Method for testing temperature of explosive ignition point

A technology of hot spot temperature and explosives, which is applied in the field of measuring the state of explosives when they detonate, can solve the problems of unclear physical meaning and inconvenient wide application, and achieve the effect of clear physical meaning and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

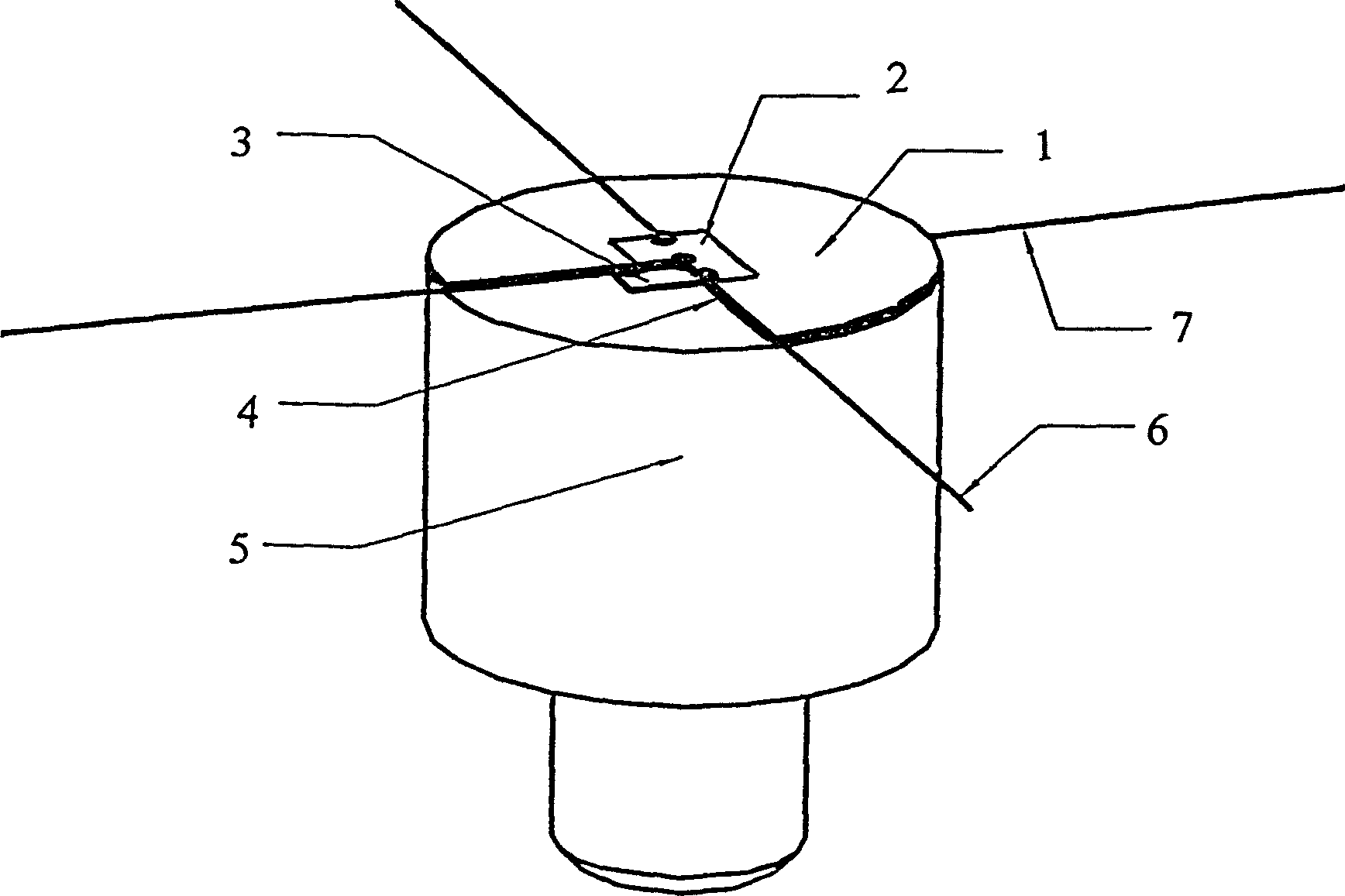

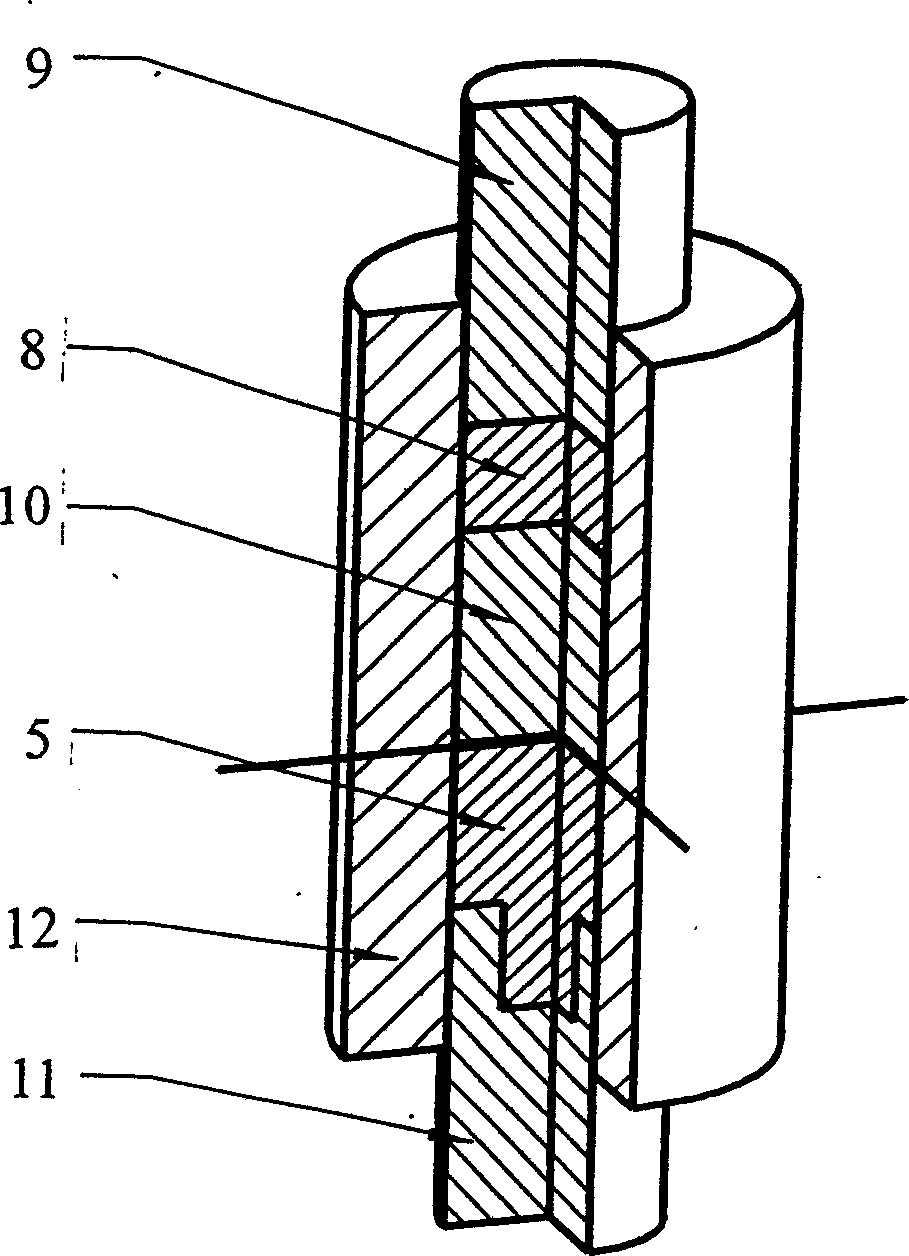

[0029] This embodiment adopts the method of electric heating thermocouple to implement the method of the present invention, and described electric heating mode is to directly heat by the heating sheet in an electric heating device being close to the thermocouple, and the area of the thermocouple is smaller than that in the electric heating device The area of the heating sheet. The thermocouple is a sheet thermometer made of two kinds of metals. The thermocouple sheet is in good contact with the explosive to be tested. There is an insulating layer between the electric heating device and the explosive to be tested except for the thermometer. In this way, When the thermocouple is heated, the explosive is also heated. Finally, the temperature rise history of the explosive is recorded through the amplifier and A / D converter connected to the thermocouple, and the temperature when the explosive is ignited is interpreted. Such as figure 2 As shown, the explosive to be tested is m...

Embodiment 2

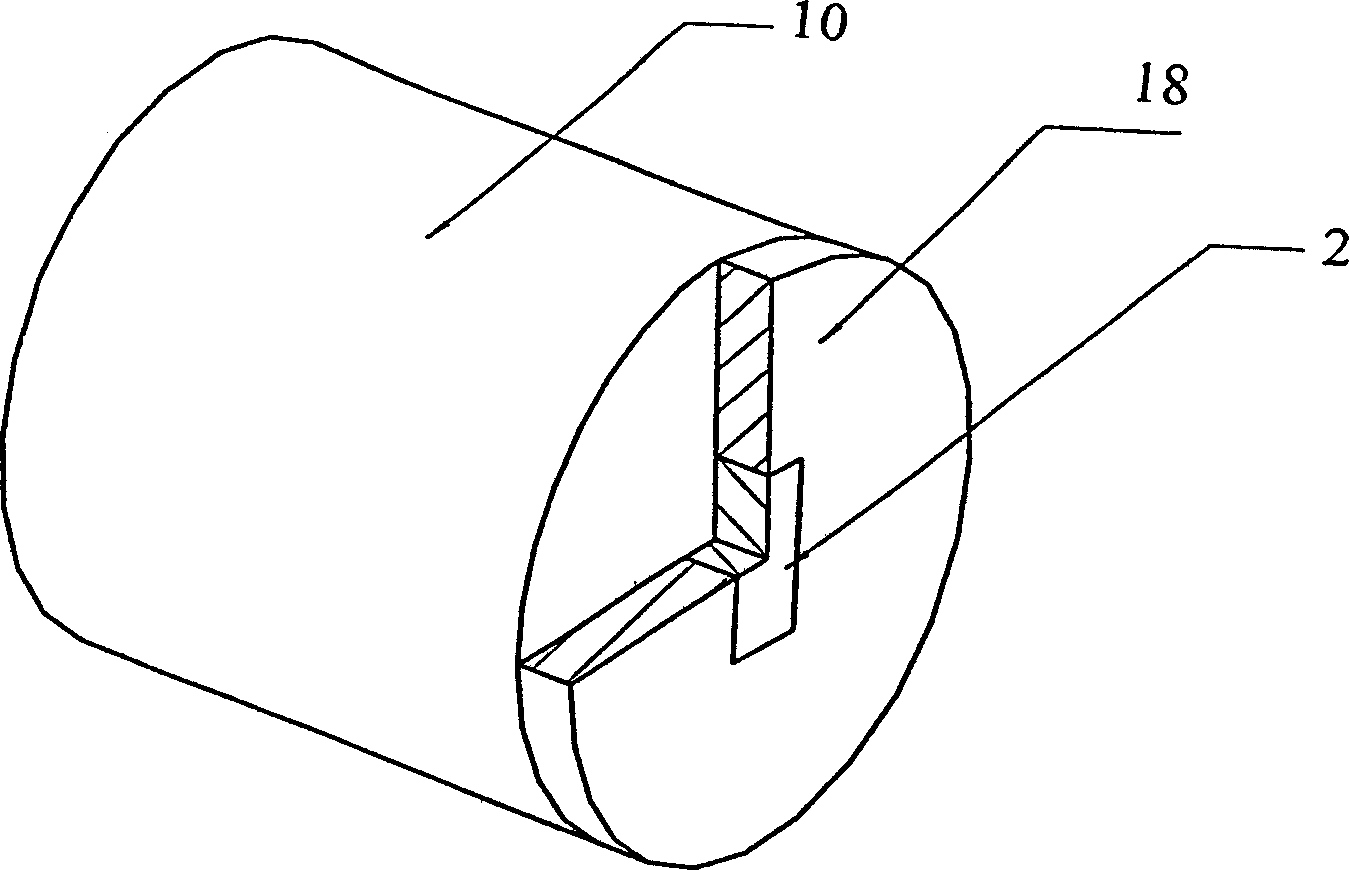

[0031] In this embodiment, the method of the present invention is implemented by means of fast compressed gas heating thermocouples. The fast compressed gas heating method is to heat the thermocouples through a compressed gas heating device, and the thermocouples are made of two kinds of metals. The thermocouple sheet is in good contact with the tested explosive, and there is an insulating layer between the gas in the compressed gas heating device and the tested explosive except for the thermometer, so that when the thermocouple is heated, the explosive is also heated. Finally, the temperature rise history of the explosive is recorded through the amplifier and A / D converter connected to the thermocouple, and the temperature when the explosive is ignited is judged. Such as image 3 As shown, the thermocouple sheet 2 is installed on the surface of the tested explosive 10, and the remaining part is coated with a layer of 502 glue as the heat insulating layer 18, and the thermocou...

Embodiment 3

[0033] This embodiment implements the method of the present invention by electrically heating platinum sheets. In this embodiment, a platinum sheet is used to make a thermometer with a thickness of about 50 microns, a length of about 3 mm, and a width of about 0.5 mm. An amplifier and an A / D converter are connected on the chip. After the signal on the platinum chip is amplified by the amplifier, it is sent to the A / D converter for recording. According to the recorded temperature history of the surface of the tested explosive, the hot spot temperature of the detonation point of the tested explosive is determined. All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com