Junction temperature simulation circuit for semiconductor power devices

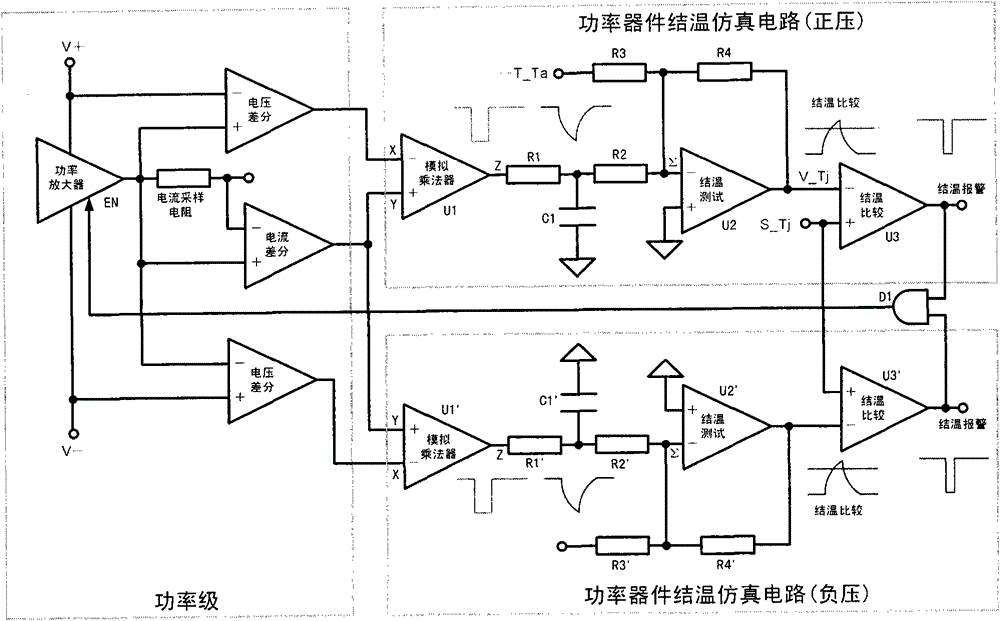

A technology for simulating circuits and power devices, used in instruments, thermometers and thermometers with electrical/magnetic components directly sensitive to heat, etc. Temperature protection power devices are difficult to apply safely, to achieve the effect of improving the safety and reliability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

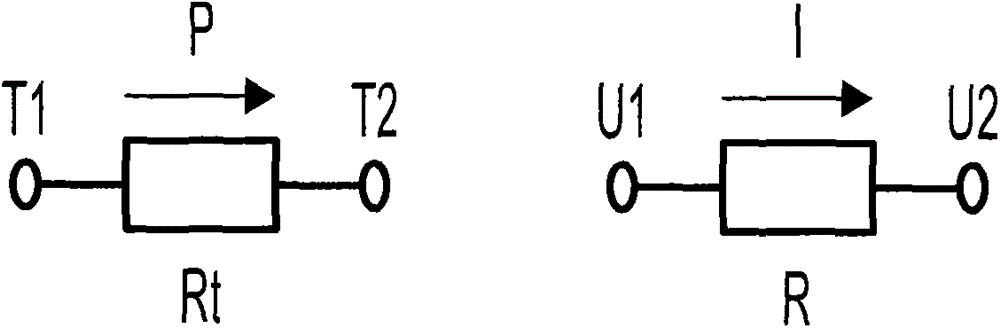

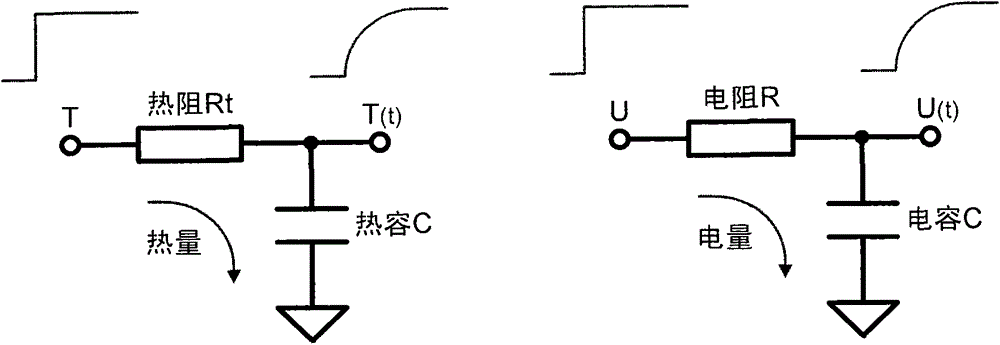

[0014] figure 1 The basic thermal model in can be expressed as:

[0015] q = λA δ ( T 1 - T 2 ) - - - ( 1 )

[0016] Formula (1) is the basic formula for heat conduction, where:

[0017] q is the heat that flows through the heat conductor per unit time;

[0018] λ is the thermal conductivity of the heat conductor;

[0019] A is the heat conduction cross-sectional area of the heat conductor;

[0020] δ is the length along the direction of heat conduction in the heat conductor;

[0021] T1 and T2 are the temperatures of the two end sections of the heat conductor.

[0022] In the formula Represents the thermal conductance of the heat conductor (that is, the reciprocal of the thermal resistance, which can also be expressed as ), so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com