Infrared detector and preparation method thereof

An infrared detector and electrode layer technology, applied in the field of infrared detection, can solve the problems of increasing the thickness of the infrared detector absorbing plate structure, increasing the thermal response time of the infrared detector, and affecting the infrared detection performance of the infrared detector, so as to reduce the thermal response Time, improve the infrared responsivity, reduce the effect of heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to more clearly understand the above objects, features and advantages of the present disclosure, the solutions of the present disclosure will be further described below. It should be noted that, in the case of no conflict, the embodiments of the present disclosure and the features in the embodiments can be combined with each other.

[0049] In the following description, many specific details are set forth in order to fully understand the present disclosure, but the present disclosure can also be implemented in other ways than described here; obviously, the embodiments in the description are only some of the embodiments of the present disclosure, and Not all examples.

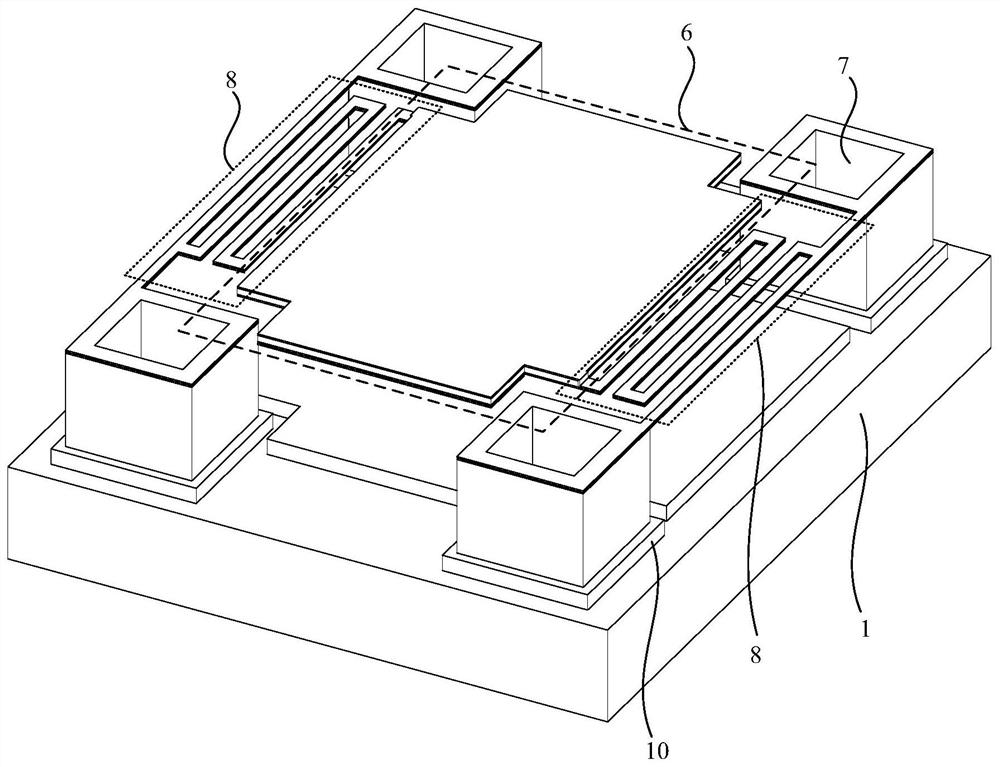

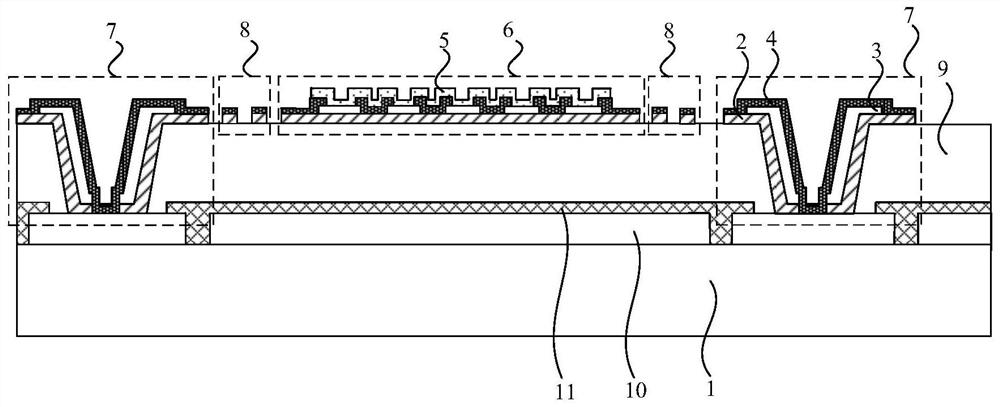

[0050] figure 1 It is a schematic diagram of a three-dimensional structure of an infrared detector provided by an embodiment of the present disclosure, figure 2 A schematic diagram of a three-dimensional structure of an infrared detector pixel provided by an embodiment of the present disclosur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com