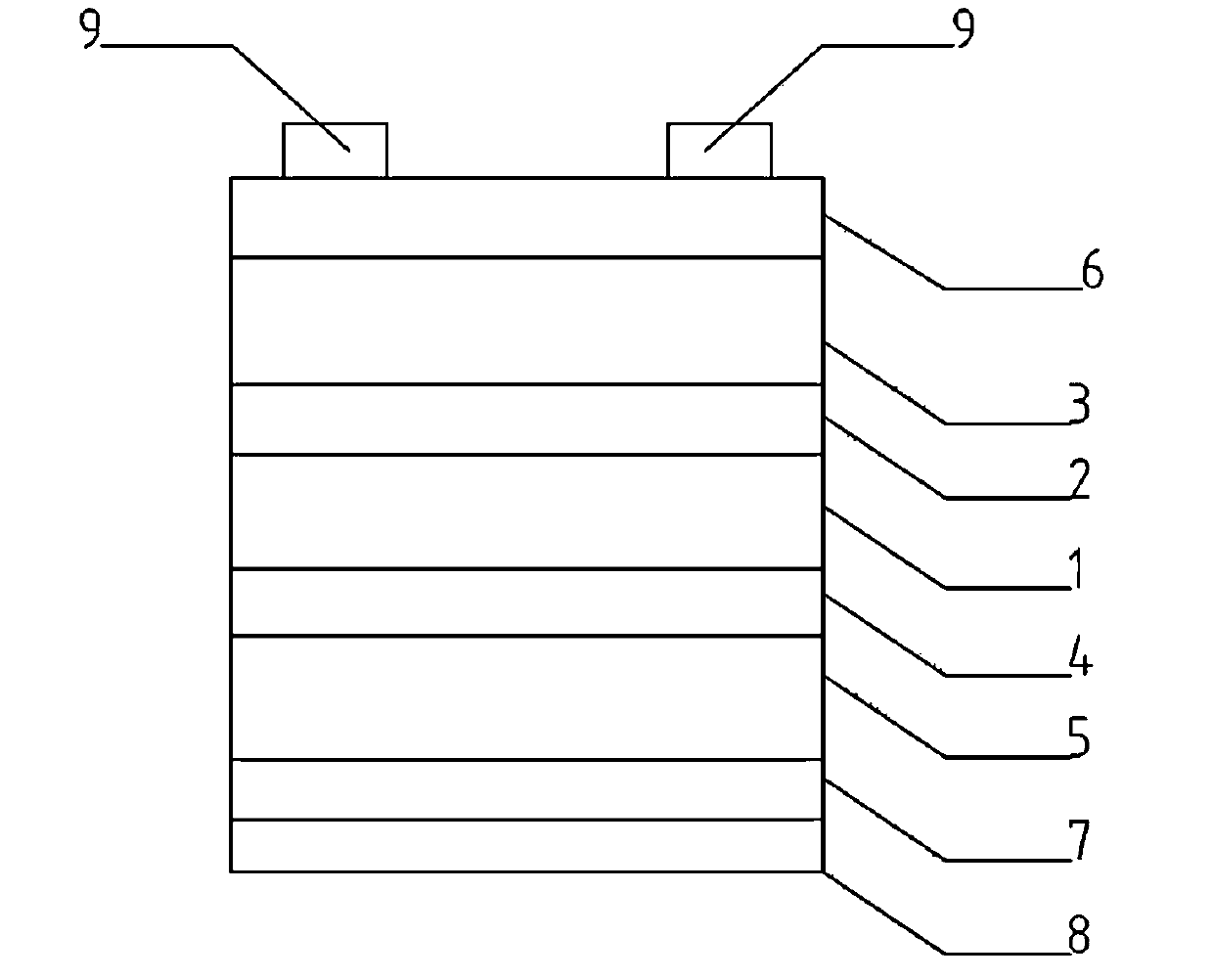

Silicon-based heterojunction double-side solar cell and preparation method thereof

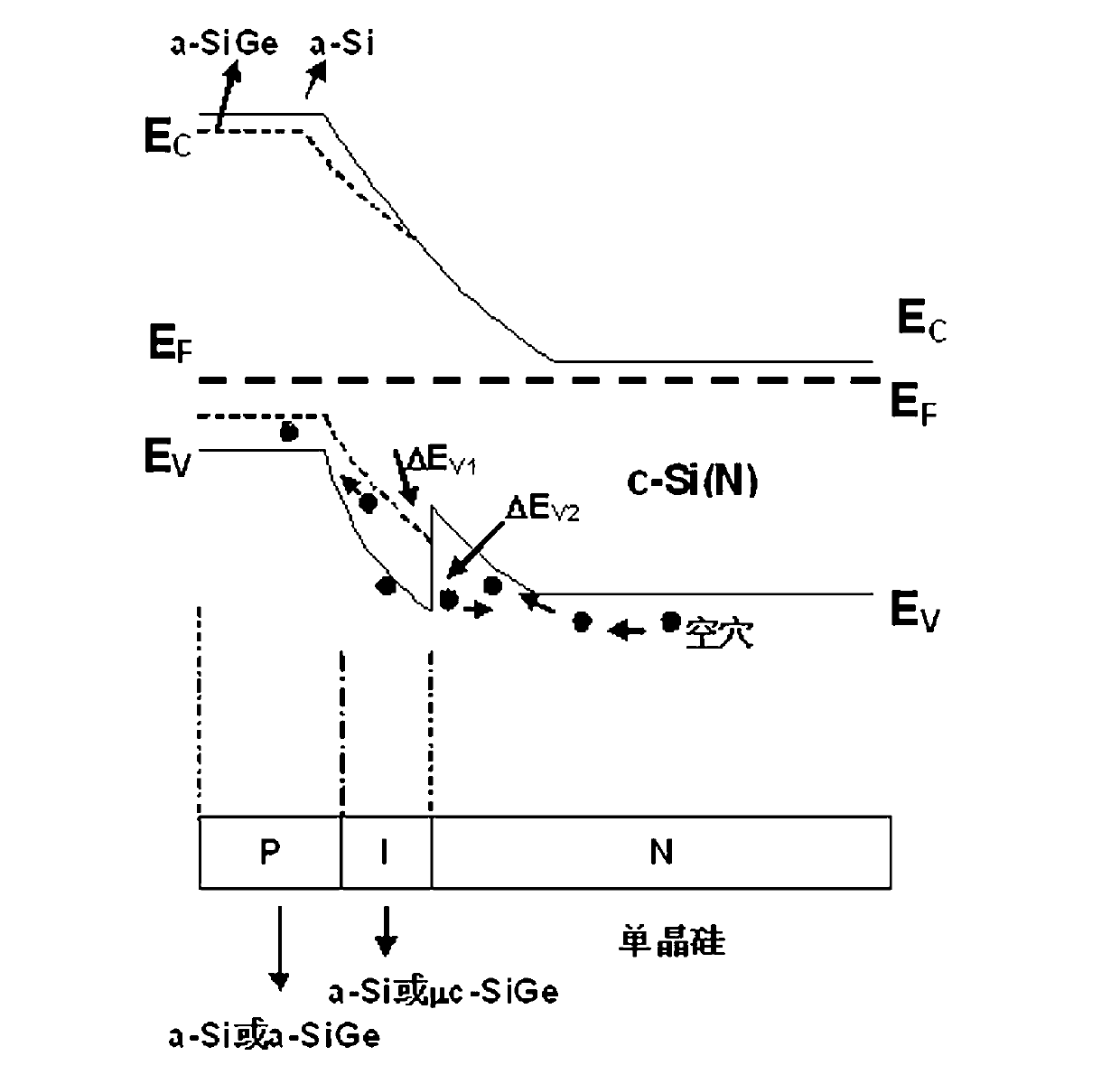

A solar cell and heterojunction technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as collection obstacles, large energy band mismatch, and unfavorable collection, and achieve the effects of reducing series resistance and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

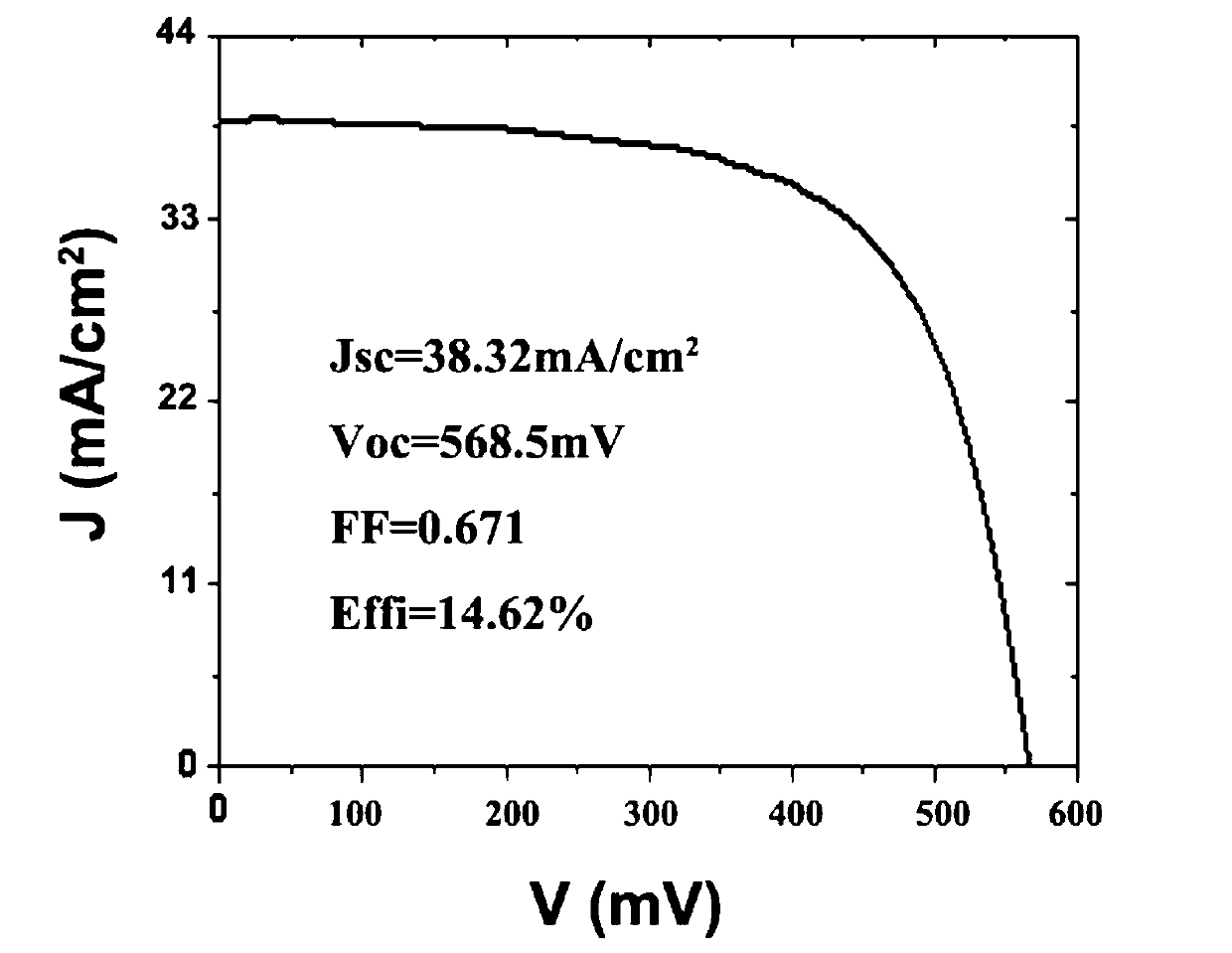

Examples

Embodiment Construction

[0029] (1) The standard cleaning procedure for silicon wafers, that is, the RCA cleaning process, is used for standard cleaning of the N-type double-sided polished single crystal silicon wafer 1 produced by the FZ method. In the experiment, the thickness of the N-type double-sided polished single crystal silicon wafer 1 is selected. It is 0.220mm, the conductivity is 1~2S / cm, and the area is 4cm 2 (a square with a side length of 2 cm);

[0030](2) Immerse the cleaned N-type double-sided polished single crystal silicon wafer 1 in a hydrofluoric acid aqueous solution with a concentration of 2%, and keep it for 10 seconds to ensure that the silicon dioxide oxide film on the surface of the single crystal silicon is removed, and at the same time It will not cause excessive etching of the silicon surface by hydrofluoric acid. Then quickly put the processed N-type double-sided polished single crystal silicon wafer 1 into the vacuum chamber, draw a high vacuum, and set the substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com