Oppositely-opened radiative heating furnace and furnace body

A technology of radiant heating and radiant heating tubes, which is applied in the field of split radiant heating furnaces and furnace bodies, can solve the problems of low cost performance and poor rapid heating and cooling performance, and achieve the effects of low cost, low processing difficulty and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

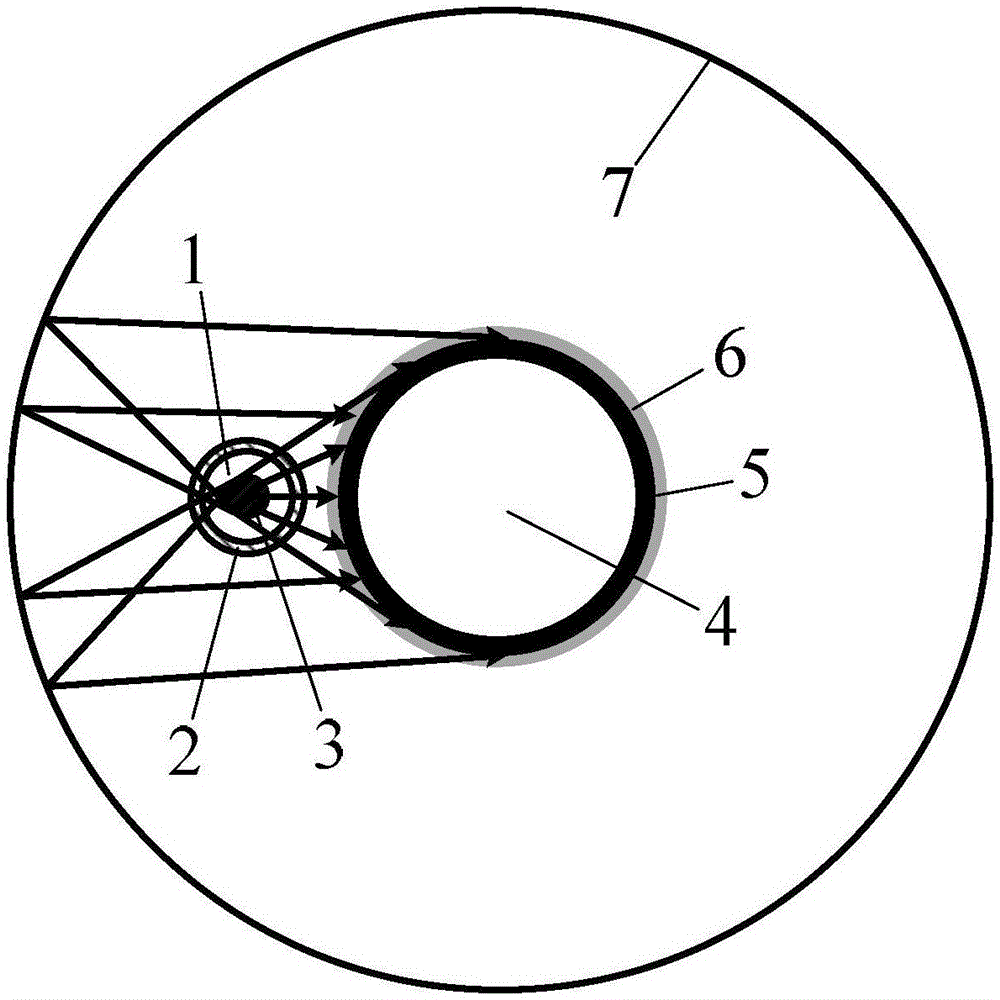

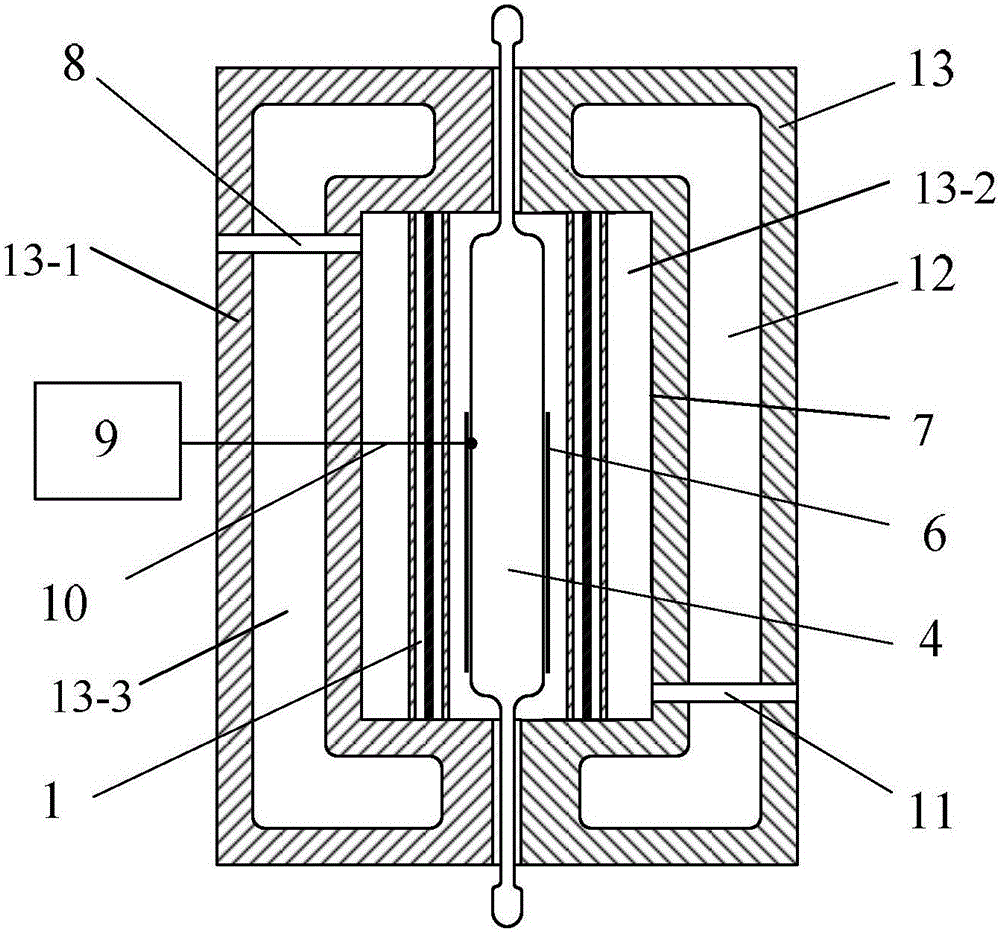

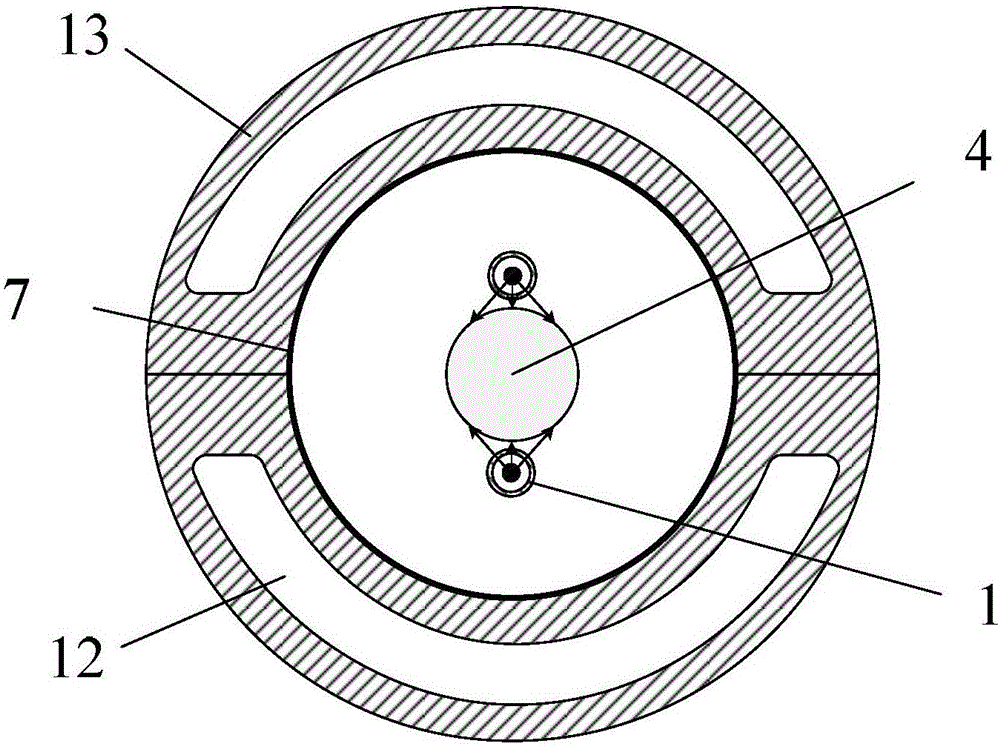

[0023] Specific implementation mode one: combine figure 1 and figure 2 The schematic diagram of the structure illustrates this embodiment. The furnace body of a split-type radiation heating furnace described in this embodiment is composed of two split 13-1, each split 13-1 has a concave cavity 13-2, and each split 13-1 There is a channel 13-3 for circulating cooling liquid to flow through on the wall body, when the two splits 13-1 are paired together, the two cavities 13-2 form a cylindrical furnace, and the wall 7 of the cylindrical furnace is smooth face.

specific Embodiment approach 2

[0024] Specific implementation mode two: combination figure 1 and figure 2 This embodiment is described. In this embodiment, the smooth surface (wall surface 7) is a metal polished surface with a surface roughness of less than 0.4 μm or a metal polished surface with a normal emissivity lower than 0.12. Various combined processing of milling, fine milling, grinding, electrochemical polishing and other processing methods can be realized. This method adopts a conventional and cheap method to obtain the mirror wall 7 that meets the requirements, avoids the strict requirements on the surface roughness of the mirror wall by the elliptical cylinder or parabolic cylinder based on directional reflection, and is easy to manufacture and use. The other components and connections of this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1 and figure 2To describe this embodiment, in this embodiment, more precisely, the wall surface 7 can be a metal polished surface with a surface roughness of less than 0.05 μm (or a normal emissivity of less than 0.05). That is, the smooth surface is a polished metal surface with a surface roughness less than 0.05 μm. The mirror wall 7 can be processed into a metal polished surface with a surface roughness of less than 0.05 μm or a normal emissivity of less than 0.05, through various processing methods such as rough turning, fine turning, rough milling, fine milling, grinding, and electrochemical polishing. A combination of processing to achieve. This way makes the insulation performance of the wall surface 7 better, makes the heating temperature higher than 1200° C., and can reduce the power consumption of heating. The other components and connections of this embodiment are the same as those of Embodiment 1 or ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com