Environmental-friendly gel plugging agent applicable to low-temperature oil pool and applications of gel plugging agent

A technology of cryogenic oil and jelly, which is applied in drilling compositions, production fluids, wellbore/well components, etc., can solve problems that are unfavorable to environmental protection, the health of operators, difficult to meet on-site construction operations, and unfavorable mine construction operations. and other problems, to achieve the effect of controllable glue forming time, convenient construction and use, and good injection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

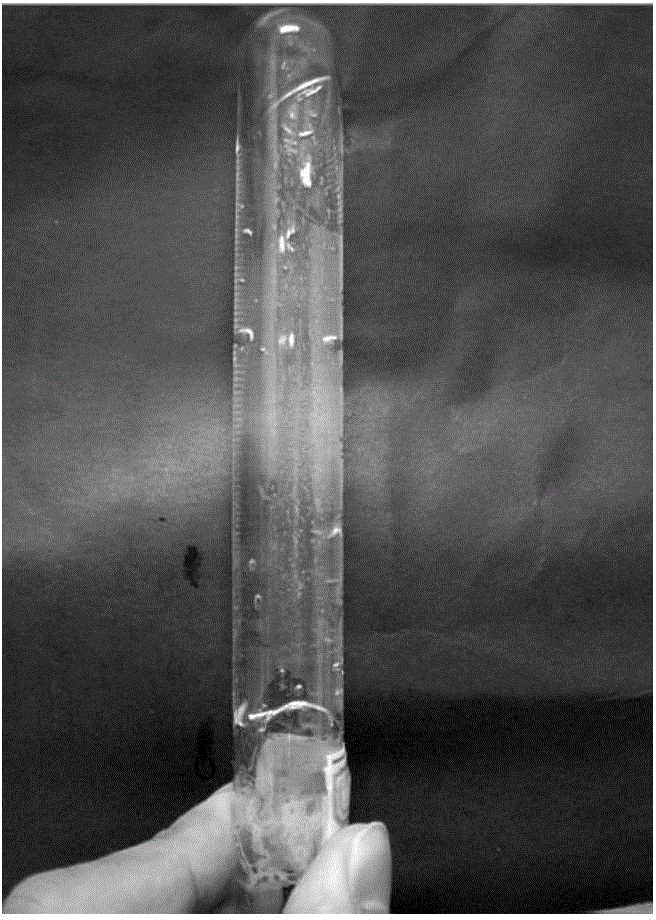

[0046] An environment-friendly plugging agent suitable for low-temperature oil reservoirs, composed of 0.2% amphoteric polyacrylamide (LPAM), 0.5% organic zirconium crosslinking agent solution, and 99.3% water. The organic zirconium crosslinking agent is a combination of zirconium citrate and zirconium lactate in a mass ratio of 2:1.

[0047] Preparation:

[0048] Weigh zirconium citrate and zirconium lactate according to the mass ratio of 2:1, add into water under stirring, mix evenly, and make an organic zirconium crosslinking agent solution with a mass fraction of 30%;

[0049] Proportionally, take 10 g of amphoteric polyacrylamide aqueous solution with a mass fraction of 1.0%, add 0.25 g of organic zirconium crosslinking agent solution prepared while stirring, and then add 39.75 g of water and stir to obtain the product.

[0050] The gelling time of the plugging agent system at 25°C is 60 hours, and the gelling strength is grade E; at 30°C, the gelling time is 50 hours, a...

Embodiment 2

[0052] The environmentally friendly plugging agent suitable for low-temperature oil reservoirs is composed of: 0.4% amphoteric polyacrylamide, 1.0% organic zirconium crosslinking agent solution, and 98.6% water. The organozirconium crosslinking agent solution is zirconium citrate and zirconium lactate mixed in a mass ratio of 1:1, added into water under stirring, and mixed evenly to make an organozirconium crosslinking agent solution with a mass fraction of 25%;

[0053] In 20 g of nonionic polyacrylamide aqueous solution with a mass fraction of 1.0%, add 0.5 g of organic zirconium crosslinking agent solution while stirring, and then add 29.5 g of water and stir to obtain the product. The gelling time of the plugging agent system is 40 hours at 25°C, and the gelling strength is G grade; the gelling time is 23 hours at 30°C, and the gelling strength is G grade; the gelling time is 14 hours at 35°C, and the gelling strength is Grade G.

Embodiment 3

[0055] The environmentally friendly plugging agent suitable for low-temperature oil reservoirs is composed of: 0.6% amphoteric polyacrylamide, 2.0% organic zirconium crosslinking agent solution, and 97.4% water. The organic zirconium crosslinking agent solution is a combination of zirconium citrate and zirconium lactate in a mass ratio of 3:1, and water is added to make an organic zirconium crosslinking agent solution with a mass fraction of 20%;

[0056] In 30 g of amphoteric polyacrylamide aqueous solution with a mass fraction of 1.0%, 1.0 g of organic zirconium crosslinking agent solution was added while stirring, and then 19 g of water was added and stirred to obtain the product. The gelling time of the plugging agent system is 15 hours at 25°C, and the gelling strength is H grade; the gelling time is 10 hours at 30°C, and the gelling strength is H grade; the gelling time is 4 hours at 35°C, and the gelling strength is Grade H.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com