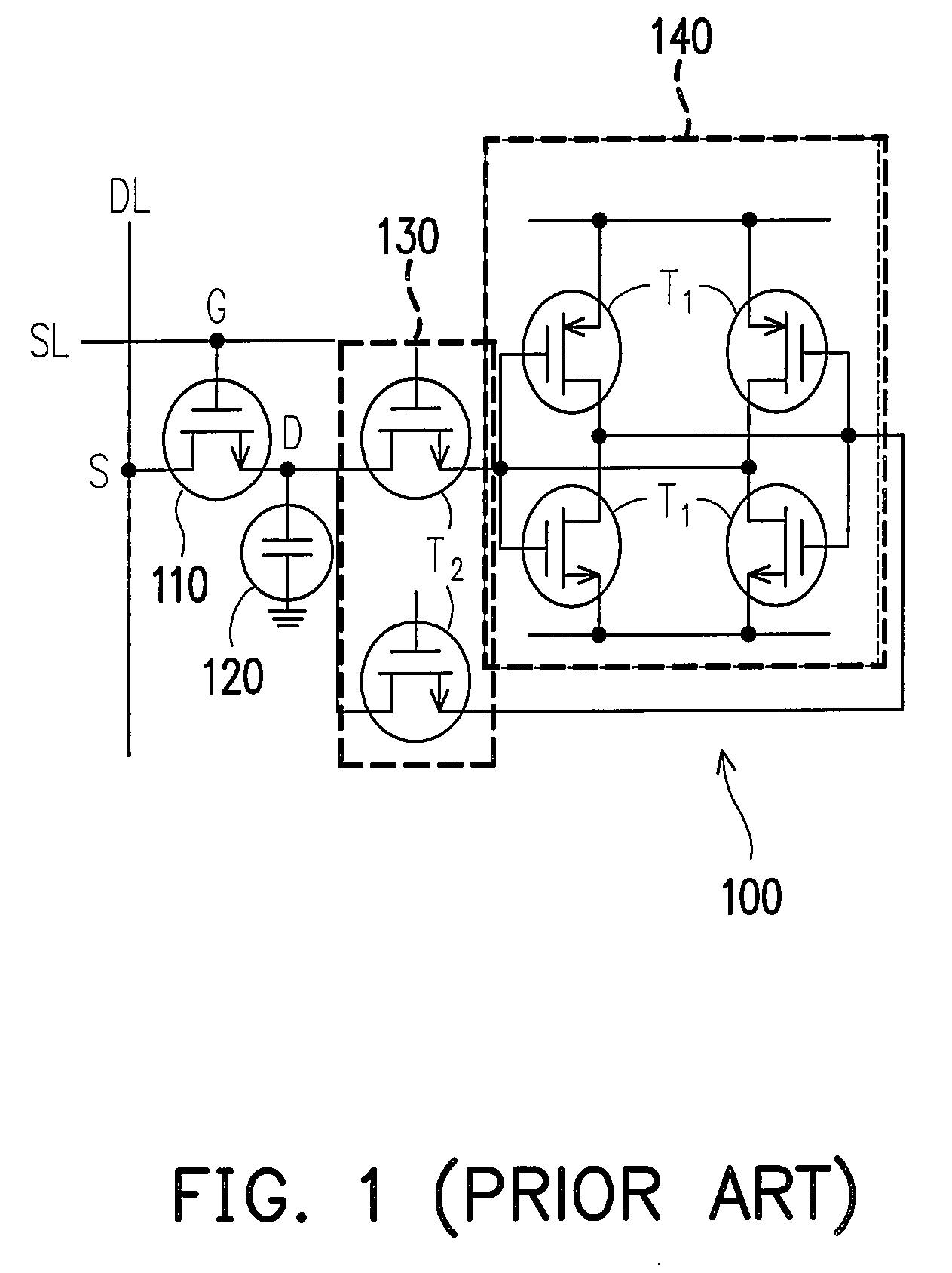

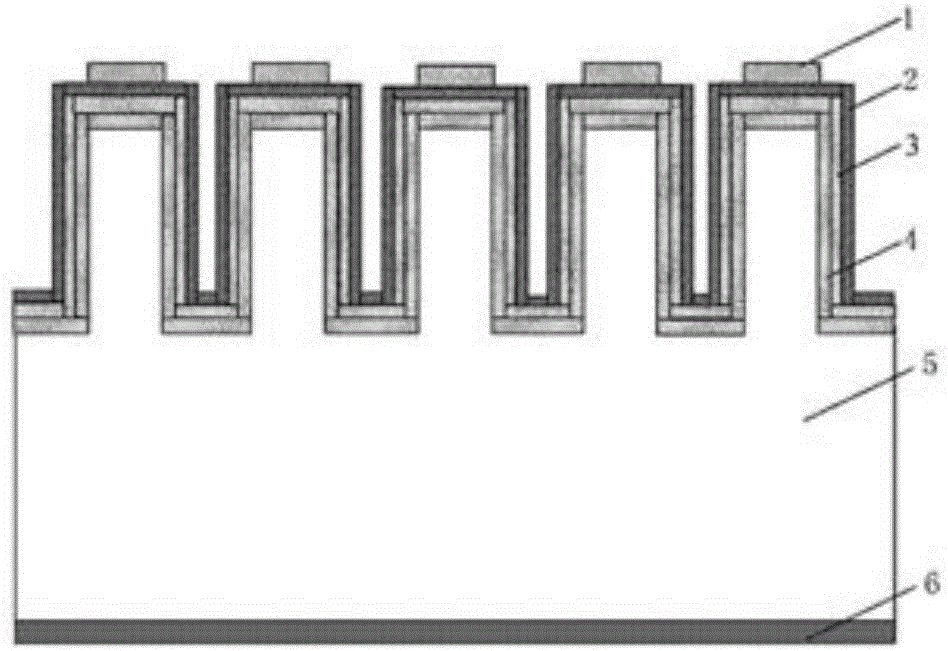

Thin film transistor array substrate, method of manufacturing the same, and display device including thin film transistor substrate

ActiveUS20190386143A1Decrease in crystallization temperatureShorten crystallization timeTransistorSolid-state devicesDisplay deviceBoron

The present disclosure discloses a method of manufacturing a thin film transistor (TFT) array substrate including a step of preparing a patterned active layer on a base substrate, wherein the step includes: sequentially forming an amorphous silicon (a-Si) thin film layer and a boron-doped (B-doped) amorphous silicon germanium (a-SiGe) thin film layer on the base substrate; performing crystallization on the a-Si thin film layer and the B-doped a-SiGe thin film layer using a thermal annealing process to obtain a polycrystalline silicon (poly-Si) thin film layer and a B-doped polycrystalline silicon germanium (poly-SiGe) thin film layer; and forming the patterned active layer by using a photolithography process to etch the poly-Si thin film layer and the B-doped poly-SiGe thin film layer. The present disclosure further discloses a TFT array substrate and a display device including the TFT array substrate.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Preparation of amorphous silicon germanium of thin film solar cell

InactiveCN104681671AQuality improvementGood precisionFinal product manufactureSemiconductor/solid-state device manufacturingChemical vapor depositionHydrogen dilution

The invention provides preparation of amorphous silicon germanium of a thin film solar cell. The technical scheme is that the influence of a hydrogen dilution ratio and substrate temperature on thin film photoelectric performance is researched. A high-quality amorphous silicon germanium thin film with an optical band gap of 1.5 eV and photosensitivity of 6*10<4> is prepared through optimization of the hydrogen dilution ratio and the substrate temperature. An amorphous silicon germanium (a. SiGe:H) single-junction solar cell with efficiency of 6.65 percent is prepared on the basis. The preparation has the advantage that the influence of the hydrogen dilution ratio and the substrate temperature on the photoelectric performance of the a. SiGe:H material in an RF-PECVD (Radio Frequency Plasma Enhanced Chemical Vapor Deposition) process is researched to prepare the high-quality a. SiGe:H thin film and prepare the a. SiGe:H cell on the basis.

Owner:QINGDAO SPARKLE ELECTRONICS SCI & TECH

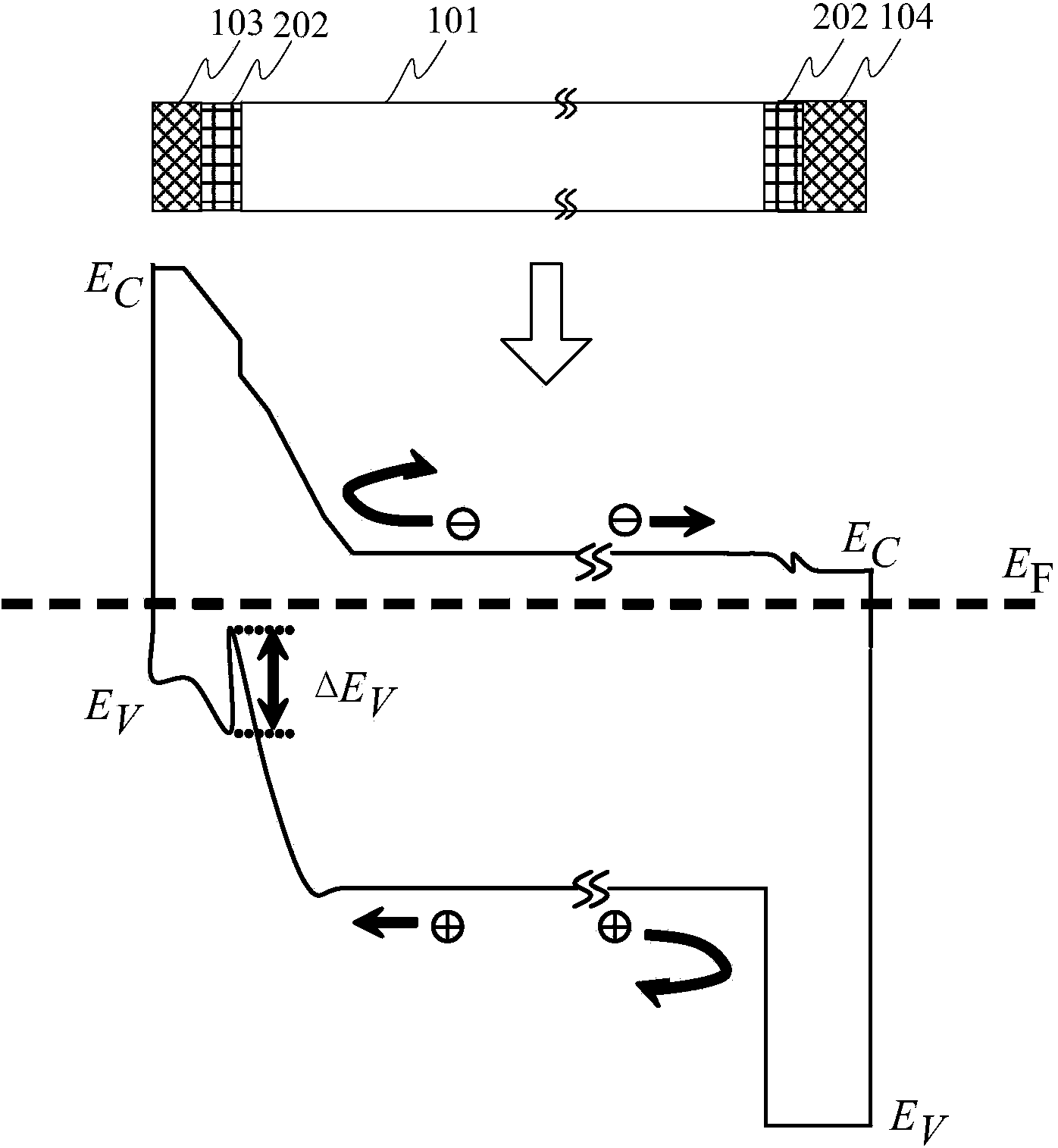

Silicon heterojunction solar cell and manufacturing method thereof

ActiveCN112002778AIncrease the open circuit voltageImprove fill factorFinal product manufacturePhotovoltaic energy generationHeterojunctionEngineering

The invention discloses a silicon heterojunction solar cell and a manufacturing method thereof, and relates to the technical field of solar cells. The invention aims to inhibit epitaxial growth of a silicon substrate interface by using an intrinsic amorphous silicon germanium layer and improve the passivation effect of the silicon substrate interface by using an intrinsic amorphous silicon layer.The silicon heterojunction solar cell comprises: an N-type silicon substrate; an intrinsic amorphous silicon germanium layer formed on one surface of the N-type silicon substrate; a first intrinsic amorphous silicon layer formed on the intrinsic amorphous silicon germanium layer; and a P-type doped amorphous silicon layer formed on the first intrinsic amorphous silicon layer. The manufacturing method of the silicon heterojunction solar cell is used for manufacturing the silicon heterojunction solar cell.

Owner:LONGI GREEN ENERGY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com