Method for detonation fracture acidizing combined operation

A fracturing acidification and deflagration technology, which is applied in chemical instruments and methods, earth drilling, mining fluids, etc., can solve the problems of lack of adaptability and flexibility, and achieve the goals of saving operation steps, enhancing effects, and ensuring operation effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

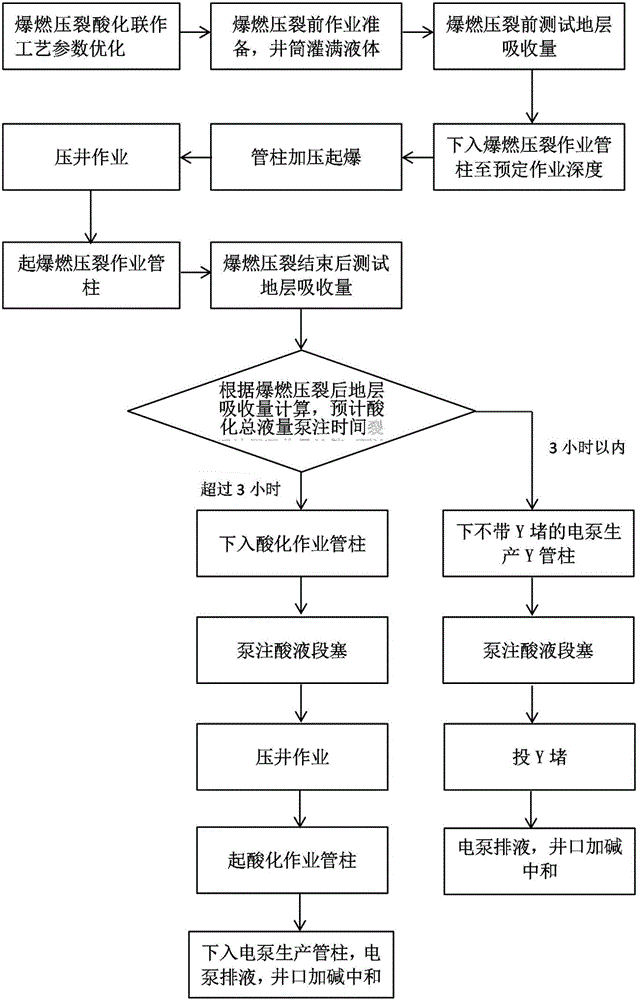

Method used

Image

Examples

Embodiment 1

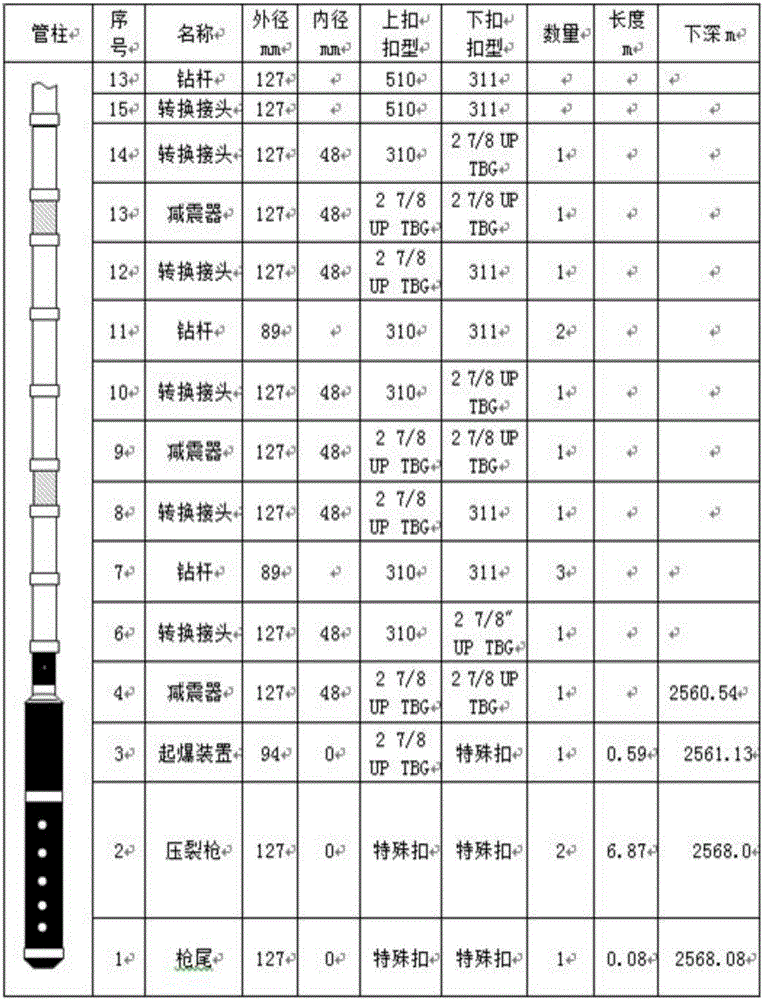

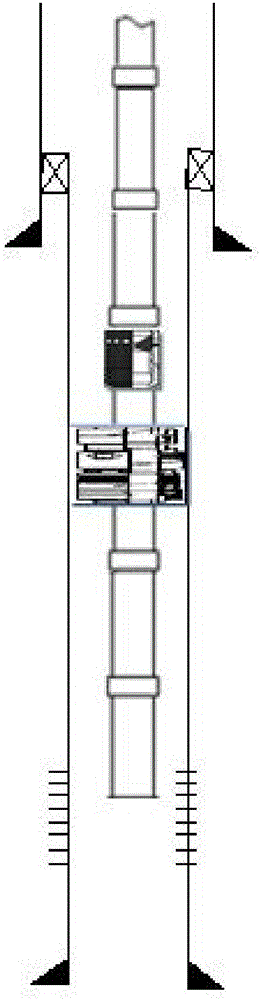

[0116] The combination of deflagration, fracturing and acidification in Well 26H in LF13-1 Oilfield has been applied figure 2 The shown deflagration fracturing string and image 3 is the acidified column shown.

[0117] The amount of deflagration fracturing powder described in step (1) is 40kg, and the peak pressure generated by simulating 40kg is 60MPa. The formation fracture pressure of this well is 45.5MPa, and the peak pressure is 1.3 times the formation fracture pressure. Pressure is 47.3MPa, satisfying P 峰 -P 破 套抗 ; The acidification slug is shown in Table 1.

[0118] Table 1 LF13-1 Oilfield 26H Well Acid Fluid Slug Consumption Table

[0119]

[0120] The acid treatment radius is designed to be 1.3m; acidification construction pressure P≤16MPa; construction displacement 0.1-1.5m 3 / min, under the condition of limited construction pressure, the displacement should be increased as much as possible; see Figure 5 .

[0121] The acid solution slug described in the...

Embodiment 2

[0130] The combination of deflagration, fracturing and acidification in well 6 of LF13-1 oil field was applied Figure 4 The Y column and Figure 5 The straight pipe column described above.

[0131] The amount of deflagration fracturing powder described in step (1) is 20kg, and the peak pressure produced by simulating 20kg is 50.2MPa. The formation fracture pressure of this well is 44.6MPa, and the peak pressure is 1.1 times the formation fracture pressure. Internal pressure is 56.2MPa, satisfying P 峰 -P 破 套抗 ; The acidification slug is shown in Table 2.

[0132] Table 2 LF13-1 Oilfield 6 Well Acid Fluid Slug Consumption Table

[0133]

[0134]

[0135] The acid treatment radius is designed to be 2.0m; acidification construction pressure P≤15.86MPa; construction displacement 0.1-1.5m 3 / min, under the condition of limiting the construction pressure, the displacement should be increased as much as possible.

[0136] The acid solution slug described in the step (10) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com