Highly dispersible environment-friendly pure acrylic emulsion for painting materials and its preparation method and application

A high-dispersity, pure acrylic emulsion technology, used in coatings, anti-corrosion coatings, etc., can solve the problems of lack of production capacity of acrylic emulsion adhesives, sub-field research and low investment, and meet basic performance requirements, Eco-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] An embodiment of the present invention also provides the preparation method of the high-dispersibility environment-friendly pure acrylic emulsion that is used for painting materials described in any one of the above, may comprise the steps:

[0068] 1) Mixed emulsifier: use 2-amino-2-methyl-1-propanol to neutralize the phosphoric acid ester type anionic emulsifier, mix it with a nonionic emulsifier to obtain a mixed emulsifier;

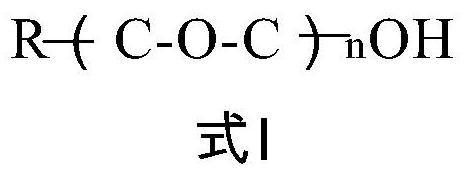

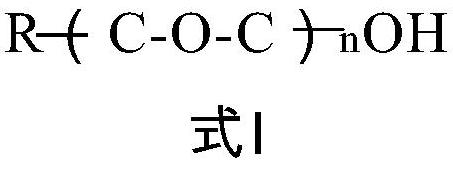

[0069] 2) Emulsion preparation: add deionized water to the emulsification tank, put part of the mixed emulsifier into the water in the emulsification tank, stir and disperse at high speed for 10-30 minutes, then slowly add unsaturated monomers and (meth)acrylic acid, and continue stirring for 10-30 minutes minutes, then add (meth)acrylic acid C 1-8 Alkyl ester, alkoxysilane 80wt%-90wt%, stirring for 10-60 minutes for later use;

[0070] 3) Preparation of the bottom material of the reaction tank: add deionized water to the reaction tank, raise ...

Embodiment 1

[0091] Composition and ratio

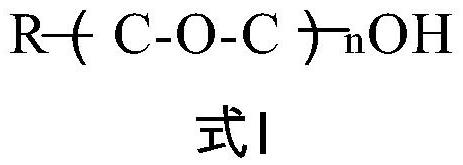

[0092] A highly dispersible environmentally friendly pure acrylic emulsion, which is composed of the following raw materials in weight ratio: methyl methacrylate: 15%; n-butyl acrylate: 15%; isooctyl acrylate: 10%; acrylic acid: 0.6%; acrylic acid Hydroxyethyl ester: 0.8%; ureidomethacrylate: 0.5%; vinyltrimethoxysilane: 0.8%; mixed emulsifier: 1.5%; the ratio of anionic emulsifier to nonionic emulsifier: 1:1; Anionic emulsification: allyl fatty alcohol polyoxyethylene ether phosphate diester (allyl tridecyl alcohol polyoxyethylene ether phosphate diester), nonionic emulsifier is isomer alcohol polyoxyethylene ether (isomeric tridecyl alcohol Polyoxyethylene ether); Initially adding initiator and dripping initiator total amount is potassium persulfate: 0.3%; Initially adding initiator and dripping initiator are distributed as: 2:8; tert-butyl hydroperoxide-sulfurous acid Sodium hydrogen, the ratio is 1:1, accounting for 0.2%; the preservative is...

Embodiment 2

[0104] Composition and ratio

[0105] A high-dispersion environment-friendly pure acrylic emulsion, which is composed of the following raw materials by weight: methyl methacrylate: 15%; n-butyl acrylate: 15%; isooctyl acrylate: 10%; acrylic acid: 0.6%; Amide: 0.8%; ureidomethacrylate: 0.5%; vinyltrimethoxysilane: 0.8%; mixed emulsifier: 1.5%; ratio of anionic emulsifier and nonionic emulsifier: 1:1; anionic emulsification It is: allyl fatty alcohol polyoxyethylene ether phosphate diester, the non-ionic emulsifier is fatty alcohol polyoxyethylene ether; the initial initiator and drip initiator are potassium persulfate: 0.3%; the initial initiator and drip The distribution of adding initiator is: 2:8; tert-butyl hydroperoxide-sodium bisulfite, the ratio is 1:1, accounting for 0.2%; the preservative is phenoxyethanol, the dosage is 0.8%; AMP-95 : The dosage is 1%; post-addition of γ-(2,3-epoxypropoxy)propyltrimethoxysilane (A-187) is 0.1%; deionized water is 53.4%.

[0106] pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com