Temperature-sensitive gel diverting agent and preparation method and application of temperature-sensitive gel diverting agent

A temperature-sensitive gel and diverting agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of restricting the large-scale application of plugging agents, poor implementation effect, short validity period, etc. Recovery factor, improved scour resistance, and the effect of enhanced scour resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of thermosensitive gel diverting agent

[0034] The temperature-sensitive gel diverting agent is composed of 1 part of acrylamide, 1 part of polyaluminum ferric sulfate, 0.5 part of potential alkali (urea), 0.05 part of N, N-methylenebisacrylamide, and 97.35 parts of tap water, and add it to the wide mouth of the plug. bottle, stirred for 15 minutes to completely dissolve, and then added 0.1 part of ammonium persulfate to obtain a temperature-sensitive gel-steering agent.

[0035] (2) Determination of gel viscosity

[0036] Take the sample in the laboratory and place it in a jar with a stopper, and observe the gelling situation in a constant temperature drying oven at 60°C. The experiment found that the diverting agent formed after 13 hours was initially gelled, and the measured apparent viscosity was 3000mPa.s .

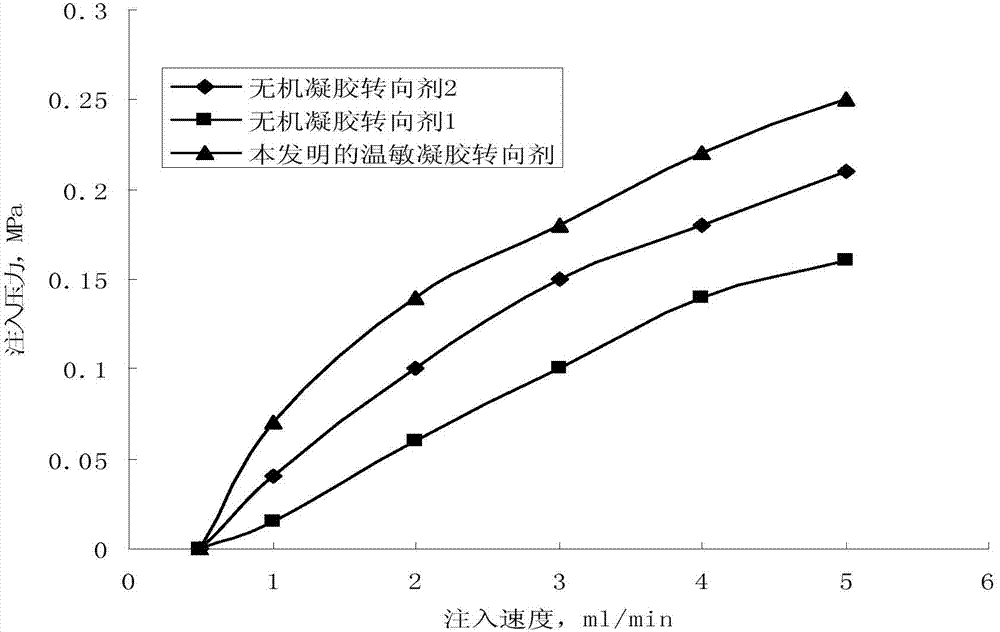

[0037] (3) Core displacement experiment of diverting agent

[0038] Fill 60-120 mesh quartz sand into a sand-filling tube with a diameter ...

Embodiment 2

[0044] (1) Preparation of thermosensitive gel diverting agent

[0045] The temperature-sensitive gel diverting agent is composed of 2 parts of acrylamide, 2 parts of polyaluminum ferric sulfate, 1 part of latent base (urea), 0.1 part of N, N-methylenebisacrylamide, and 94.75 parts of tap water, and add it to the wide mouth of the plug. bottle, stirred for 15 minutes to dissolve it completely, and then added 0.15 parts of ammonium persulfate to obtain a temperature-sensitive gel-steering agent.

[0046] (2) Determination of gel viscosity

[0047] Take the sample in the laboratory and place it in a jar with a stopper, and observe the gelation in a 60°C constant temperature drying oven. The experiment found that the diverting agent formed after 10 hours was initially gelled, and the measured apparent viscosity was 8000mPa.s .

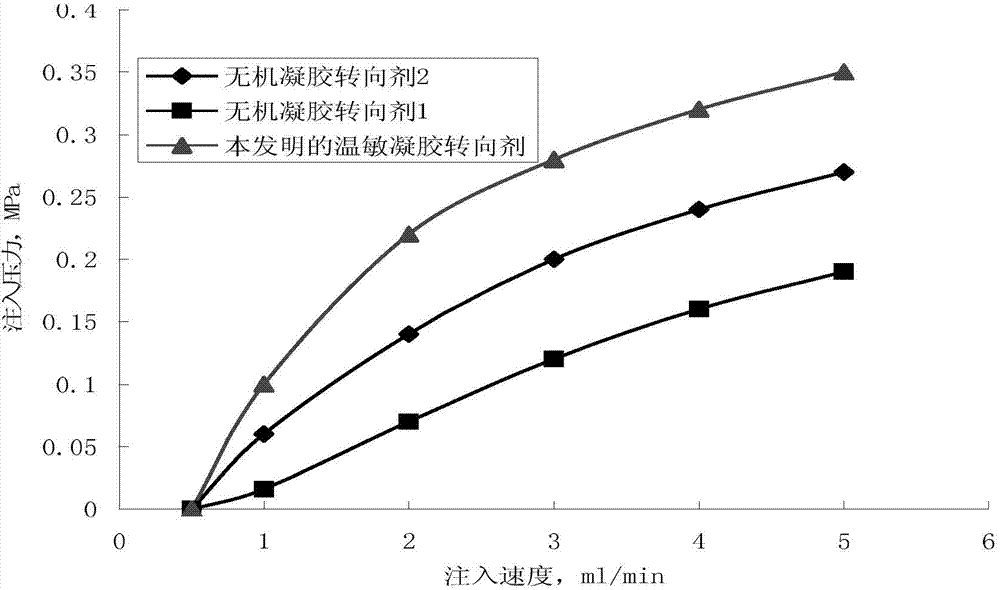

[0048] (3) Core displacement experiment of diverting agent

[0049]Fill 60-120 mesh quartz sand into a sand-filling tube with a diameter of 2.5 cm and ...

Embodiment 3

[0055] (1) Preparation of thermosensitive gel diverting agent

[0056] The temperature-sensitive gel diverting agent is composed of 3 parts of acrylamide, 3 parts of polyaluminum ferric sulfate, 1.5 parts of potential alkali (urea), 0.15 parts of N, N-methylenebisacrylamide, and 93.15 parts of tap water, and add it to the wide mouth of the plug. bottle, stirred for 15 minutes to completely dissolve, and then added 0.2 parts of ammonium persulfate to obtain a temperature-sensitive gel-steering agent.

[0057] (2) Determination of gel viscosity

[0058] Take the sample in the laboratory and place it in a jar with a stopper, and observe the gelling situation in a constant temperature drying oven at 60°C. The experiment found that the diverting agent formed after 10 hours was initially gelled, and the measured apparent viscosity was 21000mPa.s .

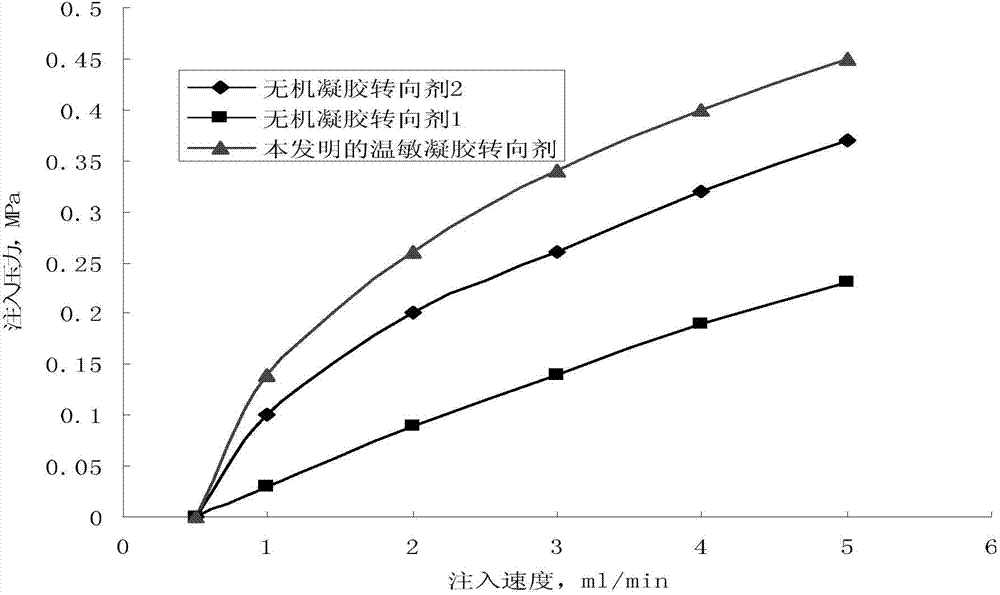

[0059] (3) Core displacement experiment of diverting agent

[0060] Fill 60-120 mesh quartz sand into a sand-filling tube with a dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com