Photonic crystal back reflector provided with adjustable forbidden band and applied to silicon-based thin-film solar cell

A technology of solar cells and silicon-based thin films, applied in semiconductor devices, circuits, photovoltaic power generation, etc., can solve the problems of Al and stainless steel reflectivity less than Ag, increase in plant area and investment, improve cell efficiency, etc., to improve cell stability. , The effect of saving plant area and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

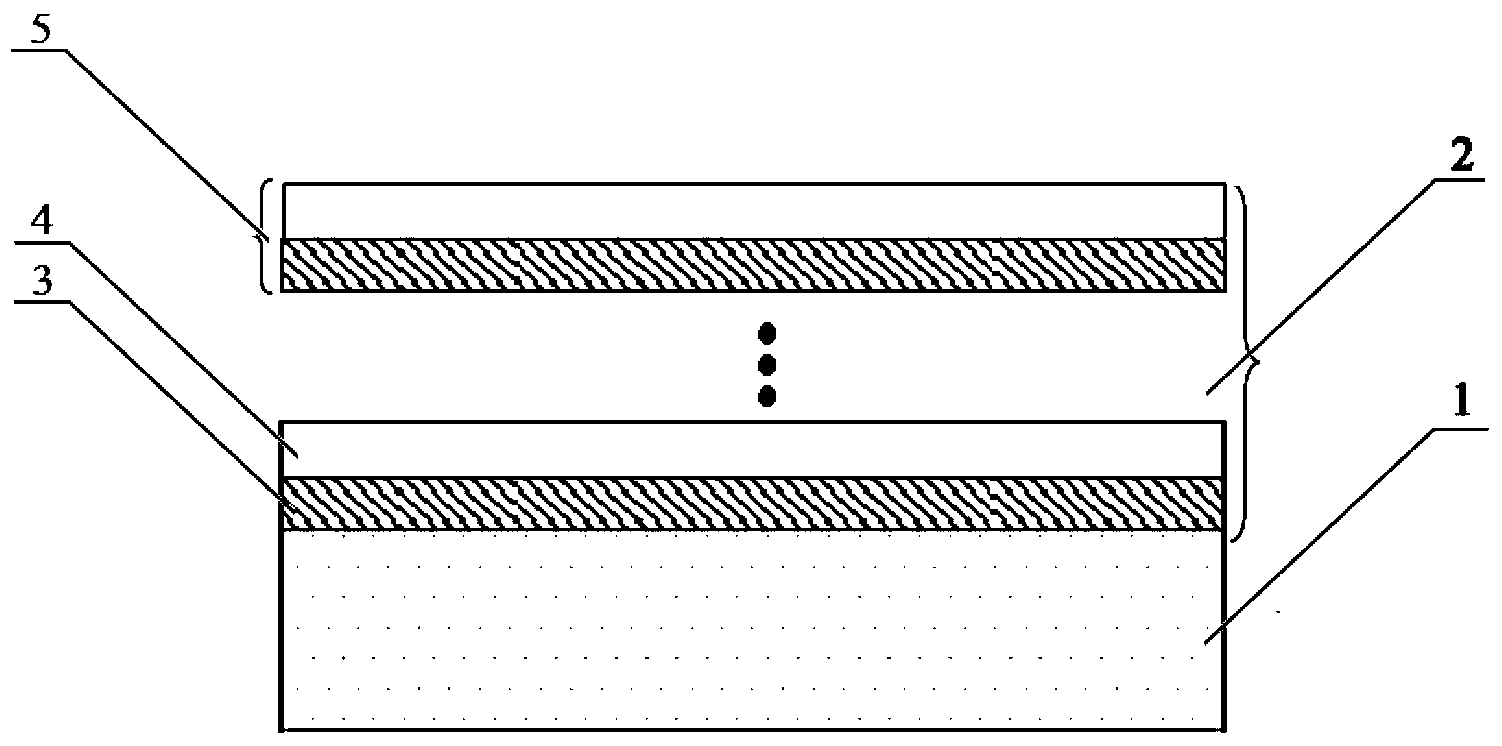

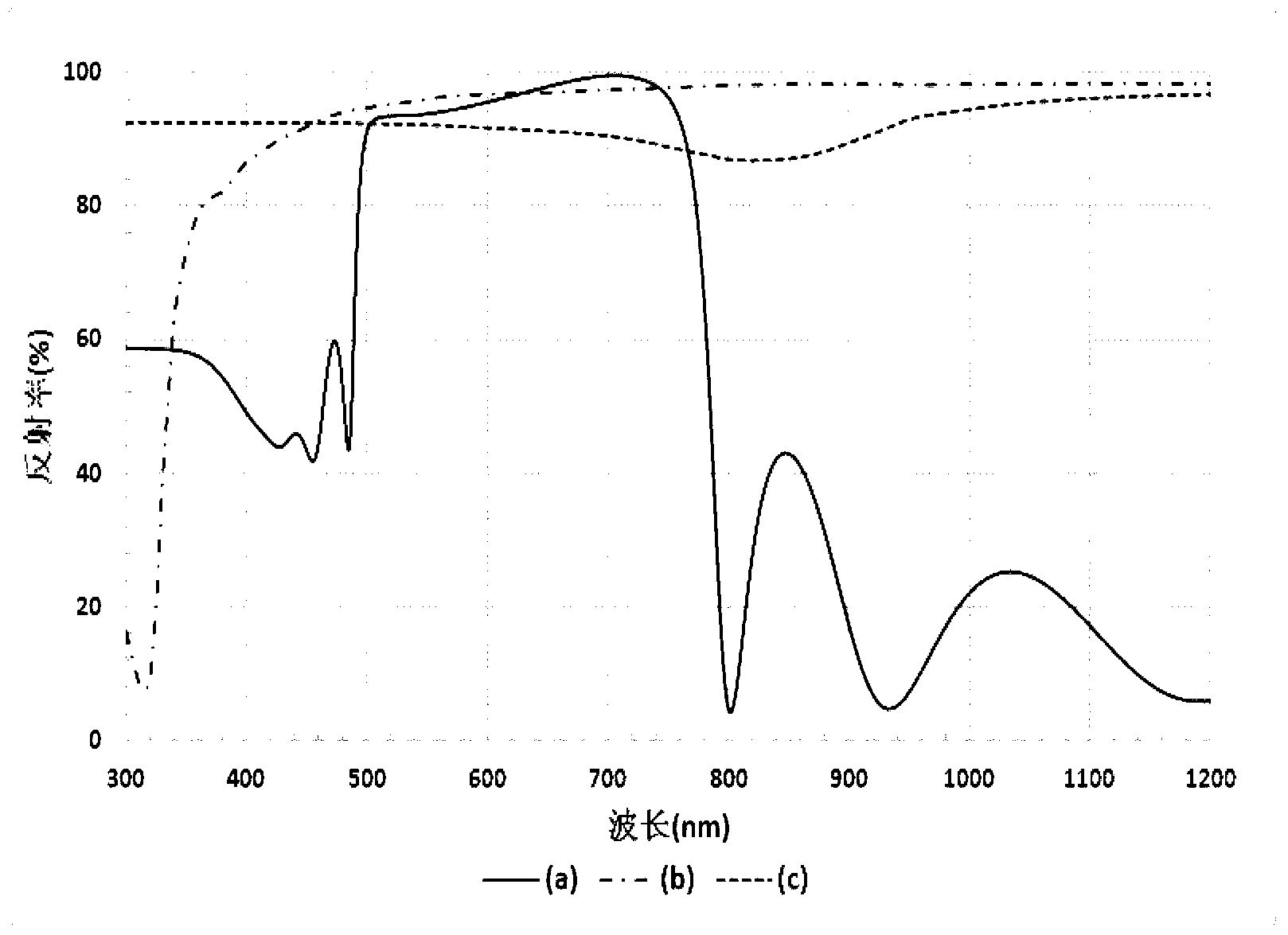

[0034] A bandgap-tunable photonic crystal back reflector, suitable for single-junction amorphous silicon thin-film solar cells, such as figure 1As shown, a substrate 1 is included, which is composed of a low-refractive-index silicon oxide film 3 and a high-refractive-index hydrogenated amorphous silicon film 4 periodically overlapped, the total number of periods is 5, and the thickness of the period is 200nm.

[0035] The silicon oxide film is prepared by RF-PECVD, the gas source is silane, hydrogen and carbon dioxide, the refractive index is 1.5, the thickness is 170nm, and the deposition parameters are as follows: power density 150mW / cm 2 , temperature 200°C, air pressure 200Pa, silane flow rate 30SCCM, hydrogen flow rate 60SCCM, carbon dioxide flow rate 20SCCM, deposition time 8min.

[0036] The hydrogenated amorphous silicon film is prepared by RF-PECVD, the gas source is silane and hydrogen, the refractive index is 4.5, the thickness is 30nm, and the deposition parameters...

Embodiment 2

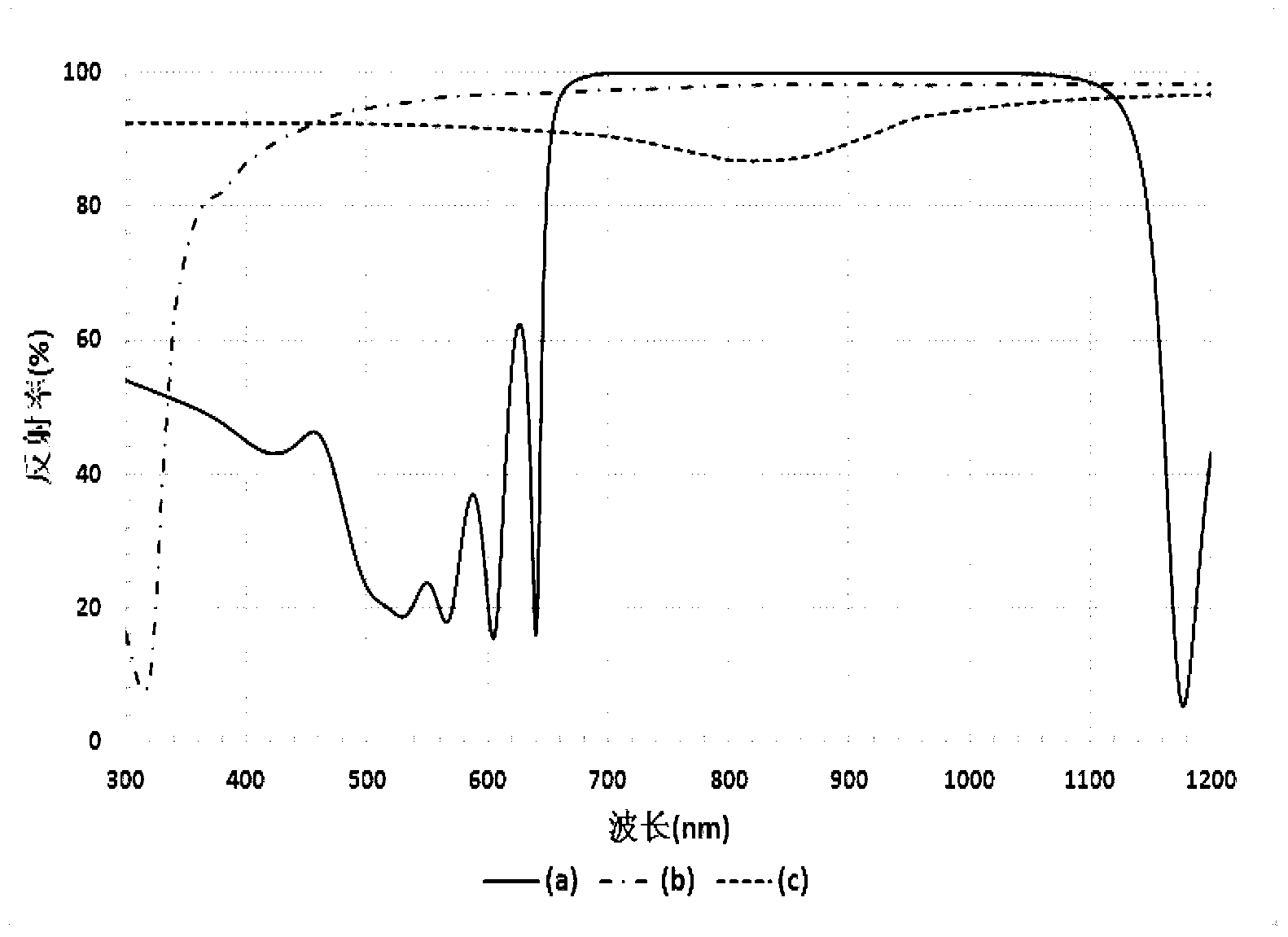

[0039] A photonic crystal back reflector with adjustable bandgap, suitable for double-junction amorphous silicon / microcrystalline silicon stacked solar cells, such as figure 1 As shown, it includes a substrate 1, which is composed of a low-refractive-index silicon oxide film 3 and a high-refractive-index hydrogenated amorphous silicon film 4 periodically overlapped, the total number of periods is 5, and the thickness of the period is 250nm. The silicon oxide film is prepared by RF-PECVD, the gas source is silane, hydrogen and carbon dioxide, the refractive index is 1.5, the thickness is 200nm, and the deposition parameters are as follows: power density 150mW / cm 2 , temperature 200°C, air pressure 200Pa, silane flow rate 30SCCM, hydrogen flow rate 60SCCM, carbon dioxide flow rate 20SCCM, deposition time: 11min.

[0040] The hydrogenated amorphous silicon film is prepared by RF-PECVD, the gas source is silane and hydrogen, the refractive index is 4.5, and the thickness is 50nm. ...

Embodiment 3

[0043] A bandgap adjustable photonic crystal back reflector, suitable for triple-junction amorphous silicon / amorphous silicon germanium / microcrystalline silicon stacked solar cells, such as figure 1 As shown, it includes a substrate 1, which is composed of a low-refractive index silicon oxide film 3 and a high-refractive index hydrogenated amorphous silicon film 4 periodically overlapped, the total number of periods is 5, and the thickness of the period is 280nm. The silicon oxide film is prepared by RF-PECVD, the gas source is silane, hydrogen and carbon dioxide, the refractive index is 1.5, the thickness is 200nm, and the deposition parameters are as follows: power density 150mW / cm 2 , temperature 200°C, air pressure 200Pa, silane flow rate 30SCCM, hydrogen flow rate 60SCCM, carbon dioxide flow rate 20SCCM, deposition time 11min.

[0044] The hydrogenated amorphous silicon film is prepared by RF-PECVD, the gas source is silane and hydrogen, the refractive index is 4.5, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com