High-temperature-resistant gel plugging agent for oil-based drilling fluid as well as preparation method and application of high-temperature-resistant gel plugging agent

A technology of oil-based drilling fluid and plugging agent, which is applied in the field of drilling fluid plugging, can solve the problems of poor temperature resistance, unusable, poor plugging effect, etc., and achieve good strength and temperature resistance, and volume expansion rate. Fast, controllable gel time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

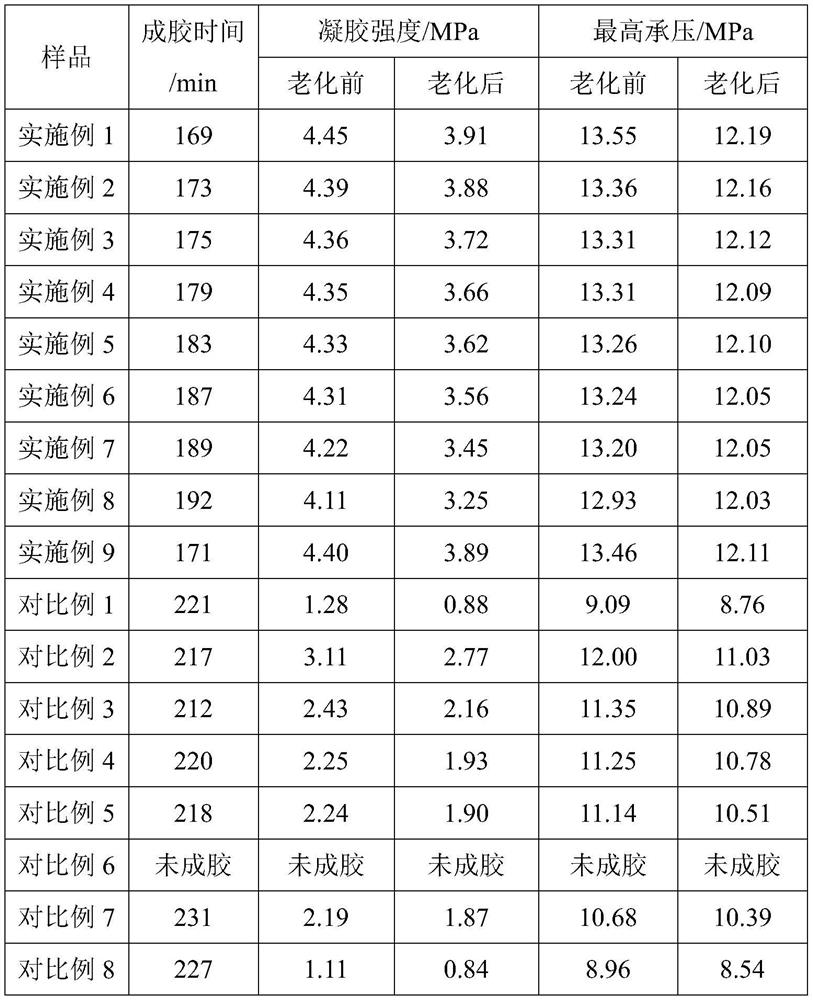

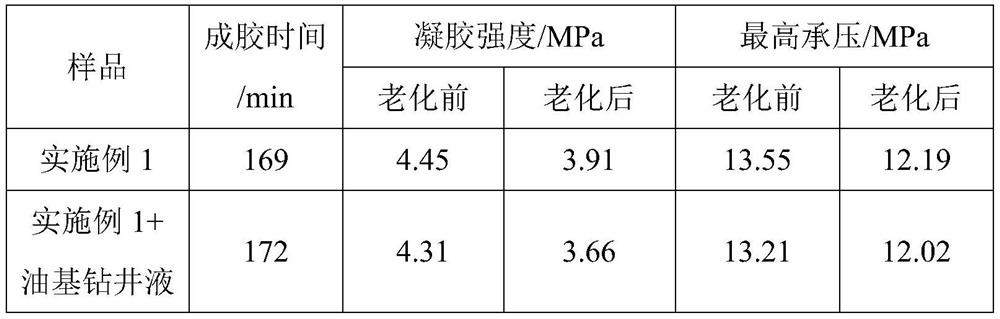

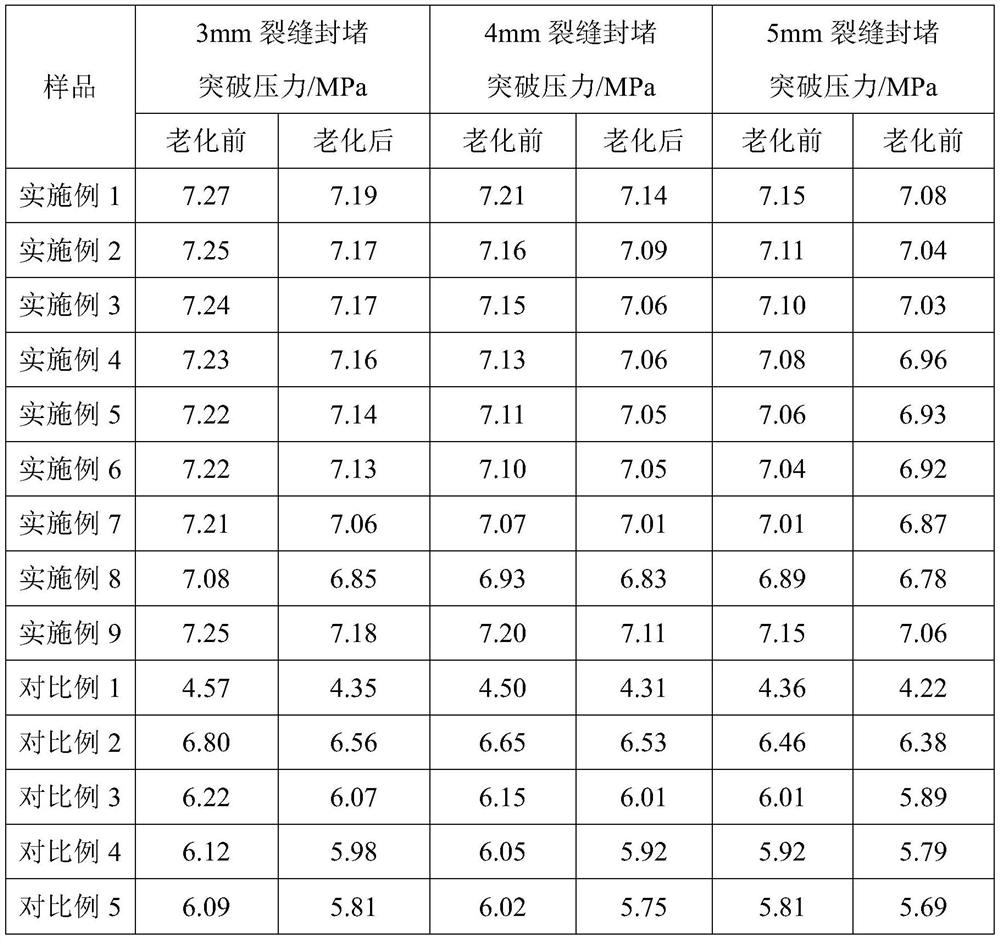

Examples

Embodiment 1

[0035] An anti-high temperature gel plugging agent for oil-based drilling fluid, comprising the following raw materials in parts by weight: 22 parts of a gelling agent, 5 parts of a crosslinking agent, 0.8 parts of an initiator, and 73.2 parts of a base oil;

[0036] Wherein, the gelling agent is a combination of diethylene glycol dimethacrylate and cetyl methacrylate, and the mass ratio of diethylene glycol dimethacrylate and cetyl methacrylate is 1 : 2; the crosslinking agent is the combination of dibutylammonium oleate and zinc acrylate, and the mass ratio is 1:1; the initiator is azobisisobutyronitrile; the base oil is white oil.

[0037] The preparation method of the above-mentioned high temperature anti-high temperature gel plugging agent for oil-based drilling fluid comprises the following steps:

[0038] (1) adding the gelling agent to the white oil at 40°C, then warming up to 50°C, at 50°C, stirring at a stirring rate of 500 rev / min for 25min to dissolve it completely...

Embodiment 2

[0042] An anti-high temperature gel plugging agent for oil-based drilling fluid, comprising the following raw materials in parts by weight: 22 parts of a gelling agent, 5 parts of a crosslinking agent, 0.4 parts of an initiator, and 72.6 parts of a base oil;

[0043] Wherein, the gelling agent is a combination of diethylene glycol dimethacrylate and cetyl methacrylate, and the mass ratio of diethylene glycol dimethacrylate and cetyl methacrylate is 1 : 2; the crosslinking agent is the combination of dibutylammonium oleate and zinc acrylate, and the mass ratio is 1:1; the initiator is azobisisobutyronitrile; the base oil is white oil.

[0044] The preparation method of the above-mentioned high temperature anti-high temperature gel plugging agent for oil-based drilling fluid is as described in Example 1.

Embodiment 3

[0046] An anti-high temperature gel plugging agent for oil-based drilling fluid, comprising the following raw materials in parts by weight: 22 parts of gelling agent, 7 parts of crosslinking agent, 0.8 part of initiator, and 70.2 parts of base oil;

[0047] Wherein, the gelling agent is a combination of diethylene glycol dimethacrylate and cetyl methacrylate, and the mass ratio of diethylene glycol dimethacrylate and cetyl methacrylate is 1 : 2; the crosslinking agent is the combination of dibutylammonium oleate and zinc acrylate, and the mass ratio is 1:1; the initiator is azobisisobutyronitrile; the base oil is white oil.

[0048] The preparation method of the above-mentioned high temperature anti-high temperature gel plugging agent for oil-based drilling fluid is as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com