Silicon-based solar cell and monocrystalline silicon piece passivation method thereof

A technology of monocrystalline silicon wafers and hydrogenated amorphous silicon, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of poor iodine passivation stability, poor passivation effect, and high growth temperature, and achieves The process is more flexible, the cost of raw materials is cheap, and the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

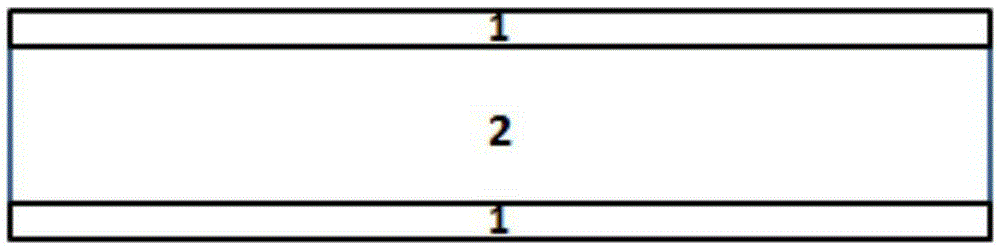

Image

Examples

example 1

[0031] A silicon-based solar cell and its monocrystalline silicon wafer, comprising the steps of:

[0032] 1) Cleaning of monocrystalline silicon wafers: monocrystalline silicon wafers can undergo dry cleaning and wet cleaning, and can also be supplemented by ultrasonic cleaning. This preferred implementation of the improved wet cleaning method is an example. The silicon wafer used is purchased from the manufacturer without any treatment, and the size is 125mm×125mm: ①The silicon wafer is pre-cleaned first, and the volume ratio is ammonia water: hydrogen peroxide: ultrapure water = 1:1.5:10 pre-cleaning solution , soaked at 75°C for 10 minutes; ② soaked in 70°C ultrapure water for 10 minutes; ③ soaked in 75°C with a volume ratio of 20% potassium hydroxide for 1 minute; ④ soaked in 70°C ultrapure water for 10 minutes; ⑤ soaked in 80°C , single crystal texturing for 30 minutes; ⑥Soak in ultrapure water at 70°C for 10 minutes; ⑦Use a volume ratio of ammonia water:hydrogen peroxi...

example 2

[0037] A silicon-based solar cell and its monocrystalline silicon wafer, comprising the steps of:

[0038]1) Cleaning of monocrystalline silicon wafers: monocrystalline silicon wafers can undergo dry cleaning and wet cleaning, and can also be supplemented by ultrasonic cleaning. This optimal implementation of dry cleaning method is an example ① silicon wafers first pass through the cleaning solution with a volume ratio of hydrochloric acid: hydrofluoric acid: ultrapure water = 1:1.5:10, soak at 75 °C for 10 minutes; ② soak in ultrapure water at 70 °C ③Take out the monocrystalline silicon wafer and dry it with nitrogen gas; ④Leave it in a sealed UV light box for 30 minutes.

[0039] 2) Preparation of hydrogenated amorphous silicon germanium passivation layer: put the clean single crystal silicon wafer into the vacuum chamber of the plasma-enhanced chemical vapor deposition system to preheat for 40min, the chamber temperature is 300°C, and the silicon wafer substrate temperature...

example 3

[0042] A silicon-based solar cell and its monocrystalline silicon wafer, comprising the steps of:

[0043] 1) Cleaning of monocrystalline silicon wafers: monocrystalline silicon wafers can undergo dry cleaning and wet cleaning, and can also be supplemented by ultrasonic cleaning. The preferred implementation of the improved wet cleaning method is supplemented by ultrasound as an example. The silicon wafers used were purchased from the manufacturer without any treatment, and the size was 125mm×125mm: ① monocrystalline silicon wafers were soaked in ultra-pure water at 70 °C for 10 min; ② soaked in 20% potassium hydroxide at 75 °C for 1 min; ③ Ultrasonic immersion in 70°C ultrapure water for 10 minutes; ④ At 80°C, single crystal texturing for 30 minutes; ⑤ Ultrasonic immersion in 70°C ultrapure water for 10 minutes; ⑥ Use the volume ratio of ammonia water: hydrogen peroxide: ultrapure water = 1:1.5:10 washing solution, soak at 75°C for 10 minutes; ⑦Use ultrasonic immersion in 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| charge carrier lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com