Patents

Literature

42results about How to "Achieve tidiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

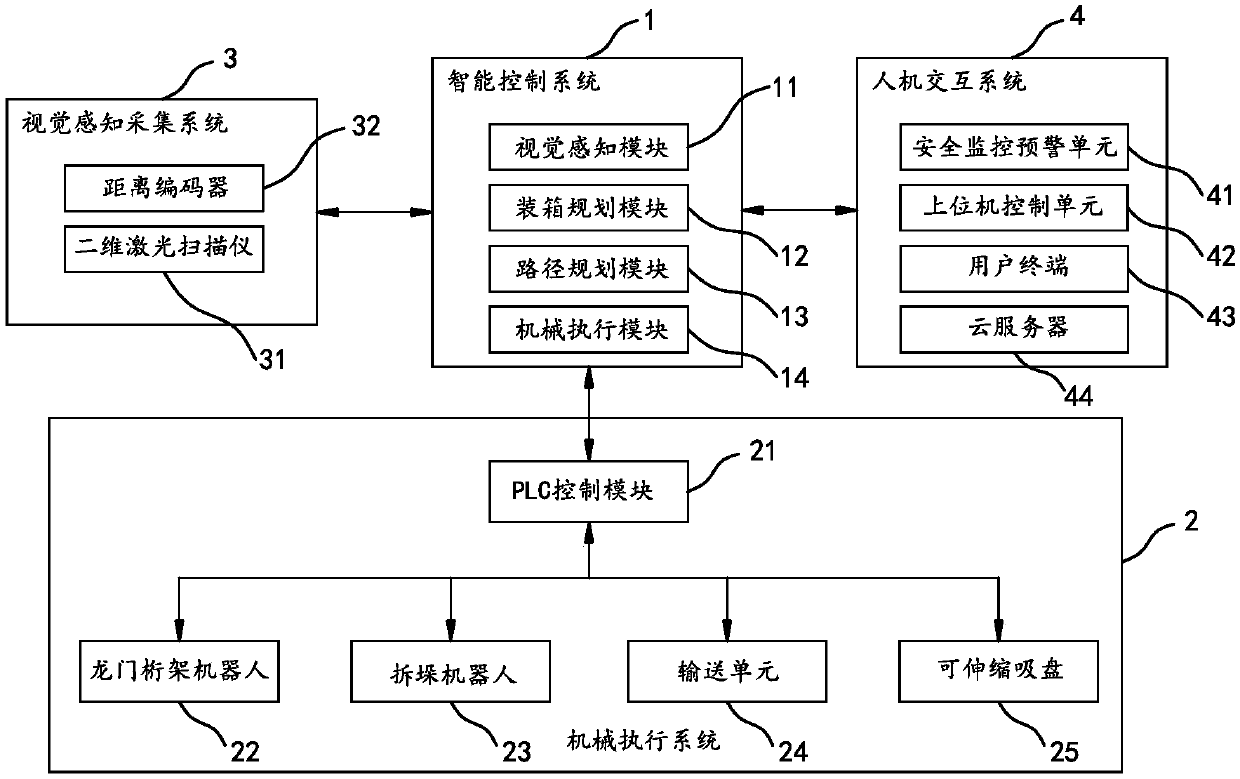

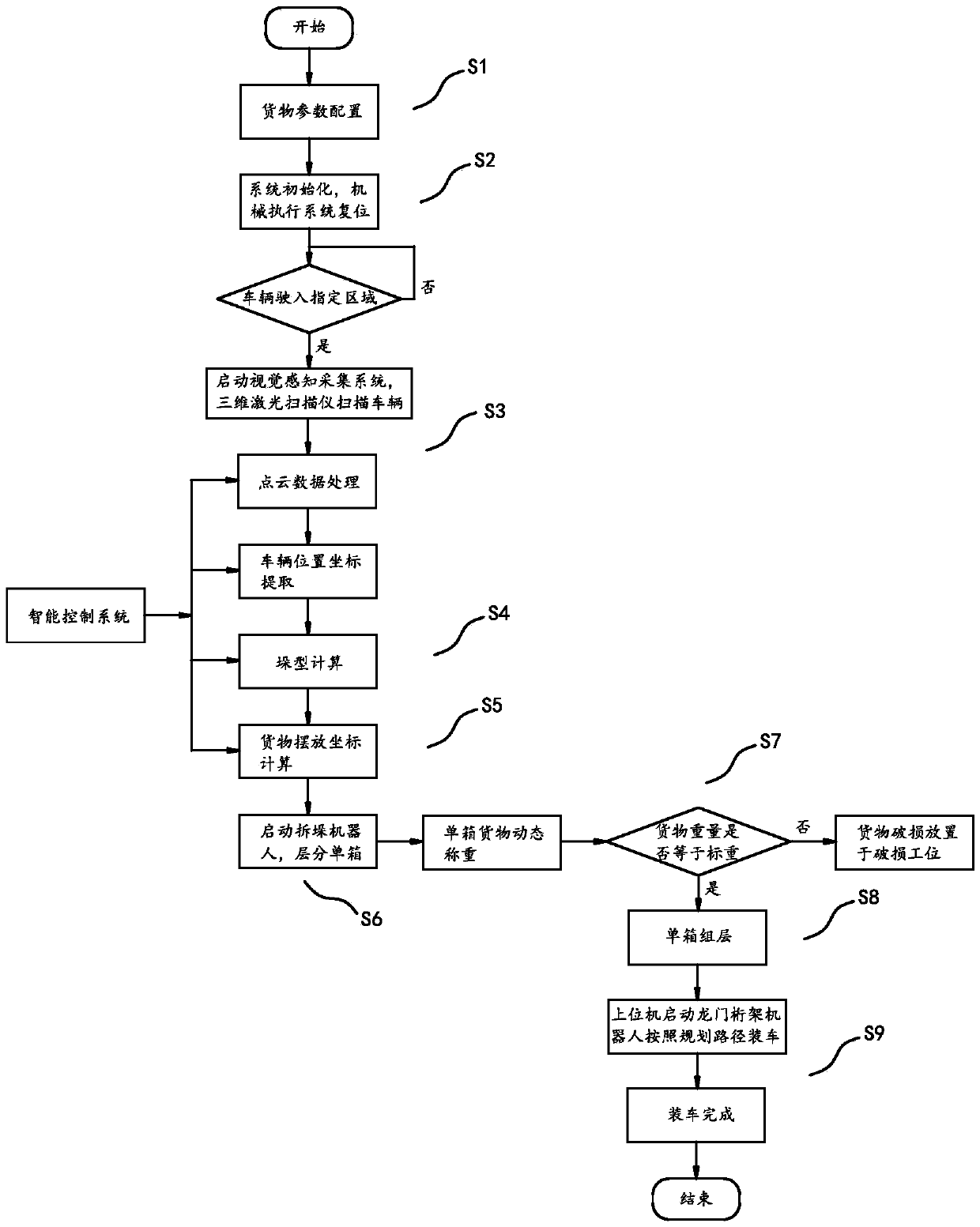

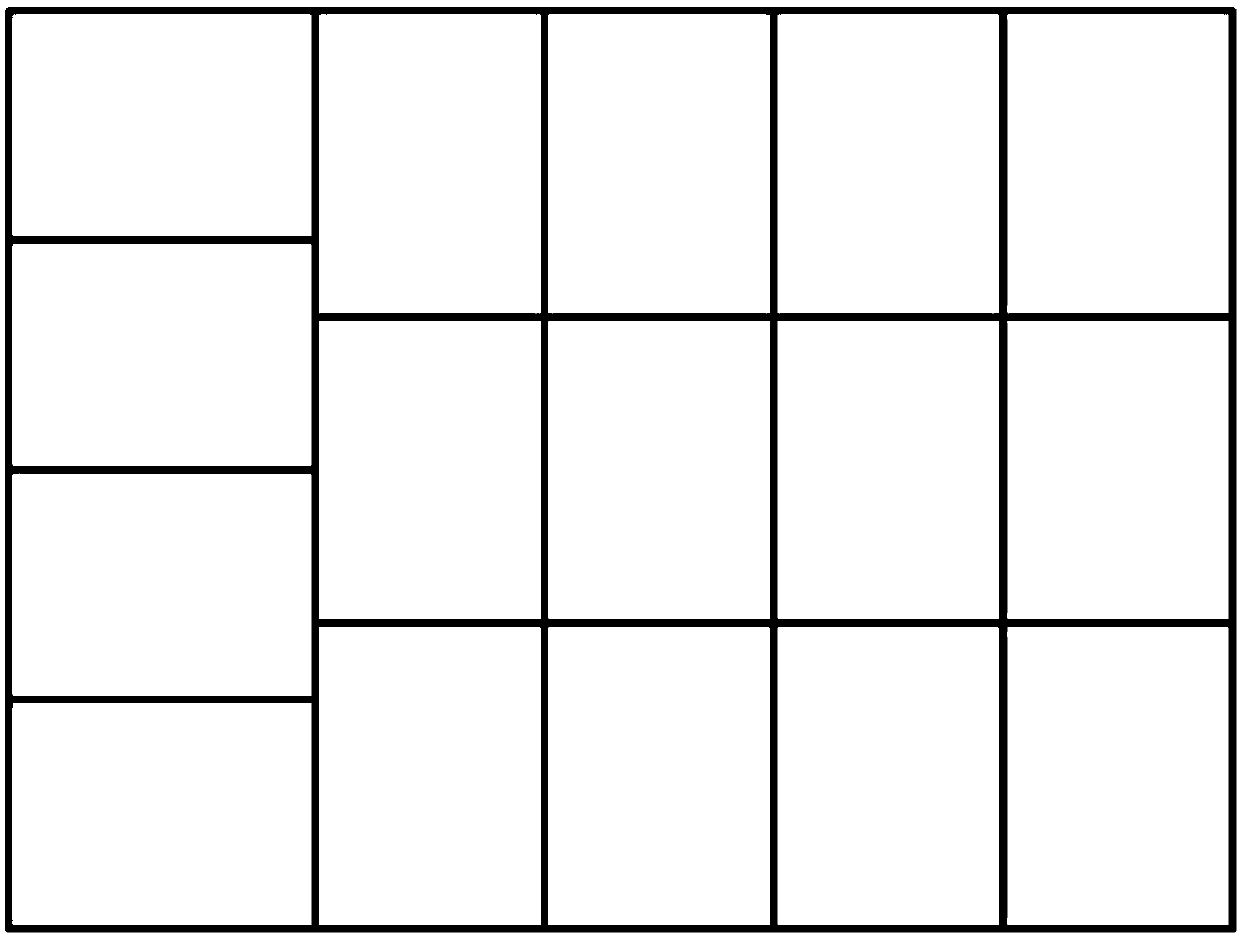

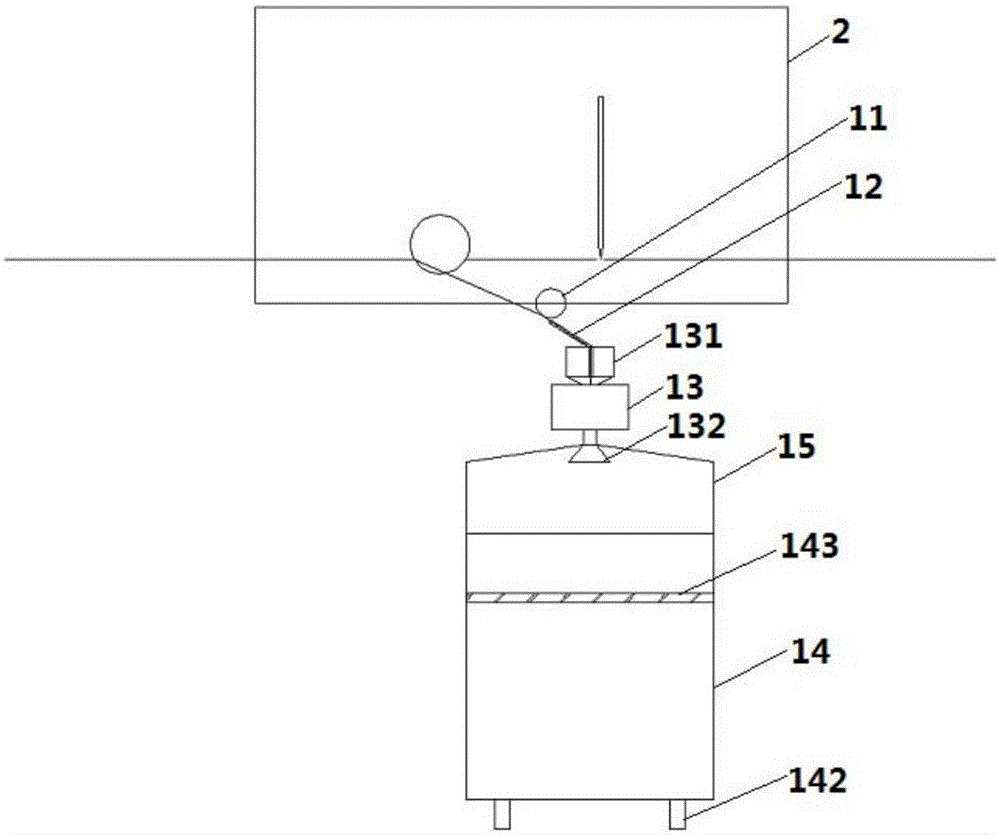

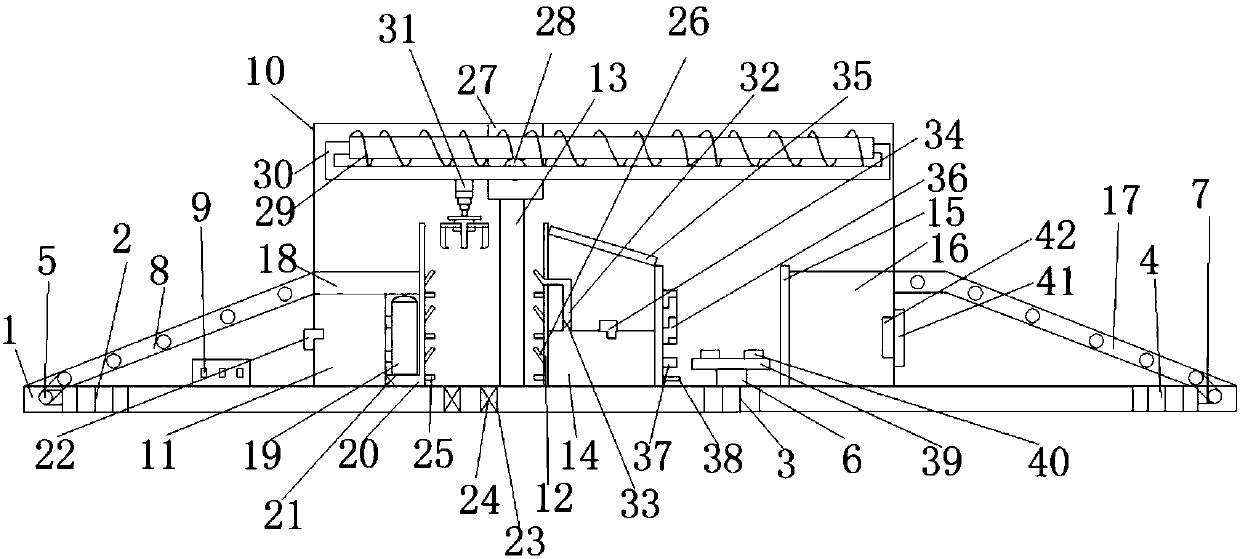

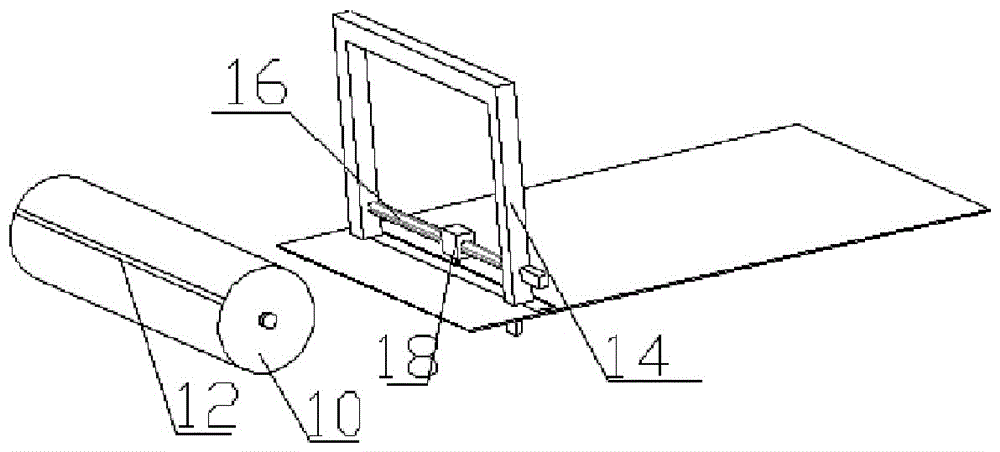

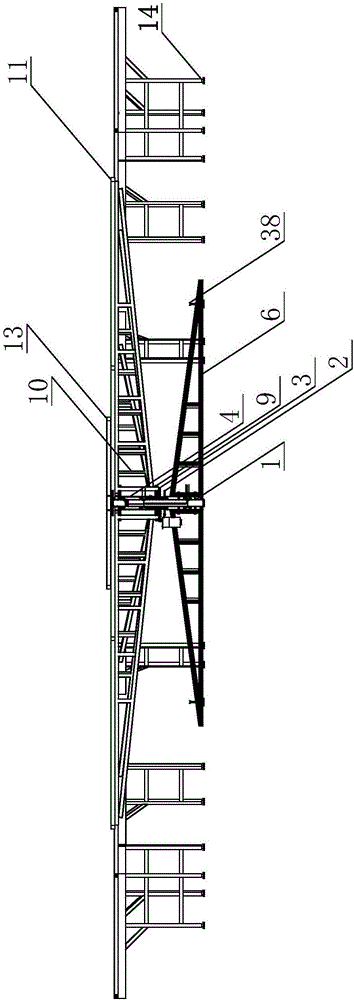

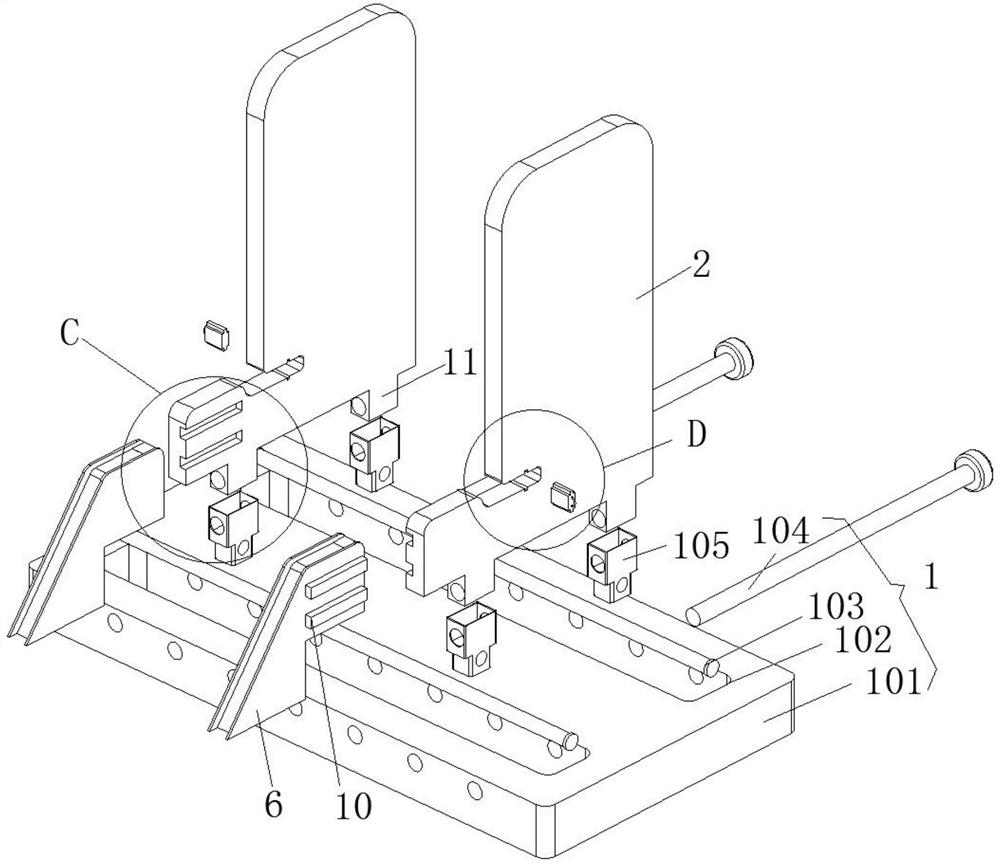

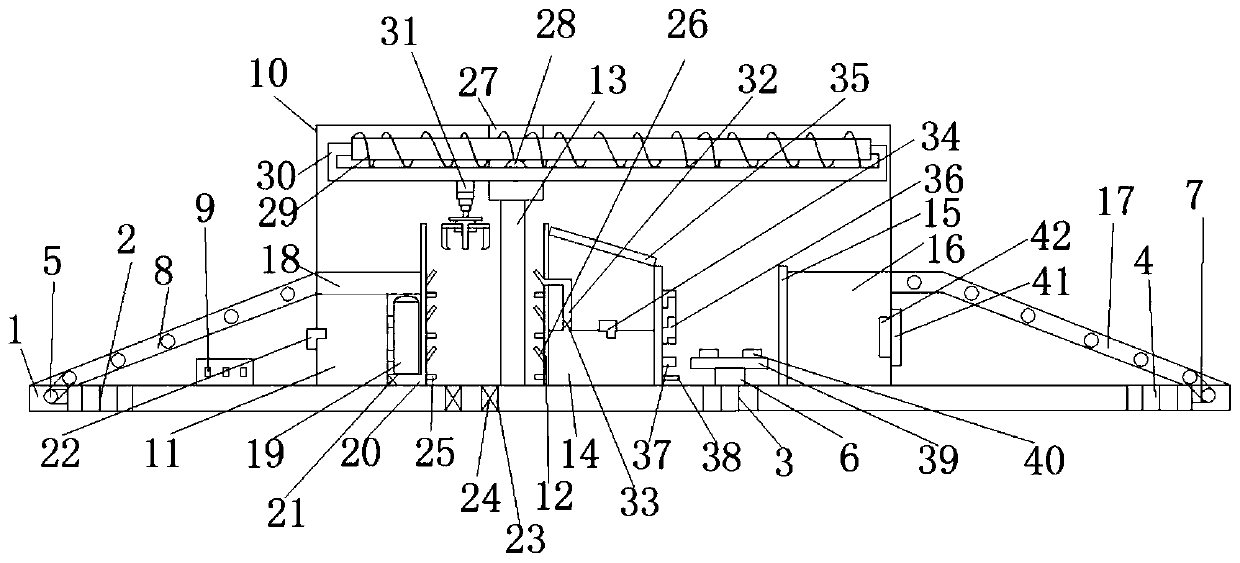

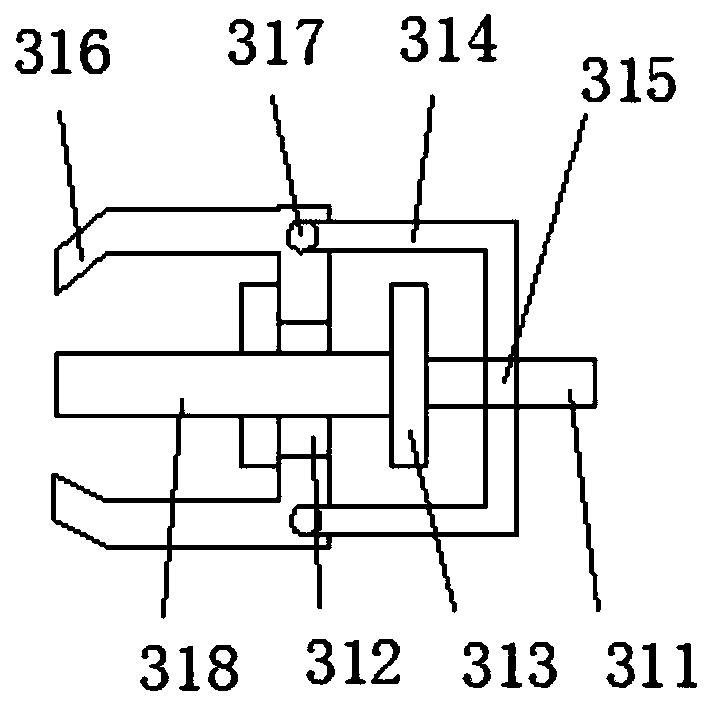

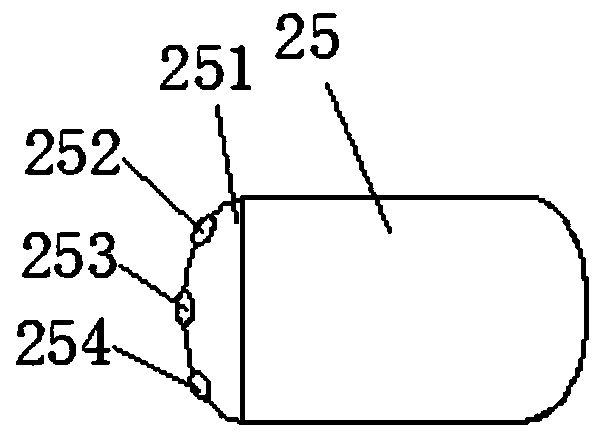

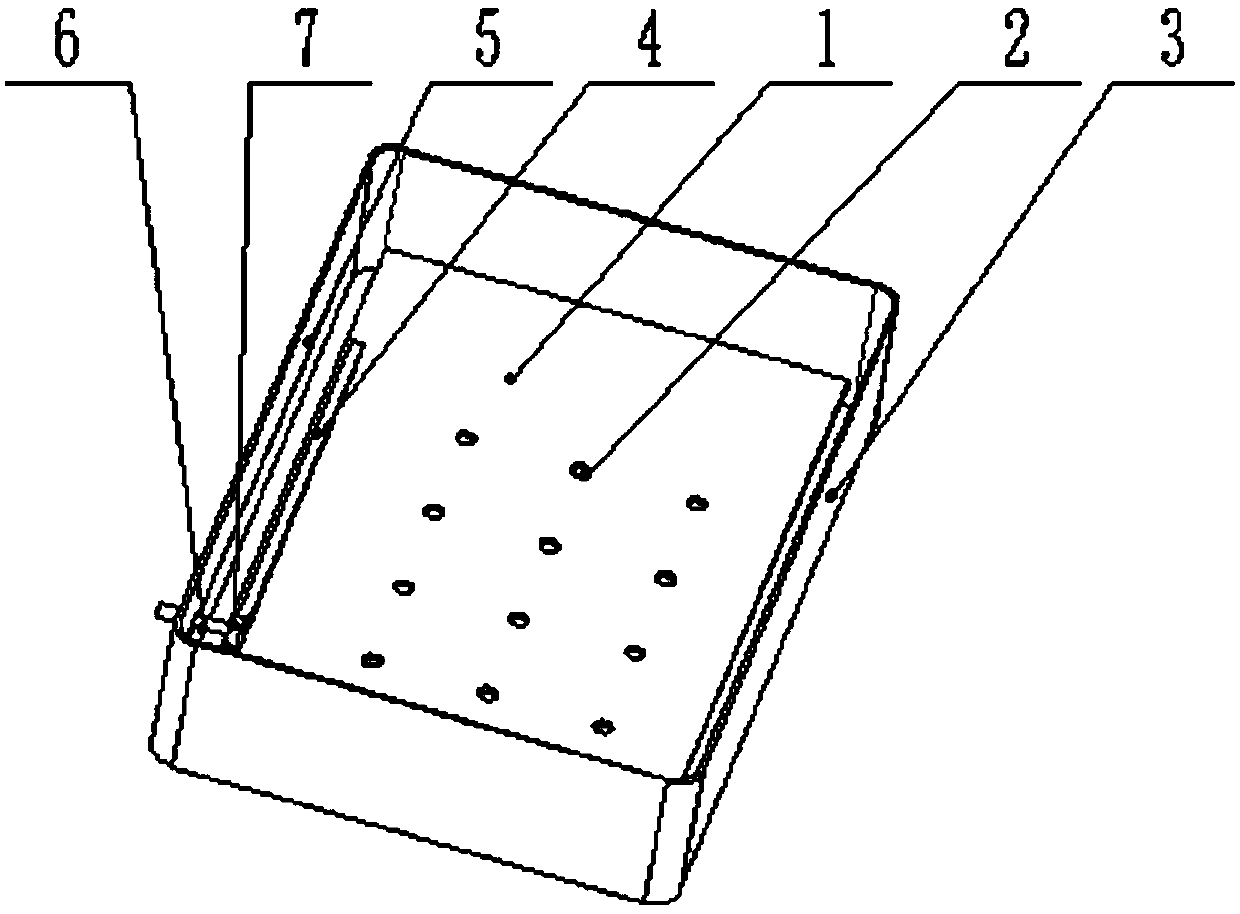

Unmanned truck loading system and method

ActiveCN109095059AImprove loading positioning accuracyAchieve orderStorage devicesLoading/unloadingTruckIntelligent control system

The invention relates to an unmanned truck loading system and method. The unmanned truck loading system comprises an intelligent control system and further comprises a mechanical executing system, a vision perception and acquisition system and a man-machine interactive system which are in two-way communication with the intelligent control system. The intelligent control system is provided with a visual perception module, a casing planning module, a route planning module and a mechanical executing module. The mechanical executing device comprises a PLC control module, a gantry truss robot, an unstacking robot, a vehicle limiting device, a retractable suction cup and a conveying unit. The PLC control module is in communication connection with the gantry truss robot, the unstacking robot, theretractable suction cup and the conveying unit. The vision perception and acquisition system comprises a two-dimensional laser scanner and a distance encoder. The man-machine interactive system comprises a safety monitoring early-warning unit, an upper computer control unit, a user terminal and a cloud server. According to the unmanned truck loading system, manual machine operation is not needed,and complete unmanned operation is achieved from unstacking and conveying of cargos to stacking and loading of the cargos.

Owner:QINGDAO ACADEMY OF INTELLIGENT IND +1

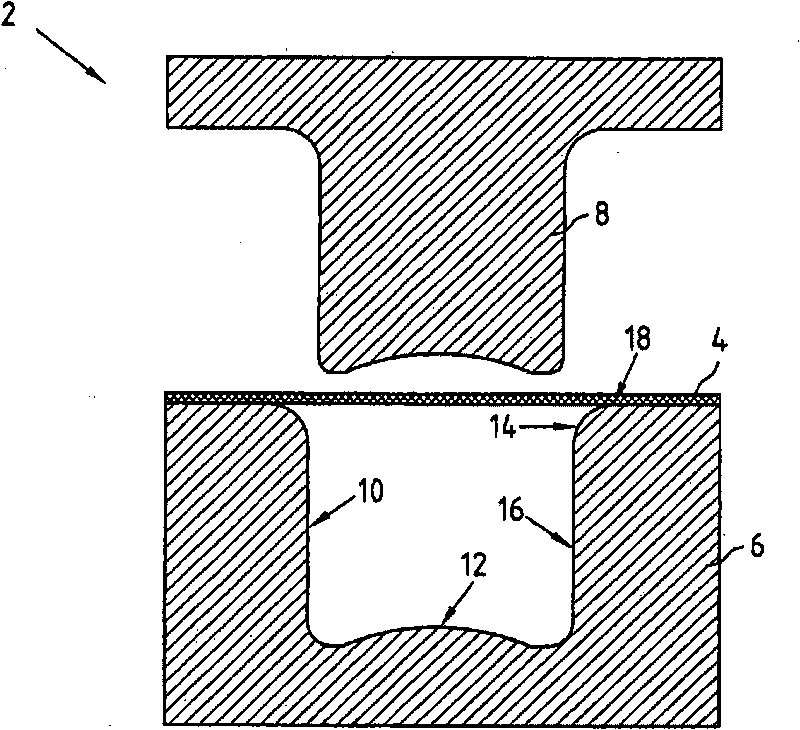

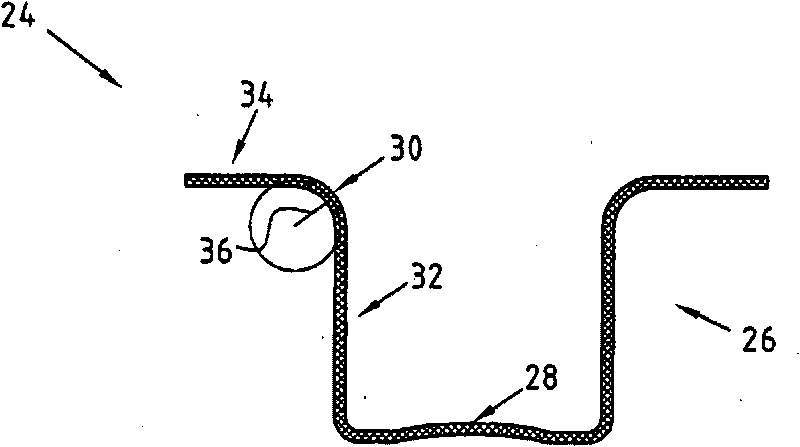

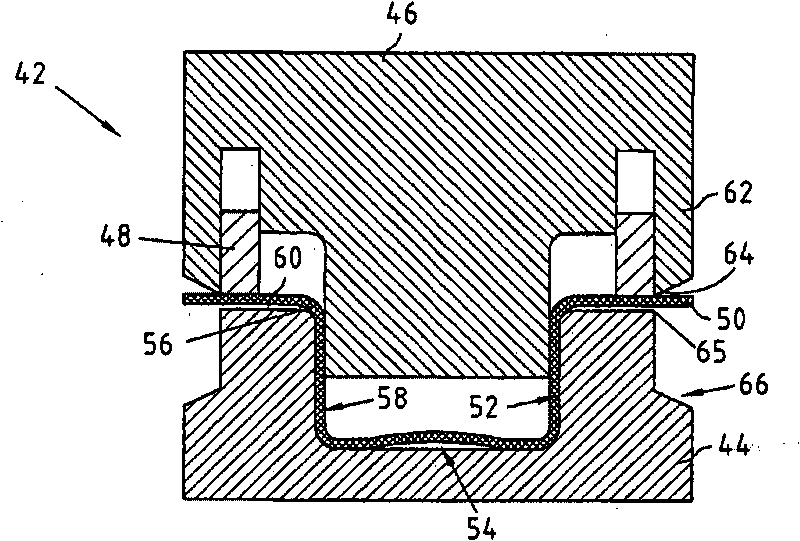

Method and device for producing highly dimensionally accurate flanged half shells

ActiveCN101758148AHigh dimensional accuracyPrevent springbackVehicle componentsBody regionDimensional precision

A method for producing highly dimensionally accurate, deep-drawn half shells with a base region (122), a body region (116) and a flange region (118), includes firstly forming a pre-formed half shell (24, 50, 72, 92) from a blank (4) and then shaping the pre-formed half shell (24, 50, 72, 92) into a finally formed half shell (112), wherein the pre-formed half shell has excess blank material due to its geometric shape and wherein, owing to the excess material during the shaping of the pre-formed half shell into its final shape the half shell is compressed into the finally formed half shell by at least one further pressing process. The method requires that the pre-formed half shell has excess blank material in a transition region between the body region and flange region.

Owner:THYSSENKRUPP STEEL EURO AG

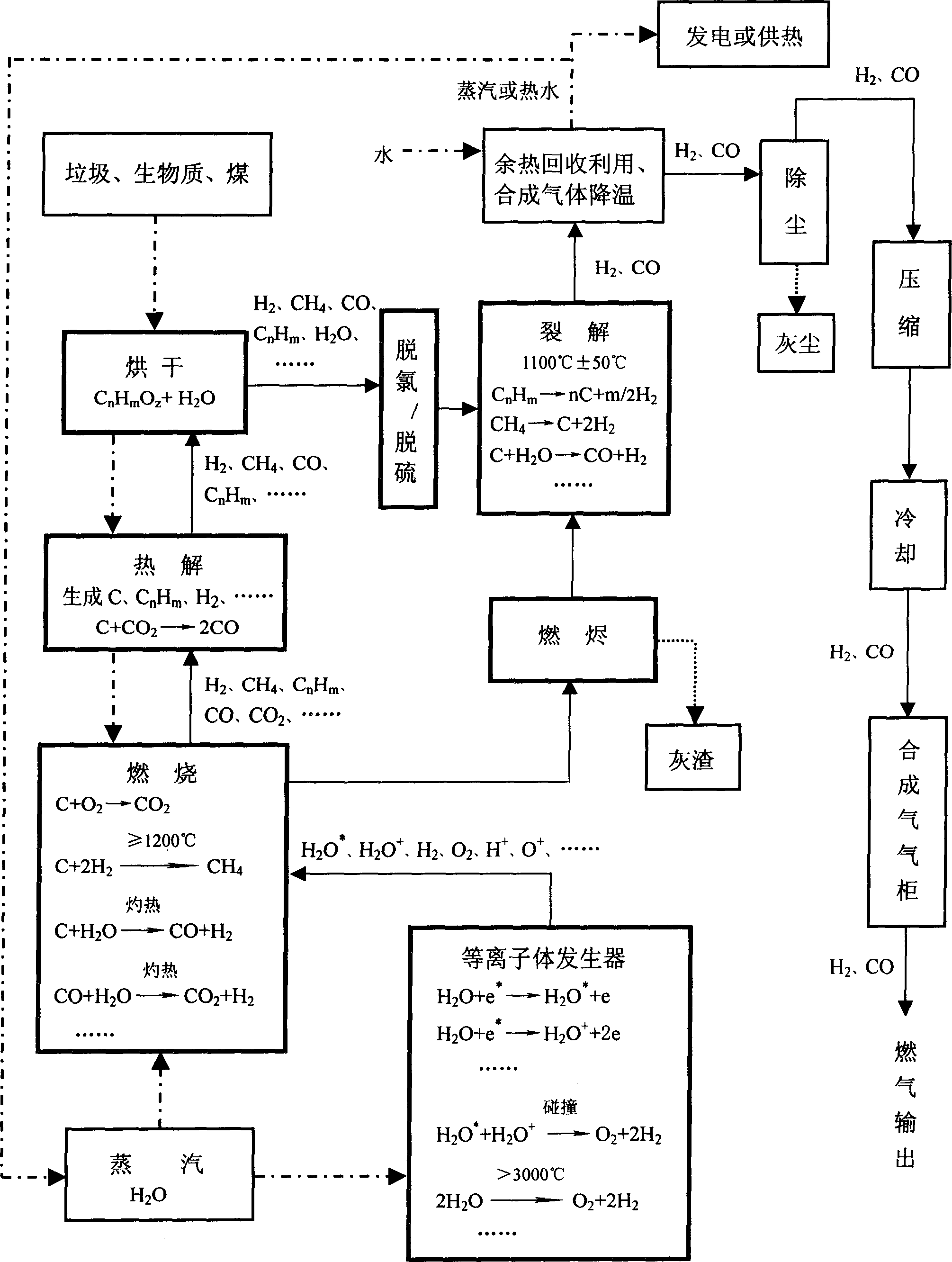

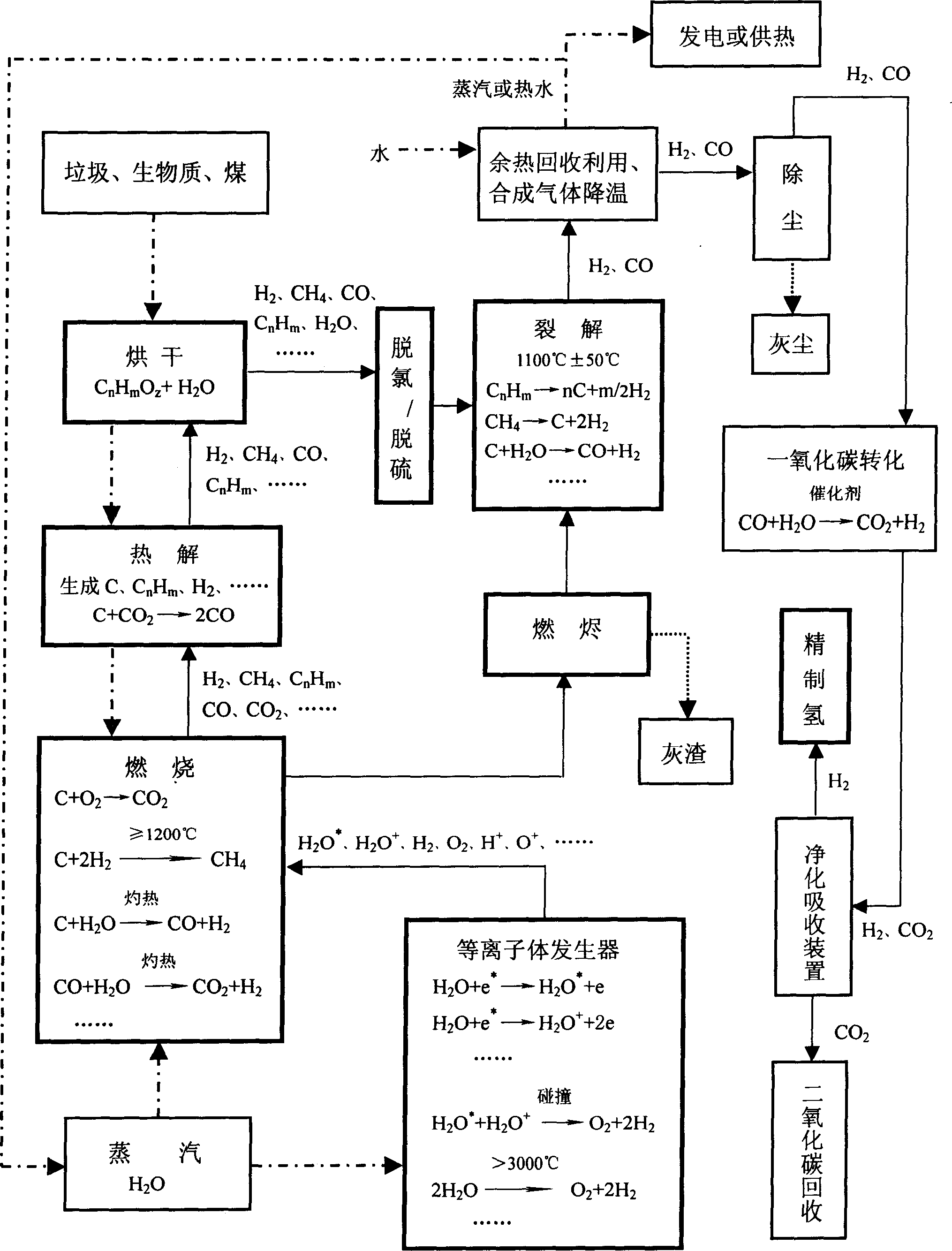

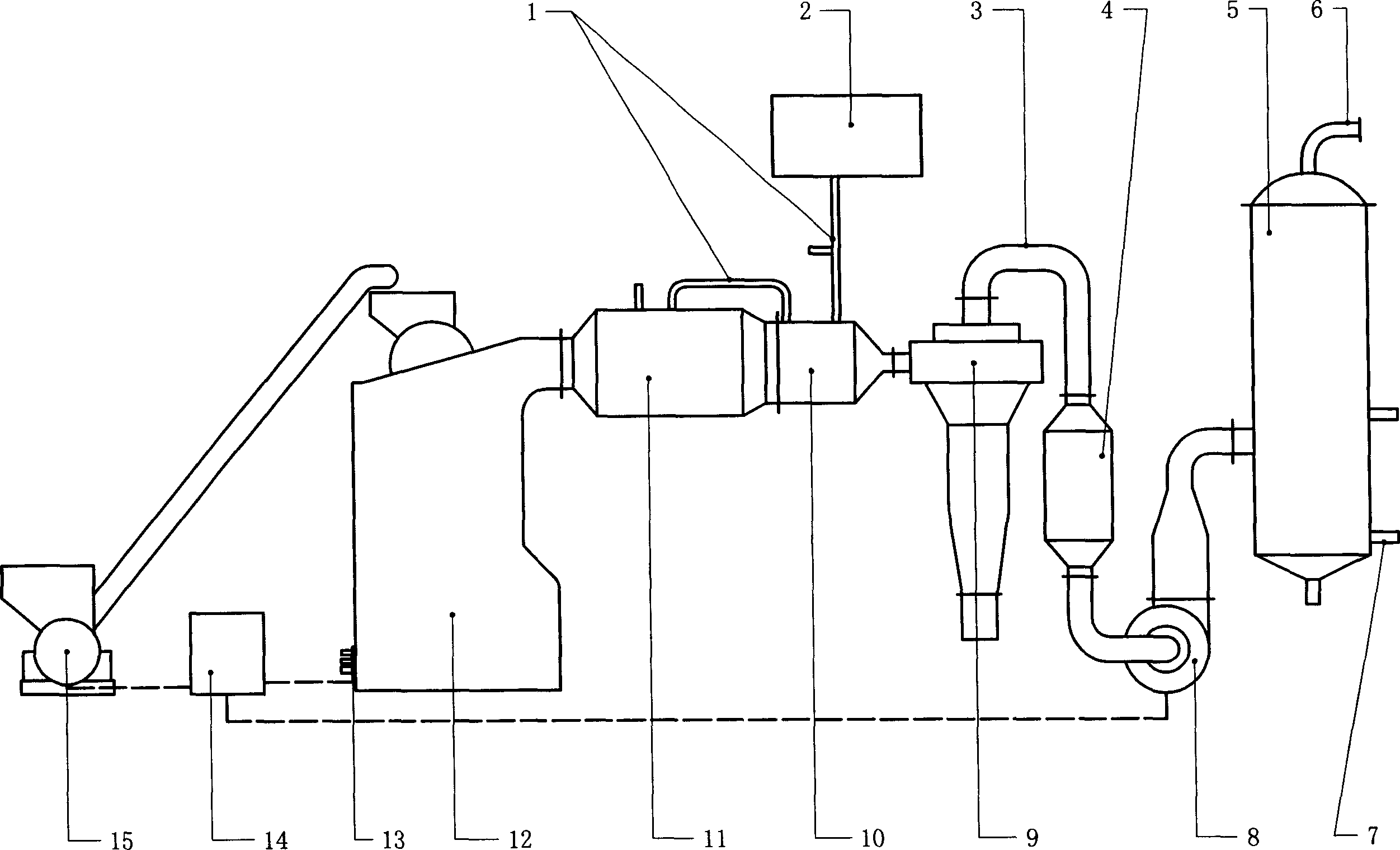

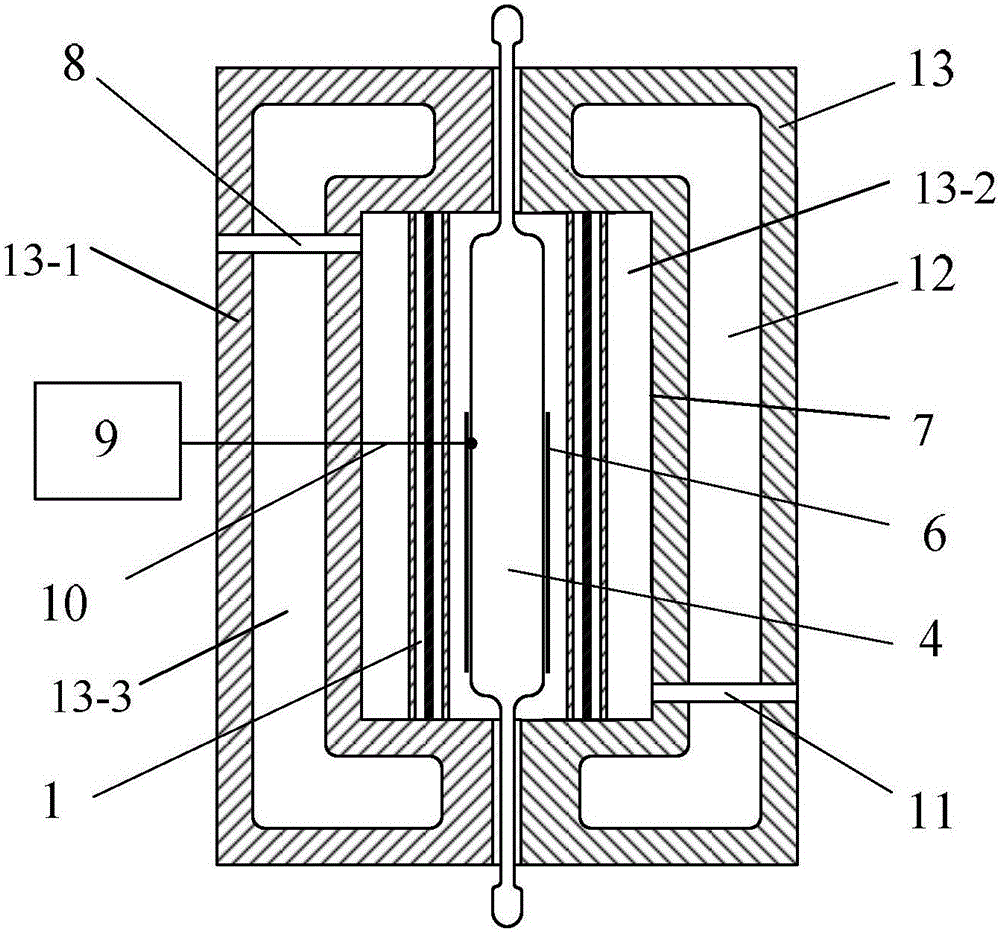

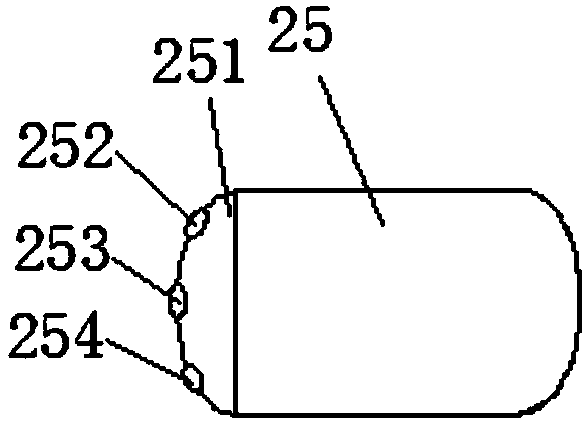

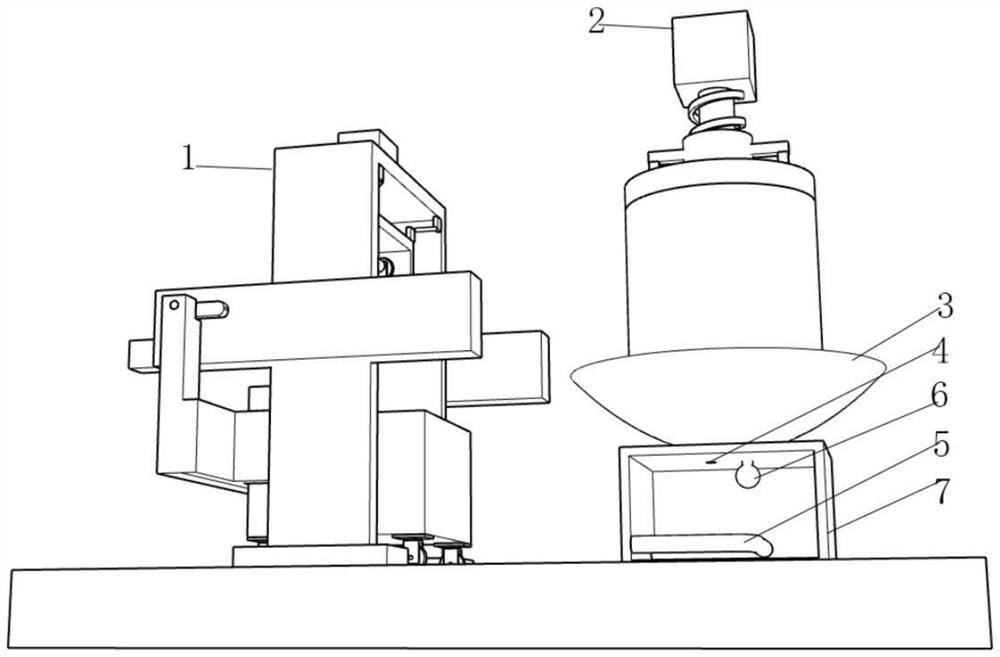

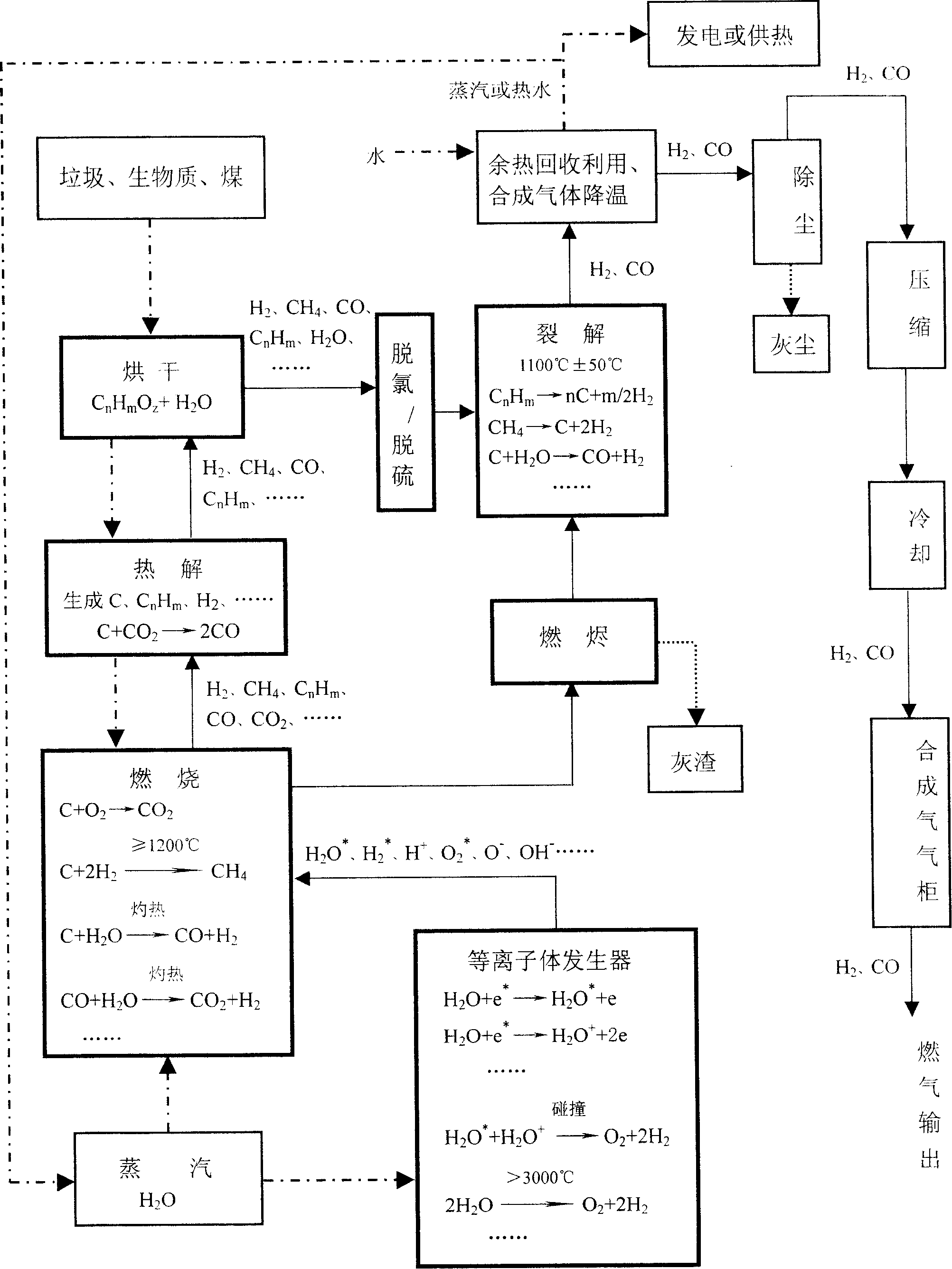

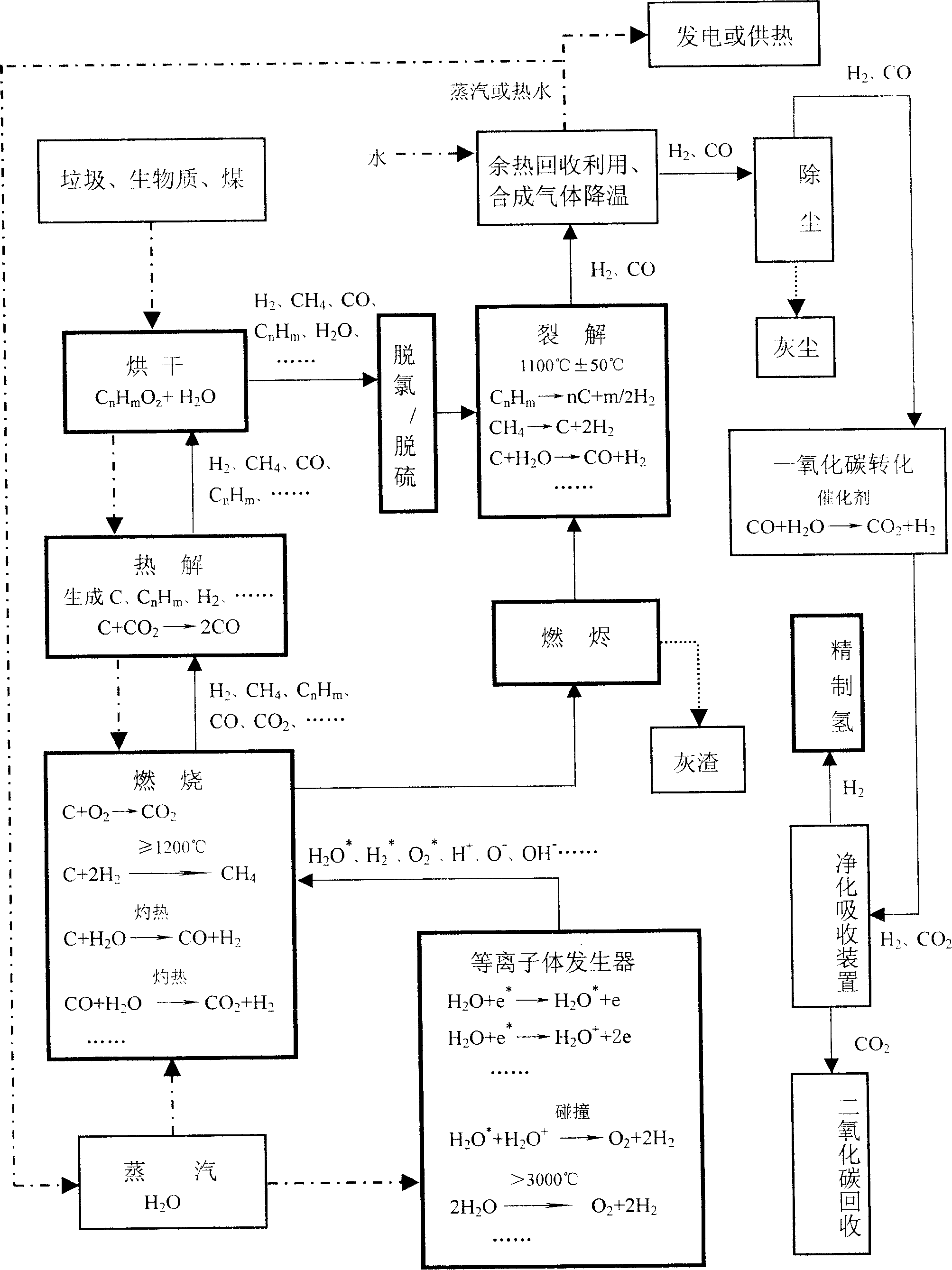

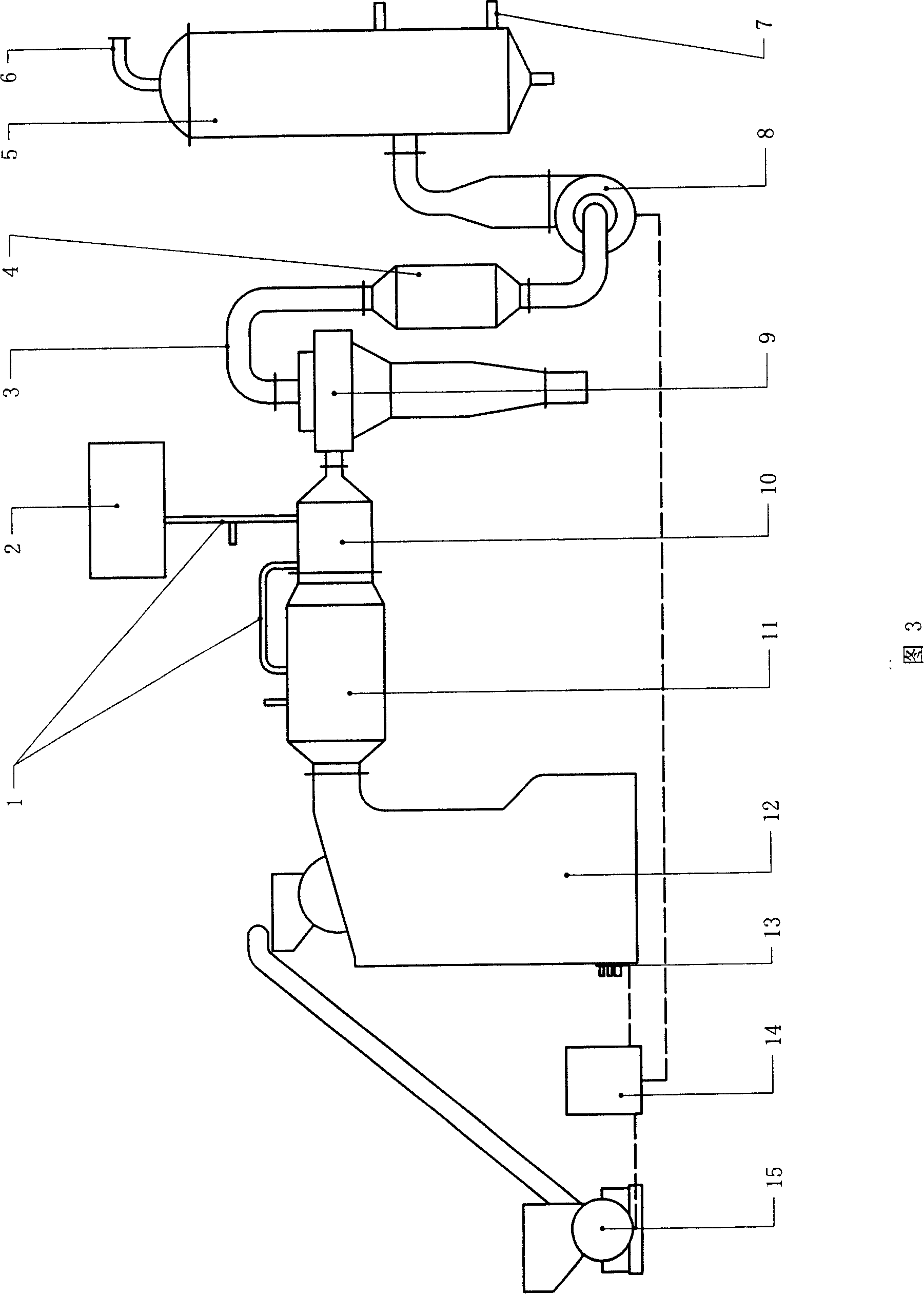

Method and device for plasma producing hydrogen by using garbage biomass and water as raw material

The hydrogen producing plasma method and apparatus uses garbage, biomass and water as material to produce hydrogen in industrial scale and low cost. The garbage and biomass material is set into furnace directly without through drying and crushing, and under the condition of isolating air, water molecule is activated and decomposed by means of plasma technology and the organic garbage and biomass serves as oxygen and hydrogen adsorbing element to inhibit the reverse reaction, so as to produce hydrogen-rich synthetic gas with high hydrogen content and no tar in high efficiency. The said process has no pollutant exhaust, high hydrogen producing speed and low power consumption.

Owner:衢州市广源生活垃圾液化技术研究所

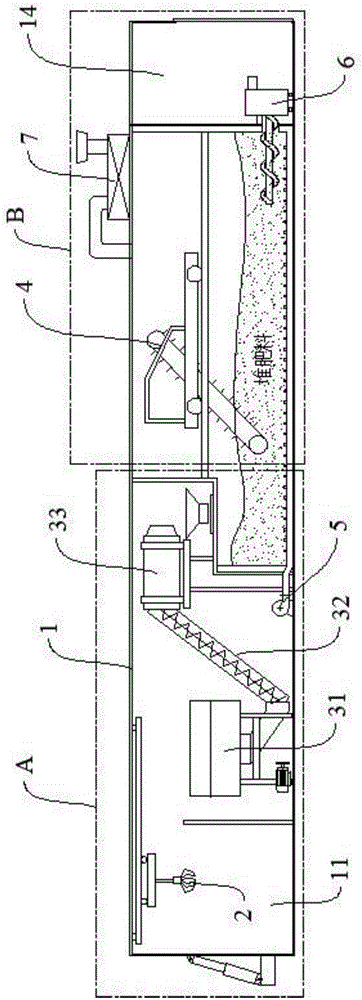

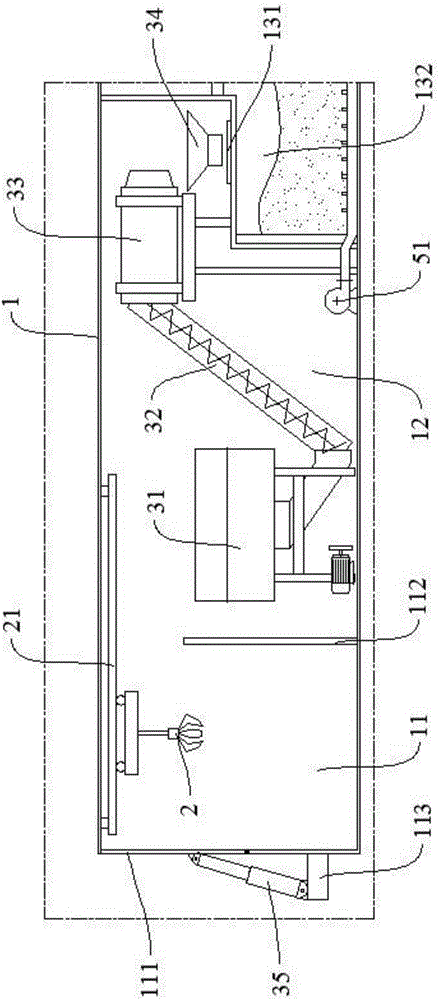

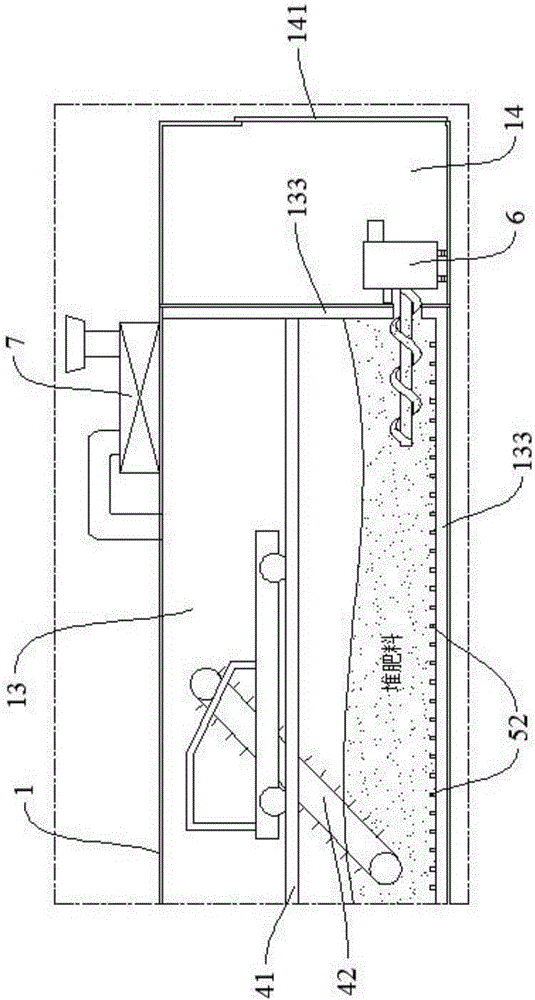

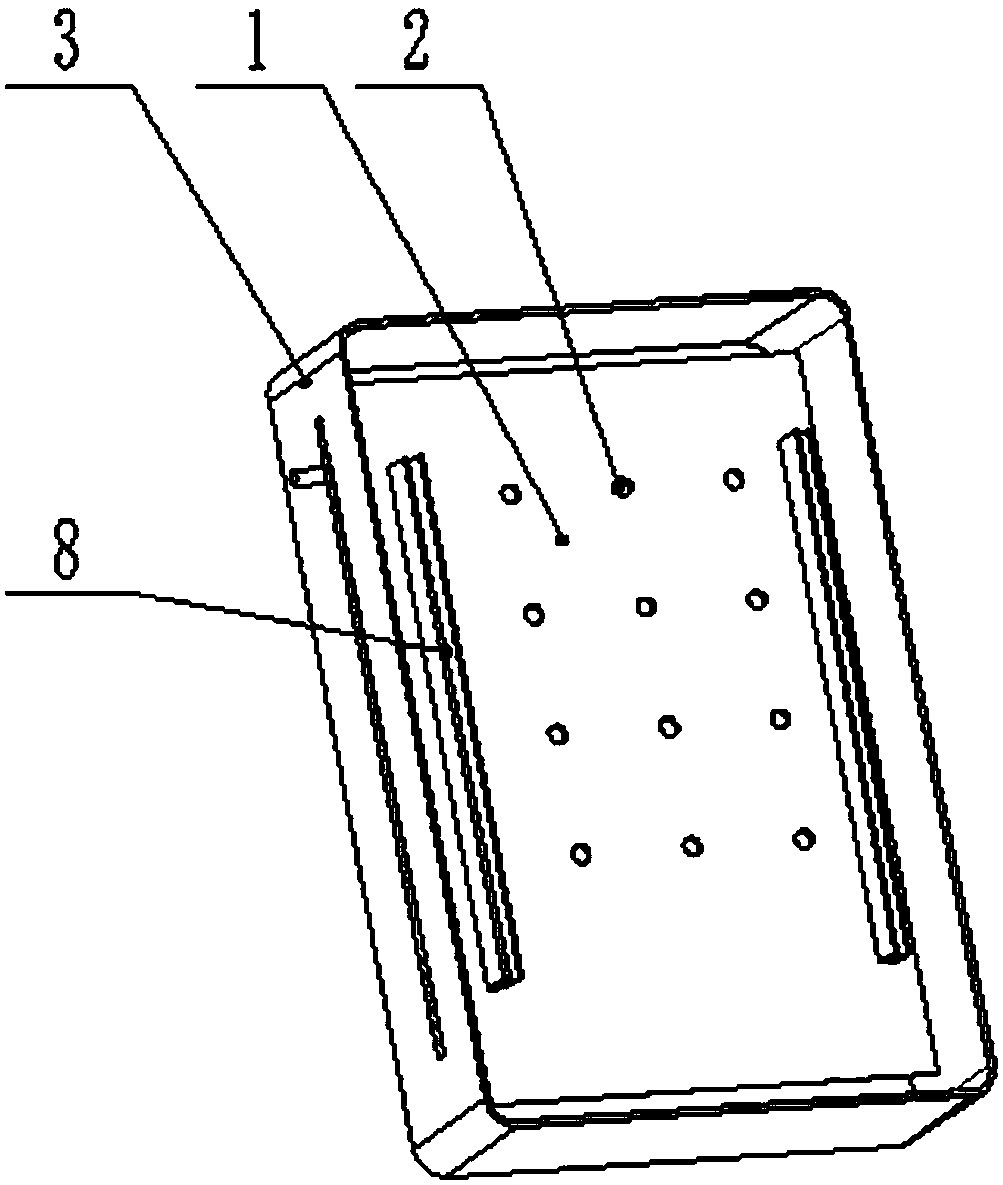

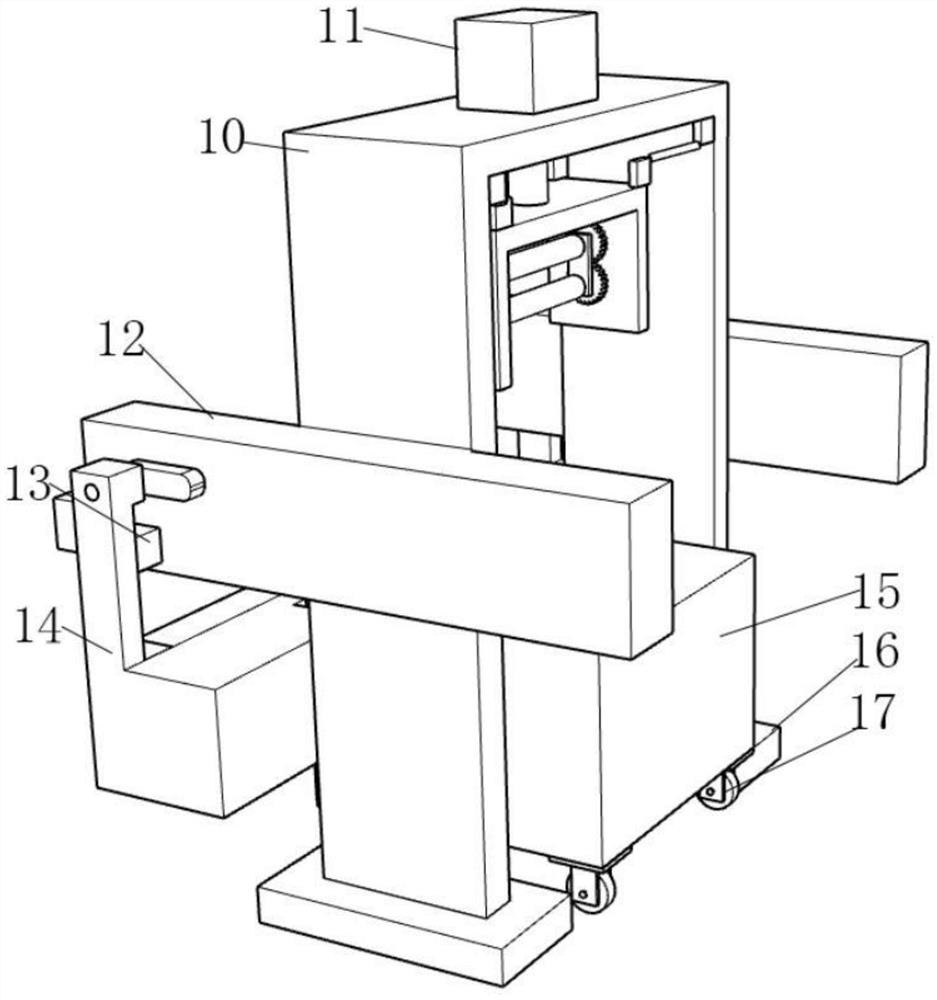

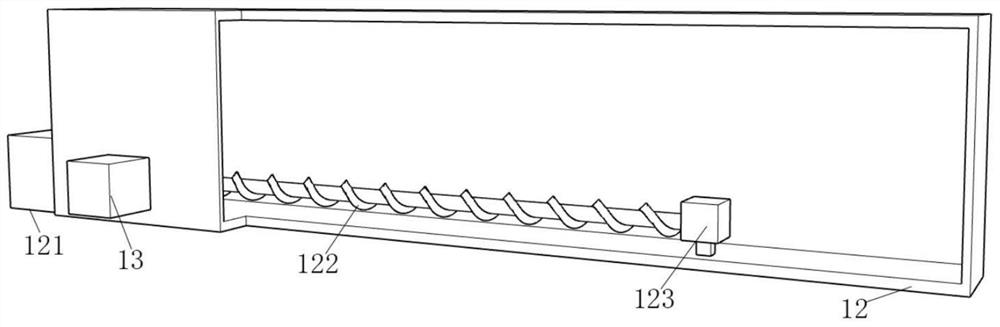

Movable solid waste biofermentation system

InactiveCN106518208AIncrease temperatureRealize comprehensive utilizationBio-organic fraction processingOrganic fertiliser preparationFermentationUtilization rate

The invention relates to a movable solid waste biofermentation system. The movable solid waste biofermentation system comprises a container body, a charging system arranged in the container body, a pulverizing device, a feeding device, a stirring and mixing device, a turning device, a forced ventilation system, a discharging device and a deodorizing system, wherein the container body is sequentially divided into a storage bin, a pretreatment bin, a fermentation bin and a finished product bin in a splicing or separation manner; the fermentation bin is a closed bin; waterproof acid / alkali-resistant inner lining layers are laid on four walls and a bottom plate in the fermentation bin; the forced ventilation system is arranged at the bottom of the fermentation bin; the turning device is arranged in the fermentation bin; a feeding gate is arranged between the fermentation bin and the pretreatment bin; and an exhaust port of the fermentation bin is connected with the deodorizing system. For rural waste straws, composting equipment is organically combined with the container to realize waste utilization of the low-cost container; and meanwhile, due to the characteristic of modular movability, one set of equipment can cover a vast territory with a sparse population, thereby increasing the equipment utilization rate.

Owner:冯汝龙

Corrugated paper waste recovery device

PendingCN105921230AAchieve tidinessEnable recyclingGrain treatmentsMetal working apparatusProduction linePaper production

The invention discloses a corrugated paper waste recovery device. The recovery device is positioned in a paper outlet of a rotating wheel cutter, and comprises a guide wheel, a guide pipe, a crusher and a recovery box; the guide wheel is positioned in the paper outlet of the rotating wheel cutter; the guide pipe is positioned below the guide wheel; a feed port of the crusher is below a bottom pipe port of the guide pipe; the recovery box is positioned below a discharge port of the crusher; the discharge port of the crusher is fixedly connected with a box cover; the shape and the size of a cover opening of the box cover are the same with that of a box opening of the recovery box; a slot is formed in the edge, parallel to a corrugated board, of the cover opening; a clamping bar matched with the slot is arranged in the box opening, and is inserted in the slot; the box opening and the cover opening are connected tightly; and pulleys are arranged at the bottom of the recovery box. The corrugated paper waste recovery device performs unified collection and treatment of waste leftovers on a corrugated paper production line, saves the labor cost, realizes the resource recycling, realizes the field tidiness, and provides guarantee for safe production.

Owner:安徽浙源再生纸业科技有限公司

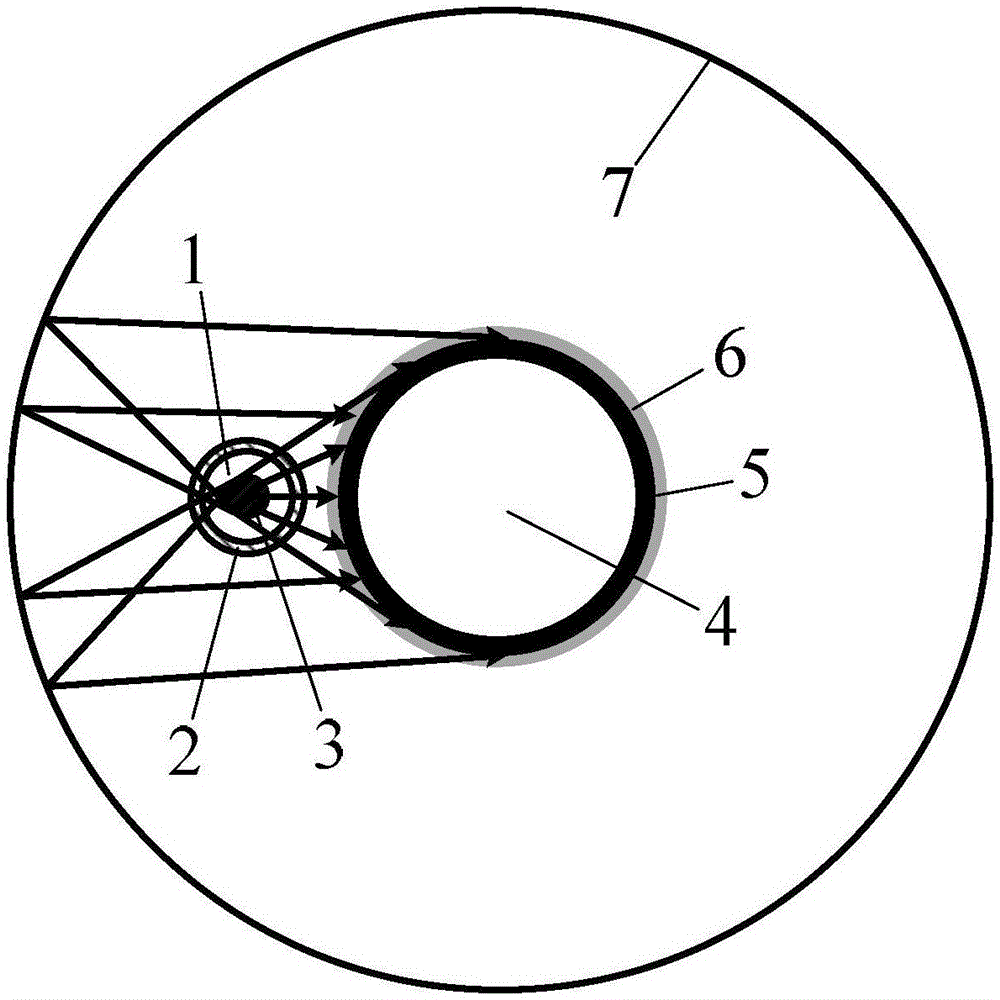

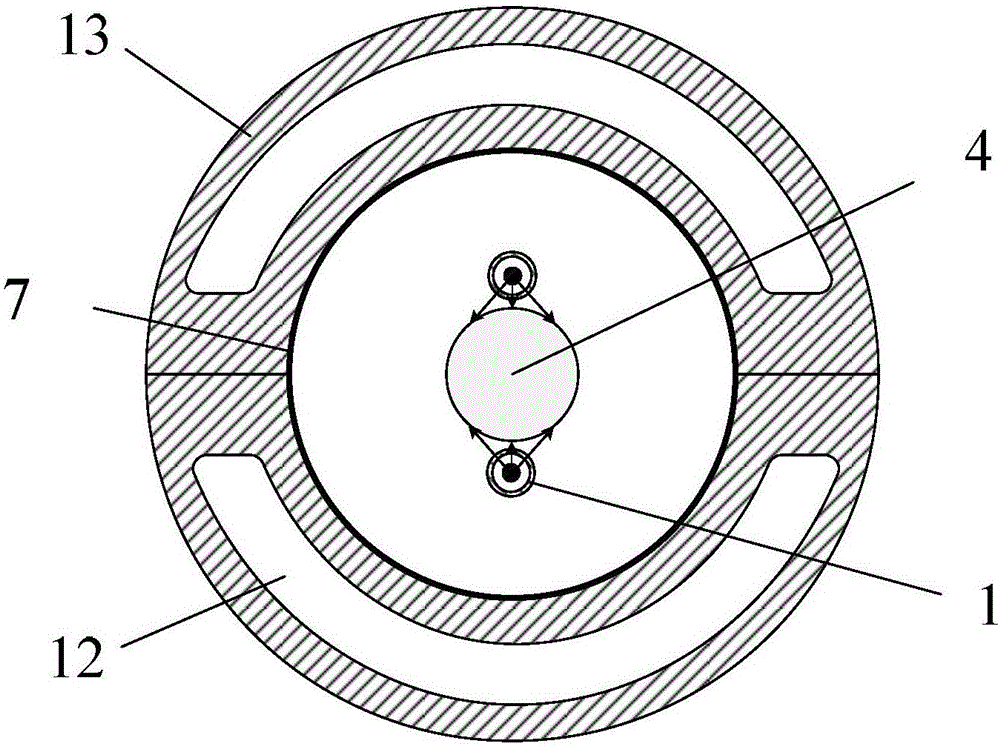

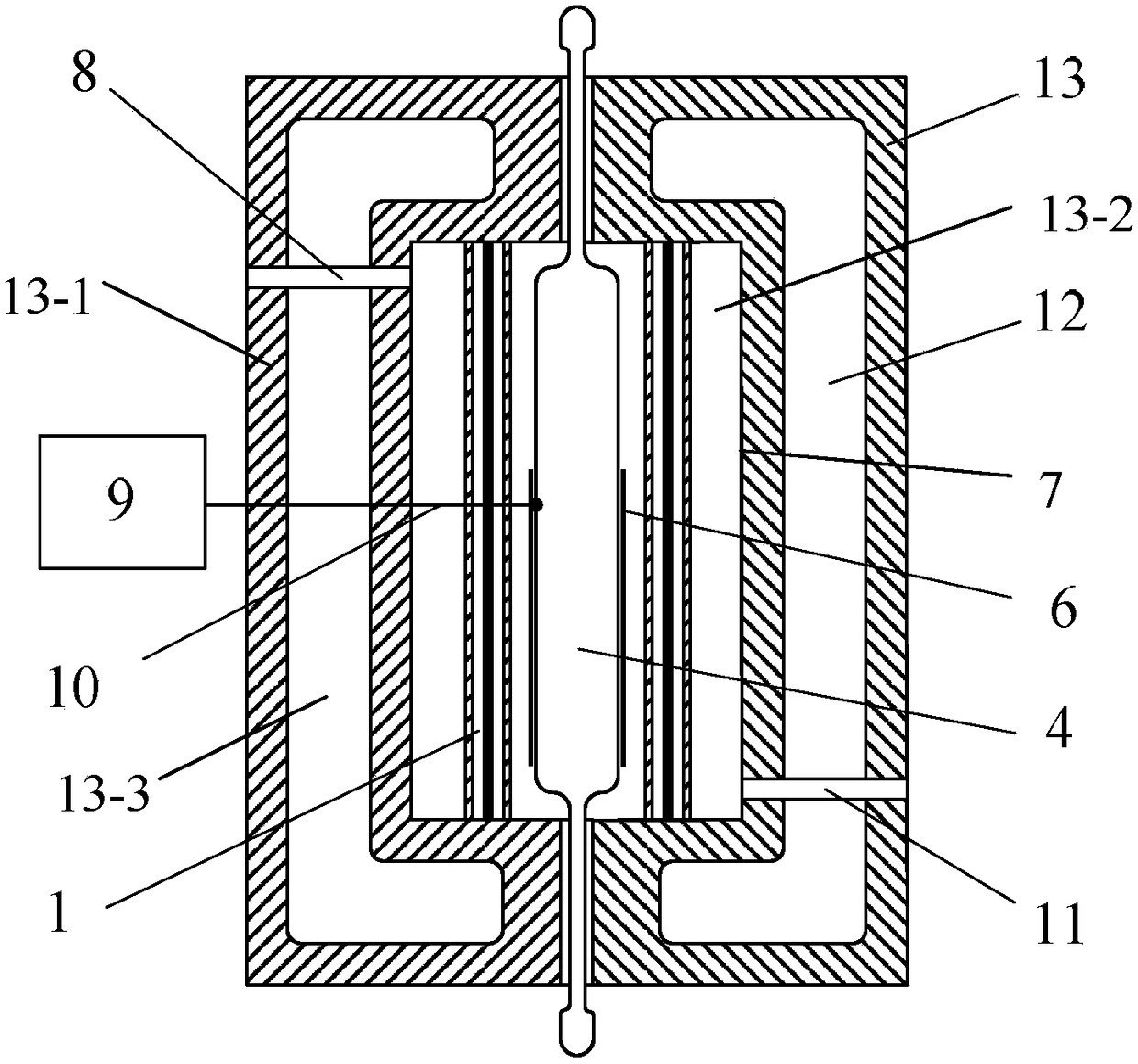

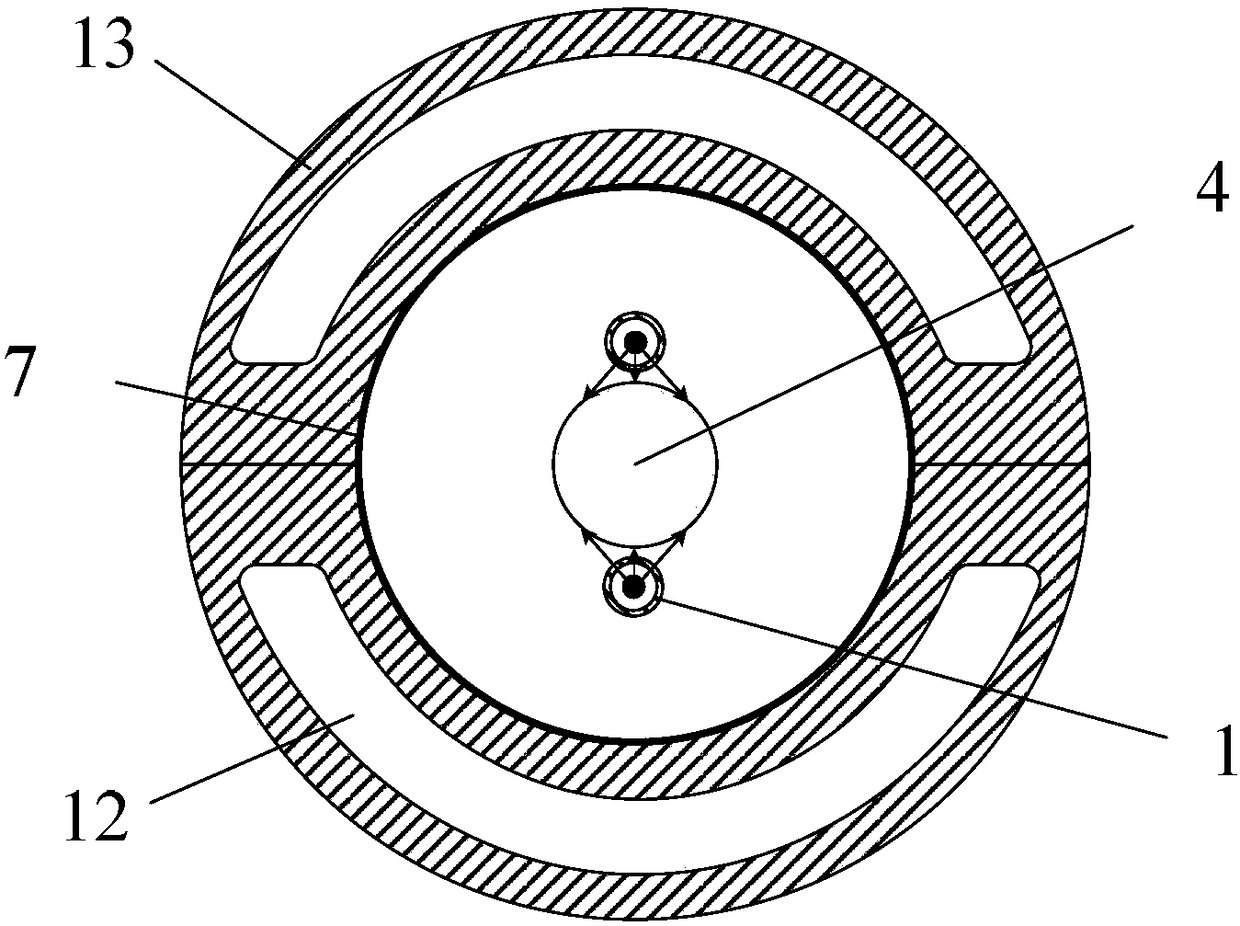

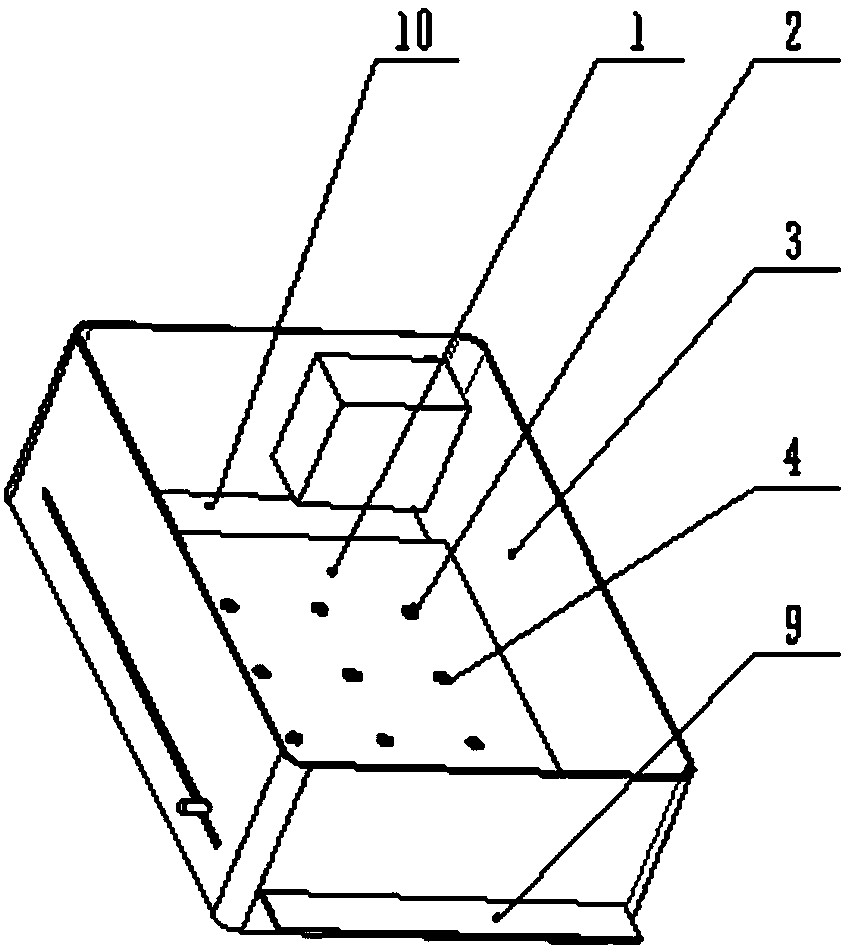

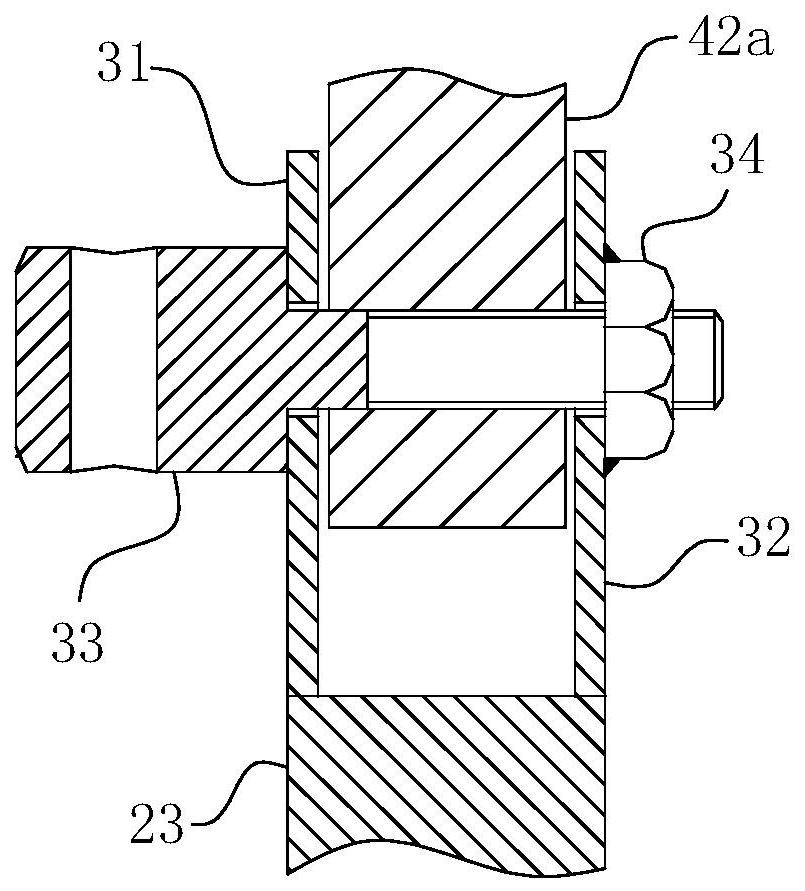

Oppositely-opened radiative heating furnace and furnace body

ActiveCN105758182AAvoid dependenceHigh positioning accuracyFurnace typesElectric heating for furnacesEmissivityHearth

The invention provides an oppositely-opened radiative heating furnace and a furnace body, belongs to the field of heating devices used in laboratories and aims at solving the problems of poor rapid heating and cooling performance and low cost performance of existing heating devices used in the laboratories.The furnace body is composed of two sections, wherein each section is provided with a sunken cavity, a wall body of each section is provided with a channel for circulating cooling liquid to flow through, the two cavities form a cylindrical hearth when the two section are oppositely combined together, and the wall face of the cylindrical hearth is a smooth and clean face.The heating furnace comprises a heating element, the furnace body and a temperature controller, wherein the heating element is a radiative heating tube, the furnace body comprises the cylindrical hearth with the smooth and clean wall face, the radiative heating tube is close to the surface of a heated object, and the surface of the heated object is coated with a high-emissivity coating so as to strengthen radiative heating.The furnace body is provided with a gas purging channel to achieve rapid cooling of the hearth, and the circulating cooling liquid flows through the whole furnace wall to ensure cooling of a whole mirror wall.The oppositely-opened radiative heating furnace and the furnace body can be used for a heating tube type reactor.The furnace body is compact and high in performance cost ratio.

Owner:HARBIN INST OF TECH

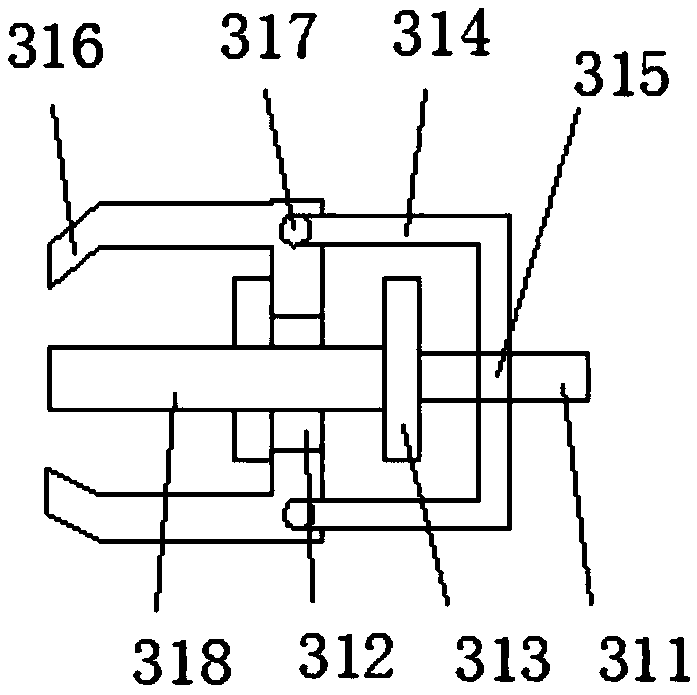

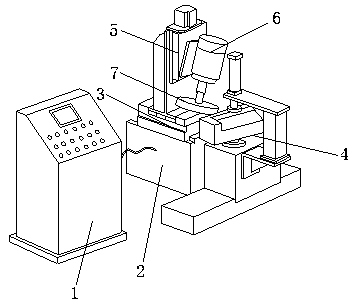

Electrophoresis paint-spraying pretreatment device for surfaces of mechanical parts and fittings

ActiveCN107904648AImprove work efficiencyAchieve tidinessElectrophoretic coatingsElectric machineryWater pipe

The invention discloses an electrophoresis paint-spraying pretreatment device for surfaces of mechanical parts and fittings. The electrophoresis paint-spraying pretreatment device comprises a housingI, wherein an inner cavity of the housing I is hollow; the bottom wall of the housing I is sequentially connected with a motor I, a motor II and a motor III in the horizontal direction; one end of themotor I, one end of the motor II and one end of the motor III are separately connected with a rotary shaft I, a rotary shaft II and a rotary shaft III; the top of the housing I is sequentially connected with a conveyor belt I, a controller, a frame body, a water tank, a barrel body, a supporting rod, a booster pump, a housing II, an electrophoresis slot and a conveyor belt II in the horizontal direction; one end, away from the housing I, of the conveyor belt I is fixedly connected with a placing plate; the placing plate is positioned on the top of the water tank; and the side wall of one side, away from the conveyor belt, of the water tank is sequentially connected with a water pump and a water introducing tube in the vertical direction. The electrophoresis paint-spraying pretreatment device is simple in structure, is convenient to operate, realizes pretreatment for electrophoresis parts and fittings and a treatment function after electrophoresis is completed, and improves electrophoresis quality.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

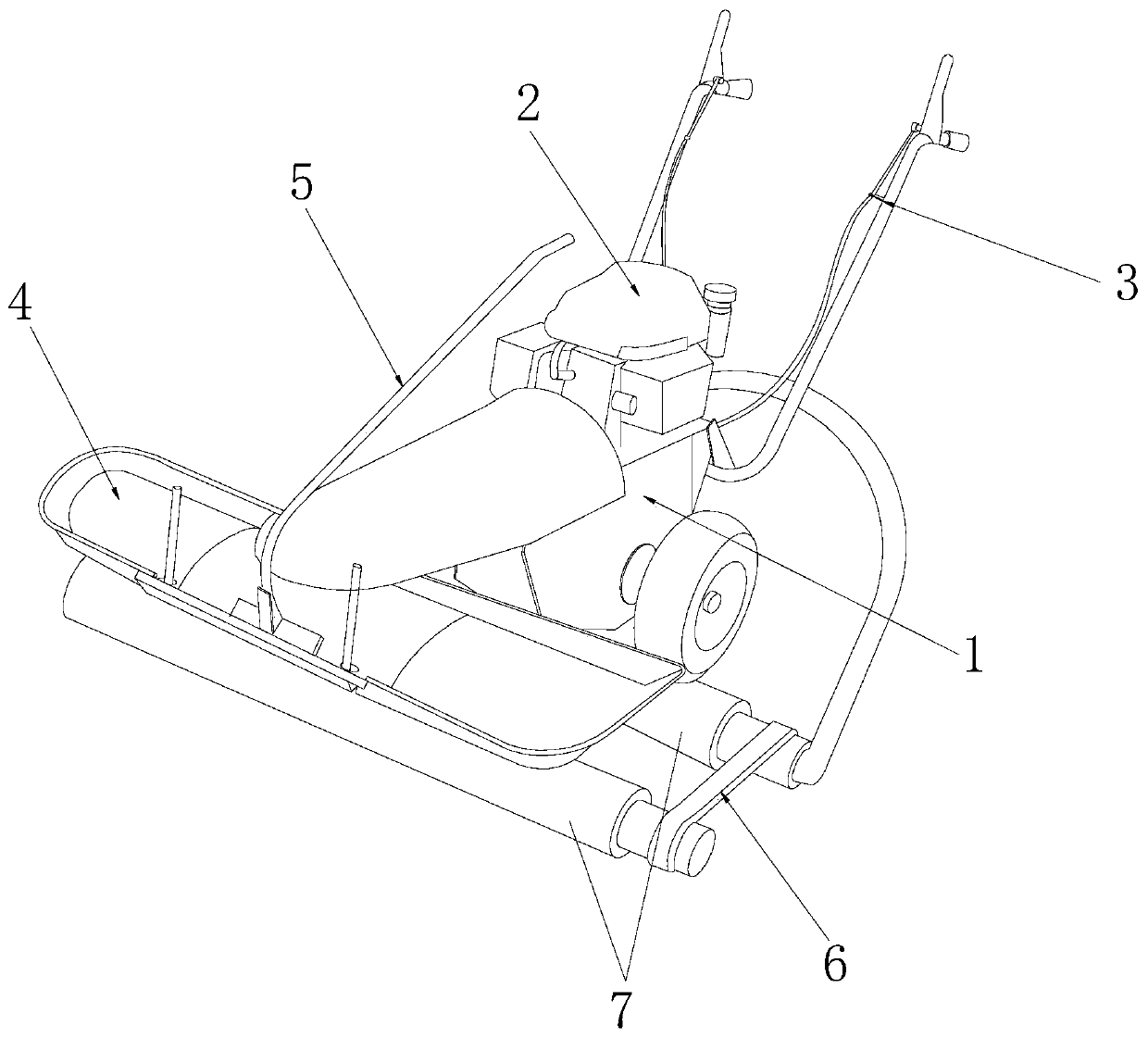

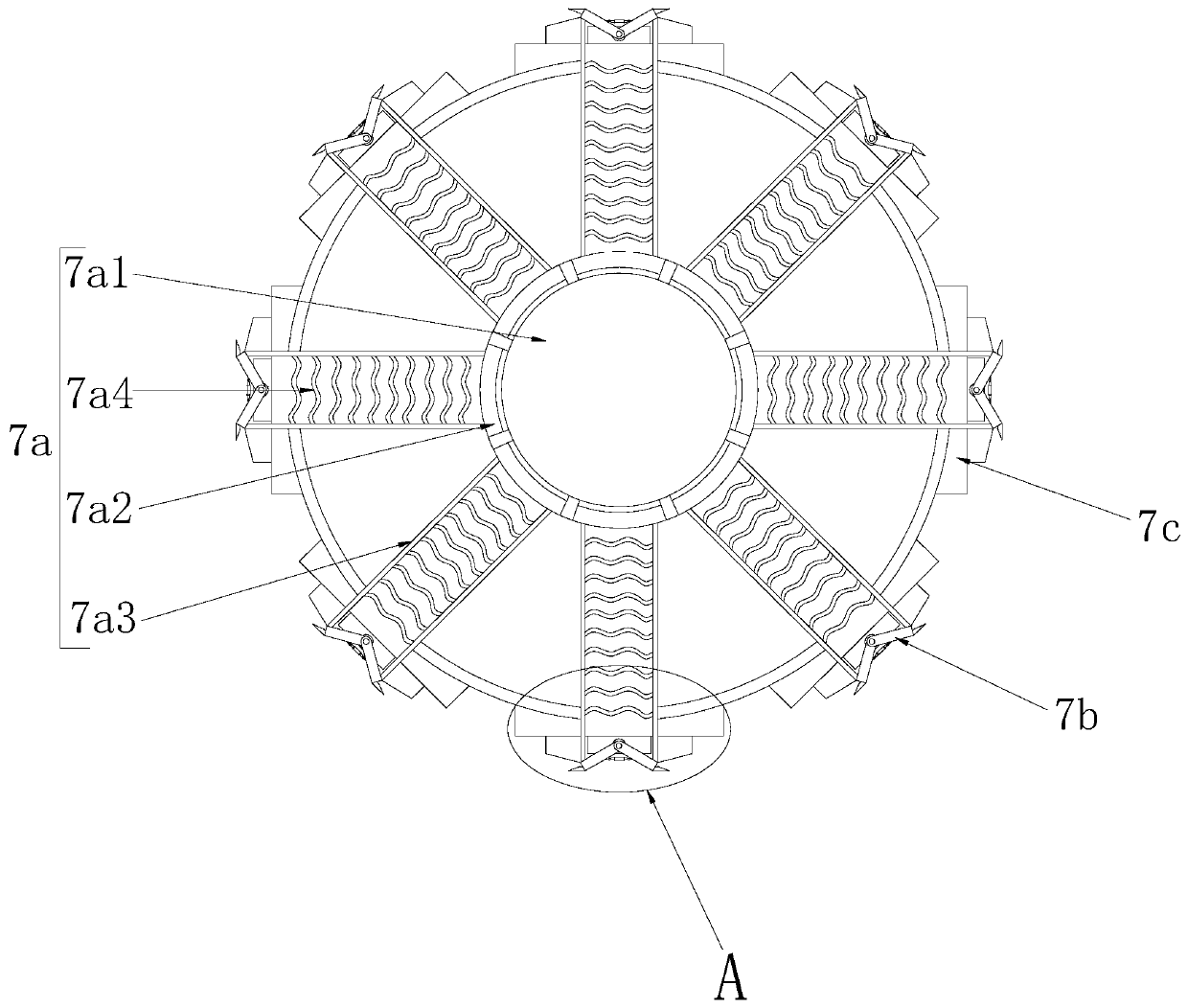

Machining site ground oil stain cleaning equipment with pit and fissure removal

The invention discloses machining site ground oil stain cleaning equipment with pit and fissure removal. The machining site ground oil stain cleaning equipment structurally comprises an equipment mainbody, a driving body, a control handle, a blocking and protecting cover, a height adjusting rod, a connecting belt and a pit and fissure cleaning device. The machining site ground oil stain cleaningequipment has the beneficial effects that when the pit and fissure cleaning device is used for effectively cleaning oil stains permeating through splicing seams on the ground of a machining site, a sharp knife blade is inserted into the seam under the action of rotation of the device; under the driving action of rotation and external force, solidified oil stain in the seam is removed such that thecleanness of ground seams is realized, massive accumulation is avoided so as to prevent a potential safety hazard phenomenon; through mutual cooperation of the oil attachment structure and the solidification balance structure, a movable opening is used for conducting buckling type removal on the solidified oil stains attached to the surface of the sharp knife blade with the help of external force, unified storage is achieved, the overall balance of the device is improved, meanwhile, under the interaction of ta frame adjusting plate and an isolation strip, solid and liquid are subjected to separation treatment, and therefore liquid oil can be recycled.

Owner:深圳市格仕乐科技有限公司

Guide paper recovery device

The invention discloses a guide paper recovery device, which comprises a frame and a material collecting barrel. The device is characterized in that: a guide paper recovery barrel is disposed on the frame and is arranged in axis parallel with the material collecting barrel; and a motor is disposed on the frame for driving the guide paper recovery barrel to rotate. In the invention, by adding the guide paper recovery barrel, the guide paper recovery device realizes the guide paper recovery, not only achieves a clean, tidy and easy-arranging workshop environment, but also can reuse the guide papers with unprinted sides. The guide paper recovery device disclosed by the invention achieves the advantages of simple structure and environment protection.

Owner:WUJIANG WALLMATE DECORATION MATERIALS

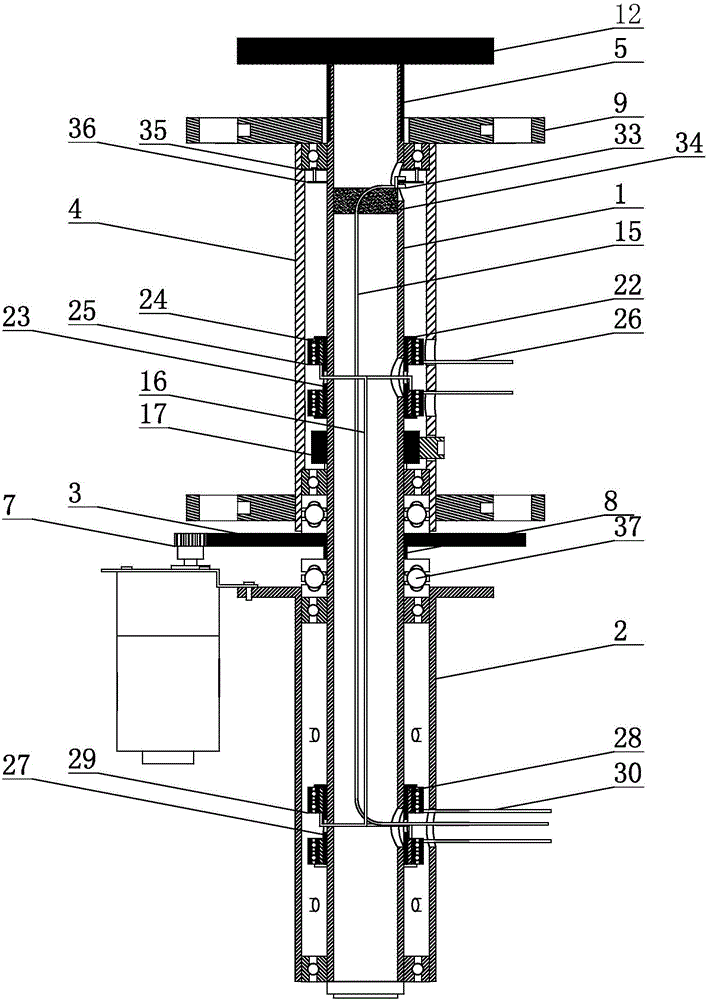

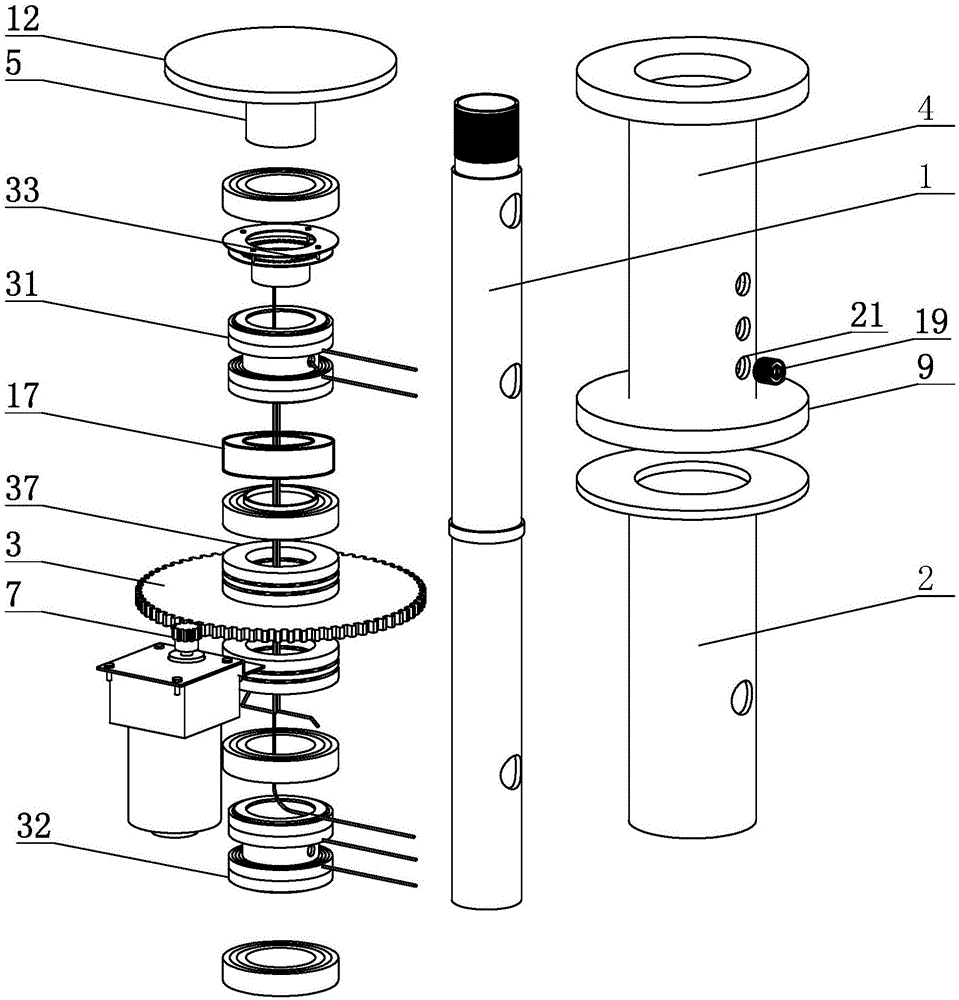

Three-layer electric dining table

InactiveCN106723960AAchieve tidinessAchieve maintenanceServing tablesVariable height tablesRound tableGear wheel

The invention discloses a three-layer electric dining table, and mainly relates to the field of automatic dinging table devices. The three-layer electric dining table comprises a centrally-arranged shaft core; the shaft core is externally and sequentially provided with a lower sleeve, a large gear disc, an upper sleeve and a threaded sleeve from bottom to top; the lower sleeve is rotationally connected with the shaft core, a triangle floor stand is fixed on the lower sleeve, the large gear disc is installed in the middle of the shaft core, the upper sleeve is rotationally connected with the shaft core, a middle round table is installed on the upper sleeve, the threaded sleeve is in threaded connection with the top end of the shaft core, a center round table is installed on the threaded sleeve, an annular floor stand is arranged on the outer side of the triangle floor stand, and an external round table is fixedly connected on the annular floor stand; an intelligent inductor for detecting the relative rotation condition of the upper sleeve and the shaft core is arranged at the top of the shaft core, and a built-in brake mechanism is arranged between the shaft core and the upper sleeve. The three-layer electric dining table has the advantages that rotating and running are stable and smooth, operation is intelligent and convenient, the fault rate is low, maintaining is easy, and the three-layer electric dining table is compared with a multi-layer rotating dining table in the prior art, prominent improvement is achieved.

Owner:湖北牧鑫智能家居股份有限公司

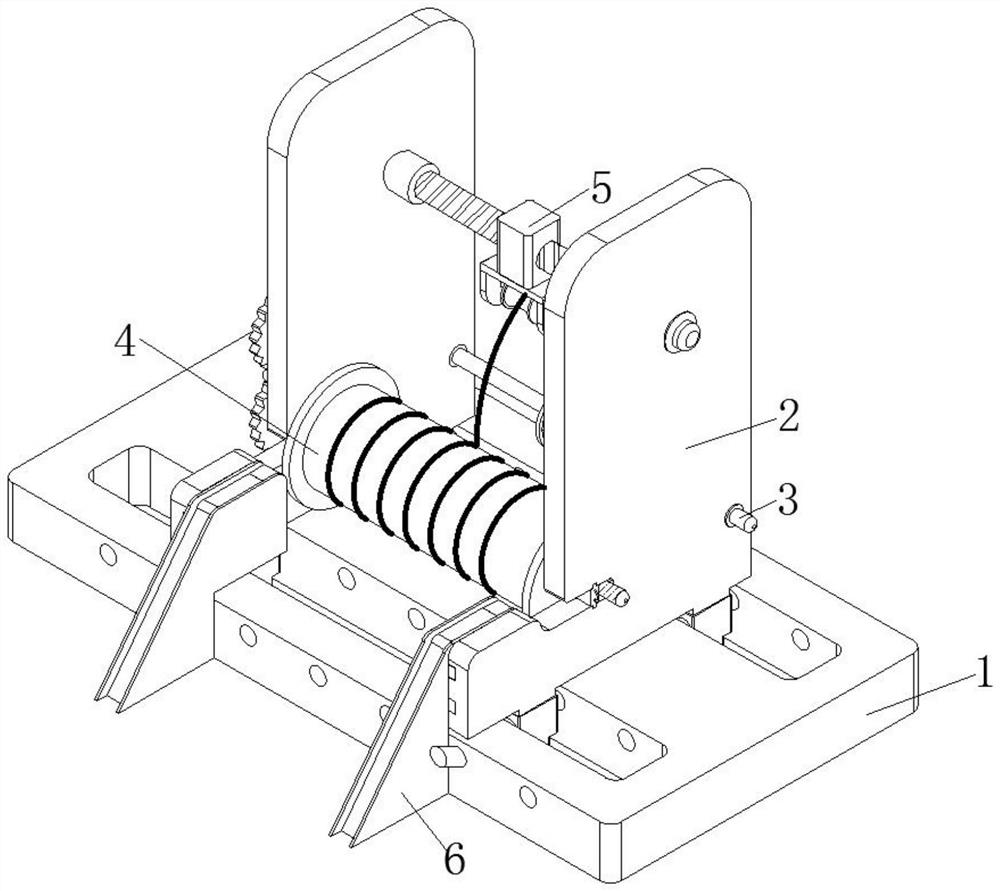

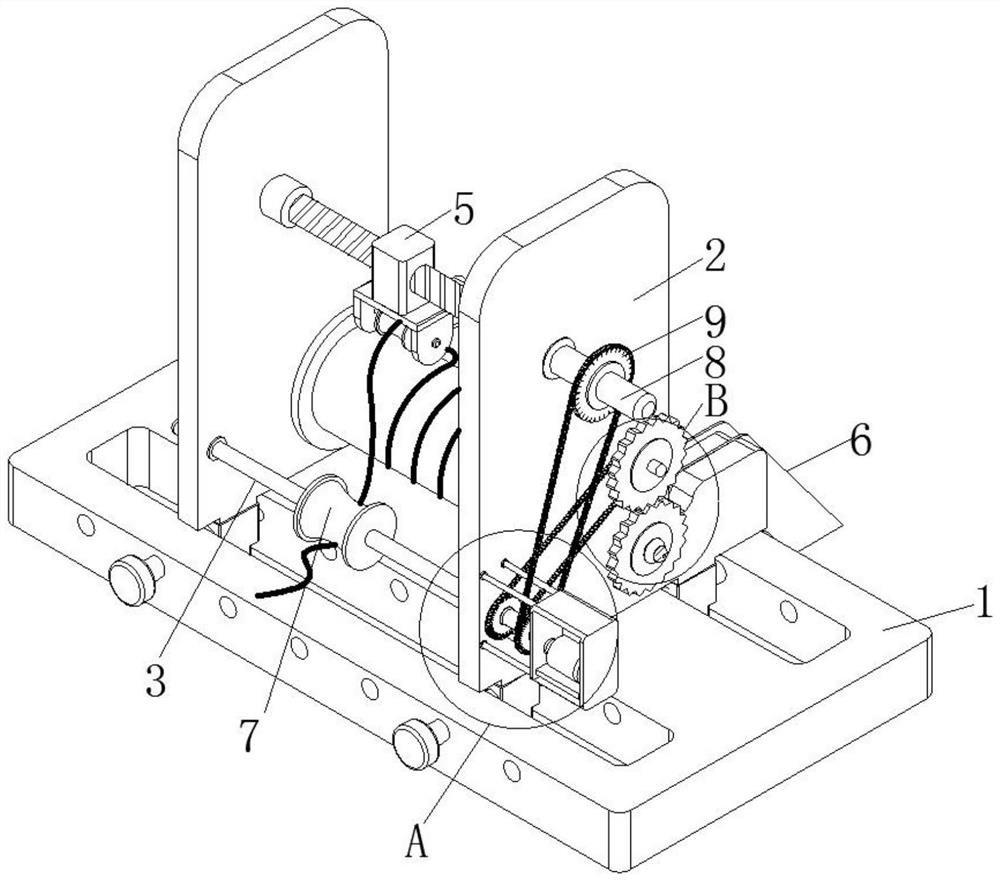

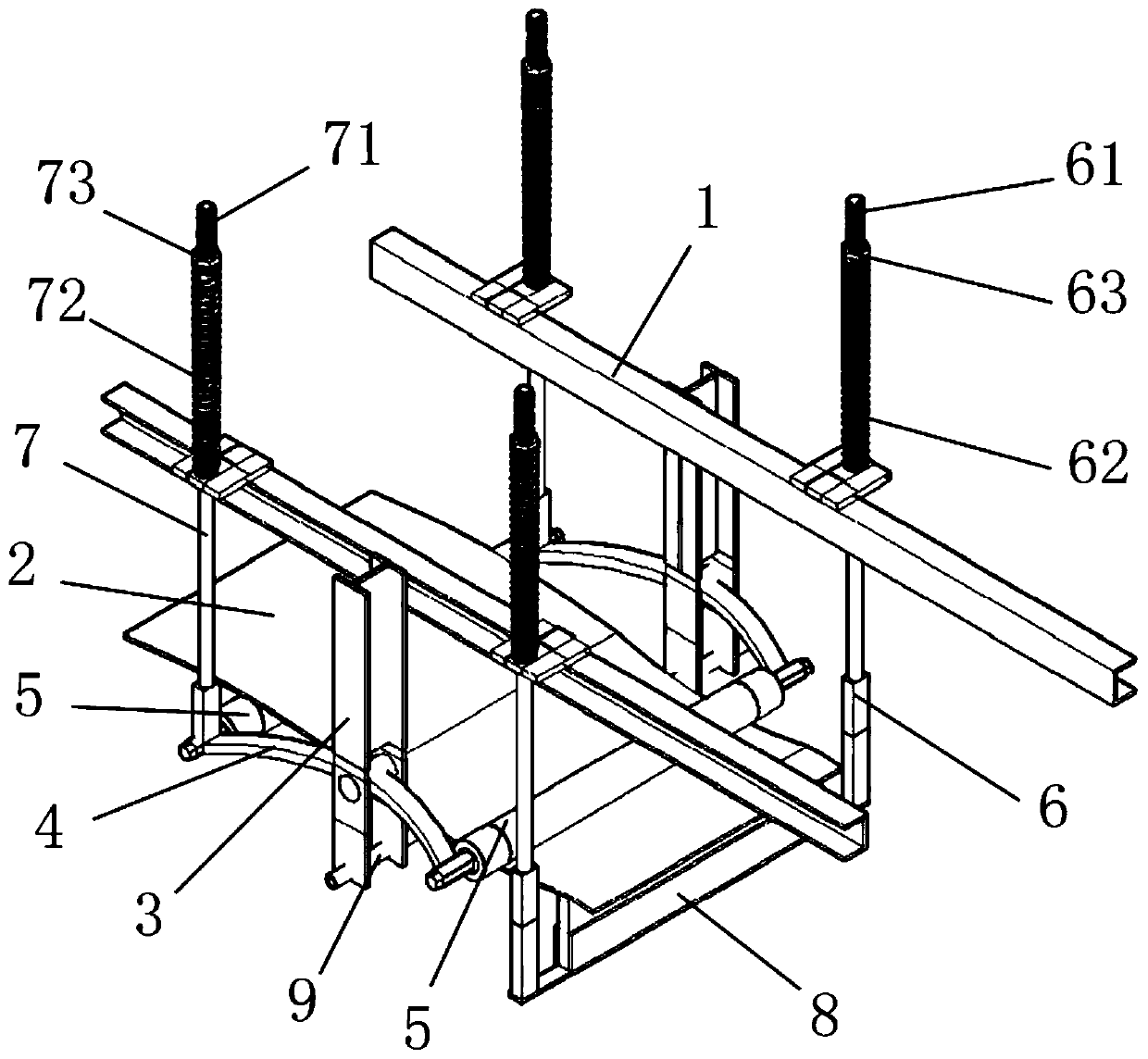

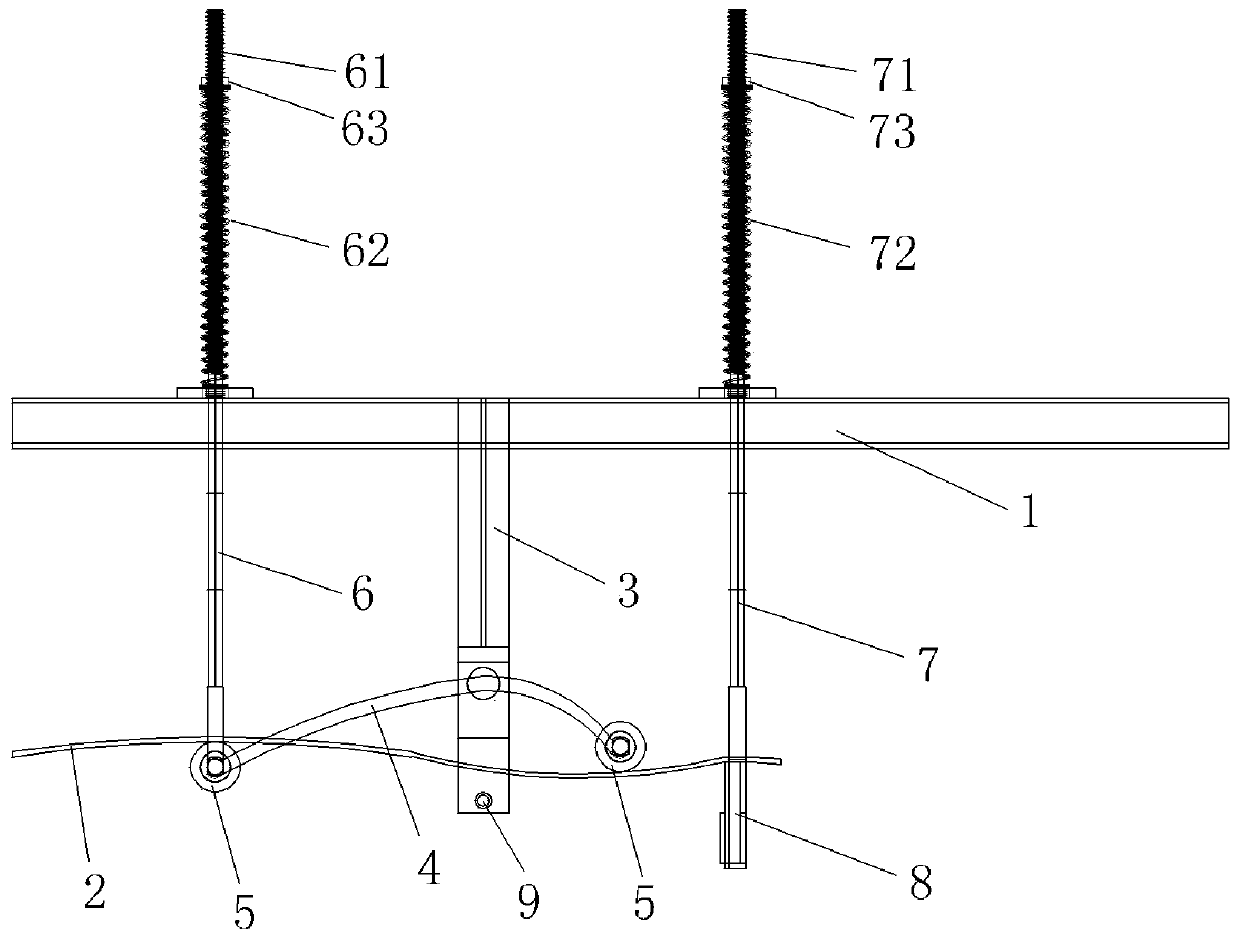

Take-up and pay-off device convenient for winding type cable reel and use method thereof

ActiveCN113955591AAchieve tidinessProblems affecting useFilament handlingApparatus for laying cablesStructural engineeringElectric cables

The invention relates to the technical field of cable take-up and pay-off, and discloses a take-up and pay-off device for a winding-type cable reel and a using method thereof. The take-up and pay-off device comprises a base assembly arranged on the ground, two partition plates consistent in specification are arranged at the top of the base assembly in a sliding mode, and inner sliding openings are formed in the front ends of the two partition plates correspondingly. A winding assembly for winding and unwinding a cable is arranged between the two inner sliding openings, a rotating shaft, a rotation rod and a rotating rod are arranged on the left side wall of the partition plate on the left side, the rotating shaft and the rotation rod are distributed in a triangular shape, and one end of the rotation rod penetrates through the partition plate on the left side and is provided with an adjusting assembly for assisting in winding and unwinding of the cable in order. The problems that in the prior art, the structure is single, in the cable take-up and pay-off process, cable laying is affected by the situation that the cable is bent in the pay-off process, in the cable take-up process, the situation that the cable is prone to being overlapped on a winding roller and is irregularly arranged in the cable take-up process occurs, consequently the cable is knotted in the winding process, and use of the cable is affected are solved.

Owner:ANHUI CABLE

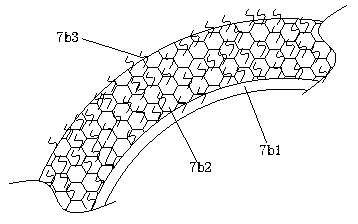

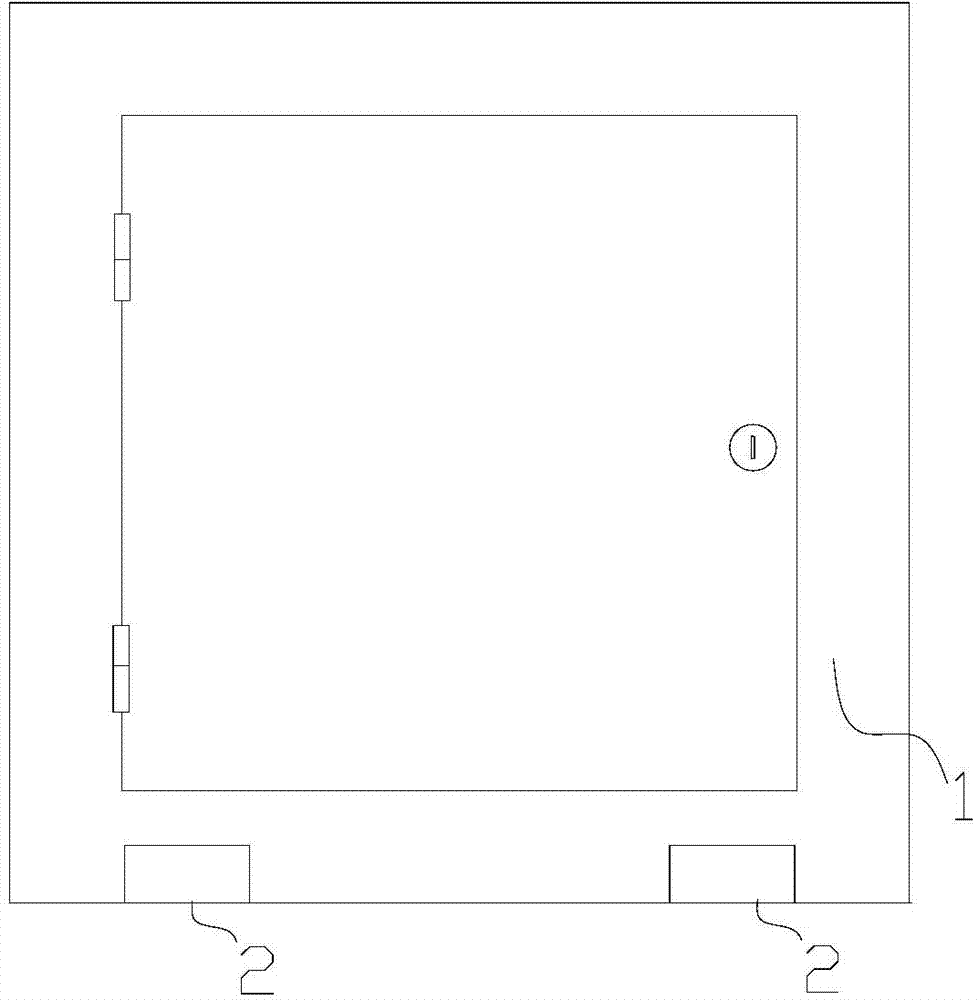

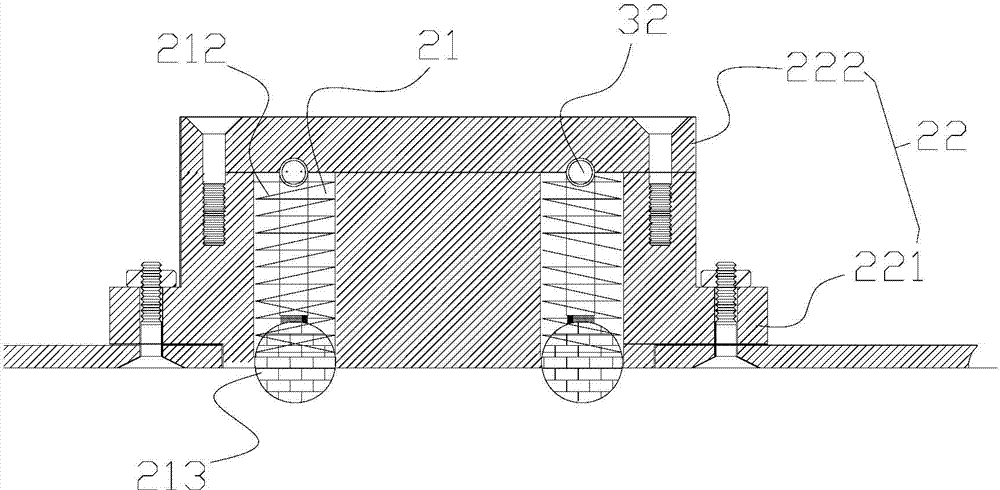

High-strength modular case and dustproof device thereof

InactiveCN110456867AEasy to convertGood for wiringFouling preventionDigital processing power distributionHigh intensityEngineering

The invention discloses a high-strength modular case and a dustproof device thereof. The high-strength modular case comprises a case main body, heat dissipation openings, a case internal bulges, a heat dissipation fan fixing device, a power supply fixing device, a hard disk fixing device, a mainboard fixing device, a dustproof net and a dustproof cover; the heat dissipation openings are formed inthe top and the side face of the machine body, the plurality of case internal bulges are arranged in the case and connected with the heat dissipation fan fixing device, the power source fixing device,the hard disk fixing device and the mainboard fixing device; a dustproof net is arranged on one part of each heat dissipation opening, and a dustproof cover is further arranged on the side face of the case main body. A high-degree-of-freedom spatial relationship of parts in the case can be realized.

Owner:LIUZHOU LIANHAI TECH

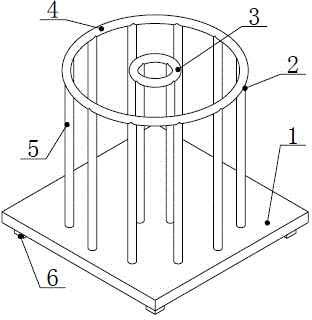

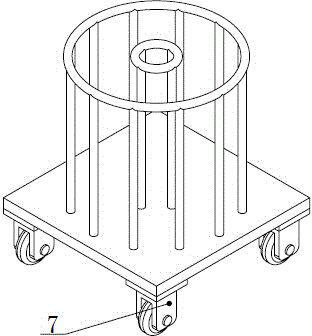

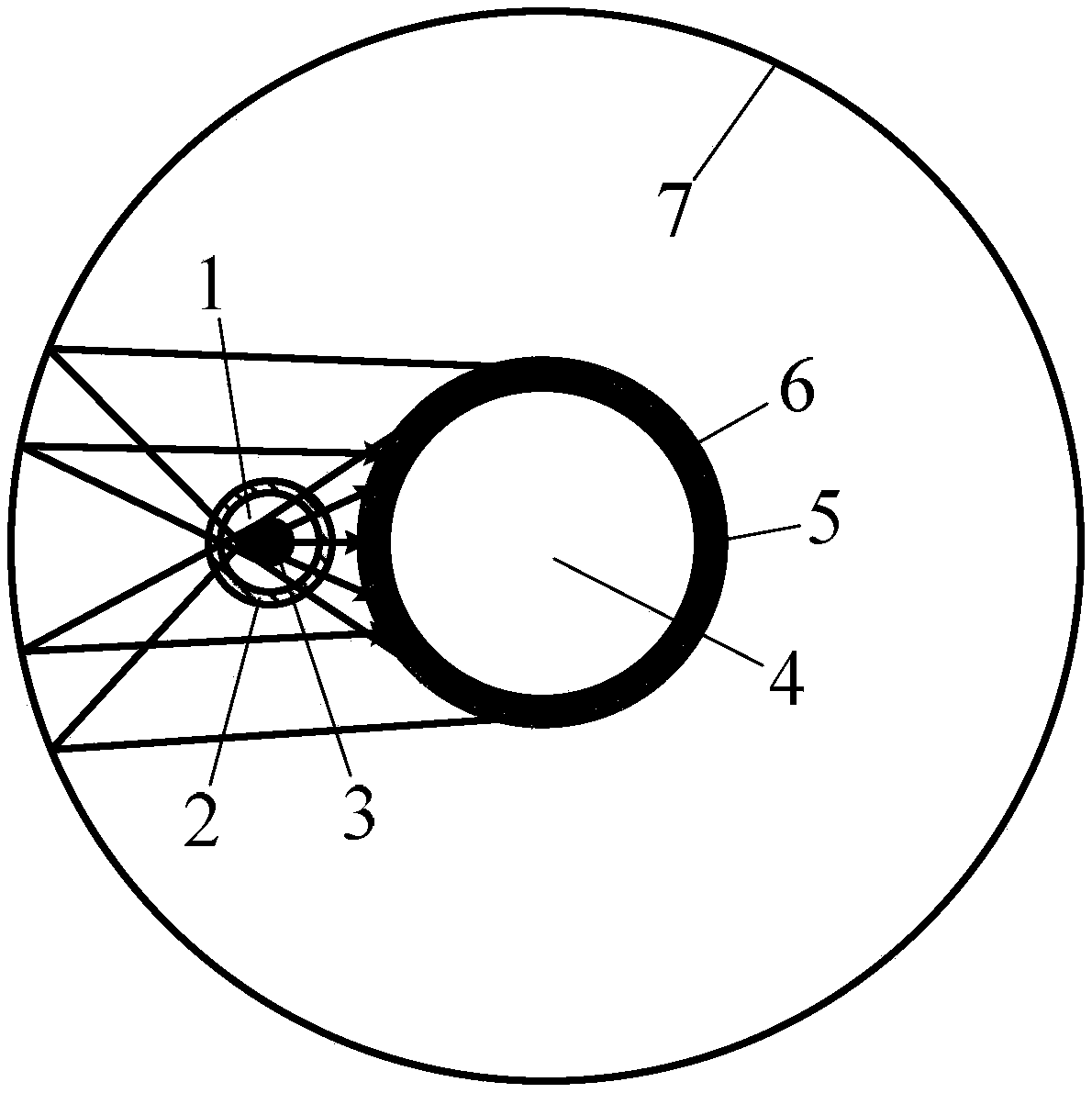

High-pressure rubber pipe placing device

The invention discloses a high-pressure rubber pipe placing device. The high-pressure rubber pipe placing device comprises a base and a squirrel-cage type columnar containing cavity vertically and fixedly connected to the upper surface of the base. The containing cavity comprises a columnar outer cavity wall and a columnar inner cavity wall. Each of the columnar inner cavity wall and the columnar outer cavity wall comprises a horizontal circular ring and a plurality of evenly-distributed connecting rods vertically and fixedly connected to the horizontal circular ring, and the other ends of the connecting rods are fixedly connected with the base. High-pressure pipelines are wound inside the squirrel-cage type containing cavity and can be tidily placed, classified placing can be achieved by adopting multiple squirrel-cage type containing cavities, corresponding high-pressure pipeline types can be conveniently found, and the problems that in the prior art, placing is disordered, and finding is hard are effectively solved; and storage operation is convenient, taking and placing are convenient, the structure is simple, cost is low, and dangerousness to maintenance personnel due to disordered placing is reduced.

Owner:GUIZHOU PANJIANG MINING MACHINERY

A split radiation heating furnace and furnace body

ActiveCN105758182BAvoid dependenceHigh positioning accuracyFurnace typesElectric heating for furnacesHearthTubing types

The invention provides an oppositely-opened radiative heating furnace and a furnace body, belongs to the field of heating devices used in laboratories and aims at solving the problems of poor rapid heating and cooling performance and low cost performance of existing heating devices used in the laboratories.The furnace body is composed of two sections, wherein each section is provided with a sunken cavity, a wall body of each section is provided with a channel for circulating cooling liquid to flow through, the two cavities form a cylindrical hearth when the two section are oppositely combined together, and the wall face of the cylindrical hearth is a smooth and clean face.The heating furnace comprises a heating element, the furnace body and a temperature controller, wherein the heating element is a radiative heating tube, the furnace body comprises the cylindrical hearth with the smooth and clean wall face, the radiative heating tube is close to the surface of a heated object, and the surface of the heated object is coated with a high-emissivity coating so as to strengthen radiative heating.The furnace body is provided with a gas purging channel to achieve rapid cooling of the hearth, and the circulating cooling liquid flows through the whole furnace wall to ensure cooling of a whole mirror wall.The oppositely-opened radiative heating furnace and the furnace body can be used for a heating tube type reactor.The furnace body is compact and high in performance cost ratio.

Owner:HARBIN INST OF TECH

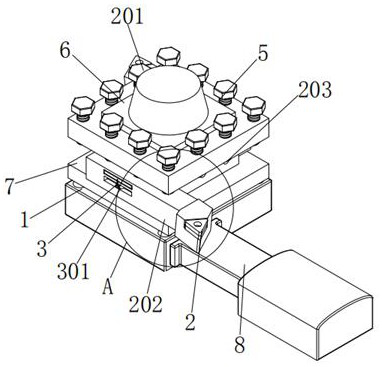

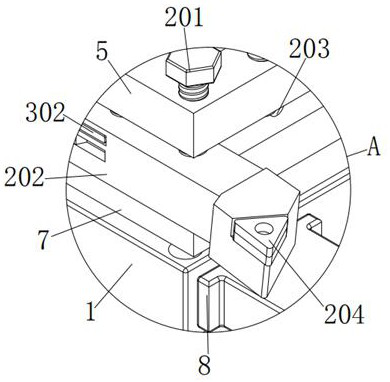

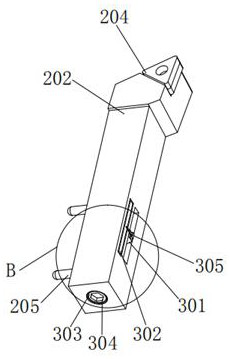

Finish machining numerical control cutter

ActiveCN112548131AScientific and reasonable structureEasy to useTurning toolsTool holdersNumerical controlTool bit

The invention discloses a finish machining numerical control cutter, comprising a base, an upper end cover, a vertical cylinder and a lower end cover. The upper end of the base is rotatably connectedwith the vertical cylinder; a turning tool assembly is arranged on the outer wall of the vertical cylinder; the turning tool assembly comprises a plurality of fastening screws, a turning tool, round holes, a movable tool bit, a round rod, a sliding block, a connecting transverse rod and a sliding groove; the plurality of fastening screws are in threaded connection with the interior of the outer side of the upper end cover; and the plurality of round holes are machined in the lower portion of the outer wall of the vertical cylinder. The finish machining numerical control cutter is scientific and reasonable in structure and safe and convenient to use; through cooperation of the turning tool, the round holes, the round rod, the vertical cylinder, the upper end cover and the lower end cover, the turning tool needing to be used is inserted into the round holes through the round rod, and the size of the position, stretching out of the outer ends of the upper end cover and the lower end cover, of the turning tool is determined, so that the temporary positioning capacity is achieved, and the problems that in the prior art, a user needs to manually control the extending length of the turning tool and auxiliary positioning needs to be implemented when screws are screwed down for fixing are solved.

Owner:DONGGUAN LONGSIDE HARDWARE TOOL CO LTD

A pretreatment device for electrophoretic spray paint on the surface of mechanical parts

ActiveCN107904648BImprove work efficiencyImplement the placement functionElectrophoretic coatingsMechanical componentsElectrophoresis

The invention discloses an electrophoresis paint-spraying pretreatment device for surfaces of mechanical parts and fittings. The electrophoresis paint-spraying pretreatment device comprises a housingI, wherein an inner cavity of the housing I is hollow; the bottom wall of the housing I is sequentially connected with a motor I, a motor II and a motor III in the horizontal direction; one end of themotor I, one end of the motor II and one end of the motor III are separately connected with a rotary shaft I, a rotary shaft II and a rotary shaft III; the top of the housing I is sequentially connected with a conveyor belt I, a controller, a frame body, a water tank, a barrel body, a supporting rod, a booster pump, a housing II, an electrophoresis slot and a conveyor belt II in the horizontal direction; one end, away from the housing I, of the conveyor belt I is fixedly connected with a placing plate; the placing plate is positioned on the top of the water tank; and the side wall of one side, away from the conveyor belt, of the water tank is sequentially connected with a water pump and a water introducing tube in the vertical direction. The electrophoresis paint-spraying pretreatment device is simple in structure, is convenient to operate, realizes pretreatment for electrophoresis parts and fittings and a treatment function after electrophoresis is completed, and improves electrophoresis quality.

Owner:ANHUI POLYTECHNIC UNIV

Movable mainboard light fixing device

InactiveCN110456872ACollective lightEasy wiringDigital processing power distributionMotherboardComputer engineering

The invention discloses a movable mainboard light fixing device. The movable mainboard light fixing device comprises a main board fixing plate, screw holes, a first case side plate, a rack, a side plate rail, a handle, a gear, a sliding groove and a second case side plate. A plurality of screw holes are formed in the main board fixing plate; a rack is arranged on one side of the main board fixingboard, the gear is matched with the rack, the gear is connected with a handle, a side board track is arranged on the first case side board, the handle penetrates through the side board track, a sliding groove is formed in the back face of the main board fixing board, and a rectangular protrusion matched with the sliding groove is arranged on the second case side board. The mainboard can move in the case.

Owner:LIUZHOU LIANHAI TECH

Surface treatment device for synthetic processing of novel polymer material with anti-overlapping mark

InactiveCN110919542AHigh damage rateAchieve tidinessBonded abrasive wheelsAbrasive surface conditioning devicesEngineeringDrive motor

The invention discloses a surface treatment device for synthetic processing of a novel polymer material with an anti-overlapping mark. The surface treatment device structurally comprises a controller,a device body, a workbench, a positioning push plate, a rotary movable stand column, a driving motor and a protective sheet device. The surface treatment device has the beneficial effects that an upper wiping plate and a lower grinding mechanism are matched with each other, so that iron chips are adsorbed by heat generated by high-speed rotation of the surface of a grinding blade, and effective unified treatment is carried out, so that the surface of the blade is clean and tidy, and the situation that the damage probability of the blade is accelerated due to the fact that a magnetic field isgenerated due to the fact that the iron chips are more is avoided; and sawtooth strips on the surface of a material suction plate are used for grinding the blade in contact with metal, so that the phenomenon that the blade is different in layer in the placing process is avoided, and the blade is relatively slow, so that a new overlapping mark is formed on the grinding surface of the equipment to be ground.

Owner:黄水泉

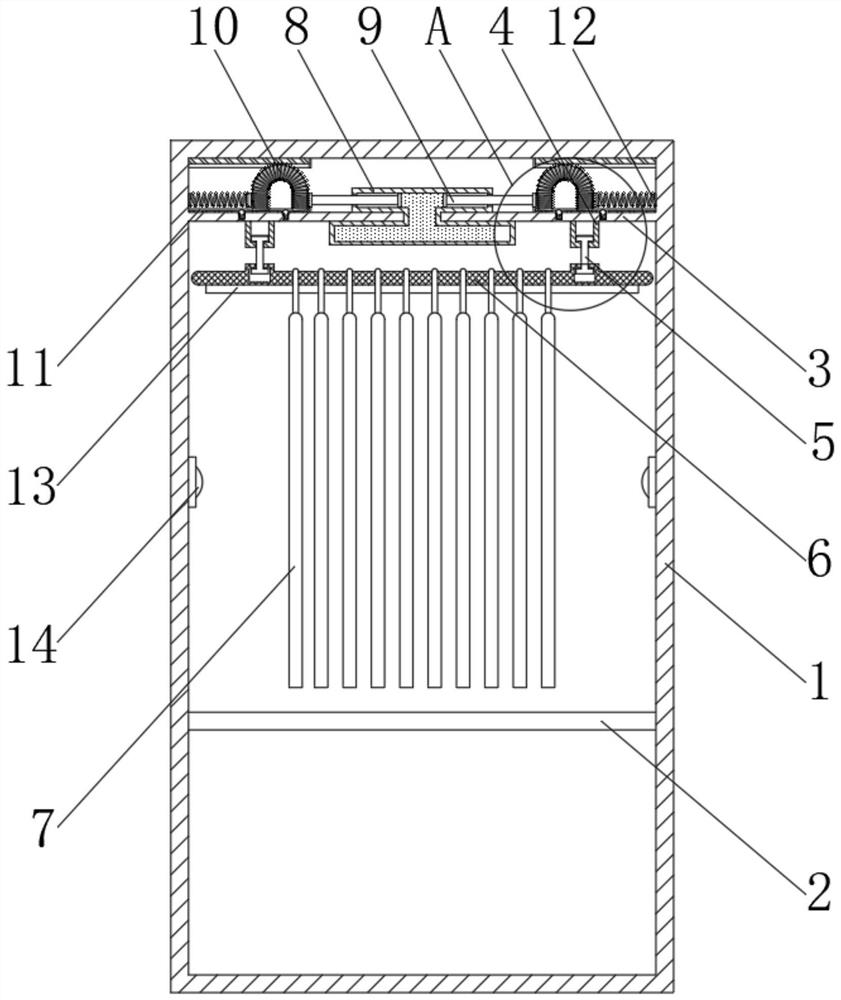

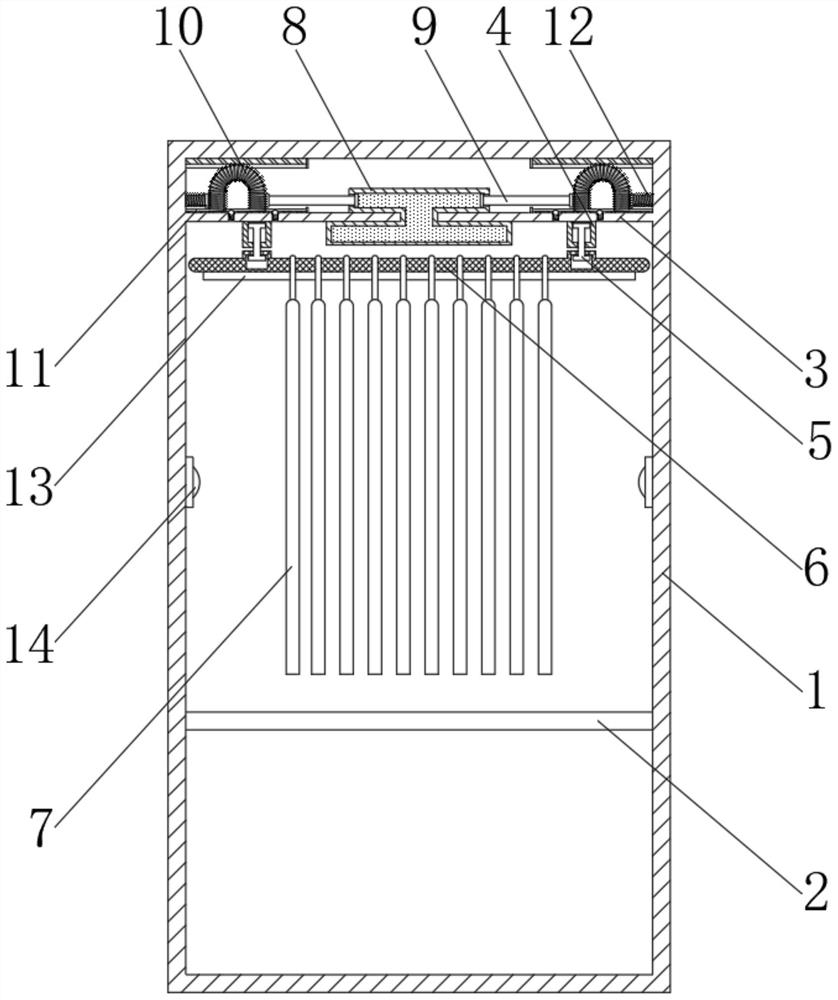

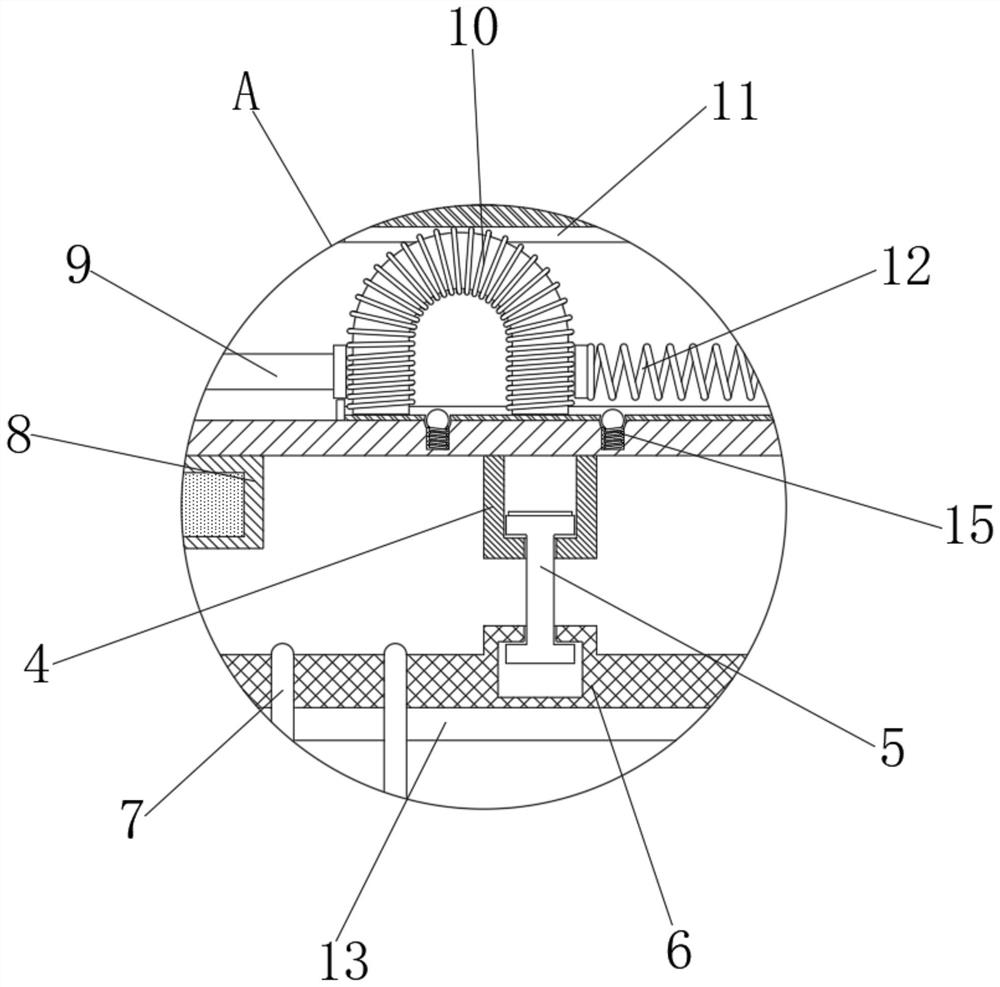

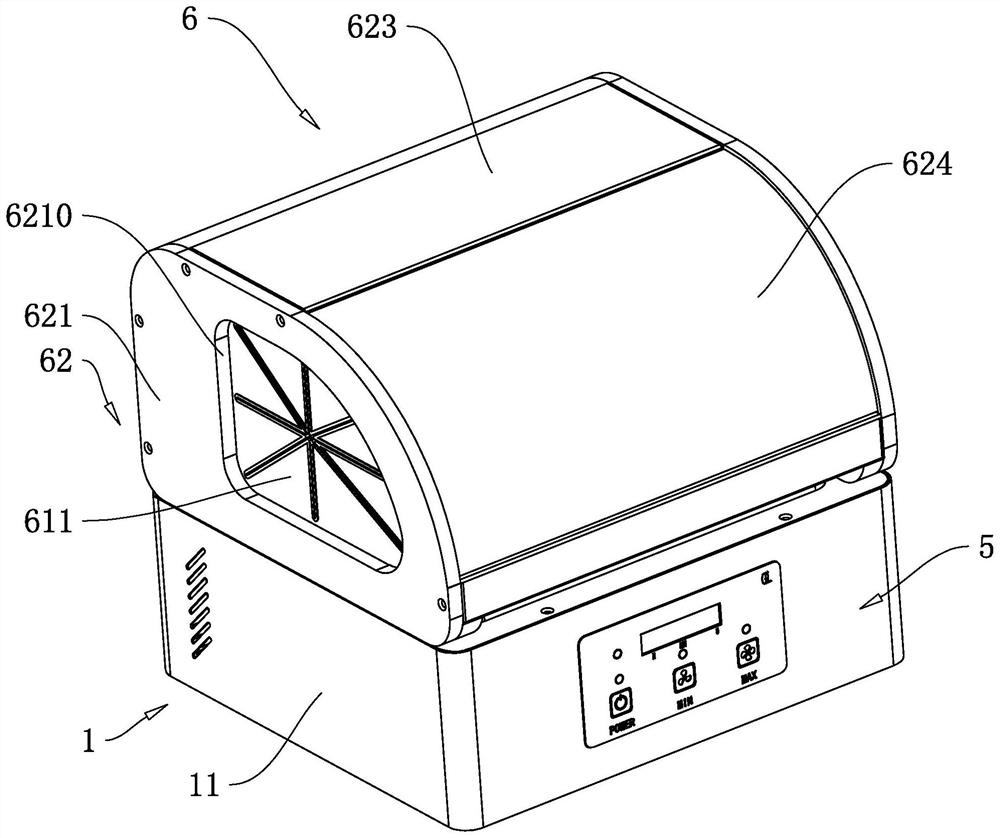

A mite-removing and antibacterial warm wardrobe

ActiveCN111955930BAvoid overgrowthAchieve dryingWardrobesLavatory sanitoryUltraviolet lightsAnti bacteria

Owner:BBMG TIANTAN FURNITURE CO LTD

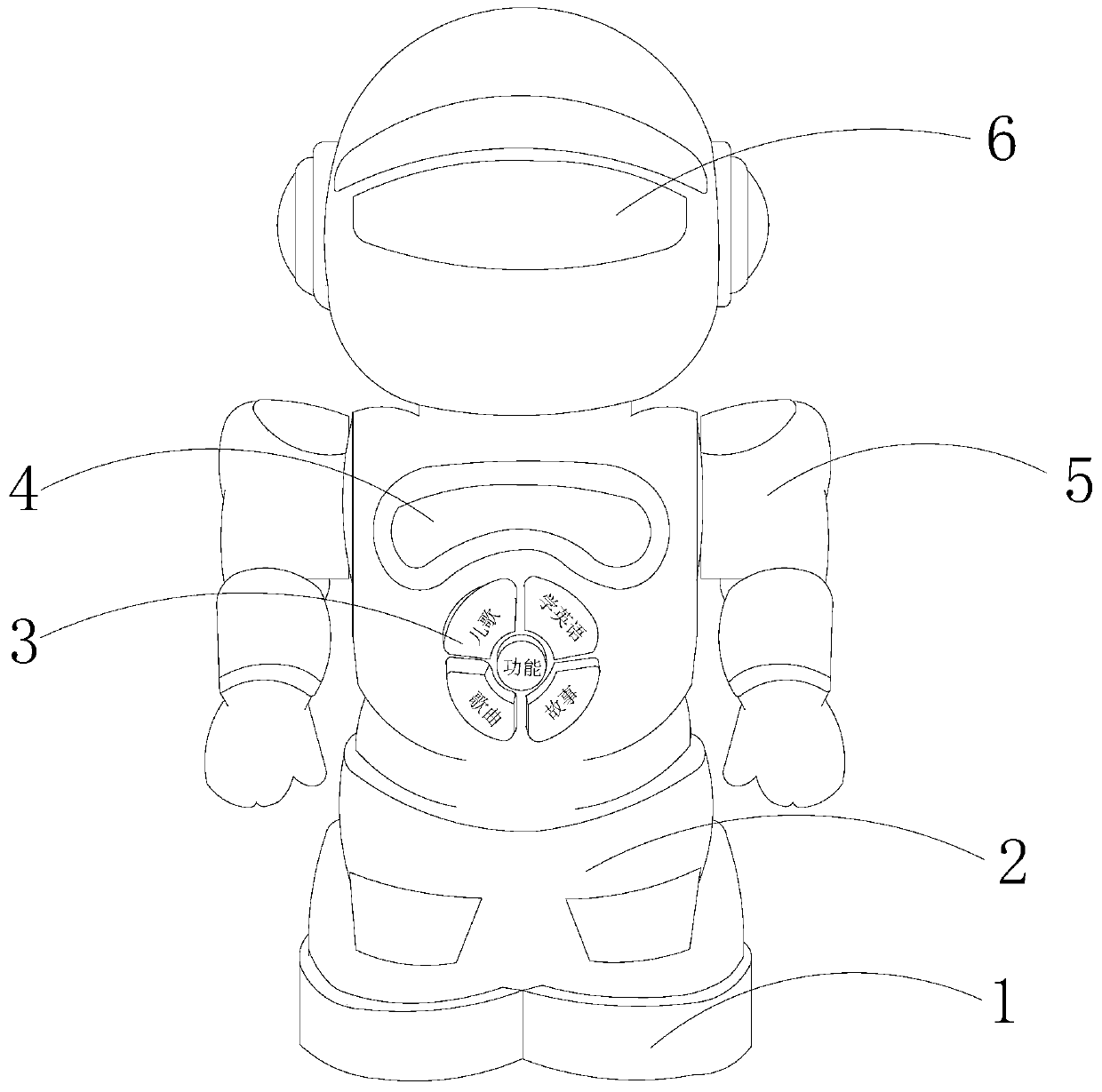

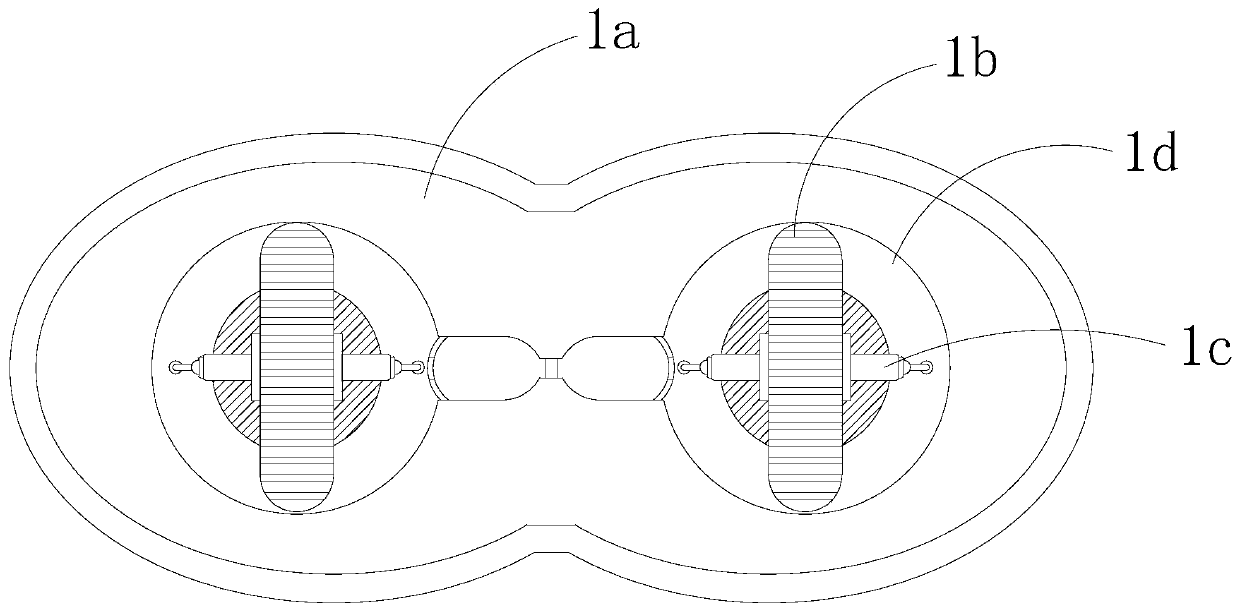

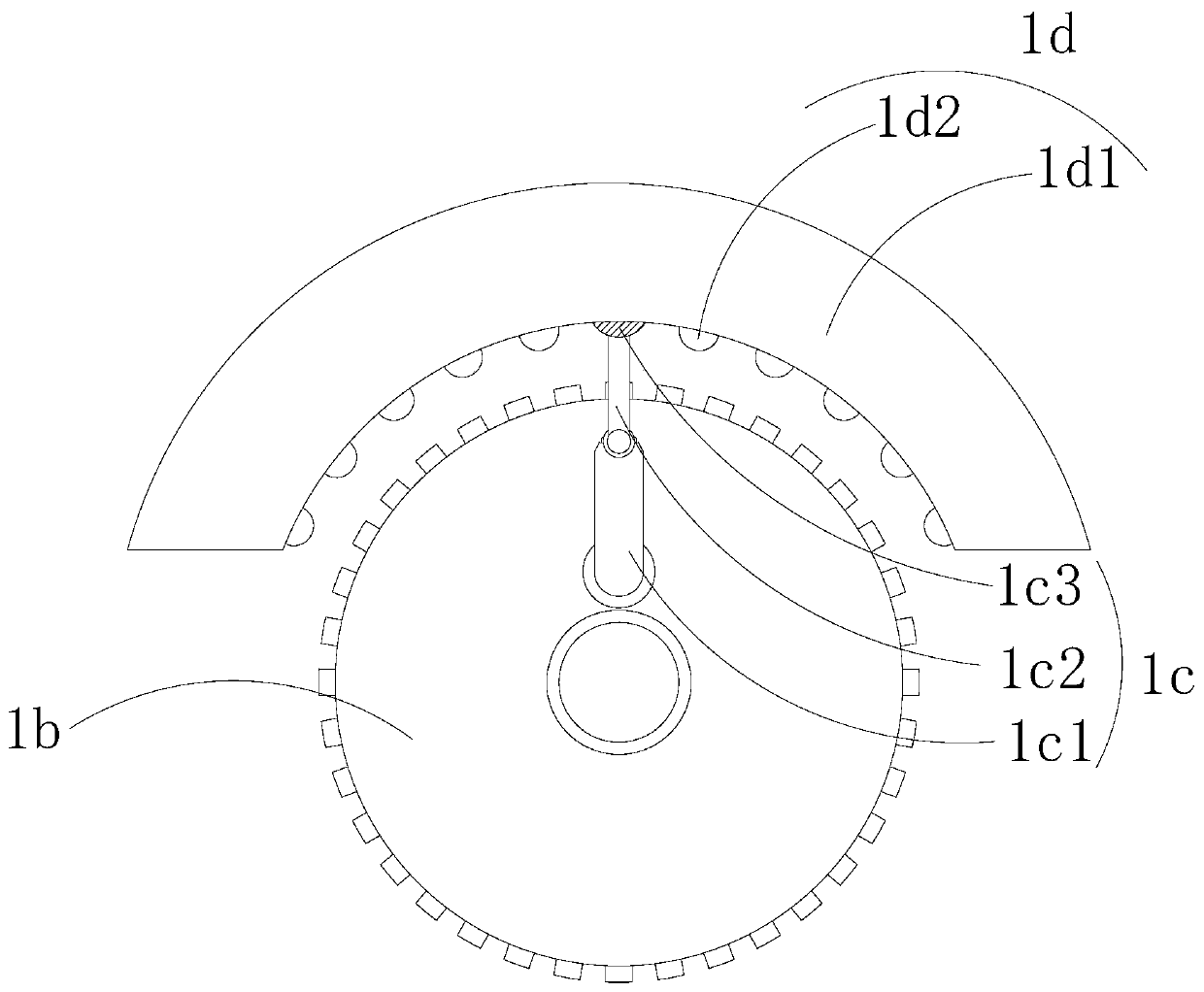

Flexibly-moving intelligence-developing toy robot for children

ActiveCN110368699AAchieve tidinessPrevent dumpingSelf-moving toy figuresEngineeringMechanical engineering

The invention discloses a flexibly-moving intelligence-developing toy robot for children. The structure of the flexibly-moving intelligence-developing toy robot for children comprises: a fixed-movingdevice, a robot main body, a function button, a loudspeaking area, an arm rod, and a video area. Through mutual cooperation of a connection piece and a mixed sticky structure, gravels clamped at the surface of a moving wheel are adhered on the surfaces of convex grains under the mutual friction action of an arc-shaped air bag which is pulled down by inflation and the convex grains, thereby achieving the neatness of the surface of the moving wheel and avoiding the robot from toppling and breaking due to the gravel in the driving process. An opening-closing silica gel sheet arranged at the surface of a cross hole is in an opening shape under the effect of pull-down of the arc-shaped air bag, so that the gravels adhered by the convex grains are absorbed in the opening-closing silica gel sheetto prevent the gravels from falling into the moving wheel again.

Owner:东莞市裕洪电子科技有限公司

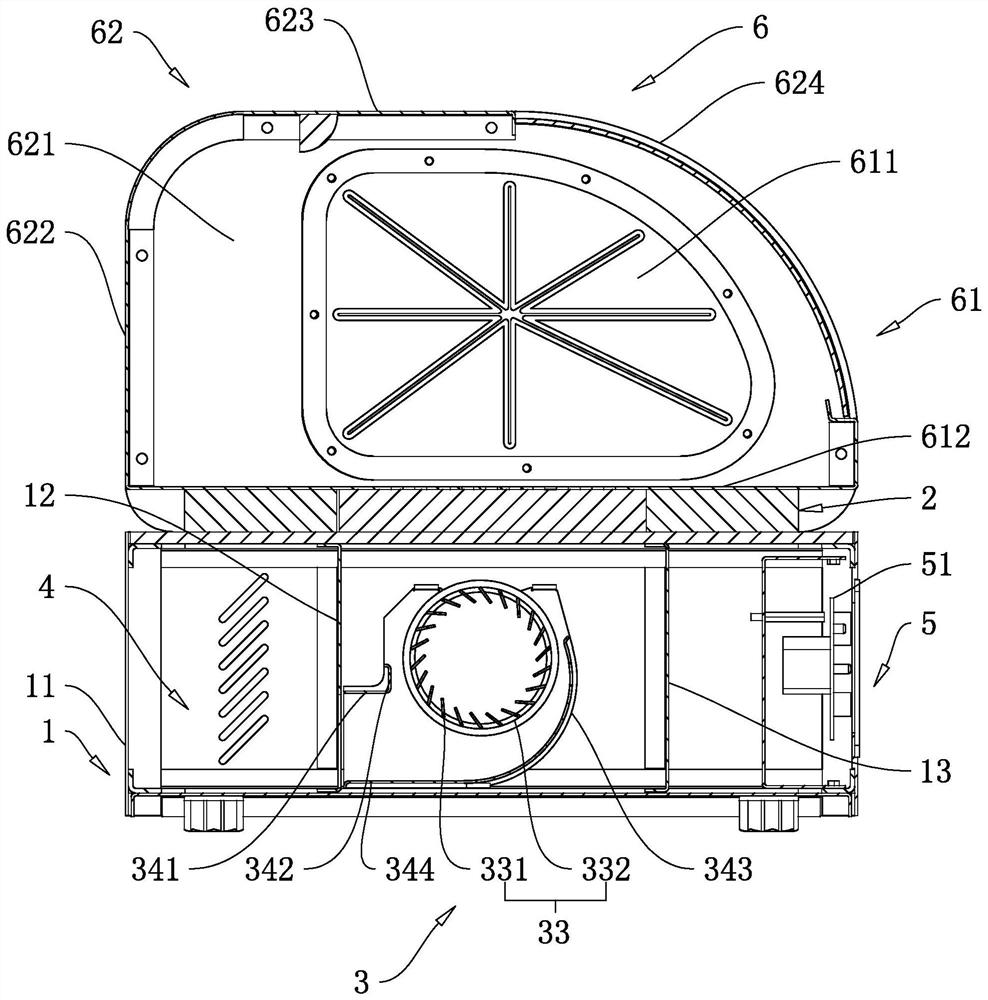

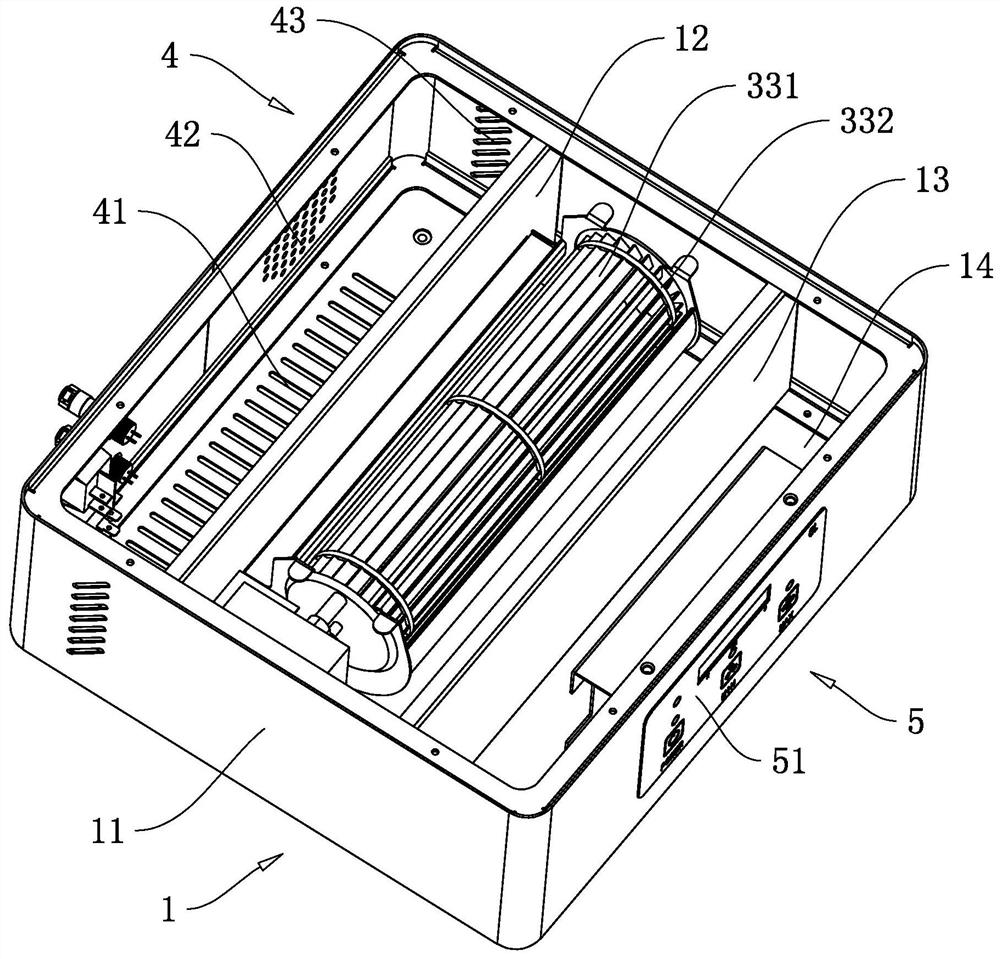

Dust collector

PendingCN112720264AAvoid flyingAchieve tidinessDispersed particle filtrationTransportation and packagingTooth polishingWaste material

The invention relates to the technical field of dust collection equipment, in particular to a dust collector which comprises a machine shell mechanism. A dust suction mechanism and an exhaust mechanism are arranged in the machine shell mechanism, an operation mechanism for polishing false tooth materials is fixedly connected to the top end of the machine shell mechanism, and a filtering mechanism for filtering false tooth waste is arranged between the operation mechanism and the machine shell mechanism. The dust collection mechanism absorbs air in the operation mechanism, the false tooth waste in the operation mechanism flows along with the air, the false tooth materials are filtered in the filtering mechanism, and the air is exhausted from the exhaust mechanism. The dust collection mechanism comprises a driving assembly, an impeller assembly and an air guide assembly, the air guide assembly is fixed in the machine shell mechanism, the impeller assembly is connected to the air guide assembly in a rotating mode, and the driving assembly is fixed in the machine shell mechanism. The dust collector has the effect of improving the false tooth polishing precision.

Owner:上海硅莱医疗器械有限公司

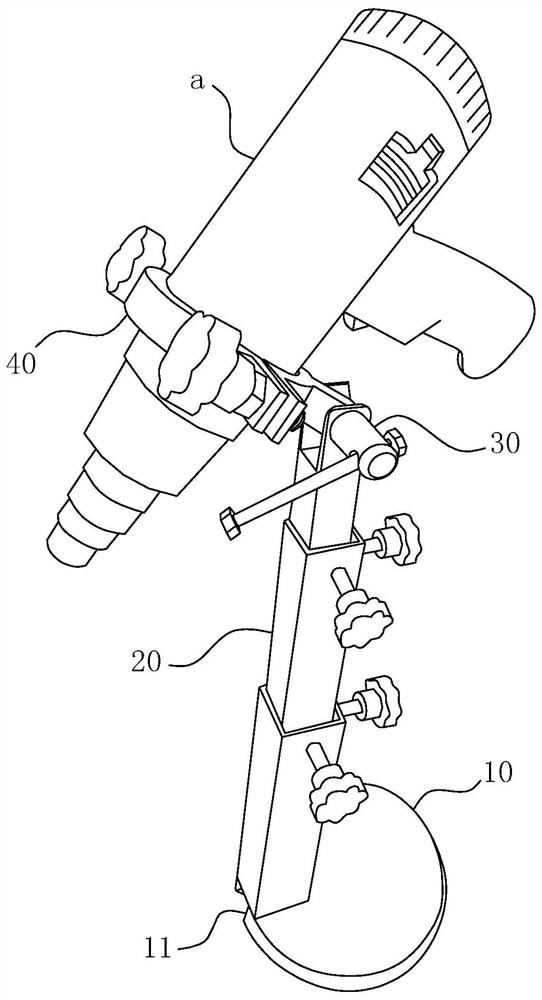

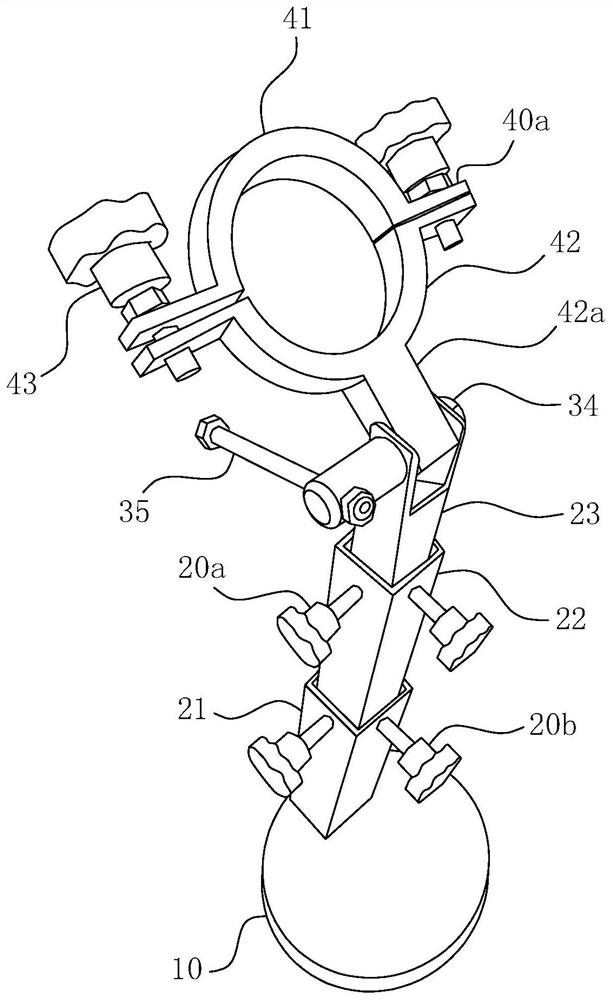

A blowing fixture for removing labels from enameled wire reels

ActiveCN111420936BRealize the heating effectAchieve cleaning effectCleaning processes and apparatusStructural engineeringMechanical engineering

The invention belongs to the technical field of enameled wire production, and in particular relates to a blowing fixing frame for removing labels of enameled wire reels. The blower fixing frame includes a base and a vertical telescopic assembly arranged on the base. The top of the vertical telescopic assembly is hinged with a fixed hoop through a horizontal joint; The fit or tight fit limits the downward sliding action of the blower relative to the fixed collar. The air blower fixing frame has an ingenious, compact and reasonable structure, and is highly convenient to use, so that cleaning personnel can free up both hands to perform other cleaning tasks simultaneously, and has strong practicability.

Owner:TONGLING JINGXUN SPECIAL ENAMELLED WIRE

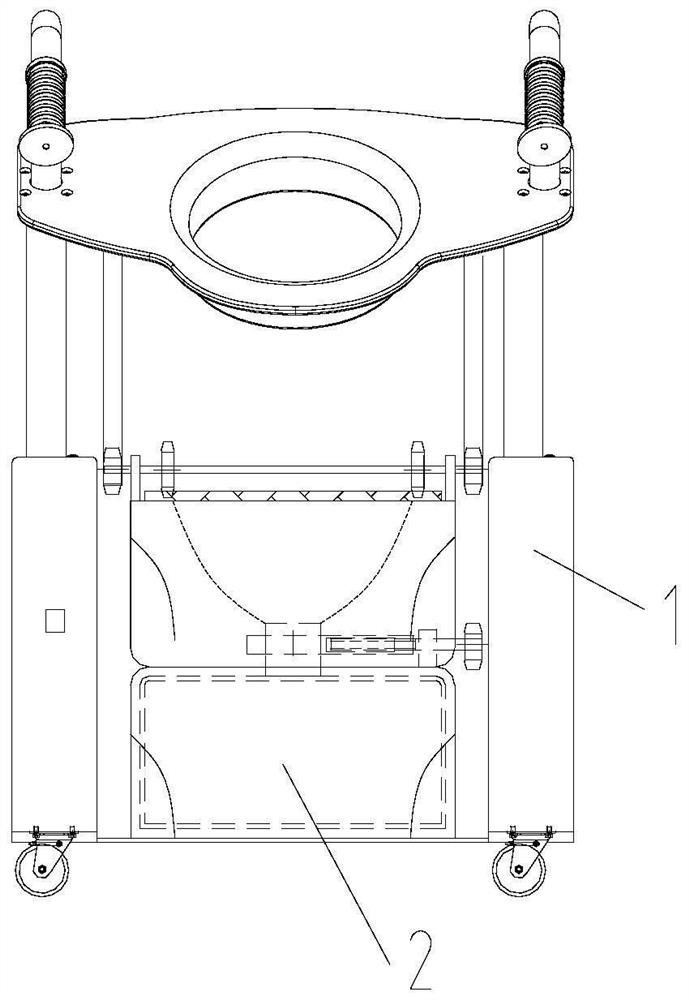

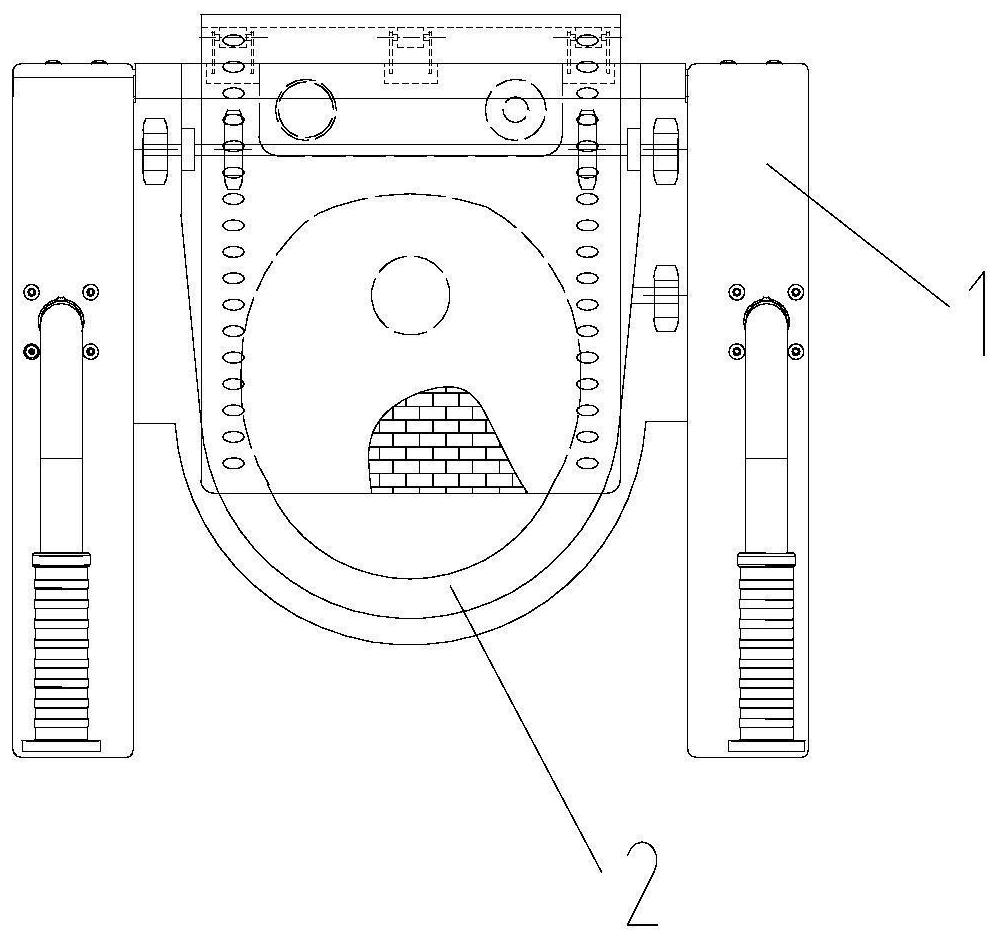

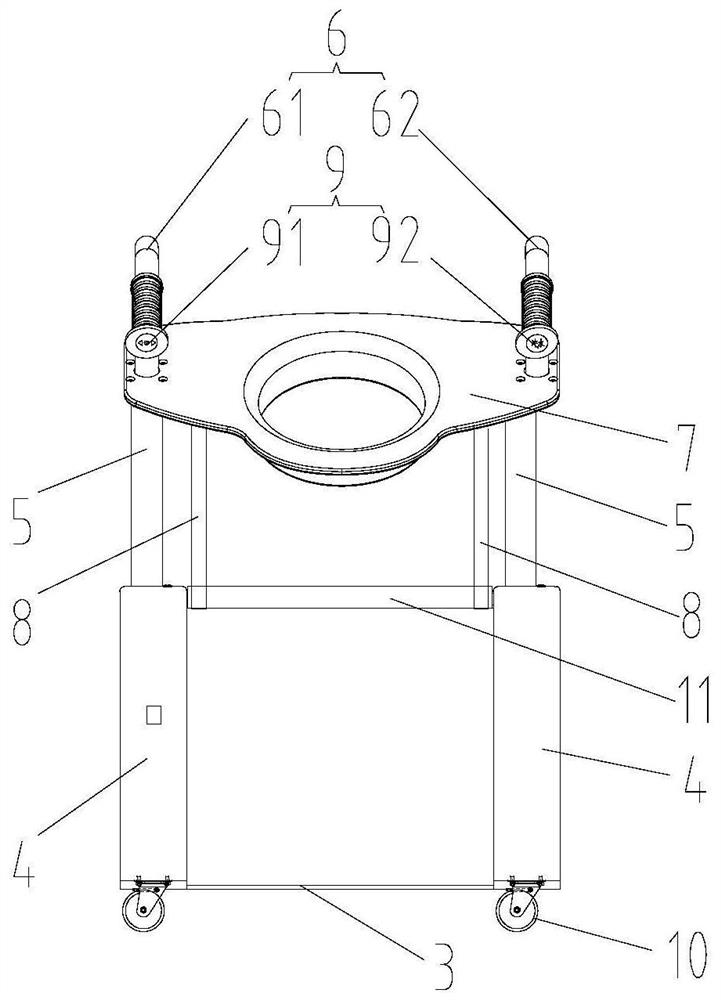

Lifting power-assisted pedestal pan device

ActiveCN113796764AEasy to useImprove comfortBathroom coversAgainst vector-borne diseasesEngineeringStructural engineering

The invention discloses a lifting power-assisted pedestal pan device, relates to the field of pedestal pan equipment, solves the problems that an existing pedestal pan is inconvenient to use and cannot deodorize and isolate odor and improves the use comfort, convenience and safety. The lifting power-assisted pedestal pan device comprises a pedestal pan chair, wherein the pedestal pan chair comprises two oppositely arranged box bodies, the box body is provided with a channel for the lifting rods to move up and down, a pedestal pan cover is connected between the lifting rods, and the bottom of the pedestal pan cover is connected with a first gear through a first rack; a pedestal pan is arranged between the two box bodies and located below the pedestal pan cover, a urinal cover is arranged on the top of the pedestal pan, the urinal cover is of a chain plate belt structure, and the urinal cover is connected with the first gear through a transmission mechanism.

Owner:CRRC SHANDONG CO LTD

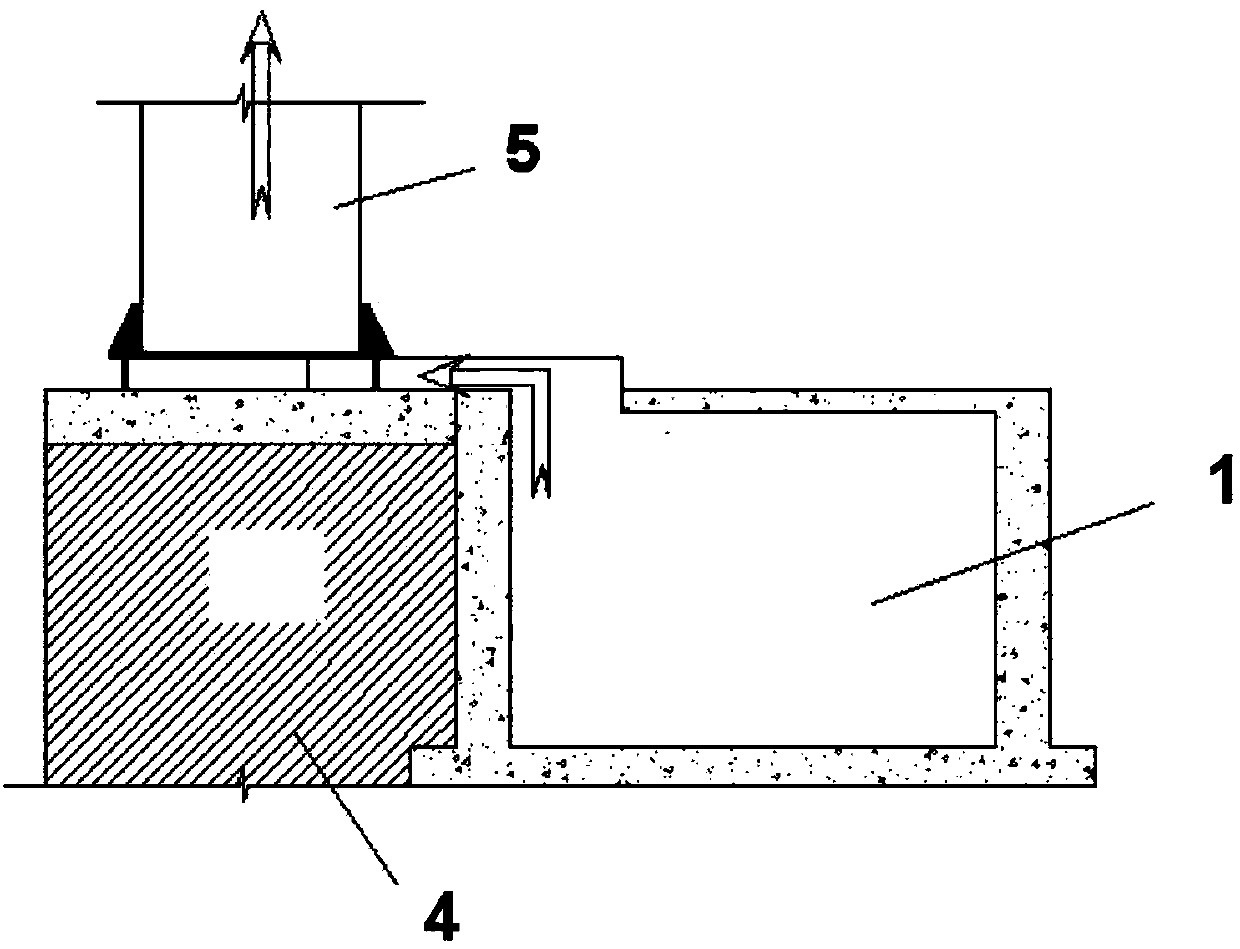

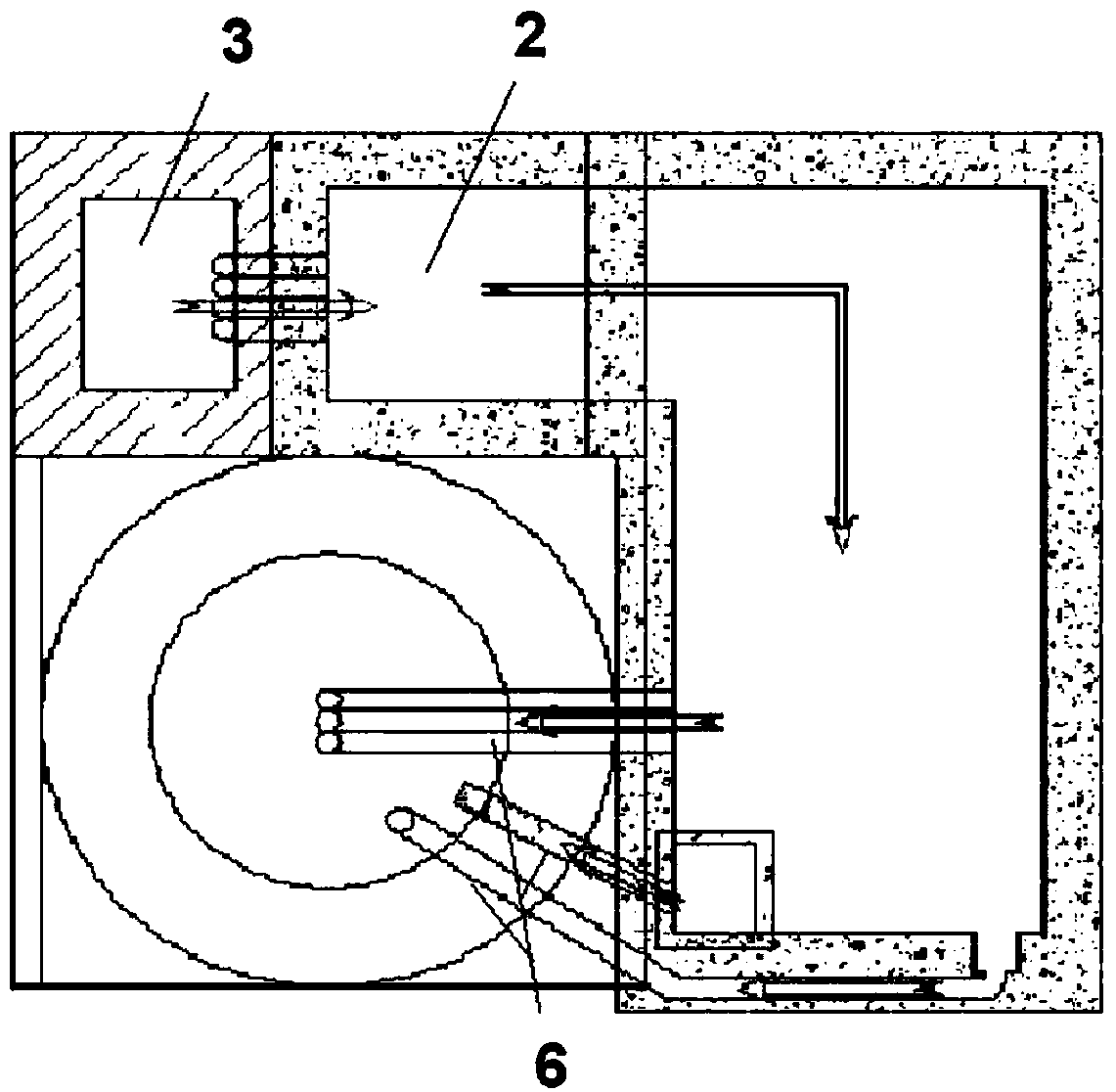

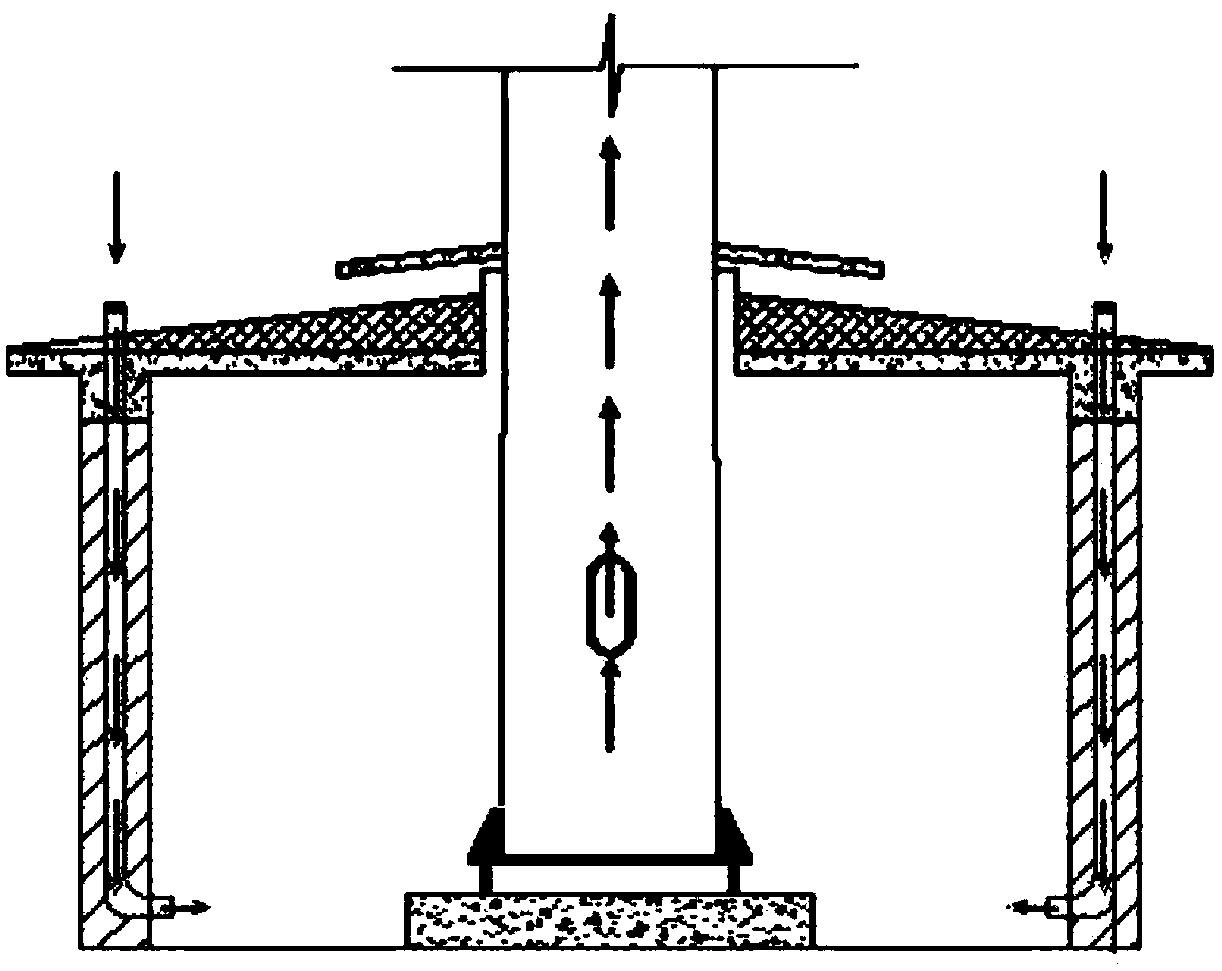

Energy-saving and emission-reduction integrally-buried machine room structure

InactiveCN107842222AConducive to urban planningEnsure constant temperature and humidityCellarsData processing centersEngineeringMechanical engineering

The invention provides an energy-saving and emission-reduction integrally-buried machine room structure. The energy-saving and emission-reduction integrally-buried machine room structure comprises a buried machine room buried underground, a lower manhole, an optical cable well and a communication tower foundation buried underground. The buried machine room, the lower manhole and the optical cablewell are arranged embracing the tower foundation; a pre-buried pipe is arranged between the buried machine room and a communication tower and used for wire passing and ventilation; and a tower body ofthe communication tower forms the chimney effect for ventilation and cold-hot adjustment of the buried machine room. The structure design is ingenious, energy saving, environmental friendless and burglary prevention are achieved, and the constant-temperature and constant-humidity effect of the indoor environment can be really achieved without an air conditioner.

Owner:宁夏易讯通电子科技有限公司

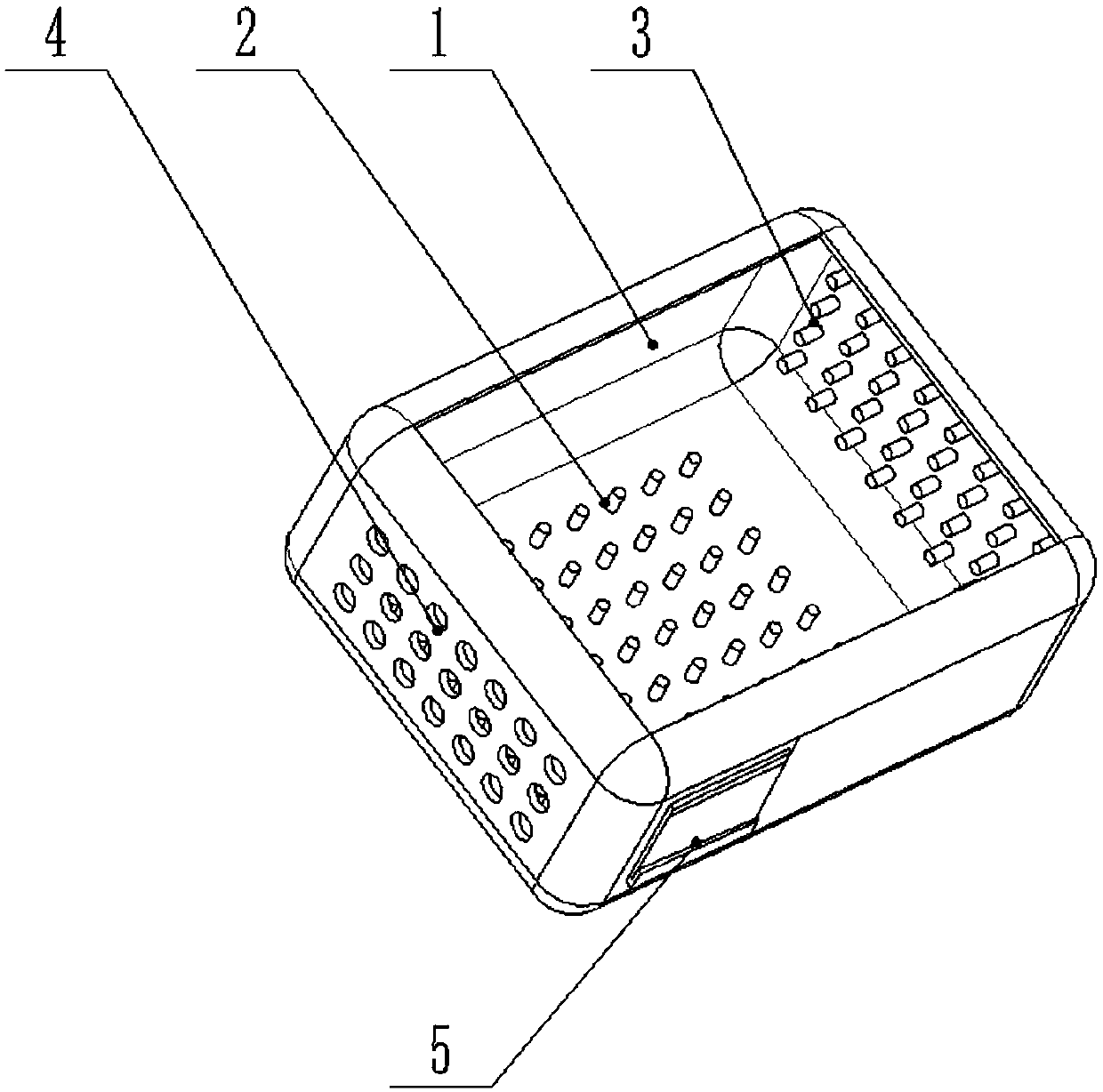

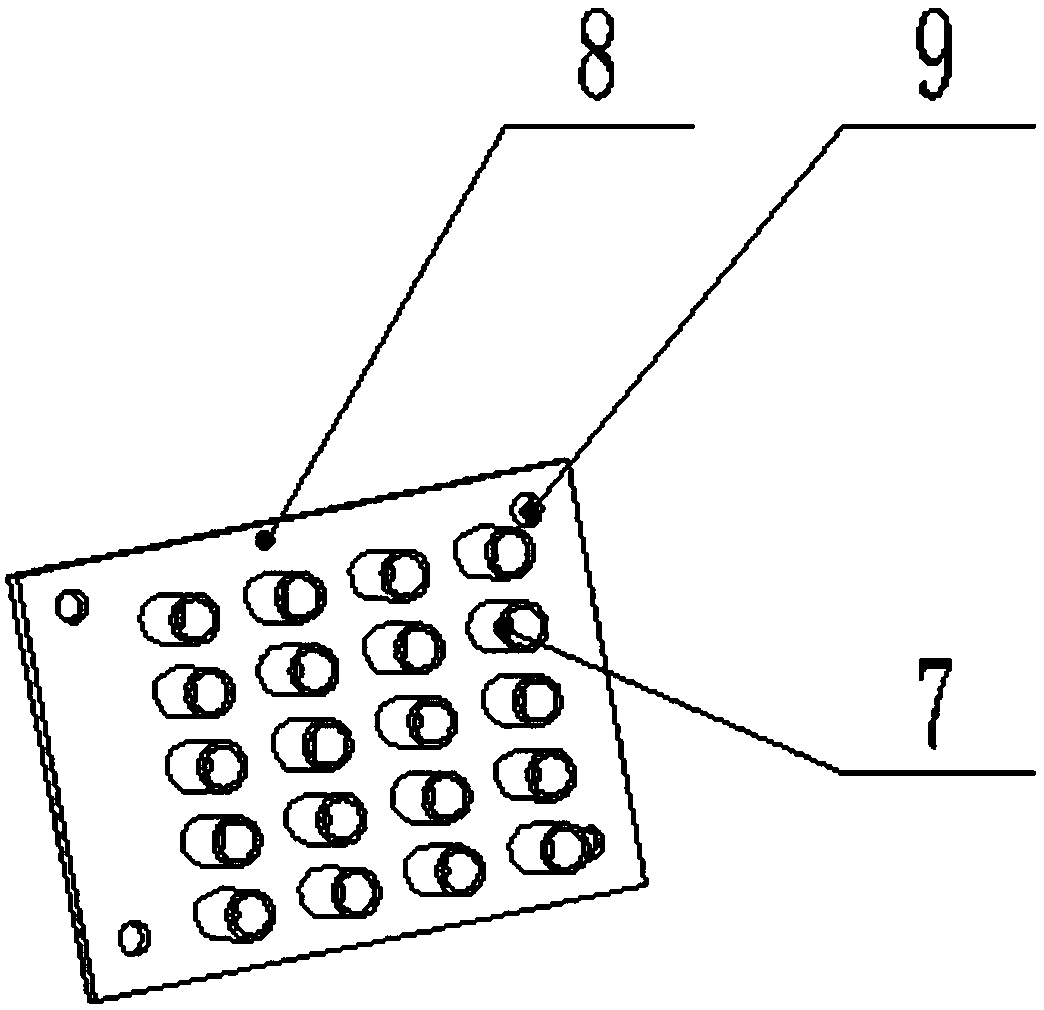

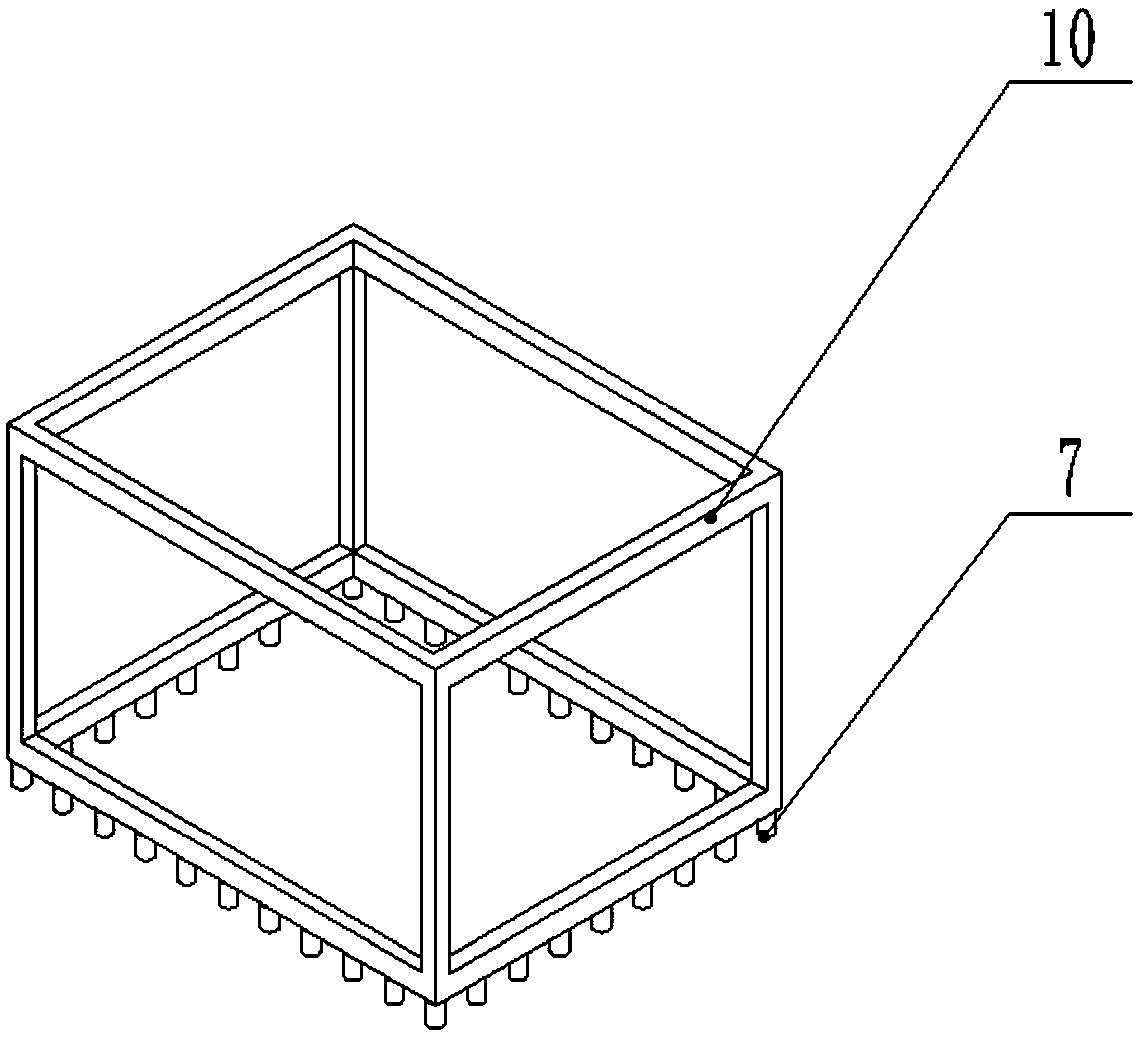

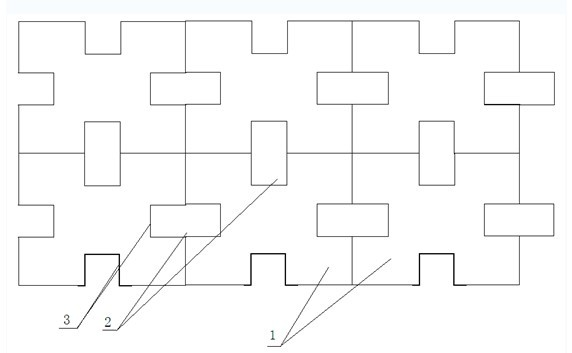

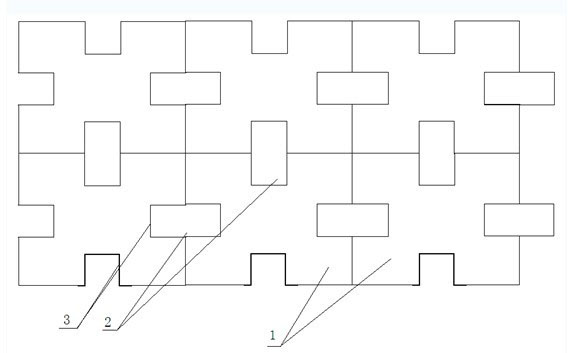

LED lamp box combination and LED display screen

ActiveCN103499069BAchieve electrical connectionEnable connectivityPoint-like light sourceElectric circuit arrangementsLED displayButt joint

The invention discloses an LED lamp box, an LED lamp box combination and an LED display screen. Connecting boxes used for being in butt joint with other LED lamp boxes are arranged on one side of the LED lamp box, when the LED lamp boxes are connected with each other in an abutting-against mode, conductive terminals inside the connecting boxes will be in contact with each other to achieve electrical connection of adjacent LED lamp boxes, and power connection and signal connection between adjacent LED lamp boxes are achieved. Therefore, no built-in connecting cable exists between the LED lamp boxes, rapid disassembly and rapid assembly are guaranteed, and safety, attractiveness, cleanness and tidiness of connection are achieved.

Owner:珠海锐拓显示技术有限公司

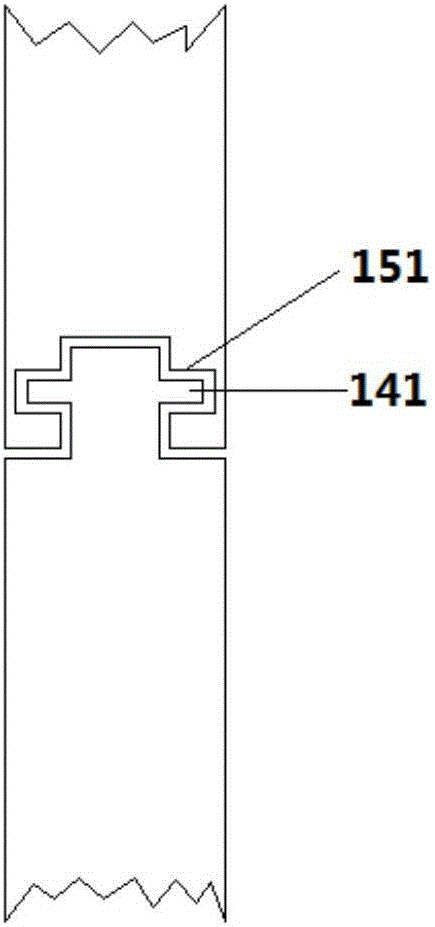

Method for splicing plates

InactiveCN102418408ASave materialFlexible cuttingCovering/liningsStructural engineeringUltimate tensile strength

The invention discloses a method for splicing plates. In the method, at least two plate blocks and at least one connector are involved. The method comprises the following steps of: firstly, forming a concave connecting opening on each edge of the two plate blocks; and secondly, inserting two ends of the connector of which the size and the shape are matched with those of the concave connecting openings into the concave connecting openings respectively until the edges of the two adjacent plate blocks are contacted with each other tightly, wherein the plate blocks are rectangular; hard sheaths are wrapped on the edges of the plate blocks and the edges of the concave connecting openings. By the method, plates which are connected in a mother-and-son buckling manner in the market are avoided; therefore, materials are saved, and the plates can be cut flexibly and are convenient to splice. Horizontal plate connectors are convenient to use, so the manufacturing efficiency is improved. In one word, the method has the advantages of flexible cutting and flexible splicing; furthermore, the hardness and the strength of the plates are improved, the service life of the plates is prolonged, and technical effects of attractiveness and neatness are achieved.

Owner:NANJING FORTUNE RECYCLING TECH

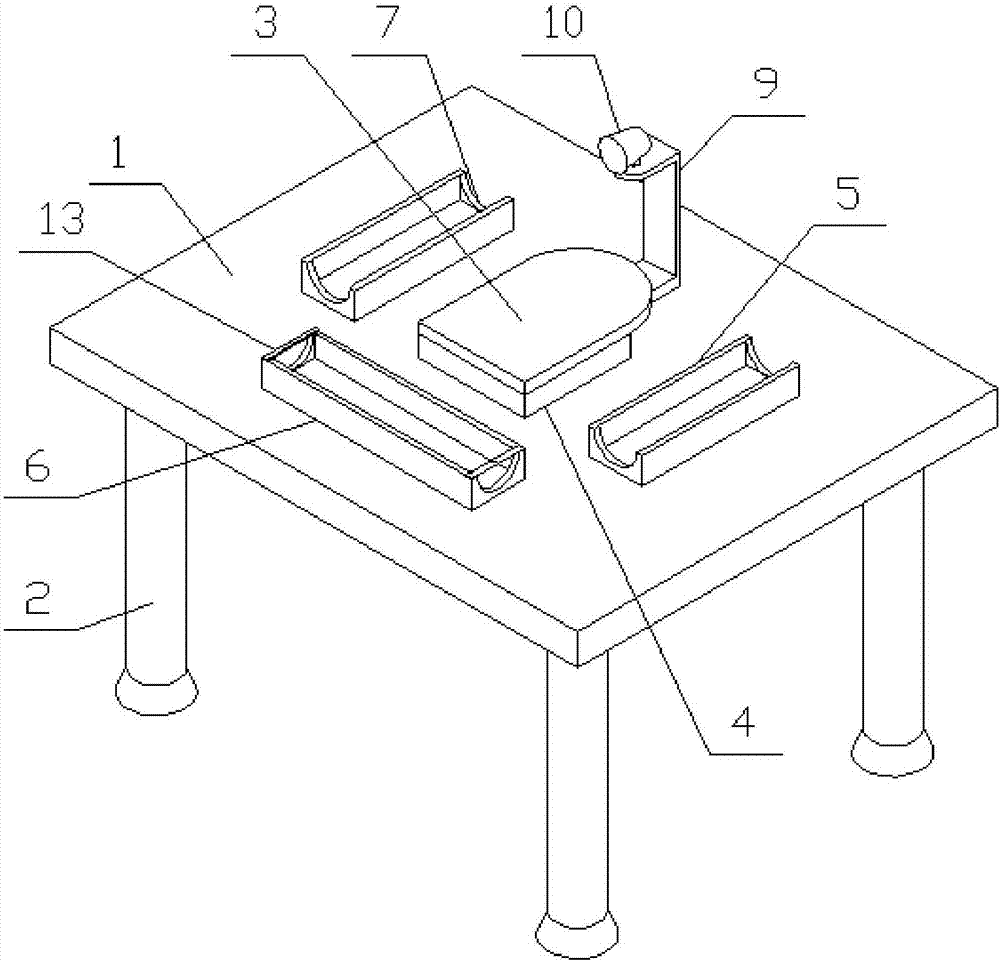

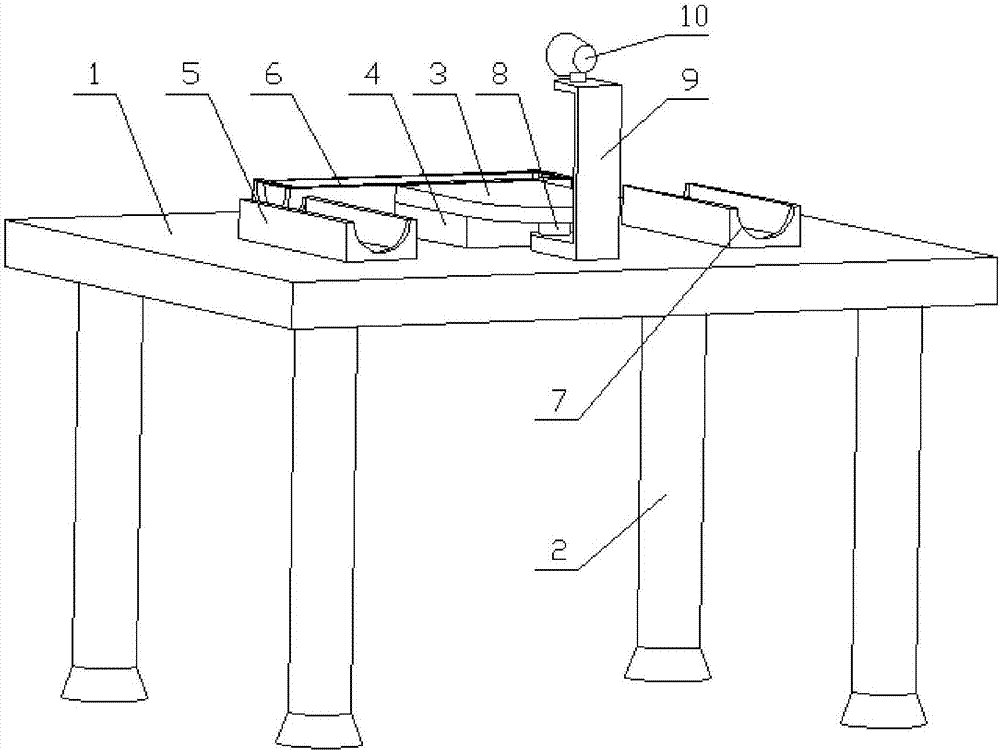

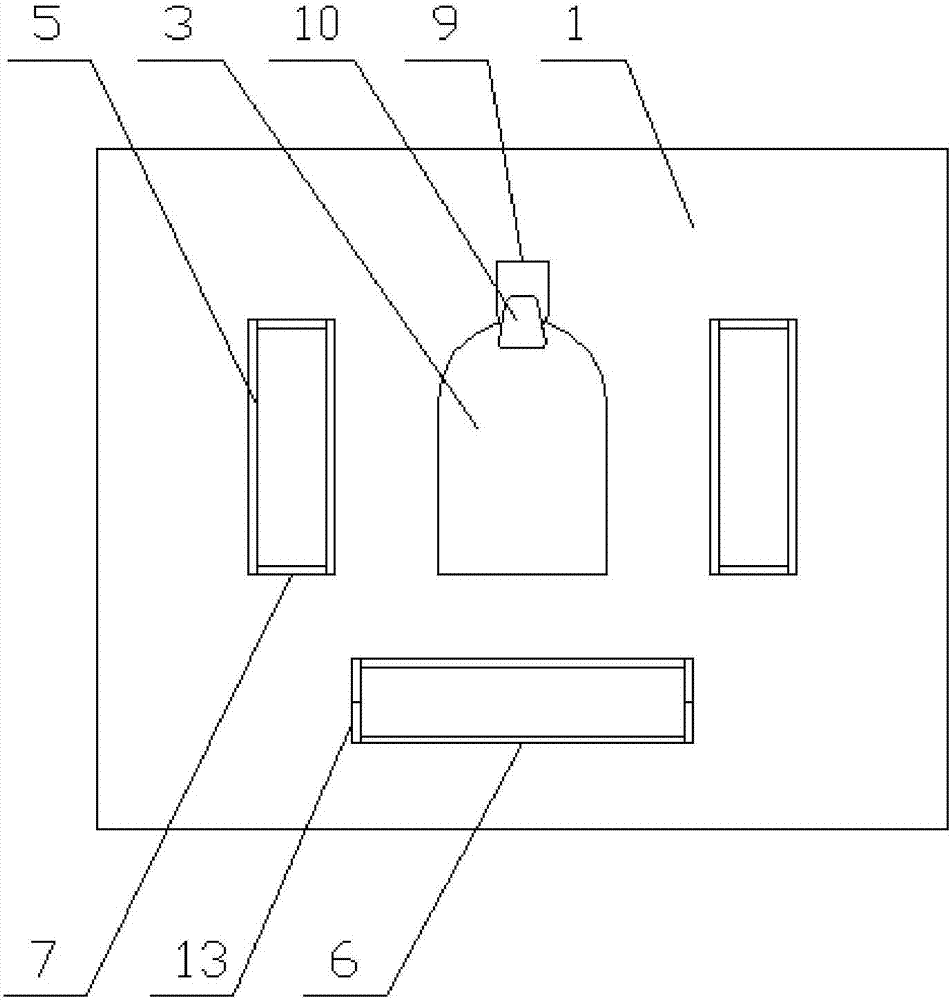

Multi-purpose adhesive tape winding workbench

The invention discloses a multipurpose tape wrapping workbench, which relates to the field of machinery and includes a desktop, a table leg, a mounting plate for installing a tape wrapping machine, a wire box 1, a wire box 2, an L-shaped support, and an LED lamp. In the present invention, by setting wire box 1 and wire box 2 on the desktop, the wiring harness to be connected can be placed in wire box 1 on both sides of the installation board in advance, and then placed in wire box 2 after being connected and wrapped with tape, which is beneficial Realize the cleanliness of the workbench and improve the work efficiency. The wiring harness is not easy to be confused. The supporting member can be rotated, so the irradiation angle can be adjusted according to people's needs, and the operation is convenient.

Owner:WUHU BOKANG ELECTRICAL

Dyeing and finishing machine cloth collecting device for textile dyeing and finishing and using method thereof

ActiveCN113550131AAvoid the problem of clutter and wrinklesAchieve tidinessMechanical cleaningPressure cleaningFiberHeater Rod

The invention discloses a dyeing and finishing machine cloth collecting device for textile dyeing and finishing and a using method thereof, and particularly relates to the field of textile. The dyeing and finishing machine cloth collecting device comprises a cloth collecting adjusting mechanism, an ironing mechanism is rotationally connected with one side of the cloth collecting adjusting mechanism, a liquid collecting funnel is fixedly installed at the bottom of the ironing mechanism, and a second ironing plate is fixedly installed at the top of the liquid collecting funnel; and a steam pipeline is fixedly installed in an inner cavity of the liquid collecting funnel, a steam box is fixedly installed at the bottom of the steam pipeline, an electric heating rod is fixedly installed on one side of an inner cavity of the steam box, and a steam collecting mechanism is fixedly installed at the top of the inner cavity of the steam box. According to the scheme of the dyeing and finishing machine cloth collecting device for textile dyeing and finishing, under the action of a cloth rolling assembly, in the cloth rolling process, broken fibers attached to the surface of cloth are removed in the rotating process through specific brush structures on the rotating surfaces of a first unhairing roller and a second unhairing roller, the problem that the cloth is disordered and wrinkles are generated due to fiber attachment is solved, and the neatness of the surface of the cloth is realized.

Owner:上海雁峰纺织品有限公司

Method and device for plasma producing hydrogen by using garbage biomass and water as raw material

InactiveCN100381352CAbundant resourcesAchieve tidinessHydrogen productionPlasma technologyIndustrial scale

The hydrogen producing plasma method and apparatus uses garbage, biomass and water as material to produce hydrogen in industrial scale and low cost. The garbage and biomass material is set into furnace directly without through drying and crushing, and under the condition of isolating air, water molecule is activated and decomposed by means of plasma technology and the organic garbage and biomass serves as oxygen and hydrogen adsorbing element to inhibit the reverse reaction, so as to produce hydrogen-rich synthetic gas with high hydrogen content and no tar in high efficiency. The said process has no pollutant exhaust, high hydrogen producing speed and low power consumption.

Owner:衢州市广源生活垃圾液化技术研究所

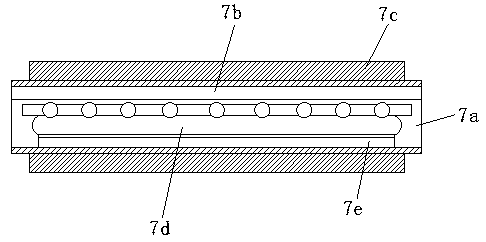

Movable belt adjusting device

PendingCN110510367AAvoid uneven forceUniform wearConveyorsCleaningFront and back endsAcceleration Unit

The invention discloses a movable belt adjusting device. A stress rod piece is fixed on a belt frame; a balance rod piece is rotationally mounted on the stress rod piece; two balance auxiliary piecesare mounted at the front and back ends of the balance rod piece; a belt penetrates through the balance auxiliary pieces at the front and back ends in sequence in a bonding mode, so that the balance auxiliary pieces at the front and back ends are staggered corresponding to the upper and lower positions of the belt; one side of a first adjusting pull rood is connected with the balance rod piece; oneside of a second adjusting pull rod is connected with a scraper; the other sides of the two adjusting pull rods penetrate through a belt frame, and adjusting limiting pieces are arranged on the sides; two adjusting springs sleeve the two adjusting pull rods; and the two ends of the adjusting springs are ejected against the belt frame and the adjusting limiting pieces. The device can inhibit flexible deformation and operation vibration of the belt in the operation process, prevents the wear acceleration caused by nonuniform stress of the scraper, and guarantees the scraping effect.

Owner:YSD RAIL TRANSIT CONSTR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com