MEMS uncooled infrared detector thermal parameter test circuit and test method

An uncooled infrared and parameter testing technology, which is applied to electric radiation detectors, radiation pyrometry, instruments, etc., can solve the problems of inconvenient operation, large error, and high cost of testing time, and achieve high efficiency, fast speed, and control Timing requires simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with specific drawings and embodiments.

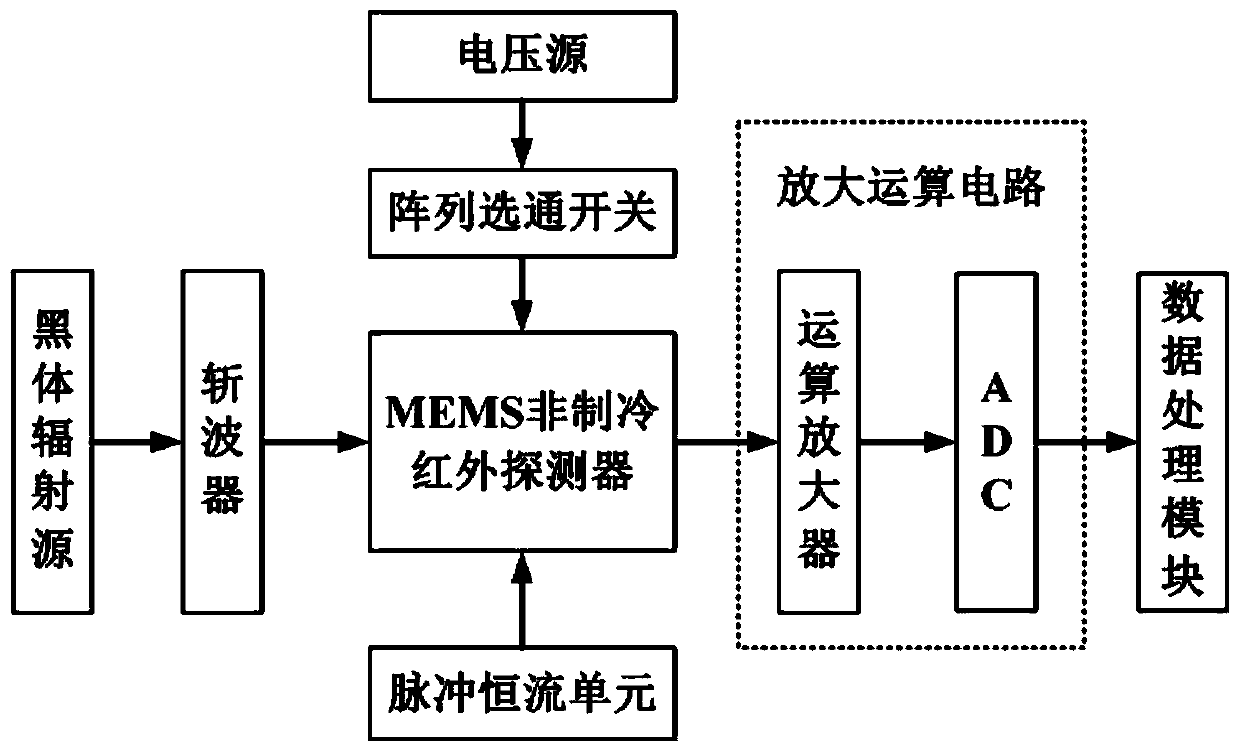

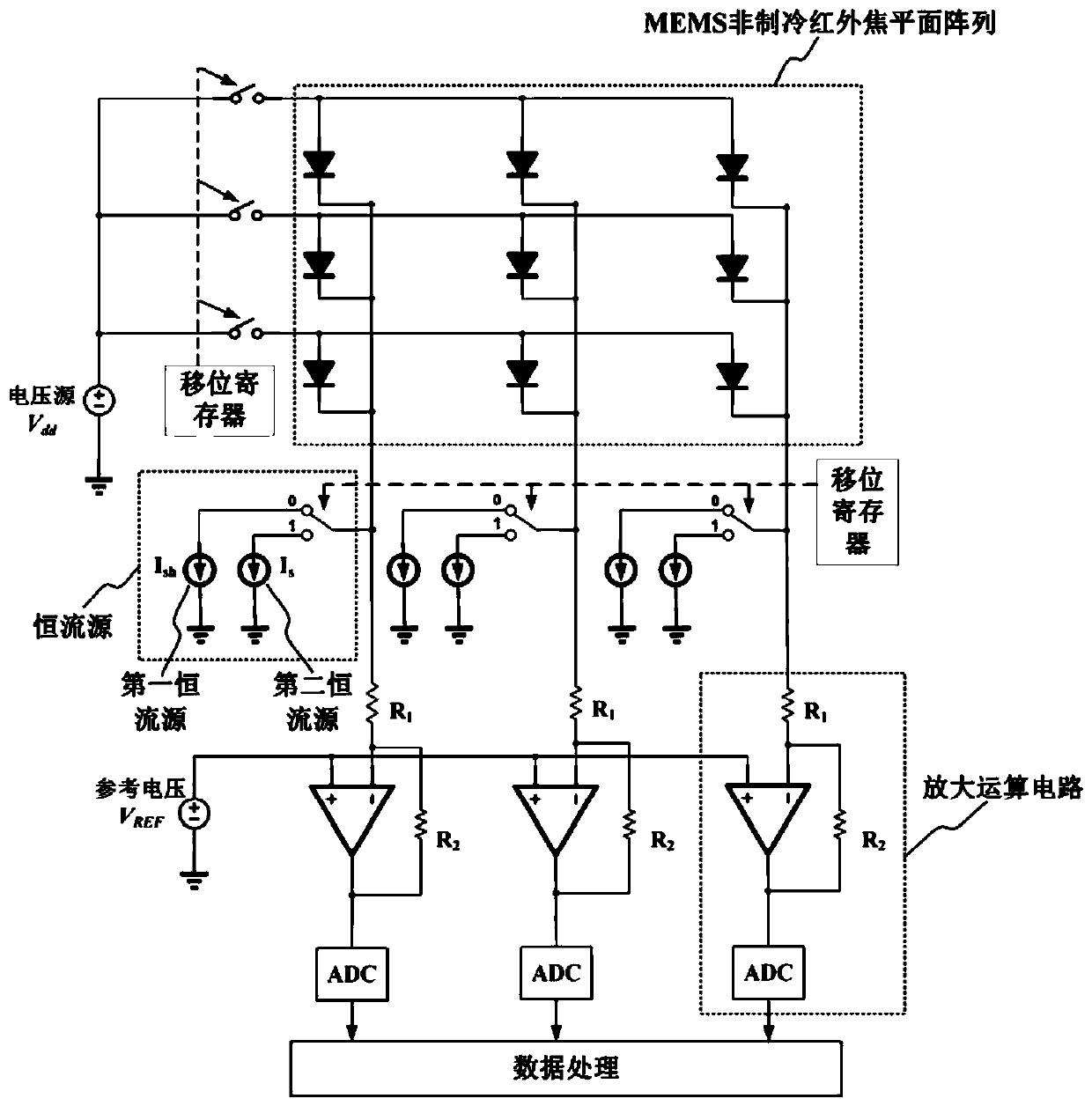

[0043] As a first aspect of the present invention, a kind of MEMS uncooled infrared detector thermal parameter testing circuit based on self-heating effect is provided, such as figure 1 and figure 2 Shown is a thermal parameter test circuit of an uncooled infrared detector array.

[0044] Described MEMS uncooled infrared detector thermal parameter testing circuit comprises: black body radiation source, chopper, power supply module, MEMS uncooled outer focal plane array, array gating switch, amplifying operation circuit and data processing module;

[0045] The light radiated by the black body is irradiated on the MEMS uncooled external focal plane array through a chopper, and the chopper is used to control the light radiated by the black body to reach the MEMS uncooled external focal plane array.

[0046]Described MEMS uncooled infrared detector comprises the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com