Epoxy color sand sealant and preparation method thereof

A technology of epoxy colored sand and beautifying agent, which is applied in the field of beautifying agent, can solve the problems of peeling damage, easy wear and scratch, growth, etc., and achieve the effect of enhanced mechanical strength, strong flexibility, and simple curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

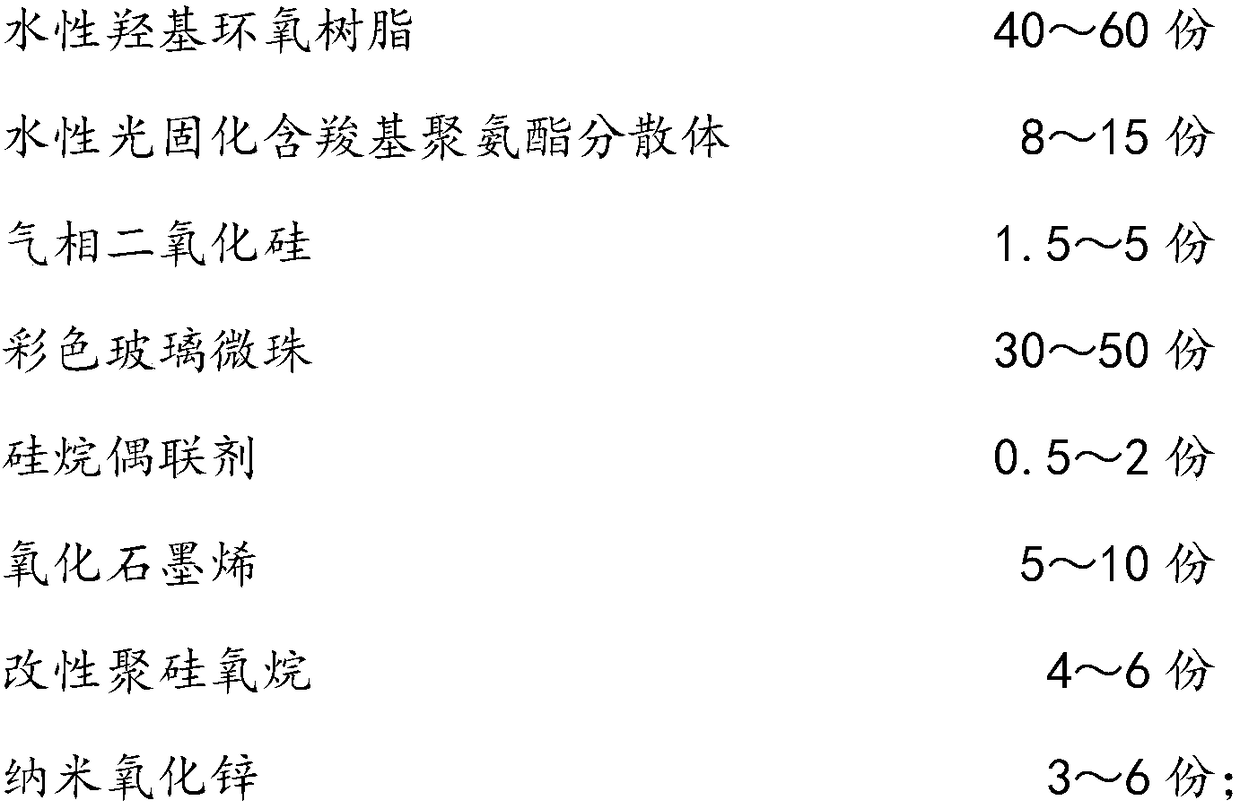

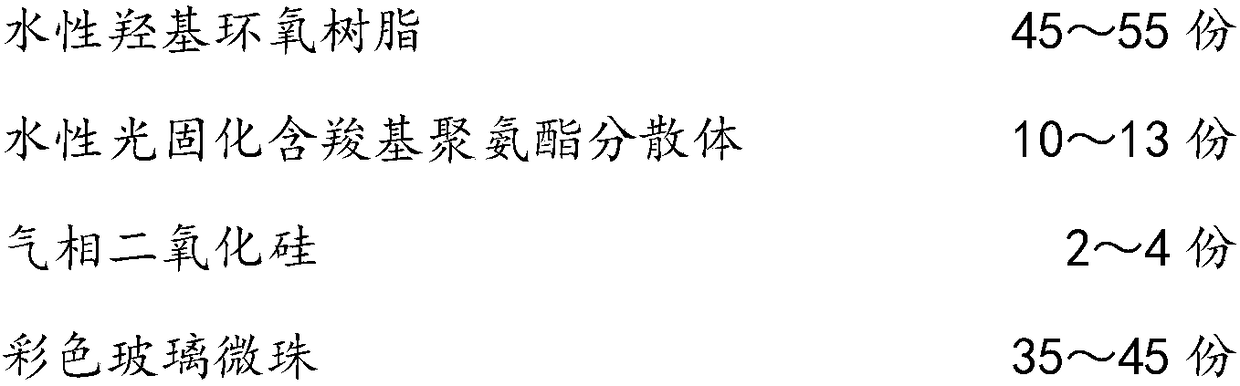

Method used

Image

Examples

Embodiment 1

[0037] The preparation steps of A component are:

[0038] Step 1. Pour 48 parts of water-based hydroxyl epoxy resin, 10 parts of water-based photocurable carboxyl group-containing polyurethane dispersion and 3 parts of fumed silica into the dispersion container, disperse at 300r / min for 15min, and then disperse at 1000r / min for 45min; Then add 38 parts of colored glass beads and 1 part of silane coupling agent, seal and maintain 0.09MPa, and disperse at 1000r / min for 25min;

[0039] Step 2. Add 8 parts of graphene oxide, 4 parts of nano-zinc oxide and 5 parts of modified polysiloxane to the product of step 1, at 35 μW / cm 2 Under the condition of ultraviolet light irradiation, disperse at 1000r / min for 30min, then add 10 parts of water-based light-curable carboxyl group-containing polyurethane dispersion, disperse at 300r / min for 20min, then disperse at 1200r / min for 40min, and then pack and discharge to get The first component;

[0040] The preparation steps of B component a...

Embodiment 2

[0043] The preparation steps of A component are:

[0044] Step 1. Pour 50 parts of water-based hydroxyl epoxy resin, 11 parts of water-based photocurable carboxyl group-containing polyurethane dispersion and 2 parts of fumed silica into a dispersion container, disperse at 300r / min for 15min, and then disperse at 1000r / min for 45min; Then add 39 parts of colored glass beads and 1 part of silane coupling agent, seal and maintain 0.09MPa, and disperse at 1000r / min for 25min;

[0045] Step 2. Add 8 parts of graphene oxide, 5 parts of nano-zinc oxide and 4 parts of modified polysiloxane to the product of step 1, at 35 μW / cm 2 Under the condition of ultraviolet light irradiation, disperse at 1000r / min for 30min, then add 11 parts of water-based light-curable carboxyl group-containing polyurethane dispersion, disperse at 300r / min for 20min, then disperse at 1200r / min for 40min, and then pack and discharge to get The first component;

[0046] The preparation steps of B component are...

Embodiment 3

[0049] The preparation steps of A component are:

[0050] Step 1. Pour 53 parts of water-based hydroxyl epoxy resin, 11 parts of water-based photocurable carboxyl-containing polyurethane dispersion and 3 parts of fumed silica into the dispersion container, disperse at 300r / min for 15min, and then disperse at 1000r / min for 45min; Then add 43 parts of colored glass beads and 1.2 parts of silane coupling agent, seal and maintain 0.09MPa, and disperse at 1000r / min for 25min;

[0051] Step 2. Add 9 parts of graphene oxide, 6 parts of nano-zinc oxide and 5 parts of modified polysiloxane to the product of step 1, at 35 μW / cm 2 Under the condition of ultraviolet light irradiation, disperse at 1000r / min for 30min, then add 11 parts of water-based light-curable carboxyl group-containing polyurethane dispersion, disperse at 300r / min for 20min, then disperse at 1200r / min for 40min, and then pack and discharge to get The first component;

[0052] The preparation steps of B component are:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com