High-sensitivity thermal-response platinum resistor temperature sensor

A technology of temperature sensor and platinum resistance, which is applied in the field of platinum resistance temperature sensor with a protective heat-conducting sleeve structure, can solve problems such as unsatisfactory use requirements, long temperature sensing time, and insensitive temperature sensing, so as to shorten thermal response time, The effect of improving the sensing sensitivity and shortening the sensing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

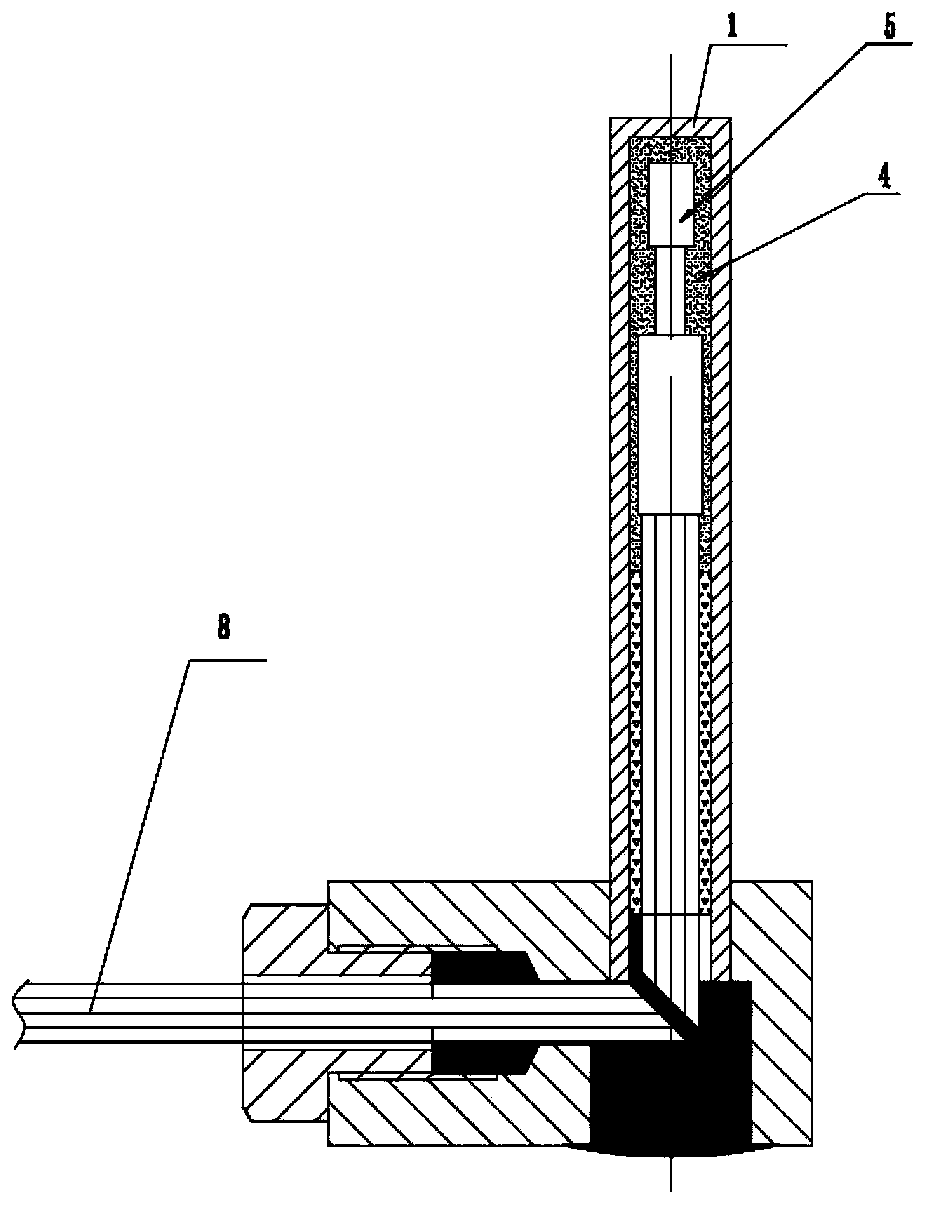

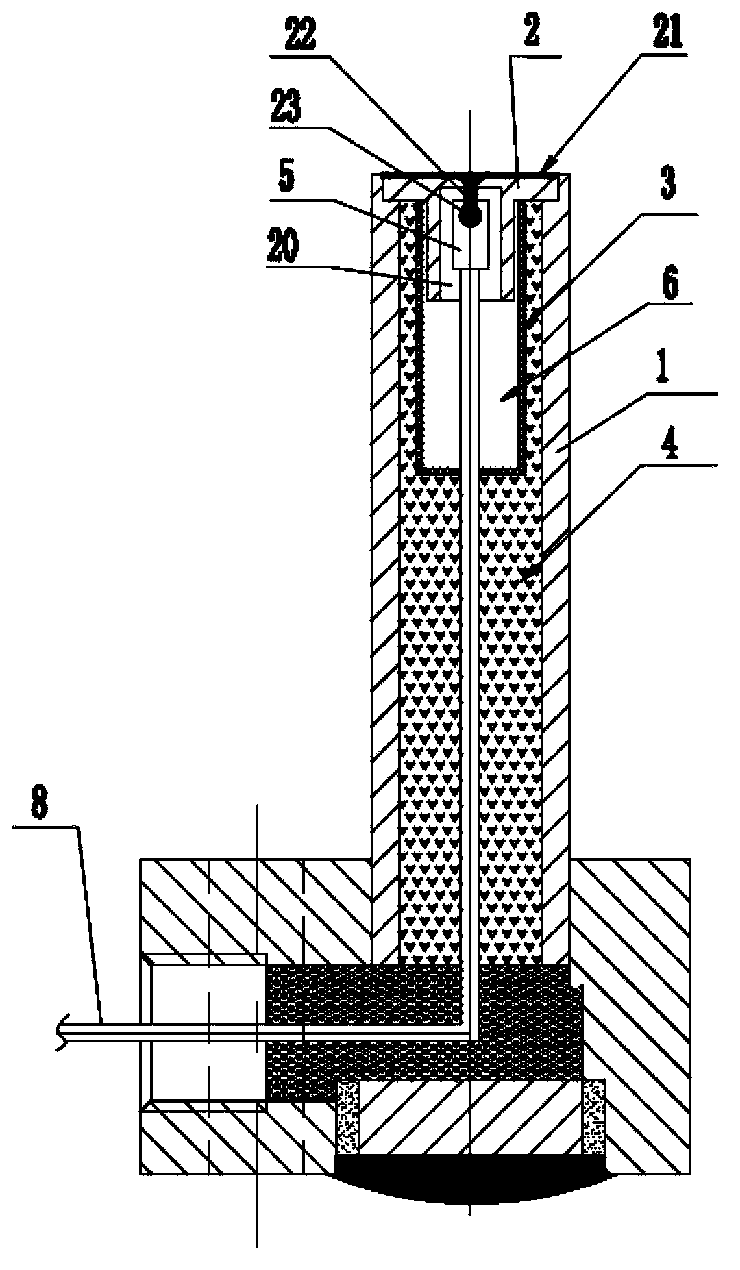

[0008] The high-sensitivity thermal response platinum resistance temperature sensor of the patent application of the present invention has a heat-conducting metal cap fixedly embedded on the top of the metal protective tube 1. The heat-conducting metal cap is made of silver or copper with excellent thermal conductivity. The metal of the heat-conducting metal cap The inner part of the protective tube is provided with a counterbore 20 for inserting the platinum resistance induction core 5, and the connecting body 22 extending from the bottom end of the counterbore 20 is thermally connected with the heat-conducting metal point 23 embedded in the back of the insulating matrix of the platinum resistance induction core 5. If the heat-conducting metal cap is made of silver, its heat conduction effect is the best, but the cost is too high; if it is made of copper, the cost can be greatly reduced, and the heat conduction effect cannot reach the ideal effect of silver. figure 2 The stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com