Novel stacked thin-film solar cell and manufacturing method thereof (a-Si:H/a-SiGe:H/CIGS or CZTS stacked solar cell and manufacturing method thereof)

A technology of thin-film solar cells and manufacturing methods, applied in sustainable manufacturing/processing, final product manufacturing, circuits, etc., can solve problems such as high absorption coefficient, narrow optical band gap, and not very matching solar spectrum, and achieve high photoelectric conversion efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

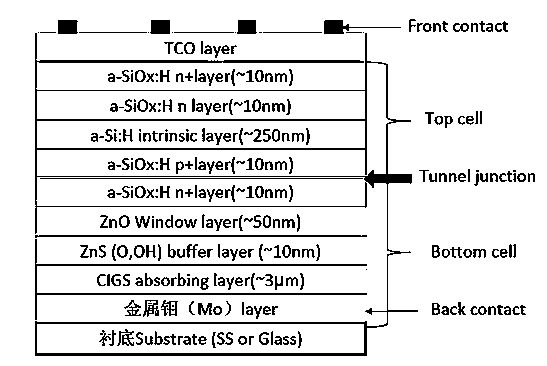

Embodiment 1

[0017] On the glass substrate, a thin layer of Mo with a thickness of ~10nm was deposited by DC magnetron sputtering technology (atmospheric pressure ~1.2-1.5pa, temperature ~400°C);

[0018] Then linearly reduce the gas pressure to ~0.2-0.5Pa, sputter ~1μm thick Mo thin layer;

[0019] Deposit ~3 μm thick CIGS (atomic ratio Cu / (In+Ga)~0.88, Ga / (In+Ga)~0.3) absorber layer;

[0020] By chemical bath deposition (ZnSO 4 (0.16 M), ammonia water (7.5 M), thiourea (0.6 M)) to prepare a ~10 μm thick ZnS buffer layer;

[0021] A dense ZnO film with a thickness of ~50nm was prepared by sputtering;

[0022] Anneal the ZnO thin film at 450°C for 30min;

[0023] Using PECVD process, in SiH 4 ,PH 3 , CO 2 , H 2 Deposit a n-type heavily doped a-SiOx:H transition layer with a thickness of ~10nm under the atmosphere;

[0024] Using PECVD process, in SiH 4 , BF 3 , CO 2 , H 2 Deposit a p-type heavily doped a-SiOx:H back electrode layer with a thickness of ~10nm under the atmospher...

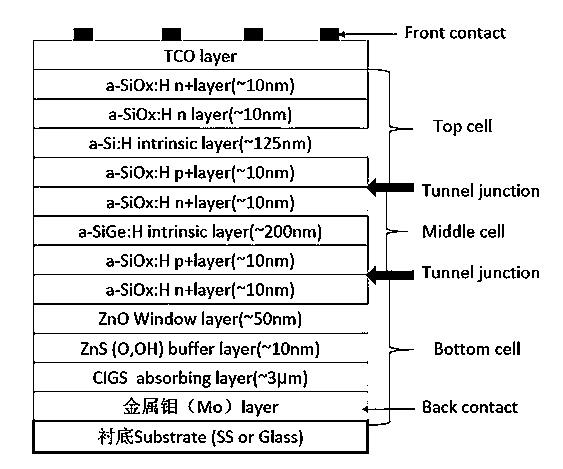

Embodiment 2

[0030] On the glass substrate, a thin Mo layer with a thickness of ~10nm was deposited by DC magnetron sputtering technology (atmospheric pressure ~1.2-1.5pa, temperature ~400℃);

[0031] Then linearly reduce the gas pressure to ~0.2-0.5Pa, sputter ~1μm thick Mo thin layer;

[0032] Deposit ~3 μm thick CIGS (atomic ratio Cu / (In+Ga)~0.88, Ga / (In+Ga)~0.3) absorber layer;

[0033] By chemical bath deposition (ZnSO 4(0.16 M), ammonia water (7.5 M), thiourea (0.6 M)) to prepare a ~10 μm thick ZnS buffer layer;

[0034] A dense ZnO film with a thickness of ~50nm was prepared by sputtering;

[0035] Anneal the ZnO thin film at 450°C for 30min;

[0036] Using PECVD process, in SiH 4 ,PH 3 , CO 2 , H 2 Deposit ~10nm thick n-type heavily doped a-SiOx:H battery transition layer under atmosphere;

[0037] Using PECVD process, in SiH 4 , BF 3 , CO 2 , H 2 Deposit a p-type heavily doped a-SiOx:H battery back electrode layer with a thickness of ~10nm under the atmosphere;

[003...

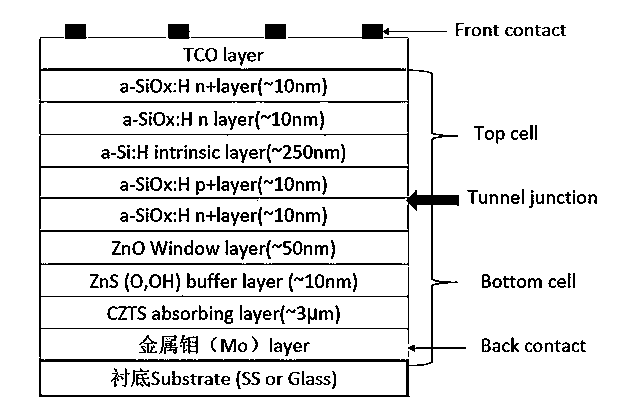

Embodiment 3

[0046] On the glass substrate, a thin Mo layer with a thickness of ~10nm was deposited by DC magnetron sputtering technology (atmospheric pressure ~1.2-1.5pa, temperature ~400℃);

[0047] Then linearly reduce the gas pressure to ~0.2-0.5Pa, sputter ~1μm thick Mo thin layer;

[0048] A CZTS absorber layer with a thickness of ~3 μm was prepared by co-evaporation technique;

[0049] By chemical bath deposition (ZnSO 4 (0.16 M), ammonia water (7.5 M), thiourea (0.6 M)) to prepare a ~10 μm thick ZnS buffer layer;

[0050] A dense ZnO film with a thickness of ~50nm was prepared by sputtering;

[0051] Anneal the ZnO thin film at 450°C for 30min;

[0052] Using PECVD process, in SiH 4 ,PH 3 , CO 2 , H 2 Deposit a n-type heavily doped a-SiOx:H transition layer with a thickness of ~10nm under the atmosphere;

[0053] Using PECVD process, in SiH 4 , BF 3 , CO 2 , H 2 Deposit a p-type heavily doped a-SiOx:H back electrode layer with a thickness of ~10nm under the atmosphere;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com