Memory cell and fabricating method thereof

a memory cell and manufacturing method technology, applied in the field of memory cells and fabricating methods, can solve the problems of increasing the thermal budget of the process, high power consumption of tft-lcd with such architecture, and not being suitable for transmissive lcd panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

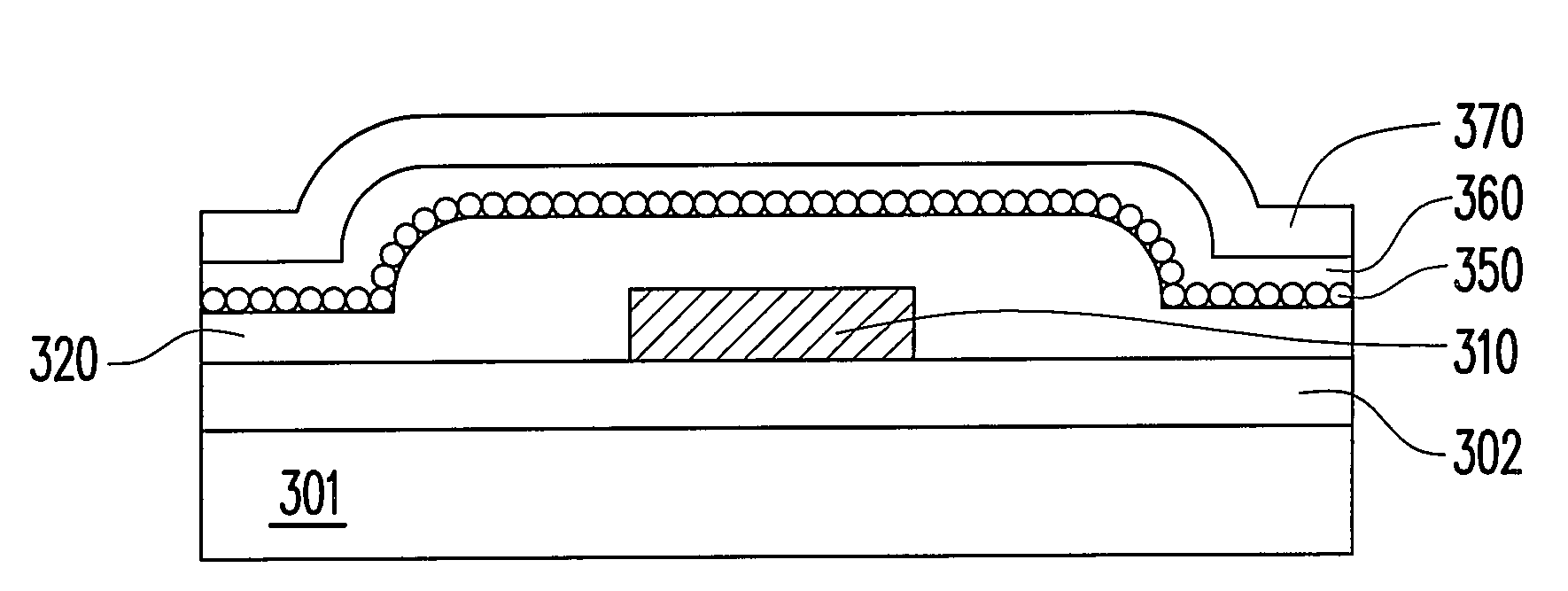

[0023]Various memory cells and fabricating methods thereof are illustrated in the following embodiments. The memory cell of the present invention has the oxide-quantum dot-oxide structure integrated into the LTPS-TFT, the methods of fabricating the memory cells illustrated in the present invention can be integrated with the LTPS-TFT manufacturing process. In other words, in the pixel structure, when the voltage applied to the control gate is insufficient to carry out “programming” or “erasing”, the following memory cell structure can still be used as a TFT.

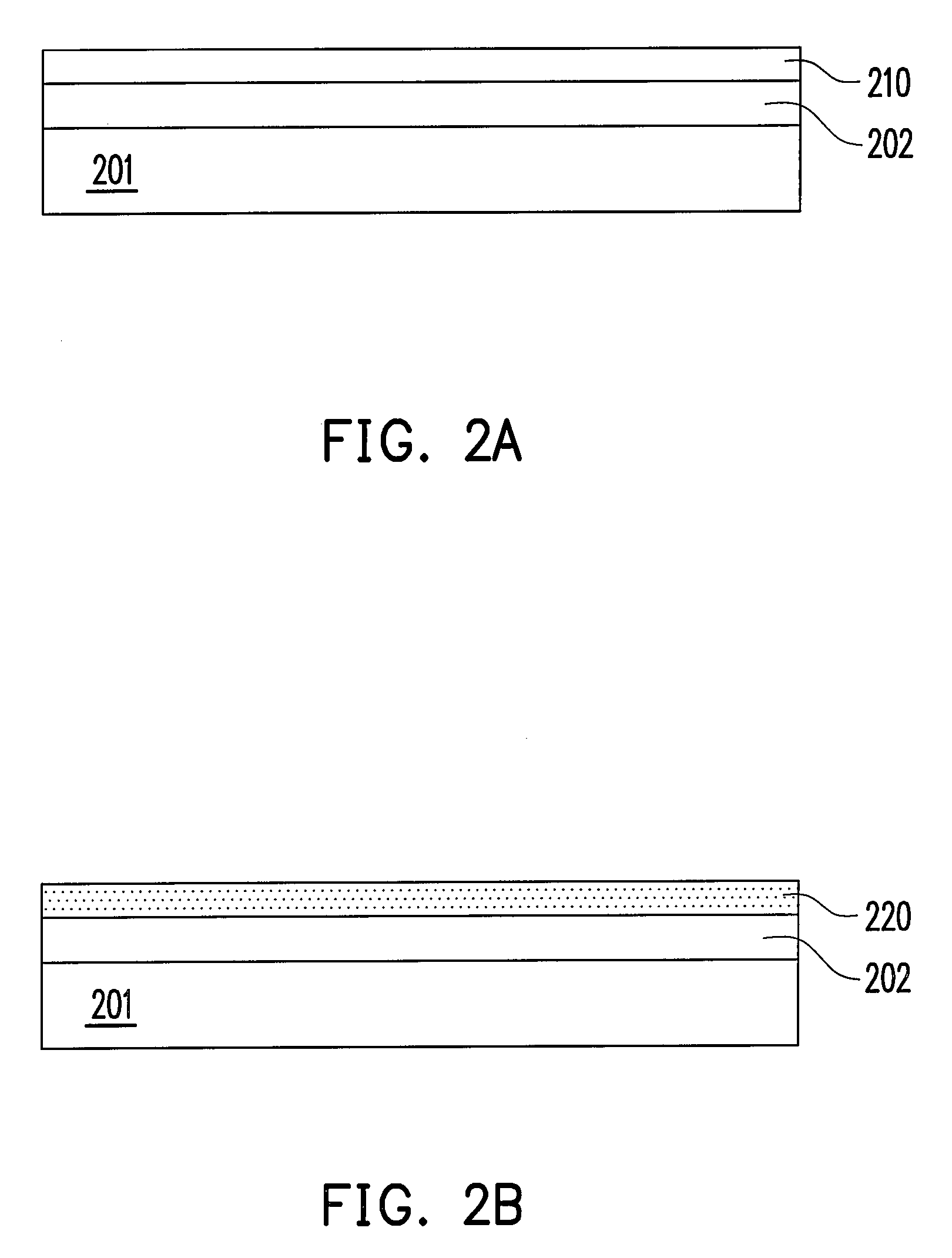

[0024]FIGS. 2A to 2F are schematic views of the processes of fabricating the memory cell according to an embodiment of the present invention.

[0025]First, referring to FIG. 2A, a substrate 201 is provided, which is, for example, a glass substrate or other transparent substrates. Then, an amorphous silicon layer 210 is formed on the substrate 201. In the present embodiment, the amorphous silicon layer 210 is, for example, formed by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com