Patents

Literature

76 results about "Thermal response time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The thermal response of a temperature sensor is the speed at which it responds to a sudden change in temperature. Thermal response time (ῖ) is the time taken for the sensor to react to this change in temperature.

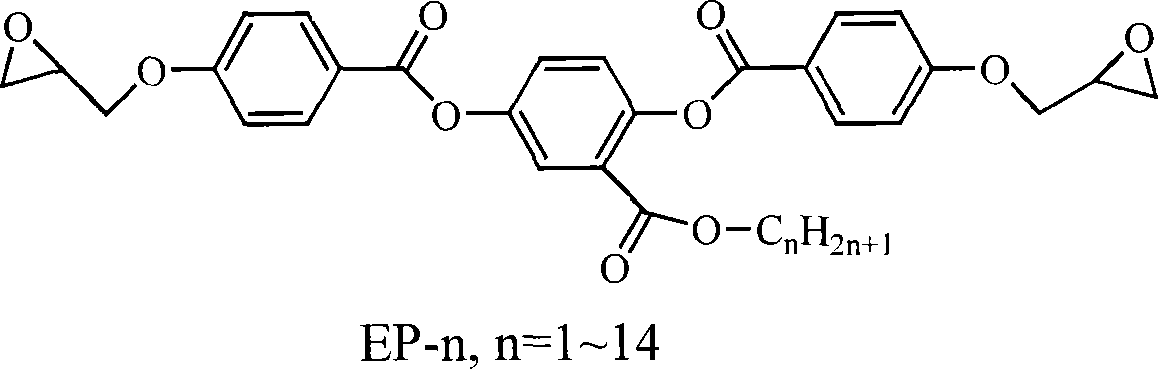

Epoxy resin shape memory polymer material and method for producing the same

InactiveCN101195701AThermal response temperature adjustableFast thermal response timeEpoxyMemory effect

The invention relates to a new epoxy resin shape memory macromolecule material and a relative preparation method, wherein the material contains liquid crystal epoxy resin monomer and curing agent at stoichiometry, which may further contains curing accelerator of 0-2% consumption of the total accounts of the liquid crystal epoxy monomer and curing agent. Compared with prior shape memory material, the inventive material has the advantages that (1), the thermal responsible temperature can be adjusted by adjusting the side chain and substituted chain of the liquid crystal epoxy monomer or by selecting curing agent, (2), the heat response time is short and the shape recover is rapid, (3), the product can realize saturated shape memory effect, (4) the product has simple preparation and clear structure.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

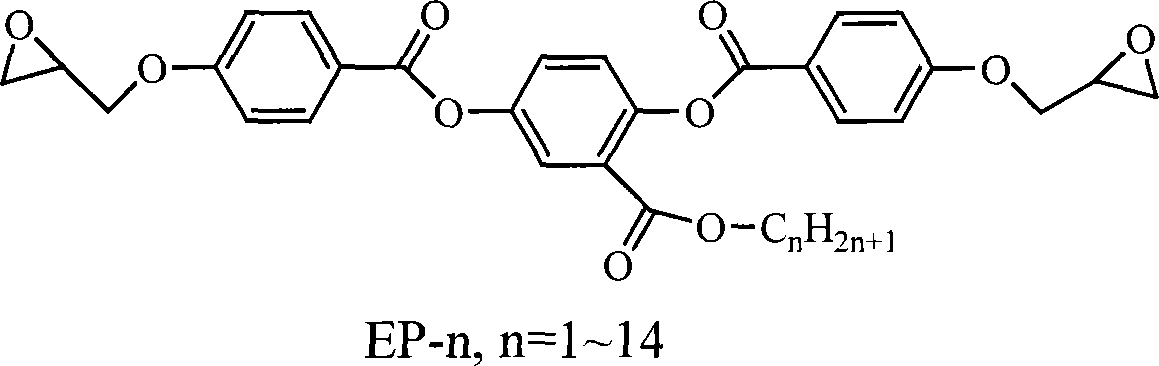

Liquid crystal epoxy resin with shape memory effect and preparation method and application thereof

InactiveCN102504202AEasy to adjustEasy to prepareLiquid crystal compositionsCollapsable antennas meansEpoxyMemory effect

The invention belongs to the field of material engineering and discloses a liquid crystal epoxy resin with a shape memory effect and a preparation method and application thereof. The preparation method of the liquid crystal epoxy resin with the shape memory effect comprises the following steps: heating to melt 100 parts of epoxy resin, adding 1.22-42.59 parts of unitary aliphatic amine, mixing uniformly, finally adding 10.57-26.20 parts of curing agent, and melting uniformly; pouring the obtained mixture into a preheating mould, heating to cure, and cooling to 20-30 DEG C to obtain the liquidcrystal epoxy shape memory material. The thermal response temperature of the liquid crystal epoxy resin with the shape memory effect can be adjusted conveniently, and the liquid crystal epoxy resin is short in thermal response time and high in shape recovery speed and still has the good shape memory effect after being subjected to repeated and circulatory shape memory.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

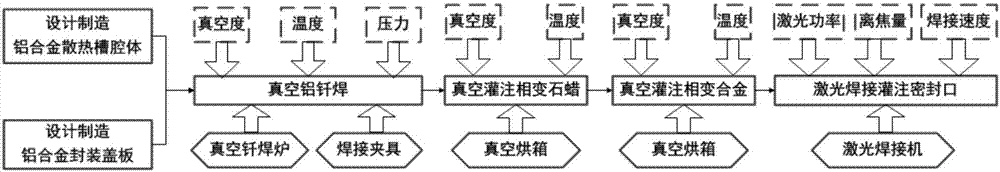

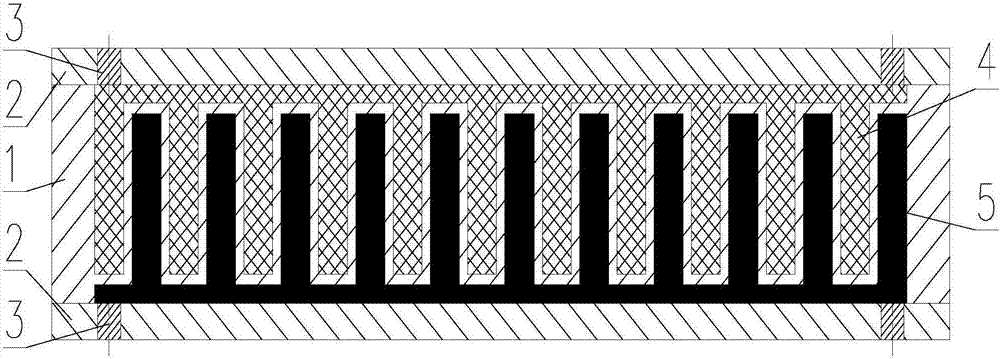

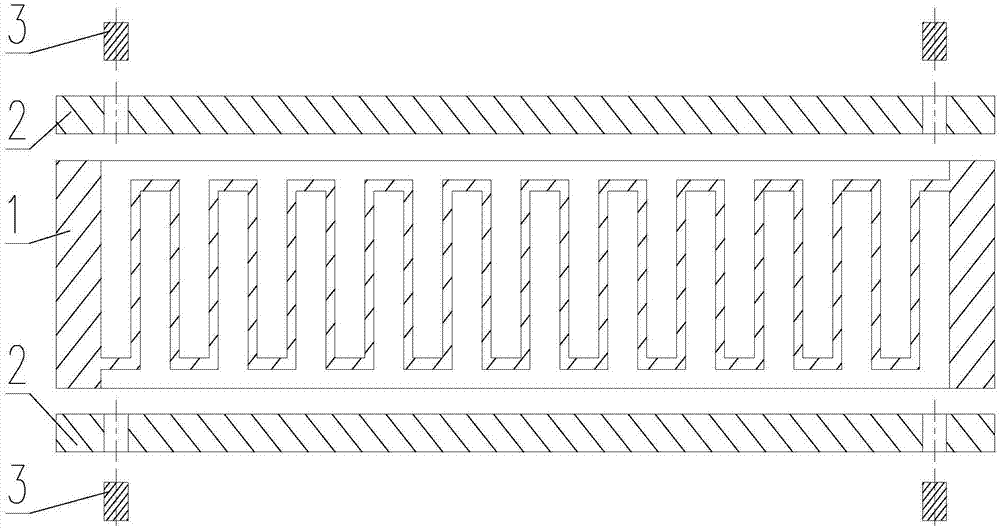

Quick thermal response composite phase change heat reservoir and preparation method thereof

ActiveCN106918259AImprove thermal conductivityThermal conductivity improvement and increaseHeat storage plantsHeat exhanger finsHeat conductingAlloy

The invention provides a quick thermal response composite phase change heat reservoir and a preparation method thereof, and can solve the problems of long thermal response time and low heat dissipating efficiency of a phase change heat reservoir prepared by single phase change paraffin. The quick thermal response composite phase change heat reservoir is realized through the following methods: forward and reverse continuous U-shaped heat dissipating groove cavities serially connected in a linear array sequence are formed in an inner cavity of a heat storage container; the forward U-shaped heat dissipating cavity serves as a paraffin cavity filled with phase change paraffin (4); the reverse U-shaped heat dissipating cavity serves as an alloy cavity filled with a phase change alloy (5); the high-heat-conductivity phase change alloy and the high-enthalpy-value phase change paraffin are sealed as a whole through sealing of upper and lower sealing cover plates (2); and a phase change paraffin and phase change alloy filling port of the heat reservoir is further welded through laser to realize preparation of the quick thermal response composite phase change heat reservoir. The high-efficiency heat transfer of the phase change heat reservoir is realized by the combined effect of the high-heat-conductivity phase change alloy with the heat conducting coefficient of being not less than 15 W / (m. K) and the high-heat-conductivity aluminum alloy of the phase change heat reservoir.

Owner:10TH RES INST OF CETC

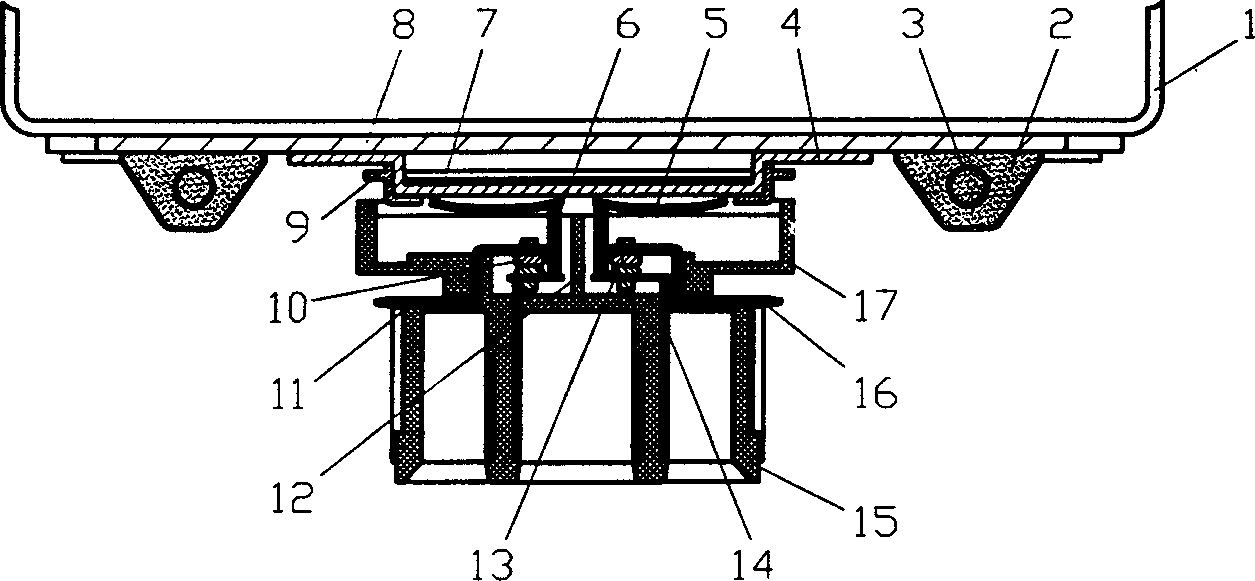

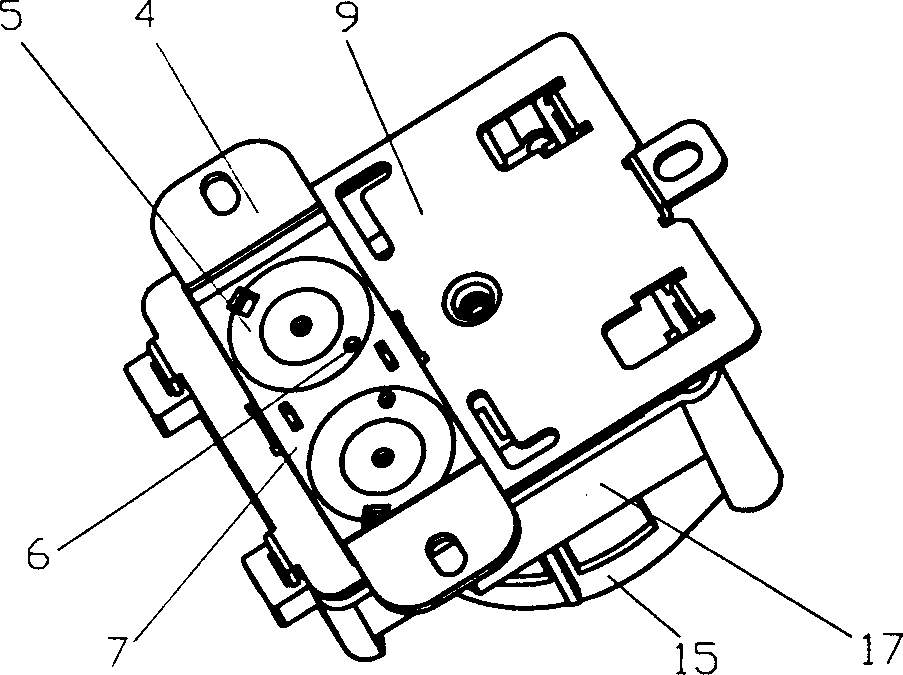

Safety protector for electric heating container

InactiveCN1805623AImprove reliabilityImprove securityElectric heatingWater-boiling vesselsDevice formEngineering

The invention relates to a safe protective device of electric heating container, which comprises a electric heating element formed by a electric heating ring and a heat conductive plate; a heat power device formed by a dual metallic plate and a top rod; and a electric switch formed by a movable contact point, a movable contact plate, a stable contact point and a stable contact plate. Wherein, the dual metallic plate are movably connected to one end of top rod; another end of top rod is supported to the movable contact plate; the central section of independent heat conductive device is insulated from the heat conductive plate which has at least one dual metallic plate; the independent heat conductive device has a thermal sensitive feeler heat connected to the heat conductive plate of electric heating container. The dual metallic actuator can feel the temperature via the feeler of heat conductive device; and the independent heat conductive device has tight heat contact with the heat conductive plate of heater to solve the problem of slow response speed. The invention has simple structure, fewer elements, and improved reliability and safety.

Owner:NINGBO SUNLIGHT ELECTRICAL APPLIANCE CO LTD

Epoxy resin with shape memory property and preparation method thereof

The invention relates to the technical field of high polymer materials, and particularly relates to an epoxy resin with the shape memory property and a preparation method thereof. The epoxy resin with the shape memory property comprises the following raw materials in parts by weight: 100 parts of epoxy resin, 20.6-35.5 parts of sebacic monobasic amine, 14.4-20.3 parts of curing agent and 0.1-2.2 parts of curing catalyst, wherein the epoxy resin is bisphenols A epoxy resin and aliphatic epoxy resin blended resin. The influence temperature can be conveniently adjusted by changing the content and the alkyl group length of the sebacic monobasic amine or the content of the epoxy resin in the formula; the epoxy resin with the shape memory property is short in heat response time and fast in shape recovery rate and has a good shape memory effect after the shape memory repeatedly circulates; the forming process of the epoxy resin with the shape memory property is mature and low in cost; the epoxy resin with the shape memory property has relatively good mechanical property and thermal property, good chemical resistance and the characteristics of super toughness, impact resistance, wear resistance, low friction coefficient and the like and is difficult to deform, melt and burn at a high temperature environment.

Owner:DONGGUAN JIEYUE SHENGSHI SPORTS GOODS

Open temperature sensor and preparation method thereof

InactiveCN106225946AEasy to operateImprove reliabilityThermometers using electric/magnetic elementsUsing electrical meansEngineeringThermistor

The invention discloses an open temperature sensor and a preparation method thereof. The open temperature sensor comprises a shell, a thermistor, and a wire. The thermistor and the wire are connected by means of welding. The shell sleeves the thermistor, and one end of the shell sleeves the end of the wire. Insulating partitions are arranged inside the shell, and the insulating partitions sleeve the solder joint of the thermistor and the wire. Compared with the prior art, the preparation method of the open temperature sensor of the invention is simple to operate and highly operable, greatly improves the production efficiency, and reduces the labor cost. In addition, the solder joint of the open temperature sensor is of high reliability in a cold and hot shock environment, and is prevented from being oxidized and corroded in an open environment. The shell is fixed by abutting clamp columns, the solder joint is insulated and protected by the insulating partitions, the shell is prevented from being filled with excessive resin, so that the heat capacity is reduced, and the thermal response time is shortened greatly.

Owner:肇庆爱晟传感器技术有限公司

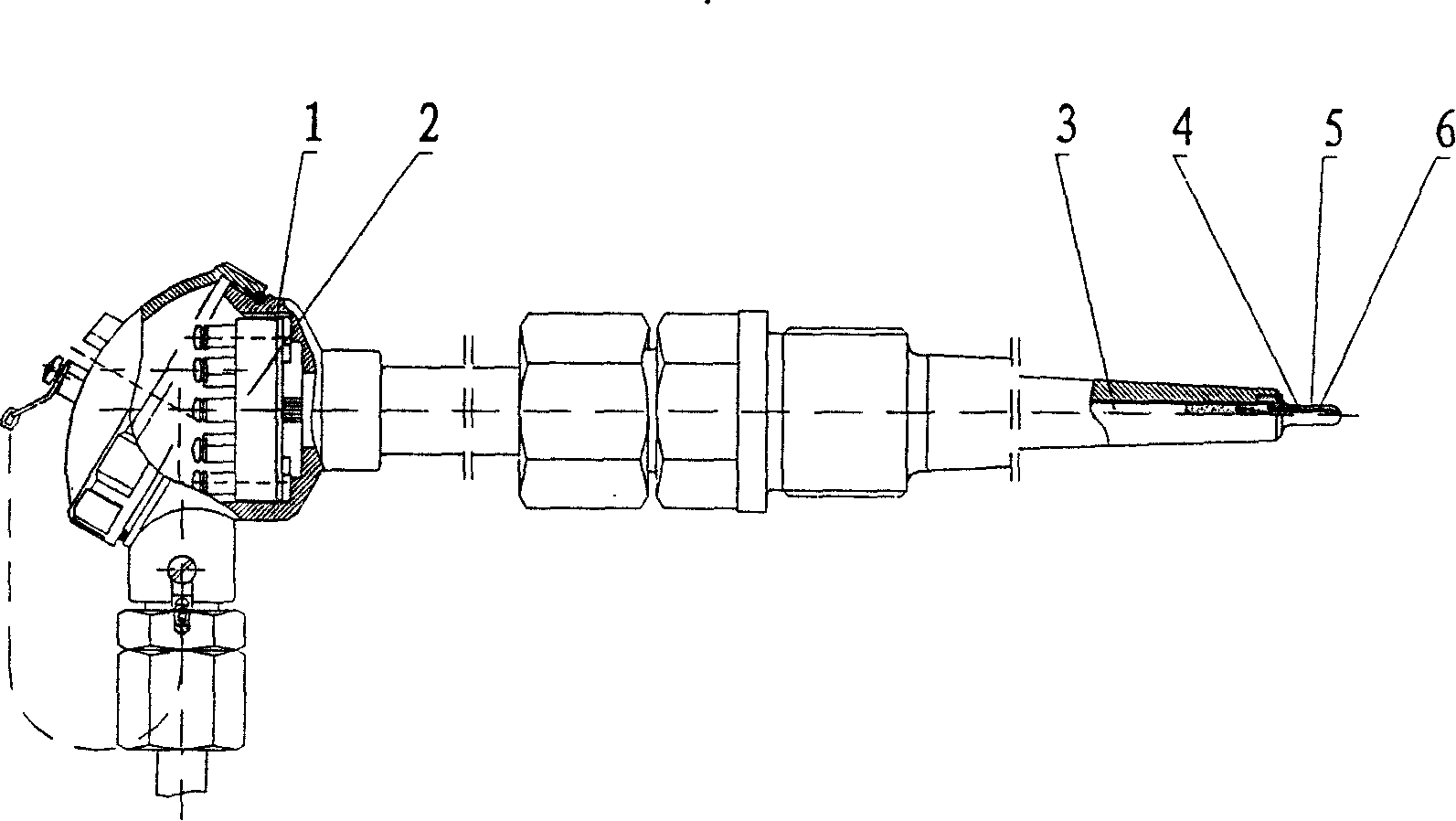

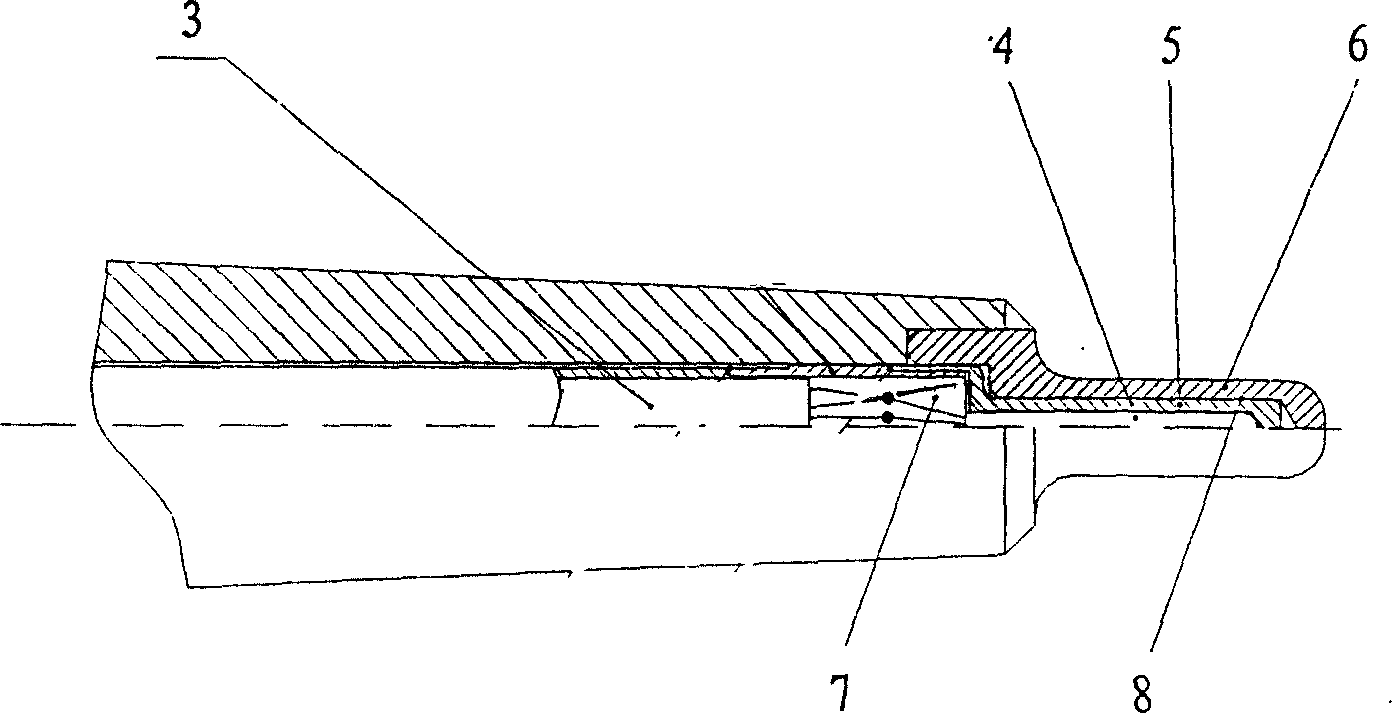

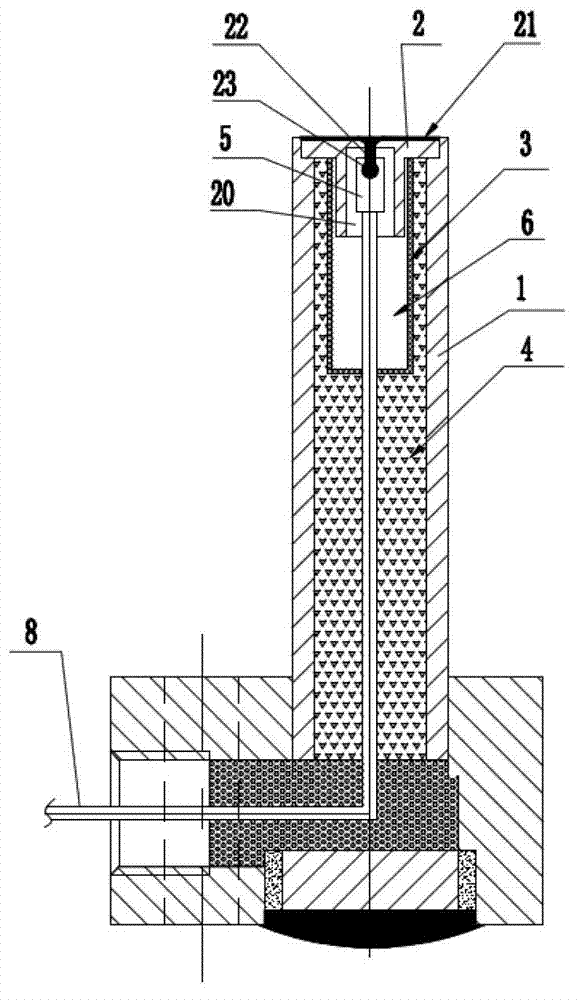

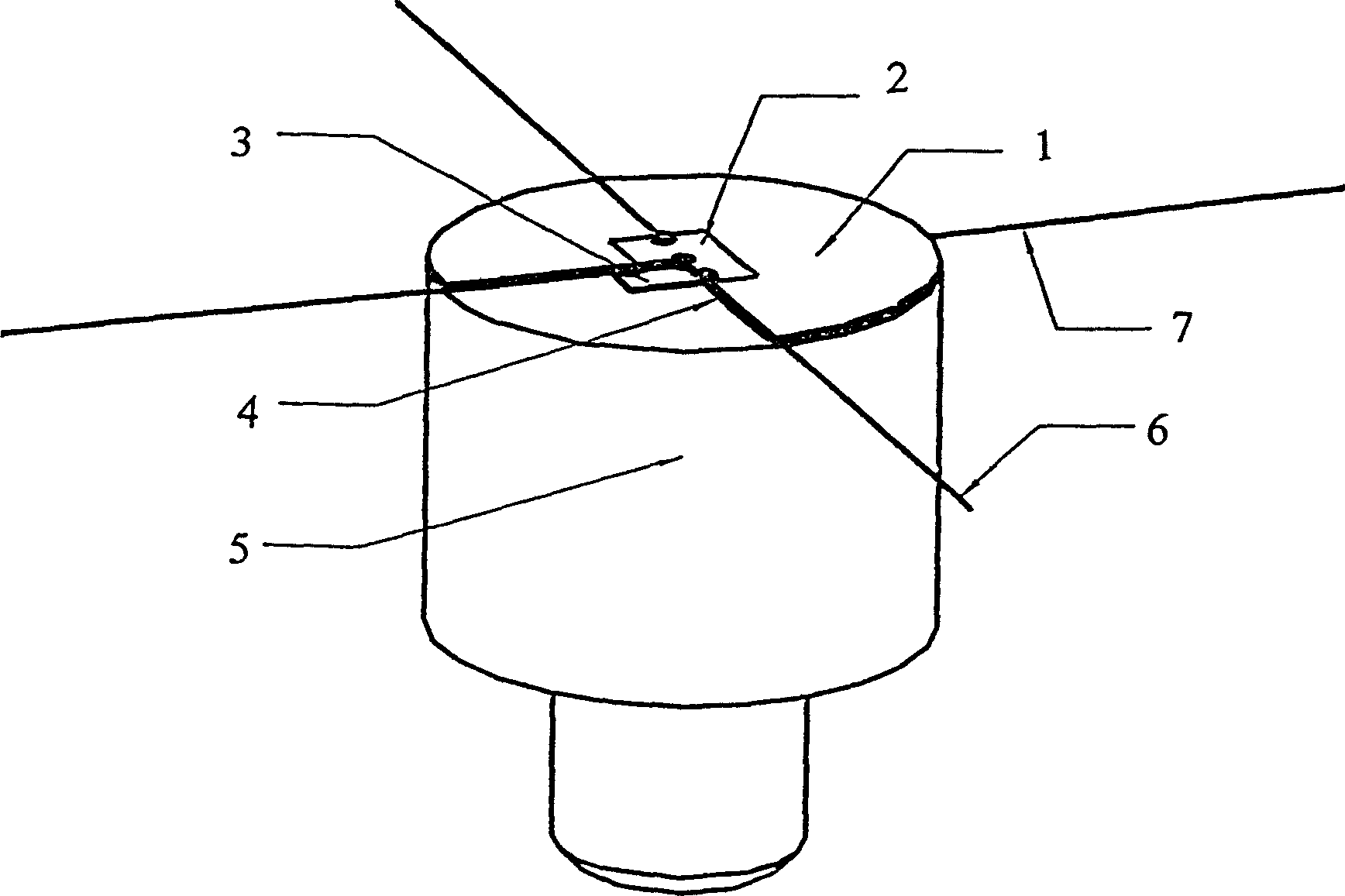

Nuclear grade platinum resistance thermometer and its method for reducing thermal response time

InactiveCN101173873AWill not stickShort thermal response timeThermometer detailsThermometers using electric/magnetic elementsPlatinum resistanceNuclear grade

The invention relates to a nuclear-grade platinum resistance thermometer and the method for reducing thermal response time with the invention, comprising a terminal box, a wiring board arranged in the terminal box, and a protective sleeve with a built-in platinum resistance element, wherein, the temperature sensing surface of the platinum resistance element is clung tightly to the inner surface of the protective sleeve, and no MgO powder is filled between the platinum resistance element and the protective sleeve; the outer surface of the protective sleeve is clung tightly to the inner surface of an external protective tube; the platinum resistance element is welded with an armored leading wire; MgO powder is filled in the armored leading wire; a metal coat is plated on the outer surface of the protective sleeve. The invention has the advantages that due to the temperature sensing surface of the platinum resistance element clung tightly to the protective sleeve and the protective sleeve clung tightly to the external protective tube, the heat conductivity of the thermometer is improved; the thermal response time is reduced; the earthquake resistant requirement for nuclear power station is satisfied; due to wear-resistant, heat-resistant, and oxidation-resistant special metal coating on the surface of the protecting sleeve, the protecting sleeve does not stick to the protective tube due to oxidation corrosion.

Owner:NO 3 AUTOMATION INSTR & METERS FACTORY SHANGHAI AUTOMATION INSTR & METERS CO LTD

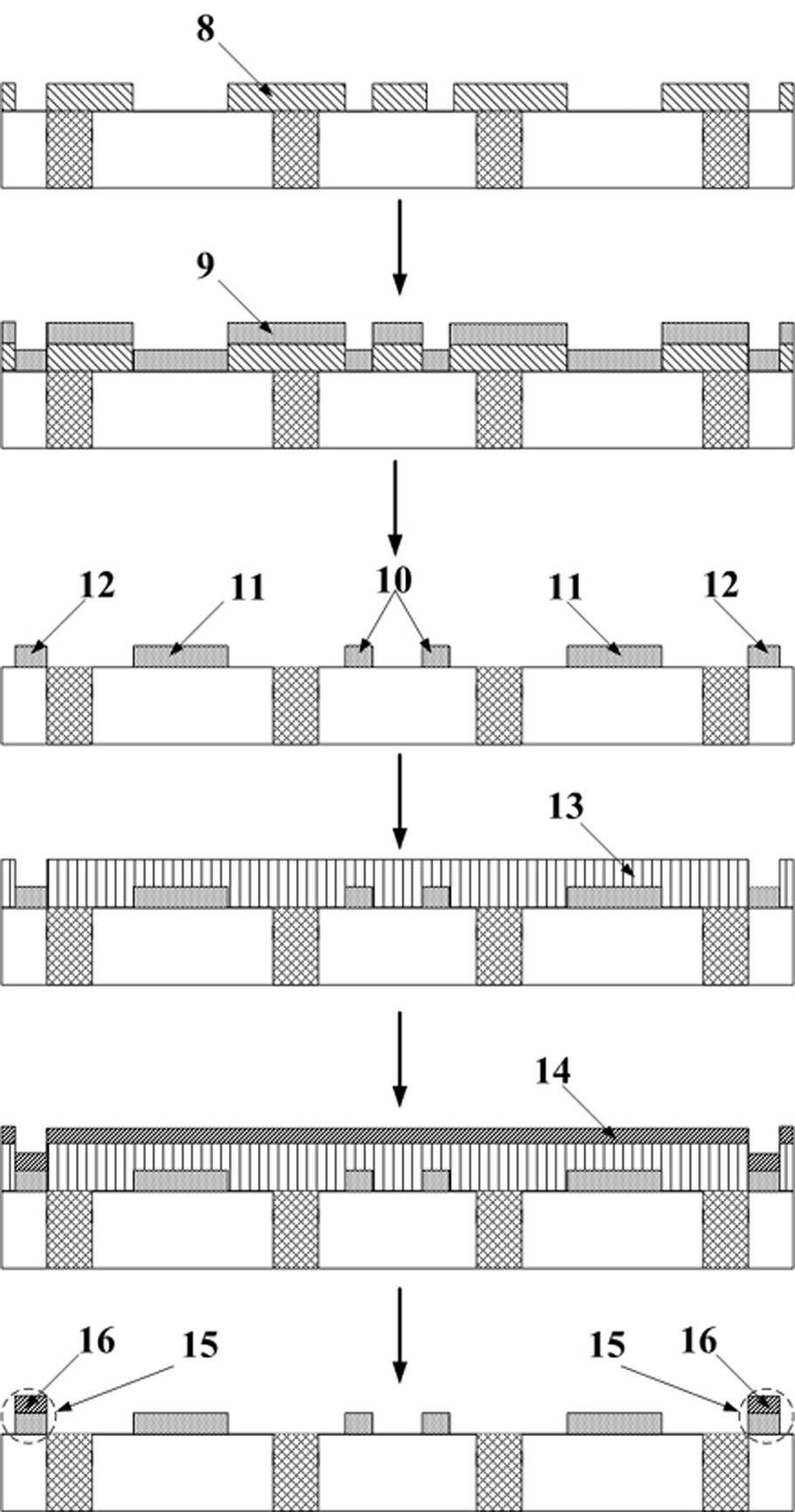

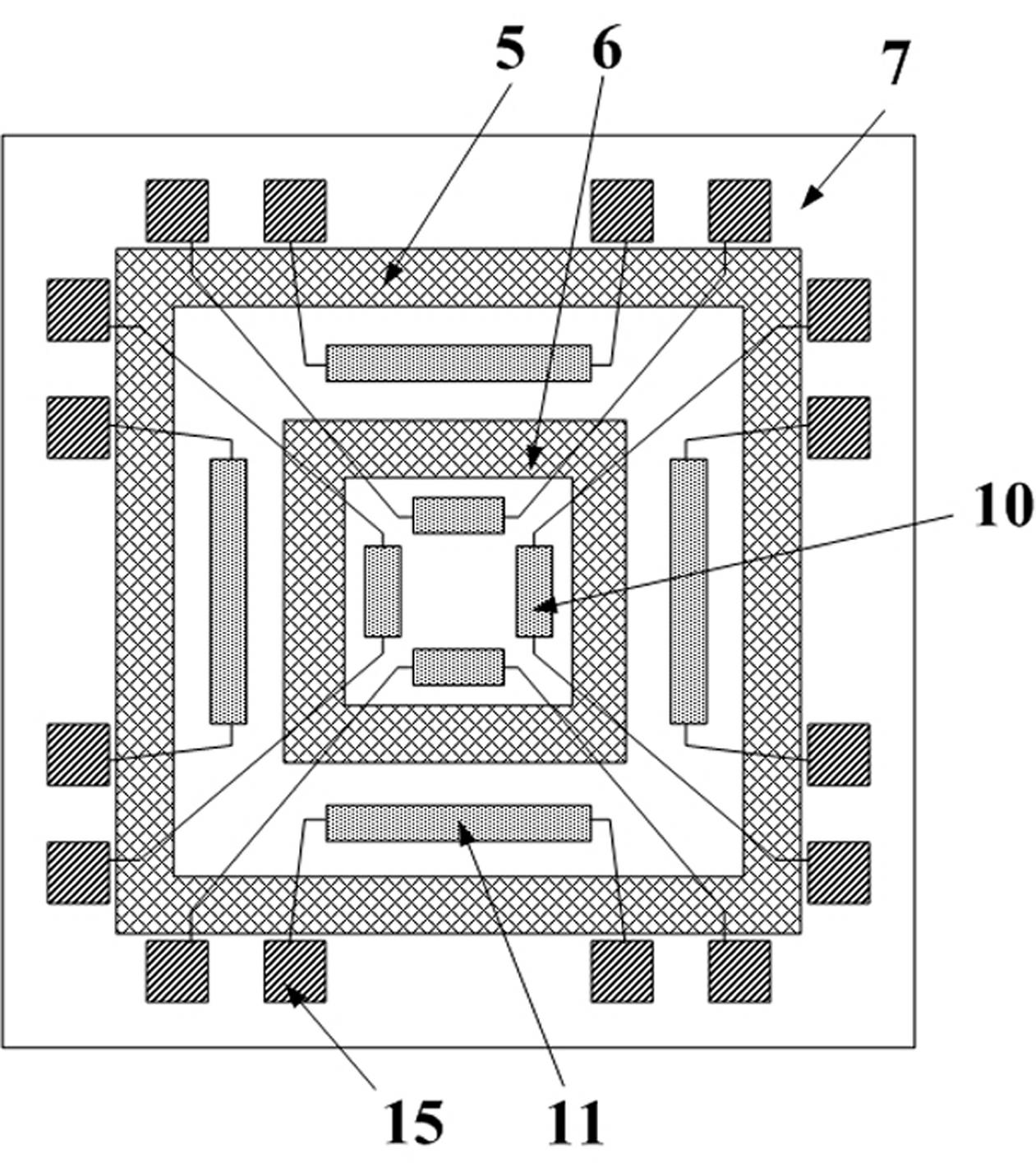

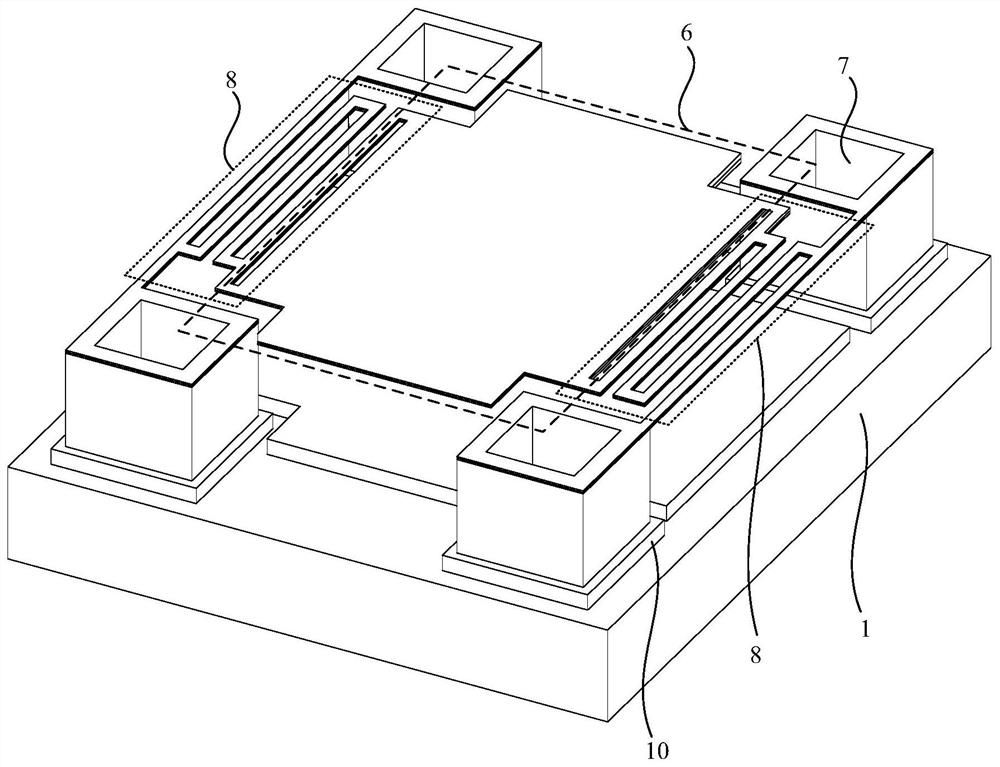

Thermal type wind sensor based on anisotropic heat-conducting substrate and preparation method therefor

InactiveCN102147421ABlock lateral heat conduction effectNo ruptureIndication/recording movementFluid speed measurement using thermal variablesHeat conductingEngineering

The invention discloses a thermal type wind sensor based on an anisotropic heat-conducting substrate; a chip of the sensor comprises the anisotropic heat-conducting substrate; four heating elements are symmetrically distributed at the center of the upper surface of the anisotropic heat-conducting substrate; four thermal sensing temperature-measuring elements are symmetrically distributed at the periphery of the four heating elements; the back surface of the anisotropic heat-conducting substrate is contacted with external environment so as to detect wind speed and wind direction; a glass heat-insulation inner ring is inlaid among the heating elements in the anisotropic heat-conducting substrate and silicon substrates under the thermal sensing temperature-measuring elements; a glass heat-insulation outer ring is inlaid among the silicon substrates under the thermal sensing temperature-measuring elements and silicon substrates at the edge of the chip; the two glass heat-insulation rings can ensure that the thickness of the anisotropic heat-conducting substrate is thinned to be about 100 microns by a thinning technology on one hand, the total power consumption of the sensor can be reduced on the other hand so that the sensor keeps higher signal sensitivity and shorter thermal response time under the lower power consumption.

Owner:SOUTHEAST UNIV

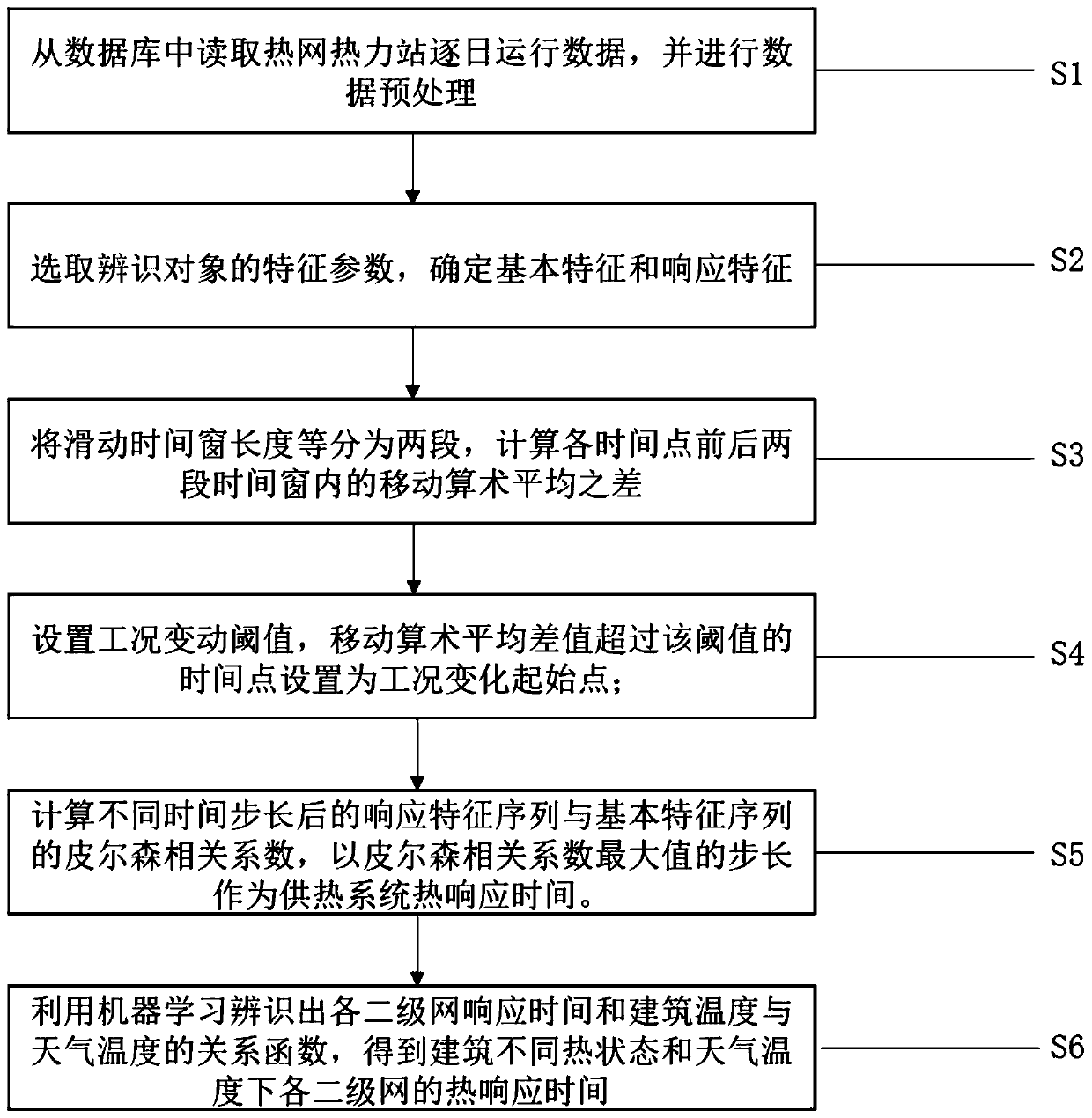

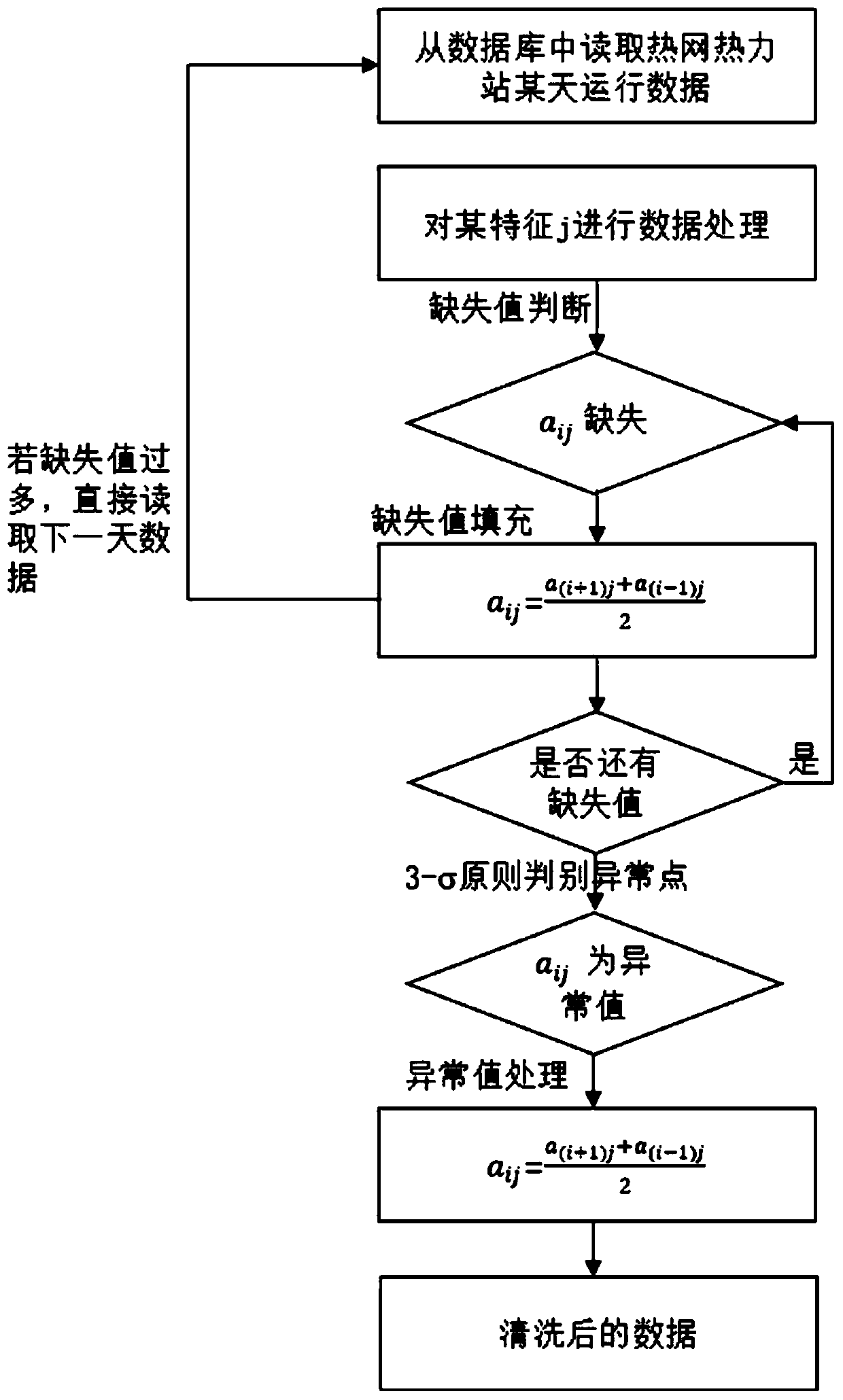

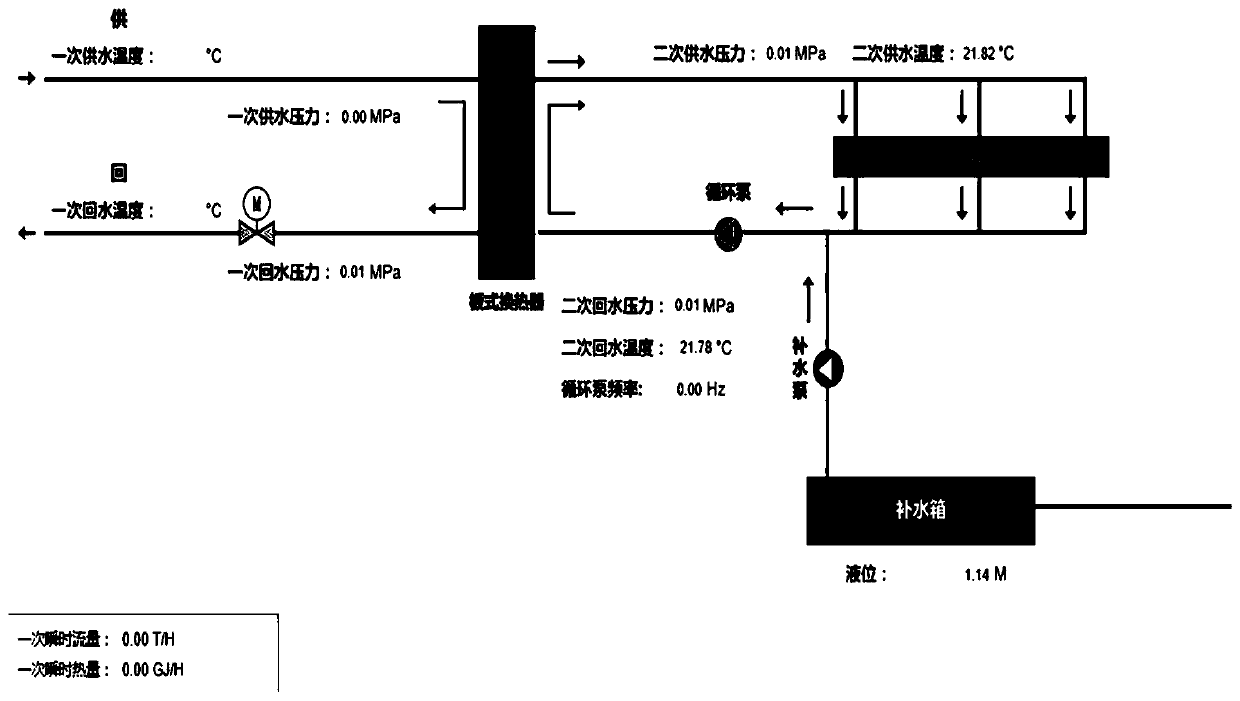

Heat supply system thermal delay time identification method based on Pearson correlation coefficient and moving average method

ActiveCN111275579ARealize automatic identificationReduce mistakesData processing applicationsDigital data information retrievalMoving averageThermal techniques

The invention relates to the technical field of heat supply, and discloses a heat supply system thermal delay time identification method based on a Pearson correlation coefficient and a moving averagemethod. The method is based on historical big data; external climate data and building temperature are combined; the method is based on a Pearson correlation coefficient and a moving average method.The thermal response time of the heating station or the secondary network is automatically obtained through a data identification method; according to the method, only common historical operation dataof the heat supply system needs to be obtained; the thermal response time of the heat supply system is identified through a big data method; the method does not depend on high-quality data collection, is not liable to be affected by single fault data or abnormal data, formulates different energy storage or scheduling strategies according to different delay time of the heat supply network based onan identification result, facilitates the improvement of the refinement degree of the operation and regulation of the heat supply system, and reduces the operation energy consumption level of the heat supply network.

Owner:ZHEJIANG UNIV

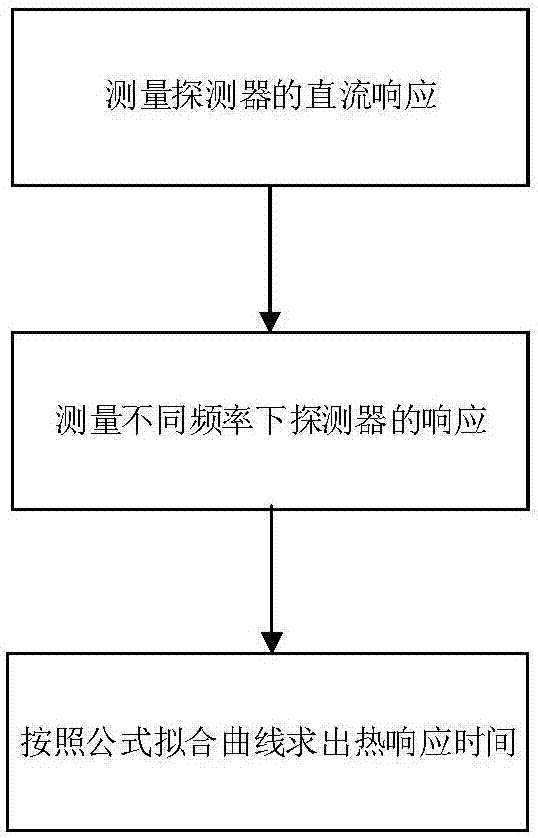

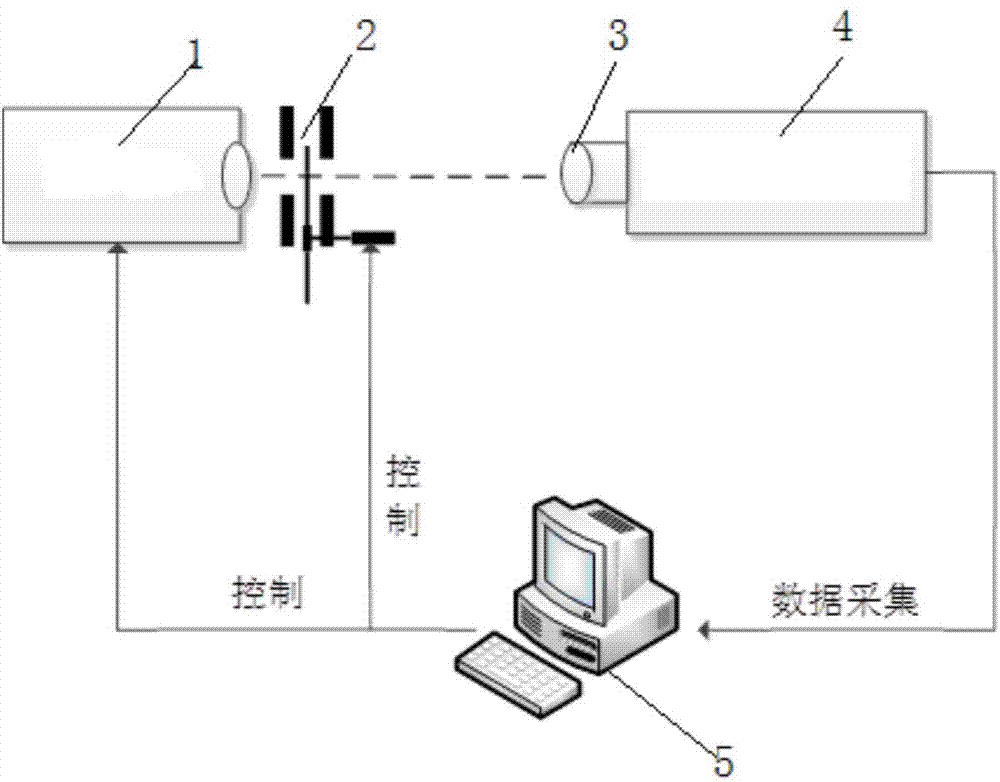

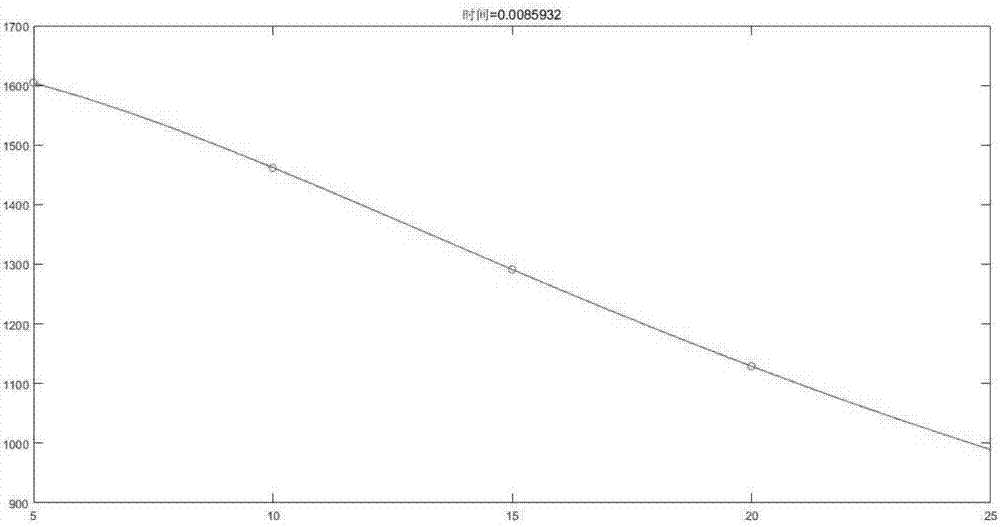

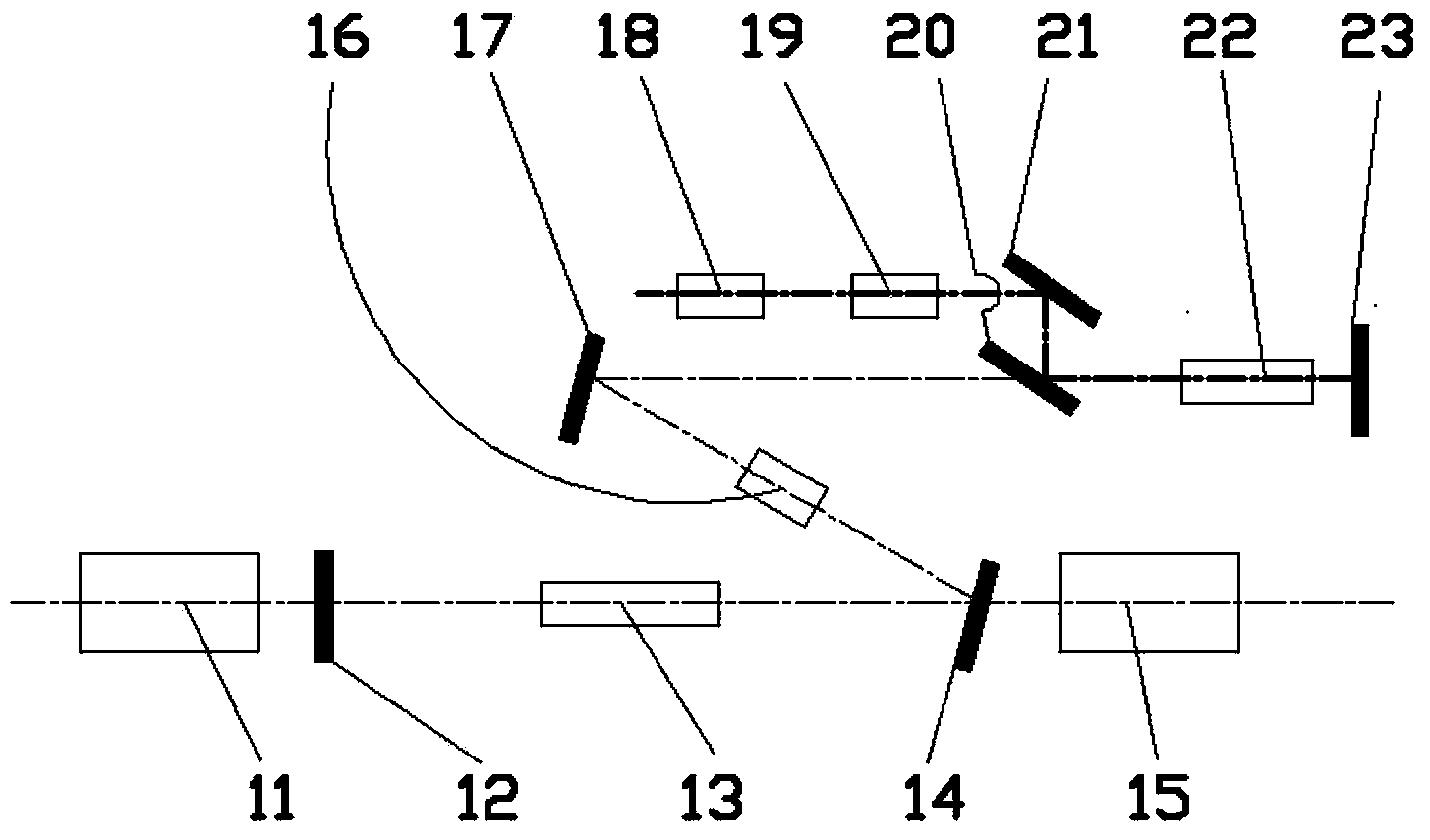

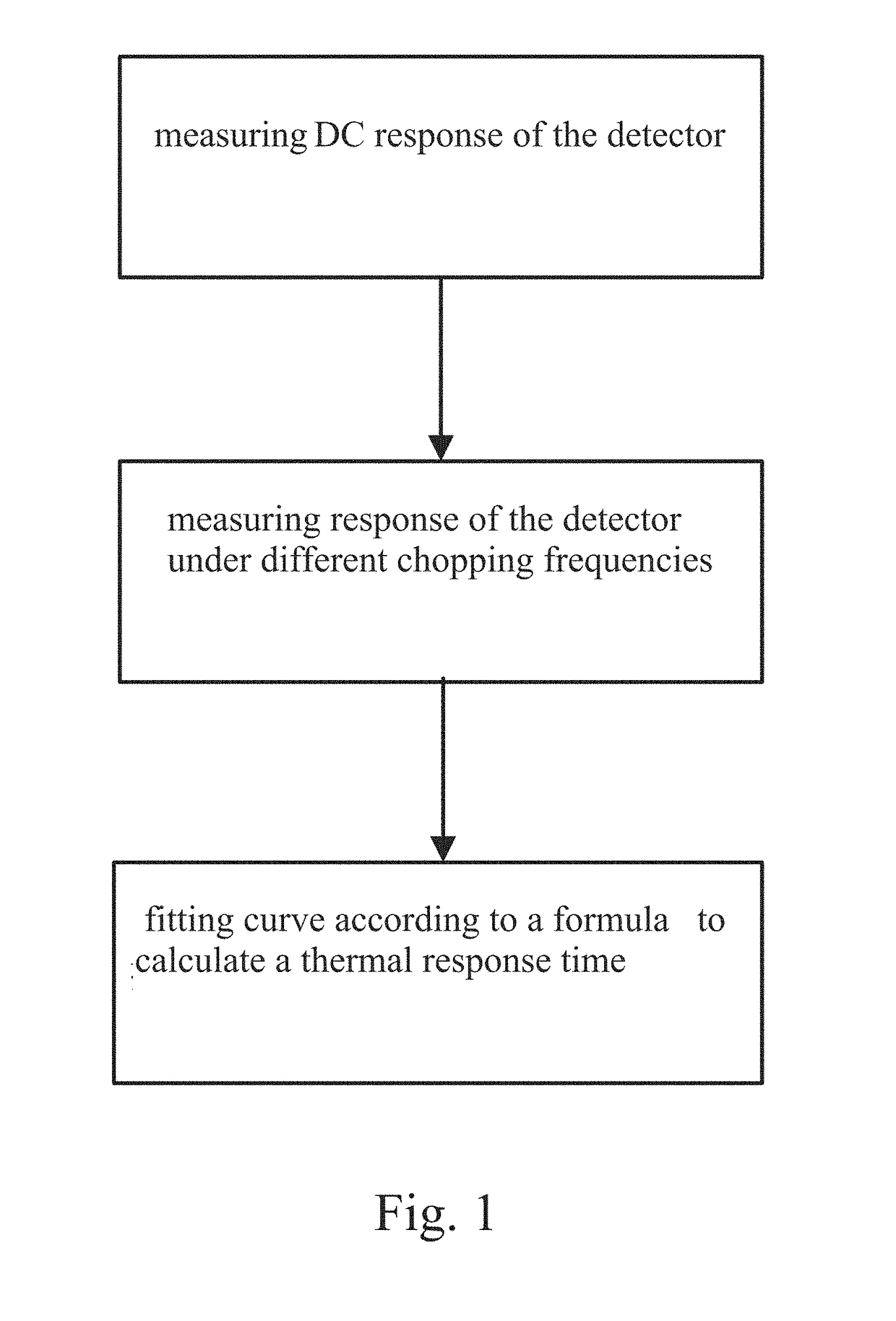

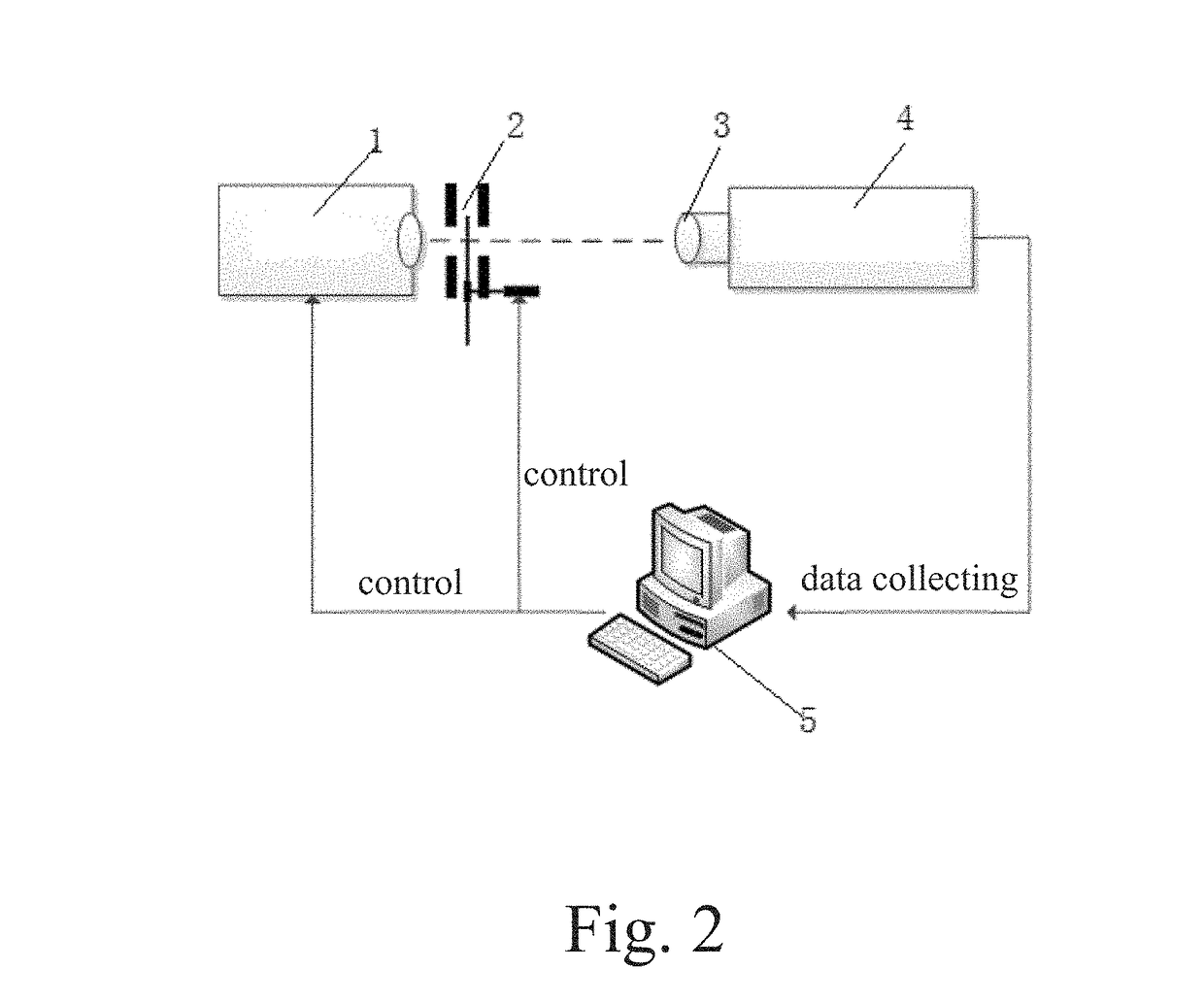

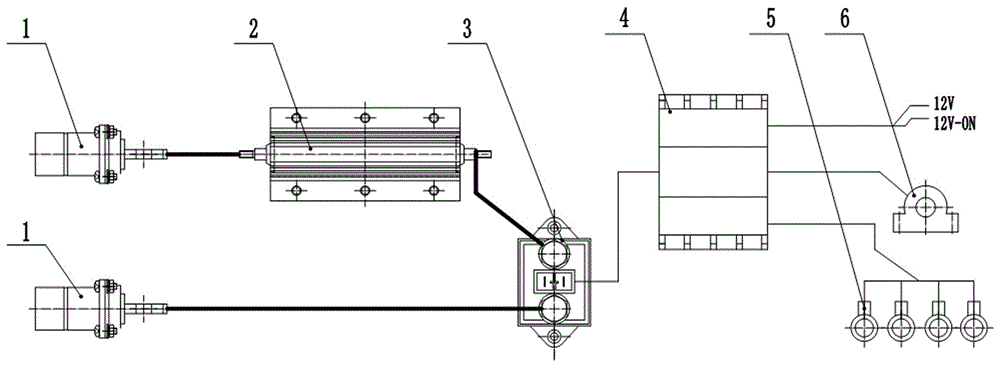

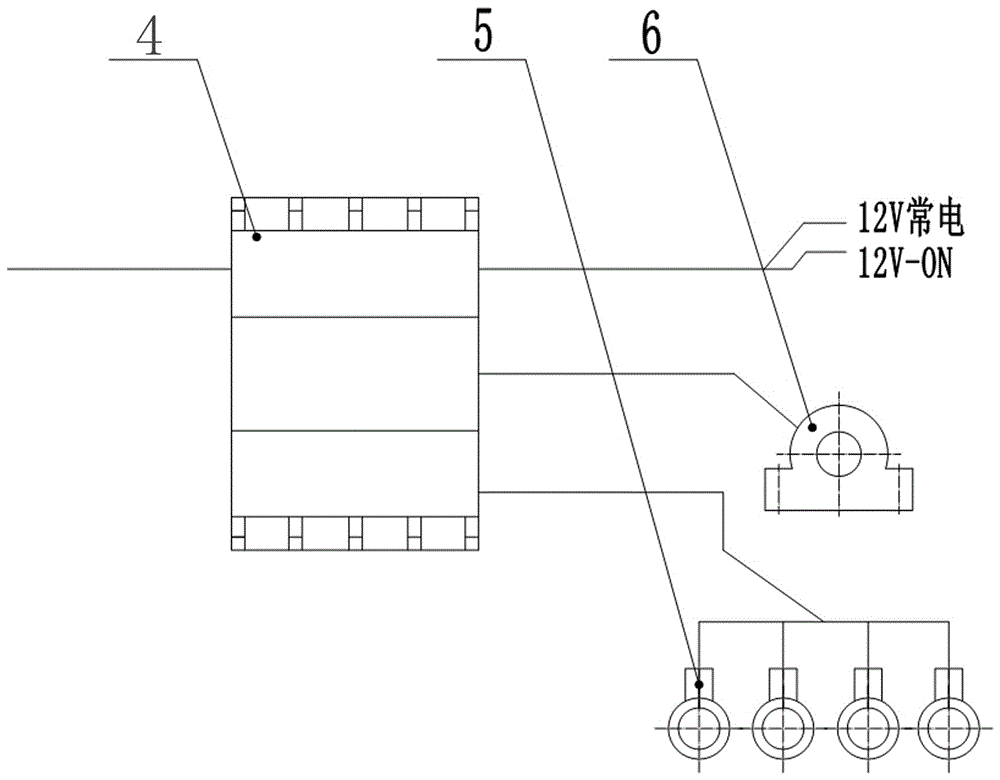

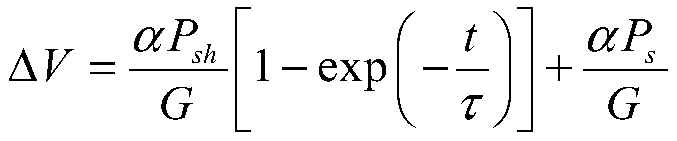

Uncooled infrared focal plane detector array thermal response time test system and method

ActiveCN107144356AExclude Effects of Thermal Response Time TestsHigh measurement accuracyElectrical testingPyrometry using electric radation detectorsFast Fourier transformBlack body

The invention provides an uncooled infrared focal plane detector array thermal response time test system and method. The system comprises a black body, a chopper, a detected detector assembly, and a test system. The test method includes: radiations emitted by the black body are chopped by the chopper and are irradiated to a tested uncooled infrared focal plane detector array, the tested uncooled infrared focal plane detector array generates different responses for the radiations of different frequencies, response values of the tested uncooled infrared focal plane detector array with different chopping frequencies are acquired, response amplitudes of corresponding frequency points in a frequency domain are obtained through fast Fourier transform (FFT), and the thermal response time is calculated through fitting according to a formula shown in the description. According to the method, FFT is employed, the influence of noise on the test of the thermal response time is effectively eliminated, the measuring precision is high, and test results are reliable and stable; and the test can be conducted by employing standard devices including the black body and the chopper etc., the test time is short, the feasibility is high, and the efficiency is high.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

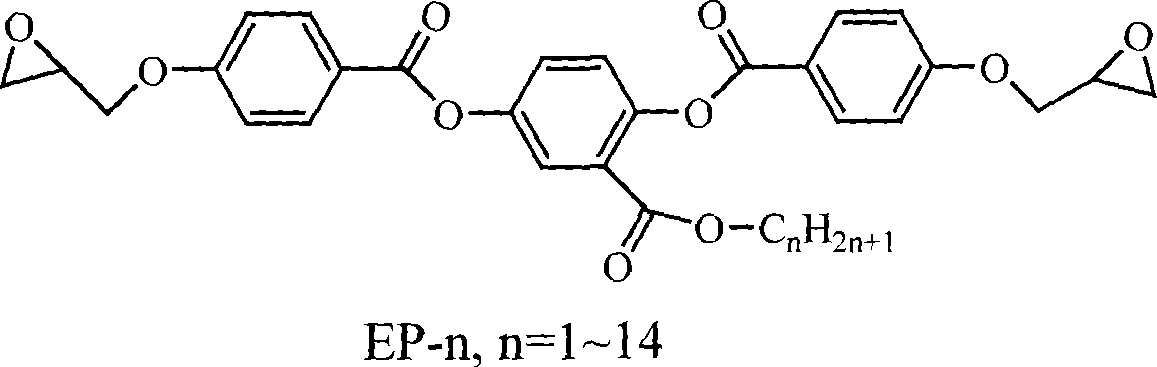

Modified epoxide resin with thermal driving shape memory function and preparation method thereof

InactiveCN102827350ANo emissionsMeet the requirements of green environmental protectionEpoxyGreen environment

The invention relates to a modified epoxide resin with a shape memory function and a preparation method of the modified epoxide resin, belonging to the technical field of a functional high molecular material. The response temperature of the modified epoxide resin material provided by the invention can be adjusted within the range of 32-60 DEG C, the material can be bent at a large angle of 720 degrees at the temperature more than the thermal response temperature, and the shape fixed rate and recovery rate of the modified epoxide resin reach 100%. The preparation method of the modified epoxide resin comprises the following steps of: firstly, preparing end sulfydryl dihydric alcohol ester; secondly, preparing modified epoxide resin; and thirdly, preparing the modified epoxide resin with the shape memory function. Compared with the existing shape memory material, the modified epoxide resin has the advantages of being simple in preparation technology, capable of meeting a green environment protection requirement, low in thermal response temperature, capable of being adjusted, capable of realizing saturated solidifying, low in solidifying temperature, short in solidifying time, short in thermal response time, large in sample flexible angle, and high in shape recovery rate.

Owner:ZHONGBEI UNIV

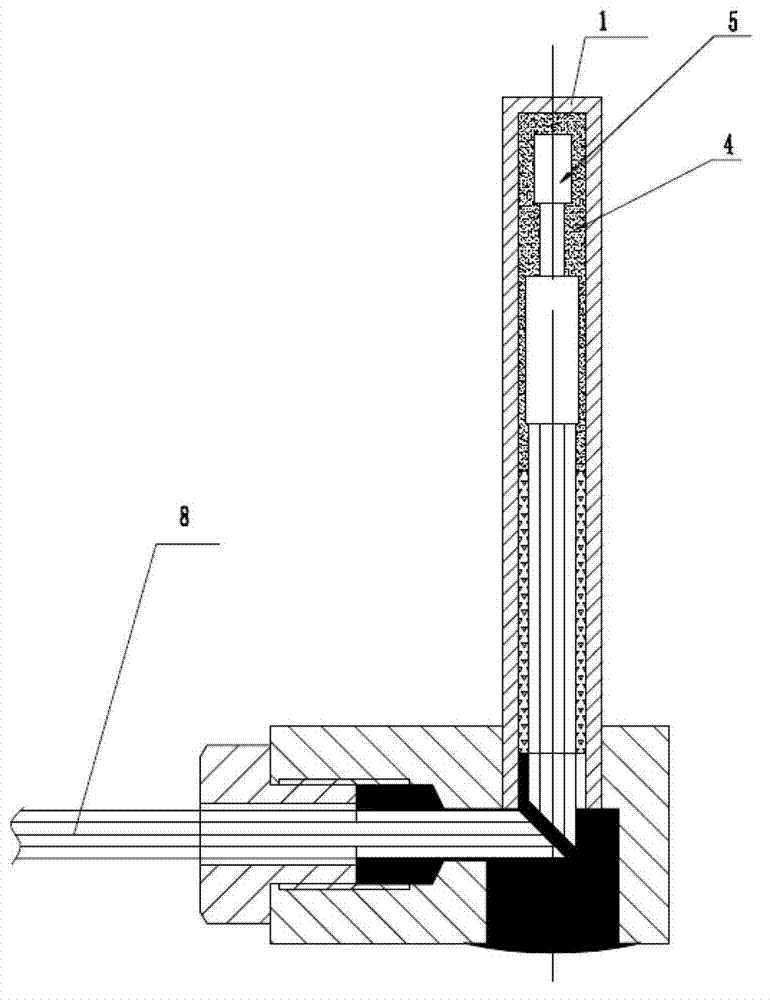

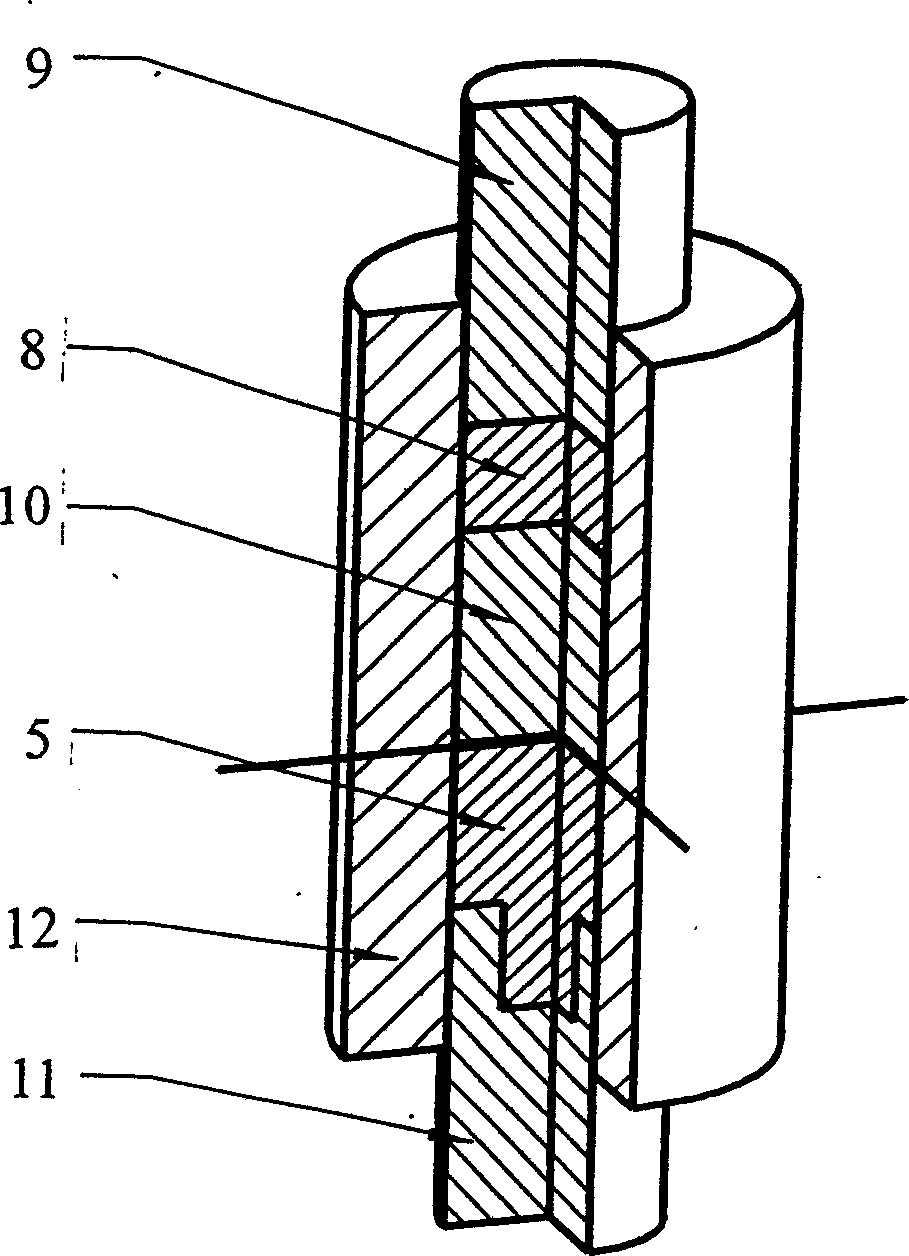

High-sensitivity thermal-response platinum resistor temperature sensor

ActiveCN103033280AKeep protectiveImprove sensing sensitivityThermometers using electric/magnetic elementsUsing electrical meansElectrical resistance and conductancePlatinum

The invention discloses a high-sensitivity thermal-response platinum resistor temperature sensor. A thermal conductive metal cap is fixedly embedded at the top end of a metal protecting pipe of the high-sensitivity thermal-response platinum resistor temperature sensor, a platinum resistor inductive core is arranged inside a counter bored hole of the thermal conductive metal cap, a signal transmission cable is in electric connection with the platinum resistor inductive core, transmitting signals are guided out of the metal protecting pipe, thermal-insulating layers are arranged on the internal part of the metal protecting pipe of the thermal conducting inductive cap and outside the counter bored hole of the thermal conducting cap, and the thermal conducting connecting body of the counter bored hole of the thermal conducting cap is linked up with thermal conducting metal points which are embedded in the backside of the insulating substrate of the inductive core of the platinum resistor in a thermal-conducting mode. The high-sensitivity thermal-response platinum resistor temperature sensor improves induction sensitivity of the sensor, shortens thermal response time, and enables the platinum inductive core to be capable of sensing temperature change of environment sensitively and outputting transmission signals of detection.

Owner:丹东鸭绿江敏感元件有限公司

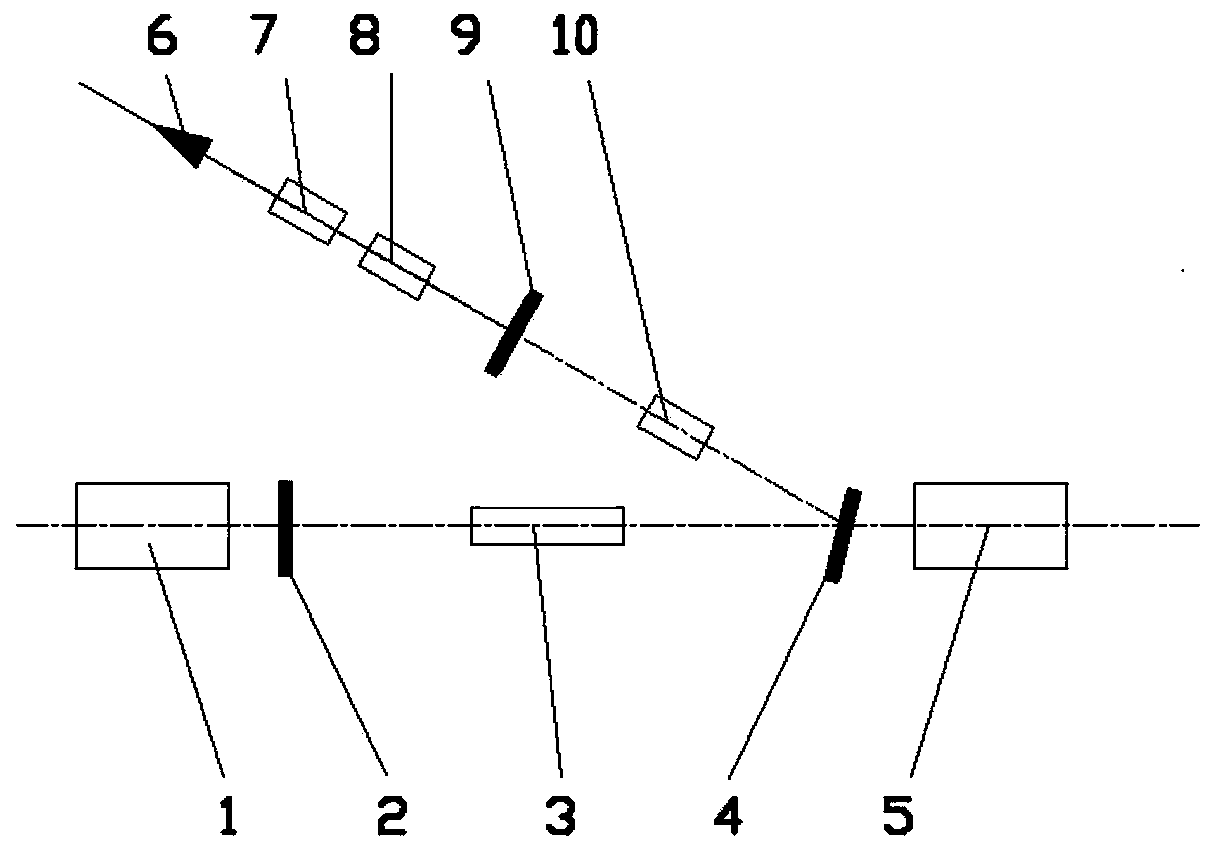

Method for increasing laser thermal response speed and multi-terminal pump solid state laser

ActiveCN103762495ALittle change in heat loadMaintain thermal stabilityLaser detailsResonant cavityLaser processing

The invention relates to a method for increasing the laser thermal response speed and a multi-terminal pump solid state laser. When Q adjusting lasers are needed for laser processing, a Q adjusting switch module is used for conducting laser Q adjusting, at the moment a laser resonant cavity outputs the Q adjusting lasers, and an external modulation optical switch is in a light-transmitting state. When laser processing coordinate positions change and light closing is needed, the Q adjusting switch module does not work or the Q adjusting power is reduced for partial light locking, the external modulation optical switch turns off or attenuates the continuous laser power output by the laser resonant cavity, and then materials to be processed are prevented from being damaged by lasers. When the Q adjusting lasers need to be output again, the external modulation optical switch is in a light-transmitting state, the Q adjusting switch module conducts Q adjusting on the lasers of the laser resonant cavity, and due to the fact that the change of thermal loads of laser crystals is small, the good laser thermal response is acquired. According to the technical scheme, laser processing efficiency is guaranteed while laser thermal response time is shortened, and the method for increasing the laser thermal response speed and the multi-terminal pump solid state laser are very suitable for being widely used in the field of laser processing.

Owner:张立国

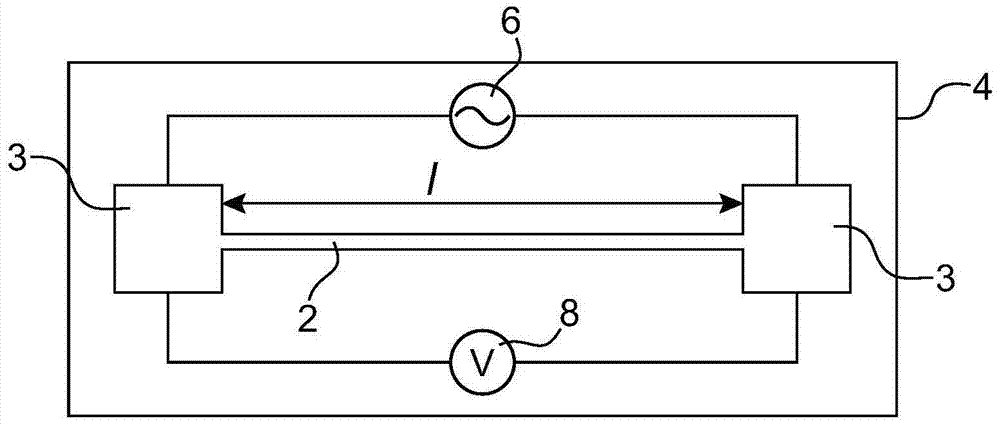

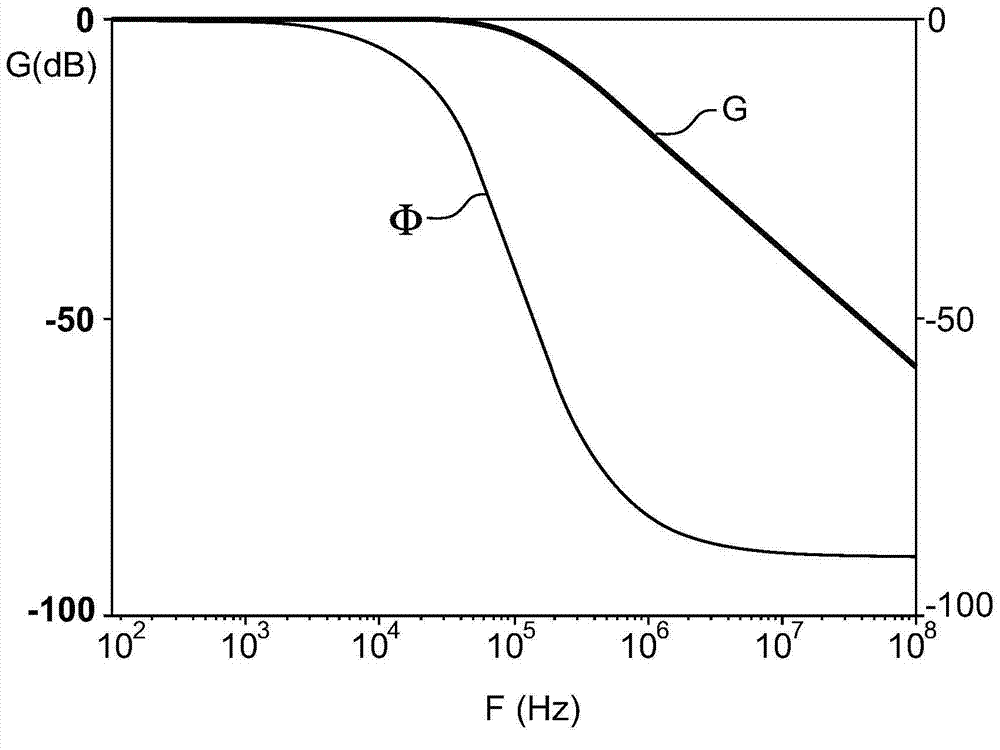

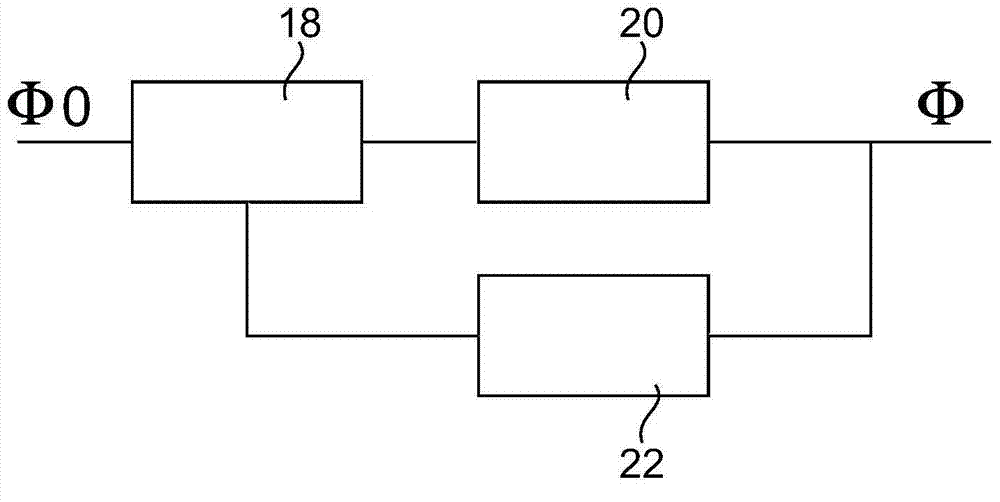

Gas concentration sensor with a suspended structure

ActiveCN104849302AHigh resolutionComponent separationDispersed particle separationPhase shiftedConductive materials

A concentration sensor for at least one given gas comprising at least one suspended structure (2) with respect to a support, said suspended structure (2) being of an electrically conductive material and said structure having a low heat response time, means for biasing said suspended element (2) and means (8) for measuring the variation of the electric voltage at the terminals of the suspended structure (2), the biasing means (6) being formed by an alternating current source the intensity of which heats the suspended structure (2) and the frequency of which gives rise to a phase shift between a signal of the biasing means and a signal measured by the measuring means, and means for determining a phase shift variation due to a gas concentration variation and means for determining the concentration variation of said gas from the phase variation.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

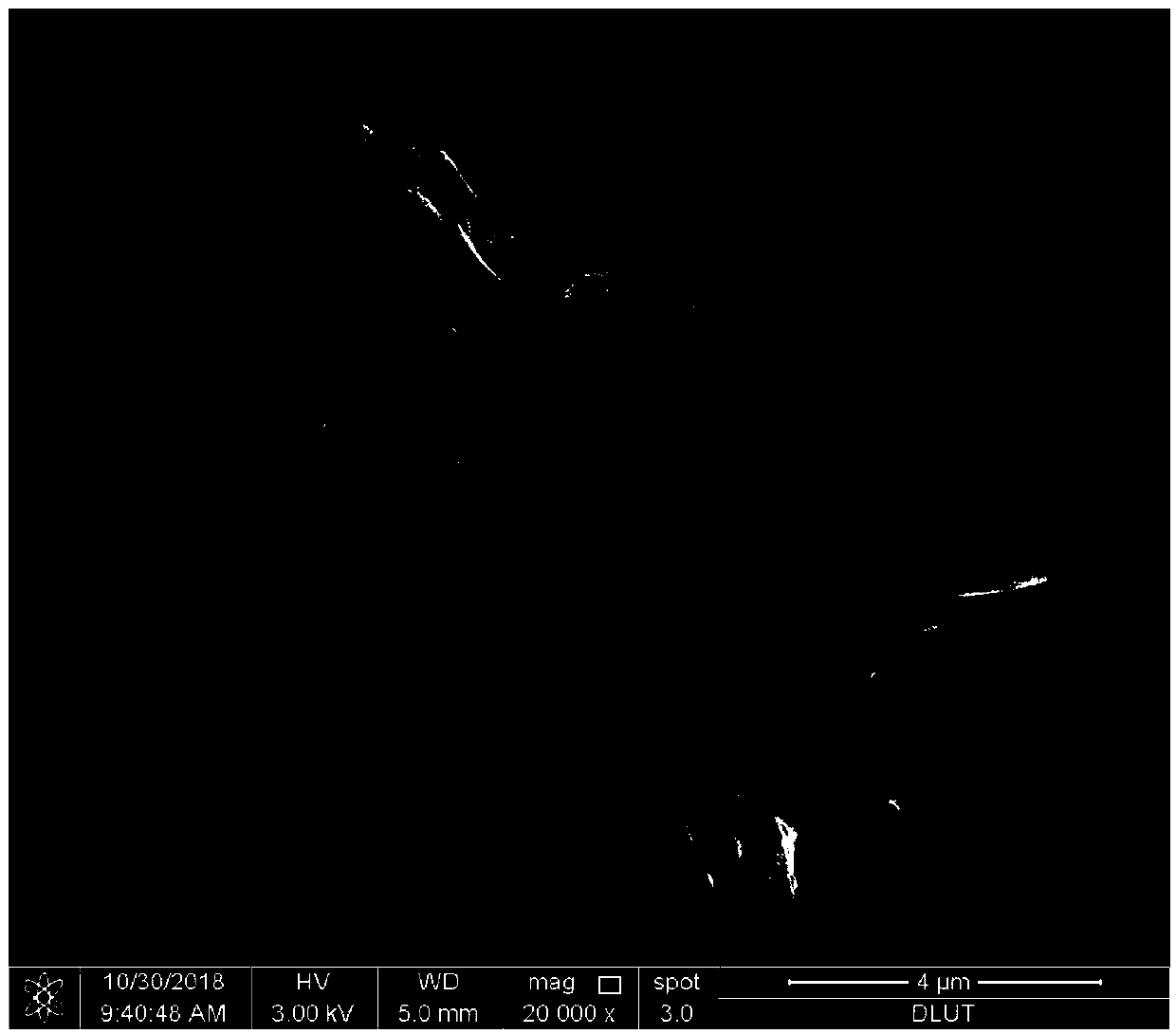

Nitrogen dioxide gas sensor based on flower-shaped SnSe2/SnO2 heterojunction, and preparation technology and application of nitrogen dioxide gas sensor

The invention belongs to the technical field of electronic components, and discloses a nitrogen dioxide gas sensor based on a flower-shaped SnSe2 / SnO2 heterojunction, and a preparation technology andapplication of the nitrogen dioxide gas sensor. The nitrogen dioxide gas sensor comprises a gas sensitive material and an interdigital electrode plate, and the surface of the interdigital electrode plate is coated with the gas sensitive material, wherein the coating thickness is 1-100 [mu]m; and the gas sensitive material is a flower-shaped SnSe2 / SnO2 nano-material. The flower-shaped nano heterojunction is obtained through a hydrothermal method and a thermal oxidation method, raw materials are convenient to obtain, low in cost and simple in preparation process, equipment investment is small, and the process flow is simple. The nitrogen dioxide sensor made of the flower-shaped SnSe2 / SnO2 nano-material selects a silicon substrate, the material and silicon-based microelectronics are integrated, and the micro hot plate type nitrogen dioxide gas sensor having the advantages of low heating power consumption, small heat loss, short heat response time, compatibility with a CMOS process, easy integration with other microelectronic devices and the like is prepared.

Owner:DALIAN UNIV OF TECH

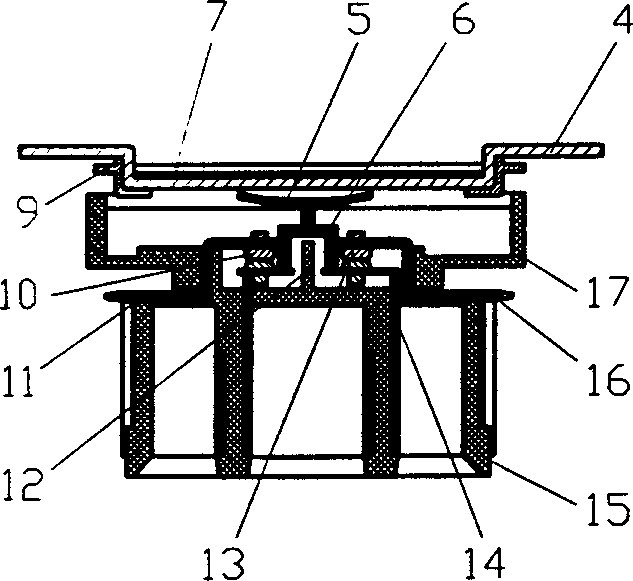

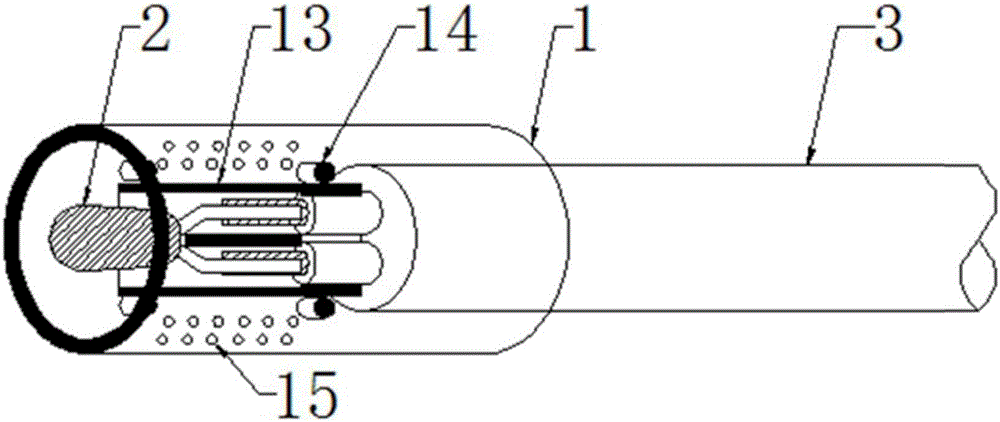

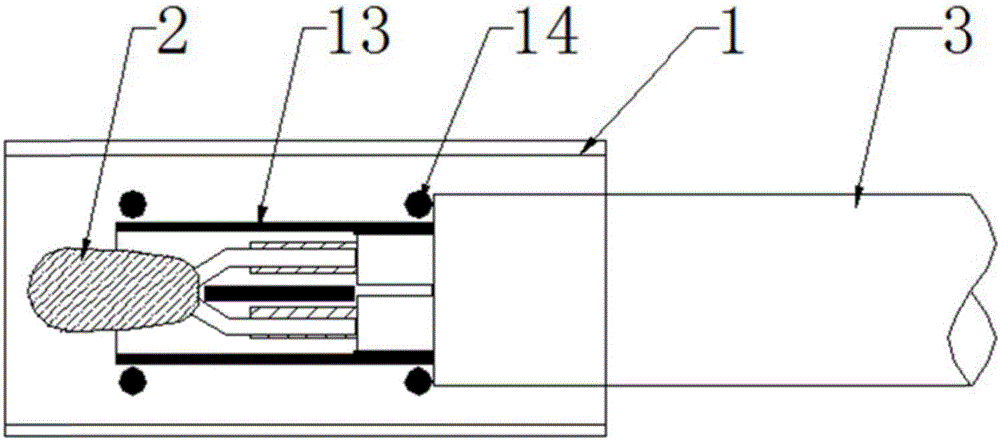

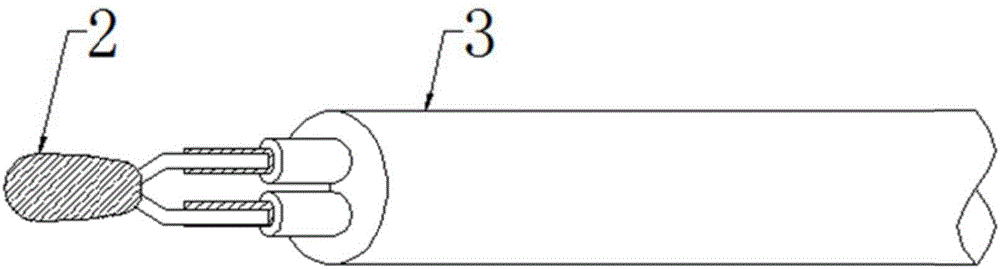

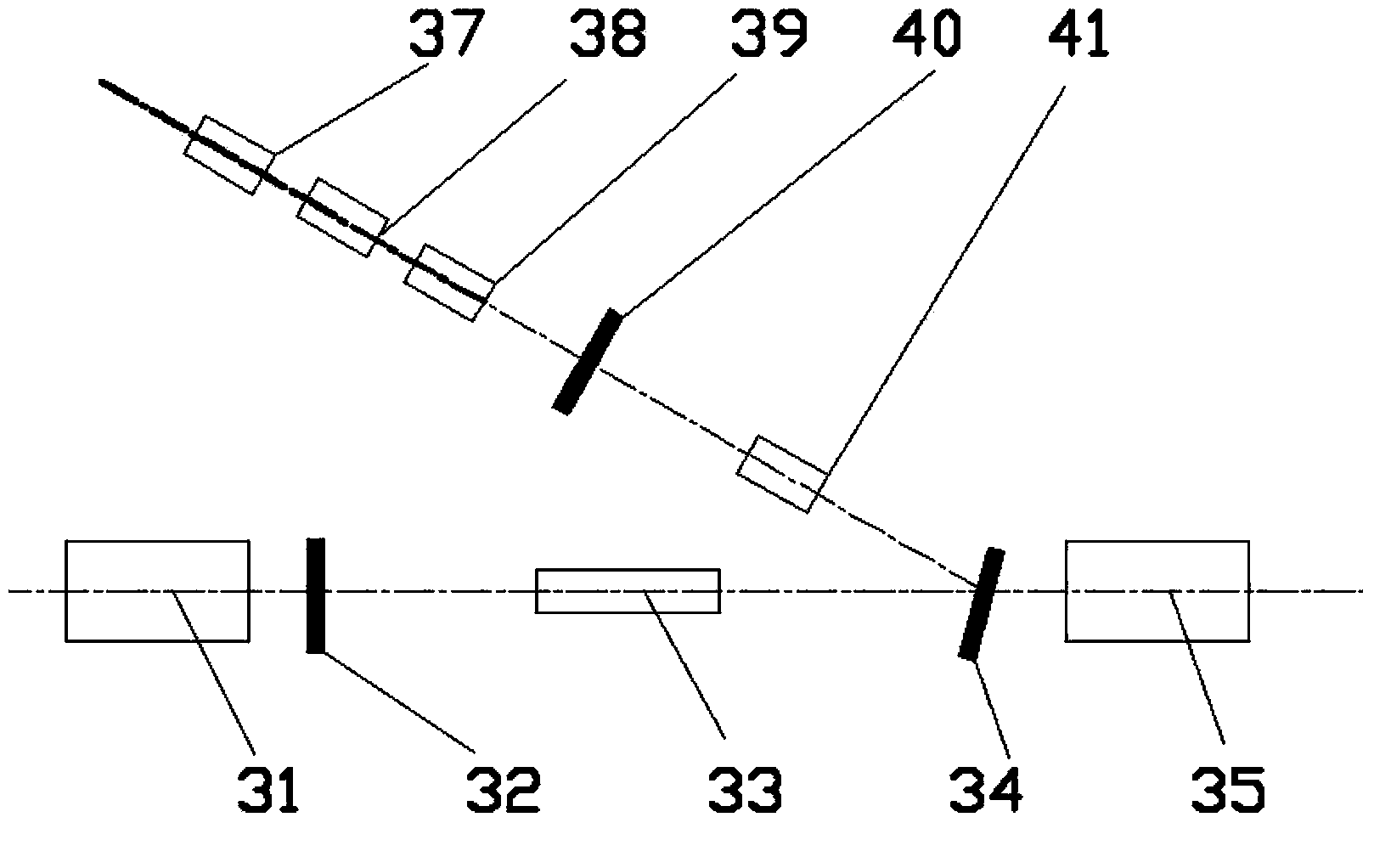

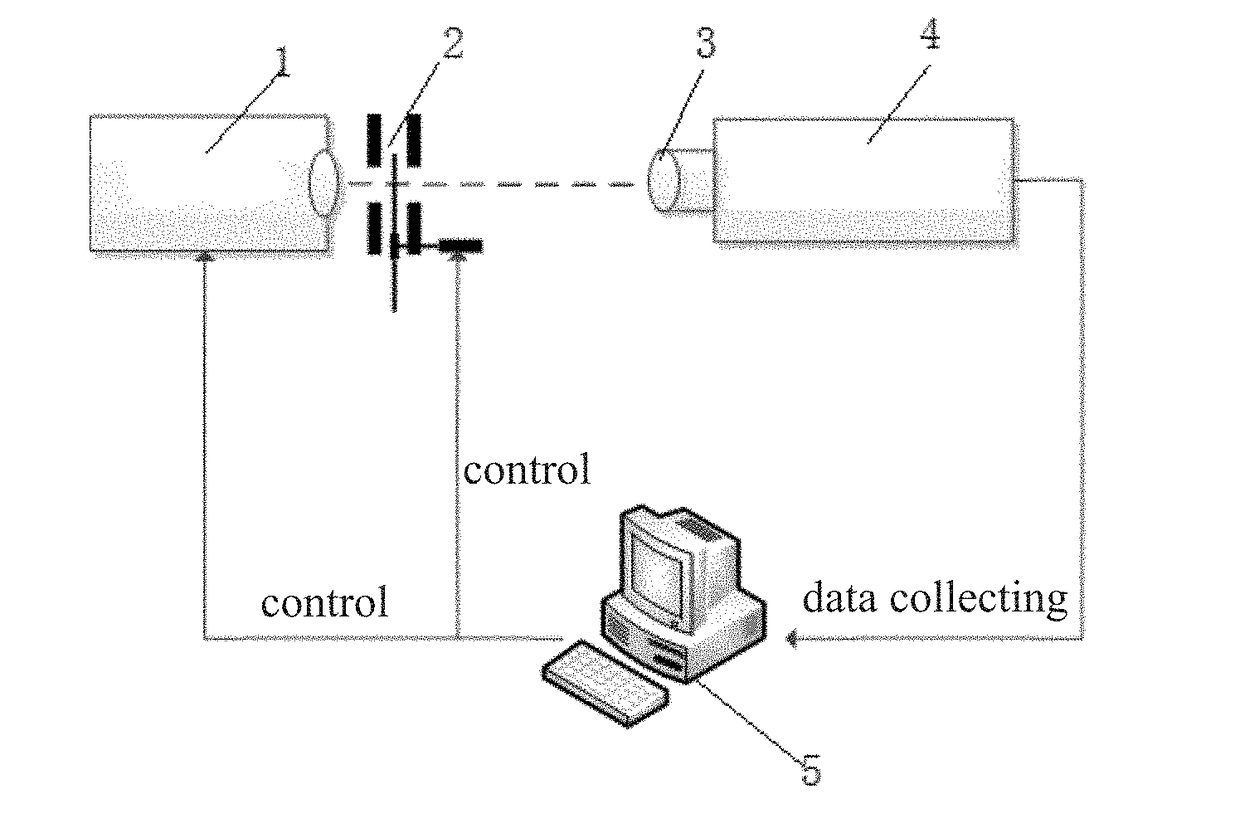

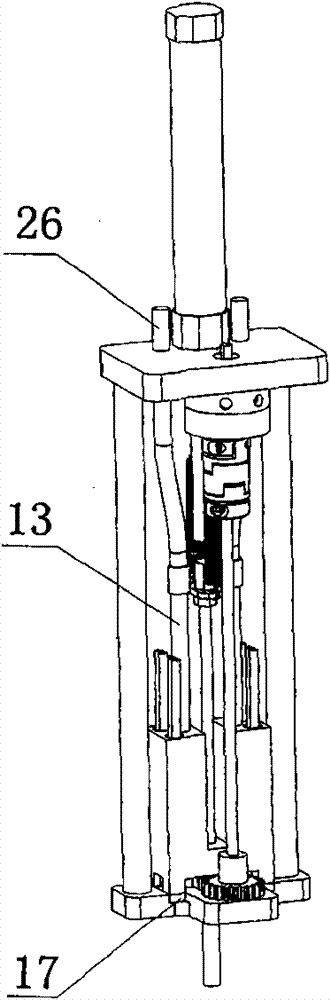

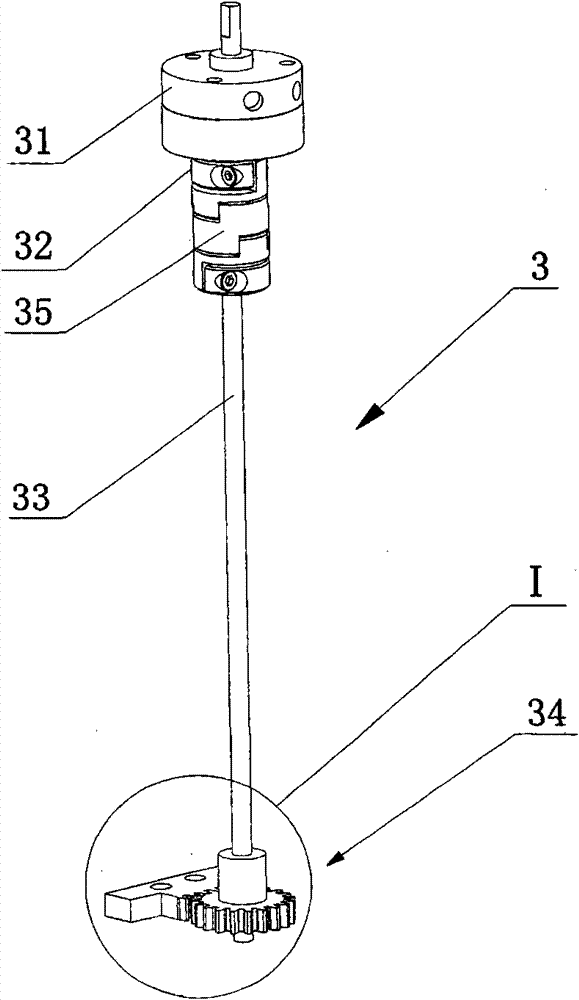

Device for measuring thermal response time of thermocouple

PendingCN106969857AEasy to controlEasy to operateThermometer testing/calibrationHigh power lasersData acquisition

The invention relates to a device for measuring the thermal response time of a thermocouple. The device comprises a large power laser A, a large power laser B, a fixed device, the thermocouple, the data acquisition card, and a computer. The large power laser A and the large power laser B are fixed to the lower part of the fixed device. The thermocouple is fixed to the upper part of the fixed device. The reference end wire of the thermocouple is connected to the input end of the data acquisition card. The output end of the data acquisition card is connected to the computer. The invention relates to the device for measuring the thermal response time of a thermocouple, the thermal response time of the thermocouple is measured through a mode of laser heating, a ladder step temperature is obtained through controlling the starting number of the large power lasers, the device is small and simple, a heating source is easy to control, the operation is facilitated, and manpower is saved.

Owner:CHINA JILIANG UNIV

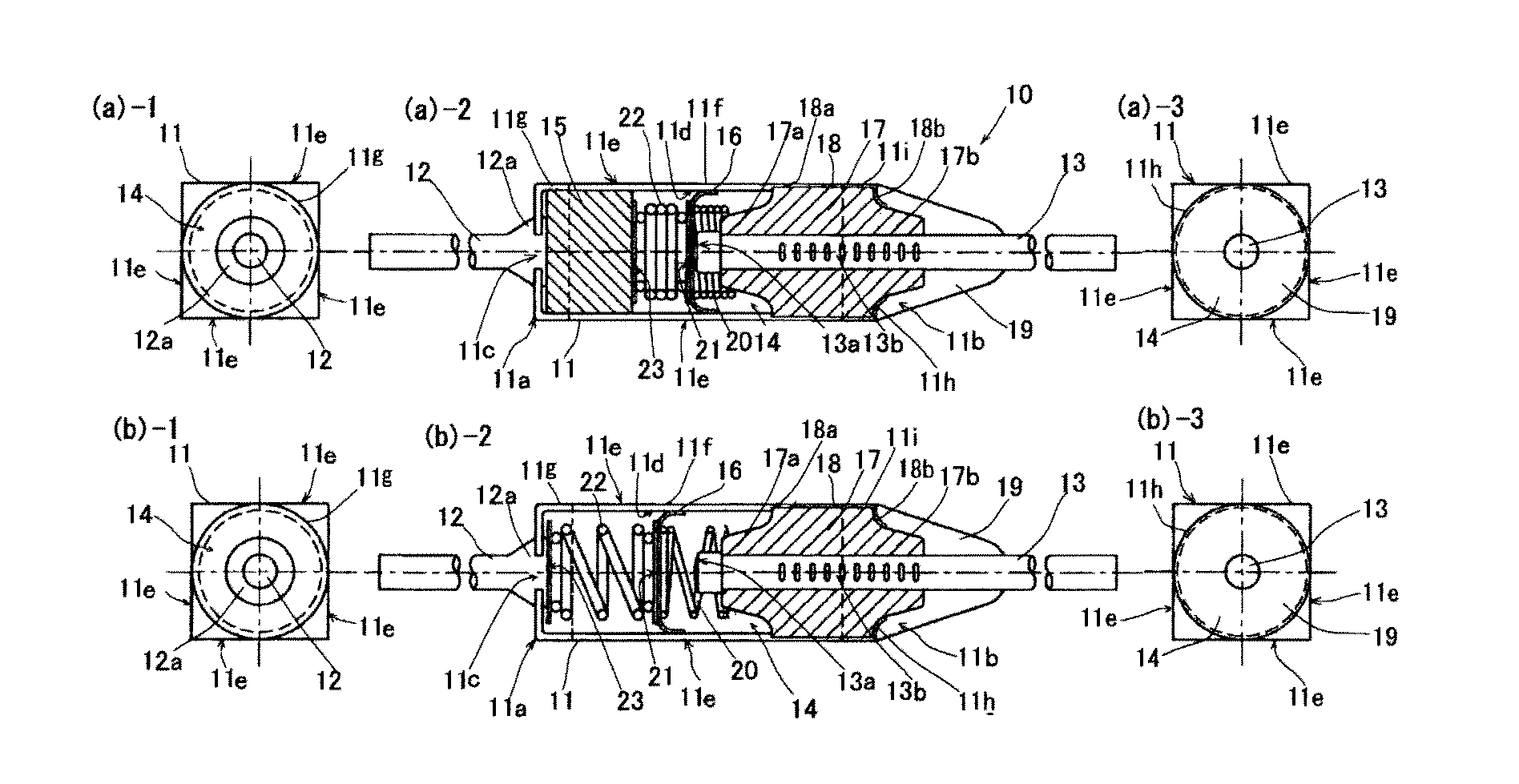

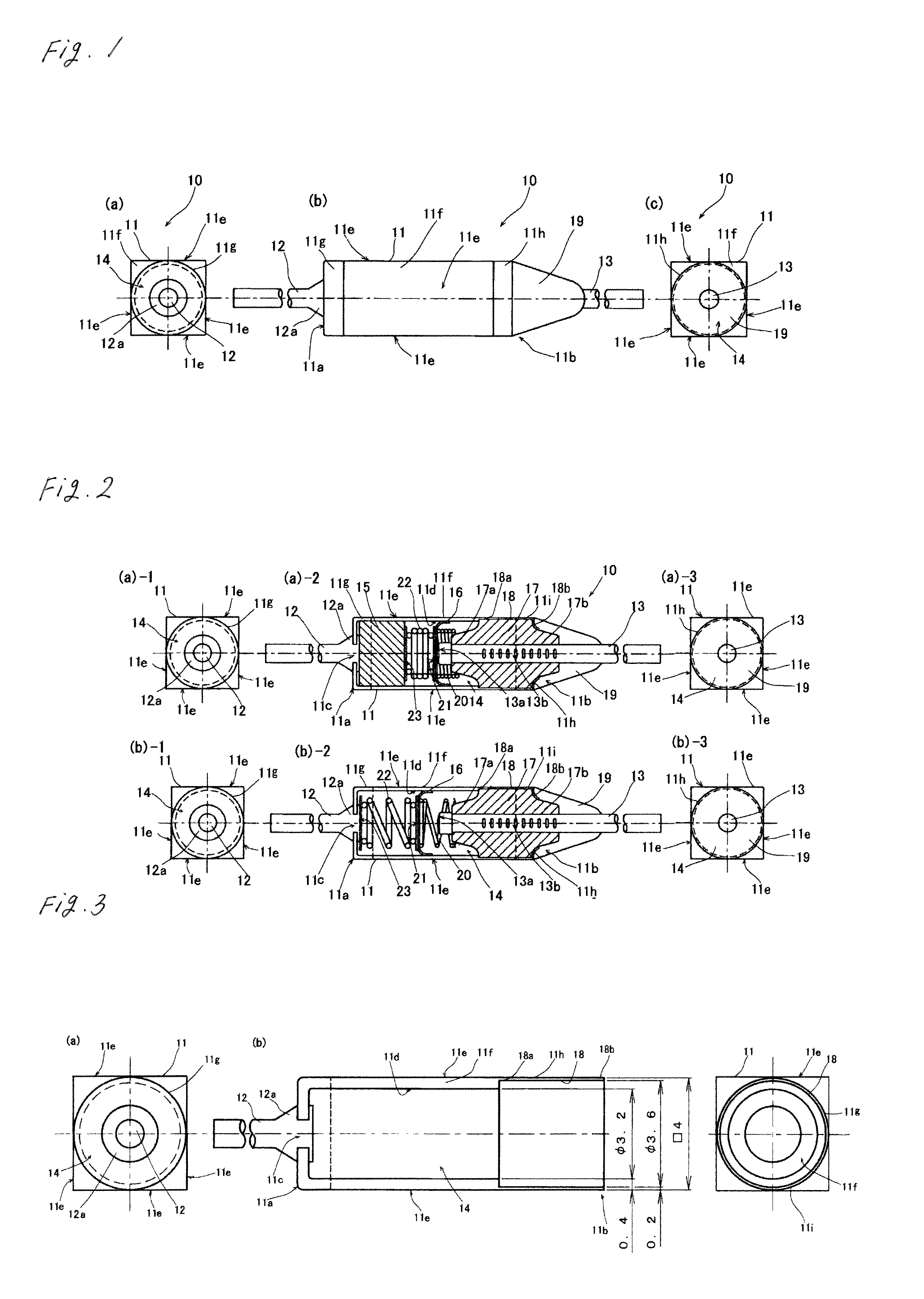

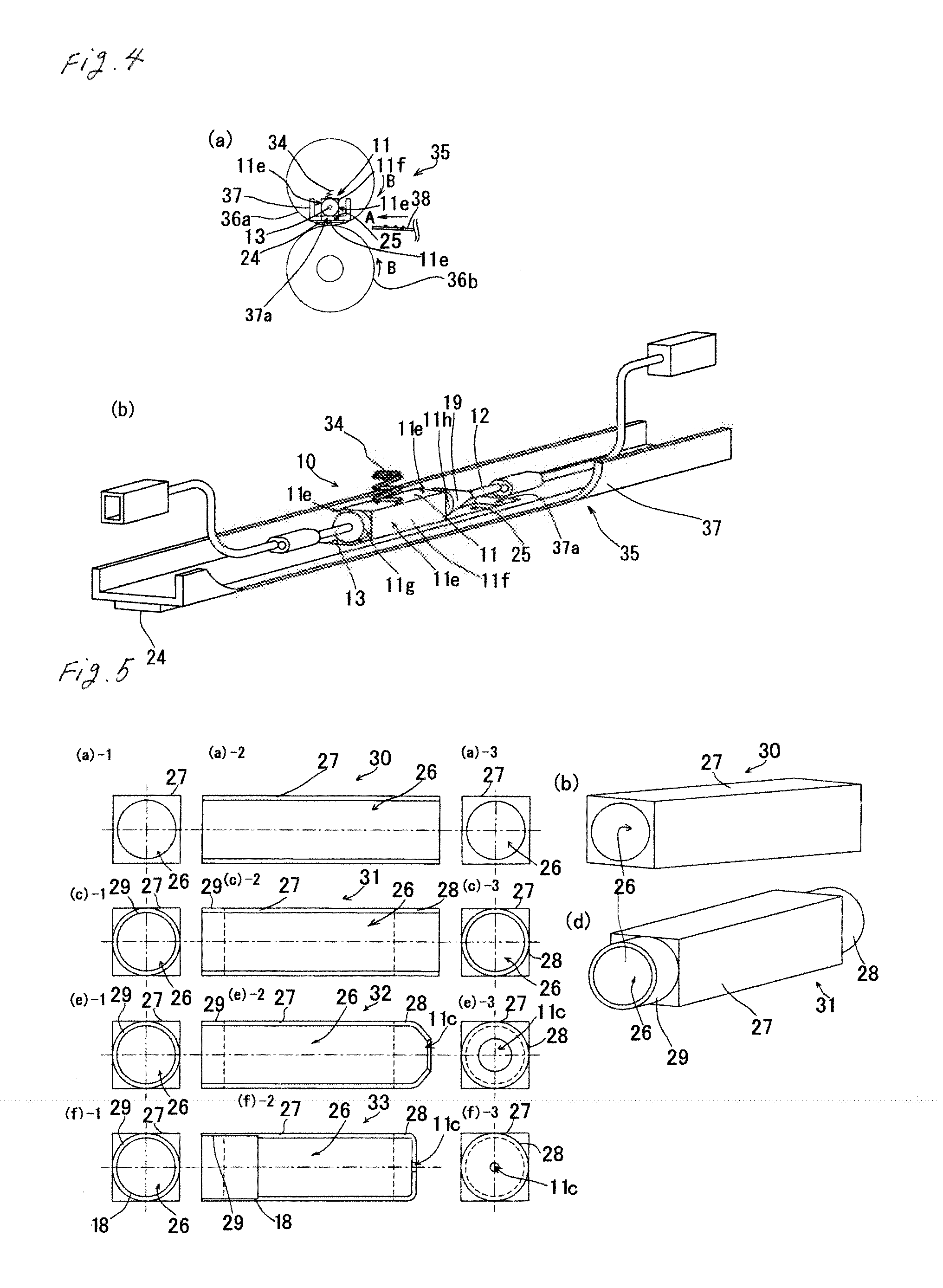

Temperature-sensitive pellet type thermal fuse

InactiveUS20120255162A1Quick responseEnsure versatilityFuse device manufactureWave amplification devicesTemperature controlManufacturing cost reduction

The present invention provides a temperature-sensitive pellet type thermal fuse, a manufacturing method of the temperature-sensitive pellet type thermal fuse and a mounting method of the temperature-sensitive pellet type thermal fuse which, when the fuse is mounted on a temperature control target object having a planar portion, can ensure a high heat response speed, can decrease the difference in a heat response time for every product, can ensure high operational reliability, reduces the number of parts, and can reduce a manufacturing cost. A temperature-sensitive pellet type thermal fuse includes: an elongated case which has a hollow portion in the inside thereof; a first lead line which is arranged on one longitudinal end portion side of the elongated case along the longitudinal direction; a second lead line which is arranged on the other longitudinal end portion side of the elongated case along the longitudinal direction; and a movable contact which is arranged in the hollow portion and is brought into contact with the second lead line which is always biased in the move-away direction by way of a molten pellet arranged in contact with the first lead line, the movable contact being movable away from the second lead line due to a biasing force when a temperature of a temperature control target object arrives at a predetermined temperature or more and the molten pellet is melted thus cutting off a power source circuit, wherein the elongated case includes a planar portion which is brought into face contact with a planar portion of the temperature control target object.

Owner:THE HOSHO CORP

Method for testing temperature of explosive ignition point

InactiveCN1504734AEasy to operateThermometers using electric/magnetic elementsUsing electrical meansEngineeringCryometer

The invention relates to a method for measuring explosive firing temperature, which comprises the steps of, (1) contacting the tested explosive with a selected temperature gauge, (2) heating-up temperature gauge through a heating arrangement, (3) recording the heating-up process of the explosive and interpreting the explosive ignition temperature. The method can facilitate the extensive use in the real world engineering.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

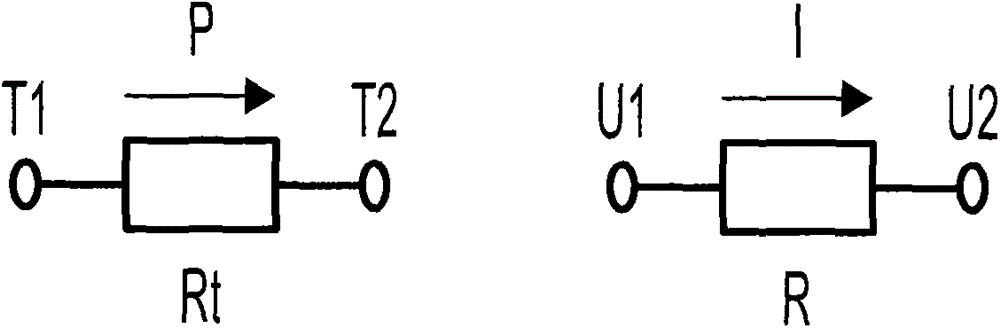

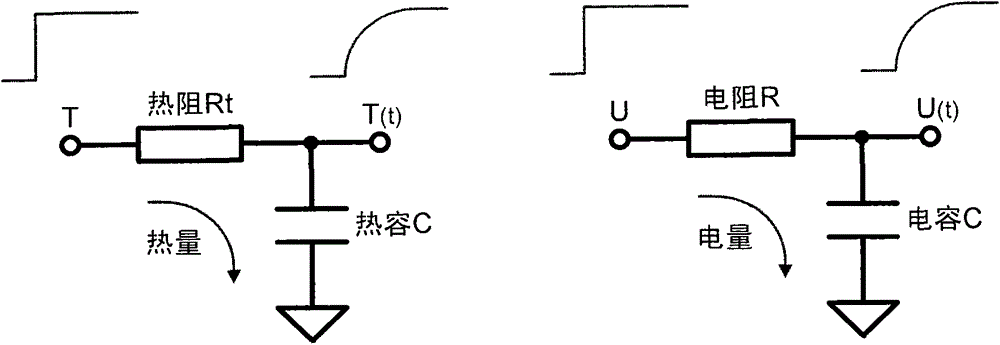

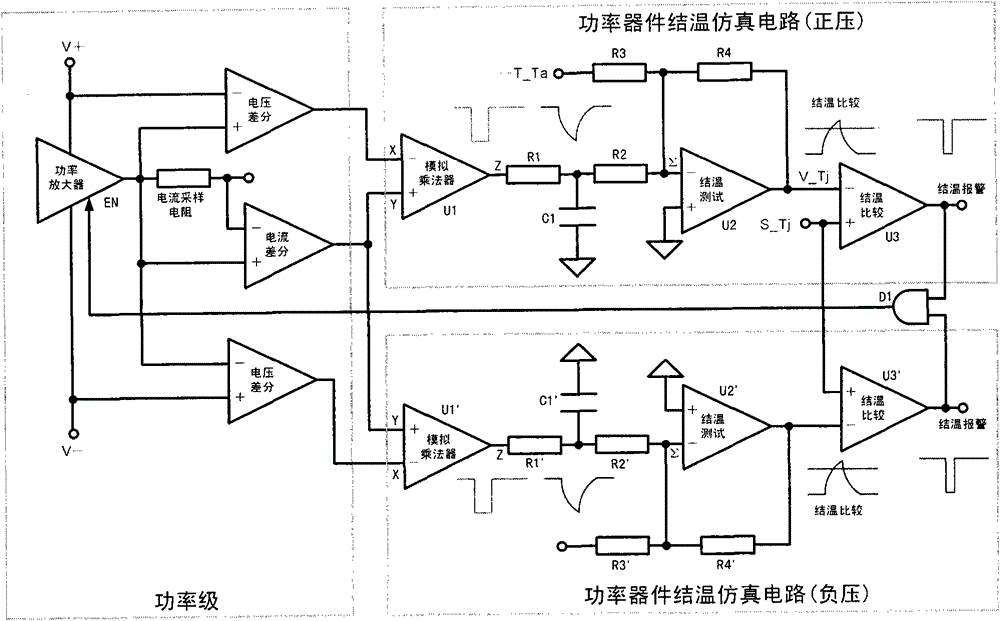

Junction temperature simulation circuit for semiconductor power devices

ActiveCN104634466AEnables indirect measurementsRealize simulationThermometers using electric/magnetic elementsUsing electrical meansRC time constantIntegrator

The invention discloses a junction temperature simulation circuit for semiconductor power devices. The junction temperature simulation circuit is characterized in that junction temperature rise of the power devices are dynamically simulated by the junction temperature simulation circuit by the aid of integrating voltages on RC (resistance-capacitance) integrators; an RC time constant of the circuit is equal to thermal response time of thermal models; output of voltages of the circuit and junction temperatures of power devices in the thermal models are in simple linear relations with one another; the circuit has an ambient temperature compensation function; electrics-to-thermal simulation can be completed by the circuit in various working modes such as constant-direct-current working modes, single-pulse working modes, repetitive-pulse working modes and optional-waveform working modes; power level cutting and alarm signals can be provided by the circuit under junction temperature over-limit conditions; normal work of power levels can be automatically recovered by the circuit when the normal junction temperatures are recovered. The junction temperature simulation circuit has the advantages that the thermal models of the power devices are simulated by electric models of the integrators by the aid of a principle that charging formulas of RC integrating circuits in the electrics are approximately identical to temperature rise formulas in the thermal physics, and accordingly real-time junction temperature information of the power devices can be obtained.

Owner:BEIJING HUAFENG TEST & CONTROL TECH CO LTD +1

System for testing thermal response time of uncooled infrared focal plane detector array and method therefor

ActiveUS20180252590A1Reduce the effects of noiseExclude influenceElectrical testingPyrometry using electric radation detectorsFocal plane detectorThermal response time

A system for testing thermal response time of an uncooled infrared focal plane detector array and a method therefor is provided. The system comprises: a blackbody, a chopper, a detector unit under test and a testing system. The method comprises: emitting radiation by the blackbody, chopping by the chopper, then radiating the radiation to the uncooled infrared focal plane detector array under test; generating different responses on the radiation at different chopping frequencies by the uncooled infrared focal plane detector array under test; collecting different response values of the uncooled infrared focal plane detector array under test at different chopping frequencies; obtaining response amplitude at a corresponding frequency in a frequency domain by FFT; fitting according to a formulaRv(f)=Rv(0)1+(2πfτ)2to obtain the thermal response time.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

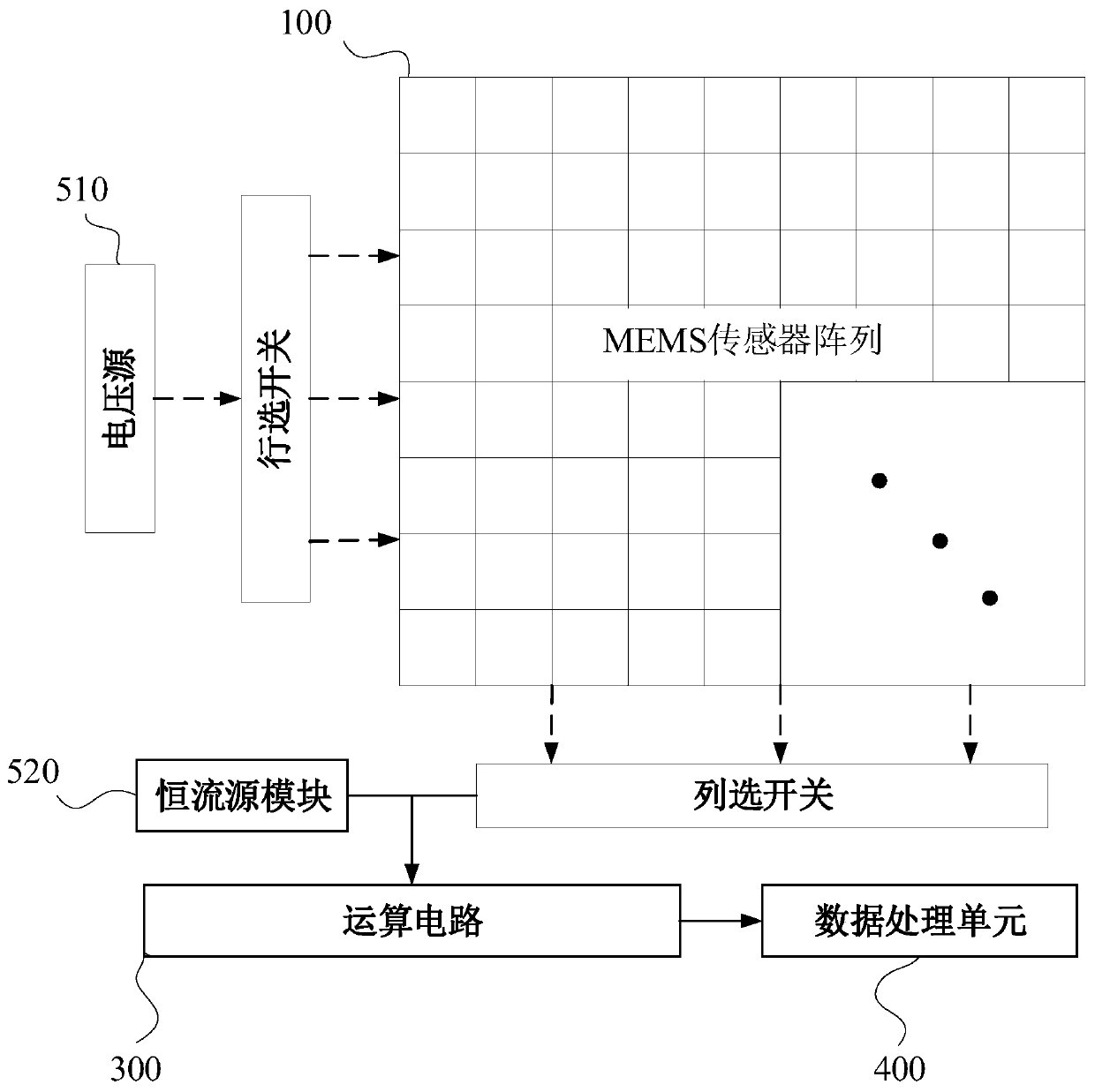

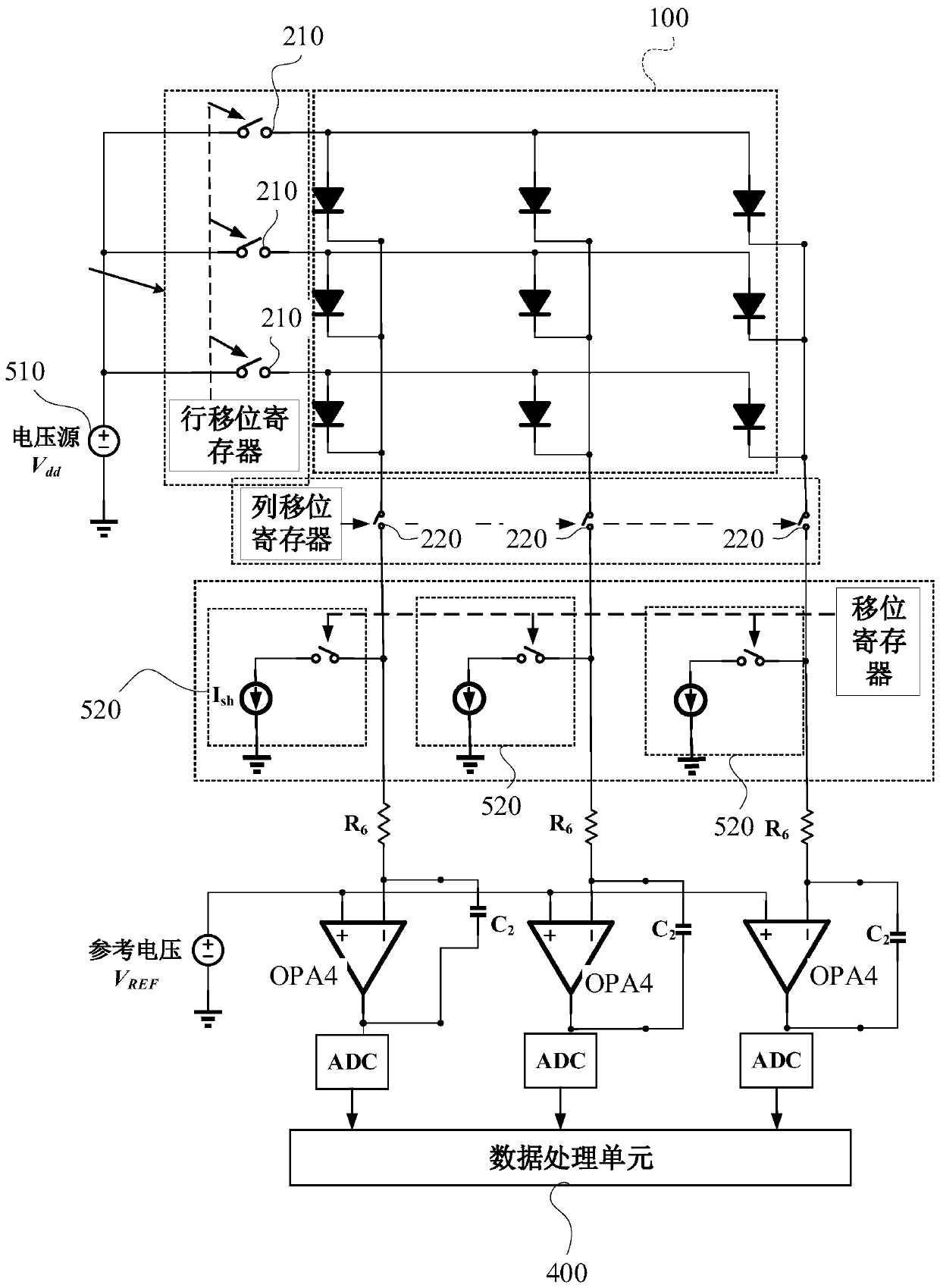

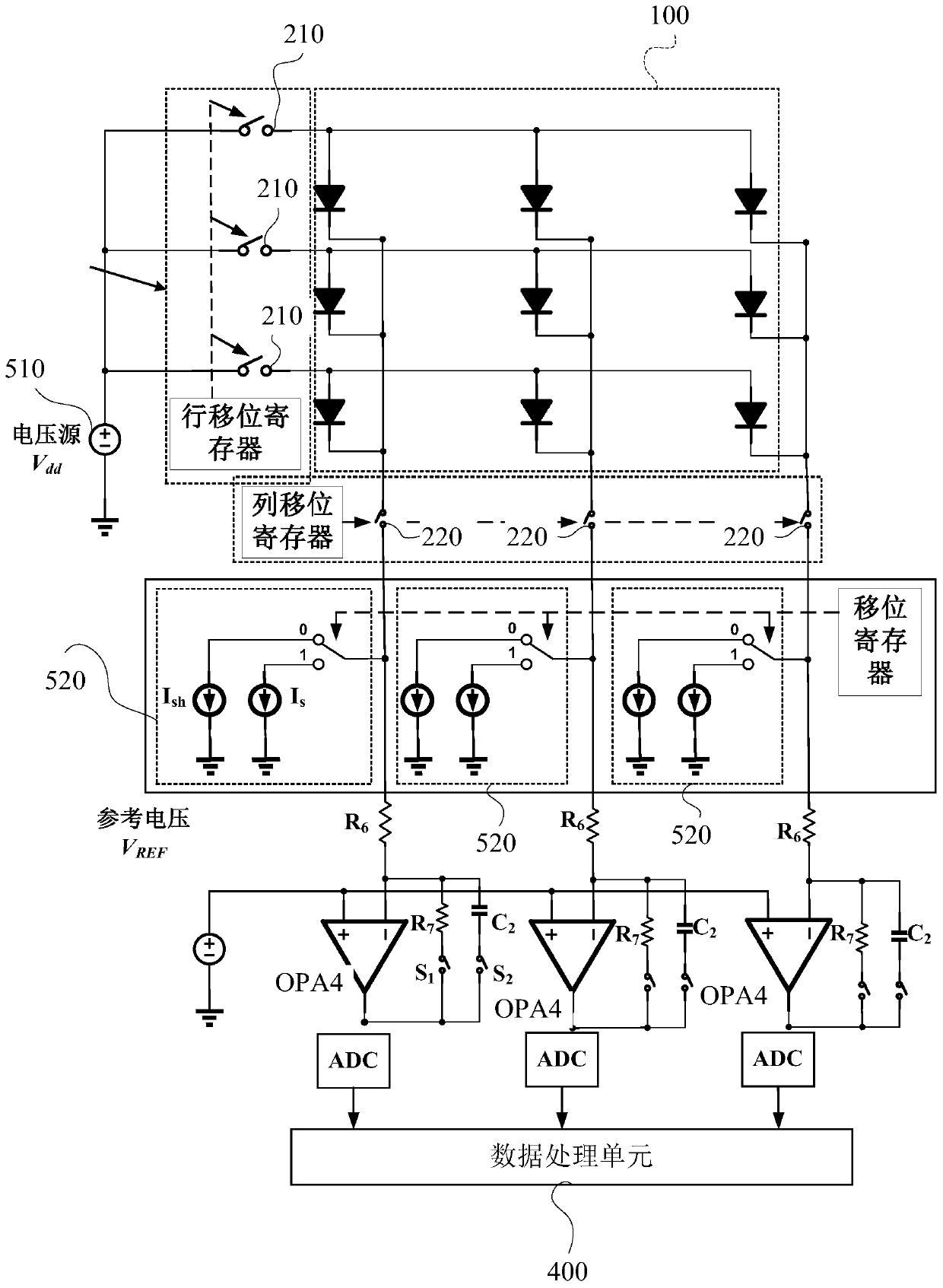

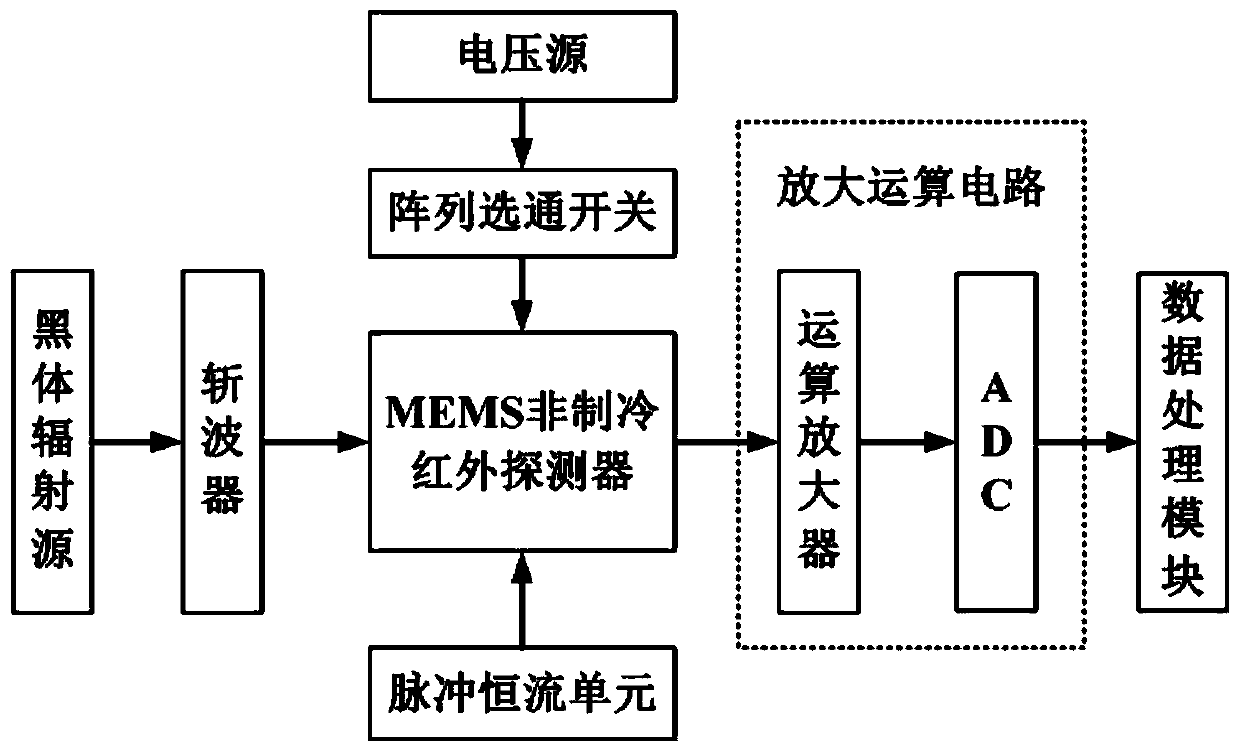

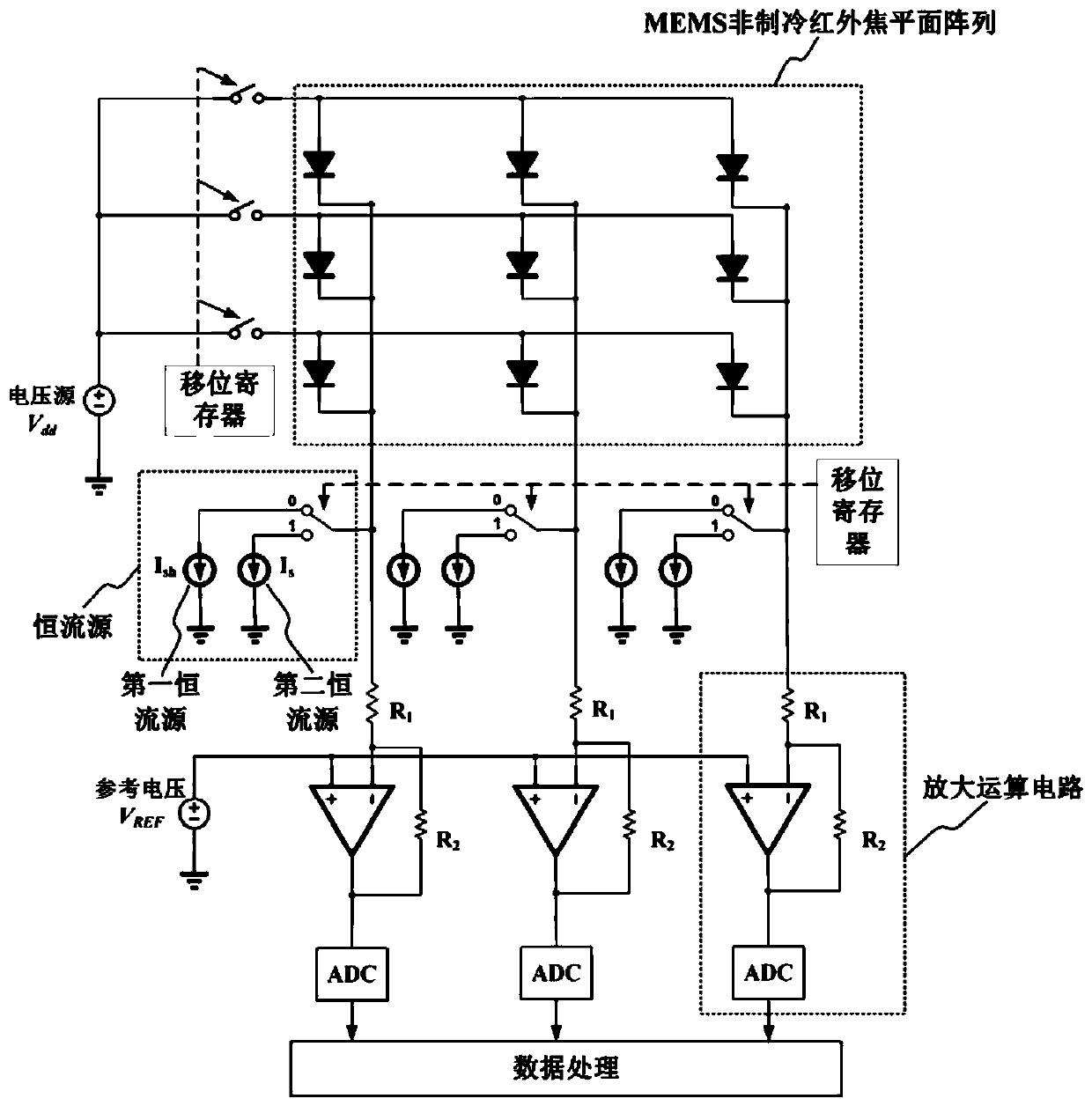

MEMS sensor thermal parameter testing circuit and testing method

ActiveCN110132428ASimple control timing requirementsLittle changePyrometry using electric radation detectorsElectricitySensor array

The invention relates to an electricity self-testing field of the thermal parameter of the micro-nano device, and specifically relates to a MEMS sensor thermal parameter testing circuit and a testingmethod. The MEMS sensor thermal parameter testing circuit comprises a MEMS sensor array including multiple lines and multiple rows of sensitive units, wherein each sensitive unit can self-heat after being electrified and produce an electricity signal corresponding to the temperature thereof; an array gating switch for orderly gating the sensitive units in the MEMS sensor array in turn, and outputting the electricity signal produced by the selected sensitive unit to an operational circuit; the operational circuit for performing amplifying operation on the change of the electricity signal, and outputting the amplifying operation result to a data processing module; a power supply module for supplying power for the sensitive unit selected by the array gating switch; and the data processing unit for computing according to the actual testing data of the operational circuit so as to obtain device thermal capacity C, thermal response time t and thermal conductance G. The testing circuit disclosed by the invention has the features of being simple in circuit, simple and convenient to operate, fast in measurement speed and high in precision.

Owner:WUXI INNOVATION CENT CO LTD

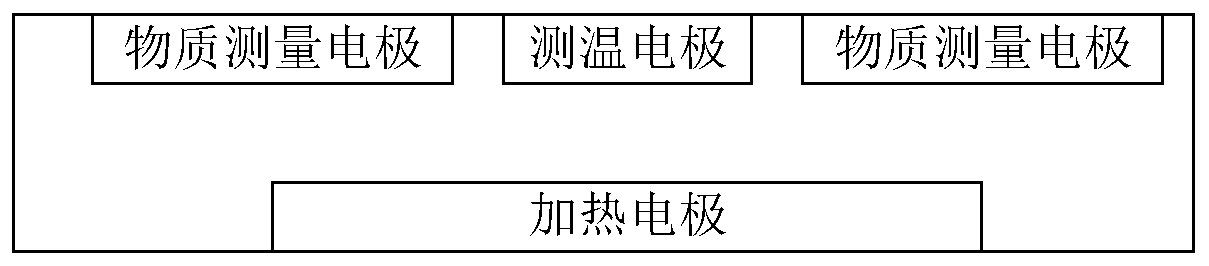

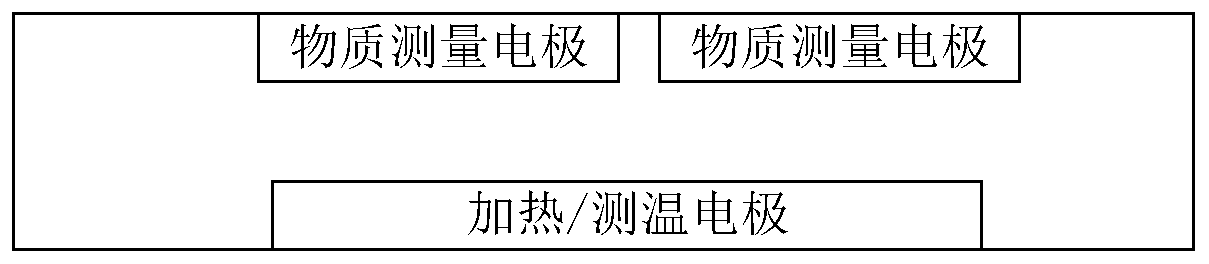

Atomization method and atomizer

InactiveCN109691693ASimple structureMechanical apparatusSpace heating and ventilation safety systemsNebulizerEngineering

The invention provides an atomization method and an atomizer. The atomizer comprises a casing, an electrode, a cavity and a control circuit, wherein the electrode heats the cavity through an electrothermal effect after voltage is applied to the electrode by the control circuit; the control circuit measures impedance spectroscopy or thermal response time of the electrode in real time and judges whether an atomizing substance exists in the cavity. According to the atomization method and the atomizer, functions of integrated heating and monitoring for presence of the atomizing substance are completely realized by the electrode, the structure is simple, the atomizer is produced based on the MEMS process, is microminiaturized and has small size, and temperature can be increased rapidly.

Owner:TSINGHUA UNIV

Modified epoxide resin with thermal driving shape memory function and preparation method thereof

The invention relates to a modified epoxide resin with a shape memory function and a preparation method of the modified epoxide resin, belonging to the technical field of a functional high molecular material. The response temperature of the modified epoxide resin material provided by the invention can be adjusted within the range of 32-60 DEG C, the material can be bent at a large angle of 720 degrees at the temperature more than the thermal response temperature, and the shape fixed rate and recovery rate of the modified epoxide resin reach 100%. The preparation method of the modified epoxide resin comprises the following steps of: firstly, preparing end sulfydryl dihydric alcohol ester; secondly, preparing modified epoxide resin; and thirdly, preparing the modified epoxide resin with the shape memory function. Compared with the existing shape memory material, the modified epoxide resin has the advantages of being simple in preparation technology, capable of meeting a green environment protection requirement, low in thermal response temperature, capable of being adjusted, capable of realizing saturated solidifying, low in solidifying temperature, short in solidifying time, short in thermal response time, large in sample flexible angle, and high in shape recovery rate.

Owner:ZHONGBEI UNIV

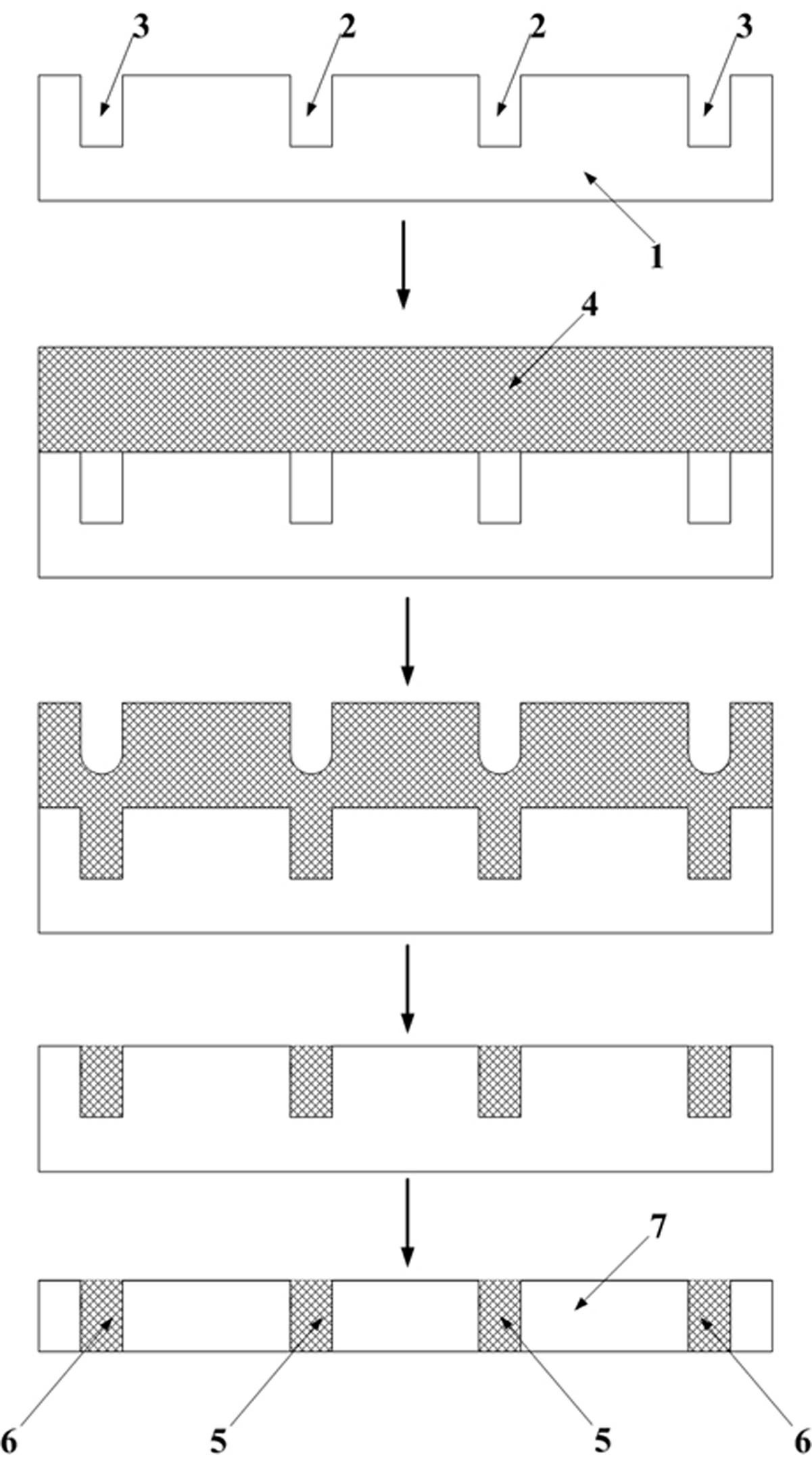

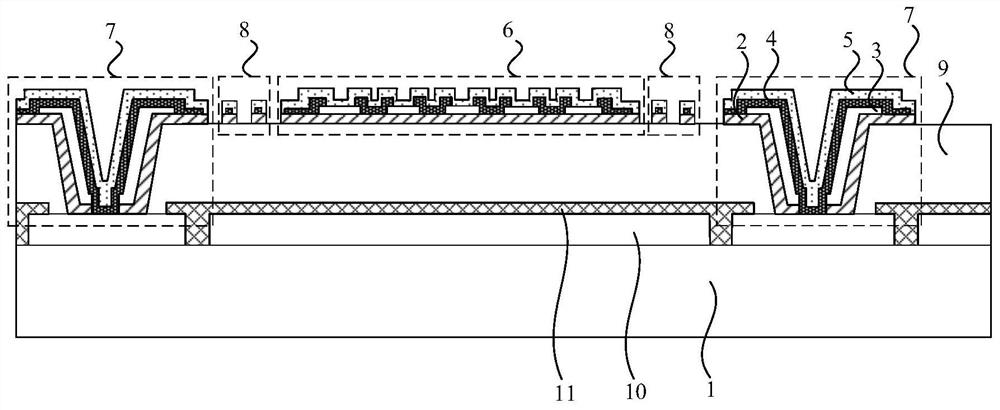

Infrared detector and preparation method thereof

ActiveCN113328002AShort thermal response timeImprove infrared responsivityFinal product manufactureSemiconductor devicesResponsivityDielectric layer

The invention relates to an infrared detector and a preparation method thereof. The infrared detector comprises a substrate, a thermosensitive layer, a dielectric layer, an electrode layer and a passivation layer, wherein the thermosensitive layer, the dielectric layer, the electrode layer and the passivation layer are located on the substrate, the dielectric layer is located between the thermosensitive layer and the electrode layer, the thermosensitive layer is located on one side, close to the substrate, of the dielectric layer, and the passivation layer is located on one side, away from the substrate, of the electrode layer. The infrared detector comprises a plurality of infrared detector pixels arranged in a matrix, each infrared detector pixel comprises an absorption plate structure, at least two micro-bridge columns and at least two beam structures, and the absorption plate structures are connected to the corresponding micro-bridge columns through the corresponding beam structures; the thermosensitive layer covers the area where the absorption plate structure and the beam structure are located, and the passivation layer covers the area where the absorption plate structure and the beam structure are located; and the material for forming the thermosensitive layer comprises one or more of amorphous silicon, amorphous carbon, amorphous germanium or amorphous silicon germanium. According to the technical scheme, the thermal response time of the infrared detector is shortened, and the infrared response rate of the infrared detector is improved.

Owner:BEIJING NORTH GAOYE TECH CO LTD

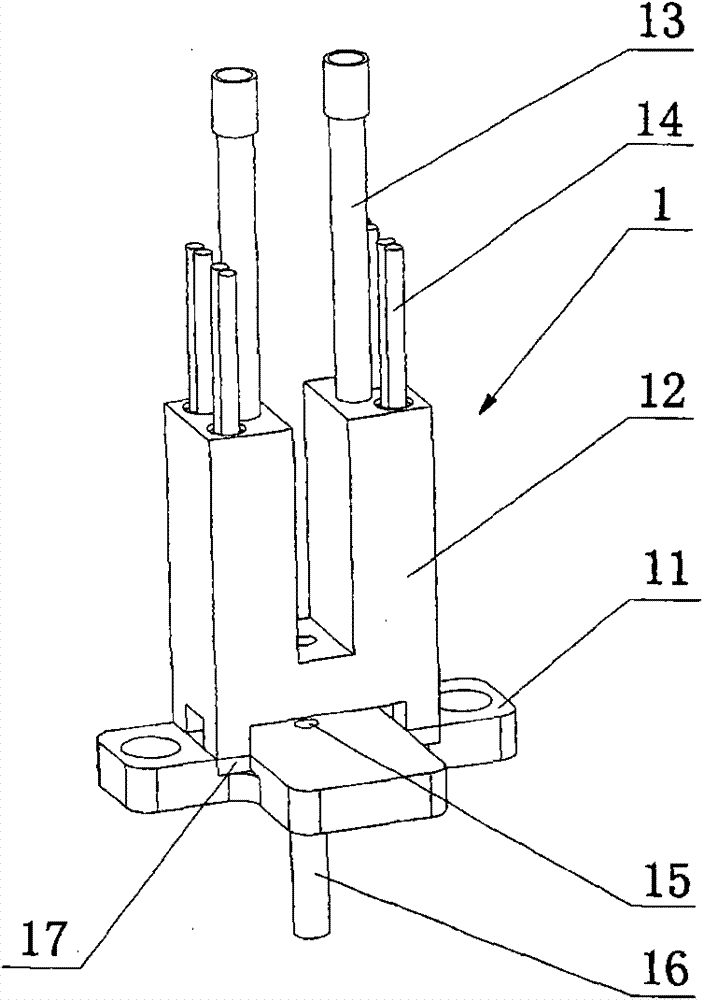

Small thermal conduction heating head

The invention discloses a small thermal conduction heating head which comprises a feed heating part and a blanked-material pressing part and further comprises a reciprocating material distributing part. The feed heating part consists of a pedestal, a plurality of heating cabins provided on the pedestal, a material conveying pipe which enables the heating cabins to communicate with each other and supplies materials to the heating cabins, and a heating member used for providing a heat source to the heating cabins, wherein the pedestal is provided with through blanking holes which are communicated with a feeding channel that is provided at the bottom surface of the pedestal and used for conveying materials to a designated position, and the feed heating part adopts two heating cabins for heating and two cabins for fetching materials by turns. The heating head provided in the invention can heat 10 to 20 nuts at one time, which enables thermal response time of nuts to be substantially reduced and the application scope of the heating head to be effectively broadened.

Owner:QINGDAO HUATE AUTOMATION EQUIP

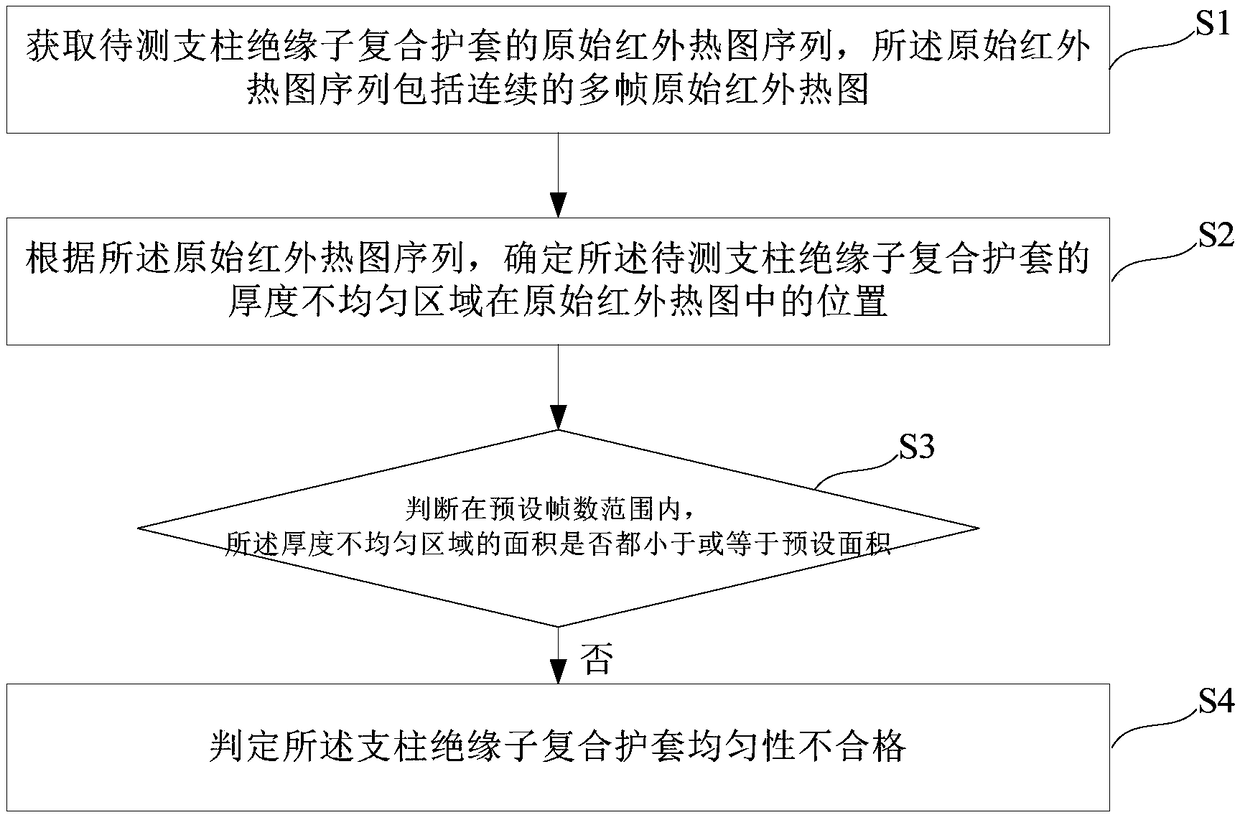

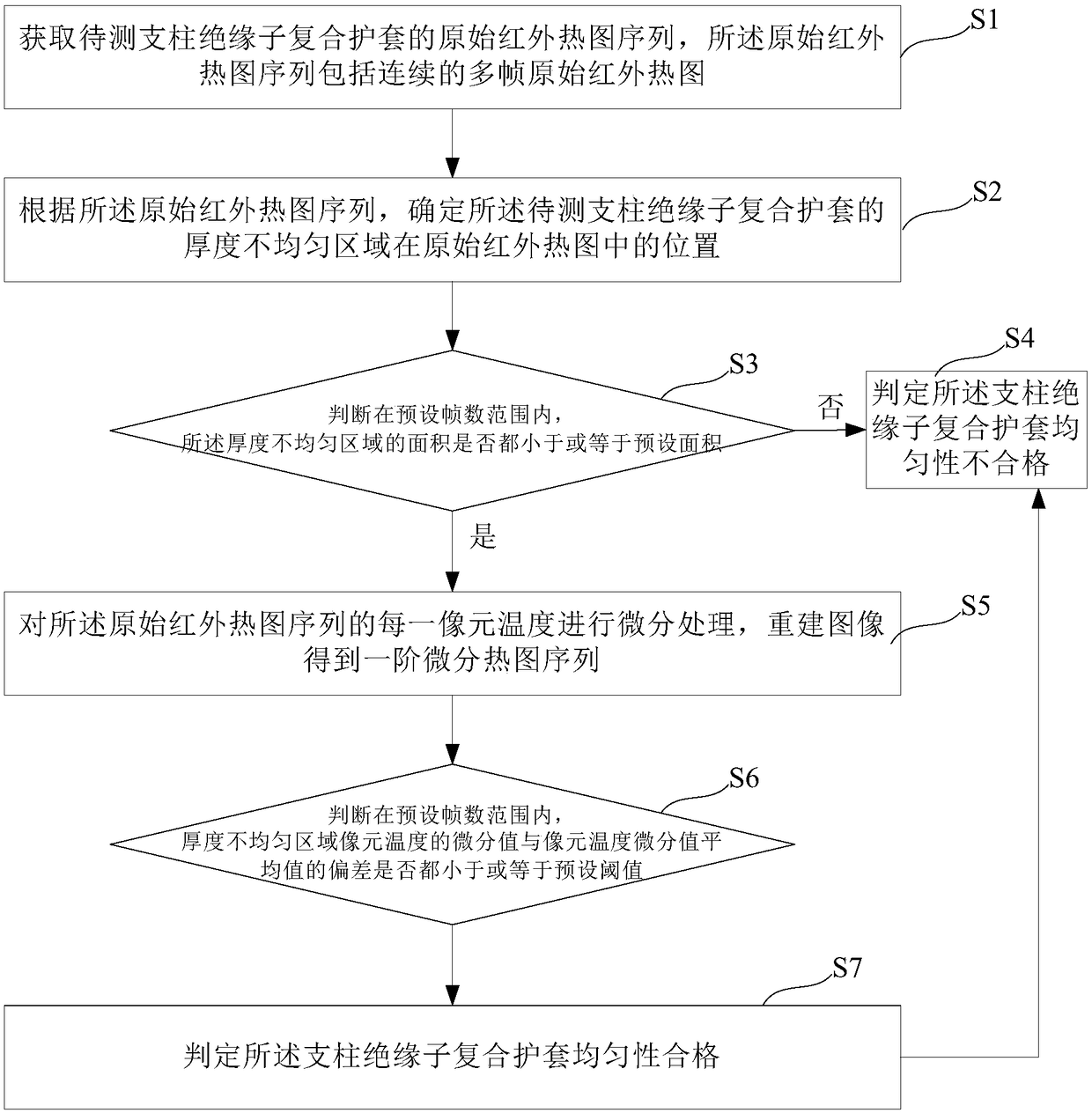

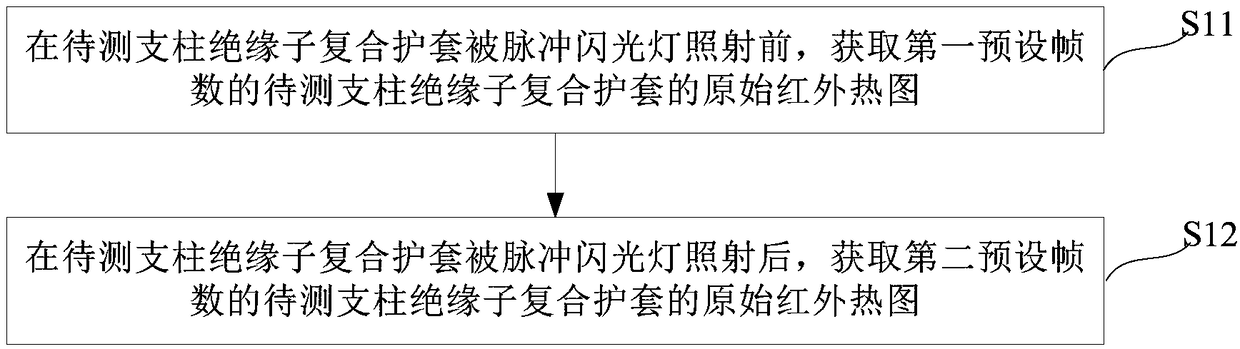

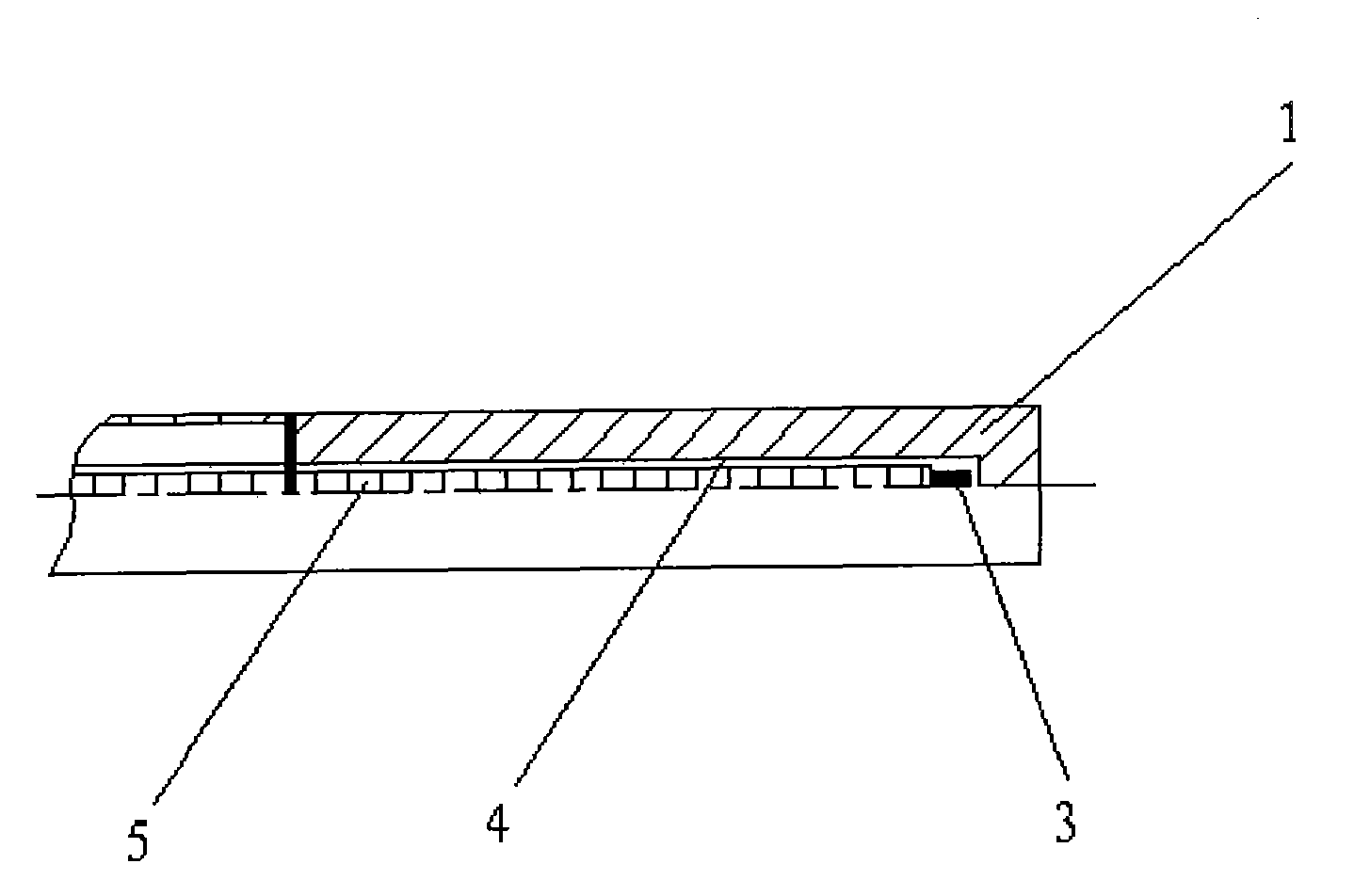

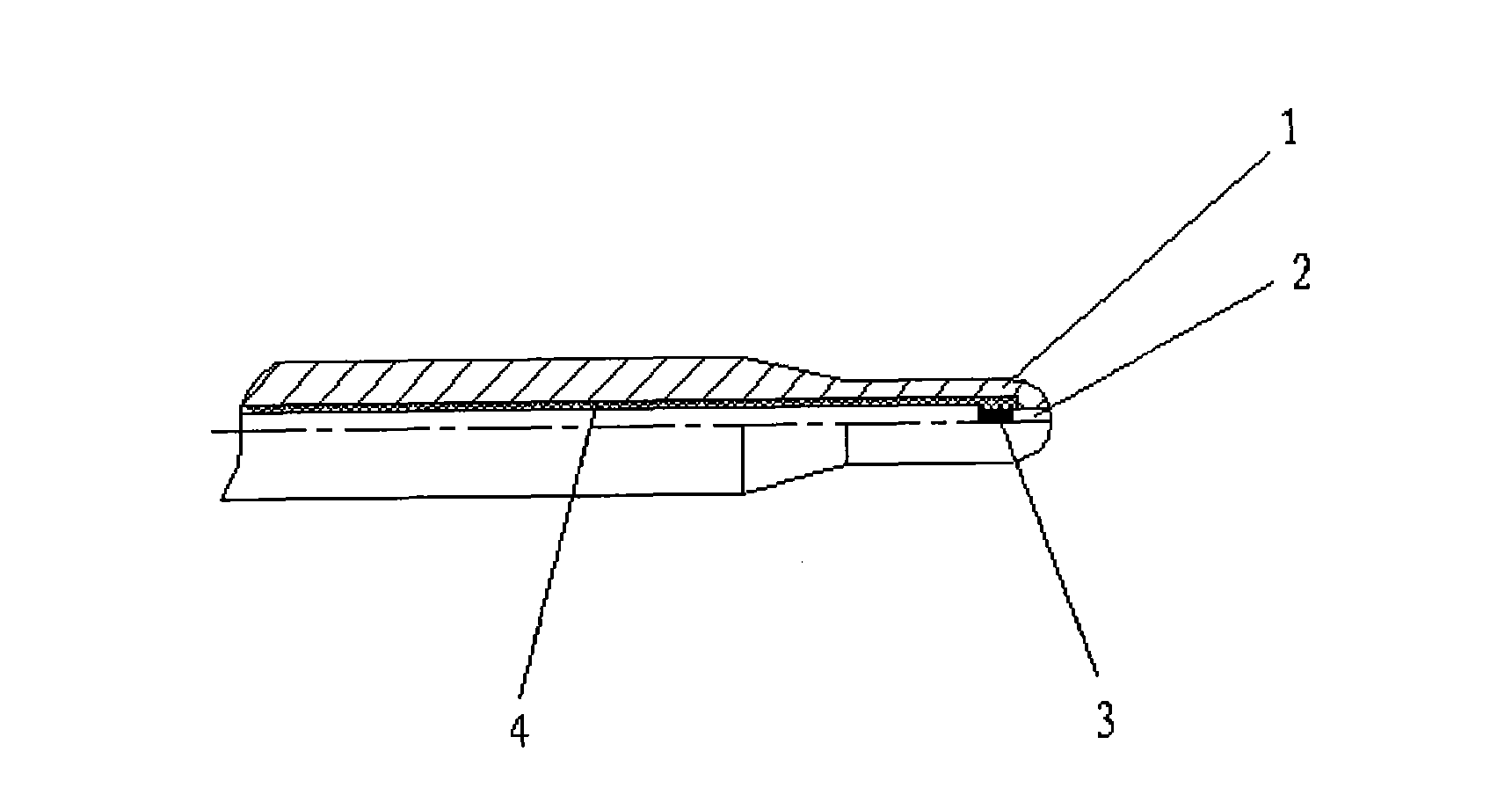

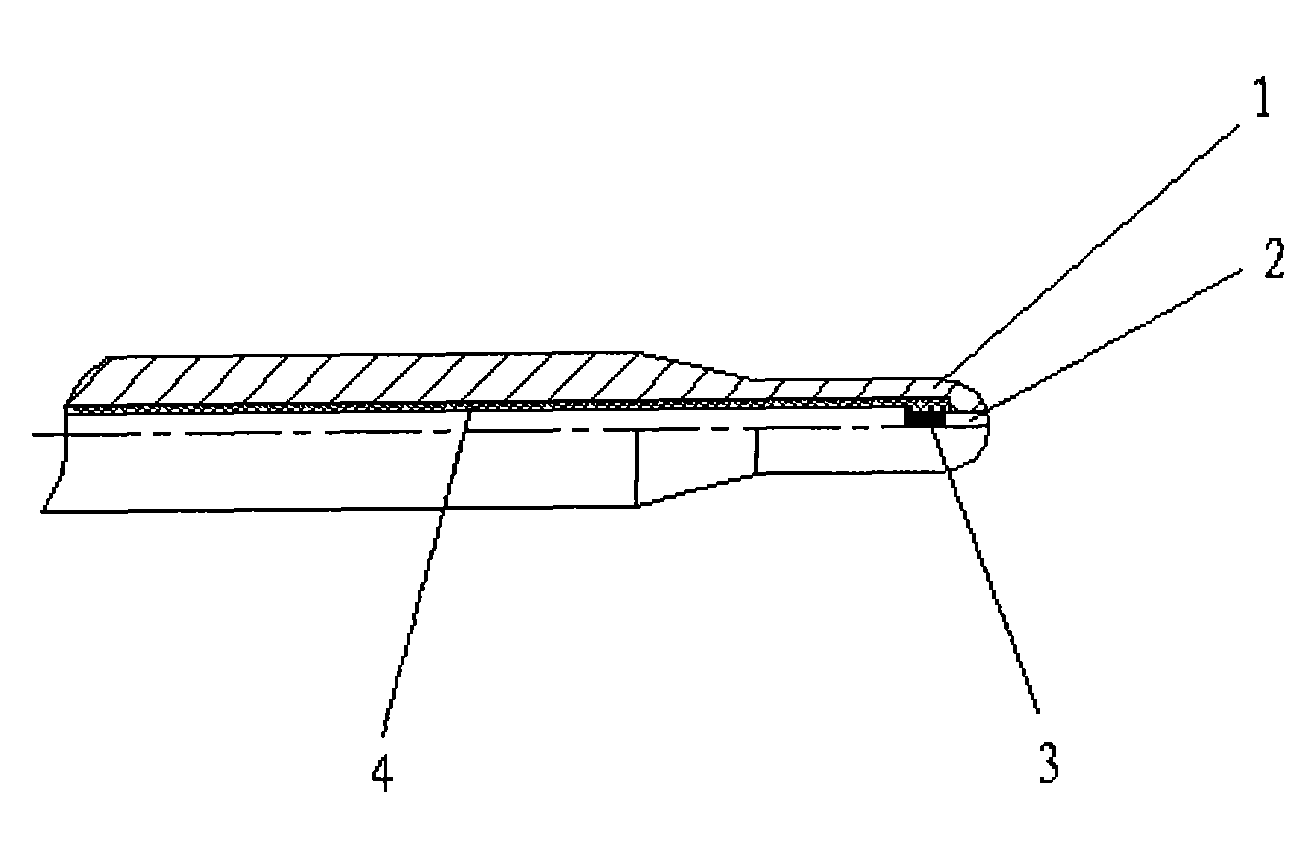

Method, device and system for detecting uniformity of post insulator composite sheath

ActiveCN108693185AQuality improvementGuaranteed safe operationOptically investigating flaws/contaminationFast measurementPower grid

The invention provides a method, device and system for detecting the uniformity of a post insulator composite sheath. The method, device and system realize pre-delivery inspection of a post insulatorcomposite sheath, accurately identify and remove uneven test pieces, prevent core shift caused by sheath nonuniformity, improve the product qualification rate, ensure the reliable quality of the pillar insulator, are conducive to the long-term safe operation of the network system, have a fast measurement rate and thermal response time of microseconds or milliseconds, have test time in seconds or dozens of seconds in each test, display the measurement results in images, can visually determine the insulator composite sheath with obvious unevenness, are free of contact with the post insulator composite sheath to be detected in detection, realize long-distance detection and do not pollute and damage the post insulator composite sheath.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

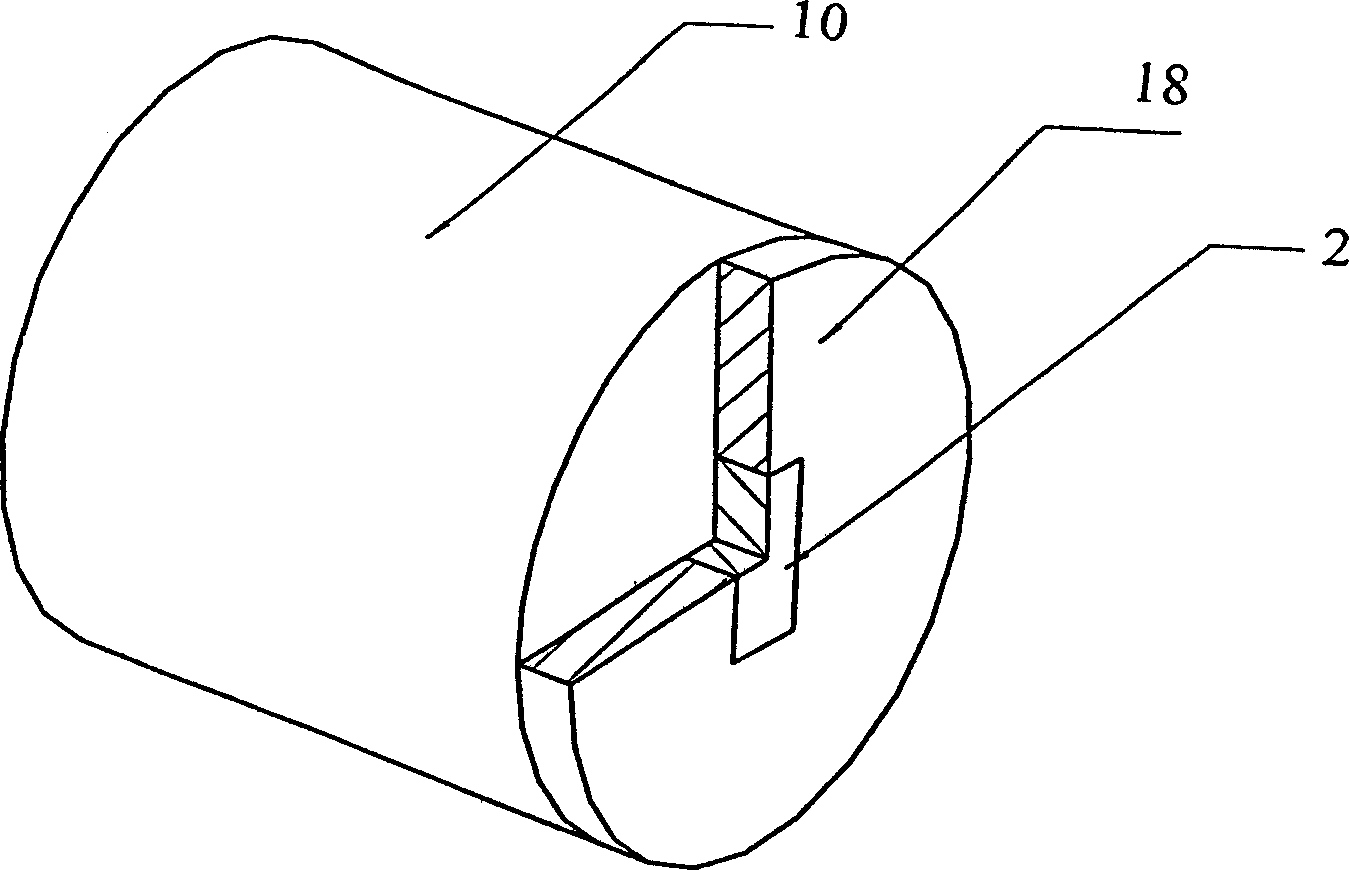

Wear-resistant quick temperature measuring platinum resistance thermometer

InactiveCN102062643AFast thermal response timeImprove temperature measurement accuracyThermometers using electric/magnetic elementsUsing electrical meansPlatinum resistanceWear resistant

The invention discloses a wear-resistance quick temperature measuring platinum resistance thermometer, which comprises a wear-resistant protecting tube and a platinum resistance thermometer arranged in the protecting tube, and is characterized in that: in the protecting tube, a quick heat conducting body connected with the platinum resistance thermometer is arranged at the temperature sensing end; the platinum resistance thermometer is tightly matched with the inner wall of the protecting tube; and a heat conducting material is filled in small gaps between the platinum resistance thermometer and the inner wall of the protecting tube. The wear-resistance quick temperature measuring platinum resistance thermometer has the advantages that: by selecting the material of the protecting tube and the platinum resistance thermometer, the wear resistance and corrosion resistance are improved by more than three times compared with those of the conventional wear-resistant protecting tube; and the platinum resistance thermometer is tightly matched with the protecting tube, the heat conducting material is filled in the gaps, and the quick heat conducting body is arranged at the temperature sensing end (heat end) of the protecting tube, so that the heat conductivity is improved by 8 times. The wear-resistance quick temperature measuring platinum resistance thermometer has a compact structure, has the thermal response time of less than 5 seconds, meets the performance requirements for corrosion resistance and wear resistance in the tyre rubber vulcanizing process, improves the effect of quickly and accurately measuring temperature of a temperature sensor, is convenient and practical to use, and has obvious effect.

Owner:上海岗崎控制仪表有限公司

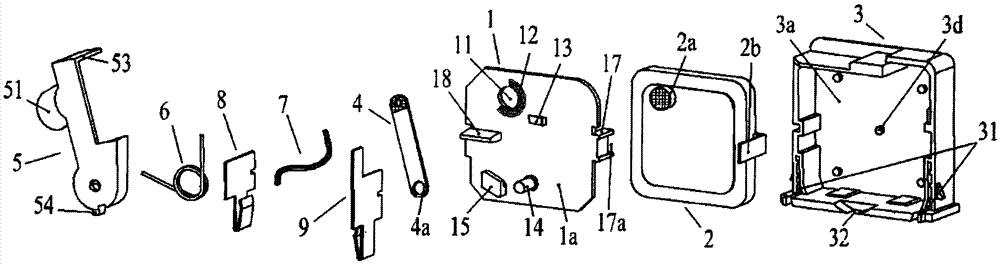

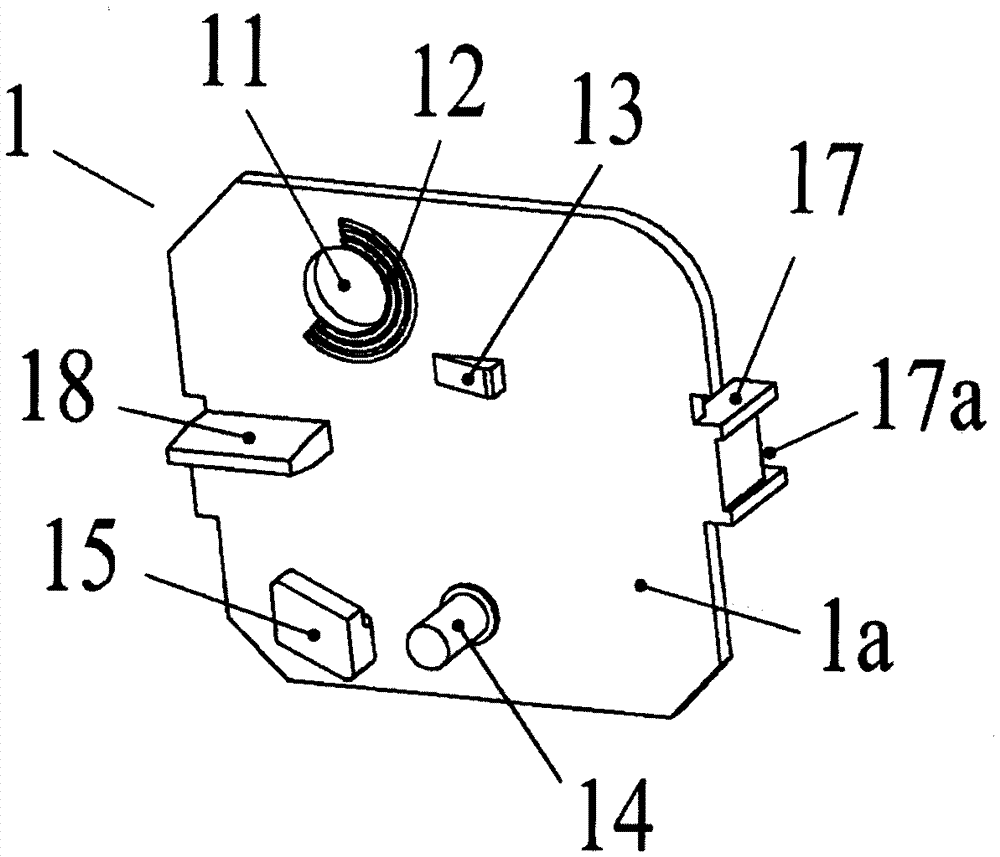

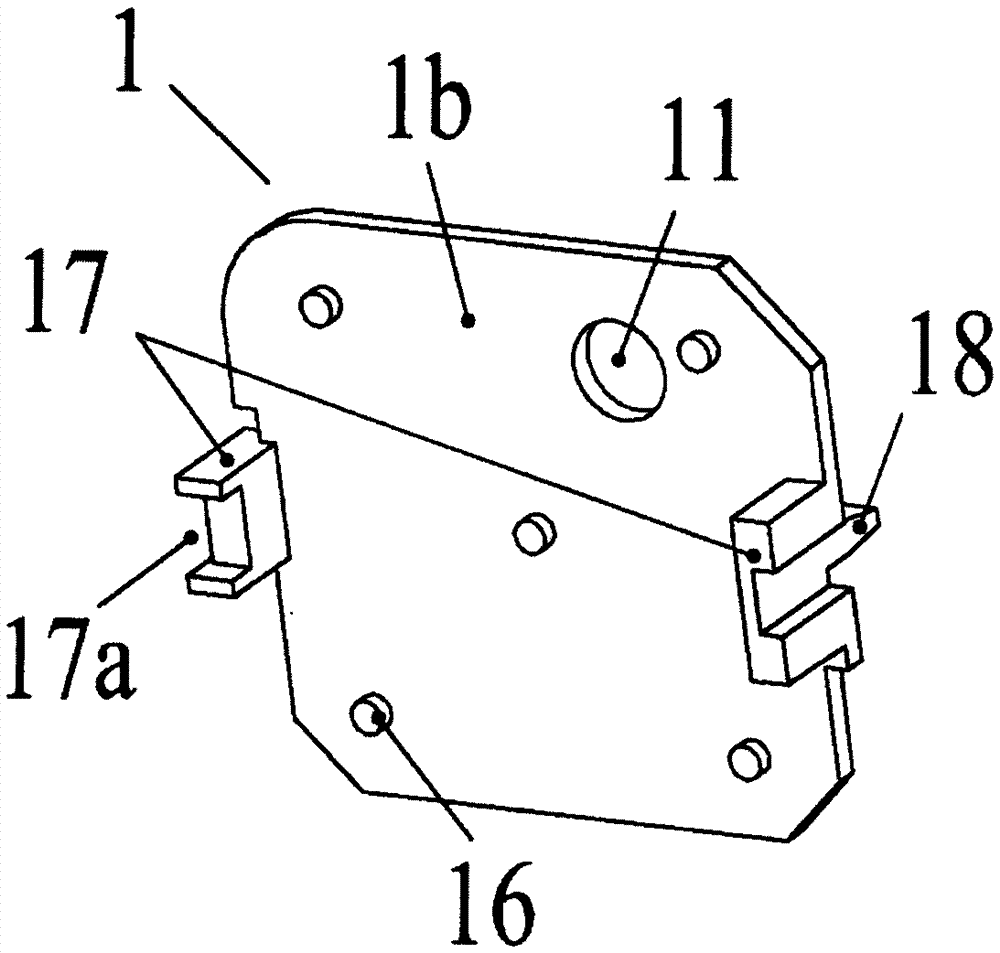

Shielding and insulating surge protection device

InactiveCN107039960AAvoid the hidden danger of secondary conductionThe hidden danger of secondary conductionEmergency protective arrangements for limiting excess voltage/currentEngineeringSurge protector

The invention discloses a shielding insulation type surge protection device for surge protection, which includes an arc shielding mechanism composed of a retainer, a tripping swing arm and an elastic member, a thermal response switch assembly, a voltage sensitive assembly and a support Functional base. When the surge protection device operates quickly due to factors such as surges on the line, it can reliably block the short-circuit arc caused by the action of the thermal response switch and ensure that the protection device is completely separated from the line.

Owner:GUANGXI NANNING BAILANSI SCI & TECH DEV

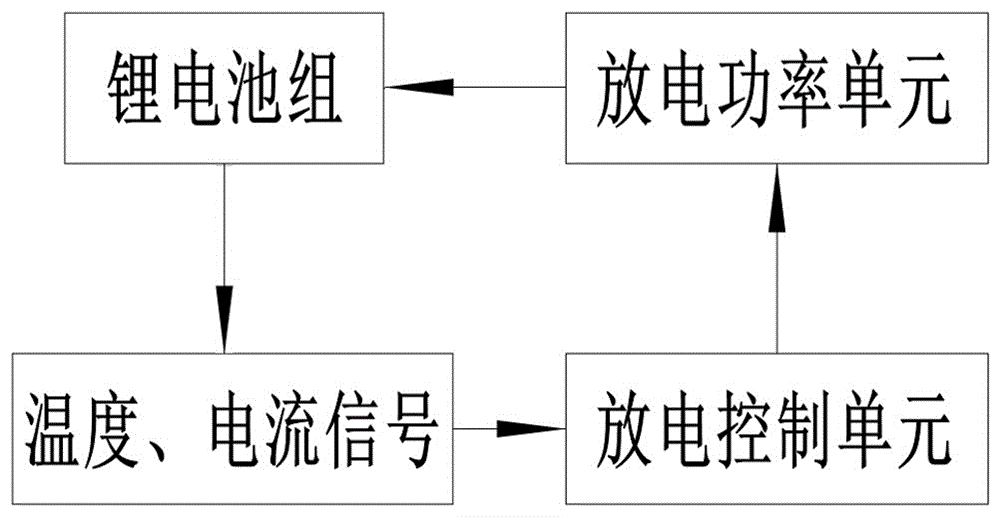

Lithium ion battery short-circuit heating system

InactiveCN105977580AExtended service lifeHeating fastSecondary cellsElectrical batteryCurrent sensor

The invention discloses a lithium ion battery short-circuit heating system. The lithium ion battery short-circuit heating system comprises a discharge power unit and a discharge control unit, wherein the discharge power unit comprises a power component, a discharge resistor and a battery pack module; the discharge control unit comprises a temperature sensor, a current sensor, a controller and a power supply module. The lithium ion battery short-circuit heating system is simple in structure and reasonable in design; the temperature sensor is used for detecting the ambient environment temperature of the lithium battery; the current sensor is used for detecting the current value of amplification current of the output end of the power component; the controller is used for controlling the power component in real time, so that the temperature control accuracy in the battery is improved; the heating response time of the battery is reduced; the operation performance of electric automobiles in the low-temperature environment is improved; the service life of the lithium battery is prolonged.

Owner:HENAN SENYUAN HEAVY IND

MEMS uncooled infrared detector thermal parameter test circuit and test method

ActiveCN110346052ASimple control timing requirementsHigh speedPyrometry using electric radation detectorsComputer moduleDetector array

The invention relates to the field of electrical self-testing of thermal parameters of infrared detectors, in particular to an MEMS uncooled infrared detector thermal parameter test circuit and test method. The MEMS uncooled infrared detector thermal parameter test circuit comprises: an MEMS uncooled infrared detector array which comprises a plurality of rows and columns of infrared sensitive units; an array gating switch used for gating the sensitive units in the MEMS uncooled infrared detector array in turn and outputting electrical signals generated by the selected sensitive units to an amplification operational circuit; the amplification operational circuit is used for carrying out amplification operation on the change of the electrical signal and outputting an amplification operationresult to a data processing module; a power supply module used for supplying power to the infrared sensitive unit selected by the array gating switch; and the data processing module used for calculating to obtain a heat capacity C, a thermal response time [tau], a thermal conductivity G, a blackbody response rate RIR and an infrared absorption efficiency [eta] of the device according to the actualtest data of the amplification operational circuit.

Owner:WUXI INNOVATION CENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com