High temperature resistance gel plugging agent and preparation method and application thereof

A technology of high temperature resistance and plugging agent, applied in chemical instruments and methods, earthwork drilling, sealing/isolation, etc., can solve the problems of effective pressure bearing plugging in well completion, and achieve high pressure bearing capacity and temperature resistance Good, the effect of broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

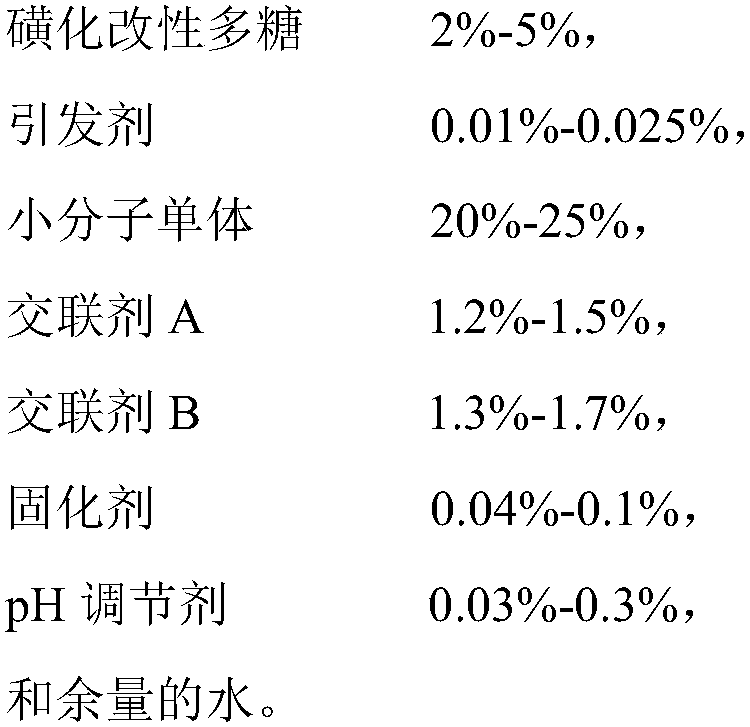

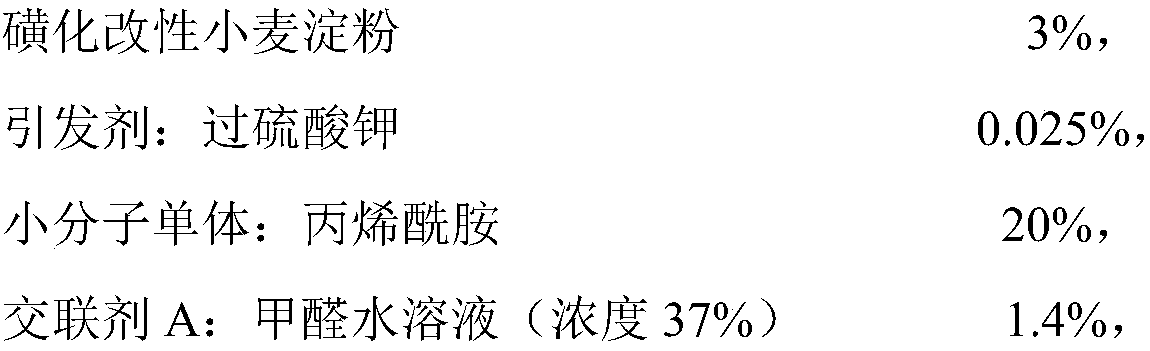

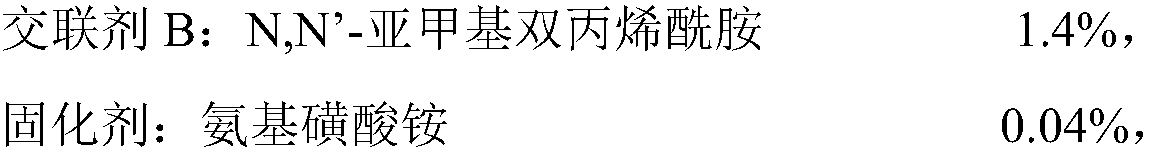

[0030] This embodiment provides a high-temperature-resistant jelly sealing agent. The raw material components of the high-temperature-resistant jelly sealing agent include:

[0031]

[0032]

[0033] pH regulator: sodium bicarbonate (for pH adjustment to 10),

[0034] and the remainder of the water.

[0035] The preparation method of sulfonated modified wheat starch in this embodiment is: in 80mL water, add 2g of wheat starch, 0.02g of cumene peroxide, 0.02g of sodium bisulfite, 4g of N-p-tolyl horseradish To imide and 6g of 2-acrylamido-2-methylpropanesulfonic acid, adjust the pH value to 10, heat and stir to 100°C, react for 90min, separate and purify with ethanol, filter and dry to obtain the sulfonated Modified wheat starch.

[0036] The present embodiment also provides a preparation method of the above-mentioned high temperature-resistant jelly plugging agent, which includes the following steps:

[0037] According to the raw material formula, add sulfonated modif...

Embodiment 2

[0040] This embodiment provides a high-temperature-resistant jelly sealing agent. The raw material components of the high-temperature-resistant jelly sealing agent include:

[0041]

[0042] The preparation method of sulfonated modified cellulose in this example is: in 80mL of water, add 2g of cellulose, 0.04g of cumene peroxide, 0.04g of sodium bisulfite, 2g of N-p-tolyl horseradish To imide and 4g of 2-acrylamido-2-methylpropanesulfonic acid, adjust the pH value to 10, heat and stir to 100°C, react for 45min, separate and purify with ethanol, and obtain the sulfonated Modified cellulose.

[0043] The present embodiment also provides a preparation method of the above-mentioned high temperature-resistant jelly plugging agent, which includes the following steps:

[0044] According to the raw material formula, add sulfonated modified cellulose, azobisisobutyronitrile, acrylamide, 2-acrylamide-2 methylpropanesulfonic acid, paraformaldehyde, melamine, ammonium chloride and wat...

Embodiment 3

[0047] This embodiment provides a high-temperature-resistant jelly sealing agent. The raw material components of the high-temperature-resistant jelly sealing agent include:

[0048]

[0049] The preparation method of sulfonated modified cornstarch in this example is: in 80mL of water, add 2g of cornstarch, 0.04g of cumene peroxide, 0.02g of sodium bisulfite, 4g of N-p-tolyl horseradish To imide and 6g of 2-acrylamido-2-methylpropanesulfonic acid, adjust the pH value to 11, heat and stir to 110°C, react for 60min, separate and purify with ethanol, filter and dry to obtain the sulfonated Modified corn starch.

[0050] The present embodiment also provides a preparation method of the above-mentioned high temperature-resistant jelly plugging agent, which includes the following steps:

[0051] According to the raw material formula, add sulfonated modified corn starch, ammonium persulfate, acrylamide, 2-acrylamide-2 methylpropanesulfonic acid, paraformaldehyde, melamine, urotropine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com