Steel sheet for can, and process for producing same

A technology for cans and steel sheets, which is applied to high-strength and high-workability steel sheets for cans and their manufacturing fields, can solve the problems of poor workability and lack of ductility of DR materials, and achieve the effect of improving workability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

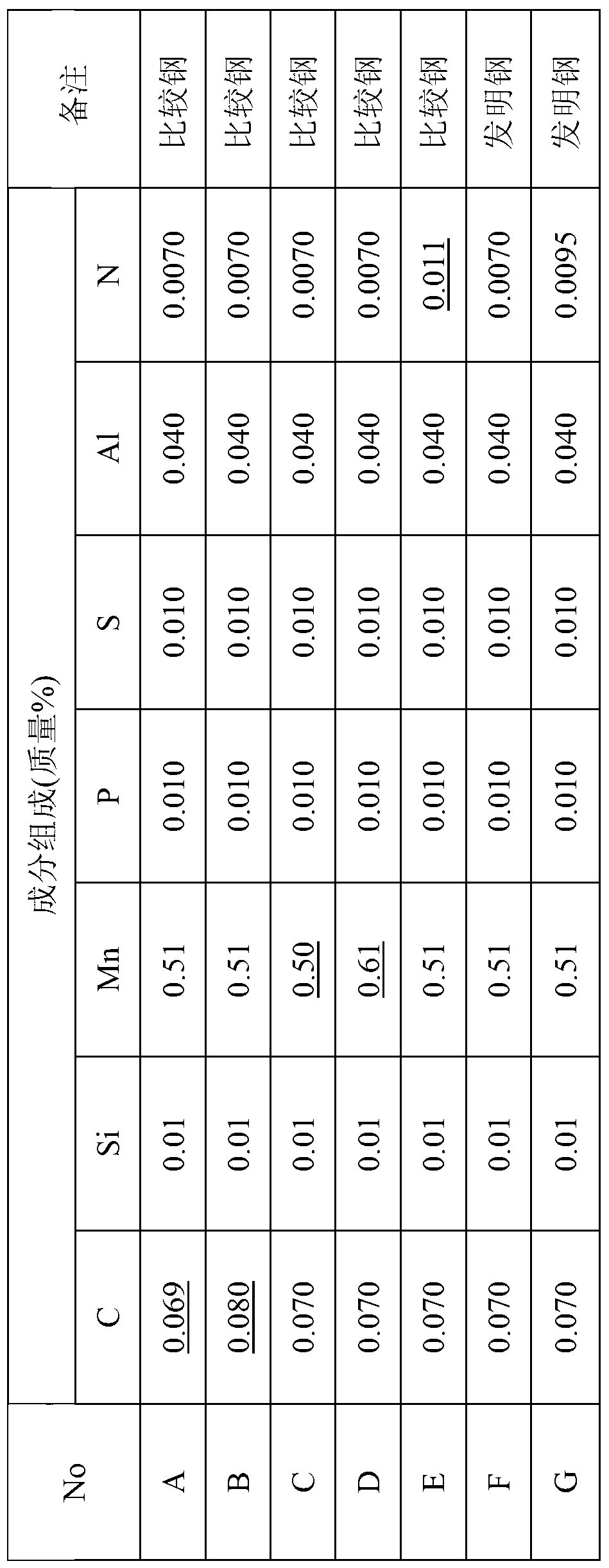

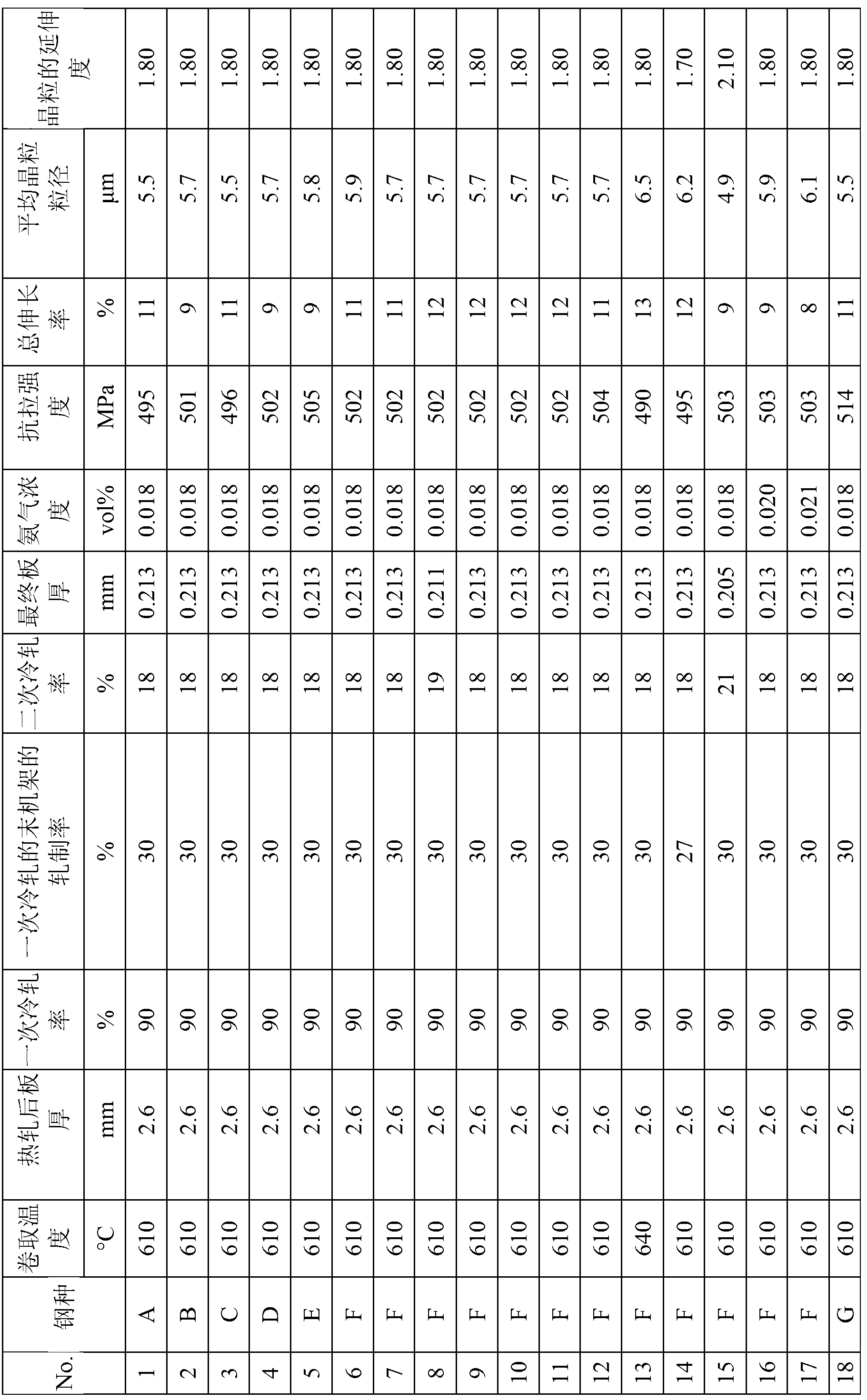

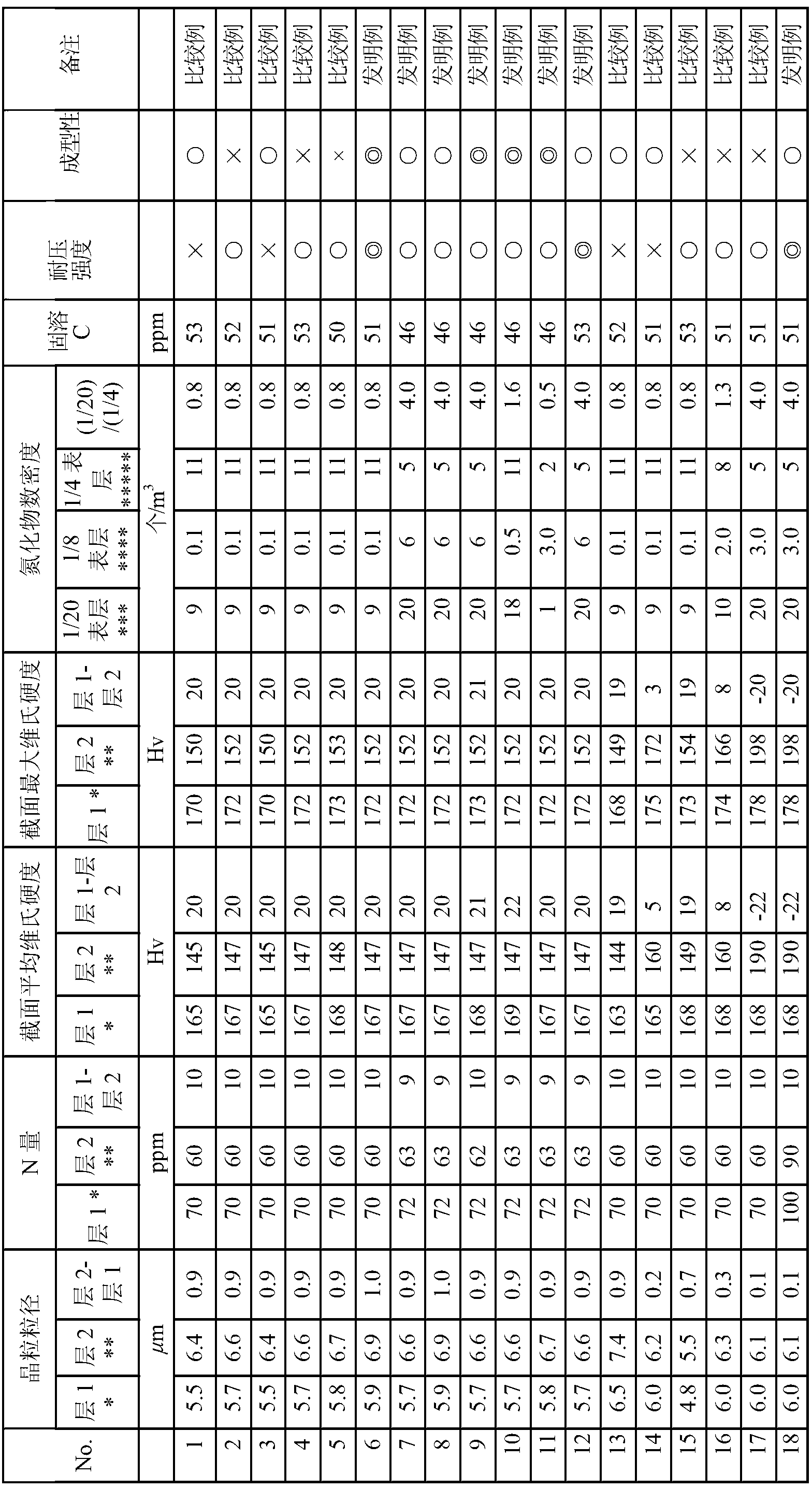

[0095] Steels containing the composition shown in Table 1 and the remainder consisting of Fe and unavoidable impurities were trial-produced, and steel slabs were obtained by casting. After reheating the obtained steel slab at 1250 degreeC, hot rolling and primary cold rolling were implemented on the conditions shown in Table 2 after that. The finishing temperature of the hot rolling was set to 890° C., and pickling was performed after rolling. Next, after the primary cold rolling, continuous annealing at a soaking temperature of 630° C. for a soaking time of 25 seconds and secondary cold rolling under the conditions shown in Table 2 were performed.

[0096] Sn plating was continuously performed on both sides of the steel sheet obtained above, and the amount of Sn deposited on one side was 2.8 g / m 2 tinplate. The test results are shown in Table 2 and Table 3. It should be noted that the grain size, N amount, and nitride number density in Table 3 refer to the average grain si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com