Method for sealing casing breaking point of casing damaged well in oil field

A technology for well casing and oil field, which is applied to the field of plugging of casing damage and well casing break points in oil fields, can solve the problems of difficult chemical plugging and squeezing construction, reduced wellbore pressure bearing capacity, poor formation water absorption capacity, etc., and achieves gel formation. Time controllable, reduced injection friction, and high compressive strength

Inactive Publication Date: 2018-12-11

PETROCHINA CO LTD

View PDF8 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] However, when the above technical solutions are applied to wells with severe casing inner wall corrosion, there are mainly the following problems: the pressure bearing capacity of the wellbore is reduced, the cement sheath cracks outside the pipe or the water absorption capacity of the formation are poor, and the construction of chemical plugging and extrusion is difficult; , it is necessary to design and develop relevant precision jam-squeeze injection technology and low-friction high-strength plugging agent, which not only require the plugging agent to be able to be injected, but also require the plugging agent to have excellent cementation performance under formation conditions, so as to improve the success rate of chemical plugging and block validity period

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

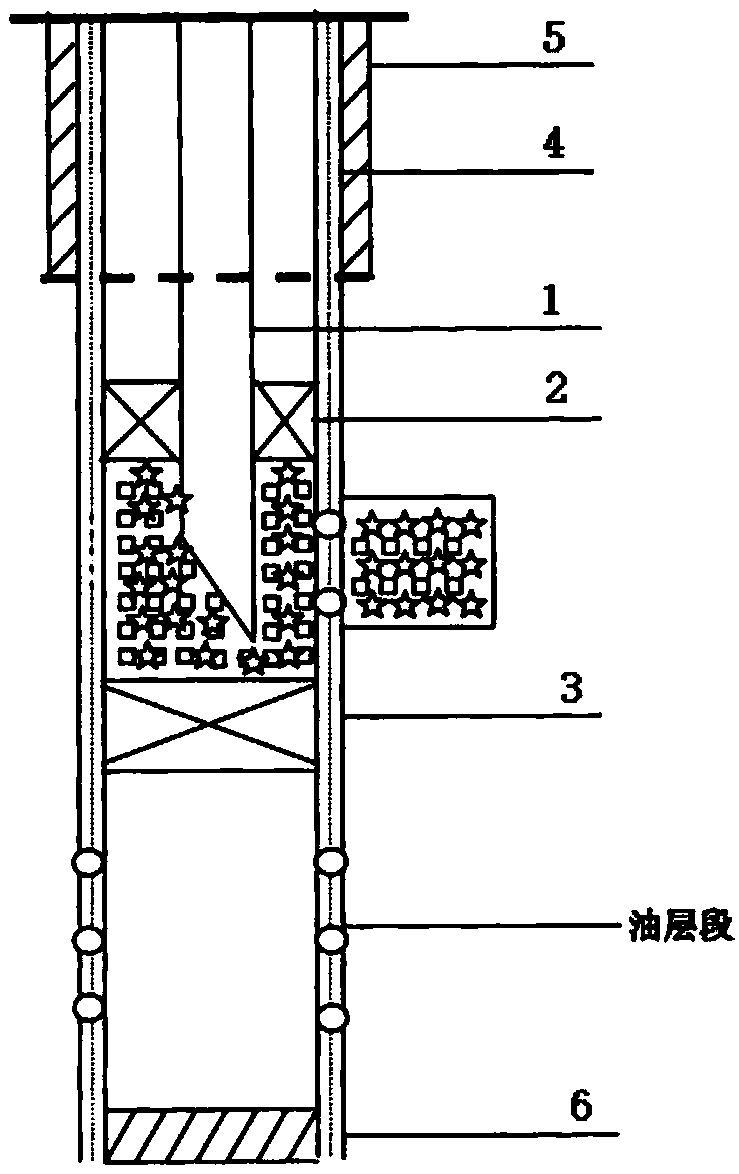

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0028] figure 1 It is an example diagram of the implementation of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a method for sealing a casing breaking point of a casing damaged well in an oil field. The method includes S1, inserting a drillable bridge plug below the casing breaking pointand filling sand to 5m below the casing breaking point, wherein a tubing and plugging type packer are inserted to the upper side of the casing breaking point to be sealed; S2, using the tubing to squeeze clean water to verify the casing breaking point and water absorption capacity thereof; S3, squeezing a low friction blocking agent A and a low viscosity liquid bridging plugging agent B; S4, unplugging the plugging type packer, plugging the wellbore, backwashing the shaft and taking out the tubing; S5, allowing the low friction blocking agent A and the low viscosity liquid bridging plugging agent B to perform non-shrinkage heat curing action at room temperature to form a solidified body after 10-24 hours; S6, inserting a screw drill to remove the plugging-type packer, the solidified body and the drillable bridging plug; S7, testing pressure to be 15MPa with clean water, wherein pressure dropping 0-0.5MPa in 30 minutes is qualified, pumping is completed, or otherwise, plugging is performed once more. With the method, plugging agent injection friction can be reduced, plugging agent injectivity is improved, high strength and non-shrinkage curing of the plugging agent entering cracks are achieved, and permanent plugging is realized.

Description

technical field [0001] The invention belongs to the field of oil and gas well casing damage well plugging and treatment, and relates to a plugging method for oilfield casing damage well casing breaking points. Background technique [0002] Perforation damage caused by oil well formation production fluid corroding the inner wall of the casing. There is a cement sheath outside the casing, and the formation water outside the pipe flows into the wellbore through the fracture of the cement sheath through the casing break point. During the process, the injection pressure of the plugging agent is high, and the construction is difficult; the cementation quality of the plugging agent is poor, and new cracks are likely to occur, resulting in formation water backflow into the wellbore. The use of low-friction high-strength plugging agent can increase the success rate of plugging and the effective plugging time. [0003] At present, this type of well plugging is mainly cement-type plug...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): E21B33/13

CPCE21B33/13

Inventor 杨立华李琼玮王小勇孙雨来李慧程碧海张鑫柱付彩利刘锐

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com