Lithium ion battery electrode binder and application thereof

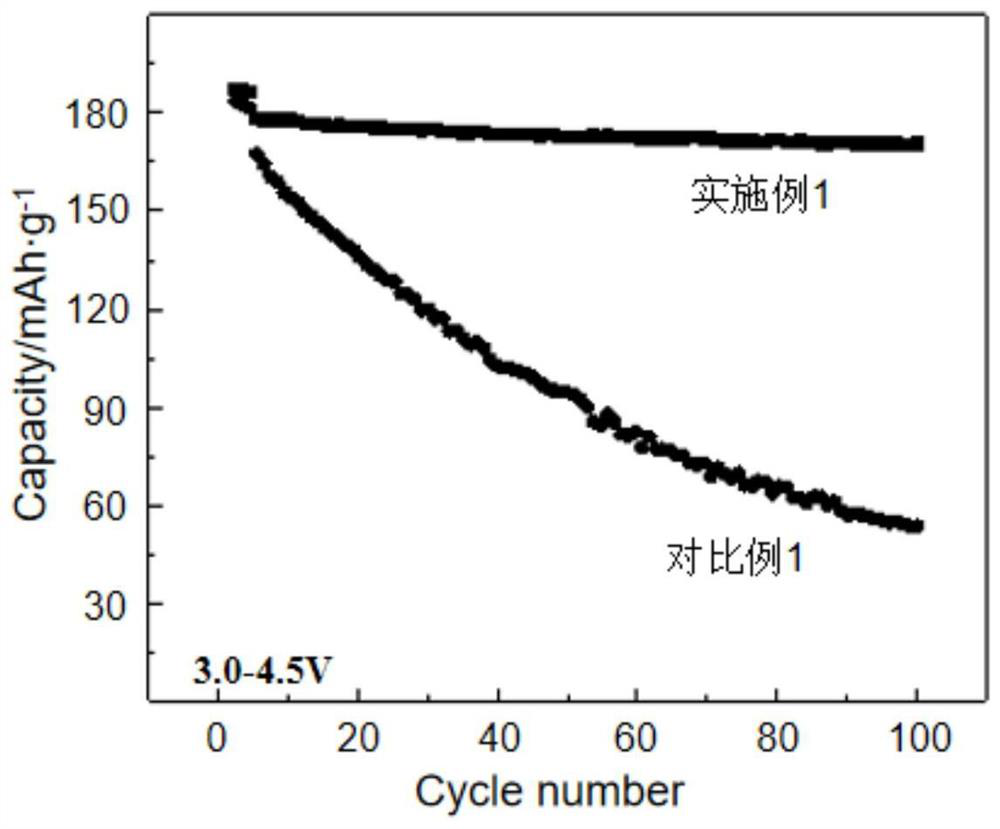

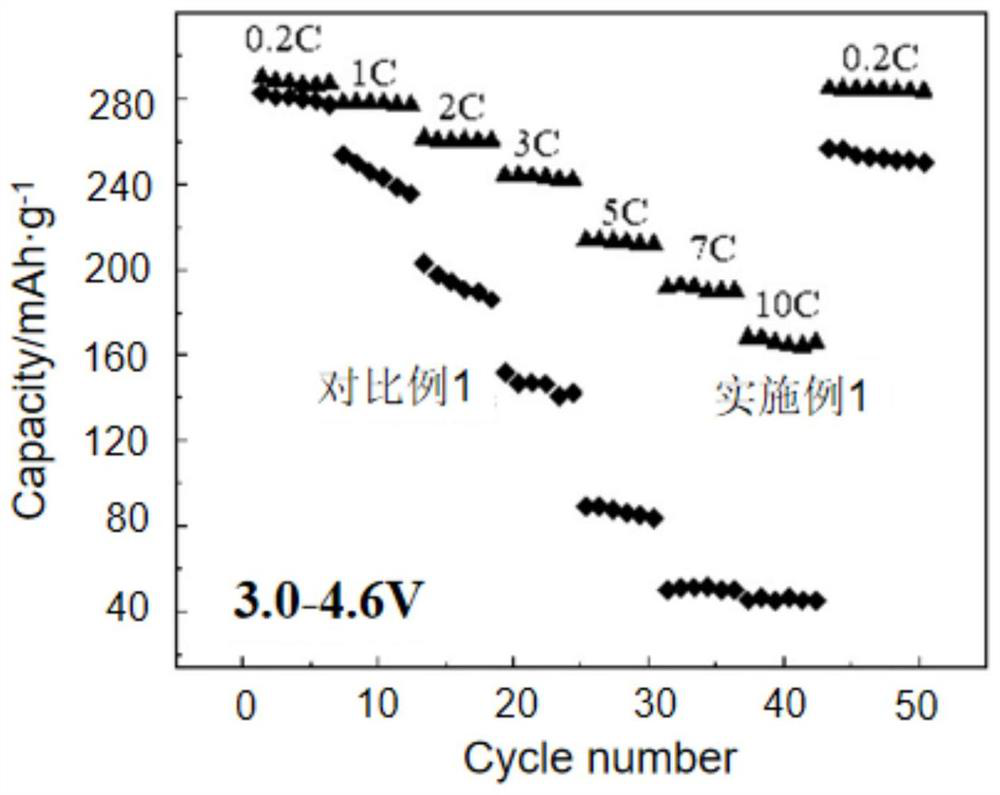

A lithium-ion battery and binder technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, lithium batteries, etc., can solve problems such as easy oxidation, difficult drying of aqueous phase systems, severe lithium dissolution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present embodiment provides a kind of positive electrode binder of lithium ion battery, and its preparation method comprises the following steps: 30g styrene-butadiene rubber emulsion (wherein solid content 40wt%) joins the four-neck flask that has condensing tube, mechanical stirrer and thermometer During the process, perform mechanical stirring at a speed of 500r / min, and add hydrazine hydrate when the temperature of the styrene-butadiene rubber emulsion rises above 55°C; weigh 2g of boric acid, dissolve it with deionized water, and add it to the reaction system in the four-necked flask; Measure the hydrogen peroxide solution (content 75%) of 30mL, dropwise in the reaction system in the four-neck flask with 1mL / min with peristaltic pump, dropwise process continues 30min, after dropwise, maintain original temperature and Pressure and other reaction conditions, continue to mechanically stir the reaction at a speed of 500r / min for 1 hour, stop heating, maintain the or...

Embodiment 2

[0042]The present embodiment provides a kind of positive electrode binder of lithium ion battery, and its preparation method comprises the following steps: join 30g lithium polyacrylate emulsion (wherein solid content 40wt%) to the four-necked flask that has condensing tube, mechanical stirrer and thermometer During the process, perform mechanical stirring at a speed of 400r / min, and add hydrazine hydrate when the temperature of the lithium polyacrylate emulsion rises above 75°C; weigh 2g of boric acid, dissolve it with deionized water, and add it to the reaction system in the four-necked flask; Measure 20mL of hydrogen peroxide solution (content 75%), and drop it into the reaction system in the four-necked flask with a peristaltic pump at a speed of 0.5mL / min. The dropping process lasts for 40min. According to the reaction conditions such as temperature and pressure, continue to mechanically stir the reaction at a speed of 400r / min for 1.5 hours, stop heating, maintain the ori...

Embodiment 3

[0045] The present embodiment provides a kind of positive electrode binder of lithium ion battery, and its preparation method comprises the following steps: join 20g polyacrylonitrile emulsion (wherein solid content 20wt%) to the four-neck flask that has condensing tube, mechanical stirrer and thermometer During the process, carry out mechanical stirring at a speed of 300r / min, and add hydrazine hydrate when the temperature of the polyacrylonitrile emulsion rises above 65°C; weigh 2g of boric acid, dissolve it with deionized water, and add it to the reaction system of the four-necked flask; Take 40mL of hydrogen peroxide solution (content 50%), and drop it into the reaction system with a peristaltic pump at 1mL / min. The dropping process lasts for 40min. Mechanically stir the reaction at a speed of 300r / min for 0.5 hours, stop heating, and maintain the original stirring speed, and when the temperature of the solution is lowered to room temperature, stop stirring and stop the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com