Nitrogen dioxide gas sensor based on flower-shaped SnSe2/SnO2 heterojunction, and preparation technology and application of nitrogen dioxide gas sensor

A gas sensor, nitrogen dioxide technology, applied in the direction of material resistance, etc., can solve the problems of difficulty in accurately detecting low-concentration gas, increased energy consumption, unsatisfactory gas characteristics, etc., to reduce stacking phenomenon, promote oxygen adsorption, Get convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

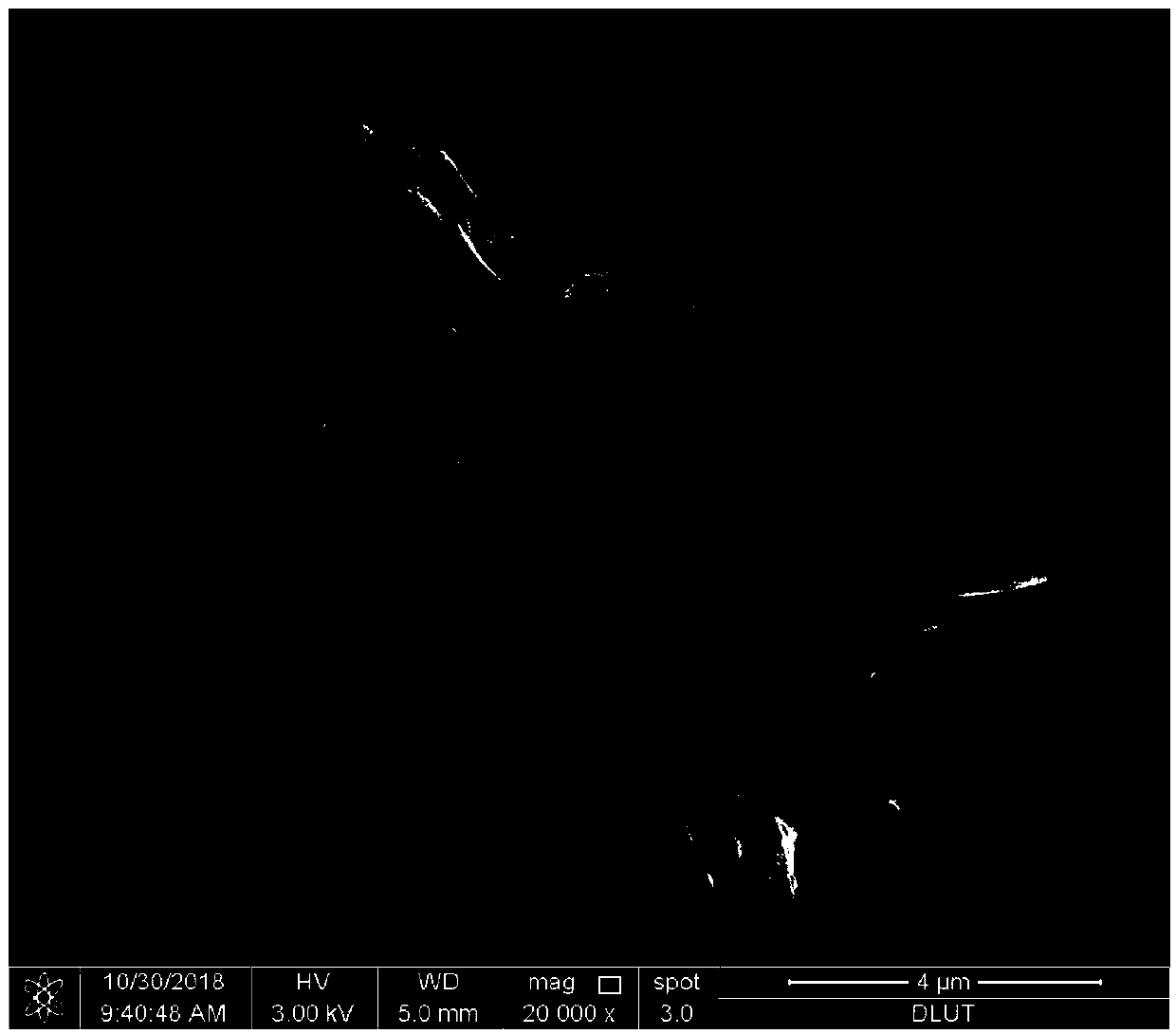

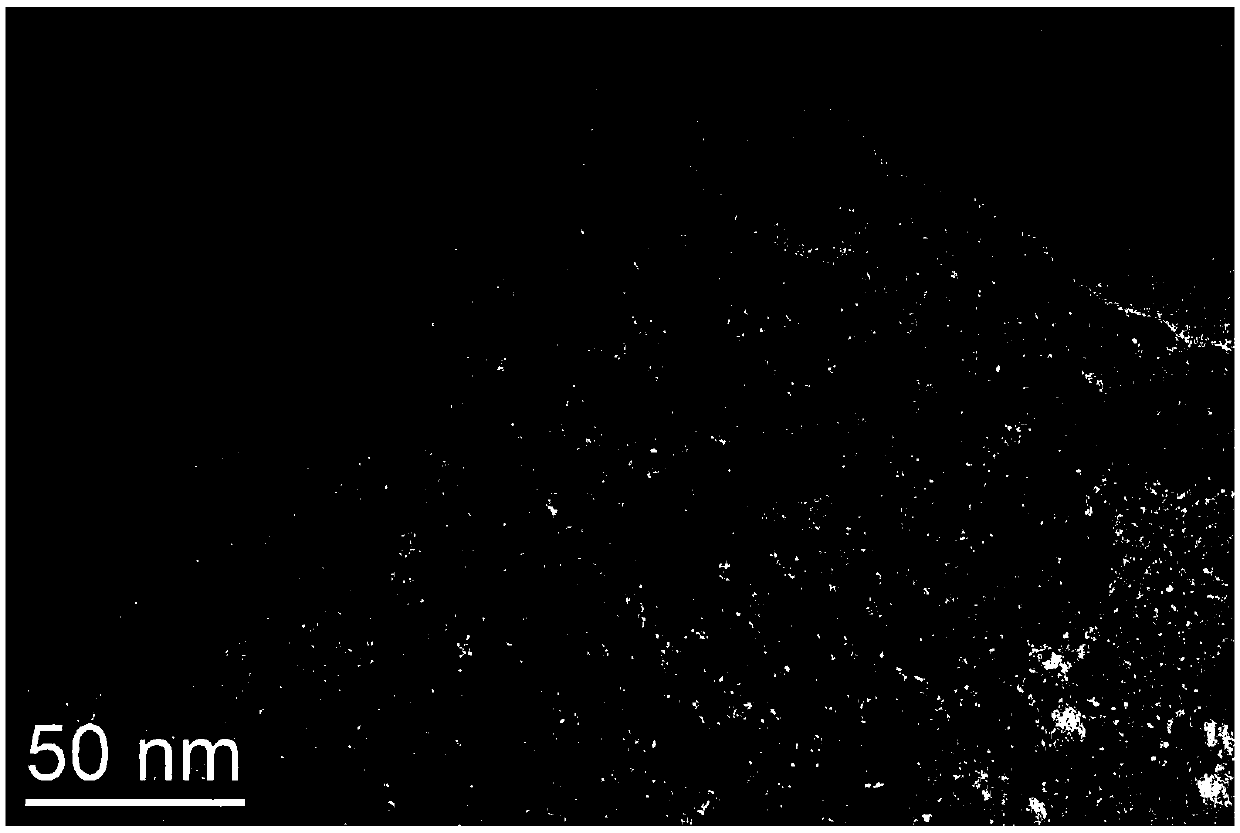

[0032] A flower-like SnSe based 2 / SnO 2 The nitrogen dioxide gas sensor is composed of a gas-sensing material and an interdigital electrode plate, and the gas-sensing material is coated on the surface of the substrate with a coating thickness of 100 μm. The composition of the gas-sensitive material is SnSe formed by calcining at 400°C for 1 hour 2 / SnO 2 Heterojunction Composite Nanomaterials. The preparation method comprises the following steps:

[0033] Step 1, preparation of flower-like SnSe 2 Nanomaterials: Dissolve 1.8mL C 2 h 8 N 2 , 34.2mL (CH 2 Oh) 2 Pour into a 50mL beaker, add 406.2mg of stannous chloride and 142.1mg of selenium powder, stir magnetically for 20 minutes, pour into a 50mL polytetrafluoroethylene liner, put it into a reaction kettle, put it in a muffle furnace, and heat up at a rate of 5 °C / min, the reaction temperature is 180 °C, the reaction time is 5 hours, and the cooling rate is 3 °C / min. After the obtained black product is separated by ...

Embodiment 2

[0040] A flower-like SnSe based 2 / SnO 2 The nitrogen dioxide gas sensor is composed of a gas-sensing material and an interdigital electrode plate, and the gas-sensing material is coated on the surface of the substrate with a coating thickness of 100 μm. The composition of the gas-sensitive material is SnSe formed by calcining at 350°C for 1 hour 2 / SnO 2 Heterojunction Composite Nanomaterials. The preparation method comprises the following steps:

[0041] Step 1, preparation of flower-like SnSe 2 Nanomaterials: Dissolve 1.8mL C 2 h 8 N 2 , 34.2mL (CH 2 Oh) 2 Pour into a 50mL beaker, add 406.2mg of stannous chloride and 142.1mg of selenium powder, stir magnetically for 20 minutes, pour into a 50mL polytetrafluoroethylene liner, put it into a reaction kettle, put it in a muffle furnace, and heat up at a rate of 5 °C / min, the reaction temperature is 180 °C, the reaction time is 5 hours, and the cooling rate is 3 °C / min. After the obtained black product is separated by ...

Embodiment 3

[0045] Nitrogen dioxide gas sensor performance test.

[0046] The sensor prepared in Example 2 was placed in an air atmosphere at a working temperature of 100° C., and then nitrogen dioxide gas molecules were introduced. The resistance change of the sensor in the air and in the 0.5ppm nitrogen dioxide atmosphere with air as the background is measured by a multimeter as the signal of the sensor.

[0047] The sensor prepared in Example 1 was placed in an air atmosphere at a working temperature of 100° C., and then nitrogen dioxide gas molecules were introduced. The resistance change of the sensor in the air and in the 8ppm nitrogen dioxide atmosphere with air as the background is measured by a multimeter as the signal of the sensor. flake SnSe 2 / SnO 2 The sensor prepared by the heterojunction is placed in the air atmosphere, the working temperature is 120°C, and then nitrogen dioxide gas molecules are introduced. The resistance change of the sensor in the air and in the 1pp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Interdigital spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com