Dry-process pre-impregnating process of thermoplastic resin based pre-impregnated tape

A technology of thermoplastic resin and pre-impregnated tape, which is applied in coating and other directions, can solve problems such as poor fluidity and difficulty in impregnating reinforcing materials, and achieve the effects of low investment, improved physical and mechanical properties, and shortened impregnation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

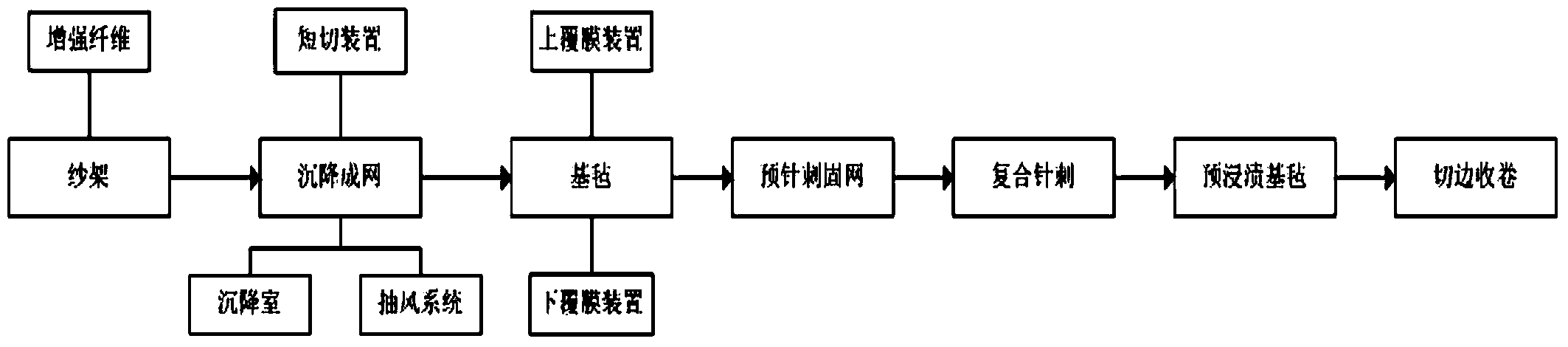

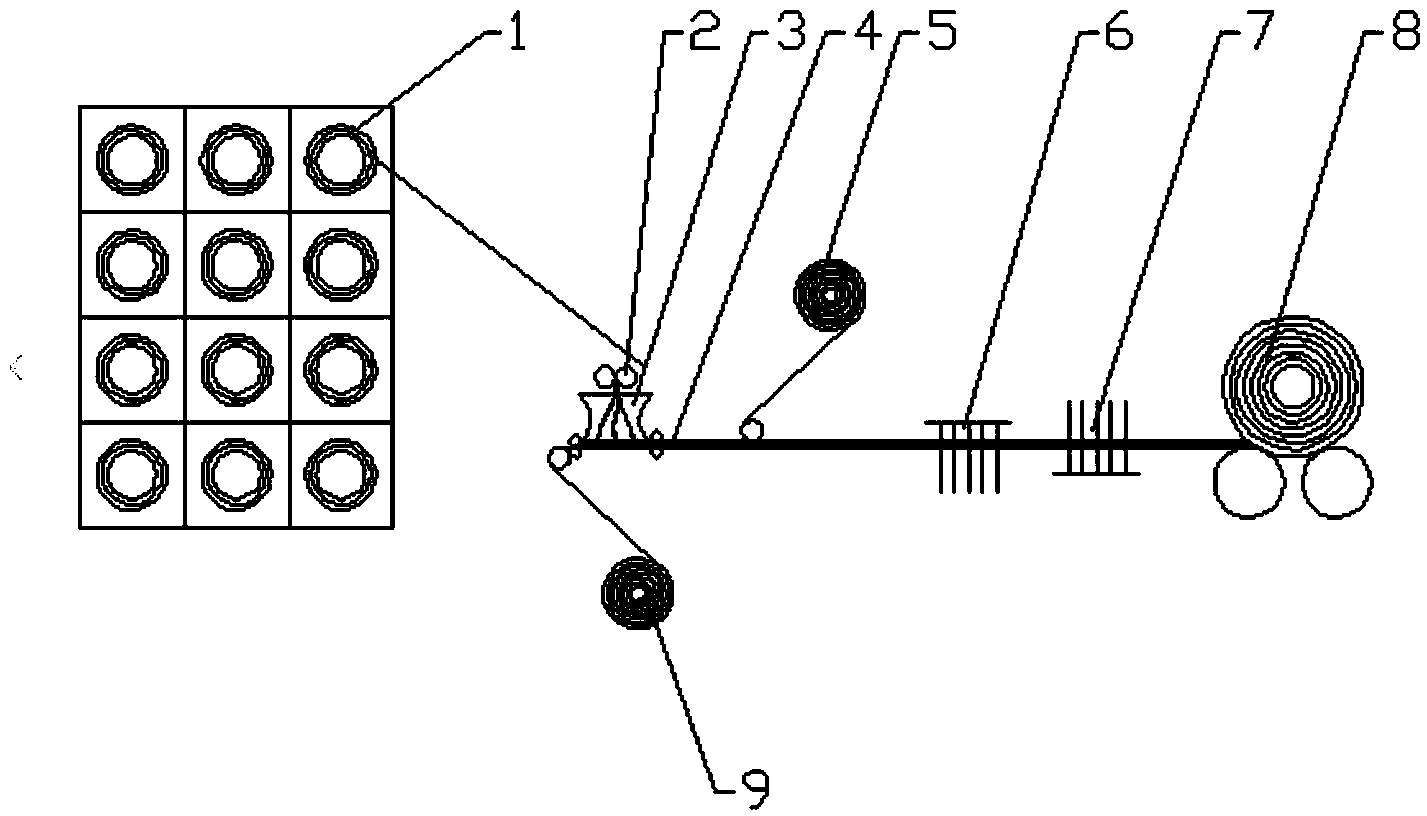

[0034] (1) The reinforcing fiber is selected as glass fiber (diameter: 17μm1200tex), and the modified resin film is selected as polypropylene resin film (single layer weight: 120g / m 2 ). The continuous glass fiber on the creel 1 is chopped into 60-90mm, and the fiber is free to fall into the net, and is quantitatively sprinkled on the conveyor belt 4 covered with the modified resin film (the weight of the fiber net is controlled at 160g / m 2 left and right), and then lay a layer of modified resin film 5 on the chopped fiber, thus forming a three-in-one premix structure;

[0035] (2) Feed the above-mentioned premixed structure into the high-speed acupuncture machines 6 and 7 for pre-acupuncture to fix the net and compound acupuncture with a needle frequency of 45 pricks / cm 2 , the acupuncture depth is 25mm;

[0036] (3) Inspection, trimming, and winding into a single-layer pre-impregnated needle felt;

[0037] (4) Unwind single-layer pre-impregnated needle-punched felt, and p...

Embodiment 2

[0044] (1) The reinforcing fiber is selected as glass fiber (diameter: 17μm1200tex), and the modified resin film is selected as nylon PA6 resin film (single layer weight: 150g / m 2 ). The continuous reinforcing fiber on the creel 1 is chopped into 60-90mm, and the fiber falls freely, and is quantitatively sprinkled on the conveyor belt 4 covered with the modified resin film (the weight of the fiber net is controlled at 200g / m 2 left and right), and then lay a layer of modified resin film 5 on the chopped fiber, thus forming a three-in-one premix structure;

[0045] (2) Feed the above-mentioned premixed structure into the high-speed acupuncture machines 6 and 7 for pre-acupuncture to fix the net and composite acupuncture with a needle frequency of 50 pricks / cm 2 , the acupuncture depth is 30mm;

[0046] (3) Inspection, trimming, and winding into a single-layer pre-impregnated needle felt;

[0047] (4) Unwind single-layer pre-impregnated needle-punched felt, and prepare contin...

Embodiment 3

[0053] (1) The reinforcing fiber is selected as glass fiber (diameter: 17μm1200tex), and the modified resin film is selected as polypropylene resin film (single layer weight: 150g / m 2 ). The continuous glass fiber on the creel 1 is chopped into 60-90mm, and the fiber falls freely into the net, and is quantitatively sprinkled on the conveyor belt 4 covered with the modified resin film (the weight of the fiber net is controlled at 200g / m 2 left and right), and then lay a layer of modified resin film 5 on the chopped fiber, thus forming a three-in-one premix structure;

[0054] (2) Feed the above-mentioned premixed structure into high-speed acupuncture machines 6 and 7 for pre-acupuncture to fix the net and composite acupuncture with a needle frequency of 40 pricks / cm 2 , the acupuncture depth is 30mm;

[0055] (3) Inspection, trimming, and winding into a single-layer pre-impregnated needle felt;

[0056] (4) Unwind single-layer pre-impregnated needle-punched felt, and prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com