Patents

Literature

95results about How to "Gel forming time is controllable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil well profile control agent and preparation therefor and application thereof

ActiveCN105368425AImprove development efficiencyRealize deep profile controlDrilling compositionTanninWater block

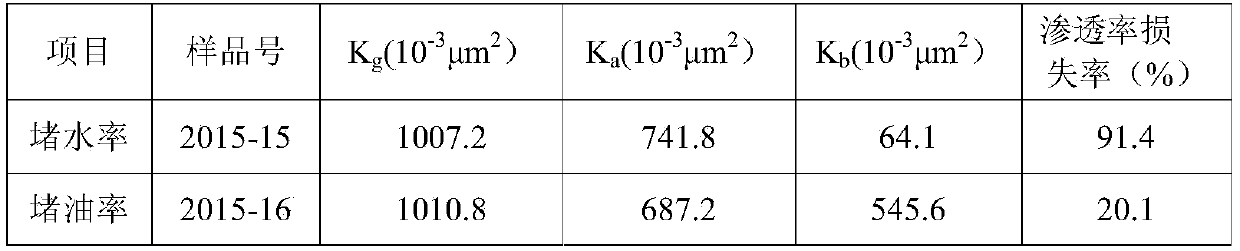

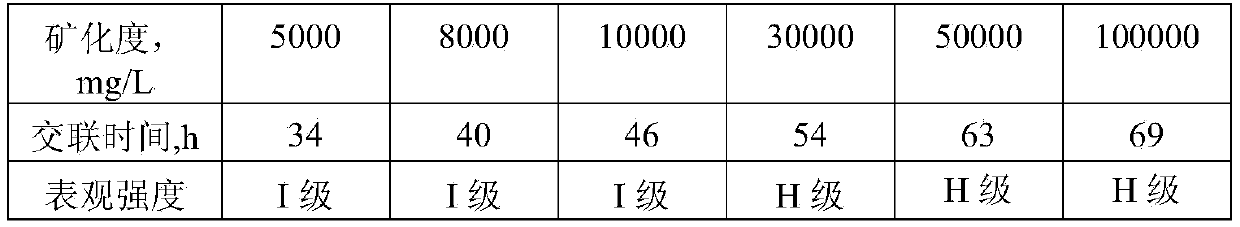

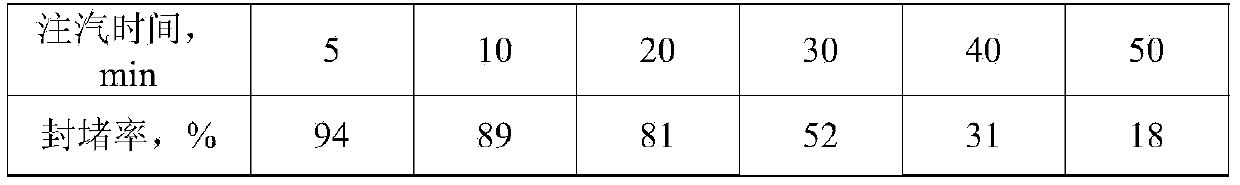

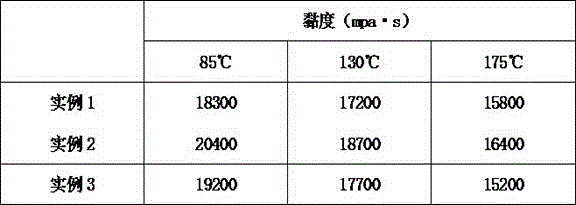

The present invention provides an oil well profile control agent and preparation therefor and application thereof. The profile control agent is prepared by the components in percentage by weight: 4-10% of a sulfonated tannin extract, 2-5% of a crosslinking agent, 0.2-0.8% of a curing agent, 0.5-2% of a flexibilizer, 0.2-1% of a dispersing agent, 0.02-0.1% of a retarder, 0.2-0.6% of a pH value modifier and the balance of water; the percentage by weight is based on the total weight of the profile control agent which is 100%. The water blocking rate of the fireflooding gas injecting well profile control agent reaches 91.4%; the oil blocking rate reaches 20.1%; the temperature resistance reaches 350 DEG C; the mineralization resistance reaches up to 100000 mg / L, and the validity period under a 300 DEG C steam condition can reach longer than 6 months.

Owner:PETROCHINA CO LTD

Preparation method of profile control agent for oil field deep temporary blocking

ActiveCN101531890AChange directionImprove adsorption capacityDrilling compositionAcetic acidOil field

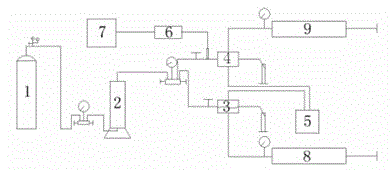

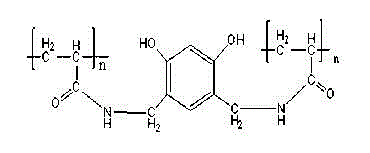

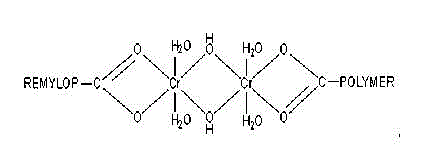

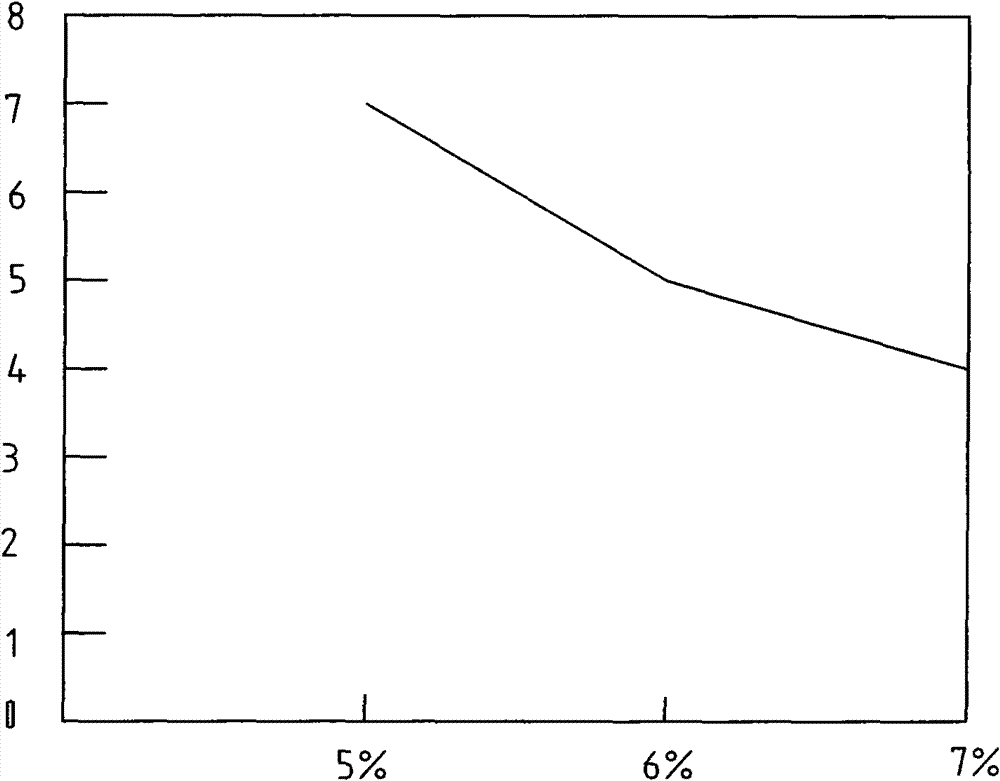

The invention relates to a preparation method of a profile control agent for oil field deep temporary blocking, belonging to the technical field of petroleum exploration. Phenolic resin, organic chromium, glacial acetic acid, resorcinol and polyacrylamide are firstly weighed according to mass percentages, then the weighed polyacrylamide is slowly added in weighed water and stirred, and the weighted other retarding crosslinking agents are sequentially added and stirred. The profile control agent for the oil field deep temporary blocking prepared by the method has the advantages that the gelling time of the profile control agent is controllable during the use by adding different crosslinking agents, the gelling time is 8-48 hours; the gel strength is great, the gel is difficult to break, and the validity period is 1-2 years; the profile control agent can effectively change the water flow of injection water of a formation and have great absorption and blocking effects on the formation.

Owner:DALIAN TRICO CHEM

Temperature-resistant salt-resistant profile control plugging agent and preparation method thereof

InactiveCN106675540AImprove thermal stabilityImprove salt resistanceDrilling compositionSalt resistanceRoom temperature

The invention discloses a temperature-resistant salt-resistant profile control plugging agent and a preparation method thereof. The temperature-resistant salt-resistant profile control plugging agent is prepared from the following raw materials in parts by weight: 1-3 parts of temperature-resistant salt-resistant polyacrylamide, 0.15-1.2 parts of crosslinking agent A, 0.03-0.1 part of crosslinking agent B, 0.01-0.1 part of setting retarder, 1-7.5 parts of pH regulator and 988-997 parts of water. The preparation method comprises the following steps: adding the pH regulator into the water, sufficiently dissolving, adding the temperature-resistant salt-resistant polyacrylamide, stirring for 2-4 hours, adding the setting retarder and crosslinking agent B, stirring at normal temperature for 1-2 hours, adding the crosslinking agent A, stirring uniformly, and standing at the constant temperature of 70-90 DEG C for 3-5 days. The profile control plugging agent has the characteristics of temperature resistance, salt resistance, high gel strength, adjustable gelling time and the like, has selectivity for oily water plugging, and can enter the deep part of the oil reservoir after being injected to plug the high-transmissibility paths, thereby improving the waterflooding development effect and enhancing the recovery ratio of the oil reservoir.

Owner:SHANDONG NUOER BIOLOGICAL TECH

High-strength multifunctional plugging agent

InactiveCN110105935AImprove the development effectImprove adhesionDrilling compositionMicron scaleSilanes

The invention discloses a high-strength multifunctional plugging agent. The plugging agent comprises, by mass, 100 parts of a structural forming agent, 0.001-15 parts of a curing agent, 0.001-10 partsof an interface adhesion agent, 0.001-200 parts of a nano filler and 0.001-30 parts of a diluent, wherein the structural forming agent comprises one or two of unsaturated polyester and vinyl resin; the curing agent comprises one or more of peroxide, persulfide and azo compounds; the interface adhesion agent comprises vinyl triethoxy silane or vinyl trimethoxy silane; the nano filler comprises oneor more of nanoscale or micron-scale carbonate, silicate and sulfate. During use, the structural forming agent, the curing agent, the interface adhesion agent, the nano filler and the diluent are mixed and react to generate liquid gel; the liquid gel is injected to a target plugged zone position and is solidified to form the high-strength multifunctional plugging agent. The plugging agent is stable in performance, good in residence property, high in adhesion force, high in elasticity modulus and high in compressive strength, and has a wide application range and good effects in oil and gas field drilling and production operation.

Owner:陕西鼎和源瑞环境工程有限公司

Environmental-friendly gel plugging agent applicable to low-temperature oil pool and applications of gel plugging agent

ActiveCN103980872AExpand the affected volumeEnhanced overall recoveryFluid removalDrilling compositionCross-linkHigh intensity

The invention relates to an environmental-friendly gel plugging agent applicable to a low-temperature oil pool and applications of the gel plugging agent. The gel plugging agent is prepared from 0.2%-0.6% of ampholytic polyacryamide, 0.5%-2.0% of an organic zirconium cross-linking agent solution, and the balance of water. The gel plugging agent is used for deep water shut-off and profile control constructions in the low-temperature oil pool of 25-35 DEG C and by virtue of the plugging agent, the recovery rate of crude oil can be raised. The gel plugging agent can form a non-flowing high-strength gel system at low temperature and has low viscosity and good injectivity; without toxic chemical materials such as chromium type cross-linking agents, the gel plugging agent is conductive to environmental friendliness.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Viscoelastic weak gel profile control agent

ActiveCN101712865AAdjustable intensityGel forming time is adjustableDrilling compositionSulfite saltAmmonium chloride mixture

The invention discloses a viscoelastic weak gel profile control agent which is applied in oil field and oil well water injection operation. The viscoelastic weak gel profile control agent comprises the following components in parts by weight: 0.15-0.25 part of viscoelastic surface activity polymer, 0.05-0.15 part of cross-linking agent, 0.001-0.005 part of conditioning agent, and 99.8-99.6 parts of water. The viscoelastic surface activity polymer comprises the following components in parts by weight: 20-30 parts of acrylic amide, 1-2 parts of 3,3-dimethylacrylic acid, 1.5-3.5 parts of 2-acrylamido-2-dodecyl ethanesulfonic acid and / or 1-4 parts of N,N-dimethyl-allyl-hexadecyl ammonium chloride, 60-75 parts of deionized water and 0.3-1 part of initiating agent. The initiating agent comprises the following components in parts by weight: 2.5-3.5 parts of ammonium persulphate and 1 part of sodium sulfite. The viscoelastic weak gel profile control agent of the invention has a certain gel strength, capacity for lowering oil-water surface tensility and adjustable gel forming time, can improve water injection profile, lower oil-water surface tensility, wash away residual oil in a pore canal and improve water injection recovery ratio.

Owner:PETROCHINA CO LTD

Profile control agent for water injection well, and preparation method and application thereof

ActiveCN103265934AWith strengthGel forming time is controllableDrilling compositionSodium BentoniteTemperature resistance

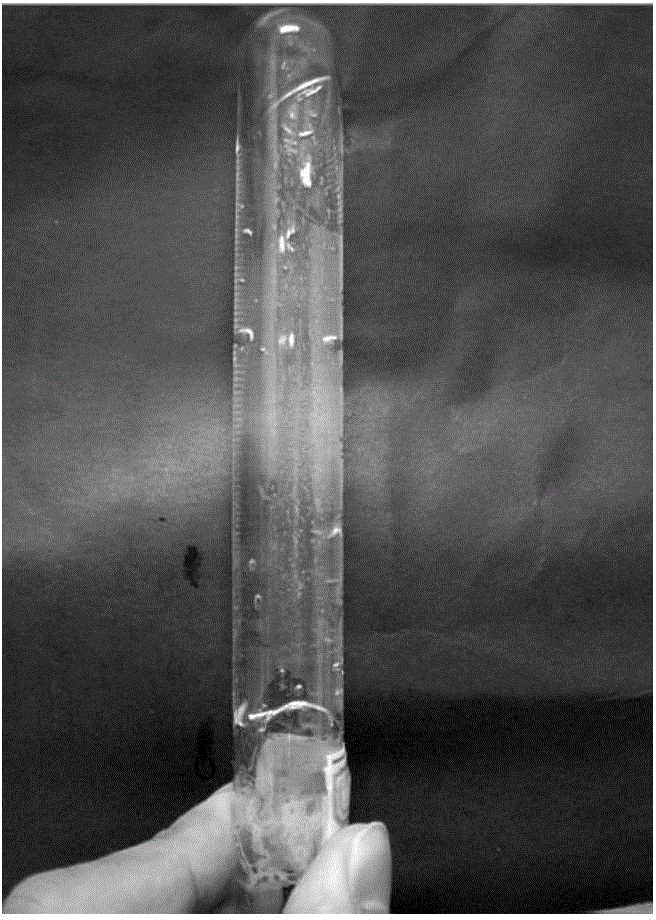

The invention provides a profile control agent for a water injection well and a preparation method and application thereof. The profile control agent is prepared from the following components by weight: 3 to 4 parts of acrylamide, 3 to 5 parts of bentonite, 0.1 to 0.2 part of a modified polypropylene fiber, 0.1 to 0.2 part of an initiator and 0.1 to 0.3 part of a cross-linking agent, with the balance being water, wherein the total weight of the components is 100 parts. The profile control agent for the water injection well has viscoelasticity and anti-shearing performance, overcomes the defects of great brittleness and no scouring resistance of an inorganic gel profile control agent prepared from single inorganic bentonite and has the excellent characteristics of temperature resistance, scouring resistance, a long profile control period and the like.

Owner:PETROCHINA CO LTD

Method for sealing casing breaking point of casing damaged well in oil field

InactiveCN108979585AReduce injection frictionNo Shrink CuringSealing/packingAbsorption capacityOil field

The invention provides a method for sealing a casing breaking point of a casing damaged well in an oil field. The method includes S1, inserting a drillable bridge plug below the casing breaking pointand filling sand to 5m below the casing breaking point, wherein a tubing and plugging type packer are inserted to the upper side of the casing breaking point to be sealed; S2, using the tubing to squeeze clean water to verify the casing breaking point and water absorption capacity thereof; S3, squeezing a low friction blocking agent A and a low viscosity liquid bridging plugging agent B; S4, unplugging the plugging type packer, plugging the wellbore, backwashing the shaft and taking out the tubing; S5, allowing the low friction blocking agent A and the low viscosity liquid bridging plugging agent B to perform non-shrinkage heat curing action at room temperature to form a solidified body after 10-24 hours; S6, inserting a screw drill to remove the plugging-type packer, the solidified body and the drillable bridging plug; S7, testing pressure to be 15MPa with clean water, wherein pressure dropping 0-0.5MPa in 30 minutes is qualified, pumping is completed, or otherwise, plugging is performed once more. With the method, plugging agent injection friction can be reduced, plugging agent injectivity is improved, high strength and non-shrinkage curing of the plugging agent entering cracks are achieved, and permanent plugging is realized.

Owner:PETROCHINA CO LTD

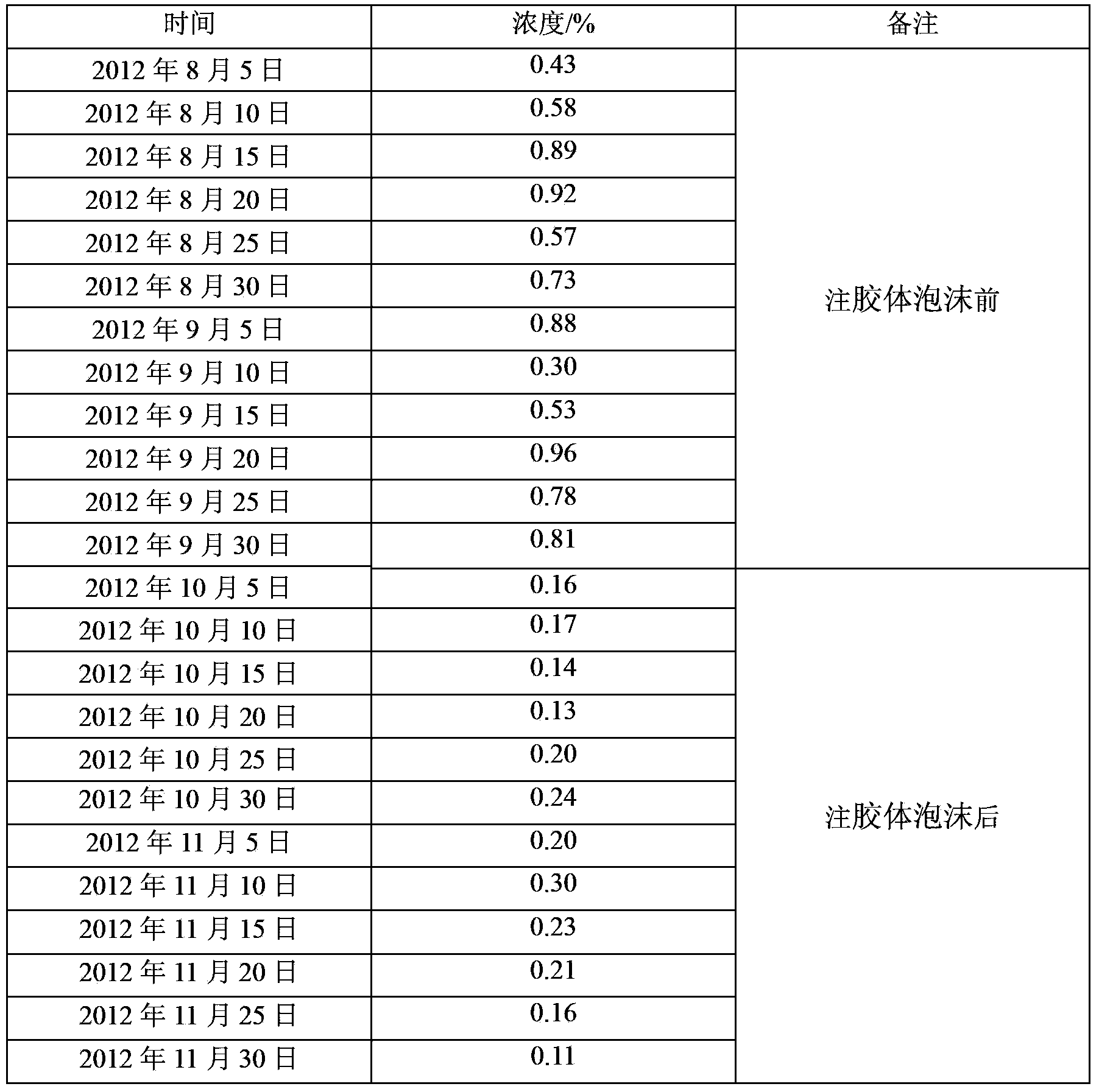

Method for preparing active-carbon-containing colloid gas foam for preventing gas emission in gob

InactiveCN103362532AIncrease in sizeGood shear thinning propertiesDust removalFire preventionActivated charcoal powderCross-link

Active-carbon-containing colloid gas foam for preventing gas emission in a gob is provided, wherein active carbon powder is dispersed into water and is added with certain amount of thickener to prepare an active-carbon-containing thick solution at a certain concentration, and small amount of cross linking agent and foaming agent are added into the solution and is physically and mechanically stirred and foamed under the action of air to prepare the active-carbon-containing colloid gas foam. After the colloid gas foam is injected into the gob through a slip casting pipeline of a mine, a large area of float coal in the gob can be covered and the coal crack can be blocked, the active carbon is used to fully adsorb the free gas in the gob, and meanwhile, a film-shaped colloid covering material like cloth is formed on the surface of the coal to achieve the purpose of long-lasting effective inhibition of emission of the coal gas. The effect of the active-carbon-containing colloid gas foam on preventing gas emission in the gob is remarkable, the cost is low, and the prospect of application is wide.

Owner:CHINA UNIV OF MINING & TECH

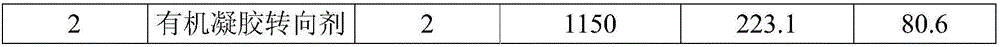

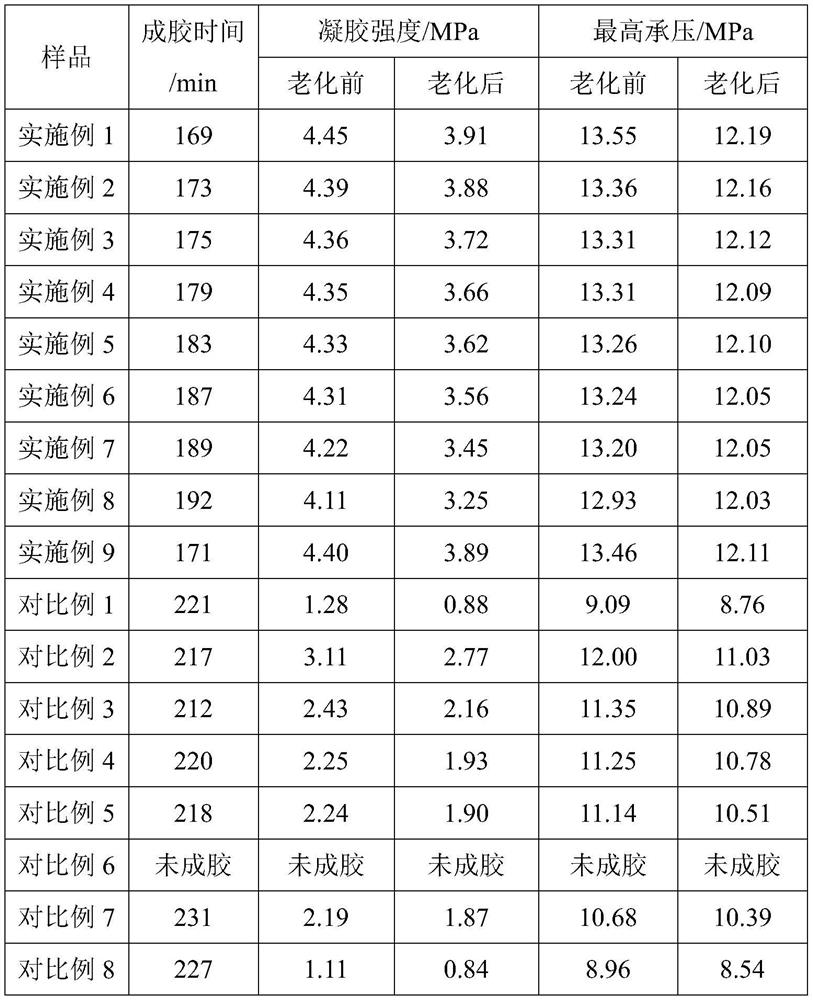

High temperature resistant gel diverting agent and manufacturing method therefor and application thereof

ActiveCN105112034AHigh strengthIncrease elasticityDrilling compositionSweep efficiencyUltimate tensile strength

The present invention provides a high temperature resistant gel diverting agent and a manufacturing method therefor and an application thereof. Based on a total weight of 100 parts, the high temperature resistant gel diverting agent comprises the following components in parts by weight : 3-5 parts of acrylamide, 1-3 parts of hydrolysis resistant monomer, 1-3 parts of salt resistant monomer, 1-3 parts of inorganic material, 0.03-0.06 parts of crosslinking agent, 0.05-0.15 parts of initiator, and water as the balance. According to the present invention, the high temperature resistant gel diverting agent not only has characteristics of high gel strength and adjustable gelling time, but also has a high temperature resistant capability and a flushing resistant property, so that a gel validity period of profile controlling and water plugging in a water injection oil well is prolonged, subsequently injected water is driven to an oil layer with a lower permeability, and water injection sweep efficiency and oil recovery efficiency are enhanced.

Owner:PETROCHINA CO LTD

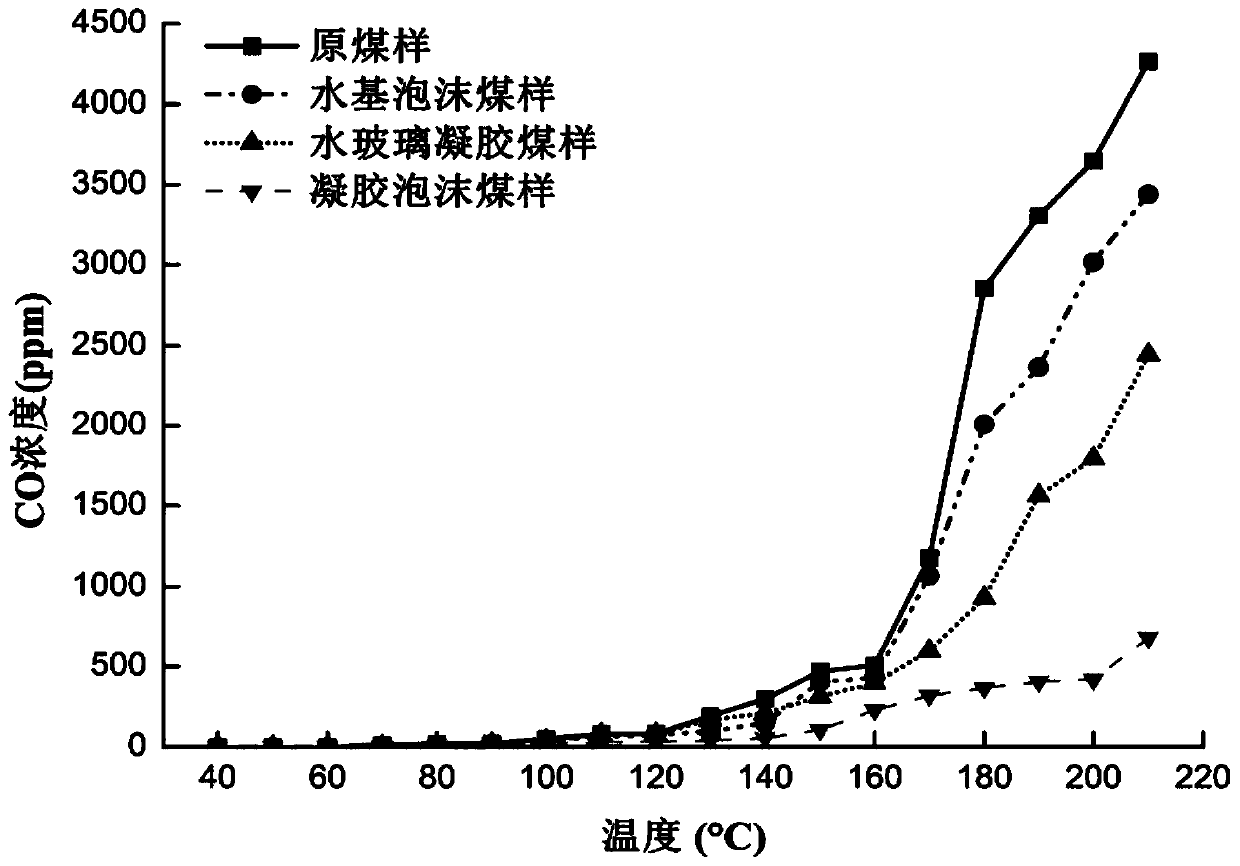

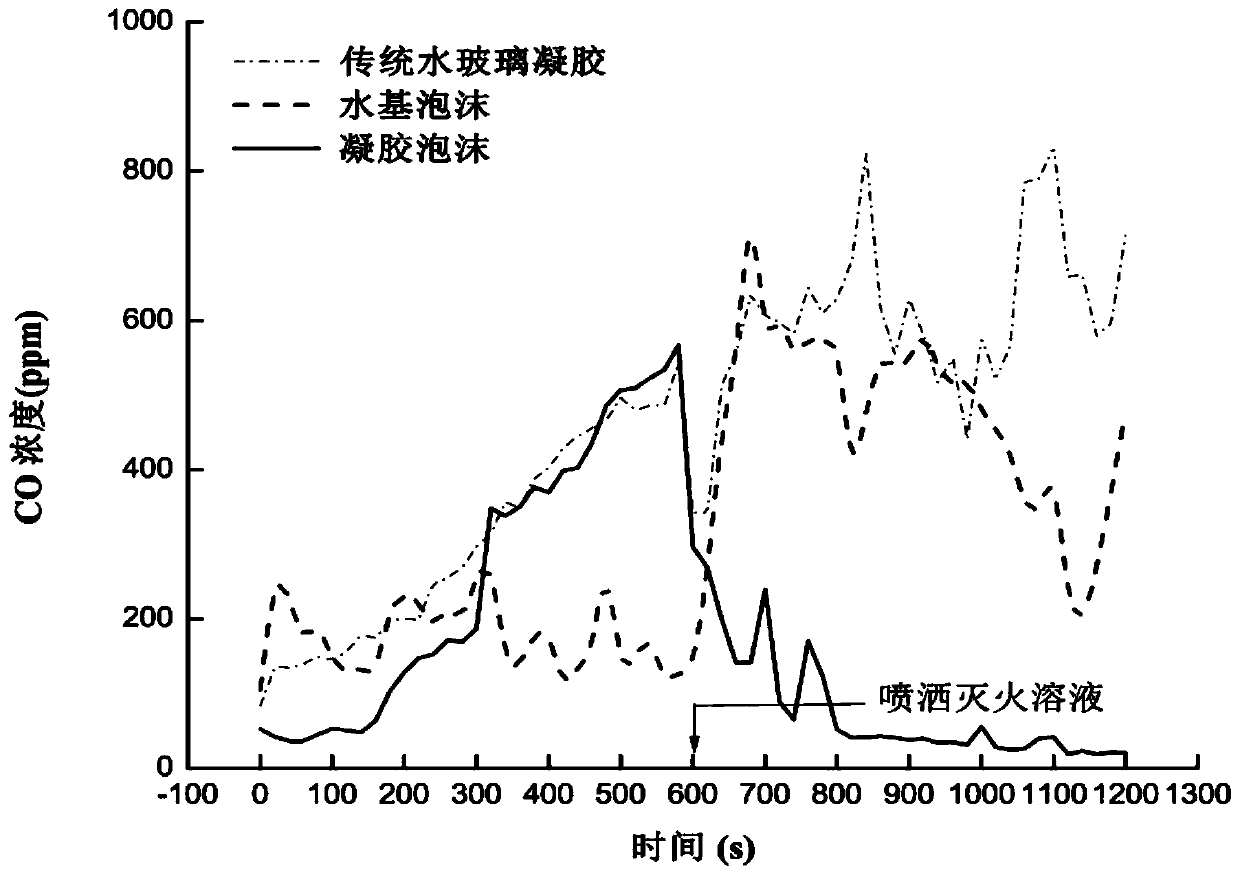

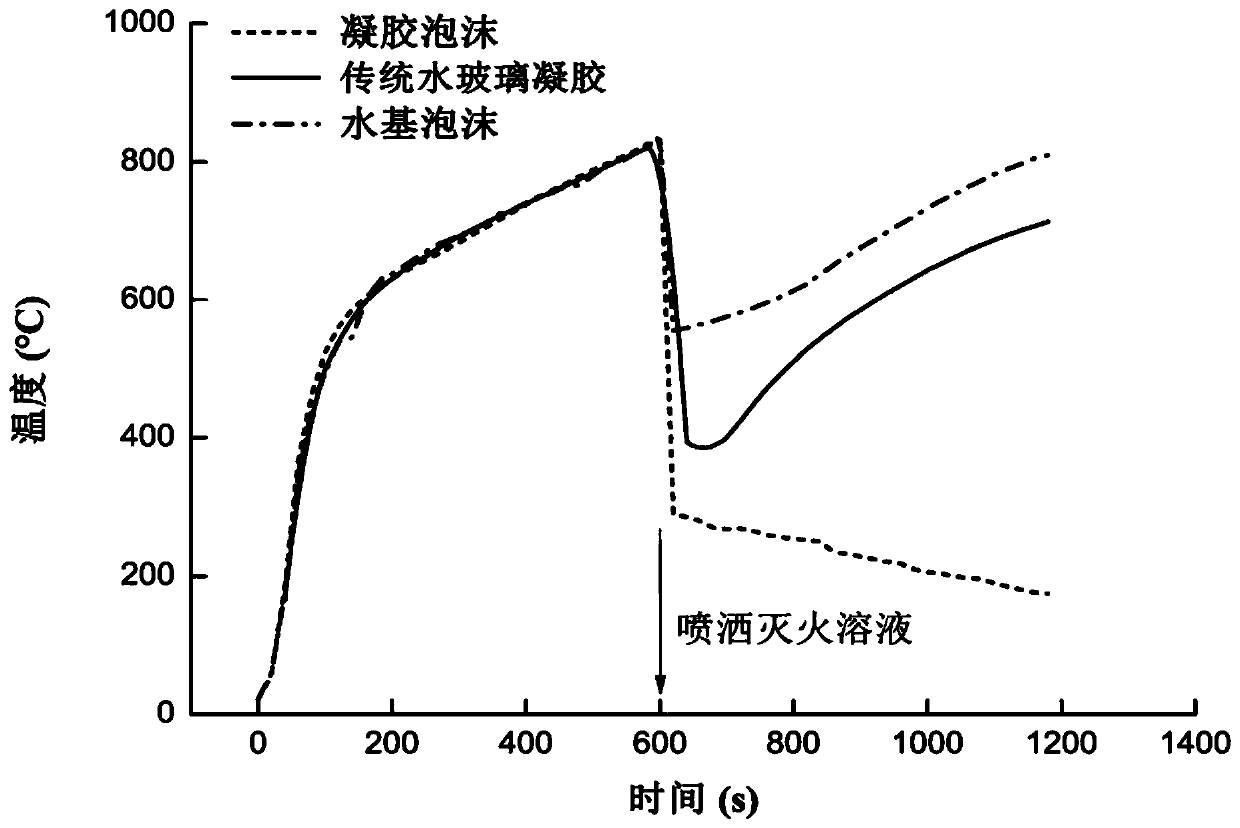

Economic and environment-friendly gel foam for preventing and curing coal spontaneous combustion

InactiveCN109899104APromote foam volumeSolve liquidity problemsMining devicesDust removalWater basedFoaming agent

The invention relates to the technical application field of coal mine fire preventing and extinguishing, and provides economic and environment-friendly gel foam for preventing and curing coal spontaneous combustion. The economic and environment-friendly gel foam is prepared from the components in percentage by weight: 4% to 35% of water glass, 0.4% to 3% of a foaming agent, 0.1% to 3% of a foam stabilizing agent, 1% to 5% of a coagulant, and the balance of water; and the foaming agent is formed by compounding two or more anionic-type foaming agents. According to the economic and environment-friendly gel foam for preventing and curing coal spontaneous combustion, the adopted foaming agent is formed by compounding two or more anionic-type foaming agents, an adopted gelatinizing system is composed of the water glass and the coagulant, the cost is low, economy and environmental protection are realized, and the gel foam is non-poisonous and harmless during using and has good economic benefits. The obtained gel foam maintains the advantages of high fluidity and good aggregation of water-based foam before gelatinizing, and after gelatinizing, the advantages of the outstanding cooling effect and the good leak sealing effect of water glass gel are maintained; and the gel foam is good in inhibition and fire extinguishing effect, the fire source temperature, thermal radiation and CO output can be significantly reduced, fire extinguishing is stable, and the reignition phenomenon does not occur.

Owner:SHANDONG UNIV OF SCI & TECH

Chromium-free crosslinking system

InactiveCN103694974AGood gelling performanceHigh viscosityDrilling compositionChromium freePolyacrylamide

The invention provides a chromium-free crosslinking system which comprises the following components in percentage by weight: 0.2-0.6wt% of crosslinking agent host, 0.1-0.3wt% of additive, 0.3-0.6wt% of polymer and the balance of water. The crosslinking agent can be aluminium citrate, polyhydroxymelamine etherate and low-crosslinking degree phenolic resin; the additive is thiourea; and the polymer is polyacrylamide. The chromium-free crosslinking system provided by the invention has the beneficial effects that the formed gel has certain viscosity and strength as well as fluidity and stability under certain pressure.

Owner:TIANJIN DAGANG OILFIELD BINGANG GRP BOHONG PETROLEUM CHEM

High pressure-resistant leak stoppage agent and leak stoppage slurry containing same

ActiveCN101955763AHigh plugging capacity and pressure bearing capacityImprove plugging success rateDrilling compositionGramHigh pressure

The invention relates to a high pressure-resistant leak stoppage agent and leak stoppage slurry containing the same. The high pressure-resistant leak stoppage agent consists of the following components in percentage by mass: 25.0 to 27.0 percent of soybean particles, 31.0 to 32.0 percent of walnut shell flour, 7.1 to 7.5 percent of vermiculite, 2.1 to 2.5 percent of peanut hull meal, 22.0 to 22.5percent of cement and 10.0 to 11.0 percent of flocculation coating agent LHB-105 for drilling fluid. The leak stoppage slurry consists of base slurry and the high pressure-resistant leak stoppage agent, wherein 3 to 9 grams of high pressure-resistant leak stoppage agent is added into every 100 milliliters of base slurry. The leak stoppage agent and the leak stoppage slurry stop leaking by combining chemical leak stoppage with particle bridging leak stoppage, so that the technical problems of aperture leak, crack leak and fracture leak under a well can be solved. The leak stoppage agent and the leak stoppage slurry are suitable for severe well leakage caused by a pore formation, a crack formation, a long-section broken formation and the like and can be applied to leak layer construction ofwhich the leak position is difficultly determined.

Owner:北京奥凯立科技发展股份有限公司

High temperature resistance gel plugging agent and preparation method and application thereof

ActiveCN109280542AMeet basic performance requirementsImprove pressure bearing capacityDrilling compositionSealing/packingCross-linkTemperature resistance

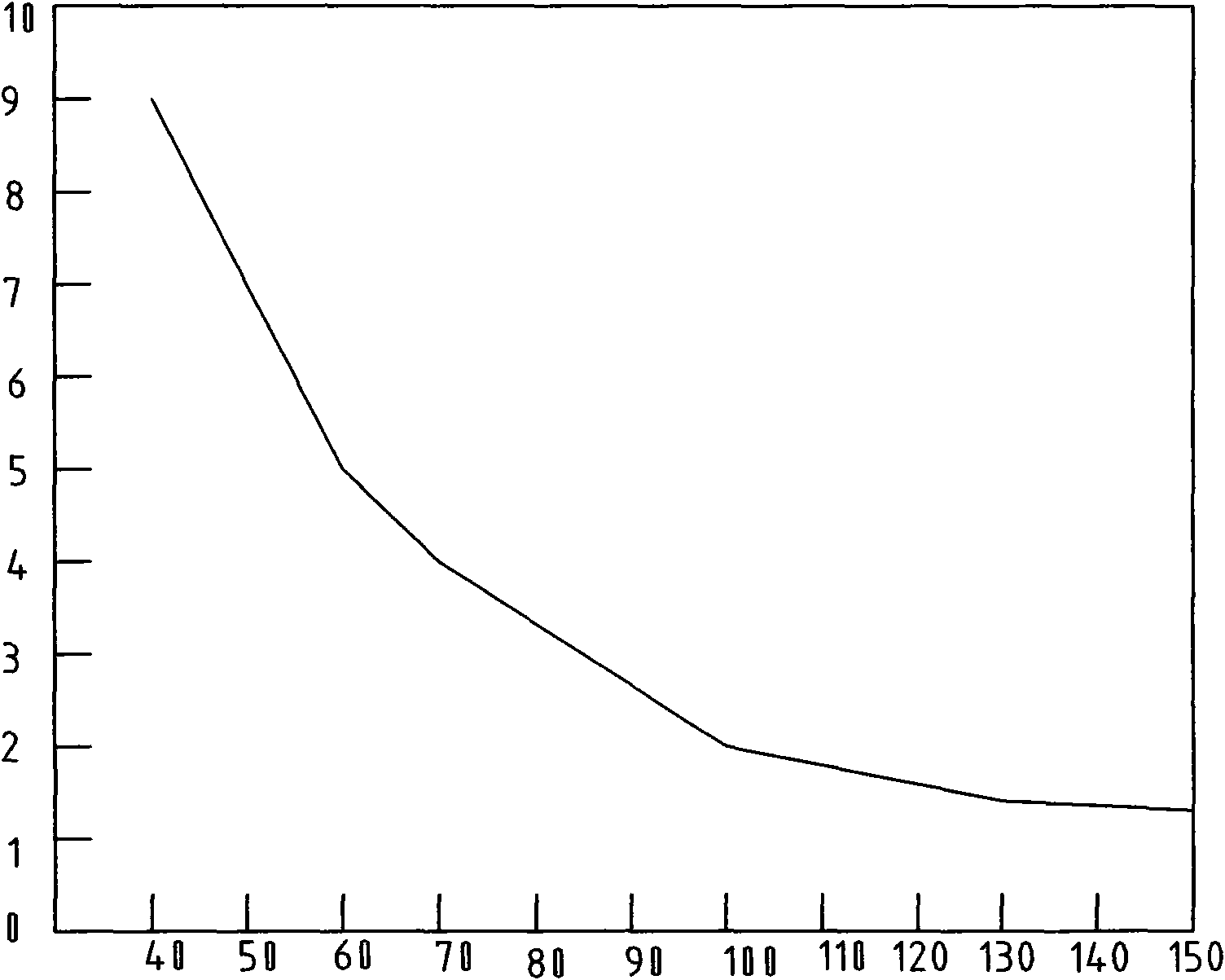

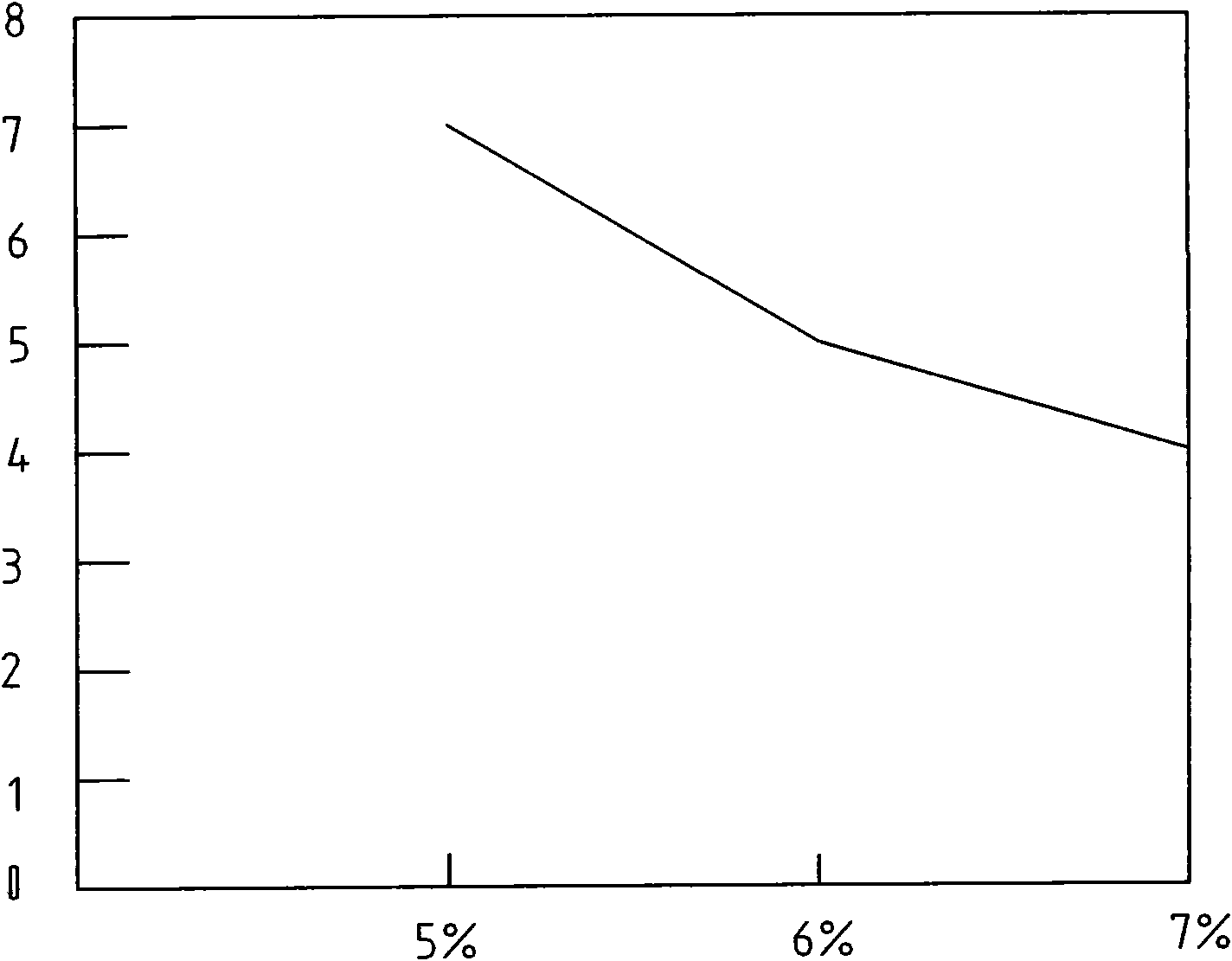

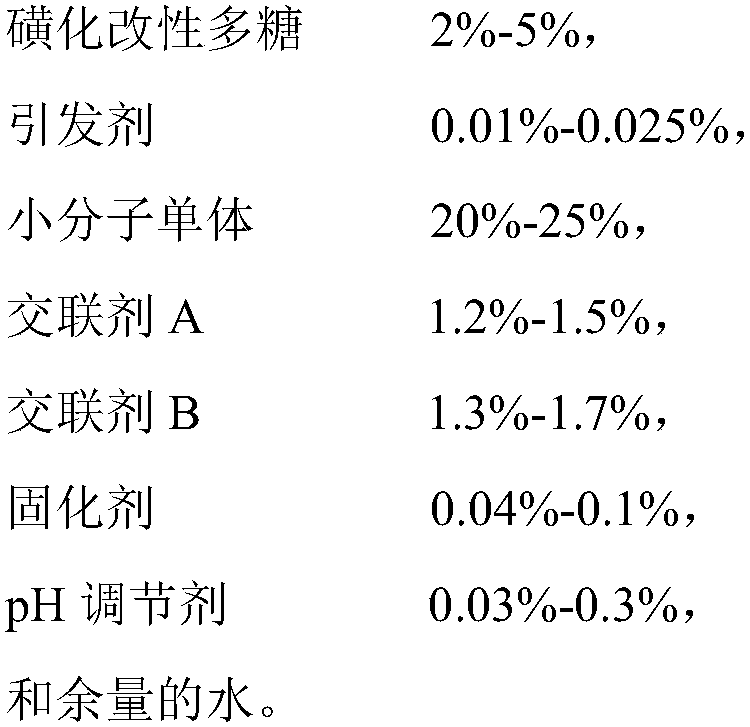

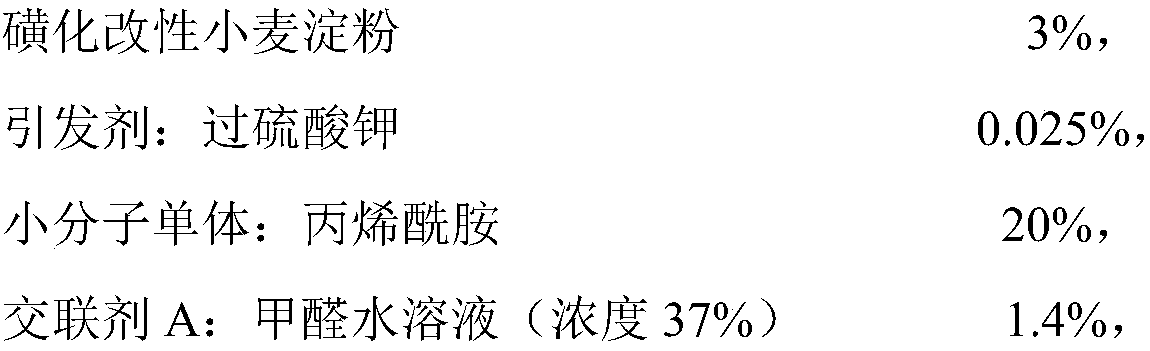

The invention provides a high temperature resistance gel plugging agent and a preparation method and an application thereof. Raw material of the high temperature resistance gel plugging agent include,100% by weight, the following components: 2%-5% of sulfonation modification polysaccharide, 0.01%-0.025% of an initiator, 20%-25% of a small molecule monomer, 1.2%-1.5% of a cross-linking agent A, 1.3%-1.7% of a cross-linking agent B, 0.04%-0.1% of a curing agent, 0.03%-0.3% of a pH conditioning agent, with the balance being water. The high temperature resistance gel plugging agent provided by the invention is high in pressure bearing capacity, can meet basic performance requirements of non-well killing job on a gel system, is particularly suitable for the field of underbalanced operation ofmedium and high pressure oil and gas wells, is controllable in glue forming time, is wide in range of application, is good in temperature resistance, can adapt to a temperature range of 100-150 DEG C,is simple in preparation process, and can meet process requirements of field applications of the non-well killing job.

Owner:PETROCHINA CO LTD +1

Volume expansion type efficient slug gel plugging agent and preparation method thereof

ActiveCN112877045AGel forming time is controllableWide temperature adaptabilityDrilling compositionPolymer scienceCross linker

The invention provides a volume expansion type efficient slug gel plugging agent and a preparation method thereof. The volume expansion type efficient slug gel plugging agent is prepared from the following raw materials in parts by mass: 10-35 parts of a polymerization reaction agent, 1-3 parts of a cross-linking agent a, 0.02-0.5 part of a suitable-temperature initiator, 0.5-5 parts of a water-soluble resin flexibilizer, 0.5-5 parts of a composite inorganic flexibilizer, 2-8 parts of modified starch, 2-10 parts of a volume expansion reaction agent and 2-8 parts of a rheological modifier, wherein the volume expansion reaction agent is prepared from the following raw materials through an inverse emulsion polymerization method: a water-soluble polymeric monomer, a dispersion medium, an emulsifier, an oil-phase initiator and a cross-linking agent b. The plugging agent disclosed by the invention has the advantages of capability of underground crosslinking gel forming, flexible and adjustable gel forming time, high pressure bearing capacity after gel forming, relatively high water absorption expansibility, excellent mechanical strength after water absorption and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

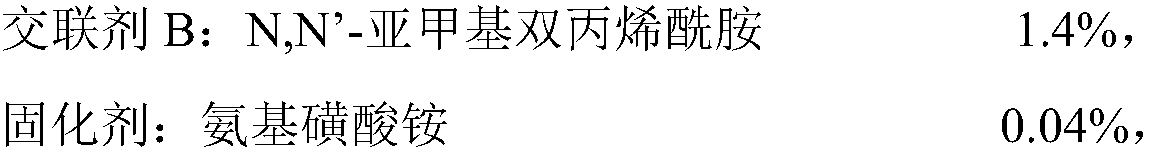

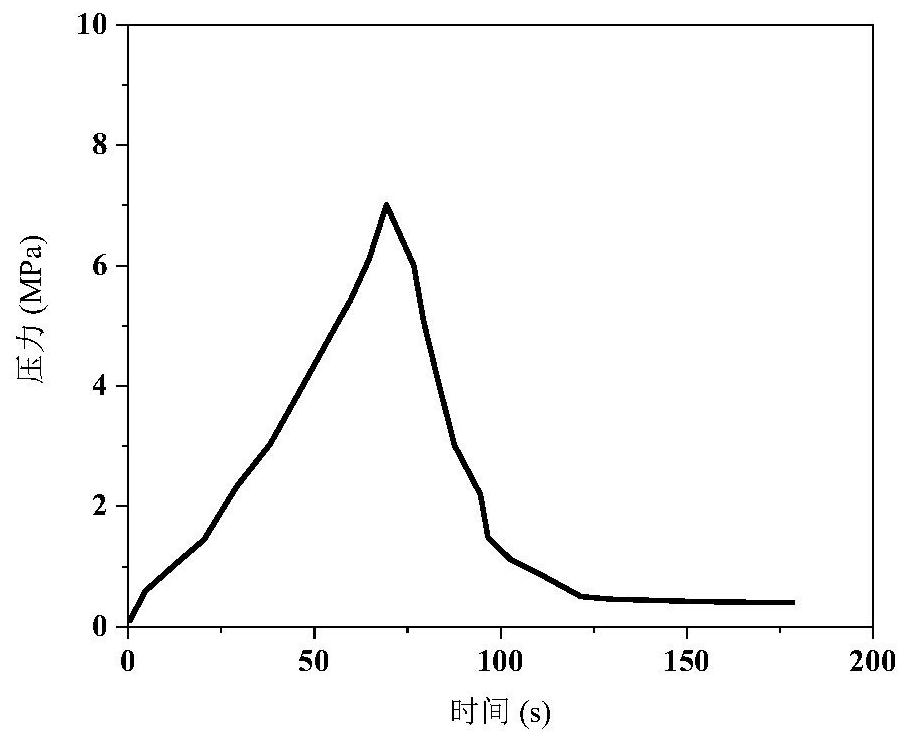

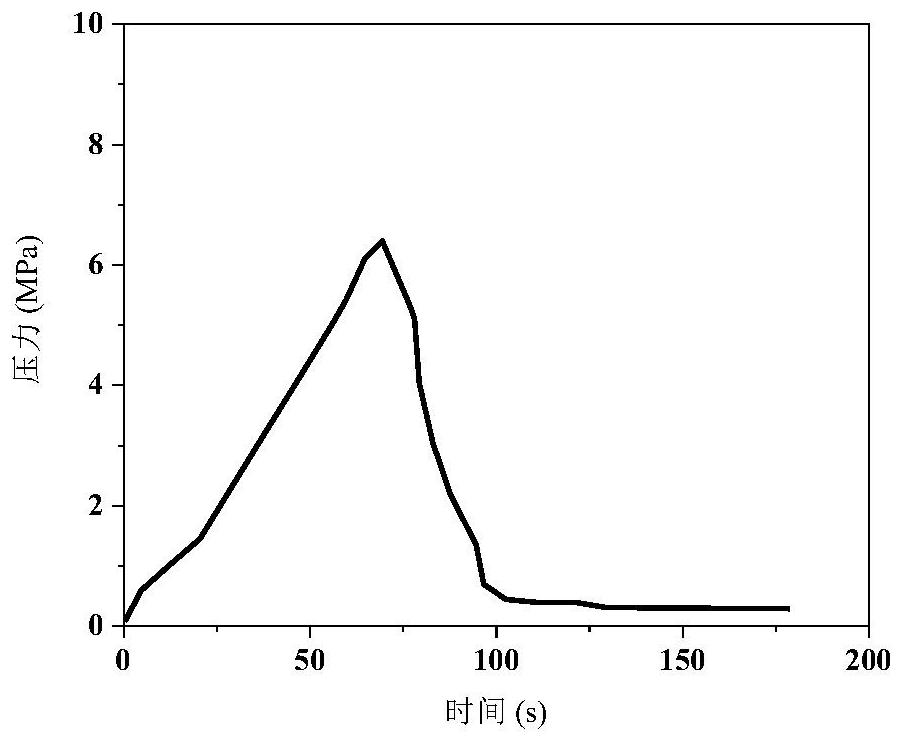

High-strength gel for snubbing operation and preparation method of high-strength gel

The invention relates to a high-strength gel for snubbing operation and a preparation method of the high-strength gel. The high-strength gel is characterized by being prepared from the following components in percentage by weight: 2%-5% of starch; 0.01%-0.1% of an oxidation-reduction initiator, 5%-13% of a cross-linking agent, 5%-20% of a cross-linking agent B, 10%-15% of an inimer, 0.015-0.1% of a curing agent and the balance of water. The preparation method comprises the steps; under the condition of stirring, dexitrinizing the starch in water in a proportion at a temperature ranging from 60 to 90 DEG C for 1-3 hours and then regulating the pH value of the solution to the range of 8-13 at the temperature of 30-150 DEG C; standing at constant temperature, sequentially adding the oxidation-reduction initiator, the inimer, the cross-linking agent A, the cross-linking agent B and the curing agent in a proportion, and uniformly stirring all the materials, and further standing, thereby obtaining the high-strength gel. The obtained high-strength gel has extremely high compressive strength and tube wall adhesion, is capable of meeting the basic property requirements of the snubbing operation on a gel system and controllable in gelation time, gel strength and viscosity, and has the characteristics of simple process, easily available raw materials and low cost.

Owner:YANGTZE UNIVERSITY

Plugging agent synergist, gel containing same as well as preparation method and application of gel

InactiveCN104357033AImprove gelationGel forming time is controllableDrilling compositionEpoxyRoom temperature

The invention discloses a plugging agent synergist, and belongs to the field of chemical engineering. The plugging agent synergist comprises the following components by weight percent: 8-10% of epoxy chloropropane, 10-15% of ammonium chloride, 20-25% of glycine betaine, 3-5% of sodium carboxymethylcellulose, and the balance of water. The gel added with the plugging agent synergist has the advantages that the gelling time is adjustable (different plugging treatment can be implemented according to different time), the gel breaking time can reach 3 months above, the applicable oil reservoir is wide in range and comprises high, medium and low permeation stratums, the applicable temperature is wide in range and is from the room temperature to 150 DEG C of an oil reservoir, and the gel can be applicable to water with different degrees of mineralization within the range from 0-100000 mg / L; therefore, a gel system can be freely applied to various aspects such as profile control, water plugging, leaking stoppage and oil displacement, and larger space is provided for the further improvement of the recovery efficiency.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

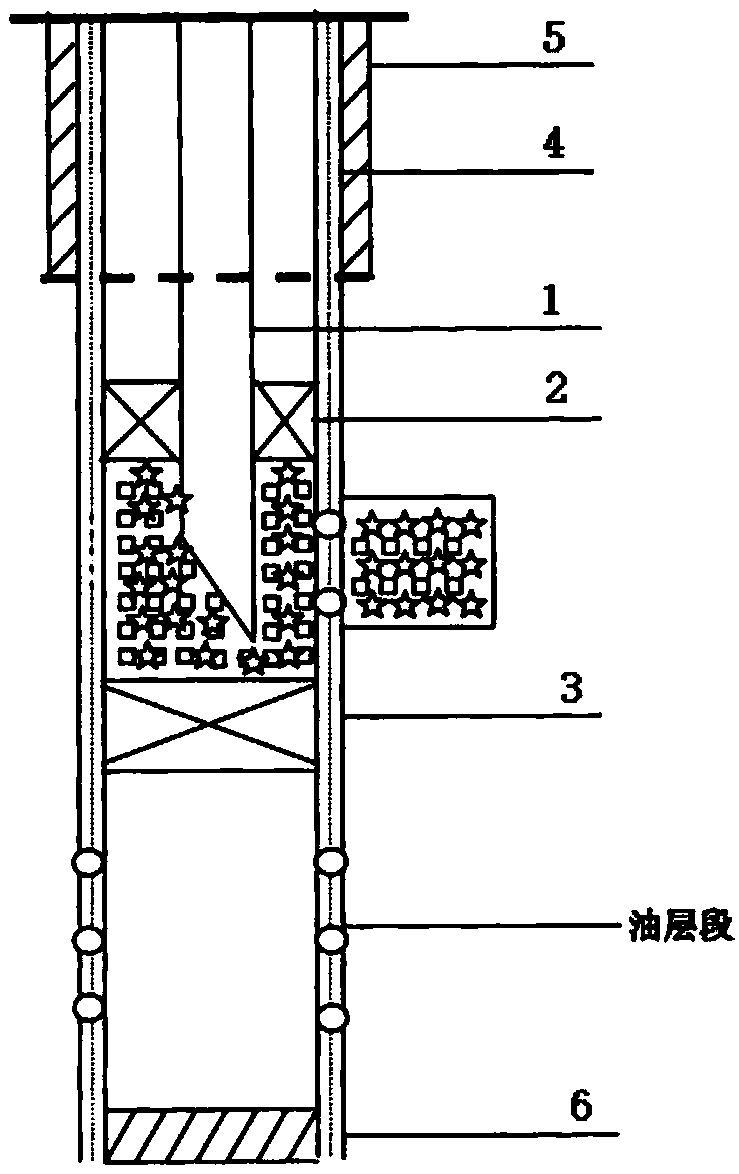

Comprehensive mining technology of drowned well

InactiveCN102767353AIncrease the blocking radiusImprove water blocking effectFluid removalPre treatmentOil production

The invention discloses a comprehensive mining technology of a drowned well, comprising the step 1: stratum unblocking pretreatment prior to water plugging; step 2: shallow plugging; step 3: deep plugging adjustment; and step 4: hydraulic deep penetration perforating and oil production recovery of an oil well. According to the characteristics of the drowned well, multiple mature technologies are organically comprehensively applied, with the combination of first dredging and subsequent plugging, the problem that no oil is produced after plugging is effectively solved. By first shallow plugging and subsequent deep plugging adjustment and in combination with hydraulic deep penetration perforating, the period of validity of mining is effectively prolonged and the input-output ratio is improved.

Owner:XINJIANG HUAYOU TECH SERVICE

High pressure-resistant leak stoppage agent and leak stoppage slurry containing same

The invention relates to a high pressure-resistant leak stoppage agent and leak stoppage slurry containing the same. The high pressure-resistant leak stoppage agent consists of the following components in percentage by mass: 25.0 to 27.0 percent of soybean particles, 31.0 to 32.0 percent of walnut shell flour, 7.1 to 7.5 percent of vermiculite, 2.1 to 2.5 percent of peanut hull meal, 22.0 to 22.5 percent of cement and 10.0 to 11.0 percent of flocculation coating agent LHB-105 for drilling fluid. The leak stoppage slurry consists of base slurry and the high pressure-resistant leak stoppage agent, wherein 3 to 9 grams of high pressure-resistant leak stoppage agent is added into every 100 milliliters of base slurry. The leak stoppage agent and the leak stoppage slurry stop leaking by combining chemical leak stoppage with particle bridging leak stoppage, so that the technical problems of aperture leak, crack leak and fracture leak under a well can be solved. The leak stoppage agent and the leak stoppage slurry are suitable for severe well leakage caused by a pore formation, a crack formation, a long-section broken formation and the like and can be applied to leak layer construction of which the leak position is difficultly determined.

Owner:北京奥凯立科技发展股份有限公司

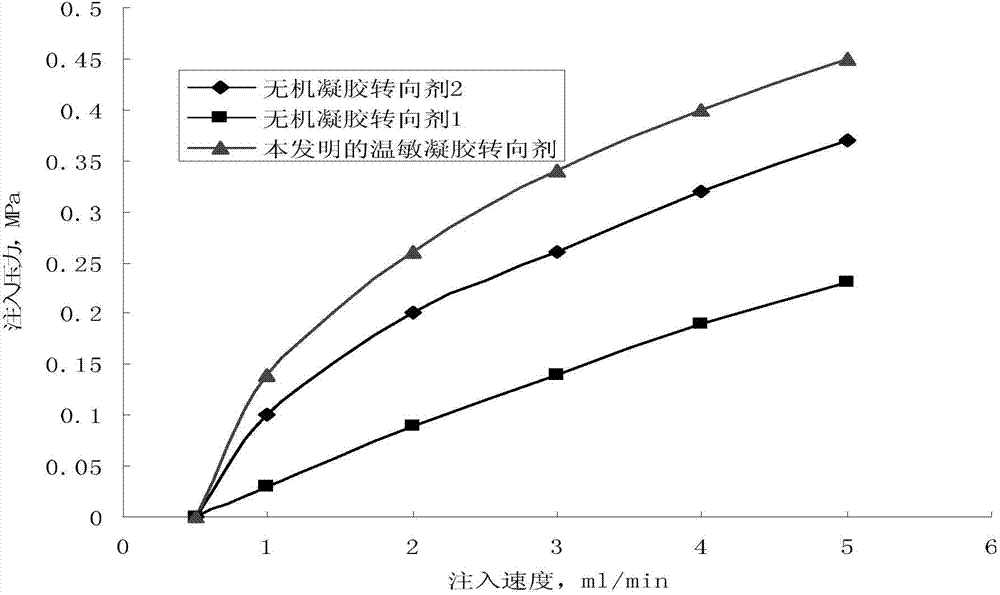

Temperature-sensitive gel diverting agent and preparation method and application of temperature-sensitive gel diverting agent

InactiveCN104263338AImprove anti-scourabilityHigh gel strengthDrilling compositionUltimate tensile strengthGel time

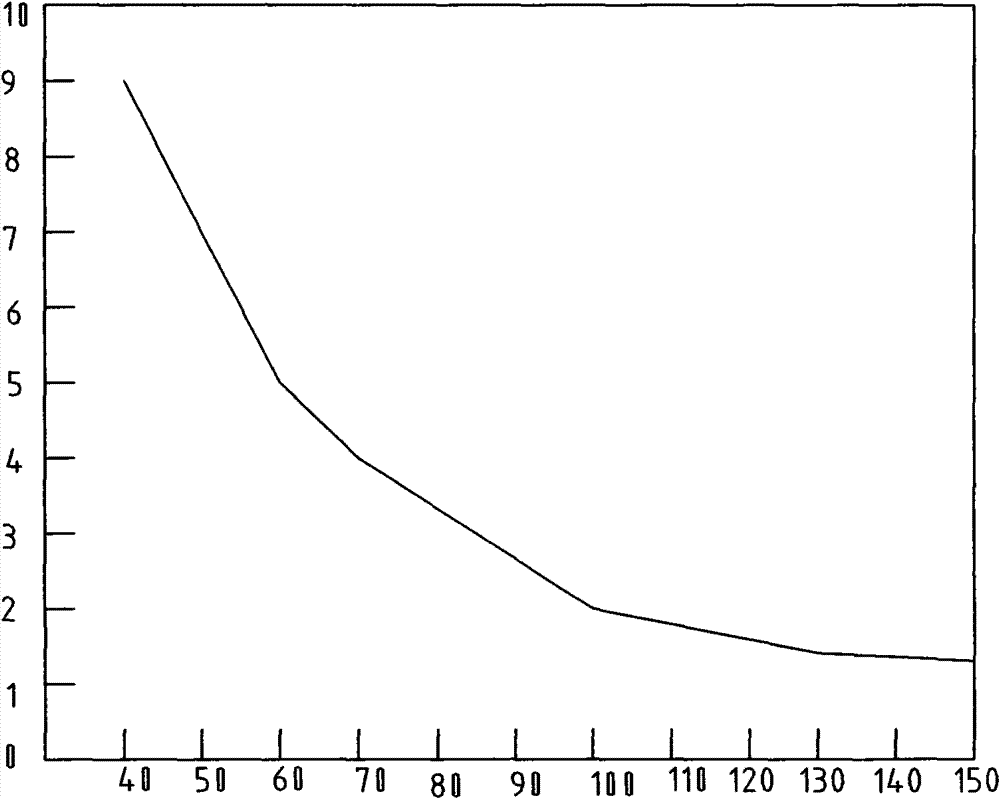

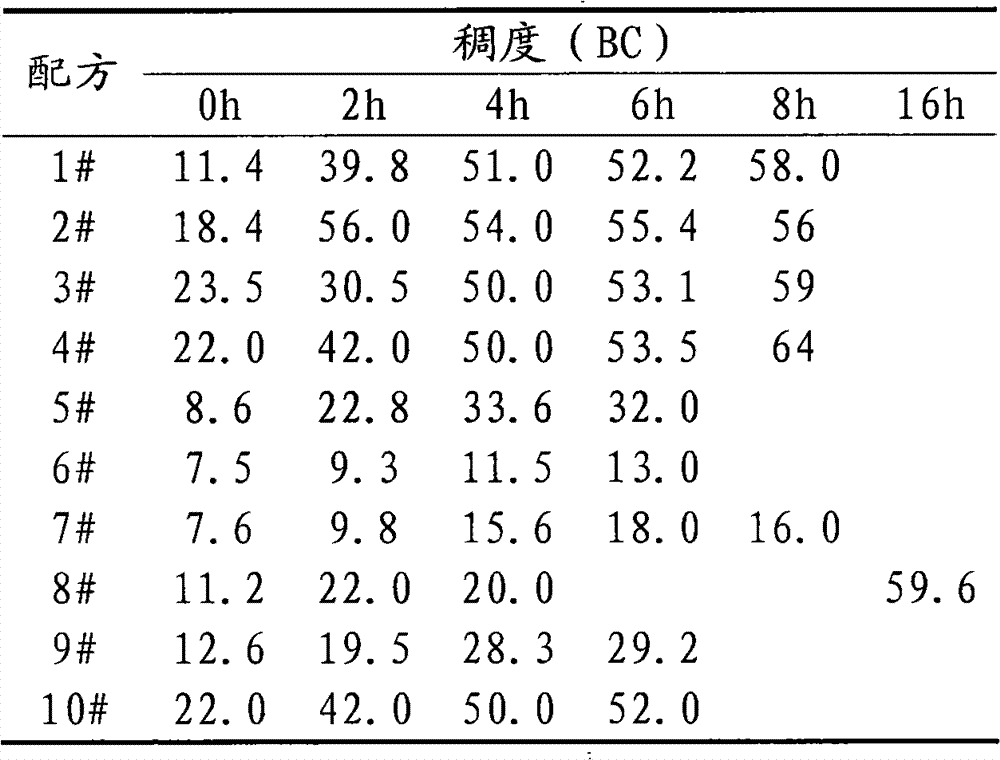

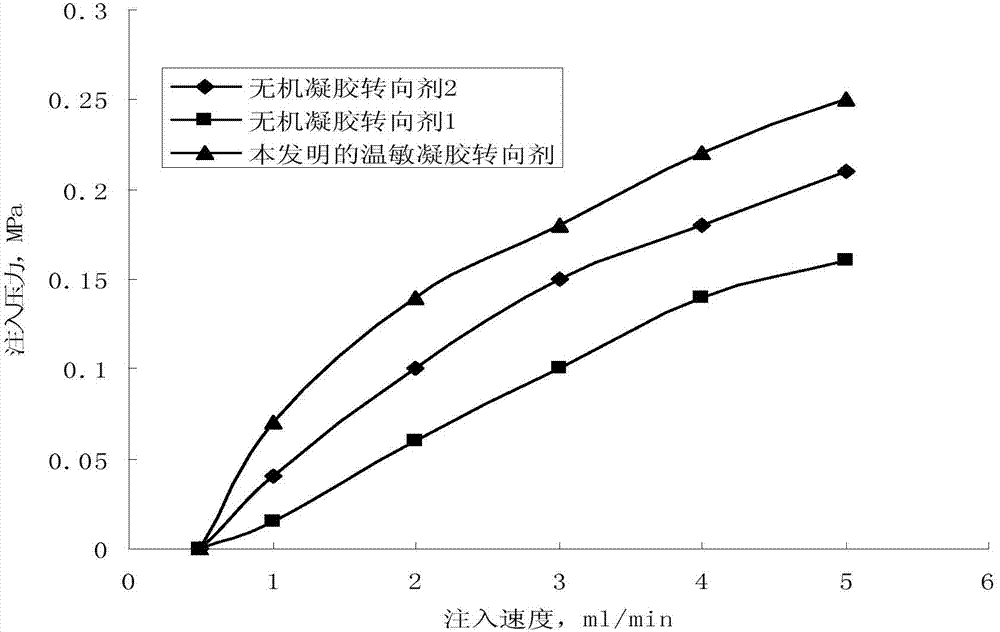

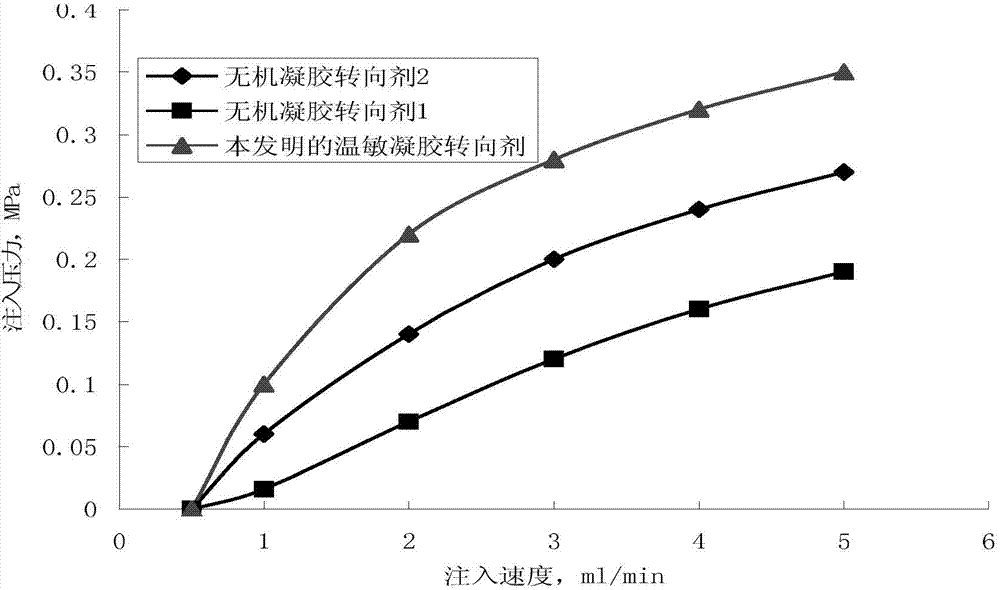

The invention provides a temperature-sensitive gel diverting agent and a preparation method and application of the temperature-sensitive gel diverting agent. The temperature-sensitive gel diverting agent is mainly prepared from the following components in parts by weight: 1-3 parts of acrylamide, 1-3 parts of an inorganic material, 0.5-1.5 parts of potential alkali, 0.05-0.15 part of a cross-linking agent, 0.1-0.2 part of an initiator and the balance of water, wherein the components are 100 parts in total weight. The novel temperature-sensitive gel diverting agent synthesized by the invention also has certain erosion resistance besides the characteristics of certain jelly strength and adjustable gelling time (5-20 hours), and is capable of prolonging the validity period of profile control of a water injection well by the gel, the subsequently injected water is compelled to turn to an oil reservoir with relatively low permeability, and the water injection wave and efficiency and the oil recovery factor can be improved.

Owner:PETROCHINA CO LTD

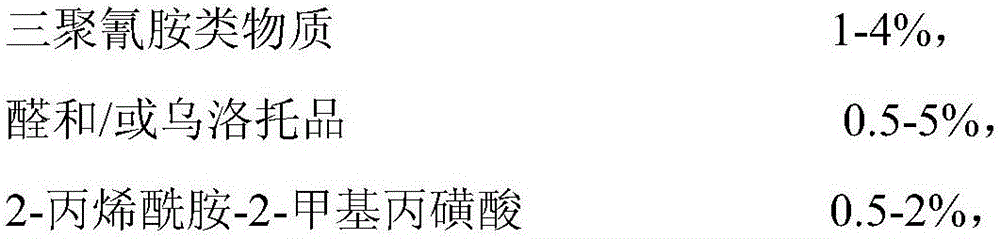

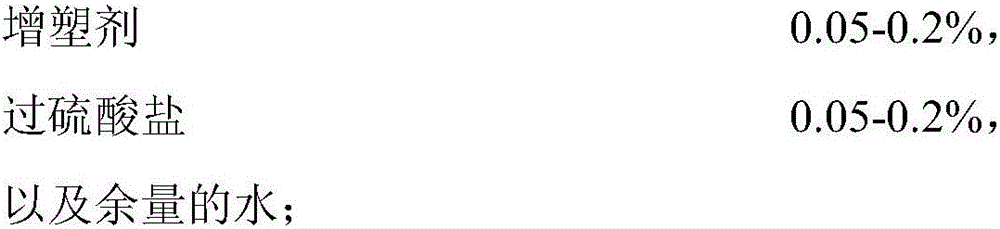

Steam-displacement ultrahigh-temperature channeling sealing agent, and preparation method and application thereof

The invention provides a steam-displacement ultrahigh-temperature channeling sealing agent, and a preparation method and application thereof. The steam-displacement ultrahigh-temperature channeling sealing agent comprises the following components in percentage by weight: 1-4% of melamine substance, 0.5-5% of aldehyde and / or urotropine, 0.5-2% of 2-acrylamido-methylpropylsulfonic acid, 0.05-0.2% of plasticizer, 0.05-0.2% of persulfate and the balance of water. The steam-displacement ultrahigh-temperature channeling sealing agent has the characteristics of favorable pumpability, favorable temperature resistance, long-term effectiveness, simple preparation process, low cost and the like, has the advantages of adjustable gelling time and high sealing, plugging capacity and wide oil reservoir variety applicability, can not easily pollute the stratum, can enter the deep stratum, and effectively solves the production problems of nonuniform steam suction cross section, steam channeling among wells and the like in the steam-displacement oil reservoir.

Owner:PETROCHINA CO LTD

Gel plugging agent for plugging fluid channeling big channel of medium-temperature oil reservoir and preparation method thereof

InactiveCN106590557AShear-resistant and salt-resistantHigh strengthDrilling compositionSalt resistanceSolubility

The invention relates to the technical field of water injection well oil extraction and especially relates to a rigid gel plugging agent for plugging a fluid channeling big channel of a medium-temperature oil reservoir. The rigid gel plugging agent comprises, by mass, 3.0% to 5.0% of acrylamide, 3.0% to 5.0% of a molecular chain-grafted enhancer, 0.03% to 0.15% of N, N-methylene bisacrylamide, 0.005% to 0.015% of azobis(isobutyramidine) hydrochloride and the balance of water. The rigid gel plugging agent has good shear and salt resistance, high strength, good thermal stability, good solubility and cold water solubility, and can form a uniform solution which is not easy to settle and has good injection performances. The solution of the rigid gel plugging agent before gelling has a certain viscosity. Through combined action of a gelling control agent and a reservoir temperature, the rigid gel plugging agent forms gel underground and gelling time can be controlled.

Owner:CNPC GREATWALL DRILLING ENG

Hydrogen-bonding hydrogel suitable for plugging cracks and caves

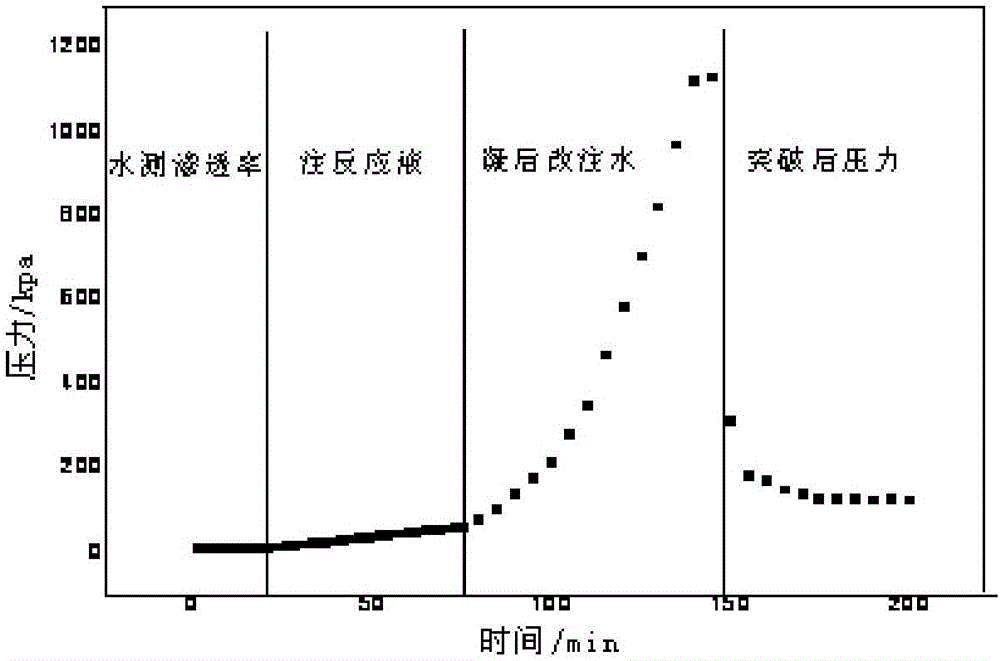

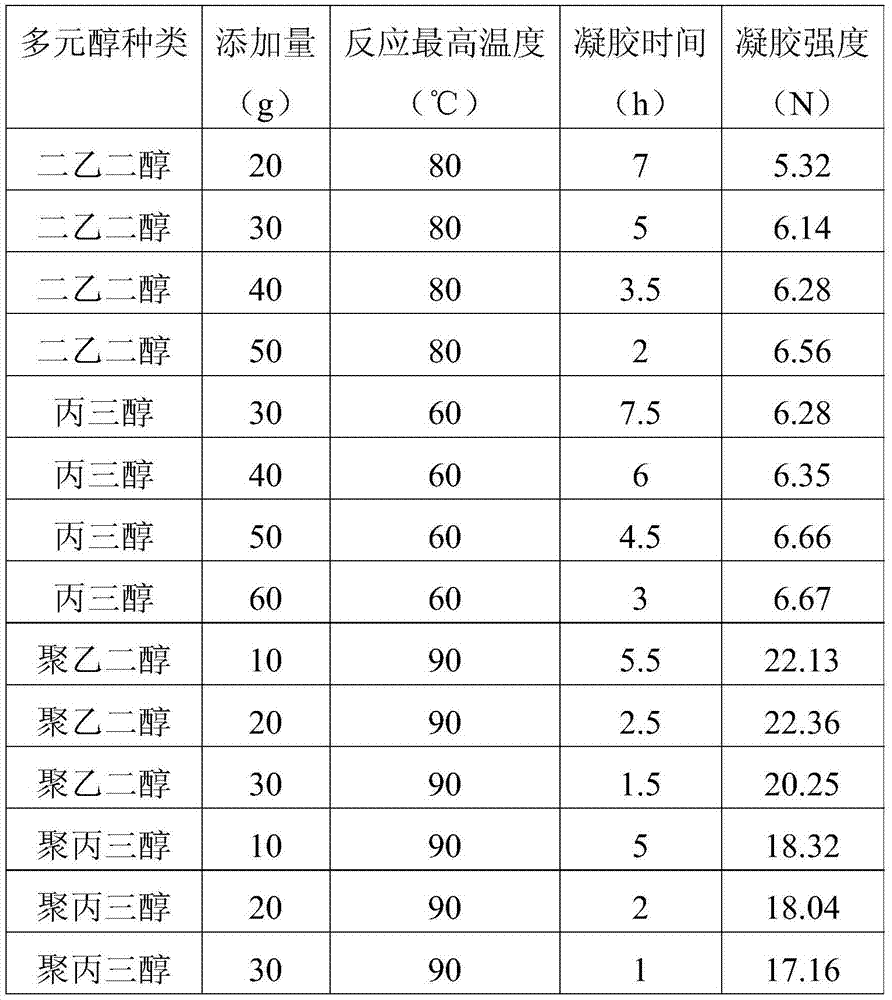

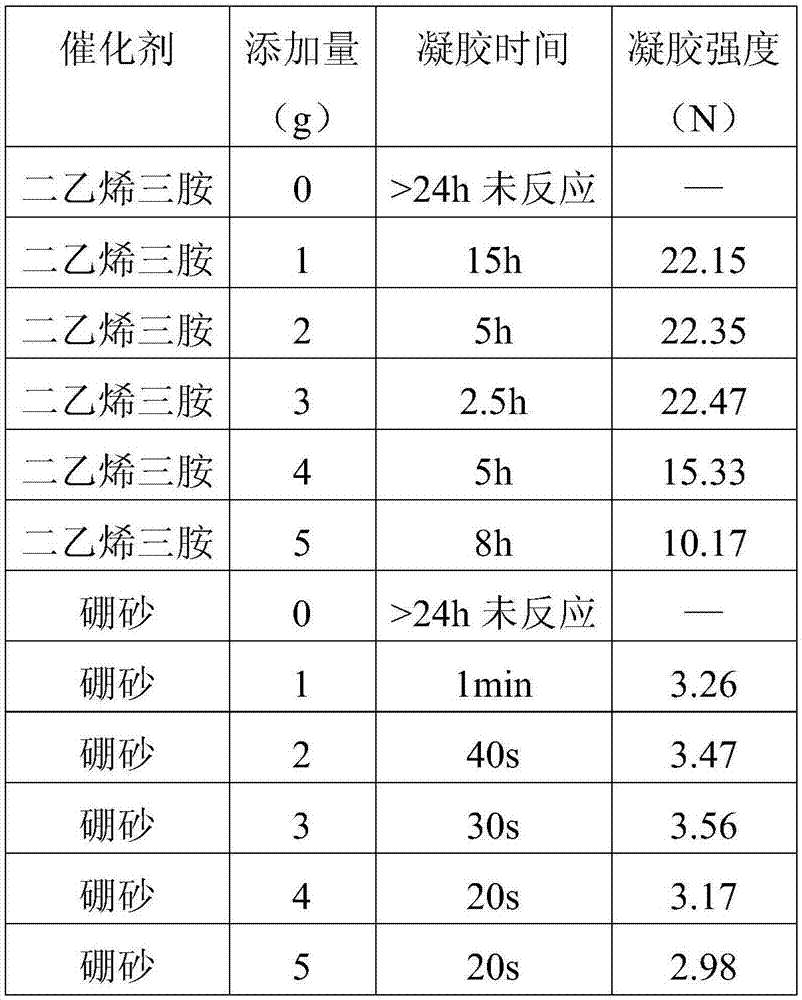

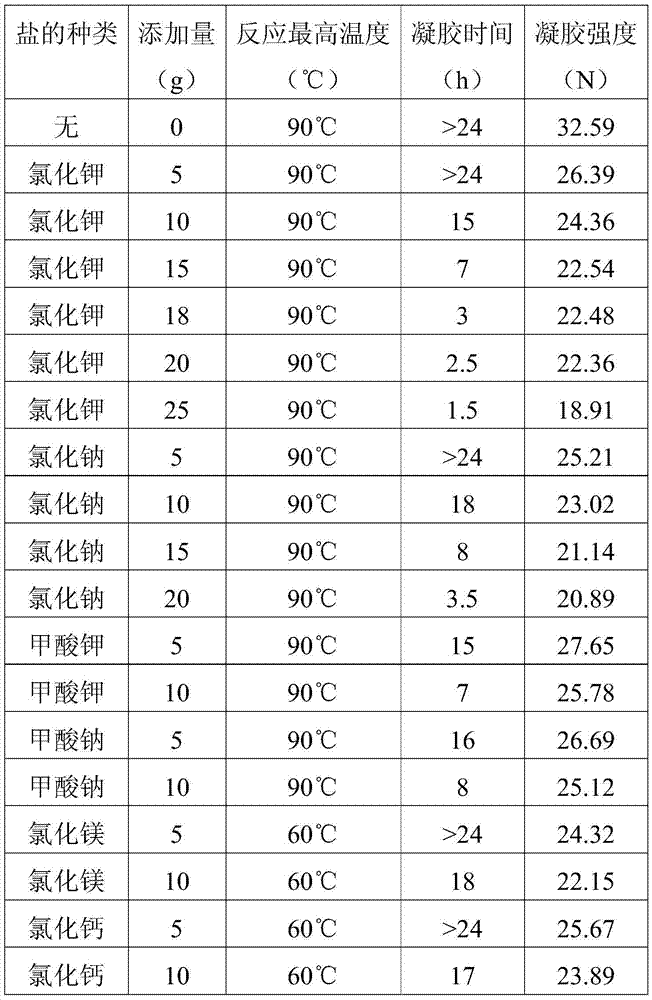

ActiveCN105441046AGel forming time is controllableMeet construction requirementsDrilling compositionPolyolHydrogen

The invention discloses hydrogen-bonding hydrogel suitable for plugging cracks and caves. The hydrogen-bonding hydrogel comprises raw materials in parts by weight as follows: 5-10 parts of polyvinyl alcohol, 10-30 parts of polyols, 1-5 parts of a catalyst, 15-25 parts of salt, 0-100 parts of a weighting agent and 100 parts of water. The gelling time of the hydrogel is controllable, the initial setting time of the hydrogel is 120-240 min according to requirements of different layers, the time interval can basically meet most construction requirements, and the hydrogel can be formed from the room temperature to 90 DEG C; the hydrogel has sufficient strength, has certain cementing power with a formation, and cannot be crushed or remain in the cracks when bearing the pressure difference between a fluid in a well and the formation.

Owner:YANGTZE UNIVERSITY +1

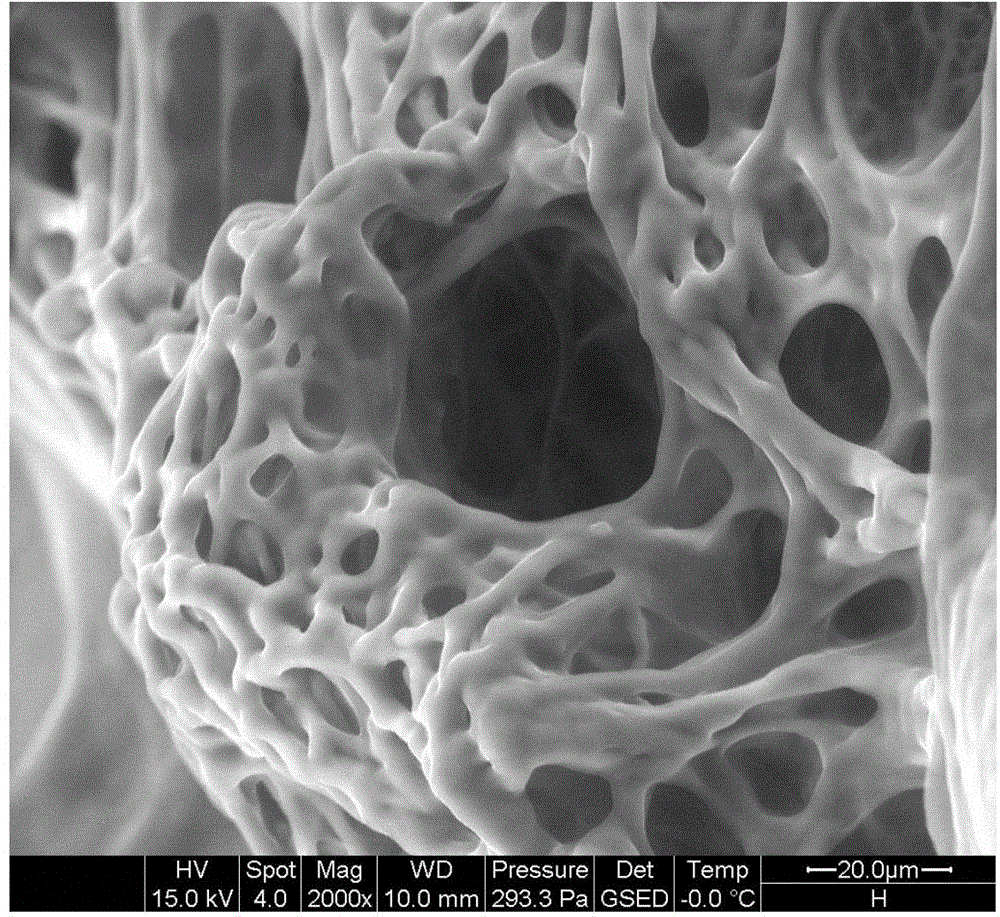

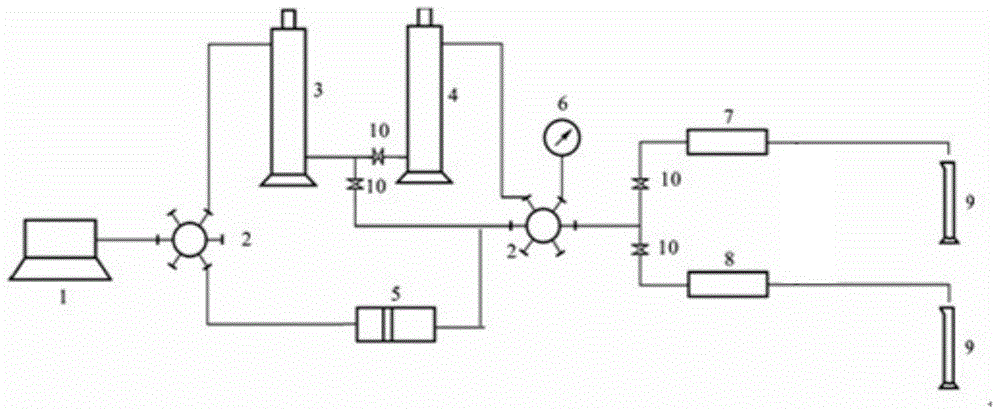

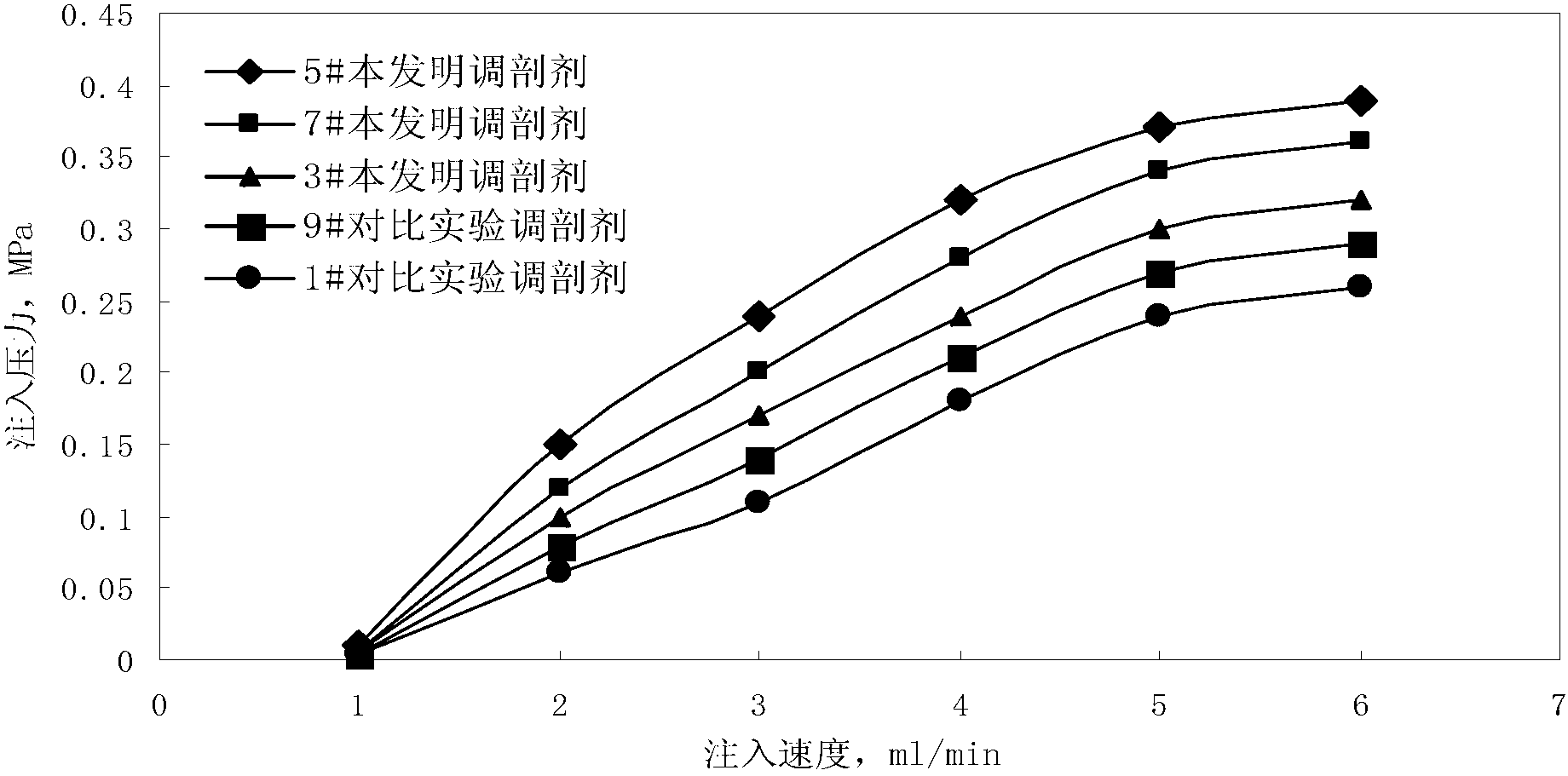

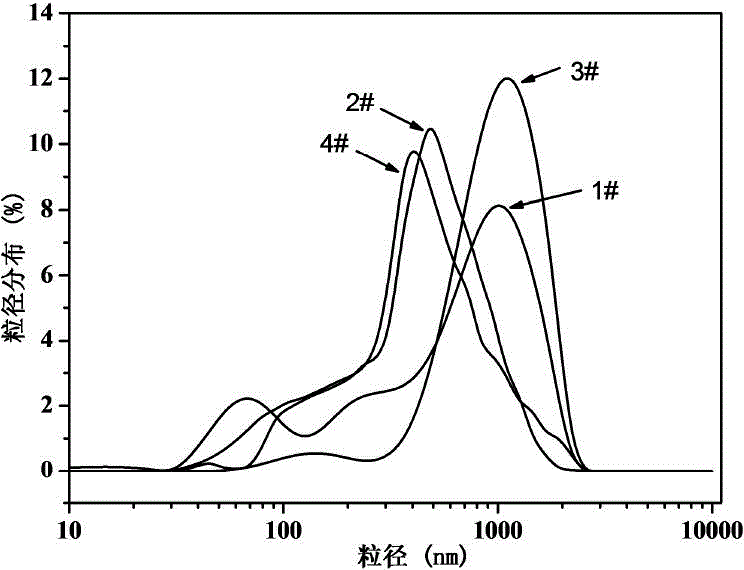

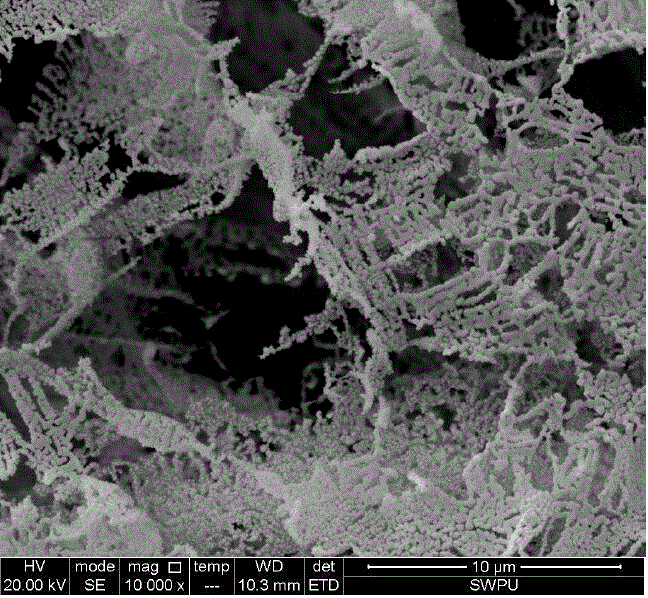

Micro-scale dynamic dispersion agent and preparation method thereof

ActiveCN104861949AGel forming time is controllableAchieving Reservoir AdaptabilityDrilling compositionAluminum trichlorideChemistry

The invention discloses a micro-scale dynamic dispersion agent and a preparation method thereof. The micro-scale dynamic dispersion agent comprises, in weight percent, 0.075%-0.15% of hyper-branched polymer, 0.005%-0.0125% of citrate, 0.0075%-0.015% of aluminum trichloride, 0.005%-0.01% of sulfite and the rest water, wherein the hyper-branched polymer is polyamide-amine hybrid nano-silica hyper-branched polymer. The preparation method includes the steps: sequentially adding hyper-branched polymer solution, citrate solution, aluminum trichloride solution and sulfite solution; adding oilfield injection water to prepare micro-scale dynamic dispersion agent base solution; placing the micro-scale dynamic dispersion agent base solution in a constant temperature oven and aging the micro-scale dynamic dispersion agent base solution into the agent. The dynamic dispersion agent can automatically change micro-scale under the condition of different mineralization degrees and is applicable to deep profile control of an oil reservoir with medium-high temperature and a wide mineralization degree, adaptivity of the oil reservoir is realized, and injection water development effects are improved.

Owner:SOUTHWEST PETROLEUM UNIV

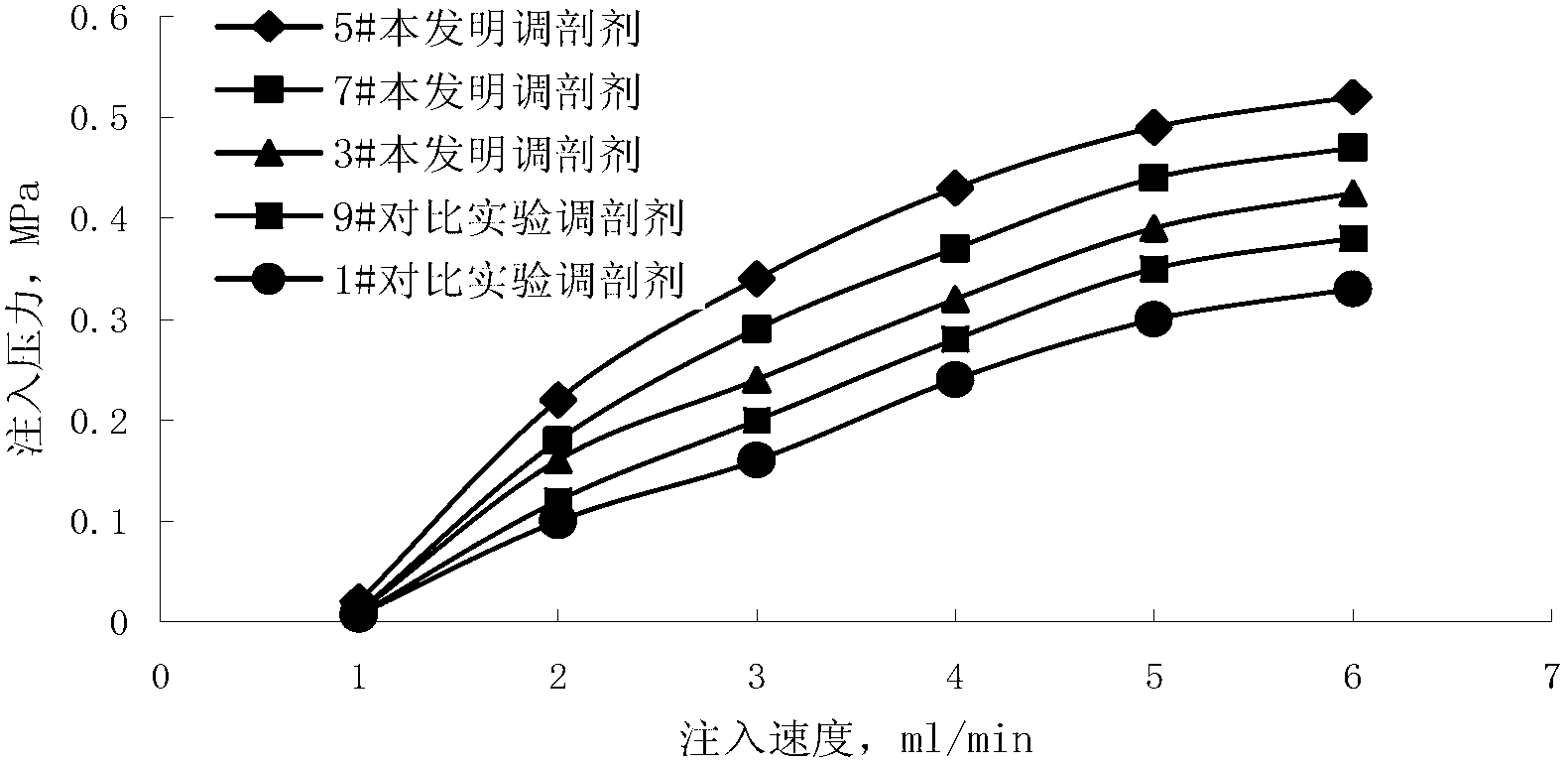

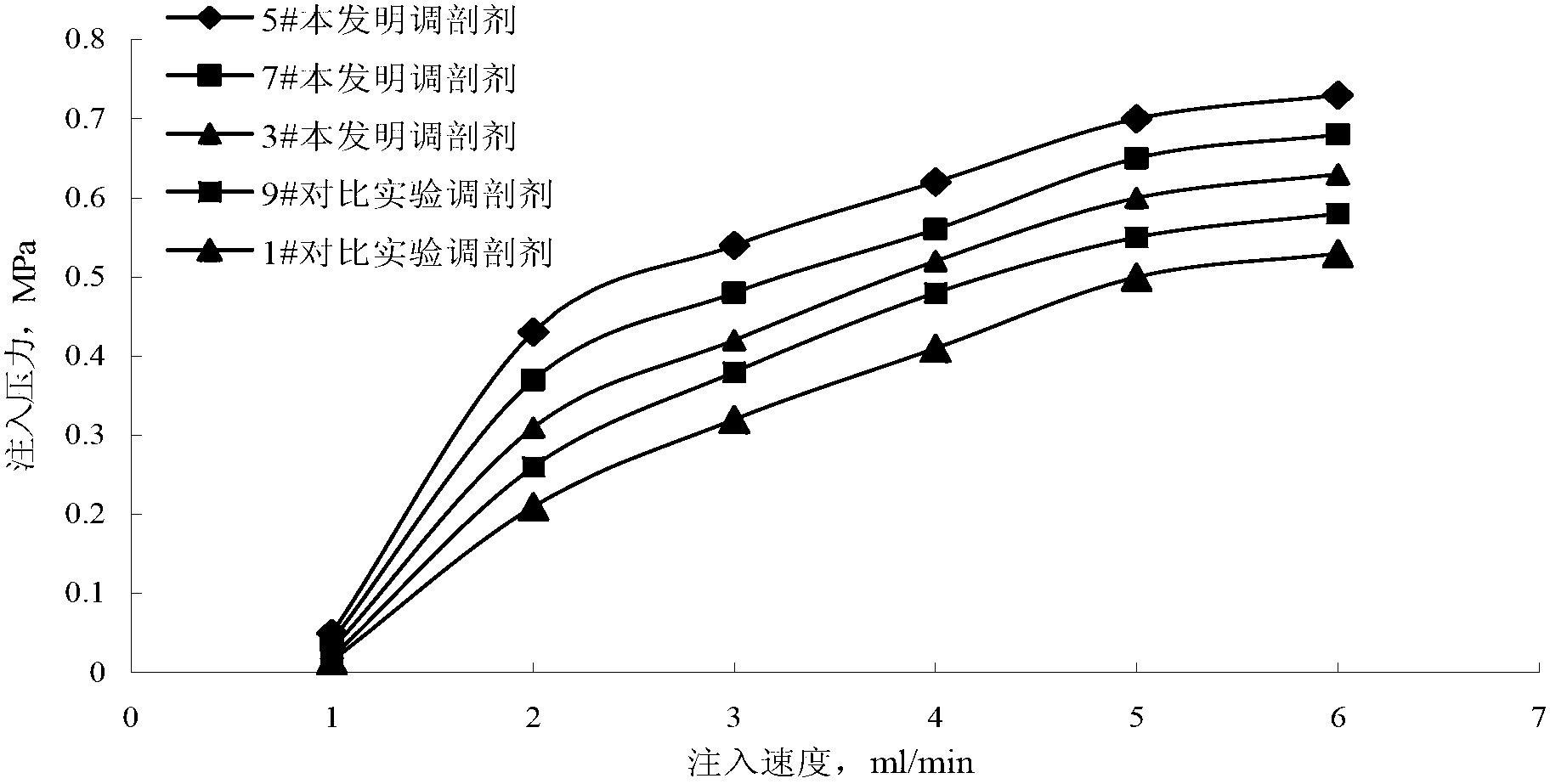

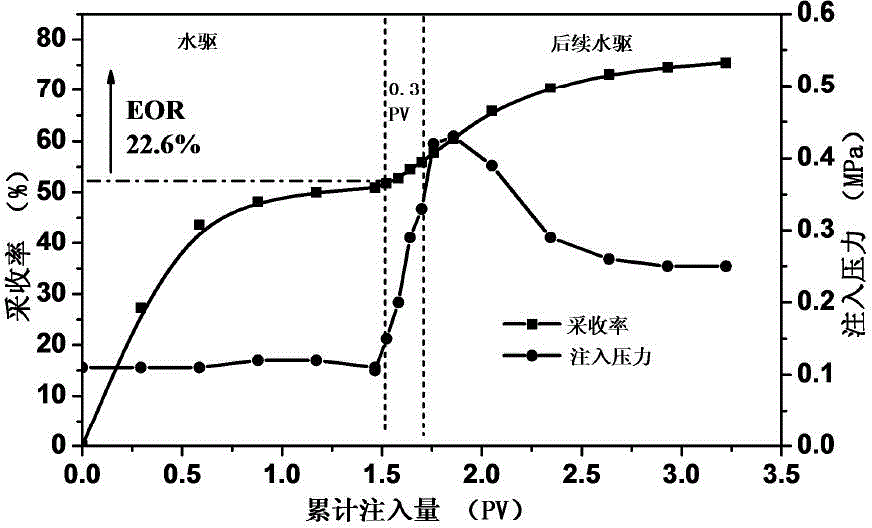

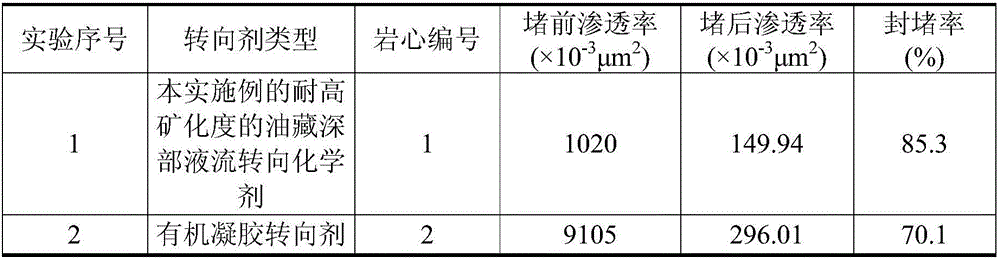

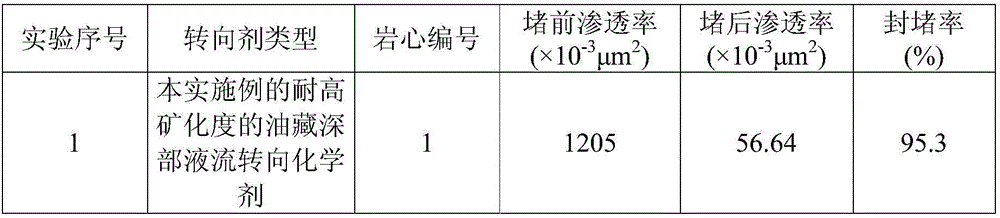

High-salinity-resistant reservoir in-depth fluid diversion chemical agent as well as preparation method and application thereof

ActiveCN105820804AHas gel strengthGel forming time is controllableDrilling compositionSalinityViscosity

The invention provides a high-salinity-resistant reservoir in-depth fluid diversion chemical agent as well as a preparation method and application thereof. The high-salinity-resistant reservoir in-depth fluid diversion chemical agent is prepared from the following raw materials by weight: 0.4-0.6 part of anti-salt polymer, 0.3-0.5 part of a crosslinking agent, 0.2-0.4 part of a stabilizer and the balance of high-salinity water. The high-salinity-resistant reservoir in-depth fluid diversion chemical agent is applied to the profile control and water shutoff during reservoir exploitation. The invention further provides a preparation method of the high-salinity-resistant reservoir in-depth fluid diversion chemical agent. The high-salinity-resistant reservoir in-depth fluid diversion chemical agent is resistant to high salinity, controllable in gelling time and high in gelling viscosity, can achieve the in-depth fluid diversion, and effectively blocks a high permeability layer, to achieve the purpose of blocking the high permeability layer of a high salinity reservoir.

Owner:PETROCHINA CO LTD

Deep plugging agent containing wood dust and gel

InactiveCN1654591ARealize liquid flow diversionEffective blockingSealing/packingWater circulationChemistry

The deep wood chip gel plugging agent is used in water injecting well to plug the high penetrating band in thick oil stratum to lower ineffective water circulation. The deep plugging agent consists of high molecular weight anionic polyacrylamide of molecular weight over 19 million and hydrolysis degree of 25-30 % 0.15-0.5 wt%, phenol compounded polyamine 0.1-0.3 wt%, resorcinol 0.01-0.02 wt%, oxalic acid 0.1-0.2 wt%, wood chip 0.5-2.5 wt% and water 96.48-99.14 wt%, which are compounded into water solution of 0.86-3.52 wt% water solution. The present invention has low use concentration, controllable gel forming time and viscosity, low cost and simple compounding process.

Owner:DAQING OILFIELD CO LTD

High-temperature-resistant gel plugging agent for oil-based drilling fluid as well as preparation method and application of high-temperature-resistant gel plugging agent

ActiveCN112341997AHigh strengthGood pollution effectDrilling compositionSealing/packingPolymer scienceEthyleneglycol dimethacrylate

The invention provides a high-temperature-resistant gel plugging agent for an oil-based drilling fluid as well as a preparation method and application of the high-temperature-resistant gel plugging agent. The gel plugging agent is prepared from the following raw materials in parts by weight: 15-30 parts of gel, 2-7 parts of a cross-linking agent, 0.3-1 part of an initiator and 60-80 parts of baseoil, wherein the gel is a combination of two or more than three of diethylene glycol dimethacrylate, pentanediol diacrylate, hexadecyl methacrylate and polyurethane resin, and the cross-linking agentis two or three of dibutyl ammonium oleate, zinc acrylate and divinyl benzene. The plugging agent disclosed by the invention enters a crack under the action of pressure difference and is automaticallygelatinized to form high-strength and high-temperature-resistant gel, so that the crack is plugged; the plugging agent is good in oil-based drilling invasion resistance, can act on cracks within a certain width range, has a good plugging effect on malignant leakage, and has the advantages of being resistant to high temperature, high in volume expansion speed, high in gel forming strength, controllable in gel forming time and the like.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Controllable cross-linked gel plugging agent and preparation method thereof

InactiveCN111117582AGel forming time is controllableBoth temperature resistanceDrilling compositionPolymer scienceMeth-

The invention relates to a controllable cross-linking type gel plugging agent and a preparation method thereof. The controllable cross-linking type gel plugging agent is prepared from a vinyl monomer,N,N-methylene bisacrylamide and a cross-linking agent. The preparation method comprises the steps: 1, under the action of an initiator, the vinyl monomer and the N,N-methylene bisacrylamide react toobtain a polymer main agent; and 2) the polymer main agent is mixed with a cross-linking agent, and a reaction is carried out at a certain temperature to obtain the gel plugging agent. The controllable cross-linking type gel plugging agent is controllable in cross-linking time, has the advantages of being good in liquidity, easy to pump and the like, and can be extruded into a leakage layer to form an integral immobile gel at the formation temperature and pressure, so that the pressure bearing strength and the plugging effect are improved, and repeated leakage is not likely to happen. Comparedwith a conventional plugging agent, the plugging agent is simple in formula and easy to construct on site.

Owner:YANGTZE UNIVERSITY +1

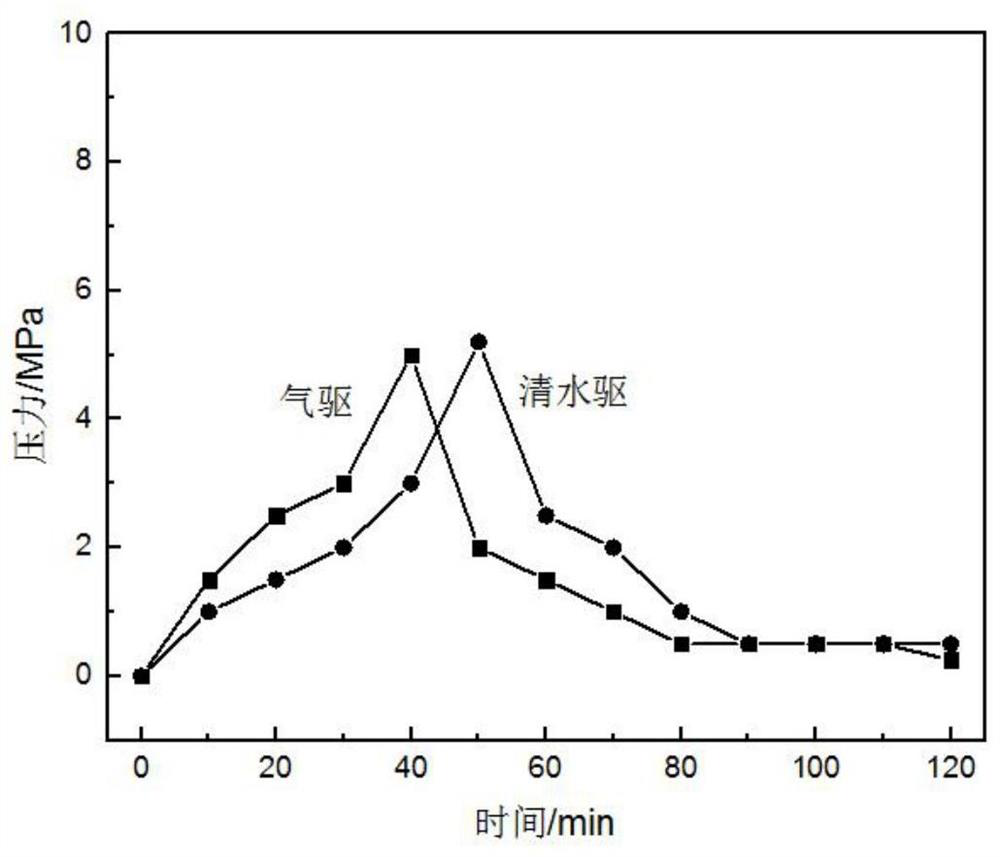

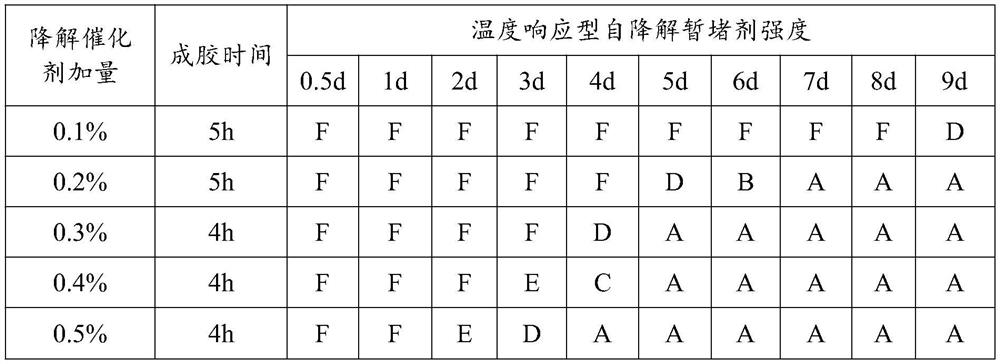

Temperature response type self-degradation temporary plugging agent and well repairing method

ActiveCN113185656AImprove adaptabilityNo pollution in the processDrilling compositionChemistryPropanol

The invention provides a temperature response type self-degradation temporary plugging agent and a well repairing method, and belongs to the technical field of oil and gas exploitation. The temperature response type self-degradation temporary plugging agent comprises the following components in percentage by mass: 4%-6% of an alkenyl-containing monomer, 0.1%-1% of a cross-linking agent, 0.1%-1% of an initiator, 0.05%-0.5% of a degradation catalyst and the balance of water, wherein the cross-linking agent is polyethylene glycol diacrylate, and the degradation catalyst is 2-amino-2-methyl-1-propanol or ethylene glycol amine. Polyethylene glycol diacrylate is used as a cross-linking agent, 2-amino-2-methyl-1-propanol or ethylene glycol amine is used as a degradation catalyst, the temporary plugging agent is gelatinized under the action of temperature, the strength is kept within a period of time, and then as time goes on, the polyethylene glycol diacrylate loses efficacy under the action of the degradation catalyst, the gel temporary plugging agent is degraded into a linear polymer, the final viscosity is reduced, and self-degradation of the gel is realized.

Owner:YANGTZE UNIVERSITY

High efficiency fracturing method using coiled tubing water-jet and soluble rubber plugs

InactiveCN106321050ARelieve pressureSolve the real problemFluid removalDrilling compositionTubing hangerCoiled tubing

The invention provides a high efficiency fracturing method using coiled tubing water-jet and soluble rubber plugs. The high efficiency fracturing method includes a sandblast and perforation stage, an annulus sand fracturing stage, a soluble rubber plug injection stage, a replacement stage, a curing and pressure test stage, and a blowout stage. The soluble rubber plugs are used as sealing members, the number of fracturing segments is not limited, the situation that sand blocks pipes can be avoided, gel-breaking of the rubber plugs can be controlled during construction, gel-breaking and rapid flow-back can be achieved at the same, and the construction efficiency and the successful rate can be greatly improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com