Patents

Literature

73results about How to "Maintain thermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

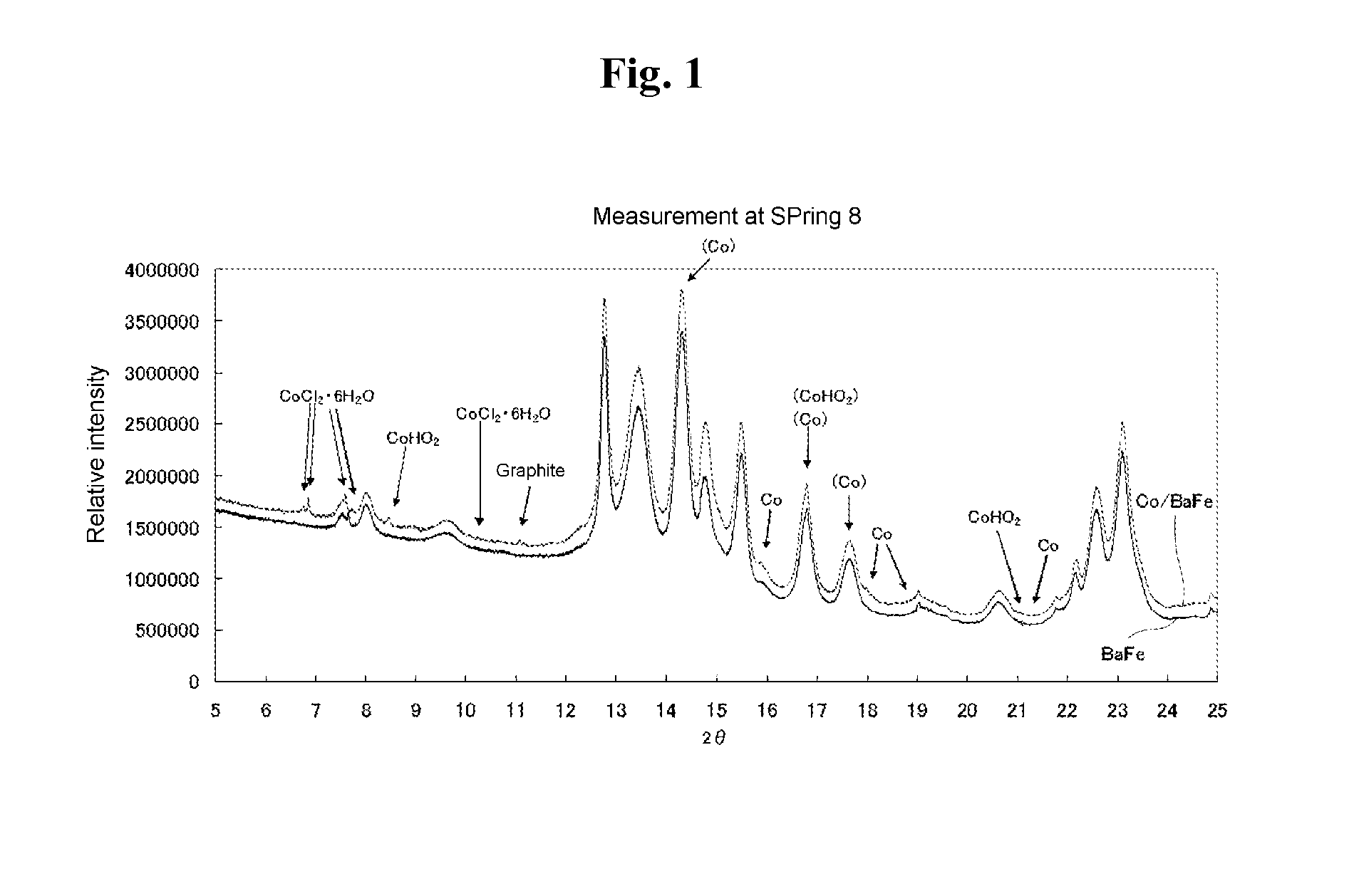

Magnetic recording medium

InactiveUS20120183811A1Improve recording effectImprove thermal stabilityRecord information storageMagnetic recordingMaterials scienceMagnetic layer

An aspect of the present invention relates to a magnetic recording medium comprising a magnetic layer containing a ferromagnetic powder and a binder on a nonmagnetic support, wherein the ferromagnetic powder is comprised of magnetic particles comprising a hard magnetic particle and a soft magnetic material deposited on a surface of the hard magnetic particle in a state where the soft magnetic material is exchange-coupled with the hard magnetic particle.

Owner:FUJIFILM CORP

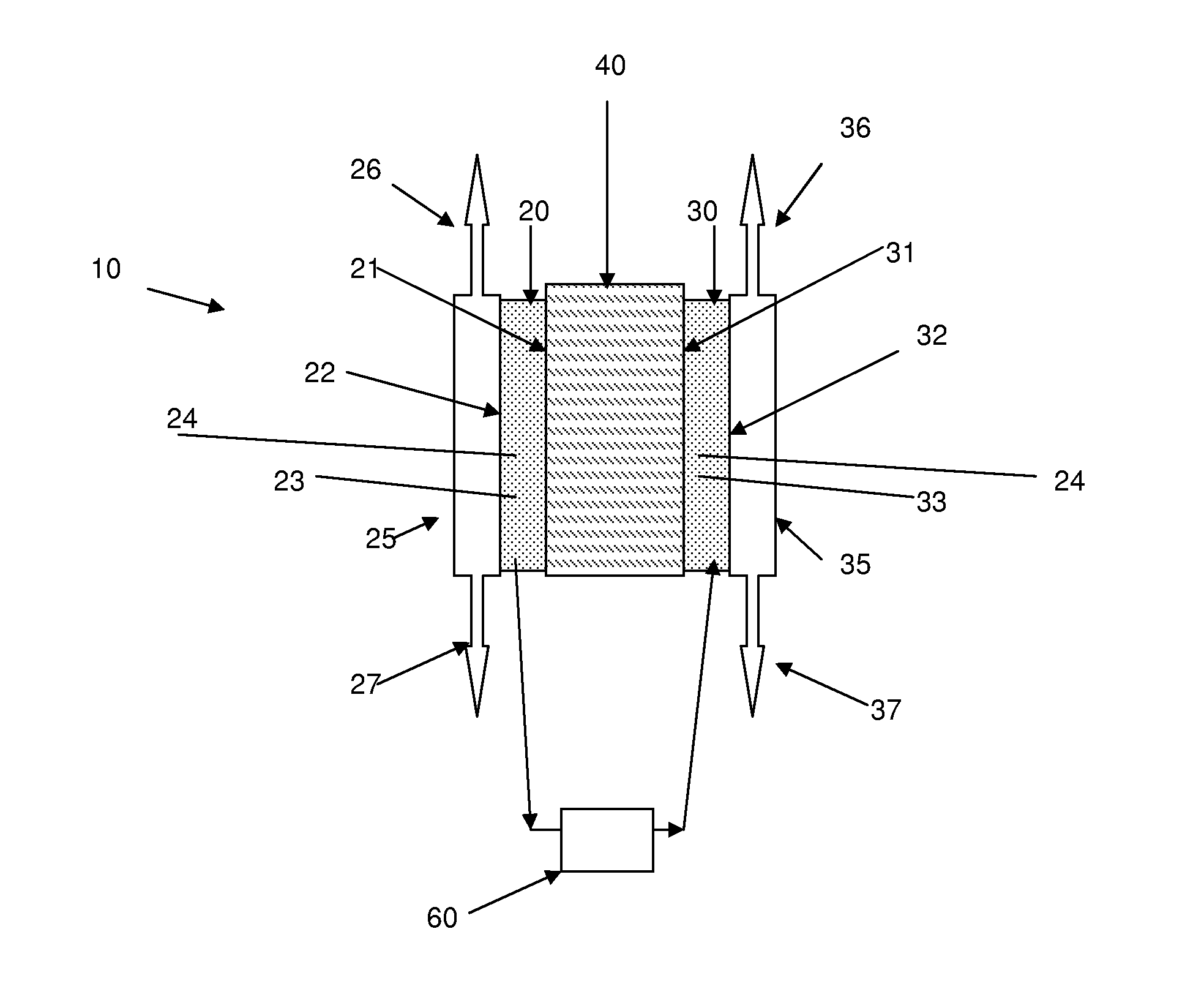

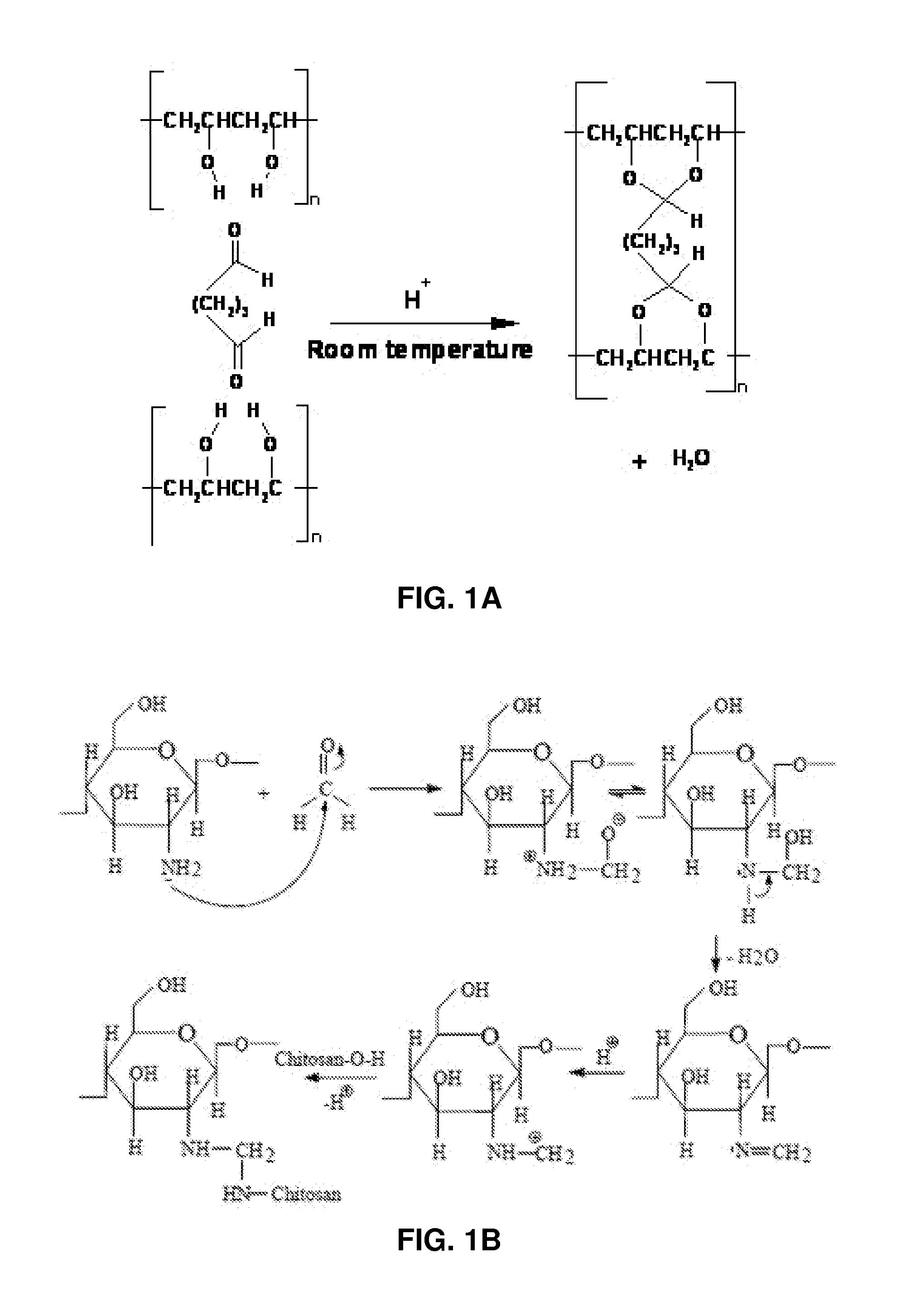

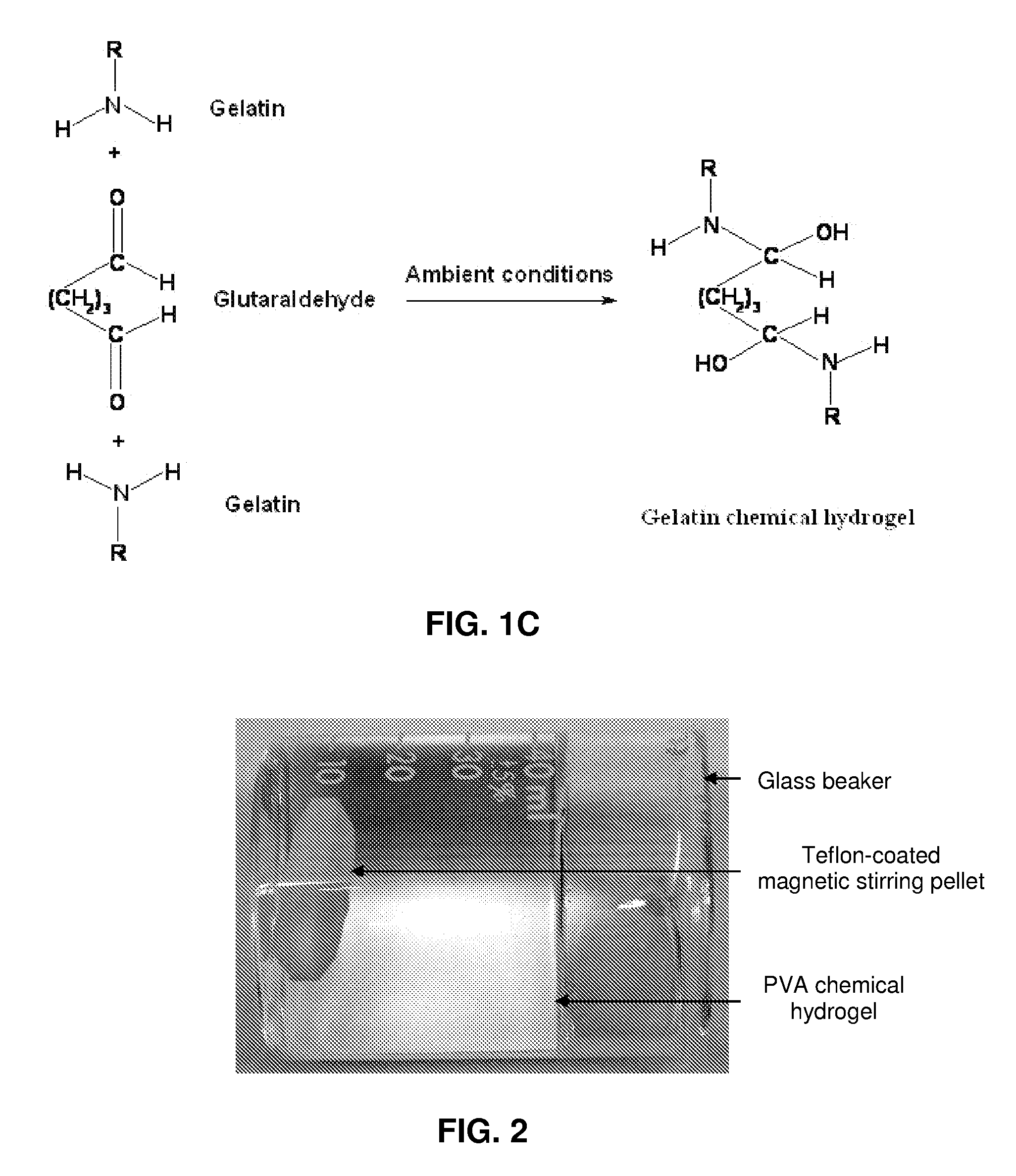

CHEMICALLY LINKED HYDROGEL MATERIALS AND USES THEREOF IN ELECTRODES and/or ELECTROLYTES IN ELECTROCHEMICAL ENERGY DEVICES

InactiveUS20110305970A1Maintain thermal stabilityCatalyst protectionElectrolytic capacitorsPtru catalystFuel cells

A chemically linked catalyst-binder hydrogel material comprised of a water-insoluble chemical hydrogel is useful in, for example, fuel cells, batteries, electrochemical supercapacitors, semi-fuel cells etc. The water-insoluble chemical hydrogel is prepared by a chemical cross-linking reaction between a polymer (such as PVA or chitosan or gelatin) and an aqueous cross-linking agent such as glutaraldehyde, which is catalyzed by protic acid under ambient conditions of temperature and pressure.

Owner:THE OHIO STATES UNIV

Thermoplastic resin composition

A thermoplastic resin composition which comprises a thermoplastic resin (a) and a block copolymer (b) comprising a methacrylic polymer block (A) and an acrylic polymer block (B).

Owner:KANEKA CORP

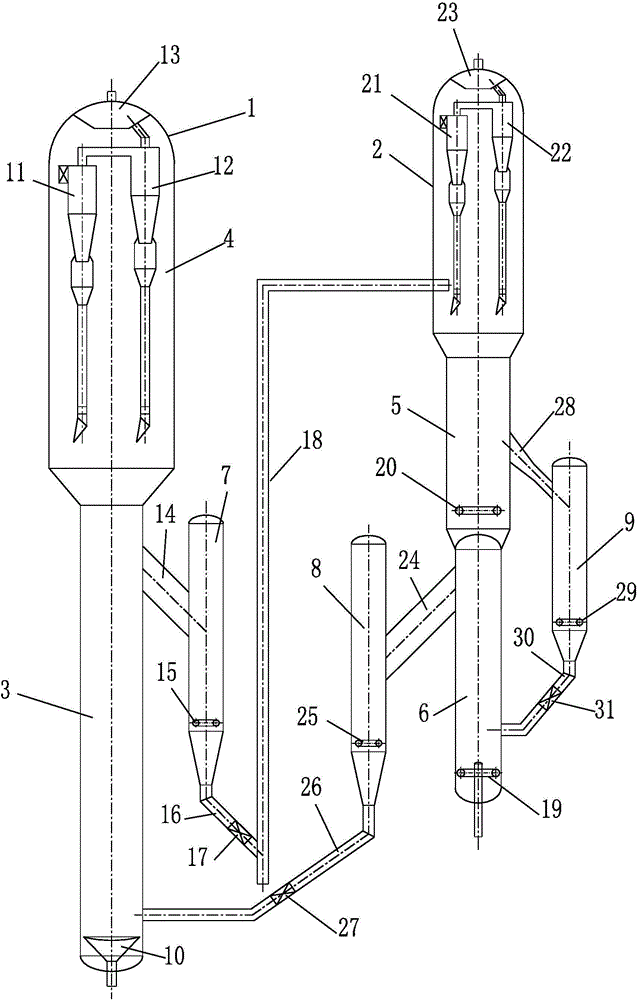

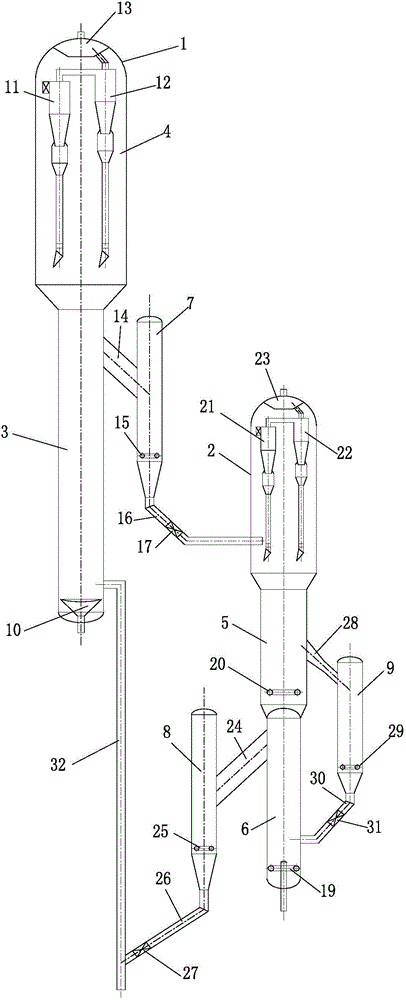

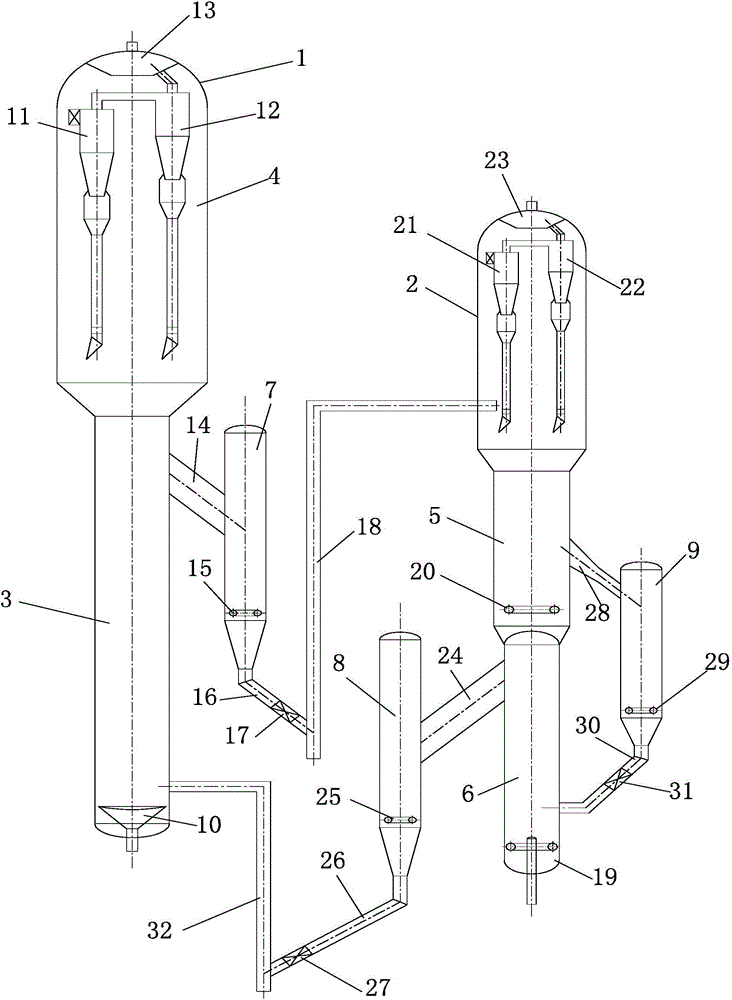

Method of producing aromatic hydrocarbon through catalytic conversion of organic oxides

ActiveCN105985209AProcess safety and stabilityContinuous operationHydrocarbon from oxygen organic compoundsChemical recyclingAromatizationOrganic Oxide

The invention discloses a method of producing aromatic hydrocarbon through catalytic conversion of organic oxides. The method includes the steps of: a) contacting the organic oxides in a dense-phase bed reaction section with a regenerated catalyst from a second regenerator to perform an aromatization reaction; b) discharging the reaction product from a reactor dilute-phase section, wherein to-be-regenerated catalyst successively passes through a first regenerator and the regenerator and then is fed back to the reactor for the reaction. The method has safe and stable process, achieves continuous operation, reduces usage amount of oxygen-containing gas for coking, catalyst loss and hydrothermal deactivation, is low in operation cost and has low environment pollution.

Owner:SINOPEC ENG +1

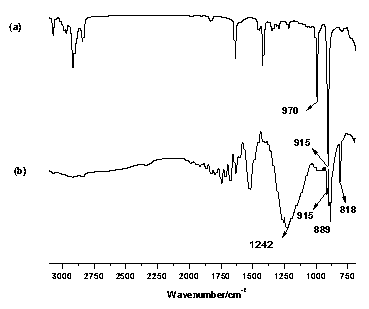

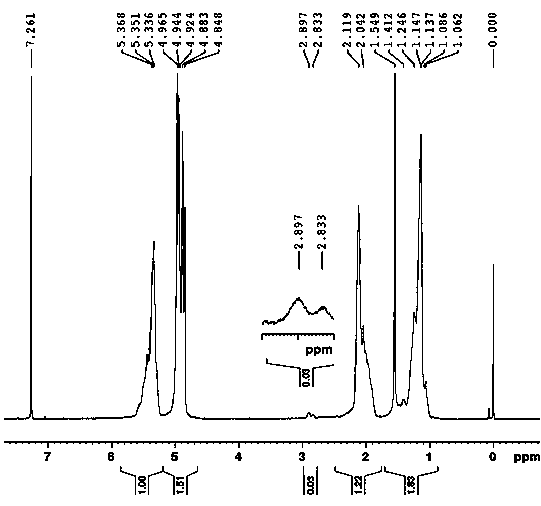

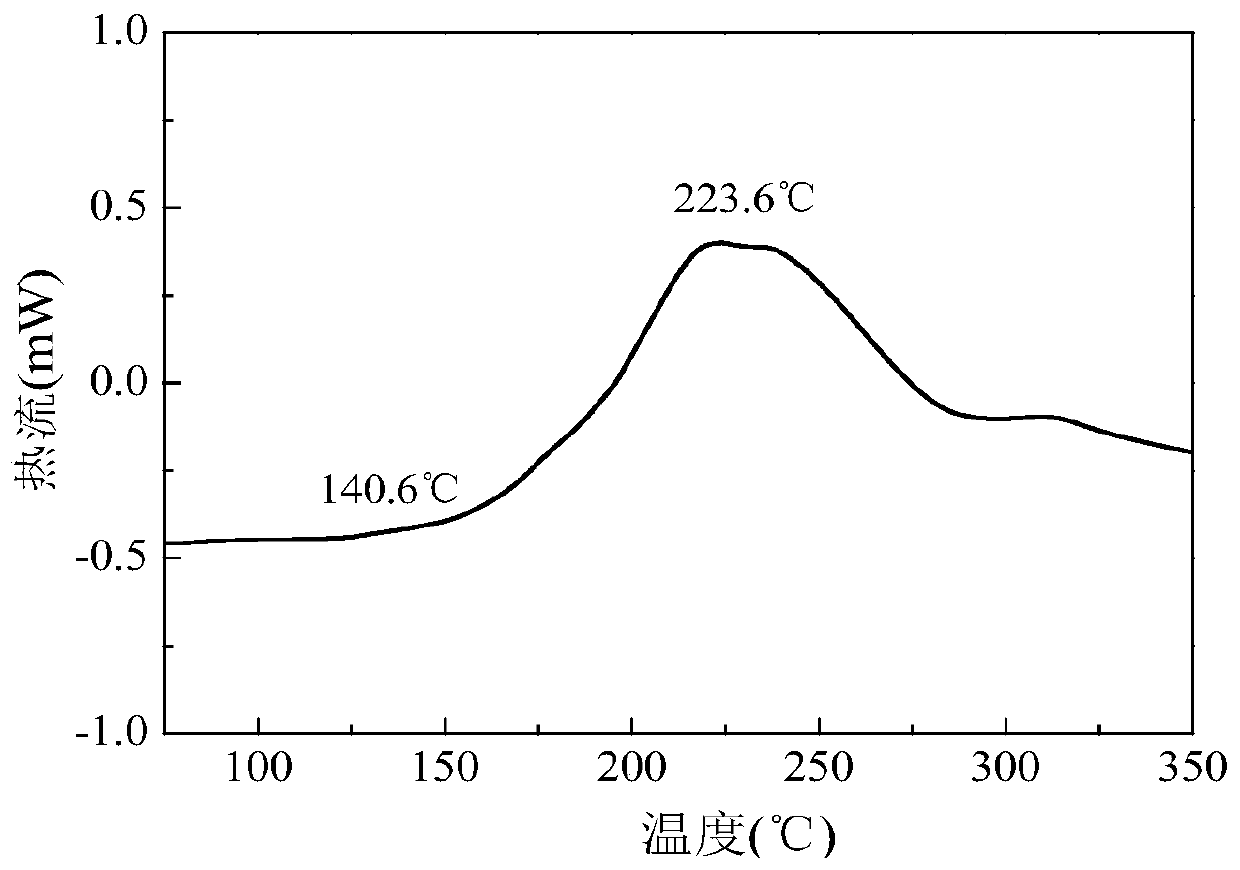

Preparation method of epoxidized 1, 2-polybutadiene

The invention relates to a preparation method of a polymeric material, in particular to a preparation method of epoxidized 1, 2-polybutadiene. Preparation steps of the preparation method are as follows: composition A and composition B are added to a reaction flask and stirred by magnetic force at the temperature of 65 DEG C until the composition A is dissolved; composition C and composition D are added to the reaction flask and stirred fully and uniformly; quantitative composition E is added to a system and reacted for a period at the constant temperature; after the reaction is finished, a product is poured out; absolute ethyl alcohol is added for precipitating a solid, sedimentation is performed for a period, suction filtration is performed, and a sodium bicarbonate solution and distilled water are used for washing a product solid for a plurality of times respectively; and the washed product solid is put into an oven for vacuum drying for 12 h at the temperature of 60 DEG C, and a product is obtained. The invention provides a synthesis method for epoxidizing 1, 2-polybutadiene. The prepared epoxidized 1, 2-polybutadiene can be used for toughening modification of other high polymer materials (such as nylon, epoxy resin and the like).

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

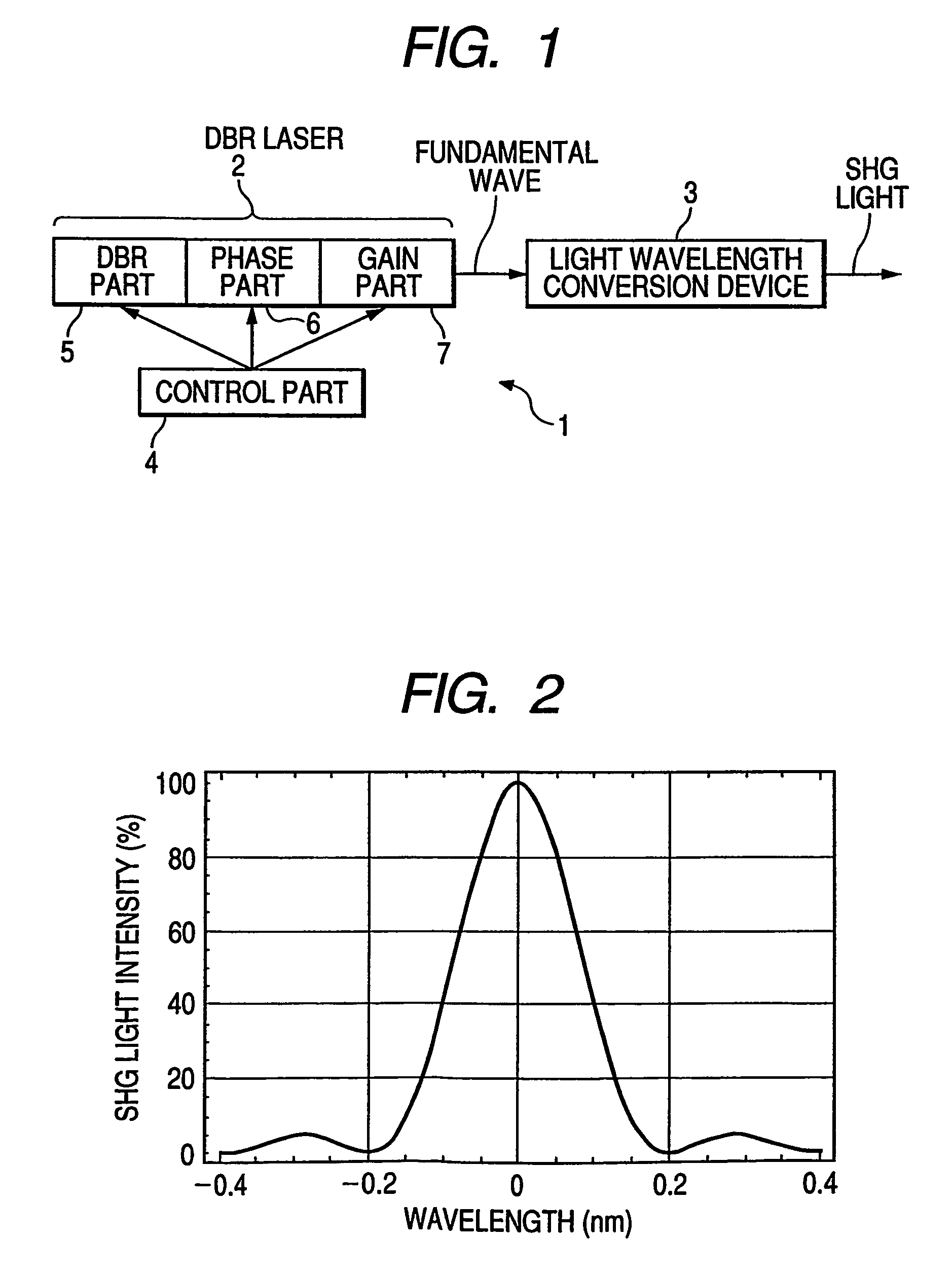

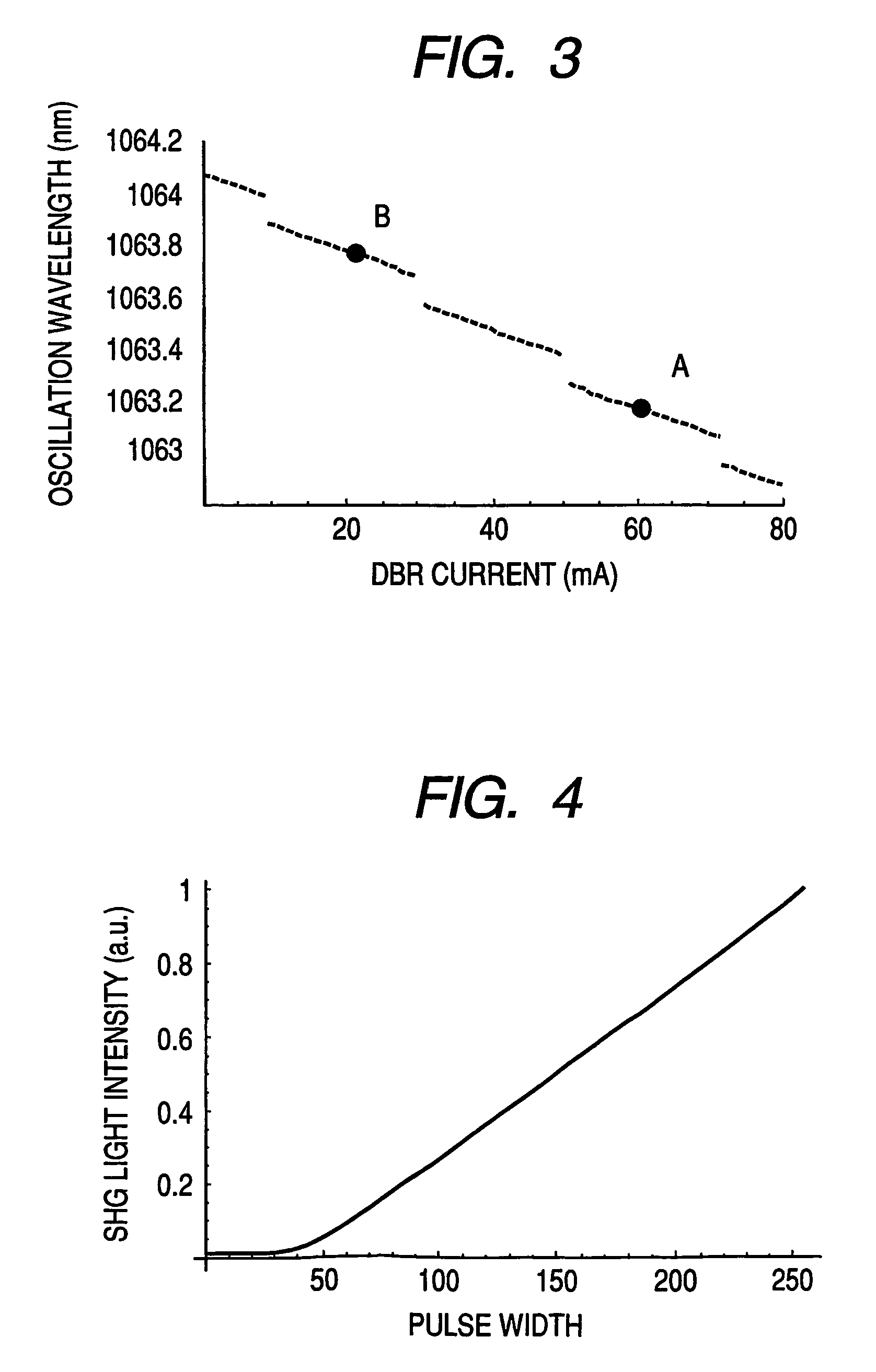

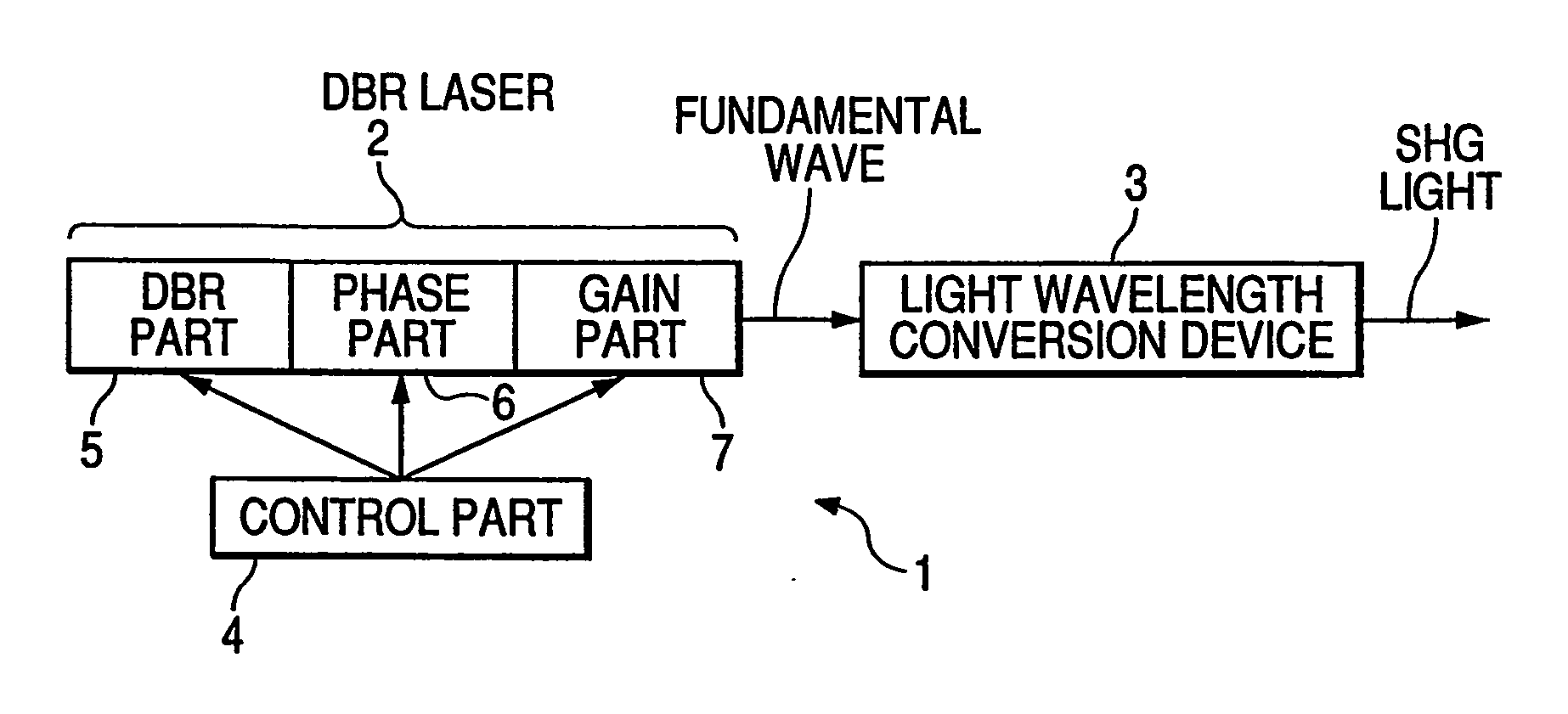

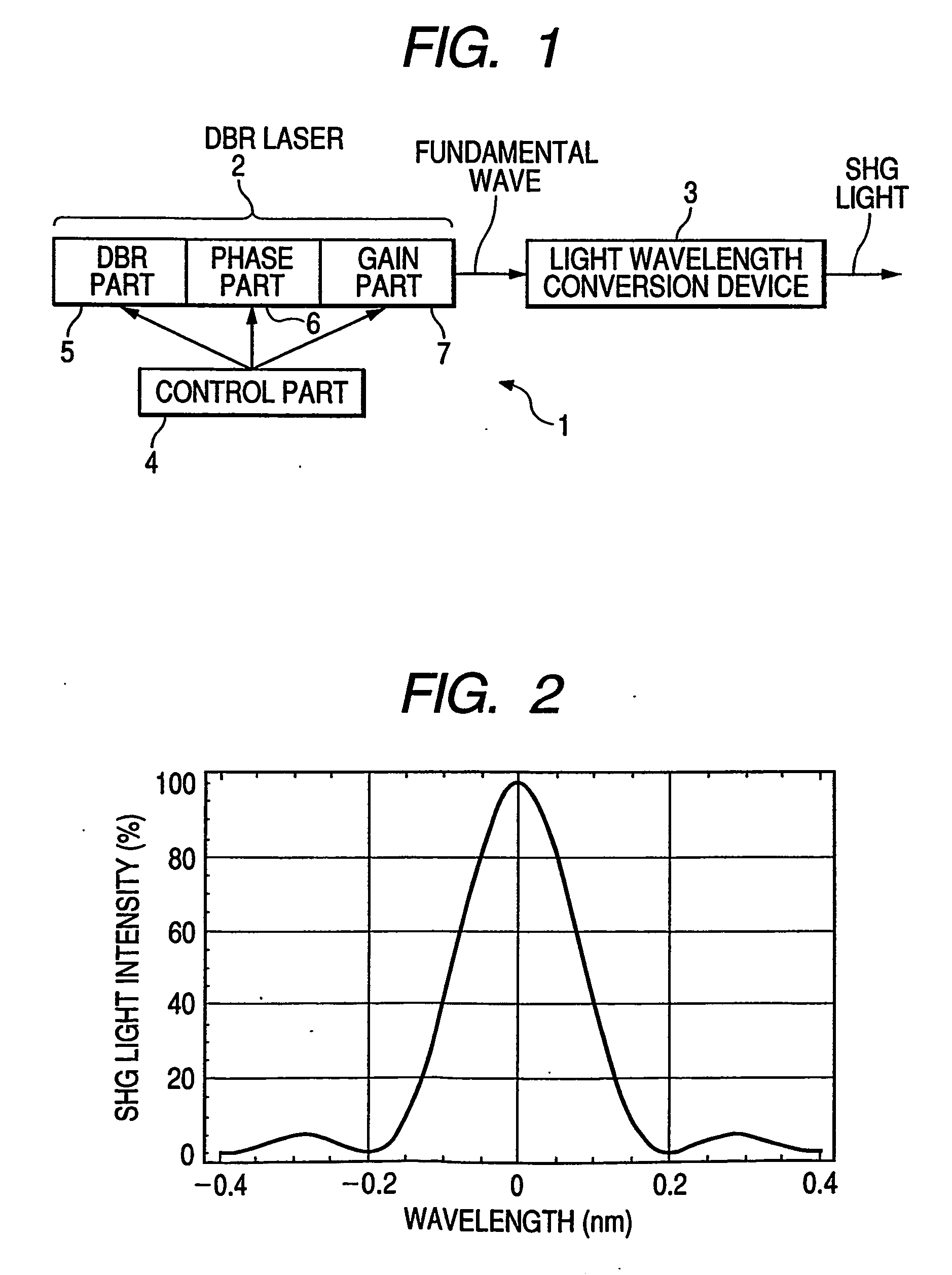

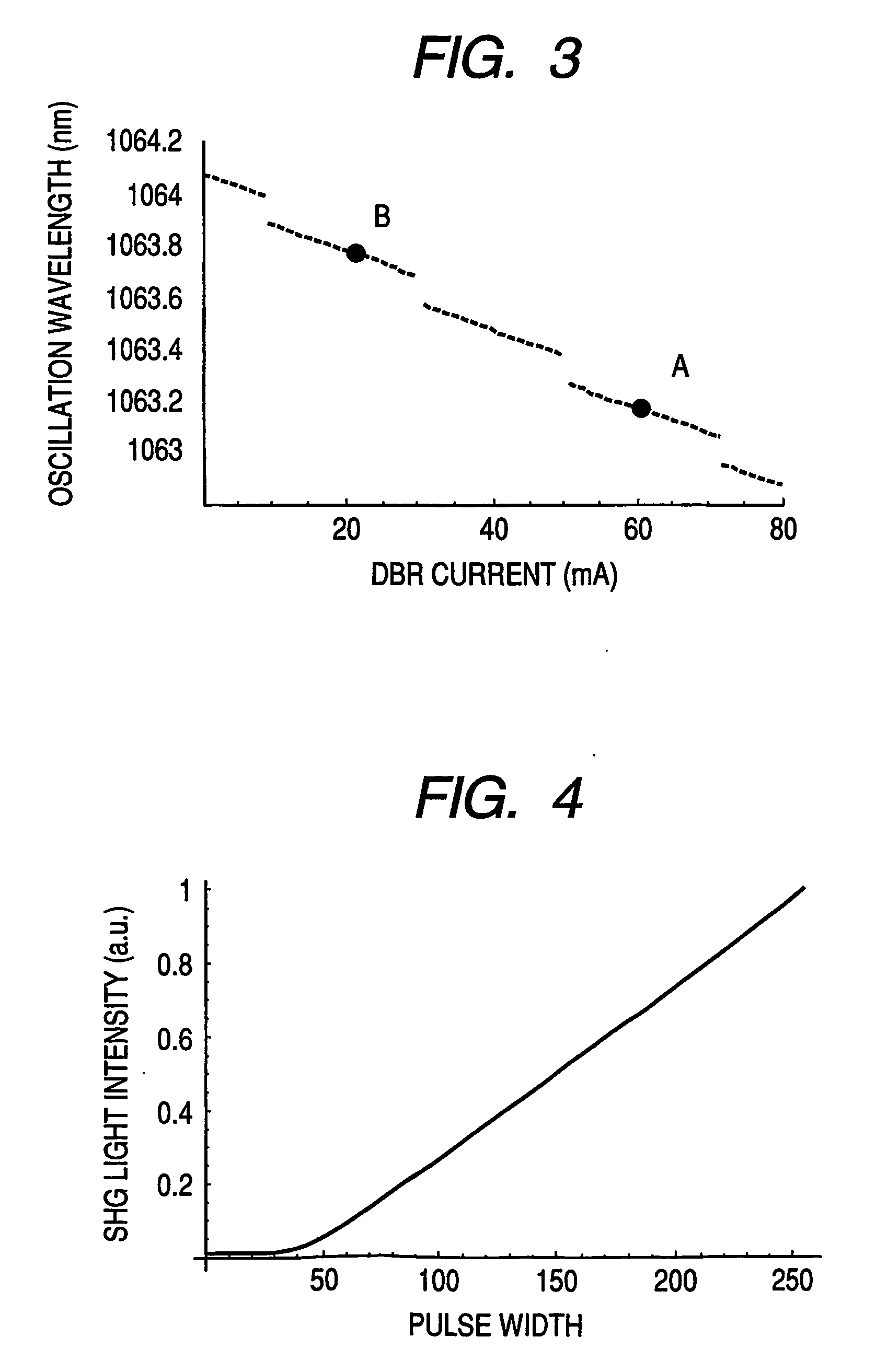

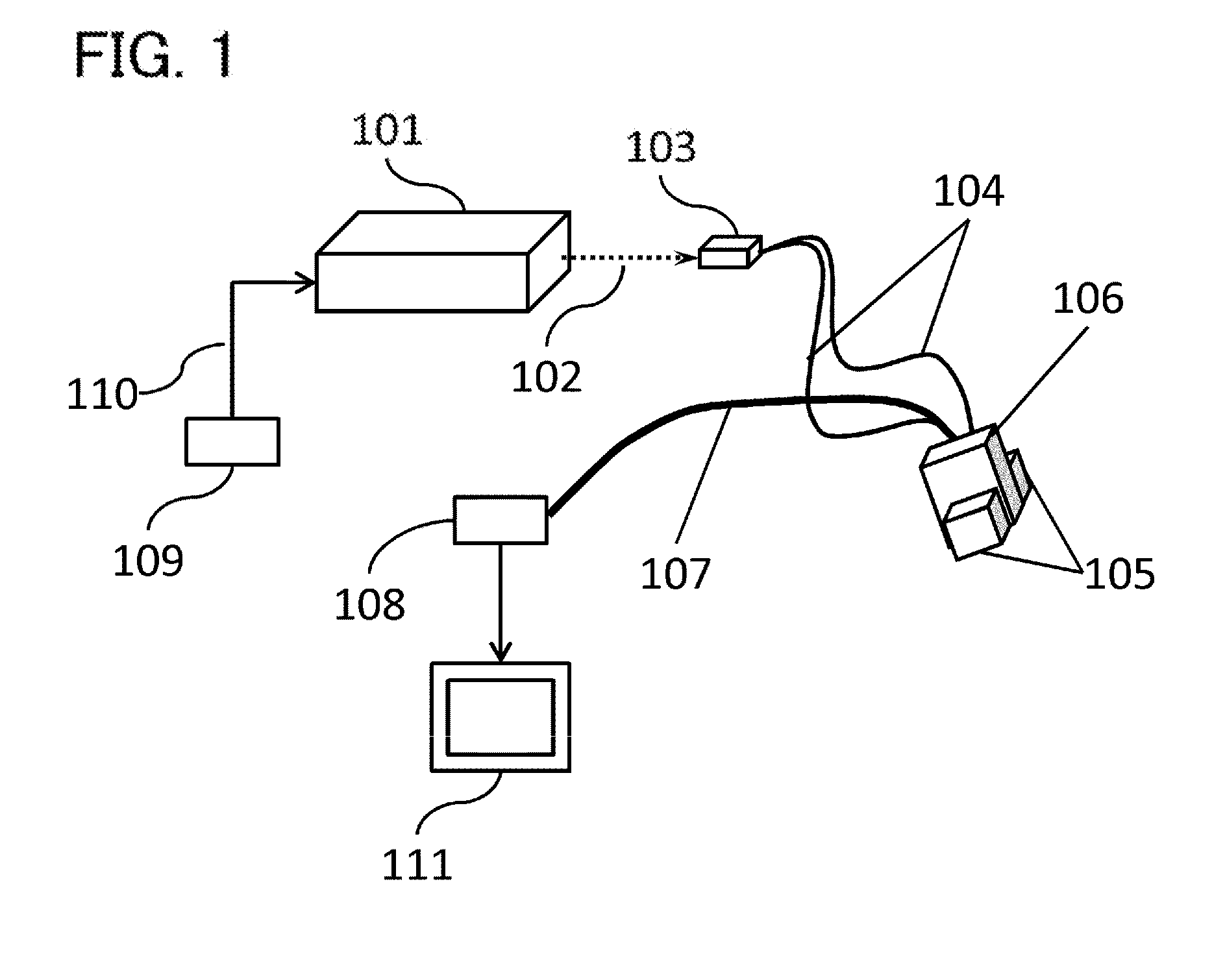

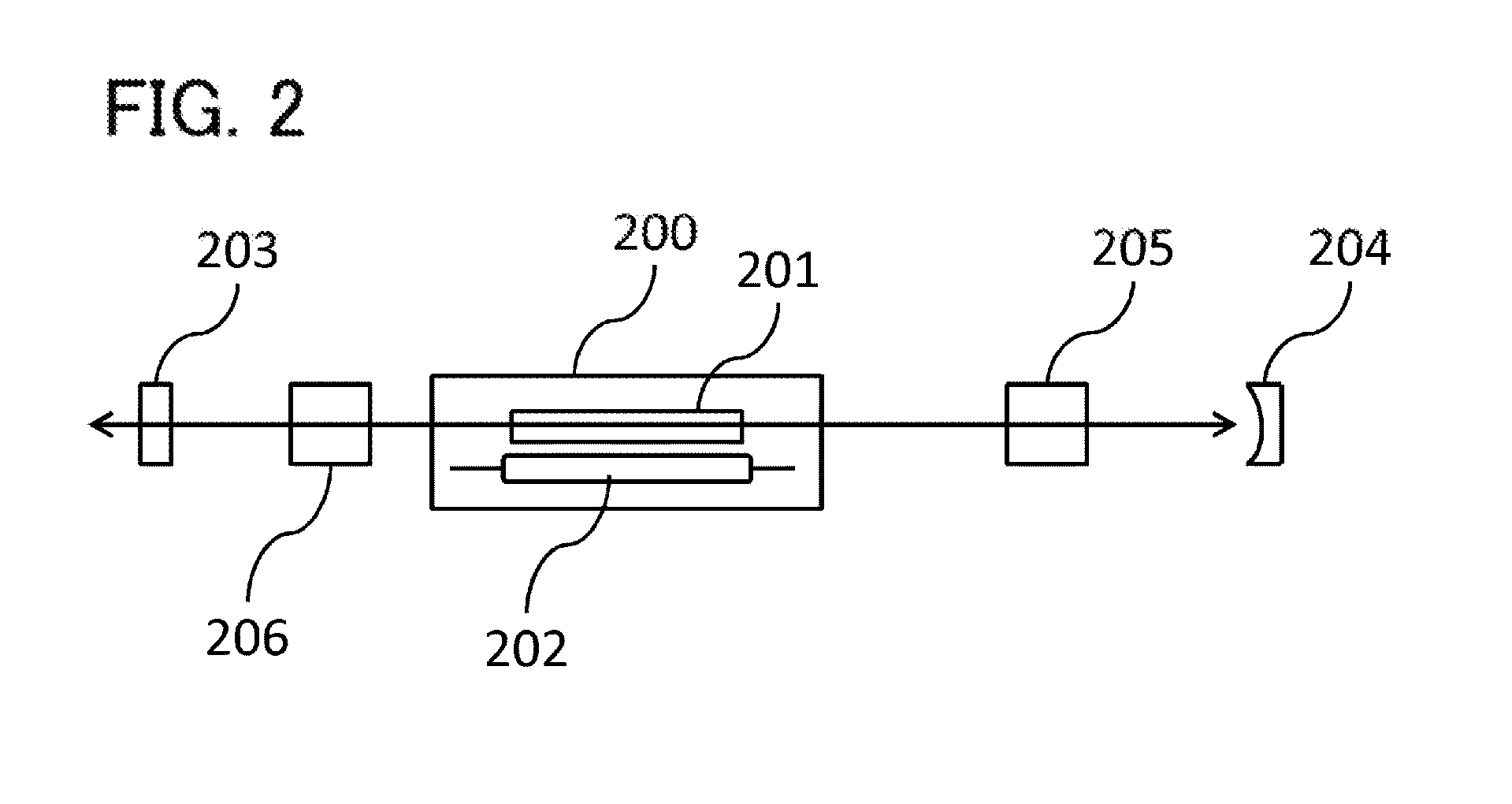

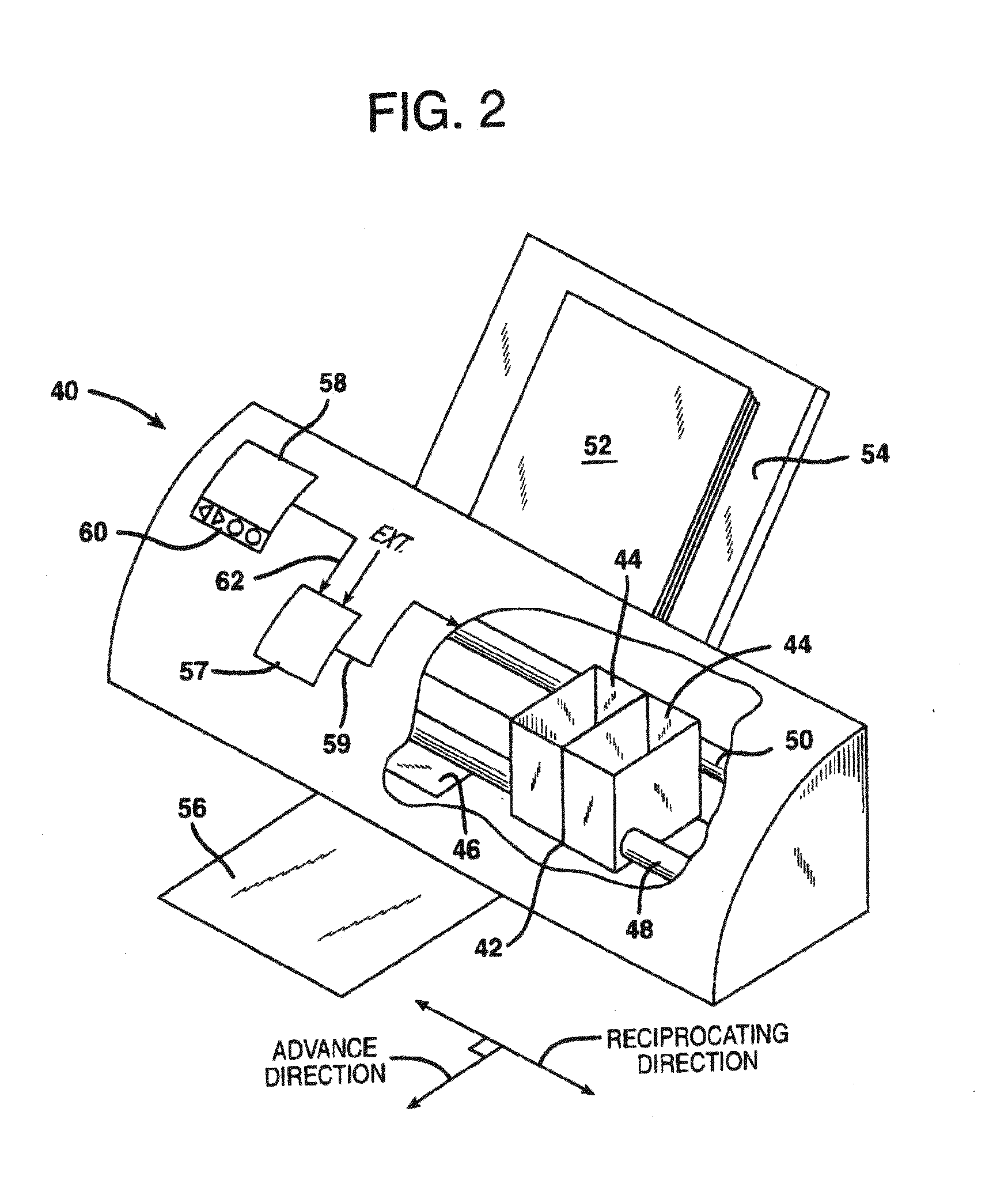

Modulation light source, image display apparatus including the same, and method of driving modulation light source

InactiveUS7376161B2Easily realizing high-resolution gradation level expression of SHG lightMaintain relatively stableSemiconductor laser optical deviceOptical resonator shape and constructionOptoelectronicsThermal stability

Owner:CANON KK

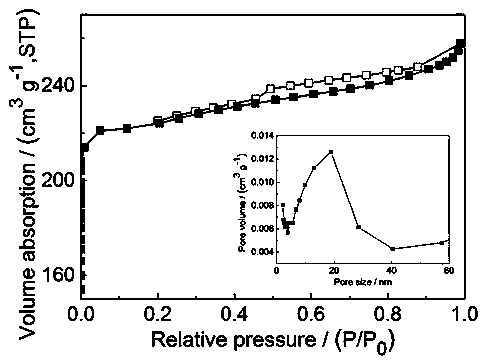

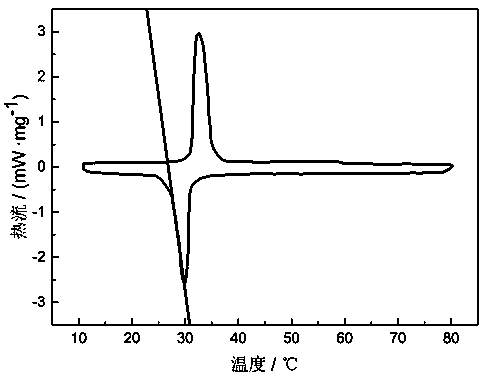

Inorganic hydrated salt porous carbon composite phase change material and preparation method thereof

ActiveCN108676550AReduce overflowReduce precipitationHeat-exchange elementsHydration reactionPhase change enthalpy

The invention discloses an inorganic hydrated salt porous carbon composite phase change material and a preparation method thereof, wherein the preparation method comprises the following steps: firstly, preparing biomass-based porous carbon subjected to activation treatment, and weighing an inorganic hydrated salt phase change material, the biomass-based porous carbon and a pore sealing agent in proportion; and then preparing a saturated solution from the inorganic hydrated salt phase change material, adding biomass-based porous carbon, impregnating, carrying out vacuum pressurization and adsorbing; and finally, adding the pore sealing agent, stirring, wind-drying, and grinding and pulverizing, to obtain the inorganic hydrated salt porous carbon composite phase change material. The composite phase change material prepared by the method has the advantages of difficult liquid leakage, no phase separation, small supercooling degree, high phase change enthalpy, no toxicity, no corrosion, good thermal stability, good durability, low preparation cost and the like, and has broad market prospects in the fields of building and energy-storage materials.

Owner:SHANDONG JIANZHU UNIV

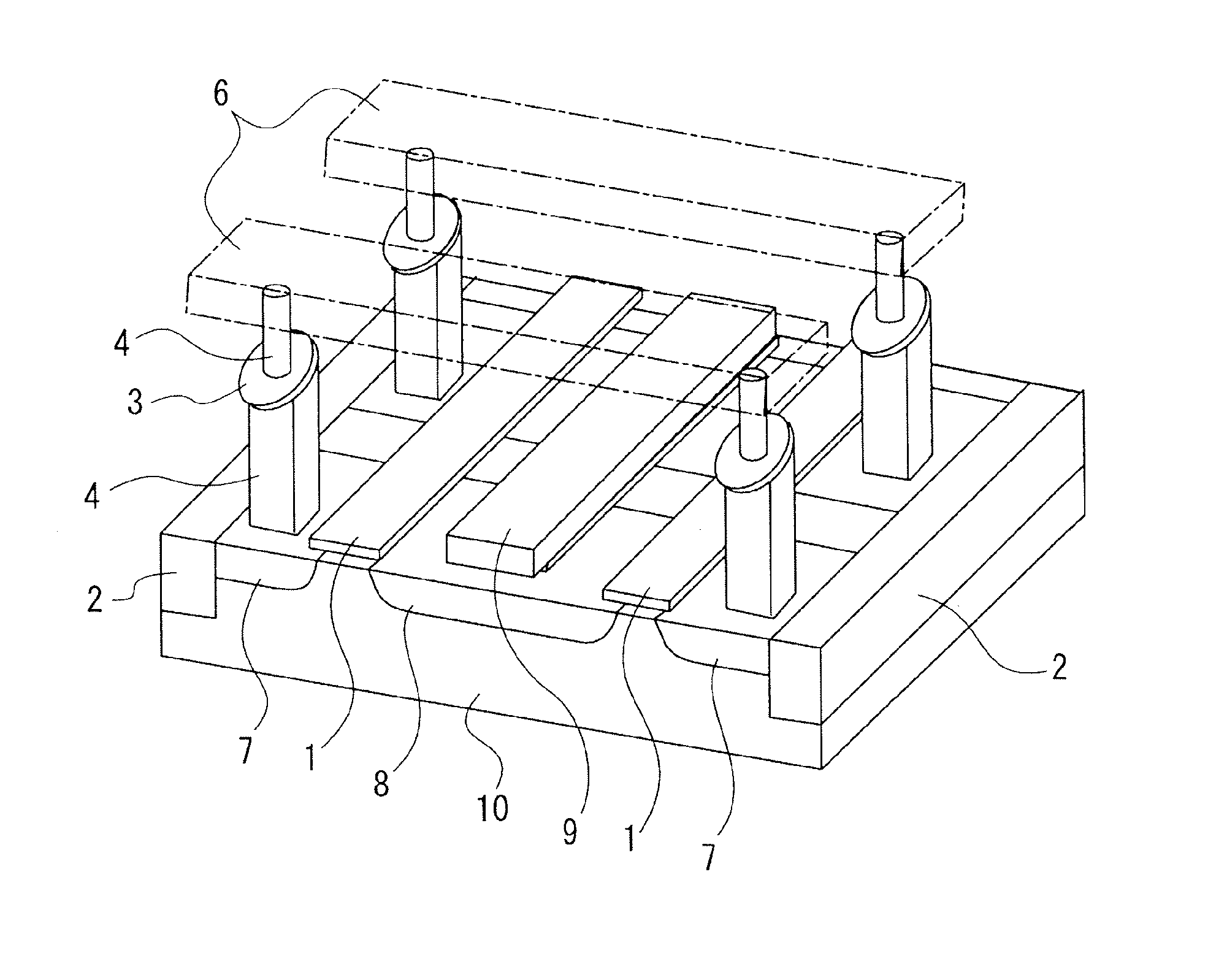

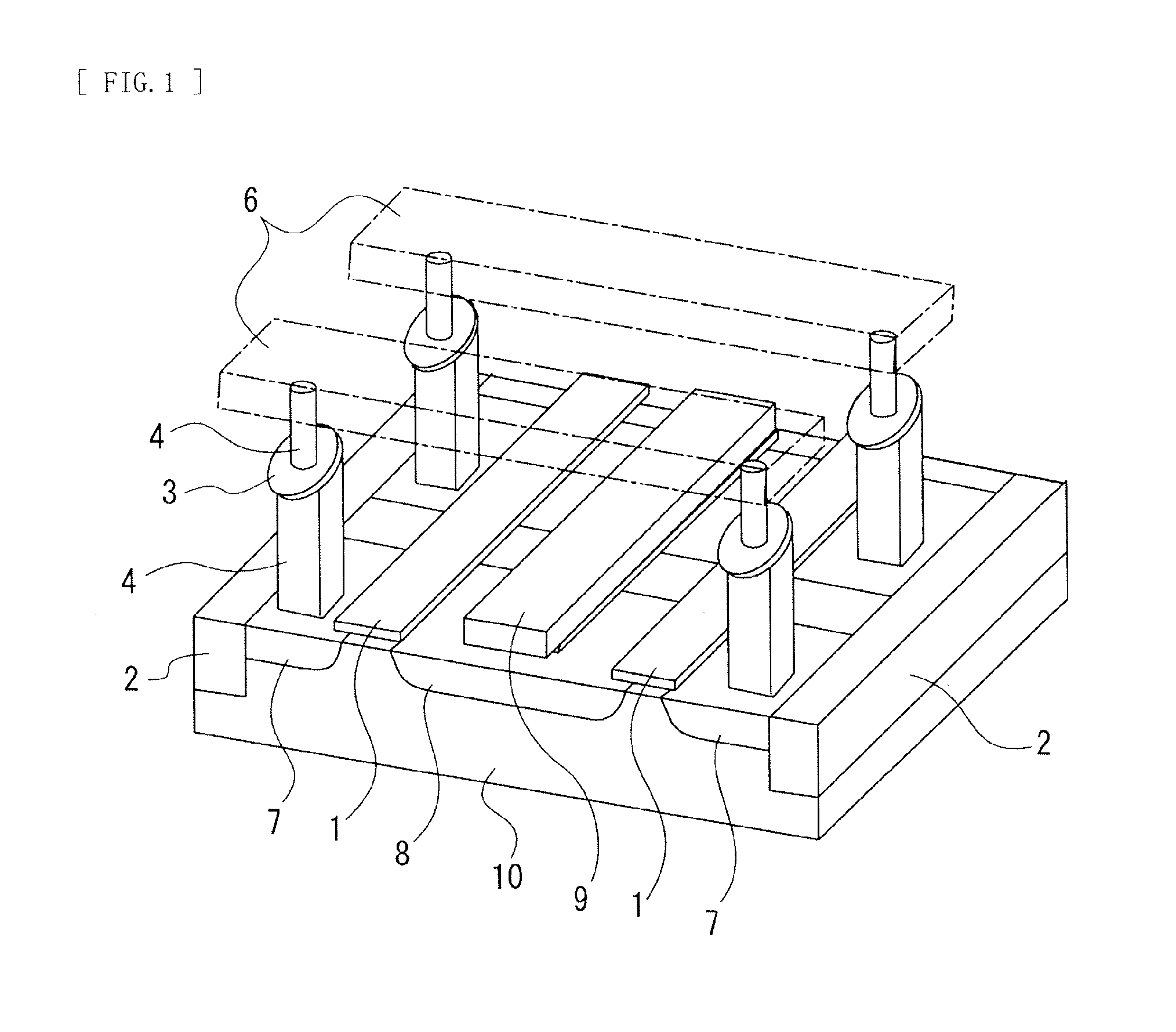

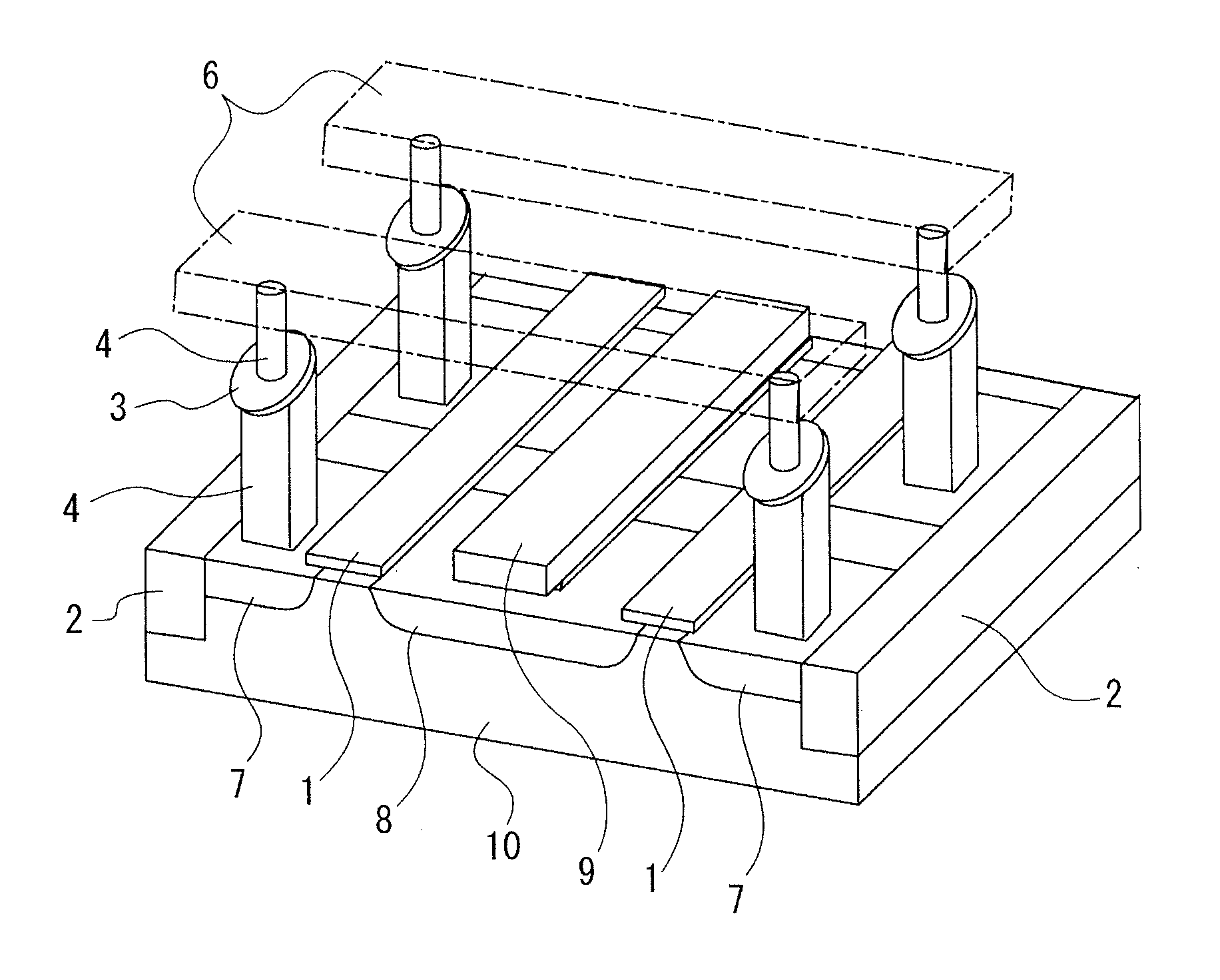

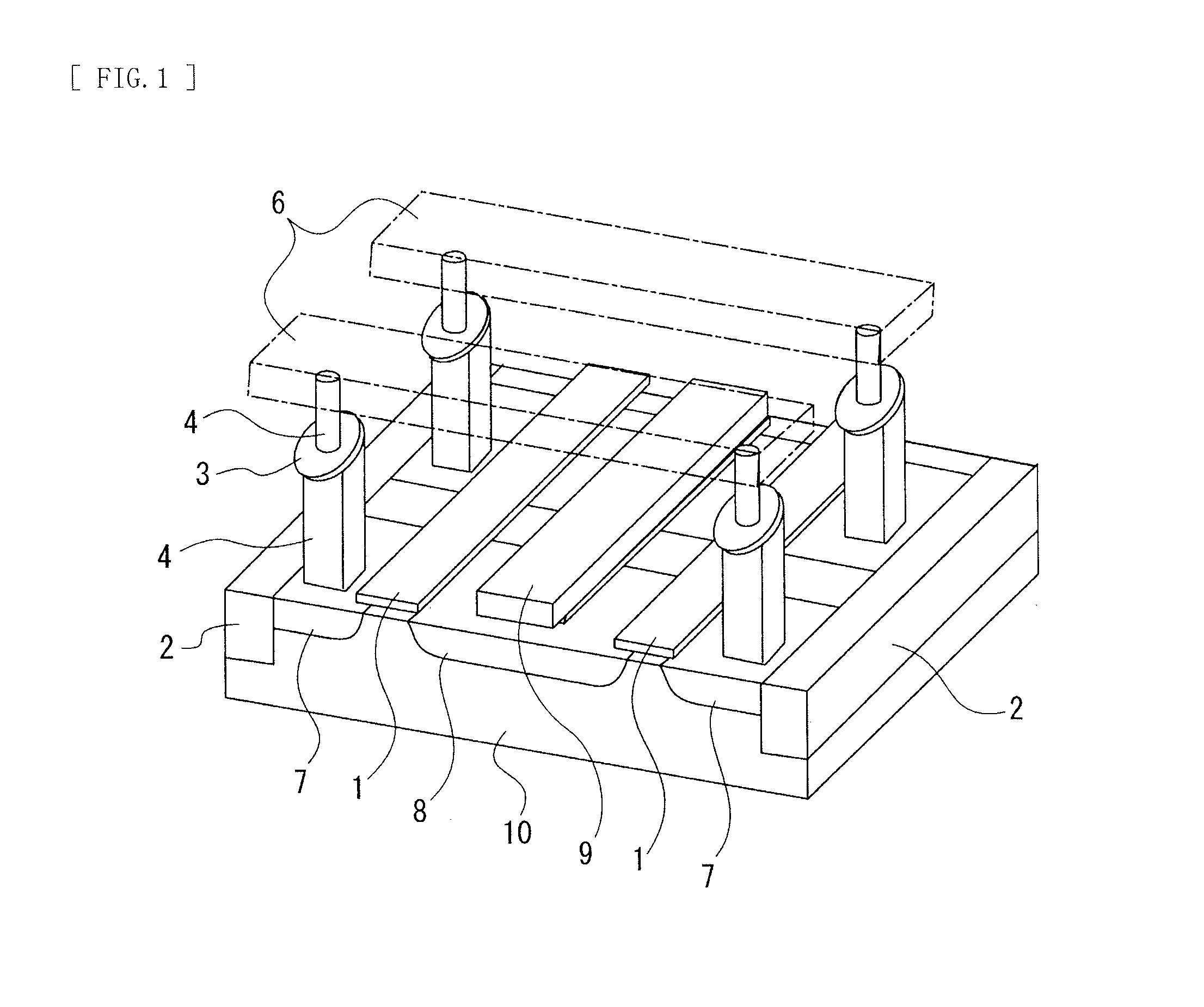

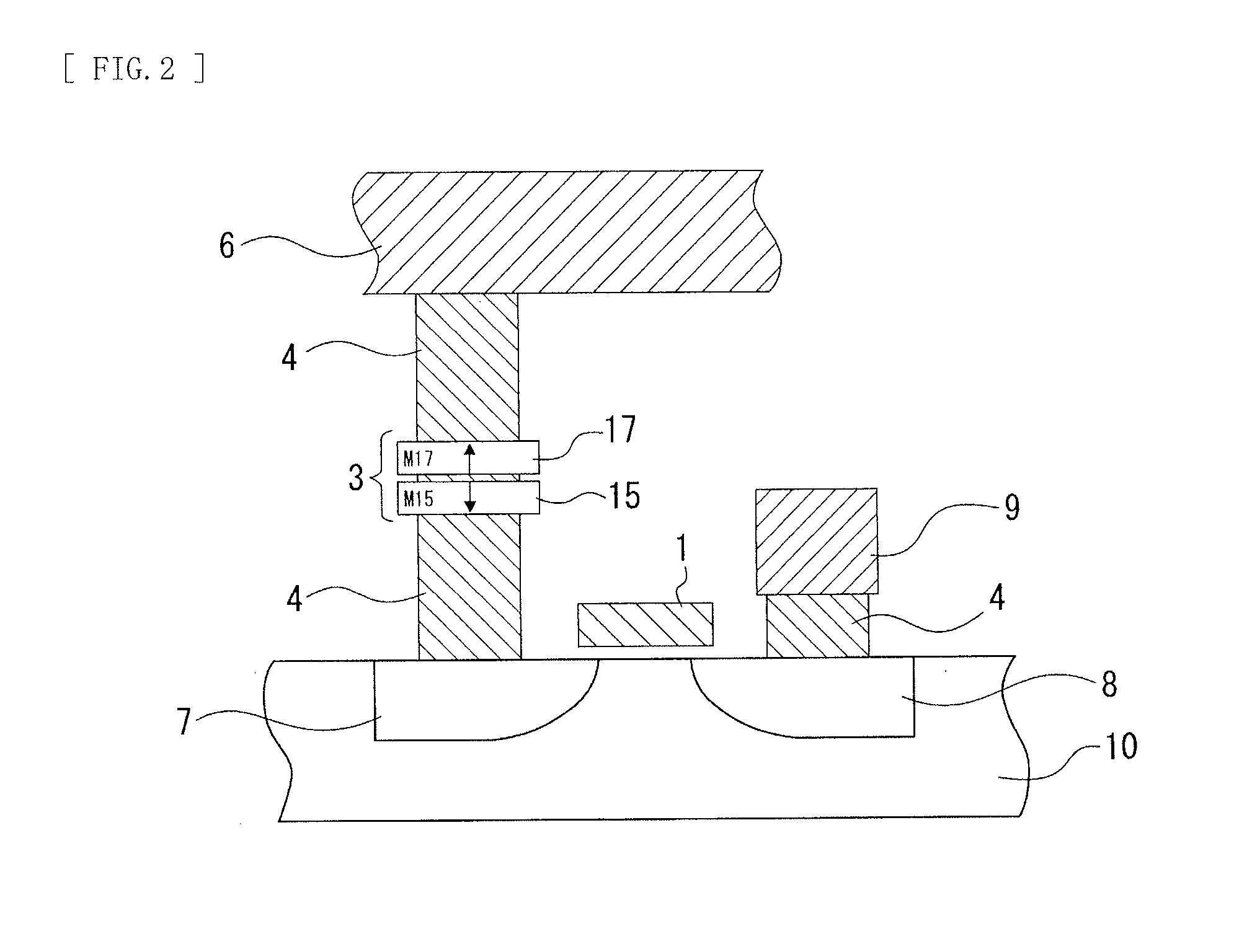

Storage cell, storage device, and magnetic head

ActiveUS20150255134A1Stably information recordedImprove reliabilityMagnetic-field-controlled resistorsGalvano-magnetic material selectionMagnetizationNon magnetic

Provided is a storage cell that makes it possible to enhance magnetic characteristics of magnetization pinned layer, a storage device and a magnetic head that include the storage cell. The storage cell includes a layer structure including a base layer, a storage layer in which a direction of magnetization is varied in correspondence with information, a magnetization pinned layer that is formed above the base layer and has magnetization that is perpendicular to a film surface and serves as a reference of information stored in the storage layer, and an intermediate layer that is provided between the storage layer and the magnetization pinned layer and is made of a nonmagnetic body. The base layer has a laminated structure of ruthenium and a nonmagnetic body having a face-centered cubic lattice, and the ruthenium is formed at a location adjacent to the magnetization pinned layer.

Owner:SONY CORP

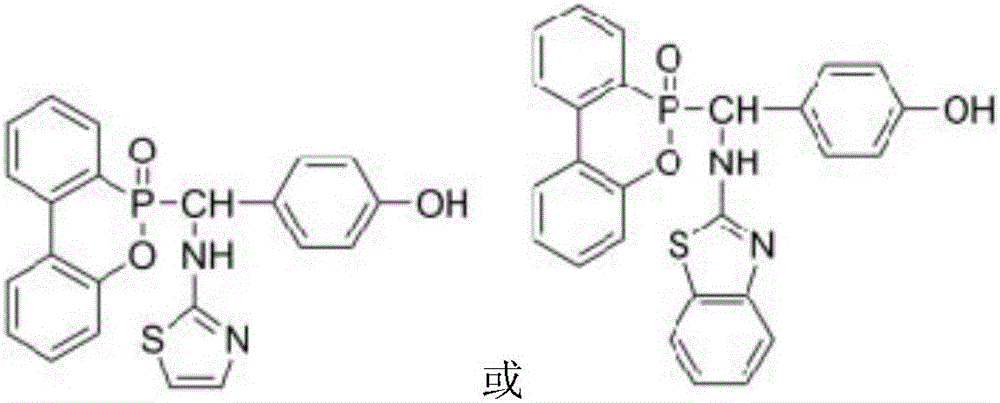

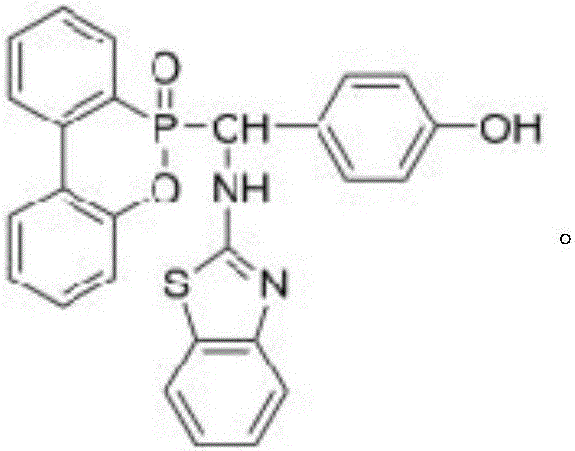

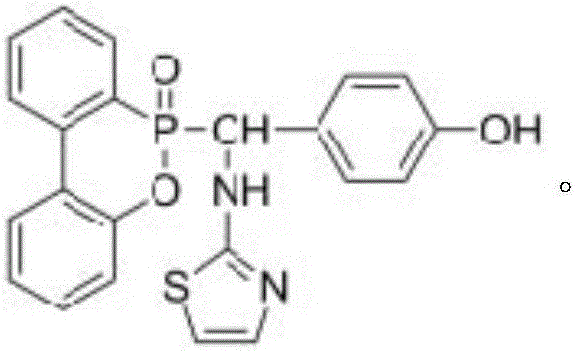

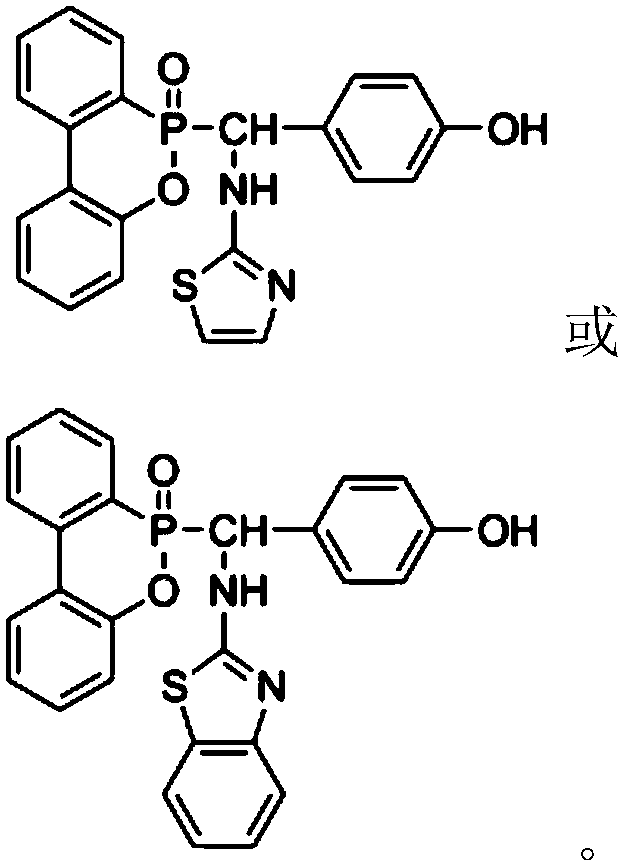

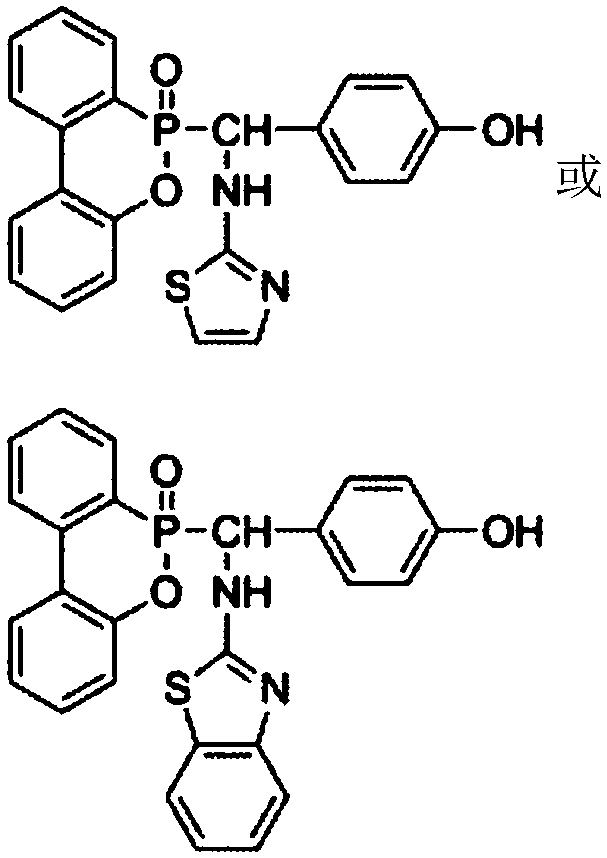

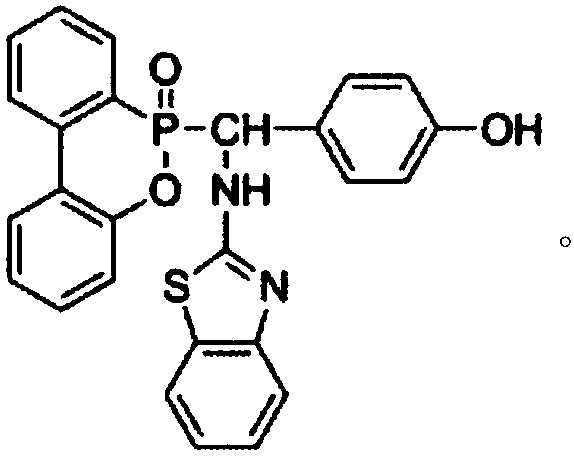

Method for preparing nitrogen phosphate sulfur-containing reactive flame retardant applied to epoxy resin

ActiveCN106749413AThe synthesis process is simpleShort cycleGroup 5/15 element organic compoundsEpoxyPhosphate

The invention relates to a method for preparing nitrogen phosphate sulfur-containing reactive flame retardant applied to epoxy resin. The preparation method comprises the following steps: sequentially adding p-hydroxy benzaldehyde, aminothiazole and a solvent into a reactor which is provided with a condensing pipe and a stirrer, and introducing inert gas to perform first reaction; adding 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide to carry out second reaction; and pumping, filtering, washing and drying the system to obtain white or light brown nitrogen phosphate sulfur-containing reactive flame retardant after the reaction is completed. The method has the advantages that 1, the synthesizing process is short, the cycle is short, post-treatment is easy, and control and industrial production are easy; 2, the prepared flame retardant contains nitrogen, phosphate and sulfur three flame-retardant elements at the same time, has a synergistic flame-retardant effect, and can be used for remarkably improving the flame retarding performance of epoxy resin; and 3, the prepared flame retardant is a reactive flame retardant, and can be used for keeping stability and mechanical performance of cured epoxy resin while improving the flame retarding effect of the cured epoxy resin.

Owner:FUJIAN NORMAL UNIV

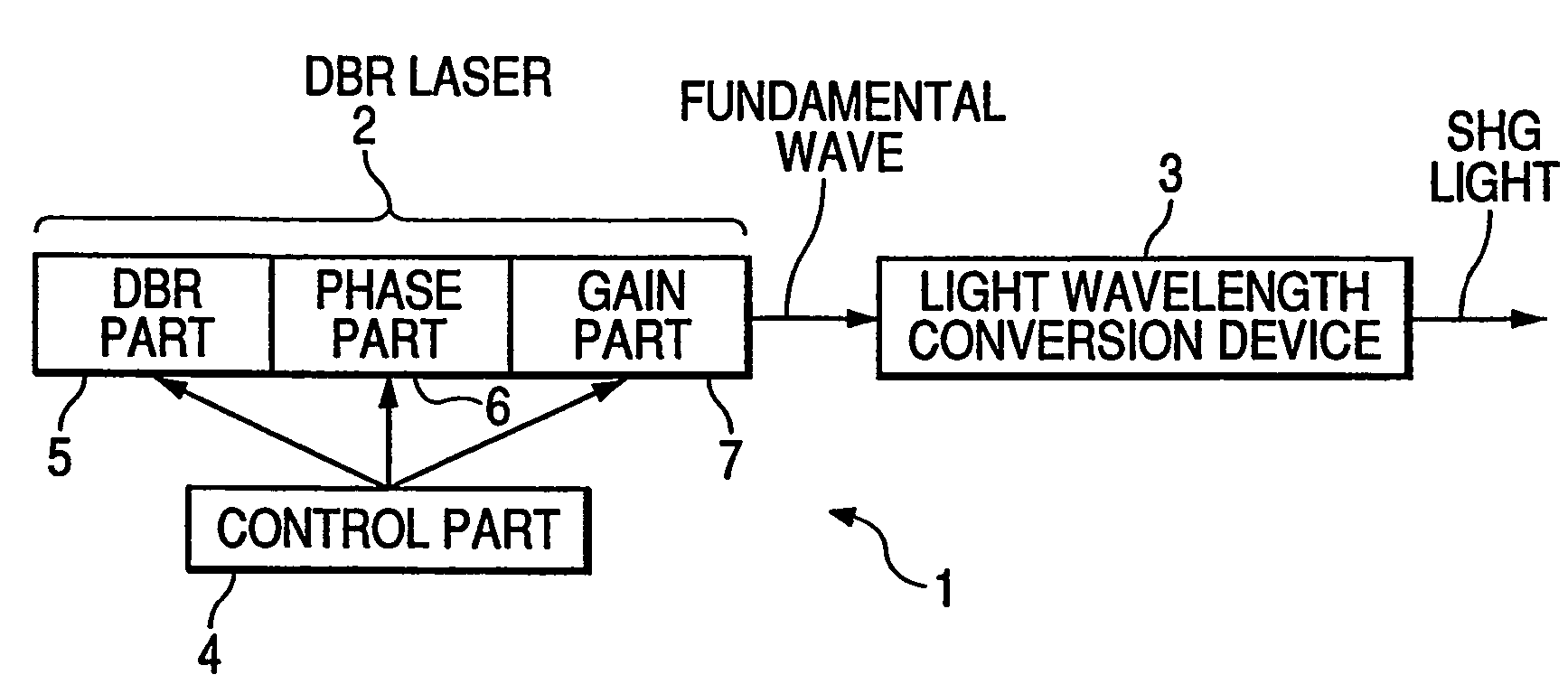

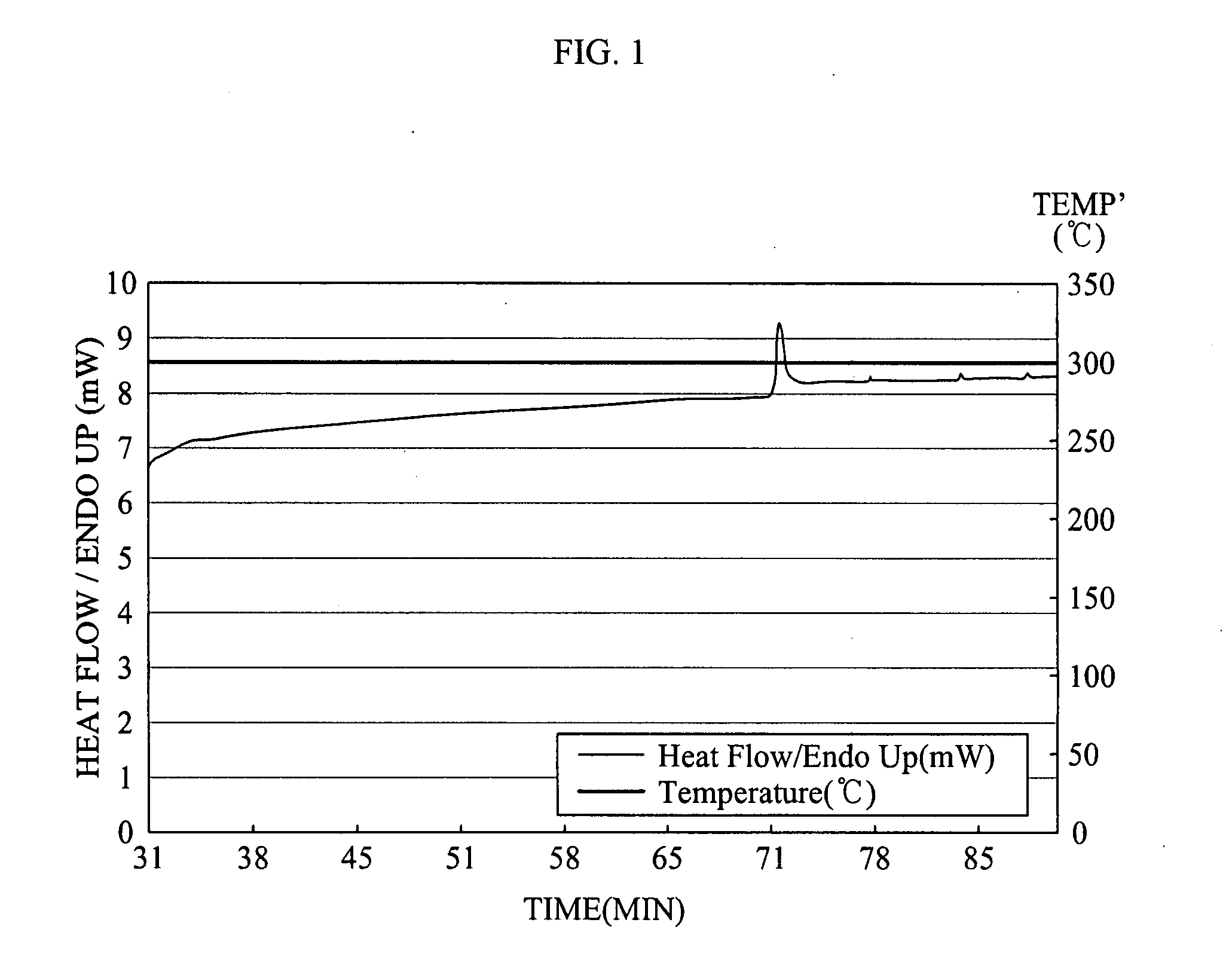

Modulation light source, image display apparatus including the same, and method of driving modulation light source

InactiveUS20070071055A1Easily realizing high-resolution gradation level expression of SHG lightMaintain relatively stableSemiconductor laser optical deviceOptical resonator shape and constructionOptoelectronicsWavelength

A modulation light source capable of maintaining thermal stability of a gain part is provided. A modulation light source includes a DBR laser having a DBR part, a phase part and a gain part, a light wavelength conversion device that receives a fundamental wave from the DBR laser and from which an SHG light is emitted, and a control means for controlling the DBR laser. A substantially constant current is supplied to the gain part for a modulation time period of a PWM signal. At least one of the DBR part and the phase part is controlled for modulation using a current based on the PWM signal.

Owner:CANON KK

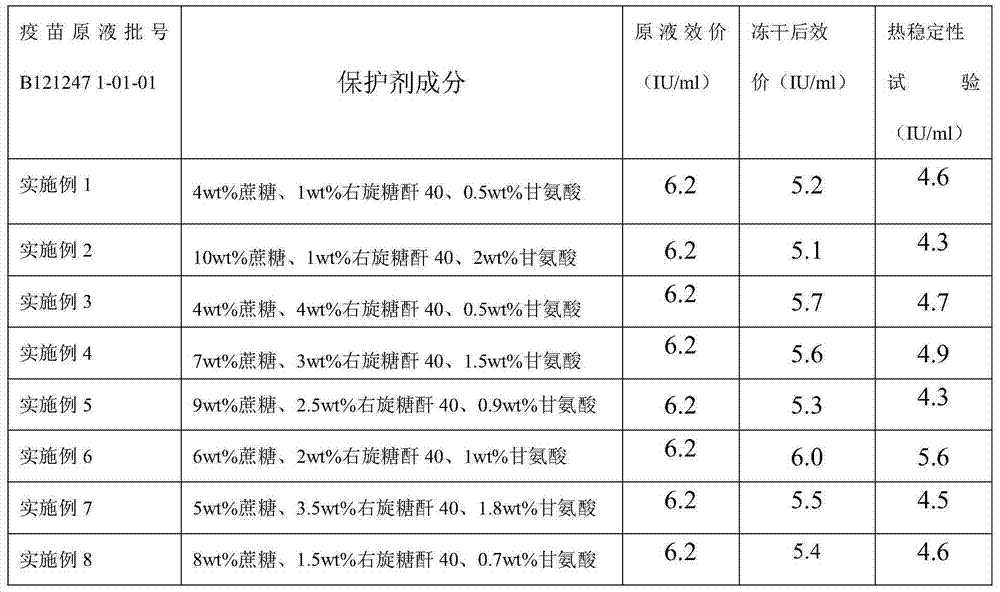

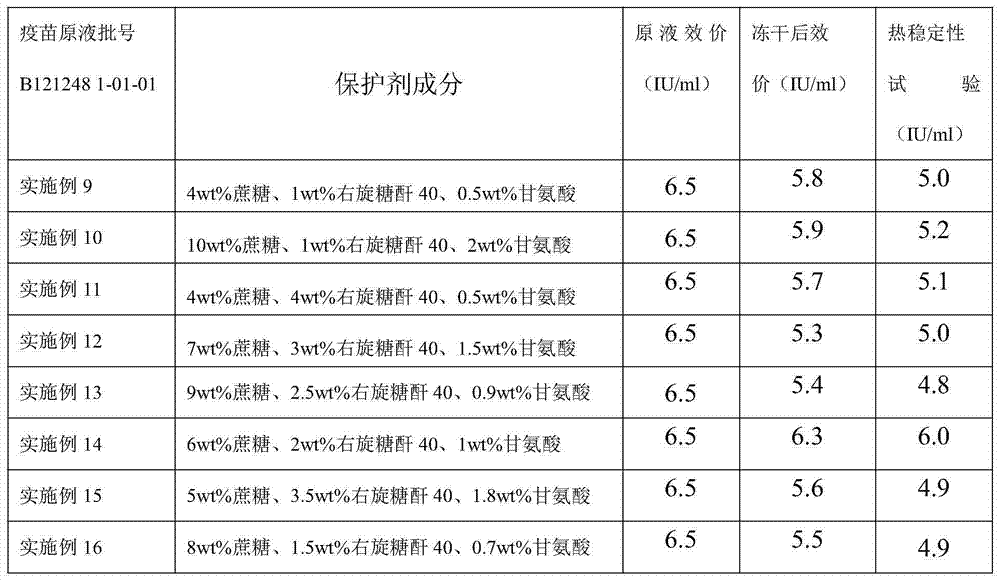

Freeze-dried rabies vaccine for human use and preparation method thereof

The invention discloses a freeze-dried rabies vaccine for human use and a preparation method thereof. The preparation method comprises the following steps: adding cane sugar and dextran 40 into water for injection respectively, stirring to a fully-dissolved state, and performing steam sterilization at the temperature of 115 DEG C under the pressure of 0.09-0.10 MPa for 45 minutes; adding glycine into water for injection of which the temperature is 15-30 DEG C, stirring to a fully-dissolved state, and degerming and filtering with a microfiltration membrane of 0.22 mu m; preparing a dose of which the total protein content does not surpass 80 mu g according to the measured protein content or antigen content of an early vaccine stock solution, and adding cane sugar of which the final concentration is 4-10 percent by weight, dextran 40 of which the final concentration is 1-4 percent by weight and glycine of which the final concentration is 0.5-2 percent by weight to obtain a semi-finished product; performing split charging on the semi-finished product, semi-plugging, putting into a freezer drier box, setting a freeze drying parameter, and performing freeze drying; performing pre-freezing, vacuum pumping, sublimation, secondary drying and vacuum plugging, and ending freeze drying to obtain the freeze-dried rabies vaccine for human use. Active ingredients in the vaccine disclosed by the invention can be well protected, the vaccine is high in thermal stability, and the period of validity can be at least up to 24 months.

Owner:DALIAN HISSEN BIO-PHARM CO LTD

Bismaleimide structural adhesive film with high temperature resistance level as well as preparation method and application thereof

ActiveCN109749641AIncreased shear strengthHigh temperature resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemistryInorganic nanoparticles

The invention relates to a bismaleimide structural adhesive film with a high temperature resistance level as well as a preparation method and application thereof, and relates to a structural adhesivefilm. The structural adhesive film solves the problem that the conventional bismaleimide structural adhesive film is low in basic intensity or low in temperature resistance level. The structural adhesive film is prepared from a bismaleimide monomer composition, an allyl phenoxyl compound monomer modifier, a high-polymer material flexibilizer, an inorganic nanometer particle thixotropic agent and acarrier. The method comprises the following steps: melting phthalazinone structural thermoplastic resin into a modifier in a hot melting manner, then performing hot melting blending on the bismaleimide monomer composition, active end group liquid rubber and the resin, feeding the thixotropic agent into a resin system, and uniformly mixing, so as to form a sizing material, and compounding the sizing material with the carrier, so as to obtain the structural adhesive film. The normal temperature shear strength of the adhesive film can reach 20.2 MPa, 316 DEG C shear strength can still reach 10.8MPa, and the honeycomb cylinder peel strength reaches 95.0 N.m / m. The adhesive film is applied to cementing of aerospace refractory metal or composite material structural pieces.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

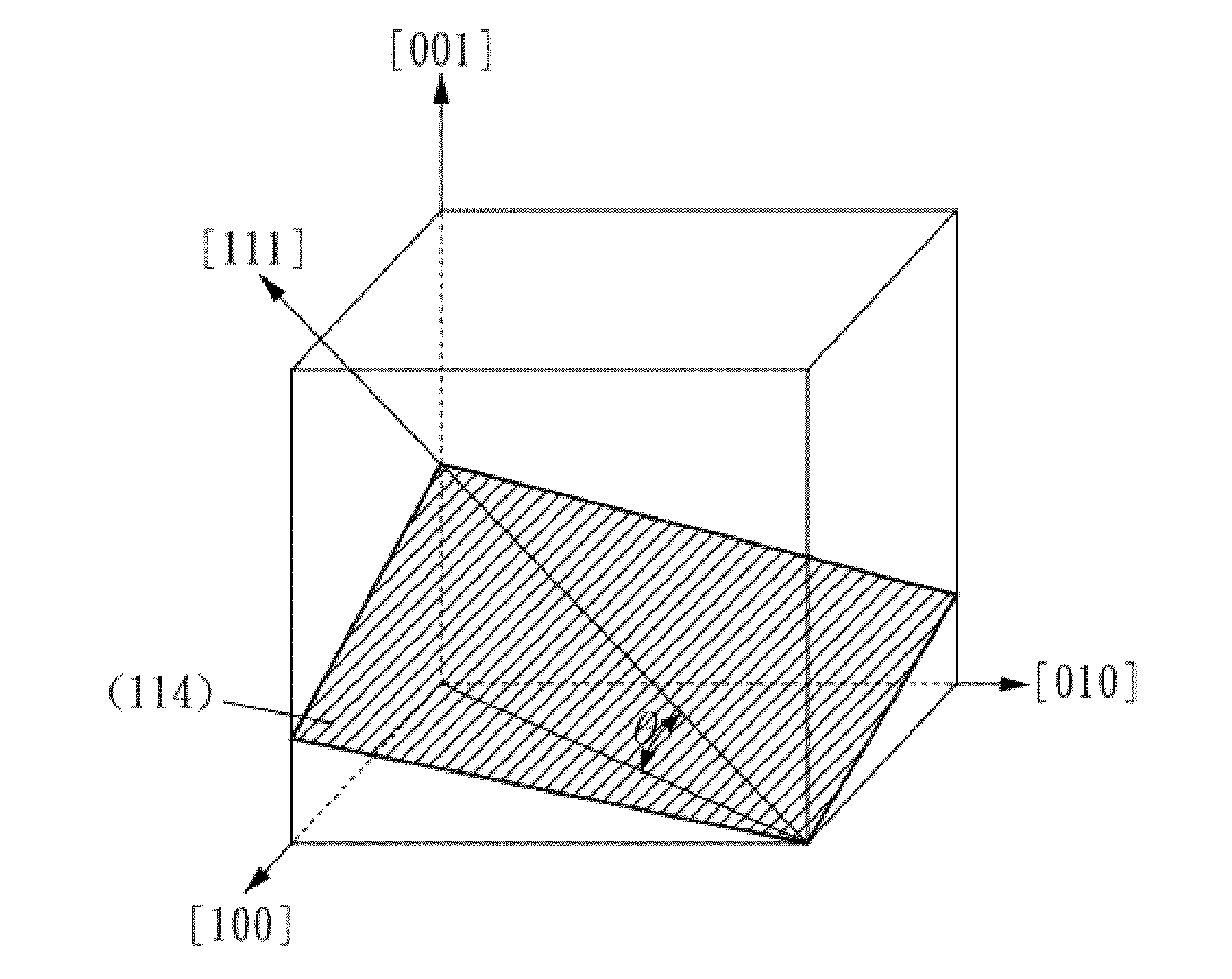

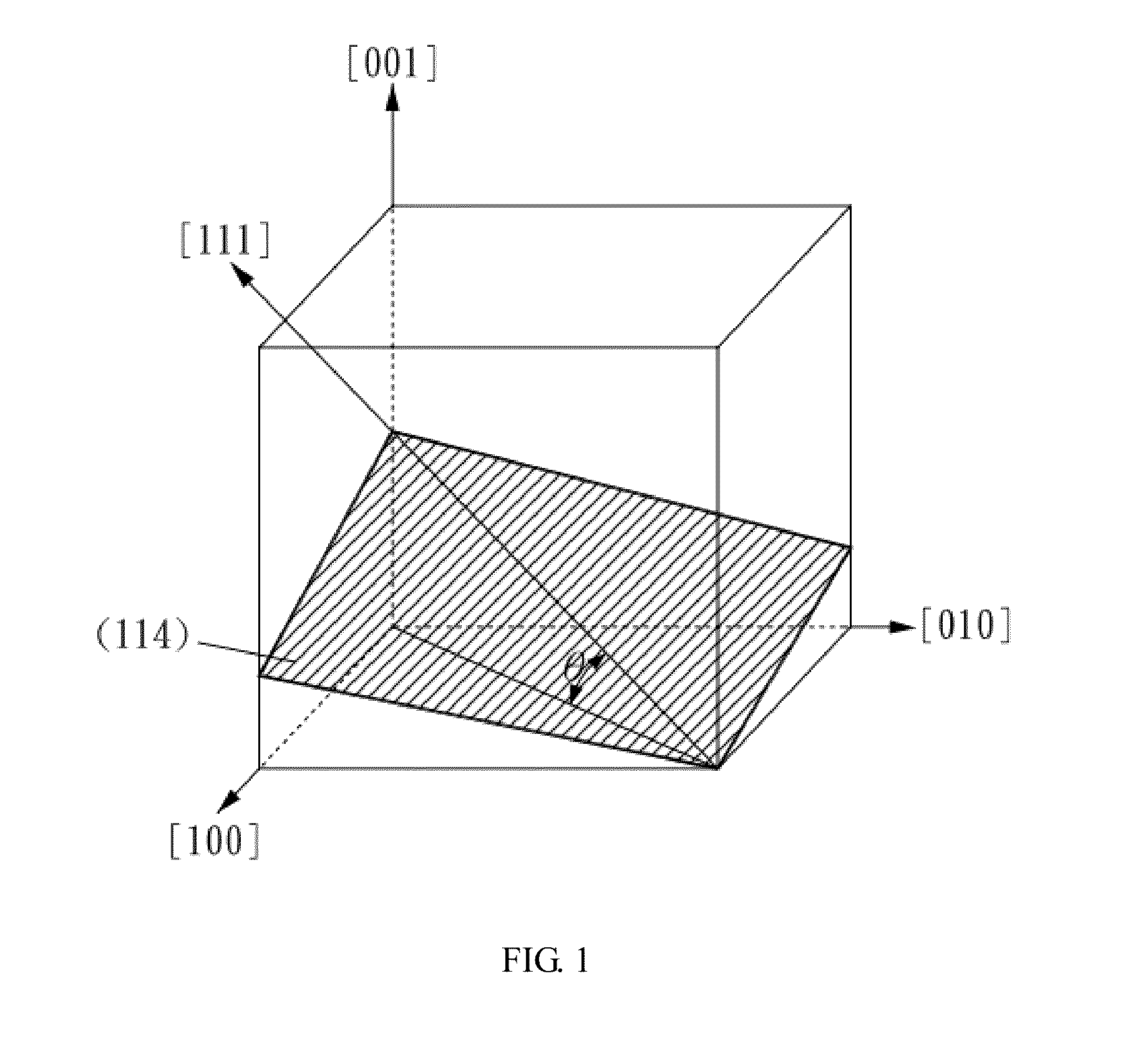

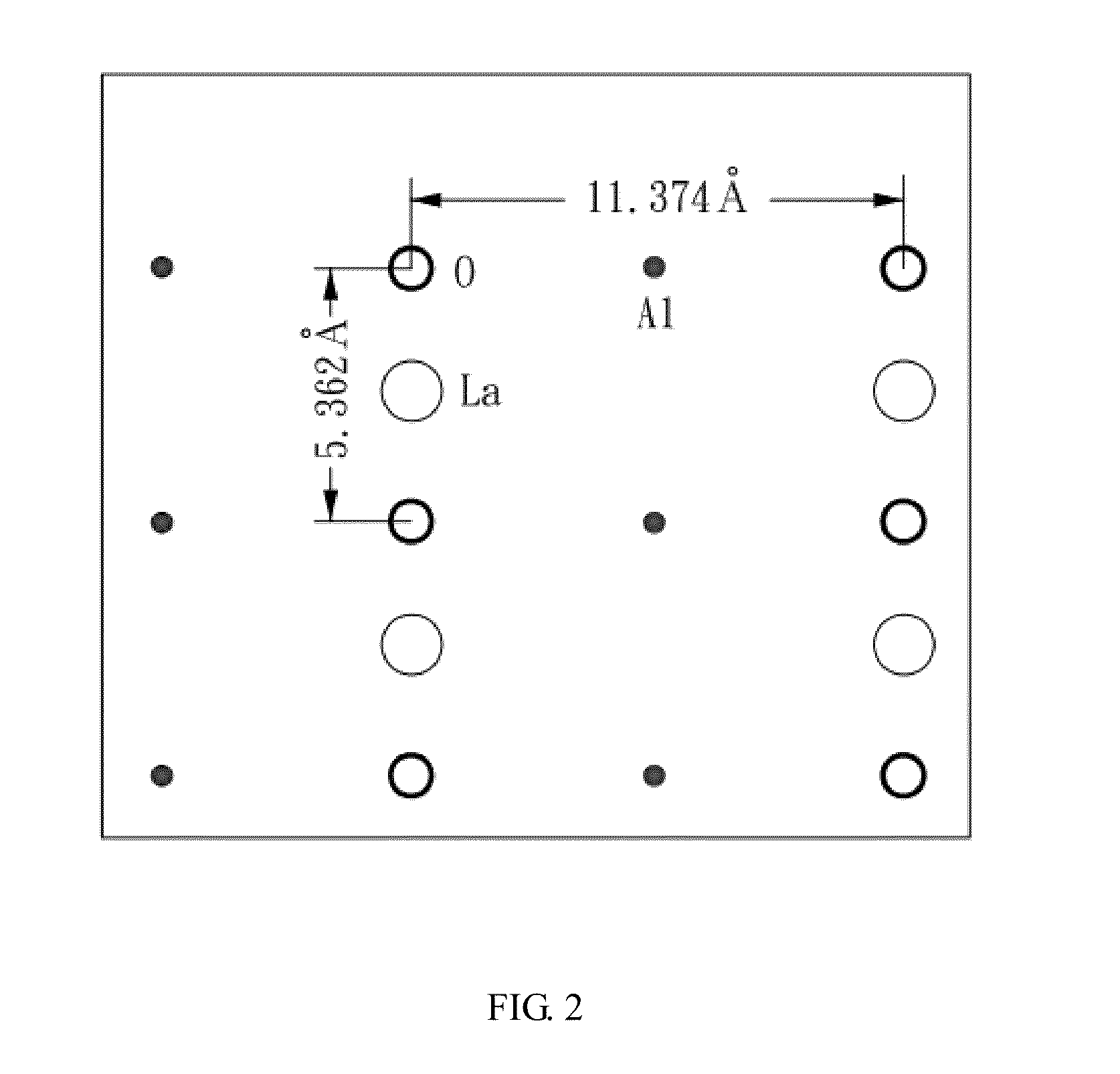

Non-polar plane of wurtzite structure material

ActiveUS20130240876A1Good optical performanceMaintain thermal stabilityPolycrystalline material growthVacuum evaporation coatingGas phaseSingle crystal

The present invention relates to a method for growing a novel non-polar (13 40) plane epitaxy layer of wurtzite structure, which comprises the following steps: providing a single crystal oxide with perovskite structure; using a plane of the single crystal oxide as a substrate; and forming a non-polar (13 40) plane epitaxy layer of wurtzite semiconductors on the plane of the single crystal oxide by a vapor deposition process. The present invention also provides an epitaxy layer having non-polar (13 40) plane obtained according to the aforementioned method.

Owner:NAT CHIAO TUNG UNIV

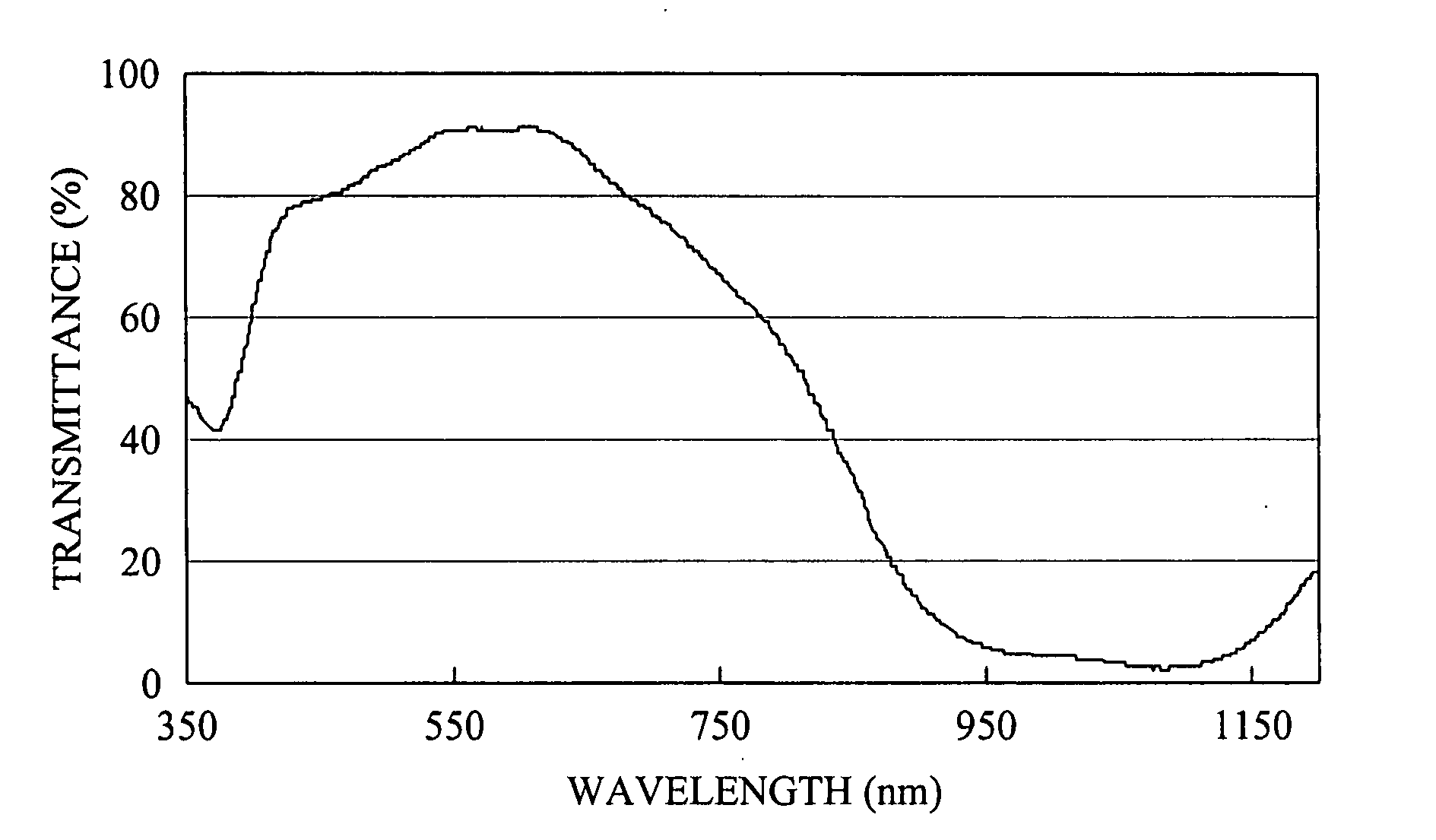

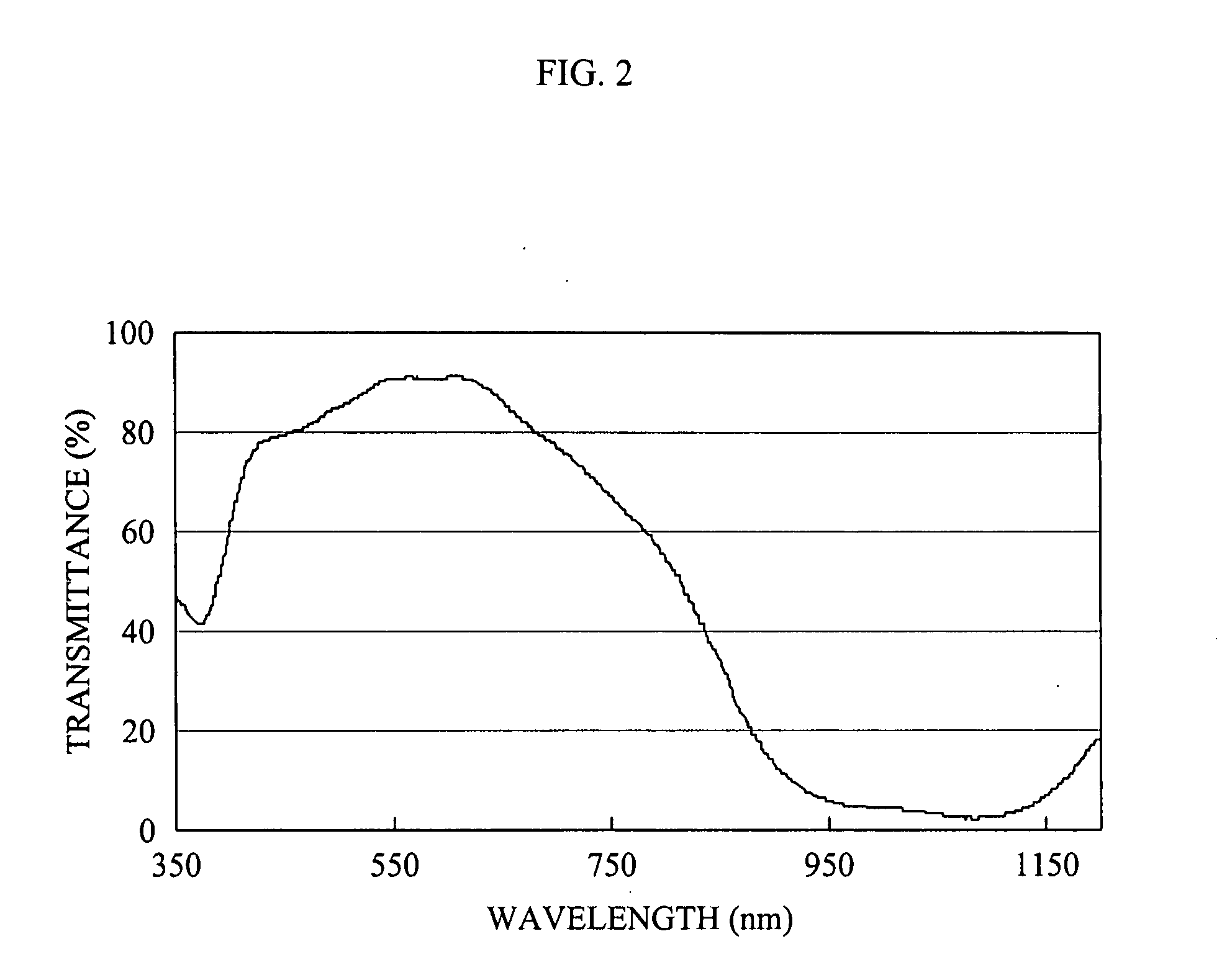

Functional film composition for display

InactiveUS20080048156A1Excellent electromagnetic wave shielding functionFunction increaseSpectral modifiersOptical elementsDisplay deviceEngineering plastic

Disclosed is a functional film composition for a display which comprises an engineering plastic resin, a first pigment absorbing a near-infrared ray; and a second pigment selectively absorbing a wavelength and maintaining thermal stability at a temperature of about 200 through 300° C., thereby exhibiting an excellent electromagnetic wave shielding function in a range of 550 to 610 nm which emits orange light in addition to in a range of 900 to 1200 nm of a near infrared ray, exhibiting a relatively good thermal resistance, moisture resistance, and light resistance in comparison with a conventional transparent plastic film, and exhibiting superior color purity and brightness, so that it can be applied to a PDP filter pursuing good quality, cost reduction, composition of each function, and simplification of structure, and particularly applied to display devices, such as an LCD, an OLED, a flexible display, and the like, pursuing improved optical properties.

Owner:SAMSUNG CORNING CO LTD

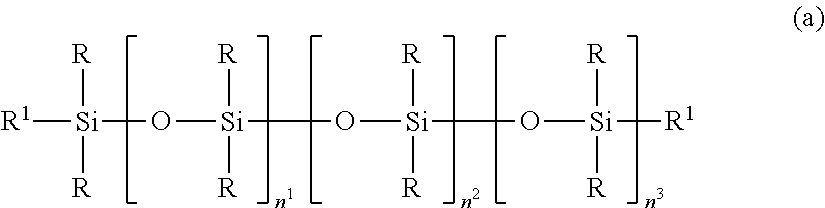

Silicone-modified epoxy resin composition and semiconductor device

ActiveUS20180334567A1Maintain thermal stabilityMaintaining temperature/humidity resistanceSemiconductor/solid-state device detailsSemiconductor devicesDevice materialCyanate compound

The invention provides a resin composition comprising a specific silicone-modified epoxy resin, a specific silicone-modified phenolic resin, black pigment, and an inorganic filler. The invention also provides a resin composition comprising a specific cyanate ester compound, a specific silicone-modified epoxy resin, and a specific phenol compound and / or silicone-modified phenolic resin.

Owner:SHIN ETSU CHEM IND CO LTD

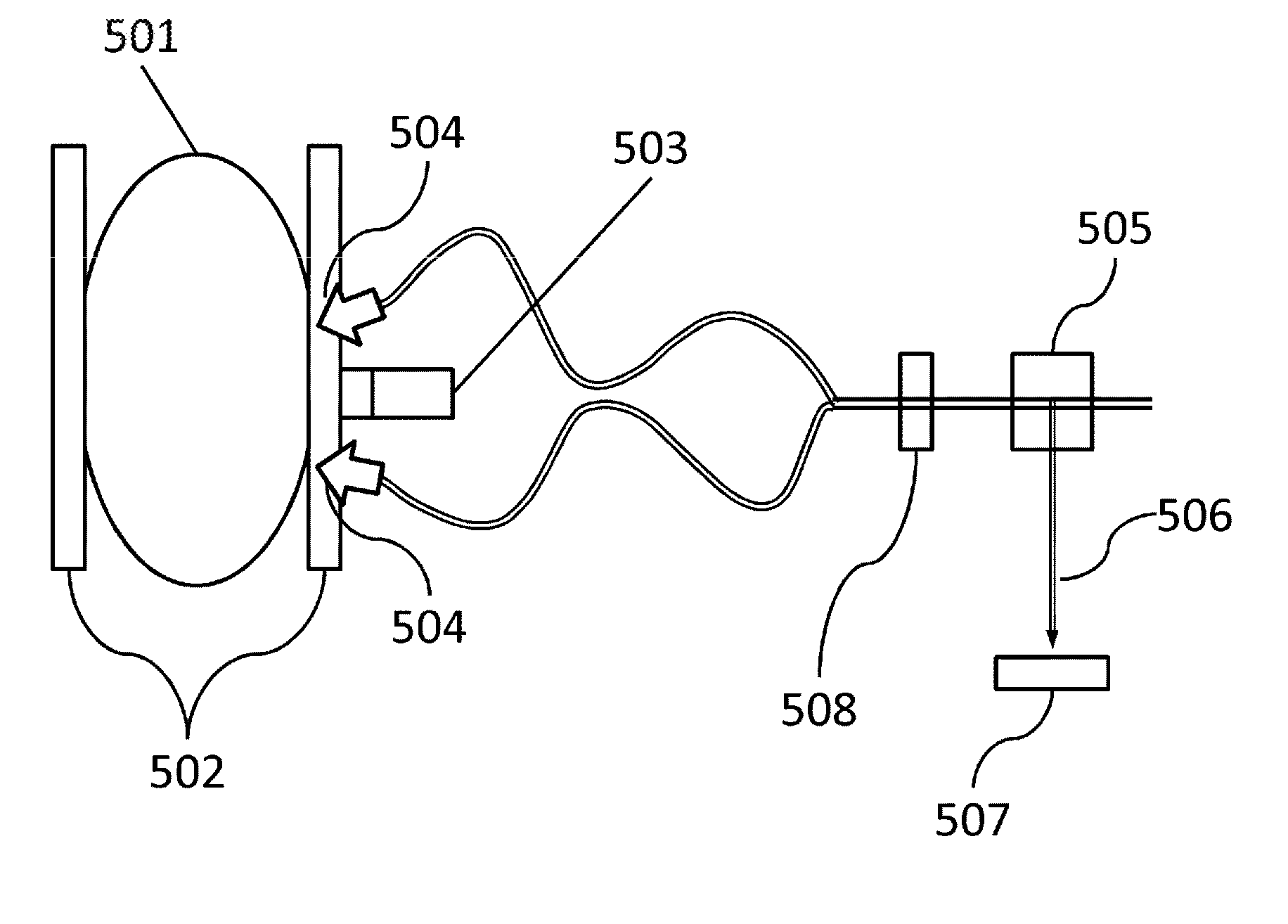

Object information acquiring apparatus and laser apparatus

InactiveUS20150018663A1Stable laser outputMaintain thermal stabilityLaser detailsDiagnostic recording/measuringPhysicsFlash-lamp

An object information acquiring apparatus has: a resonator including at least a laser medium, a flash lamp that excites the laser medium, and an output mirror that outputs laser light; an oscillator that oscillates the laser light; a controller that controls a timing at which the oscillator oscillates the laser light after excitation performed by the flash lamp is started; a selector that selects a wavelength of the laser light; a probe that detects an acoustic wave generated in an object; and a processor that acquires characteristic information on the object, wherein the controller determines the timing, at which the laser light is oscillated, for each of the wavelengths in such a manner that a difference in output energy of the laser light falls within a predetermined range.

Owner:CANON KK

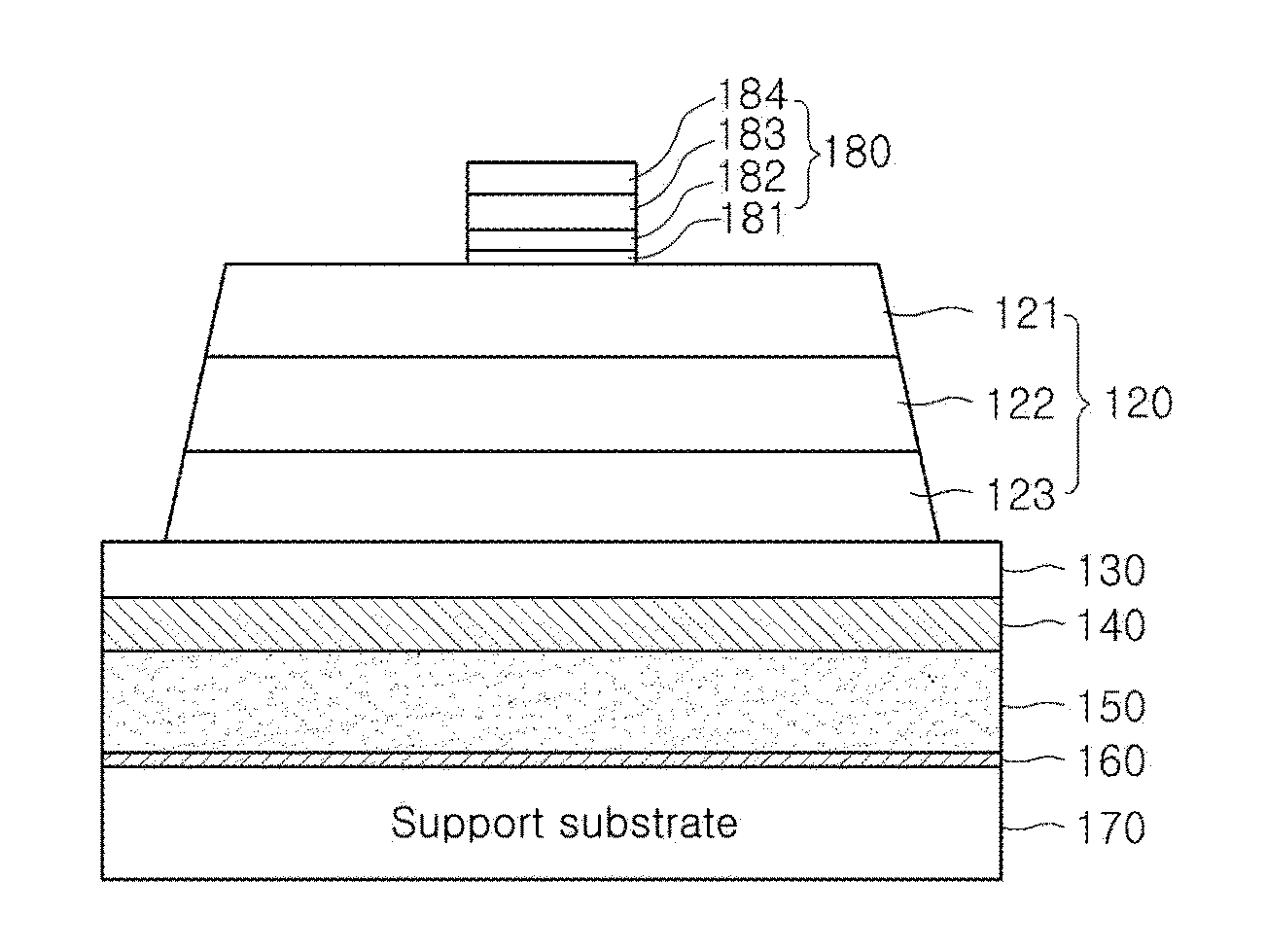

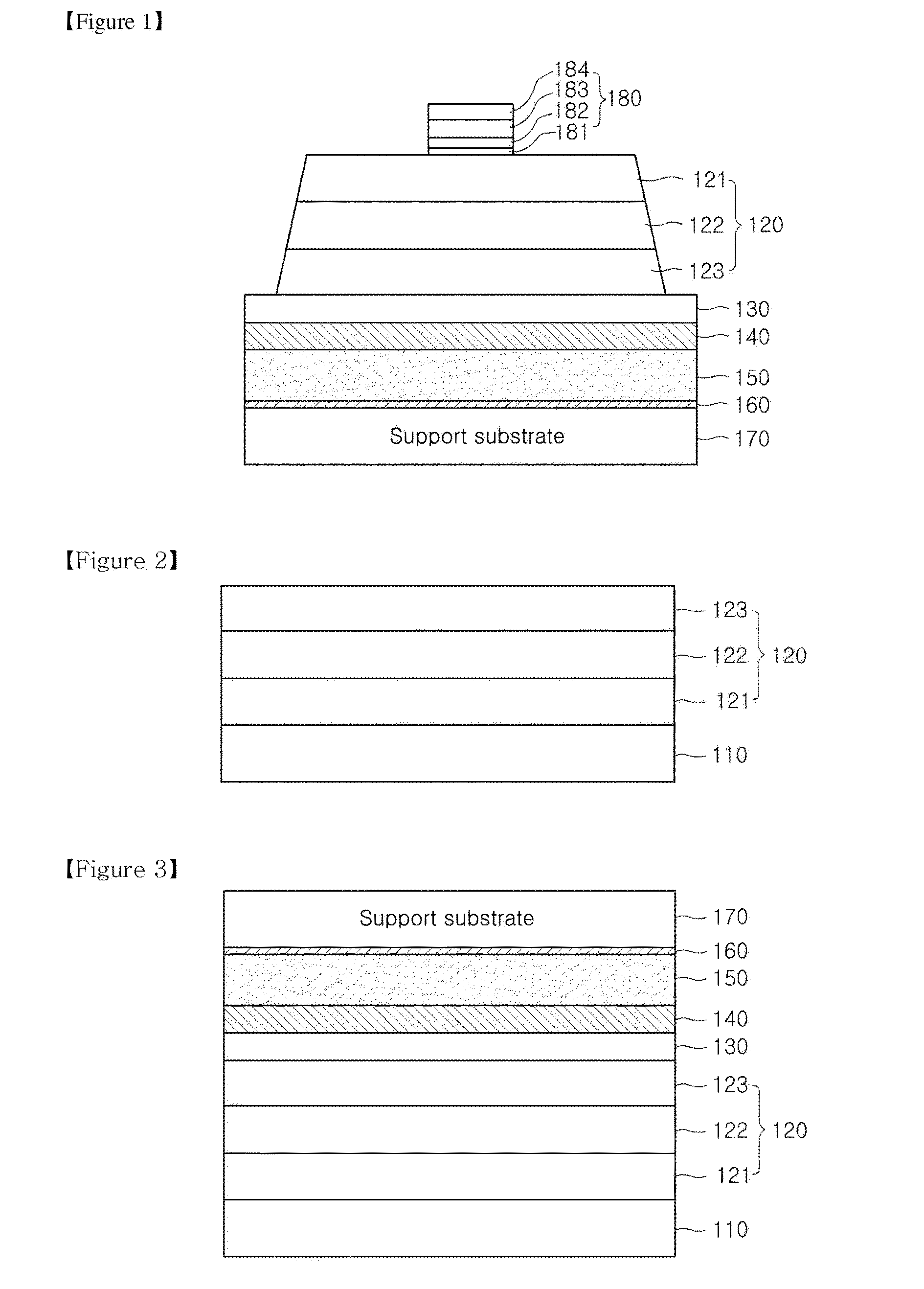

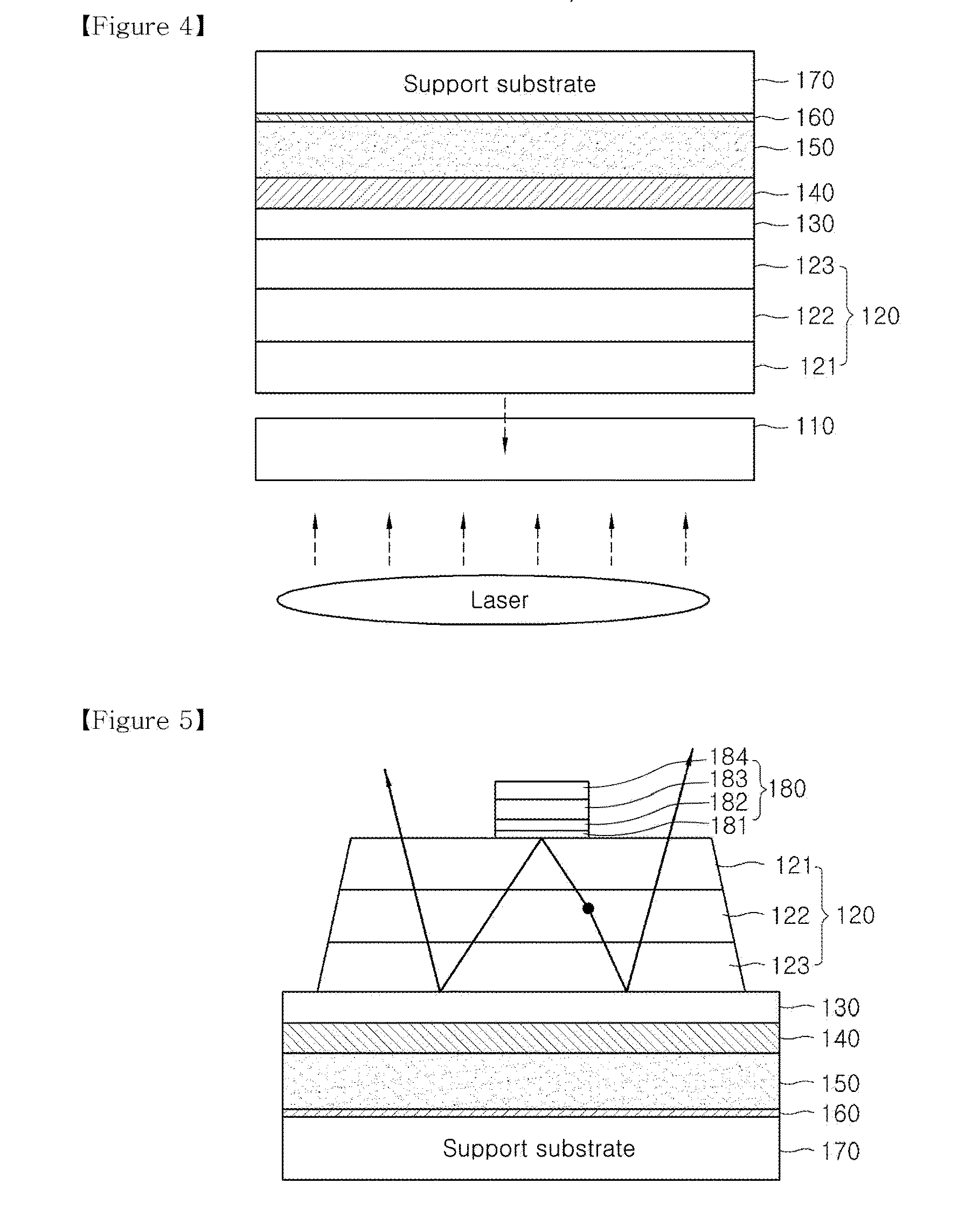

Semiconductor light emitting diode having ohmic electrode structure and method of manufacturing the same

ActiveUS20130221324A1Reduce deteriorationMaintain thermal stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesContact layerProtection layer

Embodiments of the invention provide a semiconductor light emitting diode having an ohmic electrode structure, and a method of manufacturing the same. The semiconductor light emitting diode includes a light emitting structure having an upper surface constituting an N-face; and an ohmic electrode structure located on the light emitting structure. Here, the ohmic electrode structure includes a lower diffusion preventing layer, a contact layer, an upper diffusion preventing layer, and an Al protective layer from the N-face of the light emitting structure.

Owner:SEOUL VIOSYS CO LTD +1

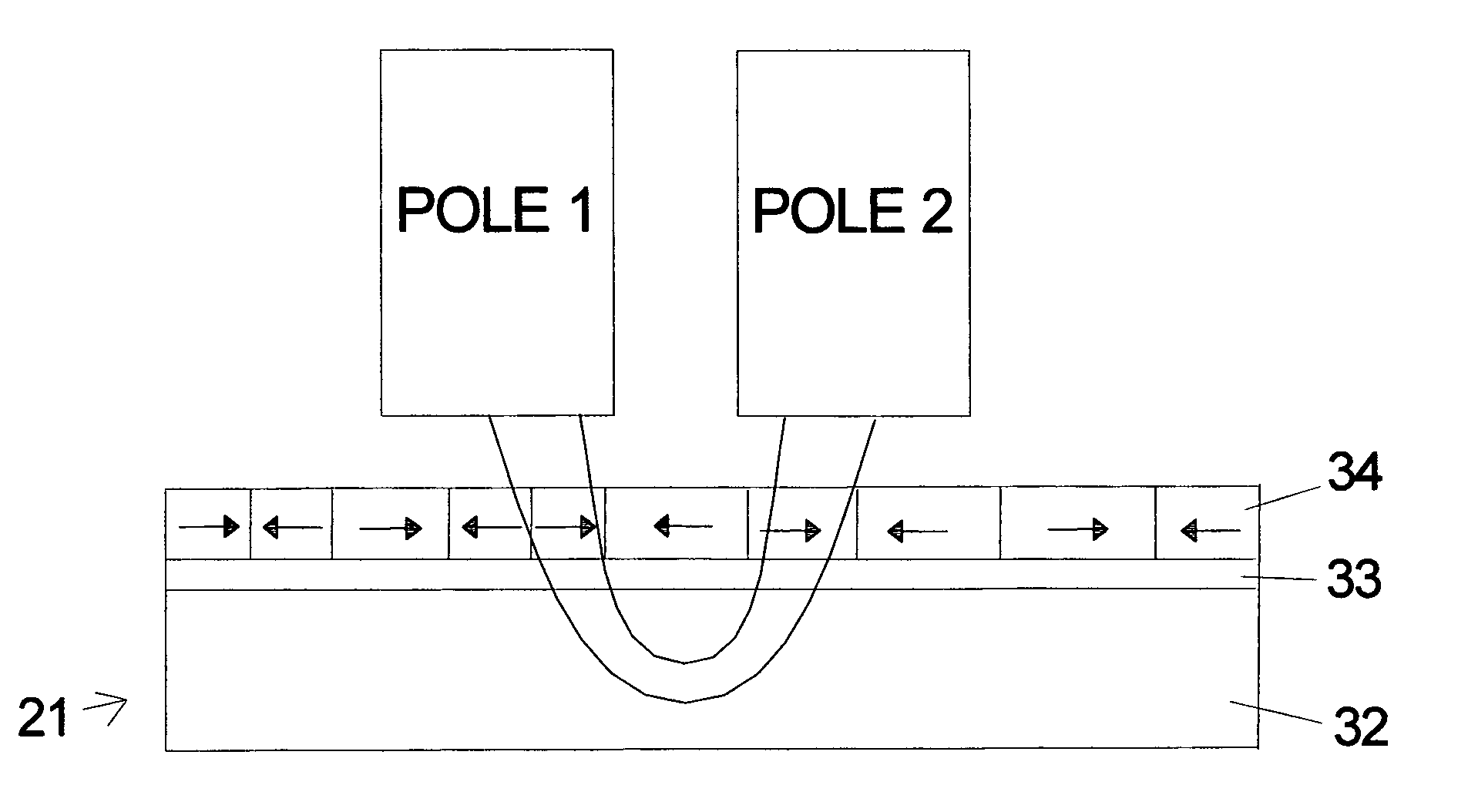

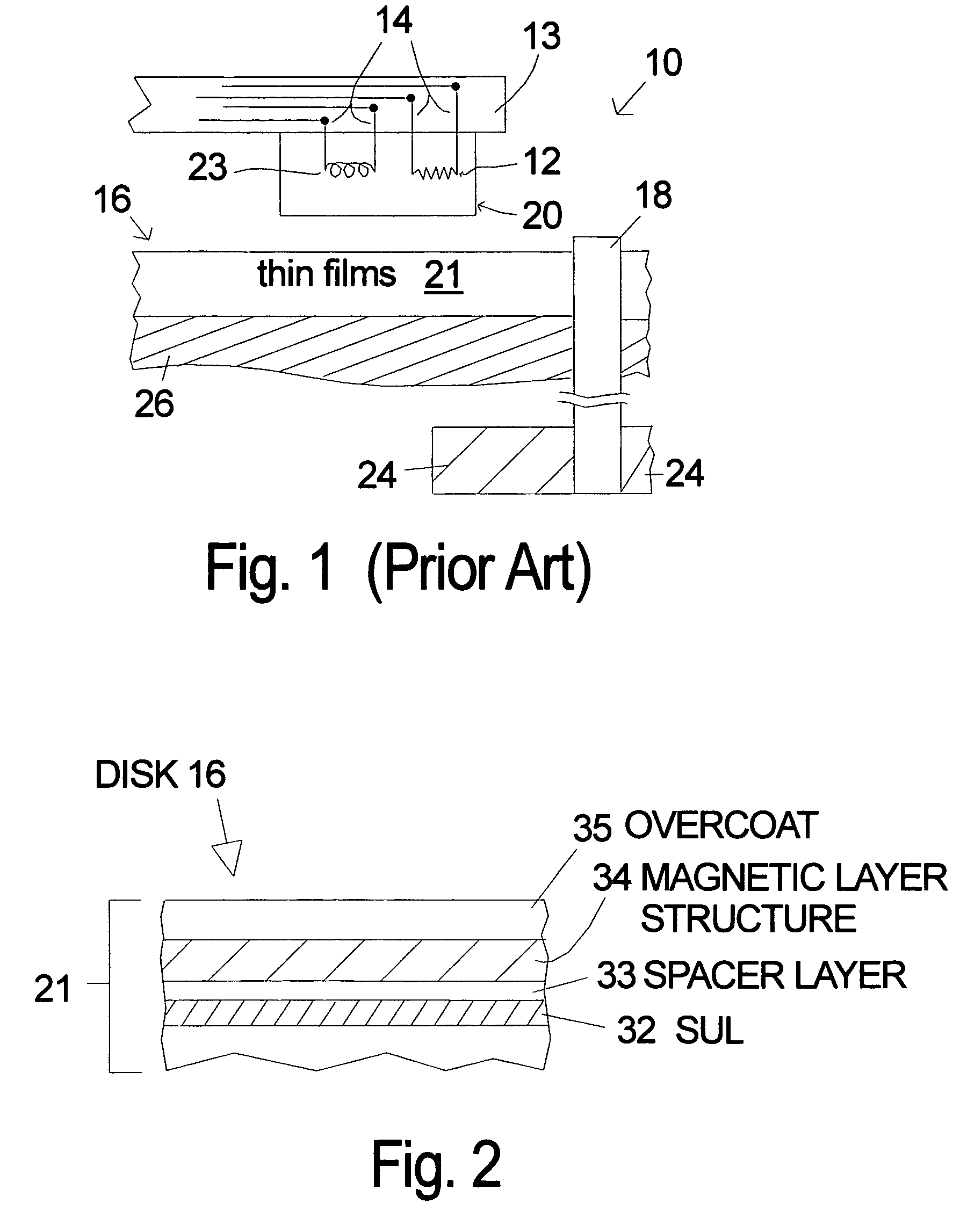

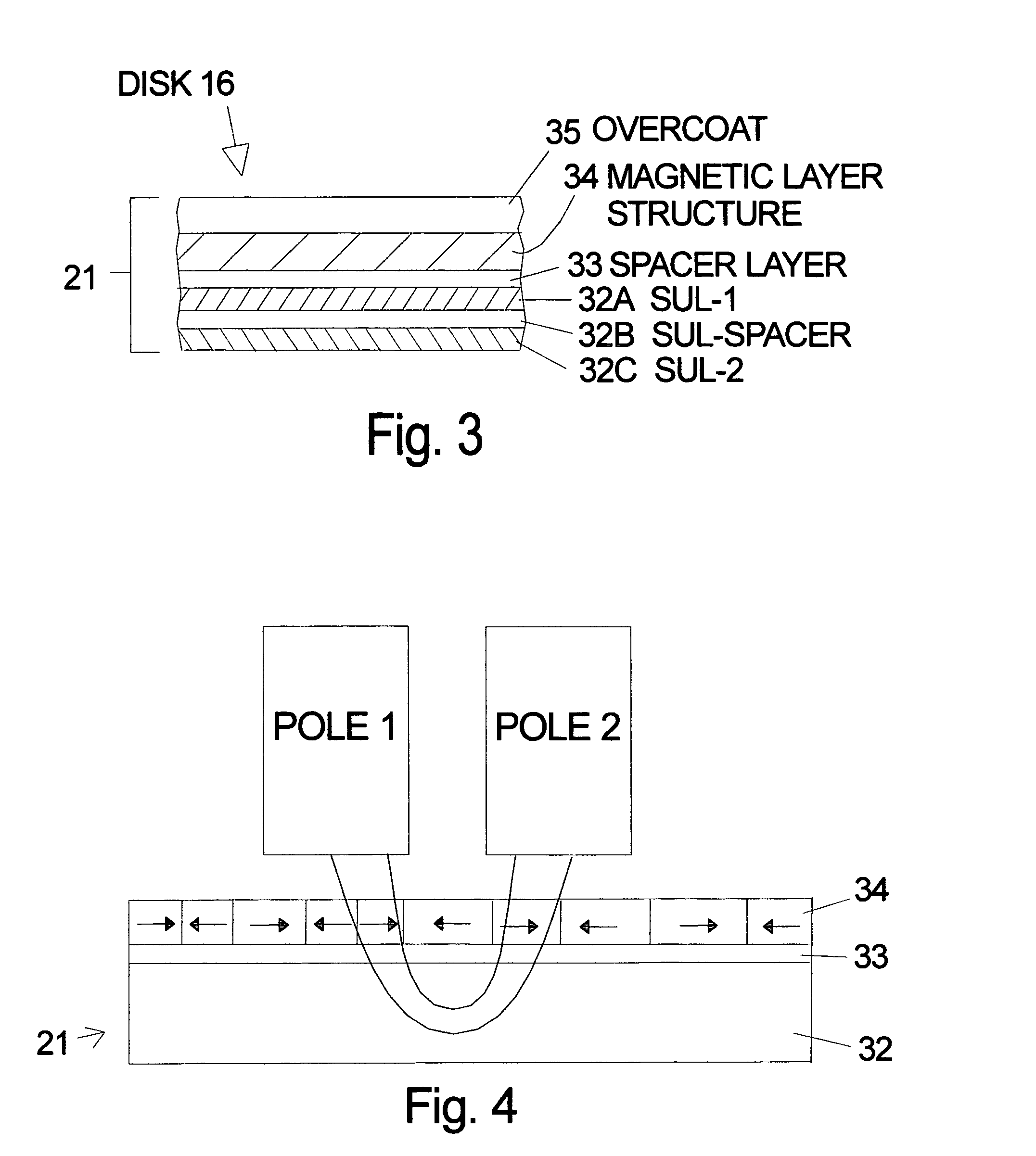

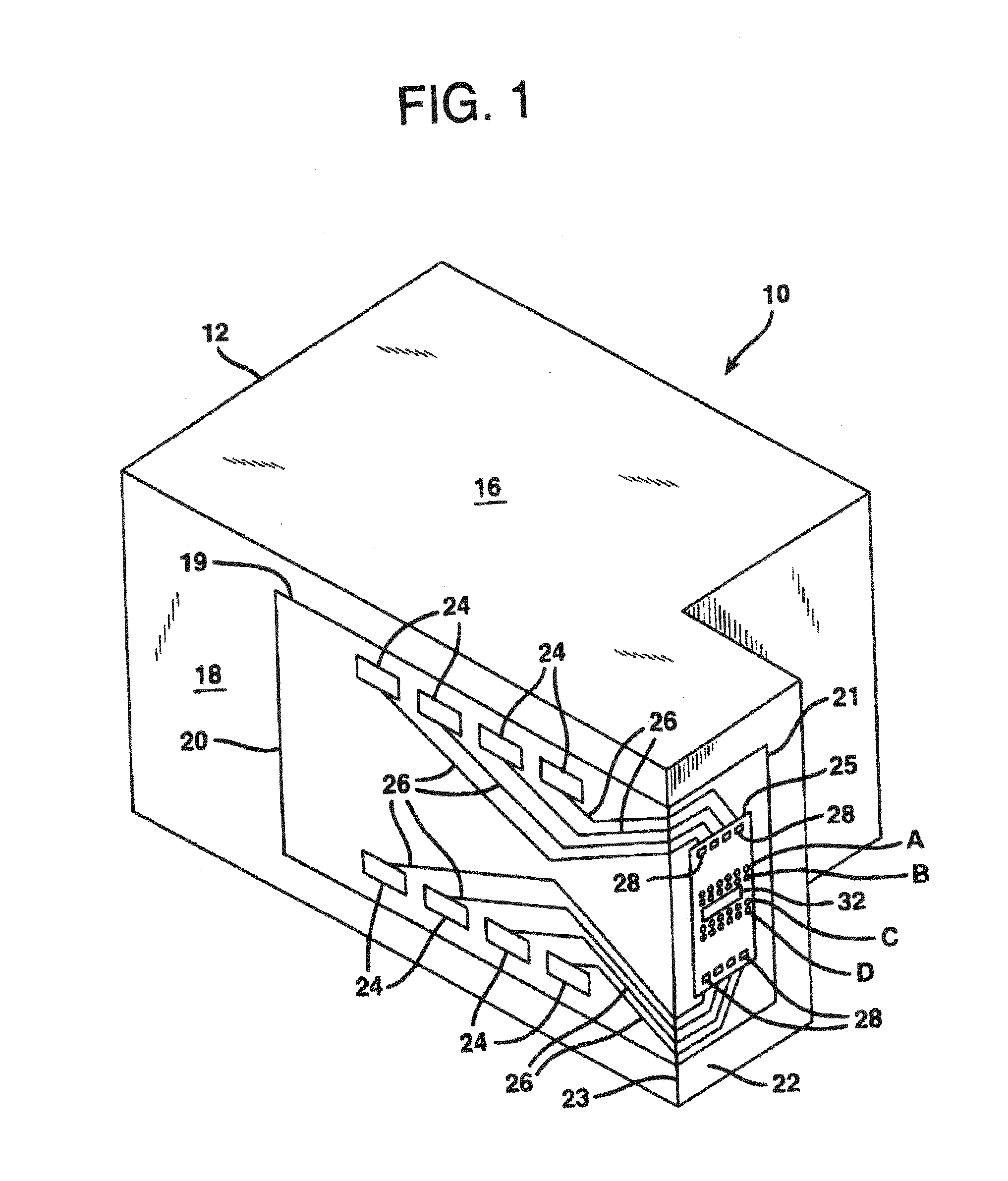

Longitudinal magnetic recording using magnetic media with a soft underlayer

InactiveUS7092209B2Increase vertical componentDynamic coercivityOrnamental textile articlesBase layers for recording layersAntiferromagnetic couplingMagnetic media

A method of longitudinal recording using a medium with a magnetically soft underlayer is described. The method includes lowering the longitudinal coercivity in a magnetic domain in the magnetic recording medium by generating a vertical component of magnetic flux in the magnetic recording medium and writing a longitudinal orientation in the magnetic domain in the magnetic recording medium by generating a larger horizontal component of magnetic flux in the magnetic recording medium using the write head. Optionally the method further includes magnetically saturating the magnetically soft underlayer after lowering the longitudinal coercivity to limit the vertical component of the magnetic flux. The recording medium has a magnetic recording layer, a spacer layer and a soft underlayer. In one embodiment the soft underlayer is an antiferromagnetically coupled magnetic layer stack with two soft magnetic layers separated by a non-magnetic spacer layer selected to achieve the antiferromagnetic coupling.

Owner:HITACHI GLOBAL STORAGE TECH NETEHRLANDS

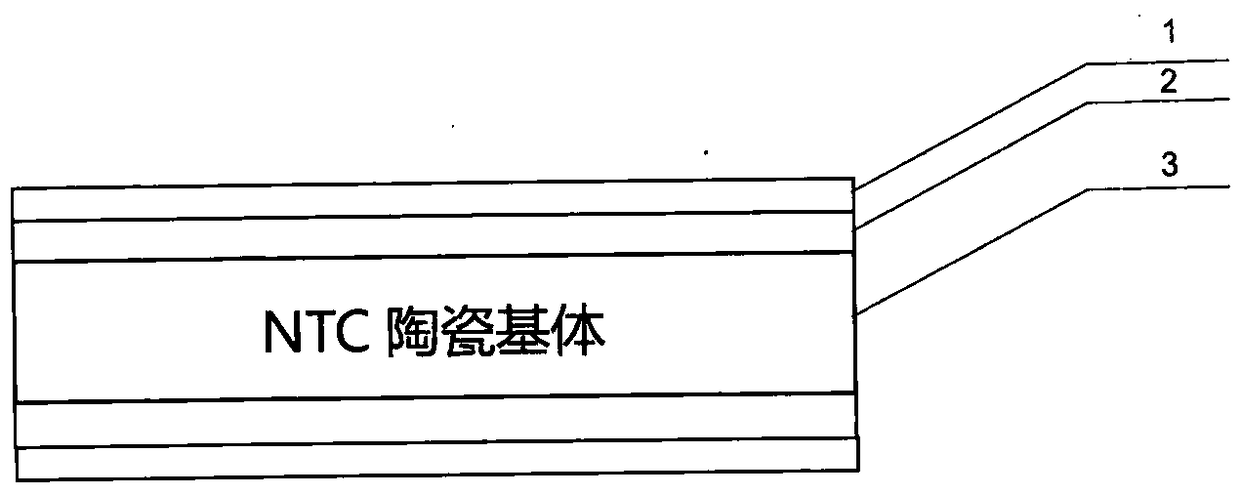

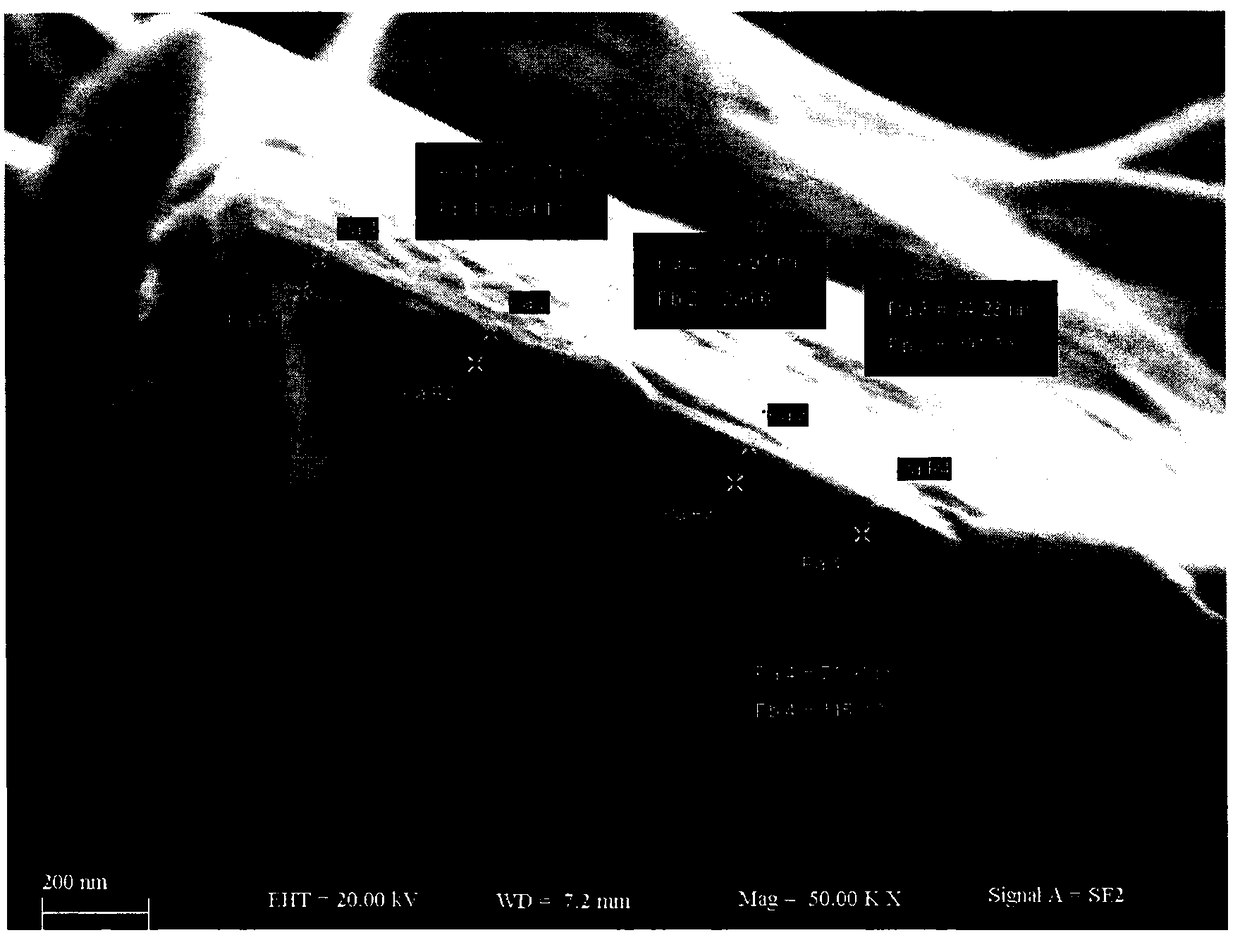

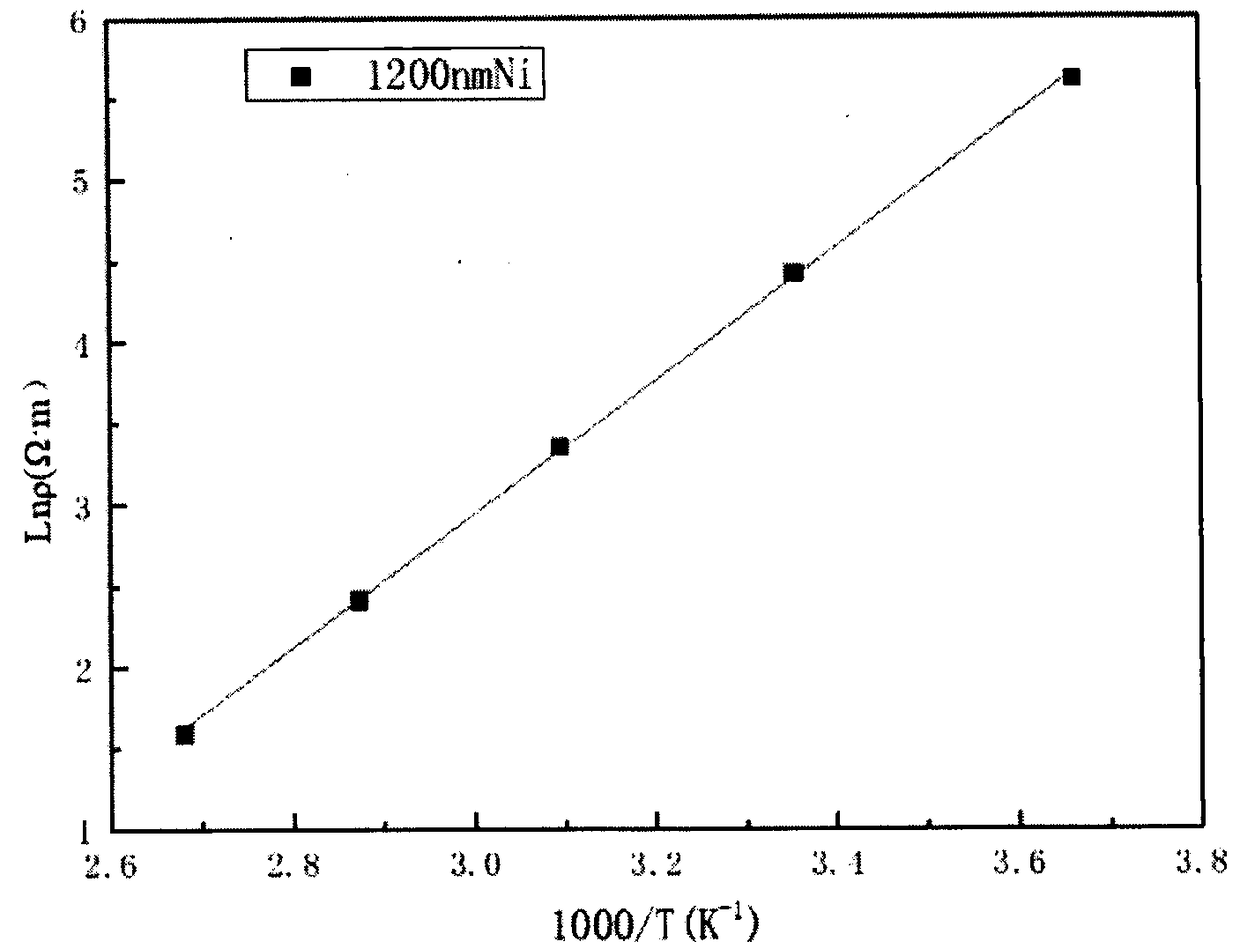

Method for preparing ohmic contact electrode of P-type negative temperature coefficient ceramic material

InactiveCN109461556AMaintain flatness and thermal stabilitySolving Penetration ProblemsNegative temperature coefficient thermistorsResistors adapted for applying terminalsOhmSolderability

The invention relates to a method for preparing an ohmic contact electrode of a P-type negative temperature coefficient ceramic material. The method comprises the following steps: using the DC magnetron sputtering technology and using the existing quaternary cobalt-manganese-iron-zinc P-type negative temperature coefficient ceramic material as a ceramic matrix, firstly evaporating the first layerof 35nm-1200nm Pd or Ni on the surface of the ceramic substrate to serve as a transition layer, then evaporating a layer of 400 nm Ag to serve as a welding layer, and then rapidly annealing at a temperature of 400-800 DEG C to obtain an electrode having good ohmic contact. The test results show that the electrode has good ohmic contact, firm adhesive force, good solderability and stability. According to the method, the metal with a higher work function is used as the transition layer to lower the contact resistance of the metal and the ceramic body, and the transition layer also solves the problem of silver penetration in a P-type negative temperature coefficient ceramic sintered silver electrode.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

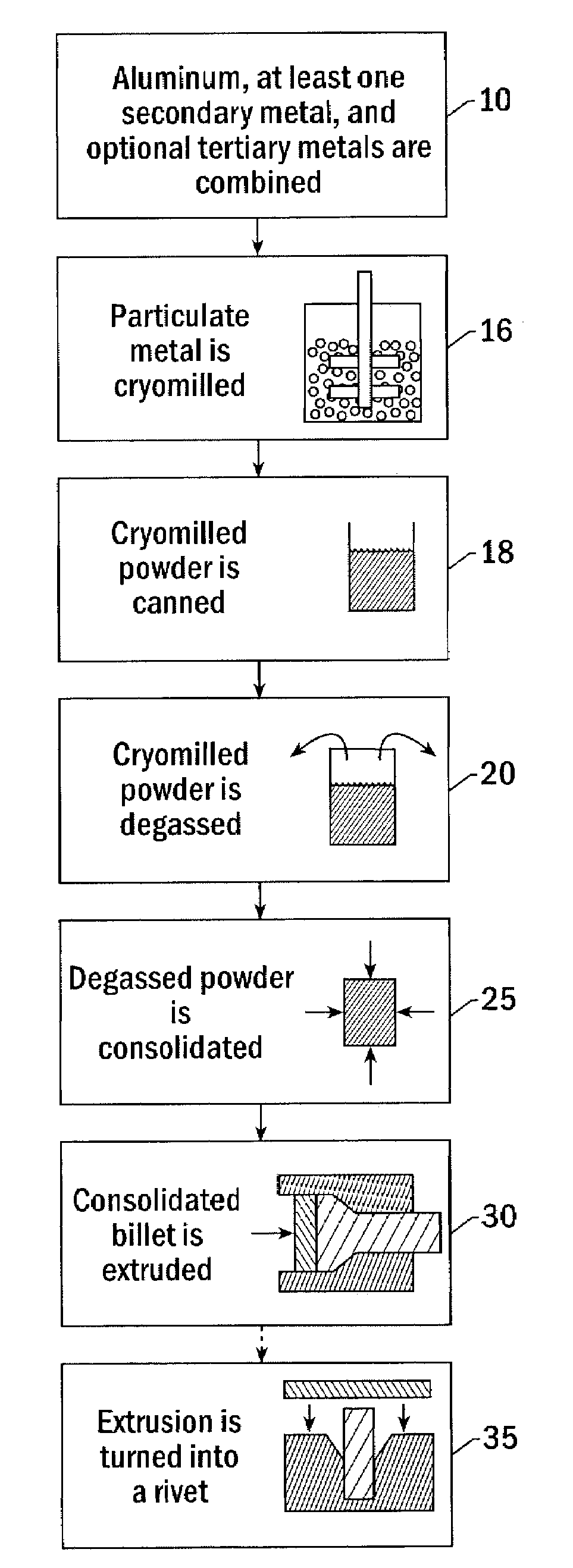

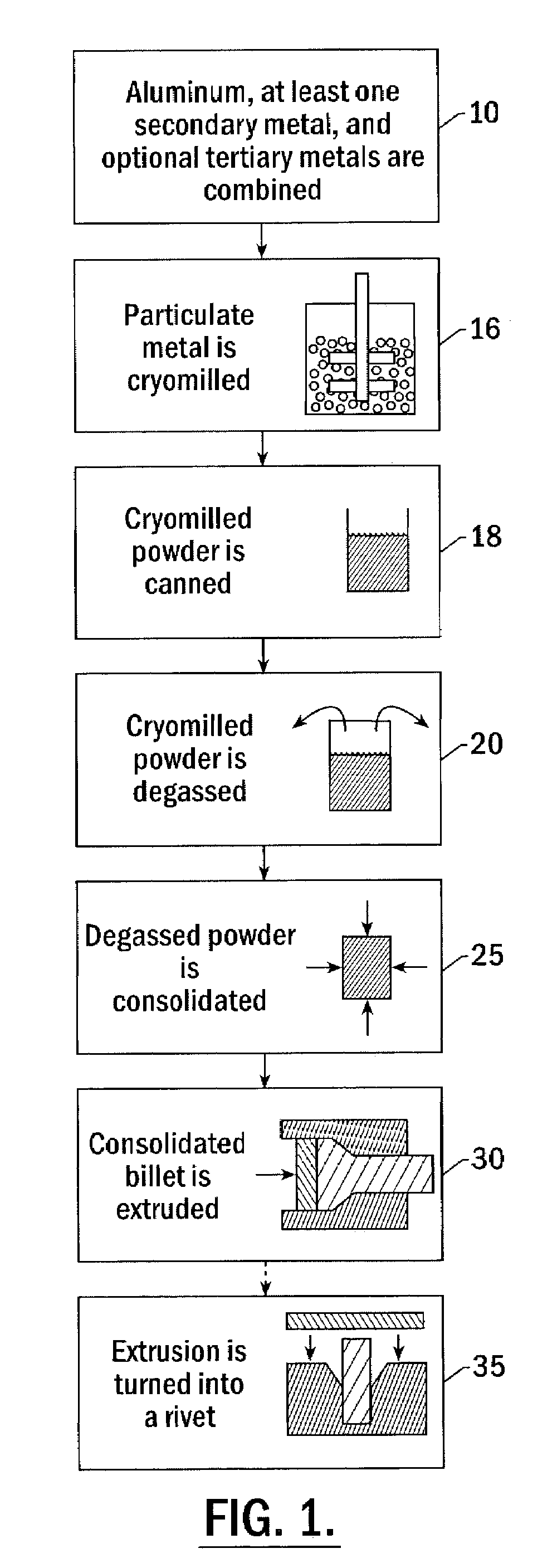

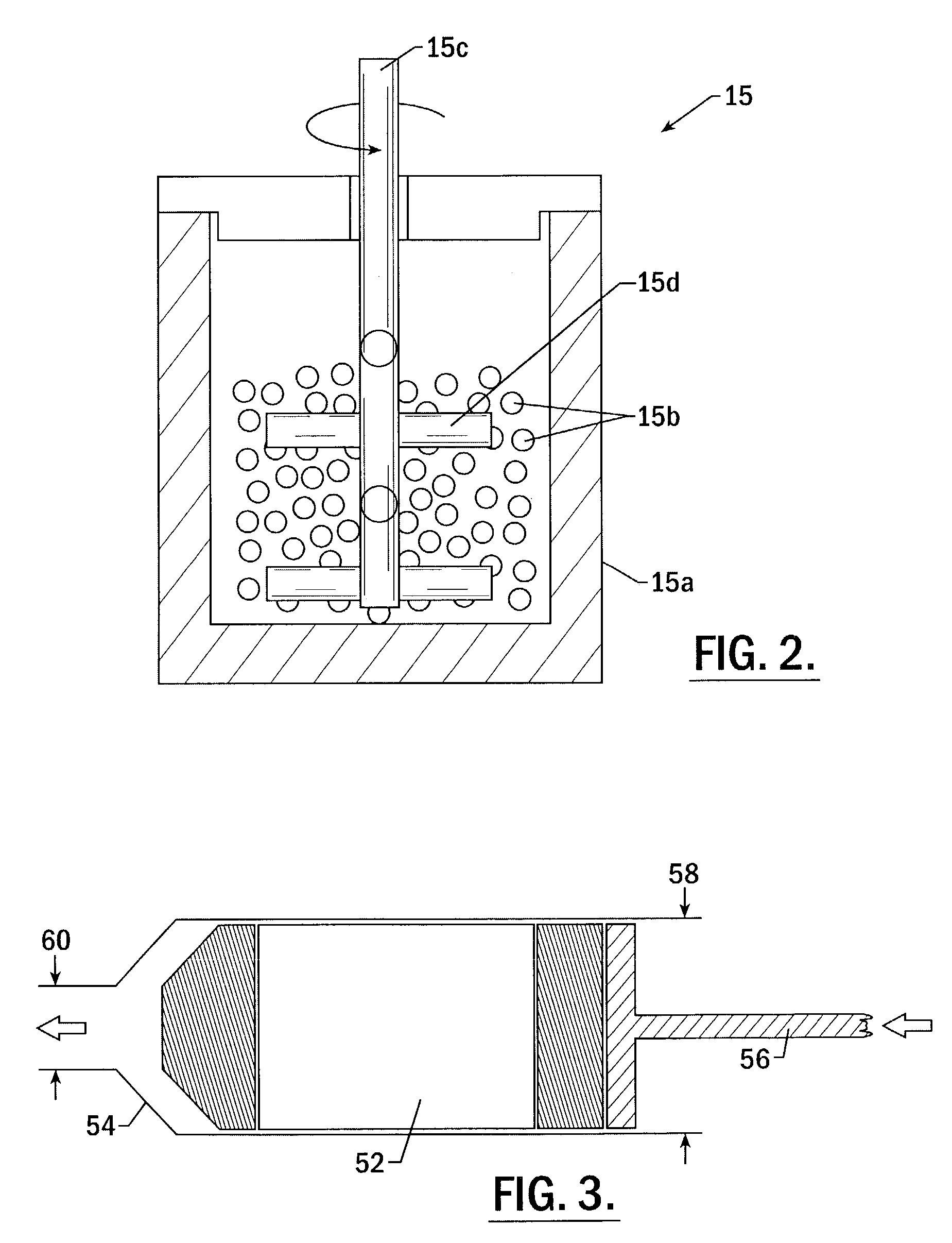

Method for preparing rivets from cryomilled aluminum alloys and rivets produced thereby

InactiveUS7435306B2Contribute to strengthContribute to resistance to strain localizationRivetsTransportation and packagingAtmospheric temperatureStress corrosion cracking

High strength aluminum alloy rivets are provided in which the aluminum alloys exhibit high strength at atmospheric temperatures and maintain high strength and ductility at extremely low temperatures. The rivets are produced from an alloy which is made by blending about 89 atomic % to 99 atomic % aluminum, 1 atomic % to 11 atomic % of a secondary metal selected from the group consisting of magnesium, lithium, silicon, titanium, zirconium, and combinations thereof, and up to about 10 atomic % of a tertiary metal selected from the group consisting of Be, Ca, Sr, Ba, Ra, Sc, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Y, Nb, Mo, Tc, Ru, Rh, Pd, Ag, Cd, W, and combinations thereof. The alloy is produced by nanostructure material synthesis, such as cryomilling, in the absence of extrinsically added refractory dispersoids. The synthesized alloy is then consolidated and formed into a solid or blind rivet. Grain size within the rivet is less than 0.5 μm, and the rivet has exceptional thermal stability, resistance to strain localization cracking during rivet head upsetting, and resistance to stress corrosion cracking during service.

Owner:THE BOEING CO

Optical glass and use thereof

ActiveUS9550698B2Increase temperatureInhibit increased colorationGlass pressing apparatusGlass press-moulding apparatusRefractive indexOptical glass

An aspect of the present invention relates to optical glass, which is oxide glass including cation components in the form of 10 to 40 cation % of P5+, equal to or more than 50 cation % of a combined quantity of Ti4+, Nb5+, W6+, Bi3+, and Te4+, with a cation ratio of a combined content of Ti4+ and Nb5+ to a combined content of W6+ and Bi3+ being equal to or less than 1.3, a combined quantity of B3+, Li+, Na+, K+, Rb+, Cs+, Mg2+, Ca2+, Sr2+, Ba2+, and Zn2+ which amounts to equal to or less than ⅓ of a combined content of Ti4+, Nb5+, W6+, Bi3+, and Te4+, and more than 0 % of Li+, Na+, K+, Rb+, and Cs+ combined, and which has a refractive index of equal to or higher than 2.02.

Owner:HOYA CORP

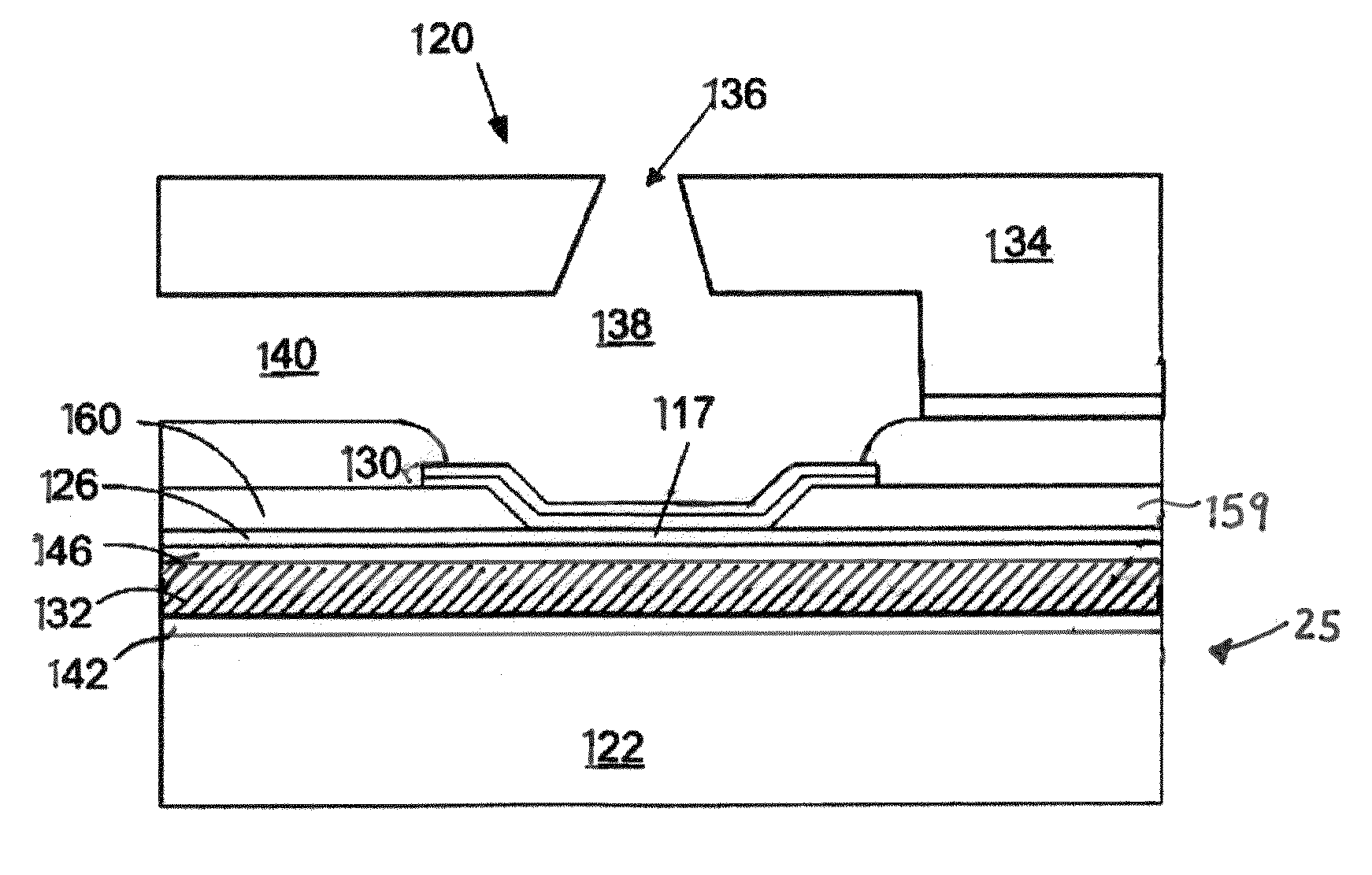

Capping Layer for Insulator in Micro-Fluid Ejection Heads

InactiveUS20110261115A1Improve adhesionMaintain thermal stabilityPrintingDielectricElectrical resistance and conductance

A micro-fluid ejection head has a resistor layer defining a heater element. An insulative layer underlies the heater element and a capping layer on the insulative layer substantially prevents ion mobility between the resistor and insulative layers. Resistance stability of the heater has been shown improved as has adhesion of the heater to the insulator. Representative layers include insulation of methyl silesquioxane (MSQ) in a thickness of about 5000 Angstroms or more, while the cap is a silicon nitride in a thickness of about 2000 Angstroms or less. Other capping layers include silicon carbide, silicon oxide or dielectrics. The resistor layer typifies TaAIN in a thickness of about 350 Angstroms, including overlying anode and cathode conductors that define the heater. Coating layers are also disclosed as are thermal barrier layers.

Owner:FUNAI ELECTRIC CO LTD

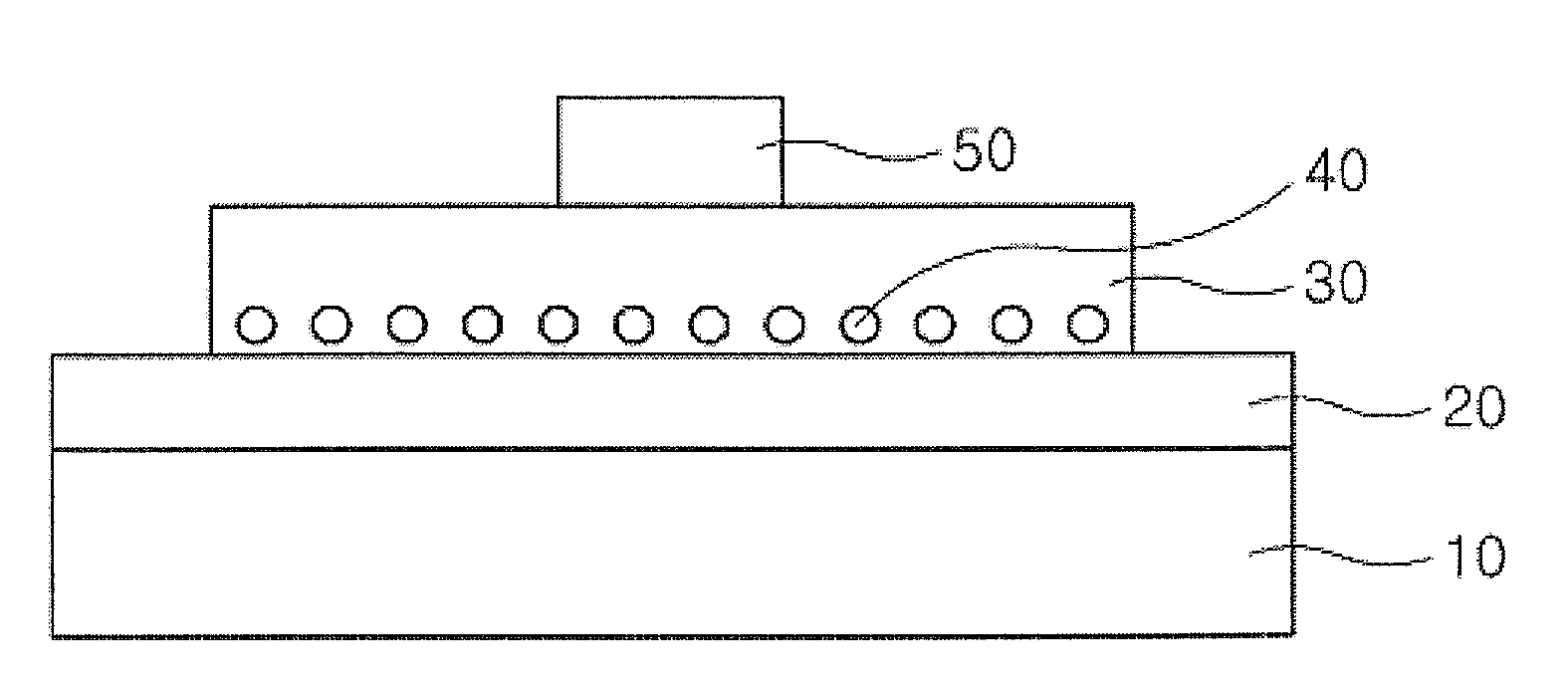

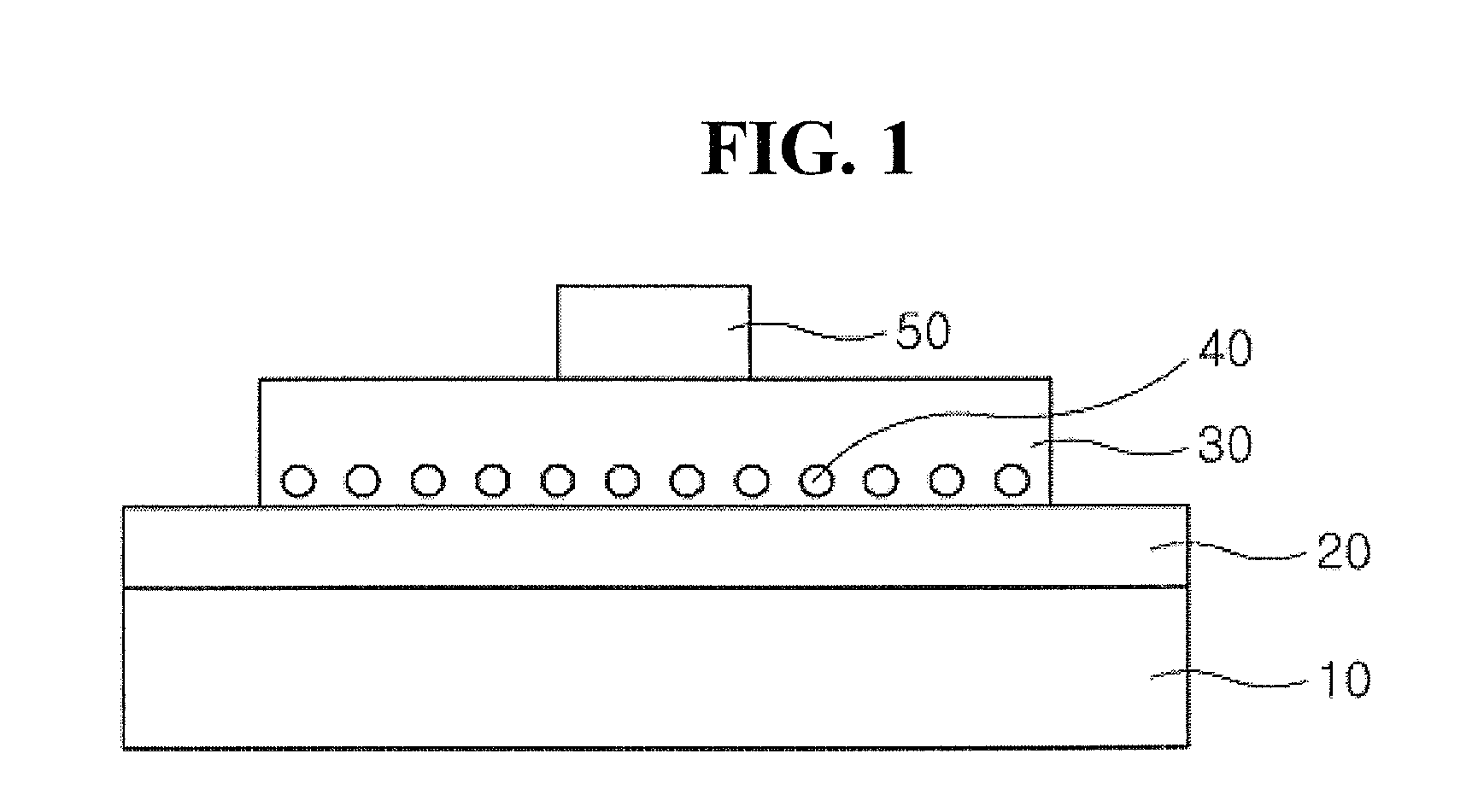

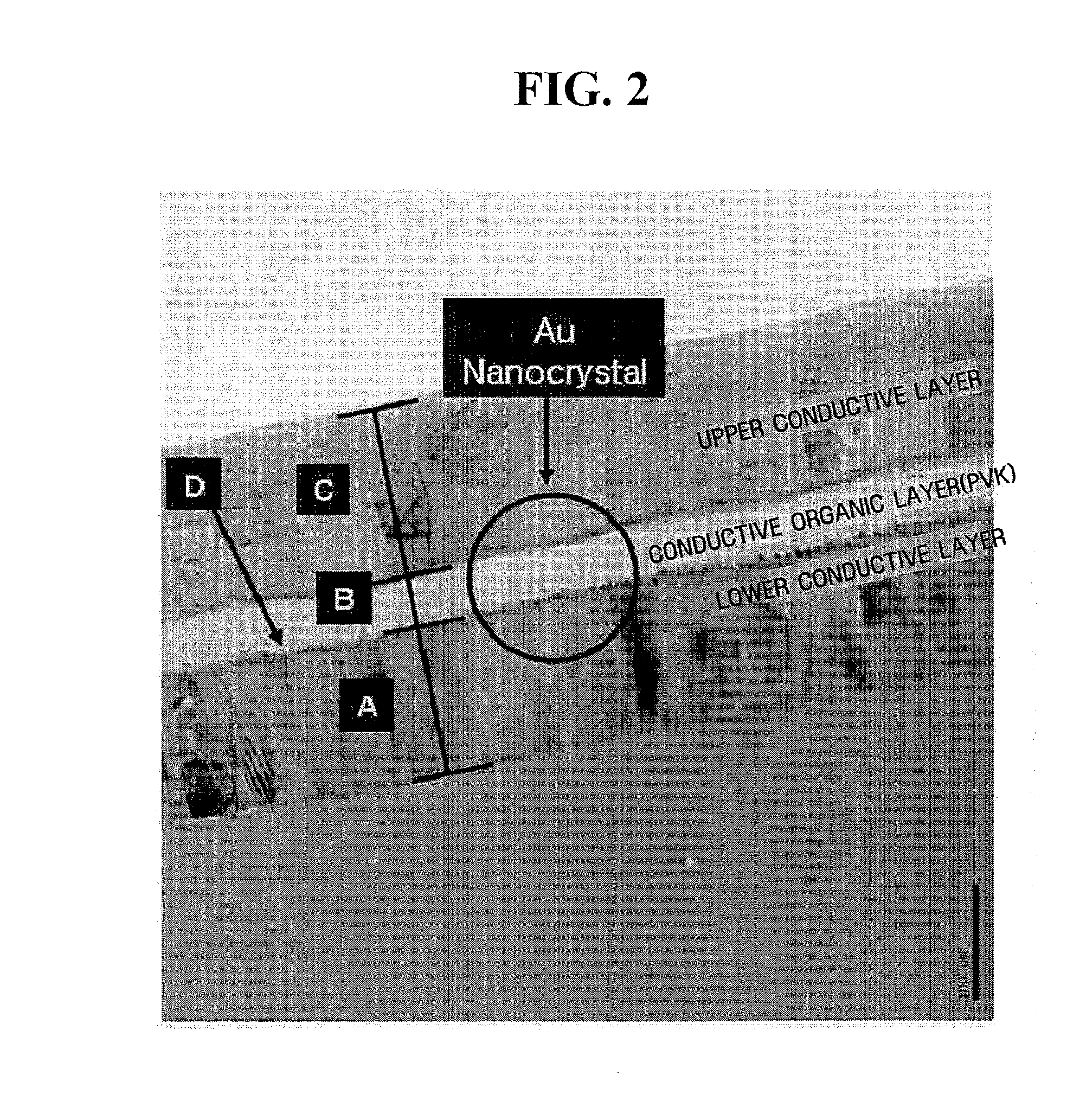

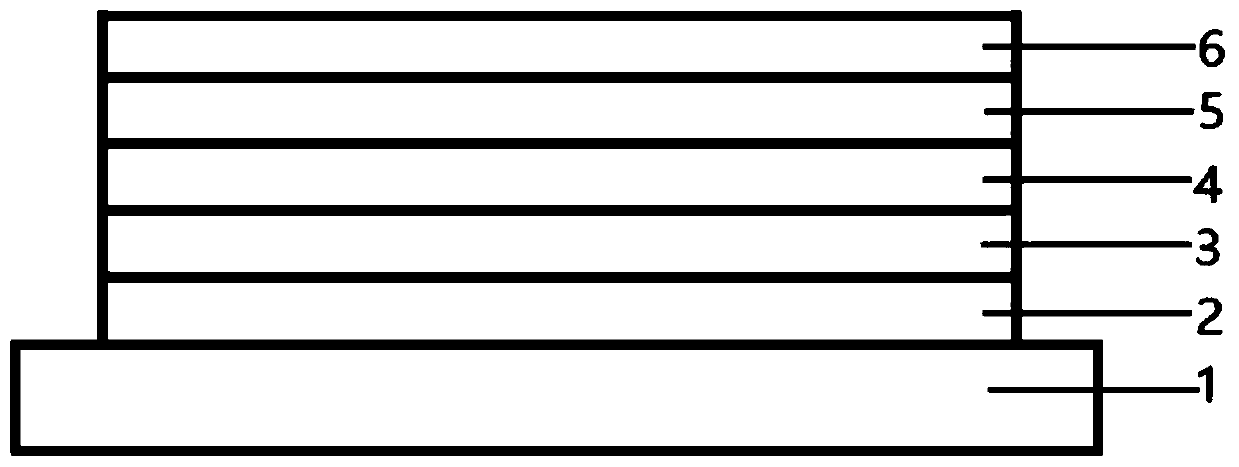

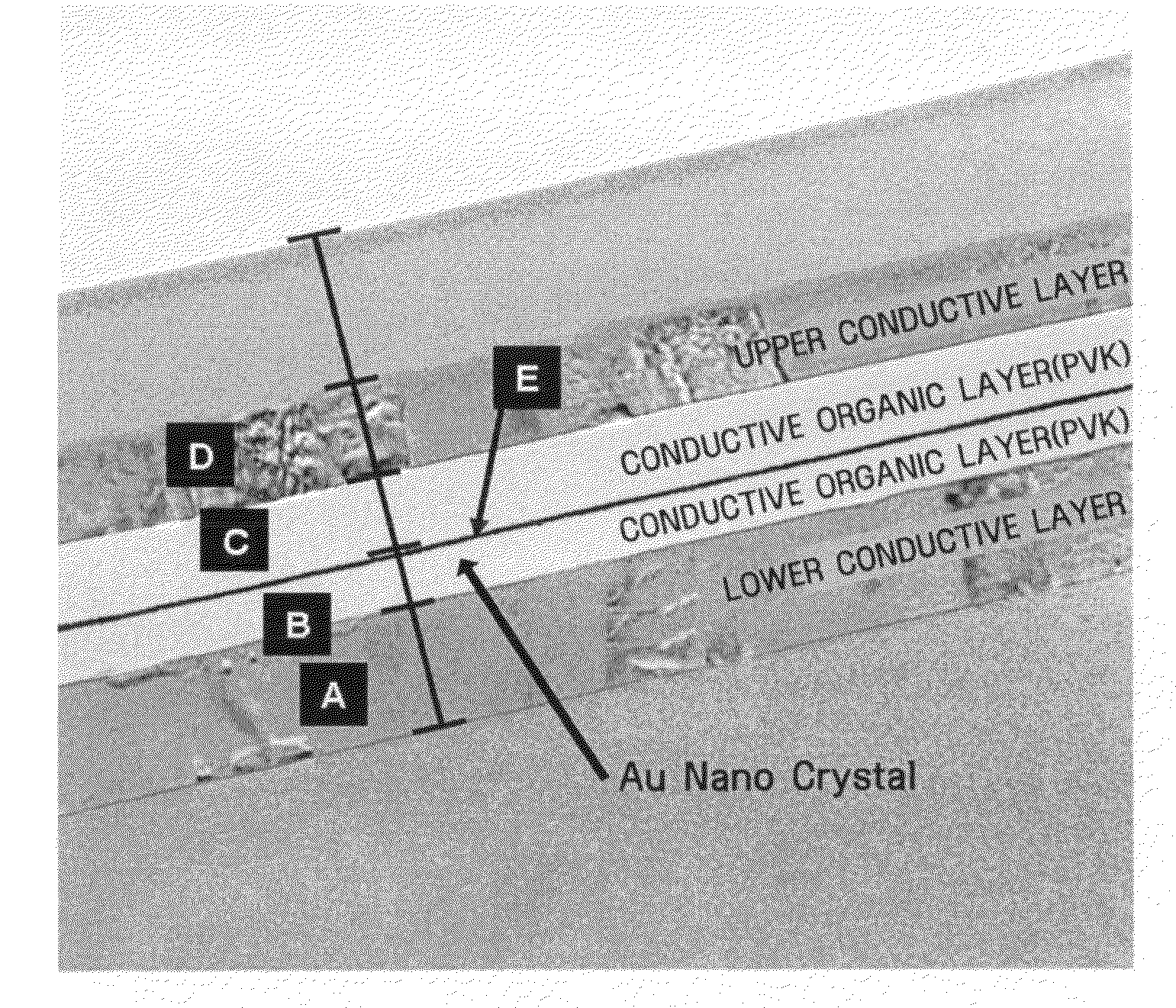

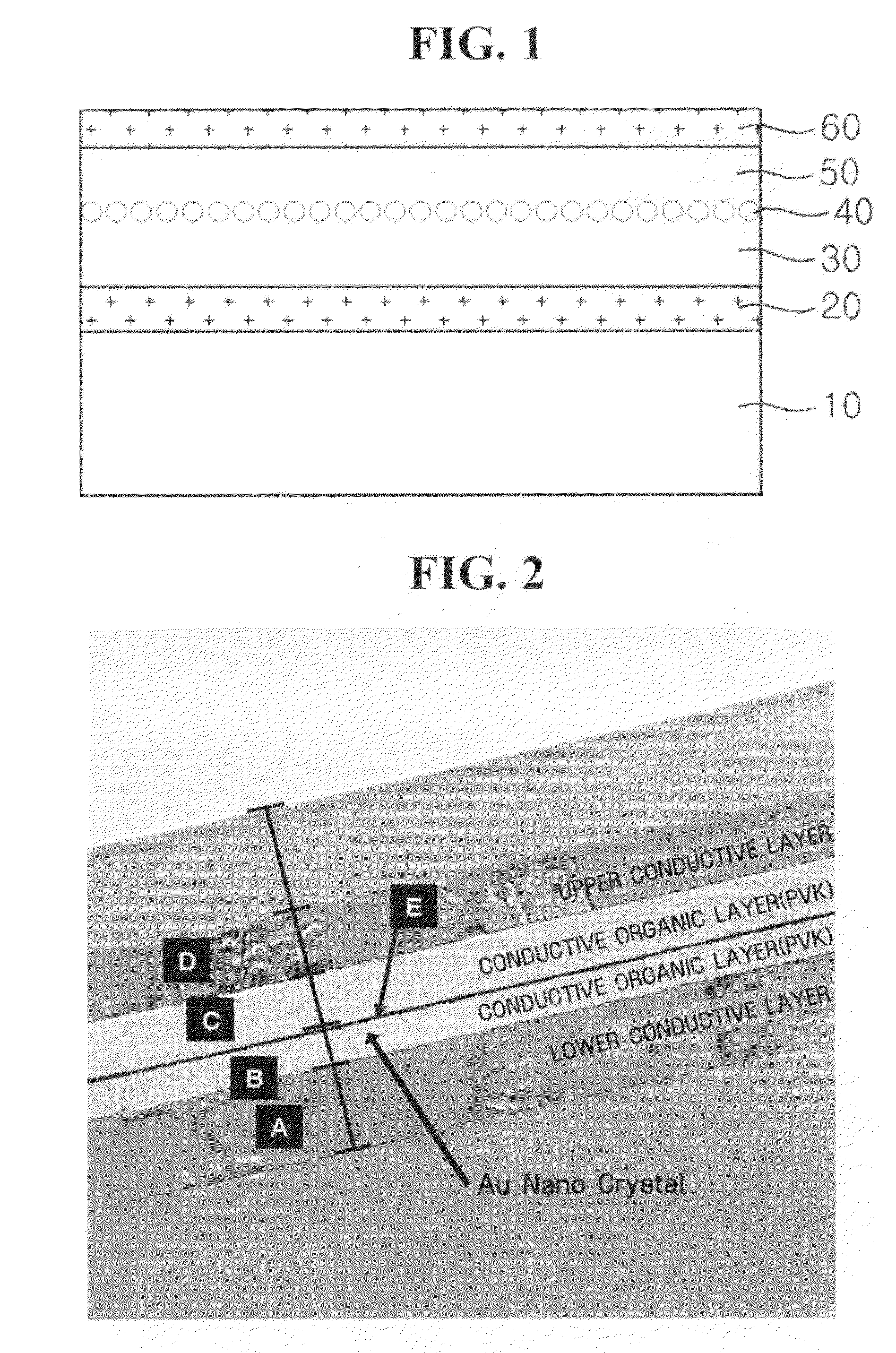

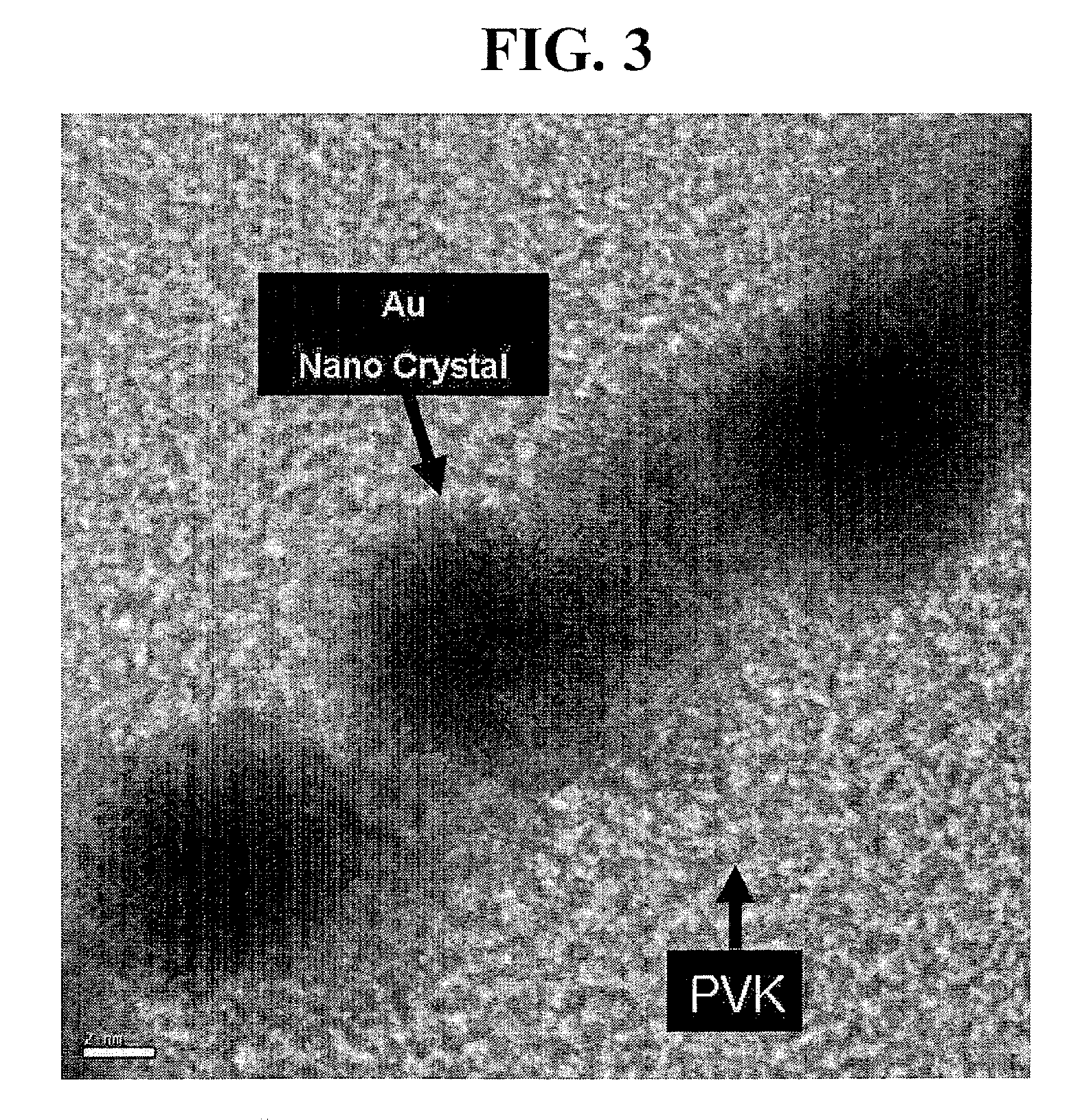

Nonvolatile memory device using conductive organic polymer having nanocrystals embedded therein and method of manufacturing the nonvlatile memory device

InactiveUS20090008633A1Consumes less powerIncrease computing speedNanoinformaticsSolid-state devicesVinyl carbazolePolystyrene

A nonvolatile memory device and a method of manufacturing the same are provided. The nonvolatile memory device which is convertible among a high current state, an intermediate current state, and a low current state, said device includes upper and lower conductive layers; a conductive organic layer comprising a conductive organic polymer and which is formed between the upper and lower conductive layers and has a bistable conduction property; and nanocrystals are formed in the conductive organic layer. The conductive organic polymer may be poly-N-vinylcarbazole (PVK) or polystyrene (PS). The method is characterized in that a conductive organic layer is formed by applying a conductive organic material such as PVK or PS using spin coating. Therefore, it is possible to provide a highly-integrated memory device that consumes less power and provides high operating speed. In addition, it is possible to provide the thermal stability of a memory device by using a conductive organic polymer. Moreover, it is possible to reduce the time required to deposit a conductive organic layer by forming a conductive layer using spin coating. Furthermore, it is possible to form a conductive organic layer in various shapes by using mask patterns that can be formed on a substrate in various shapes.

Owner:SAMSUNG ELECTRONICS CO LTD

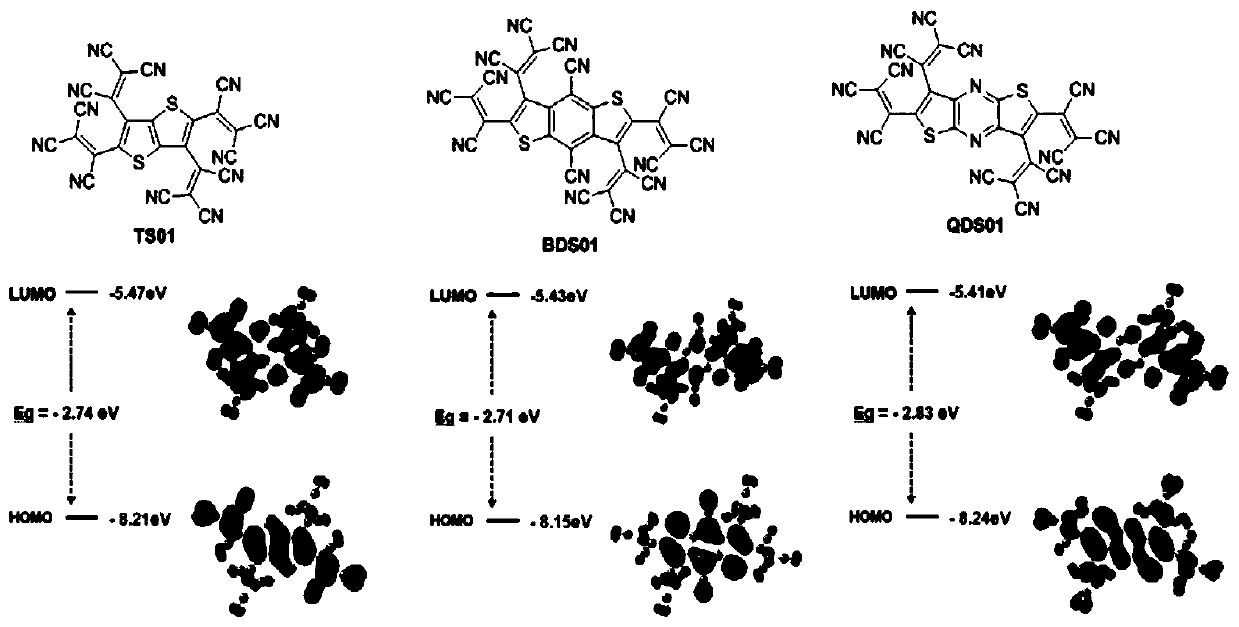

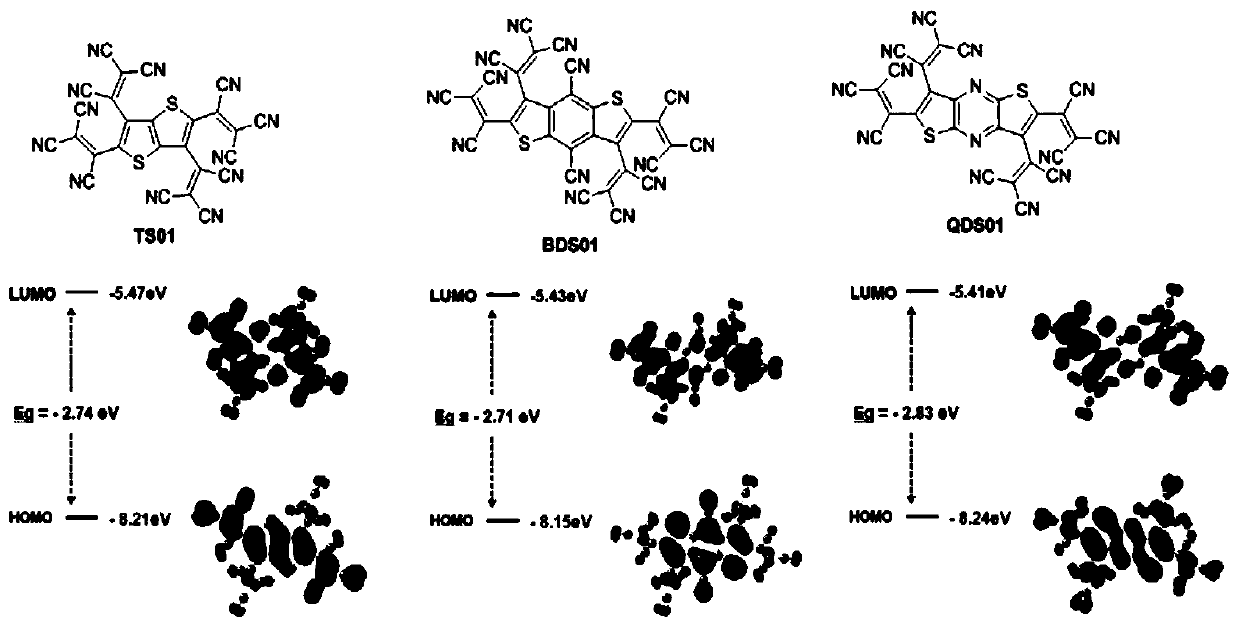

Dithiophene compound as well as preparation method and application thereof

ActiveCN109836436AExtended conjugation propertiesStrong modifiabilityOrganic chemistrySolid-state devicesSolubilityOrganic electroluminescence

The invention belongs to the technical field of display, and particularly relates to a dithiophene compound as well as a preparation method and an application thereof. The dithiophene compound has a structure as shown in formula I) or formula II), dithiophene is used as a mother nucleus, the conjugated performance is good, an electron withdrawing group increasing the modification property of the mother nucleus is introduced, the LUMO energy level of the dithiophene compound is reduced, the thermal stability of the dithiophene compound is improved, and the solubility is improved; the preparation method is simple, the yield is high, the cost is reduced, the dithiophene compound can be applied to a n-type doping material, promotes the hole generation and carrier combination, can be applied toa hole transport material, promotes hole generation, improves the hole transport speed, and can be applied to an organic electroluminescent device to reduce driving voltage and keep use stability andthe luminous efficiency of the device, and a produced product is good in luminescence property and long in service life and has a good application prospect.

Owner:NINGBO LUMILAN NEW MATERIAL CO LTD +1

Storage cell, storage device, and magnetic head

ActiveUS20150249207A1Suitable for power-savingLarge capacityMagnetic-field-controlled resistorsGalvano-magnetic material selectionCondensed matter physicsMaterials science

Provided is a storage cell that makes it possible to improve TMR characteristics, a storage device and a magnetic head that include the storage cell. The storage cell includes a layer structure including a storage layer in which a direction of magnetization is varied in correspondence with information, a magnetization pinned layer having magnetization that is perpendicular to a film surface and serves as a reference of information stored in the storage layer, and an intermediate layer that is provided between the storage layer and the magnetization pinned layer and is made of a nonmagnetic body. Carbon is inserted in the intermediate layer, and feeding a current in a laminating direction of the layer structure allows the direction of magnetization in the storage layer to be varied, to allow information to be recorded in the storage layer.

Owner:SONY CORP

Method of manufacturing nonvolatile memory device using conductive organic polymer having nanocrystals embedded therein

InactiveUS20080305574A1Consumes less powerIncrease computing speedNanoinformaticsSolid-state devicesPolystyreneOrganic layer

The method of manufacturing a nonvolatile memory device includes forming a lower conductive layer on a substrate; forming a first conductive organic layer on the substrate using spin coating; forming a metal layer for forming nanocrystals on the first conductive organic layer, the metal layer partially overlapping the first conductive organic layer; forming a second conductive organic layer on the first conductive organic layer using spin coating; transforming the metal layer into nanocrystals by curing; and forming an upper conductive layer on the second conductive organic layer, the upper conductive layer partially overlapping the nanocrystals. The conductive organic polymer may be poly-N-vinylcarbazole (PVK) or polystyrene (PS).

Owner:SAMSUNG ELECTRONICS CO LTD

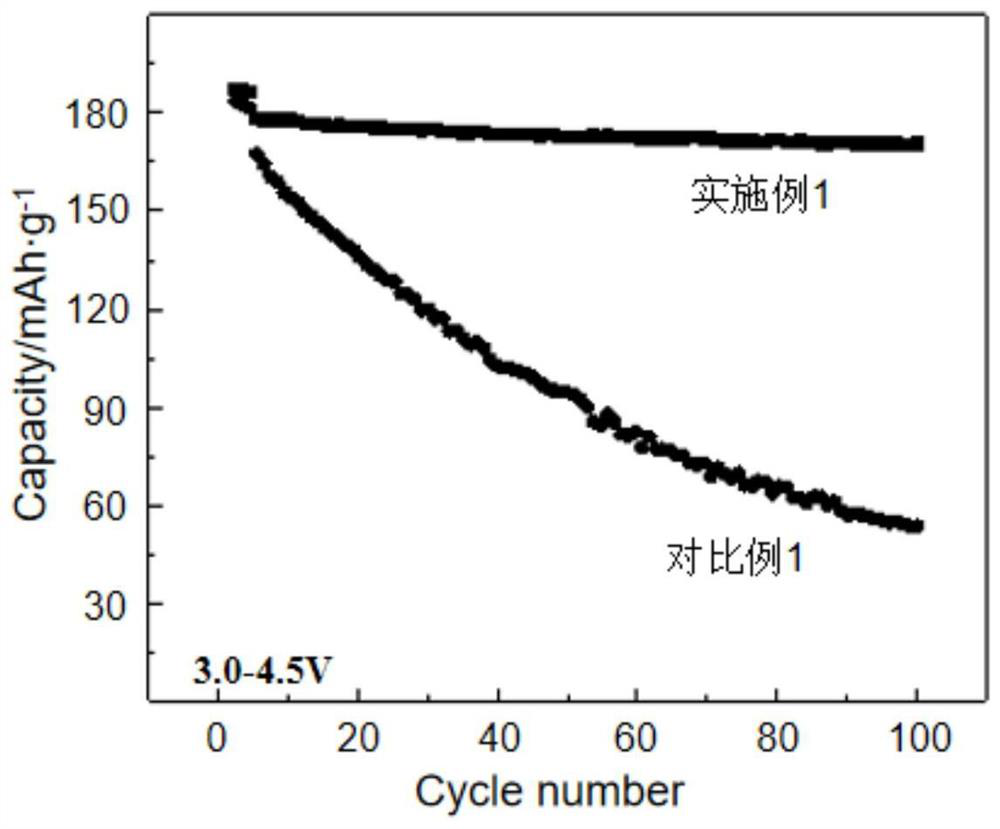

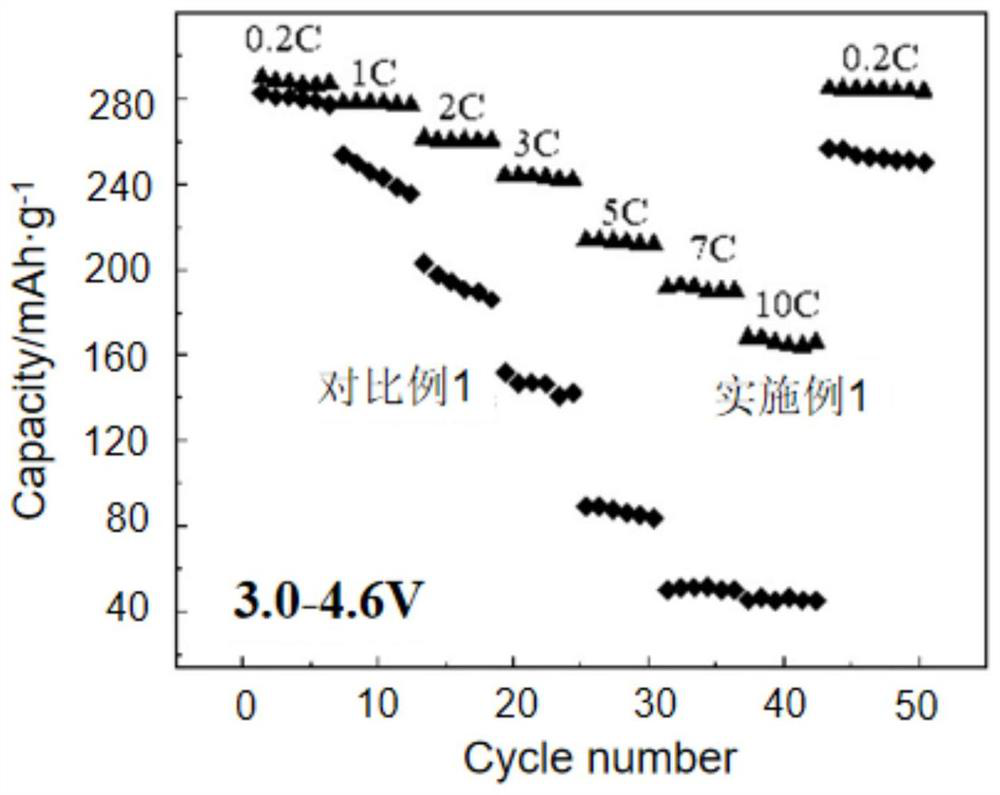

Lithium ion battery electrode binder and application thereof

InactiveCN111710864AGuaranteed specific capacityGuaranteed cycle performanceNon-aqueous electrolyte accumulator electrodesLi-accumulatorsLithium-ion batteryButadiene-styrene rubber

The invention discloses a lithium ion battery electrode binder and application thereof. The lithium ion battery electrode binder is obtained by performing hydrogenation treatment on a binder containing unsaturated bonds, and the hydrogenation treatment is used for partially or completely changing the unsaturated bonds in the binder containing the unsaturated bonds into saturated bonds so as to form the lithium ion battery electrode binder; the binder containing the unsaturated bond comprises one or a combination of several of butadiene styrene rubber, carboxymethyl cellulose sodium, lithium polyacrylate, polyacrylonitrile and sodium alginate.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

A kind of preparation method of reactive flame retardant containing phosphorus, nitrogen and sulfur in epoxy resin

ActiveCN106749413BThe synthesis process is simpleShort cycleGroup 5/15 element organic compoundsEpoxyPhosphate

The invention relates to a method for preparing nitrogen phosphate sulfur-containing reactive flame retardant applied to epoxy resin. The preparation method comprises the following steps: sequentially adding p-hydroxy benzaldehyde, aminothiazole and a solvent into a reactor which is provided with a condensing pipe and a stirrer, and introducing inert gas to perform first reaction; adding 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide to carry out second reaction; and pumping, filtering, washing and drying the system to obtain white or light brown nitrogen phosphate sulfur-containing reactive flame retardant after the reaction is completed. The method has the advantages that 1, the synthesizing process is short, the cycle is short, post-treatment is easy, and control and industrial production are easy; 2, the prepared flame retardant contains nitrogen, phosphate and sulfur three flame-retardant elements at the same time, has a synergistic flame-retardant effect, and can be used for remarkably improving the flame retarding performance of epoxy resin; and 3, the prepared flame retardant is a reactive flame retardant, and can be used for keeping stability and mechanical performance of cured epoxy resin while improving the flame retarding effect of the cured epoxy resin.

Owner:FUJIAN NORMAL UNIV

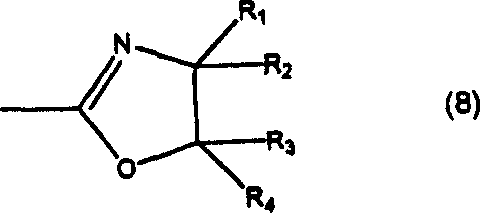

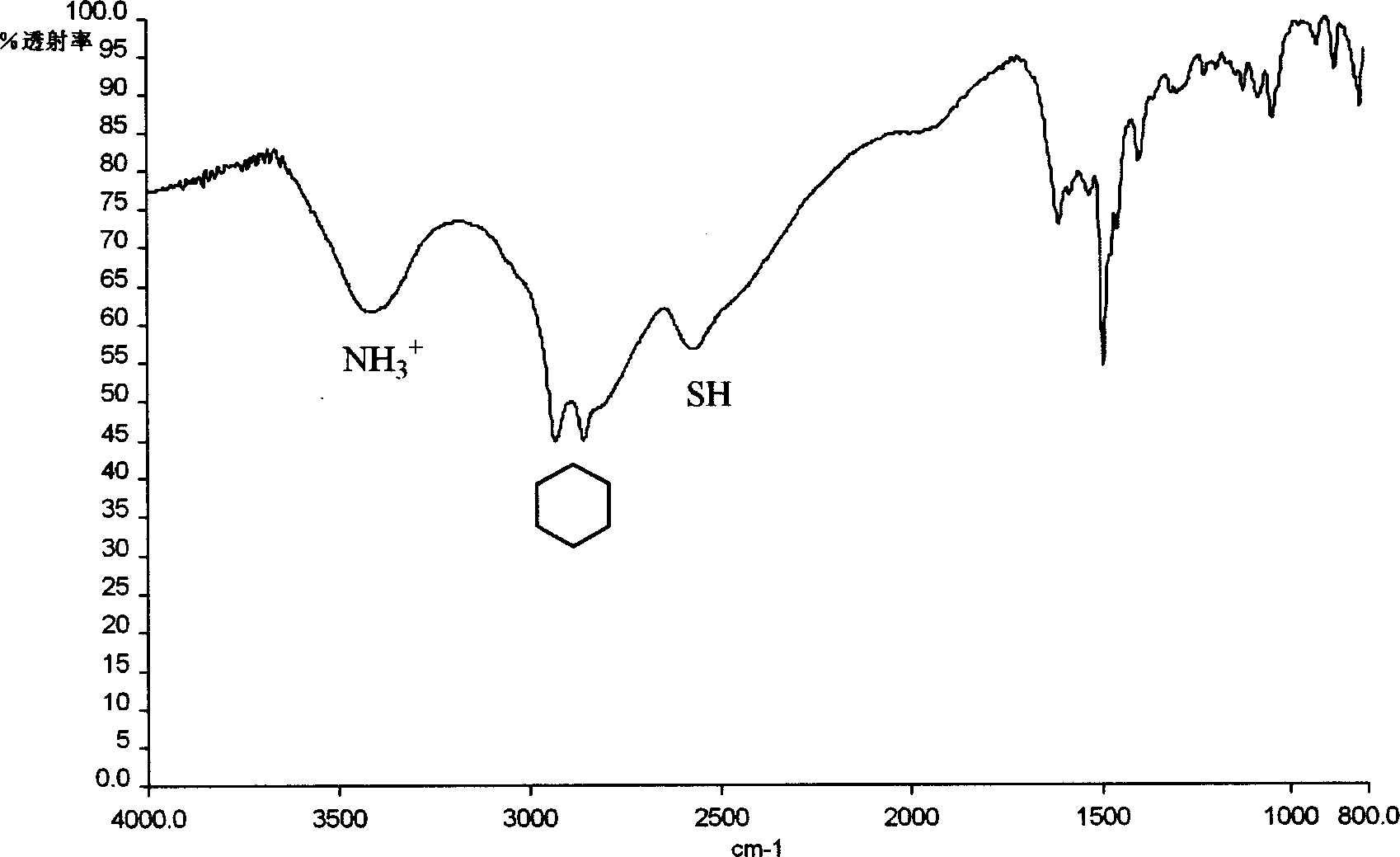

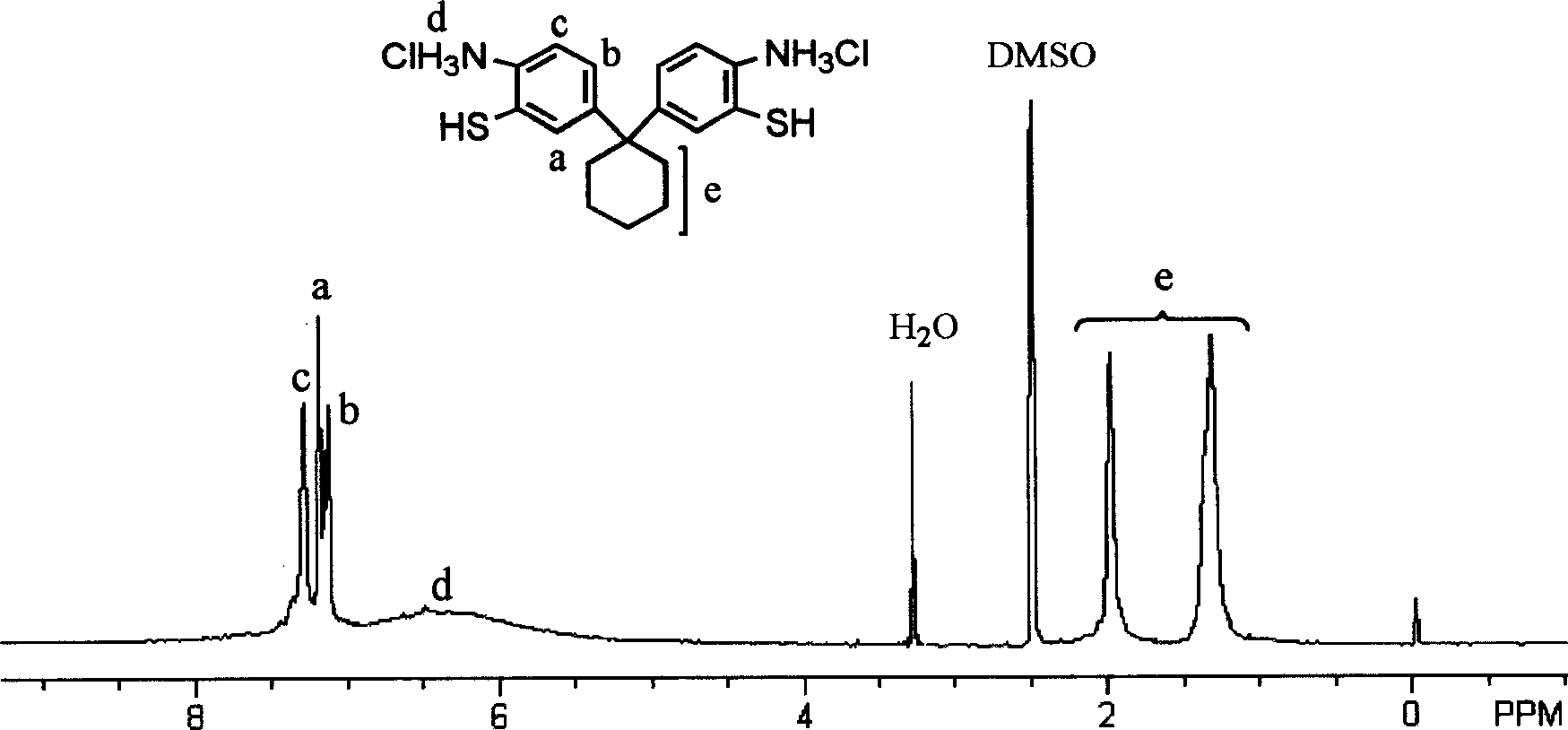

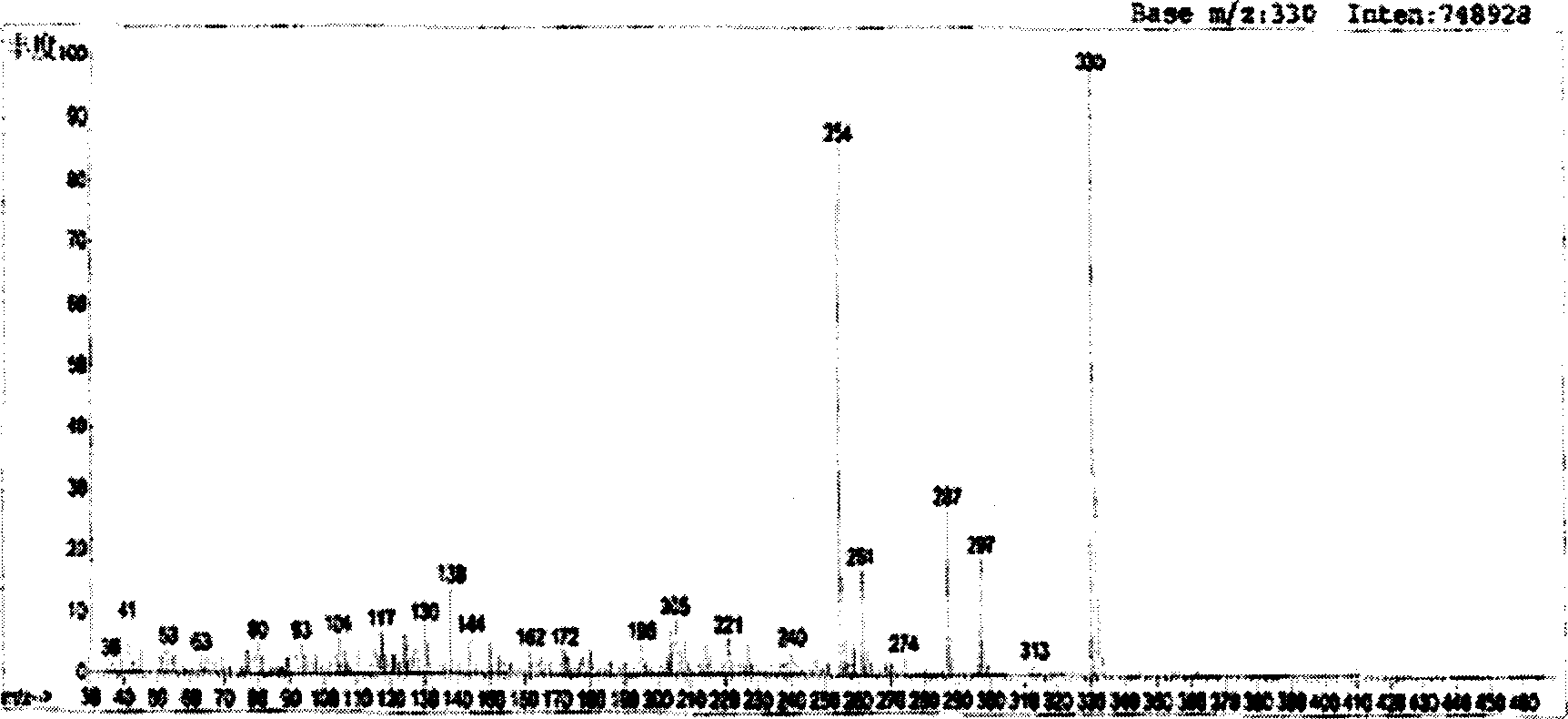

Substituted di(amino mercapto) benzene hydrochloride and process for preparing same

InactiveCN1699336AImprove solubilityMaintain thermal stabilityThiol preparationCarboxylic acidAniline

The invention discloses a substituted di(amino mercapto) benzene hydrochloride and process for preparation, which is prepared by using compounds containing benzeneamine and carbonyl as starting raw material through three-step reactions. It can be used for preparing novel benzopyrene polymers together with dicarboxylic acids through polycondensation, the dissolving property of these polymers can be increased, and fine properties of high thermal stability and chemical stability can be achieved.

Owner:SHANGHAI JIAO TONG UNIV

Stable organic cannabinoid oil blend formulations

InactiveUS20220226241A1Maintain thermal stabilityMaintain consistencyHydroxy compound active ingredientsAerosol deliveryCannabinoidLotion

The present application is directed to thermally stable cannabinoid oil-containing topical formulations, such as lotions and balms. The formulations include sodium alginate and comprise greater than 95% USDA certified organic ingredients. These formulations may be used for dermal or transdermal application useful in the treatment of, e.g., pain. Also disclosed are methods of applying such formulations.

Owner:THERABODY INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com