Method for preparing amorphous silicon germanium thin-film batteries with box type PECVD (plasma enhanced chemical vapor deposition) equipment

An amorphous silicon germanium and thin film battery technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of uneven composition, affecting the performance of battery components, uneven content of germanium components, etc., and achieve low cost and reduced cost. The effect of electric field uniformity and capacity halving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

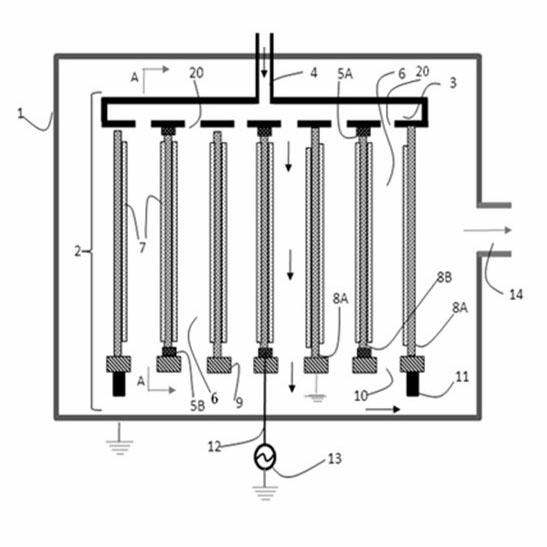

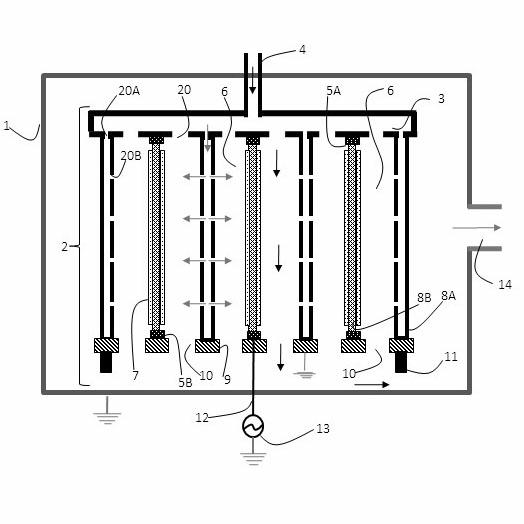

[0020] Such as Figure 3-5 As shown, all the ground electrodes 8A in this embodiment are designed in a box shape with an internal space of 5 mm to ensure that the reaction gas mixture can flow freely in the box. An air outlet hole 20B is opened in the surface opposite to the exciting electrode 8B, and not only a hole 20 is opened at the bottom of the gas box 3, but also a hole 20A is opened at the joint between the ground box-shaped electrode plate and the gas box 3 . Such a source gas mixture, such as silane (SiH 4 ), hydrogen (H 2 ) and germane (GeH 4 ) is introduced into the plasma field 6 field through the pores 20 on the one hand, and on the other hand flows down from the many pores 20A at the bottom of the gas box 3 and flows along the gap region 6A, while the source gas mixture flowing along the gap region 6A is simultaneously The gas flows from the small hole 20B to the gap region 6, thereby realizing compensation for the lack of raw material gas in the middle and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com