Patents

Literature

498results about How to "Reduce work steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

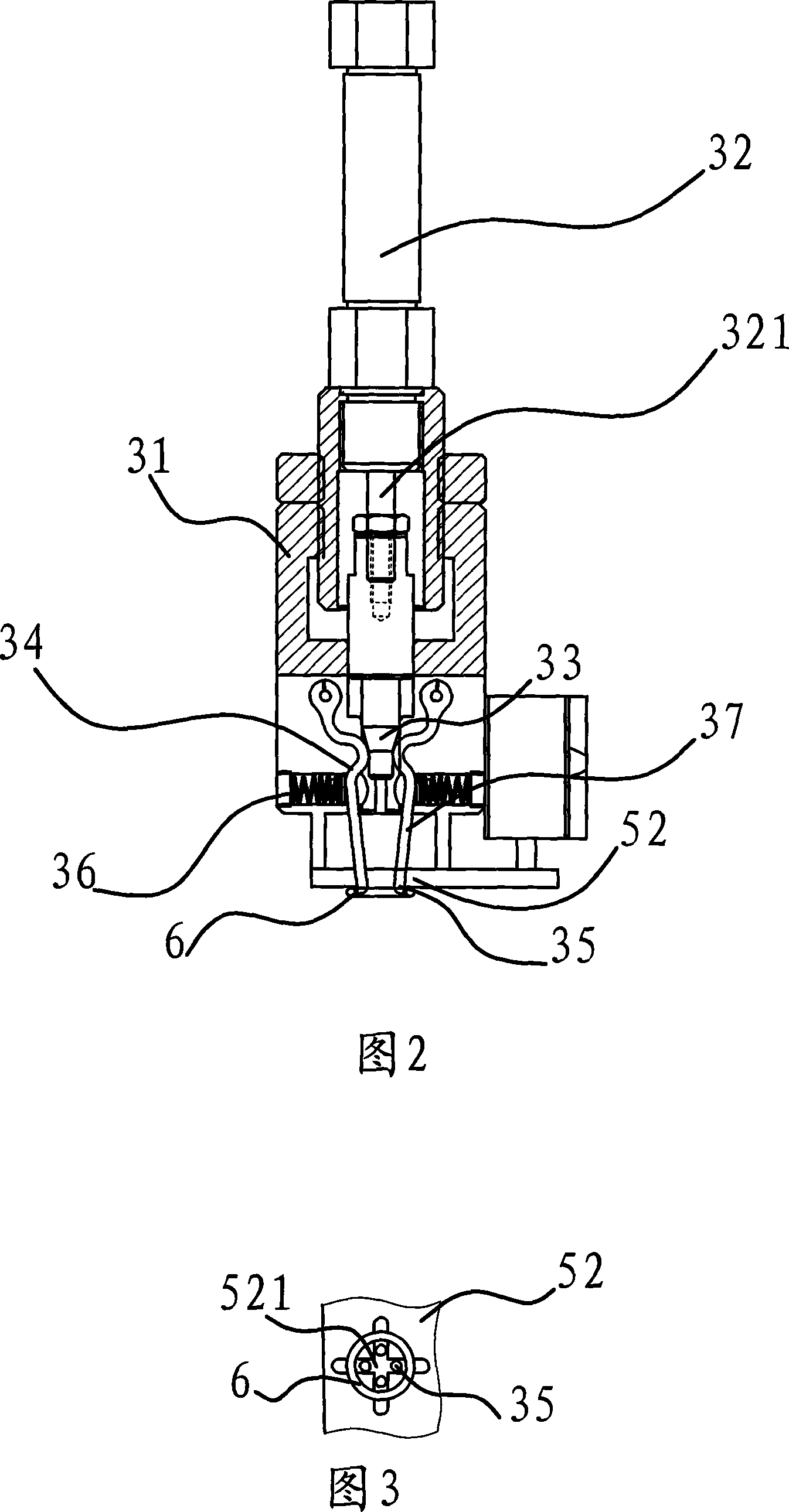

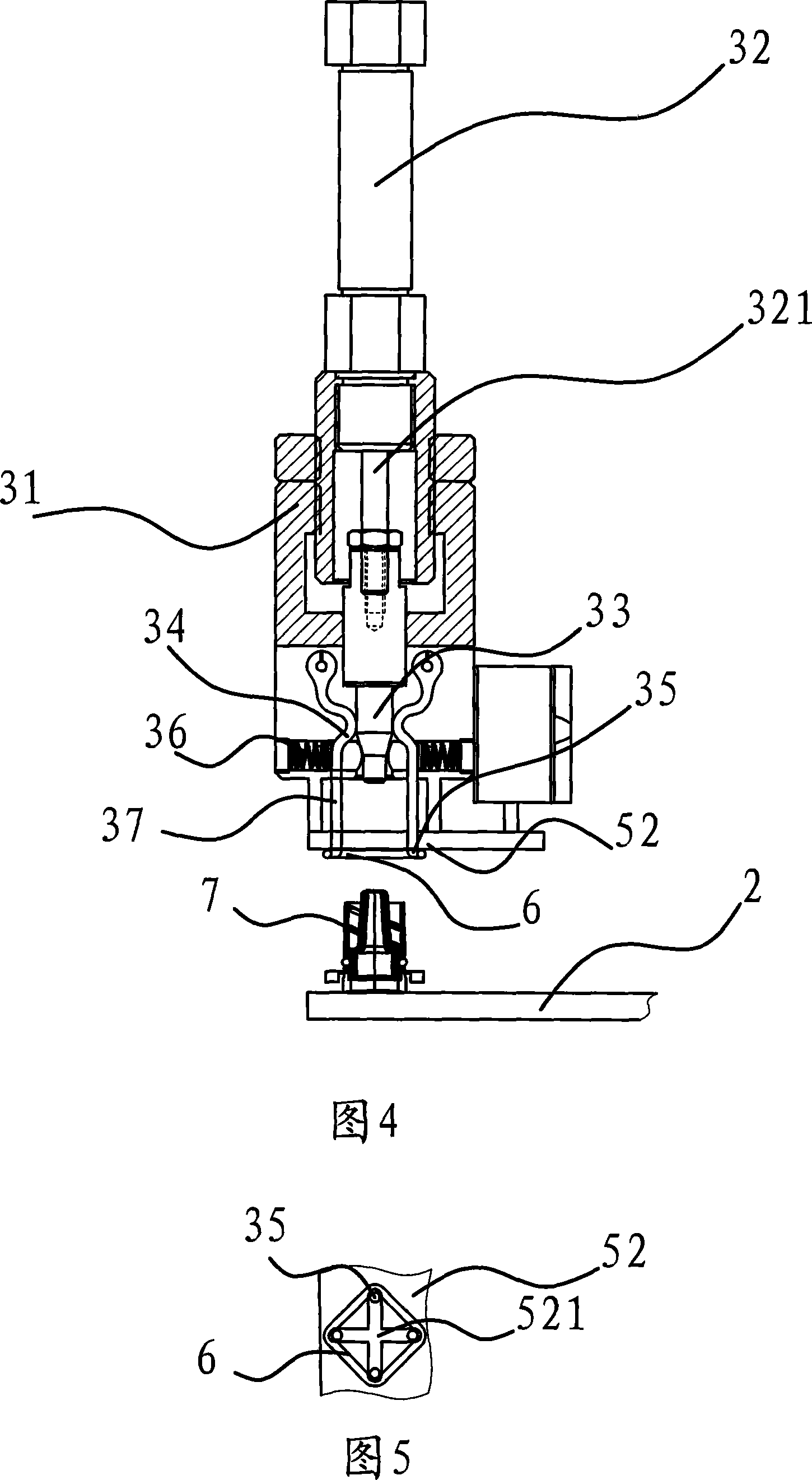

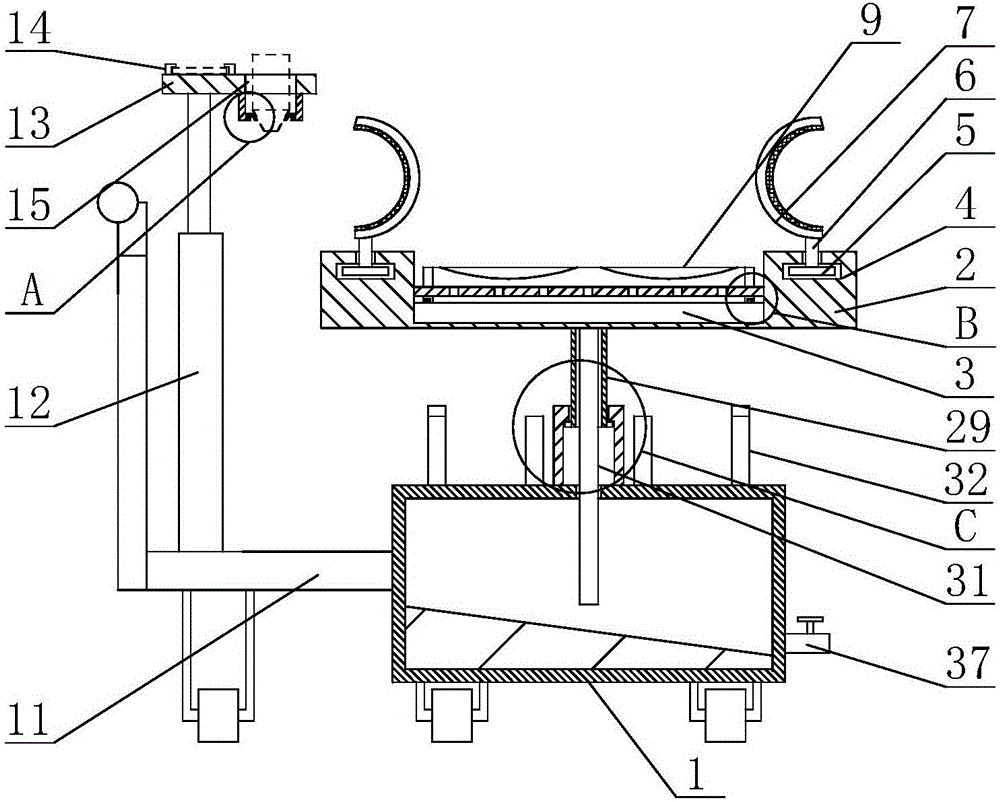

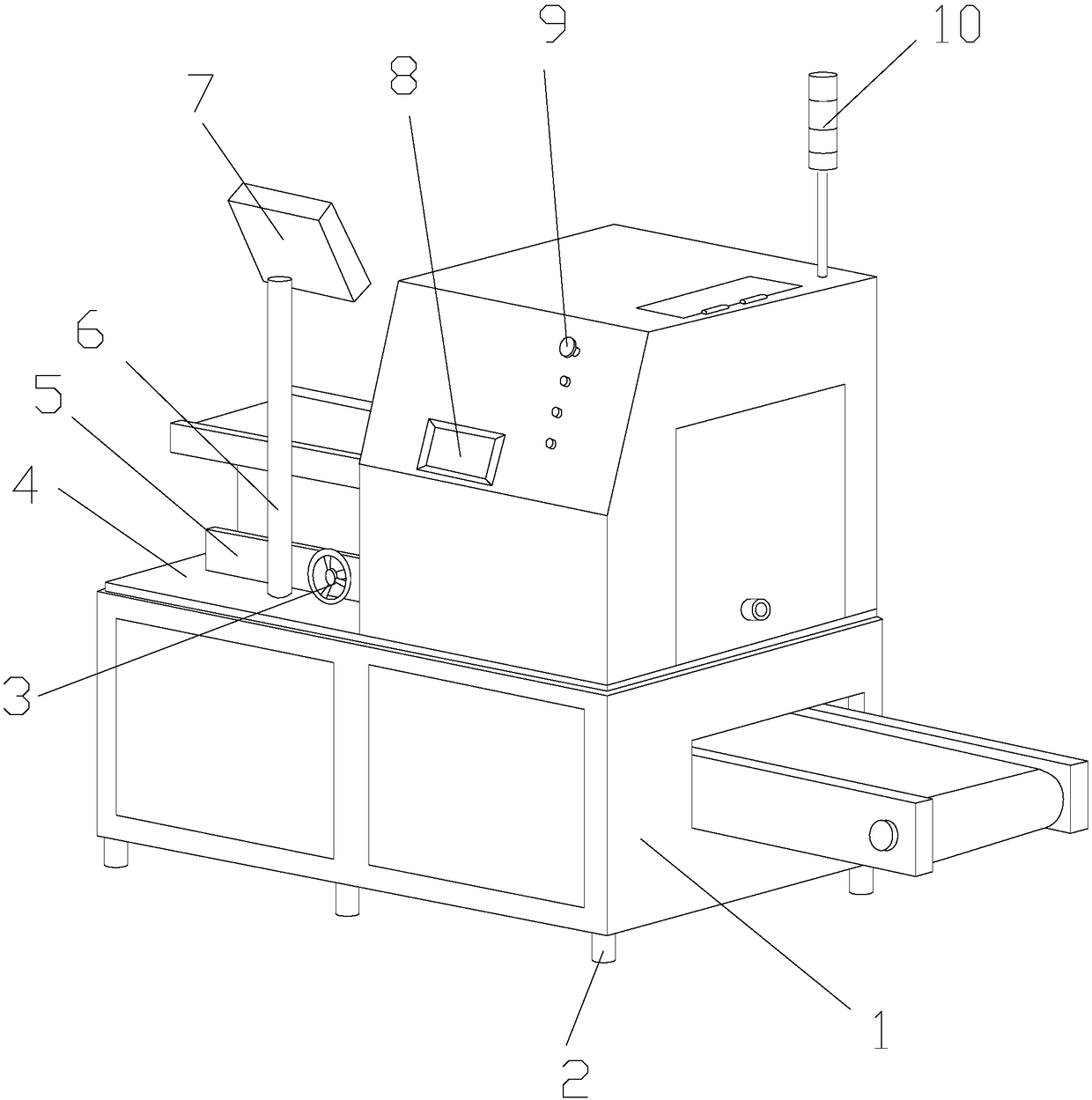

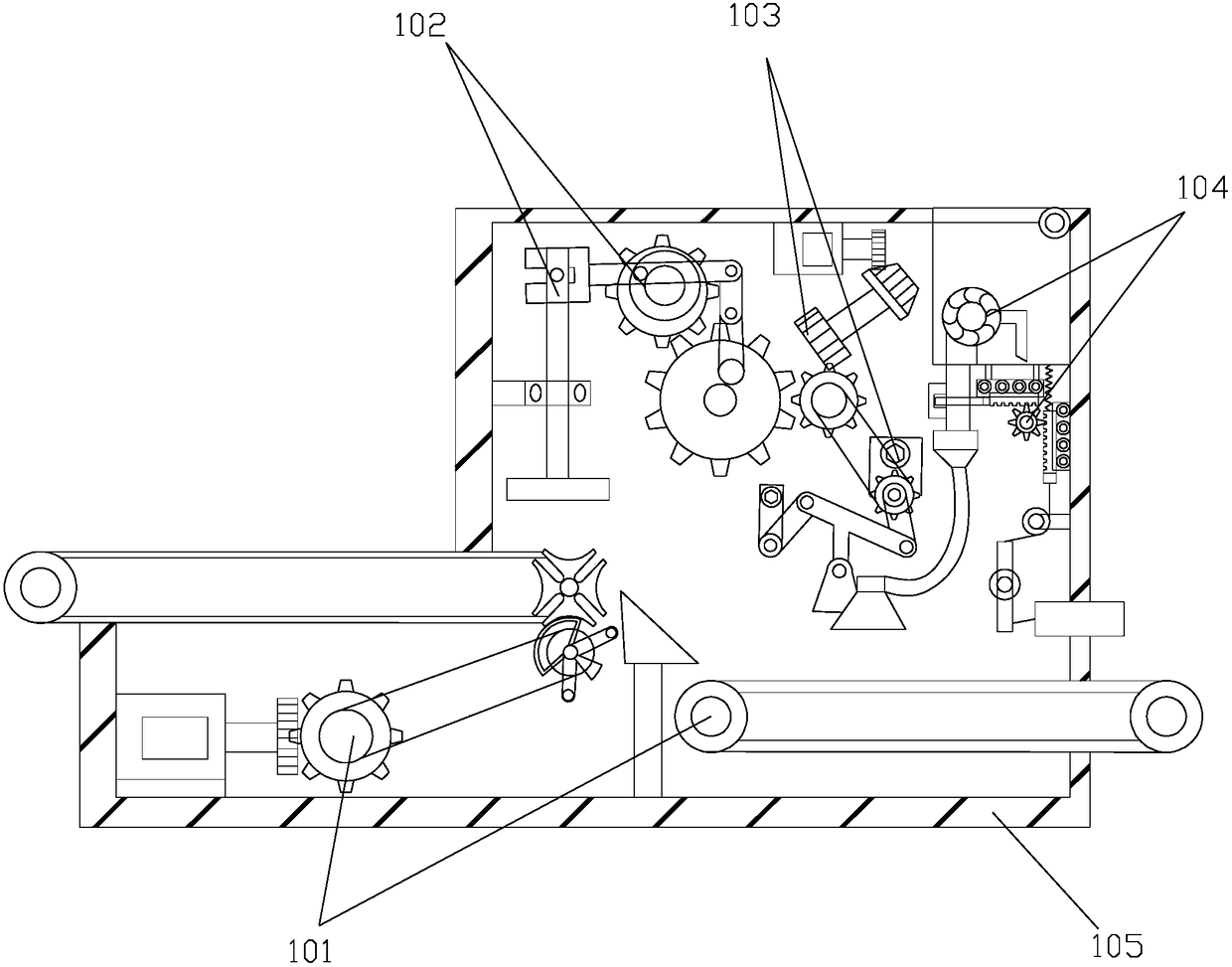

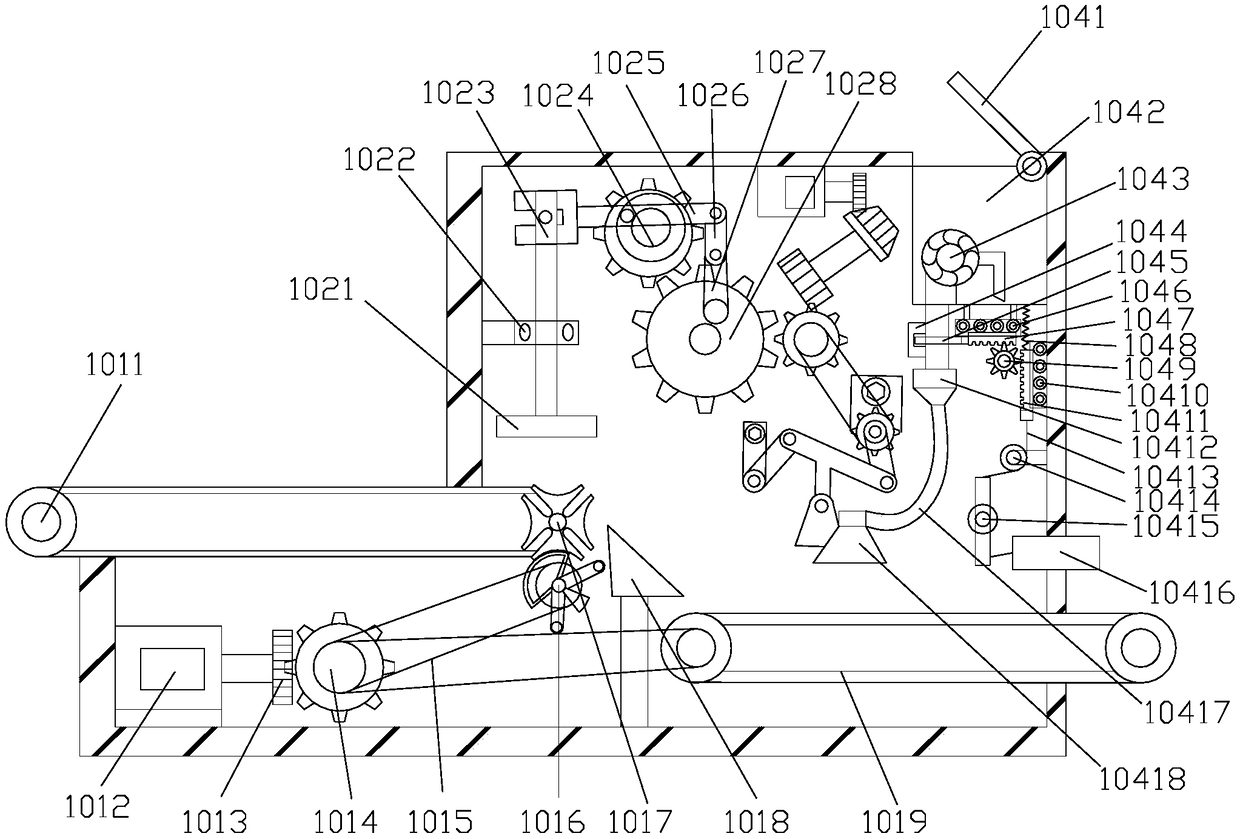

Neilsbed seal ring assembling device of the safety type self-destructing syringe assembly machine

InactiveCN101081320AIncrease productivityReduce manufacturing costInfusion syringesInfusion needlesEngineeringTransfer mechanism

The present invention provides one device for assembling needle stand sealing ring in safe self-destructing syringe assembling machine, and belongs to the field of mechanical technology. The device for assembling needle stand sealing ring set between the turntable for fixing needle stand and the feeding mechanism for conveying sealing ring includes one frame, one ring opening mechanism, one ring transferring mechanism between the frame and the ring opening mechanism, and one ring shifting mechanism for setting the ring on the needle stand. The device has high assembling efficiency, high safety, being hygienic, and other features.

Owner:王兴章

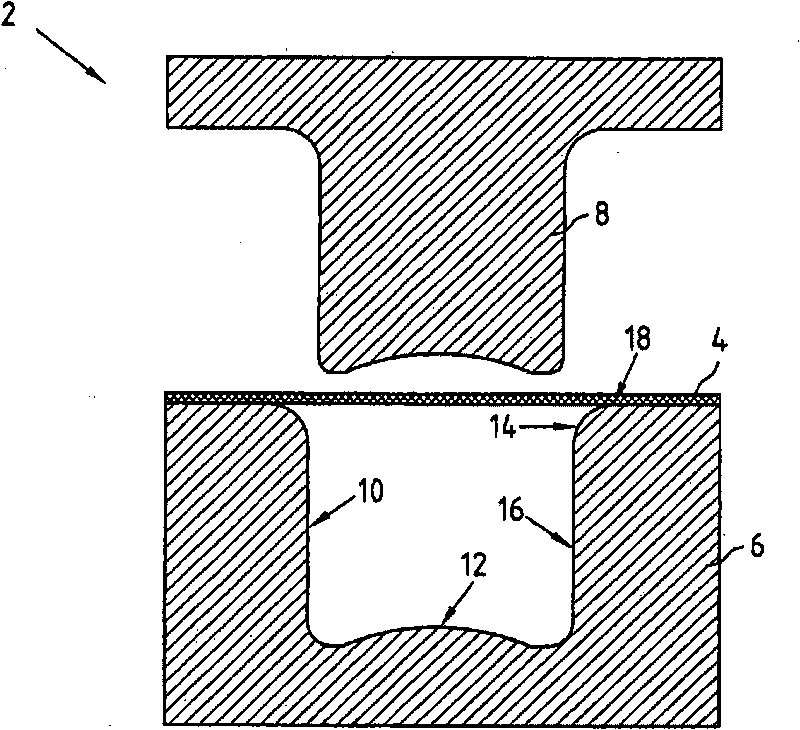

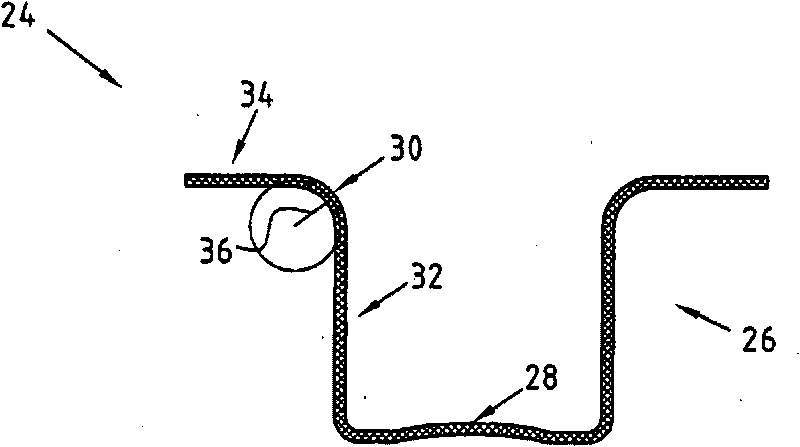

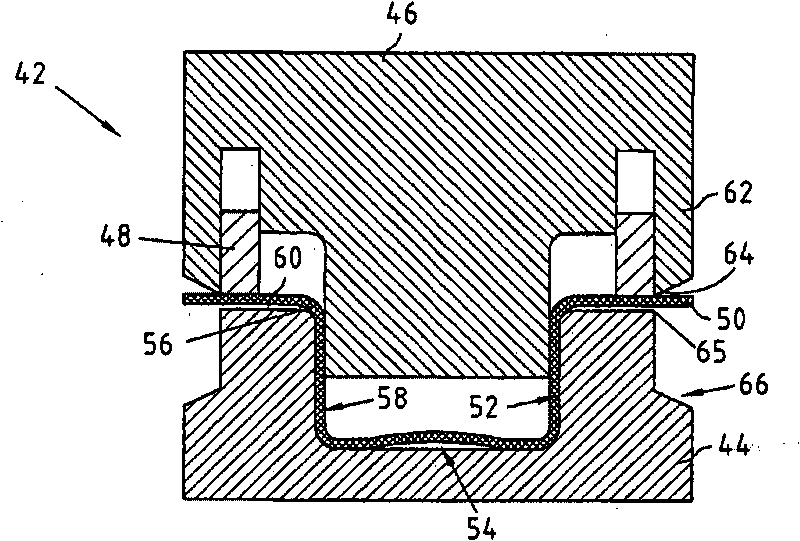

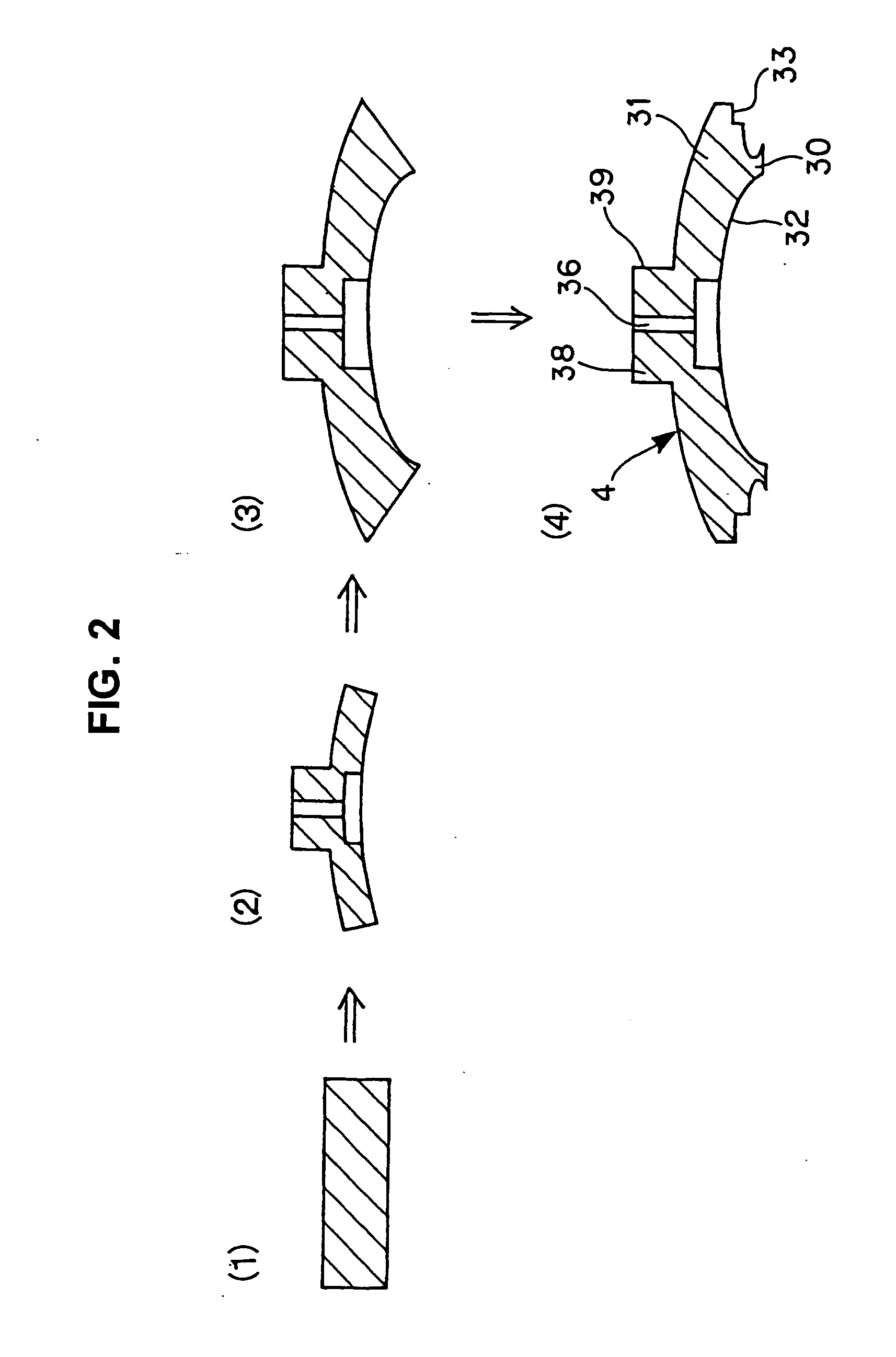

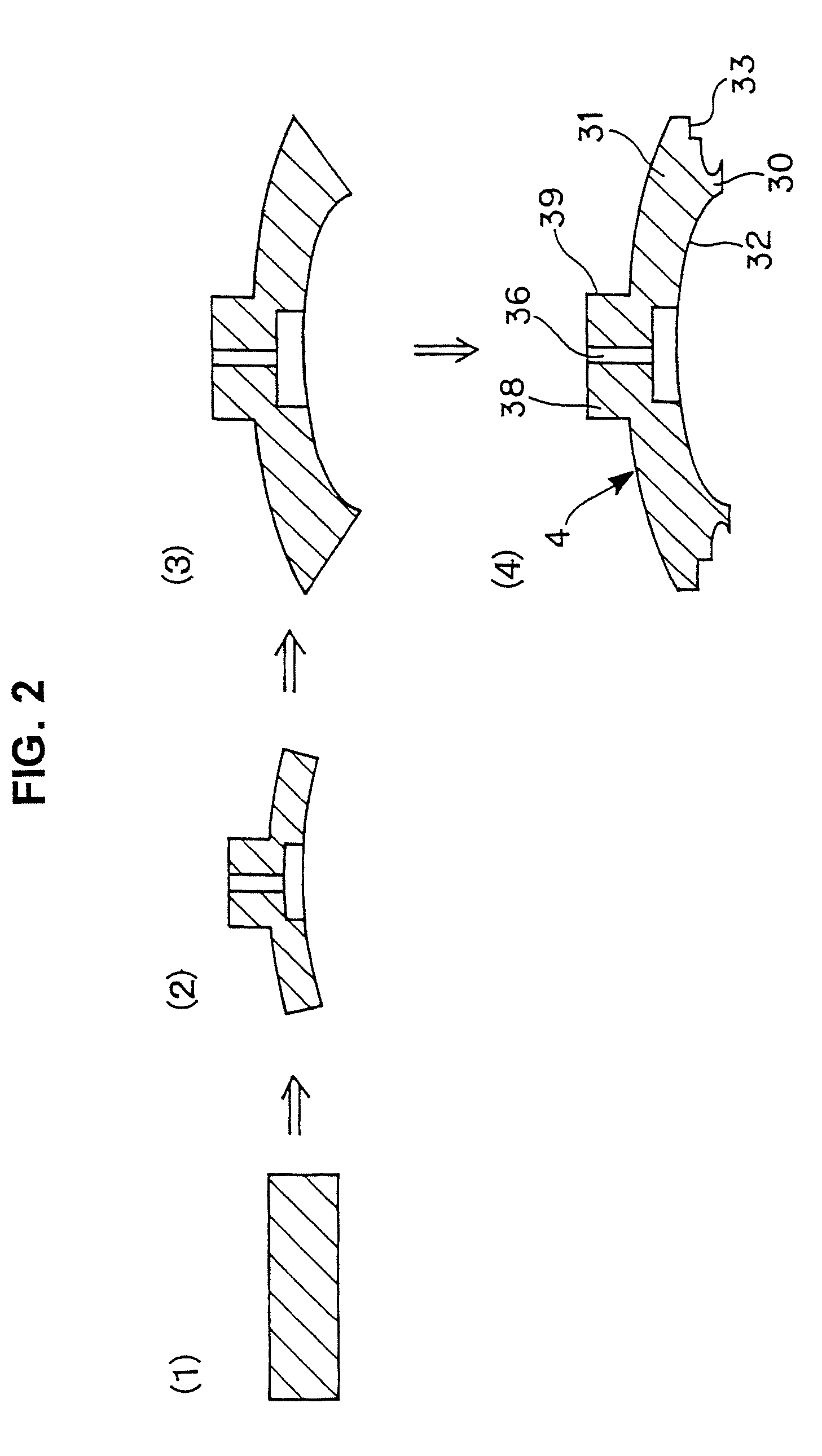

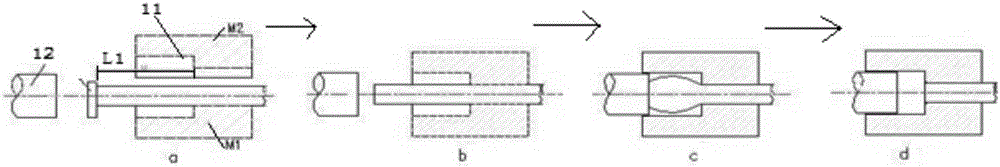

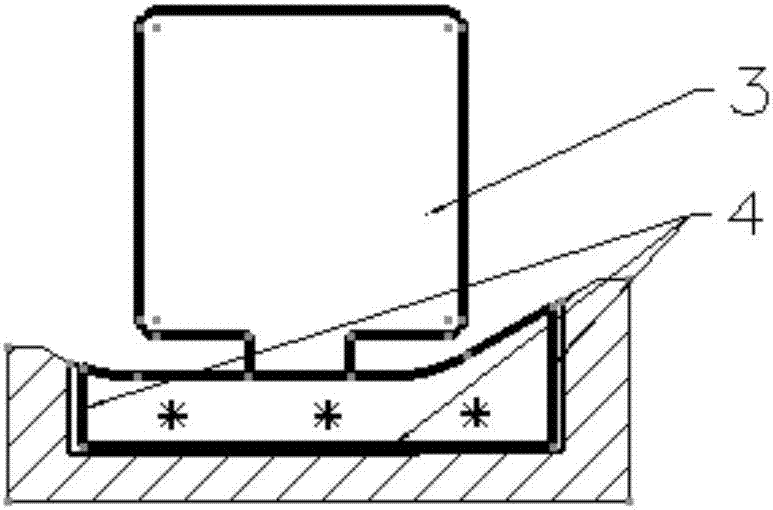

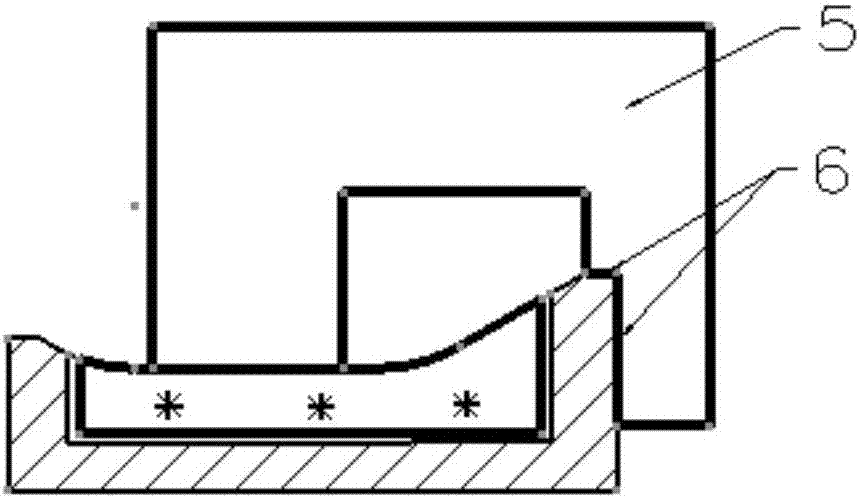

Method and device for producing highly dimensionally accurate flanged half shells

ActiveCN101758148AHigh dimensional accuracyPrevent springbackVehicle componentsBody regionDimensional precision

A method for producing highly dimensionally accurate, deep-drawn half shells with a base region (122), a body region (116) and a flange region (118), includes firstly forming a pre-formed half shell (24, 50, 72, 92) from a blank (4) and then shaping the pre-formed half shell (24, 50, 72, 92) into a finally formed half shell (112), wherein the pre-formed half shell has excess blank material due to its geometric shape and wherein, owing to the excess material during the shaping of the pre-formed half shell into its final shape the half shell is compressed into the finally formed half shell by at least one further pressing process. The method requires that the pre-formed half shell has excess blank material in a transition region between the body region and flange region.

Owner:THYSSENKRUPP STEEL EURO AG

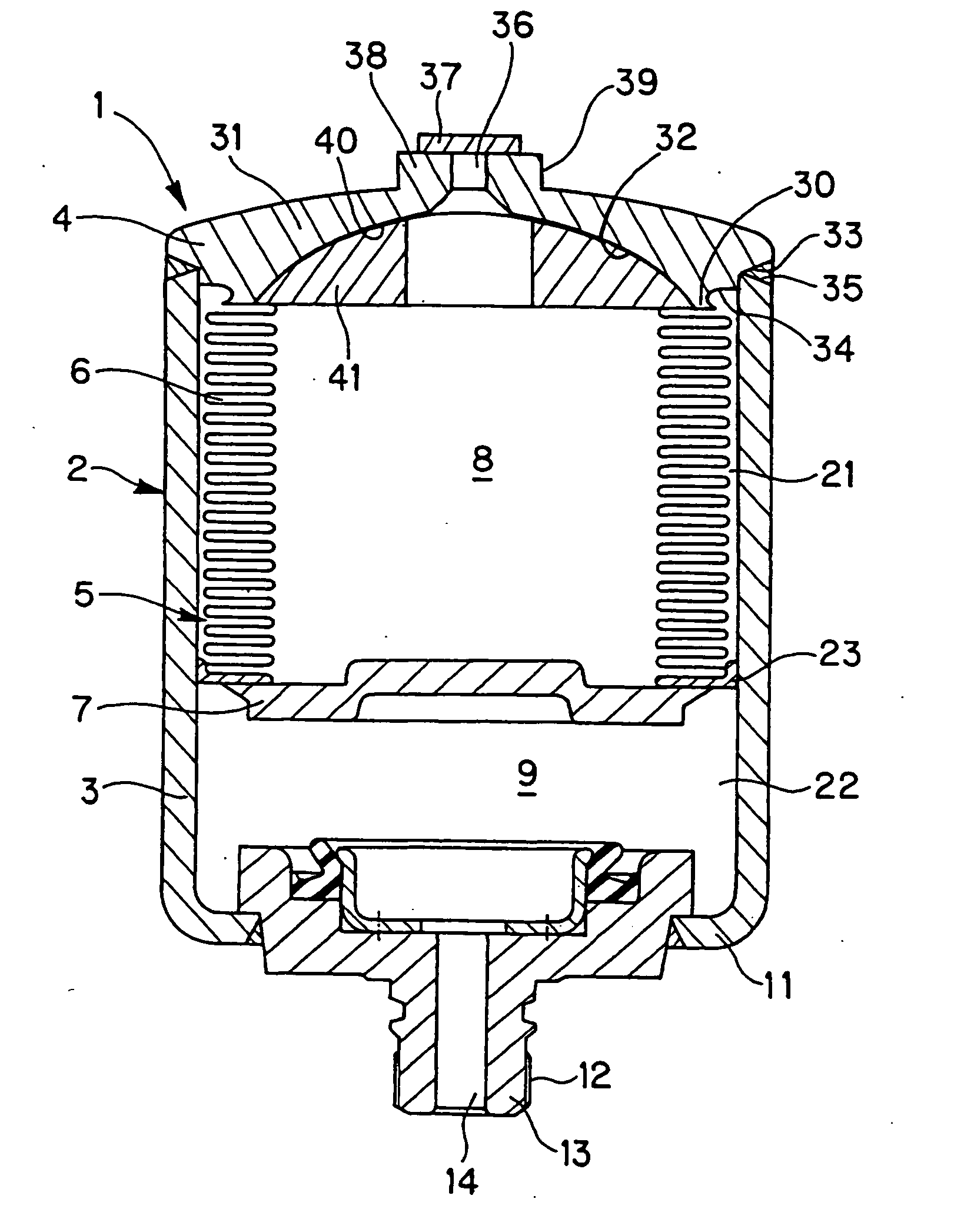

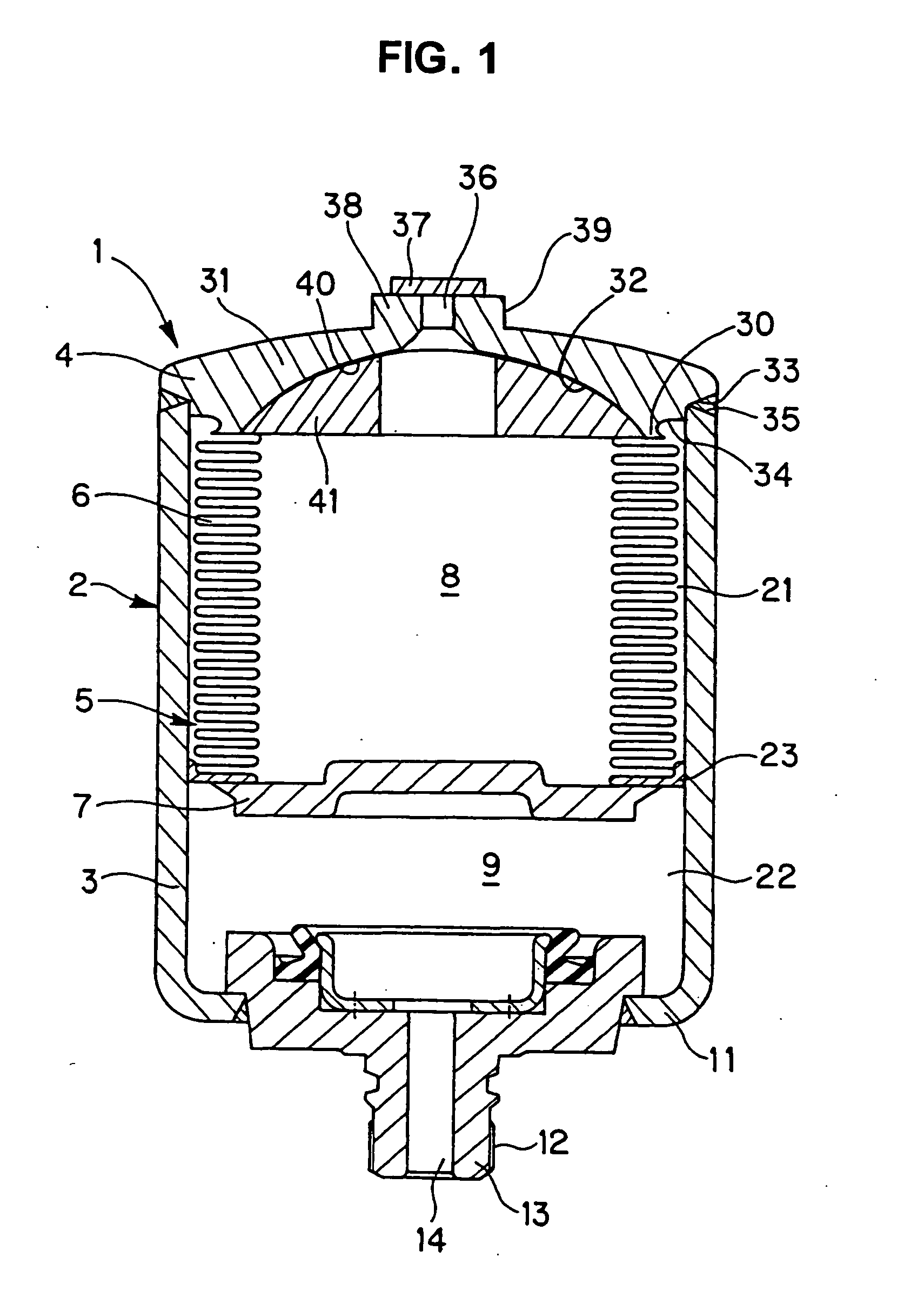

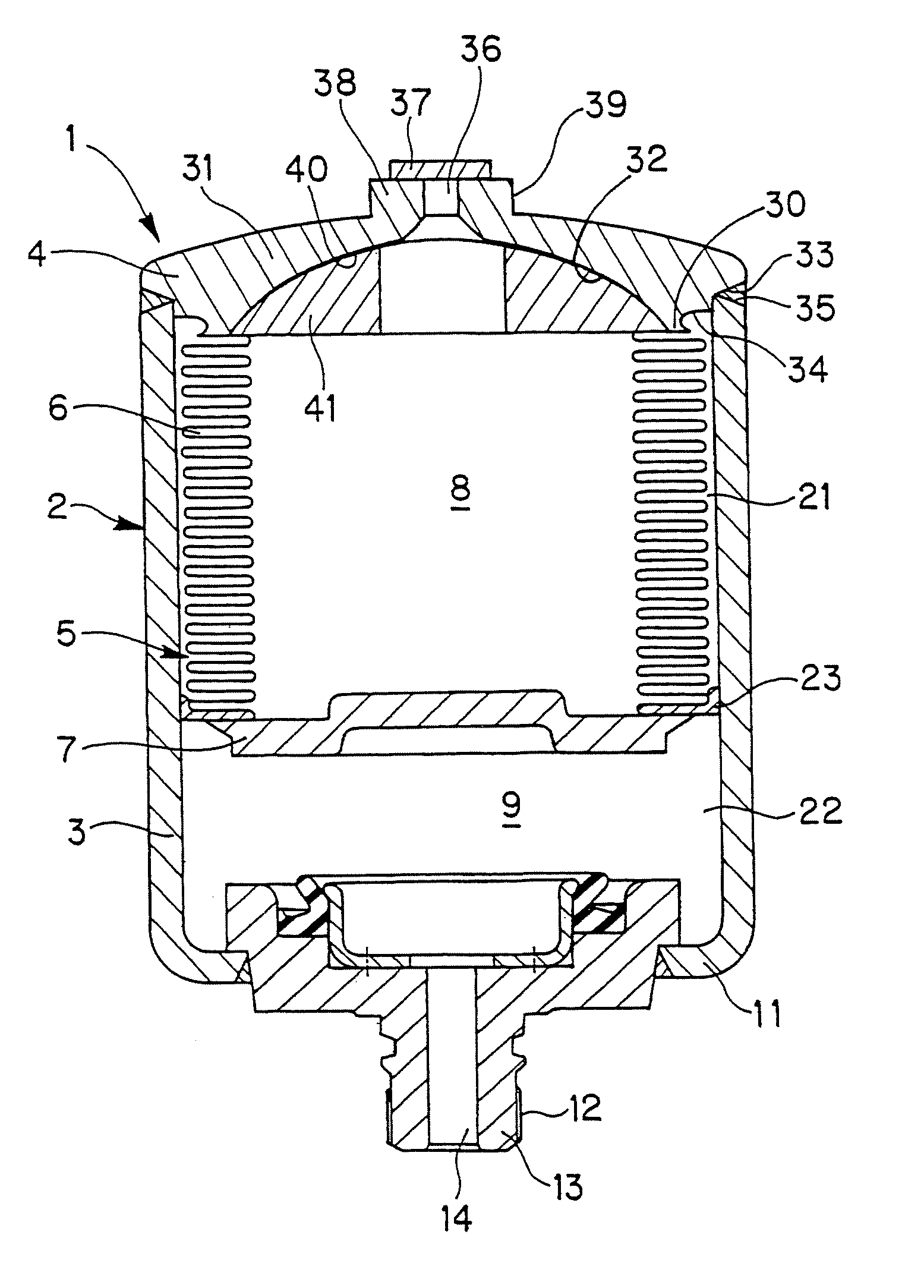

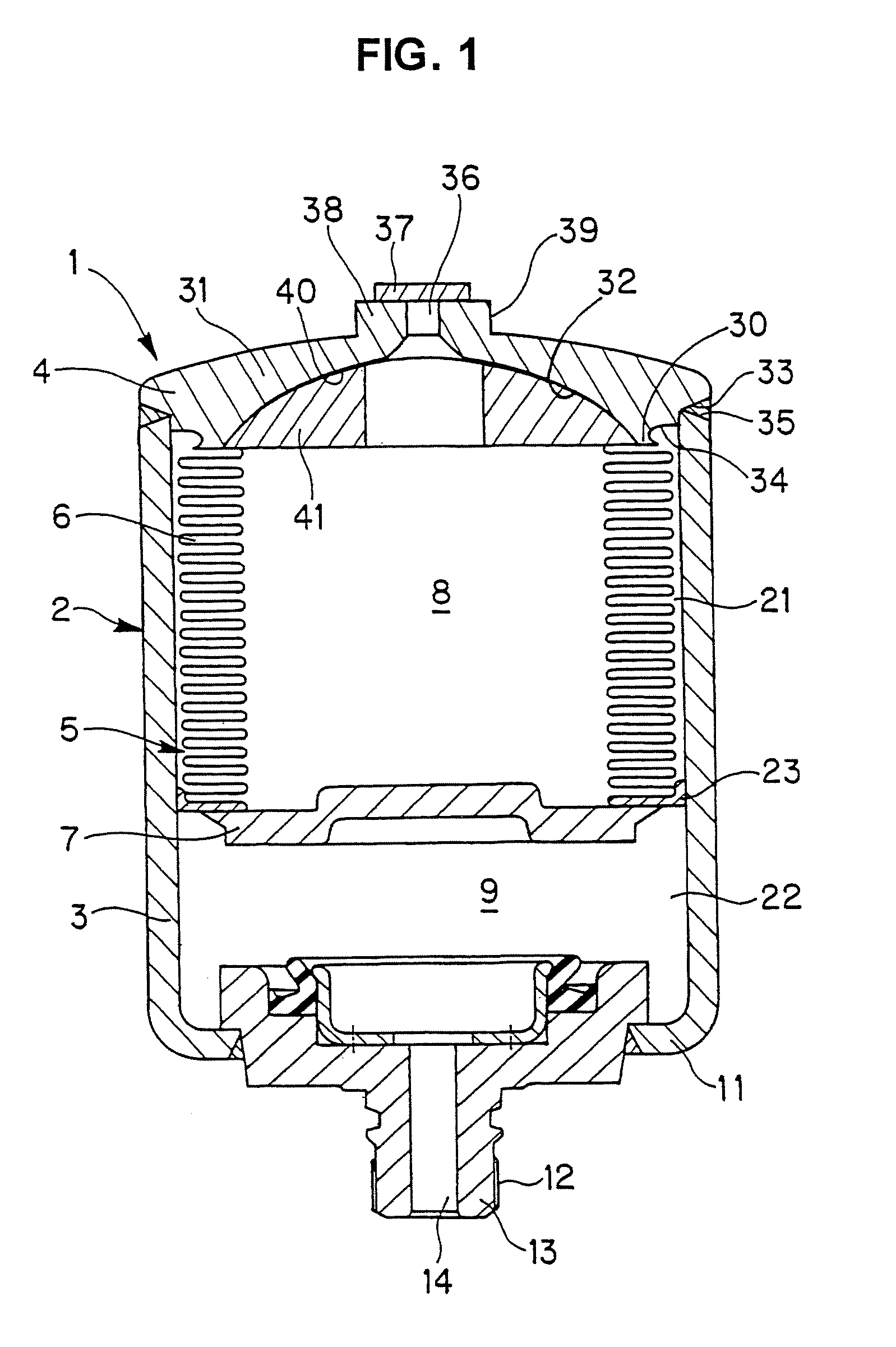

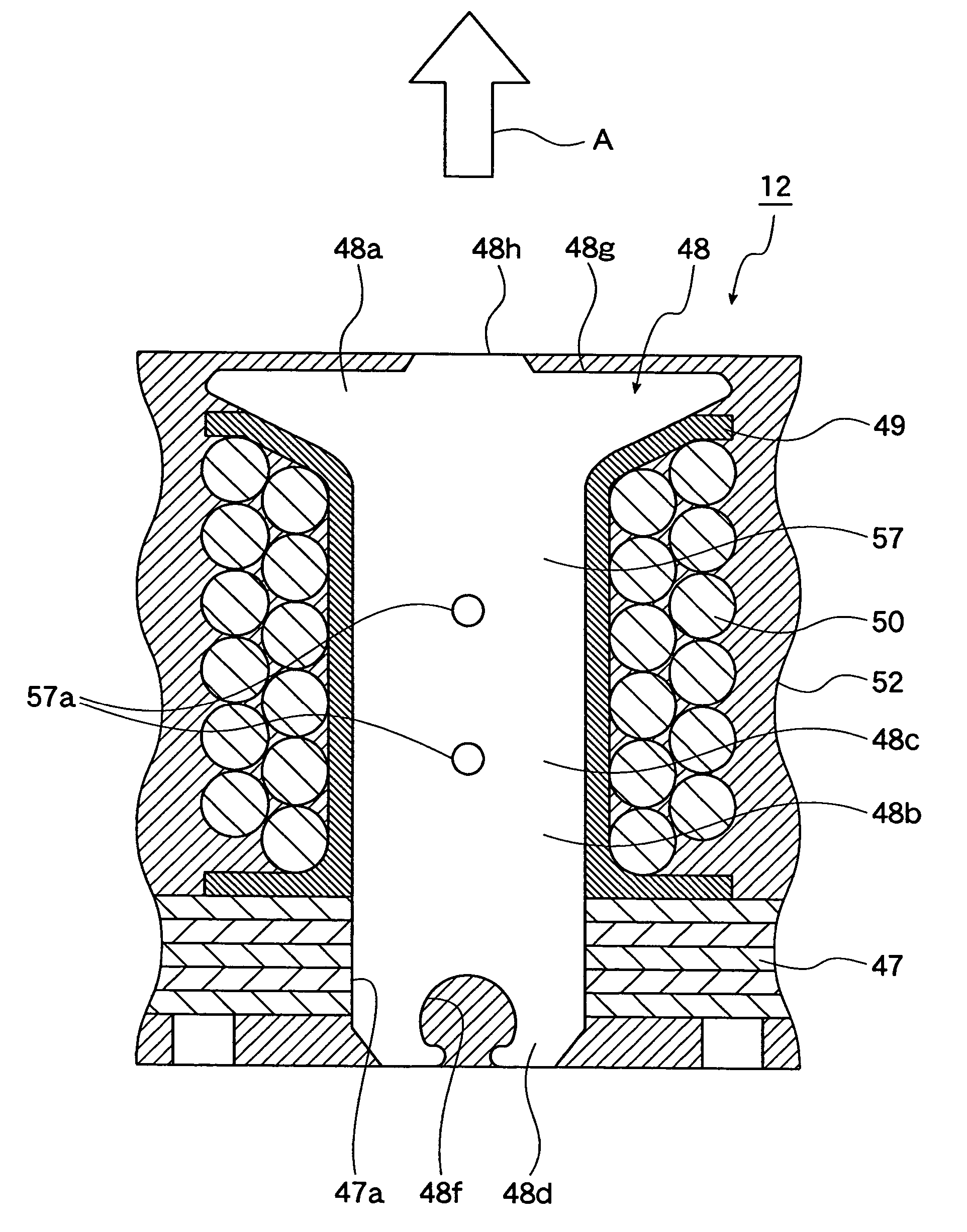

Accumulator

InactiveUS20070102052A1Made smallSolve large capacityAccumulator installationsPipe elementsEngineeringWeld penetration

An accumulator in which a pressure sealed chamber and a pressure flow-in chamber are formed by an operation member including a metallic bellows provided within a housing constituted by a gas end cover and a bottomed tubular shell, wherein a cross sectional inner outline of a peripheral edge portion of the gas end cover is an oval shape which is concave to the pressure sealed chamber side, and a dead space is not formed, so that a capacity of a volume adjusting spacer is reduced by eliminating a dead space, a working step is reduced by simplifying a shape of the gas end cover, and a margin of welding penetration depth is increased by thickening of a backing metal portion.

Owner:NOK CORP

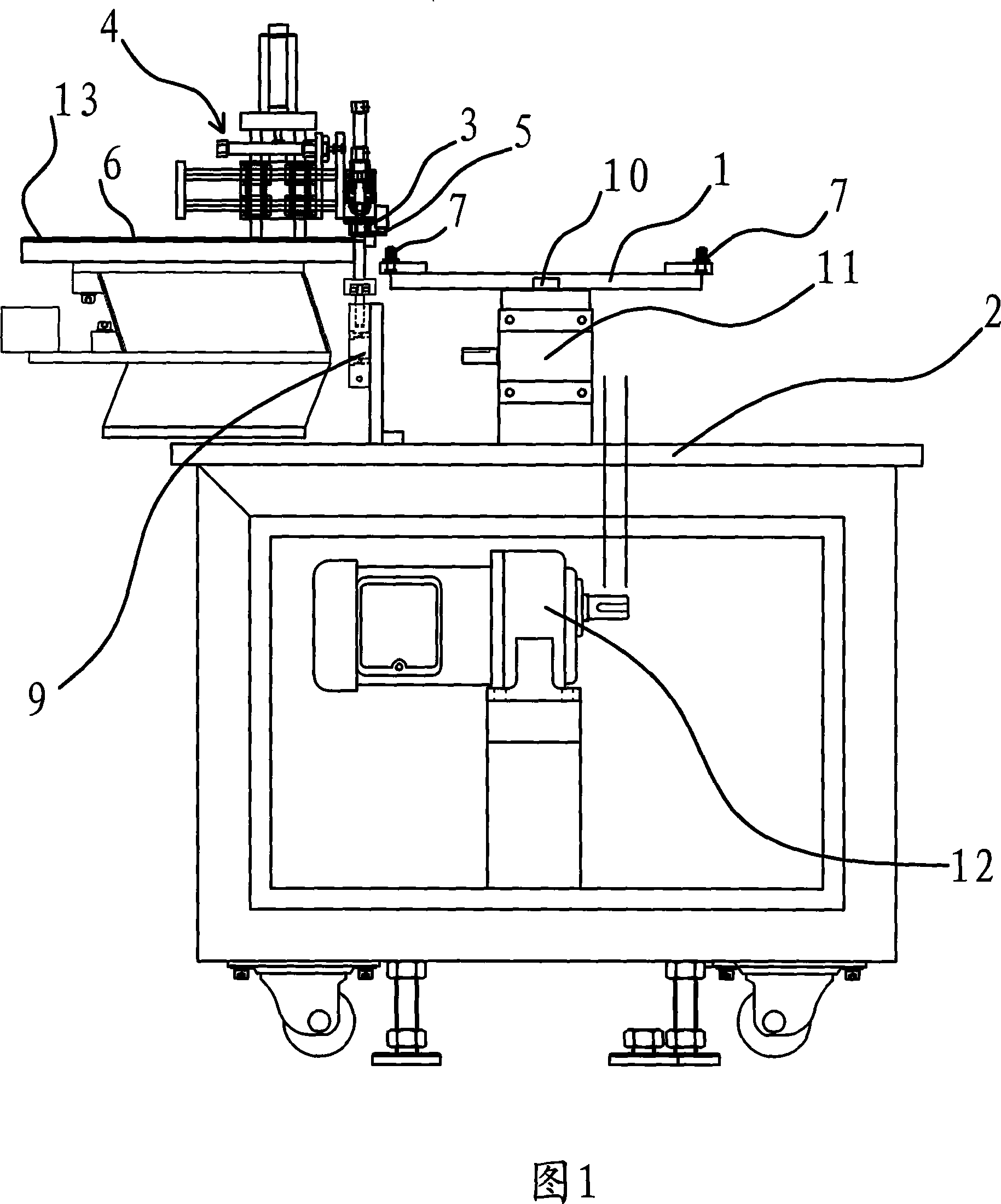

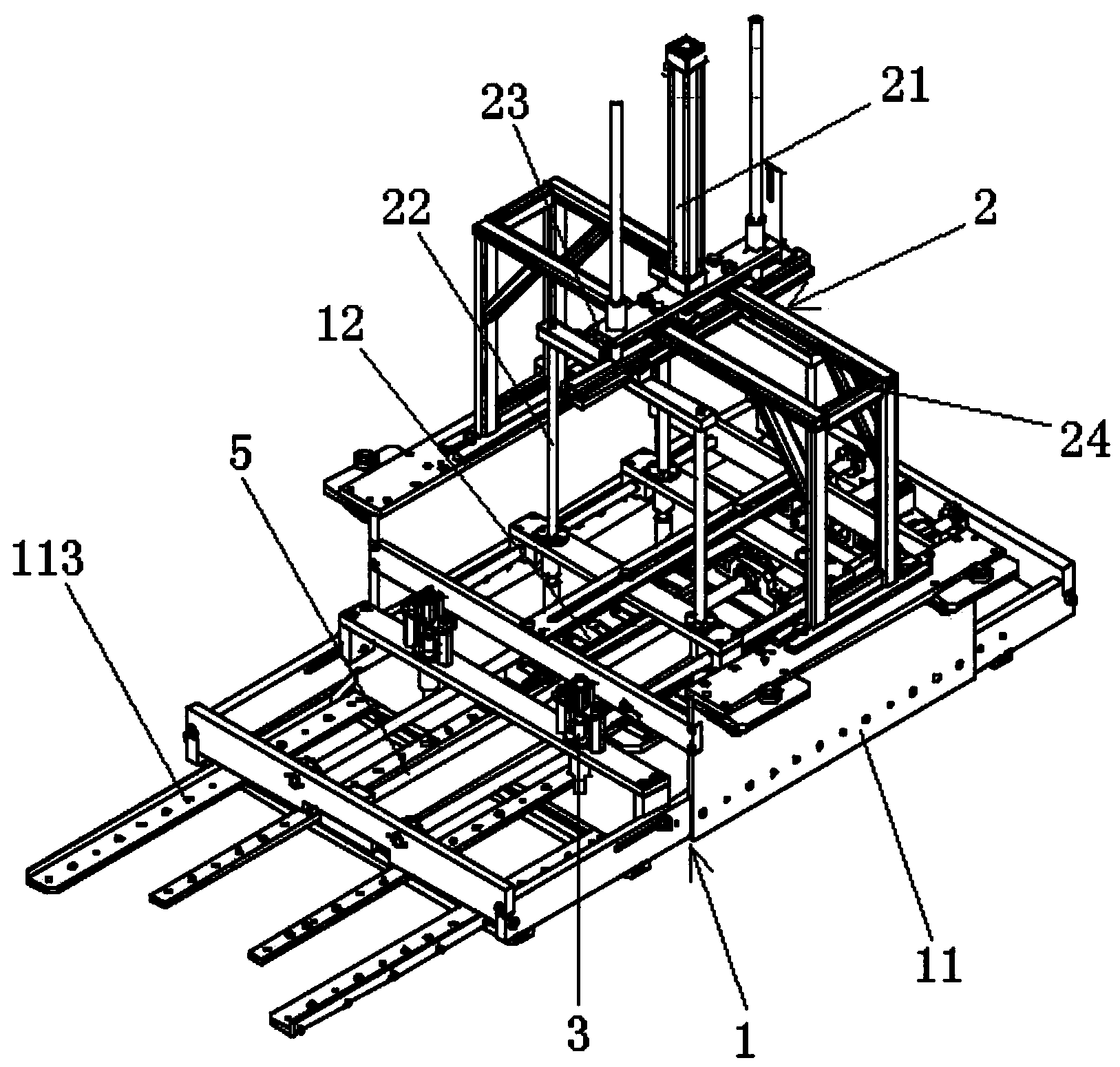

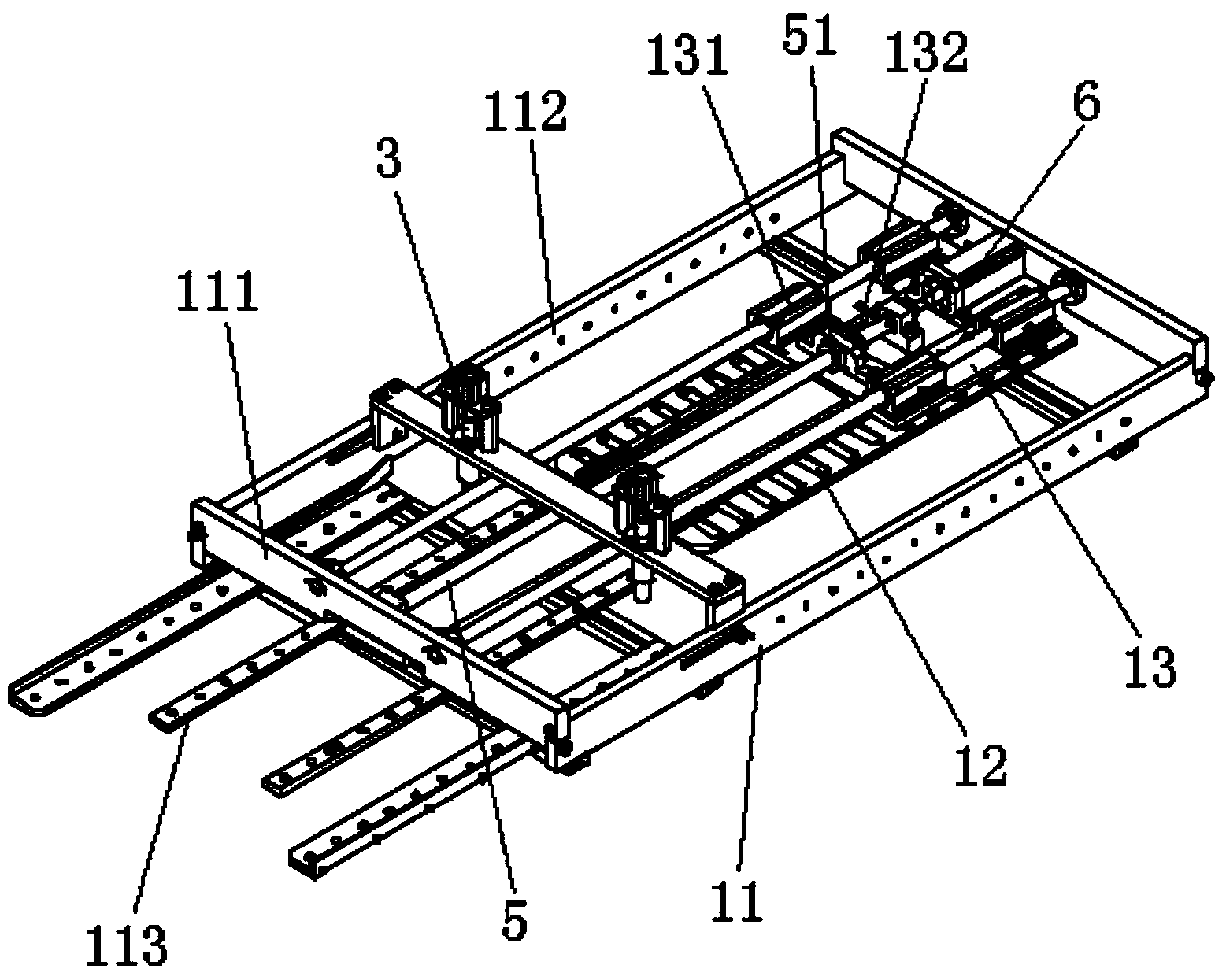

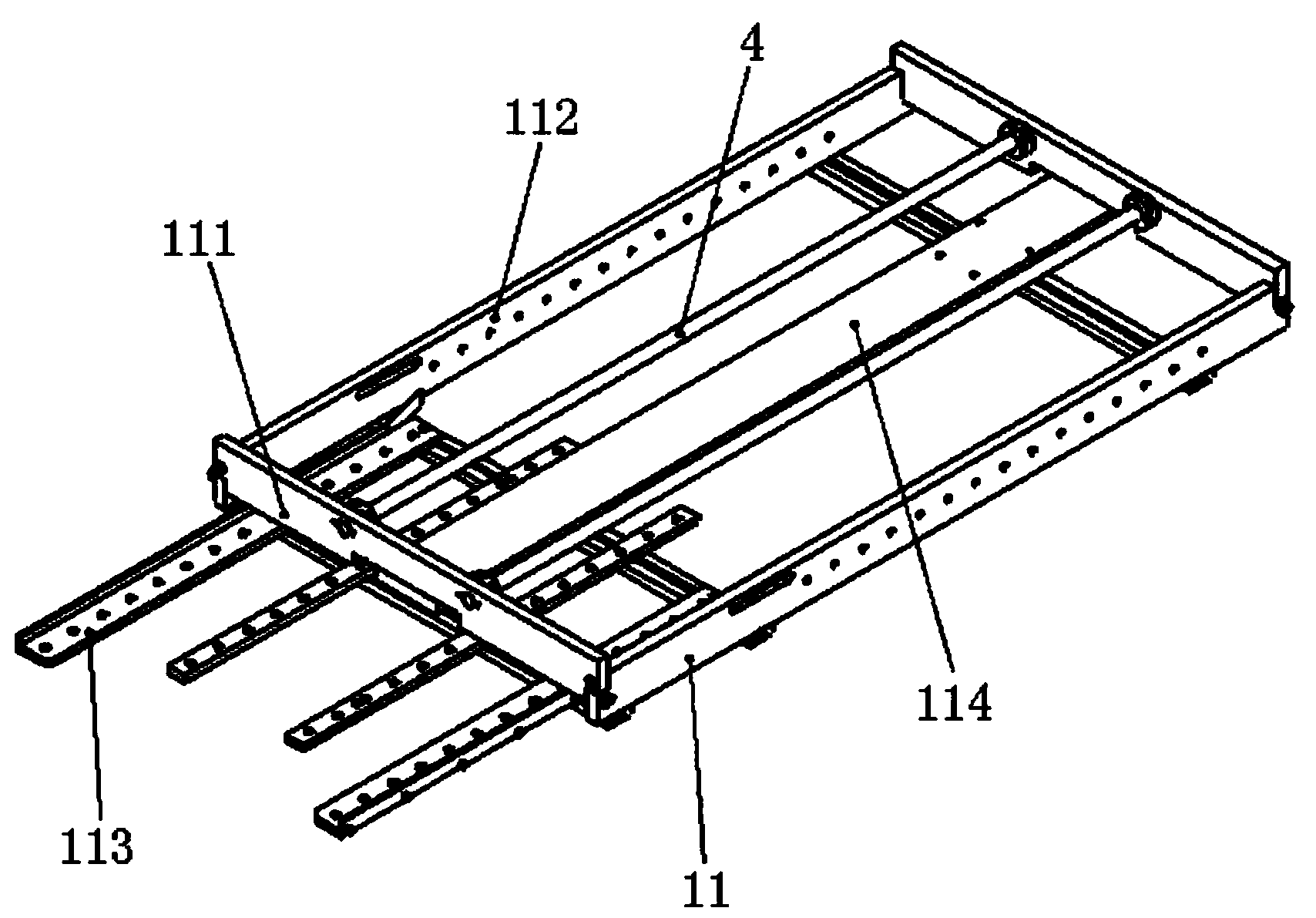

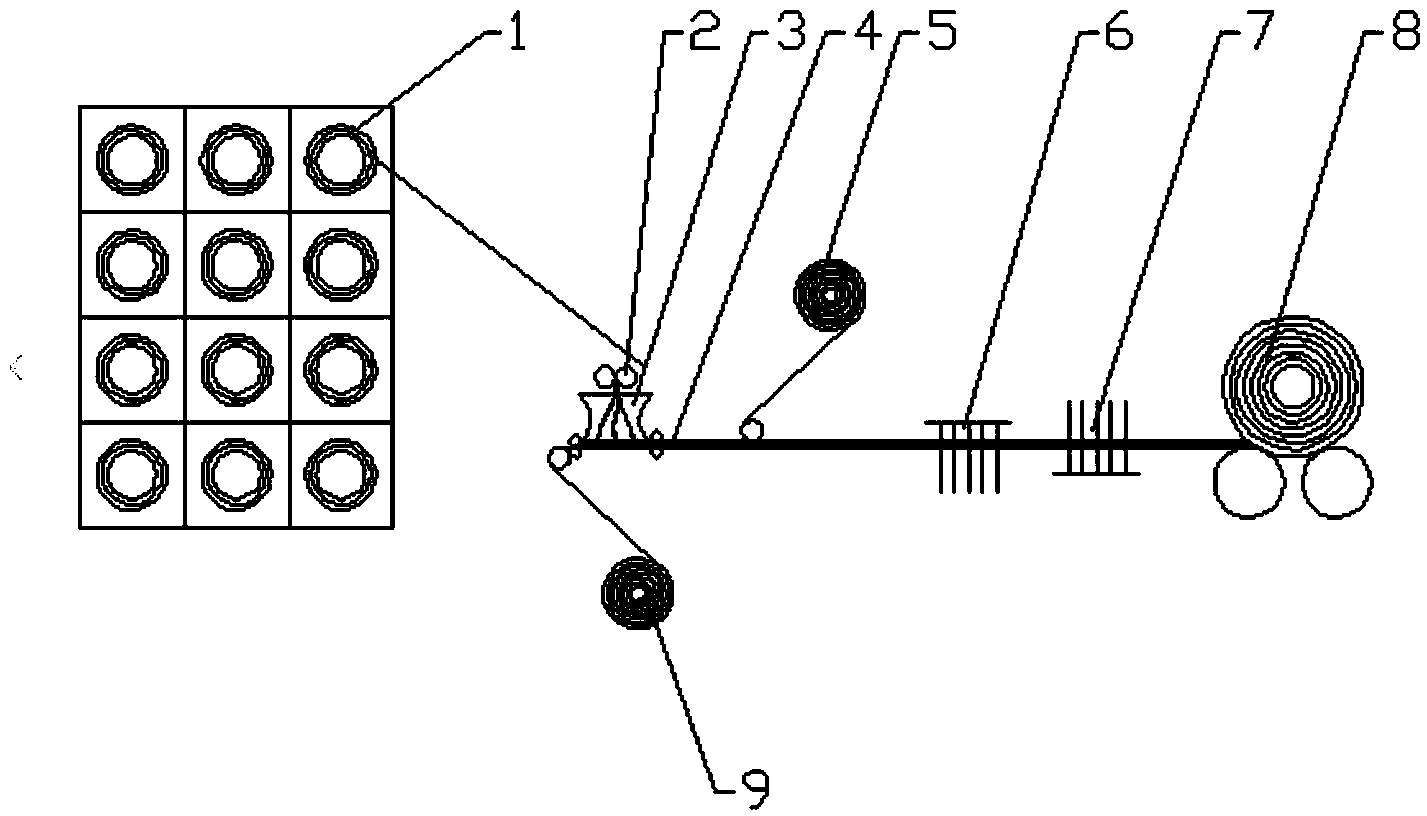

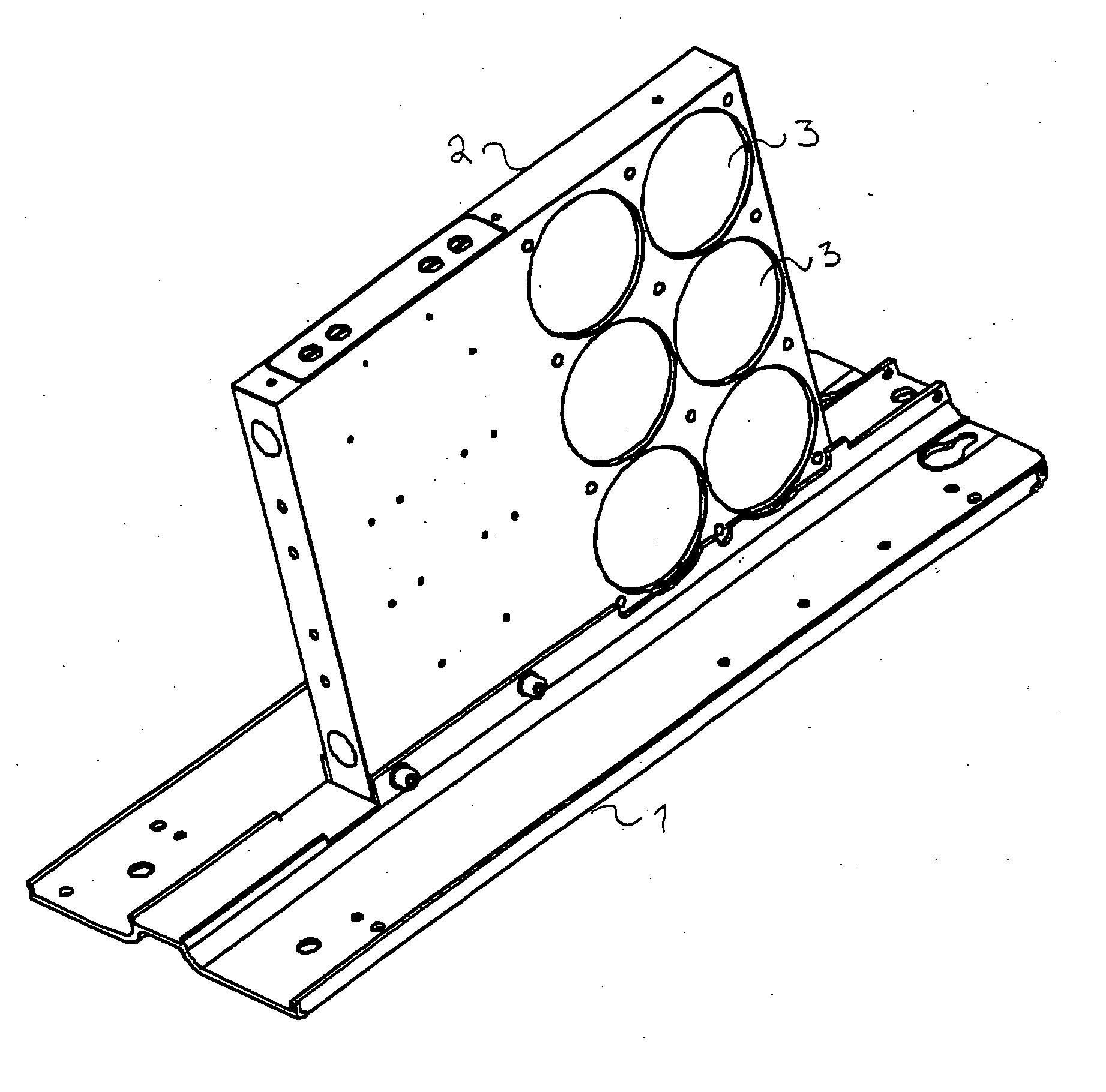

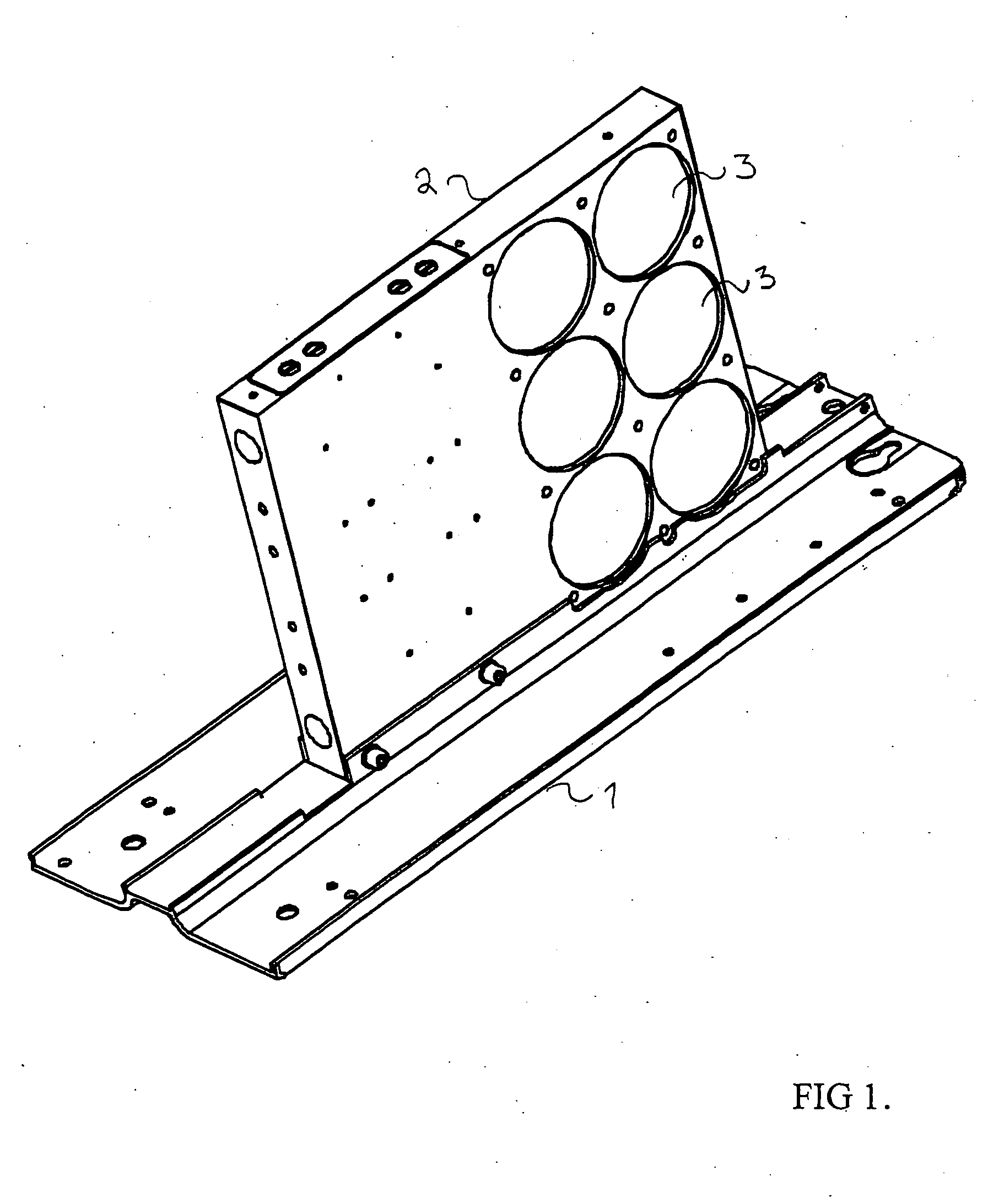

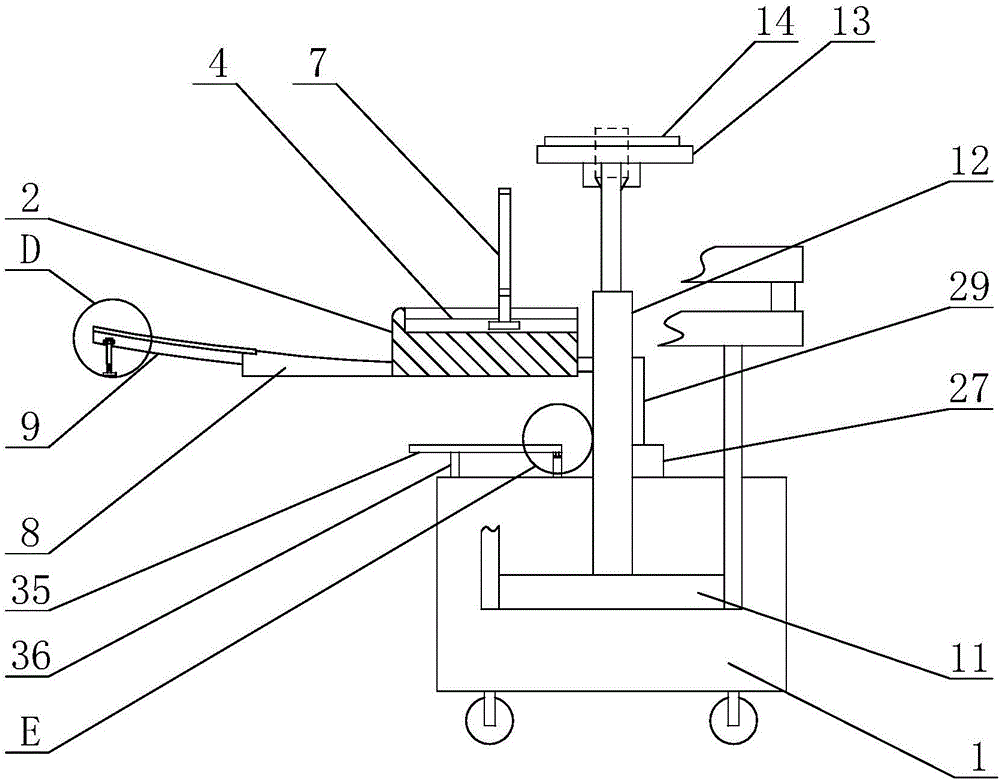

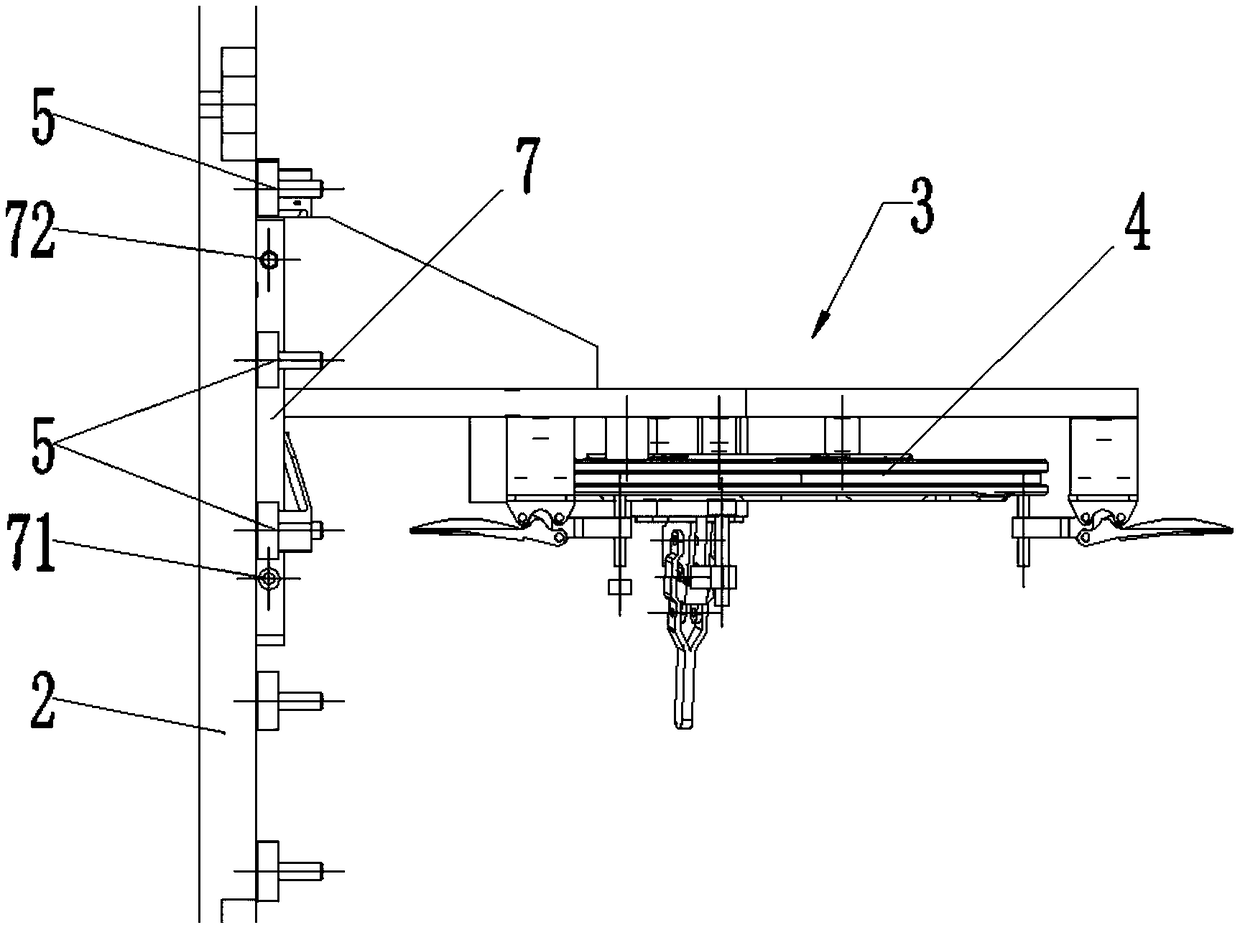

Automatic material feeding mechanism

ActiveCN103848194AReduce work stepsEliminate hazardsMetal-working feeding devicesPositioning devicesPunchingStops device

The invention provides an automatic material feeding mechanism. The automatic material feeding mechanism comprises a material sucking device and a material feeding mechanism, the material feeding mechanism comprises a material feeding platform, a power device, a material stopping device, a pushing plate and a guide device, a guide rod and a transmission device are installed on the material feeding plate, the transmission device is rotatably connected with the power device, the pushing plate is installed on the material feeding platform and is fixedly connected with the guide device, and the guide device is respectively and movably connected with the transmission device and the guide rod and can slide along the guide rod; pushing pins which can swing up and down are installed at the front end of the pushing plate; the material stopping device is installed on the material feeding platform and is used for stopping material sheets from moving back. The automatic material feeding mechanism has the advantages that the conveying distance from the automatic material feeding mechanism to a punching machine is shortened and the area occupied by the machine is reduced; the automatic material feeding mechanism is suitable for producing various material sheets with different sizes; the feeding stability is improved and the production efficiency and the production safety of the machine are also improved.

Owner:桐乡市华杰工业自动化科技有限公司

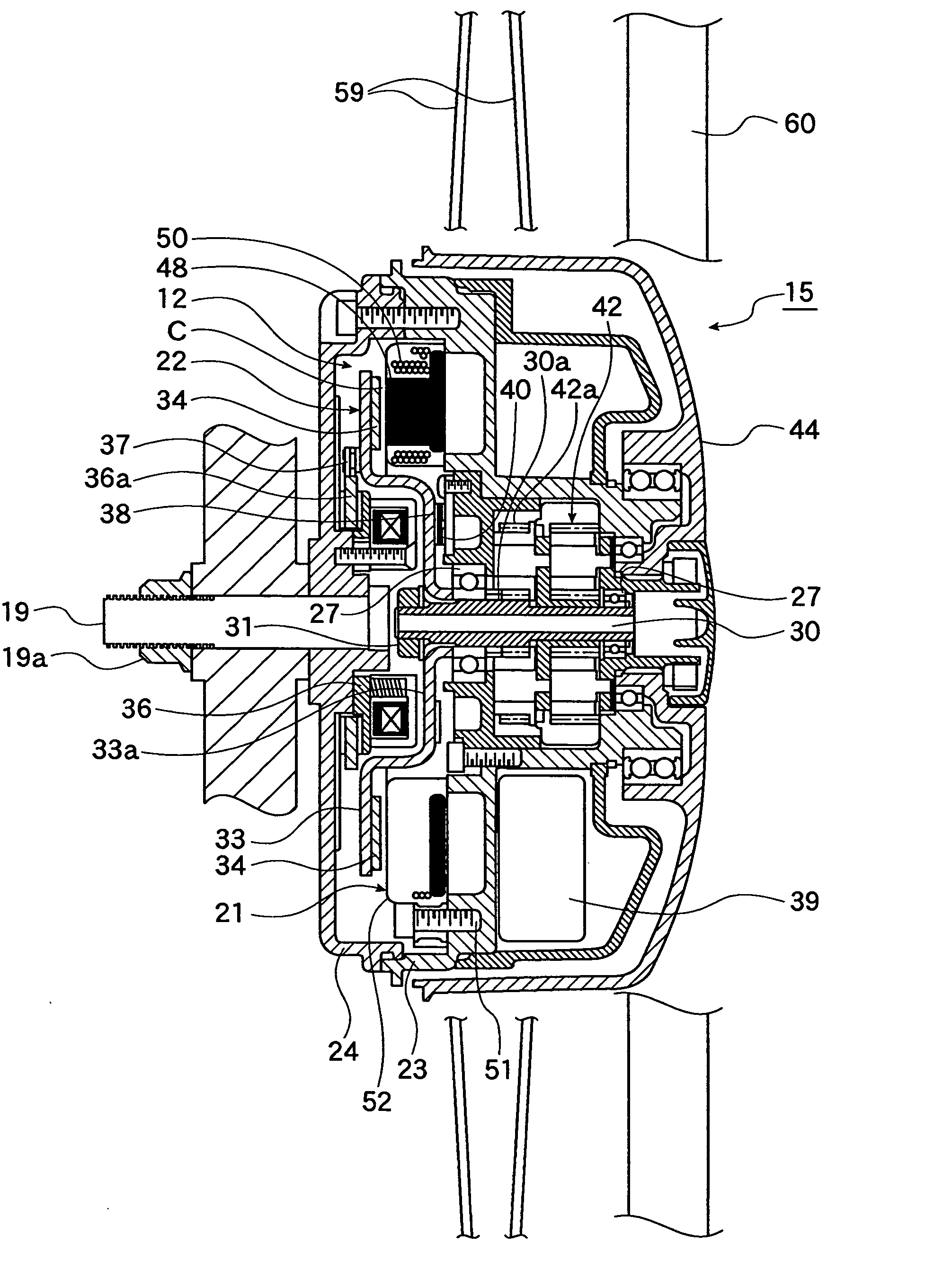

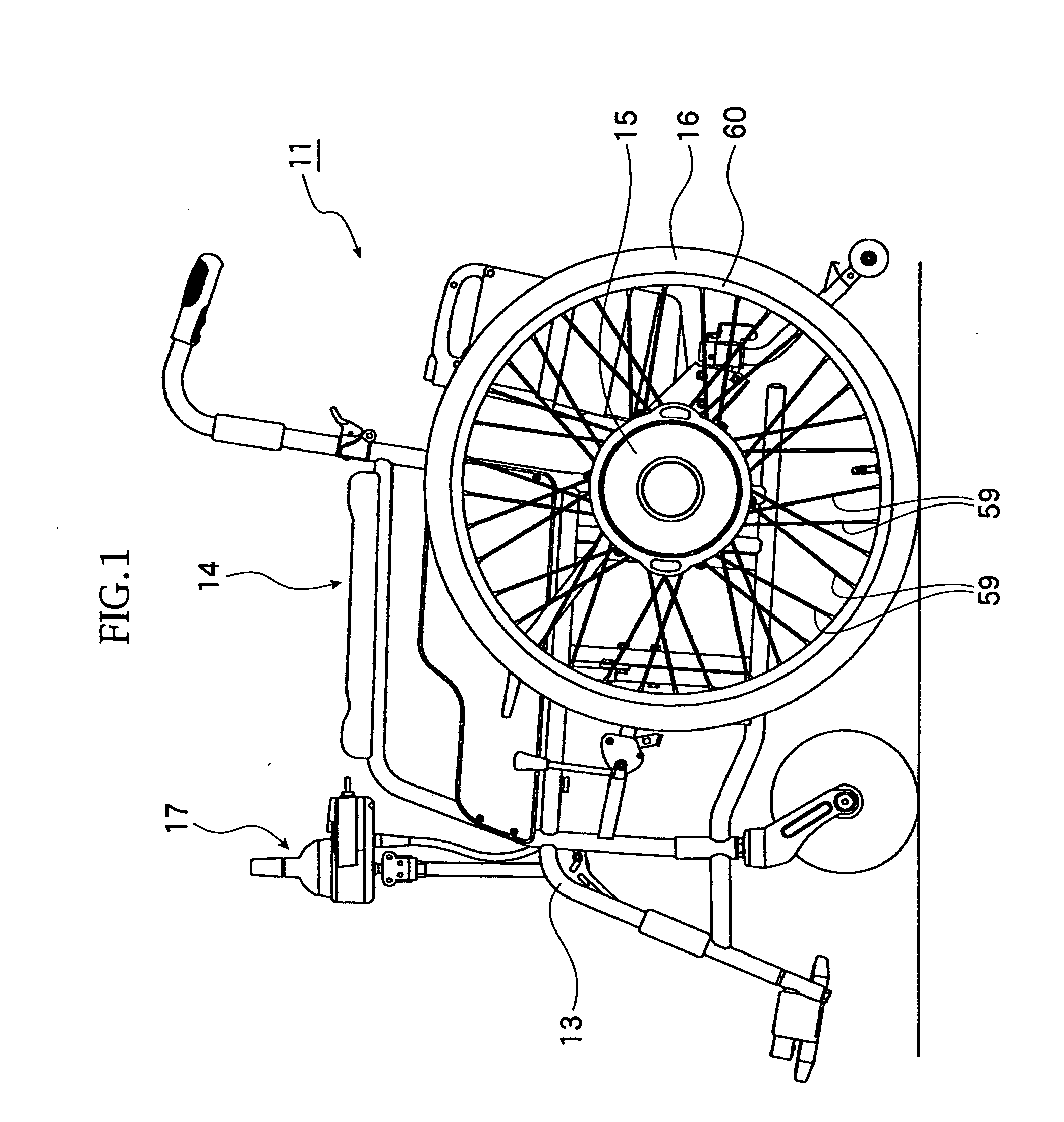

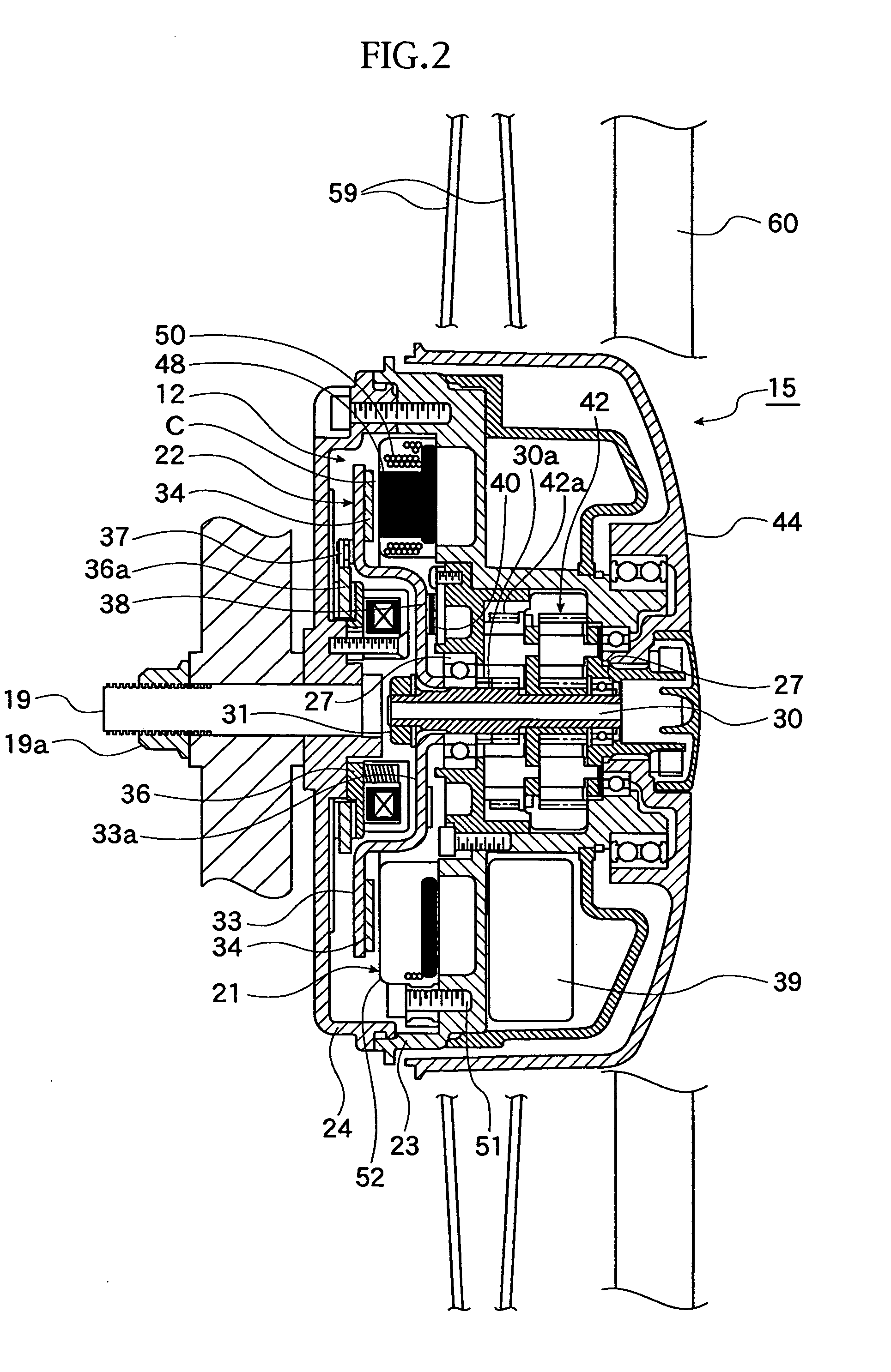

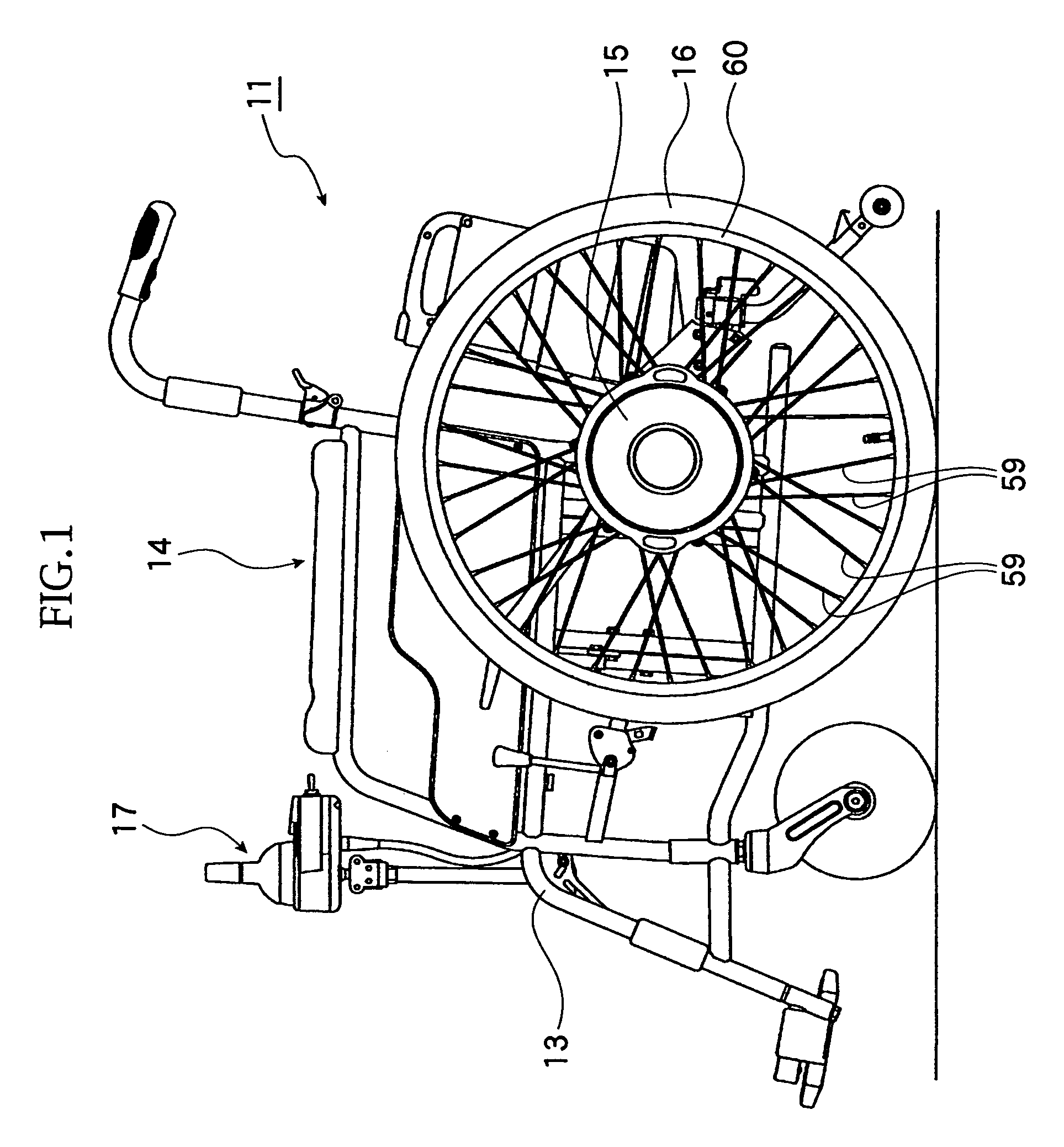

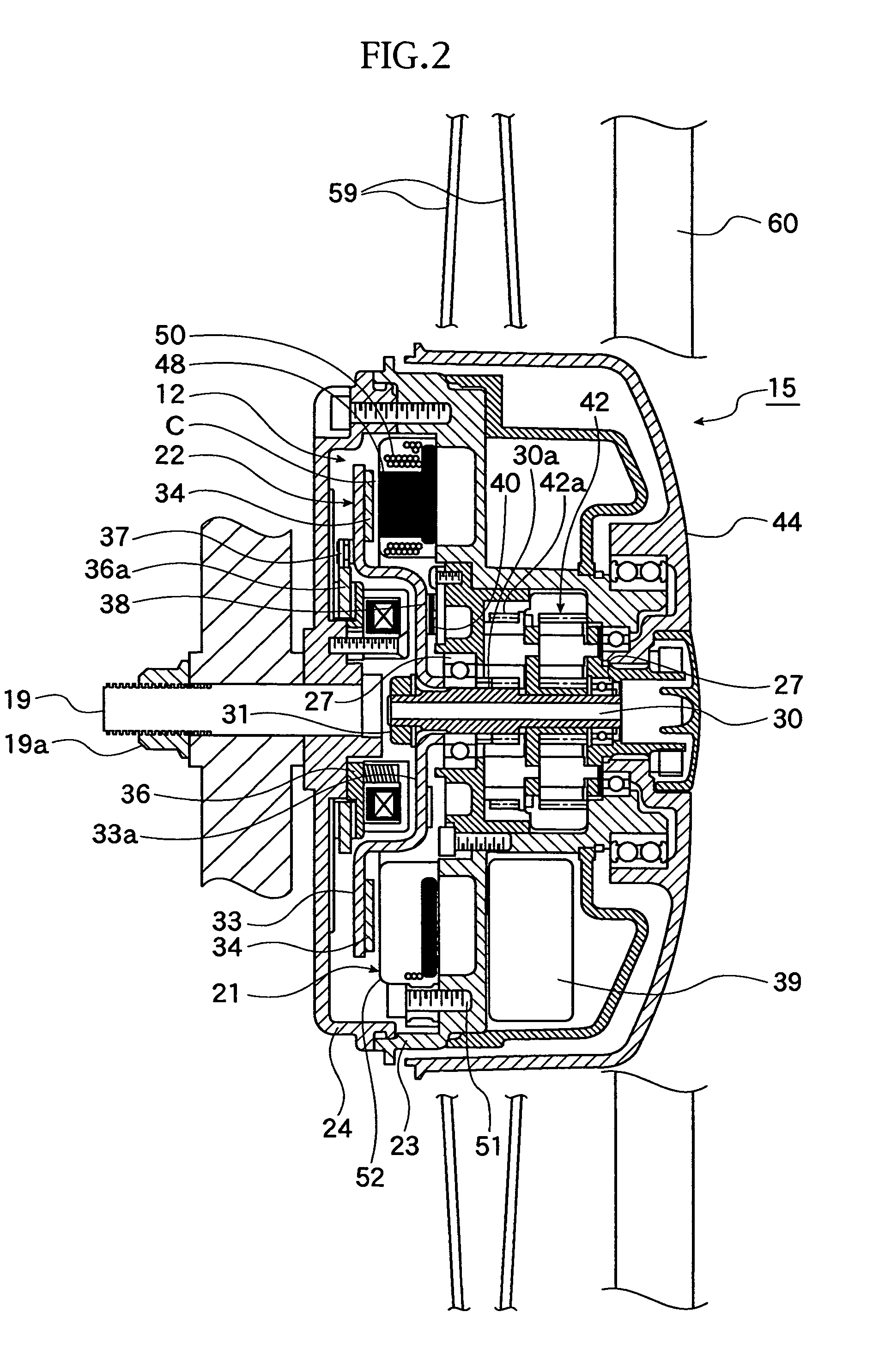

Rotary electric machine and electric wheelchair mounted with rotary electric machine

InactiveUS20070018528A1Reduce work stepsLower resistanceMagnetic circuit rotating partsElectric devicesMagnetWheelchair

A rotary electric machine includes a stator including a plurality of teeth which are each wound up by a coil and a stator yoke core connecting the respective teeth, the teeth and the stator yoke core being integrally fixed by means of molding resin; and a rotor provided with magnets disposed so as to oppose to the teeth, respectively, with a space therebetween, wherein each of the teeth is composed of a head portion opposing to the magnet, a coil wind-up portion which is wound up by the coil and an insert portion to be inserted into the stator yoke core, and a coming-off prevention portion for preventing the teeth from coming off is formed in the insert portion, the coming-off prevention portion being filled up with the molding resin.

Owner:YAMAHA MOTOR CO LTD

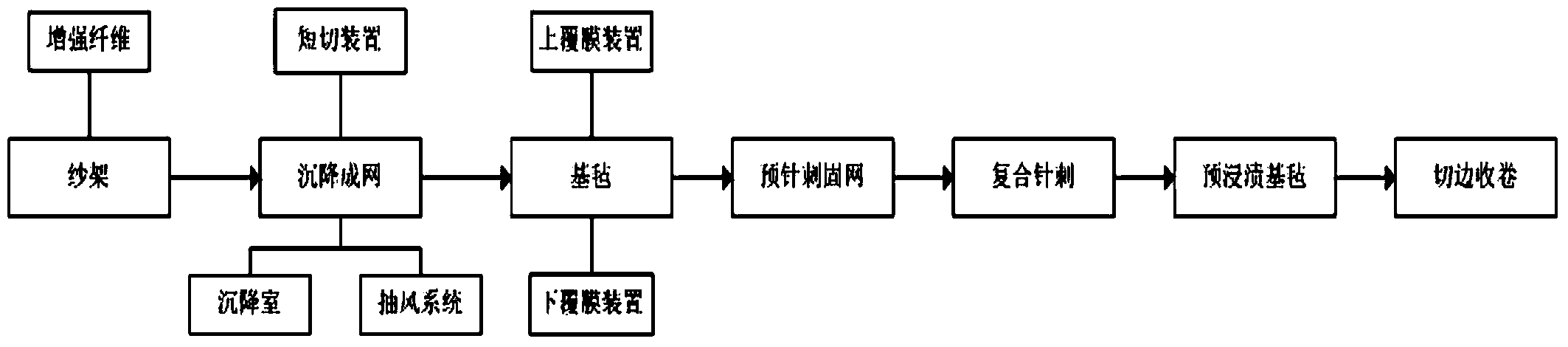

Dry-process pre-impregnating process of thermoplastic resin based pre-impregnated tape

InactiveCN103921369AIncrease primary mixingImmersion distance shortenedCoatingsThermoplasticPunching

The invention provides a dry-process pre-impregnating process of a thermoplastic resin based pre-impregnated tape. The dry-process pre-impregnating process mainly comprises the following steps: chopping reinforced fibers on a creel, enabling fibers to be quantitatively scattered on a conveyer belt paved with a resin film in a freely-falling and messy mode, and laying one resin film on the chopped fiber layer for form a three-layer premix material structure; carrying out pre-needling and web fixation to double sides of the premix material structure, utilizing the composite needle punching technology to enable fiber webs to be intertwined to form a three-dimensional structure; and finally, carrying out hot-baking plasticizing and molten rolling impregnation technology to prepare the continuous short fiber pre-impregnated tape. According to the production process route, technical equipment for the traditional dry-process air laying or carding is removed, the original production process flow is improved technically, and the process technical bottleneck that the high-temperature high-viscosity thermoplastic resin has difficulty in melting and impregnating the fibers due to poor mobility is solved, the quality and the yield of the products are improved, and the industrial production cost is reduced.

Owner:HUNAN UNIV

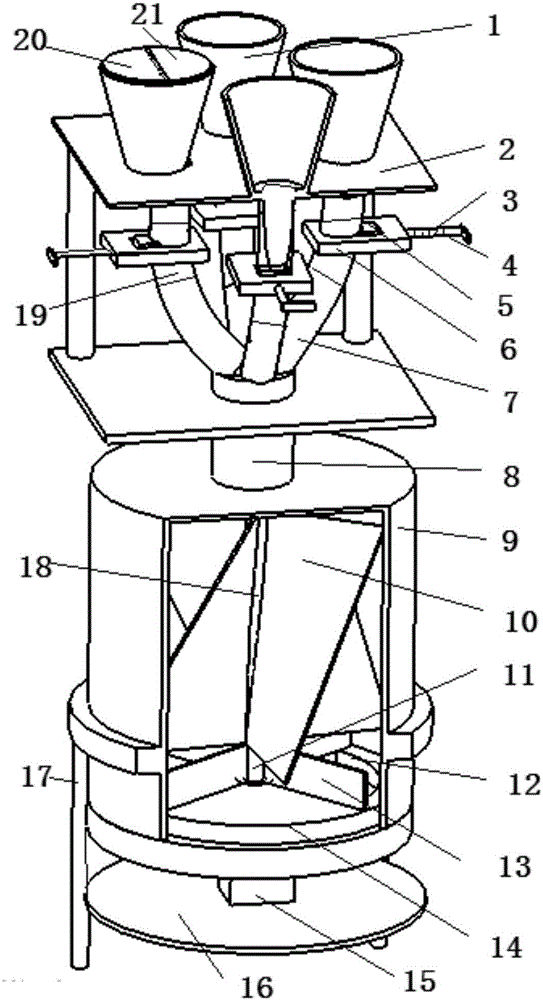

Quantitative powder mixing machine

InactiveCN106512821ARealize automatic proportioning and mixingReduce concentrationRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention provides a quantitative powder mixing machine, comprising a support and a feed hopper, wherein a first pipeline communicated with the feed hopper joins a second pipeline; the other end of the second pipeline is placed above and communicated with a mixing barrel; the inner surface of the bottom of the mixing barrel is rotatably connected with a discharging plate; the discharging plate is provided with discharging holes; the bottom of the mixing barrel is also provided with a discharging hole corresponding to the discharging plate; a stirring device is arranged in the mixing barrel; the first pipeline is provided with a section of an elastic pipe; and an adjusting device is arranged on the elastic pipe and comprises a clamp and an adjusting rod passing through and slidably connected with the clamp. The quantitative powder mixing machine realizes automatic proportioning and mixing of a plurality of materials and quantitative discharging through adjustment of the feed amounts of a plurality of feed inlets, reduces operation steps, lowers dust concentration during mixing, improves production efficiency and decreases cost.

Owner:TIANJIN RONG LEE BIOTECH DEV CO LTD

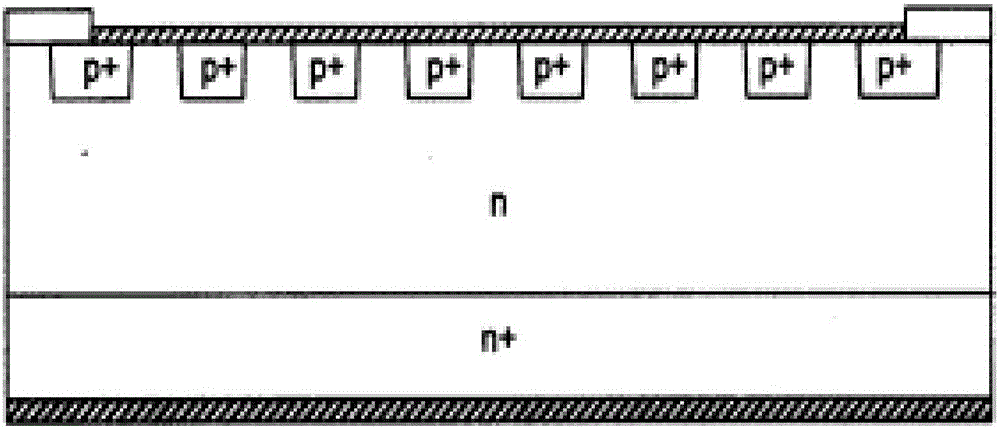

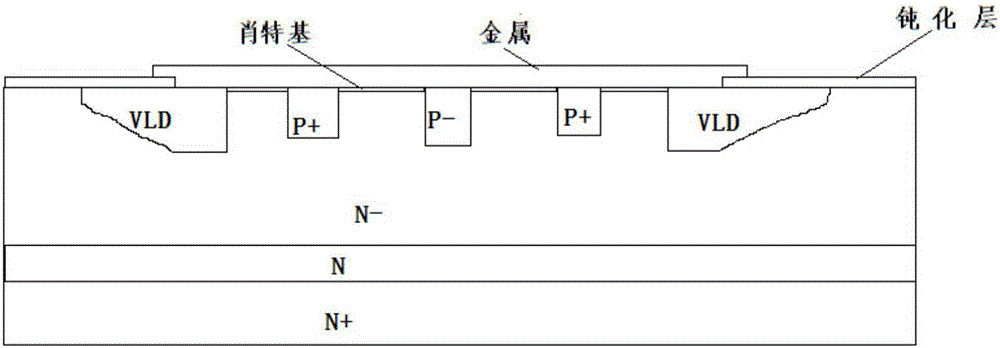

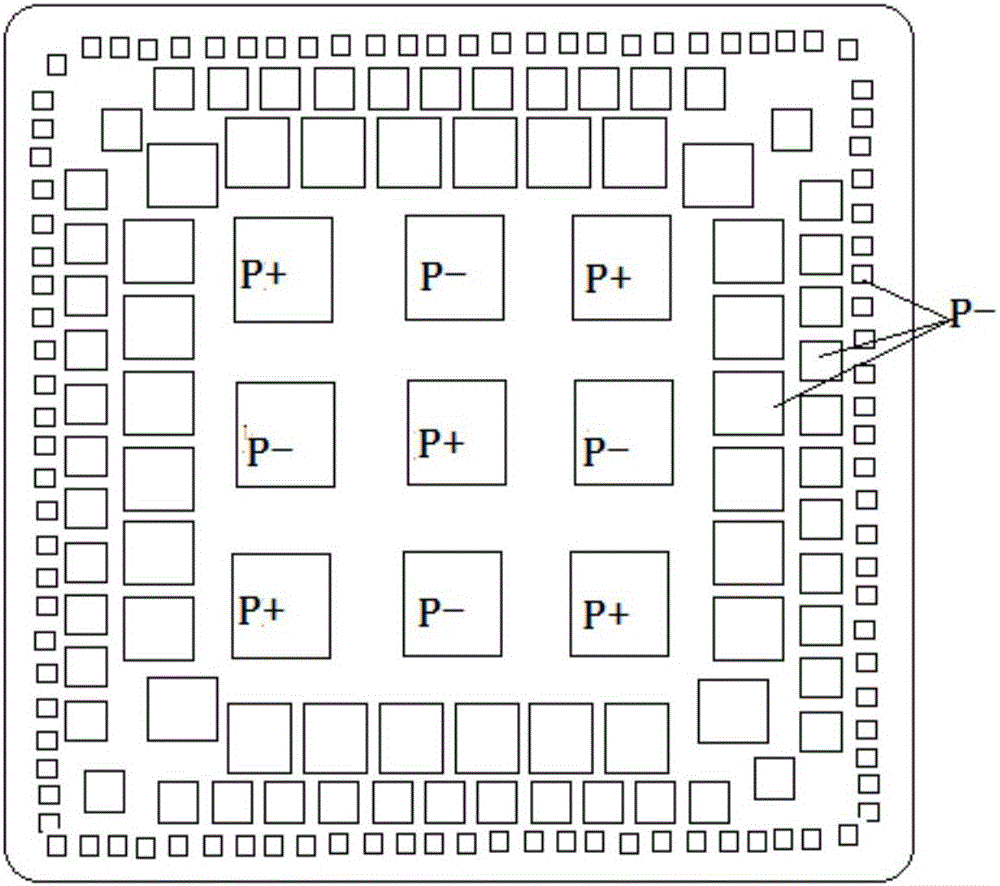

Soft fast recovery diode of multi-mixture structure and preparation method thereof

PendingCN105826399AShort reverse recovery timeLow costSemiconductor/solid-state device manufacturingSemiconductor devicesHigh concentrationReverse recovery

The main purpose of the invention is to provide a high-voltage soft fast recovery diode and a preparation method thereof. According to the invention, a structure in which Schottky is mixed with high-concentration and low-concentration PN junctions is adopted, and varied lateral doping (VLD) plane terminal protection is made synchronously. Thus, the breakdown voltage and anti-surge capability are improved, the recovery time is reduced, the soft recovery characteristic is formed, and a good low-leakage effect is achieved. High-concentration P+ / N- junction, Schottky junction, low-concentration P- / N- junction and Schottky junction structures are made and arranged at intervals on N- / N / N+ silicon wafers. By adding the P- / N- structure, the efficiency of hole injection is reduced, the time for reverse recovery is reduced, reduction in barrier height of a Schottky junction is avoided, and soft fast recovery and low leakage are both achieved. The original structure and the added P- / N- structure form a VLD terminal structure, which ensures high voltage and high anti-surge capability, simplifies the manufacturing process, and reduces the cost. Compared with the tradition fast recovery diode of a PIN and MPS structure, the diode of a multi-mixture structure recovers faster, and has a wider application range.

Owner:北海惠科半导体科技有限公司

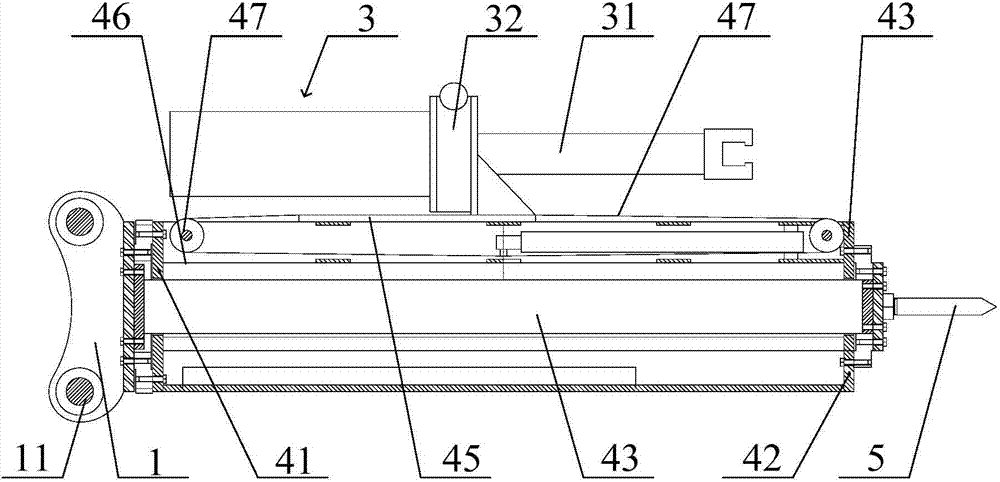

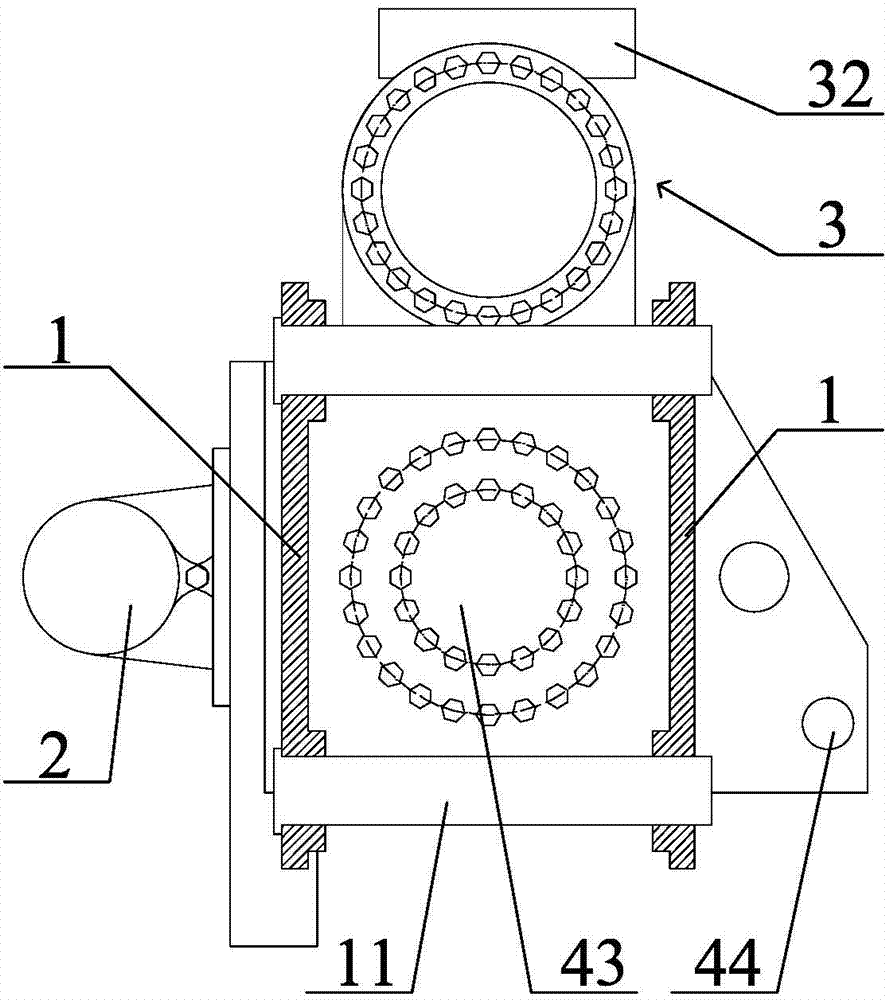

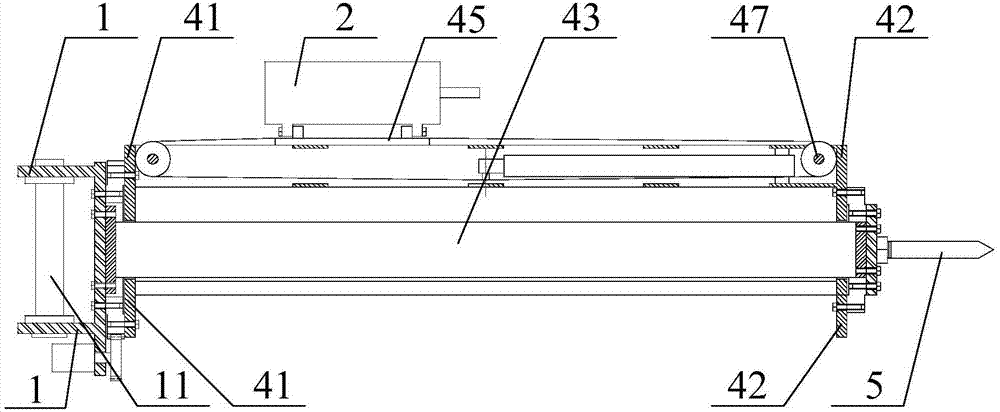

Explosion-free machine and explosion-free excavator

ActiveCN104727819AImprove work efficiencyReduce energy consumptionDisloding machinesSlitting machinesEngineeringExcavator

The invention provides an explosion-free machine and an explosion-free excavator. The explosion-free machine comprises a supporting mechanism, a slewing mechanism, a rock drilling machine and a splitting machine, wherein the slewing mechanism is arranged on the supporting mechanism; the rock drilling machine and the splitting machine are arranged on the slewing mechanism along the axial direction, can be driven to concyclically slew by the slewing mechanism and can move along the axial direction of the slewing mechanism. The explosion-free excavator comprises a hydraulic driving system and the explosion-free machine, wherein the explosion-free machine is fixedly connected to the explosion-free excavator through the supporting mechanism; the hydraulic driving system is capable of driving and controlling the slewing mechanism, the rock drilling machine and the splitting machine. According to the explosion-free machine, the rock drilling machine and the splitting machine can concyclically slew, so that the splitting machine can be accurately inserted into a drill hole without manually adjusting an angle, and the working efficiency of the explosion-free machine is improved; furthermore, the explosion-free machine further has the advantages that the energy consumption is low, the exploitation quantity is high, the equipment cost is low, and the damage caused to equipment in the operation is relatively little.

Owner:武安市精诚机械设备科技有限公司

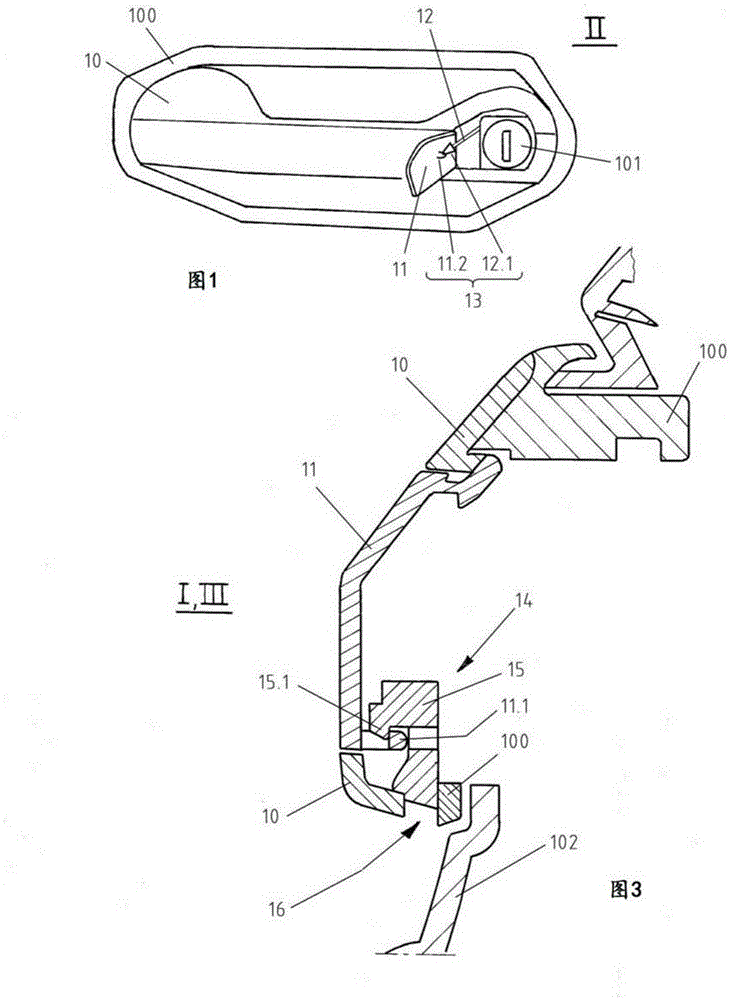

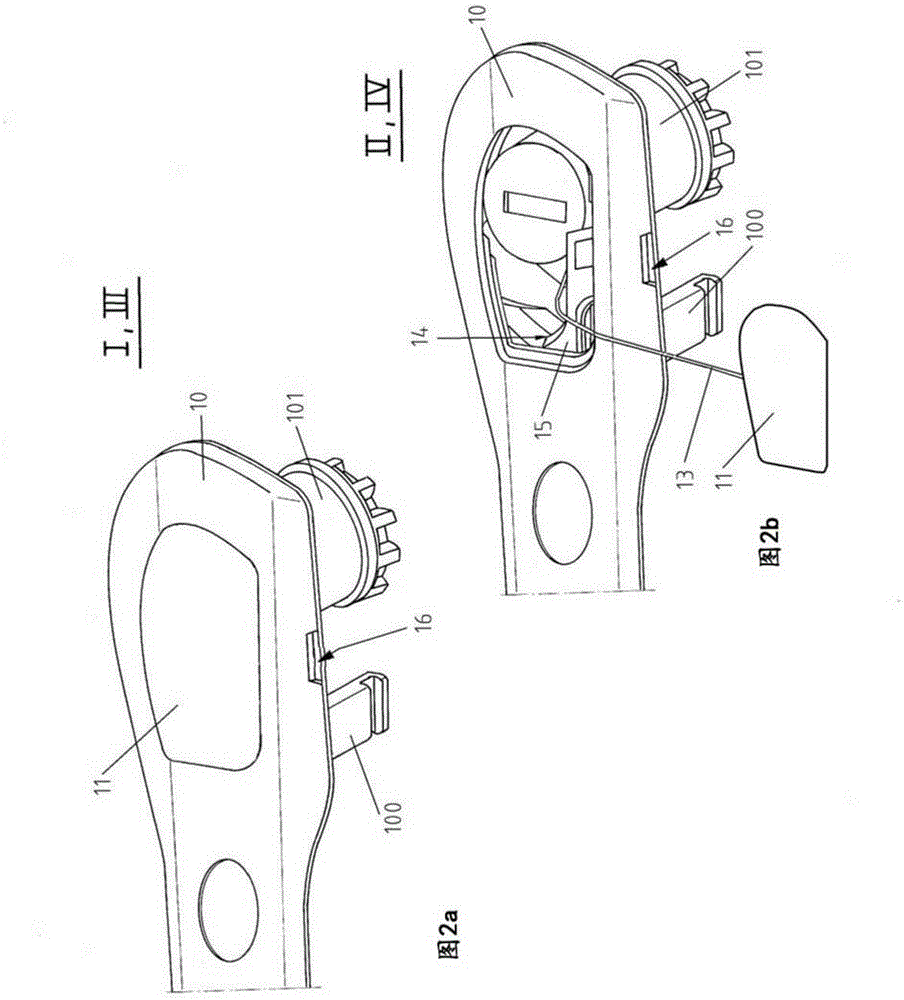

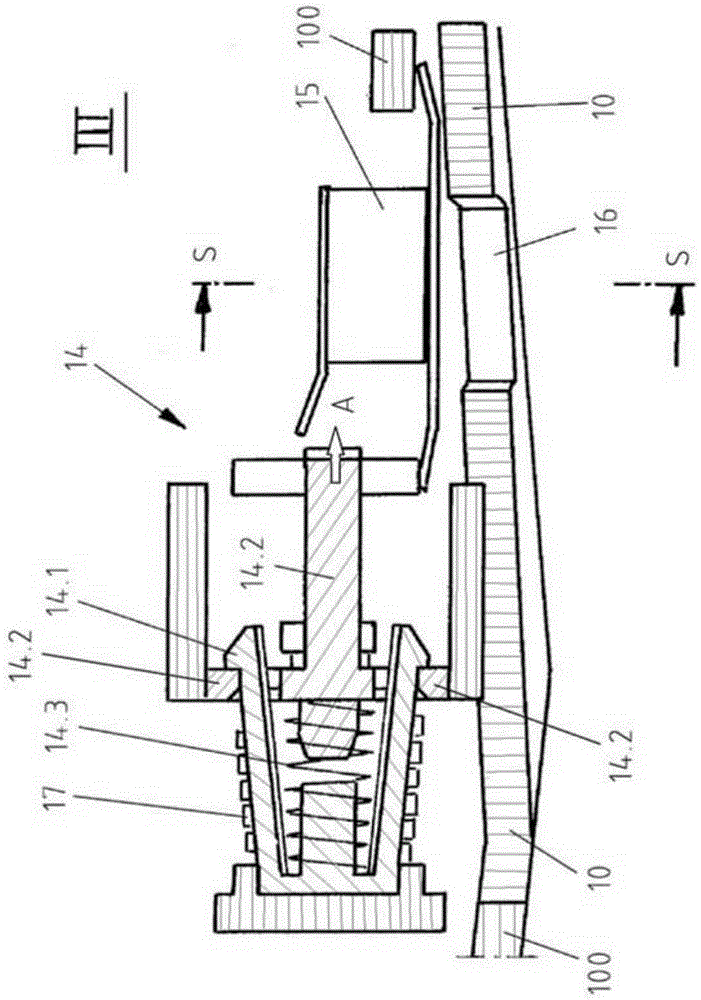

Door handle of a vehicle with a tension means

ActiveCN105604413AAchieve installationFirmly connectedElectrical locking circuitsGlobesClamp connectionEngineering

The invention relates to a door handle (10) for a vehicle door of a motor vehicle, with a removable cover element (11), in particular for covering a lock cylinder (101), wherein the lock cylinder (101) is provided for unlocking and locking a door lock, and wherein the cover element (11) can be transferred between at least two positions (I, II), specifically a covered position (I), in which in particular the lock cylinder (101) is covered by the cover element (11) so as to be inaccessible from the outside, and an open position (II), in which in particular the cylinder lock (101) is uncovered by the cover element (11), and a tension means (12) for actuating the door lock, wherein the tension means (12) can be mechanically operatively connected with the cover element (11) in the open position (II) of the cover element (11), so as to actuate the door lock by pulling on the cover element (11). It is also possible to initially detach the tension means from the cover element, for example by undoing a corresponding connection between the tension means and cover element, such as a form- and / or force fitting connection, clip and / or clamp connection, bayonet connection or the like, and then initiate the opening process directly on the tension means. To this end, the invention proposes that a triggering device (14) be provided for the cover element (11), so as to automatically transfer the cover element (11) into the open position (II), in particular in an emergency situation.

Owner:HUF HULSBECK & FURST GMBH & CO KG

Accumulator

InactiveUS7318452B2Small volumeSolve large capacityAccumulator installationsPipe elementsEngineeringWeld penetration

An accumulator in which a pressure sealed chamber and a pressure flow-in chamber are formed by an operation member including a metallic bellows provided within a housing constituted by a gas end cover and a bottomed tubular shell, wherein a cross sectional inner outline of a peripheral edge portion of the gas end cover is an oval shape which is concave to the pressure sealed chamber side, and a dead space is not formed, so that a capacity of a volume adjusting spacer is reduced by eliminating a dead space, a working step is reduced by simplifying a shape of the gas end cover, and a margin of welding penetration depth is increased by thickening of a backing metal portion.

Owner:NOK CORP

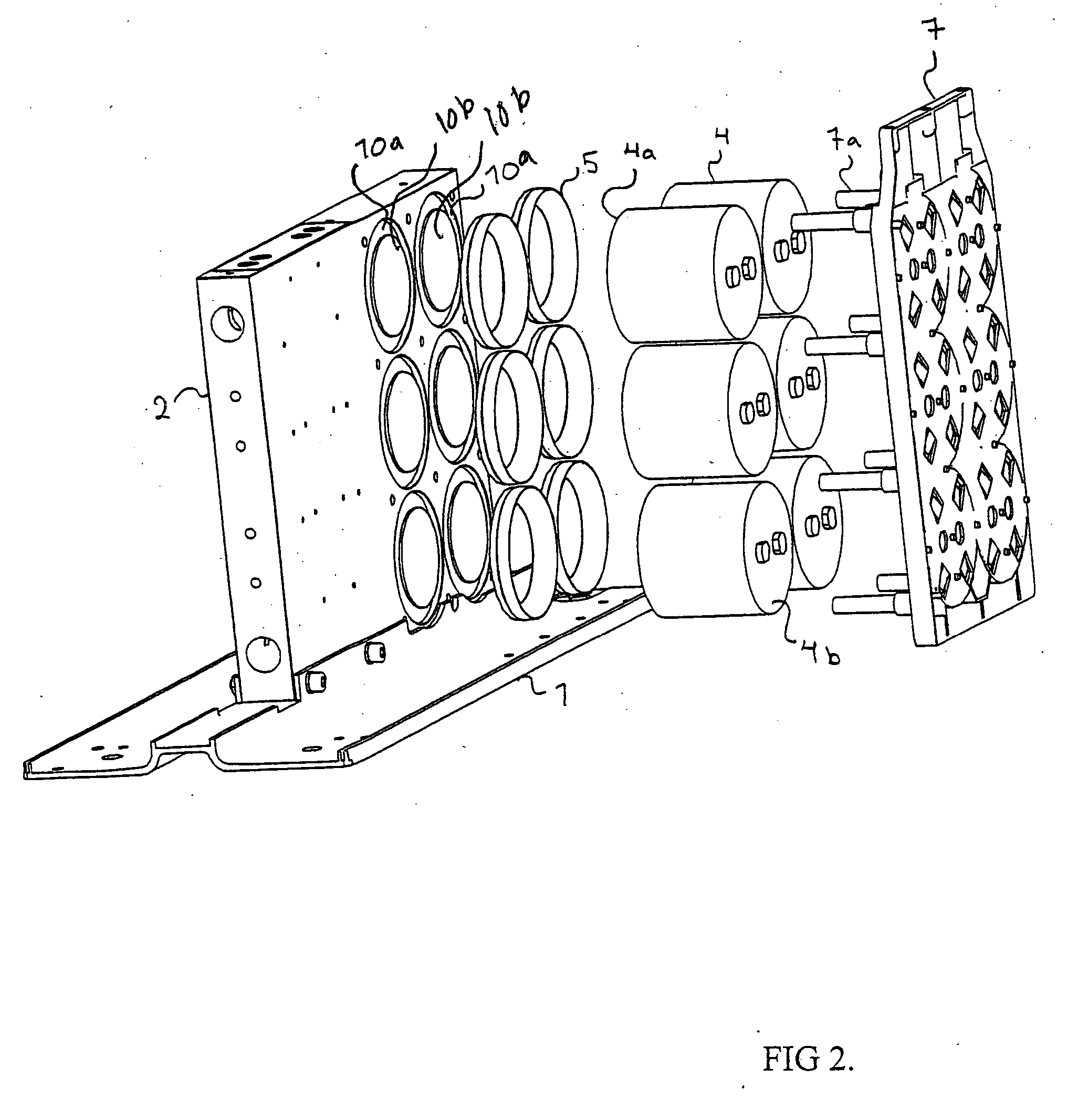

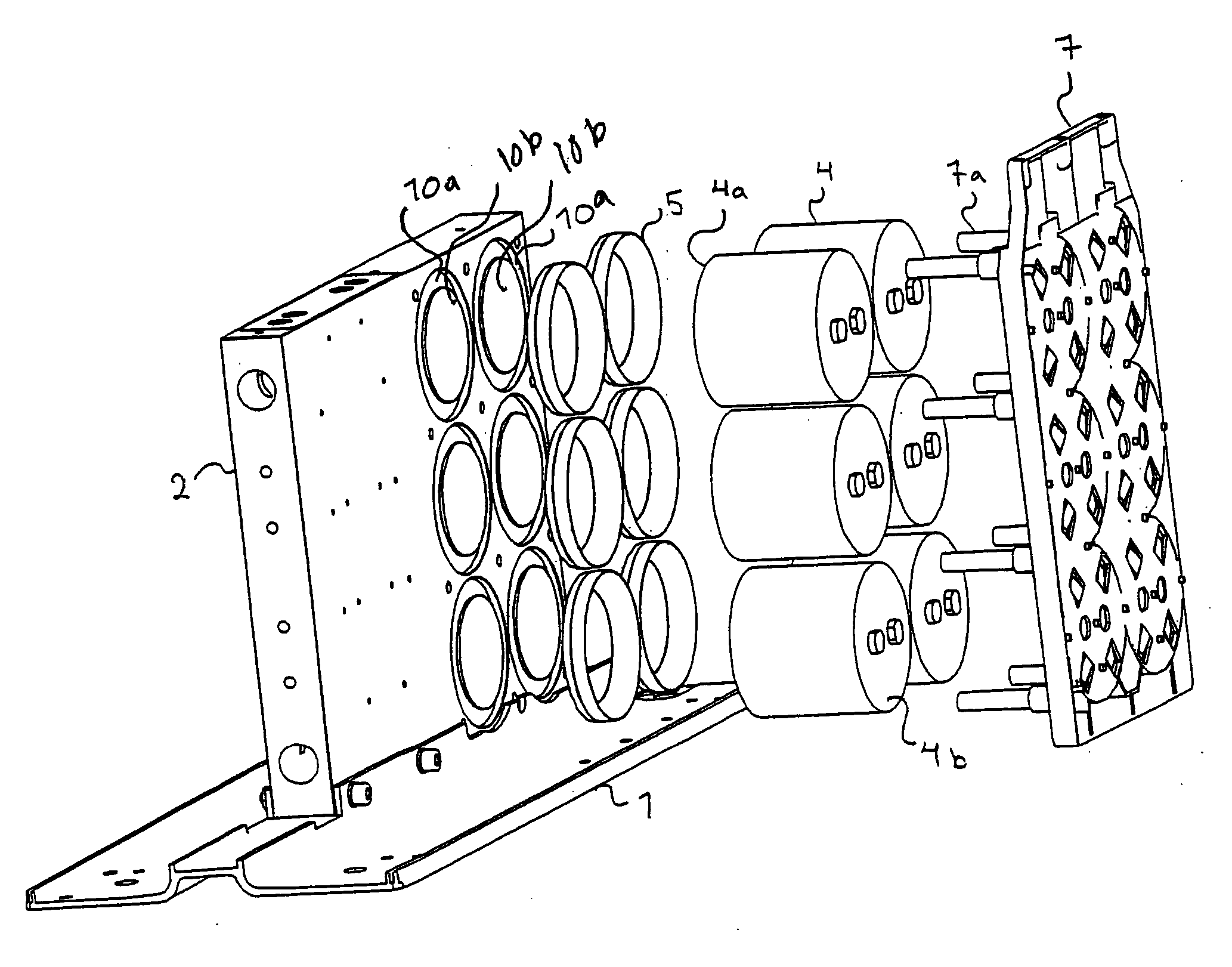

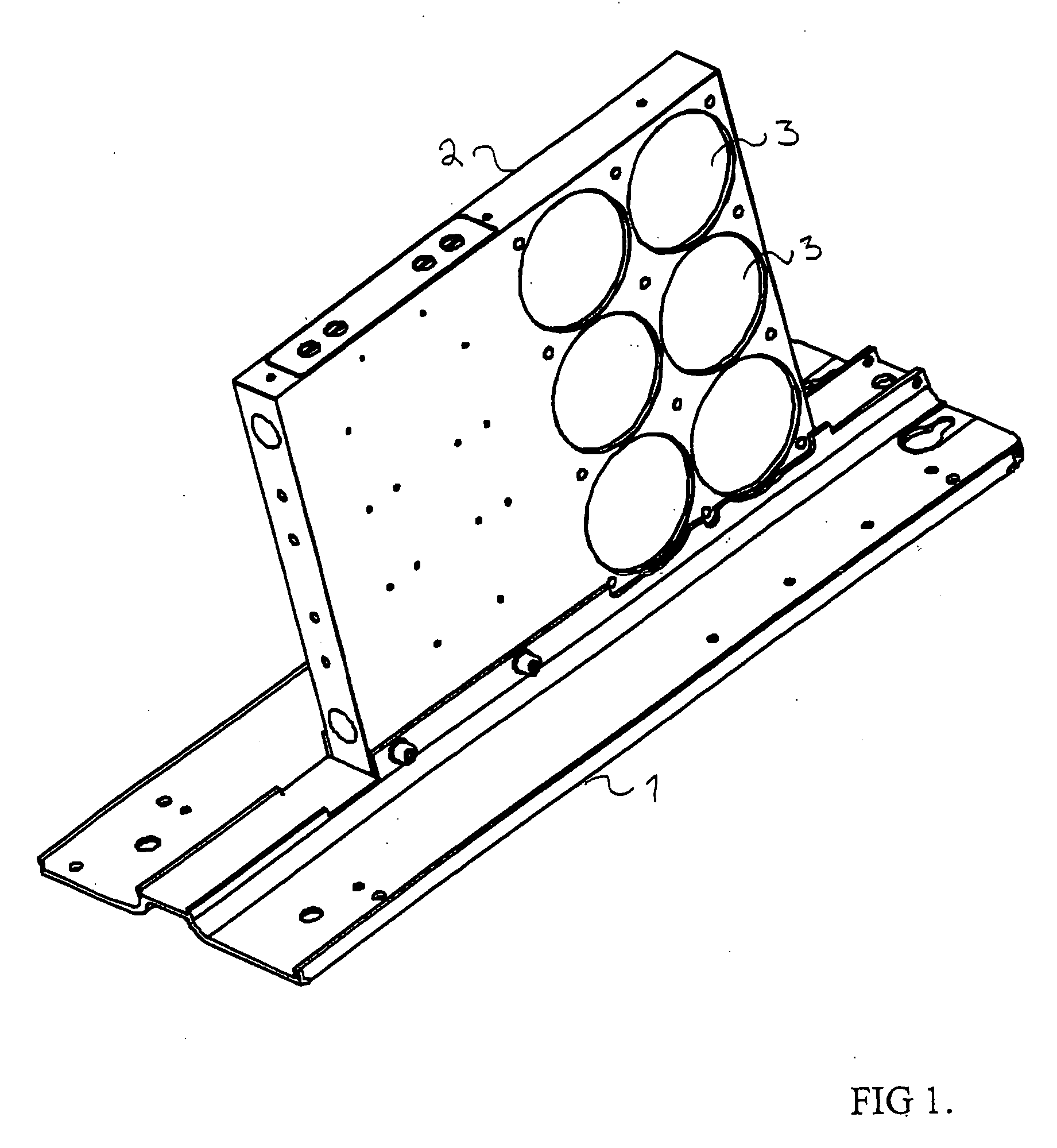

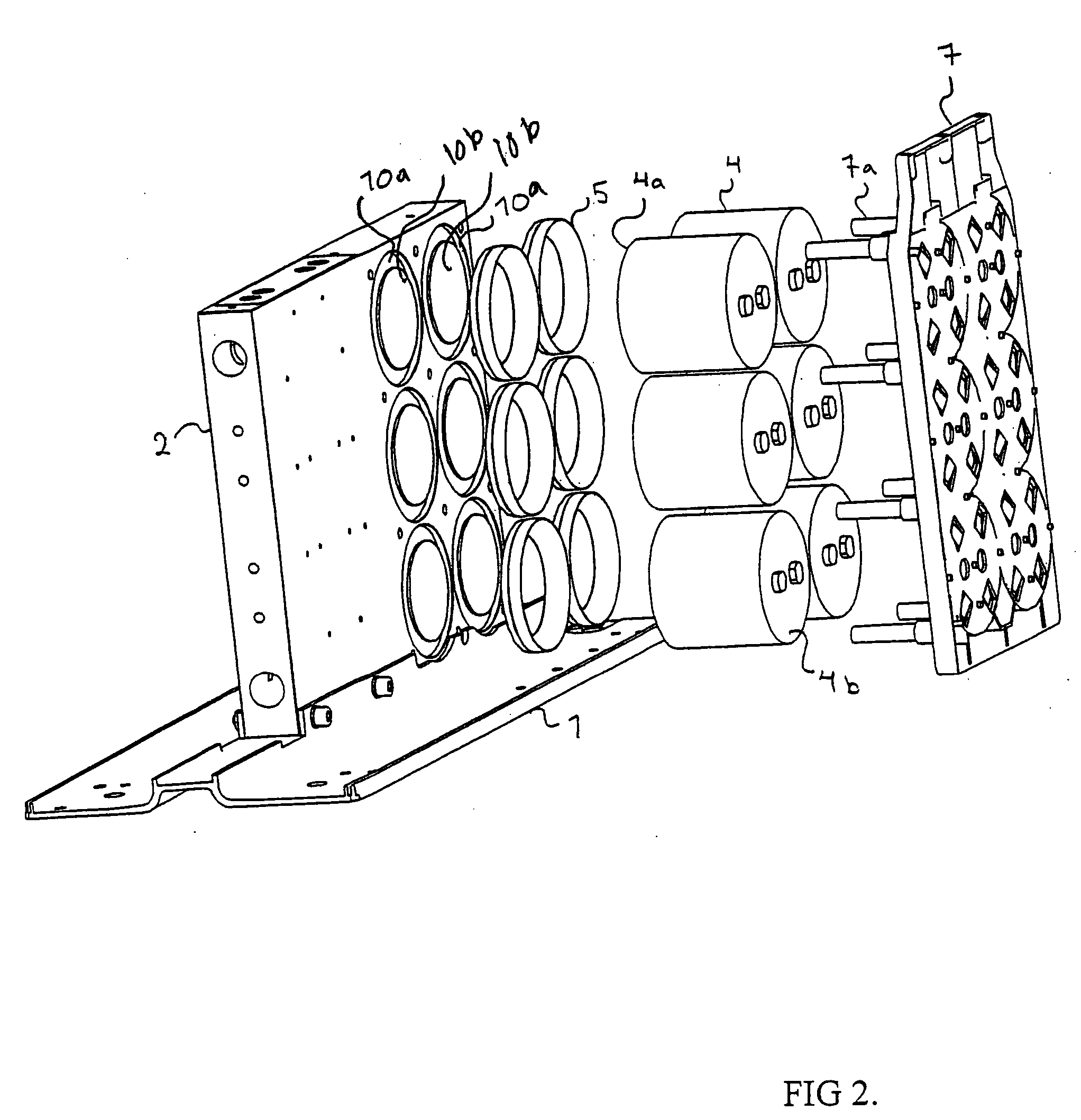

Fixing and protecting arrangement for a capacitor

ActiveUS20050007725A1Effective protection against heatingDrawback can be obviatedMultiple fixed capacitorsMechanically variable capacitorsEngineeringCapacitor

The present invention relates to a fixing and protecting arrangement for a capacitor. The arrangement comprises a cooling element, one or more recesses arranged in the cooling element, and a capacitor intended to be fixed into each recess. The arrangement is characterized in that it comprises one or more recesses arranged in the cooling element, in which recess the capacitor is intended to be arranged in such a way that the lower surface of the capacitor is in contact with the cooling element for transferring heat from the capacitor to the cooling element.

Owner:VACON OY

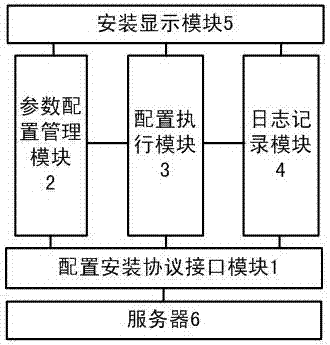

System for configuring hardware test tools to server

ActiveCN106919485AImprove the efficiency of installation test toolsImprove efficiencyFaulty hardware testing methodsNetwork interface controllerMotherboard

The invention provides a system for configuring hardware test tools to a server. The system comprises a configuration installation protocol interface module, a parameter configuration management module, a configuration execution module, a log record module and an installation display module. The configuration execution module is used for uploading a CPU test tool, a memory test tool, a hard disk test tool, a network interface card test tool, a mainboard test tool and test tool scripts to the server according to parameters configured by the parameter configuration management module, and sending environment variables to the server and configuring the test tools, so that CPU test tool installation, memory test tool installation, hard disk test tool installation, network interface card test tool installation, mainboard test tool installation, test tool scripts installation, and test database installation are achieved. The test tools are automatically installed to the server, working steps of personnel are reduced, and efficiency of installing the test tools to the server can be improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

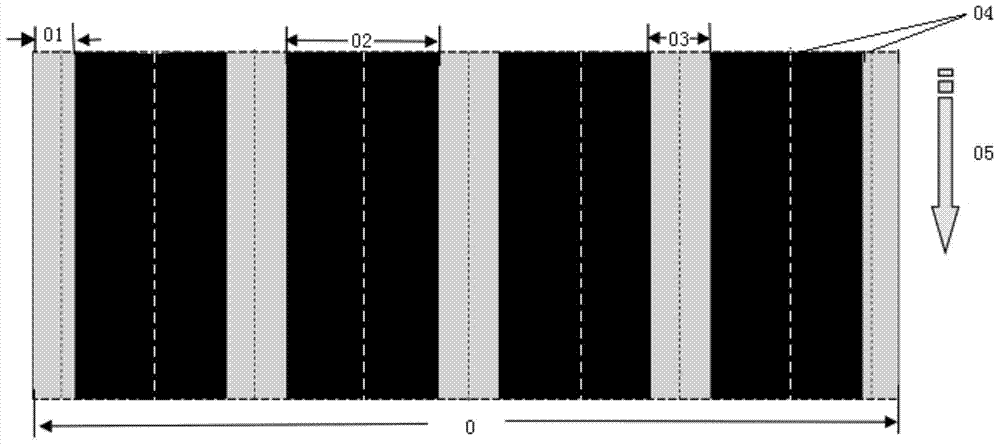

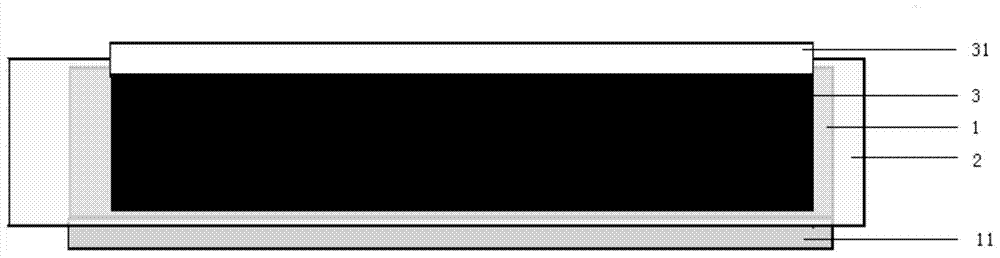

Preparation method of cylindrical battery free of tab welding

ActiveCN105449291ALower internal resistanceReduce work stepsFinal product manufactureSecondary cellsPositive currentEngineering

The invention is applicable to the field of cylindrical batteries, and provides a preparation method of a cylindrical battery free of tab welding. The method comprises the steps as follows: a positive plate base material and a negative plate base material are coated in a longitudinal intermittent manner; a positive plate and a negative plate are respectively obtained after slitting; a blank is formed in one side of each of the positive plate and the negative plate; the positive plate, a diaphragm and the negative plate are wound into a roll core after being sequentially stacked; one end, with the blank, of the positive plate and one end, with the bank, of the negative plate are arranged at the outer sides of two long sides of the diaphragm; the blanks are exposed on the edges of the diaphragm; foils with the exposed blanks are flattened to form flat and smooth positive and negative foil table boards; a negative current collector with a boss is pressed on the negative foil table board of the roll core and laser welding is carried out to form a negative welding spot; and a positive current collector with a center hole is pressed on a positive foil table board of the roll core and laser welding is carried out to form a positive welding spot.

Owner:DONGGUAN CHUANGMING BATTERY TECH

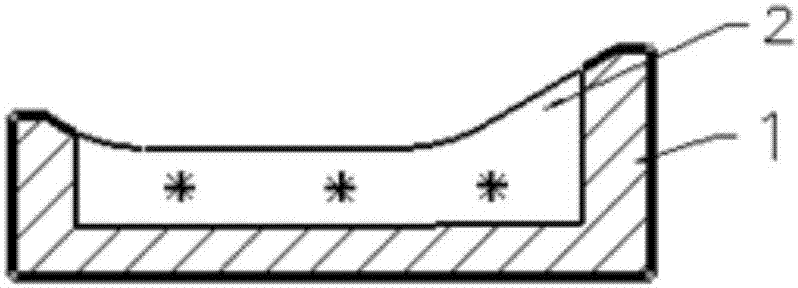

Novel high-pressure-resistant sealing system for automobile engine and manufacture method thereof

InactiveCN102558717ADimensionally stableReduce pollutionOther chemical processesChemical industryAdhesiveReciprocating motion

The invention relates to a novel high-pressure-resistant sealing system for an automobile engine and a manufacture method thereof. The manufacture method includes: step 1, improving definite elongation of rubber, adjusting proportion of raw materials of the rubber, adjusting a reinforcement system and improving definite elongation of the rubber so as to improve pressure resistance of the rubber by specifically increasing 3-4 parts by weight of white carbon black and reducing1-2 parts by weight of carbon black; and step 2, improving hardness of the rubber and increasing abrasion resistance of the rubber by increasing 30-40 parts by weight of wollastonite. The novel high-pressure-resistant sealing system has the advantages of being stable in size, oil resistant and anti-aging in engine oil, being low in friction factor, slow in temperature rise in unit time and abrasion resistant in valve guide rod reciprocating motion, enabling medium and high pressure resistance of a turbine to be increased, being capable of using environment-friendly adhesive for bonding, reducing pollution on environment, shortening vulcanizing time of an oil seal, saving energy, ensuring sealing reliability, prolonging service life of the oil seal and the like.

Owner:HUNAN MASTER SEALING

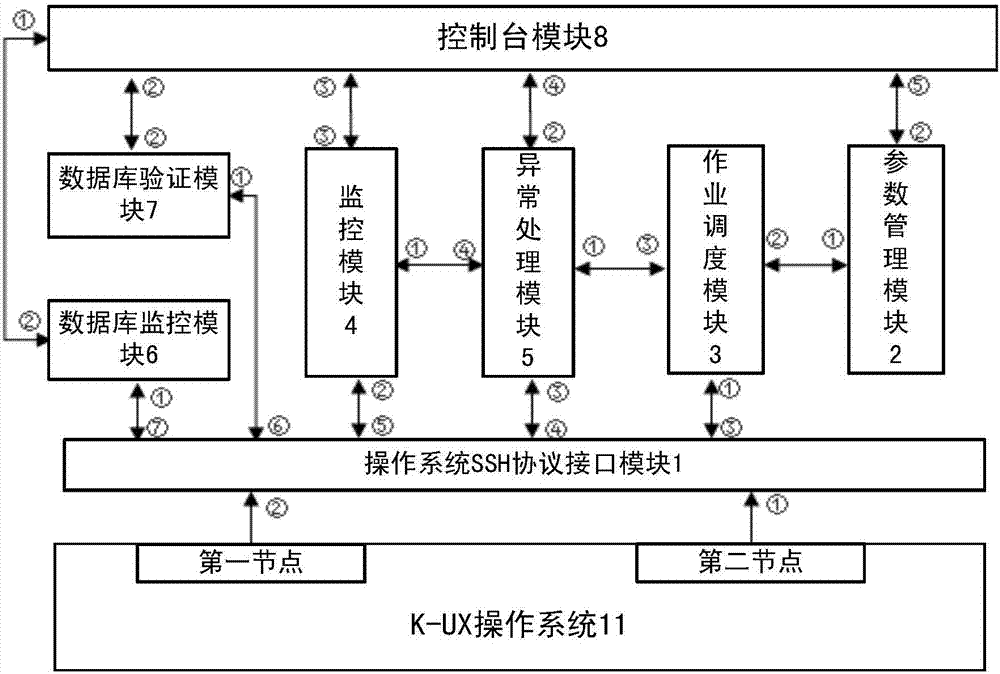

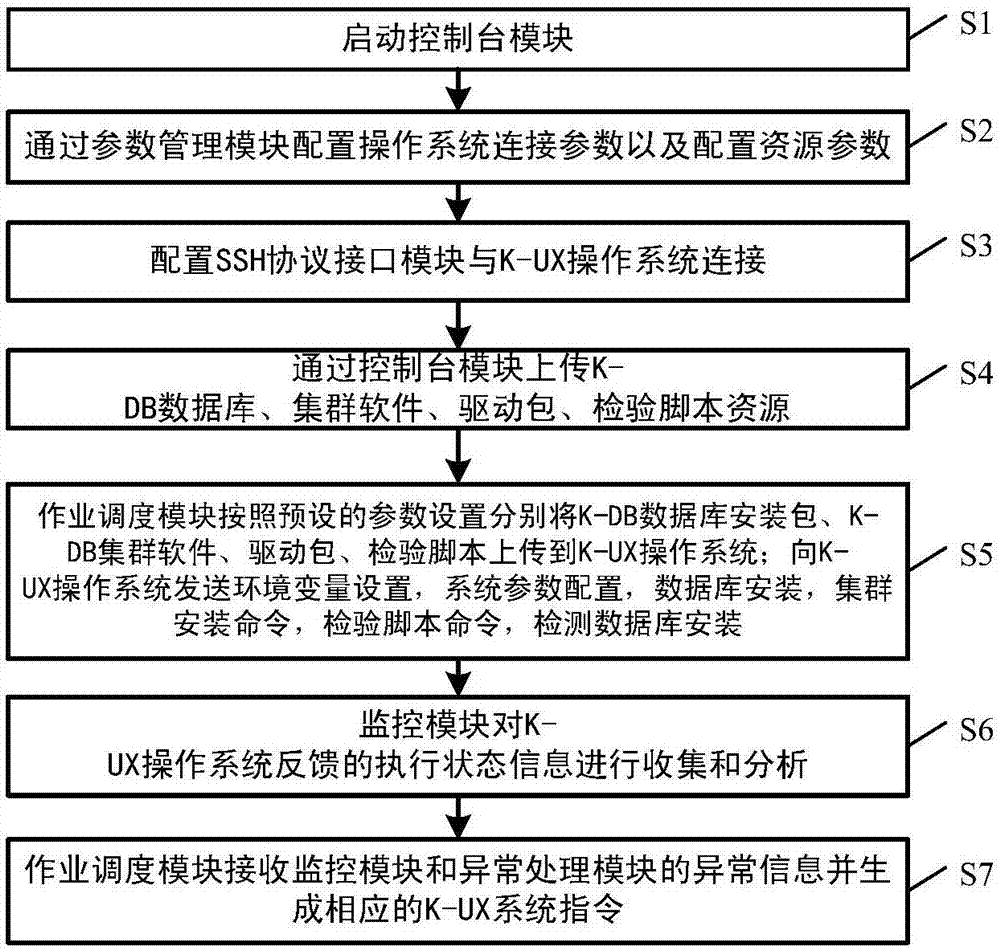

System and method for establishing database cluster in K-UX operation system

InactiveCN107066261AQuick installationQuick verificationProgram initiation/switchingVersion controlOperational systemDeployment time

The invention provides a system and a method for establishing a database cluster in a K-UX operation system. The system comprises an operation system SSH protocol interface module, a parameter management module, a job scheduling module, a monitoring module, an exception processing module, a database monitoring module, a database verification module and a console module. According to the system for establishing the database cluster in the K-UX operation system, a K-DB database cluster is installed and verified automatically, so that the working steps of implementation personnel are reduced; the efficiency of establishing and detecting the K-DB database cluster in the K-UX operation system can be greatly improved, so that the working time of the implementation personnel is shortened; by installing and verifying the K-DB database cluster in the K-UX operation system, the deployment time of the implementation personnel can be greatly shortened; and a solution for quickly installing and verifying the database cluster is provided for the K-UX operation system.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Rotary electric machine and electric wheelchair mounted with rotary electric machine

InactiveUS7642686B2Lower resistanceReduce work stepsMagnetic circuit rotating partsElectric devicesWheelchairElectric machine

A rotary electric machine includes a stator including a plurality of teeth, a coil wound around each tooth, and a stator yoke core that connects the respective teeth, the teeth and the stator yoke core integrally fixed by a molding resin. The rotary electric machine also includes a rotor with a plurality of magnets that face the teeth, the magnets and teeth separated from each other by a space therebetween. Each of the teeth comprises a head portion facing opposite the magnets, a coil wind-up portion around which the coil is wound up, and an insert portion that can be inserted into the stator yoke core, the insert portion including a groove formed in a portion of the insert portion that protrudes from the stator yoke core, where the groove is fillable with the molding resin to inhibit the teeth from disengaging from the stator yoke core.

Owner:YAMAHA MOTOR CO LTD

Cleaning and sterilization device for obstetrics and gynecology

InactiveCN107174728AHinder disinfection workAvoid getting dirtyMedical devicesMedical applicatorsObstetric historyEngineering

The invention discloses a cleaning and sterilization device for obstetrics and gynecology and mainly relates to the field of medical apparatus and instruments. The device comprises a waste liquid box, wherein a liquid collection plate is arranged on the water liquid box, a water liquid groove is formed in the liquid collection box, and a sliding groove is formed in the liquid collection plate; a limiting plate is arranged in the sliding groove, a leg blocking plate is arranged on the limiting plate, and two support plates are arranged on the back portion of the liquid collection plate; one end, close to the liquid collection plate, of each support plate is close to the top end of the back side wall of the water liquid groove, an extension plate is arranged between the support plates in a sliding mode, and the sliding groove is formed in the bottom of the extension plate; the extension plate slides along the support plates, and a device which is used for clamping a liquid medicine bottle is arranged on the side wall of the waste liquid box. The cleaning and sterilization device for the obstetrics and gynecology has the advantages that the device can extend to and be placed on the lower portion of a body of a person to be examined, it is convenient to separate two legs of the person, and the situation that when the person is subjected to medicine liquid or apparatus stimulation, the legs move, and continuous cleaning and sterilization work of doctors is hampered is avoided; it is convenient to receive waste medicine liquid after cleaning and sterilization, the situation that clothes or bed sheets of the person to be examined are dirty is avoided, the working steps are reduced, the efficiency is improved, the waste is reduced, and the device is convenient to use.

Owner:柳荣华

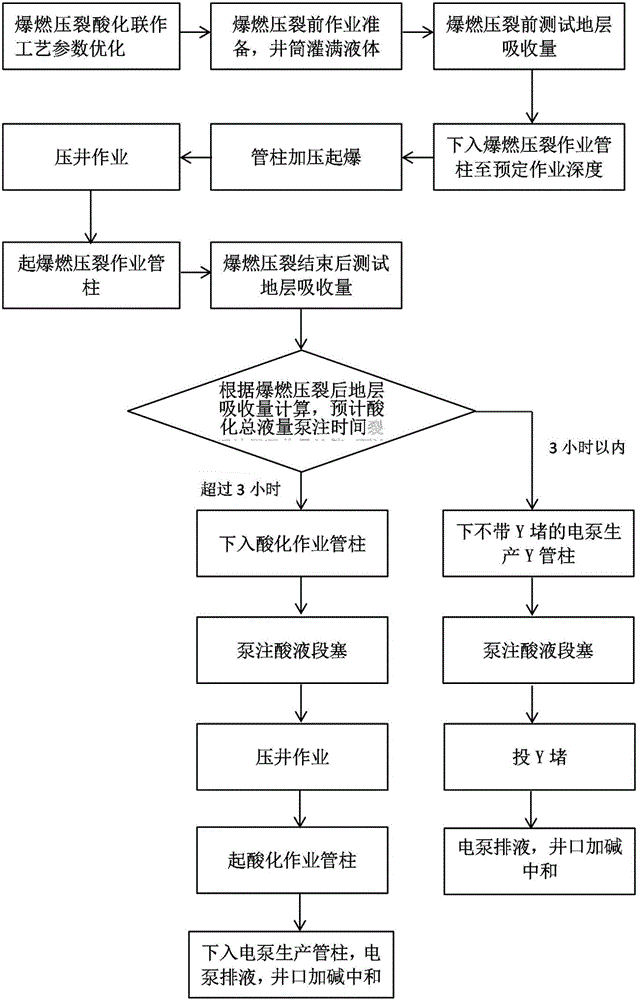

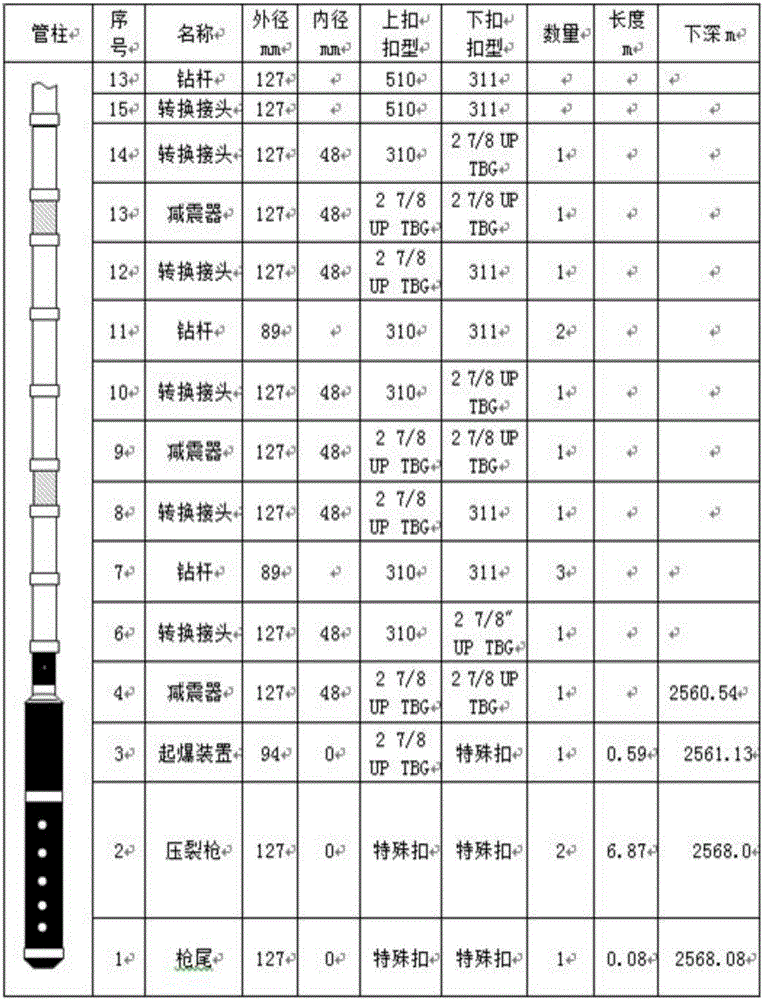

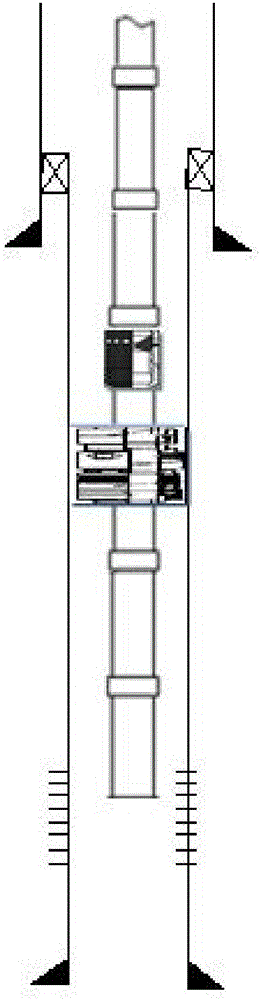

Method for detonation fracture acidizing combined operation

ActiveCN106246156AEnhancing the effectiveness of deflagration fracturingGuaranteed work effectFluid removalDrilling compositionWell killDetonation

The invention discloses a method for detonation fracture acidizing combined operation. The method comprises the steps of optimizing detonation fracture acidizing combined operation process parameters, performing operation preparation before detonation fracture and filling a pitshaft with liquid, testing stratum absorption amount before the detonation fracture, placing a detonation fracture operation tubular column to a predetermined operation depth, performing pressurization detonation of the tubular column, performing well killing operation, detonating the fracture operation tubular column, testing the stratum absorption amount after the detonation fracture, placing an acidizing operation tubular column, performing pumping injection acid liquid slug, lifting the acidizing operation tubular column, placing an electric pump production tubular column and performing electric pump liquid drainage and well opening alkalifying neutralization, placing an electric pump production Y tubular column without a Y tubular column, performing pumping injection of acid liquid slug, placing the Y tubular column, performing electric pump liquid drainage and well opening alkalifying neutralization and the like. The method has the advantages that detonation fracture and acidizing effects can be further enhanced, the acid liquid injection capability is enhanced, the acidizing radius is expanded, crack closure is further avoided, and a physical effect is enhanced; a detonation fracture effect can be enhanced, a follow-up acidizing step is selected flexibly, and the operation step is omitted while an operation effect can be guaranteed.

Owner:CHINA NAT OFFSHORE OIL CORP +1

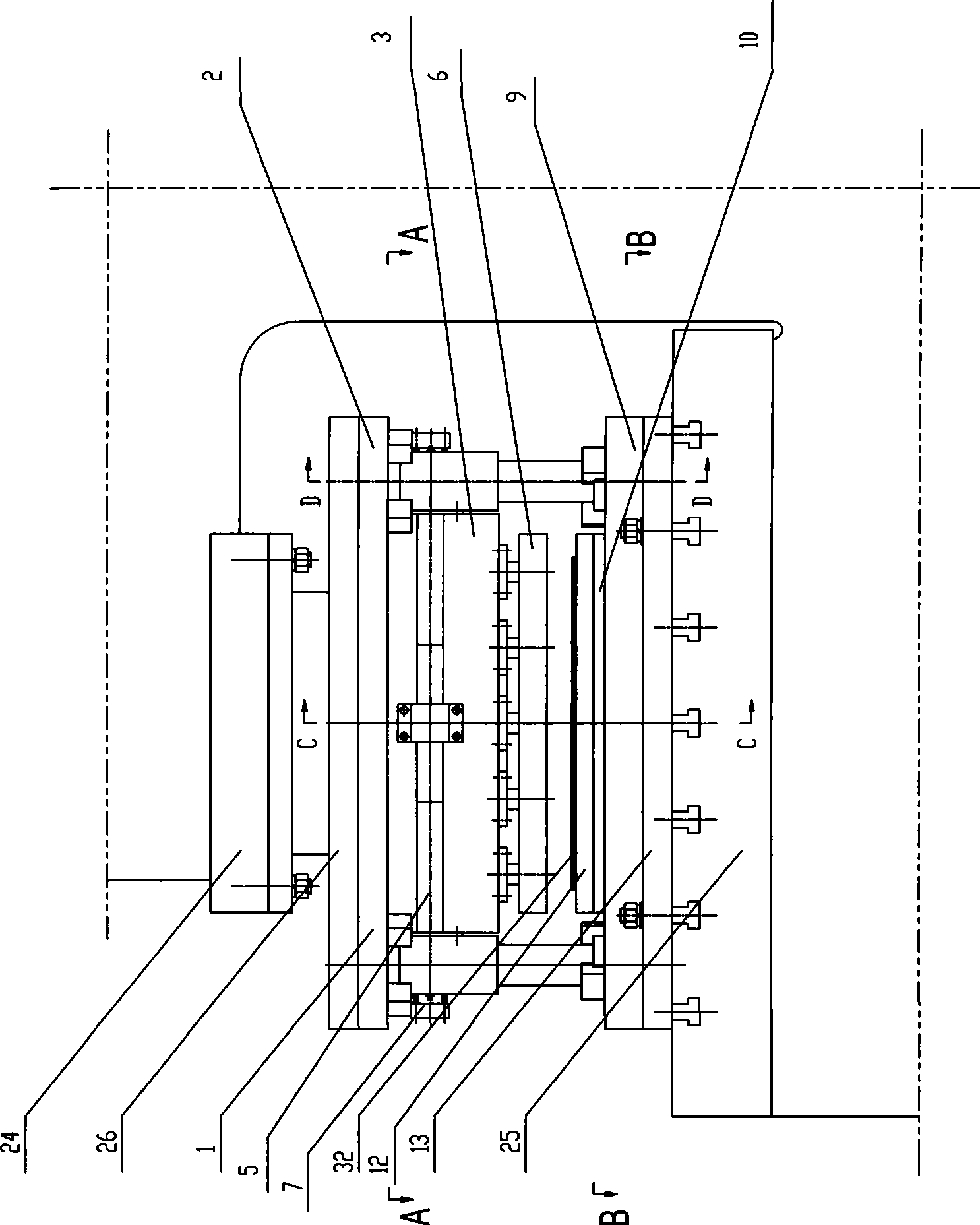

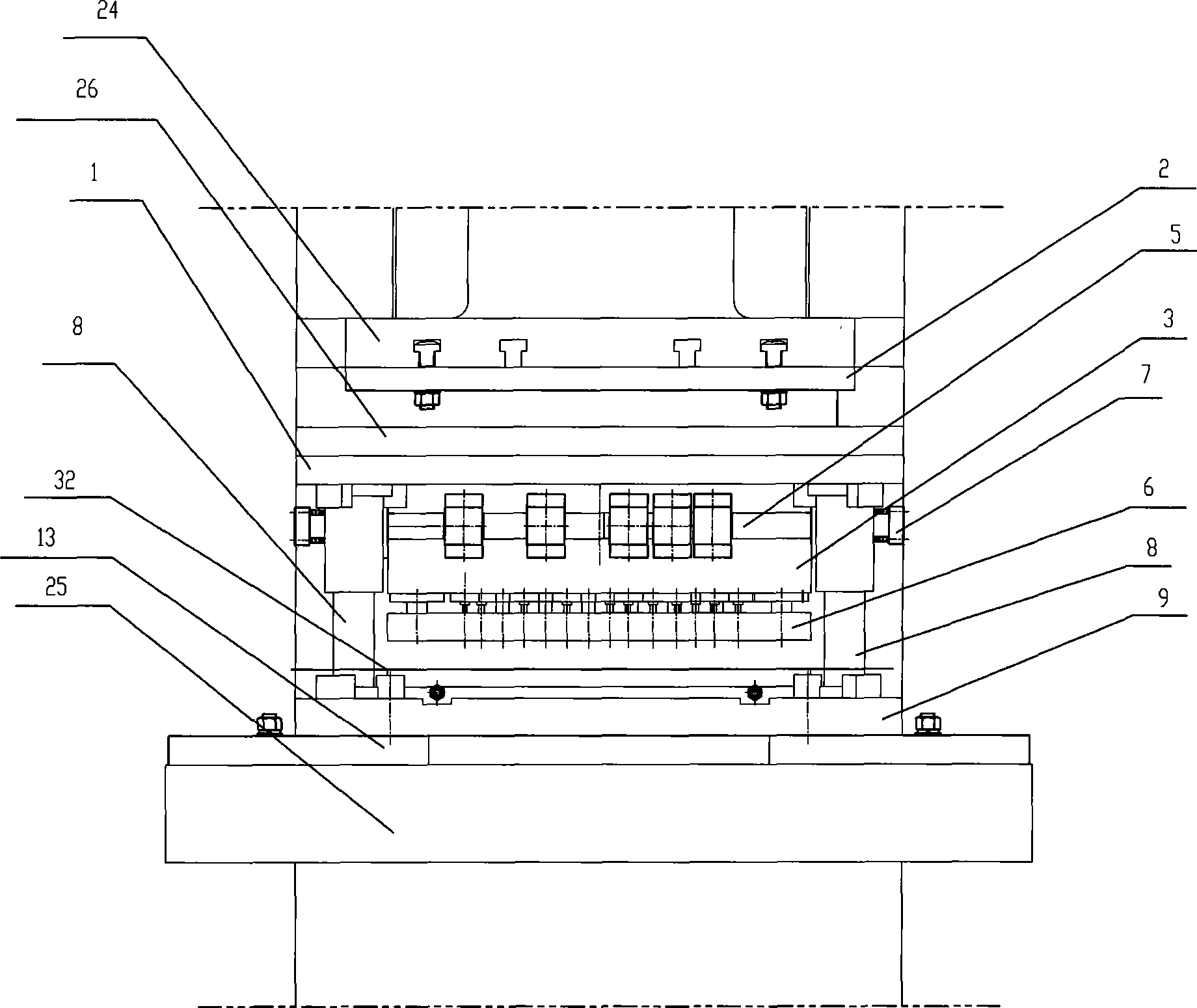

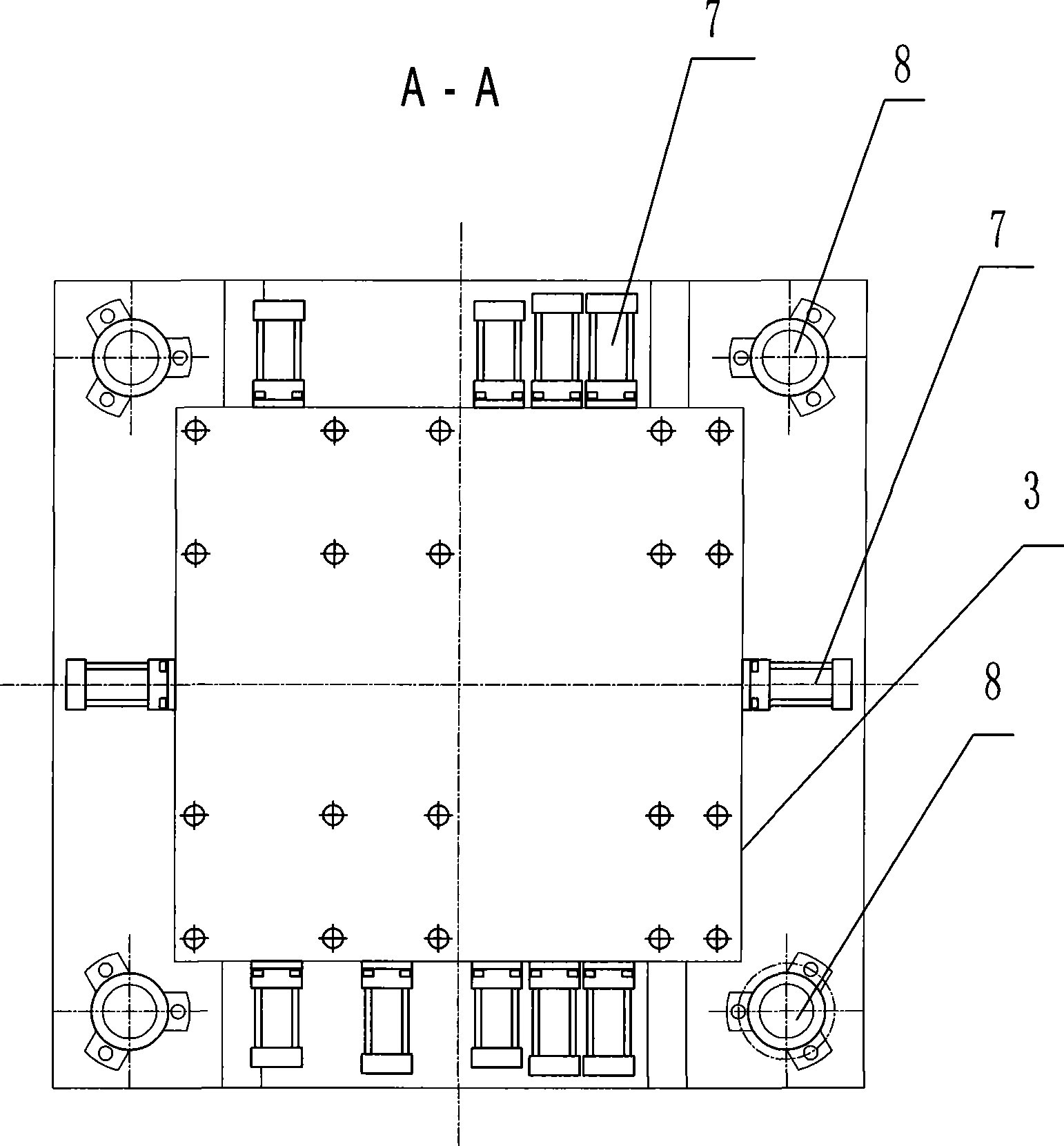

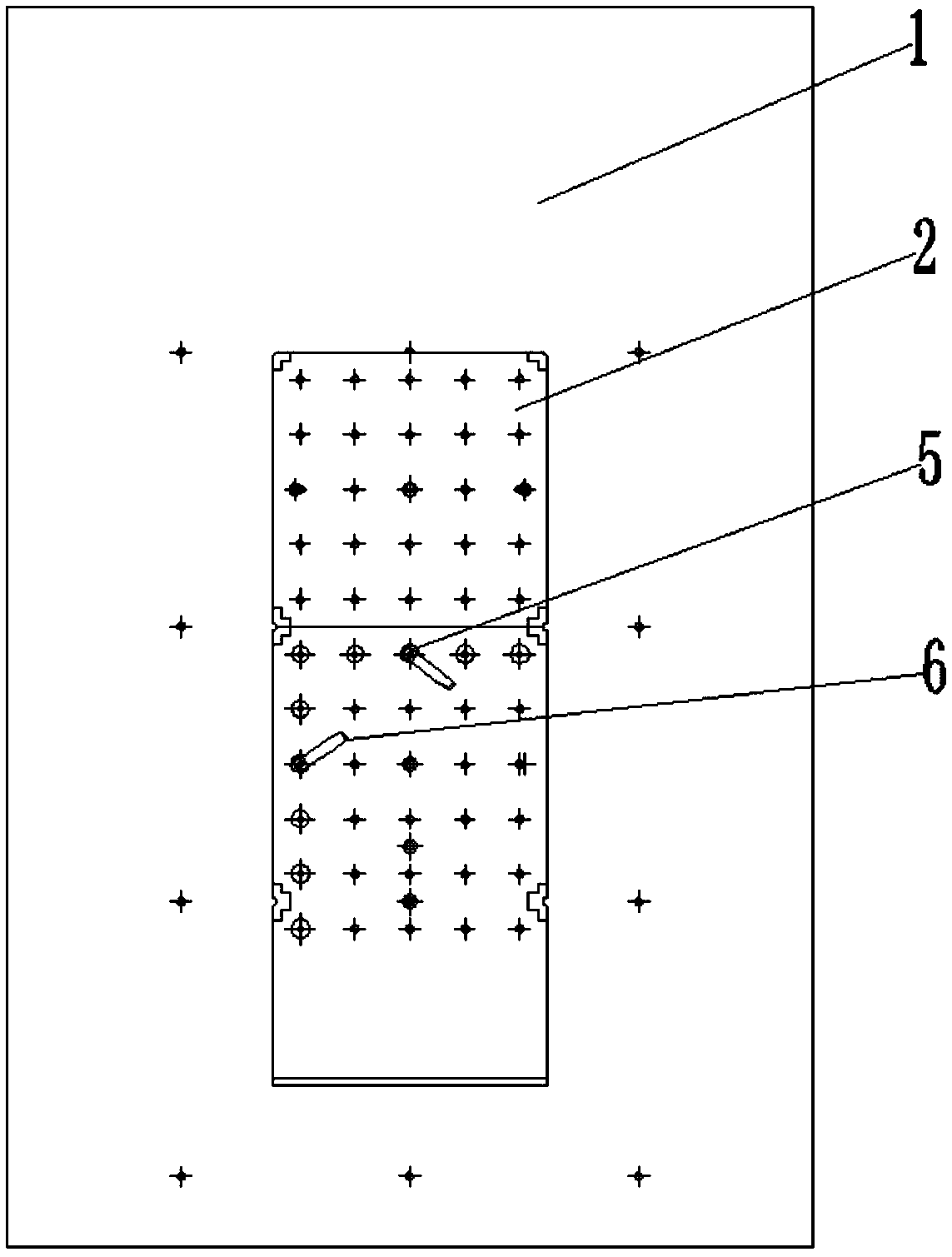

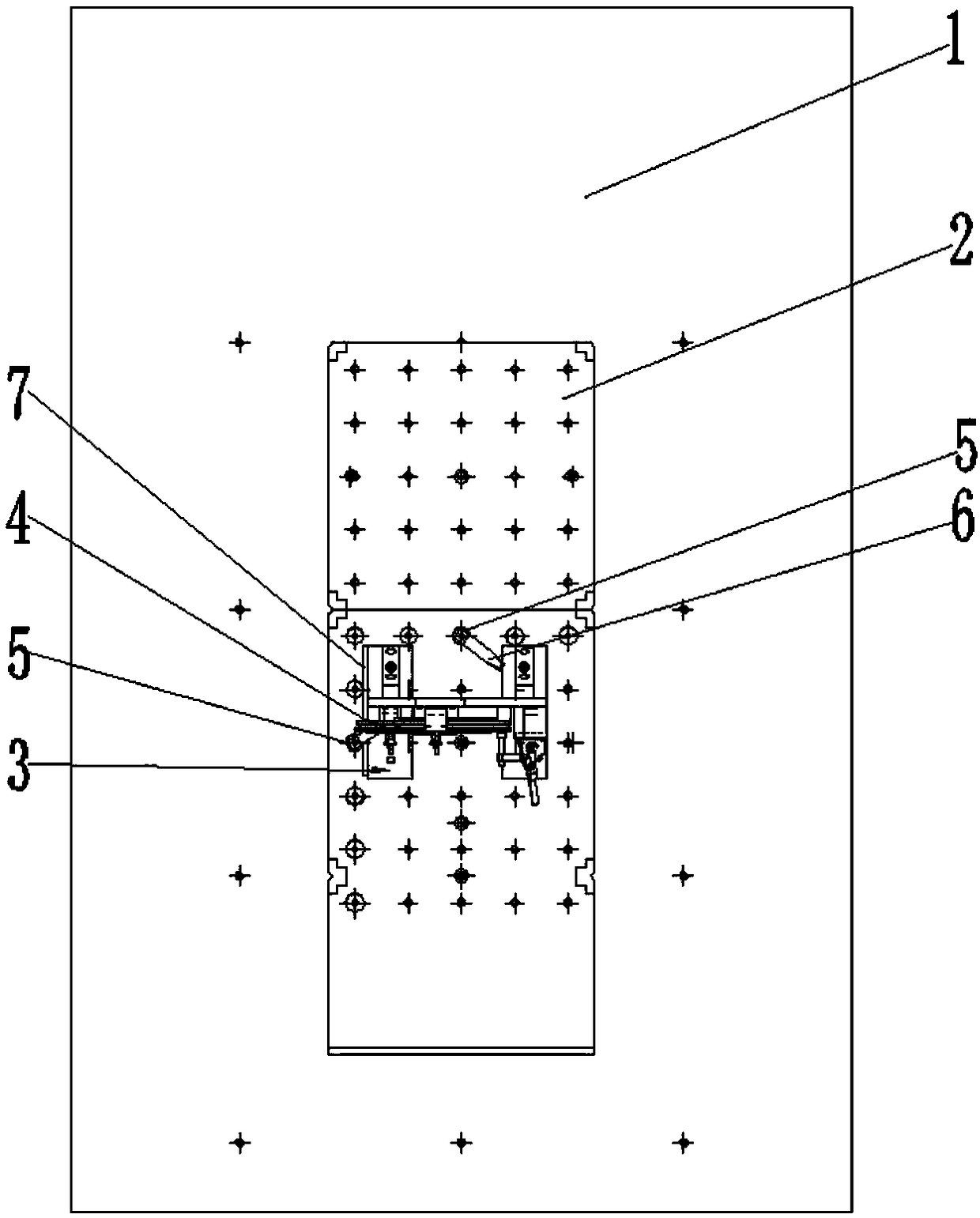

Punching device for bridge plate production line

InactiveCN101444809AReasonable designCompact structureShaping toolsPerforating toolsProduction linePunching

The invention relates to a punching device for bridge plate production line. The punching device is characterized in that the punching device consisting of a square frame body, an II# upper connecting plate, a core plate, an inserting plate, a cylinder, a stripper plate, a cavity plate, a cavity bottom plate and a liner plate is installed in a transition bracket between the upper operating platform and the lower operating platform of a press, and a lower plate in the square frame body is arranged on the liner plate; the bottom surface of an I# upper connecting plate is connected with the II# upper connecting plate, and the core plate of a core die set is arranged on the bottom surface of the II# upper connecting plate; a pressing plate, the stripper plate and the cavity plate are installed on the bottom surface of the core plate in sequence; the inserting plate driven through the cylinder is installed in the core plate between core plate and the II# upper connecting plate. The punching device has the advantages that the design is reasonable, the structure is compact, not only punching and flanging can be simultaneously realized, but also the punched hole has accurate position, the production efficiency is high, the product quality is good, the labor intensity is low, the operation is safe, and the use is very convenient.

Owner:DALIAN SAGE GROUP

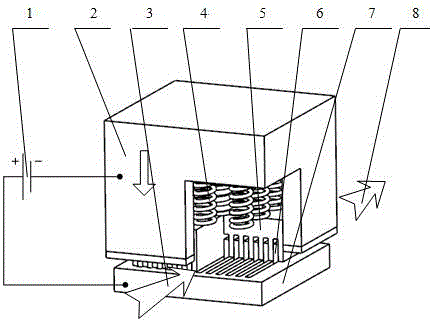

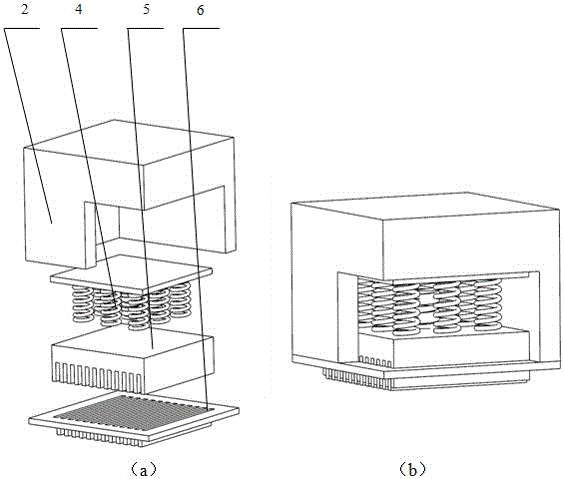

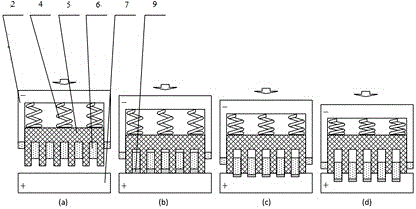

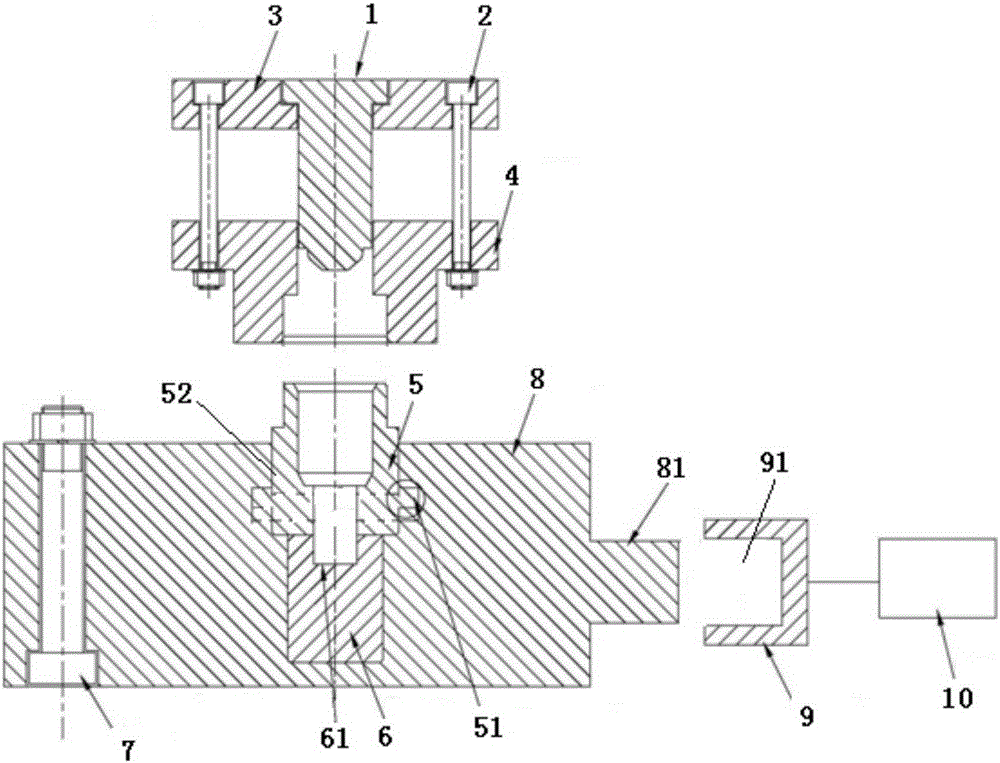

Electrolytic machining tool and method for groove group of expanding-comb-shaped liquid sealing structure

ActiveCN106670598AImprove electrolyte flow fieldImprove processing stabilityElectrical-based machining electrodesEngineeringElastomer

The invention relates to an electrolytic machining tool and method for a groove group of an expanding-comb-shaped liquid sealing structure, and belongs to the field of electrochemical machining. The tool comprises a tool base (2), an elastomer (4), a comb-shaped liquid sealing body (5) and a negative plate (6). The comb-shaped liquid sealing body (5) is made from an insulating material. The rear end of the comb-shaped liquid sealing body (5) is connected with the tool base (2) through the elastomer (4). The front end of the comb-shaped liquid sealing body (5) is provided with an ordered protruding structure matched with a hollowed-out seam group structure of the negative plate (6), and the height of the protruding structure is greater than the thickness of the negative plate. During working, the ordered protruding structure of the comb-shaped liquid sealing body (5) is inserted into the hollowed-out seam group structure of the negative plate (6) and can slide relative to the negative plate mutually. The sections (9) of electrolyte runners are a plurality of separated rectangular runners always until the groove group structure is machined and the problem that flow of electrolyte is split by clearance grooves during electrolytic machining for the groove group is thoroughly solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

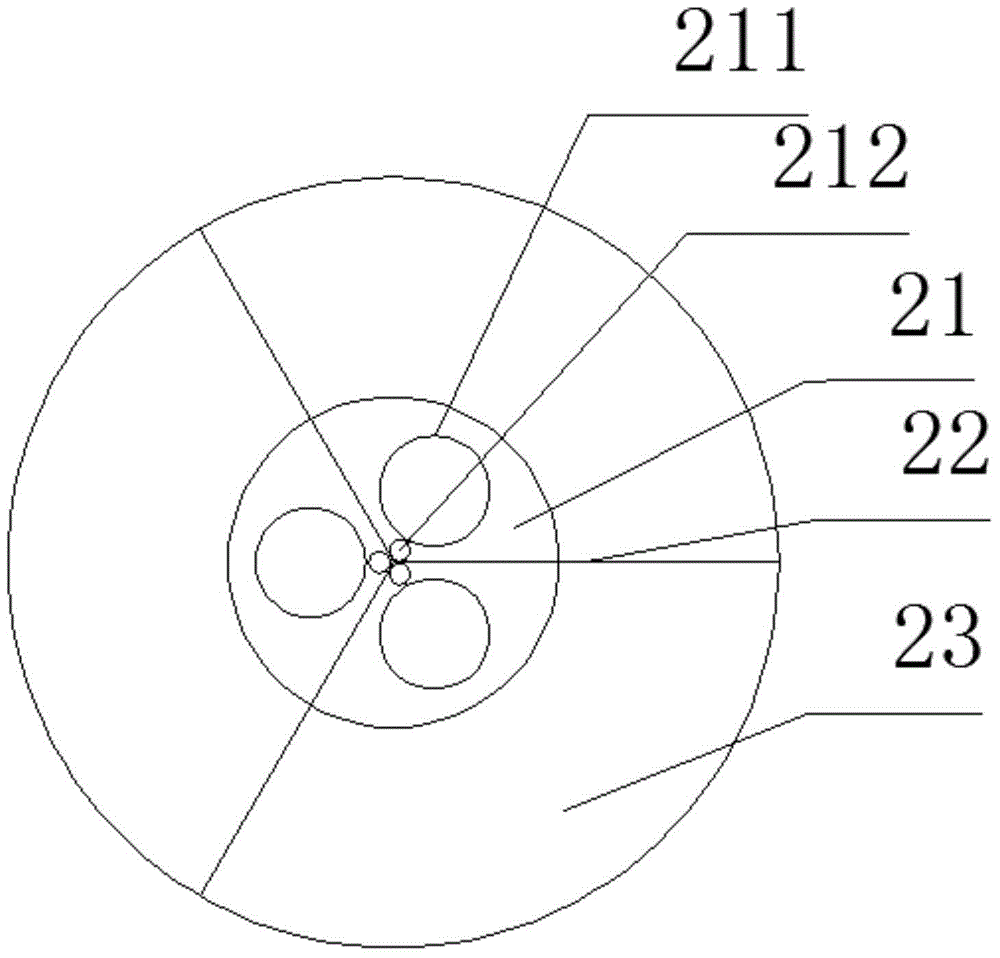

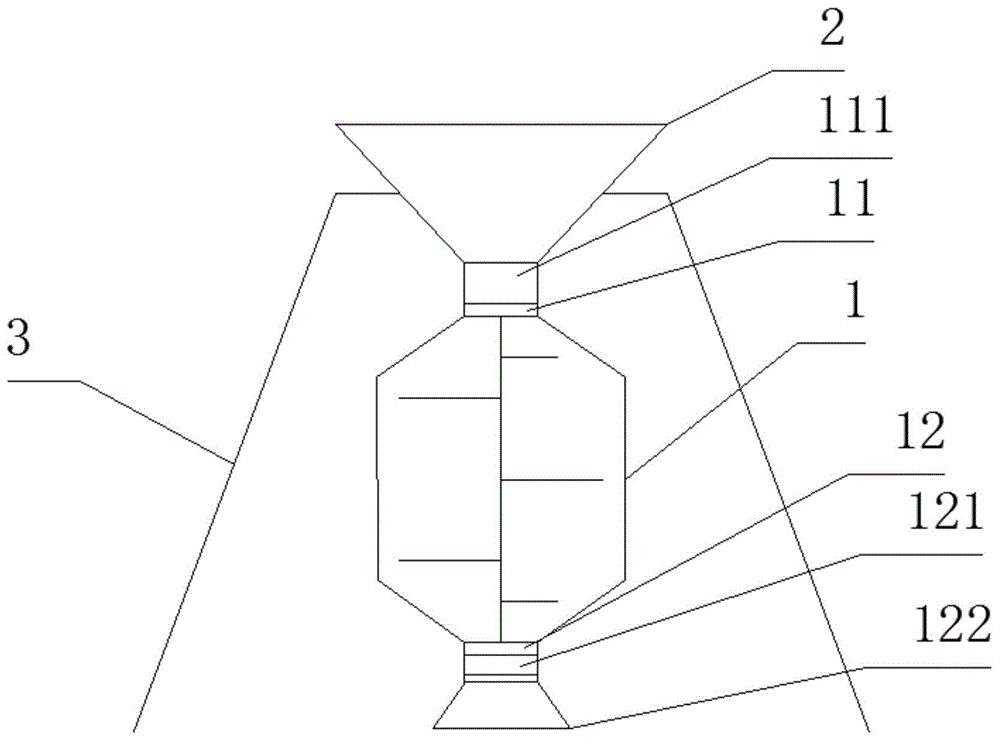

Blender mixer feeding in proportion

InactiveCN104307426AReduce work intensityReduce work stepsMixer accessoriesBLENDER/MIXERElectric machinery

The invention provides a blender mixer feeding in proportion. The blender mixer comprises a charging barrel, a feeding hopper, a motor and a controller, wherein a feeding opening and a discharging opening are formed in the charging barrel, a feeding hopper is arranged above the feeding opening, the feeding hopper is of a funnel shape, a feeding valve is arranged between the bottom of the feeding hopper and the feeding opening, a plurality of separation plates are arranged in the feeding hopper, a bottom cover is arranged at the bottom of the feeding hopper, an electric proportioning valve and a pressure sensor are arranged at the bottom of a feeding chamber formed by the separation plate and the wall of the feeding hopper, a discharging valve and a pressure sensor are arranged in the discharging opening of the charging barrel, the motor is a variable-frequency motor, the controller is arranged on the charging barrel, and the controller is connected with the feeding valve, the discharging valve, the electric proportion valve and the motor, and the blender mixer also comprises a timing module. The feeding speed of each material is controlled by the virtue of the electric proportion valve so as to further control the proportion of the materials, the working procedures are reduced, and the working intensity of the operating personnel is lowered.

Owner:天津市科成防水材料有限公司

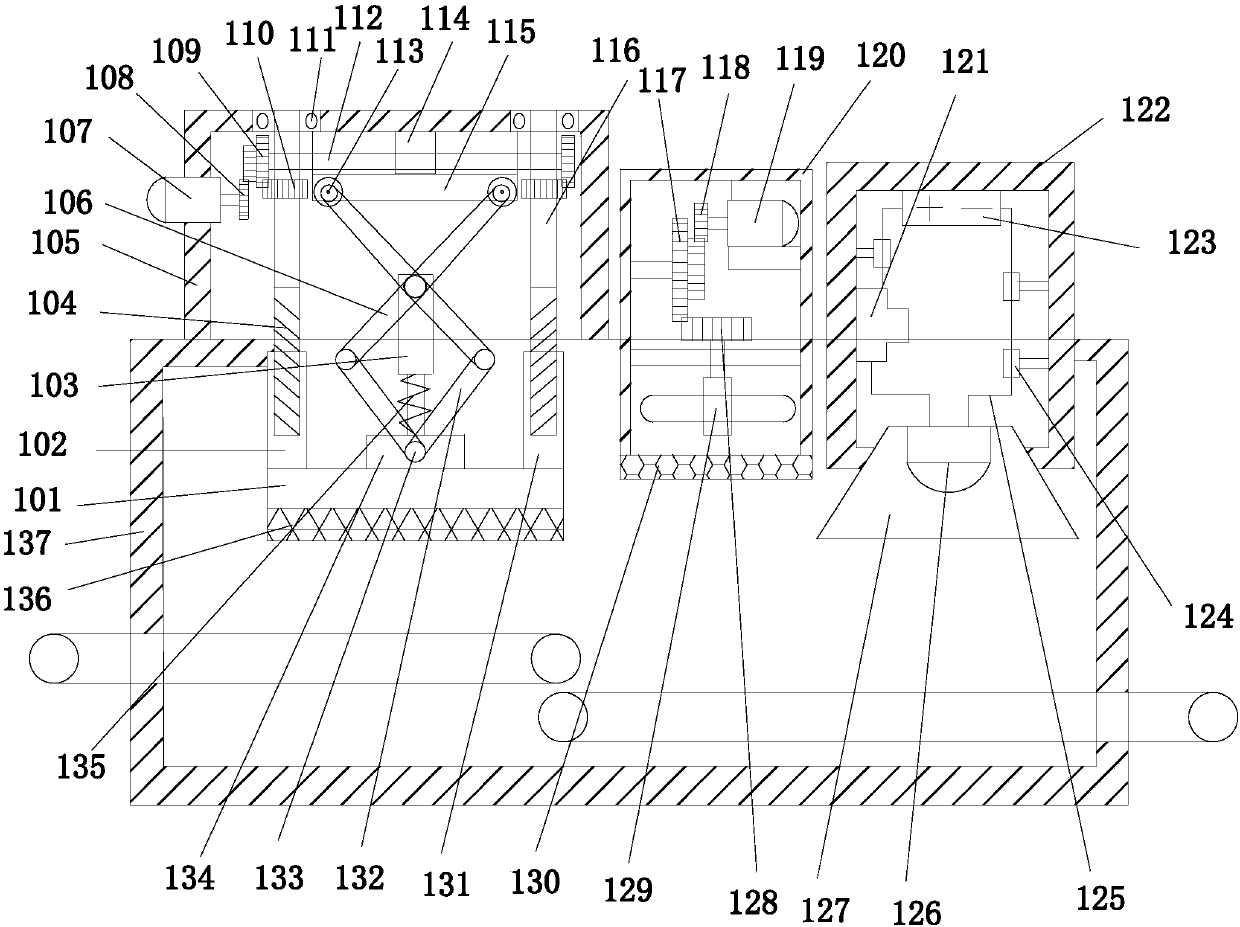

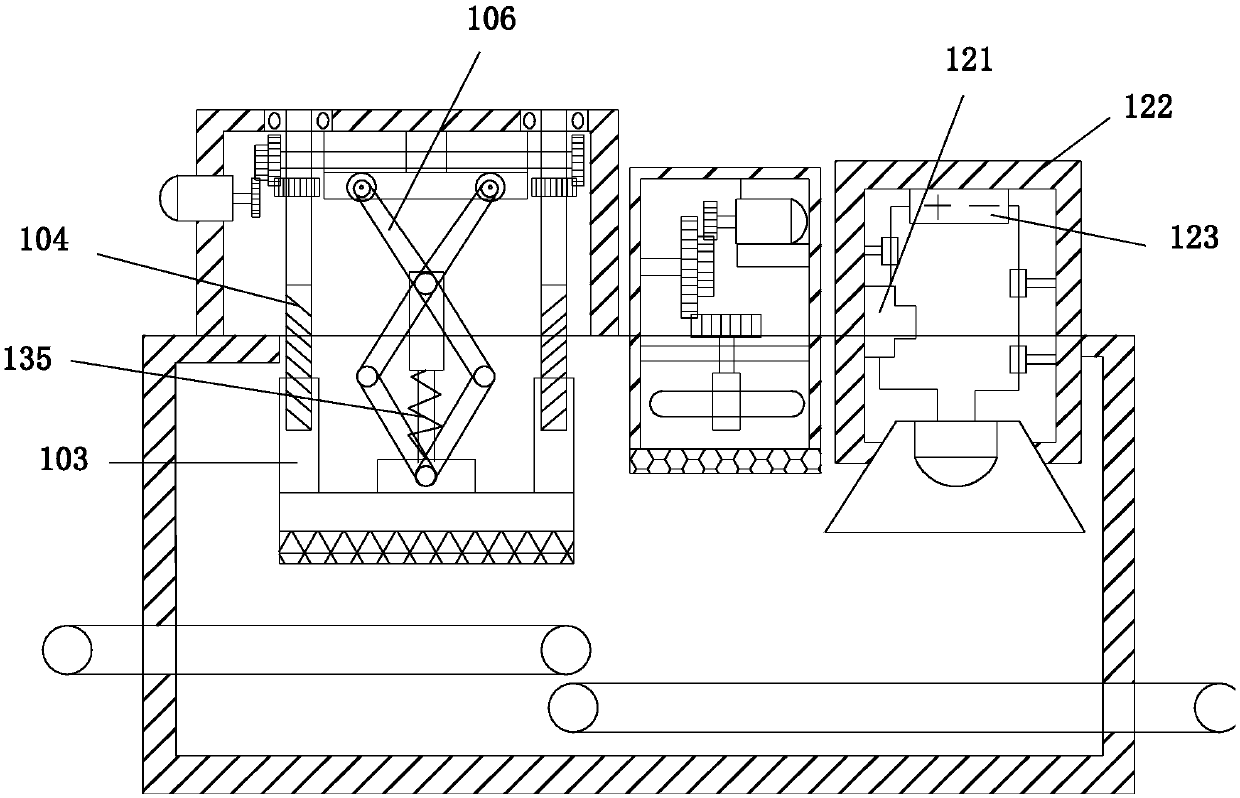

Novel pressing plate machine with gluing function

PendingCN108098942AReduce work stepsReduce work intensityPlywood pressesVeneer pressesKey pressingEngineering

The invention discloses a novel pressing plate machine with a gluing function. The structure of the novel pressing plate machine with the gluing function includes a pressing machine plate structure, non-slip mats, a rotary disk, a supporting plate, a fixed seat, a vertical pole, a placing base, a display screen, operation keys and an alarm lamp. The top portions of the non-slip mats are verticallyconnected with the bottom portion of the pressing plate machine structure, and the bottom portion of the fixed seat is welded to the top portion of the supporting plate. The bottom portion of the supporting plate is fixedly connected with the middle end of the pressing plate machine structure through rivet nails, and the rear end of the rotary disk is connected with the front end of the fixed seat in a threaded mode. The bottom portion of the vertical pole is vertically connected with the top portion of the supporting plate, and the top portion of the supporting plate is welded to the bottomportion of the placing base. The rear end of the display screen is connected with the front end of the pressing plate machine structure by a clamping groove. The novel pressing plate machine with thegluing function is provided with the pressing plate machine structure, and is capable of squeezing wood and gluing material so as to enable a pressing plate to be glued in one step. The work steps arereduced, the work intensity is reduced and the work efficiency is improved.

Owner:刘福原

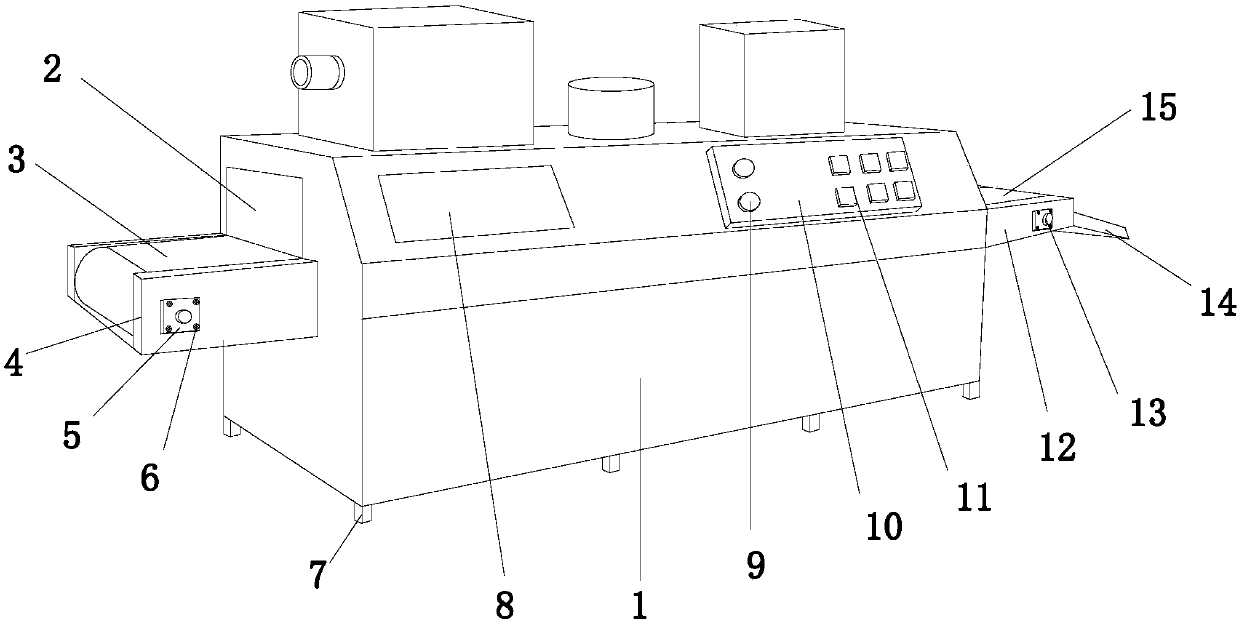

Processing, drying and disinfecting system of aquatic products

ActiveCN107744085ASpeed up the red leverPlay a buffer roleDrying gas arrangementsDrying machines with progressive movementsAquatic productPulp and paper industry

The present invention discloses a processing, drying and disinfecting system of aquatic products. A structure of the processing, drying and disinfecting system of aquatic products comprises a dryer structure, a falling curtain, a first conveyor belt, a first fixing plate, a first roller connecting seat, screws, foot stands, an observation window, a switch button, an operation panel, adjustment buttons, a second fixing plate, a second roller connecting seat, an inclined slide plate and a second conveyor belt. A bottom part of the falling curtain is matched with a top part of the first conveyorbelt, a roller is arranged inside the first conveyor belt, a rear end of the first roller connecting seat is fixedly connected with a front end of the first fixing plate, and rear ends of the screws are vertically connected with a front end of the first roller connection seat. The processing, drying and disinfecting system of the aquatic products is provided with the dryer structure in structure,can adjust the dryer, accelerates a speed of a drying rod, can be flexibly adjusted according to the different aquatic products, and is extremely practical. Besides, a fan and a disinfection lamp arecombined, so that the processing, drying and disinfecting system can achieve the drying and disinfecting of the aquatic products in one step, shortens working time, reduces working steps and thus improves work efficiencies.

Owner:义乌市嘉诗电子科技有限公司

Fixing and protecting arrangement for a capacitor

ActiveUS20060028783A1Effective protection against heatingDrawback can be obviatedMultiple fixed capacitorsMechanical engineeringCapacitor

A fixing and protecting arrangement for a capacitor may include a cooling element, one or more recesses arranged in the cooling element, and a capacitor intended to be fixed into each recess. The capacitor may be arranged in the recess in such a way that a lower surface of the capacitor is in contact with the cooling element for transferring heat from the capacitor to the cooling element.

Owner:VACON OY

Spline shaft hot forging device

InactiveCN105170858AEmission reductionReduce flash cutting stepsForging/hammering/pressing machinesEngine componentsPunchingEngineering

The invention relates to a spline shaft hot forging device. The spline shaft hot forging device comprises an upper die, a lower die and a cylinder locking device. The upper die is composed of a punch, four screws, a positioning plate and an upper guide sleeve. The upper guide sleeve and the positioning plate are connected and fixed through the four screws. The punch is arranged at the central position between the upper guide sleeve and the positioning plate. The positioning plate is connected with a punching device. The lower die is composed of a lower female die, a lower material fixing die, a bolt and a lower die holder. The lower female die and the lower material fixing die are arranged at the central position of the lower die holder. The lower female die is located above the lower material fixing die. The bolt is located on one side of the lower die holder. The cylinder locking device is composed of a round sleeve and a reciprocating stroke cylinder. The round sleeve is connected with the movable head end of the reciprocating stroke cylinder. The opening end of the round sleeve is located in the protruding head end of the lower die holder. The spline shaft hot forging device has the beneficial effects that machining procedures can be reduced, the machining cost is low, and the forge piece error range is small.

Owner:WANXIANG QIANCHAO TRANSMISSION SHAFT +1

Drilling sample plate with positioning and supplementing functions

The invention provides a drilling sample plate with positioning and supplementing functions, and belongs to the technical field of machining. The drilling sample plate with positioning and supplementing functions is characterized in that on a plane on which ribs are located, a top face and a side of a lateral edge strip of a part are used as a supplementing outer edge of a drilling sample plate, namely a positioning edge; corresponding parts of an edge of the drilling sample plate and the positioning edge of the part are adhered with each other; two edges are used as positioning references of the drilling sample plate and the part in two directions of height and width; when the drilling sample plate is used, the drilling sample plate is clamped on the part and is adhered to the ribs. When the sample plate is used in a manufacturing plant, positioning can be directly carried out, working steps of requiring measurement during numeric value positioning and sample placement can be reduced, the working time is shortened, and rapid positioning of the drilling sample plate is realized, so that convenience is provided for the manufacturing plant, and the working efficiency is improved. By adhesion of the drilling sample plate and the surface of the part, the deviation is difficult to produce during machining, and the accuracy of technological holes can be guaranteed relatively.

Owner:SHENYANG AIRCRAFT CORP

Quick positioning measuring device and method for three-coordinate fixture

PendingCN108917533ARapid positioningHigh positioning accuracyMechanical measuring arrangementsEngineeringMechanical engineering

The invention discloses a quick positioning measuring device for a three-coordinate fixture. The quick positioning measuring device comprises a measuring platform, a multi-threaded-hole protective bottom plate, the part fixture, a measuring machine, positioning pin pressing columns, a quick elastic clamp and a measuring fixture quickly-adjustable device. The positioning pin pressing columns and the quick elastic clamp lock and position the part fixture through a three-point layout. The measuring fixture quickly-adjustable device is of a long-strip-shaped structure arranged on the side face ofthe bottom plate of the part fixture, one end of the measuring fixture quickly-adjustable device is fixedly connected with the bottom plate of the part fixture, and the other end of the measuring fixture quickly-adjustable device is provided with a relative position fine adjusting part of the bottom plate of the part fixture; and the side face of the middle, back onto the bottom plate, between thetwo ends is attached to one of the three-point-type positioning pin pressing columns in an abutting mode, and thus fine adjusting of the relative position fine adjusting part obtains support reverseforce from the positioning pin pressing column to push the bottom plate to move so as to adjust the parallel states of a to-be-measured part and the part fixture relative to the measuring machine. Through structural simplification and optimization, the rough adjusting and fine adjusting precision is high.

Owner:GUANGDONG HONGTU TECHNOLOGY (HOLDINGS) CO LTD

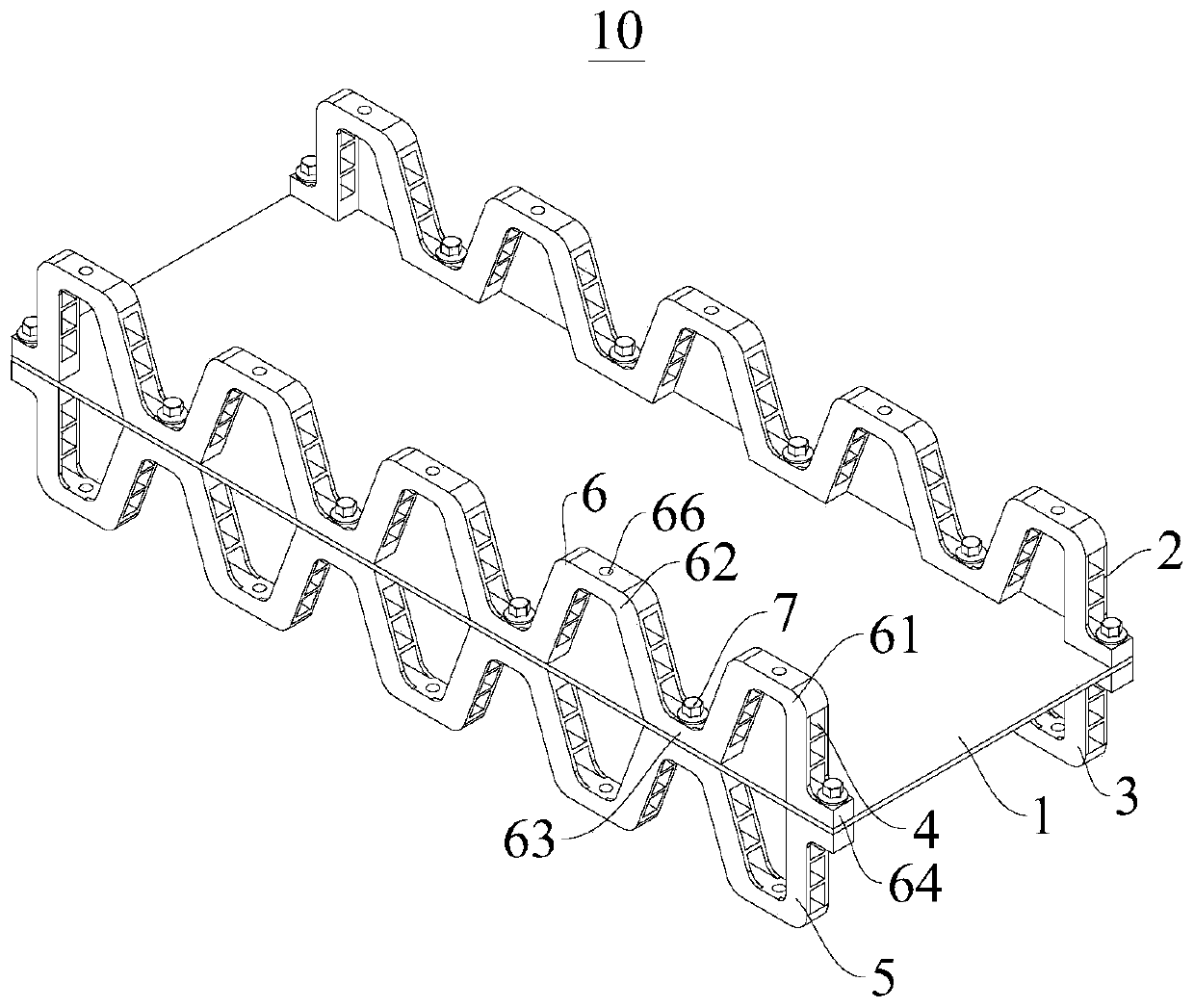

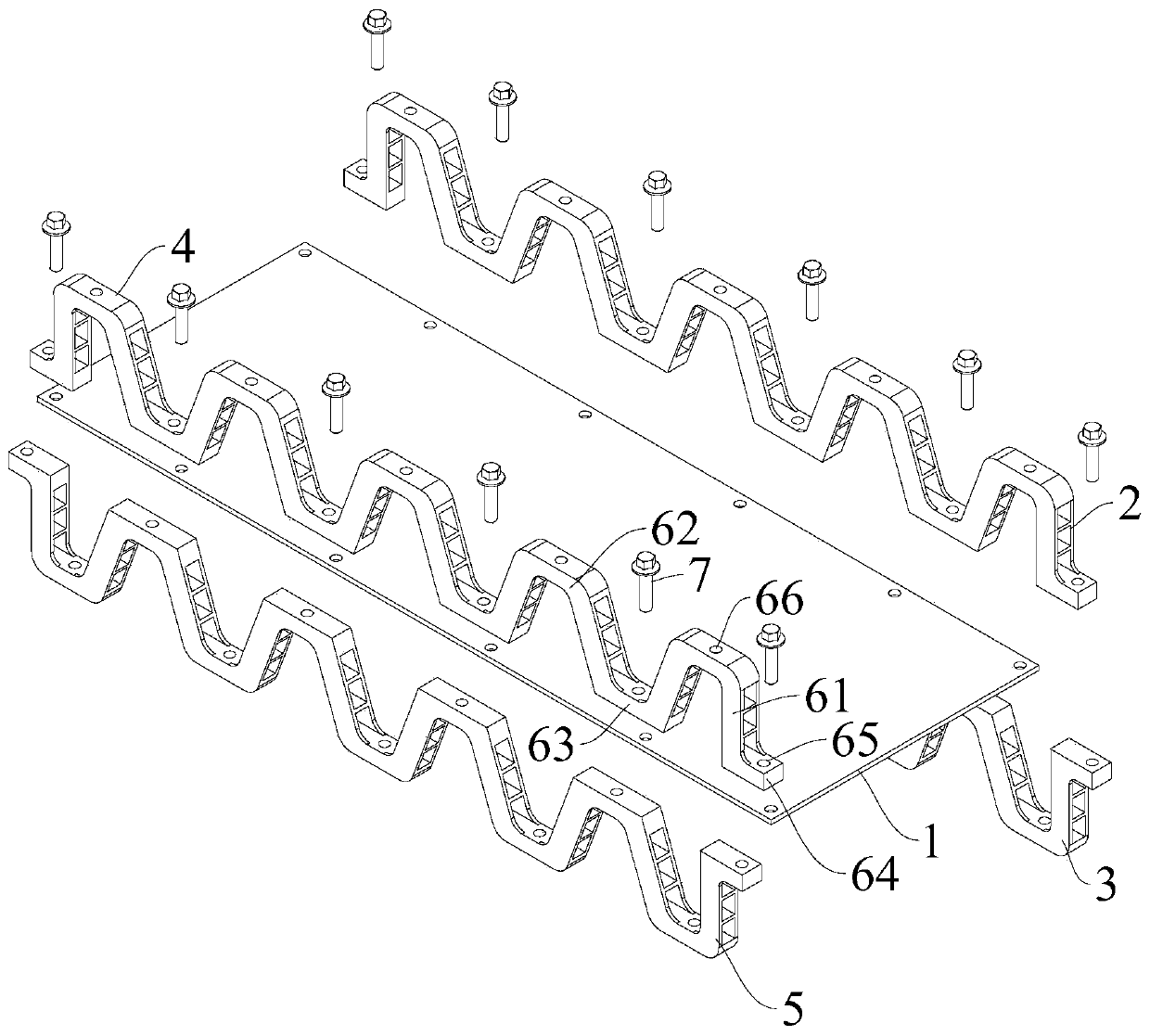

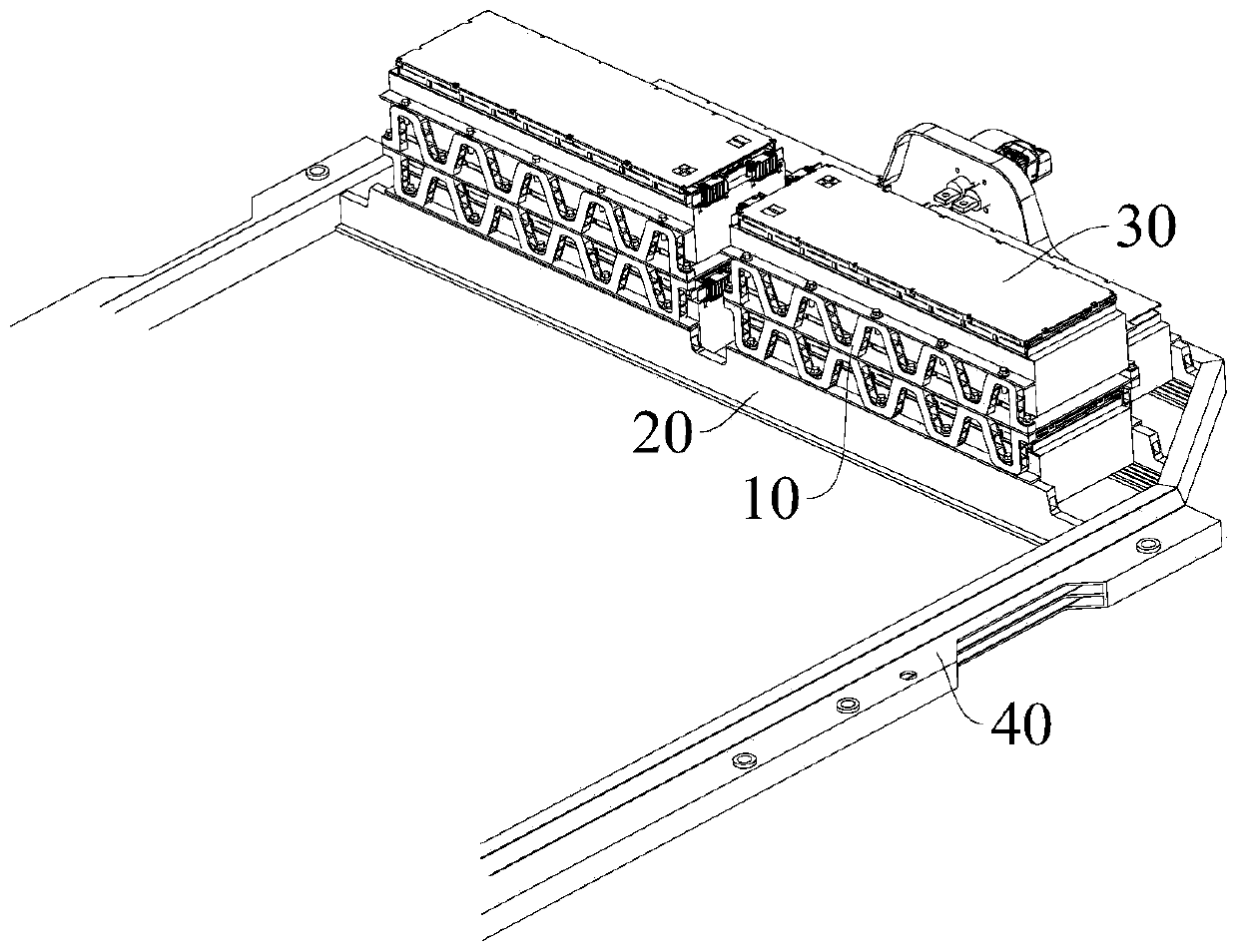

Double-layer module support of battery pack and battery pack

InactiveCN109713182ASave assembly timeEasy for workers to operateCell component detailsElbow jointsBattery pack

The invention provides a double-layer module support of a battery pack and the battery pack. The double-layer module support of the battery pack comprises a supporting plate, a first supporting beam,a second supporting beam, a third supporting beam and a fourth supporting beam. The first supporting beam and the third supporting beam are detachably arranged on the upper surface of the supporting plate and are oppositely arranged. The second supporting beam and the fourth supporting beam are detachably arranged on the lower surface of the supporting plate and are oppositely arranged. The firstsupporting beam, the second supporting beam, the third supporting beam and the fourth supporting beam are all arranged in the length direction of the supporting plate, and the second supporting beam and the fourth supporting beam are both connected with a support supporting beam in the battery pack. The first supporting beam and the third supporting beam are both connected with an upper-layer battery module in the battery pack. Therefore, through cooperation of the supporting plate, the first supporting beam, the second supporting beam, the third supporting beam and the fourth supporting beam,the working step of installing the double-layer module support through an elbow tool can be omitted, the assembling time can be saved, and worker operation can be facilitated.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

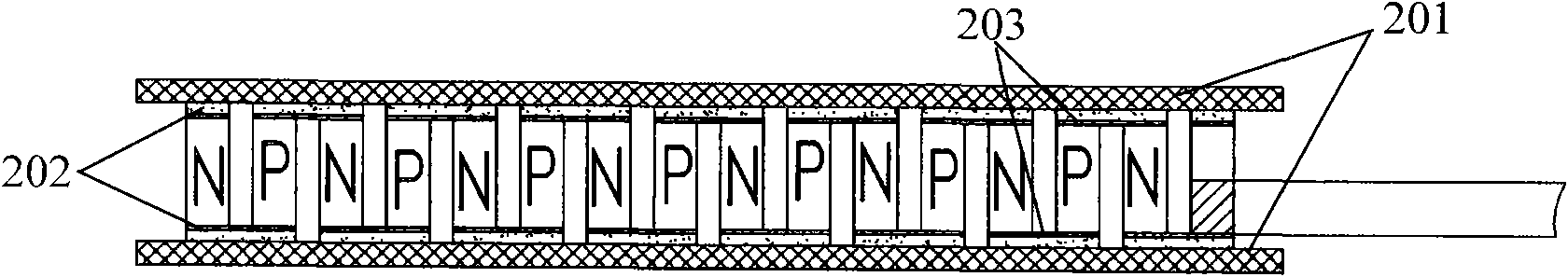

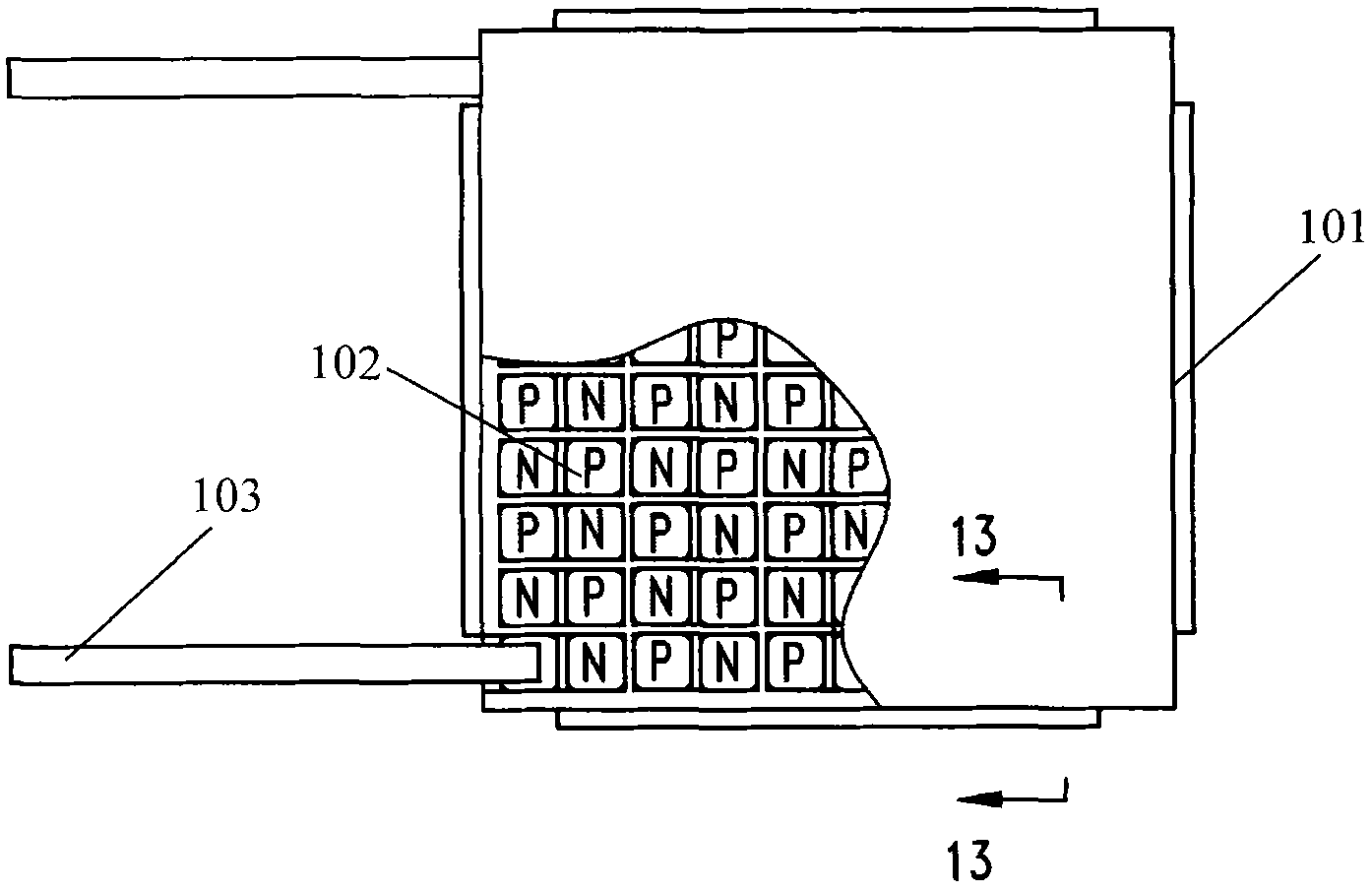

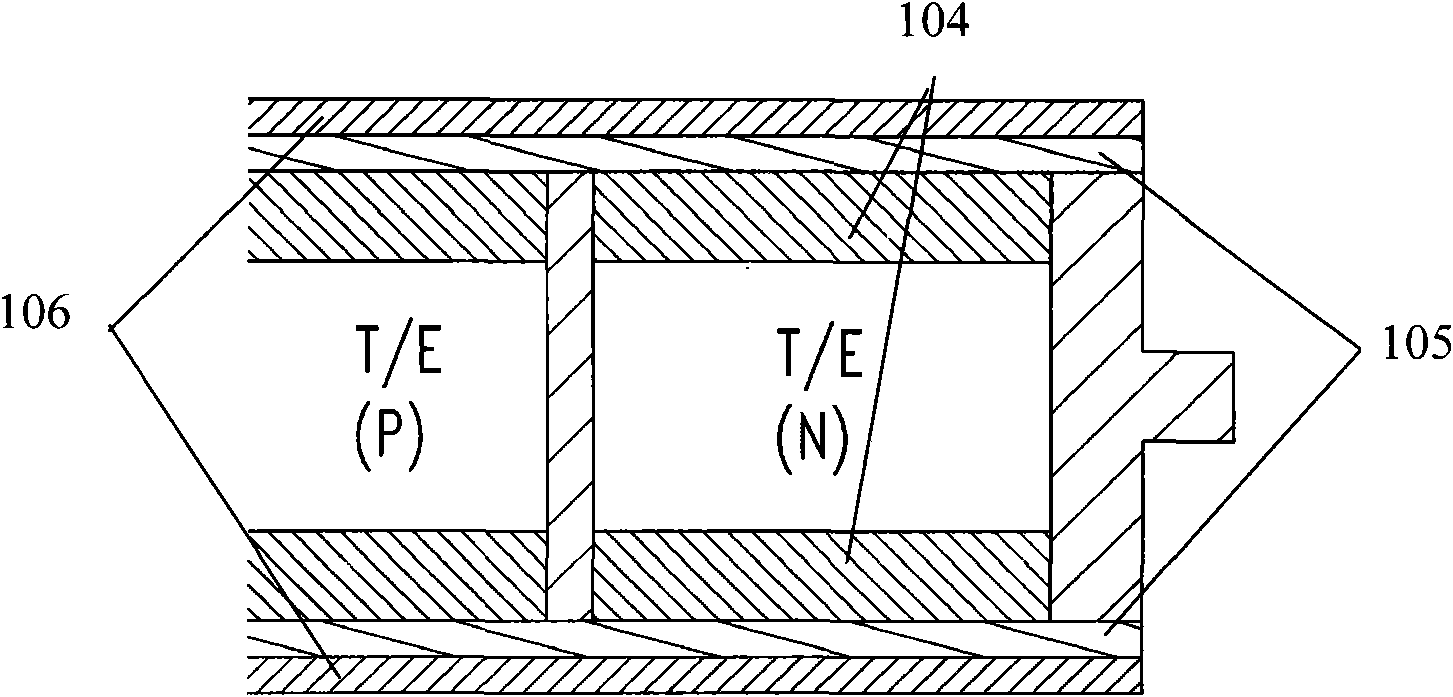

Method for manufacturing thermoelectric module having high-insulation thermal coupling surface, low thermal resistance and no brazing layer

ActiveCN101783386AReduce work stepsAvoid relative motionThermoelectric device manufacture/treatmentThermoelectric device detailsBrazingThermoelectric element

The invention relates to a method for manufacturing a thermoelectric module having a high-insulation thermal coupling surface, low thermal resistance and no brazing layer. The method comprises the following steps: manufacturing an insulated frame which is embedded with at least two metal electric-connection terminals by an injection molding method; preparing thermoelectric elements; placing the thermoelectric elements in through holes of the insulated frame; respectively spraying metal coating on the upper ends and the lower ends of the thermoelectric elements; grinding the sprayed surfaces; and covering an alumina film layer on the grounded surfaces respectively, wherein the insulated frame is provided with a plurality of through holes in which thermoelectric elements are placed; grooves of which the number corresponds to that of the metal electric-connection terminals are formed in side frames of the insulated frame and are communicated with different through holes; the first end parts of the metal electric-connection terminals are respectively arranged in the grooves, while the second end parts are positioned outside the side frames of the insulated frame. The thermoelectric module manufactured by the manufacturing method has the high-insulation thermal coupling surface, the low resistance and no brazing layer, and has the characteristics of improvement on the reliability of the electric connection between the thermoelectric elements and an external system, simplification of operation steps, reduction of material cost, excellent performance, and suitability for large-scale generalization and application.

Owner:SHANGHAI SHENHE THERMO MAGNETICS ELECTRONICS CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com