High temperature resistant gel diverting agent and manufacturing method therefor and application thereof

A high-temperature-resistant gel and steering agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of organic gels not resistant to high temperatures, short validity period, and inorganic gel technology not resistant to erosion, etc., to achieve Improve the effect of high temperature resistance and erosion resistance, strong gel strength, excellent gel strength and elastic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

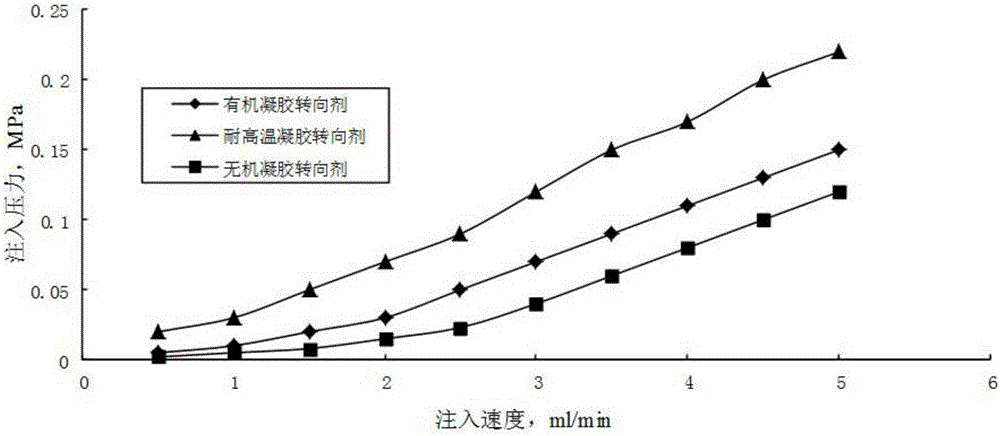

Embodiment 1

[0030] This embodiment provides a high-temperature-resistant gel diverting agent, which includes the following components based on 100 parts by weight of the total weight: 3 parts of acrylamide, 1 part of N-tert-butylacrylamide, 1 part of 2-acrylamide-2 Sodium methyl propane sulfonate, 1 part of sepiolite, 0.03 part of polyethyleneimine, 0.05 part of ammonium persulfate and 93.92 parts of tap water.

[0031] The high temperature resistant gel diverting agent of the present embodiment is prepared through the following steps:

[0032] Add 3 parts of acrylamide, 1 part of N-tert-butylacrylamide, 1 part of 2-acrylamido-2-methylpropanesulfonate sodium, 1 part of sepiolite, 0.03 part of polyethyleneimine, 0.05 part Ammonium persulfate and 93.92 parts of tap water were stirred for 10 minutes to dissolve completely, then put into a stainless steel aging tank, and gelled initially at 130°C and normal pressure for 30 hours to obtain a high temperature resistant gel diverting agent.

[...

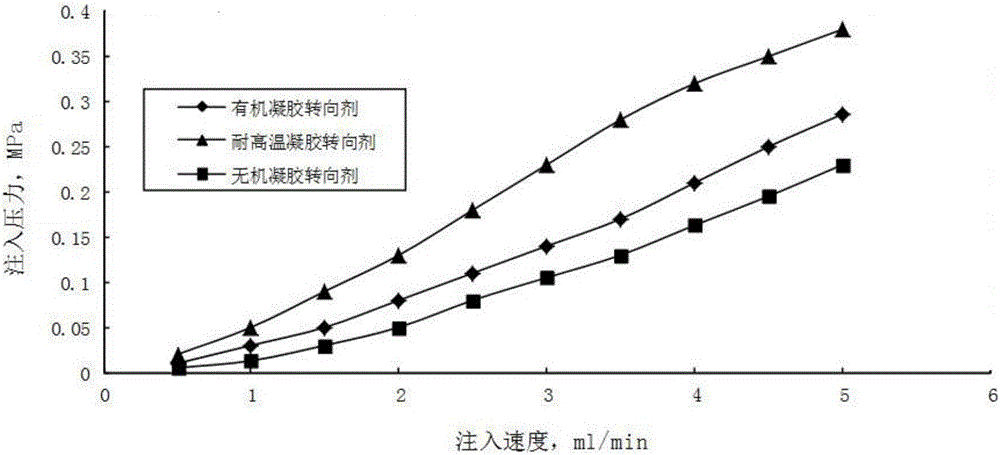

Embodiment 2

[0043] This embodiment provides a high-temperature-resistant gel diverting agent, which includes the following components based on 100 parts by weight of the total weight: 4 parts of acrylamide, 2 parts of N-tert-butylacrylamide, 2 parts of 2-acrylamide-2 Sodium methyl propane sulfonate, 2 parts of sepiolite, 0.04 parts of polyethyleneimine, 0.08 parts of ammonium persulfate and 89.88 parts of tap water.

[0044] The high temperature resistant gel diverting agent of the present embodiment is prepared through the following steps:

[0045] Add 4 parts of acrylamide, 2 parts of N-tert-butylacrylamide, 2 parts of 2-acrylamido-2-methylpropanesulfonate sodium, 2 parts of sepiolite, 0.04 parts of polyethyleneimine, 0.08 parts of Ammonium persulfate and 89.88 parts of tap water were stirred for 10 minutes to dissolve completely, then put into a stainless steel aging tank, and initially gelled at 130°C and normal pressure for 26 hours to obtain a high temperature resistant gel divertin...

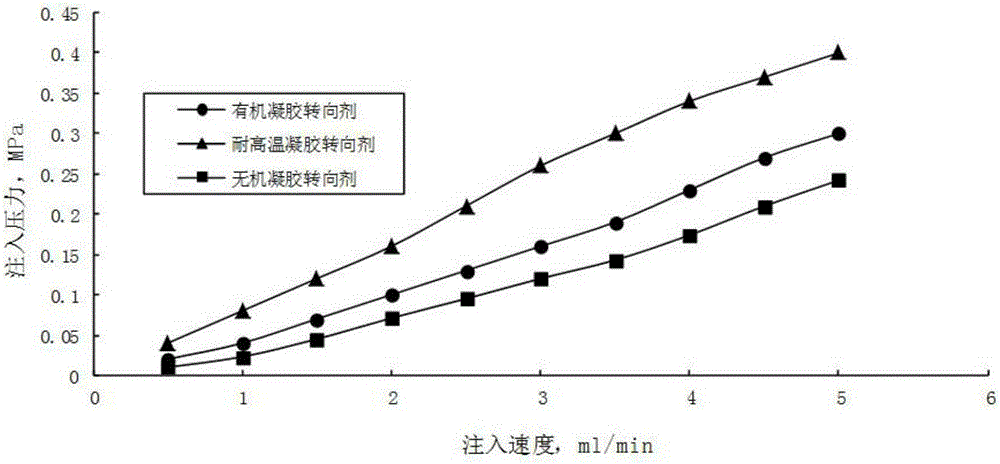

Embodiment 3

[0056] This embodiment provides a high-temperature-resistant gel diverting agent, which includes the following components based on 100 parts by weight of the total weight: 4 parts of acrylamide, 2 parts of N-tert-butylacrylamide, 3 parts of 2-acrylamide-2 Sodium methyl propane sulfonate, 2 parts of sepiolite, 0.05 part of polyethyleneimine, 0.10 part of ammonium persulfate and 88.85 parts of tap water.

[0057] The high temperature resistant gel diverting agent of the present embodiment is prepared through the following steps:

[0058] Add 4 parts of acrylamide, 2 parts of N-tert-butylacrylamide, 3 parts of 2-acrylamido-2-methylpropanesulfonate sodium, 2 parts of meerschaum, 0.05 parts of polyethyleneimine, 0.10 parts of Ammonium persulfate and 88.85 parts of tap water were stirred for 10 minutes to dissolve completely, then put into a stainless steel aging tank, and gelled initially at 130°C and normal pressure for 20 hours to obtain a high temperature resistant gel diverting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com