Patents

Literature

323results about How to "Improve injection ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

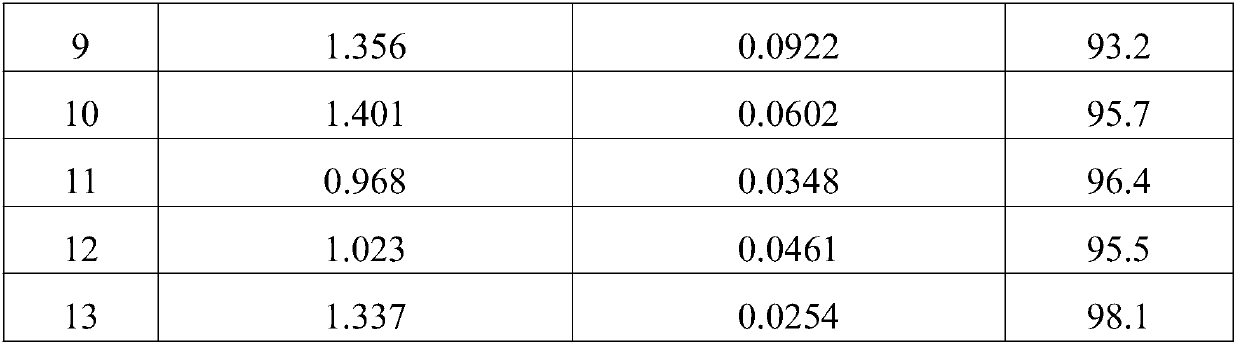

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

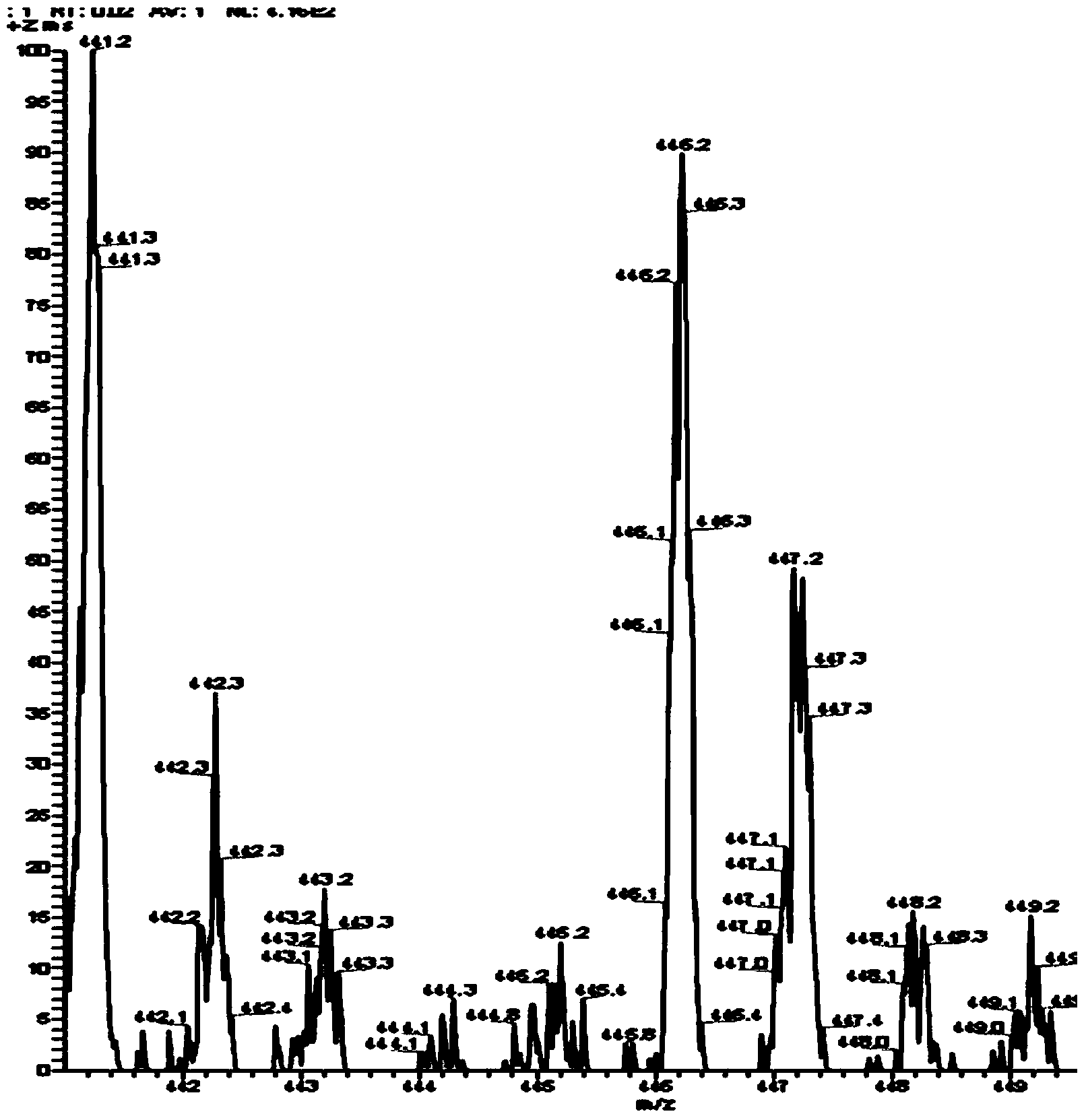

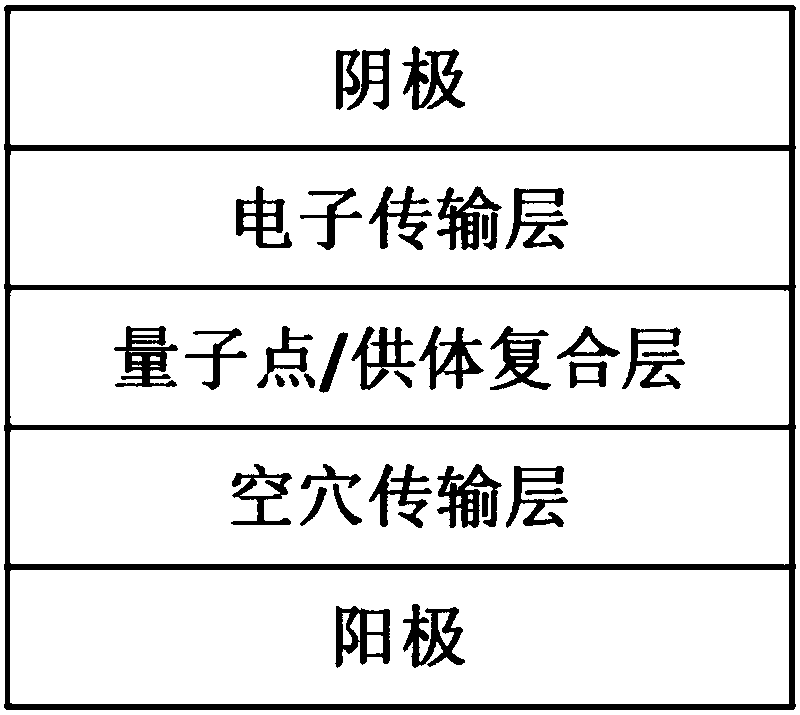

Light emitting diode including quantum dots and energy transfer molecules and fabrication method and display device thereof

InactiveCN106356462AImprove injection abilityImprove energy transferSolid-state devicesSemiconductor/solid-state device manufacturingFluorescenceClick chemistry

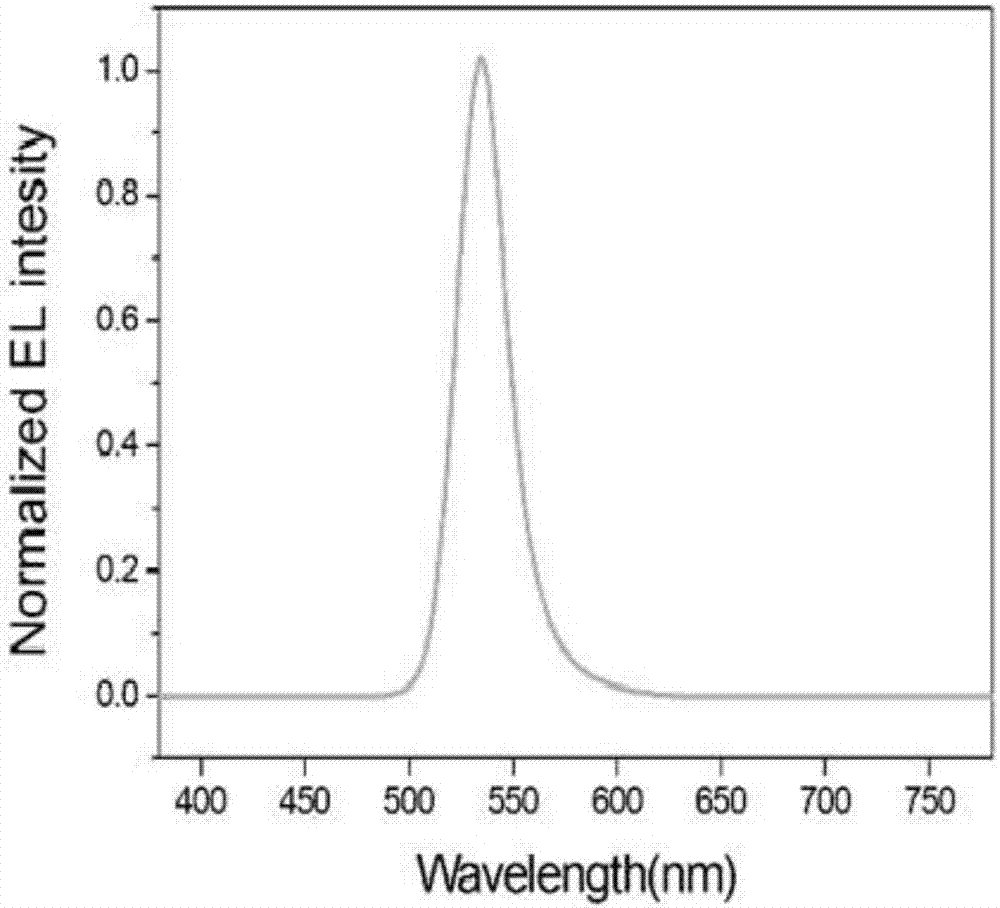

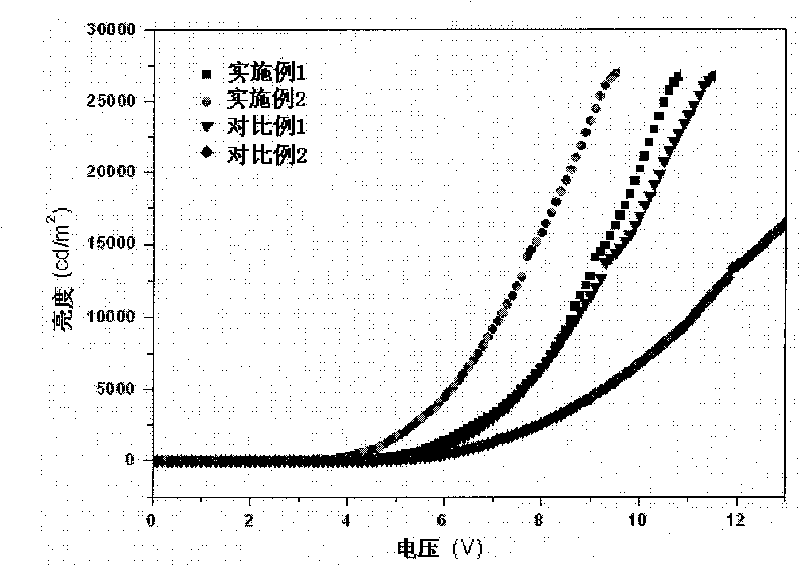

The invention provides a light emitting diode. The light emitting diode comprises a substrate, positive pole, hole transfer layer, emitting layer, electron transport layer and negative pole. The emitting layer comprises quantum dots and energy transfer molecules. The energy transfer molecules crosslink with the quantum dots by click chemistry. The energy transfer molecules, as dispersion medium of the quantum dots, have high electron / hole carrier injection ability, which can promote the production of excitons in energy transfer molecules and realize effective energy transfer from energy transfer molecules to fluorescent quantum dots. At certain voltage, the device can emit within the wavelength range of 380-900nm, with the maximum emitting peak covering ultraviolet to dark red light range. The invention further discloses the fabrication method and electronic display equipment of a light emitting diode.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

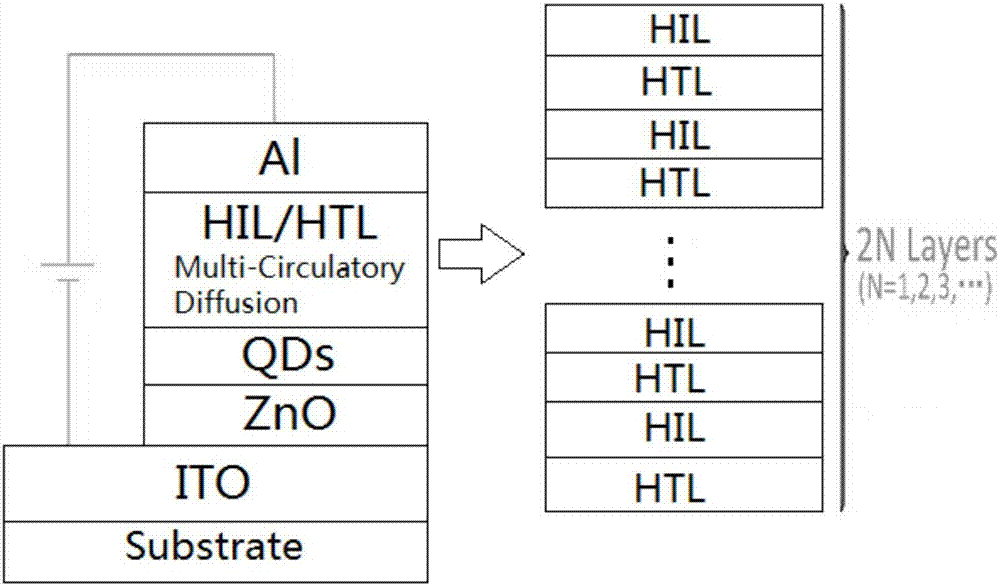

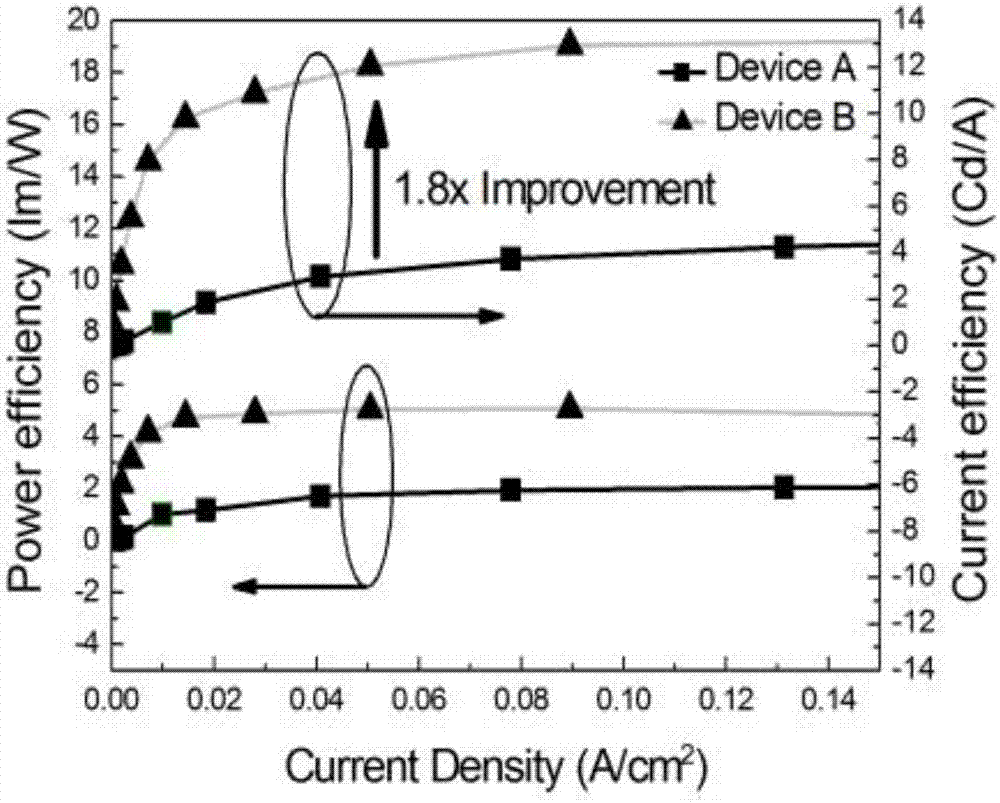

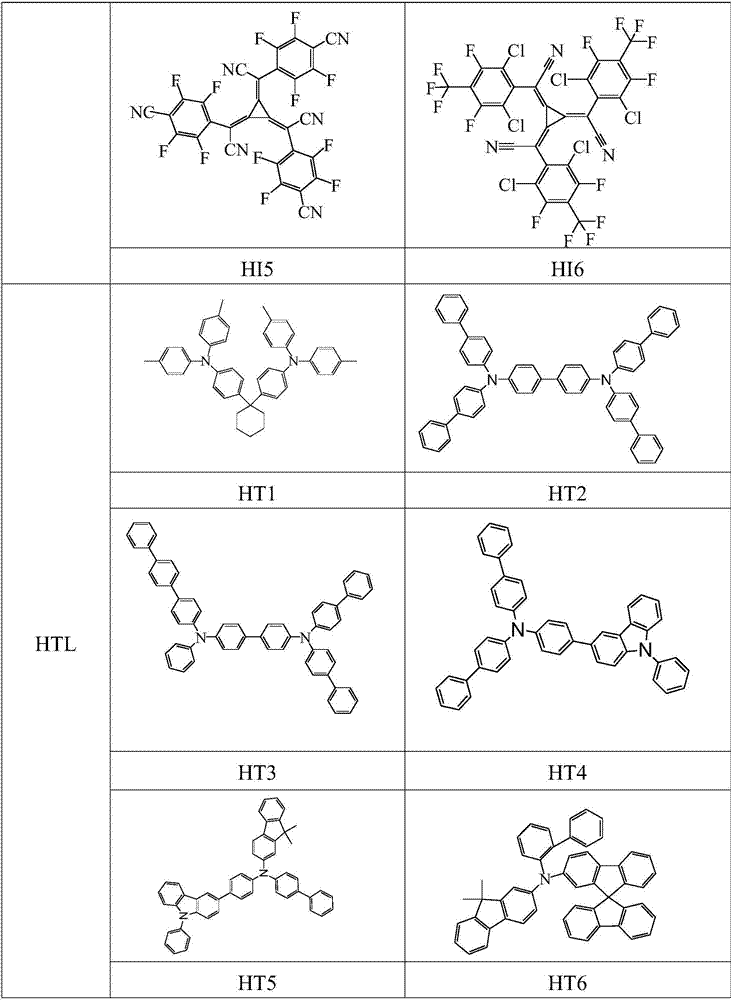

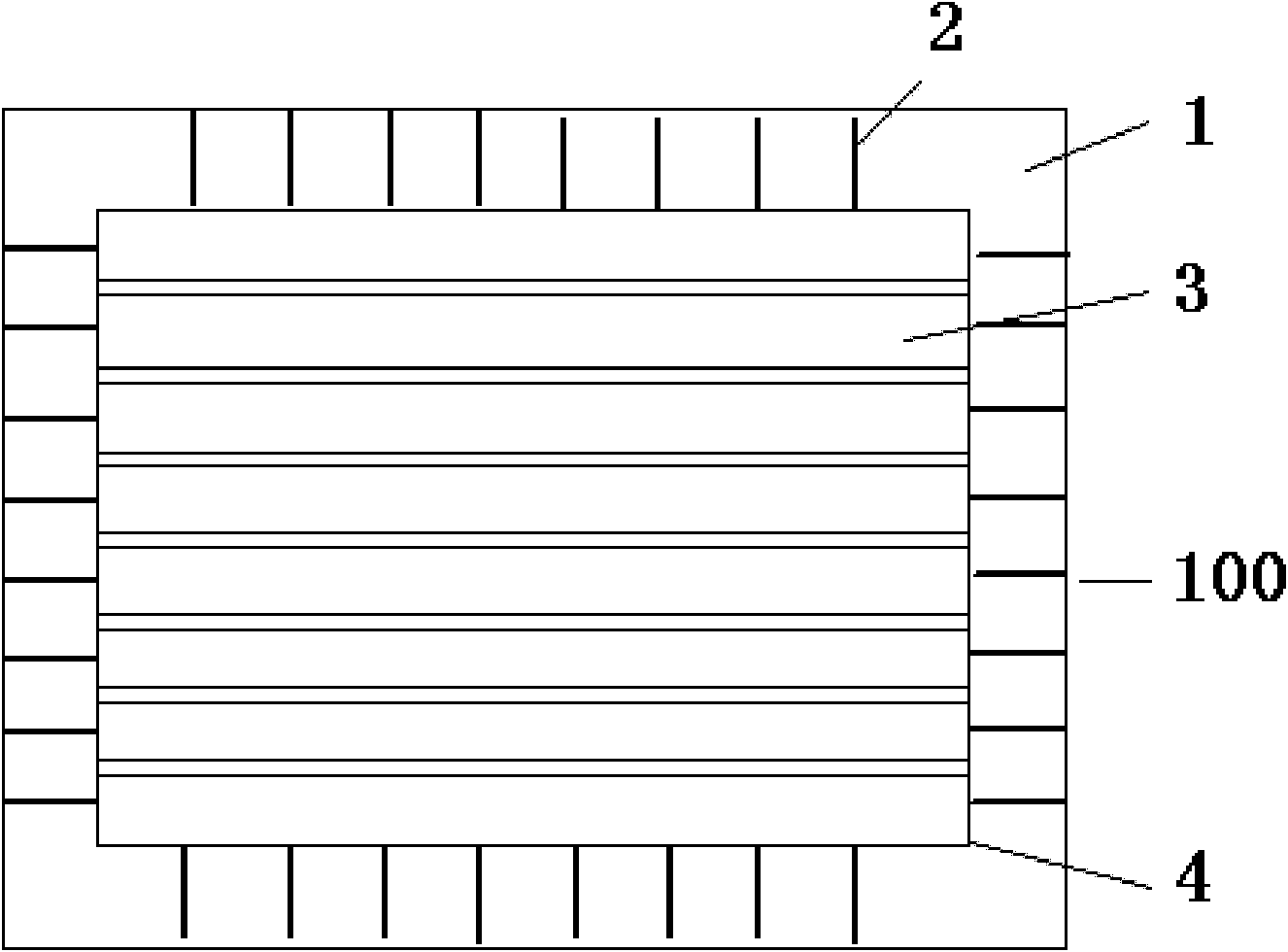

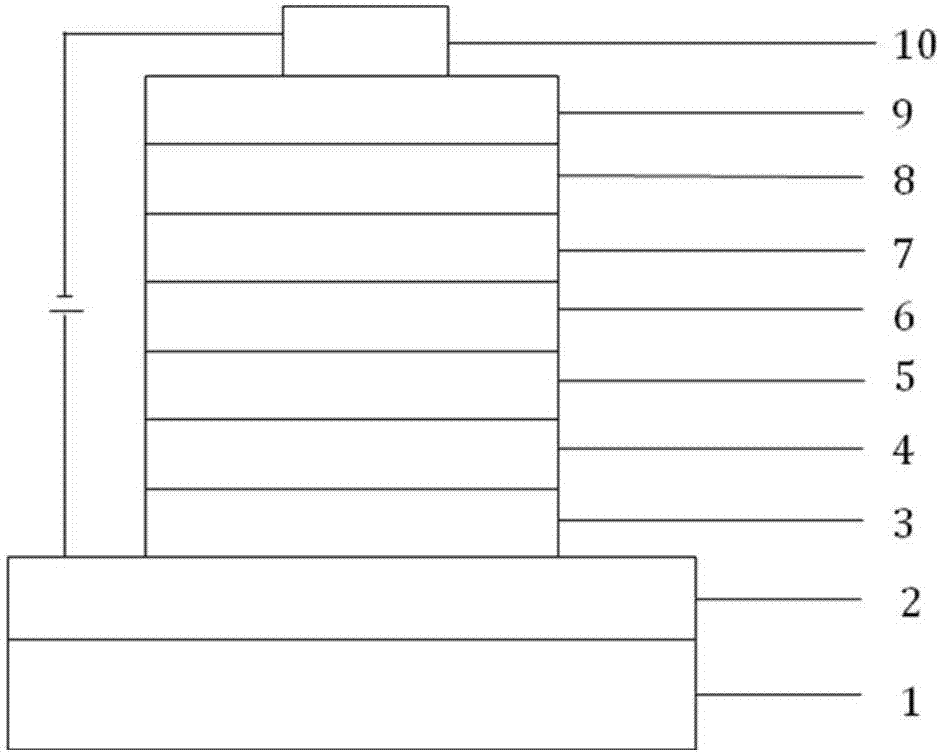

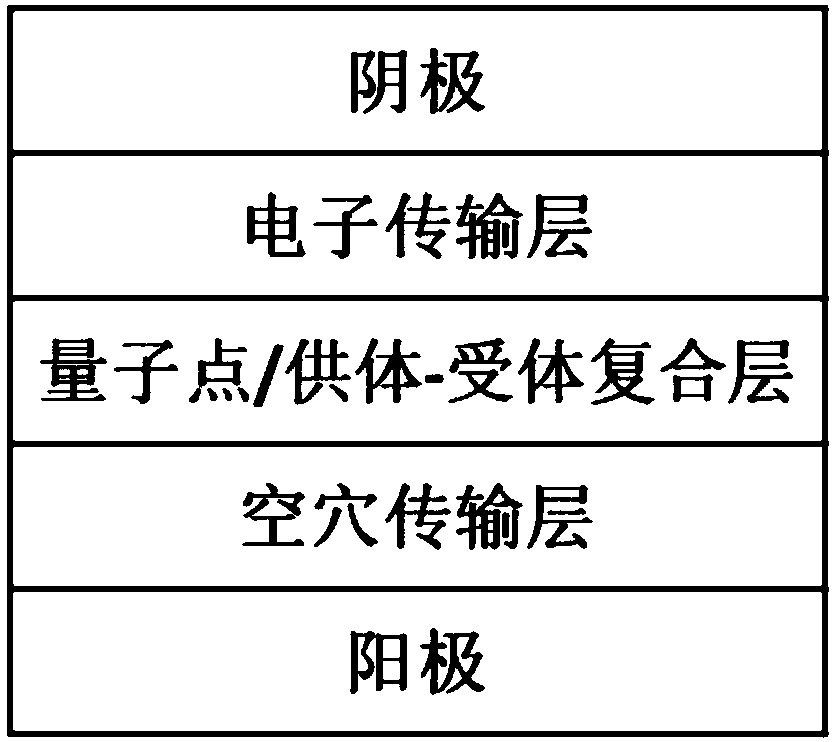

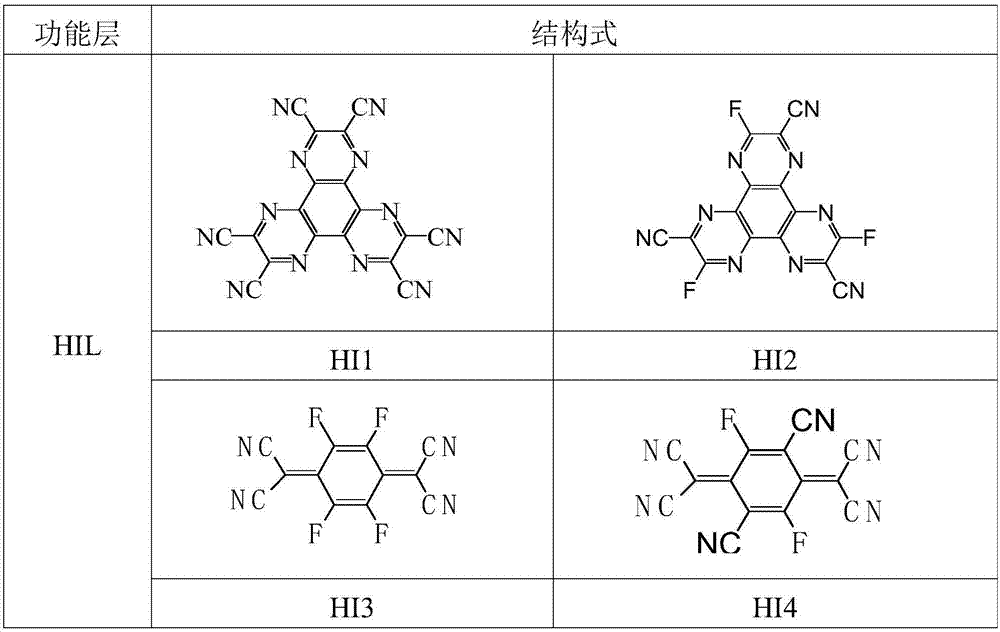

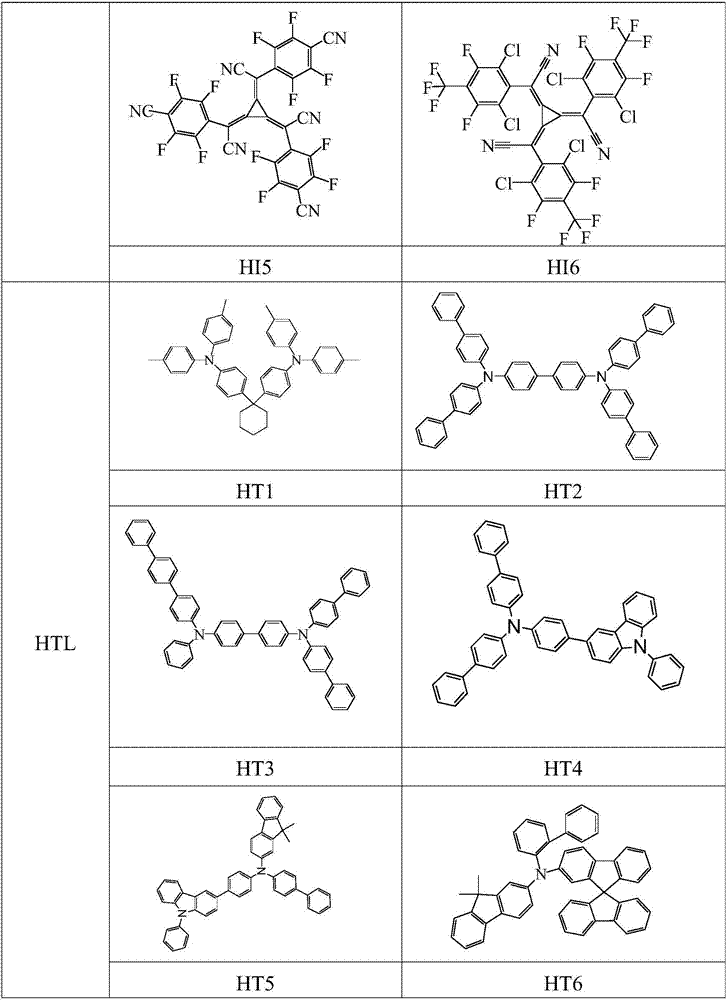

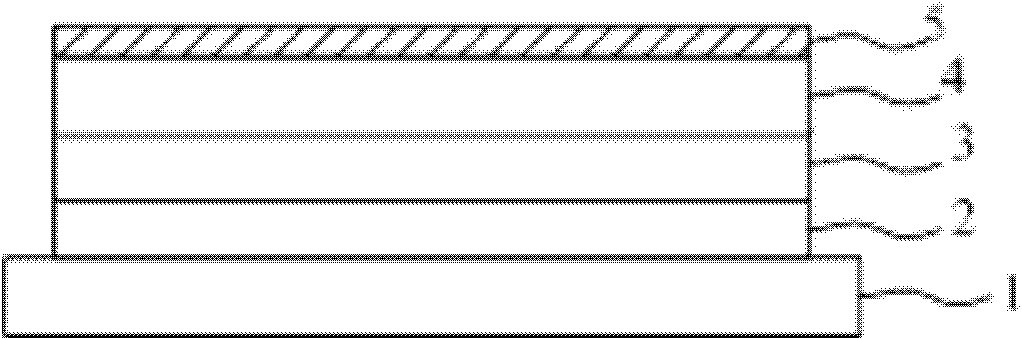

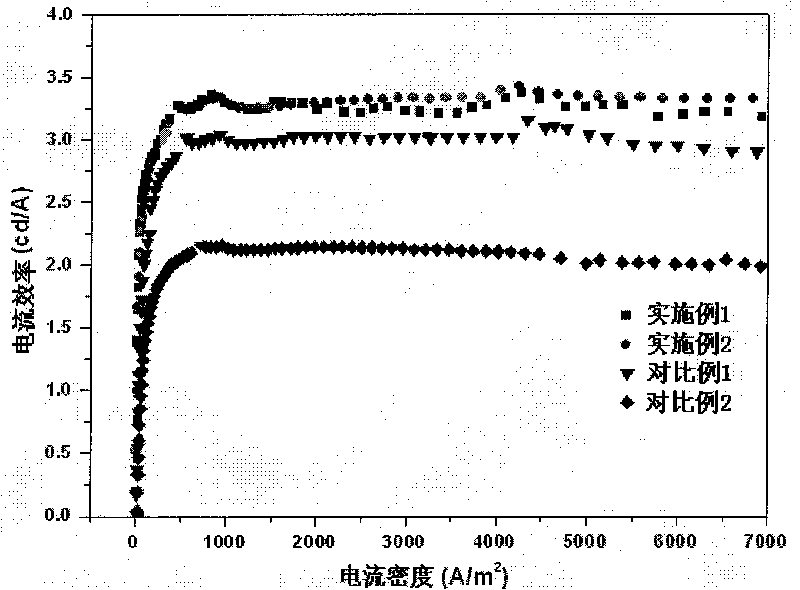

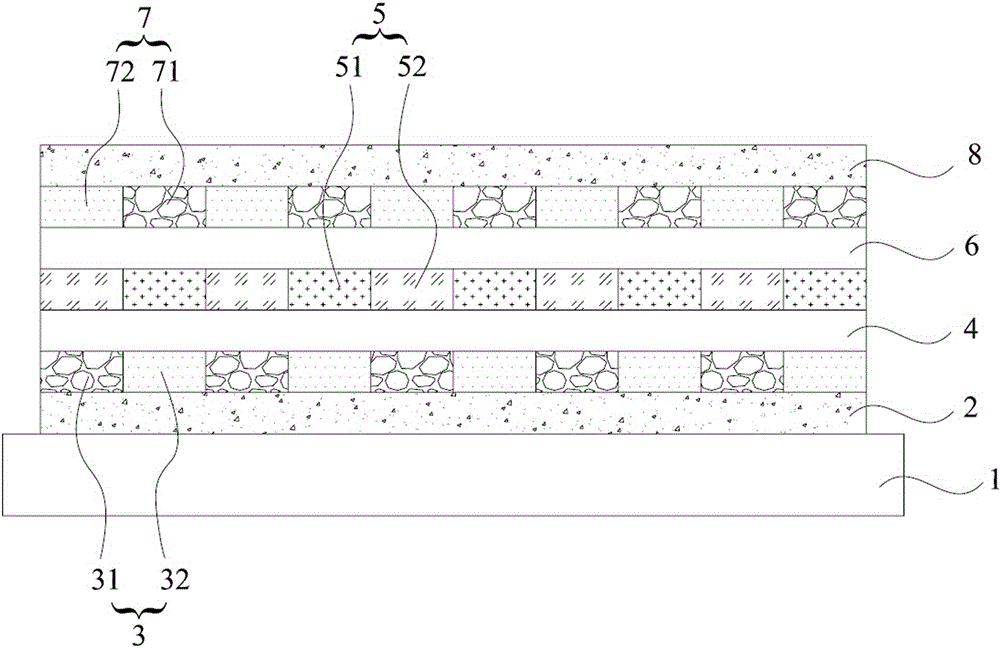

Composite hole transport layer with multi-layer periodic doping structure, LED device structure and application and preparation method of LED device structure

ActiveCN107104193AImproved hole injection performanceImprove injection balanceSolid-state devicesSemiconductor/solid-state device manufacturingTransport layerQuantum dot

The invention discloses a composite hole transport layer with a multi-layer periodic doping structure, an LED device structure and application and preparation method of the LED device structure. By doping a metal oxide material in a hole organic transport layer of a quantum-dot light emitting device, the hole transport layer (HTL) taking the doping organic layer as a structural unit and with multi-layer periodic doping is fabricated, the hole injection capability of the device is remarkably improved, so that the carrier injection balance in the device is improved. Meanwhile, the influence of the doping proportion of the metal oxide doping material in the HTL on the light emitting property of the device is symmetrically researched. The structure is not limited to a quantum-dot LED, and the device structure can be implanted to other types of photoelectric devices.

Owner:SHANGHAI UNIV

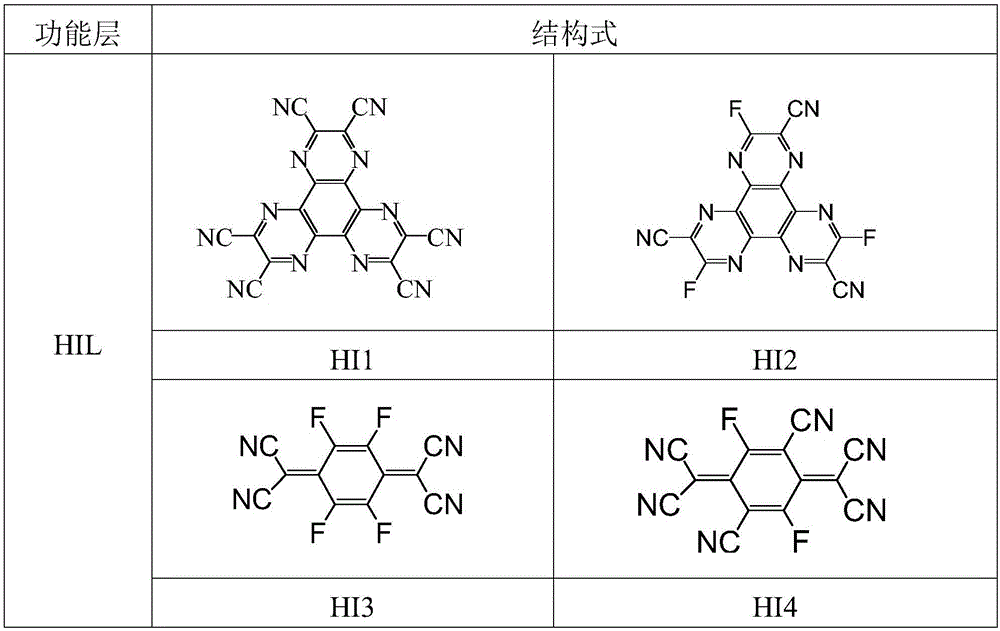

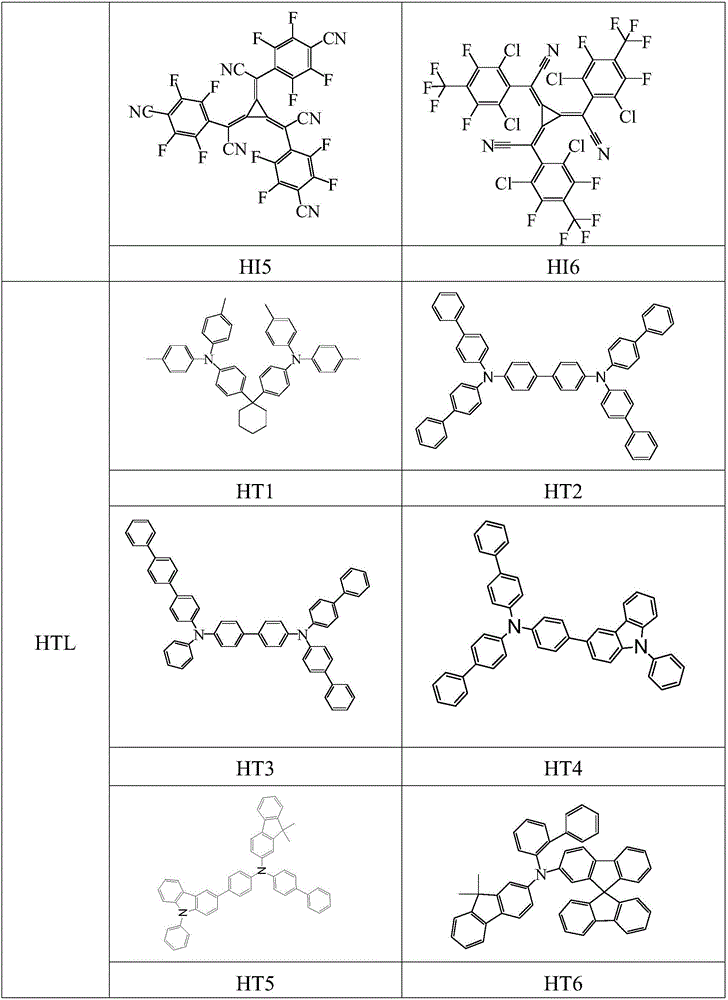

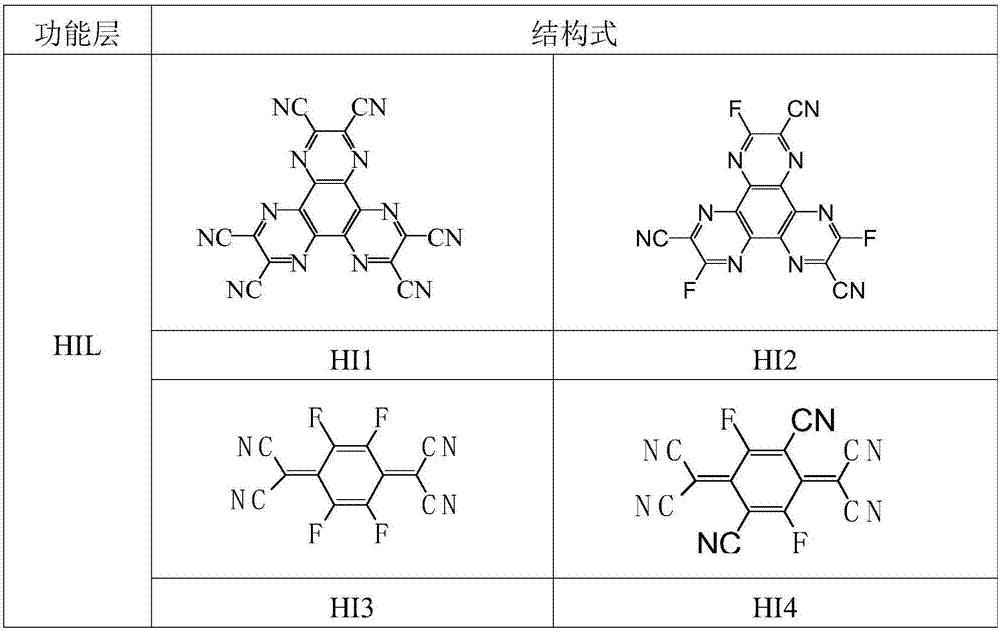

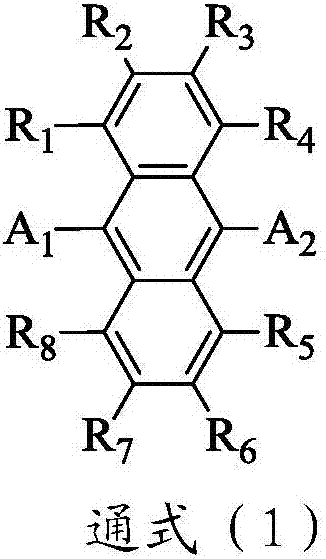

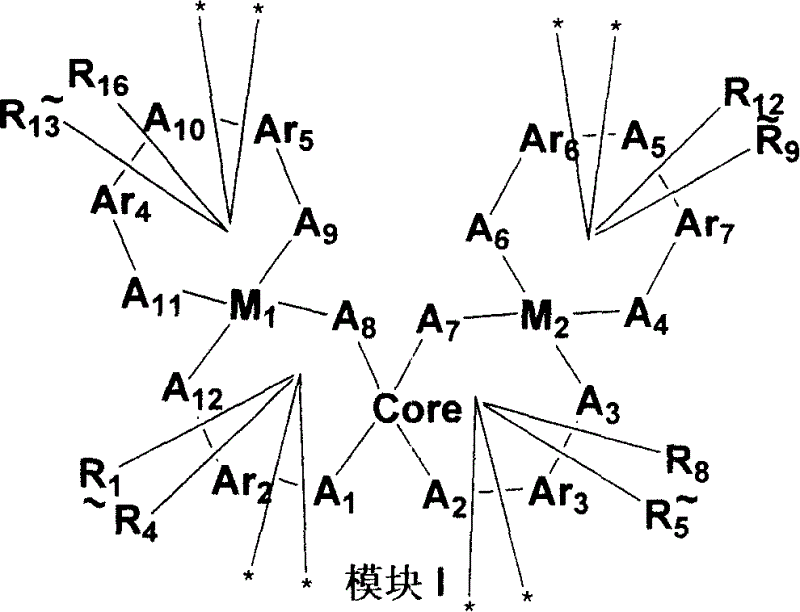

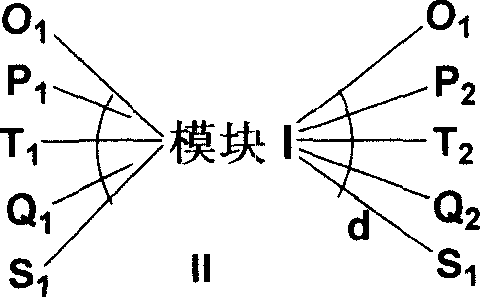

Organic electroluminescent device containing triazine compound and application thereof

InactiveCN106467522AEase of escapeSmall S1-T1 state energy gap differenceOrganic chemistrySolid-state devicesEnergy transferTriplet state

The invention discloses an organic electroluminescent device containing a triazine compound and application thereof. The device comprises a hole transport layer, a luminescent layer and an electron transfer layer. The luminescent layer material of the device contains a compound containing a triazine group. The structural formula of the compound is as shown in the general formula (1). As the triazine material has small triplet state and singlet energy difference, it is easy to realize energy transfer between host-guest materials, energy originally lost in the form of heat is easy to utilize, radiative transition efficiency of the luminescent layer is enhanced, and high efficiency of the device is easier to obtain. When a doped material is selected as a fluorescent material, luminous radiation of the doped material is easier to obtain, and long life of the material is easier to realize.

Owner:VALIANT CO LTD

Organic light emission diode device containing xanthone compound and application thereof

ActiveCN107068910AEase of escapeSmall S1-T1 state energy gap differenceSolid-state devicesSemiconductor/solid-state device manufacturingEnergy transferTransport layer

The invention discloses an organic light emission diode device containing a xanthone compound and an application thereof. The device comprises a hole transport layer, a light emission layer and an electron transport layer. The material of the light emission layer of the device comprises a compound with xanthone as a core group, and the structural formula of the compound is shown in the general formula (1). According to the material with xanthone as the core group, due to a small triplet and singlet energy difference, energy transfer between host and guest materials can be realized easily, energy that is originally lost in a heat form is easily available, and the high efficiency of the device can be acquired more easily. Further, when a fluorescent material is selected as a doped material, light emission radiation of the doped material is acquired more easily, and a long service life of the material can be acquired more easily.

Owner:VALIANT CO LTD

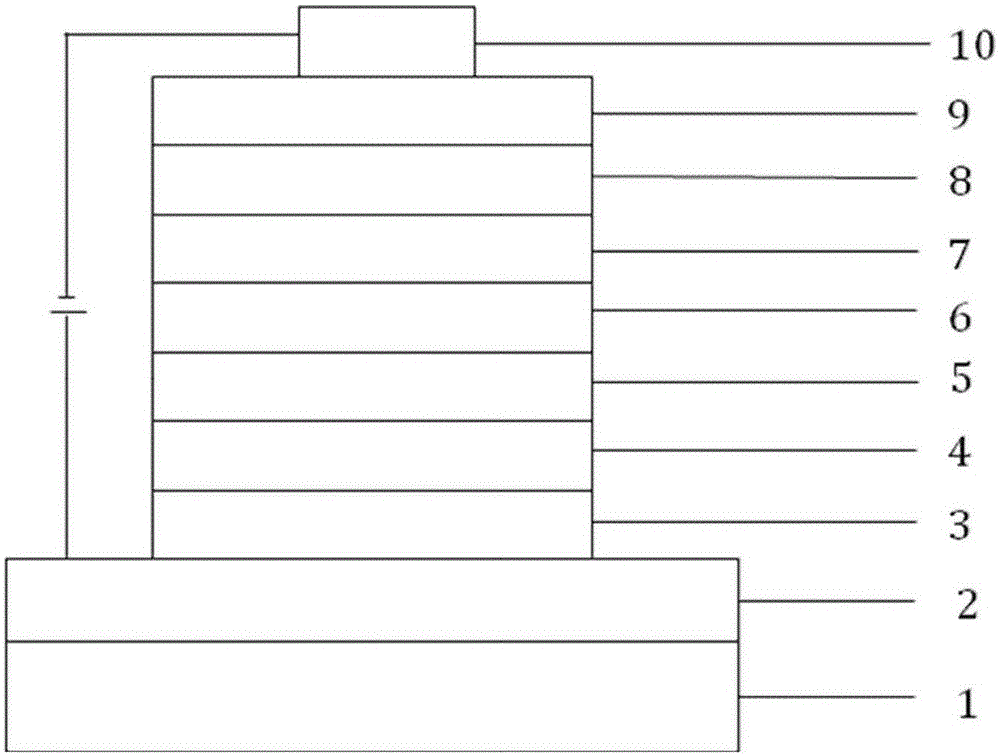

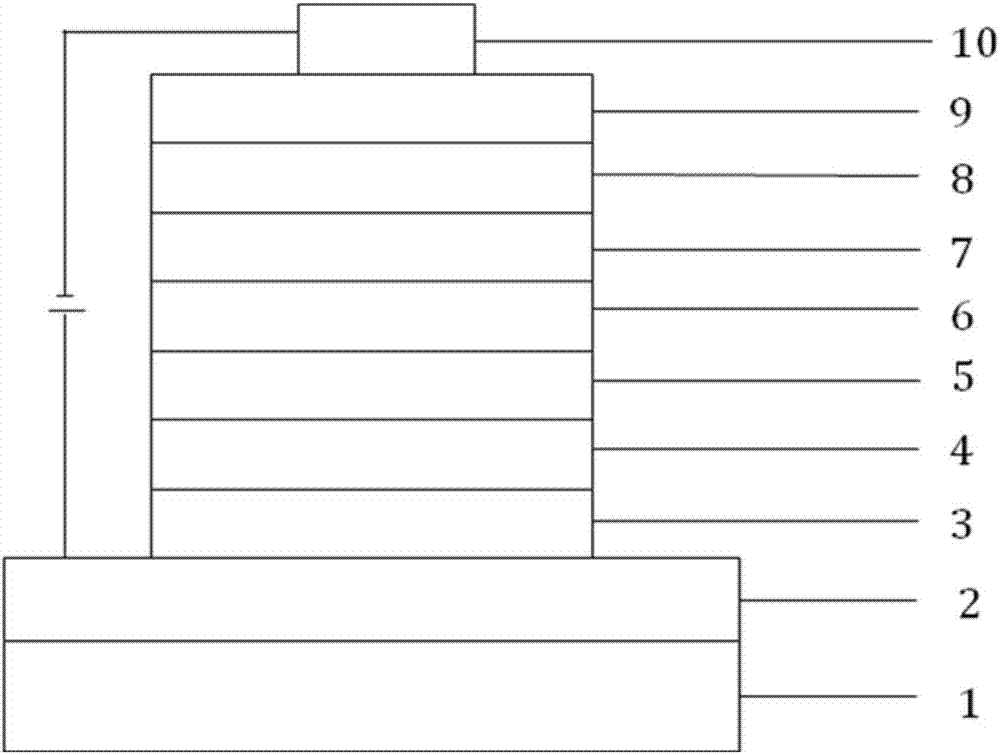

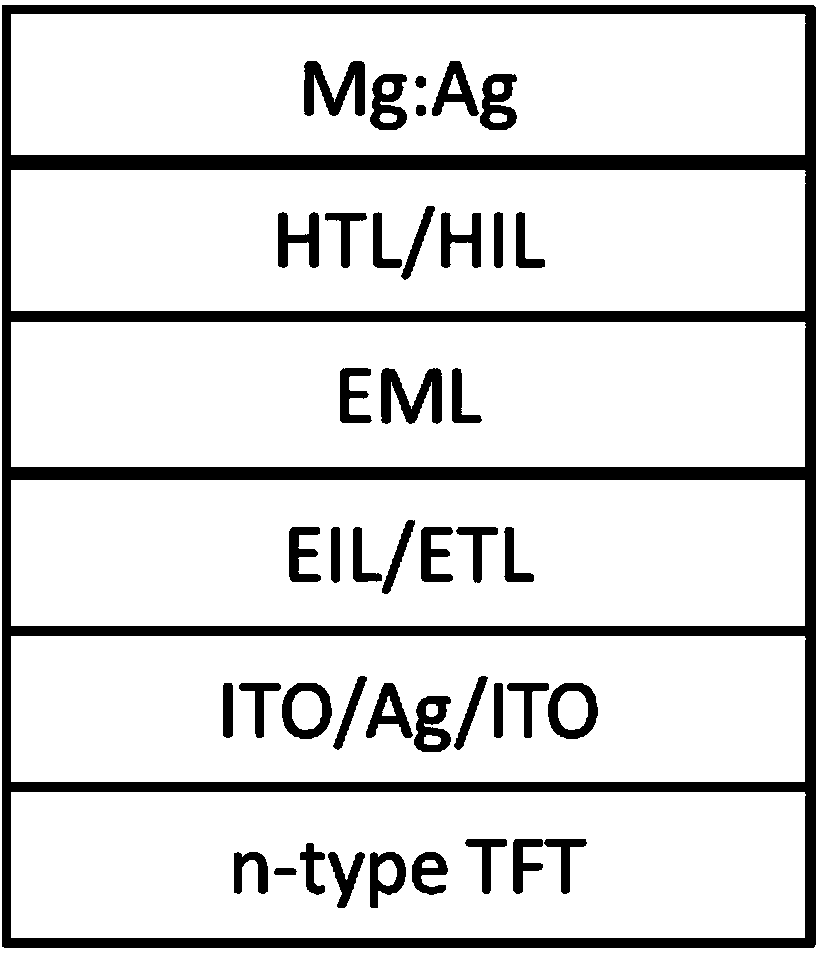

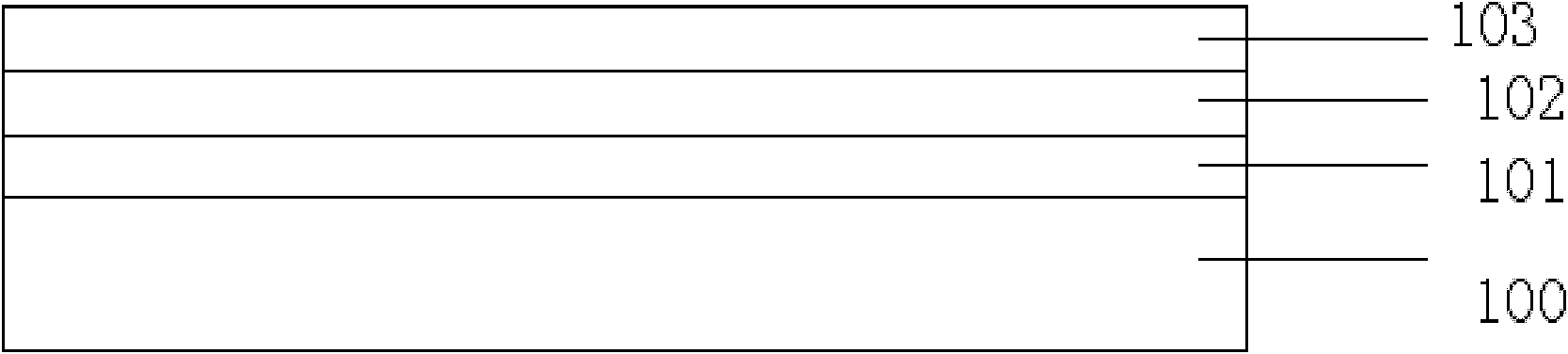

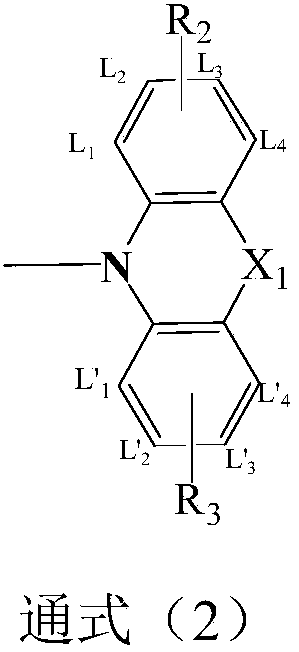

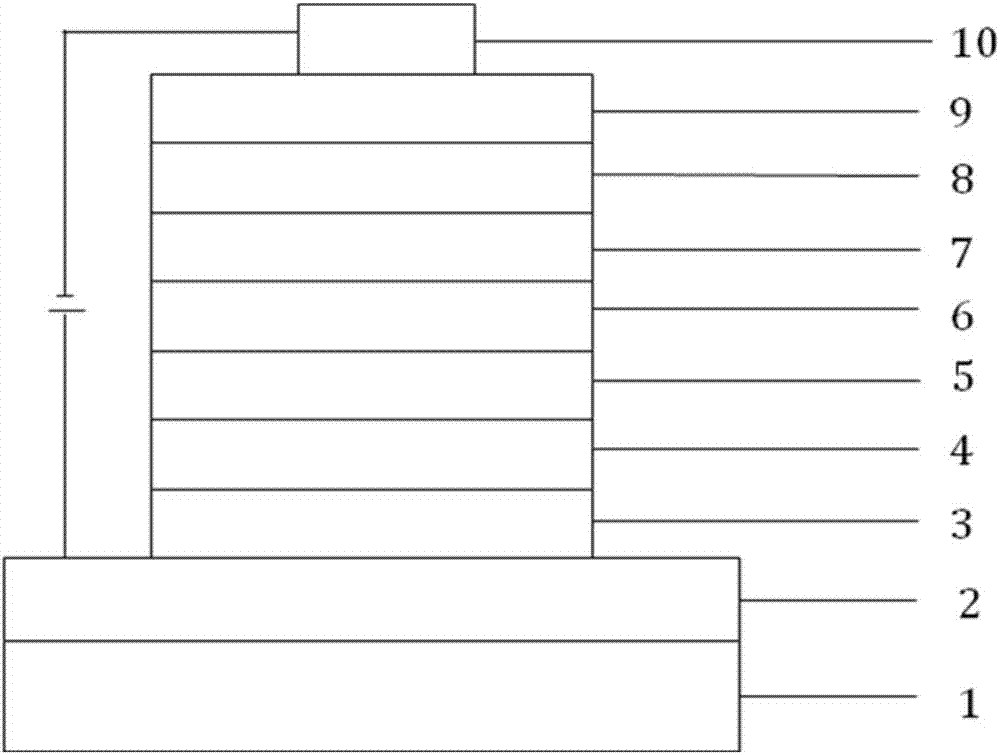

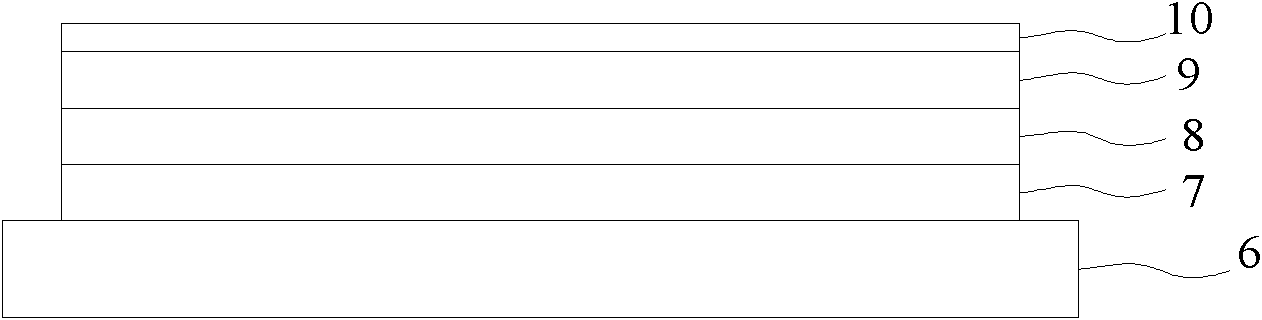

Inverted type organic electroluminescence structure

InactiveCN104201290ALower injection barrierImprove injection abilitySolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionAlloy

The invention provides an inverted type organic electroluminescence structure. The inverted type organic electroluminescence structure comprises a substrate, and a cathode layer, an electron injection layer, an electron transport layer, a luminous layer, a hole injection layer, a hole transport layer and an anode layer, which are sequentially arranged on the substrate from bottom to top, wherein the anode layer comprises a first conducting layer, a metal layer and a second conducting layer, and the cathode layer contains chemical compositions of magnesium, aluminum, silver, ytterbium and samarium and alloy of the above compositions, or the magnesium, the aluminum, the silver, the ytterbium and the samarium mixed with zinc oxide. The inverted type organic electroluminescence structure reduces the electron injection potential barrier, and improves hole injection capacity.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

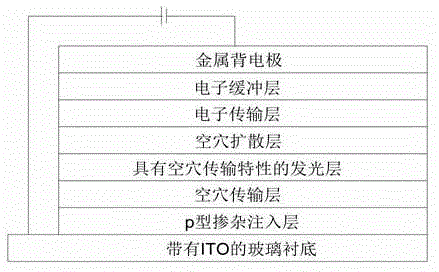

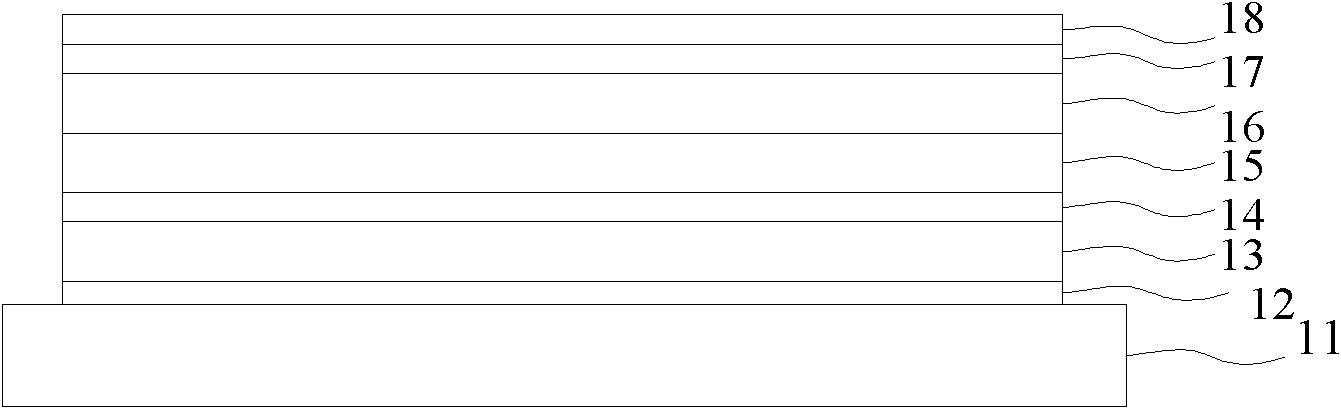

Low-voltage organic electroluminescent blue light emitting device and preparation method thereof

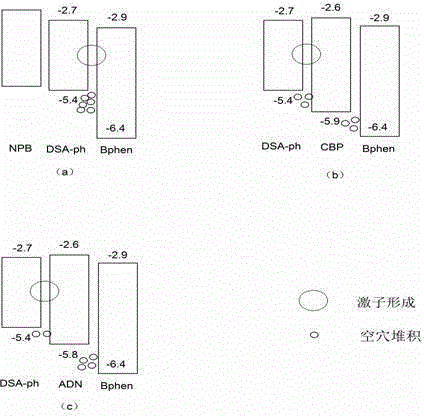

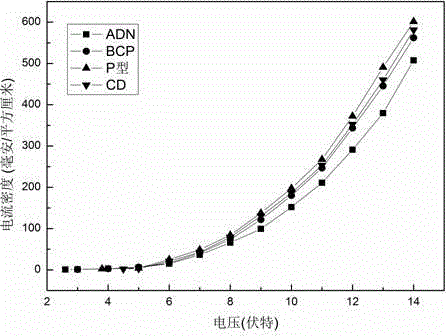

InactiveCN104377309ASolve the problem of high-efficiency lightingReduce the driving voltageSolid-state devicesSemiconductor/solid-state device manufacturingLow voltageHole transport layer

The invention discloses a low-voltage organic electroluminescent blue light emitting device. The low-voltage organic electroluminescent blue light emitting device is composed of an ITO transparent substrate, a p-type doping injection layer, a hole transport layer, a luminescent layer with the hole transport characteristic, a hole diffusion layer, an electronic transport layer, an electronic buffer layer and a metal back electrode in a stacked mode. The luminescent layer with the hole transport characteristic is made of blue light emitting materials. The hole diffusion layer is made of organic semiconductor materials with the bipolar transport characteristic. The HOMO energy level of the hole diffusion layer is between the HOMO energy level of the luminescent layer and the HOMO energy level of the electronic transport layer. A photoluminescent spectrum of the hole diffusion layer and an absorption spectrum of the luminescent layer overlap. The low-voltage organic electroluminescent blue light emitting device has the advantages that the p-type doping injection layer and the hole diffusion layer are arranged in the device, so that the injection capability of holes is improved; meanwhile, cancellation, caused by accumulation of a large number of holes, of excitons in the luminescent layer is avoided, and efficient luminescence of the device at a low voltage is realized; the device has the advantages of low driving voltage, high brightness, high efficiency, good stability and simple preparation processes.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

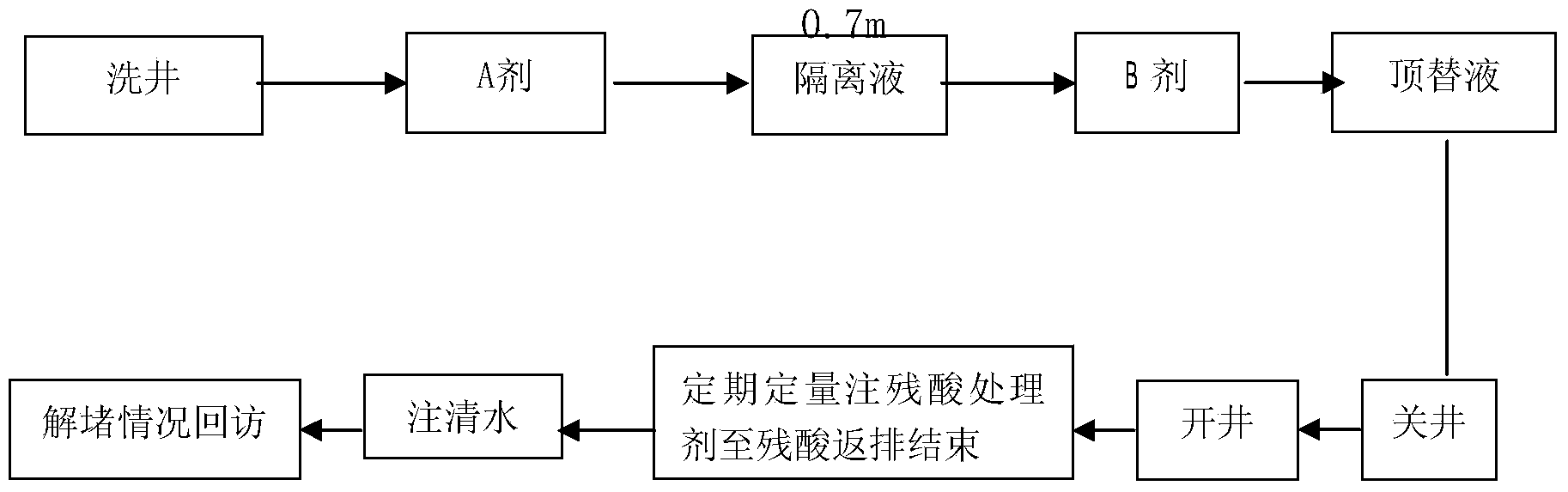

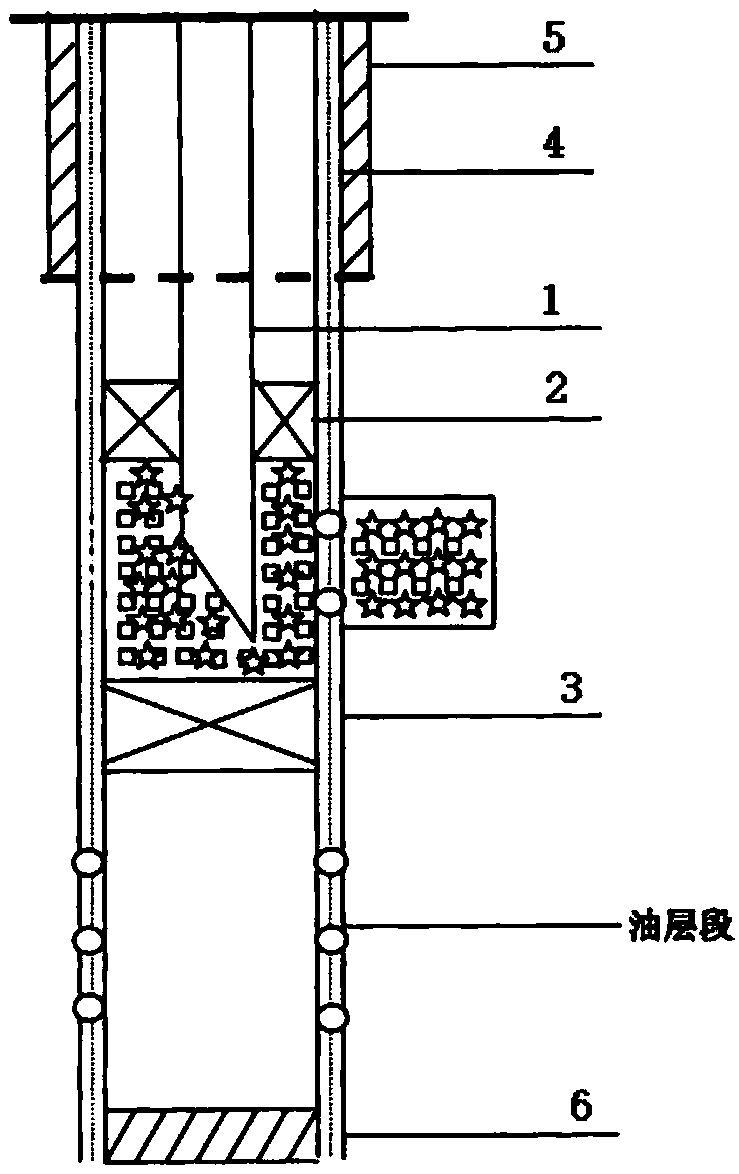

Carbon dioxide acidification blocking remover and process of not reversely discharging raffinate after acidification

ActiveCN103937475AEasy to store and absolutely safeEasy to transport and absolutely safeCleaning apparatusFluid removalActive agentSurface-active agents

The invention relates to a carbon dioxide acidification blocking remover and a process of not reversely discharging raffinate after acidification. The blocking remover comprises a reagent A which is prepared by directly mixing hydrochloric acid, hydrofluoric acid, glacial acetic acid, polyoxyethylene alkyl phenol ether, citric acid, a corrosion inhibitor, a mutual solvent and a clay stabilizer to form a homogeneous solution and a reagent B prepared by mutually mixing carbonate, a surfactant, an iron ion complexing agent, a demulsifier and clean water which are stirred for 1 hour at normal temperature. The process of not reversely discharging raffinate after acidification comprises the following steps: when an oil well is deblocked, first, injecting a medicament A into an oil layer; then, isolating the clean water by layers; then, injecting a medicament B into the oil layer; and finally, injecting clean water to extrude a mixture in a shaft to the stratum, then, injecting an acidizer into a loop space to a perforated interval, closing the well for 4-6 hours, opening the well, observing the pH value (control range from 6-7), periodically injecting the acidizer till raffinate is fully discharged out of the stratum, and finally, injecting clean water to extrude the mixture in the shaft into a dryline.

Owner:DAQING ZHONGYOU TAIKE PETROLEUM TECH SERVICE

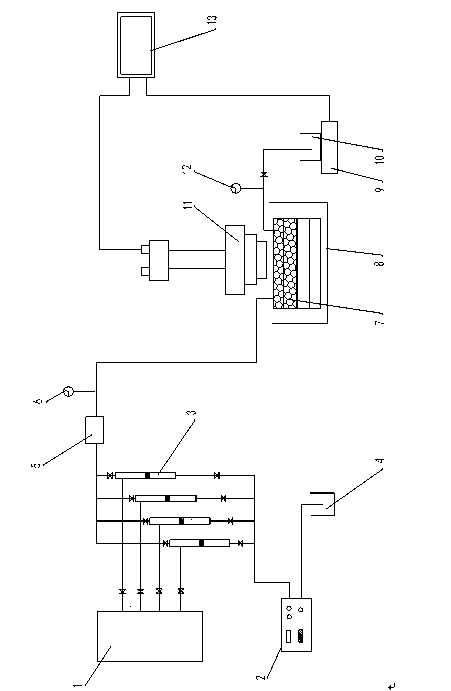

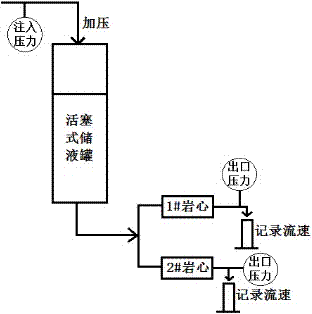

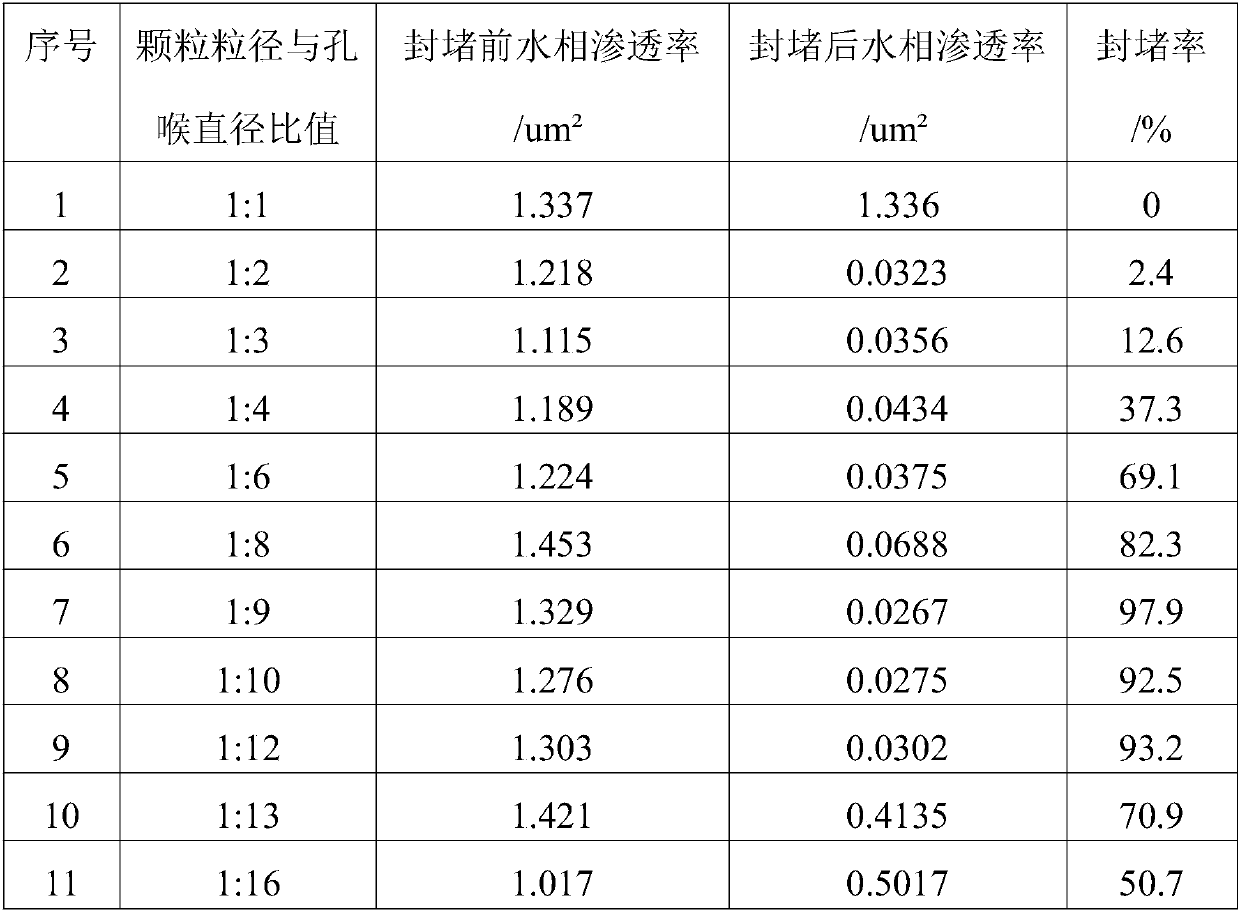

Simulation experiment device system for porous medium microscopic seepage

InactiveCN103792170AHigh degree of automationCalculation data is accuratePermeability/surface area analysisPorous mediumSimulation

The invention discloses a simulation experiment device system for porous medium microscopic seepage, which mainly comprises a precise injection pump, a high pressure container, a camera acquisition system, a microscope imaging system, a microscopic model simulation device, an automatic metering system, a back pressure control device, and a computer image processing system; the precise injection pump is connected with the microscopic model simulation device through the high pressure container; the camera acquisition system and the microscope imaging system are disposed above the microscopic model simulation device; both the camera acquisition system and the microscope imaging system are connected with the computer image processing system; the microscopic model simulation device is also connected with the automatic metering system through the back pressure control device; a constant temperature control system is disposed below the microscopic model simulation device; the automatic metering system is also independently connected with the computer image processing system. The simulation experiment device system can realize visual observation of the flowing phenomenon of multi-phase fluid in a porous medium, and the interaction between the fluid and the porous medium, realize more thorough automation of the experiment, and provide more accurate experiment data.

Owner:CHINA PETROLEUM & CHEM CORP +1

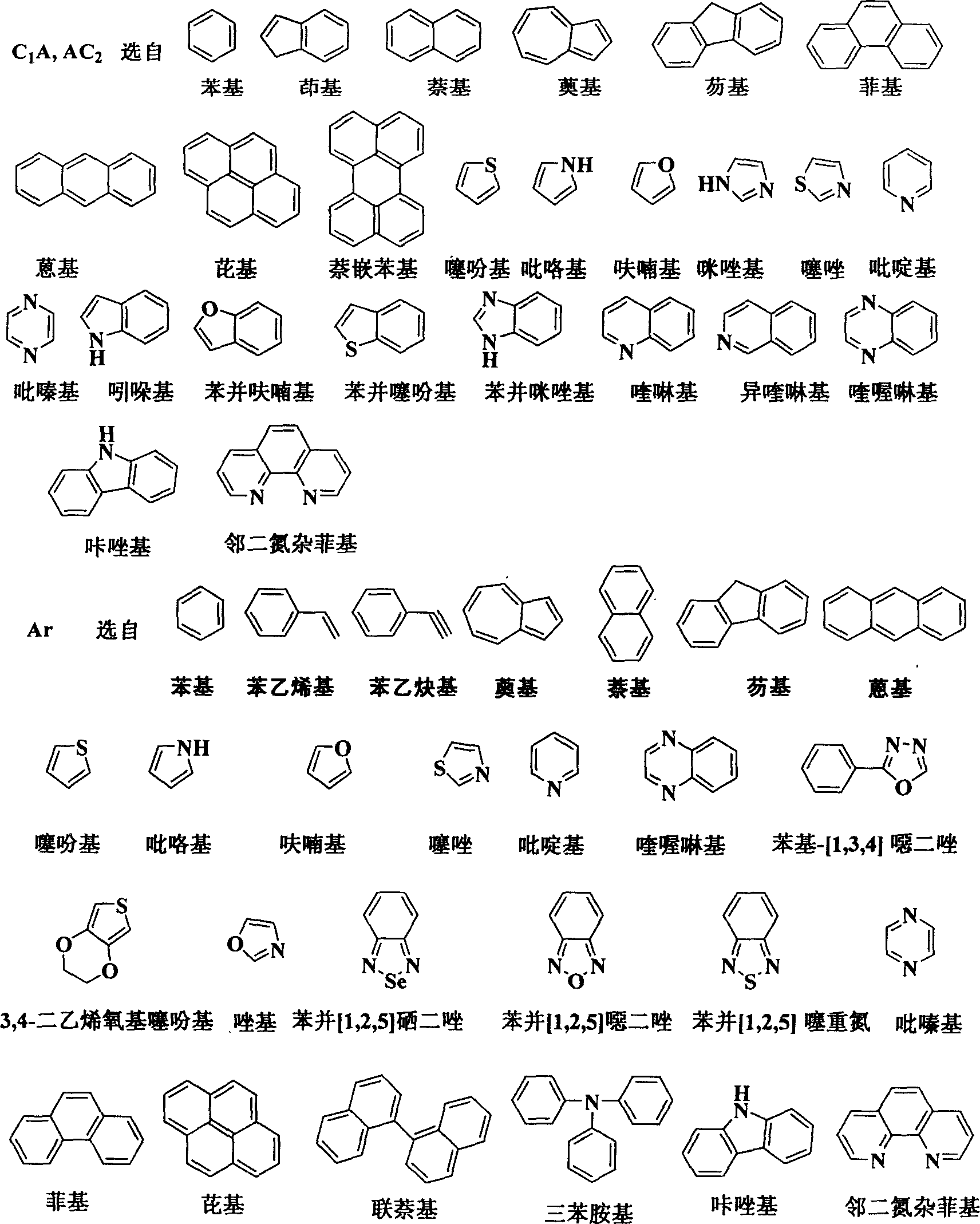

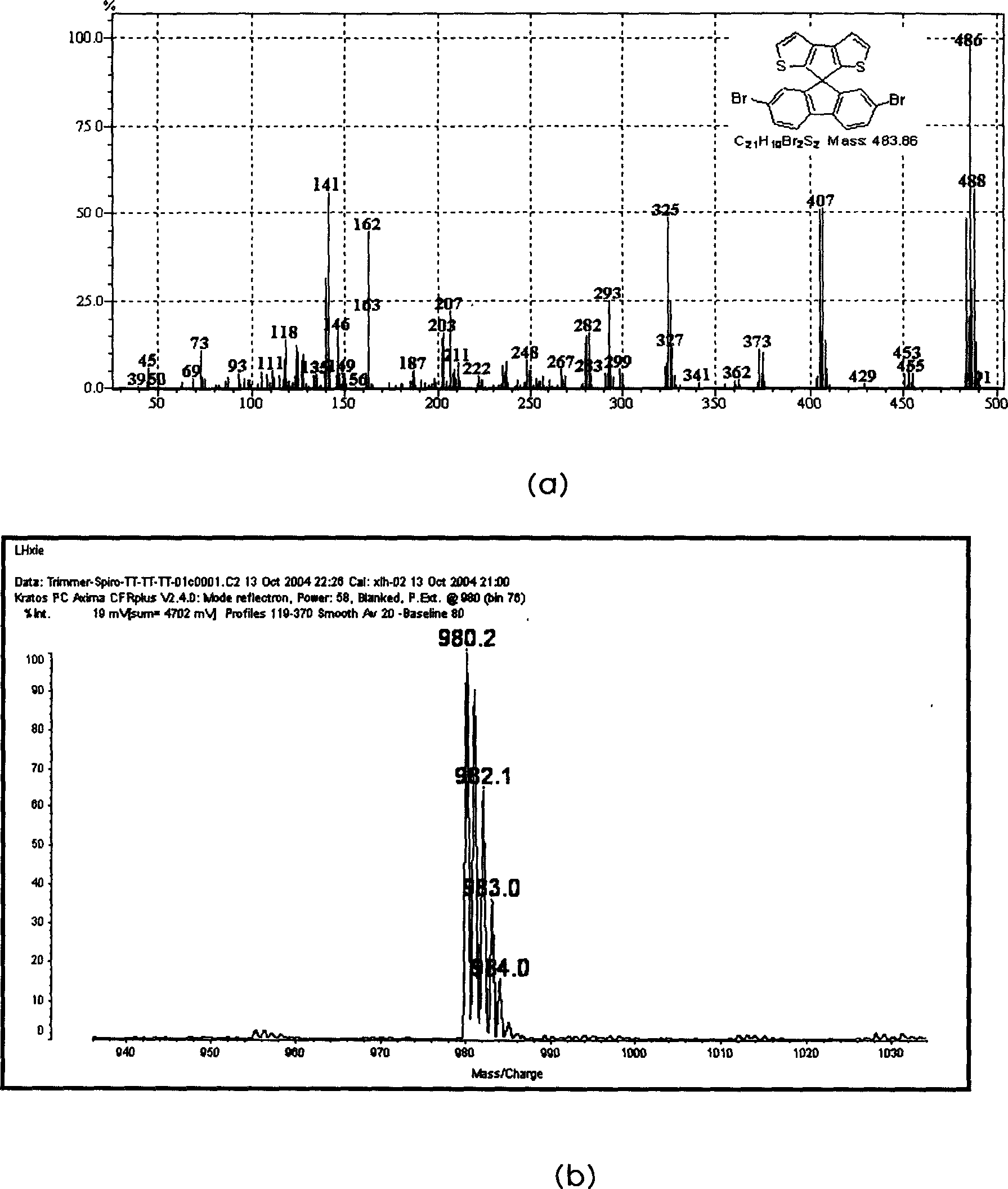

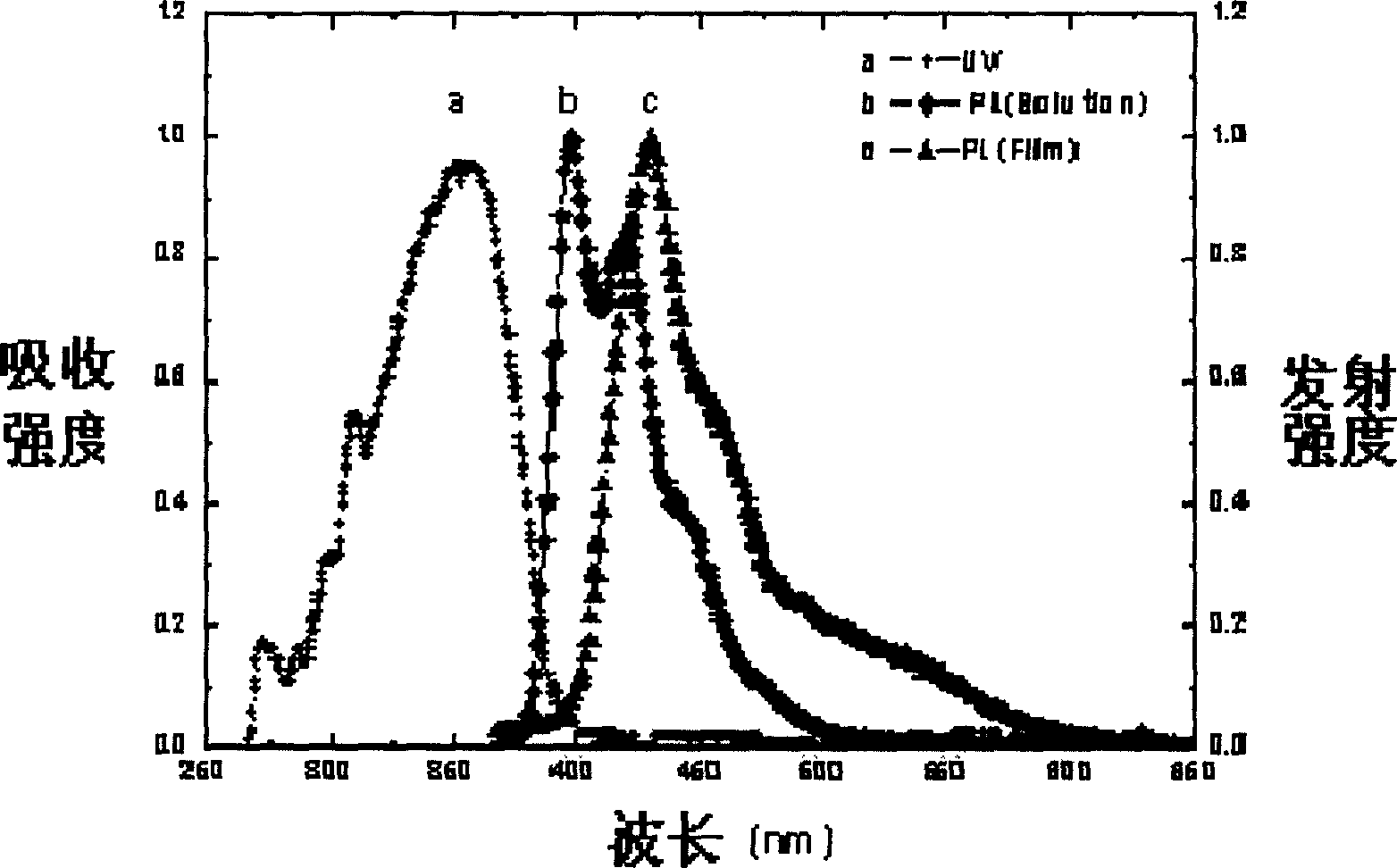

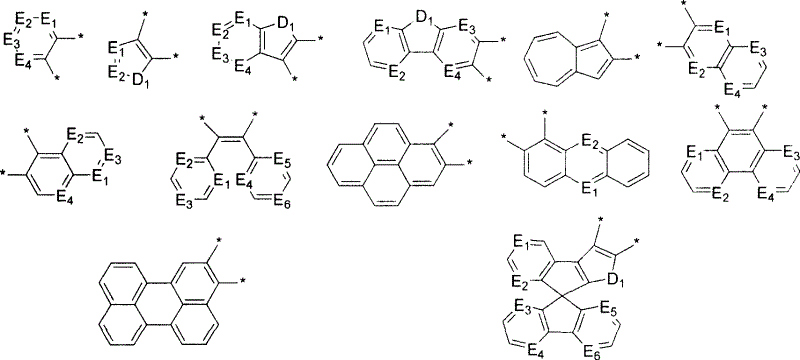

Spirofluorene materials containing non-benzene aromatic ring and synthesis and use thereof

InactiveCN1634927AEasy to introduceFlexible routingElectrical apparatusElectroluminescent light sourcesOligomerField-effect transistor

The invention belongs to photoelectric material technical field, and specifically relates to a spiral fluorine oligomer containing a non-benzene aromatic ring and polymer material and preparation method thereof. The compounds are formed by introducing a non-benzene aromatic ring into highly effective luminous fluorene system through a spirane structure. The advantages of the compounds lie in that (1) the synthesis is convenient and easy, and further products modification can be carried out; (2) the compounds have high spectral stability.

Owner:FUDAN UNIV

Color organic light emitting display panel and manufacturing method thereof

InactiveCN101777577AExtend your lifeImprove injection abilitySolid-state devicesSemiconductor/solid-state device manufacturingPhotoresistLight source

The invention relates to a color organic light emitting display panel and a manufacturing method thereof. The manufacturing method is as follows: 1) cleaning and drying bottom substrate glass, sputtering two metal layers on bottom substrate ITO, and annealing by laser; 2) coating photoresist, exposing, developing, cleansing, drying, and etching out an anode pattern; 3) cleaning and drying upper substrate glass, coating photoresist on upper substrate ITO, prebaking, exposing, developing, cleansing, drying, baking, and etching out a metal cathode pattern on upper substrate ITO by etching liquor; 4) spin-coating the bottom substrate glass, baking, exposing, developing, washing, drying, baking again and curing to obtain an insulation column; 5) evaporating various organic pixel layers on the bottom substrate glass; 6) carrying out vacuum aligning gluing on the bottom substrate glass and the upper substrate glass; and 7) carrying out vacuum lamination on a glued display panel, curing by irradiation of an ultraviolet lamp to obtain the color organic light emitting display panel. The method can effectively improve the service life and light-extraction efficiency of a device, reduce loss of light power source and save working procedures.

Owner:IRICO

Organic electroluminescent material and organic electroluminescent device

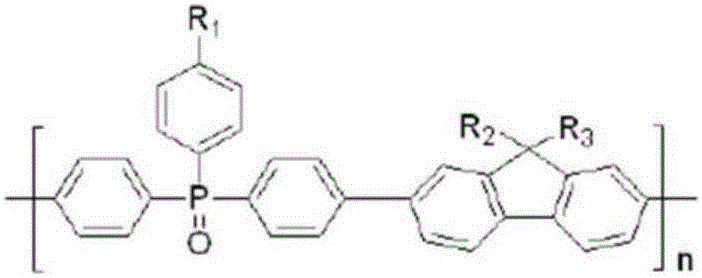

ActiveCN104342126AImprove efficiencyImprove injection abilityGroup 4/14 element organic compoundsGroup 5/15 element organic compoundsHigh electronOrganic electroluminescence

Owner:BEIJING AGLAIA TECH DEV +1

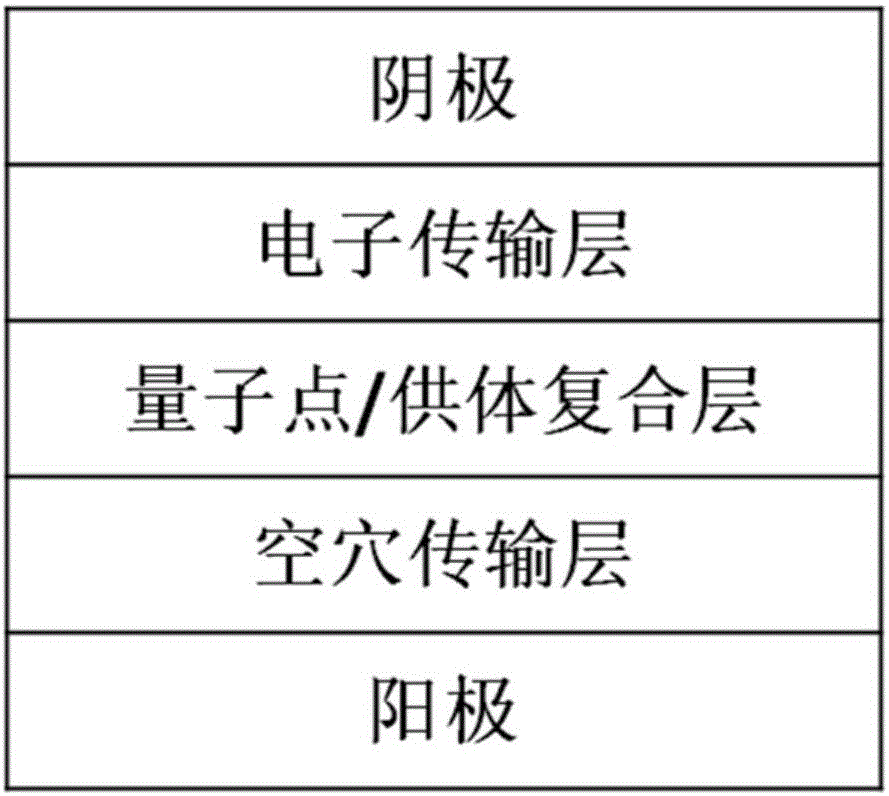

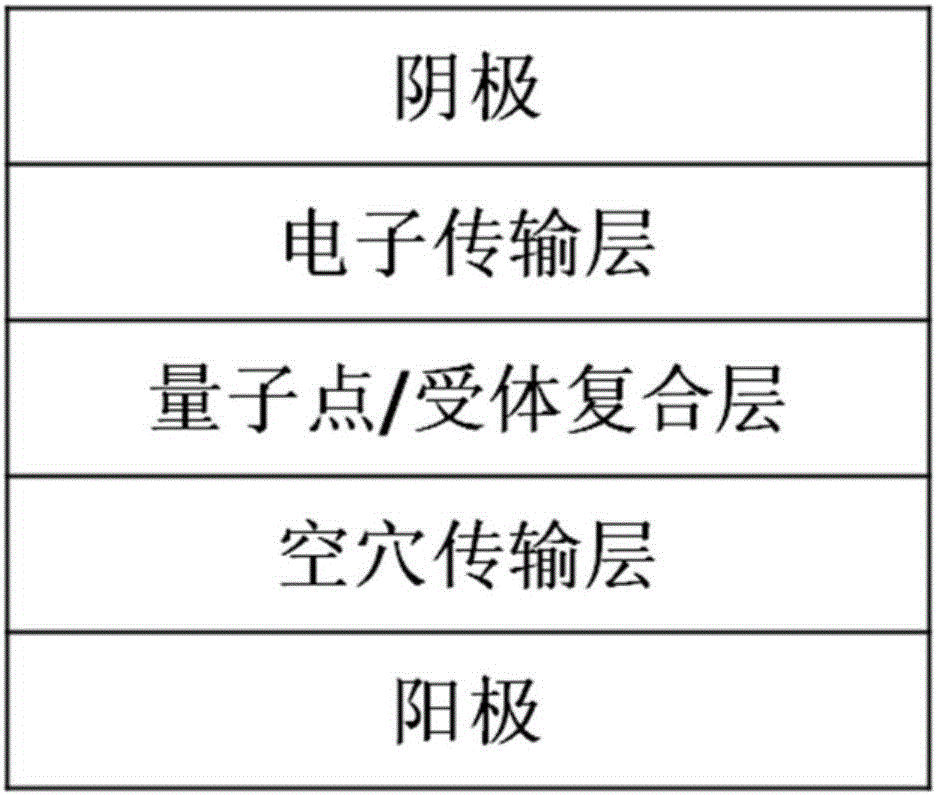

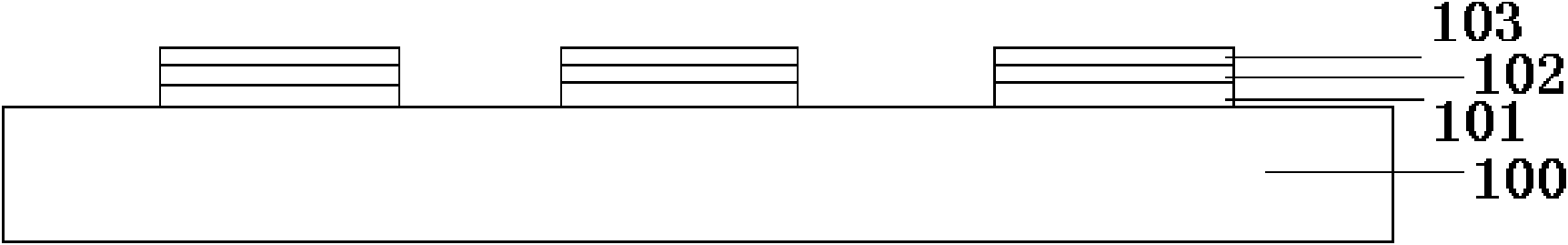

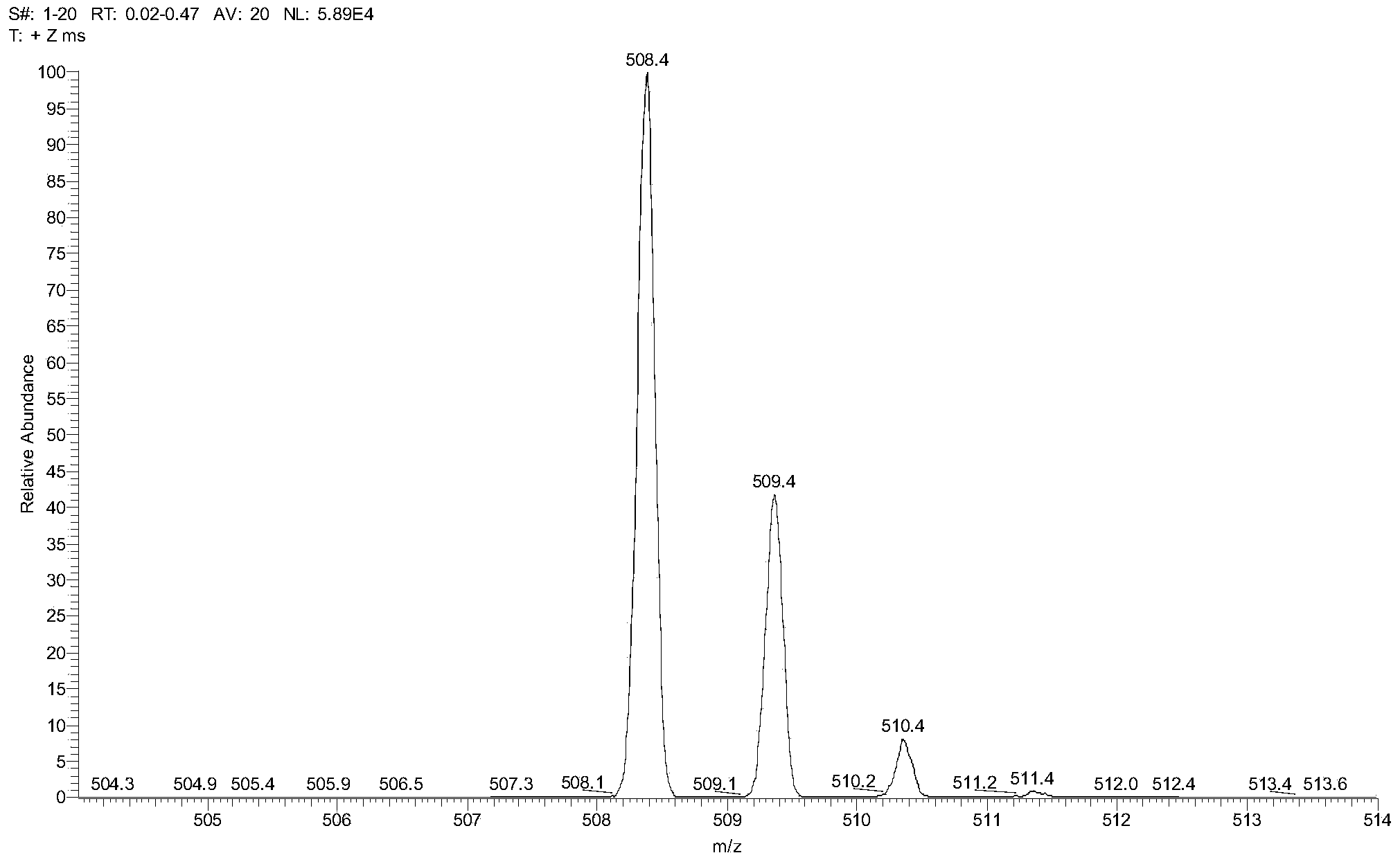

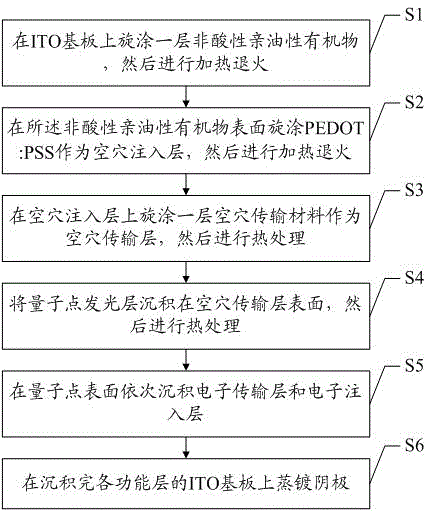

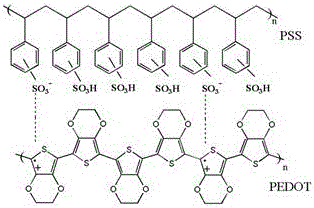

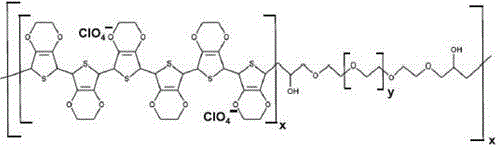

Quantum dot light-emitting diode and preparation method thereof

InactiveCN105826483AAvoid corrosionImprove injection abilitySolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeMaterials science

The invention discloses a quantum dot light-emitting diode and preparation method thereof. The preparation method includes the steps of: A. spin-coating a layer of non-acidic lipophilic organic matter on an ITO substrate, and then performing heating and annealing; B. spin-coating PEDOT on the surface of the non-acidic lipophilic organic matter: using PSS as a hole injection layer, and then performing heating and annealing; C. spin-coating a layer of hole transport material on the hole injection layer as a hole transport layer, and then performing thermal treatment; D. depositing a quantum dot light-emitting layer on the surface of the hole transport layer, and then performing thermal treatment; E. depositing an electron transport layer and an electron injection layer on the surface of a quantum dot in sequence; and F. evaporating a cathode on the ITO substrate on which functional layers are deposited. Through the preparation method, processes of ultraviolet oxidation treatment and oxygen plasma treatment are omitted in a manufacturing process, and process steps are simplified. The non-acidic lipophilic organic matter can better sink into holes, and thus a hole injection capability is enhanced, thereby improving the luminous efficiency of a QLED.

Owner:TCL CORPORATION

Method for sealing casing breaking point of casing damaged well in oil field

InactiveCN108979585AReduce injection frictionNo Shrink CuringSealing/packingAbsorption capacityOil field

The invention provides a method for sealing a casing breaking point of a casing damaged well in an oil field. The method includes S1, inserting a drillable bridge plug below the casing breaking pointand filling sand to 5m below the casing breaking point, wherein a tubing and plugging type packer are inserted to the upper side of the casing breaking point to be sealed; S2, using the tubing to squeeze clean water to verify the casing breaking point and water absorption capacity thereof; S3, squeezing a low friction blocking agent A and a low viscosity liquid bridging plugging agent B; S4, unplugging the plugging type packer, plugging the wellbore, backwashing the shaft and taking out the tubing; S5, allowing the low friction blocking agent A and the low viscosity liquid bridging plugging agent B to perform non-shrinkage heat curing action at room temperature to form a solidified body after 10-24 hours; S6, inserting a screw drill to remove the plugging-type packer, the solidified body and the drillable bridging plug; S7, testing pressure to be 15MPa with clean water, wherein pressure dropping 0-0.5MPa in 30 minutes is qualified, pumping is completed, or otherwise, plugging is performed once more. With the method, plugging agent injection friction can be reduced, plugging agent injectivity is improved, high strength and non-shrinkage curing of the plugging agent entering cracks are achieved, and permanent plugging is realized.

Owner:PETROCHINA CO LTD

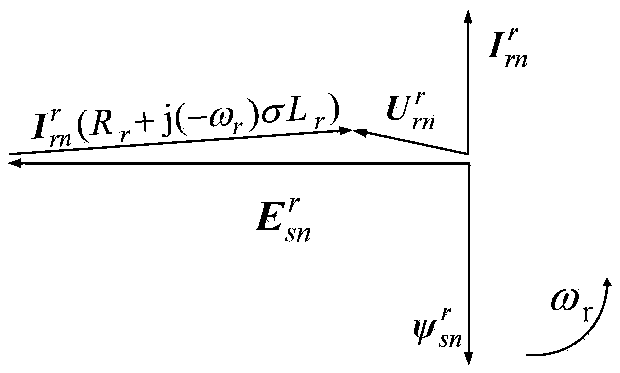

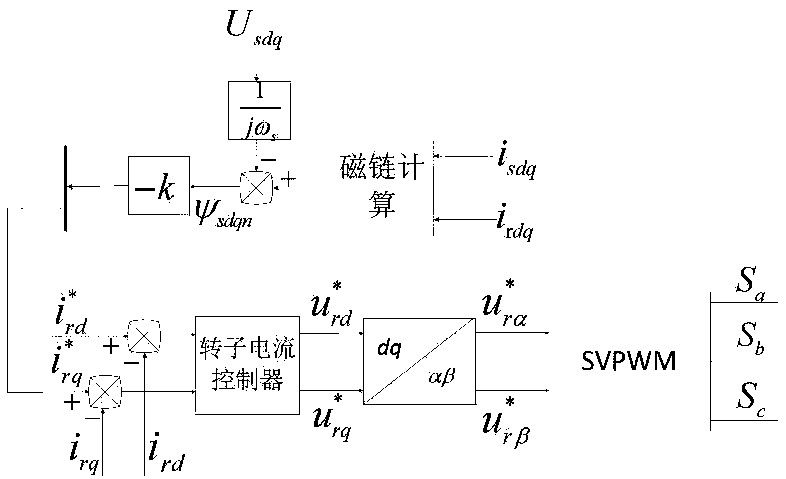

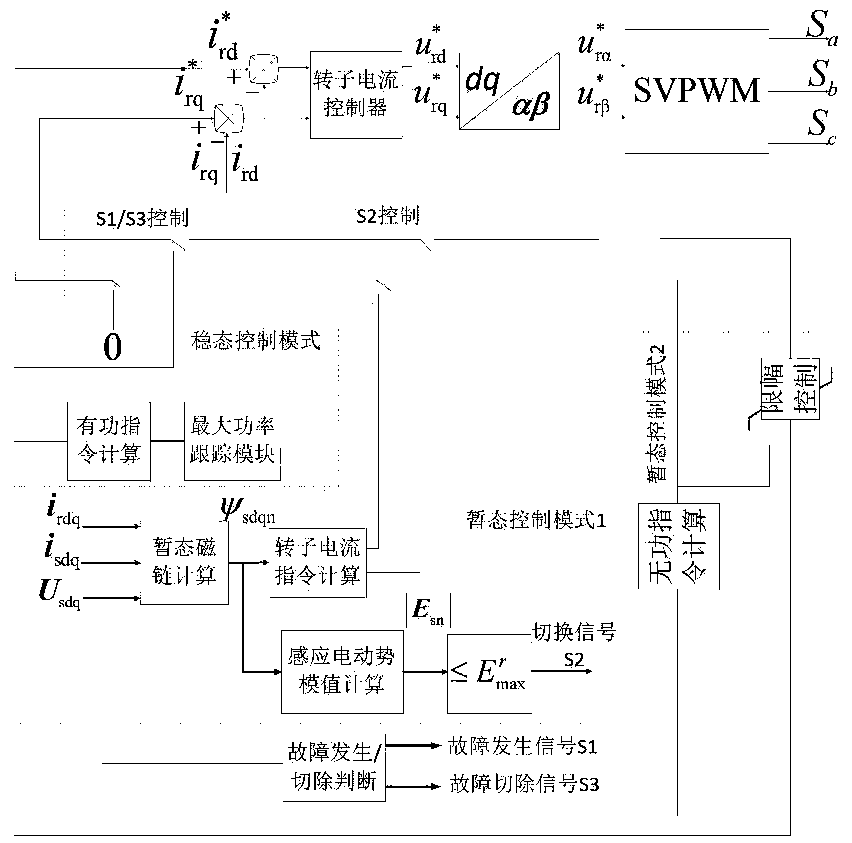

Comprehensive low voltage ride-through method for doubly-fed fan based on stator series dynamic reactor

ActiveCN108879779AImprove reactive supportThe purpose of improving reactive power supportSingle network parallel feeding arrangementsWind energy generationPeak valueEngineering

The invention relates to a comprehensive low voltage ride-through method for a doubly-fed fan based on a stator series dynamic reactor. The method comprises the following steps: when the grid voltagedrop is detected, performing control according to a transient control mode 1, wherein the transient control mode 1 is a comprehensive traversing mode in which the stator series reactor with a large value is input and a RSC adopts a control strategy of active transient flux linkage attenuation, and the setting principle of the large reactor in the mode 1 is to ensure that the peak value of the rotor current does not exceed the limit after the fault occurs; observing the modulus value of the transient induced electromotive force in real time, and switching to a control mode 2 when the modulus value decays to the set threshold value, wherein the setting principle is to ensure that the rotor current does not exceed the limit after reactor witching; restoring the normal control of the fan, andcutting off the series reactor after a delay of 100 ms, when the grid voltage returns to normal.

Owner:TIANJIN UNIV

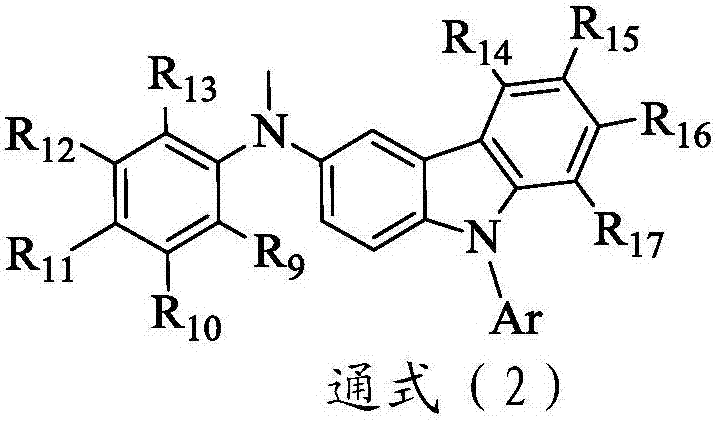

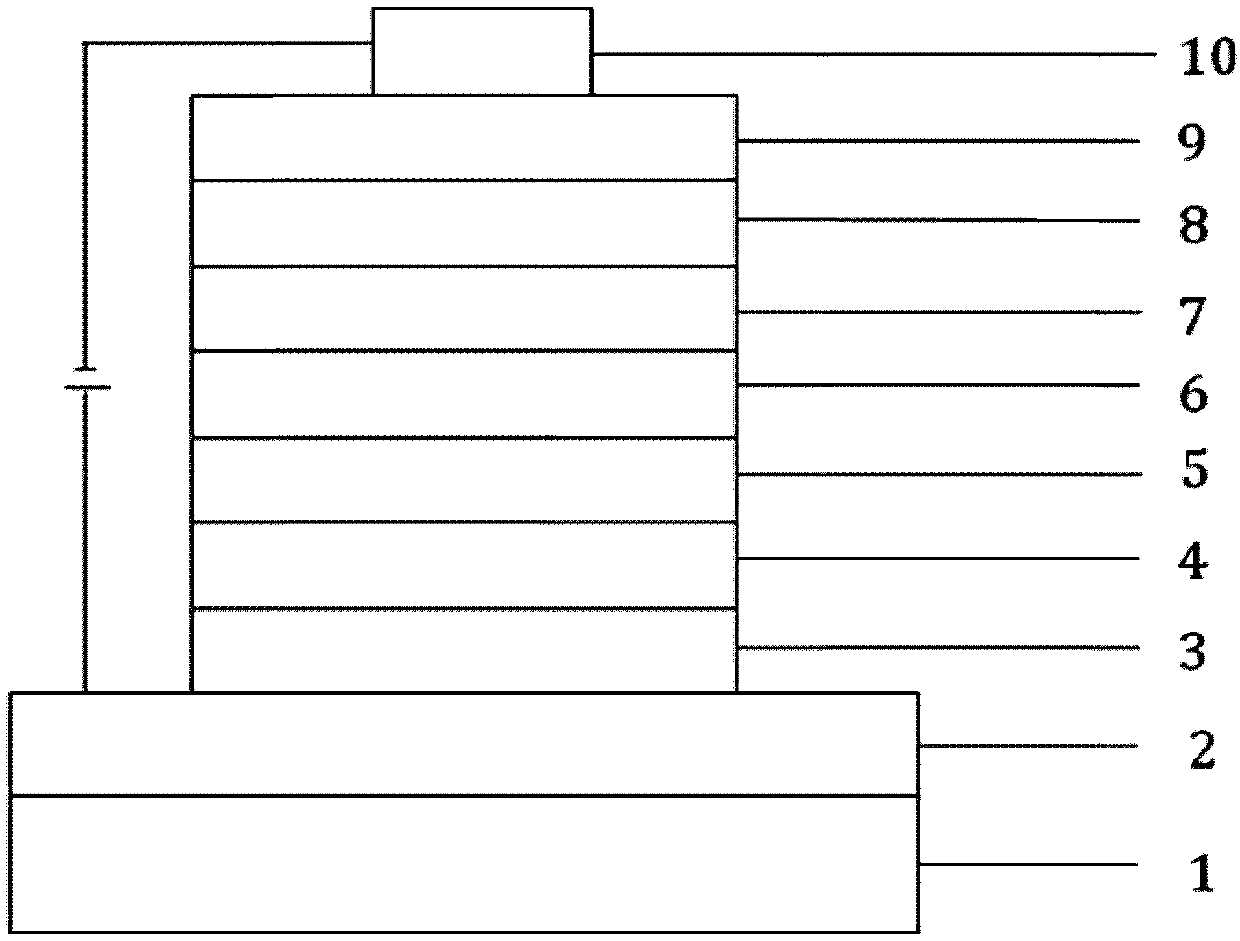

Organic electroluminescent device taking anthracene as core compound, and applications thereof

InactiveCN108003089ADestroy crystallinityInhibit aggregationOrganic chemistrySolid-state devicesAnthraceneChain structure

The invention discloses an organic electroluminescent device taking anthracene as core compound, and applications thereof. The organic electroluminescent device taking anthracene as core compound comprises a cavity transmission layer, a luminescent layer, and an electron transmission layer; and anthracene is taken as the core compound. Anthracene is combined with a branch chain structure represented by general structure (2), so that it is convenient for energy transmission among host and guest materials, and device high efficiency can be achieved easily; and in addition, the core compound possesses relatively high glass transition temperature and molecule heat stability, and appropriate HOMO and LUMO energy level, device structure optimization is capable of improving OLED device photoelectric properties and prolonging OLED device service life effectively.

Owner:VALIANT CO LTD

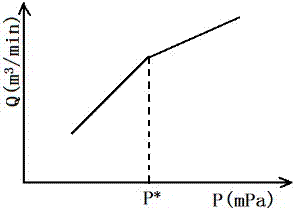

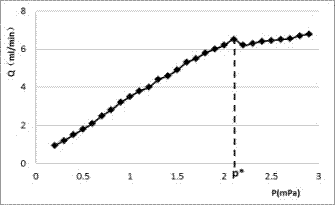

Profile control-unplugging combining technique for water injection well

ActiveCN107575183AReduce processReduce acid tankFluid removalDrilling compositionInjection pressureCellulose

The invention discloses a profile control-unplugging combining technique for a water injection well. The profile control-unplugging combining technique comprises the steps that (1), well input fluid is prepared; (2), pressure is gradually increased, water is injected into a stratum, a relation curve of injection pressure and displacement is drawn, and an injection pressure curve knee P* is determined; (3), a cellulose plugging agent A is injected at the injection pressure smaller than P* and used for remote well profile control; (4), a profile control agent B forming glue through acid catalysis is injected at the injection pressure smaller than P*; (5), displacement fluid is injected; (6), well shutting for waiting on cement setting is carried out for 2-6 hours; (7), acid liquor C is injected at the injection pressure larger than P*; (8), pressure release is carried out; (9), normal water injection is restored, and if normal water injection can be achieved, construction is completed. According to the profile control-unplugging combining technique for the water injection well, water reducing oil increase of a high water content oil well is achieved, profile control and unplugging ofthe multilayer oil deposit water injection well are achieved, an injection profile is improved, and the oilfield development effect is improved; and construction operation of the water injection wellis easy, convenient, safe and efficient, and wide market application prospects are achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Non-benzenoid aryl spiro material and its synthesis and application

InactiveCN1706839AEasy to introduceImprove solubilityOrganic chemistrySolid-state devicesSynthesis methodsField-effect transistor

The present invention belongs to the field of organic photoelectronic information material cy, and is especially one kind of high stability double spiro organic electronic material and its preparation process. This kind of compound contains double spiro structure module, which contains structural chain for increasing dissolubility, obstructing chromophore aggregation or increasing stability, contains non-conjugate, semi-conjugate or completely conjugate nuclear structure with four chemical bonds, and spiro center elements of C, Si or Ge. The present invention has the advantages of flexible synthesis path; effective regulation of the photoelectronic properties of the material with substituted radical, such as fluoro and dithiosulfone radical; and high configuration stability and environment stability, such as hindered amine structure. This kind of material may find their wide application in organic plate display, photovoltaic cell, field effect tube, etc.

Owner:方圆环球光电技术盐城有限公司

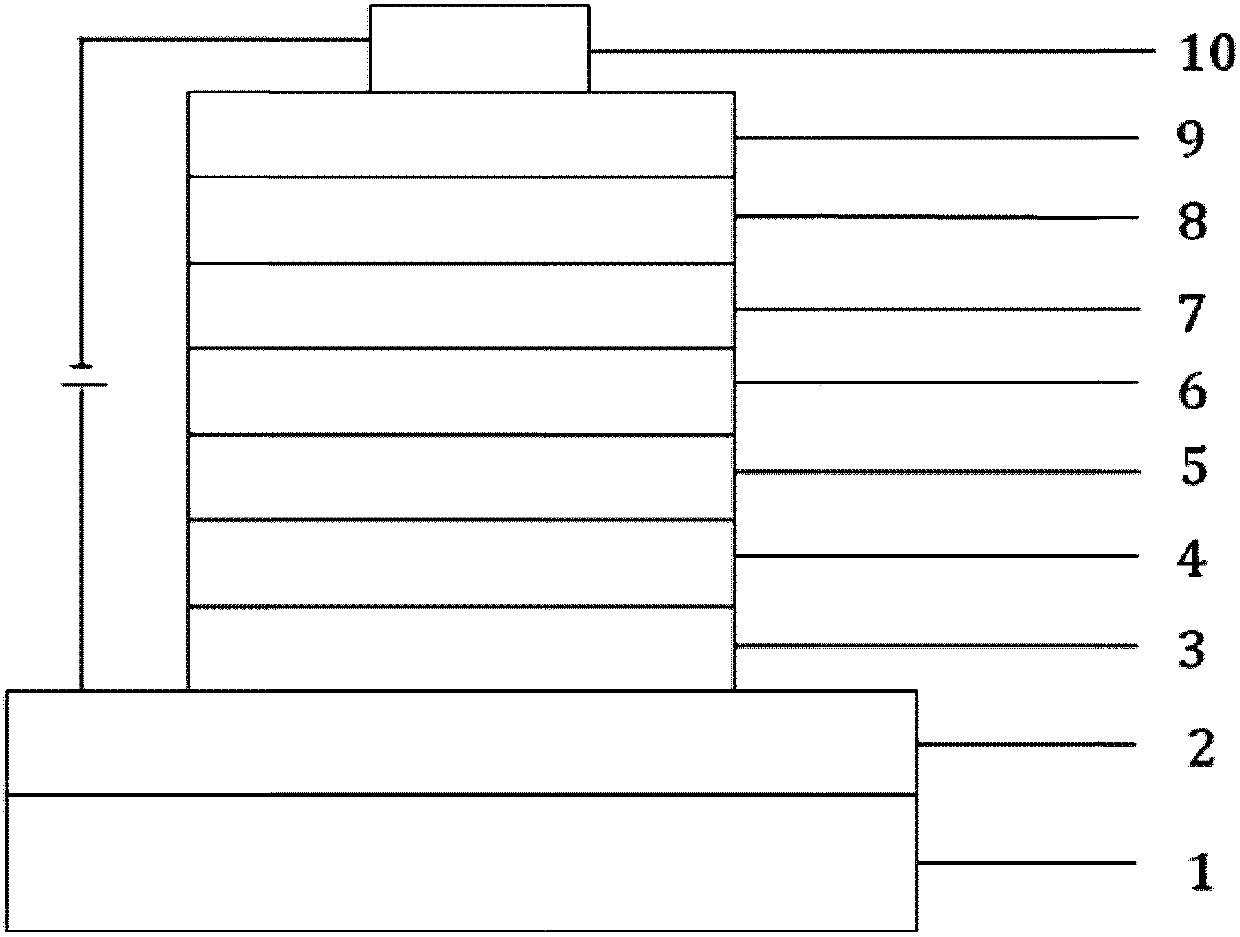

Dual-substituent-group-9-fluorenone compound-containing organic light-emitting device and application thereof

ActiveCN107046100AEasy to achieve anti-intersystem crossingAnti-intersystem crossingSolid-state devicesSemiconductor/solid-state device manufacturingEnergy transferChemical compound

The invention discloses a dual-substituent-group-9-fluorenone compound-containing organic light-emitting device and an application thereof. The device comprises a hole transport layer, a light emitting layer and an electron transfer layer; the light emitting layer of the device adopts the material of the dual-substituent-group-9-fluorenone-group-containing compound which is as shown in the general formula (1). The adopted dual-substituent-group-9-fluorenone-group compound has relatively low triplet state and singlet state energy difference, so that energy transfer between host-guest materials can be realized easily; therefore, energy which is originally dissipated in a heat form can be obtained and utilized easily, thereby obtaining high efficiency of a device more easily; and furthermore, when a fluorescent material is selected as a doping material, the light emitting radiation of the doping material can be obtained more easily, thereby achieving long service life of the material more easily.

Owner:JIANGSU SUNERA TECH CO LTD

Material contg. thiophene spirane structure, its synthesis and application

InactiveCN1757645AEasy to introduceFlexible routingOrganic chemistryElectrical apparatusVoltElectricity

This invention belongs to photo-electricity field, particularly a kind of thiophene spiral ring material and its preparation method, and its application in organic flat plate display, photo-volt cells, organic field effect tube and laser etc. organic electron field. This kind of compound introduces thiophene and functional thiophene in to conjugate semi-conductor material through spiral ring structure. The virtue are: (1) the synthesis is convenient and easy to get, and may be further modified; (2) may effectively realize photo-electricity property of modulate material; (3) with the virtue of high spectrum stability of spiral difluorene structure. The luminescence apparatus incurred by electricity prepared with this invent material has satisfaction result in brightness and luminescence efficiency. Thiophene spiral ring will be a potential commercialised photo-electricity material.

Owner:FUDAN UNIV

Oil-containing sludge profile-control plugging agent and preparation method thereof

ActiveCN107815300AImprove stabilityGood profile control effectDrilling compositionSludgeStabilizing Agents

The invention provides an oil-containing sludge profile-control plugging agent and a preparation method thereof. The oil-containing sludge profile-control plugging agent is prepared from the followingraw materials in parts by weight: 3 to 20 parts of oil-containing sludge, 0.2 to 1.0 part of dispersing agent, 0.2 to 0.5 part of suspension stabilizer, and 79.6 to 95.5 parts of water. The phenomenon that the oil-containing sludge profile-control plugging agent agglomerates, and is difficult to stably suspend and scatter can be effectively prevented, a better profile control effect on an oil layer can be achieved, the injection performance is improved, and simple operation, convenience in use and low cost are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

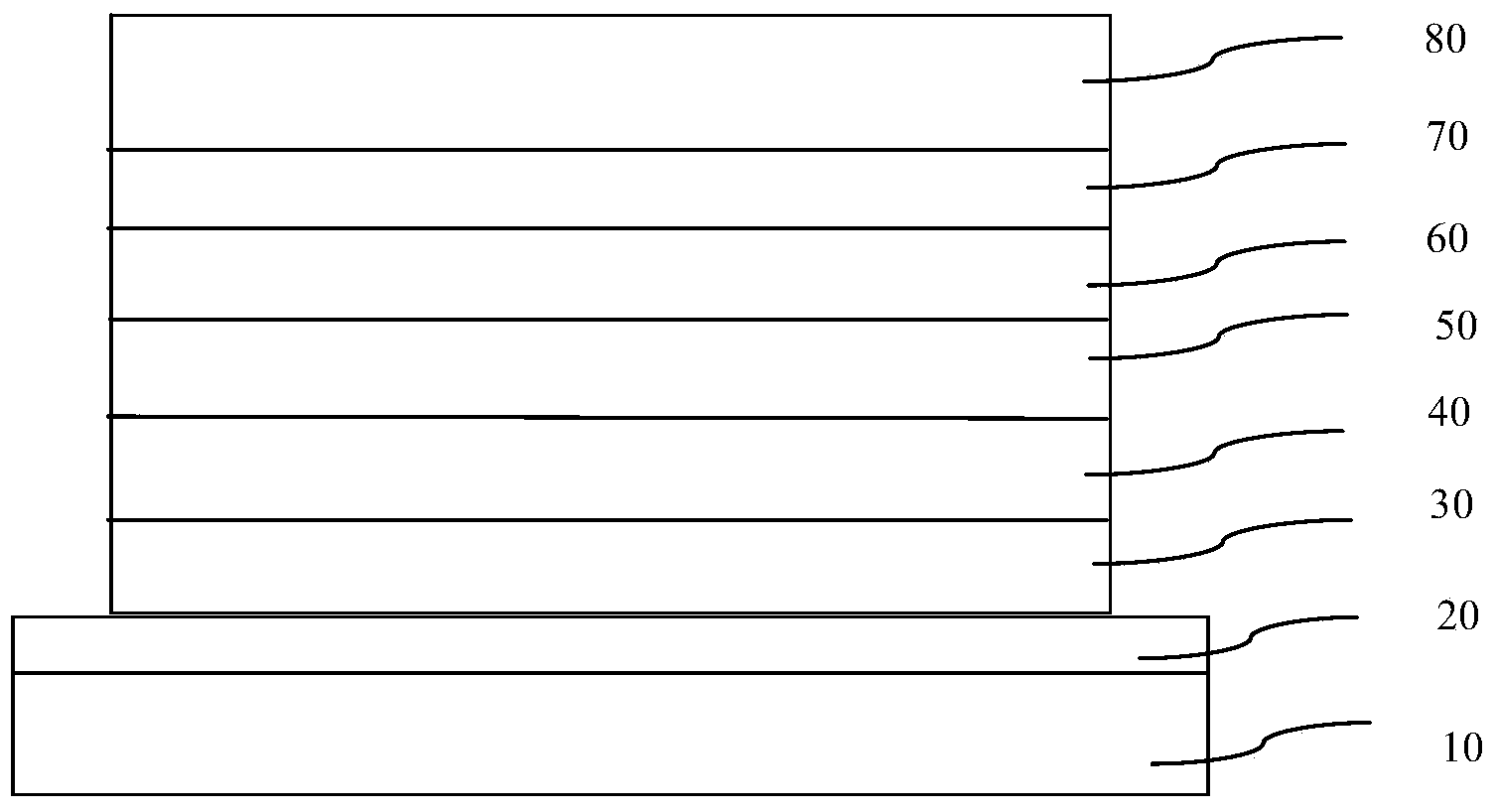

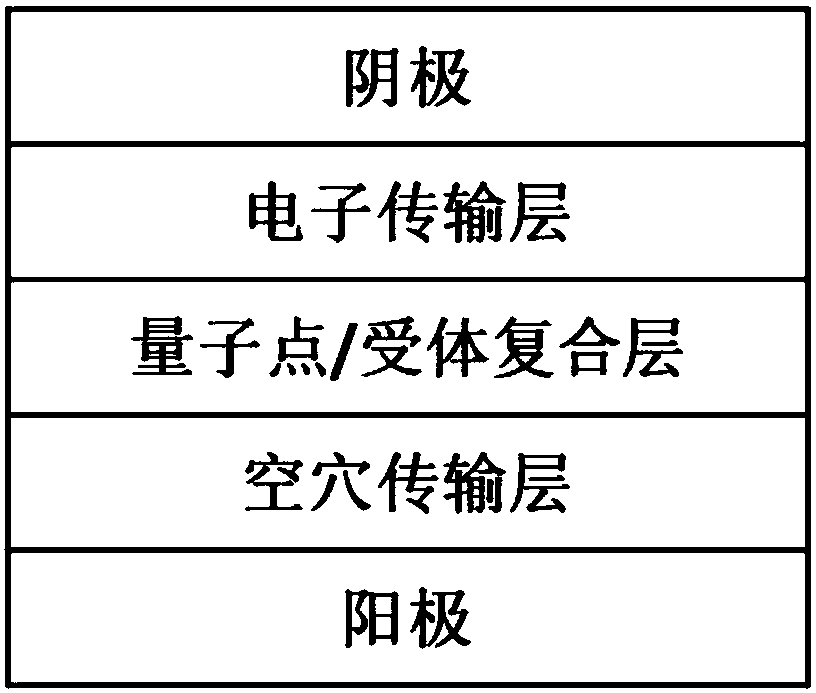

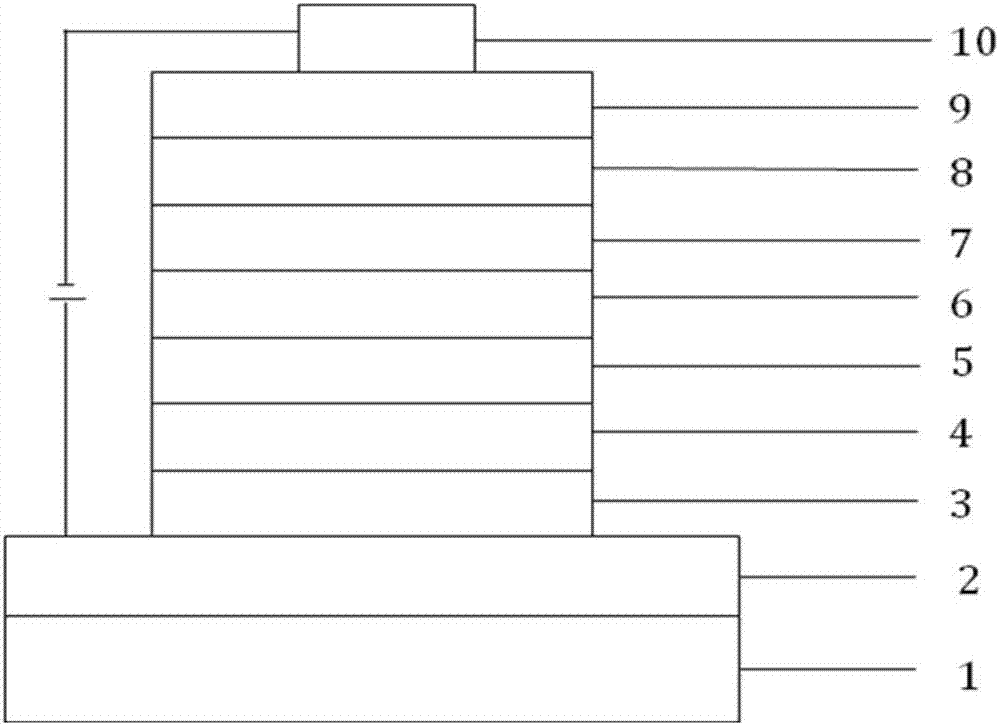

Light emitting diode apparatus and display apparatus

ActiveCN108389982AImprove injection abilityImprove energy transferSolid-state devicesSemiconductor/solid-state device manufacturingFluorescenceClick chemistry

The invention provides a light emitting diode apparatus. The light emitting diode apparatus comprises a substrate, a positive electrode, a hole transport layer, a light emitting layer, an electron transport layer and a negative electrode; the light emitting diode apparatus is characterized in that the light emitting layer is formed by quantum dots and energy transfer molecules in a combination manner; and the energy transfer molecules and the quantum dots are crosslinked through click chemistry. The energy transfer molecules, used as the dispersion medium of the quantum dots, have high electron / hole carrier injection capability, so that exciton generation in the energy transfer molecules can be promoted, and effective energy transfer from the energy transfer molecules to fluorescent quantum dots can be realized; and at a certain voltage, the apparatus can give out light within a wavelength range of 380-900nm, and the maximum emitting peak value is from ultraviolet light to deep infrared light. The invention also discloses a preparation method of the light emitting diode apparatus and electronic display apparatus.

Owner:SUZHOU XINGSHUO NANOTECH CO LTD

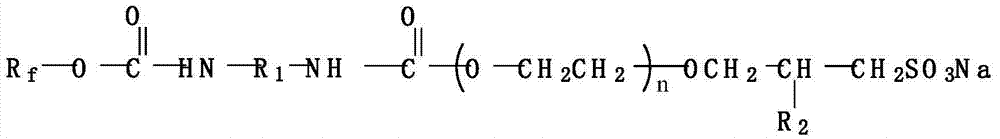

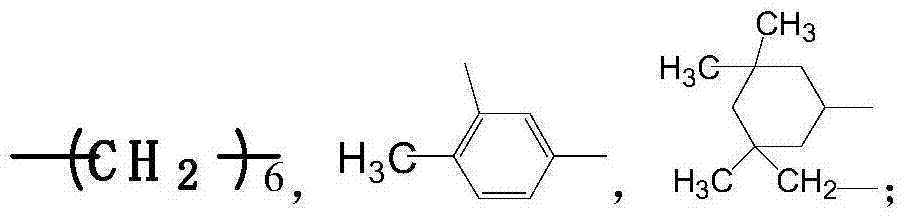

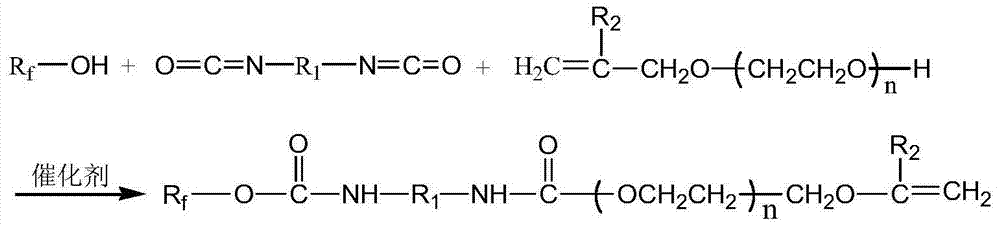

Fluoride-containing polyurethane CO2 gas soluble foaming agent and preparation method and use thereof

The invention provides a CO2 gas soluble foaming agent and a preparation method and application thereof, and belongs to the field of oil field chemicals. The CO2 gas soluble foaming agent is allyl polyoxyethylene ether fluorine-containing polyurethane sodium sulfonate which is obtained by sultified reaction of sodium bisulfate aqueous solution and allyl polyoxyethylene ether fluorine-containing polyurethane Z, wherein the allyl polyoxyethylene ether fluorine-containing polyurethane Z is a product of diazonium addition reaction of fluorine-containing alcohol Rf-Oh, R2 substituted allyl polyether and isocyanate group in diisocyanate CON-R1-NCO. The allyl polyoxyethylene ether fluorine-containing polyurethane sodium sulfonate can be alone dissolved in CO2 or dissolved in CO2 with a dissolved in CO2, subsequently injected into the formation, preferentially enters a high permeability zone with the CO2, and meets bound water in the formation or a subsequent auxiliary slug to use as a foaming agent to produce foams to inhibit fluid channeling in subsequent CO2 displacement process.

Owner:CHINA PETROLEUM & CHEM CORP +1

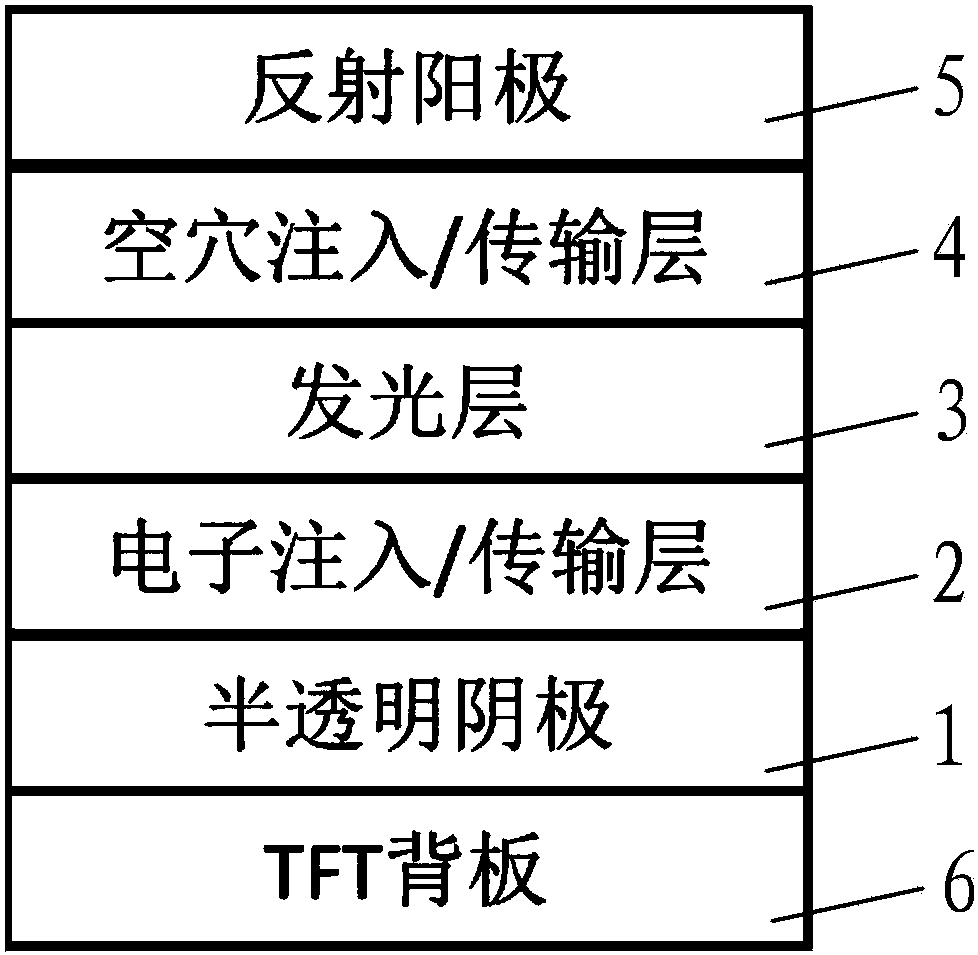

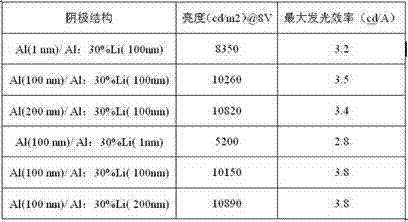

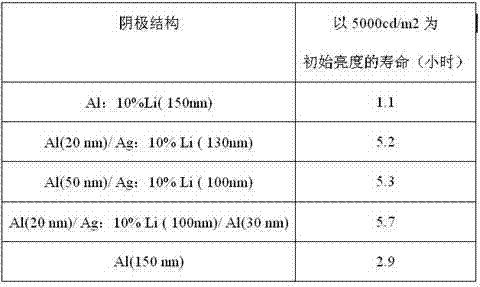

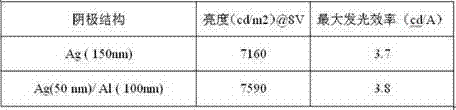

Organic electroluminescent device having multilayer cathode

InactiveCN102394275AEnhanced electron injection capabilityReduce the driving voltageSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsOrganic electroluminescence

The invention relates to an organic luminescent device, especially to an organic luminescent device that enables luminous efficiency of the device to be improved and service life of the device to be prolonged by improving a cathode layer. More particularly, the invention relates to an organic electroluminescent device having a multilayer cathode. The device comprises: a glass substrate; an anode layer, which is on the glass substrate; an organic material layer, which is formed on the anode layer; an electron injecting layer, which is formed on the organic material layer; and a cathode layer, which is formed on the electron injecting layer. Besides, the cathode layer at least includes a first metal layer and a second metal layer or an alloy layer; and the second metal layer or the alloy layer at least contains a low-work function metal. According to the invention, an electron injection capability of the device can be effectively enhanced by improving a cathode, so that luminous efficiency of the device can be substantially improved. And moreover, the service life of the device will not be obviously reduced because an active metal component is used in the multilayer cathode.

Owner:涂洪明

Organic light emission diode device containing ketone and nitrogen heterocycle compound and application thereof

ActiveCN107068888AEase of escapeEasy to achieve anti-intersystem crossingSolid-state devicesSemiconductor/solid-state device manufacturingKetoneStructural formula

The invention discloses an organic light emission diode device containing a ketone and nitrogen heterocycle compound and an application thereof. The device comprises a hole transport layer, a light emission layer and an electron transport layer. The material of the light emission layer of the device comprises a compound comprising ketone and nitrogen heterocycle groups, and the structural formula of the compound is shown in the general formula (1). According to the ketone and nitrogen heterocycle material, due to a small triplet and singlet energy difference, energy transfer between host and guest materials can be realized easily, energy that is originally lost in a heat form is easily available, the radiative transition efficiency of the light emission layer is enhanced, and the high efficiency of the device can be acquired more easily. Further, when a fluorescent material is selected as a doped material, light emission radiation of the doped material is acquired more easily, and a long service life of the material can be acquired more easily.

Owner:VALIANT CO LTD

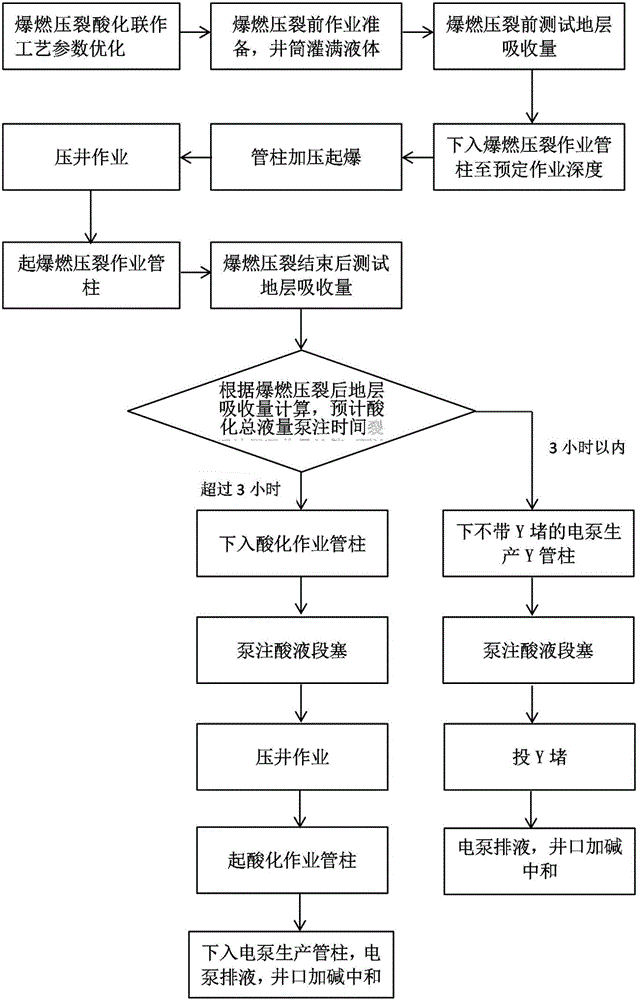

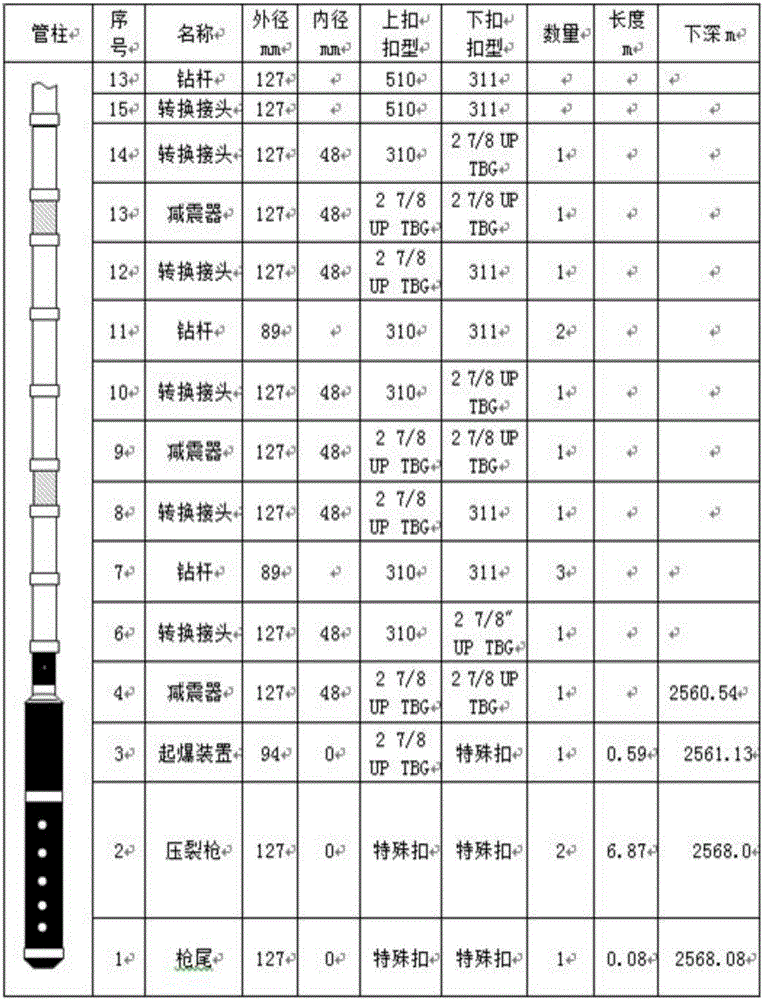

Method for detonation fracture acidizing combined operation

ActiveCN106246156AEnhancing the effectiveness of deflagration fracturingGuaranteed work effectFluid removalDrilling compositionWell killDetonation

The invention discloses a method for detonation fracture acidizing combined operation. The method comprises the steps of optimizing detonation fracture acidizing combined operation process parameters, performing operation preparation before detonation fracture and filling a pitshaft with liquid, testing stratum absorption amount before the detonation fracture, placing a detonation fracture operation tubular column to a predetermined operation depth, performing pressurization detonation of the tubular column, performing well killing operation, detonating the fracture operation tubular column, testing the stratum absorption amount after the detonation fracture, placing an acidizing operation tubular column, performing pumping injection acid liquid slug, lifting the acidizing operation tubular column, placing an electric pump production tubular column and performing electric pump liquid drainage and well opening alkalifying neutralization, placing an electric pump production Y tubular column without a Y tubular column, performing pumping injection of acid liquid slug, placing the Y tubular column, performing electric pump liquid drainage and well opening alkalifying neutralization and the like. The method has the advantages that detonation fracture and acidizing effects can be further enhanced, the acid liquid injection capability is enhanced, the acidizing radius is expanded, crack closure is further avoided, and a physical effect is enhanced; a detonation fracture effect can be enhanced, a follow-up acidizing step is selected flexibly, and the operation step is omitted while an operation effect can be guaranteed.

Owner:CHINA NAT OFFSHORE OIL CORP +1

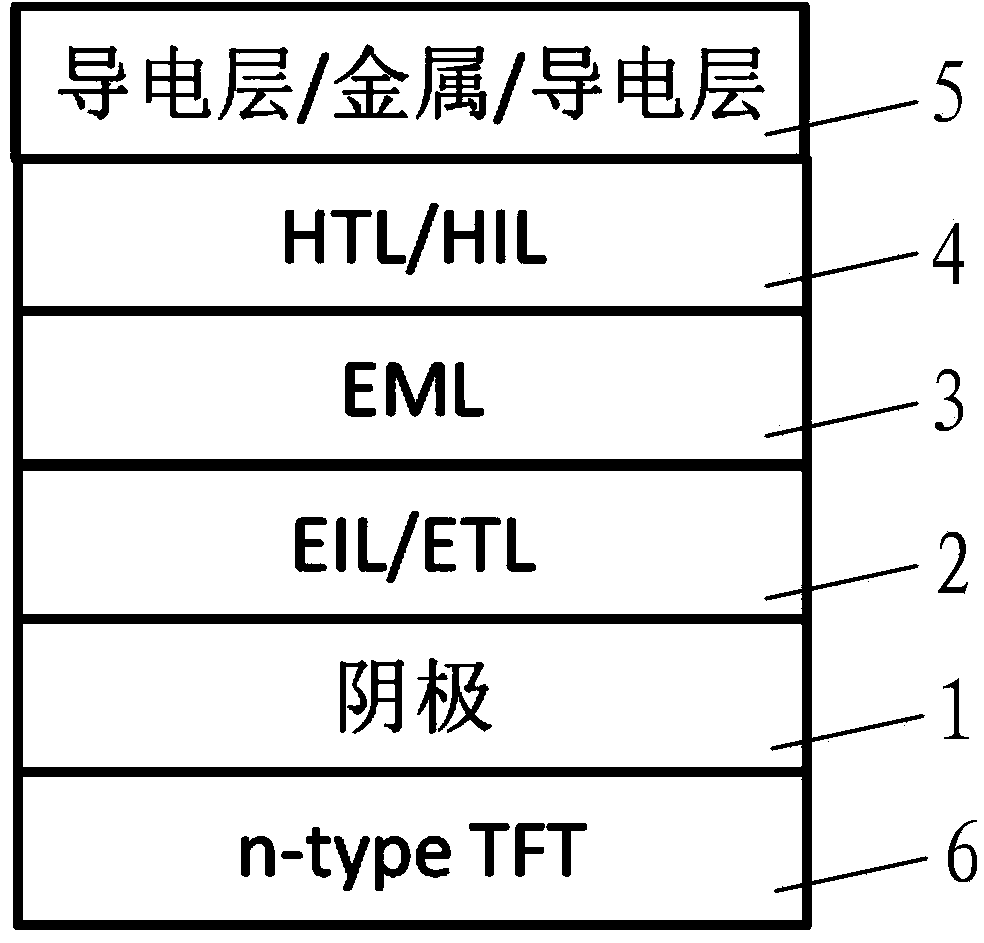

Organic light-emitting device and composite anode and manufacturing method thereof

ActiveCN101894922AImprove thermal conductivityHigh thermal conductivitySolid-state devicesSemiconductor/solid-state device manufacturingPlasma treatmentOptoelectronics

The invention provides an organic light-emitting device and a composite anode and a manufacturing method thereof. The organic light-emitting device comprises a substrate, the composite anode, a hole transmission layer, a light-emitting layer, an electron injection layer and a transparent cathode, wherein the composite anode is formed on the substrate; a multi-layer organic layer is formed on the composite anode; the electron injection layer is formed on the organic layer; the transparent cathode is formed on the electron injection layer; the composite anode comprises a bonding layer, a horizontal conducting layer and a hole injection layer; the bonding layer is formed on the substrate; the horizontal conducting layer is formed on the bonding layer; the hole injection layer is formed on the horizontal conducing layer; the horizontal conducting layer contains copper; and the hole injection layer is formed by plasma treatment of the copper-containing horizontal conducting layer in certain atmosphere. The organic light-emitting device has the advantages of improving heat conductivity, electrical conductivity and hole injection capacity of the conducting layer of the anode, and stabilizing the copper-containing horizontal conducting layer.

Owner:SHENZHEN DANBANG INVESTMENT GROUP

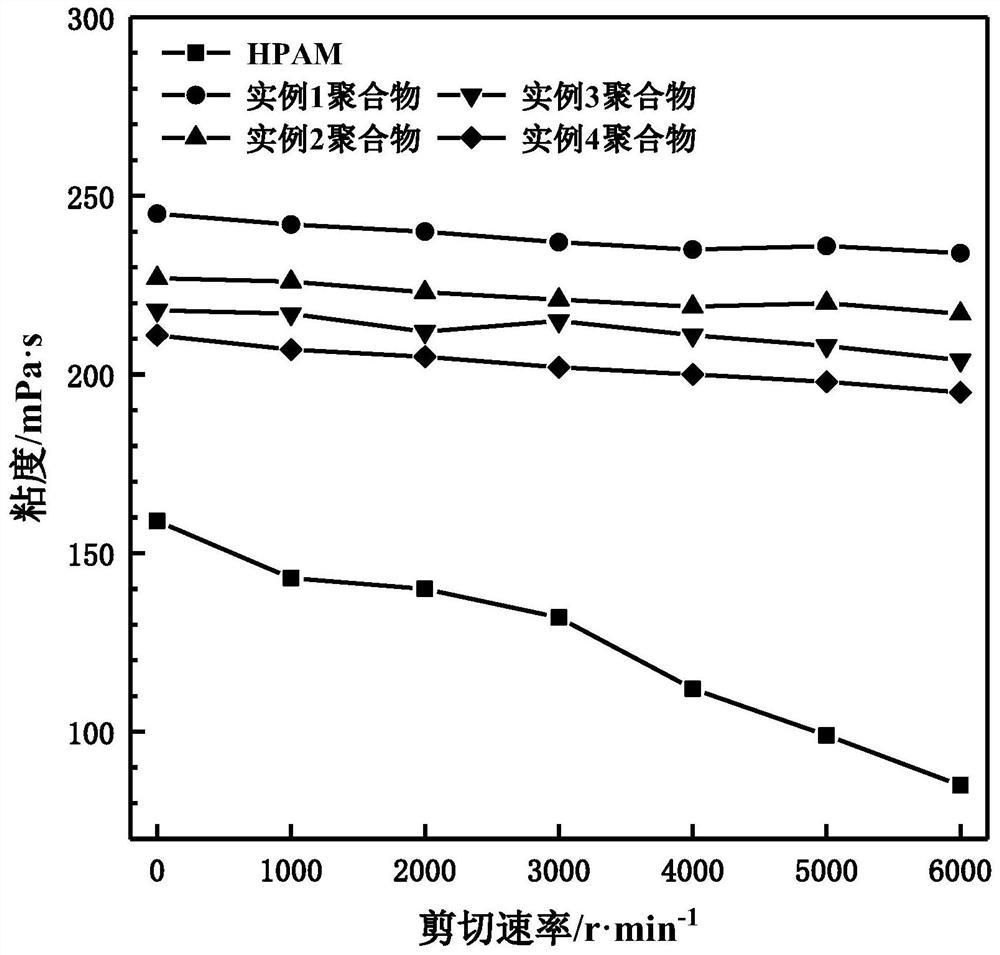

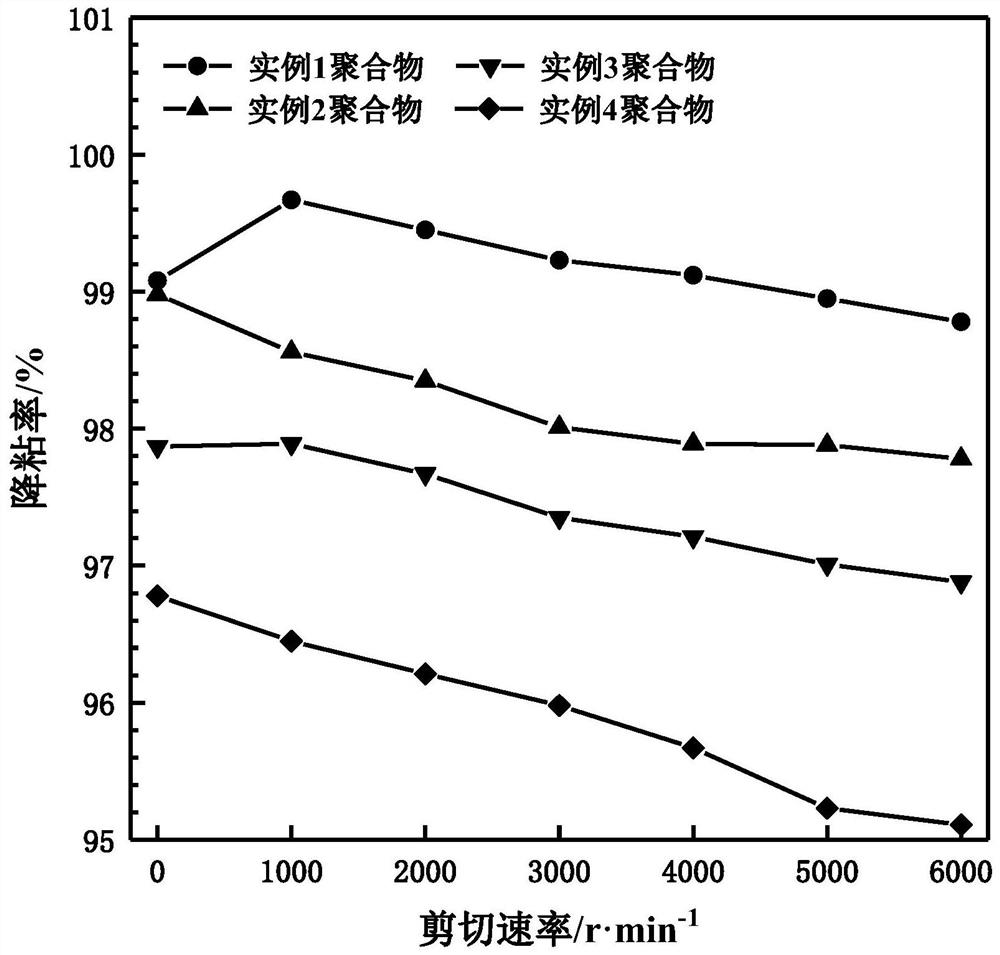

Micromolecular heavy oil viscosity reduction polymer and preparation method thereof

The invention discloses a micromolecular thick oil viscosity reduction polymer and a preparation method thereof. The micromolecular thick oil viscosity reduction polymer comprises the following raw material components: 10 wt.% to 20 wt.% of an acrylamide (AM) monomer, 1 wt.% to 10 wt.% of a sodium acrylate monomer, 1 wt.% to 3 wt.% of a hydrophobic monomer, 1 wt.% to 3 wt.% of a temperature-resistant monomer, 0.5 wt.% to 2.5 wt.% of a surface active monomer, 0.7 wt.% to 2.5 wt.% of a chain transfer agent, 0.08 wt.% to 2 wt.% of an initiator and the balance being water. The micromolecular thick / oil viscosity reduction polymer has quick dissolving performance and good injection performance, can emulsify thick oil, has oil displacement and profile control performance at the same time, and canbe suitable for thick oil recovery of offshore oil reservoirs and low-permeability oil reservoirs.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Organic electroluminescent device

ActiveCN101710612AImprove film formationImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingAlkaline earth metalElectron injection

The invention discloses an organic electroluminescent device, which comprises a substrate, an anode layer formed on the substrate, an organic functional layer formed on the anode layer and cathode layers formed on the organic functional layer, wherein the cathode layers at least comprise a first cathode layer, a second cathode layer and a third cathode layer. A composite cathode of the organic electroluminescent device utilizes alkali metal and an alkaline earth alloy layer to reduce an electron injection potential barrier to improve the efficiency of electron injection obviously.

Owner:TSINGHUA UNIV +2

Organic Light-Emitting Diodes (OLED) manufacturing method and OLED

ActiveCN104617232AInjection does not hinderExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingElectricityElectron injection

The invention discloses an OLED manufacturing method and an OLED. The OLED comprises an anode, a cathode and an organic function layer disposed between the anode and the cathode. The organic function layer comprises a first injection layer, a first transmission layer, at least one light emitting layer, a second transmission layer and a second injection layer which are stacked successively. The first injection layer comprises at least one first hole injection strip and at least one first electron injection strip which are arranged in a parallel, alternative and connected mode. The second injection layer comprises at least one second hole injection strip and at least one second electron injection strip which are arranged in a parallel, alternative and connected mode. The at least one second electron injection strip and the at least one second electron injection strip are arranged opposite to the at least one first hole injection strip and the at least one first electron injection strip respectively. Single-color or white light areas corresponding to the at least one first hole injection strip are lightened through alternating-current electricity, after positive and negative electrodes are switched, the single-color or white light areas corresponding to the at least one first electron injection strip are lightened within short time, and accordingly, the time is short, and human can only see the whole single-color or white light emitting layer through eyes.

Owner:TRULY HUIZHOU SMART DISPLAY

Organic light emission diode device containing diaryl ketone compound and application thereof

ActiveCN107068880AEase of escapeEasy to achieve anti-intersystem crossingOrganic chemistrySolid-state devicesDiaryl ketoneHole transport layer

The invention discloses an organic light emission diode device containing a diaryl ketone compound and an application thereof. The device comprises a hole transport layer, a light emission layer and an electron transport layer. The material of the light emission layer of the device comprises a compound comprising diaryl ketone, and the structural formula of the compound is shown in the general formula (1). According to the diaryl ketone material, due to a small triplet and singlet energy difference, energy transfer between host and guest materials can be realized easily, energy that is originally lost in a heat form is easily available, the radiative transition efficiency of the light emission layer is enhanced, and the high efficiency of the device can be acquired more easily. Further, when a fluorescent material is selected as a doped material, light emission radiation of the doped material is acquired more easily, and a long service life of the material can be acquired more easily.

Owner:VALIANT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com