A blowing fixture for removing labels from enameled wire reels

An enameled wire and fixing frame technology, applied in the directions of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of time-consuming and laborious, complicated wire reel cleaning steps, troublesome enameled wire reel cleaning work, etc., to improve applicability and practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

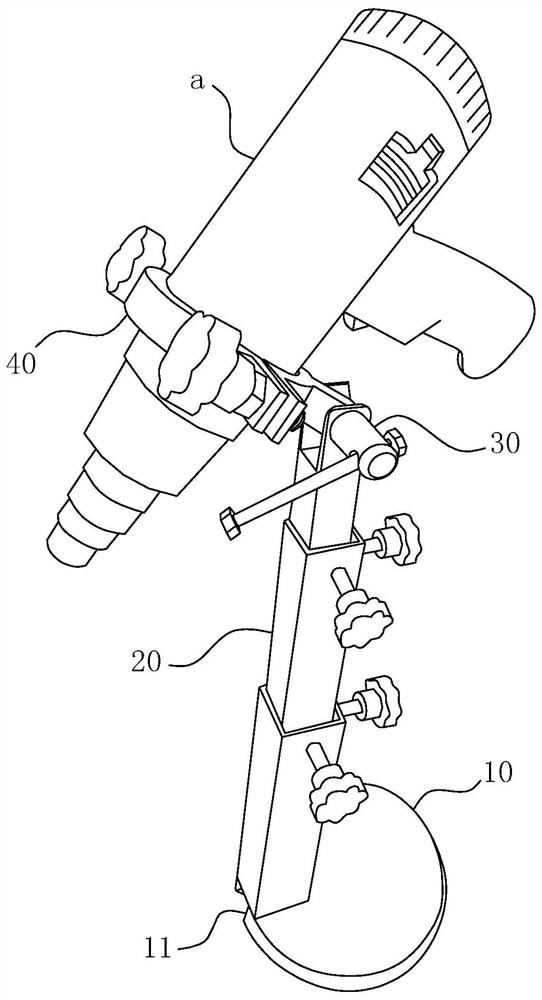

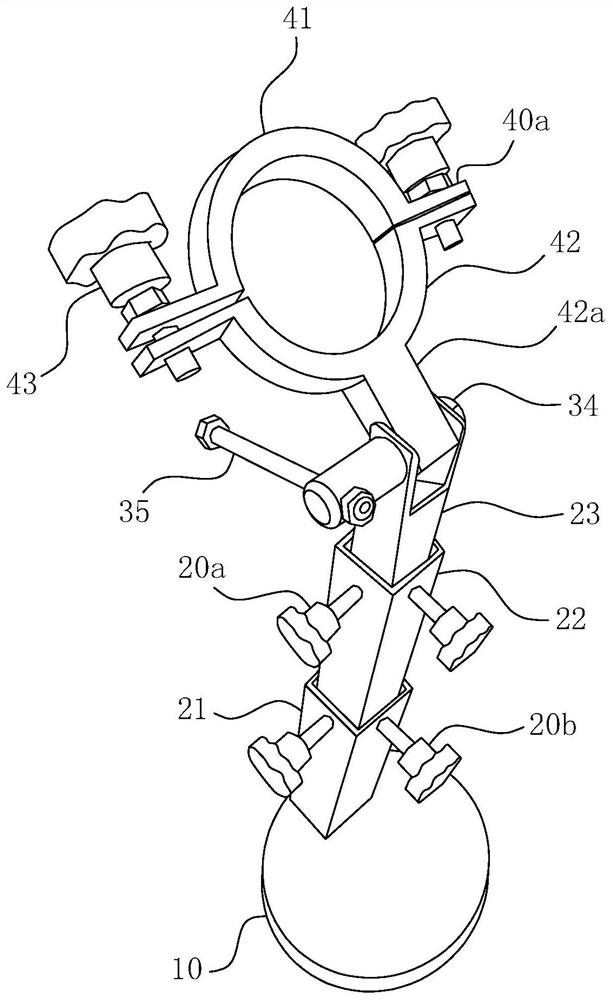

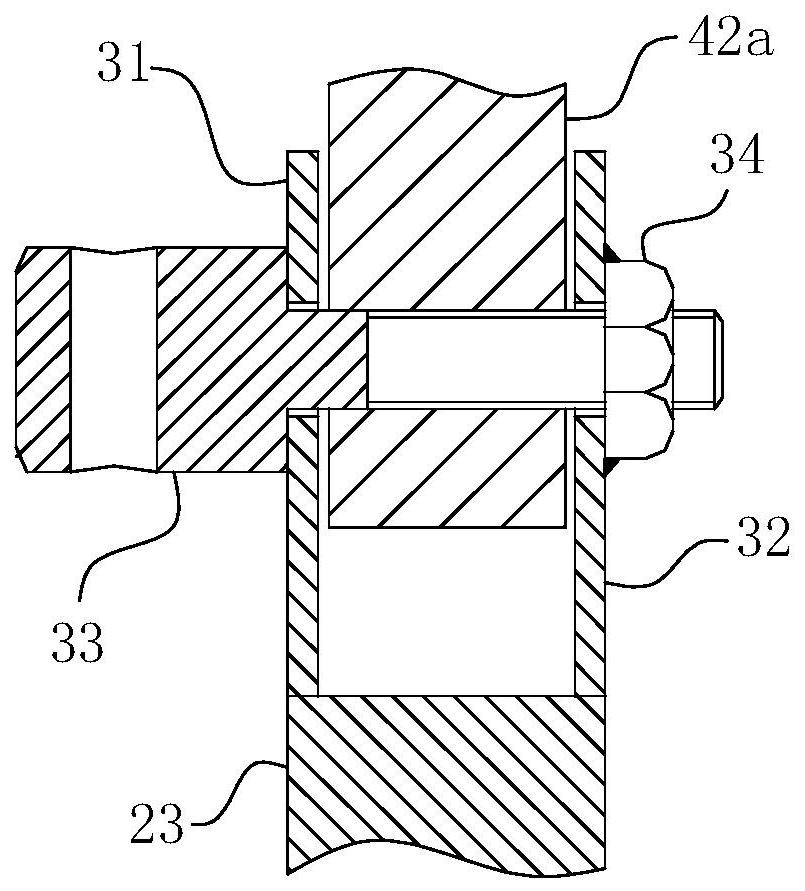

[0039] For ease of understanding, combined here Figure 1-5 Concrete implementation structure and workflow of the present invention are further elaborated as follows:

[0040] The concrete implementation structure of the present invention can refer to Figure 1-5 As shown, its structural body includes two parts, the main module and the external components, among which:

[0041] 1. Main module

[0042] main module like Figure 1-3 As shown, it includes a base 10 , a vertical telescopic assembly 20 , a horizontal joint 30 and a fixing collar 40 arranged vertically from bottom to top.

[0043] Refer to the shape of the base 10 Figure 1-2 Shown is a circular plate construction in order to provide the entire main module by its own weight to mount the base. The three-stage vertical telescopic assembly 20 includes a first set of rods 21, a second set of rods 22 and a third set of rods 23 arranged sequentially from bottom to top. The three sets of rods are interspersed with each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com