Controllable cross-linked gel plugging agent and preparation method thereof

A leak-stopping agent and cross-linking technology, which is applied in the field of controllable cross-linking gel leak-stopping agent and its preparation, can solve the problems of inconvenient on-site use, difficult to accurately control the gel formation time, easy to re-leakage, etc. Few types, controllable gel formation time and simple formula composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

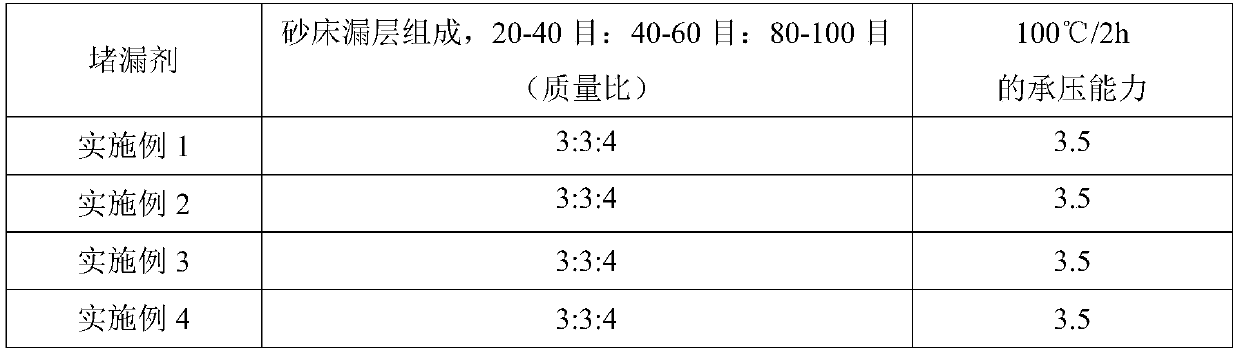

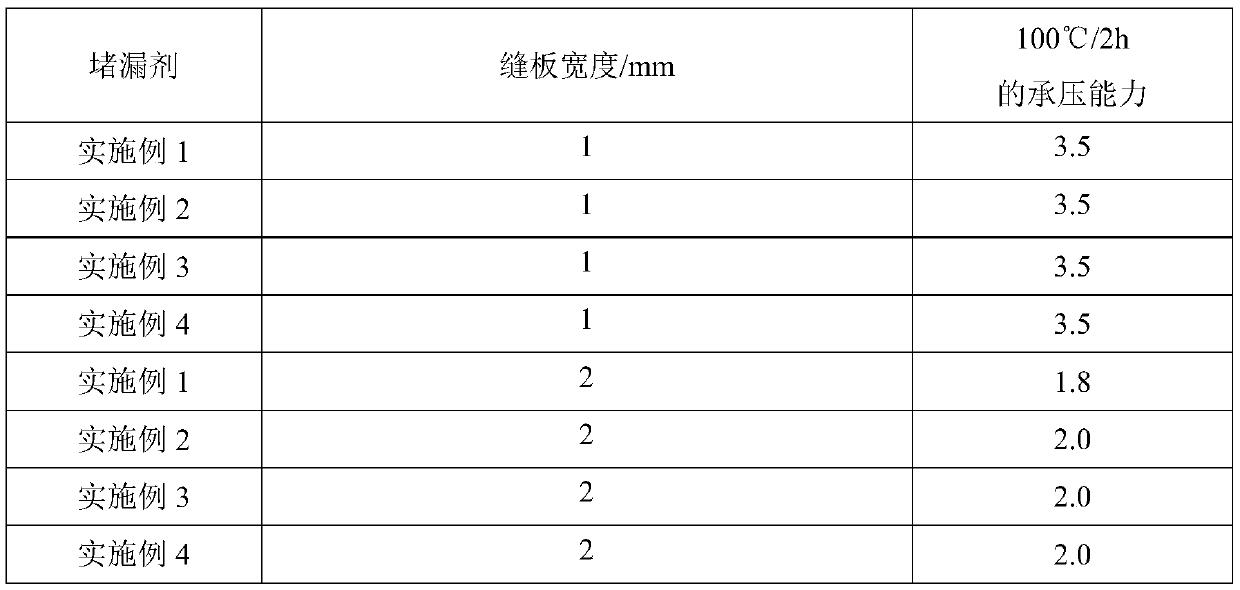

Examples

Embodiment 1

[0023] Into a three-necked flask equipped with a stirrer and a thermometer, add 200 mL of distilled water, add 9.02 g of acrylamide, 7.88 g of N,N-dimethylacrylamide, and 8.34 g of 2-acrylamide-2-methylpropanesulfonic acid while stirring. g and 0.26g of N,N-methylenebisacrylamide, adjust pH=11.0 with sodium hydroxide, purge oxygen with nitrogen for 30min, heat to 60℃ with stirring, add 0.04g of potassium persulfate, and react for 6h. The viscous liquid in the three-necked flask is precipitated with ethanol, dried, and pulverized through a 20-mesh sample sieve to obtain the polymer main agent.

[0024] 0.4 g of zirconium acetate was added to the 8% polymer main agent aqueous solution of this embodiment, and reacted at 70° C. to obtain a gel plugging agent.

Embodiment 2

[0026] Into a three-necked flask equipped with a stirrer and a thermometer, add 200 mL of distilled water, add 9.02g of acrylamide, 9.02g of 2-methyl-2-acrylamidopropanesulfonic acid, 7.20g of vinylpyrrolidone and N,N while stirring. -0.26g of methylene bisacrylamide, adjusted pH=11.0 with sodium hydroxide, purged oxygen with nitrogen for 30min, heated to a temperature of 60°C while stirring, added 0.06g of potassium persulfate, and reacted for 7h. The viscous liquid in the three-necked flask is precipitated with ethanol, dried, and pulverized through a 20-mesh sample sieve to obtain the polymer main agent.

[0027] 0.5 g of chromium acetate was added to the 6% polymer main agent aqueous solution of this embodiment, and reacted at 80° C. to obtain a gel plugging agent.

Embodiment 3

[0029] To a three-necked flask equipped with a stirrer and a thermometer, add 200 mL of distilled water, add 9.02 g of acrylamide, 6.32 g of vinylformamide, 8.30 g of 2-methyl-2-acrylamidopropanesulfonic acid and N, while stirring. 0.26g of N-methylenebisacrylamide, adjusted pH=11.0 with sodium hydroxide, purged oxygen with nitrogen for 30min, heated to a temperature of 60°C while stirring, added 0.04g of ammonium persulfate, and reacted for 7h. The viscous liquid in the three-necked flask is precipitated with ethanol, dried, and pulverized through a 20-mesh sample sieve to obtain the polymer main agent.

[0030] 0.5 g of chromium acetate was added to the 6% polymer main agent aqueous solution of this embodiment, and reacted at 90° C. to obtain a gel plugging agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com