Thermal type wind sensor based on anisotropic heat-conducting substrate and preparation method therefor

A heat-conducting substrate and anisotropic technology, applied in instruments, using thermal variables to measure fluid velocity, measuring devices, etc., can solve the problems of high power consumption of the sensor system, reduce the output sensitive signal amplitude, damage, etc., and achieve shortened thermal Response time, reduction in overall power consumption, and the effect of increasing the total amount of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of a thermal wind sensor based on an anisotropic thermally conductive substrate is as follows:

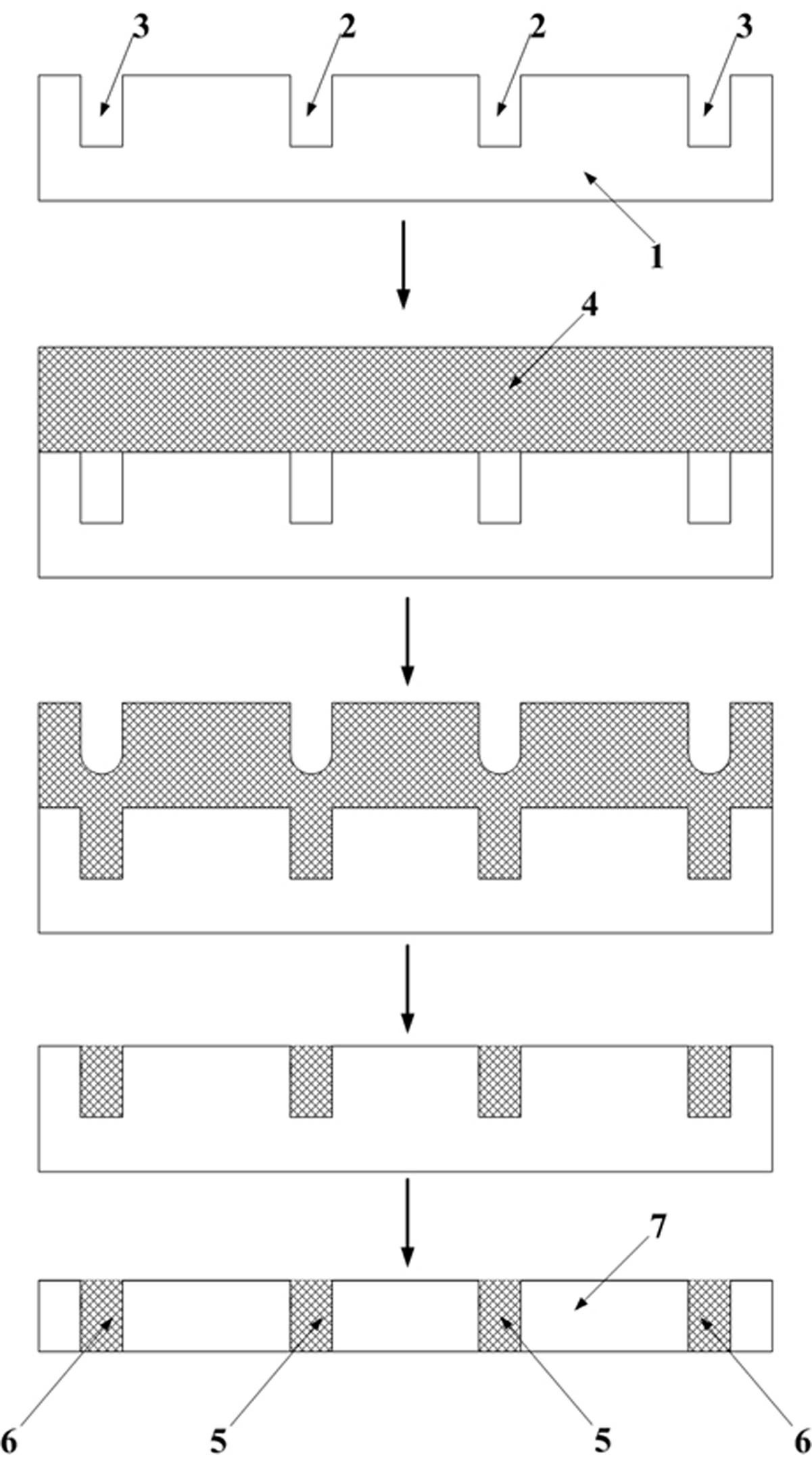

[0034] The first step, the preparation of anisotropic thermally conductive substrate, such as figure 1 shown

[0035] Step 1, using a DRIE dry etching process to prepare an annular inner groove 2 and an annular outer groove 3 of about 100 microns on the front surface of the silicon chip 1;

[0036] Step 2, performing anodic bonding of the glass 4 and the front surface of the silicon chip 1 in a vacuum environment, and vacuum sealing the annular inner groove 2 and the annular outer groove 3;

[0037] Step 3, heating the bonded glass 4 and the silicon chip 1 to a temperature range of 550°C-900°C under an atmospheric pressure, and performing thermoforming, and the pressure difference between the inner ring groove 2 and the ring outer groove 3 is filled with the softened glass 4 Into the annular inner groove 2 and the annular outer groove 3 until they are ...

Embodiment 2

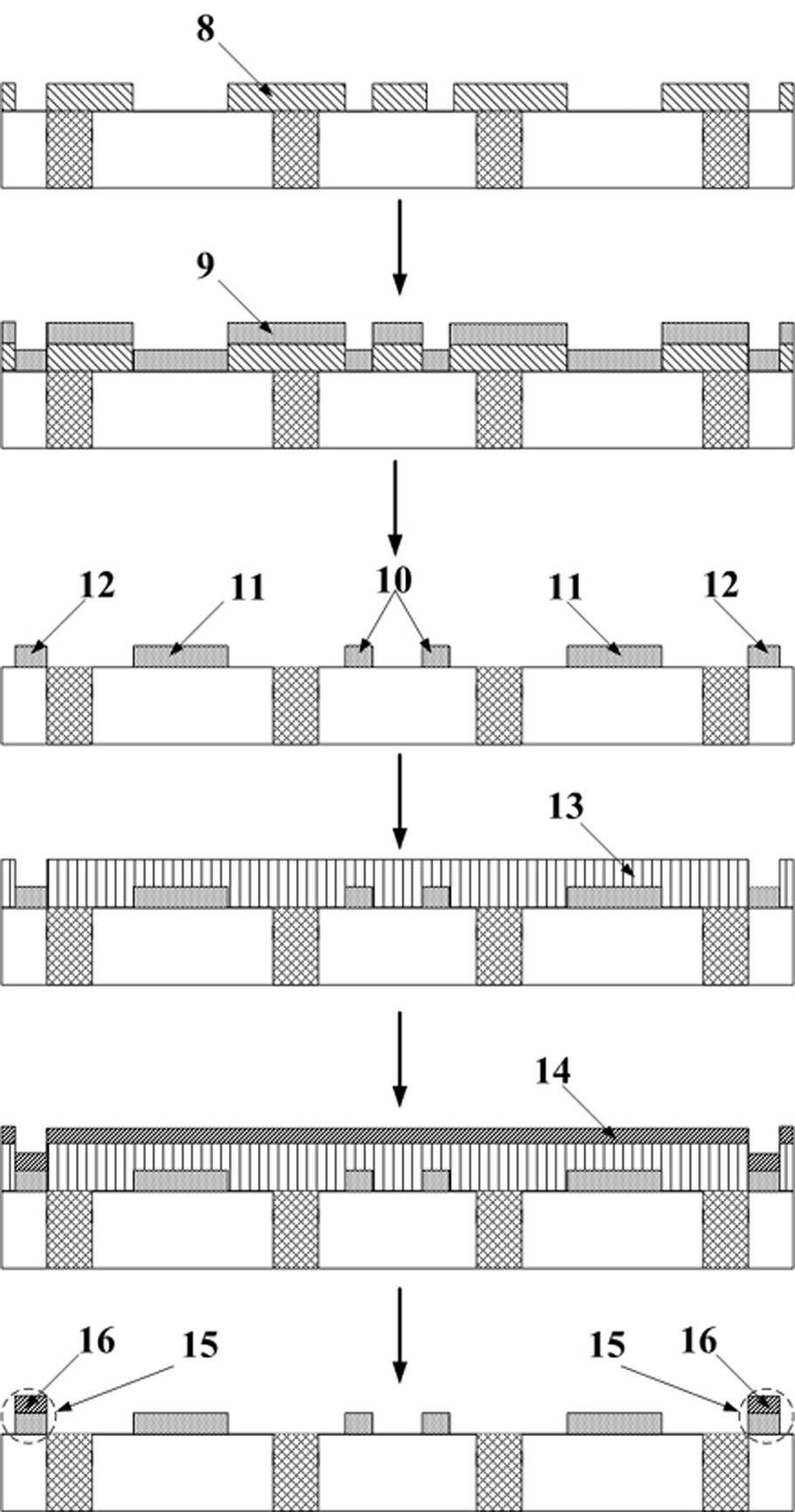

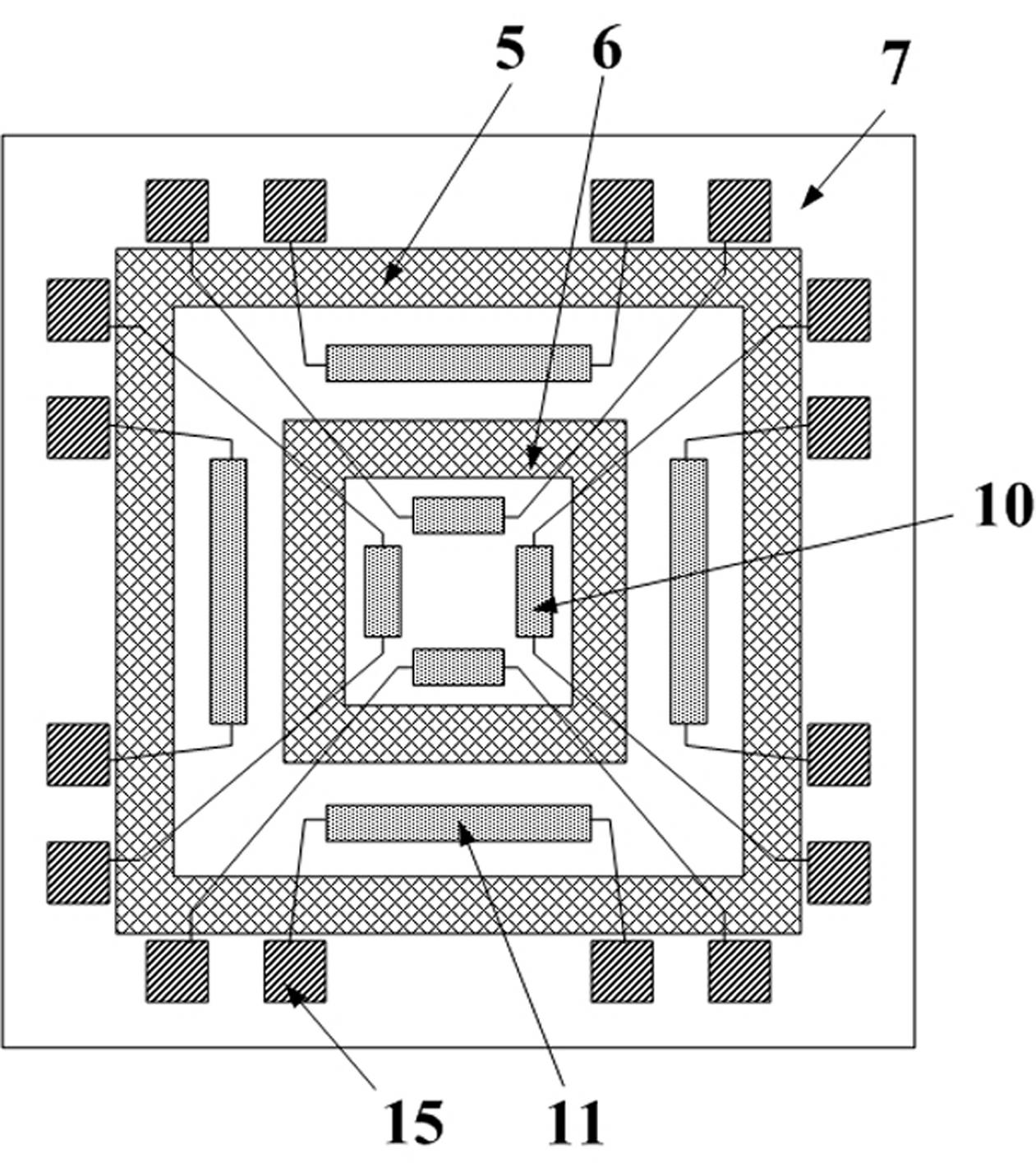

[0051] A thermal wind speed and direction sensor based on an anisotropic heat-conducting substrate structure, comprising an anisotropic heat-conducting substrate 7 in which a glass heat-insulating inner ring 5 and a glass heat-insulating inner ring 5 are symmetrically embedded around the center The glass heat-insulating outer ring 6, and the glass heat-insulating inner ring 5 divides the anisotropic heat-conducting substrate 7 into the central silicon substrate of the anisotropic heat-conducting substrate 7, the glass heat-insulating inner ring 5 and the glass heat-insulating outer ring 5. The silicon substrate between the rings 6, the lower surface of the central silicon substrate of the anisotropic heat-conducting substrate 7 is provided with four heating elements 10 symmetrically around the center, the silicon between the glass heat-insulating inner ring 5 and the glass heat-insulating outer ring 6 Four heat-sensing and temperature-measuring elements 11 are arranged around t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com