Volume expansion type efficient slug gel plugging agent and preparation method thereof

A plugging agent and volume-expanding technology, which is applied in the field of drilling fluid plugging, can solve the problems of undetermined temperature conditions and time range, poor water absorption and swelling performance of gel, and narrow application range of plugging agent temperature, etc., to achieve The gelling temperature can adapt to a wide range of conditions, the gelling time can be adjusted, and the plugging effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

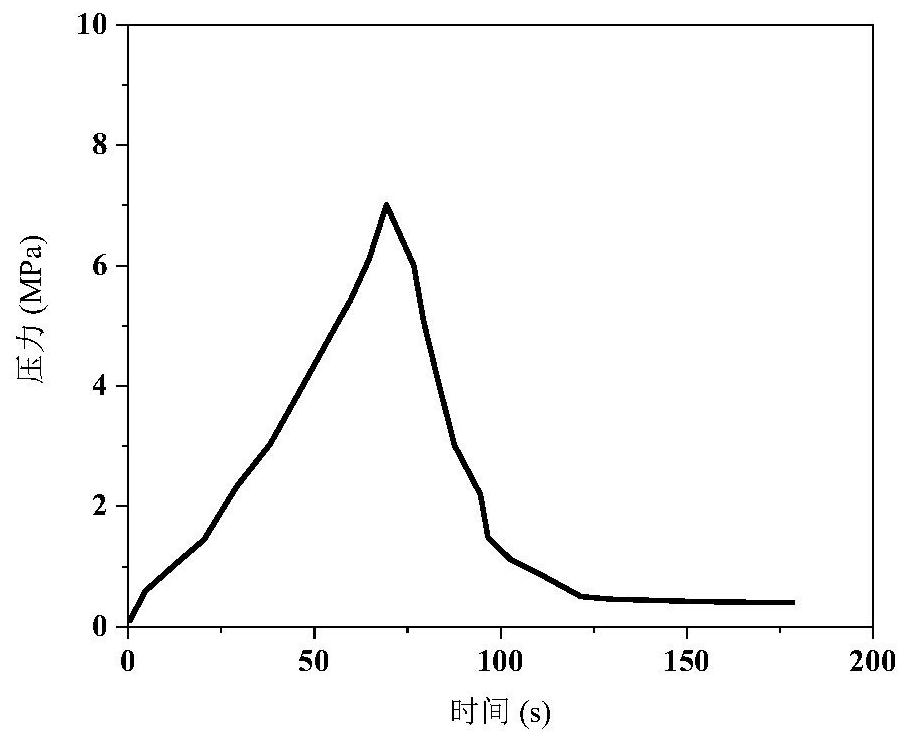

Embodiment 1

[0061] A volume-expanding high-efficiency slug gel plugging agent, which is prepared from the following raw materials in parts by mass: 25 parts of a polymerization reaction agent, 2 parts of a crosslinking agent, 0.08 parts of a temperature-appropriate initiator, and 4 parts of a water-soluble resin toughening agent 4 parts, 4 parts of composite inorganic toughening agent, 4 parts of modified starch, 6 parts of body swelling reaction agent, 4 parts of rheology modifier.

[0062] The polymerization reactant is composed of 2 (methylamino) ethyl methacrylate, N-N dimethylbisacrylamide and methylene succinic acid, of which 2 (methylamino) ethyl methacrylate, N-N dimethyl bisacrylamide The mass ratio of acrylamide to methylene succinic acid is 4:4:1.

[0063] The crosslinking agent is composed of methylolacrylamide and glutaraldehyde, wherein the mass ratio of methylolacrylamide and glutaraldehyde is 2:1.

[0064] The temperature-appropriate initiator is selected from the low-tem...

Embodiment 2

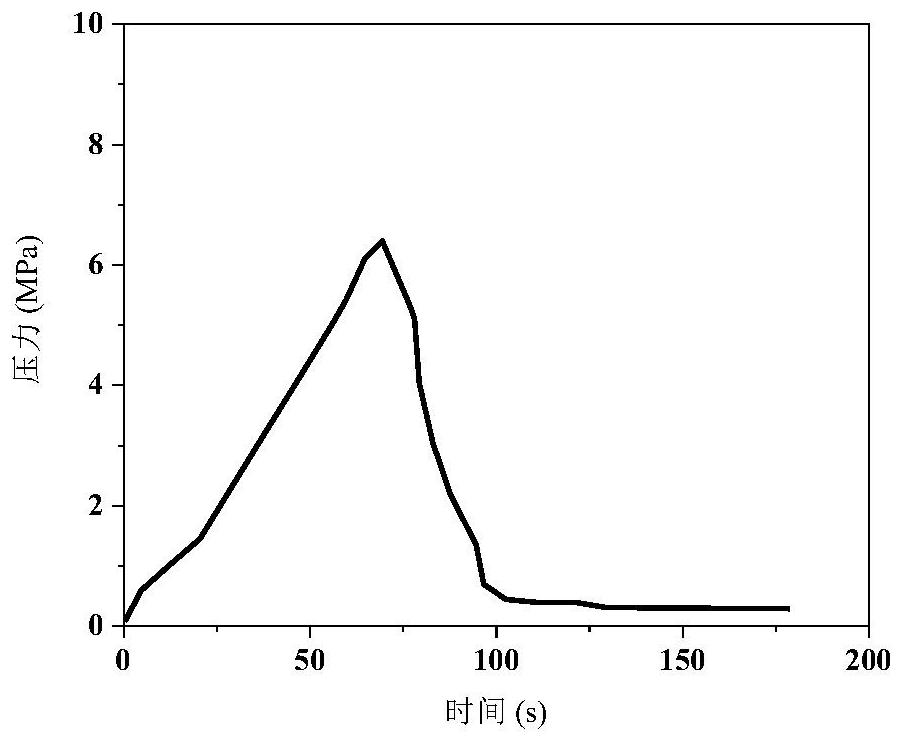

[0083] A volume-expanding high-efficiency slug gel plugging agent, prepared from the following raw materials in parts by mass: 25 parts of a polymerization reaction agent, 2 parts of a crosslinking agent, 0.1 part of a temperature-appropriate initiator, and 4 parts of a water-soluble resin toughening agent 4 parts, 4 parts of composite inorganic toughening agent, 4 parts of modified starch, 6 parts of body swelling reaction agent, 4 parts of rheology regulator.

[0084] The polymerization reactant is composed of 2 (methylamino) ethyl methacrylate, N-N dimethylbisacrylamide and 2-acrylamido-2-methylpropanesulfonic acid, in which 2 (methylamino) ethyl methacrylate The mass ratio of ester, N-N dimethylbisacrylamide and 2-acrylamido-2-methylpropanesulfonic acid is 2:2:1.

[0085] The crosslinking agent is composed of methylolacrylamide and glutaraldehyde, wherein the mass ratio of methylolacrylamide and glutaraldehyde is 2:1.

[0086] The moderate-temperature initiator is azodiis...

Embodiment 3

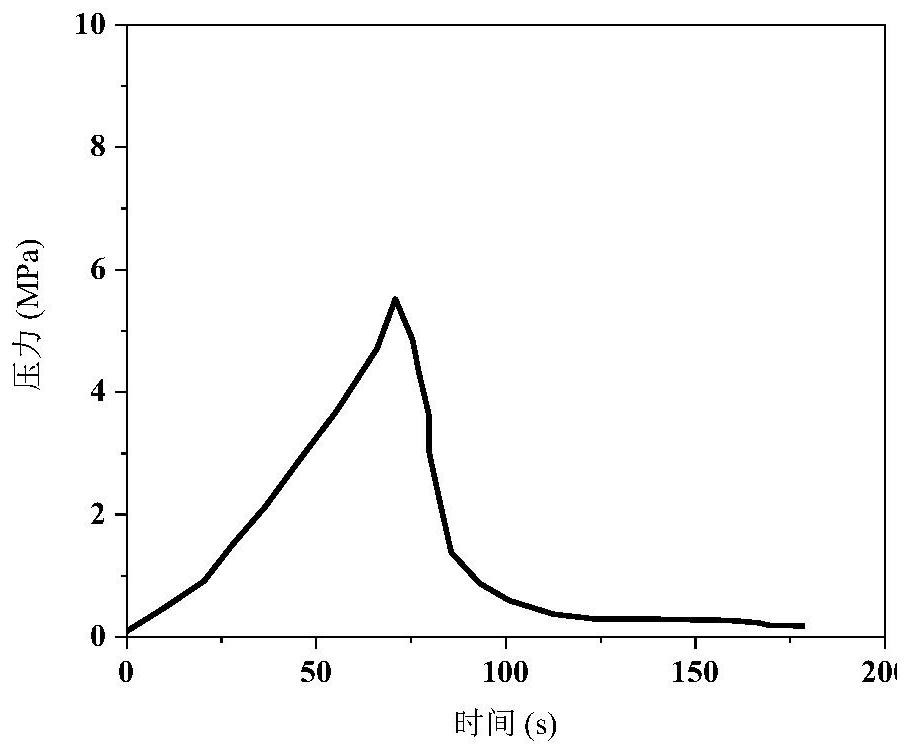

[0098] A volume-expanding high-efficiency slug gel plugging agent, which is prepared from the following raw materials in parts by mass: 25 parts of a polymerization reaction agent, 2 parts of a crosslinking agent, 0.08 parts of a temperature-appropriate initiator, and 4 parts of a water-soluble resin toughening agent 4 parts, 4 parts of composite inorganic toughening agent, 4 parts of modified starch, 6 parts of body swelling reaction agent, 4 parts of rheology modifier.

[0099] The polymerization reactant is composed of 2 (methylamino) ethyl methacrylate, N-N dimethylbisacrylamide and methylene succinic acid, of which 2 (methylamino) ethyl methacrylate, N-N dimethyl bisacrylamide The mass ratio of acrylamide to methylene succinic acid is 4:4:1.

[0100] The crosslinking agent is glutaraldehyde.

[0101] The moderate temperature initiator is selected as high temperature initiator tert-butyl hydroperoxide, and the corresponding polymerization reaction temperature is 105°C.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com