Open temperature sensor and preparation method thereof

A temperature sensor, an open technology, applied to thermometers, thermometers with directly heat-sensitive electric/magnetic elements, instruments, etc., can solve problems such as product reliability, wire sheath damage, and slow response time. Achieve high reliability, avoid oxidation and corrosion damage, and reduce heat capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

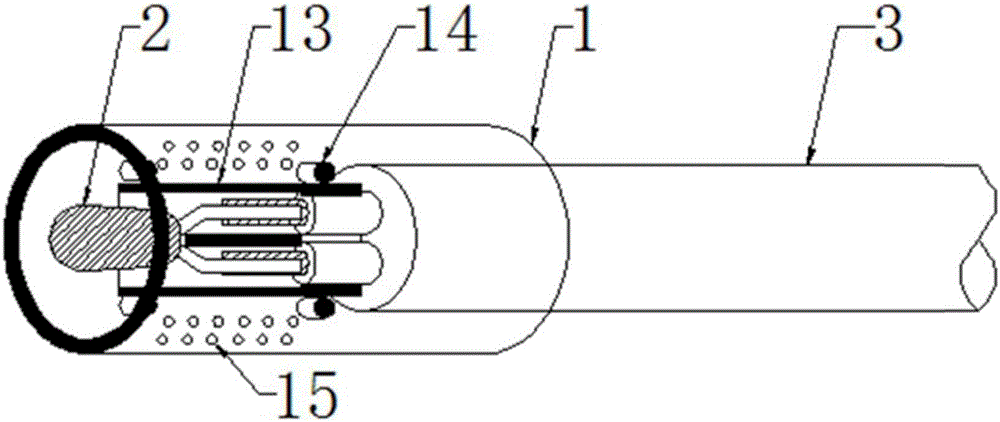

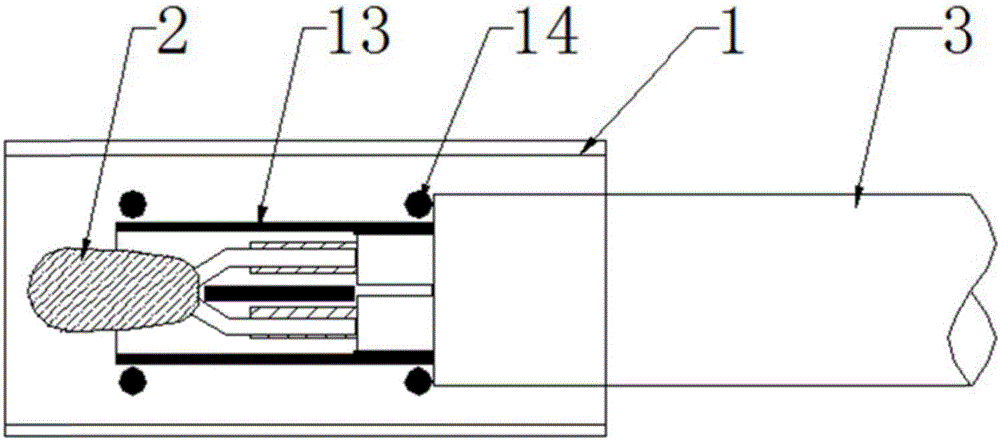

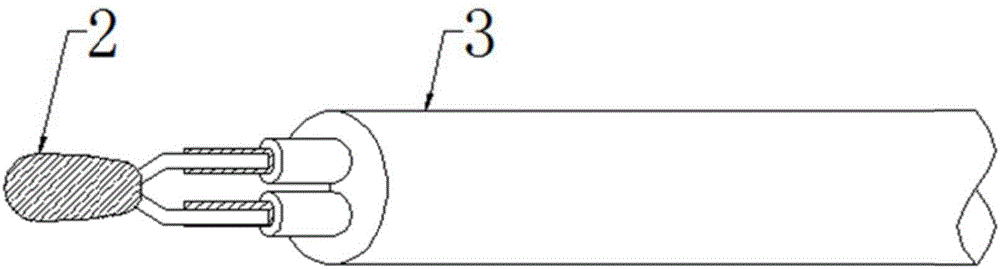

[0025] Please also see figure 1 with figure 2 , which are respectively a structural schematic diagram and a top view of the open temperature sensor of the present invention. The open temperature sensor includes a housing 1 , a thermistor 2 and a wire 3 . The thermistor 2 is connected to the wire 3 by welding. The casing 1 is sleeved on the outside of the thermistor 2 , and one end of the shell is sleeved on the end of the wire 3 .

[0026] The housing 1 includes two symmetrical semi-cylindrical hollow housings 11 and 12, and the semi-cylindrical hollow housings 11 and 12 are correspondingly provided with snap-fit insulating partitions 13 and matching butt joint posts. 14. Two symmetrical semi-cylindrical hollow shells 11 and 12 are buckled correspondingly to form a cylindrical shell 1 , and the butt joint posts 14 are correspondingly fastened so that the insulating partition 13 is sleeved outside the solder joints of the thermistor 2 and the wire 3 . In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com